EDM 01-11v8 DAG 6.1S Card User Guide

Copyright © 2005.

Published by:

Endace Measurement Systems® Ltd

Building 7

17 Lambie Drive

PO Box 76802

Manukau City 1702

New Zealand

Phone: +64 9 262 7260

Fax: +64 9 262 7261

support@endace.com

www.endace.com

International Locations

New Zealand Americas Europe, Middle East & Africa

Endace Technology® Ltd

Level 9

85 Alexandra Street

PO Box 19246

Hamilton 2001

New Zealand

Phone: +64 7 839 0540

Fax: +64 7 839 0543

support@endace.com

www.endace.com

Endace USA® Ltd

Suite 220

11495 Sunset Hill Road

Reston

Virginia 20190

United States of America

Phone: ++1 703 382 0155

Fax: ++1 703 382 0155

support@endace.com

www.endace.com

Endace Europe® Ltd

Sheraton House

Castle Park

Cambridge CB3 0AX

United Kingdom

Phone: ++44 1223 370 176

Fax: ++44 1223 370 040

support@endace.com

www.endace.com

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form or by any means electronic, mechanical, photocopying, recording, or otherwise, without the prior

written permission of the publisher. Prepared in Hamilton, New Zealand.

©2005

Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

Typographical Conventions Used in this Document

• Command-line examples suitable for entering at command prompts are displayed in

mono-space courier font. The font is also used to describe config file data

used as examples within a sentence. An example can be in more than one sentence.

Results generated by example command-lines are also displayed in mono-space

courier font.

• The software version references such as 2.3.x, 2.4.x, 2.5.x are specific to Endace

Measurement Systems and relate to Company software products only.

Protection Against Harmful Interference

When present on product this manual pertains to and indicated by product labelling, the statement "This device complies

with part 15 of the FCC rules" specifies the equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the Federal Communications Commission [FCC] Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Extra Components and Materials

The product that this manual pertains to may include extra components and materials that are not essential to its basic

operation, but are necessary to ensure compliance to the product standards required by the United States Federal

Communications Commission, and the European EMC Directive. Modification or removal of these components and/or

materials, is liable to cause non compliance to these standards, and in doing so invalidate the user’s right to operate this

equipment in a Class A industrial environment.

©2005

Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

Table of Contents

1.0 PREFACE........................................................................................................................... 1

1.1 User Manual Purpose ......................................................................................................1

1.2 DAG 6.1S Card Product Description..............................................................................2

1.3 DAG 6.1S Card Architecture ..........................................................................................3

1.4 DAG 6.1S Card Extended Functions .............................................................................. 3

1.5 DAG 6.1S Card System Requirements ...........................................................................3

2.0 INSTALLING DAG 6.1S CARD...................................................................................... 5

2.1 Installation of Operating System and Endace Software..................................................5

2.2 Insert DAG 6.1S Card into PC........................................................................................5

2.3 Connect Card Ports .........................................................................................................6

3.0 SETTING DAG 6.1S CARD OPTICAL POWER.......................................................... 7

3.1 DAG 6.1S Card Optical Power Input..............................................................................7

3.2 Splitter Losses .................................................................................................................8

4.0 CONFIDENCE TESTING DAG 6.1S CARD ................................................................. 9

4.1 Interpreting DAG 6.1S Card LED Status........................................................................9

4.2 DAG 6.1S Card LED Display Functions ......................................................................10

4.3 Configuration in WYSYCC Style.................................................................................11

4.4 dagsix Utility............................................................................................................14

4.5 DAG 6.1S Card Capture Session .................................................................................. 14

4.6 Inspect PoS Interface Statistics .....................................................................................15

4.7 Inspect 10G Ethernet Interface Statistics ......................................................................18

4.8 Reporting Problems.......................................................................................................23

5.0 RUNNING DATA CAPTURE SOFTWARE................................................................ 24

5.1 Starting Data Capture Session.......................................................................................24

5.2 High Load Performance ................................................................................................26

6.0 SYNCHRONIZING CLOCK TIME.............................................................................. 28

6.1 Configuration Tool Usage.............................................................................................29

6.2 Time Synchronization Configurations ..........................................................................30

6.2.1 Single Card no Reference Time Synchronization...................................................30

6.2.2 Two Cards no Reference Time Synchronization....................................................31

6.2.3 Card with Reference Time Synchronization........................................................... 32

6.3 Synchronization Connector Pin-outs.............................................................................34

7.0 DATA FORMATS OVERVIEW.................................................................................... 36

7.1 Data Formats .................................................................................................................36

7.2 Timestamps ................................................................................................................... 38

©2005

i Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

©2005

ii Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

1.0 PREFACE

Introduction

Viewing this

document

In this chapter

The installation of the Endace DAG 6.1S card on a PC begins with

installing the operating system and the Endace software. This is followed

by fitting the card and connecting the ports.

This document, the DAG 6.1S Card User Manual is available on the

installation CD.

This chapter covers the following sections of information.

• User Manual Purpose

• DAG 6.1S Card Product Description

• DAG 6.1S Card Architecture

• DAG 6.1S Card Extended Functions

• DAG 6.1S Card System Requirements

1.1 User Manual Purpose

Description

The purpose of this DAG 6.1S Card User Manual is to describe:

• Installing DAG 6.1S Card

• Setting DAG 6.1S Card Optical Power

• Confidence Testing DAG 6.1S Card

• Running Data Capture Software

• Synchronizing Clock Time

• Data Formats Overview

©2005 1 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

1.2 DAG 6.1S Card Product Description

Description

Figure

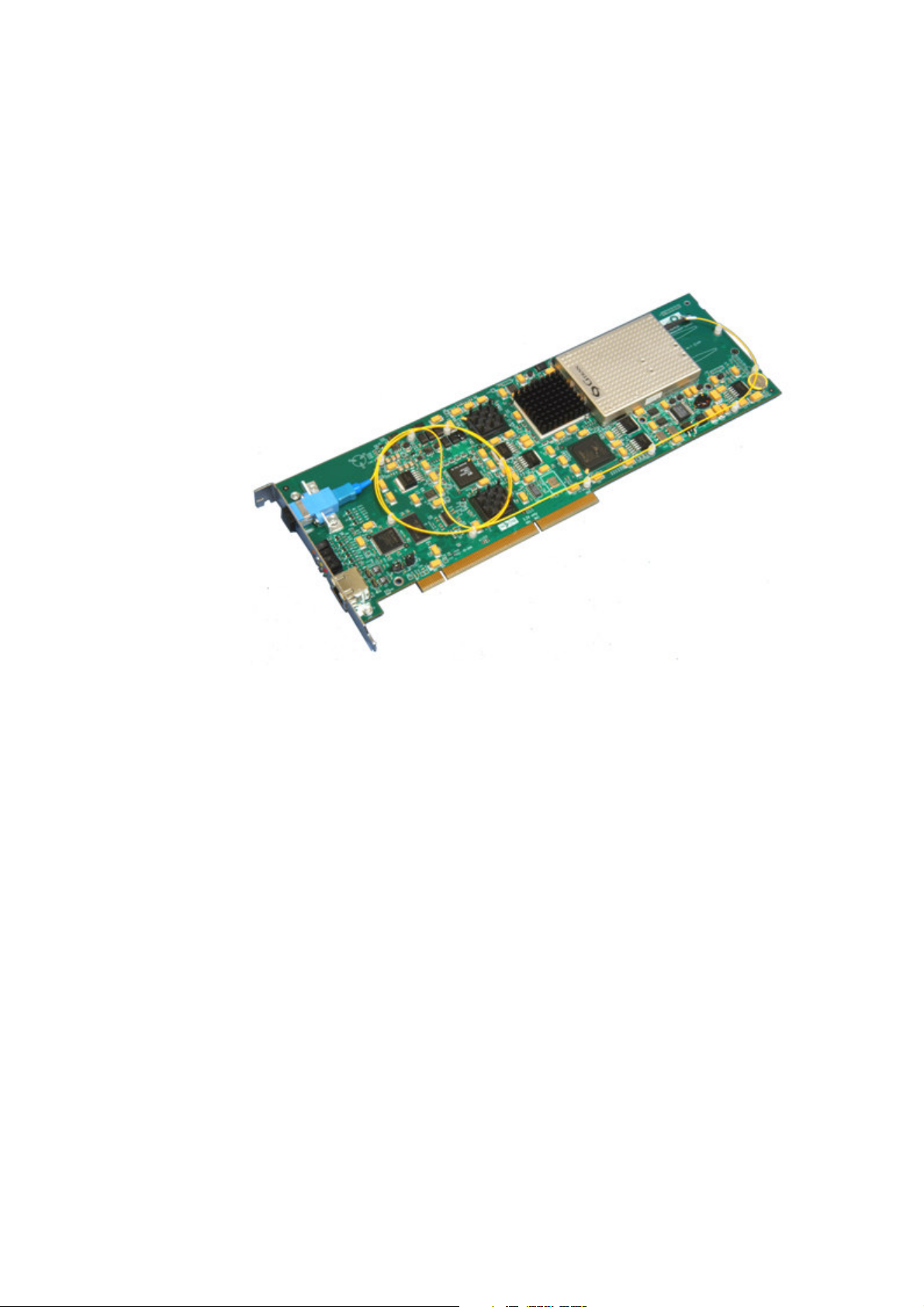

The DAG 6.1S card is of a series specifically designed for network

surveillance applications. It is optimized to enable header-only or full

packet capture from PoS OC-192c or STM-64c links, and 10 Gigabit

Ethernet 10GBase-LR and 10GBase-LW links.

