Encom EN630-2S0004, EN650A-2S0004, EN630-2S0007, EN650A-2S0007, EN630-2S0015 User Manual

...

ISO9001 Quality Management System Authentication

CE Authentication

EN630/EN650A series

0.4-1.5KW

Series Inverter

Ver.2.0

Users’Manual

SHENZHEN ENCOM ELECTRIC TECHNOLOGIES CO.,LTD.

Version:V2.0-A0

Foreword

Thank you for purchasing EN630/EN650A series inverter developed and produced by

Shenzhen Encom Electric Technologies CO., LTD.

EN630 series mini hi-performance flux vector inverter adopts advanced control mode to

achieve high torque, high precision and wide-range speed regulation drive, and it also supports

speed sensorless torque control and PG control torque. It can meet customer all kinds of

requirement to universal inverter. EN630 inverter is a organic combination for customer’s

universal and industrial control purpose and provides practical main-auxiliary frequency

provision, run channel frequency binding, PID regulator, simple PLC, spinning traverse,

programmable input&output terminal control, pulse frequency provision and inbuilt Modbus, Can

bus, Profibus, RS485 and free protocol and other function and platform. It provides high

integration solution for most manufacturing and automation customer and EN630 inbuilt input

phase loss function, output phase loss function, short circuit to earth grounding function and many

other protective function to improve effectively the system reliability and safety.

EN650A series is a mini multi-function permanent magnet synchronous inverter which

combined market demand for synchronous motor and its supporting system, built-in unique

control algorithm, can achieve high torque, high precision, wide speed range control for

permanent magnet synchronous motor and brushless DC motor, supports PG vector and PG

vector control, and also supports speed and torque mode switching.

This brochure provides the installation and wiring settings, fault check and methods,

maintenance and other relative issues to customer. To make inverter assemble and operate rightly,

and use its high performance to best, please read this brochure carefully before installation usage

and keep them well to the final users of inverter.

Please contact our office or dealer anywhere at any moment when you have any doubts or

special demands in using these inverters, and you can also contact our after service center in our

headquarters directly. We will serve you with all our heart.

We reserve our right to notice you if we change contents of this manual.

Content

Content

1 Safety information and use notice points 1

1.1Safety precautions 1

1.2Use notice points 3

1.3 Use notice points 3

2 Inverter Type and Specification 5

2.1 Incoming inverter inspect 5

2.2 Type explanation 5

2.3 Nameplate explanation 5

2.4 Inverter type explanation 6

2.5 Appearance and parts name explanation 6

2.6 Outer size & gross weight 6

2.7 Outer size of keypad and its fixing box 7

2.8 Product technic index and spec 7

3 Installation and wiring 11

3.1 Installation ambient 11

3.1.1 The demands for installation ambient 11

3.1.2 Installation direction and space 11

3.2 Parts disassembly and installation 12

3.2.1 Keyboard disassembly and installati 12

3.2.2 Plastic cover disassembly and installation

3.3 Wiring notice points

3.4 Main loop terminal wiring

3.4.1 Connection between inverter and fitting parts

3.4.2 Main loop terminal wiring

3.5 Basic running wiring diagram

3.6 Control loop collocation and wiring

3.6.1 Relative location and function for control board terminal and slide

Switch

3.6.2 Descriptions for control board terminal

16

12

13

13

14

15

15

16

17

目录

3.6.3 Analog input&output terminal wiring 19

3.6.4 Communication terminal wiring 20

3.7 Installation guidance of anti-interference

3.7.1 noise interference restraining

3.7.2 Field wiring and earth grounding

3.7.3 long distance wiring & Leak current and countermeasure

3.7.4 Installation demand for electromagnetic on-off electronic

device 25

4 Run and operation explanation for inverter

4.1 Run of inverter 26

4.1.1 Running order channels

4.1.2 Frequency-provision channel 26

4.1.3 Work state

4.1.4 Run mode

4.2 Operation and use of key board 30

4.2.1 Keypad layout 30

4.2.2 Keypad function description 30

4.2.3 LED and indicator light

4.2.4 Key board display status

4.2.5 User Management Parameters

4.2.6 Method for operating keypad

4.3 Inverter electrification

4.3.1 Check before electrification

4.3.2 First electrification

5 Function Parameter Schedule Graph 38

5.1 Symbol description

5.2 Function parameter schedule graph 38

6 Troubleshooting

6.1 Failure and countermeasure

6.2 Failure record lookup

6.3 Failure reset 84

21

21

23

24

26

26

27

28

31

31

34

34

37

37

37

38

77

77

83

Content

6.4 Alarm reset 84

7 Maintenance 85

7.1 Routine maintenance 85

7.2 Inspection and replacement of damageable parts

7.3 Repair guarantee 86

7.4 Storage

Appendix A EN650A Mini multi-function PMSM Inverter

Appendix B Free-port Communication Protocol

Appendix C Modbus communication protocol

Appendix D Braking unit and braking resistance

86

87

88

133

152

167

1 Safety information and use notice points

1 Safety information and use notice points

To make ensure personal & equipment safety, this chapter must be read

carefully before the inverter come into use.

1.1 Safety precautions

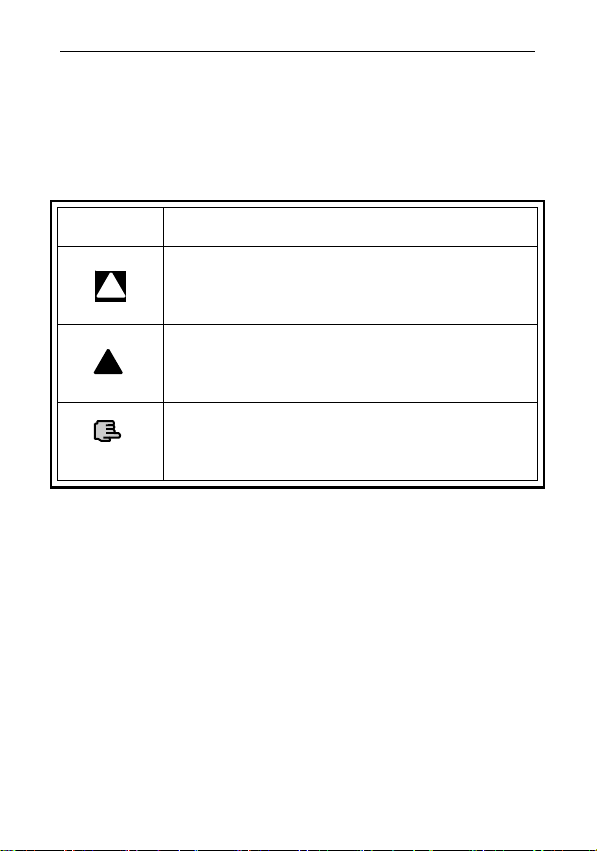

There are three kinds of safety warnings in this manual as below:

Symbol

!

!

Note

It may cause human death, serious injury or heavy property loss

with wrong operation.

It may result body or device damage with wrong and timeless

precautions under operation.

Should pay extra cautions when inverter in use under this

symbol

Symbol description

1

1 Safety information and use notice points

g

Forbid to cut off the power source directly when inverter under

running, acceleration or deceleration status. Power source could

cut off when inverter completely in halt and standby status.

!

Otherwise user should be responsible for inverter and device

e and human injury.

dama

(1) Forbid to connect AC power source to output terminal U,V,W,

otherwise it could cause inverter completely damage.

(2) Forbid to install inverter on flammable objects, otherwise it

may cause fire.

(3) Do not install inverter in a environment with explosive gas, it

may cause explosion.

(4) Bare connection terminal should be insulation treatment after

main loop connection, otherwise it may cause electric shock.

(5) Do not operate inverter with wet hands when inverter power

on, otherwise it may cause electric shock.

(6) Inverter earth terminal should be well grounding connection.

(7) Do not open the front cover for wiring when inverter power on.

Inverter wiring and check must handle after 10 minutes of

inverter power off.

(8) Wiring connection should handle by qualified person and not

allow to slip any conductive objects inside inverter, otherwise it

may cause a electric shock or inverter damage.

(9) when inverter stocked for more than 6 months, using voltage

regulator to boost voltage up and keep inverter in standy status

for 1 hour, otherwise it may cause electric shock and explosion.

(1) Forbid to connect control terminals except TA, TB, TC to AC

220V/380V signal, otherwise it may cause inverter completely

damage.

!

(2) Do not install and run inverter when inverter damage or spare

part less, otherwise it may cause fire or human injury.

(3) inverter should install in a place where can accept itself weight,

otherwise it may cause inverter drop down or belongings damage.

2

1 Safety information and use notice points

1.2 Application range

(1) This kind of inverter apply to 3 phase ac asynchronous motor only for general

industry.

(2) It should handle cautiously and consult with manufacturer when inverter apply

to high reliability required equipment which relevant to life, properties and

safety device.

(3) This kind of inverter is the general motor control device in industry. When

inverter apply to dangerous equipment, safeguard should be considerable in

case of inverter failure.

1.3 Use notice points

(1) EN630/EN650A series inverter belong to voltage type inverter, and it is

normal with up temperature, noise and vibration of motor increasing over

power frequency run slightly.

(2) It is required to match inverter with variable frequency motor running at low

speed with constant torque for long time. When match inverter with general

asynchronous motor running at low speed, it should take measures to make

motor heat dissipation or monitoring motor temperature in avoid of motor

flash.

(3) It is necessary to take measures in advance for the damage caused for the bad

lubrication of the reduction box and wheel gear mechanical devices running at

low speed for long time.

(4) It is necessary to assure at first that the use speed range of motor bearings and

mechanical devices, also the increasing of motor vibration and noise should be

considered, when motor run over rated frequency.

(5) It is necessary to select the suitable brake assembly for hoisting device and big

inertia load to make sure the normal work when inverter stripping from power

grid for the overcurrent or overvoltage failure.

(6) Inverter start and stop control through terminal or other normal command

channel, otherwise it may cause inverter damage via connecting inverter input

terminal to big current switch just like contactor direct to start and stop

inverter frequently.

(7) It is necessary to make sure inverter cut off from operation without output,

when inverter and motor connect through switch components just like

contactor etc. Otherwise it will cause inverter damage.

(8) When inverter output frequency within some range, it may meet mechanical

resonance point of load device, through setting jump frequency to avoid it.

(9) Checking power supply voltage within allowed working range before usage,

3

1 Safety information and use notice points

otherwise, it need to change voltage or custom special voltage inverter.

(10)When inverter usage site altitude over1000 meters,inverter should decrease

current to use, output current decrease about 10% of rated current per 1000

meters increase.

