Page 1

Technical Specifications

Supply voltage

230V AC +10% -20% or 12/24V AC/DC ±10%, 50/60Hz or 9-30V DC / 7-24V AC ±10%.

Power consumption

Max. 4VA

2.5mm² screw-terminal connections.

(±1%-15sec) for hour unit, (±1%-1sec) for minute unit

4 digits, 12.5mm, 7 segment yellow LED

Wiring

Scale

Sensitivity/Accuracy

Time Accuracy

Indicator

EMC

Safety requirements

The device is designed to operate in controlled electromagnetic environment)

EN 61326-1: 1997, A1: 1998, A2: 2001 (Performance criterion B is satisfied for EMC tests.

EN 61010-1: 2001 (Pollution degree 2, overvoltage category II)

CONTROL

Control type

Single-setpoint control

On-Off control

Control algorithm

Hysteresis

Adjustable between 0.1 ... 20.0°C.

ELECTRICAL CHARACTERISTICS

ENVIRONMENTAL CONDITIONS

Height

Max. 2000m

80 , up to 40% 31°C decreasing linearly 50% at °C

Ambient/storage temperature

Max. relative humidity

0 ... +50°C/-25 ... 70°C (with no icing)

-50.0 ... +110.0°C (-58.0 ... +230.0°F)

0.1°C / ±1°C

Rated pollution degree

According to EN 60529 Front panel : IP65

Rear panel : IP20

Do not use the device in locations subject to corrosive and flammable gasses.

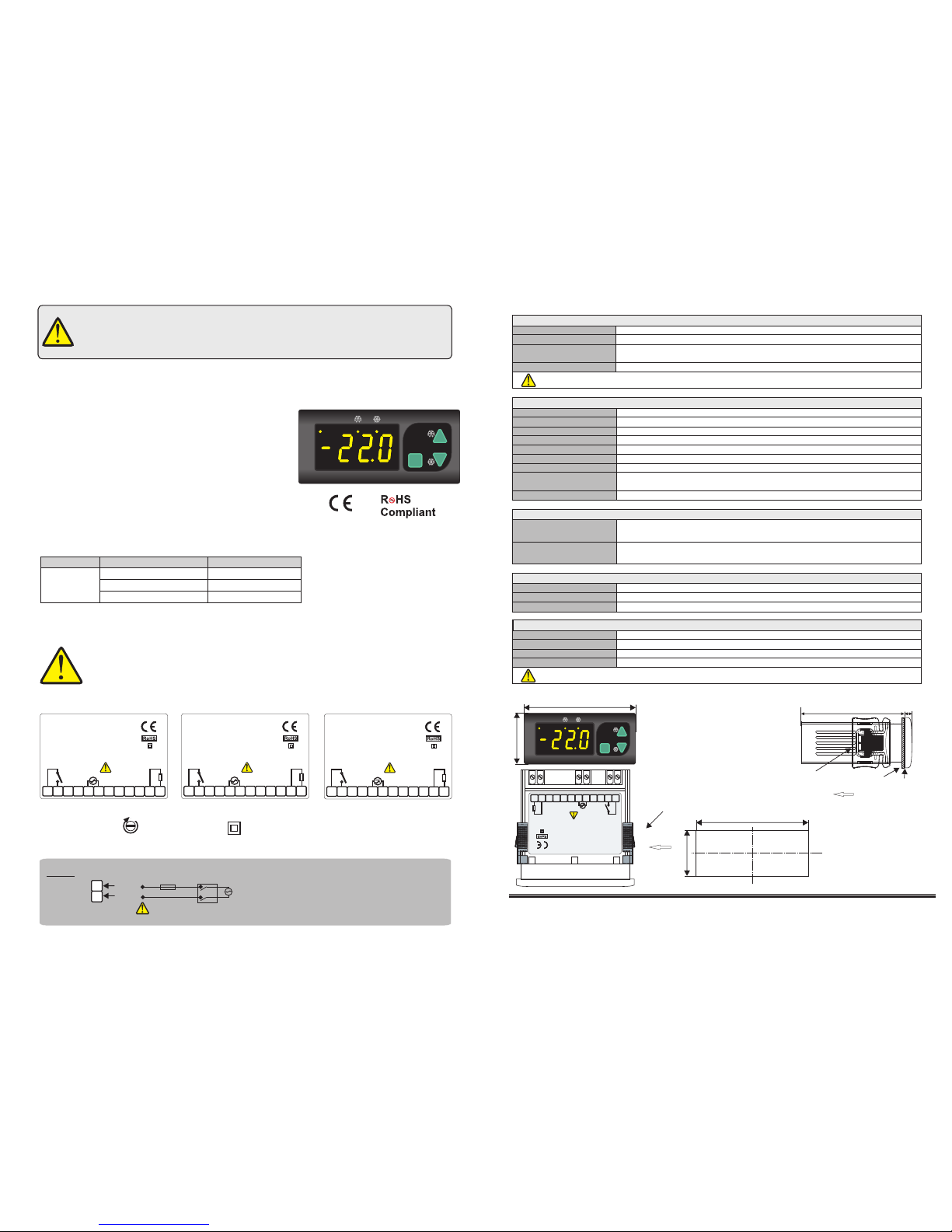

HOUSING

Housing type

Suitable for flush-panel mounting.