Figure 1-1 shows the DAG 6.1S PCI-X card.

Figure 1-1. DAG 6.1S PCI-X Card.

Installed in a PCI-X 1.0 slot the DAG 6.1S card only operates at 66, 100,

and 133 MHz PCI-X for full packet capture at line rate and allows

recording of all header information and/or payload with a high precision

timestamp.

The packet header and payload information can be stored for later in-depth

analysis, or used in real-time for a variety of network monitoring

applications, such as billing and intrusion detection systems.

IP header traces can also be used operationally to determine link

performance and application mixes, find “top talkers” or generate

source/destination AS matrices for specific network links.

©2005 2 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

1.3 DAG 6.1S Card Architecture

Description

Figure

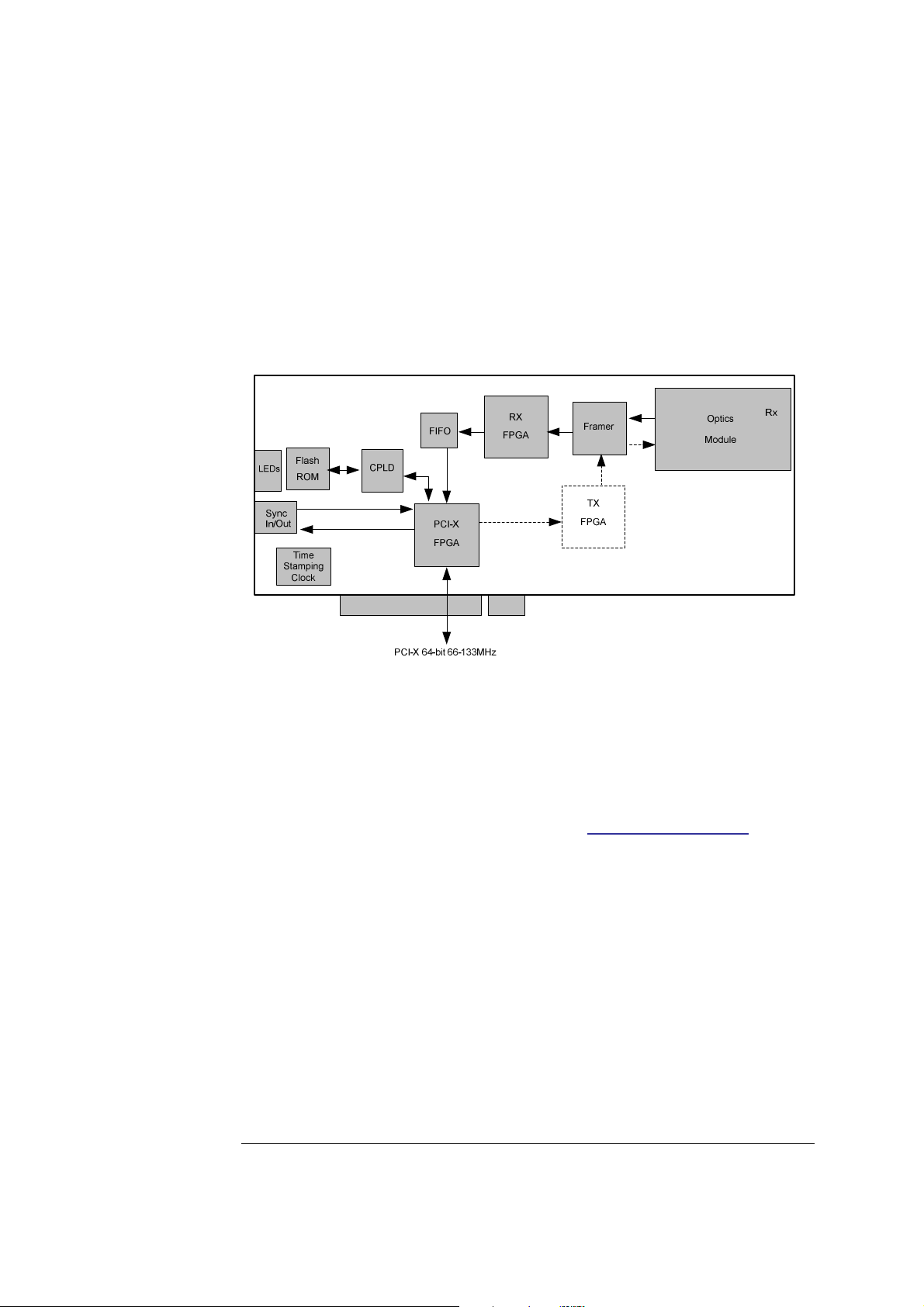

Serial optical data is received by the optical interface, and fed into a

physical layer ASIC. The packet data is then fed immediately into the Rx

FPGA. This FPGA contains the DUCK timestamp engine, and packet

record processor.

Because of component close association, packets or cells are time-stamped

accurately. Time stamped packet records are then stored in an external

FIFO and passed into the PCI-X FPGA for transmission to the host.

Figure 1-2 shows the DAG 6.1S card major components and data flow.

Figure 1-2. DAG 6.1S Card Major Components and Data Flow.

1.4 DAG 6.1S Card Extended Functions

Description

The shipped version of the DAG 6.1S does not contain a transmit path, it

is intended to be used with fibre optic splitters.

Contact the Endace customer support team at support@endace.com to

enable effective use of extended functions.

1.5 DAG 6.1S Card System Requirements

Description

The DAG 6.1S card and associated data capture system minimum

operating requirements are:

• PC, at least Intel Xeon 1.8GHz or faster

• Intel E7500, ServerWorks Grand Champion LE/HE or newer chip

set

• 256 MB RAM

• At least one free PCI-X 1.0 slot supporting 66MHz operation

• Software distribution free space of 30MB

Continued on next page

©2005 3 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

1.5 DAG 6.1S Card System Requirements

, continued

Operating

system

Different

system

For convenience, a Debian 3.1 [Sarge] Linux system is included on the

Endace Software Install CD. Endace currently supports Windows XP,

Windows Server 2000, Windows Server 2003, FreeBSD, RHEL 3.0, and

Debian Linux operating systems.

For advice on using a system substantially different from that specified

above, contact Endace support at support@endace.com

©2005 4 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

2.0 INSTALLING DAG 6.1S CARD

Introduction

Given the DAG 6.1S card can be installed in any free PCI-X 1.0 slot, it

operates at 66, 100, and 133 MHz. The DAG 6.1S will not operate in 32

or 64-bit PCI slots.

Higher speed slots are recommended for best performance.

The DAG 6.1S should be the only device on the PCI-X bus if possible, as

the cards make very heavy use of PCI-X bus data transfer resources.

Although the driver supports up to four DAG cards by default in one

system, due to band width limitations there should not be more than one

card on a single PCI-X bus.

In this chapter

This chapter covers the following sections of information.

• Installation of Operating System and Endace Software

• Insert DAG 6.1S Card into PC

• Installation of Operating System and Endace Software

2.1 Installation of Operating System and Endace Software

Description

If the DAG device driver is not installed, before proceeding with the next

chapter, install the software by following the instructions in EDM04-01

Endace Software Installation Manual.

Go to the next chapter of information when the DAG device driver is

installed.