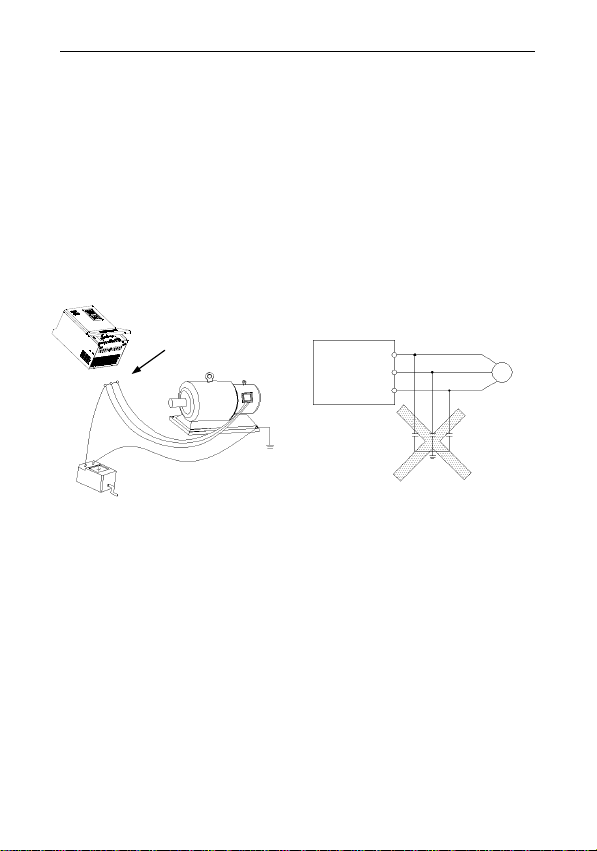

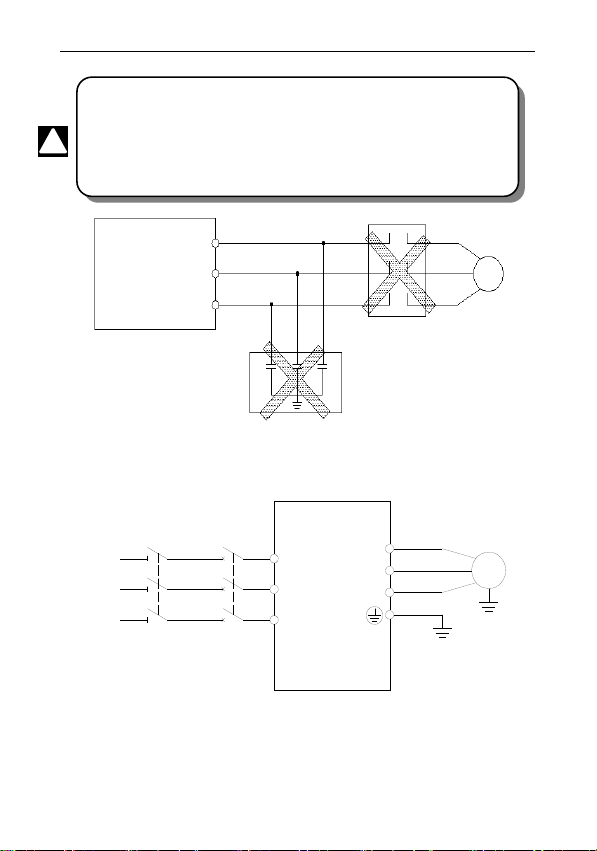

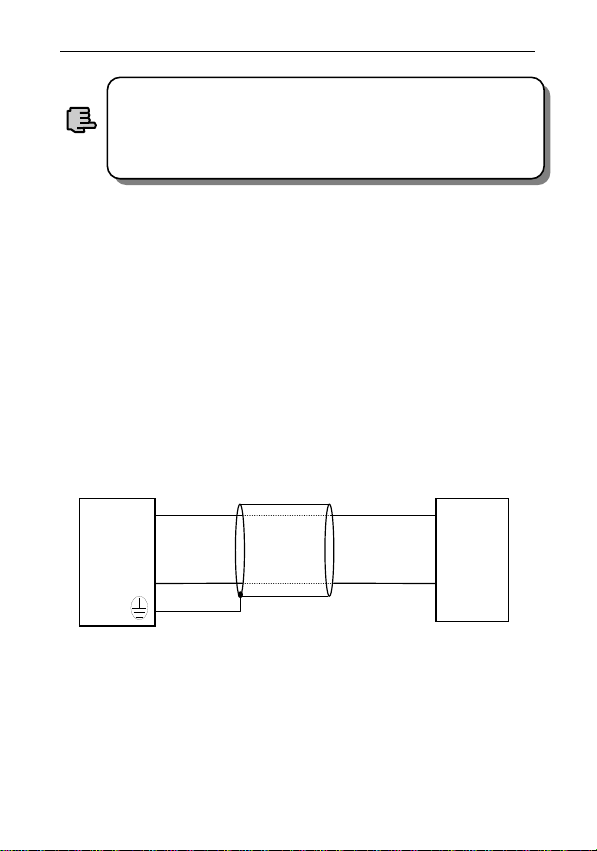

(11)Motor should do insulation check before first usage or reusage after lay aside

for long time. Checking method show as graph 1-1 below with 500V voltage

type megohm meter , insulation resistance should not smaller than 5 MΩ,

otherwise inverter maybe damaged.

(12)Forbid inverter output side to assemble capacitor to improve power factor or

anti-thunder dependent resistor etc, otherwise it may cause inverter fault trip

or component damage show as graph 1-2.

U

EN630/EN650A

After wiring finish, short-circuit U,V,W

to measure insulation resistance

W

motor

EN630/EN650A

U

V

W

M

Fig.1-1 motor insulation check Fig.1-2 capacitor at output side forbidden

megohmm

Ground

4

2 Inverter Type and Specification

2 Inverter Type and Specification

2.1 Incoming inverter inspect

(1) Check if there is damage during transportation and inverter itself has damage

or fall-off parts.

(2) Check if parts presented in packing list are all ready.

(3) Please confirm nameplate data of the inverter is in line with your order

requirement.

Our product is guaranteed by strict quality system during manufacturing,

packing, transportation etc., please contact our company or local agent rapidly

if some careless omission or mistake arise, we’ll deal with it as soon as

possible.

2.2 Type explanation

EN630–4T 0015

Code Name

EN630 series

EN650A series

Code Vo l. gr ad e

2S Single phase 220V

Three phase

4T

380V

Fig.2-1 Type description

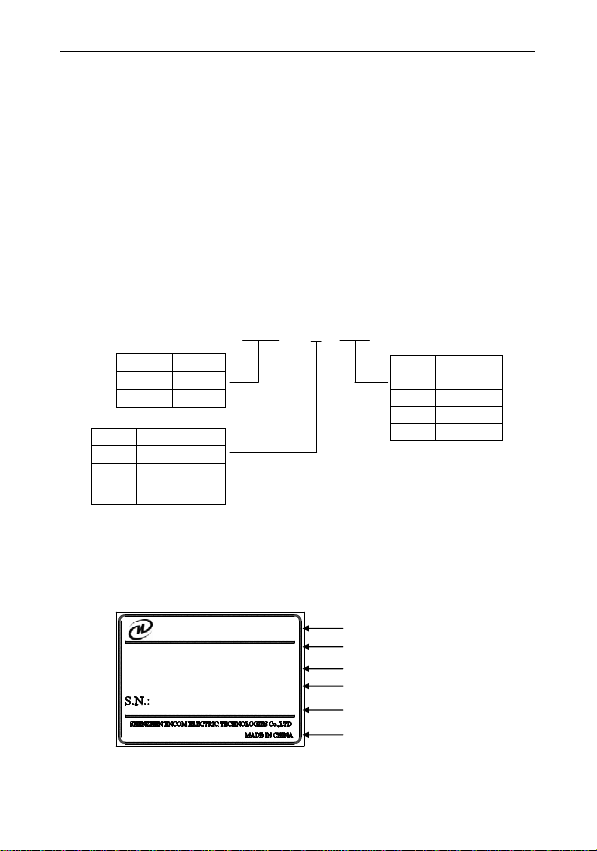

2.3 Nameplate explanation

Nameplate presented as figure 2-2 with type and rating data at the bottom of

inverter right side.

EN630 INVERTER

TYPE: EN630-4T0015

SOURCE: 3PH 380V 50/60Hz

OUTPUT: 1.5KW 3.7A

Fig.2-2 Nameplate

Series No.

Model

Rated input vol. And freq.

Motor power and output current

Serial No.

Manufacturer and origin

Match motor

Code

power (KW)

0004 0.4

0007 0.75

0015 1.5

5

2 Inverter Type and Specification

(op

2.4 Inverter type explanation

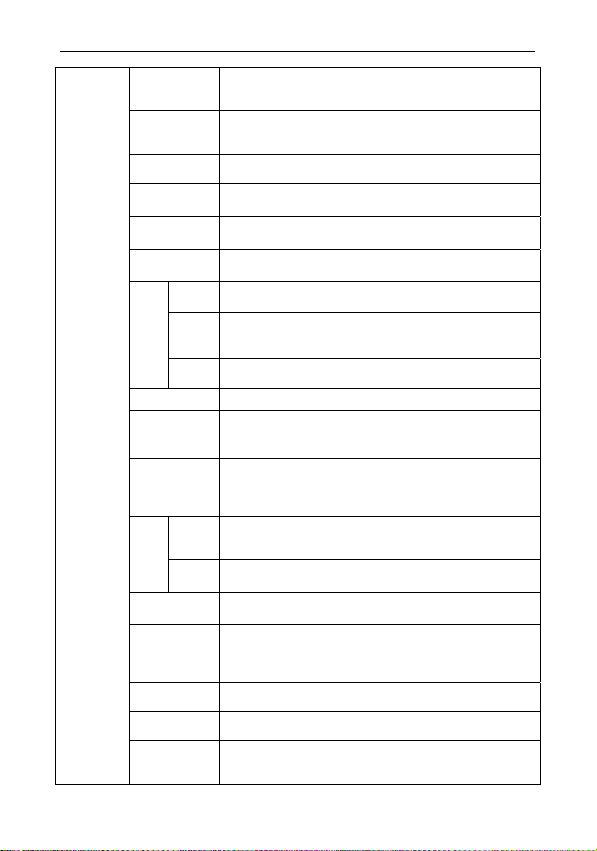

Table 2-1 inverter type explanation

Inverter type

EN630/EN650A-2S0004 2.5 0.4

EN630/EN650A-2S0007 4 0.75

EN630/EN650A-2S0015 7 1.5

EN630/EN650A-4T0007 2.3 0.75

EN630/EN650A-4T0015 3.7 1.5

Rated output

Current(A)

Adaptable motor

(KW)

2.5 Appearance and parts name explanation

Up cover plate

Operation keypad

digital tube

Digital potentiometer

Terminal wiring cover

Open here to connect brake resistor

tional)

Control cable inlet

vent

Input & output power cable inlet

Fig.2-3 Parts name sketch

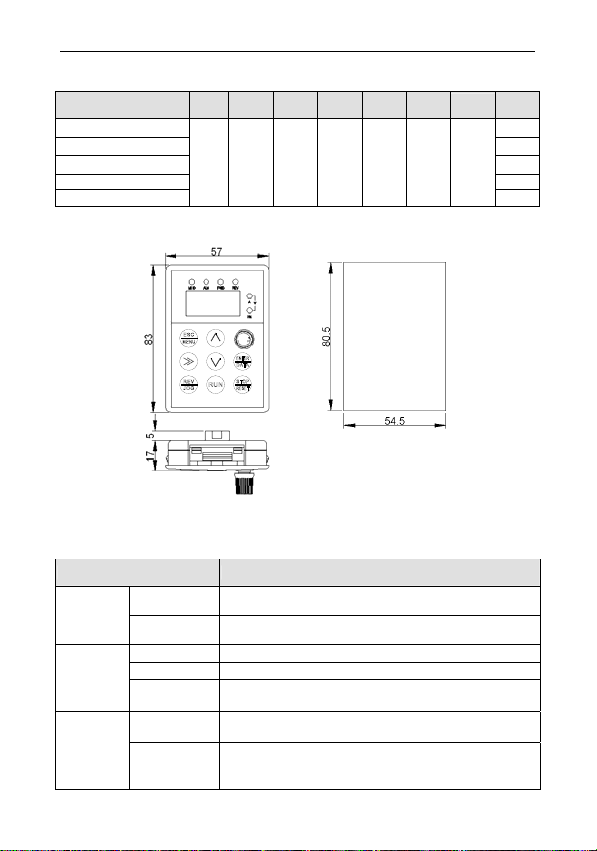

2.6 Outer size & gross weight

Fig.2-4 outer dimension

6

2 Inverter Type and Specification

Table 2-2 mounting size

Inverter type

EN630/EN650A-2S0004

EN630/EN650A-2S0007 1.1

EN630/EN650A-2S0015 1.2

EN630/EN650A-4T0007 1.1

EN630/EN650A-4T0015 1.1

W

(mm) H (mm) D (mm)

89 148.5 112.5 124.7 74 138 5

D1

(mm) A (mm) B (mm)

Fix Hole

(mm)

GW.

