Endecotts Minor 200, Octagon 200, Octagon 200CL, Titan 450, Air Sizer 200 Operating Instructions Manual

...

WHEN PARTICLE SIZE MATTERS

Minor 200 Octagon 200 Octagon 200CL Air Sizer 200 EFL 300 Titan 450

SIEVING MACHINES

Operating Instructions

Content

Copyright © 2015 by Endecotts Ltd.

1

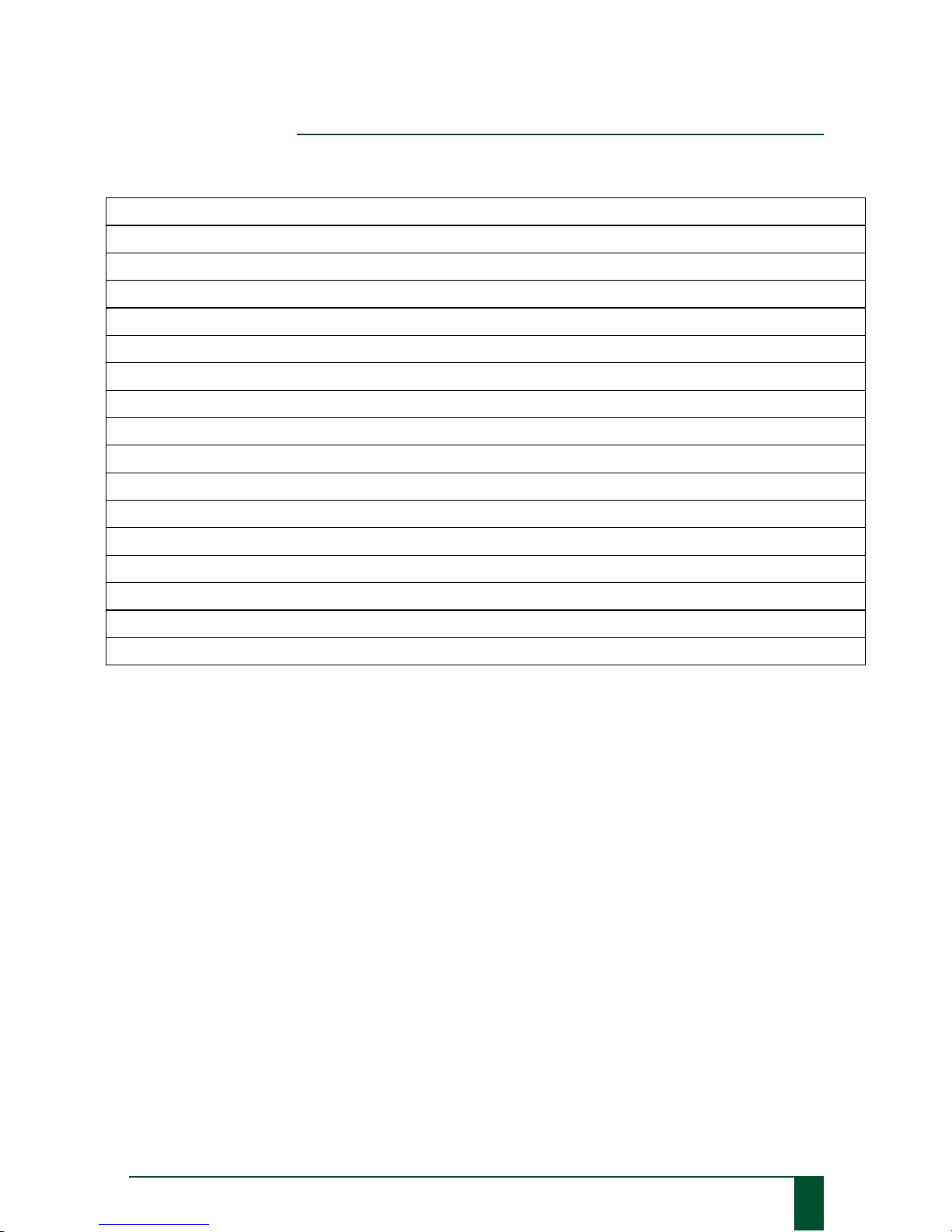

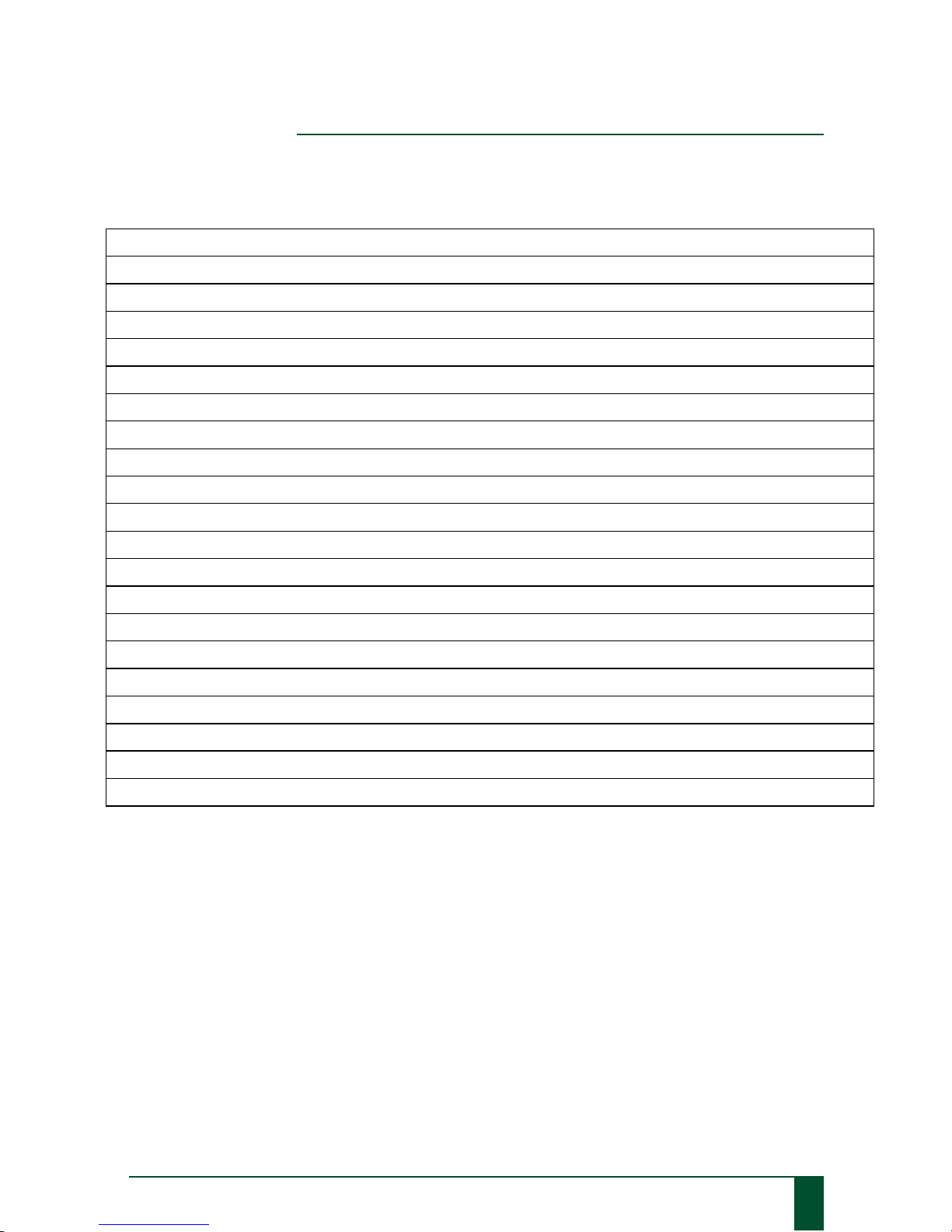

Contents

1. OPERATING INSTRUCTIONS NOTES……………………………….. 5

Warnings 5

Repairs 6

Safety 7

Safety instructions 7

Summary of safety instructions 8

Confirmation 10

2. TRANSPORT AND INSTALLATION………………………………… 11

Transport 11

Temperature fluctuations 11

Intermediate storage 11

3. OPERATING INSTRUCTIONS MINOR 200………………………… 13

Technical specifications 14

General Information 14

Specifications 15

Controls and Functions 16

Setting Up 17

Electrical connections 17

Start-up and commissioning 18

Certificate of CE-Conformity 20

4. OPERATING INSTRUCTIONS OCTAGON 200…………………… 21

Technical specifications 22

General Information 22

Specifications 23

Controls and functions 24

Setting Up 26

Electrical connections 26

Transport protection 27

Mount sieve clamping unit 28

Operating Instructions 29

Wet sieving 31

Certificate of CE-Conformity 32

5. OPERATING INSTRUCTIONS OCTAGON 200CL……………….. 33

Technical specifications 34

General Information 34

Specifications 35

Controls and functions 36

Content

2

Copyright © 2015 by Endecotts Ltd.

Setting Up 38

Electrical connections 38

Transport protection 39

Mount sieve clamping unit 39

Operating Instructions 41

Wet sieving 43

Certificate of CE-Conformity 44

6. OPERATING INSTRUCTIONS AIR SIZER 200…………………….. 45

Technical specifications 46

General Information 46

Specifications 47

Controls and functions 48

Setting Up 50

Electrical connections 50

Start-up and commissioning 51

Operating Instructions 52

Switching On and Off 52

Inserting the test sieve 52

Soft-faced mallet – Application and Use 52

Use of the machine for the intended purpose 53

Negative Pressure 55

Operating Software 55

Filter (Option) 56

Cleaning and service 56

Certificate of CE-Conformity 58

7. OPERATING INSTRUCTIONS EFL 300……………………………… 59

Technical specifications 60

General Information 60

Specifications 61

Controls and functions 62

Setting Up 64

Electrical connections 64

Transport protection 65

Mount sieve clamping unit 67

Operating Instructions 68

Wet sieving 70

Certificate of CE-Conformity 71

8. OPERATING INSTRUCTIONS TITAN 450…………………………. 73

Technical specifications 74

Content

Copyright © 2015 by Endecotts Ltd.

3

General Information 74

Specifications 75

Controls and functions 76

Setting Up 78

Electrical connections 78

Transport protection 79

Mount sieve clamping unit 81

Operating Instructions 82

Wet sieving 83

Certificate of CE-Conformity 84

GENERAL INFORMATION……………………………………………… 85

Use of Sieves 85

Test Sieves Available from Endecotts 85

EVALUATION SOFTWARE: SIEVEWARE……………………………… 87

General Information 87

Specifications 88

Function 88

4

Copyright © 2015 by Endecotts Ltd.

Copyright © 2015 by Endecotts Ltd.

All rights reserved, including the right to copy, distribute and translate this text. No part of this

document may be reproduced in any way wit hout written consent of Endecotts Ltd. nor may be

modified, copied or distributed with the help of electronic systems.

Manual can be subject to technical modification and errors.

1. Technical specifications 1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

5

1. Operating instructions notes

These operating instructions for the Endecotts test sieving machines give all

necessary information on the sections mentioned in the contents.

They give instructions to the target group(s) defined in the respective sections for

safe, correct handling of the Endecotts machines. It is important that each target

group(s) is (are) familiar with the relevant section, in order to ensure safe, reliable

handling of the machine according to its intended use.

This technical documentation is for use as a reference work and as a learning aid.

The information of each individual product (sieving machines) is complete within

their section.

Repair instructions are not included in this manual. If repairs are necessary please

contact your supplier or Endecotts Ltd directly.

Endecotts Ltd www.Endecotts.com

Warnings

The following signs are used to warn of hazards:

Personal injuries

Material damage

1. Setting up 1. Setting up 1. Setting up

6

Copyright © 2015 by Endecotts Ltd.