2.2 Insert DAG 6.1S Card into PC

Description

Procedure

Step 1. Access bus Slot

Inserting the DAG 6.1S card into a PC involves accessing the bus slot,

fitting the card, and replacing the bus slot screw.

Follow these steps to insert the DAG 6.1S card.

Power computer down.

Remove PCI-X bus slot cover.

Continued on next page

©2005 5 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

2.2 Insert DAG 6.1S Card into PC

, continued

Procedure,continued

Step 2. Fit Card

Insert into PCI-X bus slot.

Ensure free end fits securely into a card-end bracket that supports the card

weight.

Step 3. Replace bus Slot Screw

Secure card with screw.

Step 4. Power up computer

2.3 Connect Card Ports

Description

There is one square plastic SC-type optical connector on the 6.1S DAG

card for the received optical signal. There is no TX port on the card.

The card has an 8-pin RJ45 socket for time synchronization input. This

socket must never be connected to an Ethernet network or telephone line.

©2005 6 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

3.0 SETTING DAG 6.1S CARD OPTICAL POWER

Description

Optical power

measure

Configuration

In this chapter

The optical power range depends on the particular device fitted on the

DAG 6.1S card.

The DAG 6.1S card is shipped fitted with the GTRAN GT10-RXU

1310nm single mode receive module by default.

Optical power is measured in dBm – decibels relative to 1 mW where 10

dB is equivalent to a factor of 10 in power.

The numbers are all negative, showing powers below 1 mW. The most

sensitive devices can work down to about –30 dBm, or 1 uW.

The following table describes the DAG 6.1S card optics power module

configuration.

Part No. Fibre Data Rate Max Power

[dBm]

GT10-RXU SMF 10Gbps 0 -17 -9

Min Power

[dBm]

Nominal Pwr

[dBm]

This chapter covers the following sections of information.

• Interpreting DAG 6.1S Card LED Status

• DAG 6.1S Card LED Display Functions

3.1 DAG 6.1S Card Optical Power Input

Description

The optical power input into the DAG 6.1S card must be within a

receiver’s dynamic range.

When optical power is slightly out of range an increased bit error rate is

experienced. If power is well out of range the system cannot lock onto the

SONET frames. In extreme cases of being out range excess power will

damage a receiver.

When power is above the upper limit the optical receiver saturates and

fails to function. When power is below the lower limit the bit error rate

increases until the device is unable to obtain lock and fails.

Continued on next page

©2005 7 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

3.1 DAG 6.1S Card Optical Power Input

, continued

Input power

The DAG 6.1S card is set up to measure the optical power at the receiver,

and to make sure that it is well within the specified power range of -9

dBm.

Input power is adjusted by:

• Changing splitter ratio if power is too high or too low, or

• Inserting an optical attenuator if power is too high.

3.2 Splitter Losses

Description

Single mode

fibre loss

Multi-mode

fibre loss

Splitters have the insertion losses marked on packaging or in

accompanying documentation.

• A 50:50 splitter will have an insertion loss of between 3 dB and 4

dB on each output

• 90:10 splitter will have losses of about 10 dB in the high loss output,

and <2 dB in the low loss output

The GT10-RXU uses 1310nm optics. Splitters used must be designed for

1310nm as the insertion loss will vary for different wavelengths.

A single mode fibre connected to a multi-mode input has minimal extra

loss.

A multi-mode fibre connected to a single mode input creates large and

unpredictable loss.

©2005 8 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

4.0 CONFIDENCE TESTING DAG 6.1S CARD

Introduction

The confidence testing is a process to determine the DAG 6.1S card is

functioning correctly.

The process also involves a card capture session, and demonstrates

configuration in the style of 'What You See You Can Change', WYSYCC.

Interface statistics are also inspected during this process. There is also

information in this section regarding reporting of problems.

In this chapter

This chapter covers the following sections of information.

• Interpreting DAG 6.1S Card LED Status

• DAG 6.1S Card LED Display Functions

• Configuration in WYSYCC Style

• dagsix Utility

• DAG 6.1S Card Capture Session

• Inspect PoS Interface Statistics

• Inspect 10G Ethernet Interface Statistics

• Reporting Problems

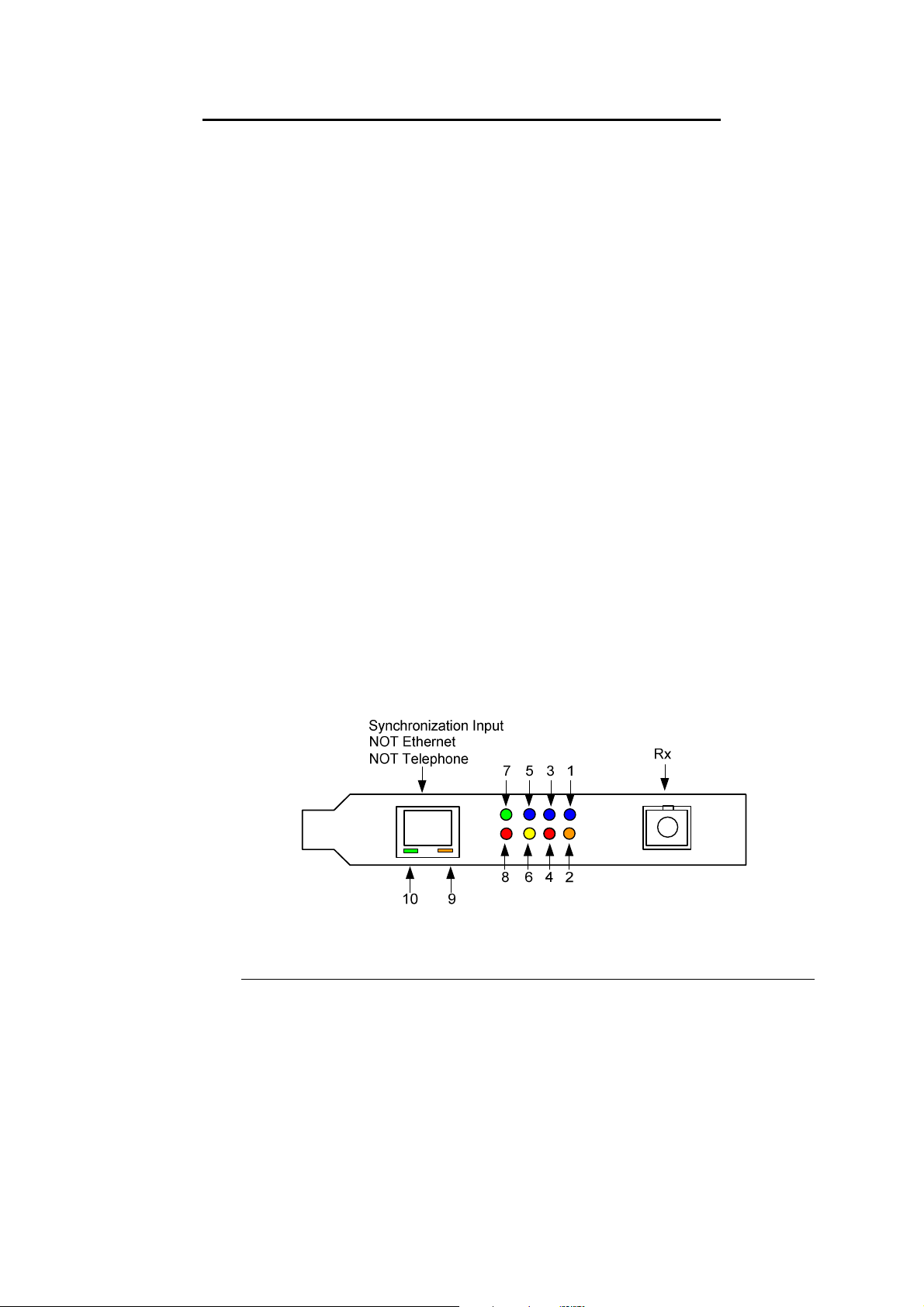

4.1 Interpreting DAG 6.1S Card LED Status

Description

Figure

The DAG 6.1S has a 8 status LEDs, three blue, one green, one orange, one

yellow, and two red.

Figure 4-1 shows the DAG 6.1S status LEDs.

Figure 4-1. DAG 6.1S Card Status LEDs.

Continued on next page

©2005 9 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

4.1 Interpreting DAG 6.1S Card LED Status

, continued

LED definitions

The following table describes the LED definitions.