(kg)

1

2.7 Outer size of keypad and its fixing box(unit:mm)

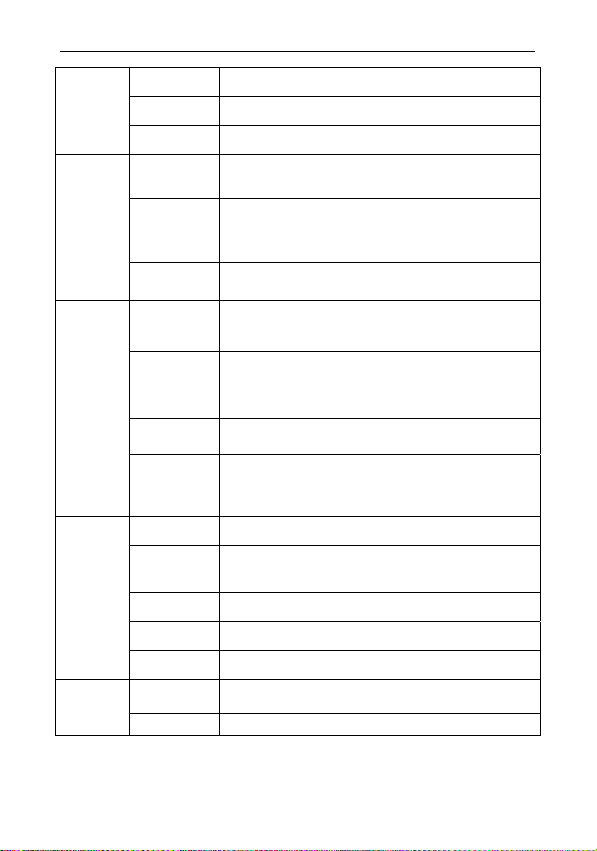

2.8 Product technic index and spec

Input

Output

Control

Performance

Fig. 2-5 EN-LED5-D keypad& Hole size of keypad

Item Item description

Rating volt.

frequency

Allowed volt

range

Vo l t age 0 ~380V

Frequency 0~600Hz

Over loading

capacity

Control mode

Velocity control

precision

1 phase 220V Grade:single phase 220V, 50Hz/60Hz;

3 phase 380V Grade:3 phase 380V, 50Hz/60Hz

1 phase 220V Grade:200~260V;

3 phase 380V Grade:320~460V

150% of rated current for 1 minute

vector control, PG vector control, open-loop V/F control, torque

control, PG torque control

±0.5% rated synchronous speed(vector control);

±0.1% rated synchronous speed(PG vector control);

±1% rated synchronous speed(V/F control);

7

2 Inverter Type and Specification

p

by

g

g

jog

y

Speed regulation

range

Start-up torque

Speed fluctuation

Torque control

precision

Torque response

Frequency

precision

Analog

setting

Freq.

Digital

resolut

setting

ion

recision

Exterior

impulse

Torque boost Automatic torque boost;manual torque boost 0.1~12.0%

V/F curve(volt.

Frequency

characteristic)

Acceleration

Deceleration

curve

Power

consumpt

ion brake

brake

DC brake

jog

Multi-section

speed run

Inbuilt PID

controller

Automatic energy

saving run

Automatic

voltage

regulate(AVR)

1:2000(PG vector control)

1:100(vector control);

1:50(V/F control);

1.0Hz:150% rated torque(V/F control);

0.5Hz:150% rated torque (vector control);

0Hz:180% rated torque(PG vector control);

±0.3% rated synchronous speed(vector control);

±0.1% rated synchronous speed(PG vector control);

±10% rated torque(vector control,torque control);

±5% rated torque(PG vector control,PG torque control).

≤20ms(vector control);

≤10ms(PG vector control);

Digital setting:max. frequency×±0.01%;Analog setting:max.

frequency×±0.5%

0.1% of max. frequency

0.01Hz

0.1% of max. frequency

Setting rated frequency at the range of 5~650Hz,

constant torque, degressive torque 1, de

degressive torque 3, self-defined V/F total 5 kinds of curve.

Two modes:strai

acceleration and deceleration; 15 kinds of acceleration and

deceleration time,time unit (0.01s, 0.1s, 1s) for option ,max.

time for 1000 minutes.

inbuilt brake unit,only add brake resistor between(+)and PB.

Start, stop action for option, action frequency 0~15Hz,action

current 0~100% of rated current,action time 0~30.0s

Jog frequency range:0Hz~up limit frequency;

and deceleration time 0.1~6000.0 seconds for setting.

Realized by inbuilt PLC or control terminal; with 15 section

speed, each section speed with separately acceleration and

deceleration time; with inbuilt PLC can achieve reserve when

power down.

Convenient to make closed-loop control system

Optimize V/F curve automatically to achieve power saving run

according to the load status.

Automaticall

voltage fluctuation

ht line acceleration and deceleration; S curve

keep output voltage constant, when the power grid

choosing

ressive torque 2,

acceleration

8

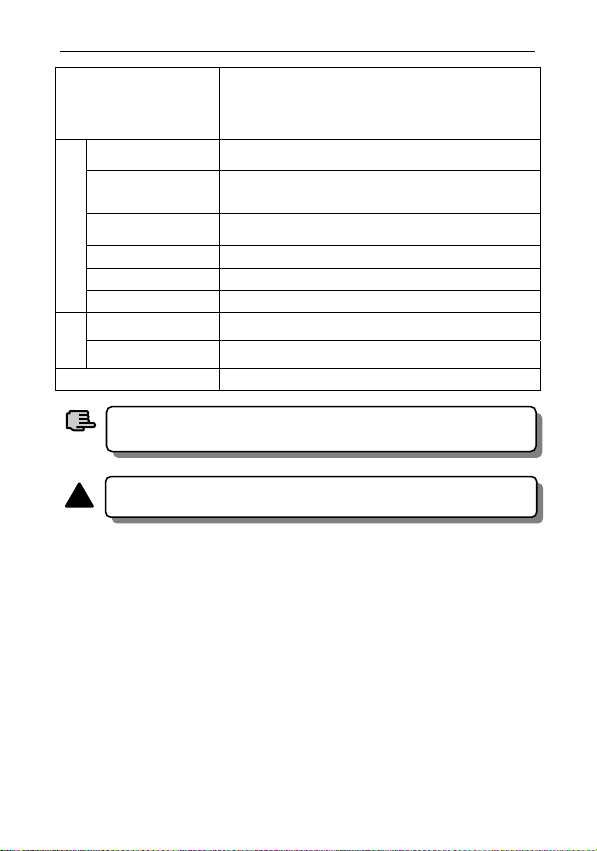

Running

y

y

g

p

y

g

g

g

g

g

function

Input output

characteristic

Unique

function

keypad

Automatic

current limiting

carrier

modulation

Speed tracking

restart

running

command

specified channel

Running

frequency

specified channel

Binding function

Digital input

channel

Analog input

channel

Pulse output

channel

Analog output

channel

Rapid current

Monopulse

control

Fixed length

control

Timing control

Virtual terminal

Keypad display

Button Locked Lock all or part of the buttons

Current limited automatically under run mode in avoid of inverter

over-current frequently to trip.

Modulate carrier wave automatically according to the load

characteristic.

Make rotating motor smoothly start without shocking

pad specified, control terminal specified, communication

Ke

specified can switch through various means.

Main & auxiliar

fine control. Digital specified, analo

ulse width specified, communication specified and others, which

can be switched by many means at any time.

Run command channel and frequenc

together randomly and switch synchronously

Channel 7 for universal di

channel 1 can be used as pulse input channel, with max. input

50KHz.

Channel 2 for analog input channel, AI1 can choose 4~20mA or

0~10V output,AI2 is differential input channel,4~20mA or

-10~10V for option.

0.1 ~ 20KHz pulse square signal output to achieve setting

frequency, output frequency and other physical quantity output.

Channel 1 for analog signal output, AO can choose 4~20mA or

0~10V to achieve settin

physical quantity output.

Limit inverter over current to the greatest point, and make it run

limit

more stably

Suitable for workin

inverter start and stop, first press to start, then press to stop, and

that cycle repeats. Its very simple and reliable.

Realize fixed length control

Timing control function: setting time range 0.1Min ~

6500.0Min

Five

control

The parameters as settin

voltage, output current can be displayed

specified to a realize one main adjusting and one

site where need one button to control

roup virtual input & output IO can realize simply logical

2 Inverter Type and Specification

specified, pulse specified,

specified channel can bind

ital input, max. Frequency 1KHz,

frequency, output frequency and other

frequency, output frequency, output

9

2 Inverter Type and Specification

g

y

g

Motor power on Shot circuit test, input & output phase loss

protection, over-current protection, over volta

Protection function

Application site

Envi

ronm

ent

struc

ture

Note

Altitude

Environment temperature

Environment humidity Smaller than 95%RH,no drop condenses

Vibration Smaller than 5.9 M/S²(0.6g)

Storage temperature -40℃~+70℃

Protection grade IP20

Cooling mode Forced air cooling and natural

Installation mode

To get a perfect usage performance of the inverter, Please check and

select right type according to this chapter before wiring.

It is necessary to select right type, otherwise it may cause motor

!

abnormal run or inverter damage.

voltage protection, over heat protection, overload protection,

under load protection, rela

protection and no stop protection under power off.

Indoor, not bare to sunlight, no dust, no corrosive

flammable gas, no vapor, no water drop or salt etc.

Under 1000 meter.(above 1000 meter require to reduce volume to

use, output current reduce about 10% of rated current per 1000

meter high)

-10℃~+40 ( environment temperature between 40℃℃~50 , ℃

need to reduce volume or strengthen heat sink )

Wall hanging

absorption protection, terminal

e protection, under

as, no

10

3 Installation and wiring

3 Installation and wiring

3.1 Installation ambient

3.1.1 The demands for installation ambient

(1) Installed in drafty indoor place,the ambient temperature should be within

-10ºC~40ºC,it needs external compulsory heat sink or reduce the volume if

temperature is over than 40ºC.

(2) Avoid installing in places with direct sunlight, much dust, floating fiber and

metal powder.

(3) Don’t install in place with corrosive, explosive gas.

(4) The humidity should be smaller than 95%RH,without condensation water.

(5) Installed in place of plane fixing vibration smaller than 5.9m/s²(0.6g).

(6) Keep away from electromagnetic disturbance source and other electronic

apparatus sensible to electromagnetic disturbance.

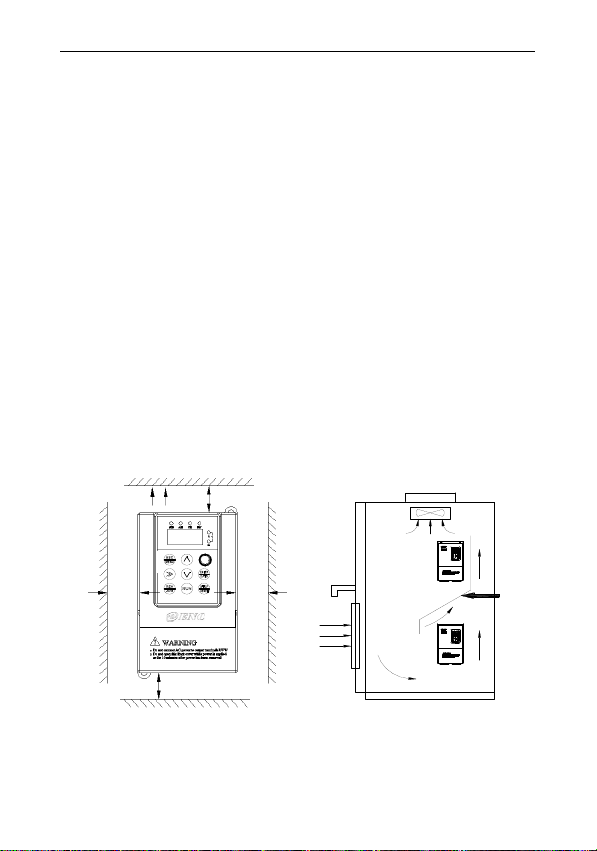

3.1.2 Installation direction and space

(1) Normally the inverter should be mounted vertically, horizontal mounting will

seriously affect heat dissipation and the inverter must be used in lower

volume.