Repairs

This operating manual does not contain any repair instructions.

In the interests of your own safety, repairs should only performed by Endecotts Ltd or

an authorised representative (service technician).

In this case, please notify the following:

The local Endecotts representative

Your supplier

Endecotts Ltd direct

Your address for service:

1. Technical specifications 1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

7

Safety

Target group:

All persons concerned with the machine in any way.

The entire Endecotts machine range is a modern, highly efficient product of

Endecotts Ltd, corresponding to state of the art works. If the machine is used

according to the intended purpose with knowledge of this technical

documentation it is completely safe and reliable to operate.

Safety instructions

As the operator it is your duty to ensure that all persons charged with working on

the Endecotts machine:

• Have read and understood all the instructions on safety,

• Before beginning work know all the instructions and regulations for the target

group relevant to their work,

• Have access to the technical documentation for this machine at all times,

without problems.

• New personnel should be familiarised with safe, proper handling of the

machine before beginning work on the Endecotts machine, either by verbal

instruction from a competent person or through this technical documentation.

• Improper operation can cause injury to persons or damage to the equipment.

You are responsible for your own safety and that of your employees.

• Ensure that unauthorised persons have no access to the Endecotts machine.

For your own protection have your employees confirm that they have been

instructed in operation of the Endecotts machine. The draft of a suitable form is

given at the end of the section on safety.

We exclude claims for damages in any form for damage to persons or

property caused through non-observance of the following safety

instructions.

8

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Summary of safety instructions

Safety instructions

Technical data

Do not make any changes to the machine and use only spare parts and

accessories which have been approved by Endecotts.

The declaration of conformity to the European directives by Endecotts will

otherwise lose its validity. Furthermore this will result in the loss of any kind of

guarantee claims.

Packing

Please keep the packing material during the guarantee period in case of a

complaint your guarantee claim will be at risk if the machine is returned in

inadequate packing.

Transport

The Endecotts machine must not be knocked, shaken or thrown during

transport; otherwise the electronic and mechanical components may be

damaged.

Temperature fluctuations

If subjected to high temperature fluctuations (e.g. during transport by plane) the

Endecotts machine must be protected against condensed water. If not damage to

the electronic components may be caused.

Supply schedule

If the delivery is incomplete and/or transport damage has occurred, you must

immediately notify the transport agent and Endecotts Ltd (within 24 hrs.). It is

possible that later complaints may not be considered.

Ambient temperature

If the ambient temperature is exceeded or drops below the normal value the

electrical and mechanical components may become damaged and the

performance data can change to an unknown degree.

We exclude claims for damages in any form for damage to persons or property

caused through non-observance of the following safety instructions.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

9

1. Technical specifications

Atmospheric humidity

At high atmospheric humidity the electrical and mechanical components may

become damaged and the performance data can change to an unknown degree.

Installation / transport protection - IMPORTANT

If the machine is operated with the transit bolts, or is transported without transit

bolts, mechanical components may become damaged.

Electrical connection / connecting the mains power supply

If the values given on the rating label are not observed electrical and mechanical

components may become damaged.

Wet sieving

Never operate your Endecotts machine directly in water.

Danger through current surge.

During wet sieving always operate your Endecotts machine connected to a

mains socket which is protected by an FI protective (safety) switch.

The water quantity added should always be dosed in such a way that the sieve

surface is only just wetted.

Sieving aids

Make sure that the wire mesh of the sieves is not excessively stretched through

overloading with sieving aids, since this will impair the precision of your test

sieves.

Damage may occur if the

shaker is allowed to operate with a loose clamping

plate.

10

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Cleaning

Do not clean the Endecotts machine under running water.

Danger to life through current surge.

Use only a cloth moistened with water; solvents are not allowed.

Wearing parts

These operating instructions do not include repair instructions.

For your own safety, repairs should be carried out only by Endecotts Ltd or an

authorised agency or Endecotts service technicians.

Confirmation

I have read and taken note of the sections – preliminary

comments and safety

________________________________________________

Signature of operator

________________________________________________

Signature of service technician

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

11

1. Technical specifications

2. Transport and installation

Packing has been adapted to the transport method and conforms to generally applicable

packing guidelines.

Packing

Please keep the packing material during the guarantee period in case of a

complaint, your guarantee claim will be at risk if the machine is returned in

inadequate packing.

Transport

The Endecotts Machine must not be knocked, shaken or thrown during transport;

otherwise the electronic and mechanical components may become damaged.

Please make sure you have removed all transit bolts before using the Endecotts

machine.

Specific operating instructions can be found on the relevant pages

for every single

Endecotts machine in this manual.

Temperature fluctuations

If subjected to high temperature fluctuations (e.g. during transport by plane) the

Endecotts machine

must be protected against condensed water. If not damage to

the electronic components may be caused.

Intermediate storage

Ensure that the Endecotts machine is kept dry also during intermediate storage.

12

Copyright © 2015 by Endecotts Ltd.

1. Setting up

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

13

1. Technical specifications

3. Operating instructions:

Minor 200

14

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Technical specifications

SIEVE SHAKER MODEL:

Minor 200

General Information

The Minor 200 has been developed and manufactured to combine low cost with the benefits of a welldesigned and engineered shaker. It incorporates many features usually found only on larger, more

expensive models. It is ideal for the use in laboratories and a plant since it is compact and genuinely

portable (weighing only 16 kg).

The sieve stack is held firmly in position by a clamping belt system. Removing it allows the whole

unit to be stored in a space less than 200 mm high. There are no rotating parts in the Minor 200 consequently it is quiet in operation and maintenance free.

Advantages

• Electromagnetic drive for quiet and virtually maintenance free operation

• Compact and portable (weighing only 16 kg)

• Requires only small storage space due to small footprint

• Easily removable clamping belt system (included)

• Easy to use

• Different voltages available

• Complies with the requirements of AASHTO T 27

The Minor 200 is not recommended for any wet sieving operations!

Do not make any changes to the machine and use only spare parts and

accessories approved by Endecotts Ltd.

The declaration of conformity to the European directives by Endecotts

will otherwise lose its validity.

Furthermore this will result in the loss of any kind of guarantee claims.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

15

1. Technical specifications

Specifications

Range 38 µ

m to 125 mm

Drive / sieving motion electromagnetic

Max. Batch / feed capacity 3 kg

Max. Number of fractions 8 full height / 16 half height (200 mm or 8”)

Amplitude ~ 1.6 mm* fixed

Speed 3,000 min-1 at 50 Hz

Time display analogue, 0 - 60 min or continuously

Suitable for dry sieving yes

Suitable for wet sieving no

Sieve diameter 100 / 200 mm or 3” / 8"

Clamping device clamping belt system (included)

Model bench top

Protection code IP 20

Electrical supply different voltages available

Power connection 1-phase

Ø x H 262 x 126 mm

Net weight 16 kg

(*) depending on load

16

Copyright © 2015 by Endecotts Ltd.

1. Setting up

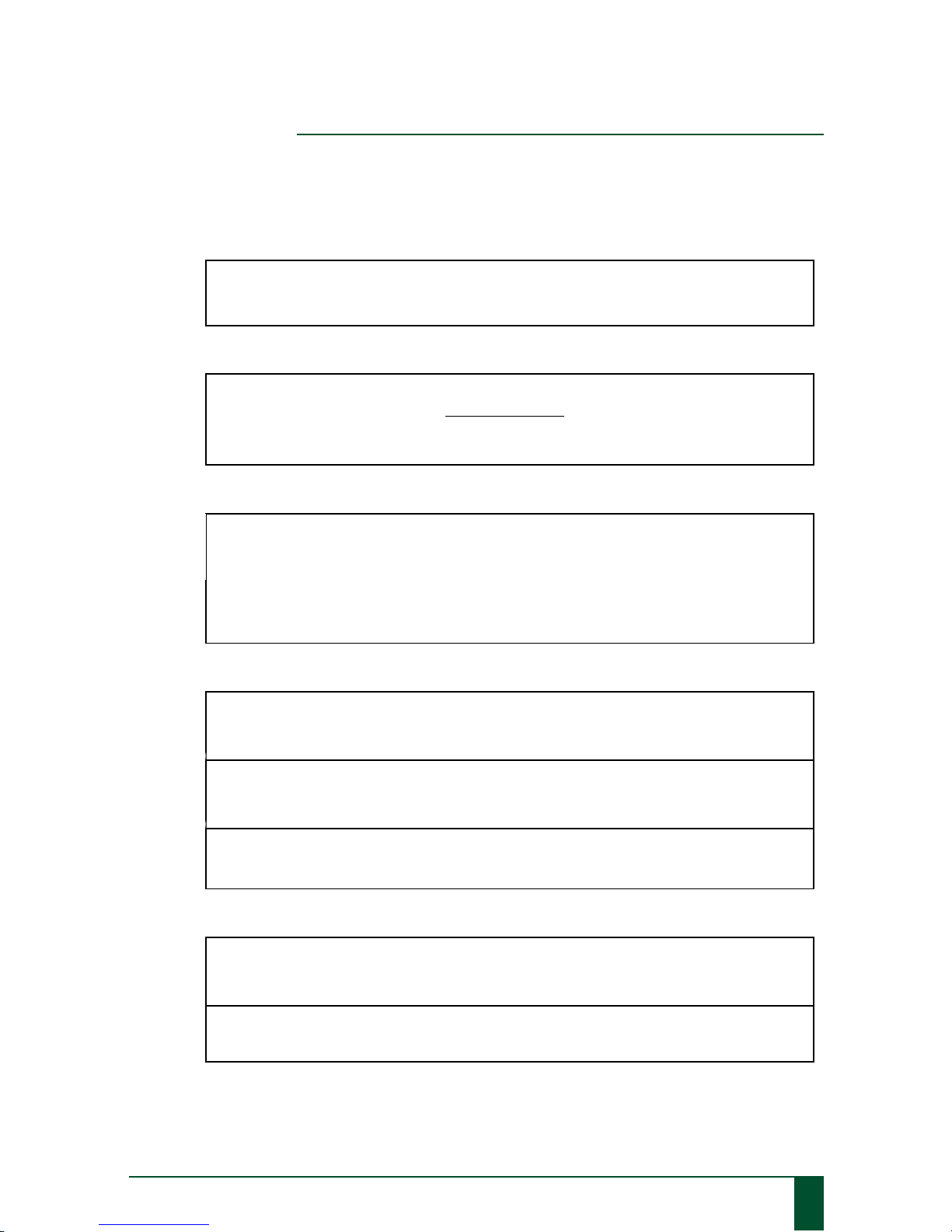

Controls and Functions

Operators should be familiar with and fully understand the controls and indicators before

operating this machine.

PLUG

(Removable knob for lid)

CLAMP PLATE

CLAMPING LATCH

ADJUSTABLE CAM

BUCKLES

MAINS SWITCH

STRAP

COVER

BASE

ANTI-VIBRATION FEET

LED (indicates

mains power to

instrument)

PROCESS TIMER

On /Off Switch

LOCATION PLATE

SIEVE STACK

MAINS POWER

CONNECTION

FUSE HOLDER

60 MIN

OFF

CONTINUOUSLY

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

17

1. Technical specifications

Setting Up

Electrical connections

Ensure that the voltage and frequency on the rating label, at the rear of the

shaker, correspond with the local electrical mains supply.

• Connect the Minor 200 to the power supply using the connection cable

provided.

Do not connect to any other supply other than stated on the rating label,

otherwise electrical and mechanical components can be damaged.

Ambient temperature: 5°C to 40°C

If the ambient temperature is exceeded or drops below the specified value

the electrical and mechanical components may become damaged and the

performance data can change to an unknown degree.

Atmospheric humidity:

Maximum relative humidity 80% at temperatures up to 31°C, with linear reduction

down to 50% relative humidity at 40°C.

