Page 1

2 6 S P 1 0 0

OPERATORS/PARTS

MANUAL

Page 2

OPERATORS MANUAL

SECTION

Page 3

WARNING:

CAUTION:

NOTES:

GENERAL

This manual contains techincal data on the

following Encore commercial mowers.

optimum performance and safety, always

purchase genuine Encore replacement parts

and accessories.

26SP100

INTRODUCTION

Your mower was built to the highest

standards in the industry. However, the

prolonged life and maximum efficiency of

your mower depends on you following the

operating, maintenance and adjustment

instructions in this manual.

We encourage you to contact your local

Encore dealer for repairs. All Encore dealers

are informed of the latest methods to service

this equipment and provide propmt and

efficient service. They carry a full line of

Encore service parts. This manual includes a

parts section to help in correctly ordering

parts when necessary.

SIGNAL WORDS

This symbol means “Attention! Become

Alert! Your Safety is Involved!” The symbol

is used with the following signal action words

to attract your attention to safety messages.

The message that follows the symbol contains important information about safety.

Signal Word:

A replacement Operator’s Manual is available

from your Encore Dealer or by contacting

Encore Manufacturing Co., Inc., Service

Department at PO Box 888, Beatrice, NE

68310. Please indicate the complete model

and serial number of your Encore product.

The “Right” and “Left”,”Front” and “Rear” of

the machine are referenced from the

operator’s perspective when in the normal

operating position and facing forward travel

direction.

GENERAL SAFETY INSTRUCTIONS

READ THIS OPERATOR’S MANUAL and

instructions furnished with attachments.

The signal action word “ WARNING” denotes

that a hazard exists on or near the machine

that can result in injury or death if proper

precautions are not taken.

The signal action word “CAUTION” is a

reminder of safety practices on or near the

machine that could result in personal injury if

proper precautions are not taken.

Perform only those maintenance procedures

described in this manual. If major repairs are

ever needed or assistance is desired, contact

an Authorized Encore Dealer. To ensure

The signal action word “NOTES” denotes

relevant information to assist you in the

performance of a task.

Page 4

GENERAL RULES OF SAFETY FOR

WARNING:

DO NOT allow children to operate the

machine. DO NOT allow any adult to operate

the machine without proper instruction.

CAUTION:

Never add fuel to a running engine. AL WA YS

WAIT at least five minutes before refueling

and REFUEL WITH THE ENGINE OFF.

KEEP FUEL AWAY FROM SPARKS OR

FLAMES. WIPE AWAY any fuel spillage

BEFORE starting unit.

OPERATION.

The follow general rules of safety should be

followed whenever THE MOWER IS

BEENING USED. Good judgement and

common sense should always prevail.

1. Read and thoroughly understand this

manual, and all decals on unit, before

attempting to operate.

2. DO NOT mow when children and/or

bystanders are present.

objects as damage to machine and/or others

may result.

9. Never mow on a surface angle greater

than 15 degrees. Mow across a slope less

than 15 degrees, NEVER up and down.

10. Do NOT alter governor setting on

engine. Engine over speed could result in

severe damage and/or injury.

11. Keep all shields and safety devices

intact. DO NOT try to circumvent or disable

these features.

12. DO NOT mow at night or in times of

low visibility.

13. DO NOT operate engine in confined

air space where carbon monoxide fumes can

collect.

3. ALWAYS WEAR SUITABLE

CLOTHING when operating machine, proper

boots, gloves, and eye protection- NO

LOOSE-FITTING APPERL that could get

caught in the moving parts of machine.

4. Always be alert when operating

machine. Do not let outside interests distract

you.

5. Always clear area to be mowed of any

foreign objects (stones, wire, cans, bottles,

etc. That could be picked up and thrown by

mower.

6. Always be certain that any selfpropelling unit is DISENGAGED before

attempting to start engine.

7. Always disengage power, stop engine,

and remove spark plug wire, before

attempting any inspection, adjustment,

cleaning, or repair .

8. Use care when mowing around fixed

objects. Never deliberately run over foreign

14. ALWAYS STOP ENGINE before

leaving mower unattended for any length of

time.

15. DO NOT operate machine without

muffler.

16. KEEP all nuts, bolts and screws tight.

Keep your High Wheel in good working

condition.