Dimensions

W77xH35xD71mm

Weight

Approx. 250g (Equipment and prob a ) fter packing

Enclosure material

Self extinguishing plastics

ENDA EDT1411P TEMPERATURE CONTROLLER

Thank you for choosing ENDA EDT1411 temperature controller.

Connection Diagram

ENDA EDT1411 is intended for installation in control panels. Make sure that the device is used

only for intended purpose. The electrical connections must be carried out by a qualified staff

and must be according to the relevant locally applicable regulations. During an installation, all of the

cables that are connected to the device must be free of electrical power. The device must be

protected against inadmissible humidity, vibrations, severe soiling and make sure that the operation

temperature is not exceeded. The cables should not be close to the power cables or components.

1/3

SÝSEL MÜHENDÝSLÝK ELEKTRONÝK SAN. VE TÝC. A.Þ.

Yukarý Dudullu Barbaros Cad. Kutup Sok. No:20 34775 - ÜMRANÝYE/ÝSTANBUL/TURKEY

Tel : +90 216 499 46 64 Pbx. Fax : +90 216 365 74 01

url : www.enda.com.tr

Panel cut-out

Dimensions

Note :

1) Panel thickness

should be maximum

7 mm.

2) If there is no 60mm

free space at the back

side of the device, it

would be difficult to

remove it from the

Panel.

EDT1411P-E-01-R

Holding screw

0.4-0.5Nm.

Equipment is protected throughout

by DOUBLE INSULATION

71mm

29mm

Flush mounting

clamp

For removing mounting clamps:

Push the flush-mounting

clamp in direction 1 as shown

in the figure below. Then, pull

out the clamp in direction 2.

1

While cleaning the device, solvents (thinner, benzine, acid etc.) or corrosive materials must not be used.

4

5

SUPPLY:

NOTE:

184-253V AC

50/60Hz 4VA

Line

Neutral

230V AC

Supply

Switch

Note:

Cable size: 1,5mm²

Fuse

F 100 mA

250V AC

Fuse should

be connected

1) Mains supply cords shall meet the requirements of

IEC 60227 or IEC 60245.

2) In accordance with the safety regulations, the power

supply switch shall bring the identification of the

relevant instrument and it should be easily

accessible by the operator.

Ple

a

s

e re

ad

th

is

d

oc

u

me

nt

c

ar

e

f

u

ll

y be

fo

re

us

in

g

th

is

p

rod

uc

t

.

T

h

e g

ua

ran

te

e w

ill be

in

va

li

da

te

d

if

the

d

e

vi

ce

is

da

mag

ed

by

no

t fo

ll

ow

in

g

in

s

t

ruc

tio

n

s

de

ta

il

ed in

t

he

man

ua

l. Th

e c

omp

a

ny

s

h

a

ll

n

ot

b

e

r

es

po

n

sib

le

f

or

an

y

da

m

ag

e

or

lo

ss

e

s

ho

we

v

e

r

cau

se

d,

w

h

ic

h

may

b

e

e

xpe

ri

e

n

ce

d

as

a

re

su

lt

of th

e

in

st

al

la

ti

on

or use

of t

h

is

p

ro

du

ct.

Flush mounting

clamp

Depth

Panel

2

71mm

5mm

Rubber

packing

35mm

77mm

SET

SET

EDT1411

ENDA

°F

°C

Order Code

Output

Supply Voltage

EDT1411-NTC-230P

Röle -16A

230V AC +%10 -%20

24V AC %10±

EDT1411-NTC-24P

9-24V AC/DC %10±

EDT1411-NTC-12P

* 35 x 77mm sized.

* On-Off control.

* Single contact output for cooling control.

* Single NTC probe input.

* Offset value can be entered for NTC probe.

* Compressor protection parameters can be entered.

* In the case of probe failure, output state can be

selected on, off or periodical running.

* Upper and lower limits of the setpoint can be adjusted.

* Defrosting duration and interval can be adjusted.

* Temperature unit can be selected °C or °F.

* Upper and lower limits of the alarm value can be adjusted depending on the setpoint value.

* CE marked according to European Norms.