At high atmospheric humidity the electrical and mechanical components

may become damaged and the performance data can change to an

unknown degree.

• Mains power connection

Mains power connection with integral line filter. Ensure the IEC connector on the mains

lead is pushed fully into the mains inlet at the rear of the machine.

• L.E.D (Mains Connected Indication)

This is a green L.E.D that indicates electrical power is connected to the equipment. The

L.E.D is illuminated when the IEC connector is pushed fully into the inlet and power is

switched on at the local outlet.

If the L.E.D fails to light with the local outlet switch in the ON position then the fuse (see

“Fuse holder”) has blown or power is not present at the mains.

• Fuse (Fuse Holder)

The fuse is a ceramic fuse. It is important that the recommended current rating is not

exceeded and the fuse is replaced with the same type and size. If the fuse blows after

replacement then a fault exists in the equipment which must be rectified.

18

Copyright © 2015 by Endecotts Ltd.

1. Setting up

• Process Timer

The process timer is a mechanical 0-60 minute timer which also provides continuous

running if desired. Operating periods are increased by rotating clockwise and decreased by

rotating anticlockwise (the timer will commence timing down as soon as the knob is

released, regardless of electrical power being connected or not). When the knob is turned

anti-clockwise from off position to the continuous running mark, the shaker will continue

running until the knob is returned to the off position.

Start-up and commissioning

The shaker should be set up according to the following procedure.

The following items should be removed from the case and checked before the shaker is operated

(Take care the shaker weighs 16 kg):

• 1 off Set-up Instructions.

• 1 off Instruction Manual.

• 1 off Mains Cable.

• 1 off Clamp Plate Assembly.

• 1 off Minor Shaker fitted with Clamping Straps and Buckles.

Position the shaker on a level, rigid and robust bench, suitable for the operation of the sieve shaker.

Being placed on a level surface ensures symmetrical distribution of the sample over the sieves, during

operation.

Operating Instructions

1. Place the receiver centrally on the location plate..

2. Stack the required test sieves on top of the receiver (min. 1x receiver + 2x sieves + 1x lid).

3. Put the sample in the top sieve and fit the lid.

In order to guarantee exact results under fast sieving conditions, the quantity of material to be sieved

should be adapted to the sieve diameter and the nominal mesh size.

More detail information is displayed in our “TEST SIEVING MANUAL”.

4. Place the clamp plate on top of the sieve stack.

5. Raise the clamping latch lever upwards to expose the latch hook.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

19

1. Technical specifications

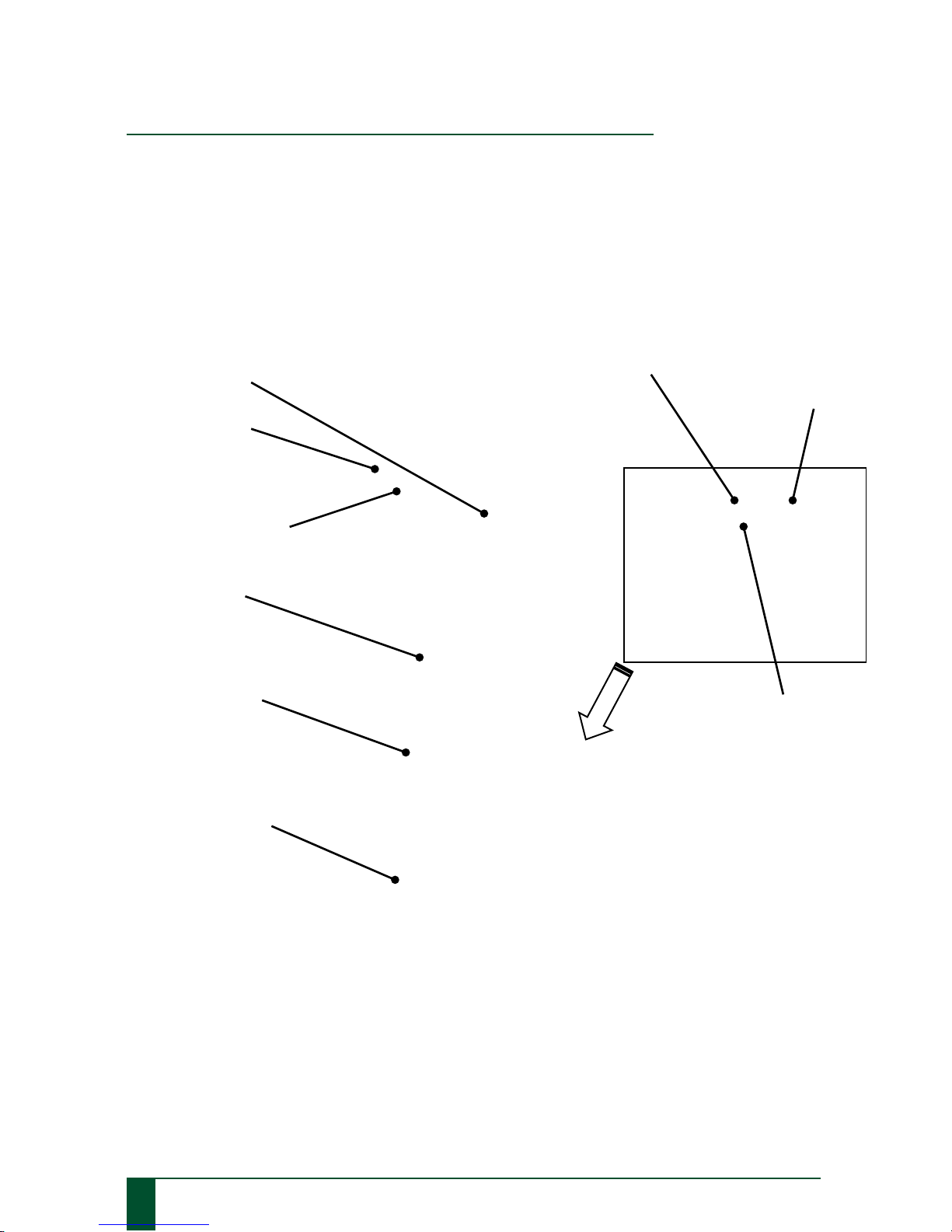

While holding the clamping latch using one hand, press the lever

on the cam buckle with the other hand. Slide the cam buckle along

the clamping strap until it can be engaged into the latch hook.

Release the cam buckle, pull the lose end of the strap downwards

to partially tension the strap.

Do not over tension. The clamping latch lever will remain in the

raised position 20-30 degrees from the vertical when partially

tensioned. Repeat these actions for the second clamping latch.

6. Press both levers down, closing the latches to clamp the sieve

stack. Do not use excessive force, it may be necessary to

loosen the straps slightly to secure.

7. Repeat previous action to release or increase tension in the strap as necessary to ensure a firm

grip!

The Endecotts Minor 200 sieve shaker is maintenance free other than keeping external surfaces clean.

Cleaning - The machine can be cleaned with a soft damp cloth using a solution of water and a mild

liquid detergent. Do not use any solvents for cleaning

Fuse - Should a fuse require replacement this must be of the identical type and rating as the original!

The rating of the fuse is marked on a label above the fuse. Disconnect from the mains supply. Remove

the blown fuse and place the new fuse in.

Do not over tighten

Damage may occur if the shaker is allowed to operate with a loose clamping plate.

Endecotts machines are fully tested and factory checked before shipping to customers. No parts

require lubrication or resetting unless disturbed. The sieve shaker has been constructed and factory

tested to ensure correct operation when connected to the specified electricity supply indicated on the

machines rating label.

All replacement parts must be ordered by quoting the shaker serial number and the correct part

number. Use of unapproved spares or any alteration to the machine would invalidate all warranties

and compliance with the European directives for ‘CE’ marking.

20

Copyright © 2015 by Endecotts Ltd.

1. Setting up

CERTIFICATE OF CE-CONFORMITY

TEST SIEVE SHAKER

MINOR 200

Certificate of CE-Conformit y according to:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

EN ISO 12100 Security of machines

EC Directive Electromagnetic Compatibility 2004/108/EC

Applied standards, in particular:

EN55011:2009+A1:2010, Group 1, Class B Radio disturbance characteristics –

Limits and methods of measurement

EN 61000-3-2:2006+A1:2009+A2:2009

EN 61000-3-3:2008

EN61326-1:2006

Additional applied standar ds, i n particular

EN 61010 Safety prescriptions concerning measuring, operating, controlling and laboratory equipment

Authorised for the compilation of technical documents:

Endecotts Ltd (technical documentation)

The following records are held by Endecotts Ltd in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required

for conformity assurance, analysis of the residual risks involved and operating instructions in due form

according to the approved regulations for preparation of user information data.

The CE-conformity of the Endecotts Test Sieve Shaker Type Minor 200 is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not licensed

spare parts and accessories this certificate will lose its validity.

Endecotts Ltd London, July 2014

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

21

1. Technical specifications

4. Operating instructions:

Octagon 200

22

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Technical specifications

SIEVE SHAKER MODEL:

Octagon 200

General Information

The sieve shaker Octagon 200 is suitable for all sieving tasks in laboratories as well as onsite and

provides optimum sieving action for fast and reproducible results.

It is robust, compact and sufficiently lightweight to be portable. Its electromagnetic drive combined

with a 3D sieving motion ensures excellent separation efficiency in a short amount of time.

A digital display as well as a quick-release clamping system makes operation very easy and

straightforward.

Advantages

• Easy-to-use sieve clamping system

• Accepts up to 8 full height 200 mm or 8" diameter sieves

• Suitable for dry and wet sieving

• 10 amplitude settings and digital timer

• 3D sieving motion allows for high separation efficiency and non-blinding

sieving action

• Different voltages available

• No mechanical moving parts

• Compact and portable

Do not make any changes to the machine and use only spare parts and

accessories approved by Endecotts Ltd.

The declaration of conformity to the European directives by Endecotts

will otherwise lose its validity.

Furthermore this will result in the loss of any kind of guarantee claims.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

23

1. Technical specifications

Specifications

Range 20 µ

m to 125 mm

Drive / sieving motion electromagnetic 3D

Max. Batch / feed capacity 3 kg

Max. Number of fractions 8 full height / 16 half height (200 mm or 8”)

Amplitude 0 - 3 mm digital setting in 10 steps

Speed 3,000 min-1 at 50 Hz

Time display digital, 0:10-99:50 min

Interval operation yes (one mode)

Suitable for dry sieving yes

Suitable for wet sieving yes

Serial interface -

Sieve diameter 100 / 200 mm or 3”/ 8''

Max. Height of sieve stack up to 450 mm

Clamping device quick-release clamping system (included)

Model bench top

Protection code IP 54

Electrical supply different voltages available

Power connection 1 – Phase

W x H x D 418 x 232 x 435 mm

Net weight 35 kg

Standards CE

Noise characteristic values:

Example 1:

Emission value related to workplace LpAeq = 63 dB (A)

(Operating conditions: Material to be sieved = quartz sand, grain size < 1mm, 5 sieves Amplitude =

1.5 mm)

Example 2:

Emission value related to workplace LpAeq = 67 dB (A)

(Operating conditions: Material to be sieved = quartz sand, grain size < 1mm, 5 sieves Amplitude =

3 mm)

24

Copyright © 2015 by Endecotts Ltd.

