ENDEAVOUR Hydralok H25BE4, Hydralok H32BE4, Hydralok H50BE4, Hydralok H32CE4, Hydralok H50CE4 User Manual

...

ENDEAVOUR Int. Ltd. Tel +44 (0) 1225 446770 Fax +44 (0) 1225 446775

Long press Jog wheel to

go to

Main Menu at any time

www.endeavouri

nternational.ltd.uk

USER MANUAL

Types H25BE4,H32BE4,H32CE4

Swaging Machine

H50BE4, H50CE4, H50CE6

1

ENDEAVOUR Int. Ltd. Tel +44 (0) 1225 446770 Fax +44 (0) 1225 446775

Long press Jog wheel to

go to

Main Menu at any time

www.endeavouri

nternational.ltd.uk

Table Of Contents

Table Of Contents .........................................................................................................................2

WARRANTY CONDITIONS.......................................................................................................3

WARRANTY CONDITIONS.......................................................................................................4

EC DECLARATION OF CONFORMITY ....................................................................................5

SAFETY REGULATIONS ...........................................................................................................6

TECHNICAL / DIMENSIONAL DATA ......................................................................................7

HANDLING/TRANSPORT..........................................................................................................7

PRELIMINARY CHECKS ...........................................................................................................7

LIGHTING ...................................................................................................................................7

ROUTINE MAINTENANCE........................................................................................................8

INSTALLATION..........................................................................................................................8

Three Phase Machines:..............................................................................................................8

Single Phase Machines: .............................................................................................................8

Starting the machine for the first time:.......................................................................................8

SAFETY PRECAUTIONS............................................................................................................8

MANUAL SWAGING PROCEDURE (Machines without Quick Change)..................................10

MANUAL SWAGING PROCEDURE (Machines with Quick Change) ......................................11

QUICK CHANGE TOOL OPERATING INSTRUCTIONS *.....................................................12

Inserting dies into the machine ................................................................................................12

AUTO MODE *..........................................................................................................................13

Dwell*: ...................................................................................................................................13

Opening Time .........................................................................................................................13

Hose Counter*.........................................................................................................................14

Swage Offset...........................................................................................................................14

ADVANCED OPTIONS.............................................................................................................15

Preset Menu *..........................................................................................................................15

Save a Preset .......................................................................................................................15

Use a preset .........................................................................................................................16

Edit a preset.........................................................................................................................17

Delete a preset .....................................................................................................................17

SETUP MENU............................................................................................................................19

Die Table.................................................................................................................................19

Custom Die Sets ..................................................................................................................19

Lubrication..............................................................................................................................21

Quick Change (QC) Position Adjustment †..............................................................................23

Calibration Instructions ...........................................................................................................24

Display....................................................................................................................................26

Language.................................................................................................................................26

Reset to Factory Settings .........................................................................................................27

TECHNICAL INFORMATION..................................................................................................28

Maintenance And Service........................................................................................................28

Spare Parts ..............................................................................................................................28

Swaging Head Drawing (Fig 1) ...............................................................................................29

Die Chart.................................................................................................................................30

Die Fitting Instructions............................................................................................................31

Electrical Diagram: 3 Phase.....................................................................................................33

2

ENDEAVOUR Int. Ltd. Tel +44 (0) 1225 446770 Fax +44 (0) 1225 446775

Long press Jog wheel to

go to

Main Menu at any time

www.endeavouri

nternational.ltd.uk

Electrical Diagram: 1 Phase.....................................................................................................34

3

ENDEAVOUR Int. Ltd. Tel +44 (0) 1225 446770 Fax +44 (0) 1225 446775

Long press Jog wheel to

go to

Main Menu at any time

www.endeavouri

nternational.ltd.uk

WARRANTY CONDITIONS

Please note that all machines undergo strict testing before shipment.

1. All machines are warranted against any defects for a period of twelve (12) months starting

from the date of delivery to the customer.

2. Defective items/machines must be returned to our address with shipping charges pre-paid. We

will return items/machines with “carriage forward”. We are unable to accept items/machines

returned to us unless carriage charges have been paid.