LED Description

LED 1

RX FPGA successfully programmed.

LED 2 LOS: Loss of Signal; no valid optical signal seen by

receiver.

LED 3 Reserved.

LED 4 Reserved.

LED 5 PCI-X FPGA successfully programmed

LED 6 Data capture in progress.

LED 7 Ethernet mode; OFF for PoS.

LED 8 Reserved.

LED 9 PPS Out: Pulse Per Second Out; indicates card is sending a

clock synchronization signal

LED 10 PPS In: Pulse Per Second In; indicates card is receiving an

external clock synchronization signal

The LED’s labelled ‘Reserved’ may be in the ON or OFF state under

varying circumstances and can be ignored.

4.2 DAG 6.1S Card LED Display Functions

Description

Figure

When a DAG 6.1S card is powered up the blue coloured LED 5 should

always come on, and the remaining LED's such as green and yellow

display for specific functions.

Figure 4-2 shows the correct LED state for DAG 6.1S card without optical

input.

Figure 4-2. LED State for DAG 6.1S Card Without Optical Input.

©2005 10 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

4.3 Configuration in WYSYCC Style

Description

Configuration

options

Configuration in WYSYCC is the 'What You See You Can Change' style.

Running the command '

dagsix'

alone shows the current configuration.

Each of the items displayed can be changed as follows:

default

pos

[no]lsfcl

[no]lseql

[no]fcl

[no]eql

Set card to normal defaults.

Set framer into Packet-over-SONET [PoS] mode.

[un]set facility loopback on line side of phy.

[un]set equipment loopback on line side of phy

[un]set facility loopback on downstream side of phy.

[un]set equipment loopback on downstream side of

phy.

[no]pscramble

[no]crc

[no]crcstrip

[no]pmin

[un]set Packet-over-SONET scrambling.

Dis/enable PoS CRC32 checking.

[Do]Don’t include CRC in ERF record or wlen count.

Ds/enable discard of packets smaller than a predefined

minimum size.

[no]pmax

Dis/enable discard of packets larger than a predefined

maximum size.

long=X

short=x

slen=X

eth

lan

wan

Maximum packet size for pmax.

Minimum packet size for pmin.

Capture X bytes of packet data.

Set framer to 10G Ethernet mode. Defaults to LAN.

Set framer to Ethernet LAN mode 10GBase-LR

Set framer to Ethernet WAN mode 10GBase-LW

Continued on next page

©2005 11 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

4.3 Configuration in WYSYCC Style

, continued

Process

Follow these steps configure the DAG 6.1S card in what you see is what

you can change style.

Step 1. Check FPGA Images

Before configuring the DAG 6.1S card, ensure the most recent FPGA image

is loaded on the card. Loading the newest available Rx FPGA image. This

will cause LED 1 to light.

Load the newest available PCI-X FPGA image.

dag@endace:~$ dagrom -rvp –d dag0 -f xilinx/dag61pcix-erf.bit

Load the newest available Rx FPGA image. This will cause LED 1 to light.

dag@endace:~$ dagld –x –d dag0 xilinx/dag61rx-erf.bit

dag@endace:~$ dagsix -d dag0

link ETH nolsfcl nolseql nofcl noeql

sonet slave

PoS nopscramble nocrc nocrcstrip nopmin nopmax long=1502 short=9

packet varlen slen=48 align64

packetA drop=0

pcix 66MHz 64-bit buf=32MB rxstreams=1 txstreams=0 mem=0:0

Step 2. Configure DAG 6.2S Card for Normal Use

The

dagsix default

command is always used:

dag@endace:~$ dagsix default

link POS nolsfcl nolseql nofcl noeql

sonet slave

PoS pscramble nocrc nocrcstrip nopmin nopmax long=1502 short=9

packet varlen slen=48 align64

packetA drop=0

pcix 66MHz 64-bit buf=32MB rxstreams=1 txstreams=0 mem=32:0

NOTE: The default command also sets the card to PoS mode, which will

cause LED 7 to go out. For Ethernet mode use

or

dagsix default eth wan

as appropriate.

dagsix default eth lan

NOTE: After loading the Rx FPGA firmware, the dagsix default command

must be issued immediately to initialise the thermal management systems of

the to prevent overheating and protective shutdown.

Continued on next page

©2005 12 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

:0

4.3 Configuration in WYSYCC Style

, continued

Process

, continued

Step 3. Turn Pos Scrambling Off

Type:

dag@endace:~$ dagsix -d dag0 nopscramble

link POS nolsfcl nolseql nofcl noeql

PoS nopscramble nocrc nopmin nopmax long=1502 short=9

packet varlen slen=48 align64

packetA drop=0

pcix 133MHz 64-bit buf=32MB rxstreams=1 txstreams=0 mem=32

Step 4. Set Configuration Options

Removing or adding the "no" prefix changes the configuration option

settings.

Step 5. Select Configuration Option

Choose from complete list of configuration options supported:

default

pos

[no]lsfcl

[no]lseql

Set card framer to normal defaults.

Set framer into Packet-over-SONET [PoS] mode.

[un]set facility loopback on line side of phy.

[un]set equipment loopback on downstream side of

phy.

[no]fcl

[no]eql

[no]pscramble

[no]crcstrip

[no]crc

[no]pmin

[un]set facility loopback on downstream side of phy.

[un] equipment loopback. This is for testing only.

[un]set Packet-over-SONET scrambling

Do [not] include CRC in ERF record or wlen count.

Dis/enable PoS CRC32 checking.

Dis/enable discard of packets smaller than a predefined

minimum size.

[no]pmax

Dis/enable discard of packets larger than a predefined

maximum size.

long=X

Step 6. Select Configuration Option, continued

Maximum packet size for pmax.

short=x

slen=X

mem=X:Y

eth

lan

wan

©2005 13 Version 8: May 2006

Minimum packet size for pmin.

Capture X bytes of packet data.

Configure memory allocated to streams 0, 1, ..

Set framer to 10G Ethernet made defaults to LAN.

Set framer to Ethernet LAN made 10G Base-LR.

Set framer to Ethernet WAN made 10G Base-LW

EDM 01-11v8 DAG 6.1S Card User Guide

4.4 dagsix Utility

Description

The

dagsix

utility supports configuration status and physical layer

interface statistics for DAG 6 series cards.

In a troubleshooting configuration options

tool to watch the operational status of the optical, SONET and framing

layers.

More details about the meaning of the various bits are supplied through

the help page (

dagsix –h)

and below.

4.5 DAG 6.1S Card Capture Session

Description

Procedure

Step 1. Check Receiver Ports Optical Signal Levels

A successful DAG 6.1S card capture session is accomplished by checking

receiver port optical signal levels and checking the card has correctly

detected the link. This is followed by configuring the DAG card for

normal use.

Follow these steps for a successful DAG 6.1S card capture session.

–si

should be passed to the

The DAG 6.1S card supports 1310 nanometer singlemode fibre attachments

with optical signal strength between 0 dBm and -17 dBm.

If there is doubt, check card receiver ports light levels are correct using an

optical power meter. The card receiver port is the single SC-style connector.

Step 2. Understand Link Layer Configuration

Learn about the link layer configuration in use at the network link being

monitored. Important parameters include specific scrambling options in use.

If the information cannot be obtained reliably, the card can be made to work

by varying the parameters until data is arriving at the host system.

Step 4. List Current Settings

For DAG 6.1S framer configuration and statistics the

supplied. Calling

dagsix -h

prints a help listing on tool usage.

dagsix

without arguments lists current settings. The

dagsix

tool is

Step 3. Check Card is Locked to Data Stream

Configure card according to local settings.

Check through the physical layer statistics that the card is locked to the data

stream.

Continued on next page

©2005 14 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

4.5 DAG 6.1S Card Capture Session

, continued

Procedure

, continued

Step 4. List Current Settings.

The

dagsix

statistics. Calling

dagsix -h

tool is supplied for the DAG 6.1S card framer configuration and

dagsix

without arguments lists current settings.

prints a help listing on tool usage.

4.6 Inspect PoS Interface Statistics

Description

Once the DAG 6.1S card has been configured for PoS mode, the PoS

interface statistics are inspected to check the card is locked to the data

stream.

dag@endace:~$ dagsix -d dag0 -si

The tool displays a number of status bits that have occurred since last

reading. The following example shows the interval is set to one second via

the -i option.

