Page 1

CLINCHING

TOOLS

AUTOMATED

M

A

CHINES

CLIPPING

SYSTEMS

FASTENERS

& CLIPS

RING TOOLS &

STAPLERS

www.encorehartco.com

info@encorefasteners.com

Northbrook, Illinois 60062 U.S.A.

Phone: 224-723-5524

Fax: 224-723-5526

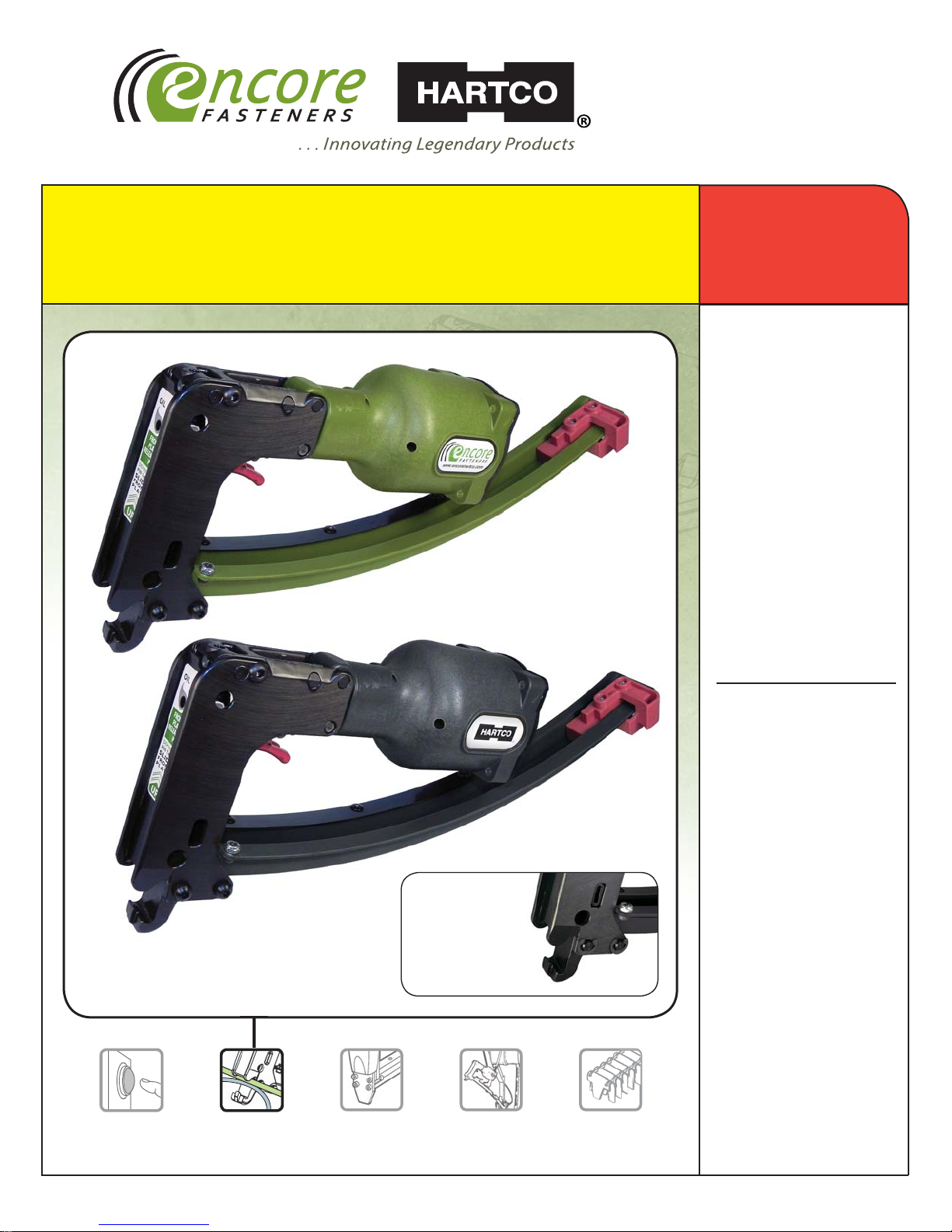

Encore Eclipser/Hartco “E” Clincher

2000 Series

OPERATING

MANUAL

ENCORE (EA)

ECLIPSER

2000 SERIES

Pneumatic Clipping Tool

Green Housing

Green Clip Magazine

HARTCO (HR)

“E” CLINCHER

2000 SERIES

Pneumatic Clipping Tool

Black Housing

Black Clip Magazine

CLINCHING

TOOLS

Thin (“T”)

Models for

Trap and Cage

Assembly

EXCLUSIVE Quick

Release Front Plate—no

tools needed for driver

blade replacement

Light, well balanced,

durable design ensures

e ortless handling

Fastest, simplest and

most trouble-free main

valve in the industry

Small contoured handle

reduces fatigue, improves

comfort and productivity

Compatible with

industry standard clips

v. 08-11-16

Page 2

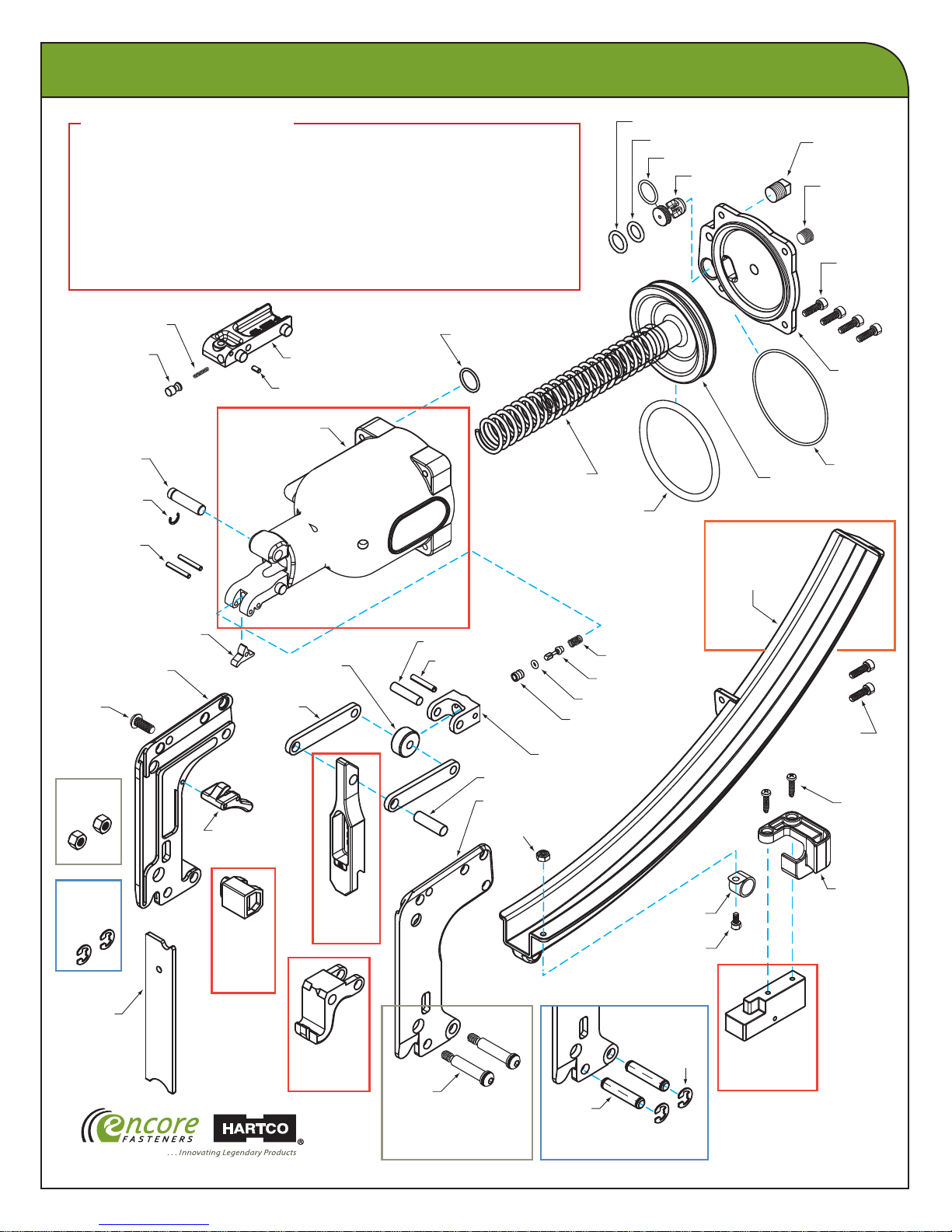

Encore Eclipser / Hartco “E” Clincher – 2000 Series

SAFETY INFORMATION

1. SAFETY GLASSES should always be

worn while operating, maintaining

or repairing a tool.

