Page 1

3 2 B 1 0 0

OPERATORS

MANUAL

Page 2

ENCORE

WARNING:

DO NOT allow children to operate the

machine. DO NOT allow any adult to operate

the machine without proper instruction.

CAUTION:

Never add fuel to the tank while the engine is

running or hot. ALWAYS WAIT at least five

minutes before refueling and REFUEL WITH THE

ENGINE OFF. KEEP FUEL AWAY FROM

SPARKS OR FLAMES. WIPE AWAY any fuel

spillage BEFORE starting unit. Never fill the fuel

tank indoors. Wipe up any spilled gasoline.

Gasoline is highly flammable - NO SMOKING .

Your mower is only as safe as the operator! Operator carelessness or error may result

in serious bodily injury. Improper maintenance of the machine may also result in injury.

Please read and follow these instructions on Safe Operation and be certain that anyone

using this mower fully understands and follows these instructions.

1. Familiarize yourself with the controls

and know how to stop this mower.

2. Inspect your work area carefully.

Remove debris from the area to be cut.

Keep all bystanders away from the

mowing area.

3. Avoid contact with moving parts. Keep

hands and feet clear of the mower deck

and all moving parts.

4. Never direct the discharge of material

toward bystanders nor allow anyone

near the machine while in operation.

5. Never tamper with safety devices or

guards. If a guard or safety device is

damaged or removed, replace it before

operating the mower.

6. Handle gasoline carefully: use an

approved gasoline container; fill the fuel

tank to within 1" from the neck with good

quality leaded or unleaded gasoline.

Operator must wear proper shoes and

clothing, which may also include safety

glasses and ear protection.

7. Mow only during daylight hours or under

very good artificial light.

8. Do NOT mow in slippery conditions ,

keep a firm grip on the handle bars,

NEVER RUN.

9. The safety shield over the grass

discharge must always be bolted in

place and in the down position unless

the grass catcher back plate is

completely installed.

10. Do NOT leave the operator position

unless the engine has been killed and

blades have stopped.

11. If a solid object has been hit by the

blades, stop the machine and check for

damage. Repair or replace damaged/

broken part(s) prior to restarting the

engine.

12. Do NOT allow anyone to stand or walk

on the grass discharge side of the

mower when the mower is in operation.

13. Do NOT mow close to drop-offs, deep

ditches or other hazards. Mow hillsides

very carefully by mowing across the face

of slopes, not up or down. Do NOT

mow on steep slopes.

14. To avoid burns, DO NOT TOUCH the

engine or muffler immediately after

operation.

1

Page 3

ENCORE

SPECIFICATIONS

Belt Tension Guide

Belt

Engine to Deck

T

ransmission Belt

Right Blade Drive Belt

Wheel Drive

Inch Deflection

1/2”

1/2”

1/2”

(48”,52”, And 60” only)

1/2”

Assembly Instructions

1. Remove inner parts box and handle from

crate. Remove outside frame work so

that the mower is setting on the pallet.

2. On a 36" mower, use 3 – 5/16" X 1 3/4"

bolts and 3 – 5/16" whizlocks and bolt the

bumper into place. (On the 48" there are

4 - bumper bolts required.)The whizlocks

should go to the inside of the deck.

When assembling a 48" mower, make

sure that the bumper is flush with the

deck on both ends of the bumper.

3. Using 6 – 3/8" X 1" bolts (3 – used for

each caster) and 6 – 3/8" whizlock nuts,

bolt the casters into place. Position

whizlock nuts to the inside of the deck.

4. Using 2 – 5/16" X 1" bolts with 2 – 5/16"

flat washers and 2 – 15/16" nyloc nuts,

take the shifter lever with grip and bolt

onto the top side of the shifter bracket on

the transmission. Place the 5/16" flat

washers on the slotted hole side of the

shifter bracket under the 5/16" nut.

Position the shift lever so that it slides

freely along the top side of the shifter

plate but still hits the stop for reverse.