Page 5

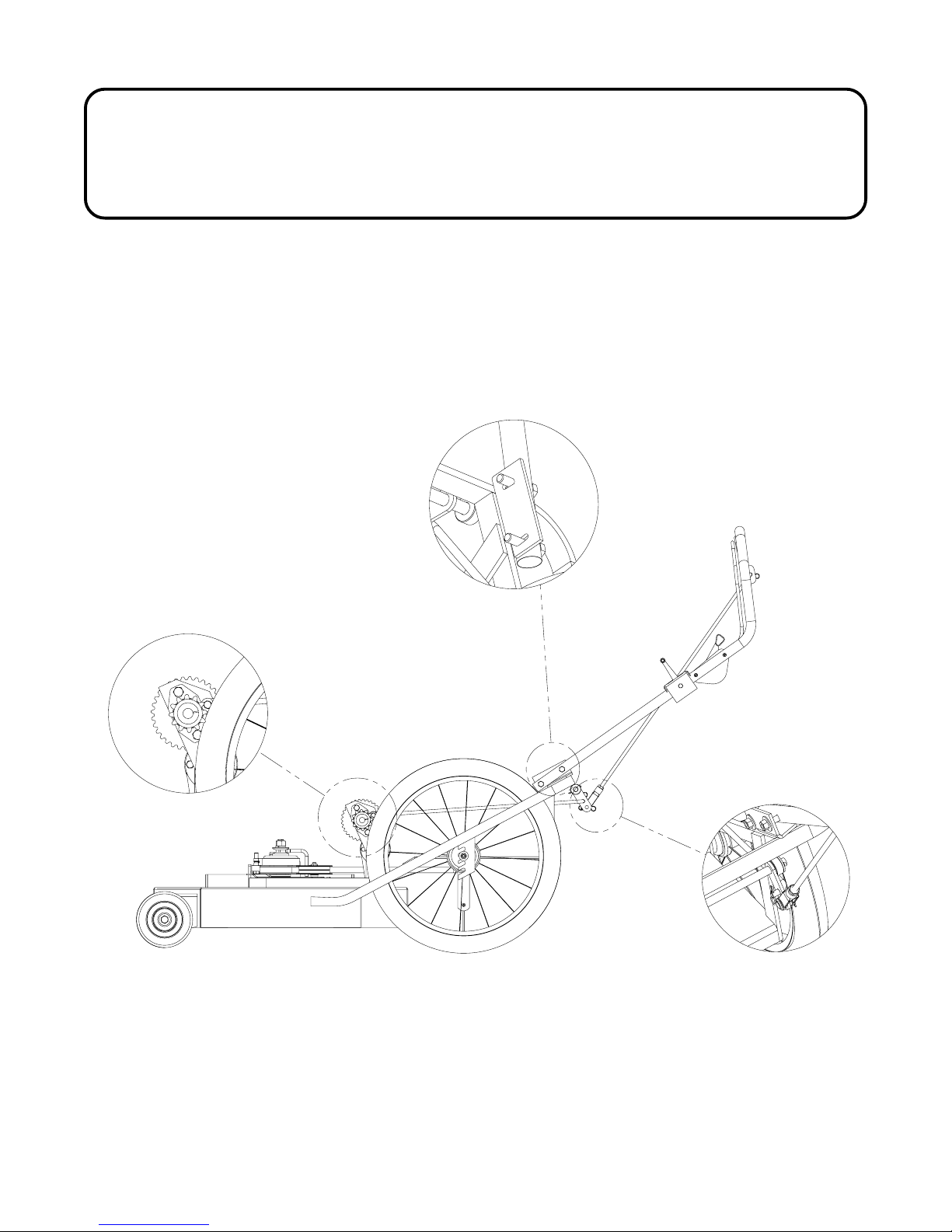

SET -UP AND MAINTIANENCE

CAUTION:

Engine has not been serviced prior to delivery. Consult engine manual to

properly service engine before use.