SET

SET

EDT1411

ENDA

°F

°C

SN: XXXXXXXXX

1 2 3 4 5 6

7 8 9

10

11 12

EDT1411-NTC-230VAC-P

DIGITAL DEFROST THERMOSTAT

ENDA INDUSTRIAL ELECTRONICS

230V AC +10% -20%

50/60Hz 4VA

COMPRESSOR

240V AC 16A

RESISTIVE LOAD

NTC

SENSOR

SN: XXXXXXXXX

1 2 3 4 5 6

7 8 9

10

11 12

EDT1411-NTC-24VAC-P

DIGITAL DEFROST THERMOSTAT

ENDA INDUSTRIAL ELECTRONICS

24V AC ±10%

50/60Hz 4VA

COMPRESSOR

240V AC 16A

RESISTIVE LOAD

NTC

SENSOR

SN: XXXXXXXXX

1 2 3 4 5 6

7 8 9

10

11 12

EDT1411-NTC-SM-P

DIGITAL DEFROST THERMOSTAT

ENDA INDUSTRIAL ELECTRONICS

COMPRESSOR

240V AC 16A

RESISTIVE LOAD

NTC

SENSOR

9-30V DC / 7-24V AC

10% 4VA±

SN: XXXXXXXXX

1 2 3 4 5 6

7 8 9

10

11 12

EDT1411-NTC-230VAC-P

DIGITAL DEFROST THERMOSTAT

ENDA INDUSTRIAL ELECTRONICS

230V AC +10% -20%

50/60Hz 4VA

COMPRESSOR

240V AC 16A

RESISTIVE LOAD

NTC

SENSOR

OUTPUT

COMPRESSOR

For EDT1411-NTC-XXP ; Relay: 240V AC, 8A (for resistive load), NO;

1 HP 230V AC CosF = 0.5 (for inductive load)

For EDT1411-NTC-XXP ; Mechanical 30.000.000 operation. (None load)

240V AC ,16A in the resistive load 30.000 operation.

Life expectancy for relay

Page 2

SET

SET

EDT1411

ENDA

°F

°C

While holding key COMPRESSOR setpoint value appears and by using and keys

the value can be adjusted.

Running Mode

Process

Value

-30.0

-29.9

-30.0

1000

If both keys are pressed and held for 3 seconds,

programming mode is entered.

-22.0

If both keys are pressed,

run mode is entered.

Used for adjusting the value of the setpoint in the run mode and for adjusting the selected parameter in the programming mode. While holding key, setpoint value of the selected parameter appears and by

using and keys the value can be adjusted.

When held down for 3 second in the run mode, manual defrost starts. After the specified time with D.dur parameter manual defrost finishes. When held down for 3 second manual defrost finishes before the

specified time ends. Used for selecting menu and increasing setpoint value of the parameters in the programming mode and for increasing the setpoint value in the run mode. When held down for a few

seconds, the change rate accelerates.

When held down for 3 second in the run mode continuous mode (*) starts. After the specified time with C.Con parameter this mode finishes. When held down for 3 second continuous mode finishes before

the specified time ends. Used for selecting parameters and decreasing the setpoint value in the programming mode and for decreasing the setpoint value in the run mode. When held down for a few seconds,

the change rate accelerates.

DEFROST

LED

COMPRESSOR

LED

FAHRENHEIT

LED

Displayed process value in the run mode, parameter name or value in programming mode.

SET

SET

SET

SET

A.lol

A.uPl

A.Set

A.dpo

The lower limit

of the setpoint.

Delay time for the compressor

after power is on.

Defrosting duration.

Limit for lower alarm level.

Limit for upper alarm level

Alarm configuration.

Energy was given the

message of alarm delayed

to show.

The upper limit

of the setpoint.

Delay time required for

compressor to restart following

a stop.

Compressor’s on the continuous

on mode length of stay.

Refrigeration differential

(hysteresis).

In the probe failure,compressor’s

output on duration.

Refrigeration

offset value.

Display resolution.

In the probe failure,compressor’s

output off duration.

D.dur

D.int

C.pon

C.ppn

C.Con

C.Fos

C.ppF

Interval between defrost

cycles.

Programming mode

R.lol

R.uPl

R.Hys

R.off

DrES

EDT1411P-E-01-R

Temperature unit.

Unit

During the defrosting

display configuration.

D.dsp

D.drE

Delay time for display real

temperature after defrost

is over.

Defrosting the process of

energy and the start of.

D.Pon

D.dPo

Defrosting’s delayed starting

after power is on.

A.dFl

Situation of alarm after the

were formed alarm message

delayed to show.

A.HYS

Alarm diffrerential

(hysteresis).

Security parameter for compressor

control menu.

Security parameter for defrosting

control menu.