3. This warranty covers the replacement and or repair of any component found to be defective

during the warranty period.

4. Replacements and repairs completed under this warranty do not extend the original twelve (12)

month warranty period.

5. This warranty does not cover normal wear under normal operating conditions

6. This warranty is not valid for damage resulting from incorrect operation, or use not in

compliance with the machine instructions.

7. This warranty is not valid in case of unauthorized machine modification.

4

ENDEAVOUR Int. Ltd. Tel +44 (0) 1225 446770 Fax +44 (0) 1225 446775

Long press Jog wheel to

go to

Main Menu at any time

www.endeavouri

nternational.ltd.uk

EC DECLARATION OF CONFORMITY

5

ENDEAVOUR Int. Ltd. Tel +44 (0) 1225 446770 Fax +44 (0) 1225 446775

Long press Jog wheel to

go to

Main Menu at any time

www.endeavouri

nternational.ltd.uk

SAFETY REGULATIONS

Always work in safe conditions and with the necessary space around the machine.

Ensure that the machine is placed on a stable and appropriate working surface.

1. DO NOT USE the equipment before reading the user manual.

2. CAUTION! If improperly used, the equipment may be dangerous and may cause

injury. Do not touch any moving parts.

3. CAUTION! It is absolutely essential that all working operations are carried out by

one operator only

4. This manual must be provided for the machine operator. Ensure that the operator

is aware of his/her responsibilities.

5. Guards must never be removed or tampered with.

6. (Where applicable) A fully trained and competent electrician must connect the

machine to the appropriate electricity supply.

