ENCAD T-200 Service Manual

SERVICE MANUAL

CADJET® T-200

COLOR INKJET

PRINTER/PLOTTER

SERVICE MANUAL

Part Number 219863-00

®

iii

CadJet T-200 Service Manual

Copyright Eastman Kodak Company, 2002

KODAK, ENCAD

®

and CadJet® are trademarks of

Eastman Kodak Company.

Other trademarks and registered trademarks are the

property of their respective owners.

Except as provided below, no part of this manual may be

copied or distributed, transmitted, transcribed, stored in

a retrieval system, or translated in any human or computing language, in any form or by any means, electronic,

mechanical, magnetic or otherwise, or disclosed to a

third party without the express written permission of

ENCAD, Inc., 6059 Cornerstone Court West, San Diego,

CA 92121, U.S.A.

Certain manuals developed by ENCAD are in an electronic format to be distributed on CDs or over the

internet. The registered user of an ENCAD product

whose manual is distributed in this fashion may print one

copy for their personal use only.

Printing history

1st Edition Rev A October 2002

iv

CadJet T-200 Service Manual

FCC Statement (U.S.A.)

The United States Federal Communications Commision has specified that

the following notice be brought to the attention of the users of the CADJET

T-200 printer.

FEDERAL COMMUNICATIONS COMMISION RADIO AND TELEVISION

INTERFERENCE FOR CLASS B DEVICE

This equipment has been tested and found to comply with the limits for a

class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications.

User Instructions:

If the equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for

help.

Changes or modifications not expressly approved by ENCAD, Inc. could

void the user’s authority to operate the equipment.

v

CadJet T-200 Service Manual

VDE Statement

Hiermit wird bescheinigt, daß der CADJET T-200 in Übereinstimmung mit

den Bestimmungen der BMPT-AmstbIVfg 234/1991 funkentstört ist. Der

vorschriftsmäßige Betrieb mancher Geräte (z.B. Meßsender) kann

allerdings gewissen Einschränkungen unterliegen. Beachten Sie deshalb

die Hinweise in der Bedienungsanleitung.

Dem Zentralamt für Zulassungen im Fernmeldewesen würde dan

Inverkehrbringen dieses Gerätes angezeigt und die Berechtigung zur

Überprüfung der Serie auf die Einhaltung der Bestimmungen eingeräumt.

ENCAD, Inc. U.S.A

vi

CadJet T-200 Service Manual

Material Safety Data Sheet

ENCAD QIS (Quality Imaging Supplies) ink is nonhazardous, requiring no

special disposal handling. It can be harmful if swallowed and should be

kept away from children.

To obtain a Material Safety Data Sheet, contact ENCAD, Inc. at:

6059 Cornerstone Court West

San Diego, CA 92121-3734

(858) 452-4350

International users should contact their local dealer or distributor.

vii

CadJet T-200 Service Manual

WARRANTY OR DAMAGE CLAIMS

United States

ENCAD®, Inc., warrants its printers ("PRODUCT") to be free from defects in workmanship

and materials for a period of one year from the date of purchase. In order to submit a

Warranty claim, please contact the ENCAD Help Desk at (619) 452-4350.

ENCAD reserves the right to make changes or improvements to Products, without incurring

any obligation to similarly alter Products previously purchased.

Buyer's sole and exclusive rights pursuant to this Warranty shall be for the repair or

replacement of defective Product. ENCAD specifically disclaims any and all other warranties, expressed or implied, including but not limited to, implied warranties of merchantability

and fitness for a particular purpose. In no event shall ENCAD be liable for any loss of

profit or other commercial damages, special, incidental or consequential damages, or any

other damages or claims, whatsoever.

This Warranty gives Buyer specific legal rights, and Buyer may also have other rights that

vary from state to state.

This Warranty applies only to printers purchased from ENCAD, or authorized ENCAD

distributors or dealers. The intent of this Warranty is to repair or replace defective Products subjected to normal wear and tear, when operated according to ENCAD instructions.

This Warranty does not cover damage to the Product resulting from the following:

• Accident or negligence.

• Unauthorized modification of the Product.

• Adverse environmental conditions.