2. KEEP HANDS AND FINGERS AWAY

from the blade and anvil area

when operating the tool or when

connecting the air supply to the tool.

3. DISCONNECT THE AIR SUPPLY

when mechanically clearing a jam,

performing maintenance or repairs,

and whenever the tool is not in use.

4. INJURY PREVENTION—Never point

the tool toward yourself or anyone

else.

20001

O-RING

20000

20003

O-RING

O-RING

30000

VALVE

20035

PLUG (RED)

20019

PLUG

20011

SCREW

30016 SPRING

30015 PIN

30006

GROOVED PIN

20036

C-CLIP

20010

PIN

SIDE PLATE R. H.

20008

BHCS

Standard

20012

NUT

30010

30012

LEVER

30002

(GREEN)

38002

(BLACK)

30011

TRIGGER

30014 TOP PLATE

20009 PIN

HOUSING

HOUSING

30018

ROLLER

30019

LINK

HOUSING

30020

20018

20004

O-RING

PIN, ROLLER

PIN

30021

30013

20021

30005

SPRING

20006

O-RING

30008

20007

30009

30017

YOKE

PIN, BLADE

SIDE PLATE L. H.

NUT

30007

O-RING

SLEEVE

SPRING

VALVE

MAGAZINE

300___

380___

(GREEN)

(BLACK)

30004

PISTON

30001

CAP

20005

O-RING

20011

SCREW

20034

SCREW

Thin “T ”

20037

E-CLIP

BLADE

GUIDE

302___

30022

FRONT

PLATE

302___

www.encorehartco.com

BLADE

302___

ANVIL

30023

SHOULDER SCREW

Standard Models

30041

PIN

Thin “T” Models

20038

30040

SPRING

SHCS

20037

E-CLIP

30051

PUSHER

300___

30029

PUSHER

PULL

PUSHER “A”

v. 08-11-16

Page 3

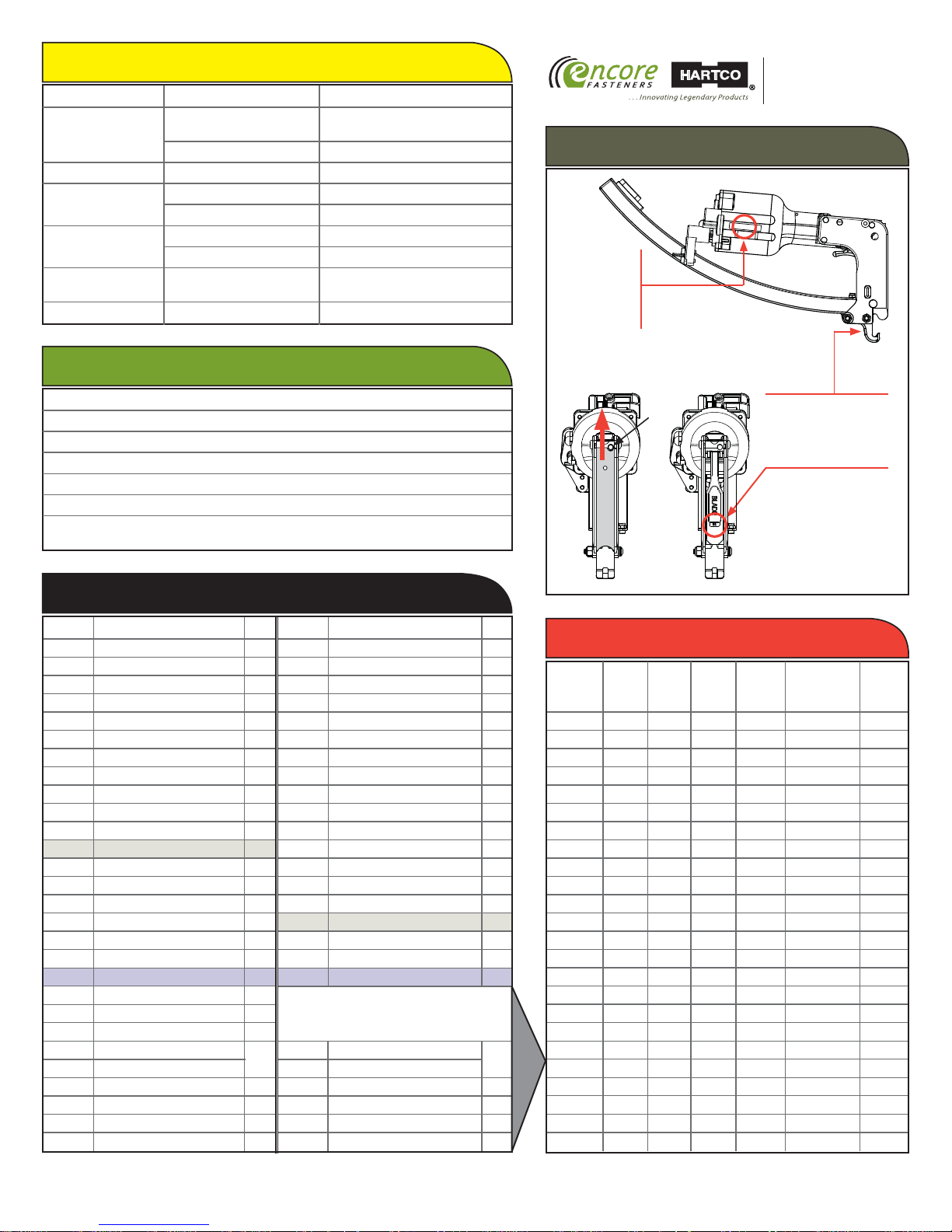

TROUBLE SHOOTING

XXXX

X

SAFETY CAUSE SOLUTION

Blade does not Sticky main valve Lubricate main valve and check

return that main valve piston moves

Loose screw in housing cap Tighten all 4 screws in cap

Sluggish tool Dry main valve Lubricate main valve

Clips not feeding Obstruction in magazine Remove obstruction

Broken pusher spring Replace pusher spring

Loose clips Low air pressure Increase pressure to 80 psi

Worn blade or anvil Replace blade or anvil

Clip jamming Clips are loaded backward Reorient strip so that single ear into

the magazine on clip is loaded forward

Tool not cycling Clogged trigger valve Clean trigger valve assembly

v. 08-11-16

www.encorehartco.com

Phone: 224-723-5524

TOOL IDENTIFICATION

5DIGIT

SERIAL

NUMBER

XXXXX

SPECIFICATIONS

WEIGHT: 4.4 lbs (2.0 kg)

DIMENSIONS: 16.5” x 7” x 4” (419.1 x 177.8 x 101.6mm)

COMPONENT MATERIALS: Composite plastic housing and clip magazine

CLIP FEEDING METHOD: Constant force spring

PRIMARY POWER UNIT: Main cylinder - Bore 3.06” (78mm) spring return

AIR SUPPLY: 80-90 psi (5.5-6.2 bars) of dry, lubricated air

AIR CONSUMPTION (SCFM): 3.56, assuming 90 psi and 1 cycle per second

3.22, assuming 80 psi and 1 cycle per second

2000 Series UNIVERSAL PARTS

Item # Description Qty Item # Description Qty

20000 O-Ring 1

20001 O-Ring 1

20003 O-Ring 1

20004 O-Ring 1

20005 O-Ring 1

20006 O-Ring 1

20007 O-Ring 1

20008 Button Head Cap Screw 1

20009 Dowel Pin 1

20010 Dowel Pin 2

20011 Socket Head Cap Screw 6

20012 Nut* 2

20018 Dowel Pin 1

20019 Plug 1

20021 Nut 1

20034 Screw 2

20036 C-Clip 1

20035 Plug (Red) 1

20037 E-Clip* 4

20038 SHCS 1

30000 Valve 1

30001 Cap 1

30002 Housing, GREEN Encore

38002 Housing, BLACK Hartco

30004 Piston Assy. 1

30005 Compression Spring 1

30006 Grooved Pin 1

30007 Spring 1

* Tools with a “T” have a narrow clipping head. On those tools, Part #20037 (E-Clip)

replaces Part #20012 (Nut) and Part #30041 (Pin) replaces Part #30023 (Shoulder Screw).