(2) Demand for minimum mounting space and distance,please see Fig.3-1.

(3) When installing multiple inverters up and down, leading divider must be

applied between them, see fig. 3-2.

Exhaust

fan

50mm

above

Fig.3-1 mounting space Fig.3-2 mounting of multiple inverters

100mm above

100mm above

50mm

above

Leading divider

导流隔板

11

3 Installation and wiring

3.2 Parts disassembly and installation

3.2.1 Keyboard disassembly and installation

(1) Disassembly

Let the forefinger press finger inlet on the keypad,press fixing flexible plate

on the top lightly,draw it outward, then you can disassemble the keypad.

(2) Assembly

First interface the fixed hook of on the bottom of keyboard with the keyboard

installation claw of inverter, then press the fixed shrapnel on the top of keyboard

to push it assemble well properly (keyboard assemble well when sounding of

crisp).

3.2.2 Plastic cover disassembly and installation

(1) Disassembly

Located the thumbs to the side bayonet,with thumbs press inside and pull

upside at the same time until the bayonet open between cover and whole case,

then pull back cover to make it off the inverter.

3.3 Wiring notice points

!

Assure power be cut off completely for above 10 m⑴ inutes before

wiring, otherwise there is danger of getting electric shock.

Forbid connecting power wire to output U, V, W of the inverter.⑵

If there is current leakage inside inverter, when current leaka⑶ ge

greater than 5mA for medium & big power inverter, inverter and motor

must be earth grounding for safety assurance, and the diameter of earth

grounding copper cable is greater than 3.5mm², resistor less than 10Ω.

Before shipment compression resistance⑷ test of the inverter is

passed, so users should not conduct compression resistance test again.

Do not add absorbing capacitor or other resistance⑸ -capacitor

absorbing device between inverter and motor; also do not add

electromagnetic contact, show as Fig.3-3

To provide inverter over⑹ -current protection in output side and

convenient maintenance under power off, it should be connected to

power source through relay.

Relay, input & output circuit wiring (X1⑺~X7、Y1、Y2/DO、TA、

TB、TC、AI1、AI2、AO、485A、485B) should select greater than

0.75mm² stranded wire or shielding wire. One end of the shielding layer

hang in the air, and the other end connect to inverter earth grounding

terminal, connection wire shorter than 20m.

12

3 Installation and wiring

(1)Before wiring, assure power supply is cut off completely for 10

minutes and all LED indicator light extinguished.

(2) Wiring can only be done by professional person trained and qualified.

(3) Before power on, check if voltage grade of the inverter is in line with

!

that of power supply volt., otherwise will cause personnel injured and

L1(R)

device da

inverter

U

V

W

、

Fig.3-3 Forbid to use contactor and absorbing capacitor

3.4 Main loop terminal wiring

Power

三相

source

交流

电源

Air switch

空气开关

breaker

(断路器)

contactor

接触器

Fig.3-4 main loop simple wiring

EN630/

EN650A

R

S

T

U

V

W

M

M

13

3 Installation and wiring

3.4.1 Connection between inverter and fitting parts

(1) Breaking device like isolation

Switch must assemble between power

source and inverter to keep persona

safety under repairing and

R

S

T

N

inverter requirement for compulsory power off.

(2) There must be over-current

protection breaker or fuse in inverter

power supply circuit to avoid failure

expanding because of the second device failure.

(3) AC input reactor

When high harmonics between inverter

and power supply is strong which cannot

meet system requirement or input side

power factor need to improve, ac input reactor

can be added.

(4) Contactor is used to power supply only,

do not use it to control inverter start and stop.

(5) Input side EMI filter

EN630/EN650A

UVW

Optionally EMI filter to restrain high frequency

transduction interference and radio-frequency

interference from inverter power line.

(6) Output side EMI filter

Choosing optionally EMI filter to

restrain radio-frequency Interference

and wire leakage current from inverter

output side.

Fig.3-5 connection of inverter and

fitting parts

(7) AC output reactor

Installing AC output reactor is suggested

to avoid motor insulation damage, oversize current leakage and inverter

frequent protection when connecting wire between inverter and motor exceeds

50m. While to consider the voltage decrease issue of AC output rector, it can

follow to boost inverter input & output voltage or use smaller power motor to

avoid motor damage.

(8) Safety earth ground wire

Inverter and motor must be earth ground connection, connection wire should

select as shorter and thicker as above 3.5mm² multi-core copper wire, and

earth grounding resistance smaller than10Ω.

14

空气开关

Isolation switch

断路器或熔断器

Breaker or fuse

Ac input reactor( In option)

交流输入电抗器(可选)

Contactor

接触器

Input EMI filter( In option)

输入EMI滤波器(可选)

TSR

(+)

制动单元(可选)

Brake unit( In option)

(-)

BrS0~10485A

Input EMI filter( In option)

输出EMI滤波器(可选)

Ac output reactor(Note 1

交流输出电抗器(可选)

M

3 Installation and wiring

t

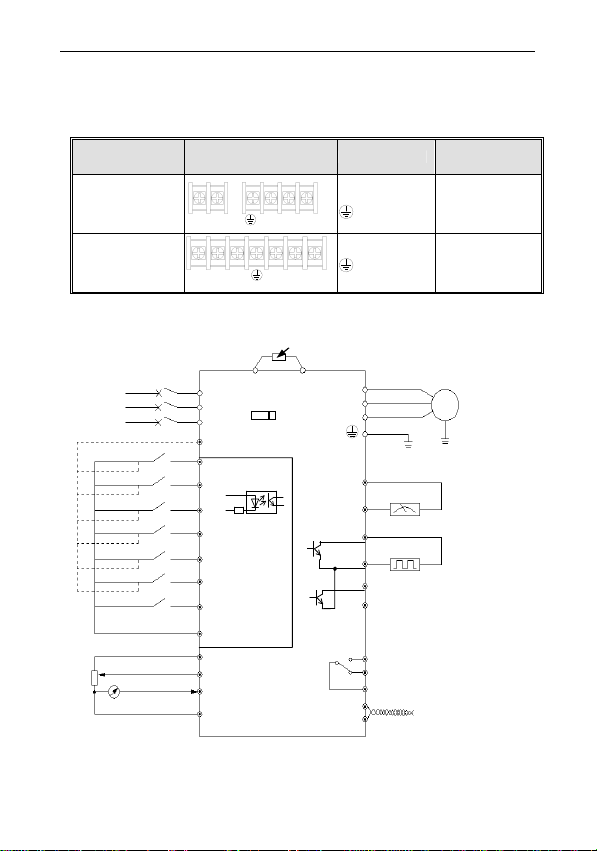

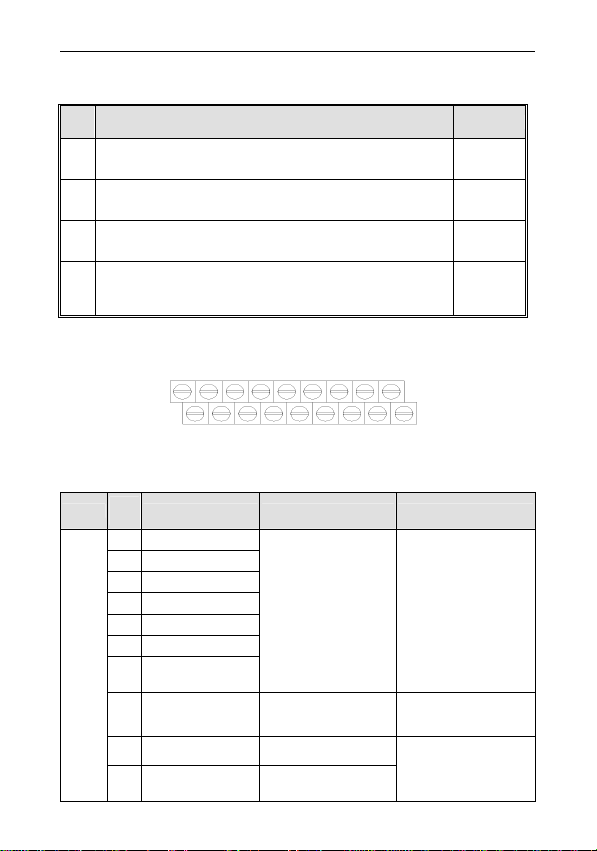

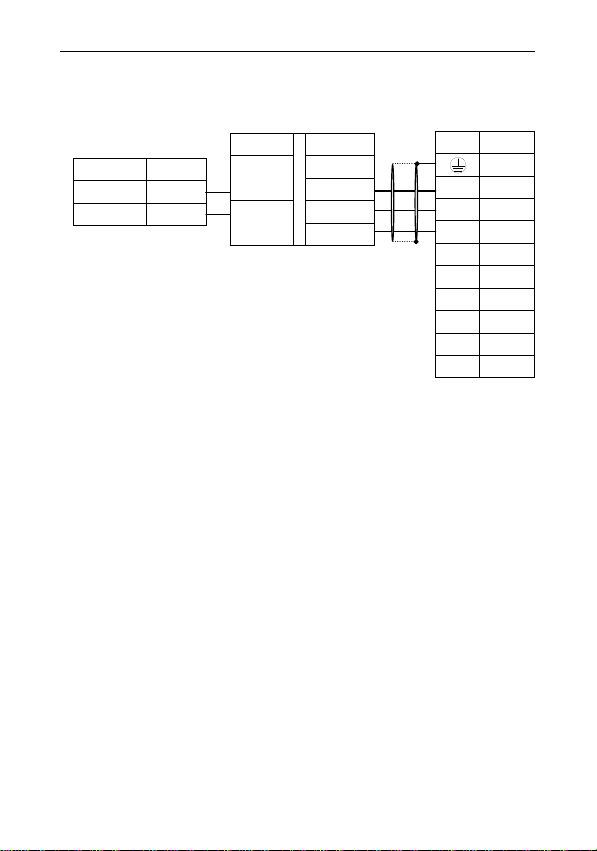

3.4.2 Main loop terminal wiring

Main loop input output terminal show as table 3-1.

Table 3-1 main loop input output terminal description

Adapted type Main loop terminal Terminal name Function description

EN630/EN650A-2S0004

~

EN630/EN650A-2S0015

EN630/EN650A-4T0007

~

EN630/EN650A-4T0015

L1(R)

L2(S)

L3(T)

U V

U V

W

48

L1

L2

U、V、W

L1(R)、L2(S)、L3(T)

U、V、W

Zero line

Live line

Grounding terminal

3 phase AC output terminal

3 phase AC input terminal

Grounding terminal

3 phase AC output terminal

3.5 Basic running wiring diagram

Note 1:When X1~X7 terminal input signal low electric level valid , push SW1 to “L” side.

Note 2:When X1~X7 terminal input signal high electric level valid , push SW1 to “H” side.