7. Always wear protective gloves, safety glasses and appropriate clothing.

8. (Where applicable) Disconnect the power supply before removing any covers, or

attempting any maintenance of the machine

9. Only original spare parts can be used in the maintenance of the machine.

6

ENDEAVOUR Int. Ltd. Tel +44 (0) 1225 446770 Fax +44 (0) 1225 446775

Long press Jog wheel to

go to

Main Menu at any time

www.endeavouri

nternational.ltd.uk

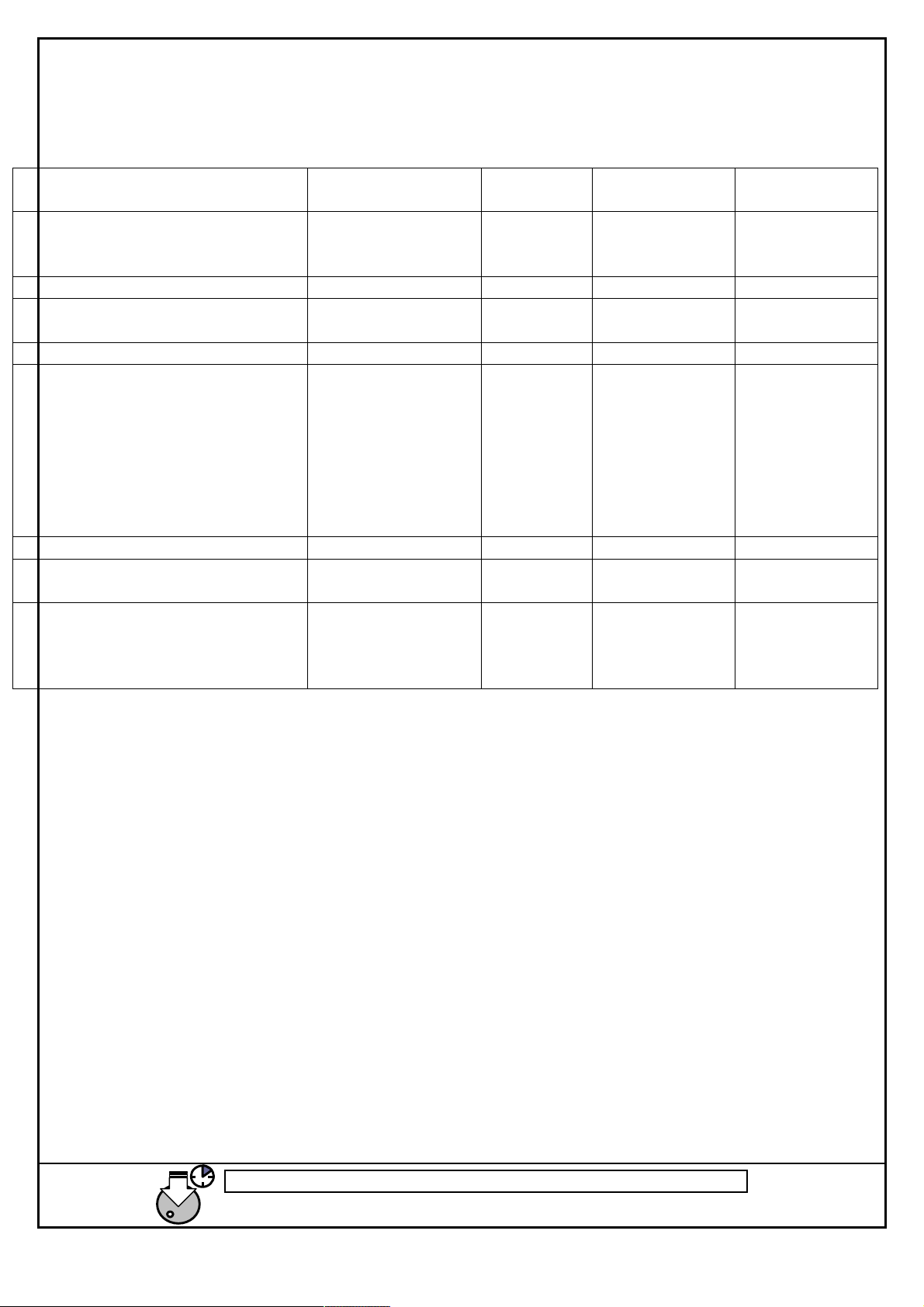

TECHNICAL / DIMENSIONAL DATA

TECHNICAL/DIMENSIONAL

DATA

Capacity 3/16”- 1” (4 wire)

Motor 2.2KW 2.2KW 2.2KW 2.2KW

Packed Dimensions in mm 900x600x900 940x640x10

Gross weight in Kg 130 130 175 300 Kg

Voltage (Current) 1 Phase

Swaging force 24 AC & DC 1750 Kn 2509 KN 4500 KN

Swaging range 6 mm – 45.9

Standard dies Not exceeding

H25BE4 H32BE4/

H32CE4

3/16”- 11/4”

R9R/4SP

220/240-150HZ (15) or

380/440-3-50HZ (5)

73dB(A)

(4 wire)

R9R/4SP

220/240-1-

220/240 -

380/440-3-

225/280 –

440/480 60

16 19 22 26

30 34 40 46

30

50HZ

50 Hz

Hz

mm

H50BE4/

H50CE4

3/16”- 2” (4

wire)

R9R/4SP

940x640x1030 800x1200x930

220/240-1-50HZ

or

220/240 -

380/440-3-50

Hz 225/280 –

440/480 60 Hz

0.6 mm – 76

mm

16 19 22 26 30

34

40 46 52 58 64

70

H50C6

3/16”- 2” (6

wire)

220/240-1-50HZ

or

220/240 -

380/440-3-50

Hz 225/280 –

440/480 60 Hz

0.6 mm – 82

mm

16 19 22 26 30

34 40 46 52 58

64 70 76

HANDLING/TRANSPORT

The machine will normally be shipped bolted to a wooden pallet . The bolts should be removed

and the machine lifted onto the work place using suitable lifting equipment.

PRELIMINARY CHECKS

Place the machine on a flat and stable base.

Where applicable, ensure that the power supply line is fitted with a differential safety breaker and

overload cut-out.

LIGHTING

The equipment does not have its own lighting and so it must be used in a suitably illuminated area.