30008 Trigger Valve 1

30009 Valve Sleeve 1

30010 Trigger Lever 1

30011 Trigger Assy. 1

30012 Side Plate, Right Hand 1

30013 Side Plate, Left Hand 1

30014 Top Plate 1

30015 Pin 1

30016 Spring, Top Plate Pin 1

30017 Yoke 1

30018 Roller 1

30019 Link 2

30020 Pin, Roller 1

30021 Pin, Blade 1

30022 Front Plate 1

30023 Shoulder Screw* 2

30029 Pusher Pull 1

30040 Spring (Equiv. to HR55040) 1

30041 Pin* 2

The following parts are MODEL

SPECIFIC. See chart at right for those

part numbers.

300__ Magazine, GREEN Encore

1

380__ Magazine, BLACK Hartco

300__ Pusher -w- Latch 1

302__ Blade Guide #__ 1

302__ Anvil #__ 1

302__ Blade #__ 1

MODEL NUMBER = 2000-AABB

PIN

ANVIL NUMBER AA

LOCATED ON BACK

OF ANVIL

BLADE NUMBER BB

LOCATED UNDER

FRONT COVER.

TO FIND, PRESS IN

PIN AND SLIDE THE

COVER UP.

MODEL-SPECIFIC PARTS

Blade Magazine Pusher

Model Anvil Blade Guide Fits Clip 300__ (Green) w/L atch

2000-___ 302__ 302__ 302__ Width 380__ (Black) 300__

1020 10 20 02 A 50 51

1020S 10 20 03 A 50 51

1022 10 22 01 A 50 51

1024 10 24 08 A 50 51

1121 11 21 01 A 50 51

1234 12 34 54 A 50 51

1533 15 33 55 A 50 51

1929 19 29 03 A 50 51

3236 32 36 07 E 24 31

4139 41 39 09 E 24 31

4151T* 41 51 05 F 24 30

4157T* 41 57 04 F 24 30

6075 60 75 00-0 F, H 24 29

6080 60 80 00-0 F, H 24 29

6082 60 82 00-0 F, H 24 25

6181 61 81 00-0 F, H 24 25

6181T* 61 81 00-0 F, H 24 25

6183 61 83 00-1 F, H 24 25

1

6183T* 61 83 00-1 F, H 24 25

6185 61 85 00-0 F, H 24 25

6187T* 61 87 00-1 F, H 24 25

6189 61 89 00-1 F, H 24 25

6788 67 88 06 F, H 60 25

6791T* 67 91 06 F, H 60 25

* Tools with a “T” designation have a narrow clipping head, ideal for

shing/lobster pots, traps and cage assembly.

Page 4

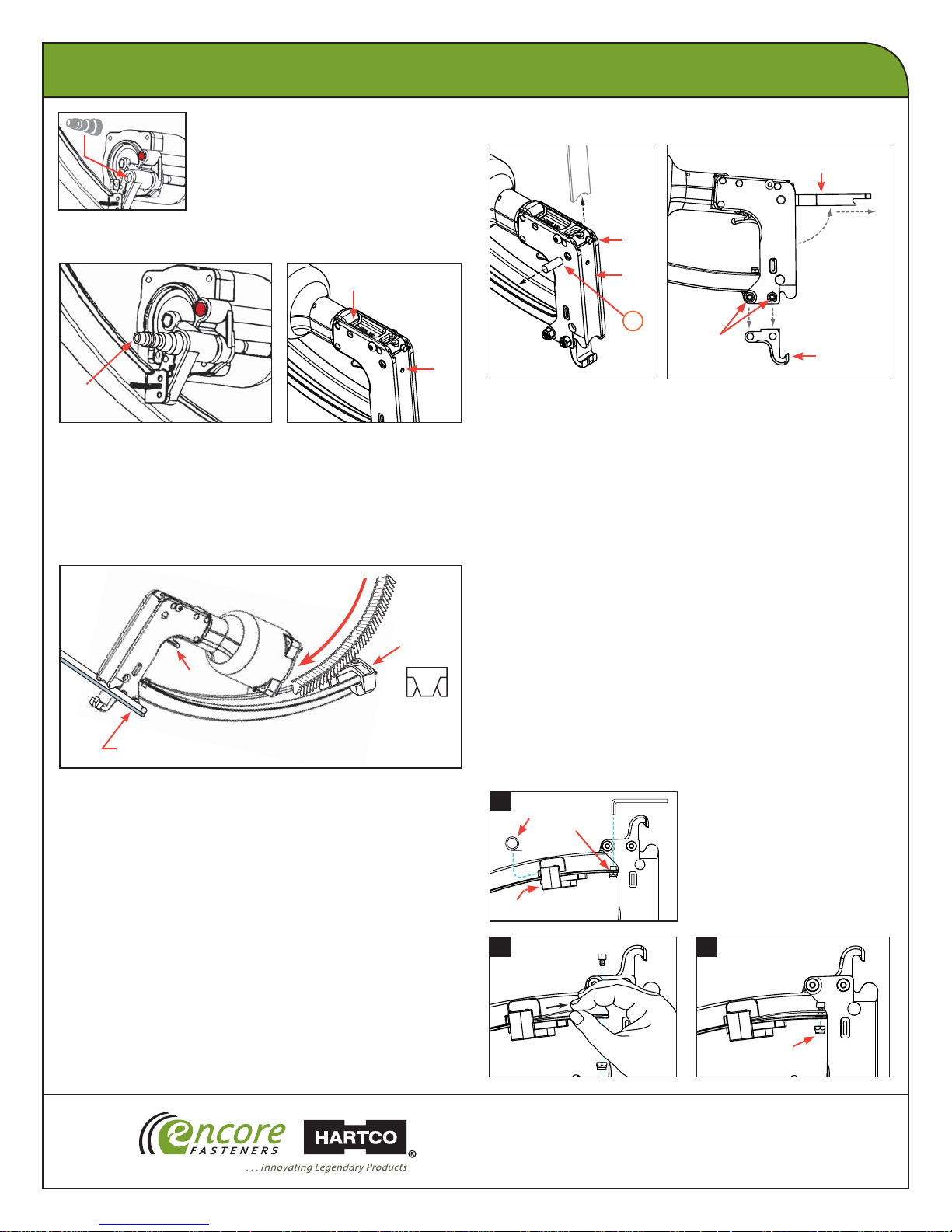

OPERATING INSTRUCTIONS

TO GET STARTED

Install a ¼” NPT tting (not included) into air

inlet opening in the back of the housing, using

suitable thread sealant. DO NOT REMOVE

RED PLUG LOCATED ABOVE THIS OPENING.

RECOMMENDED DAILY MAINTENANCE

B

C

A

Add 2-3 drops of air tool oil (10-weight recommended) to air inlet hose

tting

(A); and openings between the side plates at these two locations:

• in the gap at the back of the top plate and the housing

• the opening on the front plate (C), as shown on a xed label

TOOL OPERATION

(B)

PARTS REPLACEMENT

BLADE

H

F

G

I

J

BLADE: Disconnect air. Remove clips from tool.

1. Depress pin

2. Swing blade

plates. Remove pin through holes and take out old blade.

3. Lubricate new blade.

4. With new blade at 90° angle, align blade hole with links and side plate

holes on either side. Insert link pin through aligned holes to secure

blade. Firmly strike blade face to swing back into original position.

5. Re-lubricate front plate. Depress pin

until pin

(F) at top of front plate (G); slide plate up and remove.

(H) from tool and align link pin (I) with holes in side

(F) and slide front plate down

is released, securing plate in place.

DIRECTION

SHOWN TO

REMOVE

PART(S).

REVERSE TO

PUT IN NEW

PAR T

ANVIL

K

E

D

SINGLE

EAR FACES

FRONT OF

SMALLER WIRE ON BOTTOM

1. Connect air supply to hose tting, keeping ngers and hands away

from blade and anvil area. Recommended air supply is 80-90 psi

(5.5–6.2 bars) of dry, lubricated air.

Eclipser air consumption (SCFM), assuming 90psi and 1 cycle per

second, is 3.56. Assuming 80psi and 1 cycle per second, SCFM is 3.22.

2. Load clips into magazine.

3. Set wires to be fastened into side plate notches. For best results,

smaller wire should be on the bottom. Squeeze trigger

install clip.

LOADING CLIPS:

1. Pull pusher

2. Remove strip of clips from box. Load entire strip into magazine with

the single “ear” facing towards the front of the tool.

3. Secure clips in place by depressing pusher latch on underside

of magazine.

(E) back until it latches at the end of magazine.

TOOL

(D) to

ANVIL: Disconnect air. Remove clips from tool.

1. Remove lower shoulder screws

a “T” model.

2. Remove old anvil

(K) and replace.