• Service of the Product by other than an ENCAD authorized service provider.

• Unauthorized or improper use, including but not limited to:

– Use in applications for which the Product was not designed.

– Using cartridges or ink other than those supplied by ENCAD or authorized

ENCAD resellers.

– Using media other than that supplied by ENCAD or authorized ENCAD

resellers.

– Lubricating any part of the printer.

Internationally: Contact your dealer or distributor for warranty information.

viii

CadJet T-200 Service Manual

Table of Contents

Chapter 1 General Description ............................................................ 1-1

Introduction ............................................................................................................... 1-1

Overview ................................................................................................................... 1-3

Related Publications .......................................................................................... 1-3

Electrostatic Discharge (ESD) Sensitivity ................................................................. 1-3

Warnings, Cautions and Notes ................................................................................. 1-4

Printer Specifications ................................................................................................ 1-5

Contents of this Service Manual ................................................................................ 1-6

Technical Support ..................................................................................................... 1-8

Chapter 2 Theory of Operation ............................................................ 2-1

Introduction ............................................................................................................... 2-1

CadJet T-200 Printer General Block Diagram ............................................................ 2-1

Paper (Media) Axis Drive .......................................................................................... 2-3

The Carriage Axis Drive ............................................................................................. 2-4

Main Printed Wiring Assembly (MPWA) ................................................................... 2-5

Microprocessor .................................................................................................. 2-6

Gate Array ......................................................................................................... 2-6

Memory Circuits ................................................................................................. 2-7

Flash EEPROM ........................................................................................... 2-7

DRAM .......................................................................................................... 2-8

Serial EEPROM ........................................................................................... 2-8

Stepper Motor Controller ..................................................................................... 2-9

Servo Motor Controller ...................................................................................... 2-11

Control Panel ................................................................................................... 2-13

Interface Circuits: Serial & Parallel ................................................................... 2-14

Carriage Assembly Circuits ..................................................................................... 2-15

Display Assembly ................................................................................................... 2-16

Power Supply ......................................................................................................... 2-17

Fan Operation ......................................................................................................... 2-17

Chapter 3 Maintenance ........................................................................ 3-1

Introduction ............................................................................................................... 3-1

Scheduled Maintenance ........................................................................................... 3-1

Cleaning Procedures .......................................................................................... 3-2

External Cleaning ......................................................................................... 3-2

ix

CadJet T-200 Service Manual

Slide Shaft Cleaning ..................................................................................... 3-2

Service Station Cleaning .............................................................................. 3-3

Linear Encoder Strip Cleaning ...................................................................... 3-4

Cartridge Dimples Cleaning .......................................................................... 3-5

Flex Cable Contact Cleaning ........................................................................3-6

Clean and Inspect Stepper Motor Gears....................................................... 3-7

Clean and Inspect MPWA ............................................................................ 3-7

Clean and Inspect Carriage Assembly ......................................................... 3-8

Reseat Connectors on MPWA and Carriage Board ............................................. 3-8

Replace Carriage Bushings .............................................................................. 3-11

Servo Motor Winding Resistance Check ................................................................. 3-12

Stepper Motor Winding Resistance Check .............................................................. 3-13

Banding: Hardware vs Software ............................................................................... 3-14

Common Banding Causes ......................................................................... 3-15

Alignments/Adjustments ......................................................................................... 3-17

Slide Shaft Profile Adjustment .......................................................................... 3-17

Head Height Alignment Procedure .................................................................... 3-20

Paper Skew Adjustment ................................................................................... 3-24

Paper Skew Adjustment Sequence ............................................................ 3-24

Mounting Screw Information ....................................................................... 3-25

Other Functional Requirements .................................................................. 3-28

Adjustment of Pinch Roller Supports .......................................................... 3-29

Visual Verification ................................................................................ 3-29

Observation of Paper Skew at Rear Media Alignment Mark .................. 3-30

Observation of Paper Skew at Front Media Alignment Mark ................. 3-31

Adjustment of the Mounting Screws .................................................... 3-32

Paper Axis Calibration ...................................................................................... 3-33

Deadband Alignments ....................................................................................... 3-35