7

ENDEAVOUR Int. Ltd. Tel +44 (0) 1225 446770 Fax +44 (0) 1225 446775

Long press Jog wheel to

go to

Main Menu at any time

www.endeavouri

nternational.ltd.uk

ROUTINE MAINTENANCE

Ensure that moving parts are always lightly greased. Where applicable check periodically that the

limit switches and emergency controls are in good working order.

At the top of the machine base, remove the oil filler cap and check that the oil level correct. Where

necessary add oil (ISO 32 Hydraulic oil).

INSTALLATION

The machine must be bolted to a firm workbench in a horizontal position. If a quick change rack is

supplied, the machine must be bolted to it with the bolts supplied. The machine is top heavy,

therefore ensure that it is stable and does not pose a danger for the user or other people.

Three Phase Machines:

When operating the machine for the first time check that the motor rotation direction is correct.

(Three phase machines only) If the motor starts but jaws of the swaging head do not begin to close

when the green button is pressed to swage, the phase rotation of the motor will have to be

reversed. To reverse the rotation of the motor change over any two of the phase cables in the

machine’s plug. A competent electrician should carry out the rewiring of the electric plug.

Single Phase Machines:

Ensure that the power loop is for industrial use, rated for at least 20Amps. Install the machine as

close to the socket as possible. Do not use long extension leads as this increases the current

demand from the machine. Do not connect to residential rated 13Amps loops.

Starting the machine for the first time:

After the machine is connected to the power supply, if the Emergency Stop is pressed, rotate it to

disengage. The LCD screen will still show the E-Stop message. This is a safety measure to avoid

starting the machine by accident. Press the jog wheel once to acknowledge the message and start

the machine..

Emergency Stop

Restart ()

SAFETY PRECAUTIONS

Switch off machine when not in use, using the latching emergency stop button To unlatch the stop

button twist the red knob clockwise and release.

To stop the machine in an emergency press the RED EMERGENCY STOP BUTTON.

DO NOT START THE MACHINE UNDER LOAD.

ALWAYS RELEASE PRESSURE BEFORE RESTARTING.

ISOLATE THE MACHINE FROM THE ELECTRICAL SUPPLY WHEN NOT IN USE.