(J) or pins/e-clips if tool is

PUSHER SPRING: Disconnect air. Remove clips from tool.

For better access, turn tool upside down.

1. Loosen screw

damaged pusher spring from magazine. Insert new spring

back of pusher

1

M

P

2

(L) with a 9/64" hex key (allen wrench) and remove

(P).

2. Pull spring out from pusher with

ngers or by using the screw.

L

Align the spring hole with the

magazine screw hole. Insert

screw and secure with nut

Be careful not to deform spring.

3. Pull pusher back and latch at

end of magazine.

3

N

(M) into

(N).

www.encorehartco.com • info@encorefasteners.com

Northbrook, Illinois 60062 U.S.A.

Phone: 224-723-5524 • Fax: 224-723-5526

v. 08-11-16

Page 5

Page 1 of 3 Rev. 3/24/16

E-Clips & Tool Guide BY CLIPS

Updated 12/10/15

ENCORE E-Clip # HARTCO Clip #

#/STRIP CLIPS/CTN LBS/CTN KGS/CTN HEIGHT WIDTH DEPTH HEIGHT WIDTH DEPTH

CLASSIC

A SERIES

B SERIES

C SERIES

(OBSOLETE)

E SERIES

STRIP

52A14SG – 58 15,834 25 11.4 0.32 0.40 0.20 8.2 10 5.1 EA2000-1234 0 0 0 0 HR2000-1234

64A18SG CLP-15G 47 10,857 24 10.9 0.41 0.43 0.26 10.4 11 6.6 EA2000-1020 0 HR-45i 0 0 HR2000-1020

64A18SG CLP-15G 47 10,857 24 10.9 0.41 0.43 0.26 10.4 11 6.6 EA2000-1929 0 HR-45TN 0 0 HR2000-1929

68H18S CLP-22 47 4,700 22 10.0 0.47 0.86 0.26 11 .9 22 6.6 EA2000-6075 0 0 0 0 HR2000-6075

71A16SAL CLP-13AL 47 9,400 22 10.0 0.45 0.43 0.26 11. 4 11 6.6 EA2000-1929 0 HR-45TN 0 0 HR2000-1929

71A18S CLP-13 47 9,400 22 10.0 0.45 0.43 0.26 11 .4 11 6.6 EA2000-1020 0 HR-45i 0 0 HR2000-1020

71A18S CLP-13 47 9,400 22 10.0 0.45 0.43 0.26 11 .4 11 6.6 EA2000-1929 0 HR-45TN 0 0 HR2000-1929

71A18SG CLP-13G 47 9,400 22 10.0 0.45 0.43 0.26 11 .4 11 6.6 EA2000-1020 0 HR-45i 0 0 HR2000-1020

71A18SG CLP-13G 47 9,400 22 10.0 0.45 0.43 0.26 11 .4 11 6.6 EA2000-1929 0 HR-45TN 0 0 HR2000-1929

72E18S CLP-20 47 6,110 24 10.9 0.47 0.67 0.26 11. 9 17 6.6 EA2000-3236 0 HR-68 HR-68B HR-68C-100 HR2000-3236

74F18S CLP-2312 47 5,076 22 10.0 0.49 0.73 0.26 12.4 19 6.6 EA2000-6080 0 HR-65AT HR-65BAT HR-65C-130 HR2000-6080

74H18S CLP-23 47 4,230 22 10.0 0.49 0.86 0.26 12.4 22 6.6 EA2000-6080 0 HR-65AT HR-65BAT HR-65C-130 HR2000-6080

74H18SC CLP-23C 47 4,230 23 10.5 0.49 0.86 0.26 12.4 22 6.6 EA2000-6080 0 HR-65AT HR-65BAT HR-65C-130 HR2000-6080

74H18SG CLP-23G 47 4,230 22 10.0 0.49 0.86 0.26 12.4 22 6.6 EA2000-6080 0 HR-65AT HR-65BAT HR-65C-130 HR2000-6080

78E18S CLP-20L 47 5,499 23 10.5 0.50 0.67 0.26 12.7 17 6.6 EA2000-3236 0 HR-68 HR-68B HR-68C-100 HR2000-3236

80F23S CLP-312 40 4,320 22 10.0 0.51 0.73 0.31 13.0 19 7.9 EA2000-6181 0 HR-66 HR-66B 0 HR2000-6181

80H18S CLP-25 0 4,230 22 10.0 0.52 0.86 0.26 13.2 22 6.6 EA2000-6080 0 HR-65AT HR-65BAT HR-65C-130 HR2000-6080

80H23S CLP-3 40 3,600 22 10.0 0.51 0.86 0.31 13.0 22 7.9 EA2000-6181 0 HR-66 HR-66B HR-66C-110 HR2000-6181

85A22S CLP-33 42 6,720 24 10.9 0.54 0.43 0.29 13.7 11 7.4 EA2000-1022 0 0 0 0 HR2000-1022

88A22S CLP-32 42 6,720 25 11 .4 0.55 0.43 0.29 14.0 11 7.4 EA2000-1022 0 0 0 0 HR2000-1022

88F23S CLP-412 40 3,840 23 10.5 0.57 0.73 0.31 14.5 19 7.9 EA2000-6181 0 HR-66 HR-66B HR-66C-110 HR2000-6181

88F23S CLP-412 40 3,840 23 10.5 0.57 0.73 0.31 14.5 19 7.9 EA2000-6185 HR-66 HR-66B HR-66C-110 HR2000-6185

88F23S CLP-72 40 3,840 23 10.5 0.57 0.73 0.31 14.5 19 7.9 EA2000-6185 0 0 0 0 HR2000-6185

88F23SAL CLP-4NAL 0 1,920 8 3.6 0.57 0.73 0.31 14.5 19 7.9 EA2000-4151T 0 0 0 0 HR2000-4151T

88F23SAL CLP-4NAL 0 1,920 8 3.6 0.57 0.73 0.31 14.5 19 7.9 EA2000-6181T 0 0 0 0 HR2000-6181T

88H23S CLP-4 36 3,200 23 10.5 0.57 0.86 0.31 14.5 22 7.9 EA2000-6181 0 HR-66 HR-66B HR-66C-110 HR2000-6181

88H23SAL CLP-4AL 36 3,200 8 3.6 0.57 0.86 0.31 14.5 22 7.9 EA2000-6181T 0 0 0 0 HR2000-6181T

ECLIPSER MODELS

Encore and Hartco tool equivalents, pack/ship configurations, and

clips to use with each

HARTCO MODELS

INCHES

MILLIMETERS

3485 Commercial Avenue Voice: (224) 723-5524

Northbrook, IL 60062 USA Fax: (224) 723-5526

info@encorefasteners.com

www.encorehartco.com

W D

H

A-H

ZZ

XX

S–STRIPS

R–ROLLS

B–BULK

CLP–STRIPS

CCP–ROLLS

(BLANK) = COLD ROLLED STEEL 1006-1010

A = ALUMINUM

C = CUSHIONED (PAPER LINING INSIDE)

G = GALVANIZED

L = 4 MIL PVC VINYL COATING (INSIDE)

S = STAINLESS STEEL (430)

XX = LENGTH in 100

ths

/inch

A-H = CLIP WIDTH

ZZ

= OPENING in 100

ths

/inch

TYPE OF PACKAGING

74H18

S G

A

=

7

/

16"

(11.0 mm)

E

=

11

/

16"

(17.5 mm)

F

=

3

/

4"

(19.0 mm)

H

=

7

/

8"

(22.0 mm)

(BLANK) or P = POLYCORD

T = TAPED COLLATION D = DETENT

MATERIAL

DESIGNATIONS

Page 6

Page 2 of 3 Rev. 3/24/16

E-Clips & Tool Guide BY CLIPS

Updated 12/10/15

ENCORE E-Clip # HARTCO Clip #

#/STRIP CLIPS/CTN LBS/CTN KGS/CTN HEIGHT WIDTH DEPTH HEIGHT WIDTH DEPTH

CLASSIC

A SERIES

B SERIES

C SERIES

(OBSOLETE)

E SERIES

ECLIPSER MODELS

Encore and Hartco tool equivalents, pack/ship configurations, and

clips to use with each

HARTCO MODELS

INCHES

MILLIMETERS

3485 Commercial Avenue Voice: (224) 723-5524

Northbrook, IL 60062 USA Fax: (224) 723-5526

info@encorefasteners.com

www.encorehartco.com

W D

H

A-H

ZZ

XX

S–STRIPS

R–ROLLS

B–BULK

CLP–STRIPS

CCP–ROLLS

(BLANK) = COLD ROLLED STEEL 1006-1010

A = ALUMINUM

C = CUSHIONED (PAPER LINING INSIDE)