RAI

Receive Alarm Indication. The optics report a receive

error. One or more of the following two bits will also

be set.

RLE

Receive Lock Error. The optics report a failure in

clock recovery from the received signal.

RPA

Receive Power Alarm. The optics report insufficient

optical input power (<-30dBm).

LOS

Loss Of Signal. The framer reports there is either no

signal at receiver, or optical signal strength is too low

to be recognized.

LOC

Loss Of Clock. The framer is not receiving a valid

clock from the optics.

OOF

Out Of Frame. The framer is not locked to the SONET

frame stream.

LOF

Loss Of Frame. The framer has asserted OOF for more

than 3 milliseconds.

LOP

Loss Of Pointer. The framer cannot lock to the

SONET/SDH frame pointers.

FCS_ERR

Number of PoS FCS [CRC32] errors since last

reading.

GOOD_PACKET

RXF

Number of PoS frames received since last reading.

Receive Fifo Errors. Framer receive FIFO errors since

last reading.

The

Continued on next page

©2005 15 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

0 0 0 0 0 0 0

0

0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0

4.6 Inspect PoS Interface Statistics

, continued

Example

The following is an example of a card locked to a PoS OC-192c stream

carrying no traffic load:

dag@endace:~$ dagsix –d dag0 –si

RAI RLE RPA LOS LOC OOF LOF LOP FCS_ERR POS_PACKET RXF

0

0

0

0

4194303

255

Example

NOTE: The first second has high values as the counters have accumulated

their values over more than one second and usually include pre-setup

confirmation.

Extended

statistics

RAI RLE RPA LOS L OC OOF LOF LOP FCS_ERR GOOD_PACKET RXF BIPI BIP2 BIP3 C2 RX_PARITY TEMP

0 0 0 0 0 0 0 0 0 0 0 0 0 0 16 0 44

0 0 0 0 0 0 0 0 0 0 0 0 0 0 16 0 44

0 0 0 0 0 0 0 0 0 0 0 0 0 0 16 0 44

0 0 0 0 0 0 0 0 0 0 0 0 0 0 16 0 44

Extended statistics are also available.

dag@endace:~$ dagsix –d dag0 –ei

Extra counters

The following extra counters are available with the extended statistics

option:

BIP1 Bit Interleaved Parity 1. SONET/SDH Section parity

error count.

BIP2 Bit Interleaved Parity 2. SONET/SDH Line parity

error count.

BIP3 Bit Interleaved Parity 3. SONET/SDH Path parity

error count.

C2 Reflects content of SONET/SDH C2 overhead octet,

or Path Signal Label. Typical settings are as follows:

16 PoS

CF Cisco HDLC

RX_PARITY Receive parity error count between the framer and

receive FPGA.

TEMP Temperature of the RX FPGA in degrees Celcius.

Continued on next page

©2005 16 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

1 1 0 0 1 1 1 0 0 0

1 1 0 0 1 1 1 0 0 0

1 1 0 0 1 1 1 0 0 0

1 1 0 0 1 1 1 0 0 0

4.6 Inspect PoS Interface Statistics

, continued

Optical light

levels

RAI RLE RPA LOS LOC OOF LOF LOP FCS_ERR POS_PACKET RXF

1

1

1

1

The following situation indicates a problem with optical light levels.

dag@endace:~$ dagsix –d dag0 –si

Although no signal is present, RPA is high, LOS and LOC may not be

asserted. This can occur if the optics module outputs random noise when

no input is present. In this case RPA, the Framing [LOF, OOF] and

Pointer [LOP] errors can still be used to detect an error condition.

Correct

configuration

In order to correct the configuration, proceed as follows:

•

Ensure RAI, RLE and RPA, being the first three columns, are zero,

check light levels

•

Ensure no bip errors occur, otherwise check cabling and light levels

•

Ensure scrambling settings are correct.

Little or no

data

information

On Packet-over-SONET [PoS] links it can happen that there is very little

or no data information received. This typically indicates incorrect

scrambling settings. While a default that matches typical link settings is

provided, the actual configuration varies from network to network.

In this situation, vary the pscramble option and retry.

©2005 17 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

4.7 Inspect 10G Ethernet Interface Statistics

Description

LAN Statistics

Once the DAG 6.1S card has been configured for PoS mode, the 10G

Ethernet interface statistics are inspected to check the card is locked to the

data stream.

dag@endace:~$ dagsix -d dag0 -si

The tool displays a number of status bits that have occurred since last

reading. The following example shows the interval is set to one second via

the -i option.

For LAN mode, the following statistics are available.

RAI

Receive Alarm Indication. The optics report a

receive error. One or more of the following two bits

will also be set.

RLE

Receive Lock Error. The optics report a failure in

clock recovery from the received signal.

RPA

Receive Power Alarm. The optics report insufficient

optical input power (<-30dBm).

LOS

Loss Of Signal. The framer reports there is either no

signal at receiver, or optical signal strength is too

low to be recognized.

LOC

Loss Of Clock. The framer is not receiving a valid

clock from the optics.

LOF

Loss Of Frame. The framer has asserted OOF for

more than 3 milliseconds.

BER

LFT

High Bit Error Rate detected, check optical level.

Local Fault, signal from peer is not being received

correctly.

RFT

Remote Fault, peer is not receiving a signal

correctly.

FCS_ERR

BAD_PACKET

Number of Ethernet FCS errors since last reading.

Number of errored packets received since last

reading.

GOOD_PACKET

Number of correct packets received since last

reading.

RXF

Receive Fifo Errors. Framer receive FIFO errors

since last reading.

Continued on next page

©2005 18 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

4.7 Inspect 10G Ethernet Interface Statistics

, continued

WAN Statistics

For WAN mode, the following statistics are available.

RAI

Receive Alarm Indication. The optics report a

receive error. One or more of the following two bits

will also be set.

RLE

Receive Lock Error. The optics report a failure in

clock recovery from the received signal.

RPA

Receive Power Alarm. The optics report insufficient

optical input power (<-30dBm).

LOS

Loss Of Signal. The framer reports there is either no

signal at receiver, or optical signal strength is too

low to be recognized.

LOC

Loss Of Clock. The framer is not receiving a valid

clock from the optics.

OOF

Out Of Frame. The framer is not locked to the

SONET stream.

LOF

Loss Of Frame. The framer has asserted OOF for

more than 3 milliseconds.

LOP

Loss Of Pointer. The framer cannot find the

SONET/SDH frame pointers.

LOF

Loss Of Frame. The framer has asserted OOF for

more than 3 milliseconds.

BER

LFT

High Bit Error Rate detected, check optical level.

Local Fault, signal from peer is not being received

correctly.

RFT

Remote Fault, peer is not receiving a signal

correctly.

BER

LFT

High Bit Error Rate detected, check optical level.

Local Fault, signal from peer is not being received

correctly.

RFT

Remote Fault, peer is not receiving a signal

correctly.

FCS_ERR

BAD_PACKET

Number of Ethernet FCS errors since last reading.

Number of errored packets received since last

reading.

GOOD_PACKET

Number of correct packets received since last

reading.

RXF

Receive Fifo Errors. Number of Framer receive

FIFO errors since last reading.

Continued on next page

©2005 19 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

4.7 Inspect 10G Ethernet Interface Statistics

, continued

Example

The following is an example of a card locked to a 10G Ethernet LAN

stream carrying no traffic load:

dag@endace:~$ dagsix –d dag0 –si

RAI RLE RPA LOS LOC LOF BER LFT RFT FCS_ERR BAD_PACKET GOOD_PACKET RXF

0 0 0 0 0 0 0 0 0 0 0 9090612 0

0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0

Example

The following is an example of a card locked to a 10G Ethernet WAN

stream carrying no traffic load:

dag@endace:~$ dagsix –d dag0 –si

RAI RLE RPA LOS LOC OOF LOF LOP LOF BER LFT RFT FCS_ERR BAD_PACKET GOOD_PACKET RXF

0 0 0 0 0 0 0 0 0 0 0 0 0 0 5458160 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

NOTE: The first second has high values as the counters have accumulated

their values over more than one second.