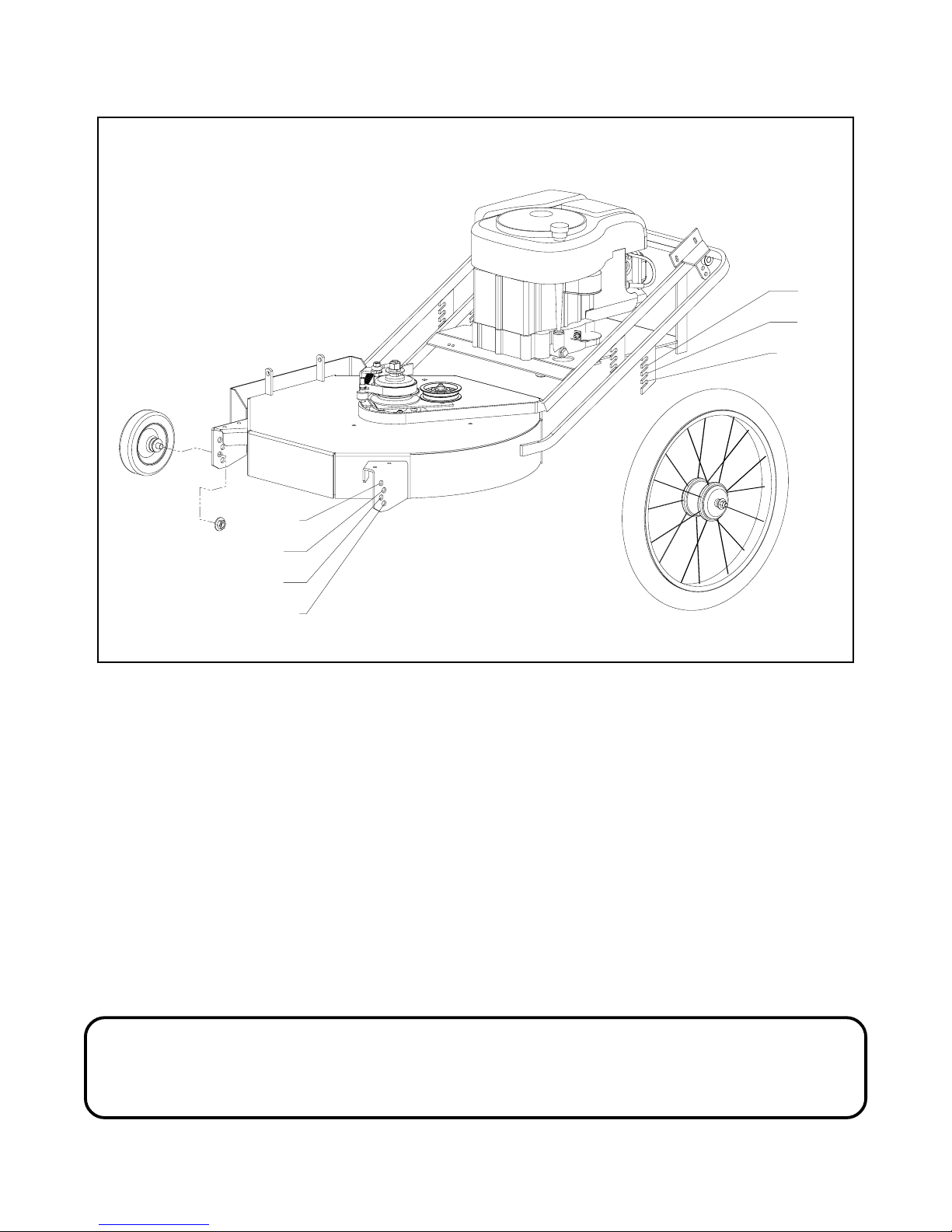

1. Install handle by flipping handle into place using the bolts located in the

handle support. See diagram a. (Note that the handle frame is slotted so the

handle can be adjusted to the right operator height for operator comfort).

Diagram A

Diagram C

2. Install wheel drive engaging rod and adjust so that the drive cogs engage

the tire. See diagram (b & c). Note that the tires should be inflated to 30

pounds.