Security parameter for alarm

control menu.

Security parameter for refrigeration

set value.

A.-re

A.-al

A.-de

A.-Cp

A.rE.S.

Security parameter for refrigeration

menu.

RE

CP

DE

Al

SE

2/3

S.Cod

Access code for security menu.This

parameter should be 321.

On the side on display at sight message,thermostat probe is short circuit or measured

temperature value is higher than the scale.

On the side on display at sight message, measured value is higher than the upper alarm

value.

Error Messages

On the side on display at sight message,measured value is lower than the lower alarm

value.

Alo

Ahi

Pfa

PsC

On the side on display at sight message,thermostat probe is broken or measured

temperature value is lower than the scale.

Page 3

EDT1411P-E-01-R

3/3

C.pon

C.FoS

C.PPn

C.PPF

Delay time for the compressor after power is on.

Delay time required for the compressor to restart following a stop.

In the probe failure.compressor’s output on duration.

In the probe failure,compressor’s output off duration.

0 255 min. 1

0 255 min. 0

C.Con

Compressor’s on the continuous on mode length of stay.

0 255 min. 0

0 255 min. 1

0.0 24.0 h. 0.1

Menu of Compressor control parameters

CP

Menu of Alarm control parameters

A.LoL

A.uPL

A.dFL

A.HYS

A.set

Alarm configuration (A.Abs = Absolute alarm. Alarm values are A.LoL and A.uPL.

A.rEF = Relative alarm. Alarm values are SET-A.LoL and SET+A.uPL.)

Limit for lower alarm level. When A.set is changed, should be readjusted.

Limit for upper alarm level. When A.set is changed, should be readjusted.

Alarm differential (hysteresis)

Situation of alarm after the were formed alarm message delayed to show.

-50.0 A.uPL °C -50.0

A.LoL 110.0 °C 110.0

0 255 min. 0

0.0 15.0 °C 2

A.AbS A.rEF A.AbS

A.dPo

Time delay to display alarm message after power is on.

Al

A. rEA. CP-

A. ALA.rE.S.

Security parameter for refrigeration menu

Security parameter for refrigeration setpoint value ( P.yes= Setpoint value is invisible.,P.no= Setpoint value is only visible.)

Security parameter for menu of compressor control

Security parameter for menu of defrost control

Security parameter for menu of alarm control

A. DE-

Menu of Parameter security

SE

R.HYS

R.LoL

R.uPL

R.oFF

Refrigeration differential(hysteresis)

The lower limit of the setpoint.

The upper limit of the setpoint.

The offset value for the refrigeration.

-50.0 °C -50R.uPL

-20.0 20.0 °C 0.0

MÝN MAX UNIT DEF.SET

Unit

Temperature unit

DrES

Display resolution (no= no decimal point , yes= with decimal point .)

°C °F °C

Yes

No

No

R.LoL 110.0 °C 110

Menu of Refrigeration control parameters

RE

Menu of Defrost control parameters

D.dur

D.int

D.dSP

D.drE

D.Pon

D.dPo

Defrosting duration.(If d.dur=0, then defrost is disable.)

Interval between defrost cycles.

Display configuration during defrost (rEAL= Real temperature is displayed during defrost.

def= During the defrosting on the display def message visible.)

Defrosting after power is on.(yes=Defrosting begins when power is on, no=Defrosting doesn’t begin when power is on.)

Delay time for defrosting after power is on.

Delay time for display real temperature after defrost is over.

0 255 1

1 120 1

REAL

def

Yes

def

No

No

0 30 min. 1

0 255 1

DE

min.

sec.

h.

min.

min.

sec.

= Menu is invisible.NonE

P.yes

P.no

= Parameters of menu are changeable.

= Parameters of menu are only visible.

If A.typ = A.rEF , then A.LoL = SET-ALoL & A.uPL = SET+A.uPL.

NOTE : Variables for lower and upper alarm level are determined according to A.SET parameter. If A.SET = A.AbS ,then A.LoL = A.LoL & A.uPL = A.uPL.

EDT1411 DEFROST CONTROLLED REFRIGERATION THERMOSTAT OUTPUT AND PARAMETER TABLE

Defrost

LED

Compressor

LED

Power

D.int

D.dPo

(Ifd.Pon = y

then d.dPo timer

runs)

D.dur

C.Pon

Compressor

OUT

C.Con

Continuous mode

Defrost mode

A.uPl

SET

A.uPl-A.HYS

SET+ r.HYS

A.LoL

A.LoL+A.HYS

A.dPo

A.dFL

Alarm

situation

AHi enable

AHi able dis

Alo enable

Alo able dis

0 23.5 hr. 0.3

0.1 20.0 °C 0.1

Loading...

Loading...