LAN Extended

statistics

Extended statistics are also available. The following example shows

extended statistics for the above LAN configuration.

dag@endace:~$ dagsix –d dag0 –ei

RAI RLE RPA LOS LOC LOF BER LFT RFT FCS_ERR BAD_PACKET GOOD_PACKET RXF RX_PARITY TEMP

0 0 0 0 0 0 0 0 0 0 0 64057561 0 0 67

0 0 0 0 0 0 0 0 0 0 0 14629029 0 0 67

0 0 0 0 0 0 0 0 0 0 0 14629444 0 0 67

0 0 0 0 0 0 0 0 0 0 0 14629463 0 0 67

LAN Extra

counters

The following extra counters are available with the extended statistics

option:

RX_PARITY Receive parity error count between the framer and

receive FPGA.

TEMP Temperature of Rx FPGA in degrees Celsius.

Continued on next page

©2005 20 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

4.7 Inspect 10G Ethernet Interface Statistics

, continued

WAN Extended

statistics

Extended statistics are also available. The following example shows

extended statistics for the above WAN configuration.

dag@endace:~$ dagsix –d dag0 –ei

RAI RLE RPA LOS LOC OOF LOF LOP LOF BER LFT RFT FCS_ERR BAD_PACKET GOOD_PACKET RXF BIP1 BIP2 BIP3 C2 RX_PARITY TEMP

1 1 0 0 0 1 1 1 1 0 1 0 1 1 1114253956 0 65535 65535 65535 01 0 49

1 1 0 0 0 1 1 1 1 0 1 0 0 0 0 0 32885 24725 24725 01 0 49

1 1 0 0 0 1 1 1 1 0 1 0 0 0 0 0 32994 24717 24717 01 0 49

1 1 0 0 0 1 1 1 1 0 1 0 0 0 0 0 33056 24711 24711 01 0 49

1 1 0 0 0 1 1 1 1 0 1 0 0 0 0 0 32991 24727 24727 01 0 50

Extra counters

The following extra counters are available with the extended statistics

option:

BIP1 Bit Interleaved Parity 1. SONET/SDH Section parity

error count.

BIP2 Bit Interleaved Parity 2. SONET/SDH Line parity

error count.

BIP3 Bit Interleaved Parity 3. SONET/SDH Line parity

error count.

C2 Reflects content of SONET/SDH C2 overhead octet,

or Path Signal Label. Typical settings are as follows:

16 PoS

CF Cisco HDLC

RX_PARITY Receive parity error count between the framer and

receive FPGA.

TEMP Temperature of Rx FPGA in degrees Celsius.

Optical light

levels in LAN

mode

The following situation indicates a problem with optical light levels in

LAN mode.

dag@endace:~$ dagsix –d dag0 –si

RAI RLE RPA LOS LOC LOF BER LFT RFT FCS_ERR BAD_PACKET GOOD_PACKET RXF RX_PARITY TEMP

1 1 1 0 0 1 0 1 0 0 0 0 0 0 54

1 1 1 0 0 1 0 1 0 0 0 0 0 0 54

1 1 1 0 0 1 0 1 0 0 0 0 0 0 54

1 1 1 0 0 1 0 1 0 0 0 0 0 0 54

Optical light

levels in WAN

mode

RAI RLE RPA LOS LOC OOF LOF LOP LOF BER LFT RFT FCS_ERR BAD_PACKET GOOD_PACKET RXF BIP1 BIP2 BIP3 C2 RX_PARITY TEMP

1 1 1 0 0 1 1 1 1 0 1 0 0 0 0 0 65535 65535 65535 01 0 52

1 1 1 0 0 1 1 1 1 0 1 0 0 0 0 0 32972 24769 24769 01 0 52

1 1 1 0 0 1 1 1 1 0 1 0 0 0 0 0 33099 24755 24755 01 0 52

1 1 1 0 0 1 1 1 1 0 1 0 0 0 0 0 33120 24767 24767 01 0 52

The following situation indicates a problem with optical light levels in

WAN mode.

dag@endace:~$ dagsix –d dag0 –si

Although no signal is present, RPA is high, LOS and LOC may not be

asserted. This can occur if the optics module outputs random noise when

no input is present. In this case RPA, the Framing [LOF, OOF] and

Pointer [LOP] errors can still be used to detect an error condition.

Continued on next page

©2005 21 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

4.7 Inspect 10G Ethernet Interface Statistics

, continued

Correct

configuration

Little or no

data

information

In order to correct the configuration, proceed as follows:

• Ensure RAI, RLE and RPA (first three columns) are zero, check

light levels

• Ensure no bip errors occur, otherwise check cabling and light levels

• Ensure the scrambling and CRC settings are ok

On WAN links it can happen that there is very little or no data information

received. This typically indicates incorrect scrambling settings. While a

default that matches typical link settings is provided, the actual

configuration varies from network to network.

In this situation, vary the

pscramble

option and retry.

©2005 22 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

4.8 Reporting Problems

Description

Problem

checklist

Support is provided with a service contract. When problems occur with a

DAG card or supplied software, contact Endace Technical Support via the

email address support@endace.com. Supplying sufficient information in

an email enables effective response.

The exact information available to users for trouble, cause and correction

analysis may be limited by nature of the problem. The following items

assist a quick problem resolution:

Ref Item

1. DAG card[s] model and serial number.

2. Host PC type and configuration.

3. Host PC operating system version.

4. DAG software version package in use.

5. Any compiler errors or warnings when building DAG driver or

tools.

6. For Linux and FreeBSD, messages generated when DAG device

driver is loaded. These can be collected from command

or from log file

/var/log/syslog.

dmesg

,

7.

Output of

8.

Firmware versions from

daginf -v

.

dagrom –x

.

9. Physical layer status reported by:

dagsix

10. Network link statistics reported by:

dagsix –si

11. Network link configuration from the router where available.

12. Contents of any scripts in use.

13. Complete output of session where error occurred including any

error messages from DAG tools. The typescript Unix utility may

be useful for recording this information.

14. A small section of a captured packet trace illustrating the

problem.

©2005 23 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

5.0 RUNNING DATA CAPTURE SOFTWARE

Introduction

For a typical measurement session, ensure the driver is loaded, the

firmware is downloaded, and the card has been configured.

In this chapter

This chapter covers the following sections of information.

• Starting Data Capture Session

• High Load Performance

5.1 Starting Data Capture Session

Description

Process

The various tools used for data capture are in the

Starting the capture of data involves a typical measurement session, the

card operating in variable length mode, starting and stopping the session.

The following process describes starting a data capture session.

Process Description

Typical measurement

session.

For a typical measurement session, first move to

the

FPGA images to each DAG card. For example:

drv/dagload

tools/dagrom -rvp –d dag0 -f

xilinx/dag61pcix-erf.bit

tools/dagld –x –d dag0 xilinx/dag6 rxerf.bit

Then set, and check the integrity of the cards

physical layer. This process is described in

Chapter 4 of this document.

tools/dagsix –d dag0 default

tools

dag

directory, load the driver, then load the

sub-directory.

Continued on next page

©2005 24 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

5.1 Starting Data Capture Session

Process (continued)

Process Description

Variable length mode. The DAG 6.1S always operates in variable-

length mode.

The number of bytes collected from the packet

is configured with

and can range from 48 to 2040, and be a

multiple of 8.

Packets longer than

slen.

Packets shorter than

records, saving bandwidth and storage space.

For example, for full packet capture:

tools/dagsix –d dag0 slen=1552

Values of

to increased packet loss during captures under

high link load, due to limited PCI-X bandwidth.

Starting a capture

session.

Stopping

running

dagsnap

A capture session is started as follows:

tools/dagsnap –d dag0 –v –o tracefile0

The option -v is used to provide user

information during capture; this can be omitted

for automated trace runs.

If the

tracefile

tool will write to stdout, which can be used to

pipeline

dagtools

By default

can be stopped with a signal:

killall dagsnap

dagsnap

fixed number of seconds and then exit with the

–s

option.

, continued

slen

. This defaults to 48,

slen

will be truncated to

slen

produce shorter

slen

higher than the default may lead

parameter is not specified the

dagsnap

with other tools from the

package.

dagsnap

will run forever.

dagsnap

can also be configured to run for a

©2005 25 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

5.2 High Load Performance

Detecting

packet losses

Avoiding

packet loss

Increasing

buffer size

Until some data is read out of the buffer to free some space, any arriving

packets subsequently are discarded by the DAG card.

Any loss can be detected in-band by observing the Loss Counter

lctr

field of the Extensible Record Format.

In order to avoid any potential packet loss, the user process must read

records faster than they arrive from the network.