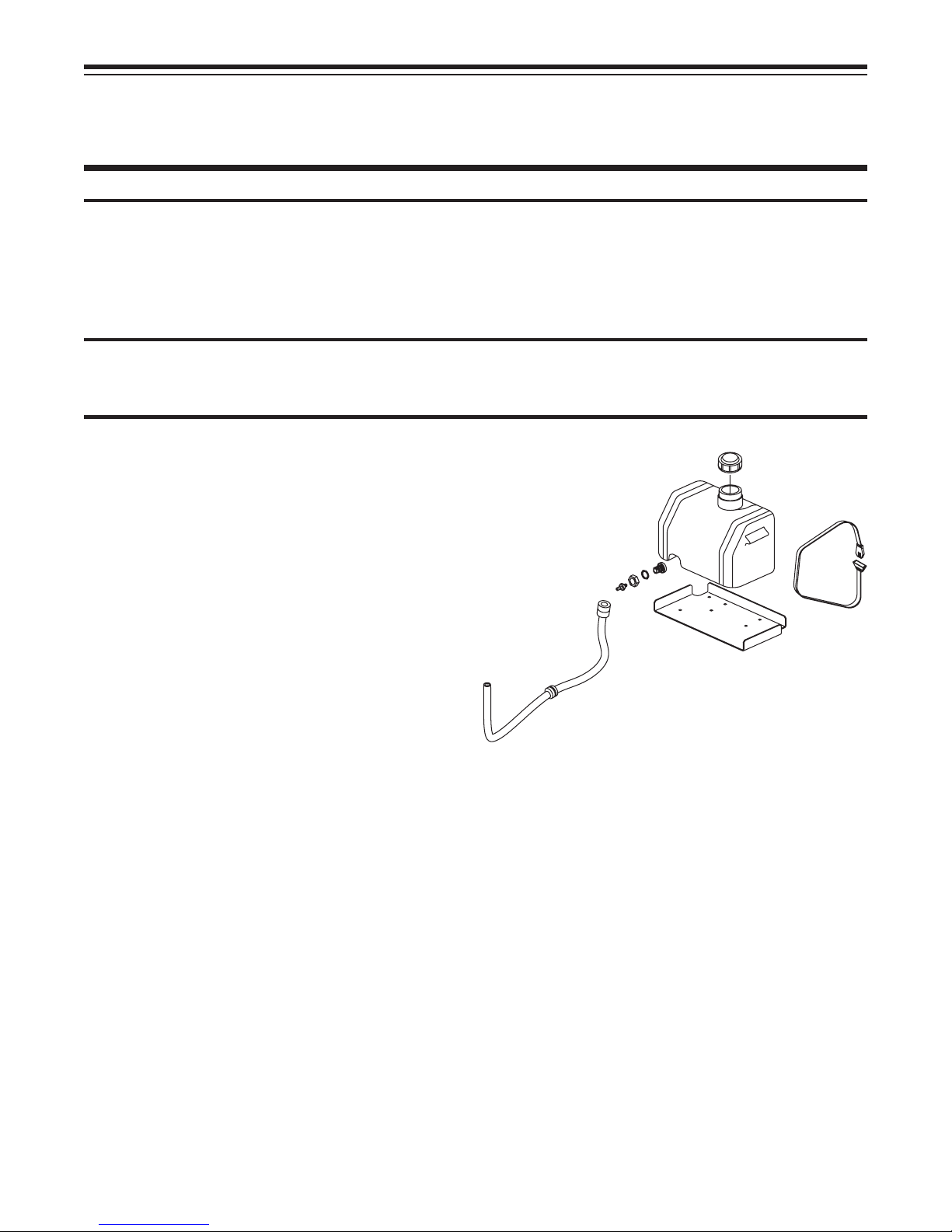

5. Mount the gas tank using the 2 – nylon

hold down straps, pulling tension on the

buckles until secure. Attach the quick

coupler, on the end of the fuel line, to the

bottom of the tank. (See Fig. 1)

6. Using the remaining 4 - 3/8" X 1" bolts

and the 4 – 3/8" nyloc nuts, bolt the

upper handle into position. (Remember

that there are 3 – height settings for the

handle for operator comfort.) Route the

wiring harness along the handle,

plugging it into the blade control switch,

using the screws to attach the harness to

the Operator Presence Control switch.

There is not a specific color for hooking

up the harness.