G = GALVANIZED

L = 4 MIL PVC VINYL COATING (INSIDE)

S = STAINLESS STEEL (430)

XX = LENGTH in 100

ths

/inch

A-H = CLIP WIDTH

ZZ

= OPENING in 100

ths

/inch

TYPE OF PACKAGING

74H18

S G

A

=

7

/

16"

(11.0 mm)

E

=

11

/

16"

(17.5 mm)

F

=

3

/

4"

(19.0 mm)

H

=

7

/

8"

(22.0 mm)

(BLANK) or P = POLYCORD

T = TAPED COLLATION D = DETENT

MATERIAL

DESIGNATIONS

88H23SC CLP-4C 36 3,200 24 10.9 0.57 0.86 0.31 14.5 22 7.9 EA2000-6181 0 HR-66 HR-66B HR-66C-110 HR2000-6181

90A29SG – 0 5,220 24 10.9 0.50 0.43 0.41 12.7 11 10.4 EA2000-1533* 0 0 0 0 HR2000-1533*

90F18S CLP-24N 47 3,948 24 10.9 0.62 0.73 0.26 15.7 19 6.6 EA2000-6082 0 0 0 0 HR2000-6082

90F18SG CLP-2412G 47 3,948 24 10.9 0.62 0.73 0.26 15.7 19 6.6 EA2000-6082 0 0 0 0 HR2000-6082

90H18S CLP-24 47 3,290 24 10.9 0.62 0.86 0.26 15.7 22 6.6 EA2000-6082 0 0 0 0 HR2000-6082

90H18SG CLP-24G 47 3,290 24 10.9 0.62 0.86 0.26 15.7 22 6.6 EA2000-6082 0 0 0 0 HR2000-6082

91A23S CLP-14 40 5,600 23 10.5 0.56 0.43 0.31 14.2 11 7.9 EA2000-1121 0 HR-46 0 0 HR2000-1121

96A23S CLP-9 0 5,600 24 10.9 0.59 0.43 0.31 15.0 11 7.9 EA2000-1121 0 HR-46 0 0 HR2000-1121

n/a WA-39 0 0 0 0.0 0.00 0.00 0.00 0.0 0 0.0 EA2000-6791T 0 0 0 0 HR2000-6791T

101F23SAL CLP-34NAL 40 3,360 9 4.1 0.68 0.73 0.31 17.3 19 7.9 EA2000-4157T 0 HR-85SLN HR-85SBLN 0 HR2000-4157T

101F23SAL CLP-34NAL 40 3,360 9 4.1 0.68 0.73 0.31 17.3 19 7.9 EA2000-4151T 0 0 0 0 HR2000-4151T

101F23SS4 CLP-34NS430 40 3,360 22 10.0 0.68 0.73 0.31 17.3 19 7.9 EA2000-4157T 0 HR-85SLN HR-85SBLN 0 HR2000-4157T

101H23S CLP-34 40 2,800 24 10.9 0.68 0.86 0.31 17.3 22 7.9 EA2000-6183 0 HR-85 HR-85B HR-85C-100 HR2000-6183

101H23SAL CLP-34AL 40 2,800 9 4.1 0.68 0.86 0.31 17.3 22 7.9 EA2000-6183T 0 0 0 0 HR2000-6183T

101H23SAL CLP-34AL 40 2,800 9 4.1 0.68 0.86 0.31 17.3 22 7.9 EA2000-6187T 0 HR-85SL HR-85SBL 0 HR2000-6187T

101H23SC CLP-34C 40 2,800 25 11 .4 0.68 0.86 0.31 17.3 22 7.9 EA2000-6183 0 HR-85 HR-85B HR-85C-100 HR2000-6183

110A 18S – 47 6,580 18 8.2 0.68 0.43 0.26 17.3 11 6.6 EA2000-1024 0 0 0 0 HR2000-1024

110E25SS4 CLP-35430 37 2,886 18 8.2 0.75 0.67 0.33 19.1 17 8.4 EA2000-6189 0 HR-85S HR-85SB 0 HR2000-6189

110E25SS430 CLP-35S434 0 2,886 23 10.5 0.75 0.67 0.33 19.1 17 8.4 EA2000-4139 0 HR-85SN HR-85BSN 0 HR2000-4139

110E25SS430 (half) CLP-35S434 0 1,443 13 5.7 0.75 0.67 0.33 19.1 17 8.4 EA2000-4139 0 HR-85SN HR-85BSN 0 HR2000-4139

110F25SAL CLP-36NAL 0 2,664 8 3.6 0.72 0.73 0.33 18.3 19 8.4 EA2000-4157T 0 HR-85SLN HR-85SBLN 0 HR2000-4157T

110H 25S CLP-36 36 2,220 18 8.2 0.72 0.86 0.33 18.3 22 8.4 EA2000-6189 0 HR-85S HR-85SB 0 HR2000-6189

110H25SAL CLP-36AL 36 2,220 8 3.6 0.72 0.86 0.33 18.3 22 8.4 EA2000-6187T 0 HR-85SL HR-85SBL 0 HR2000-6187T

110H25SC CLP-36C 36 2,220 19 8.6 0.72 0.86 0.33 18.3 22 8.4 EA2000-6189 0 HR-85S HR-85SB 0 HR2000-6189

125A38SS CLP-61 25 3,000 26 11 .8 0.69 0.43 0.50 17.5 11 12.7 EA2000-4528* 0 0 0 0 HR2000-4528*

132A38SS CLP-64 0 3,000 28 12.7 0.72 0.43 0.50 18.3 11 12.7 EA2000-4528* 0 0 0 0 HR2000-4528*

132F27SAL WA-40 0 1,920 8 3.6 0.86 0.73 0.38 21.8 19 9.5 EA2000-6791T 0 0 0 0 HR2000-6791T

135H31S CLP-38 31 1,550 16 7.3 0.86 0.86 0.38 21.8 22 9.5 EA2000-6788 0 HR-88 HR-88B 0 HR2000-6788

Page 7

Page 3 of 3 Rev. 3/24/16

E-Clips & Tool Guide BY CLIPS

Updated 12/10/15

ENCORE E-Clip # HARTCO Clip #

#/STRIP CLIPS/CTN LBS/CTN KGS/CTN HEIGHT WIDTH DEPTH HEIGHT WIDTH DEPTH

CLASSIC

A SERIES

B SERIES

C SERIES

(OBSOLETE)

E SERIES

ECLIPSER MODELS

Encore and Hartco tool equivalents, pack/ship configurations, and

clips to use with each

HARTCO MODELS

INCHES

MILLIMETERS

3485 Commercial Avenue Voice: (224) 723-5524

Northbrook, IL 60062 USA Fax: (224) 723-5526

info@encorefasteners.com

www.encorehartco.com

W D

H

A-H

ZZ

XX

S–STRIPS

R–ROLLS

B–BULK

CLP–STRIPS

CCP–ROLLS

(BLANK) = COLD ROLLED STEEL 1006-1010

A = ALUMINUM

C = CUSHIONED (PAPER LINING INSIDE)

G = GALVANIZED

L = 4 MIL PVC VINYL COATING (INSIDE)

S = STAINLESS STEEL (430)

XX = LENGTH in 100

ths

/inch

A-H = CLIP WIDTH

ZZ

= OPENING in 100

ths

/inch

TYPE OF PACKAGING

74H18

S G

A

=

7

/

16"

(11.0 mm)

E

=

11

/

16"

(17.5 mm)

F

=

3

/

4"

(19.0 mm)

H

=

7

/

8"

(22.0 mm)

(BLANK) or P = POLYCORD

T = TAPED COLLATION D = DETENT

MATERIAL

DESIGNATIONS

135H31SAL CLP-38AL 31 1,550 0 0.0 0.86 0.86 0.38 21.8 22 9.5 EA2000-6791T 0 0 0 0 HR2000-6791T

n/a WA-39 0 0 0 0.0 0.00 0.00 0.00 0.0 0 0.0 EA2000-6791T 0 0 0 0 HR2000-6791T

[Hartco]: CLP=Clip Strip; CCP=Clip Coil

* In development

[Encore]: T = Thin/Low Profile Pin [Hartco]: L = Lobster w Low Profile Pin; N = Narrow

ENCORE E-Clip # HARTCO Clip #

– CLIPS/ROLL LBS/ROLL KGS/ROLL HEIGHT WIDTH DEPTH HEIGHT WIDTH DEPTH

CLASSIC

A SERIES

B SERIES

C SERIES

(OBSOLETE)