Breaker

Power source

Note 2

Multifunction select 1

Multifunction select 2

Multifunction select 3

Multifunction select 4

Multifunction select 5

Multifunction select 6

Multifunction selec

Note 1

Speed command

0~10V or 4~20mA

7

-10~10V

P+

L1(R)

L2(S)

H

L3(T)

+10V

X1

X2

X3

Internal optocoupler

isolation input

X4

X5

X6

X7

(Multifunction select 7 can

use as high speed pulse

input)

COM

+10V

AI2

AI1

GND

Fig.3-6 basic wiring diagram

Brake resistor (external, fitting parts: connect to

right side of inverter)

PB

SW1

L

EN630/EN650A

Y2/DO

Y1

+24V

485A

485B

U

V

W

GND

AO

COM

2 circuit open collector output

Provide +24V power source outside

TA

Fault relay output

TB

TC

M

Analog meter 4-20mA

current signal or 0~10V

voltage signal

frequency meter output 24V

pulse signal

Standard 485

communication

15

3 Installation and wiring

y

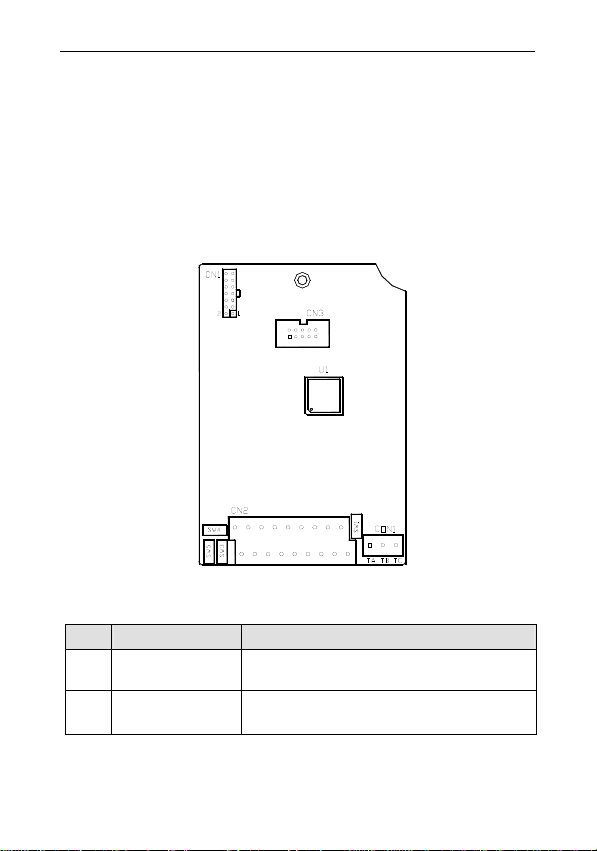

3.6 Control loop collocation and wiring

3.6.1 Relative location and function for control board terminal and slide

switch:

Control board terminal and slide switch location show as Fig 3-7.

User terminal function explanation can be seen in table 3-2,The setting

description and function of slide switch check table3-3, terminal CN3 is for

manufacturer usage. Please do the right terminal wiring and setting to the switch

on control board before using inverter and it is suggested to use greater than 24

AWG cable to connect terminal.

Fig 3-7 sketch map of CPU board

T able 3-2 function description of terminal provided for user

No. Function Description

CON1 Fault relay signal output

External terminal input &

CN2

output quantity control

when inverter alarm failure, the rela

will close.

Use the terminal when external terminal to control inverter

operate.

16

open normal switch

3 Installation and wiring

g

g

Table 3-3 Slide switch function description for users

No. Function Default

Analog AO output,0~10V & 4~20mA switch.

SW4

Locate “V” side, 0~10V output;locate “I” side,4~20mA output

Analog AI1 input,0~10V & 4~20mA switch.

SW3

Locate “V” side,0~10V input;locate “I” side,4~20mA input

Analog AI2 input,-10~10V & 4~20mA switch.

SW5

Locate “V” side,-10~10V input;locate “I” side,4~20mA input

Xi terminal input valid electric level switch:locate “H” side, Xi input hi

SW1

electric level valid(valid voltage range 15~30V);locate “L” side,Xi

input low electric level valid(valid voltage range 0~6V)

0~10V

0~10V

-10~10V

h

Low electric

level valid

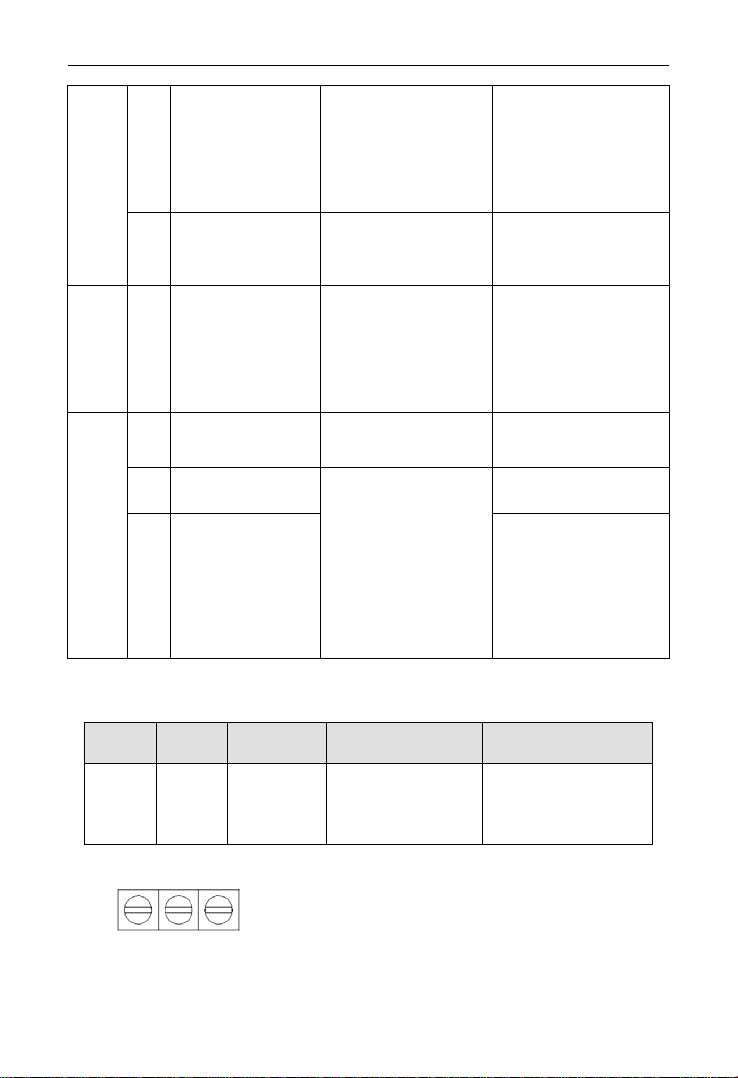

3.6.2 Descriptions for control board terminal

⑴ CN2 terminal layout as following

X1 X2 X3 X4 X5 COM X6 X7 485A

+10V

AI1 AI2 GND AO Y2/DO +24V Y1 485B

⑵ CN2 terminal function description show as Table 3-4

T able 3-4 function table for control board terminal

Symb

Type

Multfun

ction

input

terminal

+10V +10V power source

COM

GND

Description Terminal Function Specification

ol

X1 Multifunction input 1

X2 Multifunction input 2

X3 Multifunction input 3

X4 Multifunction input 4

X5 Multifunction input 5

X6 Multifunction input 6

Multifunction input 7/

X7

high-speed pulse input

Common terminal +24V

power negative polarity

+10V power ne

polarity

Programmable defined as

multifunction switch

quantity input terminal,

see switch quantity input

function parameter (F08

group) input terminal

description.

Provide power source

+10V outside(negative

polarity:GND)

+24V earth

Analog signal and +10V

ative

power source reference

Input impedance: R=2KΩ

Max. input

frequency:200Hz

X6、X7 can used as encoder

input

Max. input

frequency:50KHz

Input voltage range:15~

30V

Max. output current:10mA

17

3 Installation and wiring

Analog

SW5.

polarity:COM)

Open circuit collector

Open circuit collector

/ high

speed pulse input

frequency max. is 20KHz.

AI1 Analog input AI1

inpu

AI2 Analog input AI2

Analog

function

terminal

AO Analog output

output

+24V +24V power source

Multi-

output

Y1

Y2/D

O

output terminal 1

output terminal 2

terminal

Accept analog

voltage/current quantity

input,voltage, current

selected by switch SW3,

factory default is voltage.

(reference:GND)

Accept analog voltage

quantity input,voltage,

current selected by switch

Provide analog

voltage/current quantity

output,output voltage/

output current selected by

switch SW4,factory

default is output voltage.

(reference:GND)

Provide power source

+24V outside(negative

Programmable defined as

multi-function pulse signal

output terminal, particulars

see switch quantity, analog

quantity function parameter

(F09 Group) terminal

introduce

Input voltage range:0~

10V (Input impedance:

20KΩ)

Input current range:4~

20mA (Input impedance:

250Ω)

resolution:1/4000

Input voltage range:-10~

10V (Input impedance:

20KΩ) resolution:1/2000

current output range:4~

20mA

voltage output range:0~

10V

Max. output current:100mA

Max. output voltage:30V

Max. output current:50mA

Through F00.22 to select

terminal output means as

open collector output, with

same specification as Y

terminal, when used to high

pulse output: output pulse

voltage is 24V, output

⑴ RS485 terminal function description show as Table 3-5

Table 3-5 RS485 terminal function on control board

Type Symbol Description Terminal Function Specification

communi

cation

(4) terminal CON1, layout as following:

(5) CON1 terminal function description show as Table 3-6

18

485A

485

communicatio

n interface

485 differential signal

positive terminal

Standard 485

communication port

should use shielding wire

or twisted wire.

3 Installation and wiring

Table 3-6 CON1 terminal function on control board

Type Symbol Description Terminal Function Specification

Relay

output

terminal

TA

TB

TC

Fault output

relay

normal:TB-TC

close,TA-TC open

alarm:TB-TC open,TA-TC

close

TB-TC: close normal,TA - TC :open normal.

Contactor capacity :

AC250V/2A (COSΦ=1)

AC250V/1A (COSΦ=0.4)

DC30V/1A

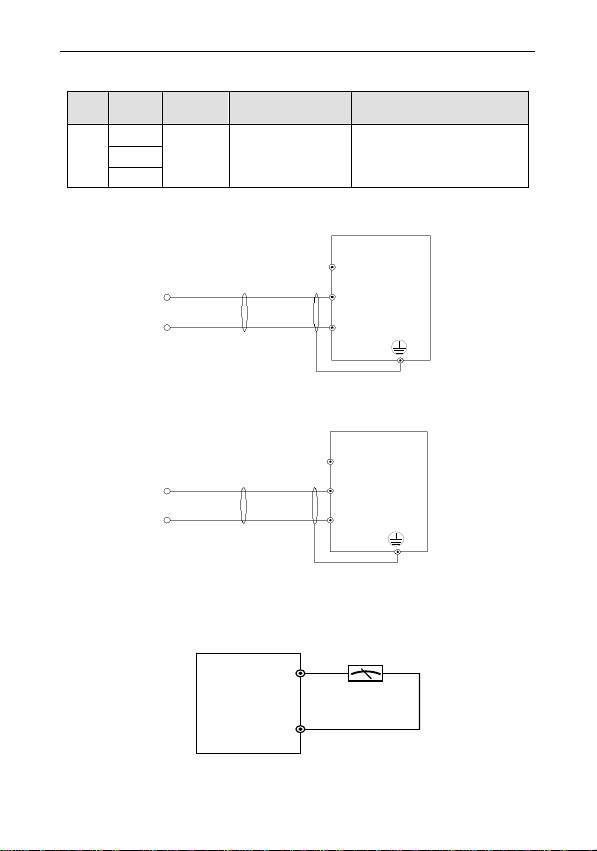

3.6.3 Analog input&output terminal wiring

(1) AI1 receive analog voltage signal input, wire as below:

or4~20mA

+

―

0~+10V

hield cable near-end earth

S

grounding

+10V

EN630/EN6

AI1

50A

GND

Fig.3-8 AI1 terminal wiring diagram

(2) AI2 receive analog signal input, input voltage

-10~+10V20mA

+

―

or 4~20mA

Shield cable near-end

earth grounding

wire as below:

(-10~10V)and input current (4~20mA),

+10V

EN630/

AI2

EN650A

GND

Fig.3-9 AI2 terminal wiring diagram

(3) analog output terminal AO wire

analog output terminal AO external connect to analog meter can indicate

several physical quantity, wire as below:

EN630/

EN650A

AOL1

GNDL2

Analog meter

Fig.3-10 AO terminal wiring diagram

19

3 Installation and wiring

(1) Under analog input mode, filter capacitor or common mode

choke can be installed between AI1 and GND or AI2 and GND.