How to Adjust

Turnbuckle at Idler

Sliding Idler

Threaded Rod to Idler

Self-Adjusting

Fig. 1

2

Page 4

Assembly Instructions

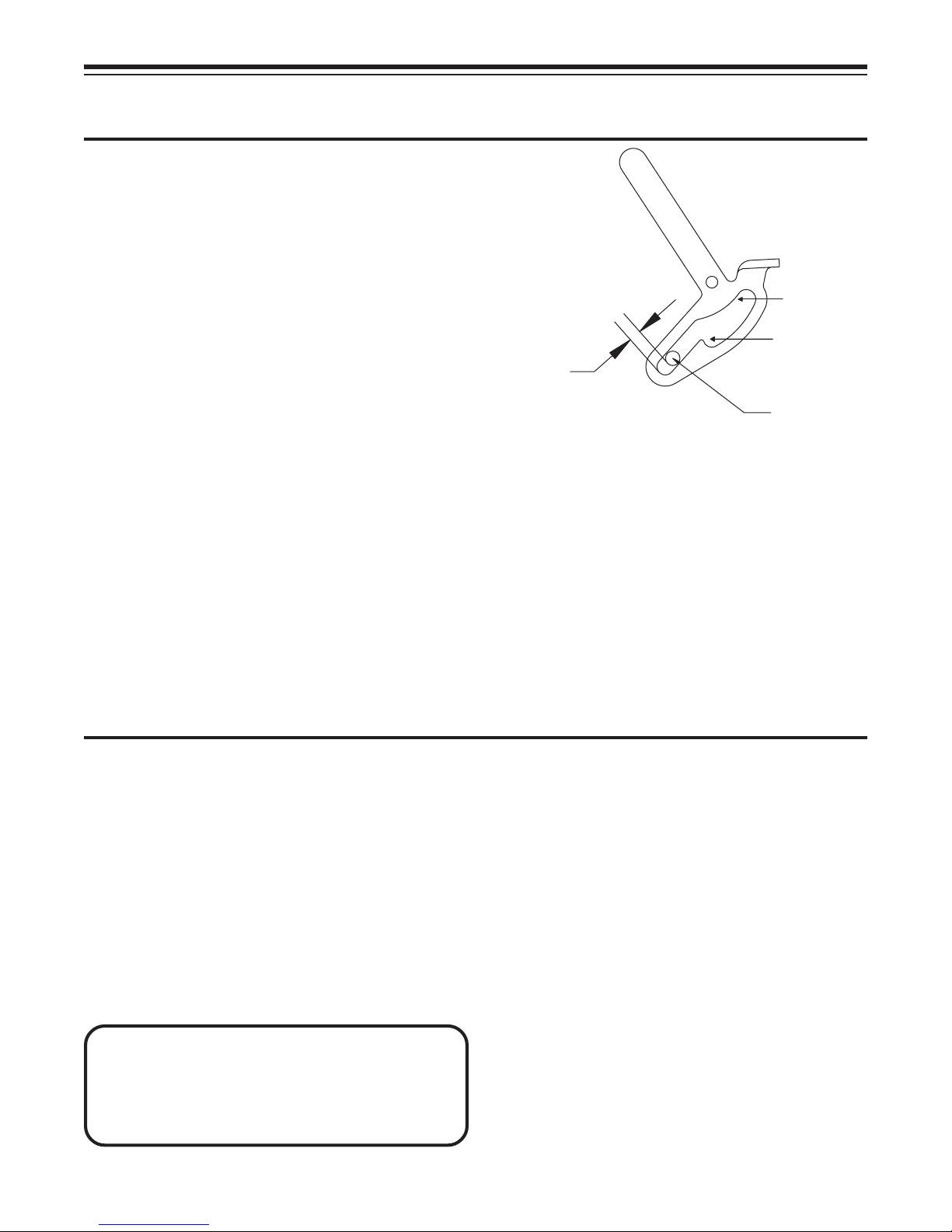

Neutral Neutral

LockLock

Park Park

PositionPosition

Drive-RodDrive-Rod

1/4" - 3/8"1/4" - 3/8"

Fig. 2

CAUTION:

Excessive belt tension may cause damage!!

7. Using drive rods provided, turn them into

the 5/16" swivel located in the left and

right hand idler engagement bracket.

Adjust the rods so that there is

approximately 1/4" to 3/8" between the

rod and the bottom of the thumb latch.

Rods should be locked in place by using

4 – hair pin cotters and by placing a 5/

16" flat washer to be inside of the drive

handle between the drive lever and hair

pin cotter. (See fig.2)

8. With the thumb latches locked in the

neutral position, adjust the brake swivel

until you feel a slight resistance when

hooking it back to the idler assembly.

Remember with thumb locks in the

neutral position, you should be able to

free wheel the machine. When the

thumb locks are rotated all the way to the

lock position, the brake should lock the

wheel. At this time, you may also hook

up the blade engagement rod, adjusting

the length of the rod so the bell crank will

not bottom out in the slot.

9. At this point, oil and fuel engine. Make

sure that the air pressures in the rear

tires are equal at (12 psi). Adjust the

front tire pressures to (20 psi). Your

mower is now ready for use.

ENCORE

Final Check / Adjustment

1. Adjust the brake control rod to obtain

“free wheeling” with the drive levers in

the neutral position and positive braking

when the drive levers are squeezed close

to the handle grips. Shorten the effective

length of the brake rod to increase

braking.

2. Check air pressure in drive wheels (12

psi) and caster wheels (20psi). This is

critical for appropriate mower tracking.

3. Check for proper belt tension (see belt

tension guide).

Keep a 1/8" to 1/4" clearance between

belt guides and belts. Be sure the drive

control rod is properly adjusted in the

thumb latch. (See Fig 2.)

3. After a 10 hour “Break-In” period go

through steps 1 thru 3.

4. Proper adjustments must be maintained

to insure safe, trouble free, long life

operation of the mower. After completing

the foregoing instructions and

recommended procedures you are ready

to put the mower into operation.

3

Page 5

ENCORE

WARNING:

FAILURE T O FOLLOW THE PREVIOUS

INSTRUCTIONS MAY RESULT IN

SEVERE BODILY INJURY OR

MECHANICAL FAILURE.

CAUTION:

Machine must be at a full “STOP” before

shifting from forward to reverse or from

reverse to forward. Failure to do so may

result in personal injury and/or damage

to the transmission.

Before Operating

Know your machine top to bottom.

Make certain all safety standards and

instructions have been fully read and

understood.

Be acquainted with all “SAFETY

INSTRUCTIONS” in this manual – to

start.

1. Fill the fuel tank and open the fuel valve.

2. Shift the transmission to neutral.

3. Blades engagement lever must be in the

“Off” position or back.

4. Thumb latches need to be in the “Neutral

Lock” position.

5. Choke the engine as required and start.

11. This unit is equipped with “Operator

Presence Controls” on the upper handle.

When the operator leaves the operator

position removing both hands from the

“Operator Presence Control” levers it will

cause the engine to shutdown.

THIS FEATURE IS FOR YOUR SAFETY!

6. After engine is running, push blade

engagement lever forward to engage

blades.

7. Shift the transmission to the desired gear

(1 thru 4) for mowing, 5th gear is for

transport only.

8. Squeeze the control levers and push

forward on the thumb latches to unlock

the levers. Slowly release control levers

to engage the drive wheels.

9. In a normal mode the mower will travel in

a straight line. To turn; squeeze the drive

lever on the side in which you want to

turn.