E SERIES

ROLL (COIL)

STANDARD

w/out BJR

64A18R CCP-15 0 15,000 34 15.5 0.41 0.43 0.26 10.4 11 6.6 EA2800-1020 EA2500-1020 HR-49CC 0 0 HR2800-1020

71A18R CCP-13 0 15,000 36 16.4 0.45 0.43 0.26 11.4 11 6.6 EA2800-1020 EA2500-1020 HR-49CC 0 0 HR2800-1020

73A18R CCP-19 0 14,000 34 15.5 0.48 0.43 0.26 12.2 11 6.6 EA2800-1020 EA2500-1020 HR-49CC 0 0 HR2800-1020

74F18R CCP-74 0 5,076 22 10.0 0.49 0.73 0.26 12.4 19 6.6 EA2800-6082 EA2500-6082 0 0 0 HR2800-6082

76A18R CCP-26 0 14,500 39 17.7 0.50 0.43 0.26 12.7 11 6.6 EA2800-1020 EA2500-1020 HR-49CC 0 0 HR2800-1020

76A22R – 0 12,300 34 15.5 0.50 0.43 0.29 12.7 11 7.4 EA2800-1022 EA2500-1022 HR-48CC 0 0 HR2800-1022

80A22R – 0 13,700 38 17.3 0.52 0.43 0.29 13.2 11 7.4 EA2800-1022 EA2500-1022 HR-48CC 0 0 HR2800-1022

80F23R CCP-71 0 6,667 33 15.0 0.51 0.73 0.31 13.0 19 7.9 EA2800-6181 0 0 0 0 HR2800-6181

85A18R CCP-30 0 13,500 40 18.2 0.55 0.43 0.26 14.0 11 6.6 EA2800-1020 EA2500-1020 HR-49CC 0 0 HR2800-1020

85A22R CCP-33 0 12,300 38 17.3 0.54 0.43 0.29 13.7 11 7.4 EA2800-1022 EA2500-1022 HR-48CC 0 0 HR2800-1022

88A22R CCP-32 0 12,300 39 17.7 0.55 0.43 0.29 14.0 11 7.4 EA2800-1022 EA2500-1022 HR-48CC 0 0 HR2800-1022

88A23R CCP-14S 0 9,375 37 16.8 0.56 0.43 0.31 14.2 11 7.9 EA2800-1121 EA2500-1121 HR-46CC 0 0 HR2800-1121

88F23R CCP-72 0 5,521 30 13.6 0.57 0.73 0.31 14.5 19 7.9 EA2800-6185 0 0 0 0 HR2800-6185

90F18R CCP-73 0 3,948 24 10.9 0.62 0.73 0.26 15.7 19 6.6 EA2800-6082 EA2500-6082 0 0 0 HR2800-6082

91A23R CCP-14 0 9,375 37 16.8 0.56 0.43 0.31 14.2 11 7.9 EA2800-1121 EA2500-1121 HR-46CC 0 0 HR2800-1121

96A23R CCP-9 0 10,000 37 16.8 0.59 0.43 0.31 15.0 11 7.9 EA2800-1121 EA25 00-1121 HR-46CC 0 0 HR2800-1121

110A18R (10mm

Flat BW)

– 0 9,300 37 16.8 0.68 0.43 0.26 17.3 11 6.6 EA2800-1024 0 0 0 0 HR2800-1024

HARTCO MODELS

INCHES

MILLIMETERS

ECLIPSER MODELS

Page 8

Page 1 of 2 Rev. 3-24-16

E-Clips & Tool Guide BY TOOL

STRIP

CLASSIC

A SERIES

B SERIES

C SERIES

(OBSOLETE)