(2) Analog input and output signal can be interfered easily by

ambient environment, it need use shield cable for connection and

Note

earth grounding well as short as possible.

3.6.4 Communication terminal wiring

EN630/EN650A inverter provide RS485 serial communication interface to

user.

The following wire connection can make up of single-main single-sub

control system or single-main multi-sub control system. To use host computer

software(PC or PLC controller)can realize real time monitoring and operation to

inverter,and to achieve complicated run control like long-distance control, high

degree automation. It can also use one host inverter and others slave inverter to

make up of the cascade or synchronous control inverter network.

Inverter ⑴ RS485 interface and other device with RS485 interface wire connection

show as following

EN630

/EN650A

RS485

A(485+)

B(485-)

A(485+)

B(485-)

Device with

RS485 o

EN630

/EN650A

r

Fig.3-11 Communication terminal wiring

20

3 Installation and wiring

⑵ Inverter RS485 interface and host computer (device with RS232 interface)

connection:

EN630/EN650A inverter

description name

Signal B

Signal A

RS232/RS485 converter

name description

B

A

+5V

TXD

RXD

GND

Shield cable

Host computer

Signal

Pin No.

shell

RXD 2

TXD 3

GND 5

DTR 4

DSR 6

RI 9

CD 1

RTS 7

CTS 8

Fig.3-12 RS485 communication wiring

3.7 Installation guidance of anti-interference

Inverter main circuit consist of high power semiconductor and switch

component, for which will generate electromagnetic noise when working, and to

avoid or reduce inverter interference to ambient environment, this chapter

introduce installation means to restrain interference from aspect of interference

restrain, field wiring, system earth grounding, leakage current and power filter

usage.

3.7.1 noise interference restraining

Inverter interference generating for run may have effect to nearby electronic

device and the effect depend on the inverter installation surrounding

electromagnetic environment and the restrain interference ability of the device.

(1)interference noise type

Because of inverter working principle, there are mainly 3 kinds of noise

interference source::

⑴ circuit conduction interference;

⑵ space emission interference;

⑶ electromagnetic induction interference;

21

3 Installation and wiring

ductio

p

Circuit conduction

interference

Leak current

漏电流接

earth grounding

地线回路

wire loop

干扰

interference

route

路径①

(2)noise transmission route

22

Power wire high

电源线高次

harmonic current

谐波电流传

conduction

导干扰

interference

route

路径②

Inverter main circuit

变频器的主回路

switch and switch

开关与开关电源

ower radio

的射频干扰

interference

路径③

route

Fig.3-13 interference noise type

Sensor power

sensor

①

Fig.3-14 noise interference transmission route diagram

②

⑤

⑤

Interference Type

Space emission

interference

Motor wire

电机线

U,V,W radio

U、V、W

interference

的射频干扰

路径④

route

⑧

inverter

⑦

motor

Input wire

induction

⑥

Electromagnetic

induction interference

输入线

感应

route

路径⑥

Power wire

电源线

R,S,T radio

R、S、T

interference

的射频干扰

route

路径⑤

Wireless

device

Inverter power

变频器功率

component

部件感应

n

in

route

路径⑦

TV

meter

Output wire

induction

输出线

感应

路径⑧

route

3 Installation and wiring

g

p

g

g

(3)Basic countermeasure for restrain interference

Table 3-7 interference restrain countermeasure

Noise

spread

road

①

②

③④⑤

⑥⑦⑧

Earth

up of the closed-loop and leakage current of inverter earth grounding

cable will make device perform wrong action. It will decrease wrong

action when device not connect to earth grounding.

When the power of

same power source, high harmonic generating from inverter will

transmit the voltage and current along with the power line which will

interfere other devices within the same power source system. Take

some restraining measures as below:install electromagnetic noise

filter at inverter input end; use isolation transformer to isolate other

devices; connect power end of peripheral device to remote power

grid;add power ferrite filter magnetic ring to inverter R、S、T three

phase wire to restrain high harmonic current conduction

Keep other sensitive devices and si

inverter. it should use shield wire and make the shield layer single

end earth grounding. Besides keep distance from inverter and its

input & output wire as possible as. When signal wire need to

intersect with strong current cable, it should make them orthogonal

crossing not parallel.

Install high frequency noise filter (ferrite common code choke,

also called magnetic ring) at the bottom end of the inverter input &

output to restrain radio frequency interference of dynamic wire

effectively.

Motor cable should be placed in protective object with large

thickness, such as placed in larger thickness(over 2mm) pipeline or

buried in cemented tank. Putting dynamic wire in metal tube and

connect to earth grounding with shield wire (motor cable use 4-core

cable, one side is earthed through the inverter, the other side

connected to motor casing).

To prevent wire parallel or bundled of stron

should keep away from inverter assemble device, and wiring should

away from inverter R,S,T,U,V,W power line. Devices with high field

and high magnetic field should notice the corresponding installation

position of inverter and keep distance and orthogonal crossing.

Countermeasure of weakening effect

rounding cable of peripheral device and inverter wiring make

eripheral device and inverter power belong to the

nal wire installed away from

and weak current, it

3.7.2 Field wiring and earth grounding

inverter terminal motor connection wire ⑴(U,V,W terminal output wire)and

inverter terminal power connection wire(R,S,T terminal input wire)should

keep distance enough as more as 30cm。

23

3 Installation and wiring

U⑵ ,V,W terminal 3 motor wires should be placed in metal tube or metal wiring

tank as possible as.

Generally control signal wire should use shield cable, when shield layer⑶

connect to inverter terminal, it should be the single end earth grounding

which closed to inverter side.

Inverter⑷ terminal earth grounding cable must directly connect to floor, it cannot

connect to earth grounding through other device.

⑸ strong current cable(R,S,T,U,V,W) cannot parallel wiring closely with control

signal wire, and bundled together is prohibited. It should keep distance from

over 20~60 cm(relative to strong current size). When it’s necessary to intersect,

it should be orthogonal crossing, show as Fig.3-15.

电源线或电动机线

Power wire or motor cable

控制信号线

Control signal wire

Fig.3-15 system wiring demand

earth grounding wire for strong current should separately connect to earth ⑹

grounding with control signal and sensor earth grounding wire for weak current.

Forbid to connect inverter ⑺ input terminal(R,S,T) to other devices.

3.7.3 long distance wiring & Leak current and countermeasure

When inverter connect to motor in a long distance, high harmonic wave

through distributed capacitance will generate leak current to earth and

wire-to-wire. Restraining methods as below:

install ferrite magnetic ring or output reactor at the inverter output terminal.⑴

When rea ctor in stalle d with r ated voltage drop more 5% and long

wiring to U, V, W terminal, it would reduce motor’s voltage

apparently. When motor run at full load, it is possible to flash

!

motor, and it should be used by derating or boosting input and

output voltage.

24

3 Installation and wiring

(2) as carrier frequency low, the motor noise would increase accordingly.

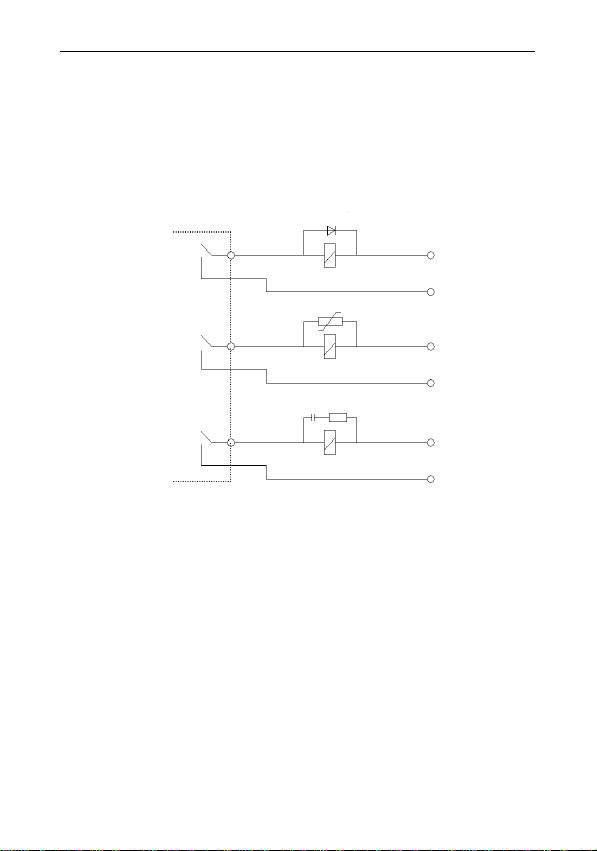

3.7.4 Installation demand for electromagnetic on-off electronic device

It should pay attention that surge absorber must be installed when electromagnetic

on-off electronic device like relay, electromagnetic contactor and electromagnetic

iron generating noise easily and largely installed near to inverter or in the same

control cabinet, show as Fig. 3-16.

Inverter or

变频器或其

other devices

它电气设备

diode

二极管

压敏电阻器

varistor

filter

RC-滤波器

+

24V

DC

_

~

220V

AC

~

~

220V

AC

~

Fig.3-16 install demand for electromagnetic on-off device

25

4 Run and operation explanation for inverter

4 Run and operation explanation for inverter

4.1 Run of inverter

4.1.1 Running order channels

There are 3 kinds of order channel for controlling run action of the inverter

such as run, stop, jog etc.

0:keypad

Control by key 、 、 on keypad (factory default).

1:Control terminal

Use control terminal Xi(defined as FWD), Xi(defined as REV) and COM to

make of double-line control, or use anyone terminal of X1~X8 except terminal

FWD and REV to make of three-line control.

2:Communication port

Control run and stop of the inverter through upper machine or other device

which can communicate with the inverter.

Choose order channel by setting function code F01.15;and also can choose

by multi-function input terminal (F08.18~F08.25 choose function 49,50,51,52,53).

Please make switching debugging in advance when switch the order

channel to check if it can fulfill system requirement, otherwise have

!

danger of damaging device and injuring personal.

4.1.2 Frequency-provision channel

EN630/EN650A includes main frequency provision and assist frequency

provision:

Main frequency provision:

0: keypad analog potentiometer provision;

1: AI1 analog setting;

2: AI2 analog setting;

3: terminal UP/DOWN adjustment provision;

4: communication provision (Modbus and external bus share a main frequency

memory);

5: Reserved;

26

4 Run and operation explanation for inverter

6: Reserved;

7: high speed pulse provision (X7 terminal need select the corresponding

function);

8~14: Reserved

Assist frequency provision:

0: keypad analog potentiometer provision;

1: AI1 analog setting;

2: AI2 analog setting;

3: terminal UP/DOWN adjustment provision;

4: communication provision (Modbus and external bus share a main frequency

memory);

5: Reserved;

6: Reserved;

7: Terminal pulse provision (X7 terminal need select the corresponding

function);

8~20: Reserved

4.1.3 Work state

Work state of EN630/EN650A includes of Waiting state, Running state and

Parameter setting state.