Diagram B

Page 6

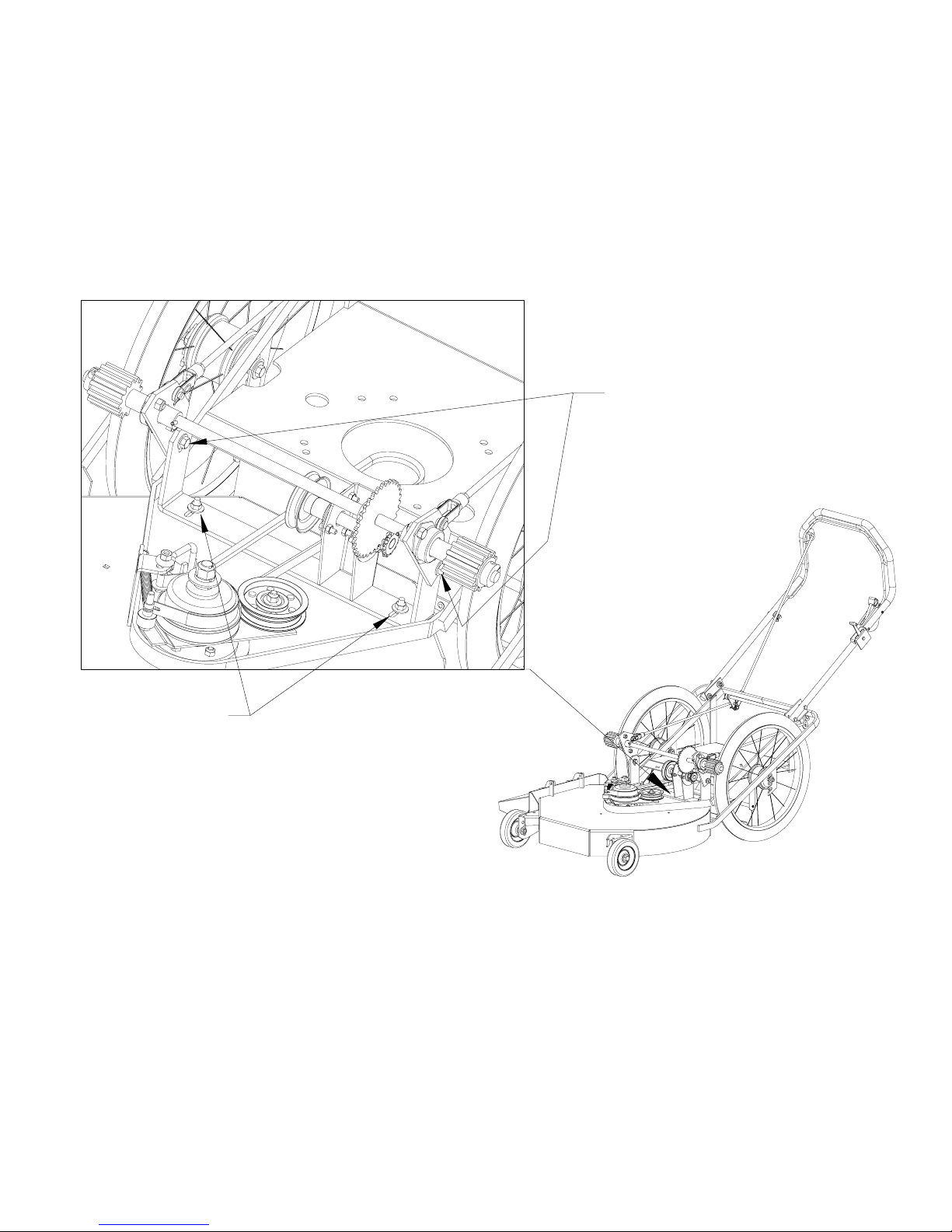

3. Drive chain may be adjusted by loosing the top bracket located by the cog

assemble (Refer to figure d) When adjusting the drive chain you must adjust

both sides equally. After adjusting the chain reset cog tension by removing the

pin in the yoke attached to the cog bracket and shortening the rod length to

increase cog pressure.

Figure D

Figure E

4. The drive belt maybe adjusted by loosening the bolts in the lower frame

support and shifting it forward of back. (Refer to f)

Page 7

HEIGHTS ADJUSTMENTS:

CAUTION:

Stop engine and remove spark plug for safety.

1 1/2"

2"

3"

3 1/4"

2"

3"

3 1/4"

Figure C

Adjust cut setting by changing wheel heights according to figure (c).

Mower blade:

Check sharpness of mower blades after every 10 hours of operation. To sharpen

blades proceed as follows.

a. Block front of mower up.

Page 8

b. Remove blade by turning bolt counter clockwise.

c. Blades should be discarded when worn excessively. See Sketch.

New Blade

25 Degrees

When Notch Starts

Discard Blade

Dangerous!

d. Sharpen blades with a hand file, electric grinder or blade sharpener. Wear

gloves and eye protection when sharpening. Grind blade at original bevel.

e. Check balance of blade by positioning the blade on a nail or blade balance

pedestal.

f. Reinstall blade making sure that the disc spring washer is bowl side up and re-

torque bolt to 90 ft pounds.