For Linux and FreeBSD, when the PC buffer becomes full, the message:

kernel: dagN: pbm safety net reached

is displayed on the PC screen, and printed to

log /var/log/messages

.

If the user process is writing records to hard disk, it may be necessary to

use a faster disk or disk array. If records are being processed in real-time,

a faster host CPU may be required.

The host PC buffer can be increased to deal with bursts of high traffic load

on the network link.

By default the

dagmem

driver reserves 32MB of memory per DAG card in

the system. Capture at OC-12/STM-4 (622Mbps) rates and above may

require a larger buffer.

128MB or more is suggested for Linux/FreeBSD.

For the DAG 6.1S card Windows operating system the upper limit is

256MB.

In Debian Linux the amount of memory reserved is changed by editing the

file

/etc/modules

.

# For DAG 3.x, default 32MB/card

dagmem

#

# For DAG 4.x or 6.x, use more memory per card, E.G.

# dagmem dsize=128m

The option

dsize

sets the amount of memory used per DAG card in the

system.

The value of

dsize

multiplied by the number of DAG cards must be less

than the amount of physical memory installed, and less than 890MB.

©2005 26 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

©2005 27 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

6.0 SYNCHRONIZING CLOCK TIME

Description

DUCK

configuration

Common

synchronization

In this chapter

The Endace DAG range of products come with sophisticated time

synchronization capabilities, in order to provide high quality timestamps,

optionally synchronized to an external time standard.

The system that provides the DAG synchronization capability is known as

the DAG Universal Clock Kit (DUCK).

An independent clock in each DAG card runs from the PC clock. A

card’s clock is initialised using the PC clock, and then free-runs using a

crystal oscillator.

Each card's clock can vary relative to a PC clock, or other DAG cards.

The DUCK is configured to avoid time variance between sets of DAG

cards or between DAG cards and coordinated universal time [UTC].

Accurate time reference can be obtained from an external clock by

connecting to the DAG card using the synchronization connector, or the

host PCs clock can be used in software as a reference source without

additional hardware.

Each DAG card can also output a clock signal for use by other cards.

The DAG card synchronization connector supports a Pulse-Per-Second

(PPS) input signal, using RS-422 signalling levels.

Common synchronization sources include GPS or CDMA (Cellular

telephone) time receivers.

Endace produces the TDS 2 Time Distribution Server modules and the

TDS 6 units that enable multiple DAG cards to be connected to a single

GPS or CDMA unit.

More information is on the Endace website,

http://www.endace.com/accessories.htm, or the TDS 2/TDS 6 Units

Installation Manual.

This chapter covers the following sections of information.

• Configuration Tool Usage

• Time Synchronization Configurations

• Synchronization Connector Pin-outs

©2005 28 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

6.1 Configuration Tool Usage

Description

Example

The DUCK is very flexible, and can be used in several ways, with or

without an external time reference source. It can accept synchronization

from several input sources, and can also be made to drive its

synchronization output from one of several sources.

Synchronization settings are controlled by the

dag@endace:~$ dagclock -h

Usage: dagclock [-hvVxk] [-d dag] [-K <timeout>] [-l

<threshold>] [option]

dagclock

utility.

-h --help,--usage this page

-v --verbose increase verbosity

-V --version display version information

-x --clearstats clear clock statistics

-k --sync wait for duck to sync before

exiting

-d dag DAG device to use

-K timeout sync timeout in seconds, default

60

-l threshold health threshold in ns, default

596

Option:

default RS422 in, none out

none None in, none out

rs422in RS422 input

hostin Host input (unused)

overin Internal input (synchronize to

host clock)

auxin Aux input (unused)

rs422out Output the rs422 input signal

loop Output the selected input

hostout Output from host (unused)

overout Internal output (master card)

set Set DAG clock to PC clock

reset Full clock reset. Load time

from PC, set rs422in, none out

By default, all DAG cards listen for synchronization signals on their RS422 port, and do not output any signal to their RS-422 port.

dag@endace:~$ dagclock –d dag0

muxin rs422

muxout none

status Synchronized Threshold 596ns Failures 0 Resyncs 0

error Freq -30ppb Phase -60ns Worst Freq 75ppb Worst

Phase 104ns

crystal Actual 100000028Hz Synthesized 67108864Hz

input Total 3765 Bad 0 Singles Missed 5 Longest

Sequence Missed 1

start Thu Apr 28 13:32:45 2005

host Thu Apr 28 14:35:35 2005

dag Thu Apr 28 14:35:35 2005

©2005 29 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

6.2 Time Synchronization Configurations

Description

The DUCK is very flexible, and can be used in several ways, with or

without an external time reference source.

The use includes a single card with no reference, two cards with no

reference, and a card with reference.

In this section

This section covers the following topics of information.

• Single Card no Reference Time Synchronization

• Two Cards no Reference Time Synchronization

• Card with Reference Time Synchronization

6.2.1 Single Card no Reference Time Synchronization

Description

When a single card is used with no external reference, the card can be

synchronized to the host PC’s clock.

The clock in most PC’s is not very accurate by itself, but the DUCK drifts

smoothly at the same rate as the PC clock.

If a PC is running NTP to synchronize its own clock, then the DUCK

clock is less smooth because the PC clock is adjusted in small jumps.

However, overall the DUCK clock does not drift away from UTC.

The synchronization achieved in this case is not as accurate as when using

an external reference source such as GPS.

The DUCK clock is synchronized to a PC clock by setting input

synchronization selector to overflow:

dag@endace:~$ dagclock –d dag0 none overin

muxin overin

muxout none

status Synchronized Threshold 11921ns Failures 0 Resyncs

0

error Freq 1836ppb Phase 605ns Worst Freq 143377ppb

Worst Phase 88424ns

crystal Actual 49999347Hz Synthesized 16777216Hz

input Total 87039 Bad 0 Singles Missed 0 Longest

Sequence Missed 0

start Wed Apr 27 14:27:41 2005

host Thu Apr 28 14:38:20 2005

dag Thu Apr 28 14:38:20 2005

NOTE:

dagclock

should be run only after appropriate Xilinx images have

been loaded. If the Xilinx images must be reloaded, the

command must be rerun afterwards to restore the configuration.

dagclock

©2005 30 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

6.2.2 Two Cards no Reference Time Synchronization

Description

Synchronizing

cards

Locking cards

together

When two DAG cards are used in a single host PC with no reference

clock, the cards are to be synchronized in some way if timestamps

between the two cards are to be compared. For example, if two cards

monitor different directions of a single full-duplex link.

Synchronization between two DAG cards is achieved in two ways. One

card can be a clock master for the second, or one can synchronize to the

host and also act as a master for the second.

If both cards are to be accurately synchronized, but not so for absolute

time of packet time-stamps being correct, then one card is configured as

the clock master for the other.

Although the master card’s clock will drift against UTC, the cards are

locked together.

The cards are locked together by connecting the synchronization

connector ports of both cards with a standard RJ-45 Ethernet cross-over

cable.

Configure one of the cards as the master, the other defaults to being a

slave.

dag@endace:~$ dagclock –d dag0 none overout

muxin none

muxout over

status Not Synchronized Threshold 596ns Failures 0

Resyncs 0

error Freq 0ppb Phase 0ns Worst Freq 0ppb Worst Phase

0ns

crystal Actual 100000000Hz Synthesized 67108864Hz

input Total 0 Bad 0 Singles Missed 0 Longest Sequence

Missed 0

start Thu Apr 28 14:48:34 2005

host Thu Apr 28 14:48:34 2005

dag No active input - Free running

The slave card configuration is not shown, the default configuration is

sufficient.

Continued on next page

©2005 31 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

6.2.2 Two Cards no Reference Time Synchronization

, continued

Preventing

time-stamps

drift

To prevent the DAG card clocks time-stamps drifting against UTC, the

master can be synchronized to the host PC’s clock which in turn utilises

NTP. This then provides a master signal to the slave card.

The cards are locked together by connecting the synchronization

connector ports of both cards with a standard RJ-45 Ethernet cross-over

cable.

Configure one card to synchronize to the PC clock and output a RS-422

synchronization signal to the second card.

dag@endace:~$ dagclock –d dag0 none overin overout

muxin over

muxout over

status Synchronized Threshold 11921ns Failures 0 Resyncs

0

error Freq -691ppb Phase -394ns Worst Freq 143377ppb

Worst Phase 88424ns

crystal Actual 49999354Hz Synthesized 16777216Hz

input Total 87464 Bad 0 Singles Missed 0 Longest

Sequence Missed 0

start Wed Apr 27 14:27:41 2005

host Thu Apr 28 14:59:14 2005

dag Thu Apr 28 14:59:14 2005

The slave card configuration is not shown, the default configuration is

sufficient.