10. To STOP forward motion, squeeze both

drive levers, lock thumb latches and shift

the transmission to neutral.

4

Page 6

HEIGHT ADJUSTMENT

Caster Arm

Caster Arm

Spacers

Caster Assy

Blade Spacers

Highest

Rear Deck

Mount Position

Lowest

CAUTION:

When greasing Cutter Housing, grease

each one with TWO PUMPS ONLY.

Excessive greasing can force seals out

causing premature bearing failure.

ENCORE

REAR DECK MOUNT IN HIGHEST POSITION

(5) spacers on top of caster arm = 1 7/8" to 3 1/8"

(4) spacers on top of caster arm = 2 1/8" to 3 3/8"

(3) spacers on top of caster arm = 2 1/2" to 3 3/4"

(2) spacers on top of caster arm = 2 5/8" to 3 7/8"

(1) spacer on top of caster arm = 2 7/8" to 4 1/8"

All spacers under caster arm = 3 1/4" to 1 1/2"

NOTE: Use 1/4" blade spacers to achieve cutting height between the above measurements.

Caster Arm

Caster Arm

Spacers

Caster Assy

REAR DECK MOUNT IN LOWEST POSITION

(5) spacers on top of caster arm = 1 1/2" to 2 3/4"

(4) spacers on top of caster arm = 1 3/4" to 3"

(3) spacers on top of caster arm = 2" to 3 1/4"

(2) spacers on top of caster arm= 2 3/8" to 3 3/8"

(1) spacer on top of caster arm = 2 5/8" to 3 7/8"

All spacers under caster arm = 2 7/8" to 4 1/8"

Rear Deck

Mount Position

Lowest

Highest

LUBRICATION / MAINTENANCE

The following recommendations should be used to ensure proper and safe operation of the

mower.

LUBRICATION

(Units Prior to Serial Number 33333)

Grease Daily:

Idler Arm

Caster Wheels and Caster Pivots

Drive Wheels

Grease Every 100 Hours:

Bell Crank Pivot Bearing

Grease Every 250 Hours:

Cutter Housing Bearings

Blade Spacers

5

Fig. 4

Page 7

ENCORE

NOTE:

The Peerless Transmission is “LIFETIME

LUBRICATED”. If service is required,

contact an authorized Peerless Dealer or

Repair Center.

CAUTION:

DO NOT ADJUST OR CHANGE ATTACHMENTS

UNLESS SPARK PLUG WIRE HAS BEEN

DISCONNECTED AND THE ENGINE HAS

STOPPED.

WARNING:

AVOID SERIOUS INJURY OR DEATH:

THE BATTERY CONTAINS SULFURIC ACID.

AVOID CONTACT WITH SKIN, EYES OR

CLOTHING. ANTIDOTE: INTERNAL – DRINK

LARGE QUANTITIES OF WATER OR MILK.

FOLLOW WITH MILK OF MAGNESIA,

BEATEN EGG OR VEGETABLE OIL. CALL A

PHYSICIAN IMMEDIATELY. EYES AND SKIN

– FLUSH WITH WATER AND GET PROMPT

MEDICAL A TTENTION.

BATTERIES PRODUCE EXPLOSIVE GASES,

KEEP SPARKS, FLAMES AND SMOKING

MATERIALS AWAY. VENTILATE WHEN

CHARGING IN AN ENCLOSED SPACE.

WEAR EYE PROTECTION WHEN WORKING

NEAR BATTERIES.

KEEP OUT OF REACH OF CHILDREN.

LUBRICATION / MAINTENANCE

LUBRICATION

(Units After Serial Number 33333)

Grease Daily:

Idler Arm

Caster Wheels and Caster Pivots

Drive Wheels

Grease Every 100 Hours:

Bell Crank Pivot Bearing

MAINTENANCE

1. Engine: For complete maintenance and

operating information for your engine,

please refer to your engine operating and

maintenance manual provided by the

engine manufacturer.

2. Belts: The drive and deck belts should

be checked and adjusted after the first

10 hours of use and then every 50 hours

from that point on.

New Blade

25 Degrees

5. Mower Blades: Check sharpness of

mower blades after every 10 hours of

operation.

To sharpen blades proceed as follows:

• Block the front end of the mower up or

run front end up on ramps

• Remove blade by turning bolt counter

clockwise.

• Sharpen blade with a hand file, electric

grinder or blade sharpener. Wear gloves

and eye protection when sharpening.

Grind blade at original bevel.

• Check balance of blade by positioning

the blade on a nail or blade balance

pedestal. Grind the blade on the end

that is heavier until both sides balance.

• Reinstall blades.

6. BATTERY:

See battery manufacturer’s instructions

for proper maintenance of battery.

When Notch Starts

Discard Blade

Dangerous!

3. Tires: Correct tire pressure is essential

for efficient operation of the mower.

4. Check tire air pressure periodically.

Inflate tires to the pressures listed:

Drive Wheels = 12 psi

Caster Wheels = 20 psi

6

Page 8

ENCORE

SAFETY DECALS

In order to promote safe operation, Encore Mfg. Co., Inc. supplies safety decals on all

products manufactured. Because damage can occur to safety decals through shipment, use

or reconditioning, Encore will, upon request, provide safety decals for any of our products in

the field at

No Charge. Contact your authorized Encore dealer for more information.