Color Deadband Alignment ......................................................................... 3-36

Color Calibration ............................................................................................... 3-38

Diagnostics Menu ................................................................................................... 3-40

Clearing the NVRAM ............................................................................................... 3-42

Firmware Download/Upgrading for the PC ............................................................... 3-43

Internal Cabling and Signal Flow Diagrams ............................................................. 3-44

Table of Contents (cont)

Chapter 3 Maintenance (cont)

x

CadJet T-200 Service Manual

Chapter 4 Troubleshooting .................................................................. 4-1

Introduction ............................................................................................................... 4-1

No Power ........................................................................................................... 4-1

Initialization Failure............................................................................................. 4-2

Media Does Not Move ........................................................................................ 4-2

Internal ERROR “Carriage Axis Failure” .............................................................. 4-3

Internal ERROR “Encoder Sensor Failure” .......................................................... 4-5

Internal ERROR “Paper Sensor Failure” .............................................................. 4-5

Internal ERROR “Auto-Sensor Failure” ................................................................4-6

Internal ERROR “MPCB Failure” ......................................................................... 4-6

Unrecognized Cartridges Error ............................................................................ 4-6

Image Skews or Moves ...................................................................................... 4-7

Does Not Print.................................................................................................... 4-7

Ink Cartridge Misfiring ......................................................................................... 4-7

Paper Skewing ................................................................................................... 4-9

Printer Output is Banding (Horizontal) ................................................................ 4-9

Printer Output is Banding (Vertical) .................................................................. 4-11

Printer Output is Banding (Horizontally and Vertically) ...................................... 4-12

Keypad Locked-Up or Not Functioning Properly ............................................... 4-12

Noisy Operation ............................................................................................... 4-13

Line Quality Degraded ...................................................................................... 4-14

Fan Does Not Power Up ................................................................................... 4-15

Media is Not Measured Properly ...................................................................... 4-15

Initialization Troubleshooting ................................................................................... 4-16

Chapter 5 Assembly\Disassembly ...................................................... 5-1

Introduction ............................................................................................................... 5-1

Removing the Right Cover Assembly ......................................................................... 5-2

Removing the MPWA Connectors ............................................................................. 5-4

Removing the MPWA ............................................................................................... 5-5

Removing the Right SidePlate ...................................................................................5-6

Reinstalling the Right SidePlate ................................................................................5-7

Reinstalling the MPWA............................................................................................. 5-7

Reinstalling the MPWA Connectors .......................................................................... 5-7

Table of Contents (cont)

xi

CadJet T-200 Service Manual

Memory Module Removal ..........................................................................................5-8

Memory Module Installation ...................................................................................... 5-9

Reinstalling the Right Cover Assembly ...................................................................... 5-9

Removing the Left Cover ........................................................................................... 5-9

Reinstalling the Left Cover....................................................................................... 5-10

Removing the Servo Motor ...................................................................................... 5-10

Reinstalling the Servo Motor ................................................................................... 5-12

Removing the Display Assembly ............................................................................. 5-13

Reinstalling the Display Assembly .......................................................................... 5-14

Removing the Service Station Assembly ................................................................. 5-14

Reinstalling the Service Station Assembly .............................................................. 5-15

Removing the Carriage Assembly, Carriage Belt and the Frame Tensioner ............. 5-16

Removing the Carriage PWA................................................................................... 5-20

Reinstalling the Carriage PWA................................................................................ 5-21

Remove the Paper Sensor or the Encoder Sensor .................................................. 5-21

Install the Paper Sensor or the Encoder Sensor...................................................... 5-23

Replacing the Carriage Bushings ............................................................................ 5-24

Reinstalling the Carriage Assembly, Carriage Belt and the Frame Tensioner .......... 5-26

Removing the Trailing Cable .................................................................................... 5-28

Reinstalling the Trailing Cable ................................................................................. 5-29

Removing the Power Supply and ON/OFF Switch ................................................... 5-30

Reinstalling the Power Supply and ON/OFF Switch ................................................ 5-32

Remove the Stabilizer Bracket and Encoder Strip ................................................... 5-33