E SERIES

ENCORE E-Clip # HARTCO Clip #

#/STRIP CLIPS/CTN LBS/CTN KGS/CTN

EA2000-1020 0 HR-45i 0 0 HR2000-1020 64A18SG CLP-15G 47 10,857 24 10.9

EA2000-1020 0 HR-45i 0 0 HR2000-1020 71A18S CLP-13 47 9,400 22 10.0

EA2000-1020 0 HR-45i 0 0 HR2000-1020 71A18SG CLP-13G 47 9,400 22 10.0

EA2000-1022 0 0 0 0 HR2000-1022 85A22S CLP-33 42 6,720 24 10.9

EA2000-1022 0 0 0 0 HR2000-1022 88A22S CLP-32 42 6,720 25 11.4

EA2000-1024 0 0 0 0 HR2000-1024 110A1 8S – 47 6,580 18 8.2

EA2000-1234 0 HR2000-1234 52A14SG – 58 15,834 25 11.4

EA2000-1121 0 HR-46 0 0 HR2000-1121 91A23S CLP-14 40 5,600 23 10.5

EA2000-1121 0 HR-46 0 0 HR2000-1121 96A23S CLP-9 0 5,600 24 10.9

EA2000-1533* 0 0 0 0 HR2000-1533* 90A29SG – 0 5,220 24 0.5

EA2000-1929 0 HR-45TN 0 0 HR2000-1929 64A18SG CLP-15G 47 10,857 24 10.9

EA2000-1929 0 HR-45TN 0 0 HR2000-1929 71A16SAL CLP-13AL 47 9,400 22 10.0

EA2000-1929 0 HR-45TN 0 0 HR2000-1929 71A18S CLP-13 47 9,400 22 10.0

EA2000-1929 0 HR-45TN 0 0 HR2000-1929 71A18SG CLP-13G 47 9,400 22 10.0

EA2000-3236 0 HR-68 HR-68B HR-68C-100 HR2000-3236 72E18S CLP-20 47 6,110 24 10.9

EA2000-3236 0 HR-68 HR-68B HR-68C-100 HR2000-3236 78E18S CLP-20L 47 5,499 23 10.5

EA2000-4139 0 HR-85SN HR-85BSN 0 HR2000-4139 110E25SS430 CLP-35S434 0 2,886 23 10.5

EA2000-4139 0 HR-85SN HR-85BSN 0 HR2000-4139 110E25SS430 (half) CLP-35S434 0 1,443 13 5.7

EA2000-4151T 0 0 0 0 HR2000-4151T 88F23SAL CLP-4NAL 0 1,920 8 3.6

EA2000-4151T 0 0 0 0 HR2000-4151T 101F23SAL CLP-34NAL 40 3,360 9 4.1

EA2000-4157T 0 HR-85SLN HR-85SBLN 0 HR2000-4157T 101F23SAL CLP-34NAL 40 3,360 9 4.1

EA2000-4157T 0 HR-85SLN HR-85SBLN 0 HR2000-4157T 101F23SS4 CLP-34NS430 40 3,360 22 10.0

EA2000-4157T 0 HR-85SLN HR-85SBLN 0 HR2000-4157T 110F25SAL CLP-36NAL 0 2,664 8 3.6

EA2000-6075 0 0 0 0 HR2000-6075 68H18S CLP-22 47 4,700 22 10.0

EA2000-6080 0 HR-65AT HR-65BAT HR-65C-130 HR2000-6080 74F18S CLP-2312 47 5,076 22 10.0

EA2000-6080 0 HR-65AT HR-65BAT HR-65C-130 HR2000-6080 74H18S CLP-23 47 4,230 22 10.0

EA2000-6080 0 HR-65AT HR-65BAT HR-65C-130 HR2000-6080 74H18SC CLP-23C 47 4,230 23 10.5

EA2000-6080 0 HR-65AT HR-65BAT HR-65C-130 HR2000-6080 74H18SG CLP-23G 47 4,230 22 10.0

EA2000-6080 0 HR-65AT HR-65BAT HR-65C-130 HR2000-6080 80H18S CLP-25 0 4,230 22 10.0

EA2000-6082 0 0 0 0 HR2000-6082 90F18S CLP-24N 47 3,948 24 10.9

EA2000-6082 0 0 0 0 HR2000-6082 90F18SG CLP-2412G 47 3,948 24 10.9

EA2000-6082 0 0 0 0 HR2000-6082 90H18S CLP-24 47 3,290 24 10.9

EA2000-6082 0 0 0 0 HR2000-6082 90H18SG CLP-24G 47 3,290 24 10.9

EA2000-6181 0 HR-66 HR-66B 0 HR2000-6181 80F23S CLP-312 40 4,320 22 10.0

EA2000-6181 0 HR-66 HR-66B HR-66C-110 HR2000-6181 80H23S CLP-3 40 3,600 22 10.0

EA2000-6181 0 HR-66 HR-66B HR-66C-110 HR2000-6181 88F23S CLP-412 40 3,840 23 10.5

EA2000-6181 0 HR-66 HR-66B HR-66C-110 HR2000-6181 88H23S CLP-4 36 3,200 23 10.5

EA2000-6181 0 HR-66 HR-66B HR-66C-110 HR2000-6181 88H23SC CLP-4C 36 3,200 24 10.9

EA2000-6181T 0 0 0 0 HR2000-6181T 88F23SAL CLP-4NAL 0 1,920 8 3.6

EA2000-6181T 0 0 0 0 HR2000-6181T 88H23SAL CLP-4AL 36 3,200 8 3.6

EA2000-6183 0 HR-85 HR-85B HR-85C-100 HR2000-6183 101H23S CLP-34 40 2,800 24 10.9

Encore and Hartco tool equivalents, pack/ship configurations, and

clips to use with each

ECLIPSER MODELS

HARTCO MODELS

3485 Commercial Avenue Voice: (224) 723-5524

Northbrook, IL 60062 USA Fax: (224) 723-5526

info@encorefasteners.com

www.encorehartco.com

A-H

ZZ

XX

S–STRIPS

R–ROLLS

B–BULK

CLP–STRIPS

CCP–ROLLS

(BLANK) = COLD ROLLED STEEL 1006-1010

A = ALUMINUM

C = CUSHIONED (PAPER LINING INSIDE)

G = GALVANIZED

L = 4 MIL PVC VINYL COATING (INSIDE)

S = STAINLESS STEEL (430)

XX = LENGTH in 100

ths

/inch

A-H = CLIP WIDTH

ZZ

= OPENING in 100

ths

/inch

TYPE OF PACKAGING

74H18

S G

A

=

7

/

16"

(11.0 mm)

E

=

11

/

16"

(17.5 mm)

F

=

3

/

4"

(19.0 mm)

H

=

7

/

8"

(22.0 mm)

(BLANK) or P = POLYCORD

T = TAPED COLLATION D = DETENT

MATERIAL

DESIGNATIONS

Page 9

Page 2 of 2 Rev. 3-24-16

E-Clips & Tool Guide BY TOOL

STRIP

CLASSIC

A SERIES

B SERIES

C SERIES

(OBSOLETE)

E SERIES

ENCORE E-Clip # HARTCO Clip #

#/STRIP CLIPS/CTN LBS/CTN KGS/CTN

Encore and Hartco tool equivalents, pack/ship configurations, and

clips to use with each

ECLIPSER MODELS

HARTCO MODELS

3485 Commercial Avenue Voice: (224) 723-5524

Northbrook, IL 60062 USA Fax: (224) 723-5526

info@encorefasteners.com

www.encorehartco.com

A-H

ZZ

XX

S–STRIPS

R–ROLLS

B–BULK

CLP–STRIPS

CCP–ROLLS

(BLANK) = COLD ROLLED STEEL 1006-1010

A = ALUMINUM

C = CUSHIONED (PAPER LINING INSIDE)

G = GALVANIZED

L = 4 MIL PVC VINYL COATING (INSIDE)

S = STAINLESS STEEL (430)

XX = LENGTH in 100

ths

/inch

A-H = CLIP WIDTH

ZZ

= OPENING in 100

ths

/inch

TYPE OF PACKAGING

74H18

S G

A

=

7

/

16"

(11.0 mm)

E

=

11

/

16"

(17.5 mm)

F

=

3

/

4"

(19.0 mm)

H

=

7

/

8"

(22.0 mm)

(BLANK) or P = POLYCORD

T = TAPED COLLATION D = DETENT

MATERIAL

DESIGNATIONS

EA2000-6183 0 HR-85 HR-85B HR-85C-100 HR2000-6183 101H23SC CLP-34C 40 2,800 25 11. 4

EA2000-6183T 0 0 0 0 HR2000-6183T 101H23SAL CLP-34AL 40 2,800 9 4.1

EA2000-6185 HR-66 HR-66B HR-66C-110 HR2000-6185 88F23S CLP-412 40 3,840 23 10.5

EA2000-6185 0 0 0 0 HR2000-6185 88F23S CLP-72 40 3,840 23 10.5

EA2000-6187T 0 HR-85SL HR-85SBL 0 HR2000-6187T 101H23SAL CLP-34AL 40 2,800 9 4.1

EA2000-6187T 0 HR-85SL HR-85SBL 0 HR2000-6187T 110H25SAL CLP-36AL 36 2,220 8 3.6

EA2000-6189 0 HR-85S HR-85SB 0 HR2000-6189 110E25SS4 CLP-35430 37 2,886 18 8.2

EA2000-6189 0 HR-85S HR-85SB 0 HR2000-6189 110H 25S CLP-36 36 2,220 18 8.2

EA2000-6189 0 HR-85S HR-85SB 0 HR2000-6189 110H25SC CLP-36C 36 2,220 19 8.6

EA2000-6788 0 HR-88 HR-88B 0 HR2000-6788 135H31S CLP-38 31 1,550 16 7.3

EA2000-6791T 0 0 0 0 HR2000-6791T 132F27SAL WA-40 0 1,920 8 3.6

EA2000-6791T 0 0 0 0 HR2000-6791T 135H31SAL CLP-38AL 31 1,550 0 0.0

EA2000-6791T 0 0 0 0 HR2000-6791T n/a WA-39 0 0 0 0.0

* In development

[Encore]: T = Thin/Low Profile Pin [Hartco]: L = Lobster w Low Profile Pin; N = Narrow [Hartco]: CLP=Clip Strip; CCP=Clip Coil

ROLL (COIL)

STANDARD

w/out BLADE

JAM RELEASE

CLASSIC

A SERIES

B SERIES

C SERIES

(OBSOLETE)

E SERIES

ENCORE E-Clip # HARTCO Clip #

– CLIPS/ROLL LBS/ROLL KGS/ROLL

EA2800-1020 EA2500-1020 HR-49CC 0 0 HR2800-1020 64A18R CCP-15 0 15,000 34 15.5

EA2800-1020 EA2500-1020 HR-49CC 0 0 HR2800-1020 71A18R CCP-13 0 15,000 36 16.4

EA2800-1020 EA2500-1020 HR-49CC 0 0 HR2800-1020 73A18R CCP-19 0 14,000 34 15.5

EA2800-1020 EA2500-1020 HR-49CC 0 0 HR2800-1020 76A18R CCP-26 0 14,500 39 17.7

EA2800-1020 EA2500-1020 HR-49CC 0 0 HR2800-1020 85A18R CCP-30 0 13,500 40 18.2

EA2800-1022 EA2500-1022 HR-48CC 0 0 HR2800-1022 76A22R – 0 12,300 34 15.5

EA2800-1022 EA2500-1022 HR-48CC 0 0 HR2800-1022 80A22R – 0 13,700 38 17.3

EA2800-1022 EA2500-1022 HR-48CC 0 0 HR2800-1022 85A22R CCP-33 0 12,300 38 17.3

EA2800-1022 EA2500-1022 HR-48CC 0 0 HR2800-1022 88A22R CCP-32 0 12,300 39 17.7

EA2800-1024 0 0 0 0 HR2800-1024

110A18R (10mm

Flat BW)

– 0 9,300 37 16.8

EA2800-1121 EA2500-1121 HR-46CC 0 0 HR2800-1121 88A23R CCP-14S 0 9,375 37 16.8

EA2800-1121 EA2500-1121 HR-46CC 0 0 HR2800-1121 91A23R CCP-14 0 9,375 37 16.8

EA2800-1121 EA2500-1121 HR-46CC 0 0 HR2800-1121 96A23R CCP-9 0 10,000 37 16.8

EA2800-6082 EA2500-6082 0 0 0 HR2800-6082 74F18R CCP-74 0 5,076 22 10.0

EA2800-6082 EA2500-6082 0 0 0 HR2800-6082 90F18R CCP-73 0 3,948 24 10.9

EA2800-6181 0 0 0 0 HR2800-6181 80F23R CCP-71 0 6,667 33 15.0

EA2800-6185 0 0 0 0 HR2800-6185 88F23R CCP-72 0 5,521 30 13.6

ECLIPSER MODELS

HARTCO MODELS

Page 10

Page 1 of 2

Parts Support Only

ENCORE ECLIPSER

HARTCO® CLINCHER

"E" SERIES

HARTCO® CLASSIC

CLINCHER "A" SERIES

HARTCO® CLASSIC

CLINCHER "B" SERIES

HARTCO® CLASSIC

CLINCHER "C" SERIES

COMPOSITE PLASTIC BODY

(HOUSING) & CLIP MAGAZINE,

GREEN

COMPOSITE PLASTIC BODY

(HOUSING) & CLIP MAGAZINE,

BLACK

CAST ALUMINUM BODY

(HOUSING) & STEEL CLIP

MAGAZINE

CAST ALUMINUM BODY

(HOUSING) & BLACK COMPOSITE

PLASTIC MAGAZINE

MAGNESIUM BODY (HOUSING)