363038

363001

363023

363233

7

Page 9

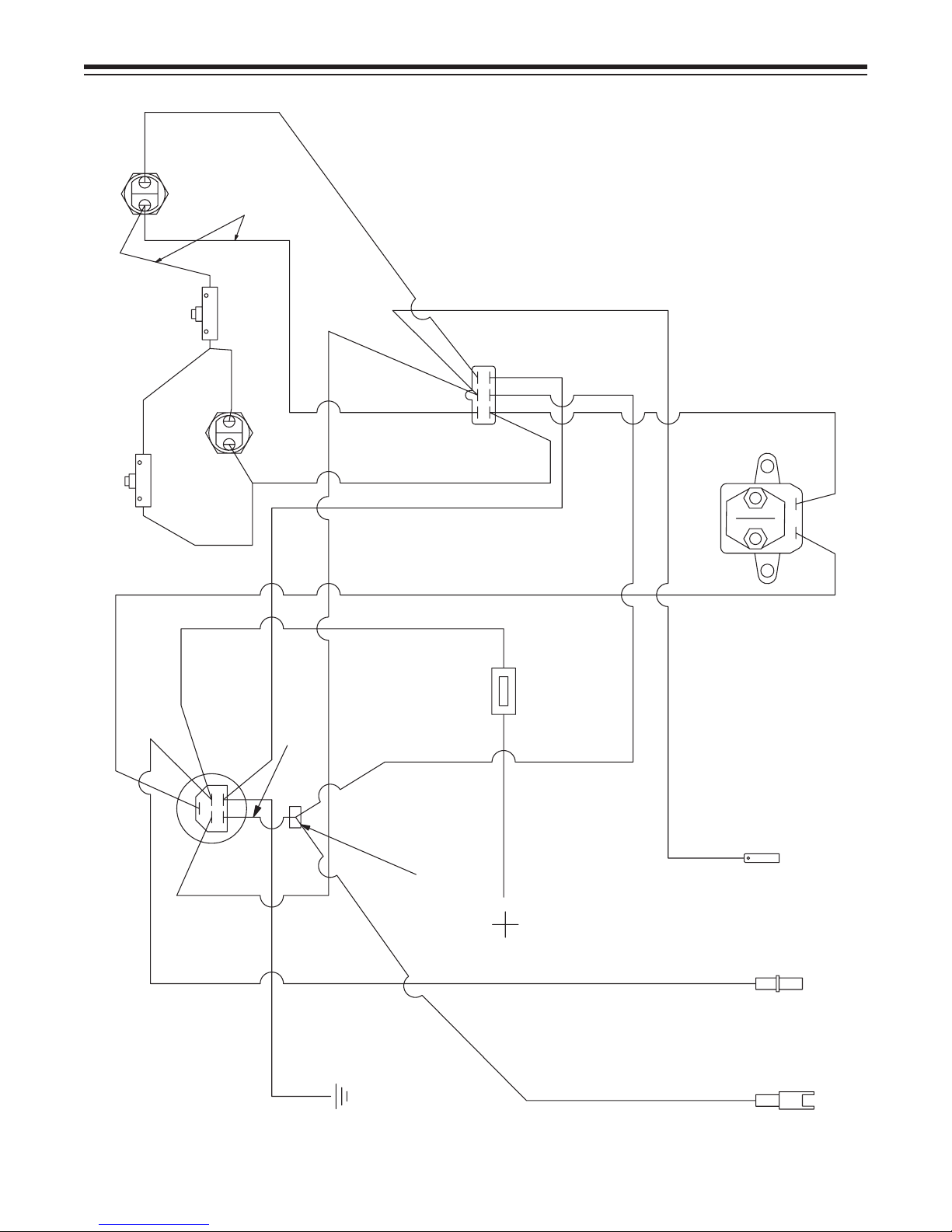

ENCORE

RED /BLACK STP. 18 GA.

YELLOW 16 GA.

TO BATT.

GROUND

TO BATT.

POS.

ENGINE KILL

BLACK 16 GA.

BLACK 16 GA.

BROWN 18 GA.

RED 12 GA.

RED 12 GA.

RED 14 GA.

ORANGE 18 GA.

ENGINE FUEL

SOLENOID

ENGINE

CHARGING

ORANGE / WHITE 18 GA.

20 AMP FUSE

FUSE BLOCK

BROWN 18 GA.

N/C

ORANGE 12 GA.

WIRE JUNCTION

MODULE

CONN.

423030

423017

STARTER RELAY

RED /BLACK STP. 18 GA.

YELLOW 18 GA.

WHITE 16 GA.

OPC

SWITCH

363208

N/O

363164

BLADE

SWITCH

363164

NEUTRAL

SWITCH HYDRO

BLACK / WHITE 18 GA.

GREEN 18 GA.