8

ENDEAVOUR Int. Ltd. Tel +44 (0) 1225 446770 Fax +44 (0) 1225 446775

Long press Jog wheel to

go to

Main Menu at any time

www.endeavouri

nternational.ltd.uk

9

ENDEAVOUR Int. Ltd. Tel +44 (0) 1225 446770 Fax +44 (0) 1225 446775

Long press Jog wheel to

go to

Main Menu at any time

www.endeavouri

nternational.ltd.uk

L16

BUZZ

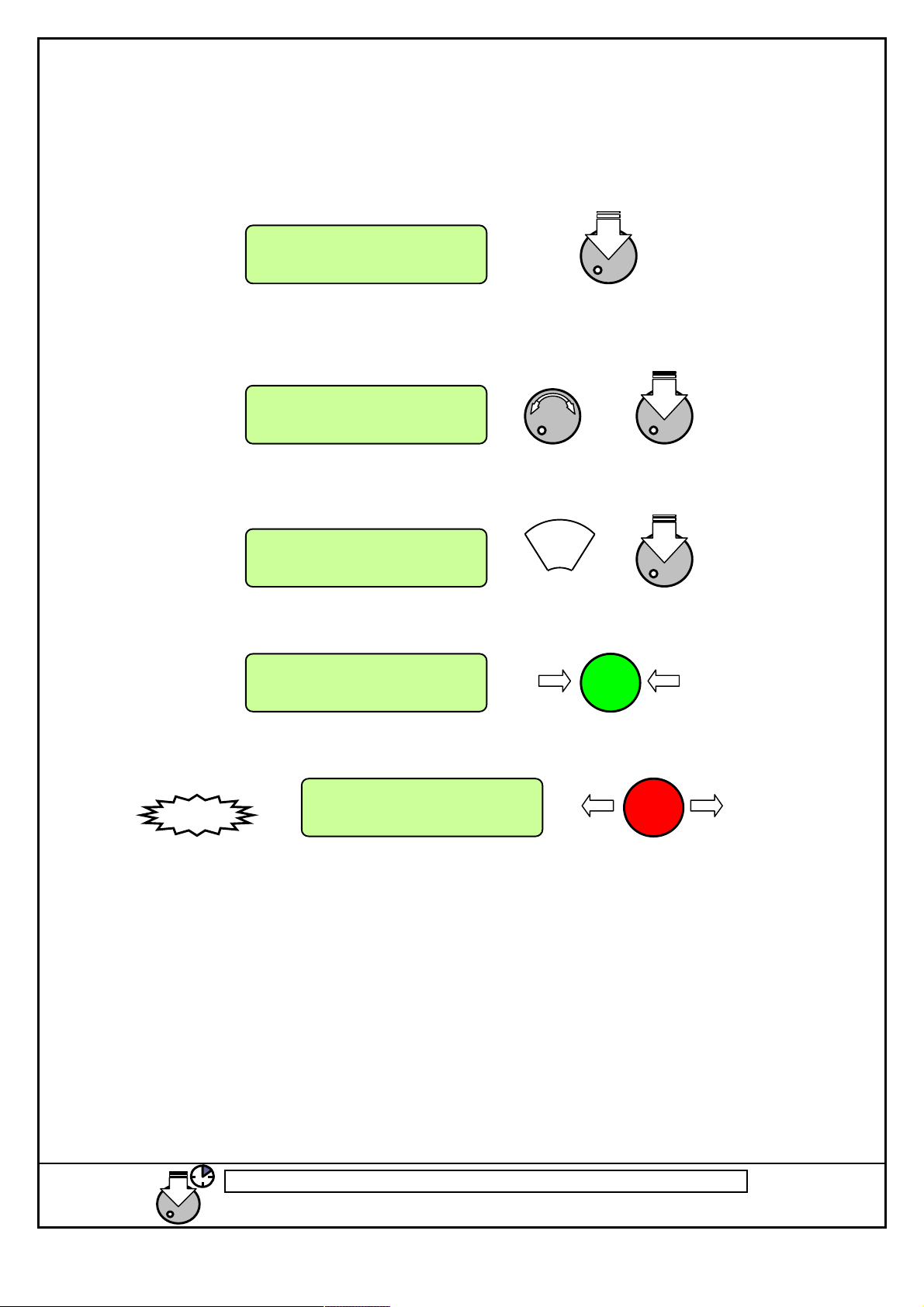

MANUAL SWAGING PROCEDURE (Machines without Quick Change)

From the main menu, press the jog wheel once to access the diameter selection option.

Main Menu

Set Diameter

Rotate the jog wheel to select the swage size. Clockwise to increase / anticlockwise to decrease

size. Once the size is selected, press jog wheel to confirm.

Push to Confirm

17.90mm

Manually fit the dies as shown on screen and press Jog wheel to confirm.

Fit Die L16

Manual OK(↓)

Place the hose in position and press green button to swage to selected size

Swage to 17.90mm

Menu() --.--mm

Buzzer will sound and machine will stop when size is reached. Press Red Button to open.