Waiting state :

If there is no running command after the inverter electrified or after stop

command during running state, the inverter enters into waiting state.

Running state:

The inverter enters into running state after receiving run command.

Parameter setting state:

After receiving the parameter identification command, enter the parameter

setting state, then turning into the shutdown state.

27

4 Run and operation explanation for inverter

d

y

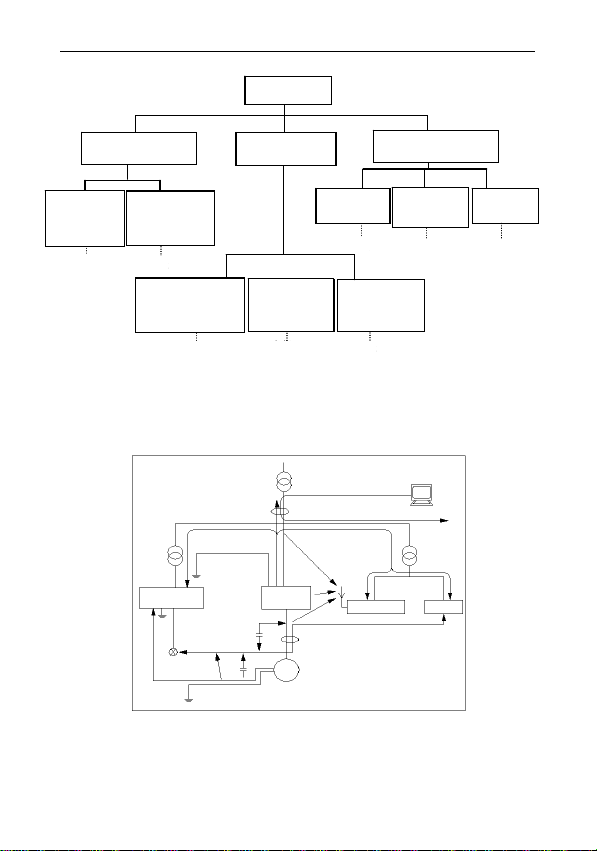

4.1.4 Run mode

EN630/EN650A inverter have 6 kinds of run mode, following is in turn

according

to their priority, jog run →closed-loop run →PLC run →multi-section speed

run→swing frequency run →common run. Shown as Fig.4-1.

electrification

Any jog command?

N

Run command effective?

Closed-loop effective

PLC effective?

Multi-section terminal effective?

Traverse run?

Common run?

waiting

state

N

Y

N

N

N

N

N

Y

Y

?

Y

Y

Closed-loop invalidation

terminal closed

Y

Y

Y

Y

PLC invalidation

terminal closed

N

?

N

?

high priorit

low priority

Fig.4-1 logic flow chart of EN630/EN650A inverter running state

0:Jog run

Upon receiving jog run command (for instance, press the key on keypad)

during waiting state, the inverter run at jog frequency (see function code

F01.25~F01.29).

1:Closed-loop run

28

Jog run

close

run

PLC run

Multi-section

traverse

run

common

run

-loop

run

4 Run and operation explanation for inverter

The inverter will come into closed-loop run mode when closed –loop run

control effective parameter is set (F11.00=1 or F12.00=5). Namely carry on PID

adjustment to specified value and feedback value (proportion integral differential

calculation, see F11 group function code) and PID adjuster output is inverter output

frequency. Can make closed-loop run mode ineffective and switch to lower level

run mode by multi-function terminal (function 31).

2:PLC run

The inverter will enter into PLC run mode and run according to run mode

preset(see F10 group function code description) through setting PLC function

effective parameter(F10.00 last bit≠0). Can make PLC run mode ineffective and

switch to lower level run mode by multi-function terminal (function 36).

3:multi-section speed run

By nonzero combination of multi-function terminal (5, 6, 7, 8, function),

choose multi-section frequency 1~15(F10.31~F10.45) to run at multi-section

speed.

4:swing frequency run

The inverter will enter into swing frequency run mode when swing frequency

function effective parameter (F13.00=1) is set. Set relevant swing frequency run

special parameter according to textile swing frequency craft to realize swing

frequency run.

5:common run

Common open loop run mode of general inverter.

In above 6 kinds of run mode except “jog run” the inverter can run according

to kinds of frequency setting method.

29

4 Run and operation explanation for inverter

y

4.2 Operation and use of key board

4.2.1 Keypad layout

The operating keyboard is the main unit of frequency inverter to accept

commands, display parameters. Keyboard outline diagram shown in Figure 4-2.

Failure alarm indicator light

Mode indicator light

Digital display (LED)

UP

Program/exit key

Multi-function key

Rev/Jog key

Fig.4-2 keypad layout sketch

4.2.2 Keypad function description

There are 8 key-presses and a digital potentiometer on inverter keypad,and

function definition of each key is as shown in table 4-1.

Table 4-1 keypad function table

Key Name Function description

Program/Exit

Shift/Supervisi

on key

Function/Data

Rev/Jog key

Run key Enter into forward run under keypad mode

Enter into or exit programming state

key

Can choose modification digit of set data under editor state;

can switch display status supervision parameter under other state

Enter into or exit programming state

key

Under keypad mode: to press this key can set reverse run or Jog run

according to the 1

st

bit of parameter F00.15

Forward run indicator light

Reverse run indicator light

Current unit(A)

Voltage unit (V)

Frequency unit(Hz)

Digital potentiometer

Confirm/Date ke

Decrease key

Stop/reset key

Forward run key

30

4 Run and operation explanation for inverter

Stop/reset key

Digital

potentiometer

Increasing

button

Decreasing

button

In common run status the inverter will be stopped according to set mode

after pressing this key if run command channel is set as keypad stop

effective mode. The inverter will be reset and resume normal stop status

after pressing this key when the inverter is in malfunction status.

It is the same as the function of increase and decrease key, rotate to

the left means decrease, rotate to the right means increase.

To increase data or function code (to press it continuously can

improve increasing speed)

To decrease data or function code (to press it continuously can

improve decreasing speed)

4.2.3 LED and indicator light

4 status indicator light: they are MOD(mode):ALM(alarm):FWD(forward

run): REV(reverse run)from left to right on the LED: their respective indicating

meaning is as shown in table 4-2.

Table 4-2 status indicator light description

Item Function description

Display current run status parameter and set parameter

A、

Unit for relevant current digital displayed physical parameter(for

Hz、V

current is A:for voltage is V:for frequency is Hz)

This indicator light is lit in non-supervision status and extinguished

MOD

if no key pressed for a minute: then come back to supervision status

Alarm indicator light: indicate that the inverter is in over current or

ALM

over voltage suppressing status or failure alarm status currently

Forward run indicator light, indicate

that the inverter output forward phase

FWD

order and the connected motor rotate

Reverse run indicator light: indicate

that the inverter output reverse phase

REV

order and the connected motor rotate

in reverse direction

The inverter work in DC

brake status if FWD,REV

indicator light is lit at the

same time

Display

function

Digital display

Status

indicat

or light

4.2.4 Key board display status

EN630/EN650A keypad display status is classified as Waiting status parameter

display; Function code parameter editing status display; Malfunction alarm status

display; Run status parameter display; Alarm state display in total 5 kinds of status.

LED indicator light will all be lit after the inverter electrified. Then enter into set

frequency display. As shown in Fig.4-3 a.

31

4 Run and operation explanation for inverter

(1) Waiting parameter display status

The inverter is in waiting status and waiting status supervision parameter is

displayed on keyboard: normally parameter F00.13 decide which status supervision

parameter to be displayed. As shown in Fig.4-3 b, the indicator light shows the unit of

the parameter.

To press key, it can display different waiting status supervision

parameter circularly: for detail please see C-00 to C-05 group supervision

parameter details decide by F00.07~F00.12.

(2) Run parameter display status

The inverter enters into run status when receiving effective run command and

normally parameter F00.13 decide which status supervision parameter to be displayed

on the keypad. As show n in Fig.4-3 c, the indicator light shows the unit of the

parameter.

To press key can display run status supervision parameter circularly.

For detail please see C-00 To C-05 group supervision parameter details decide by

F00.01~F00.06 .

Set frequency

Output frequency

Fig.a Electrification,

display 8.8.8.8.8.

Fig.4-3 inverter electrification: waiting: run status display

Fig.b waiting status, display

waiting status parameter

Fig.c run status: display run

status parameter

(3) Failure alarm display status

The inverter enters into failure alarm display

status upon detecting failure signal and display

failure code sparklingly(as shown in Fig.4-4);

To press key can look over relative

parameter after stopping running;

Can press key to enter into program status

32

over current in accelerating

Fig.4-4

4 Run and operation explanation for inverter

to see about F26 group parameter if want to search failure information.

Can carry on failure restoration by key: control terminal or

communication command on the keypad after troubleshooting. Keep displaying

failure code if failure exist continuously.

For some serious failure, such as inverse module protect, over

current: over voltage etc.: must not carry on failure reset for cibly

!

to make the inverter run again without failure elimination

confirmed. Otherwise have danger of damaging the inverter!

(4) Function code editing status

Under waiting, run or failure alarm status, press key, can enter into

editing status(If user password is set, can enter into editing status after inputting the

password, see also F27.00 description and Fig.4-10),and editing status is

displayed according to three classes menu mode, as shown in Fig. 4-5. To press

key can enter into one class by one class. Under function parameter display

status, press key to carry on parameter storage operation; press key can

only come back to

electrificati

upper class menu without storing modified parameter.

ESC/MENU

First class menu

ENTER/DATA

Second-class menu

Output frequency

Waiting status parameter Display

or run status parameter display

or failure alarm display

Switch display

ESC/MENU

ESC/MENU

Fig.4-5 keypad display status switching

Para. group Display control

(5) Alarm state display

When under running and standby situation:

It means enter failure alarm display status upon

detecting failure signal and display failure

code sparklingly (Fig4-6)Inverter keeping

running state But this alarm display can not

be reset button eliminated: After only find

the cause of the alarm: in order to eliminate

this factor Normal.

Same main/assist frequency channel

Fig.4-6

33

4 Run and operation explanation for inverter

r

4.2.5 User Management Parameters

In order to facilitate the user parameter management: EN630/EN650A

component model parameter menu for display management. The parameters do not

need to be displayed can be shielded.

⑴ Method parameter setting mode display.

By setting F00.00 = 0,1,2,3 respectively parameter mode is set: Basic menu

mode: menu mode Intermediate: Advanced menu mode and user menu mode.

Basic menu F00,F01,F02,F03,F26

Middle menu

Advance

menu

User custom F00.00 and F25 parameters group

F00,F01,F02,F03,F04,F05,F06,F07,F08,F09,F10,F11,F12,F13,F14,

F15,F16,F18,F19,F26

F00,F01,F02,F03,F04,F05,F06,F07,F08,F09,F10,F11,F12,F13,F14,

F15,F16,F17,F18,F19,F20,F21,F22,F23,F24,F25,F26,F27

4.2.6 Method for operating keypad

Can carry on various operation to the inverter through keypad, for example:

(1) Status parameter display switching:

After pressing key ,display C group status supervision parameter; after

displaying one supervision parameter code for 1 second will display this parameter

value automatically. Press key will go back to supervision interface.

LED displayed

content

Key-press operation

orde

C-00

0.00 C-01

1s

Para.

1s

Para. C-02

1s

Para. C-05

∫…∫

Fig.4-7 waiting status parameter display operating example

(2) Function code parameter setting

Take function code F01.01 modified from 5.00Hz to 6.00Hz as

example.Boldface in Fig.4-8 shows flickering digit.