N/O

NEUTRAL

SWITCH

363207

423027

IGNITION SWITCH

ENCORE PART #: 363344

WIRE HARNESS FOR 32B100E ; 12 HP BRIGGS

WIRE HARNESS FOR 36B100E ; 12 HP BRIGGS

WIRE HARNESS FOR 48B300E ; 16 HP BRIGGS

WIRE HARNESS FOR 52B300E ; 16 HP BRIGGS

WIRE HARNESS FOR 60B300E ; 16 HP BRIGGS

WIRE HARNESS FOR 60B400E ; 18 HP BRIGGS

WIRE HARNESS FOR 48B350EWT ; 16 HP BRIGGS

WIRE HARNESS FOR 48B450EWT ; 18 HP BRIGGS

WIRE HARNESS FOR 52B350E ; 16 HP BRIGGS

WIRE HARNESS FOR 52B450E ; 18 HP BRIGGS

WIRE HARNESS FOR 60B350E ; 16 HP BRIGGS

WIRE HARNESS FOR 60B450E ; 18 HP BRIGGS

WIRE H

ARNESS FOR WB32B12ES; 12 HP BRIGGS

WIRE HARNESS FOR WB36B12ES; 12 HP BRIGGS

BLACK / WHITE 18 GA.

363164

N/O

NEUTRAL

SWITCH HYDRO

363164

WHITE 16 GA.

OPC

363208

SWITCH

BLADE

SWITCH

363207

SWITCH

NEUTRAL

BROWN 18 GA.

N/O

GREEN 18 GA.

N/C

BROWN 18 GA.

YELLOW 18 GA.

RED 12 GA.

ENCORE PART #: 363344

WIRE HARNESS FOR 32B100E ; 12 HP BRIGGS

WIRE HARNESS FOR 36B100E ; 12 HP BRIGGS

WIRE HARNESS FOR 48B300E ; 16 HP BRIGGS

WIRE HARNESS FOR 52B300E ; 16 HP BRIGGS

WIRE HARNESS FOR 60B300E ; 16 HP BRIGGS

BLACK 16 GA.

WIRE HARNESS FOR 60B400E ; 18 HP BRIGGS

WIRE HARNESS FOR 48B350EWT ; 16 HP BRIGGS

WIRE HARNESS FOR 48B450EWT ; 18 HP BRIGGS

WIRE HARNESS FOR 52B350E ; 16 HP BRIGGS

WIRE HARNESS FOR 52B450E ; 18 HP BRIGGS

WIRE HARNESS FOR 60B350E ; 16 HP BRIGGS

WIRE HARNESS FOR 60B450E ; 18 HP BRIGGS

WIRE H

ARNESS FOR WB32B12ES; 12 HP BRIGGS

WIRE HARNESS FOR WB36B12ES; 12 HP BRIGGS

CONN.

423030

MODULE

YELLOW 16 GA.

423017

STARTER RELAY

423027

IGNITION SWITCH

ORANGE 12 GA.

RED /BLACK STP. 18 GA.

BLACK 16 GA.

GROUND

TO BATT.

WIRE JUNCTION

FUSE BLOCK

RED 12 GA.

RED 14 GA.

20 AMP FUSE

ORANGE / WHITE 18 GA.

POS.

TO BATT.

ORANGE 18 GA.

RED /BLACK STP. 18 GA.

ENGINE KILL

ENGINE

CHARGING

ENGINE FUEL

SOLENOID

8

Page 10

ENCORE

363208

OPC SWITCH

TO ENGINE KILL

N/O

N/O

603060

ON/OFF

KEY SWITCH

363164

BLADE

SWITCH

18 GA YELLOW

C

A

F

B

TO ENGINE GND.

18 GA BLACK

18 GA WHITE

363207

TRANS.NEUTRAL

SWITCH

18 GA VIOLET

18 GA YELLOW

18 GA RED

REAR VIEW OF SAFETY

MODULE CONN.

363372

N/C

18 GA GREEN

18 GA BROWN

ENCORE PART #: 363371

WIRE HARNESS FOR 48K400 ; 17 HP KAWASAKI

WIRE HARNESS FOR 52K400 ; 17 HP KAWASAKI

WIRE HARNESS FOR 60K400 ; 17 HP KAWASAKI

WIRE HARNESS FOR WB32K13; 13 HP KAWASAKI

WIRE HARNESS FOR WB36K13; 13 HP KAWASAKI

WIRE HARNESS FOR WB36K15; 15 HP KAWASAKI

WIRE HARNESS FOR WB48K15; 15 HP KAWASAKI

WIRE HARNESS FOR WB48K17; 17 HP KAWASAKI

NOTE CHANGES AT CONN .red wire was at A slot

Yellow wire was at D slot

brown wire was at B slot

black wire was at F slot

green wire was at E slot

12-9-98 dlm

NOTE CHANGES AT CONN .red wire was at B slot

black wire was at E slot

1-21-99 dlm

NOTE CHANGES AT CONN .red wire was at B slot

black wire was at E slot

1-21-99 dlm

NOTE CHANGES AT CONN .red wire was at A slot

Yellow wire was at D slot

brown wire was at B slot

black wire was at F slot

green wire was at E slot

12-9-98 dlm

18 GA BLACK

TO ENGINE GND.

REAR VIEW OF SAFETY

A

MODULE CONN.