1. Setting up

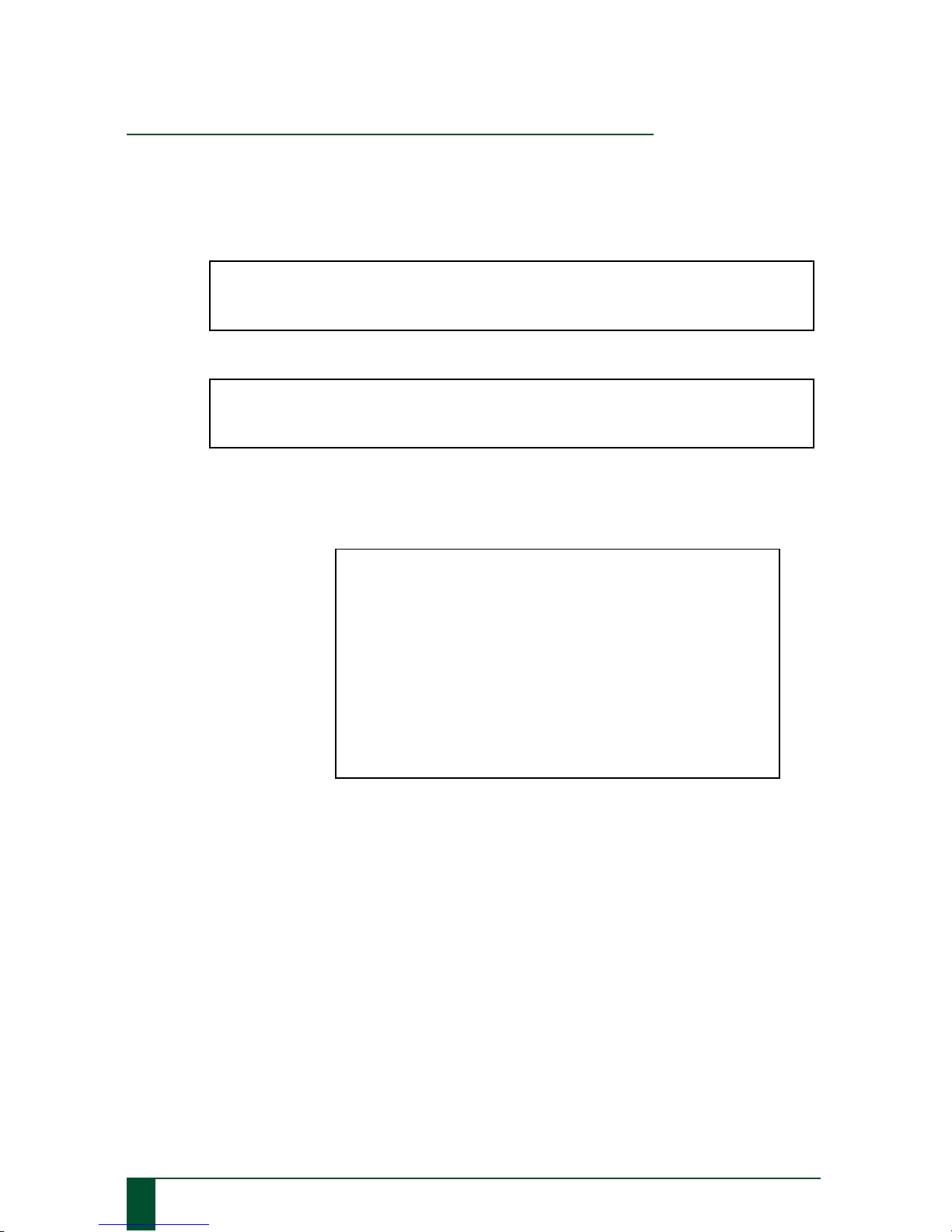

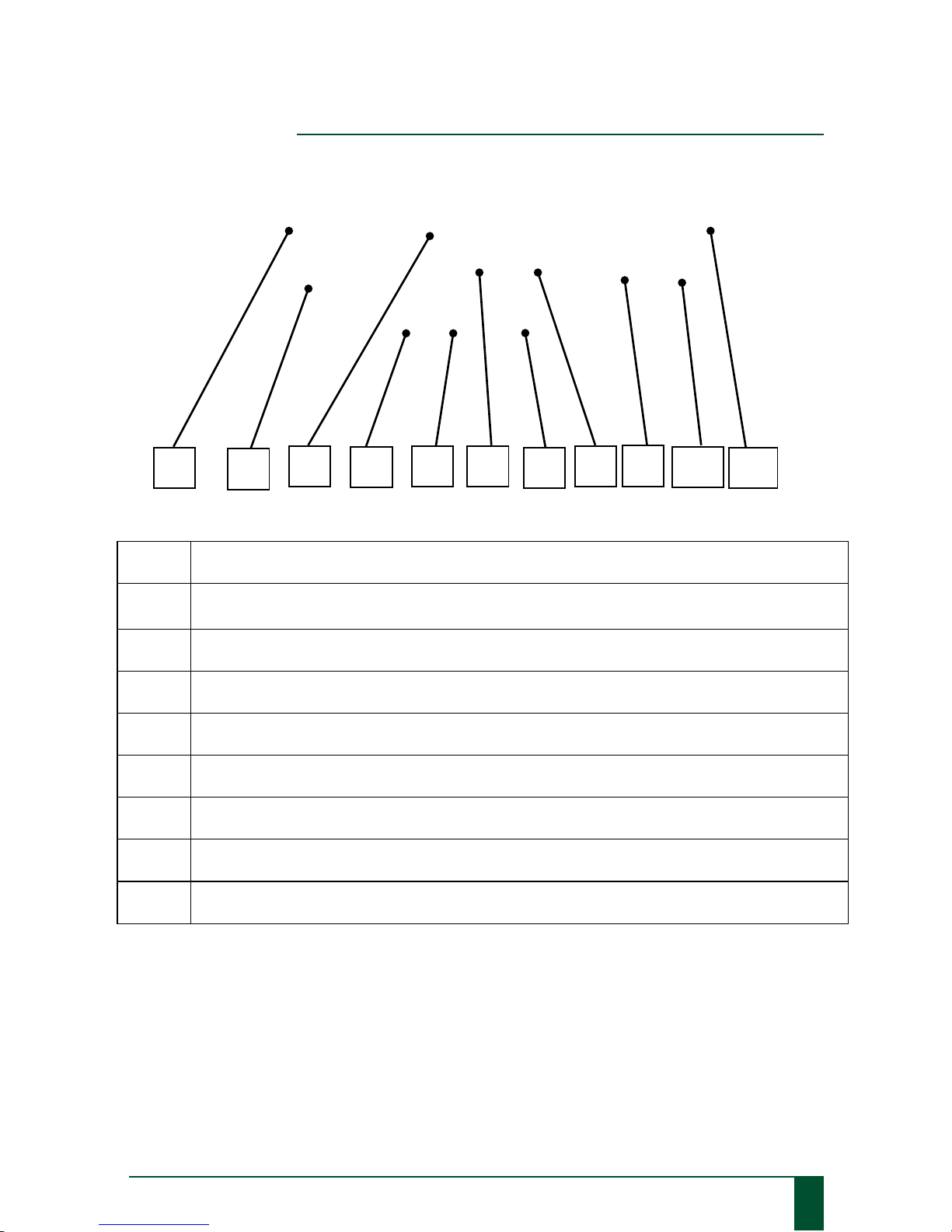

Controls and functions

The sieve shaker should be placed on a level surface to ensure symmetrical distribution of the sample

over the sieve mesh. The surface should be rigid and robust where vibration will not cause problems.

Operators should be familiar with and fully understand the controls and indicators before

operating this machine. This should be done in conjunction with the diagram below and control

panel description.

CLAMP PLATE

CLAMP HAND

WHEELS

SIEVE STACK

LARGE PLAIN

CLAMP WASHERS

ROUND

CLAMP RODS

MAINS SWITCH

MAINS POWER CONNECTION

FUSE HOLDER

CONTROL PANEL

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

25

1. Technical specifications

1 LED light to indicate interval operation ON.

2

Interval mode button M1 switches interval operation ON/OFF,

upper LED lights up; 10 seconds on, 2 seconds off

3 Display shows the preselected sieving time, 00:10 – 99:50 min.

4 LED light to indicate START button “>” ON

5 Start the machine by pressing the START button “>”.

6 & 8 “˅“ and “˄” button reduces/increases the sieving time, 00:10 – 99:50 min

7

Stop the machine by pressing the STOP button “

□“.

9 & 10 “˅“ and “˄” button reduces/increases the amplitude, in 10 steps

11 10 LED’s for the Power bar indicating amplitude setting in 10 steps

6

7 4 1

5

3

11 2 9

10

8

26

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Setting Up

Electrical connections

* The voltage and frequency for the Octagon 200 is

given on the rating label.

* Ensure that the values agree with the existing power

supply.

* Connect the Octagon 200 to the power supply using

the connection cable provided.

* When connecting the power cable to the mains

external fusing is necessary according to the

regulations of the installation location

Do not connect to any other supply other than stated on the rating label,

otherwise electrical and mechanical components can be damaged.

Ambient temperature: 5°C to 40°C

If the ambient temperature is exceeded or drops below the specified value

the electrical and mechanical components may become damaged and the

performance data can change to an unknown degree.

Atmospheric humidity:

Maximum relative humidity 80% at temperatures up to 31°C, with linear

reduction down to 50% relative humidity at 40°C.

At high atmospheric humidity the electrical and mechanical components

may become damaged and the performance data can change to an

unknown degree.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

27

1. Technical specifications

Transport protection

Place the Octagon 200 on a stable laboratory bench, since otherwise unpleasant vibrations will

be transmitted. Being placed on a level surface ensures symmetrical distribution of the sample

over the sieves, during operation.

• Unscrew the two hexagon screws (transit bolts) on the bottom of the sieve shaker with

an open ended spanner until the sieve plate is movable.

• Keep hexagon screws (transit bolts) for possible transport at a later date.

If the machine is operated with the transit bolts

, or is transported without

transit bolts, mechanical components may become damaged.

Reusing transit bolts

• Dismount the clamping unit.

• Screw the hexagon screws (transit bolts) into the two holes on the bottom of the sieve

shaker and tighten with open ended spanner until the sieve plate is no longer movable.

28

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Mount sieve clamping unit

Fit one M12 nut onto each clamp rod selected for use, then

screw the pair of clamp rods into the location plate and tighten

the locknuts.

Place the two large plain washers over the 20 mm threads of the clamp sleeves. These can be seen

protruding vertically from the two side lugs on the clamp plate. Screw the two hand wheels

loosely onto the 20 mm threads; leave a gap of 5 mm between the large washer and the hand

wheel face. Do not tighten right down at this point.

WASHER

HAND WHEEL

SIDE

HANDLE

LEVER

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

29

1. Technical specifications

Operating Instructions

1. Place the receiver centrally on the location plate in the appropriate recess.

2. Stack the required test sieves on top of the receiver (min. 1x receiver + 2x sieves + 1x lid).

3. Put the sample in the top sieve and fit the lid

In order to guarantee exact results under fast sieving conditions, the quantity of material to be sieved

should be adapted to the sieve diameter and the nominal mesh size.

More detailed information is displayed in our “TEST SIEVING MANUAL”.

4. Align the locking assemblies in figure 1 the two side lugs of the clamp plate with the round

clamp rods. Slide the clamp plate down squarely onto the lid at the top of the sieve stack.

Ensure that the clamping hand wheels at the top (figure 2) are loose and the locking assemblies are

fully pushed down. There should be a 5mm gap between the large plain washer and the face of the

hand wheel.

Place one hand on the top of the clamp plate (figure 3) and hold square while locking one side handle

lever. Repeat for the opposite side handle lever.

The side handle levers can be set vertically downwards by pressing on the Red button and pulling

the handle outwards to release (figure 4). Turn the handle to a safe, convenient angle downwards and

30

Copyright © 2015 by Endecotts Ltd.

1. Setting up

release to engage the teeth. Screw the two clamping hand wheels down simultaneously to ensure the

clamping plate is square.

Continue until the hand wheels are tight against the internal stop. Hand tightness must be exerted so

that the assembly does not loosen during vibration.