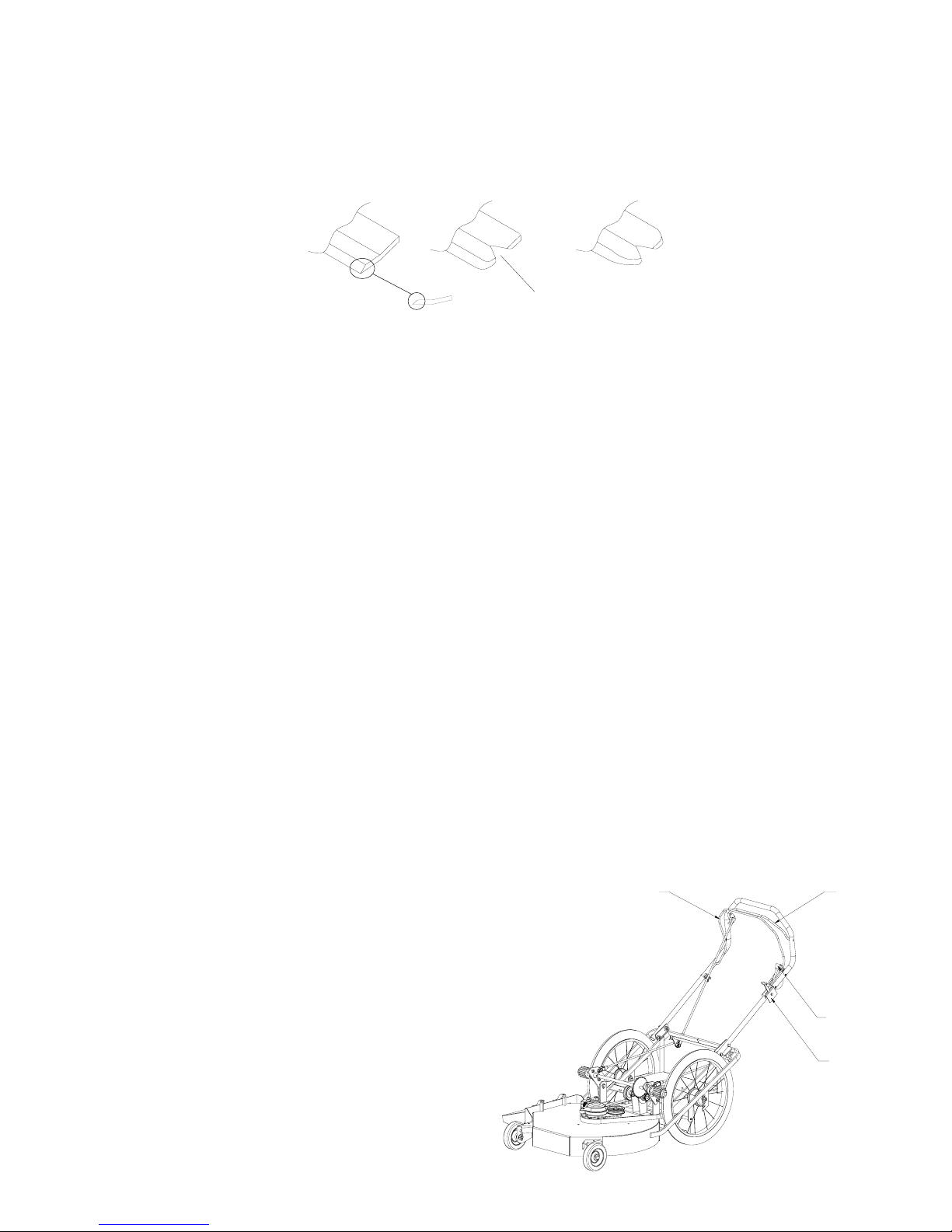

To Begin Operation

The throttle control/choke lever is located on left side of handlebar. To engage

choke, push throttle control lever all the way forward.

Choke as required and start engine.

With engine running, engage the brake bail by squeezing it to the handlebar.

Then push forward on the black plastic drive lever (located on left side of

handlebar just above the throttle control) until it locks into the forward position.

To drive machine forward, engage the

wheel drive bail (located on the

uppermost part of handlebar) by

squeezing it to the handlebar.

To stop machine from pulling forward,

release only the wheel drive bail.

To shut off engine: release the wheel

drive bail and the brake bail. Adjust the

throttle control to the engine stop

position.

Brake Bail Drive Bail

Drive Lever

Throttle Control

Page 9

6

5

7

8

12

13

4

3

2

1

11

1. 12 V electric starter

2. Oil dra in plug

3. F uel fill

4. Fuel tank

5. Oil fill/Dips tick

6. Finger guard

7. R ope ha ndle

8. Air cleaner

GENERAL INFORMATION

ENGINE MODEL

T his is a s ingle cylinde r, L -head, a ir-coole d e ngine. It is a

low emissions engine.

MODE L S E R IE S 280000

Bore 3-7/16 in. (87.31 mm). . . . . . . . . . . . . . . . . . . . . . . . . .

S troke 3-1/16 in. (77.78 mm). . . . . . . . . . . . . . . . . . . . . . . .

Displacement 28.42 cu. in. (465.7 cc). . . . . . . . . . . . . . . .

Note: For pra ctical opera tion, the hors e power loading s hould

not exceed 85% of rated horsepower. E ngine power will decrease 3-1/2% for each 1,000 feet (300 meters) above sea

level and 1% for each 10 F (5.6 C) above 77 F (25 C).

Engine will operate satisfactorily at an angle up to 15 .

9

10

9. E ngine Model Type Code

xxxxx xxxx xx xxxxxxxx

10. Muffler/(Muffler gua rd, if equipped)/

(S park a rres ter, if equipped)

11. S park plug wire

12 . R ota ting s cre e n

13. Blower housing

14. Fuel filter

15. Carburetor

OIL CAPACITY

E ngine Model Series 280000 holds about 1-1/2

qts (48 ozs or 1.4 ltrs).

TYPE OF OIL TO USE

Us e a high qua lity de tergent oil clas s ified “F or S ervice

SF, SG, SH, SJ” or higher, such as Briggs & Stratton

30W, P art Number 100005 (20 oz) or 100028 (48 oz).

Do not us e s pecia l additives .

Choose a viscosity according to the table opposite.

Note: Synthetic oil meeting ILSAC GF-2, API

ce rtification ma rk a nd A P I s ervice symbol

(shown at left) with “S J /C F E NE R GY C ONS E R V I N G ” or higher, is a n acce ptable oil a t all

temperatures. Us e of s ynthetic oil does not

alter required oil change intervals.