363372

EEDDC

B

ENCORE PART #: 363371

WIRE HARNESS FOR 48K400 ; 17 HP KAWASAKI

WIRE HARNESS FOR 52K400 ; 17 HP KAWASAKI

WIRE HARNESS FOR 60K400 ; 17 HP KAWASAKI

WIRE HARNESS FOR WB32K13; 13 HP KAWASAKI

WIRE HARNESS FOR WB36K13; 13 HP KAWASAKI

WIRE HARNESS FOR WB36K15; 15 HP KAWASAKI

WIRE HARNESS FOR WB48K15; 15 HP KAWASAKI

WIRE HARNESS FOR WB48K17; 17 HP KAWASAKI

F

18 GA GREEN

18 GA RED

TO ENGINE KILL

18 GA BROWN

18 GA YELLOW

363207

TRANS.NEUTRAL

SWITCH

18 GA VIOLET

N/C

603060

ON/OFF

KEY SWITCH

363164

BLADE

SWITCH

N/O

18 GA WHITE

18 GA YELLOW

363208

OPC SWITCH

N/O

9

Page 11

ENCORE

N/C

MODULE

CONN.

BROWN 18 GA.

STARTER RELAY

WIRE JUNCTION

BLACK 16 GA.

TO BATT.

POS.

RED 12 GA.

ORANGE 12 GA.

RED /BLACK STP. 18 GA.

ORANGE / WHITE 18 GA.

ORANGE 18 GA.

TO BATT.

GROUND

RED 14 GA.

RED /BLACK STP. 18 GA.

YELLOW 18 GA.

BLACK 16 GA.

RED 12 GA.

20 AMP FUSE

FUSE BLOCK

ENGINE

CHARGING

ENGINE

FUEL

ENGINE

KILL

OPC

SWITCH

GREEN 18 GA.

N/O

BLADE

SWITCH

YELLOW 16 GA.

IGNITION SWITCH

NEUTRAL

SWITCH

NEUTRAL SWITCH

HYDRO

BLACK / WHITE 18 GA.

BROWN 18 GA.

N/O

WHITE 16 GA.

ENCORE PART #: 363373

WIRE HARNESS FOR 48K450EWT ; 17 HP KAWASAKI

WIRE HARNESS FOR 52K450E ; 17 HP KAWASAKI

WIRE HARNESS FOR 52K550E ; 19 OR 20 HP KAWASAKI

WIRE HARNESS FOR 60K550E ; 19 OR 20 HP KAWASAKI

WIRE HARNESS FOR WB48K17ES; 17 HP KAWASAKI

BLACK / WHITE 18 GA.

N/O

OPC

SWITCH

BLADE

SWITCH

HYDRO

NEUTRAL SWITCH

BROWN 18 GA.

N/O

GREEN 18 GA.

SWITCH

NEUTRAL

N/C

BROWN 18 GA.

YELLOW 18 GA.

ENCORE PART #: 363373

WIRE HARNESS FOR 48K450EWT ; 17 HP KAWASAKI

WIRE HARNESS FOR 52K450E ; 17 HP KAWASAKI

WIRE HARNESS FOR 52K550E ; 19 OR 20 HP KAWASAKI

WIRE HARNESS FOR 60K550E ; 19 OR 20 HP KAWASAKI

WIRE HARNESS FOR WB48K17ES; 17 HP KAWASAKI

CONN.

MODULE

BLACK 16 GA.

STARTER RELAY

YELLOW 16 GA.

WHITE 16 GA.

ORANGE 12 GA.

IGNITION SWITCH

BLACK 16 GA.

RED 12 GA.

RED /BLACK STP. 18 GA.

GROUND

TO BATT.

FUSE BLOCK

RED 12 GA.

WIRE JUNCTION

RED 14 GA.

20 AMP FUSE

POS.

TO BATT.

ORANGE 18 GA.

ORANGE / WHITE 18 GA.

RED /BLACK STP. 18 GA.

KILL

ENGINE

ENGINE

CHARGING

FUEL

ENGINE

10

Page 12

TO ENGINE

KILL

N/C

363207

TRANS. NEUTRAL

SWITCH

18 GA YELLOW

18 GA BROWN

18 GA WHITE

18 GA BLACK

18 GA RED

TO ENGINE GND.

N/O

18 GA VIOLET

N/O

363164

BLADE

SWITCH

363208

OPC SWITCH

C

F

18 GA GREEN

REAR VIEW OF SAFETY

REAR VIEW OF SAFETY

MODULE CONN.

363372

ENCORE PART #: 363388

WIRE HARNESS FOR 32B100 ; 12 HP BRIGGS

WIRE HARNESS FOR 36B100 ; 12 HP BRIGGS

WIRE HARNESS FOR WB32B12; 12 HP BRIGGS

WIRE HARNESS FOR WB36B12; 12 HP BRIGGS

MODULE CONN.

363372

C

AABBDDEEF

ENCORE

ENCORE PART #: 363388

WIRE HARNESS FOR 32B100 ; 12 HP BRIGGS

WIRE HARNESS FOR 36B100 ; 12 HP BRIGGS

WIRE HARNESS FOR WB32B12; 12 HP BRIGGS

WIRE HARNESS FOR WB36B12; 12 HP BRIGGS

TO ENGINE

KILL

18 GA RED

18 GA BROWN

363207

TRANS. NEUTRAL

SWITCH

N/C

18 GA GREEN

18 GA BLACK

TO ENGINE GND.

18 GA YELLOW

363164

BLADE

SWITCH

18 GA WHITE

363208

OPC SWITCH

N/O

18 GA VIOLET

11

N/O

Page 13

ENCORE

18 GA WHITE

18 GA BLACK

18 GA RED

N/C

363207

TRANS.NEUTRAL

SWITCH

18 GA YELLOW

18 GA BROWN

TO ENGINE GND.