The locking side handle levers and clamping hand wheels must be tightened sufficiently to ensure

that the sieves and receiver are clamped securely during operation.

5. Set time, interval and amplitude.

6. Press START

Damage may occur if the shaker is allowed to operate with a loose clamping plate.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

31

1. Technical specifications

Wet sieving

The Wet Sieving Adaptor Kit is supplied as an optional extra for 200 mm or 8” diameter sieves and

should be ordered separately.

The Wet Sieving Adaptor Kit consists of the following items:

• 1 off Special Wet Sieving Clamp Plate.

• 1 Set off O-ring Seals (One required for

each sieve in the stack.)

• 1 off Special Wet Sieving Receiver with a spout.

(Specify for 200 mm or 8” diameter sieves )

The O-ring seals are fitted on to the outside of the bottom rim of each sieve, which means the

sieves are stacked onto each other and they form a seal.

The bottom sieve is placed on the special receiver with a spout.

A nylon hose tail must be fitted and must have a suitable length of hose fitted to drain into a

convenient drainage point.

Fit a suitable length of hose to the spout to drain into a convenient drainage point.

The clamp plate is usually supplied with the rose reversed to avoid damage. Undo and reverse,

so that the rose head is on the inside. Remove the lid from the sieve stack and replace the standard

clamp plate with the wet sieving clamp plate. Fit a suitable length of hose to the inlet of the rose on

the clamp plate and connect to the fluid supply with flow regulation.

Never operate your Sieve shaker directly in water.

Danger through current surge.

During wet sieving always operate your Sieve shaker connected to a mains socket

protected by an FI protective (safety) switch.

The water quantity added should always be dosed in such a way that the sieve

surface is only just wetted.

32

Copyright © 2015 by Endecotts Ltd.

1. Setting up

CERTIFICATE OF CE-CONFORMITY

TEST SIEVE SHAKER

OCTAGON 200

Certificate of CE-Con f ormity according t o:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

EN ISO 12100 Security of machines

EC Directive Electromagnetic Compatibility 2004/108/EC

Applied standards, in particular:

EN55011:2009+A1:2010, Group 1, Class B Radio disturbance characteristics –

Limits and methods of measurement

EN 61000-3-2:2006+A1:2009+A2:2009

EN 61000-3-3:2008

EN61326-1:2006

Additional applied standards, in particular

EN 61010 Safety prescriptions concerning measuring, operating, controlling and laboratory equipment

Authorised for the compilation of technical documents:

Endecotts Ltd (technical documentation)

The following records are held by Endecotts Ltd in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required

for conformity assurance, analysis of the residual risks involved and operating instructions in due form

according to the approved regulations for preparation of user information data.

The CE-conformity of the Endecotts Test Sieve Shaker Type Octagon 200 is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not licensed

spare parts and accessories this certificate will lose its validity.

Endecotts Ltd London, July 2014

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

33

1. Technical specifications

5. Operating instructions:

Octagon 200CL

34

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Technical specifications

SIEVE SHAKER MODEL:

Octagon 200CL

General Information

The new Octagon 200CL for precise, reproducible and error-free sieving processes competes with the

most advanced sieve shakers in the world. Several unique features have been developed specifically

for this machine, including the ‘Closed Loop' amplitude control for ultimate reproducibility. The

Octagon 200CL is designed to work with Endecotts SieveWare, the new software for easy evaluation

and documentation of the sieving process.

Advantages

• 'Closed Loop' total amplitude control ensures reproducible sieving

• Digital controls for easy and reliable operation

• Easy-to-use sieve clamping system

• Accepts up to 8 full height 200 mm or 8" diameter sieves

• Suitable for dry and wet sieving

• 3D sieving motion allows for high separation efficiency and non-blinding

• sieving action

• Full compatibility with new SieveWare evaluation and control software via RS232 Port

(printed or digital protocols)

• Voltage-independent

• No mechanical moving parts

• Compact and portable

Do not make any changes to the machine and use only spare parts and

accessories approved by Endecotts Ltd.

The declaration of conformity to the European directives by Endecotts will

otherwise lose its validity.

Furthermore this will result in the loss of any kind of guarantee claims.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

35

1. Technical specifications

Specifications

Range 20 µ

m to 125 mm

Drive / sieving motion electromagnetic 3D

Max. Batch / feed capacity 3 kg

Max. Number of fractions 8 full height / 16 half height (200 mm or 8”)

Amplitude 0 - 3 mm digital setting in 0.1 mm steps " Closed

Loop" amplitude control

Speed 3,000 min-1 at 50 Hz

Time display digital, 0:10-99:50 min

Interval operation yes (two modes)

Suitable for dry sieving yes

Suitable for wet sieving yes

Serial interface yes (RS232)

Sieve diameter 100 / 200 mm or 3” / 8’’

Max. Height of sieve stack up to 450 mm

Clamping device quick-release clamping system (included)

Model bench top

Protection code IP 54

Electrical supply 100-240V 50/60Hz

Power connection 1 - Phase

W x H x D 418 x 232 x 435 mm

Net weight 35 kg

Standards CE

Noise characteristic values:

Example 1:

Emission value related to workplace LpAeq = 63 dB (A)

(Operating conditions: Material to be sieved = quartz sand, grain size < 1mm, 5 sieves Amplitude =

1.5 mm)

Example 2:

Emission value related to workplace LpAeq = 67 dB (A)

(Operating conditions: Material to be sieved = quartz sand, grain size < 1mm, 5 sieves Amplitude =

3 mm)

36

Copyright © 2015 by Endecotts Ltd.

1. Setting up

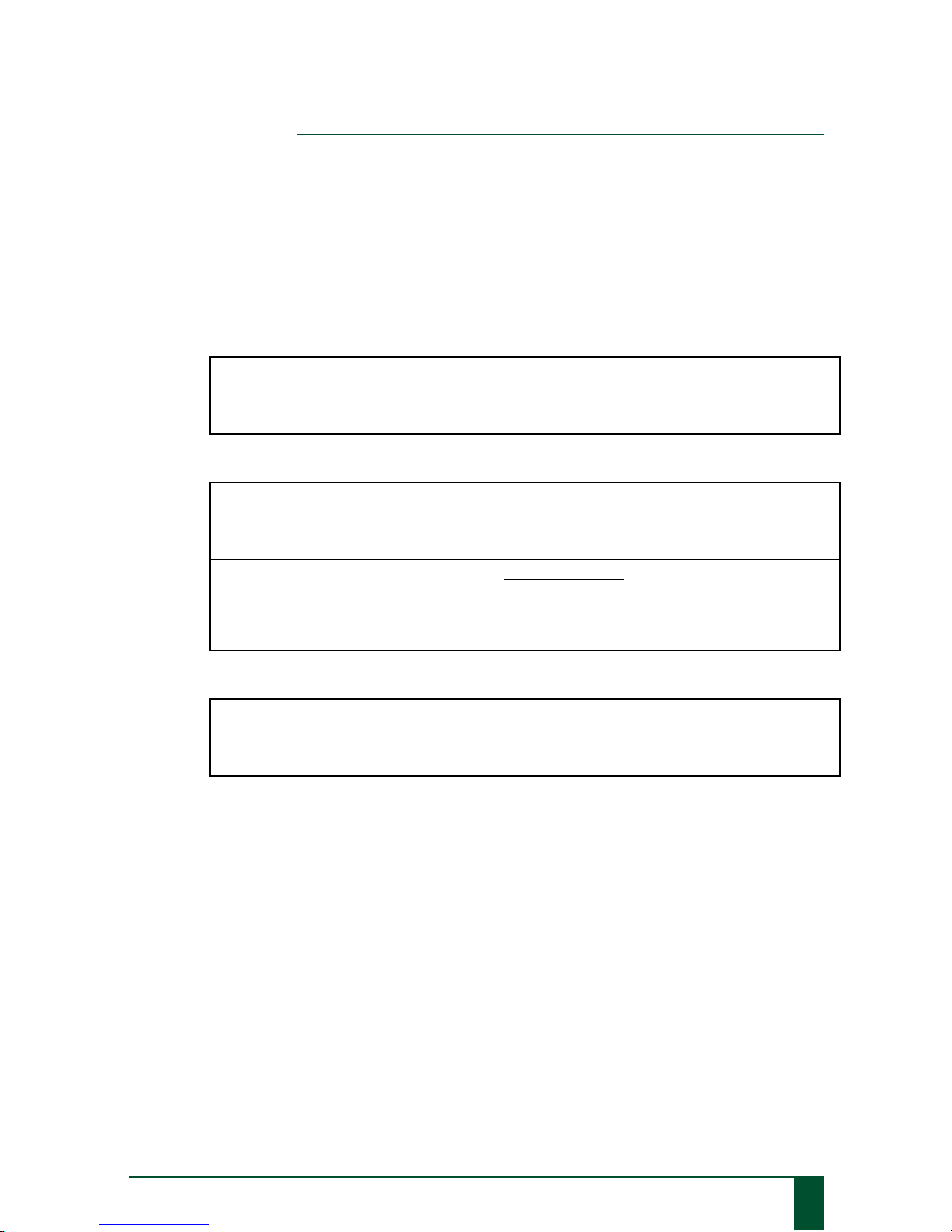

Controls and functions

The sieve shaker should be placed on a level surface to ensure symmetrical distribution of the sample

over the sieve mesh. The surface should be rigid and robust where vibration will not cause problems.

Operators should be familiar with and fully understand the controls and indicators before

operating this machine. This should be done in conjunction with the diagram below and control

panel description.

CLAMP PLATE

CLAMP HAND

WHEELS

SIEVE STACK

LARGE PLAIN

CLAMP WASHERS

ROUND

CLAMP RODS

MAINS SWITCH

MAINS POWER CONNECTION

SERIAL CONNECTION

FUSE HOLDER

CONTROL PANEL

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

37

1. Technical specifications

1 & 3 LED light to indicate chosen interval operation, ON.

2

Interval mode button M1 switches interval operation ON/OFF,

upper LED lights up – 1 second on, 1 second off.

3

Interval mode button M2 switches interval operation ON/OFF,

upper LED lights up – 10 seconds on, 2 seconds off.

5 Display shows the preselected sieving time, 00:10 – 99:50 sec‘s.

6 LED light to indicate START button “>” ON.

7 Start the machine by pressing the START button “>”.

8 & 10 “˅“ and “˄” button reduces/increases the sieving time, 00:10 – 99:50 min.

9

Stop the machine by pressing the STOP button “

□“.

11 & 12

“˅“ and “˄” button reduces/increases the amplitude, 0.20 – 3.00mm, with digital

display

13 Display amplitude shows the amplitude of 0.20 – 3.00mm

8 9 13 1 4 6 2 3 7

11 5 12

10

38

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Setting Up

Electrical connections

* The voltage and frequency for the Octagon 200CL is

given on the rating label.

* Ensure that the values agree with the existing power

supply.

* Connect the Octagon 200CL to the power supply using

the connection cable provided.

* When connecting the power cable to the mains

external fusing is necessary according to the

regulations of the installation location

Do not connect to any other supply other than stated on the rating label,

otherwise electrical and mechanical components can be damaged.

Ambient temperature: 5°C to 40°C

If the ambient temperature is exceeded or drops below the specified value

the electrical and mechanical components may become damaged and the

performance data can change to an unknown degree.

Atmospheric humidity:

Maximum relative humidity 80% at temperatures up to 31°C, with linear

reduction down to 50% relative humidity at 40°C.

At high atmospheric humidity the electrical and mechanical components

may become damaged and the performance data can change to an

unknown degree.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

39

1. Technical specifications

Transport protection

Place the Octagon 200CL on a stable laboratory bench, since otherwise unpleasant

vibrations will be transmitted. Being placed on a level surface ensures symmetrical

distribution of the sample over the sieves, during operation.