14

15

TUNE -UP S PE C IFIC ATIONS

Armature air gap 0.010 – 0.014 in. (0.25 – 0.36 mm). . .

S park plug gap 0.030 in. (0.76 mm). . . . . . . . . . . . . . . . . .

Va lve clea rance with valve s prings ins talle d a nd pis ton 1/4 in.

(6 mm) past top dead center (check when engine is cold).

S ee R epair Manual P/N 270962.

Model 280000 intake .005 – .007 in. (.13 – .18 mm). . . . .

Model 280000 exhaust .009 – .011 in. (.23 – .28 mm). . .

C AU T ION: T his engine is s hipped from B riggs &

S tratton without o il

e n gine . I f you s ta rt the e ngine withou t oil, the e ngine

will be da ma ged be yond repair a nd will not be

covered under warranty.

. C heck oil le vel before s tarting

SAE Viscosity Grades

**

*

-20 0 20 40 60 80 100

F

-30 -20 -10 0 10 20 30 40

C

STARTING TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

* CAUT ION: Air cooled engines run hotter than

automotive engines. T he use of non-synthetic

multi-vis cos ity oils (5W-30 , 10W-30, e tc.) in

tempera ture s above 40 F (4 C ) will re s ult in higher

than norma l oil cons umption. W he n us ing a

multi-vis cos ity oil, check oil leve l more freque ntly.

** C A UTION: SAE 30 oil, if used below 40 F (4 C), will

res ult in hard s tarting and pos sible engine bore

damage due to inadequa te lubrication.

32

Page 10

PARTS MANUAL

SECTION

Page 11

HANDLE ASSEMBLY

16

16

1

151314

4

6

5

8

11

3

2

2

18

20

19

17

20

5

9

10

18

12

25

Page 12

26" High Wheel Walk-Behind

Handle Assembly

QTY

1

1

QTY

PART #

PART #

QTY

PART #

# QTY

1

12

22

31

41

53

61

71

81

91

10 1

11 1

12 1

13 1

14 1

15 1

16 2

17 1

18 4

19 7

20 4

DESCRIPTION

HANDLE ASSY.

DESCRIPTION

100258

101298

103003

103021

104255

105259

105507

262006

263036

263058

263062

263088

263089

363165

363196

FINAL ASSY

100295 3/8-16 X 1-3/4 HHCS

104257 3/8 – 16 NYLOC NUT

105260 3/8 STD FLAT WASHER

1/4 - 20 X 2.00 HHCS

# 10 – 24 x 2 1/4

#10-14 x 1/2 PLASTITE SCREW (FOR PLASTIC)

ROPE GUIDE

1/4 - 20 NYLOC NUT

3/8 SAE FLAT WASHER

POP RIVET BURR 3/16

DRIVE BAIL WELDMENT

DRIVE CABLE

HANDLE

BRAKE BAIL

BAIL PUSH NUT

THROTTLE CONTROL

ENGAGEMENT ROD ASSY.

PART # DESCRIPTION

104754 3/8 – 24 HEX JAM NUT

263066 DRIVE ENGAGEMENT ROD

363192 LARGE YOKE

# 3 HAIRPIN

CLEVIS PIN – 3/8

DESCRIPTION

Page 13

MOWER DECK ASSEMBLY

5

7

17

31

29

32

32

30

13

16

44

41

40

11

3

22

37

38

34

39

32

1

15

35

38

43

42

20

38

33

3

18

14

24

26

27

25

26

26

9

25

12

2

19

5

9

25

27

24

26

10

21

Page 14

26" High Wheel Walk-Behind

Mower Deck Assembly

# QTY

11

210

311

47

52

62

71

84

94

10 1

11 1

12 1

13 3

14 1

15 1

16 1

17 1

18 1

19 1

20 1

21 1

22 1

23 2

24 1

25 1

26 2

27 1

28 1

29 1

30 1

31 1

32 2

33 1

34 1

35 2

PART # DESCRIPTION

QTY

1

PART # DESCRIPTION

100273 5/16 – 18 X 1 HHCS

104256 5/16 – 18 NYLOC NUT

104257 3/8 – 16 NYLOC NUT

104512 5/8 – 18 HEX NUT

104755 1/2 - 20 HEX JAM NUT PLATED

105009 LOCKWASHER - .625

105260 3/8 STD FLAT WASHER

105264 1/2 STD. FLATWASHER

107009 WOODRUFF KEY

107266 3/16 X 3/16 X 2 MACHINE KEY

107503 5/16 – 18 x 3/4 CARRIAGE HEAD BOLT

109007 3/8 - 16 WHIZLOCK NUT

263008 BLADE SPINDLE PULLEY

263012 SPACER - BLADE SHAFT

263016 BLADE BRAKE HUB

263072 BRAKE CONDUIT HOLDER

263092 26” BLADE

263097 RETAINING RING

263098 BLADE DRIVER

263115 BLADE BRAKE - GUIDE

QTY

QTY

AR

QTY

DEFLECTOR SHIELD

FINAL ASSY

MAIN FRAME WELDMENT – PAINTED

FRONT WHEEL ASSY.