Swage to 17.90mm

Menu() 17.90mm

10

ENDEAVOUR Int. Ltd. Tel +44 (0) 1225 446770 Fax +44 (0) 1225 446775

Long press Jog wheel to

go to

Main Menu at any time

www.endeavouri

nternational.ltd.uk

L16

BUZZ

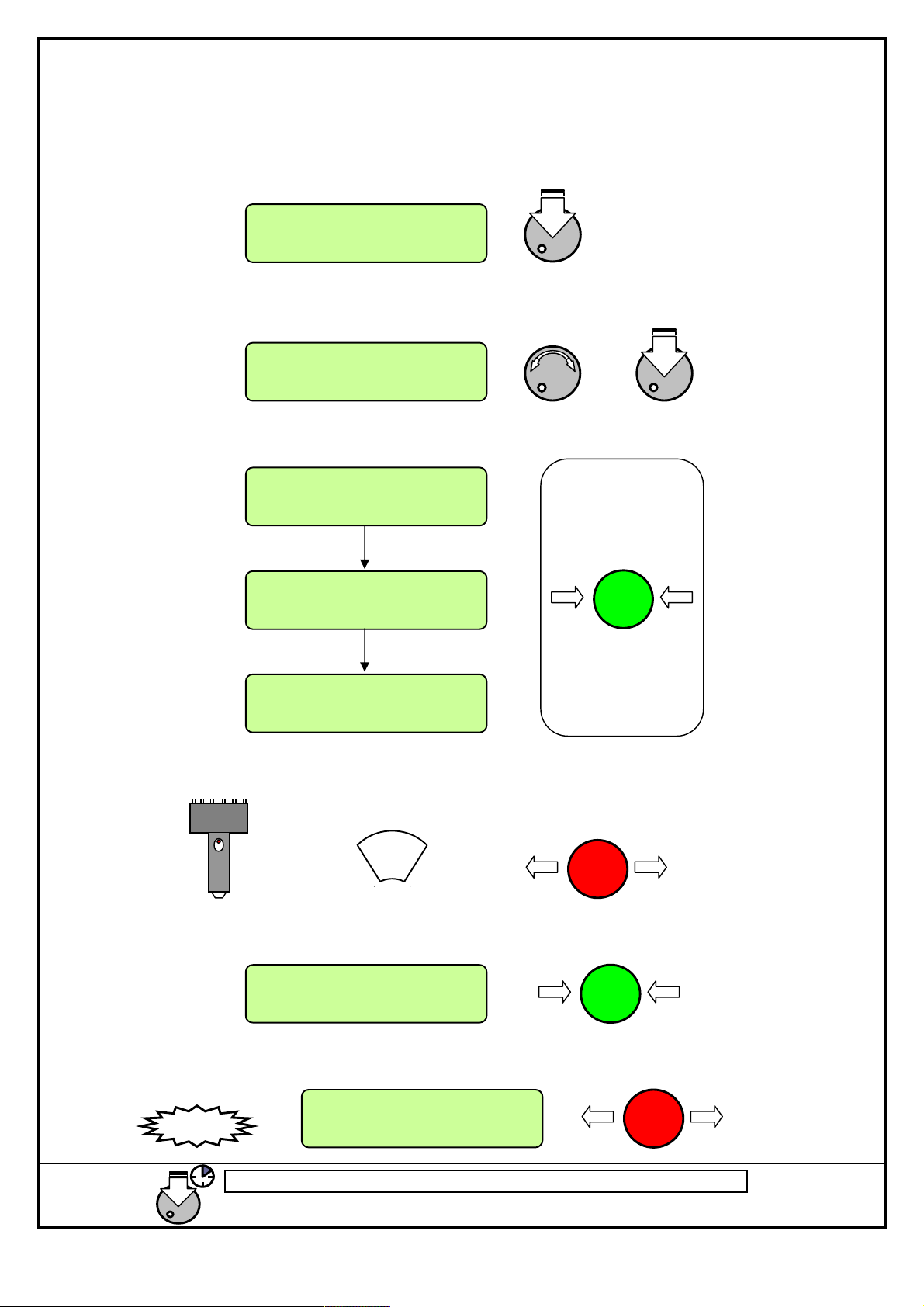

MANUAL SWAGING PROCEDURE (Machines with Quick Change)

From the main menu, press the jog wheel to access the diameter selection option.

Main Menu

Set Diameter

Rotate the jog wheel to select the swage size. Clockwise to increase / anticlockwise to decrease

size. Once the size is selected, press jog wheel to confirm.

Push to Confirm

17.90mm

Press and hold green button to go to Quick Change Position

Fit Die L16

Q/C(Grn) OK(↓)

Fit Die L16

Hold Green Btn

Fit Die L16

Red When Fitted

Fit the dies using quick change tool, remove tool and press red button to open machine.

Place the hose in position and press green button to swage to selected size

Swage to 17.90mm

Menu() --.--mm

Buzzer will sound and machine will stop when size is reached. Press Red Button to open.

Swage to 17.90mm

Menu() 17.90mm

11

Loading...

Loading...