• Unscrew the two hexagon screws (transit bolts) on the bottom of the sieve shaker with

an open ended spanner until the sieve plate is movable.

• Keep hexagon screws (transit bolts) for possible transport at a later date.

If the machine is operated with the transit bolts

, or is transported without

transit bolts, mechanical components may become damaged.

Reusing transit bolts

• Dismount the clamping unit.

• Screw the hexagon screws (transit bolts) into the two holes on the bottom of the sieve

shaker and tighten with open ended spanner until the sieve plate is no longer movable.

Mount sieve clamping unit

Fit one M12 nut onto each clamp rod selected for use, then screw the pair of clamp rods into the

location plate and tighten the locknuts.

40

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Place the two large plain washers over the 20mm threads of the clamp sleeves. These can be seen

protruding vertically from the two side lugs on the clamp plate. Screw the two hand wheels

loosely onto the 20mm threads; leave a gap of 5 mm between the large washer and the hand wheel

face. Do not tighten right down at this point.

WASHER

HAND WHEEL

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

41

1. Technical specifications

Operating Instructions

1 Place the receiver centrally on the location plate in the appropriate recess.

2 Stack the required test sieves on top of the receiver (min. 1x receiver + 2x sieves + 1x lid).

3 Put the sample in the top sieve and fit the lid

In order to guarantee exact results under fast sieving conditions, the quantity of material to be sieved

should be adapted to the sieve diameter and the nominal mesh size.

More detailed information is displayed in our “TEST SIEVING MANUAL”.

4 Align the locking assemblies in figure 1 the two side lugs of the clamp plate with the round

clamp rods. Slide the clamp plate down squarely onto the lid at the top of the sieve stack.

Ensure that the clamping hand wheels at the top (figure 2) are loose and the locking assemblies are

fully pushed down. There should be a 5mm gap between the large plain washer and the face of the

hand wheel.

Place one hand on the top of the clamp plate (figure 3) and hold square while locking one side handle

lever. Repeat for the opposite side handle lever.

The side handle levers can be set vertically downwards by pressing on the Red button and pulling

the handle outwards to release (figure 4). Turn the handle to a safe, convenient angle downwards and

42

Copyright © 2015 by Endecotts Ltd.

1. Setting up

release to engage the teeth. Screw the two clamping hand wheels down simultaneously to ensure the

clamping plate is square.

Continue until the hand wheels are tight against the internal stop. Hand tightness must be exerted so

that the assembly does not loosen during vibration.

The locking side handle levers and clamping hand wheels must be tightened sufficiently to ensure

that the sieves and receiver are clamped securely during operation.

5 Set time, interval and amplitude

6 Press START

Damage may occur if the shaker is allowed to operate with a loose clamping plate.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

43

1. Technical specifications

Wet sieving

The Wet Sieving Adaptor Kit is supplied as an optional extra for 200 mm or 8” diameter sieves and

should be ordered separately.

The Wet Sieving Adaptor Kit consists of the following items:

• 1 off Special Wet Sieving Clamp Plate.

• 1 Set off O-ring Seals (One required for

each sieve in the stack.)

• 1 off Special Wet Sieving Receiver with a spout

(Specify for 200 mm or 8” diameter sieves )

The O-ring seals are fitted on to the outside of the bottom rim of each sieve, which means the

sieves are stacked onto each other and they form a seal.

The bottom sieve is placed on the special receiver with a spout.

A nylon hose tail must be fitted and must have a suitable length of hose fitted to drain into a

convenient drainage point.

Fit a suitable length of hose to the spout to drain into a convenient drainage point.

The clamp plate is usually supplied with the rose reversed to avoid damage. Undo and reverse,

so that the rose head is on the inside. Remove the lid from the sieve stack and replace the standard

clamp plate with the wet sieving clamp plate. Fit a suitable length of hose to the inlet of the rose on

the clamp plate and connect to the fluid supply with flow regulation.

Never operate your Sieve shaker directly in water.

Danger through current surge.

During wet sieving always operate your Sieve shaker connected to a mains socket

protected by an FI protective (safety) switch.

The water quantity added should always be dosed in such a way that the sieve

surface is only just wetted.

44

Copyright © 2015 by Endecotts Ltd.

1. Setting up

CERTIFICATE OF CE-CONFORMITY

TEST SIEVE SHAKER

OCTAGON 200CL

Certificate of CE-Conformit y according to:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

EN ISO 12100 Security of machines

EC Directive Electromagnetic Compatibility 2004/108/EC

Applied standards, in particular:

EN55011:2009+A1:2010, Group 1, Class B Radio disturbance characteristics –

Limits and methods of measurement

EN 61000-3-2:2006+A1:2009+A2:2009

EN 61000-3-3:2008

EN61326-1:2006

Additional applied standards, in particular

EN 61010 Safety prescriptions concerning measuring, operating, controlling and laboratory equipment

Authorised for the compilation of technical documents:

Endecotts Ltd (technical documentation)

The following records are held by Endecotts Ltd in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required

for conformity assurance, analysis of the residual risks involved and operating instructions in due form

according to the approved regulations for preparation of user information data.

The CE-conformity of the Endecotts Test Sieve Shaker Type Octagon 200CL is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not licensed

spare parts and accessories this certificate will lose its validity.

Endecotts Ltd London, July 2014

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

45

1. Technical specifications

6. Operating instructions:

Air Sizer 200

46

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Technical specifications

SIEVING MACHINE MODEL:

Air Sizer 200

General Information

The Air Sizer 200 has an air nozzle, which is set rotating. The sieve with a Plexiglas lid is put on top of that. A

vacuum unit generates a jet of air, which disperses the particles through the air nozzle on the sieve.

The material, which is smaller than the mesh size of the air jet sieve, is transported by the backflow of the air

into the filter unit or directly into the vacuum cleaner. The jet of air de-agglomerates the particles and cleans the

sieve mesh constantly.

The Air Sizer 200 is specially designed for the dry sieving and the particle size determination of fine-grained,

dry, pourable and dispersed bulk materials. The sieve holder is suitable for 8“(203 mm) diameter test sieves

(premium air jet sieves)

Advantages

• Compact and portable (weighing only 14 kg)

• Requires only small storage space due to small footprint

• The device is essentially maintenance free if cleaned regularly

• Easy to use

• Ideal for electrostatic materials

• Wide range voltage supply

• Can reduce the average sieving times in samples with a high fine fraction

• Variable vacuum control

The Air Sizer 200 is not recommended for any wet sieving operations!

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

47

1. Technical specifications

Specifications

Range 20 µm to 4 mm

Drive / sieving motion stepping motor

Max. Batch / feed capacity 100 g (depending on material and mesh)

Max. Number of fractions 1

Amplitude N/A

Speed 5 to 55 rpm

Time display digital, 00:10 – 99:50 min

Suitable for dry sieving yes

Suitable for wet sieving no

Sieve diameter 203 mm = 8” (premium air jet sieves)

Clamping device N/A

Model bench top

Protection code IP 40

Electrical supply 100 - 240V 50/60 Hz

Power connection 1-phase

W x H x D 430 x 235 x 435 mm

Net weight 14 kg

Standards CE

48

Copyright © 2015 by Endecotts Ltd.

1. Setting up

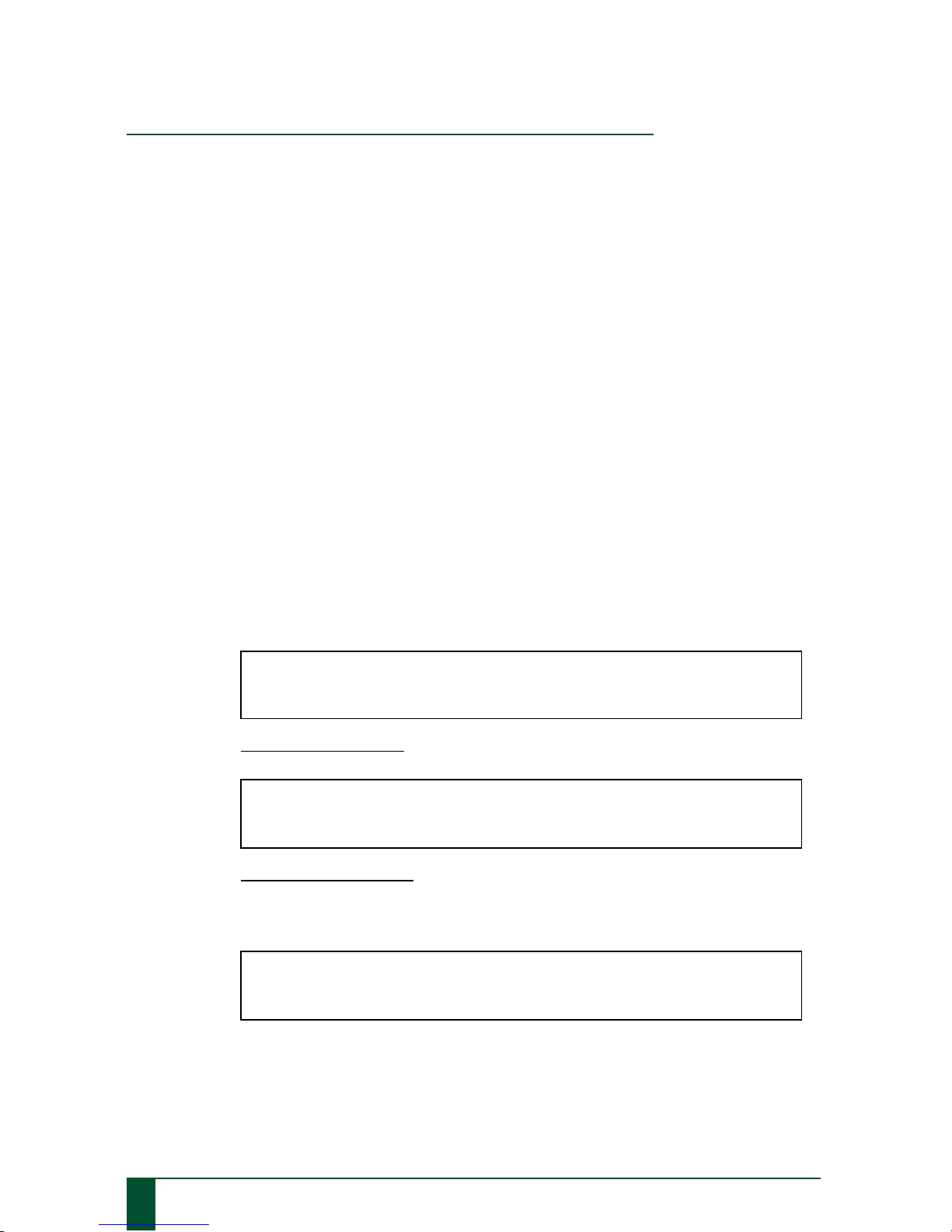

Controls and functions

Operators should be familiar with and fully understand the controls and indicators before

operating this machine.

PLEXIGLASS LID FOR AIR JET

SIEVING

TEST SIEVE

AIR OUTLET

CHANNEL

MAINS SWITCH

CONTROL

PANEL

COVER

BASE

NOZZLE

COMPARTMENT

MAINS POWER

CONNECTION

Electrical Connection

to vacuum cleaner

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

49

1. Technical specifications

1 Vacuum pressure in mbar

2 Display shows the preselected sieving time, 00:10 – 99:50 min

3 LED light to indicate START button “>” ON.

4 Start the machine by pressing the START button “>”.

5 & 7 “˅“ and “˄” button reduces/increases the sieving time, 00:10 – 99:50 min

6

Stop the machine by pressing the STOP button “

□“.