Install the Stabilizer Bracket and Encoder Strip....................................................... 5-34

Disassembly of Plotter Before Removing the Inner Platen Parts .............................. 5-35

Removing the Inner Platen Parts ............................................................................. 5-37

Removing the Stepper Motor ................................................................................... 5-39

Reinstalling the Stepper Motor ................................................................................ 5-41

Reinstalling the Inner Platen Parts .......................................................................... 5-41

Reassembly of Plotter After Reinstalling the Inner Platen Parts............................... 5-43

Removing the Upper Pinch Roller Supports ............................................................. 5-44

Reinstalling the Upper Pinch Roller Supports .......................................................... 5-46

Chapter 6 Parts List .............................................................................. 6-1

Table of Contents (cont)

Chapter 5 Assembly/Disassembly (cont)

xii

CadJet T-200 Service Manual

List of Illustrations

Figure Page

Chapter 1 General Description

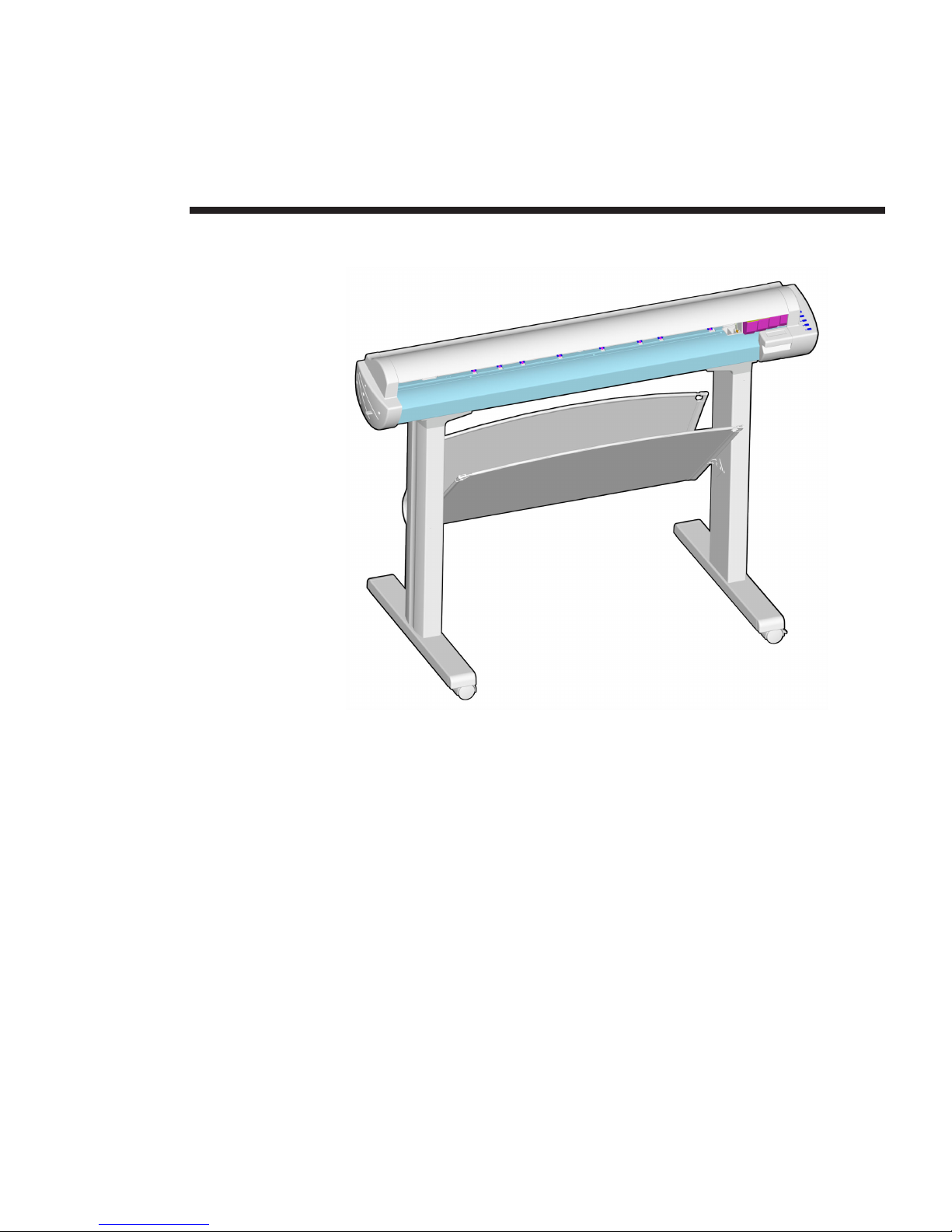

1-1. CadJet T-200 Inkjet Printer/Plotter ................................................................... 1-1

Chapter 2 Theory of Operation

2-1. General Block Diagram ................................................................................... 2-2

2-2. Paper (Media) Axis Drive ................................................................................. 2-3

2-3. Carriage Axis Drive ..........................................................................................2-4

2-4. Main Printed Wiring Assembly ........................................................................ 2-5

2-5. Gate Array ...................................................................................................... 2-6

2-6. Stepper Motor Controller ................................................................................. 2-9

2-7. Servo Motor Controller ................................................................................... 2-11

2-8. Quadrature Signal Generation ....................................................................... 2-12

2-9. Control Panel ................................................................................................ 2-13

2-10. Interface Circuits ........................................................................................... 2-14

2-11. Carriage Assembly Circuits ........................................................................... 2-15

2-12. Display Assembly ......................................................................................... 2-16

Chapter 3 Maintenance

3-1. Encoder Strip Cleaning ................................................................................... 3-5

3-2. Cartridge Dimple Region ..................................................................................3-5

3-3. Flex Cable Contacts ....................................................................................... 3-6

3-4. Main PWA Connection Locations .................................................................... 3-9