6.2.3 Card with Reference Time Synchronization

Description

Pulse signal

from external

sources

The best timestamp accuracy occurs when a DAG card is connected to an

external clock reference, such as a GPS or CDMA time receiver.

The DAG synchronization connector accepts a RS-422 Pulse Per Second

[PPS] signal from external sources.

This is derived directly from a reference source, or distributed through the

Endace TDS 2 [Time Distribution Server] module which allows two DAG

cards to use a single receiver.

More cards can be accommodated by daisy-chaining TDS-6 expansion

units to the TDS-2 unit, each providing outputs for an additional 6 DAG

cards.

Continued on next page

©2005 32 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

6.2.3 Card with Reference Time Synchronization

, continued

Using external

reference

source

Connecting

time

distribution

server

Testing signal

To use an external clock reference source, the host PC’s clock must be

accurate to UTC to within one second. This is used to initialise the

DUCK.

The external time reference allows high accuracy time synchronization.

When the time reference source is connected to the DAG synchronization

connector, the card automatically synchronizes to a valid signal.

dag@endace:~$ dagclock –d dag0

muxin rs422

muxout none

status Synchronized Threshold 596ns Failures 0 Resyncs 0

error Freq 30ppb Phase -15ns Worst Freq 2092838ppb Worst

Phase 33473626ns

crystal Actual 100000023Hz Synthesized 67108864Hz

input Total 225 Bad 0 Singles Missed 1 Longest Sequence

Missed 1

start Thu Apr 28 14:55:20 2005

host Thu Apr 28 14:59:06 2005

dag Thu Apr 28 14:59:06 2005

The TDS 2 module connects to any DAG card with a standard RJ-45

Ethernet cable and can be placed some distance from a DAG card.

Existing RJ-45 building cabling infrastructure can be used to cable

synchronization ports.

CAUTION: Never connect a DAG card and/or the TDS 2 module to

active Ethernet or telephone equipment.

For Linux and FreeBSD, when a synchronization source is connected the

driver outputs some messages to the console log file

/var/log/messages

The

dagpps

tool is used to test a signal is being received correctly and is

of correct polarity. To perform the test, run:

dagpps –d dag0.

The tool measures input state many times over several seconds, displaying

polarity and length of input pulse.

Some DAG cards have LED indicators for synchronization (PPS) signals.

.

©2005 33 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

6.3 Synchronization Connector Pin-outs

Description

Pin assignments

Figure

DAG cards have an 8-pin RJ45 connector with two bi-directional RS422

differential circuits, A and B. The PPS signal is carried on circuit A, and

the serial packet is connected to the B circuit.

The 8-pin RJ45 connector pin assignments are:

1. Out A+

2. Out A-

3. In A+

4. In B+

5. In B-

6. In A-

7. Out B+

8. Out B-

Figure 6-1 shows the RJ45 plug and socket connector pin-outs.

Out-pin

connections

Ethernet

crossover cable

Support

Figure 6-1. RJ45 Plug and Socket Connector Pin-outs.

Normally the GPS input should be connected to the A channel input, pins

3 and 6. The DAG card can also output a synchronization pulse; used

when synchronizing two DAG cards without a GPS input.

Synchronization output is generated on the Out A channel, pins 1 and 2.

A standard Ethernet crossover cable can be used to connect the two cards.

TX_A+ 1 3 RX_A+

TX_A- 2 6 RX-ARX_A+ 3 1 TX_A+

RX_B+ 4 7 TX_B+

RX_B- 5 8 TX_BRX_A- 6 2 TX_ATX_B+ 7 4 RX_B+

TX_B- 8 5 RX_B-

For cables and further advice on using GPS and CDMA time receivers

email support@endace.com.

©2005 34 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

©2005 35 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

7.0 DATA FORMATS OVERVIEW

In this chapter

This chapter covers the following sections of information.

• Data Formats

• Timestamps

7.1 Data Formats

Description

Table

Data format

The DAG 6.1S card uses the ERF Type 1 POS HDLC Variable Length

Record. Timestamps are in little-endian [Pentium native] byte order. All

other fields are in big-endian [network] byte order. All payload data is

captured as a byte stream, no byte re-ordering is applied.

Table 7-1 shows the generic variable length record. The diagram is not to

scale.

The following is an overview of the data format used.

timestamp

timestamp

type flags rlen

lctr wlen

(rlen - 16) bytes of record

Table 7-1. Generic Variable Length Record.

Data Format Description

type: This field contains an enumeration of the frame

subtype. If the type is zero, then this is a legacy

format.

0: TYPE_LEGACY

1: TYPE_HDLC_POS: PoS w/HDLC framing

2: TYPE_ETH: Ethernet

3: TYPE_ATM: ATM Cell

4: TYPE_AAL5: reassembled AAL5 frame

5: TYPE_MC_HDLC: Multi-channel HDLC

frame

6: TYPE_MC_RAW: Multi-channel Raw link

data

7: TYPE_MC_ATM: Multi-channel ATM Cell

Continued on next page

©2005 36 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

Packet length including some protocol overhead.

7.1 Data Formats

, continued

Data Format Description

flags: This byte is divided into 2 parts, the interface

identifier, and the capture offset.

1-0: capture interface 0-3

2: varying record lengths present

3: truncated record [insufficient buffer space]

4: rx error [link error]

5: 5: ds error [internal error]

7-6: reserved

Rlen: record length Total length of the record transferred over PCI

bus to storage.

Lctr: loss counter A 16 bit counter, recording the number of

packets lost since the previous record. Records

can be lost between the DAG card and memory

hole due to overloading on PCI bus. The

counter starts at zero, and sticks at 0xffff.

Wlen: wire length

The exact interpretation of this quantity depends

on physical medium.

Table

Table 7-2 shows the Type 1 POS HDLC variable length record. The

diagram is not to scale.

timestamp

timestamp

type:1 flags rlen

lctr wlen

HDLC Header

(rlen - 20) bytes of packet

Table 7-2. Type 1 POS HDLC Variable Length Record.

Continued on next page

©2005 37 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

7.1 Data Formats

, continued

Table

Table 7-3 shows the Type 2 Ethernet variable length record. The diagram

is not to scale.

The Ethernet frame begins immediately after the pad byte so that the layer

3 [IP] header is 32Bit-aligned.

7.2 Timestamps

Description

The ERF format incorporates a hardware generated timestamp of the

packet’s arrival.

The format of this timestamp is a single little-endian 64-bit fixed point

number, representing seconds since midnight on the first of January 1970.

The high 32-bits contain the integer number of seconds, while the lower

32-bits contain the binary fraction of the second. This allows an ultimate

resolution of 2

Another advantage of the ERF timestamp format is that a difference

between two timestamps can be found with a single 64-bit subtraction. It

is not necessary to check for overflows between the two halves of the

structure as is needed when comparing Unix time structures, which are

also available to Windows users in the Winsock library.

Different DAG cards have different actual resolutions. This is

accommodated by the lowermost bits that are not active being set to zero.

In this way the interpretation of the timestamp does not need to change

when higher resolution clock hardware is available.

timestamp

timestamp

type:2 flags rlen

lctr wlen

offset pad rlen-18

bytes of frame

Table 7-3. Type 2 Ethernet Variable Length Record.

-32

seconds, or approximately 233 picoseconds.

Continued on next page

©2005 38 Version 8: May 2006

EDM 01-11v8 DAG 6.1S Card User Guide

7.2 Timestamps

, continued

Example code

Here is some example code showing how a 64-bit ERF timestamp (erfts)

can be converted into a struct timeval representation (tv).

unsigned long long lts;

struct timeval tv;

lts = erfts;

tv.tv_sec = lts >> 32;

lts = ((lts & 0xffffffffULL) * 1000 * 1000);

lts += (lts & 0x80000000ULL) << 1; /* rounding */

tv.tv_usec = lts >> 32;

if(tv.tv_usec >= 1000000) {

tv.tv_usec -= 1000000;

tv.tv_sec += 1;

}

©2005 39 Version 8: May 2006

Loading...

Loading...