8 & 9 “˅“ and “˄” button reduces/increases the rpm, 5-55rpm, with digital display

10 Display speed shows the speed of 5-55rpm

5

6

10 3 1

4 8 2 9 7

50

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Setting Up

Electrical connections

• Ensure that the voltage and frequency on the rating label, at the rear of the Air Sizer 200

correspond with the local electrical mains supply.

• Connect the Air Sizer 200 to the power supply using the connection cable provided.

Do not connect to any other supply other than stated on the rating label,

otherwise electrical and mechanical components can be damaged.

Ambient temperature: 5°C to 40°C

If the ambient temperature is exceeded or drops below the specified value

the electrical and mechanical components may become damaged and the

performance data can change to an unknown degree.

Atmospheric humidity:

Maximum relative humidity 80% at temperatures up to 31°C,

with linear reduction down to 50% relative humidity at 40°C.

At high atmospheric humidity the electrical and mechanical components

may become damaged and the performance data can change to an

unknown degree.

• Mains power connection

Mains power connection with integral line filter. Ensure the IEC connector

on the mains lead is pushed fully into the mains inlet at the rear of the machine.

• Mains Connection Indication

If the power of the Air sizer 200 is switched “ON”, the display LED lights up.

• Process Timer

The process timer is a digital 00:10-99:50 minute timer. Operating periods

are increased by pressing the “˄” button and decreased by pressing the “˅“ button.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

51

1. Technical specifications

Start-up and commissioning

The machine should be set up according to the following procedure.

The following items should be removed from the carton and checked before the Air Sizer 200 is

operated (Take Care the Air sizer 200 weighs 14 kg):

• 1 off Set-up Instructions.

• 1 off Mains Cable.

• 1 off Air Sizer fitted

• 1 off Plexiglas lid

• Soft-Faced Mallet

• Test Sieving Manual.

Position the Air Sizer 200 on a level, rigid and robust bench, suitable for the operation of the Air

Sizer. Being placed on a level surface ensures symmetrical distribution of the sample over the sieve,

during operation.

52

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Operating Instructions

Switching On and Off

• Press the on/off switch at the back to turn on the device.

When the switch is in the "off" position, the device must be disconnected completely from the mains

power supply (f.e. before cleaning the device).

Inserting the test sieve

The

Air Sizer 200 is intended for test sieves with a diameter of 203mm (8 inches). The range of mesh

fineness extends from 10

µm

to approx. 4mm.

• Pla

ce the sieve in the nozzle compartment.

• Fit the Plexiglas lid provided.

NOTE:

The Air Sizer 200 cannot be started until the sieve has been inserted and the lid put on.

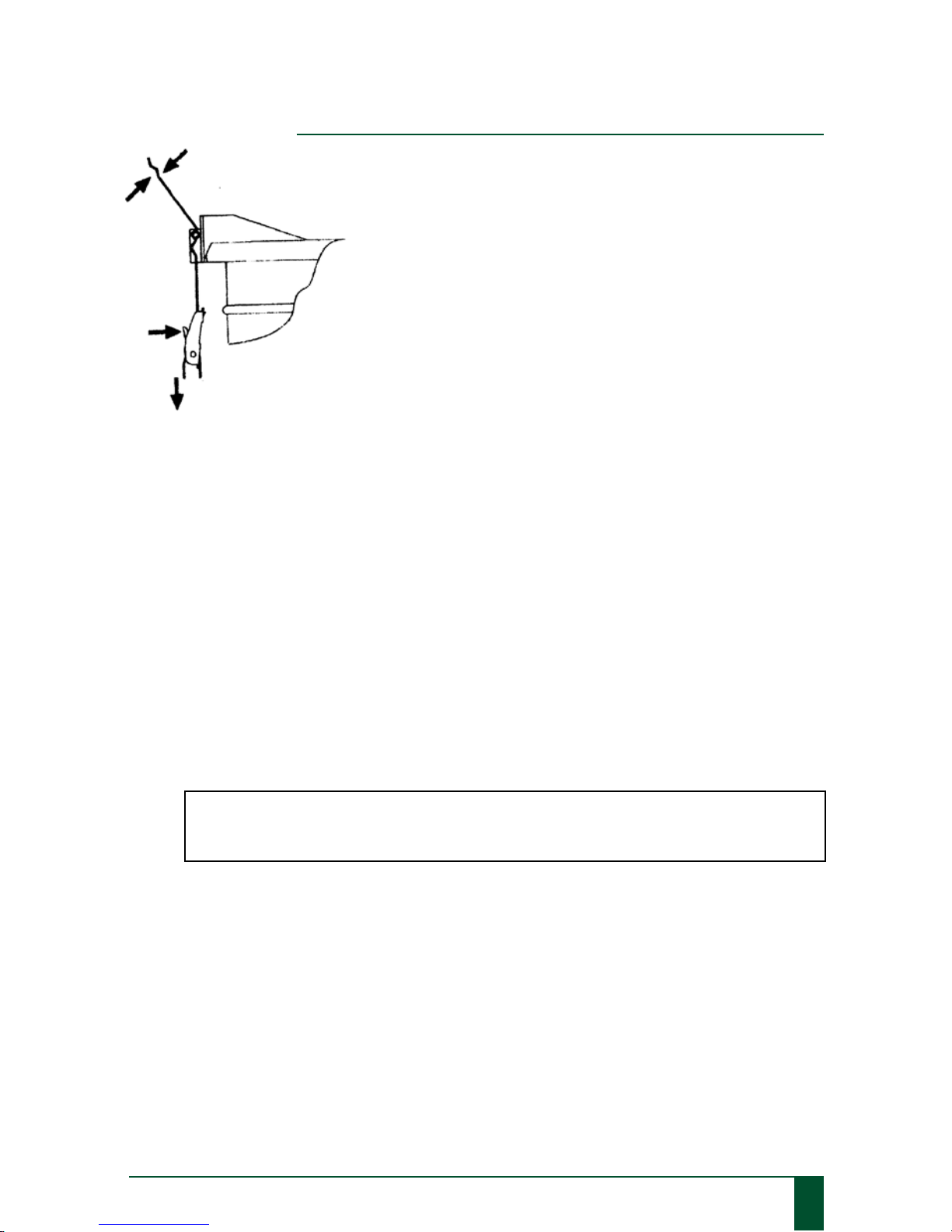

Soft-faced mallet – Application and Use

Any caking that has built up during the sieving process is knocked off the inside of the lid by means

of the soft-faced mallet.

Tap lightly, striking the centre of the knob as far as possible.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

53

1. Technical specifications

Use of the machine for the intended purpose

Risk of explosion or fire

• On account of its design, the device is not suitable for use in hazardous

(potentially explosive) atmospheres.

• Do not operate the device in a hazardous atmosphere.

Risk of explosion or fire

Changing sample characteristics

• Note that the characteristics and accordingly the danger presented by a sample

can change during sieving.

• Do not sieve any potentially explosive or combustible materials in this device.

Danger of personal injury

Dangerous nature of the sample

• Depending on the dangerous nature of your sample, take the necessary

measures to rule out any danger to persons.

•

Observe the safety guidelines and datasheets of your sample material.

Note:

Area of use of the machine

• This machine is a laboratory machine designed for 8-hour single-shift operation.

•

This machine may not be used as a production machine nor is it intended for

continuous operation.

Note:

Defects in components due to liquids

Penetration of liquids inside the housing

• Components are damaged and the correct functioning of the device is no longer

assured.

• Do not use this device for any wet sieving.

Hearing damage or hearing loss

Suction noise at the suction opening

• The volume and/or force of drawn-in air can damage hearing or cause hearing

loss.

• Keep your ears away from the air inlet in the channel. Use hearing protection.

Failure to hear acoustic signals

Loud suction noise on the air inlet

• It is possible that some acoustic warnings and voice communication may not be

noticed.

• Take the strength of the suction noise into consideration when designing your

acoustic signals in the working environment.

Possibly additionally use visual

signals.

Noise characteristics:

The Air Sizer 200 itself is constructed in a manner that prevents any significant development of noise. The noise

characteristics of the connected industrial vacuum cleaner depend on the set suction force and suction load.

54

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Note:

Ensure that the differential pressure or vacuum generated by your vacuum cleaner or

the suction is not greater than 99 mbar.

The maximum quantity of material to be sieved depends on the mesh size and sieve

size.

Rated Power:

Air Sizer 200 : maximum 50 watts

Air Sizer 200 + vacuum cleaner: maximum 1450 watts

When connecting the power cable to the mains supply, use an external fuse that

complies with the regulations applicable to the place of installation .

• Please check the rating label for details on the necessary voltage and frequency

for the device.

• Make sure the levels agree with the existing mains power supply.

• Use the supplied connection cable to connect the device to the mains power

supply.

The external fuse must be at least T15A (230V) T15A (100/120V).

Danger to life through electric shock

• An electric shock can lead to burns and to cardiac arrhythmias or to respiratory

arrest and cardiac arrest.

• The device may only be operated with plugs that have a protective conductor

(earthed).

Connecting the external Industrial Vacuum cleaner

Electric shock

Faulty power cable

• When you switch the device on there is danger of an electrical shock if the power

cable for the external suction device is damaged.

• Before use, check the power cable between the sieve device and the suction

device for possible damage.

•

Never use a damaged power cable!

Objects thrown-out or falling down

Connection of compressed air instead of vacuum cleaner

• If compressed air is connected to one of the two air openings, the sieve lid and

the sieve will be hurled out.

• This device may not be operated with compressed air.

The Air Sizer 200 can be operated only with a suction extractor, such as for example a vacuum

cleaner.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

55

1. Technical specifications

Connection of the industrial vacuum cleaner

• Connect your vacuum cleaners suction tube to the air outlet channel

• Insert the type F IEC C14 connector on the vacuum cleaner into the IEC C13 panel-mounted

outlet. The power for the industrial vacuum cleaner is supplied from the Air Sizer 200.

Negative Pressure

Display shows the neg. Pressure........... (Range from 00 to 99 mbar)

NOTE:

If the neg. pressure is more than 99 mbar -> sensor could be destroyed

The air jet can be changed by turning the manual air jet setting.

[1] Air entry opening closed è maximum air jet

[2] Air entry opening open è minimum air jet

The difference in air pressure (differential pressure) between the air inlet and air outlet at a given

moment is displayed.

Operating Software

The operating software version is displayed for 5 seconds having switched on the machine.

Starting, Stopping

• Switch the device on by pressing the on/off switch at the back.

• set the sieving parameters you want.

• Put the test sieve with the sample onto the nozzle compartment.

• Place the lid on the sieve.

56

Copyright © 2015 by Endecotts Ltd.

1. Setting up

NOTE:

The sieving will not start if the lid is not on.

• Start sieving by pressing the START button “>”.

• Stop the sieving by pressing the STOP button “

□“.

Filter (Option)

Electrostatic charge inside the devices is prevented by earthing the device via the protective

conductor on the electrical connection. Ensure the correct assembly of filter unit in order to

guarantee sufficient earthing.

NOTICE:

Despite this, electrostatic charge separation may however still occur between the sample and

receptacle wall inside the collecting receptacle depending on the sample property, flow speed and air

humidity.

Cleaning and service

WARNING:

Risk of a fatal electric shock

- An electric shock can cause injuries in the form of burns and cardiac arrhythmia, respiratory arrest

or cardiac arrest.

• Do not clean the machine under running water. Use only a cloth dampened with water.

• Disconnect the power supply plug before cleaning the blender.

Cleaning

We recommend ultrasonic baths for thorough, gentle and time-saving cleaning of your test sieves.

Clean the air outlet channel regularly using a brush to remove any deposits.

• Vacuum cleaner – changing the vacuum cleaner bag

• Change the vacuum cleaner bag or empty the dust container on your vacuum cleaner

regularly as required.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

57

1. Technical specifications

• Check the degree of soiling of the vacuum cleaner filter regularly and change the filter

where applicable.