PART # DESCRIPTION

100537 1/2 - 20 x 2 1/2 HHCS UNF

104755 1/2 - 20 HEX JAM NUT

105264 1/2 STD. FLATWASHER

263087 FRONT WHEEL

SPINDLE HOUSING ASSY

PART # DESCRIPTION

262018 SPINDLE HOUSING WELDMENT

263023 BLADE SPINDLE

263097 RETAINING RING

553011 SPINDLE BEARINGS

THREAD LOCKER 242

BLADE BRAKE ARM ASSY

PART # DESCRIPTION

100295 3/8 – 16 X 1.75 HHCS

100296 3/8 – 16 x 2.0 HHCS

104257 3/8 – 16 NYLOC NUT

Page 15

26" High Wheel Walk-Behind

Mower Deck Assembly

# QTY

36 1

37 1

38 3

39 1

40 1

41 1

42 1

43 1

44 1

PART # DESCRIPTION

QTY

PART # DESCRIPTION

104753 3/8 – 16 JAM NUT

105259 3/8 SAE WASHER

105260 3/8 STD WASHER

262012 BLADE BRAKE WELDMENT

263028 BRAKE BAND

263076 BRAKE SPRING

363097 SPACER - TURNBUCKEL

523328 FLAT IDLER – MULE DRIVE

823309 FRAME SPACER – pltd.

Page 16

DRIVE ASSEMBLY

5

34

32

23

31

32

24

25

27

22

20

12

14

35

4

6

34

11

16

8

9

26

23

31

35

15

18

8

30

29

9

33

9

7

28

9

22

9

33

11

13

29

9

19

17

19

21

32

30

20

22

32

5

12

3

10

2

1

Page 17

26" High Wheel Walk-Behind

Drive Assembly

# QTY

12

21

31

41

51

61

72

82

96

10 1

11

12 2

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

PART # DESCRIPTION

FINAL ASSY

QTY

2

1

PART # DESCRIPTION

107509 5/16-18 X 1 CARR. BOLT

263050 BELT SHIELD

263063 DRIVE BELT

264012 DRIVE ROD ASSY

QTY

QTY

1

1

1

PART # DESCRIPTION

104754 3/8 – 24 HEX JAM NUT

263034 DRIVE ROD

363192 LARGE YOKE

FINAL DRIVE ASSY.