in YELLOW & BLACK

COMPOSITE PLASTIC

MAGAZINE

ENCORE E-CLIP

SIZE NUMBERS

HARTCO CLIP

SIZE NUMBERS

ECLIPSER 2000-1020 HR2000-1020 HR-45i

64A18SG, 71A18S,

71A18SG

CLP-15G, CLP-13, CLP13G

Housing Construction

Panels, Cages, Traps

ECLIPSER 2000-1022 HR2000-1022

85A22S, 88A22S CLP-33, CLP-32

Bedding

ECLIPSER 2000-1024 HR2000-1024

110A18S –

Bedding, 10mm Flat

Border Frames

ECLIPSER 2000-1121 HR2000-1121 HR-46

91A23S, 96A23S CLP-14, CLP-9 Bedding, 5mm BW

ECLIPSER 2000-1929 HR2000-1929 HR-45TN

64A18SG, 71A16SAL,

71A18S, 71A18SG

CLP-15, CLP-13AL,

CLP-13, CLP-13G

Thin & Narrow, for Cages

& Traps with tight access

ECLIPSER 2000-3236 HR2000-3236 HR-68 HR-68B HR-68C-100

72E18S, 78E18S CLP-20, CLP-20L Bedding

ECLIPSER 2000-4139 HR2000-4139 HR-85SN HR-85SBN

110E25SS430 CLP-35S434 Fencing Gabions

ECLIPSER 2000-4151T HR2000-4151 T

88F23SAL, 101F23SAL CLP-4NAL, CLP-34NAL Crab Pots, Lobster Traps

ECLIPSER 2000-4157T HR2000-4157 T HR-85SLN HR-85SBLN

101F23SAL, 101F23SS4,

110F25SAL

CLP-34NAL, CLP-34NS430,

CL-36NAL

Crab Pots, Lobster Traps

ECLIPSER 2000-6075 HR2000-6075

68H18S CLP-22 Bedding, Furniture

ECLIPSER 2000-6080 HR2000-6080 HR-65AT HR-65BAT HR-65C-130

74F18S, 74H18S, 74H18SC,

74H18SG, 80H18S

CLP-2312, CLP-23, CLP23C, CLP-23G, CLP-25

Bedding, Furniture

ECLIPSER 2000-6082 HR2000-6082

90F18S, 90F18SG,

90H18S, 90H18SG

CLP-24N, CLP-2412G,

CLP-24, CLP-24G

Bedding, Furniture

ECLIPSER 2000-6181 HR2000-6181 HR-66 HR-66B HR-66C-110

80F23S, 80H23S, 88F23S,

88H23S, 88H23SC

CLP-312, CLP-3, CLP-412,

CLP-4, CLP-4C

Bedding, Furniture

ECLIPSER 2000-6181T HR2000-6181 T

88F23SAL, 88H23SAL CLP-4NAL, CLP-4AL Crab Pots, Lobster Traps

ECLIPSER 2000-6183 HR2000-6183 HR-85

HR-85B (SQUARE

DRIVER)

HR-85C-100 (SQ.

DRIVER)

101H23S, 101H23SC CLP-34, CLP-34C Bedding

ECLIPSER 2000-6183T HR2000-6183 T (HR-85SLT) 101H23SAL CLP-34AL Crab Pots, Lobster Traps

ECLIPSER 2000-6185 HR2000-6185

88F23S CLP-412, CLP-72 Bedding

ECLIPSER 2000-6187T HR2000-6187 T HR-85SL HR-85SBL

101H23SAL, 110H25SAL CLP-34AL, CLP-36AL Crab Pots, Lobster Traps

ECLIPSER 2000-6189 HR2000-6189 HR-85S HR-85SB

110E25SS4, 110H 25S,

110H25SC

CLP-35430, CLP-36,

CLP-36C

Bedding

ECLIPSER 2000-6788 HR2000-6788 HR-88 HR-88B

135H31S CLP-38 Cages, Concrete Forms

ECLIPSER 2000-6791T HR2000-6791 T

132F27SAL, 135H31SAL

WA-40, CLP-38AL,

WA-39

Crab Pots, Lobster Traps

Encore ECLIPSER & Hartco® CLASSIC CLINCHERS

xxxSide-By-Side Comparison Guide

USES CLIPS COLLATED IN STRIPS

COMMON

APPLICATIONS

3485 Commercial Avenue Voice: (224) 723-5524

Northbrook, IL 60062 USA Fax: (224) 723-5526

info@encorefasteners.com

www.encorehartco.com

Page 11

Page 2 of 2

Encore ECLIPSER & Hartco® CLASSIC CLINCHERS

xxxSide-By-Side Comparison Guide

3485 Commercial Avenue Voice: (224) 723-5524

Northbrook, IL 60062 USA Fax: (224) 723-5526

info@encorefasteners.com

www.encorehartco.com

ENCORE ECLIPSER

HARTCO® CLINCHER

"E" SERIES

ENCORE ECLIPSER

HARTCO® CLINCHER

"E" SERIES

HARTCO® CLASSIC

CLINCHER "A" SERIES

GREEN COMPOSITE PLASTIC BODY

(HOUSING) & STEEL CLIP

STRAIGHT MAGAZINE

BLACK COMPOSITE PLASTIC

BODY (HOUSING) & STEEL CLIP

MAGAZINE

GREEN COMPOSITE PLASTIC

BODY (HOUSING), STEEL

STRAIGHT CLIP MAGAZINE &

BLADE JAM RELEASE VALVE

BLACK COMPOSITE PLASTIC BODY

(HOUSING), STEEL STRAIGHT CLIP

MAGAZINE & BLADE JAM

RELEASE VALVE

CAST ALUMINUM BODY

(HOUSING) & STEEL STRAIGHT

CLIP MAGAZINE

ENCORE E-CLIP

SIZE NUMBERS

HARTCO CLIP

SIZE NUMBERS

ECLIPSER 2500-1020 HR-2500-1020 ECLIPSER 2800-1020 HR-2800-1020 HR-49CC

64A18R, 71A18R,

73A18R, 76A18R,

85A18R

CCP-15, CCP-13, CCP19, CCP-26, CCP-30

Housing Construction

Panels, Cages, Traps

ECLIPSER 2500-1022 HR-2500-1022 ECLIPSER 2800-1022 HR-2800-1022 HR-48CC

85A22R, 88A22R,

76A22R, 80A22R

CCP-33, CCP-32 Bedding

ECLIPSER 2500-1024 HR-2500-1024 ECLIPSER 2800-1024 HR-2800-1024

110A18R CLIP - (10mm

Flat BW)

–

Bedding, 10mm Flat

Border Frames

ECLIPSER 2500-1121 HR-2500-1121 HR-46CC

88A23R, 91A23R,

96A23R

CCP-14S, CCP-14,

CCP-9

Bedding, 5mm BW

ECLIPSER 2500-6082 HR-2500-6082

74F18R, 90F18R CCP-74, CCP-73 Bedding, Furniture

ECLIPSER 2500-6181 HR-2500-6181 ECLIPSER 2800-6181 HR-2800-6181

80F23R (9ga. or 4mm

Border Frame)

CCP-71 (9ga. or 4mm

Border Frame)

Bedding, Furniture

ECLIPSER 2500-6185 HR-2500-6185 ECLIPSER 2800-6185 HR-2800-6185

88F23R (6ga. or 5mm

Border Frame)

CCP-72 (6ga. or 5mm

Border Frame)

Bedding

CONTINUOUS COIL

CLIPPING SYSTEM

QUICK BLADE JAM

RELEASE

HANGER ASSEMBLY

Includes ADJUSTABLE HEIGHT FEATURE

Standard on Encore Eclipser

and Hartco "E" Series

2800 Series Tools

Standard on 2500 and 2800

Series Tools. Optional for

2000 Series Tools.

Rev. 160324

For 2500/2800 Series Tools

Includes STAND, BALANCER,

REGULATOR, HOSES &

TRACK

USES CLIPS ON A CONTINUOUS COIL

KING SIZE ROTATING TABLE

Tool Systems and Add-Ons

COMMON

APPLICATIONS

Loading...

Loading...