• The vacuum or differential pressure generated by the vacuum cleaner may otherwise be

too low for sieving.

• Maintenance

This device is essentially maintenance-free if cleaned regularly.

E11

MOTOR

FAULTY/BLOCKED

Service required

E83

VACUUM TOO LOW

Check whether

• the suction apparatus is connected;

• the suction apparatus is generating

sufficient vacuum;

• The collecting receptacle in the suction

apparatus is full;

• the sieve cover is attached.

E84

DROP IN VACUUM

Check whether

• the sieve cover is attached;

• the suction hose has been connected;

• the vacuum cleaner bag is full.

58

Copyright © 2015 by Endecotts Ltd.

1. Setting up

CERTIFICATE OF CE-CONFORMITY

ANALYTICAL SIEVE SHAKER

Air Sizer 200

Certificate of CE-Conformit y according to:

EC Mechanical Engineering Directive 2006/42/EC

Applied harmonized standards, in particular:

EN ISO 12100 Security of machines

EC Directive Electromagnetic Compatibility 20 04/108/EC

Applied standards, in particular:

EN55011:2009+A1:2010, Group 1, Class B Radio disturbance characteristics –

Limits and methods of measurement

EN 61000-3-2:2006+A1:2009+A2:2009

EN 61000-3-3:2008

EN61326-1:2006

Additional applied standards, in particular

EN 61010 Safety prescriptions concerning measuring, operating, controlling and laboratory equipment

Authorised for the compilation of technical documents:

Endecotts Ltd (technical documentation)

The following records are held by Endecotts Ltd in the form of Technical Documentation:

Detailed records of engineering development, construction plans, study (analysis) of the measures required

for conformity assurance, analysis of the residual risks involved and operating instructions in due form

according to the approved regulations for preparation of user information data.

The CE-conformity of the Endecotts Analytical Sieve Shaker Type Air Sizer 200 is assured herewith.

In case of a modification to the machine not previously agreed with us as well as the use of not licensed

spare parts and accessories this certificate will lose its validity.

Endecotts Ltd London, July 2014

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

59

1. Technical specifications

7. Operating instructions:

EFL 300

60

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Technical specifications

SIEVE SHAKER MODEL:

EFL 300

General Information

The new EFL 300 combines the best features of the EFL2 whilst incorporating modern sieve

shaker technology. It is still extremely robust but lightweight and more powerful than its

predecessor. Heavier and larger samples can be sieved with the new EFL 300.

It is extremely versatile. Amplitude setting is now standard and interval mode possible.

The heavy electric motor is replaced by the electromagnetic system found in all modern

sieve shakers. Its lighter form means that it can be either floor standing or even bench

mounted making it suitable for the both laboratory and industrial environments. Sieving

parameters are set by the remote control unit. Its functions are logical and very simple to

operate.

Advantages

• New electromagnetic drive for EFL 300

• Adjustable amplitude

• Floor or table mounted

• Suitable for wet or dry sieving

• Digital controls for easy and reliable operation via external interface

• Economical

Do not make any changes to the machine and use only spare parts and

accessories approved by Endecotts Ltd.

The declaration of conformity to the European directives by Endecotts

will otherwise lose its validity.

Furthermore this will result in the loss of any kind of guarantee claims.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

61

1. Technical specifications

Specifications

Range 20 µ

m to 125 mm

Drive / sieving motion electromagnetic 3D

Max. Batch / feed capacity 6 kg

Max. Number of fractions 6 full height / 12 half height (300 mm or 12”)

Amplitude 0 - 2 mm digital setting in 10 steps

Speed 3,000 min-1 at 50 Hz

Time display digital, 0:10-99:50 min

Interval operation yes (one mode)

Suitable for dry sieving yes

Suitable for wet sieving yes

Serial interface -

Sieve diameter 100 / 150 / 200 / 250 / 300 / 315 mm or 3” / 8” / 12”

Clamping device quick-release clamping system (included)

Model bench top or floor standing

Protection code IP 54

Electrical supply different voltages available

Power connection 1 – Phase

Ø x H 427mm x 240 mm (without clamping unit)

Net weight ~ 45 kg

Standards CE

Noise characteristic values:

Example 1:

Emission value related to workplace LpAeq = 63 dB (A)

(Operating conditions: Material to be sieved = quartz sand, grain size < 1mm, 5 sieves Amplitude =

1.5 mm)

Example 2:

Emission value related to workplace LpAeq = 67 dB (A)

(Operating conditions: Material to be sieved = quartz sand, grain size < 1mm, 5 sieves Amplitude =

3 mm)

62

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Controls and functions

The sieve shaker should be placed on a level surface to ensure symmetrical distribution of the sample

over the sieve mesh. The surface should be rigid and robust where vibration will not cause problems.

Operators should be familiar with and fully understand the controls and indicators before

operating this machine. This should be done in conjunction with the diagram below and control

panel description.

CLAMP PLATE

CLAMP HAND

WHEELS

SIEVE STACK

LARGE PLAIN

CLAMP WASHERS

ROUND

CLAMP RODS

REMOVABLE

CONTROL BOX

FUSE HOLDER

MAINS POWER

CONNECTION

MAINS SWITCH

INTERFACE FOR

CONTROL BOX

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

63

1. Technical specifications

Control Box

• Connected to the machine by a 2 m serial line

• Could be mounted on the wall or placed on a table next to the machine

1 LED light to indicate interval operation ON.

2

Interval mode button M1 switches interval operation ON/OFF,

upper LED lights up; 10 seconds on, 2 seconds off

3 Display shows the preselected sieving time, 00:10 – 99:50 min.

4 LED light to indicate START button “>” ON

5 Start the machine by pressing the START button “>”.

6 & 8 “˅“ and “˄” button reduces/increases the sieving time, 00:10 – 99:50 min.

7

Stop the machine by pressing the STOP button “

□“.

9 & 10 “˅“ and “˄” button reduces/increases the amplitude, in 10 steps

11 10 LED’s for the Power bar indicating amplitude setting in 10 steps

6 7 4 1 5 3 11 2 9

10

8

64

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Setting Up

Electrical connections

* The voltage and frequency for the EFL 300 is given on

the rating label.

* Ensure that the values agree with the existing power

supply.

* Connect the EFL 300 to the power supply using the

connection cable provided.

* When connecting the power cable to the mains

external fusing is necessary according to the

regulations of the installation location

Do not connect to any other supply other than stated on the rating label,

otherwise electrical and mechanical components can be damaged.

Ambient temperature: 5°C to 40°C

If the ambient temperature is exceeded or drops below the specified value

the electrical and mechanical components may become damaged and the

performance data can change to an unknown degree.

Atmospheric humidity:

Maximum relative humidity 80% at temperatures up to 31°C, with linear

reduction down to 50% relative humidity at 40°C.

At high atmospheric humidity the electrical and mechanical components

may become damaged and the performance data can change to an

unknown degree.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

65

1. Technical specifications

Transport protection

Warning!

Serious personal injury

• THE APPLIANCE IS VERY HEAVY AND CAN THEREFORE CAUSE SERIOUS

PERSONAL INJURIES.

• NEVER LIFT ABOVE HEAD HEIGHT.

Unscrew the screws on either side of the machine

NOTICE

The transport lock can also be used as carrying aid

You can also use the transport lock for lifting the device with a

crane.

NOTICE

The housing can be damaged if the lifting straps are too short.

- Use 4 sufficiently long lifting straps.

- Observe the minimum distance between the device and the lifting gear.

IMPORTANT

If the machine is operated with the transit bolts, or is transported without transit

bolts, mechanical components may become damaged.

66

Copyright © 2015 by Endecotts Ltd.

1. Setting up

The transit bolts are fixed to the underneath of the device.

Use a 13 mm wrench to attach and remove the four screws.

Place the EFL 300 on a stable floor, since otherwise unpleasant vibrations will be

transmitted. Being placed on a level surface ensures symmetrical distribution of the sample

over the sieves, during operation.

• Unscrew the two hexagon screws (transit bolts) on the bottom of the sieve shaker with

an open ended spanner until the sieve plate is movable.

• Keep hexagon screws (transit bolts) for possible transport at a later date.

IMPORTANT

If the machine is operated with the transit bolts

, or is transported without

transit bolts, mechanical components may become damaged.

Reusing transit bolts

• Dismount the clamping unit.

• Screw the hexagon screws (transit bolts) into the two holes on the bottom of the sieve

shaker and tighten with open ended spanner until the sieve plate is no longer

movable.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

67

1. Technical specifications

Mount sieve clamping unit

Fit one M12 nut onto each clamp rod selected for use, then screw the pair of clamp rods into the

location plate and tighten the locknuts.

Place the two large plain washers over the 20mm threads of the clamp sleeves. These can be seen

protruding vertically from the two side lugs on the clamp plate.

Screw the two hand wheels loosely onto the 20mm threads; leave a gap of 5 mm between the large

washer and the hand wheel face. Do not tighten right down at this point.

WASHER

HAND WHEEL

SIDE

HANDLE

LEVER

68

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Operating Instructions

1. Place the receiver centrally on the location plate in the appropriate recess.

2. Stack the required test sieves on top of the receiver (min. 1x receiver + 2x sieves + 1x lid).

3. Put the sample in the top sieve and fit the lid

In order to guarantee exact results under fast sieving conditions, the quantity of material to be sieved

should be adapted to the sieve diameter and the nominal mesh size.

More detailed information is displayed in our “TEST SIEVING MANUAL”.

4. Align the locking assemblies in figure 1 the two side lugs of the clamp plate with the round

clamp rods. Slide the clamp plate down squarely onto the lid at the top of the sieve stack.

Ensure that the clamping hand wheels at the top (figure 2) are loose and the locking assemblies are

fully pushed down. There should be a 5mm gap between the large plain washer and the face of the

hand wheel.

1. Technical specifications

Copyright © 2015 by Endecotts Ltd.

69

1. Technical specifications

Place one hand on the top of the clamp plate (figure 3) and hold square while locking one side handle

lever. Repeat for the opposite side handle lever.

The side handle levers can be set vertically downwards by pressing on the Red button and pulling

the handle outwards to release (figure 4). Turn the handle to a safe, convenient angle downwards and

release to engage the teeth. Screw the two clamping hand wheels down simultaneously to ensure the

clamping plate is square.

Continue until the hand wheels are tight against the internal stop. Hand tightness must be exerted so

that the assembly does not loosen during vibration.

The locking side handle levers and clamping hand wheels must be tightened sufficiently to ensure

that the sieves and receiver are clamped securely during operation.

5. Set time and amplitude.

6. Press START

Damage may occur if the shaker is allowed to operate with a loose clamping plate.

70

Copyright © 2015 by Endecotts Ltd.

1. Setting up

Wet sieving

The Wet Sieving Adaptor Kit is supplied as an optional extra for 300mm or 12” diameter sieves and

should be ordered separately.

The Wet Sieving Adaptor Kit consists of the following items:

• 1 off Special Wet Sieving Clamp Plate.

• 1 Set off O-ring Seals (One required for

each sieve in the stack.)

• 1 off Special Wet Sieving Receiver with a spout

(Specify for 300 mm or 12” diameter sieves )

The O-ring seals are fitted on to the outside of the bottom rim of each sieve, which means the

sieves are stacked onto each other and they form a seal.

The bottom sieve is placed on the special receiver with a spout.

A nylon hose tail must be fitted and must have a suitable length of hose fitted to drain into a

convenient drainage point.

Fit a suitable length of hose to the spout to drain into a convenient drainage point.

The clamp plate is usually supplied with the rose reversed to avoid damage. Undo and reverse,

so that the rose head is on the inside. Remove the lid from the sieve stack and replace the standard

clamp plate with the wet sieving clamp plate. Fit a suitable length of hose to the inlet of the rose on

the clamp plate and connect to the fluid supply with flow regulation.