PART # DESCRIPTION

100293 3/8-16 X 1-1/4 HHCS

104257 3/8-16 NYLOC NUT

105258 5/16 STD. FLATWASHER

263090 DRIVE CHAIN

263091 CONN. LINK

QTY DESCRIPTION

6 1/4 -20 x 3/4 HHCS

6 1/4 - 20 NYLOC NUT

1 JACK SHAFT WELDMENT

1 CONVERSION PULLEY

1 MED. SPROCKET

1 17mm JACK SHAFT

1 BEARING SPACER

2 3 BOLT 17mm BEARING

QTY DESCRIPTION

4 3/8 – 16 X 3/4 HHCS

2 5/16 – 18 X 3/8 SET SCREW

4 3/8 – 16 NYLOC NUT

4 5/8 SAE WASHER

2 3/16 x 1.50 ROLLPIN

1 DRIVER w/ BEARING RIGHT

1 DRIVER w/ BEARING LEFT

1 DRIVE SHAFT

1 LARGE SPROCKET

2 DRIVE SHAFT SUPPORT

QTY DESCRIPTION

2 FLANGE BEARING

PART #

PART #

PART #

JACKSHAFT ASSY

100252

103293

104255

262010

263020

263056

263109

263111

263112

DRIVE ASSY

100291

103293

104257

105267

106328

262021

262022

263018

263024

263026

363292

SETSCREWS - KNURLED CUP

POINT

Page 18

26" High Wheel Walk-Behind

Drive Assembly

# QTY

31

32

33 2

34 4

35 2

PART # DESCRIPTION

QTY DESCRIPTION

2 5/8 CLAMP COLLAR

4 BLADE SPACER

363174 EYEBOLT SPACER

363165 COTTER PIN # 2 HAIRPIN

363196 CLEVIS PIN –3/8

PART #

363339

373086

Page 19

HEIGHT ADJUSTMENT ASSEMBLY

16

16

20

4

16

18

7

19

13

3

1

11

9

10 12

5

6

1

3

11

8

3

13

2

21

15

9

22

14

Page 20

26" High Wheel Walk-Behind

Height Adjustment Assembly

# QTY

12

27

34

41

51

61

71

82

94

10 1

11 2

12 1

13 2

14 2

15 2

16 2

17 4

18 1

19 1

20 1

21 2

22 4

PART # DESCRIPTION

QTY

1

1

PART # DESCRIPTION

QTY

QTY

FINAL ASSY

100306 3/8 – 16 x 5 HHCS

104257 3/8 – 16 NYLOC NUT

105260 3/8 STD FLAT WASHER

105266 1/2 SAE FLAT WASHER

106763 1/8 x 11/4 COTTER PIN

262008 DRIVE CRANK WELDMENT

263064 DECK DRIVE BELT

263086 DRIVE WHEELS

263117 DRIVE WHEEL SPACER

DRAG FLAP ASSY

PART # DESCRIPTION

262023 DRAG FLAP w/ STIFFENERS

263014 DRAG SHIELD STRAP

263075 DRAG FLAP ROD

363219 PUSH NUT

8.5 HP BRIGGS ENGINE ASSY.

PART # DESCRIPTION

100275 5/16 – 18 X 1 1/2 HHCS

100276 5/16 – 18 X 1 3/4 HHCS

103293 SET SCREWS 5/16 – 18 X 3/8

104256 5/16 – 18 NYLOC NUT

107259 .25 X .25 X 1.00 MACH. KEY

263085 ENGINE PULLEY

SEE NOTE 8.5 HP BRIGGS W/FUEL TANK

363075 BELT GUIDE

363226 DISC SPRING

NOTE:

ENCORE MFG. CO. DO NOT SERVICE OR STOCK PARTS FOR ENGINES ON OUR UNITS.

PLEASE CONTACT ENGINE MFG. FOR PART INFORMATION.

Page 21

DECAL LIST

Page 22

26" High Wheel Walk-Behind

Decal List

# QTY

11

21

31

41

52

61

71

81

91

PART # DESCRIPTION

263031 CLASSIC LABEL

263069 PRO 26 LABEL

263118 WHEEL DRIVE DECAL

363001

363023

363026

363317

363318 POLY ENCORE LOGO

823323 ROTATING PARTS DECAL

CAUTION DECAL

DANGER DECAL

SERIAL NO. PLATE

POLY ENCORE LABEL

Page 23

ENCORE WARRANTY

This warranty extends to the original retail purchaser only and commences on the date of

original retail purchase. Any part of the Encore commercial mower manufactured by Encore

Mfg. Co., Inc. and found in reasonable judgment of Encore Mfg. Co., Inc. to be defective in

material or workmanship, will be repaired or replaced by an authorized Encore Dealer without

charge for parts and labor. The Encore mower including any defective part must be returned to

an authorized Encore service dealer within the warranty period. The expense of delivering the

mower to the dealer for warranty work and the expense of returning it back to the owner after

repair or replacement will be paid by the owner. Should any part prove to be defective within

the two years (tires, belts and batteries are 90 days) of original purchase (90 days for rental

purposes), the part will be replaced F.O.B. Beatrice, Nebraska.

Cutter housings, electrical components, hydraulic components and electric clutch must be

returned before warranty will be paid.

The responsibility of Encore Mfg. Inc. In respect to claim is limited to making the required

repairs or replacements, and no claim of breach of warranty shall be cause for cancellation or

recession of the contract of sale of any Encore mower.

Proof of purchase is required by both Encore and servicing Dealer before any warranty will be

paid, and warranty work must be preformed by an authorized Encore service dealer.

This warranty does not cover any Encore mower that has been altered or modified so as to

adversely affect the intended use of the product, it operation, performance, or durability. As will

as any mower that has been subject to misuse, neglect, negligence, accident or that has been

operated in any way contrary to the operating instructions as specified in the Operators

Manual.

This warranty does not cover the engine, which is warranted separately by the engine

manufacturer. However this warranty covers the Peerless 5 Speed Transmission for a period of

one year.

Encore Mfg. Co., Inc. reserves the right to change or improve the design of any mower without

assuming any obligation of any mower without assuming any obligation to modify any mower

previously manufactured.

Encore Mfg. Co., Inc. obligation under warranty is strictly and excessively limited to repair or

replacement of defective parts. Encore Mfg. Co., Inc. does not assume or authorize anyone to

assume for them any other obligation.

ENCORE MFG. CO., INC. CANNOT BE RESPONSIBLE FOR THE WAY YOU

OPERATE, OR THE CONDITIONS IN WHICH YOU OPERATE THE MOWER.

USE COMMON SENSE AT ALL TIMES.

Page 24

0802 A

All rights reserved. Contents subject to change. Part Number

,ENCORE MANUFACTURING CO., INC.

26SP100 - OPERATORS/PARTS MANUAL

CLASSIC

933113

Loading...

Loading...