TO ENGINE

KILL

N/O

18 GA VIOLET

N/O

363164

BLADE

SWITCH

363208

OPC SWITCH

C

F

18 GA GREEN

REAR VIEW OF SAFETY

MODULE CONN.

363372

ENCORE PART #: 603027

WIRE HARNESS FOR 48B300 ; 16 HP BRIGGS

WIRE HARNESS FOR 52B300 ; 16 HP BRIGGS

WIRE HARNESS FOR 52B400 ; 18 HP BRIGGS

WIRE HARNESS FOR 60B300 ; 16 HP BRIGGS

WIRE HARNESS FOR 60B400 ; 18 HP BRIGGS

REAR VIEW OF SAFETY

MODULE CONN.

363372

C

AABBDDEEF

ENCORE PART #: 603027

WIRE HARNESS FOR 48B300 ; 16 HP BRIGGS

WIRE HARNESS FOR 52B300 ; 16 HP BRIGGS

WIRE HARNESS FOR 52B400 ; 18 HP BRIGGS

WIRE HARNESS FOR 60B300 ; 16 HP BRIGGS

WIRE HARNESS FOR 60B400 ; 18 HP BRIGGS

TO ENGINE

KILL

18 GA RED

18 GA BROWN

363207

TRANS.NEUTRAL

SWITCH

18 GA BLACK

N/C

18 GA GREEN

TO ENGINE GND.

18 GA YELLOW

363164

BLADE

SWITCH

18 GA WHITE

363208

OPC SWITCH

N/O

18 GA VIOLET

12

N/O

Page 14

Notes:

Page 15

ENCORE WARRANTY

This warranty extends to the original retail purchaser only and commences on the date of

original retail purchase. Any part of the Encore commercial mower manufactured by Encore

Mfg. Co., Inc. and found in reasonable judgement of Encore Mfg. Co., Inc. to be defective in

material or workmanship will be repaired or replaced by an authorized Encore Mfg. Co., Inc.

dealer without charge for parts and labor. The Encore mower, including any defective part,

must be returned to an authorized Encore service dealer within the warranty period. The

expense of delivering the mower to the dealer for warranty work and the expense of returning

it back to the owner after repair or replacement will be paid by the owner. Should any part

prove to be defective within the two years of original purchase (90 days for rental purposes),

this part will be replace F.O.B. Beatrice, Nebraska, without charge, provided, the defective part

is returned to us transportation charges prepaid. Return Authorization is not required for

cutter housings, electrical components, hydraulic components or belts. Return Authorization

is required for all other components. The responsibility of Encore Mfg. Co., Inc. in respect to

claim is limited to making the required repair or replacements, and no claim of breach of

warranty shall be cause for cancellation or recession of the contract of sale of any Encore

mower. Proof of purchase will be required by the dealer to substantiate any warranty claim.

All warranty work must be performed by an authorized Encore service dealer. This warranty is

limited to two years from the date of original retail purchase for any Encore mower that is used

for commercial purposes or 90 days rental. This warranty DOES NOT cover any Encore

mower that has been subject to misuse, neglect, negligence, accident or that has been

operated in any way contrary to the operating instructions as specified in the Operator’s

Manual. The warranty DOES NOT apply to any damage to the mower that is the result of

improper maintenance, or to any mower parts that have not been assembled or installed as

specified in the assembly instructions. The warranty DOES NOT cover any mower that has

been altered or modified so as to adversely affect the intended use of the product, its

operation, performance or durability. In addition, the warranty DOES NOT extend to repairs

made necessary by normal wear or by the use of parts or accessories which, in the

reasonable judgement of Encore Mfg. Co., Inc. are either incompatible with the mower or

adversely affect its operation, performance or durability. This warranty DOES NOT cover the

engine, which is warranted separately by the engine manufacturer and for different periods of

time. This warranty DOES cover (if equipped) the battery for a period of 90 days. Encore

Mfg. Co., Inc. reserves the right to change or improve the design of any mower without

assuming any obligation to modify any mower previously manufactured. Encore Mfg. Co.,

Inc’s. obligation under warranty is strictly and excessively limited to repair or replacement of

defective parts. Encore Mfg. Co., Inc. DOES NOT assume or authorize anyone to assume

for them any other obligation. Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you. Encore Mfg. Co., Inc. assumes

no responsibility for incidental, consequential or other damages including, but not limited to

expense of delivering the mower to an authorized service dealer and expense of returning it

back to the owner, mechanic’s travel time, telephone or telegram charges, rental of a like

product during the time warranty repairs are being performed, travel, loss of use of the mower,

loss of time or inconvenience. Some states do not allow the exclusion or limitation of

incidental or consequential damages so that above limitation or exclusion may not apply to

you. This warranty gives you specific legal rights which vary from state to state.

ENCORE MFG. CO., INC. CANNOT BE RESPONSIBLE FOR THE WAY, OR CONDITIONS

IN WHICH YOU OPERATE THE MOWER. USE COMMON SENSE AT ALL TIMES.

Page 16

0403 B

All rights reserved. Contents subject to change. Part Number

,ENCORE MANUFACTURING CO., INC.

PREMIER PRO

32B100 - OPERATORS MANUAL

933010

Loading...

Loading...