34

Para.

1s

C-03

4 Run and operation explanation for inverter

LED displayed

content

Key-press

operation

order

0.00

Exit editing

status

F00.00 F01.00

Enter into

editing Status

display first-class

menu

Choose

F01 group

function code

F01.02

Store modified

value: back to

first -class menu

Display next

Fig.4-8 example for parameter setting and modification

function code

Parameter

modification,

5→6

006.00

F01.00

Move to the

position to be

adjusted

005.00

Parameter

modification,

Choose parameter

digit

…

F01.01

Choose

function

code F01.01

005.00

Function code

confirmation,

Enter into

second-class

Description: under second -class menu: if the parameter has no blinking digit,

this function code can’t be modified, possible reasons are as follows:

1>This function code shouldn’t be modified: for example actual

status

parameter: run record parameter etc.;

detected

2>This function code can’t be modified under run status and can be changed

after stopping running;

3>Parameter protected. All the function code can’t be modified when function

code F00.14=1 or 2,in order to avoid wrong operation. Need to set the function

code F00.14 to 0 if you want to edit function code parameter.

(3) Specified frequency adjustment for common run

Take example modifying specified frequency from 50.00Hz to 40.00Hz at

F01.06=1,F01.03=0 during running for explanation.

LED displayed

content

Key-press

operation order

50.00

49.99

Press decreasing

button for one

time

Fig.4-9 set frequency adjustment operation example

45.00 40.00

…

Adjust frequency

based on

requirement

Stop pressing after set

value reached: go back

to normal display status

after 1s

(4) Jog run operation

For example: keypad as current run command channel: jog run frequency 5Hz:

waiting status.

35

4 Run and operation explanation for inverter

p

d

LED

displayed

Key-press

operation

order

0.00

waiting

Display

set frequency

ress

0.01

keep

Display run

output

…

5.00 0.00

Output frequency

Increased by 5Hz

Fig.4-10 Jog run operating example

(5) Operation for entering to function code editing status after setting user

password

For example :“User password” F27 is set to“12345”. Boldfaced digit in

Fig.4-11 shows blinking bit.

LED displayed

content

Key-press

operation order

0.00

None-editing

status

Move to

the unit

Increase to“5”

user password

effective: go into

password validation

status

Increase to“4”

12345

00000

10000

At first last

Digit flash,

Increase to“1”

Move to

secon

Press confirmation

Key: pass validation,

Go into editing status

F27.00

12300 12000 12340 12340 12300

Increase

to“3”

Fig.4-11 inputting password to go into function code operation

(6) See about failure parameter under failure status:

If press key under failure status the user can quickly locate to the F26

group function code parameter. Press can quickly switch value between

F26.06 ~ F26.10 parameters and fault alarm, easy to view the fault records.

(7) Keypad key-press locking operation

Under unlocked keypad situation , press key for 2s to lock the keypad.

For detailed operation please refer to 2

nd

bit of F00.14 function code.

(8) Keypad key-press unlocking operation

Under locked keypad situation, press key for 5s to unlock the keypad.

36

0.01

release

Output frequency

Fall down to 0Hz

Stop running

10000 12000

move cursor

position to

forth digit

Move to third

Increase

to“2”

waiting

4 Run and operation explanation for inverter

4.3 Inverter electrification

4.3.1 Check before electrification

Please carry on wiring based on operation requirement provided in “inverter

wiring” of this Service manual.

4.3.2 First electrification

Close input side AC power supply switch after correct wiring and power

supply confirmed: electrify the inverter and keypad LED display “8.8.8.8.8”,

contactor closed normally: LED displayed set frequency shows that

electrification is finished. First electrification operation process is shown as

Fig.4-12:

N

N

Fig.4-12 first electrification operation flow

start

wiring based on 3.5 section

wiring correct?

Y

input voltage

correct?

Y

electrify

Y

Display 8.8.8.8.8.?

Y

Hear contactor closed sound?

Y

Display 0.00Hz?

Y

success

N

N

N

Failure

Cut off power

check reason

37

5 Function parameter schedule graph

5 Function Parameter Schedule Graph

5.1 Symbol description

× ---- parameter can’t be changed in process of running

○ ---- parameter can be changed in process of running

* ---- read-only parameter, unchangeable

5.2 Function parameter schedule graph

F00-System Parameter Group

Function

code

F00.00 Parameter group display

F00.01 C-00 display parameter

38

Name Set range

control

selection when operation

0:Basic list mode(only displayF00~F03 basic control

parameter group and F26 fault record parameter group.)

1:Middle list mode. Display all parameter except for

extension: virtual and reserve parameter group.

2: Senior list mode. All parameter display.

3:User list mode. Display parameter defined by user: and

monitor parameter: F00.00 display all the time.

0:main setup frequency(0.01Hz)

1:auxiliary setup frequency(0.01Hz)

2:setup frequency(0.01Hz)

3:output frequency(0.01Hz)

4:output current(0.1A)

5:output voltage(1V)

6:DC bus voltage(0.1V)

7:motor speed(1 circle/min)

8:motor line velocity(1 circle/min)

9:inverter temperature(1 )

10: latest working time (0.1min)

11:current accumulate working time(1h)

12:current accumulate power-on time(1h)

13:inverter status

14:input terminal status

15:output terminal status

16: reserve

17: reserve

18:communication virtual input terminal status

19:internal virtual input node status

20:analog input AI1(before checkout)

(0.01V / 0.01mA)

21:analog input AI2(before checkout)

(0.01V / 0.01mA)

22:reserve

23:reserve

24:analog AO output(checked) (0.01V /0.01mA)

25:reserve

26:reserve

27:reserve

28:external pulse input frequency (before checkout) (1Hz)

29:reserve

30:process PID provide(0.01V)

31:process PID feedback(0.01V)

32:process PID deviation(0.01V)

℃

Min.

Factory

unit

default

1 0 ○

1 3 ○

Modifi

-cation

5 Function parameter schedule graph

33:process PID output(0.01Hz)

34:simple PLC current segment No.

35:external multi-speed current segment No.

36:constant pressure water supply provide

pressure(0.001Mpa)

37:constant pressure water supply feedback

pressure(0.001Mpa)

38:constant pressure water supply relay status

39:current length(1M)

40:accumulate length(1M)

41:current internal count value

42:current internal time value

43:run command setup channel(0:keyboard 1:terminal

2:communication)

44:main frequency provide channel

45:auxiliary frequency provide channel

46:rated current(0.1A)

47:rated voltage(1V)

48:rated power(0.1KW)

49:electric torque limit value(0.1% motor specified torque)

50:braking torque limit value(0.1% motor specified torque)

51:frequency after add or subtract speed (0.01Hz)

52:motor rotor frequency(0.01Hz)

53:current present torque(relate specified percent of torque,

with direction)

54:current output torque(relate specified percent of torque,

with direction)

55:torque current at present(0.1A)

56:flux current at present(0.1A)

57:setting motor speed(r/min)

58:output power(act power) (0.1kw)

59:total electric cost low-order(1 degree)

60:total electric cost high-order(1 means 10,000degree)

F00.02 C-01 display parameter

selection when operation

F00.03 C-02 display parameter

selection when operation

F00.03 C-03 display parameter

selection when operation

F00.05 C-04 display parameter

selection when operation

F00.06 C-05 display parameter

selection when operation

F00.07 C-00 display parameter

selection when stop

F00.08 C-01 display parameter

selection when stop

F00.09 C-02 display parameter

selection when stop

F00.10 C-03 display parameter

selection when stop

F00.11 C-04 display parameter

selection when stop

F00.12 C-05 display parameter

selection when stop

61-65:reserve

Same as above 1 2 ○

Same as above 1 4 ○

Same as above 1 5 ○

Same as above 1 6 ○

Same as above 1 9 ○

Same as above 1 2 ○

Same as above 1 6 ○

Same as above 1 48 ○

Same as above 1 14 ○

Same as above 1 20 ○

Same as above 1 9 ○

39

5 Function parameter schedule graph

F00.13 Power-on fault monitor

parameter selection

F00.14 Parameter operation

control

F00.15 Button function selection

F00.16 Multi-function key run

command channel

switching order selection

F00.17 Motor speed display

coefficient

F00.18 Line speed display

coefficient

F00.19 PG card valid selection 0:invalid

0~5 1 0 ○

LED units digit: Parameter modification operations

0:All parameters are allowed to be modified

1:Except current parameter, all other parameters are not

allowed to modify

2:ExceptF01.01,F01.04and current parameter , all other

parameters are not allowed to be modified

LED tens digit: Reset to factory defaults

0:No action.

1:All parameters return to default.(not include fault record

parameter group(F26 group) parameter).

2:Except for motor parameter: all parameters return to

default.(not include F15 and F26 group parameter).

3:Extension parameter return to default.(only F21~F24 group

parameter return to default).

4:Virtual parameter return to default.(only F20 group

parameter return to default).

5:Fault record return to default.(only fault

record parameter group(F26 group)

parameter return to default)

LED hundreds digit: key operation

0:All locked

1:Except button: the others locked

2:Except , , button: the others locked

3:Except , button: the others locked.

4:Except , button: the others locked.

LED units digit: panel button selection

0:Reversal command action button

1:Jog action button

LED tens digit: Reserve

LED hundreds digit: terminal run command control

0:Keyboard button invalid

1:Keyboard button valid

LED thousands digit: communication run command control

0:Keyboard button invalid

1:Keyboard button valid

0: Keyboard control→ terminal

control→ communication control

1: Keyboard control←→terminal control

2: Keyboard control←→communication

control

3: Terminal control←→communication

control

0.1~999.9% 0.1% 100.0% ○

0.1~999.9% 0.1% 1.0% ○

1:reserve

2:reserve

3:incremental PG coder card(F08.24 can’t be 91) (terminal

X6, X7 correspond A, B; terminal X5 correspond Z)

40

1 000 ×

1 0001 ○

1 0 ○

1 0 ×

5 Function parameter schedule graph

F00.20 Analog input

terminal configuration

F00.21 Analog output

terminal configuration

F00.22 Y output

terminal

configuration

F00.23 Reserved 1 0 ×

F00.24 Motor control mode 0:V/F control

F00.25 Monitor parameter 2

selection

F00.26 Bus bar voltage adjust

coefficient

F00.27 Parameters copy LED units digit: reserved

4~10: reserved

LED units digit:AI1 configuration

0:0~10V input

1:4~20mA input

LED tens digit: AI2 configuration

0:-10~10V input

1:4~20mA input

LED hundreds digit: reserve

LED thousands digit: reserve

LED units digit: AO configuration

0:0~10V output

1:4~20mA output

LED tens digit: reserve

LED hundreds digit: reserve

LED thousands digit: reserve

LED units digit~ LED hundreds

digit: reserved

LED thousands digit: Y2 output configuration

0:Open collector output

1:DO output

1: No Speed Vector Control 1( compare to control 2, it more

suit 160kw or less asynchronous motor control, support speed

and torque control)

2: Speed sensors vector control( support asynchronous motor

speed and vector control)

3: No Speed sensors vector control 2( only support

asynchronous speed control, more suit 185kw or bigger

motor.

Same to F00.01 parameter

0.900~1.100

LED tens digit: update parameter or download (digital

potentiometer keyboard valid)

0: no action

1: update

2: download 1 (no motor parameter)

3: download 2 (include motor parameter

1 0000 ×

1 0000 ×

1 0000 ×

1 0 ×

F01-Basic Run Function Parameter Group

Function

code

F01.00 Main frequency input

Name Set range

channel selection

0: Operation keyboard digital setup

1: AI1 analog setup

2: AI2 analog setup

3:Terminal UP/DOWN adjusting setup