3-5. Carriage PWA Connection Locations............................................................. 3-10

3-6. Ribbon Connector Locking Mechanism ......................................................... 3-11

3-7. Servo Motor ................................................................................................... 3-12

3-8. Stepper Motor ............................................................................................... 3-13

3-9. Examples of Banding .................................................................................... 3-14

3-10. Dial Gauge Micrometer Assembly ................................................................. 3-18

3-11. Measurement Positions for Slide Shaft.......................................................... 3-19

3-12. Slide Shaft Profile Adjustment ....................................................................... 3-19

3-13. Carriage Head Height Tolerance .................................................................... 3-20

3-14. Setting Up Tools from Height Gauge Kit ........................................................ 3-21

3-15. Zeroing the Micrometer Gauge ...................................................................... 3-21

xiii

CadJet T-200 Service Manual

List of Illustrations (cont)

Figure Page

Chapter 3 Maintenance (cont)

3-16. Test Cartridge Installed .................................................................................. 3-22

3-17. Pinch Roller Supports Numbering Sequence ................................................. 3-24

3-18. Pinch Roller Support and Mounting Screws ................................................... 3-26

3-19. Correct Positioning of the Spring in the Pinch Roller Support......................... 3-27

3-20. Test for Minimum Acceptance Gap ................................................................ 3-28

3-21. Visual Verification of Gap between Roller and Y-Arm ..................................... 3-29

3-22. Paper Skew Acceptance Range for Rear Media Alignment Mark ................... 3-30

3-23. Paper Skew Acceptance Range for Front Media Alignment Mark .................. 3-31

3-24. Motion of Rollers and Adjustment of Mounting Screws .................................. 3-32

3-25. Paper Axis Test ............................................................................................. 3-34

3-26. Slow Deadband ............................................................................................. 3-35

3-27. Color Calibration ............................................................................................ 3-38

3-28. MPWA Connections Diagram ........................................................................ 3-45

3-29. Carriage PWA Connections Diagram ............................................................. 3-46

Chapter 4 Troubleshooting

4-1. Carriage Board LED D2 and D5 Locations ..................................................... 4-17

Chapter 5 Assembly/Disassembly

5-1. Removal of Right Cover Assembly ................................................................... 5-3

5-2. MPWA Connection and Screw Locations ........................................................ 5-4

5-3. Removal of Right Side Plate ............................................................................ 5-6

5-4. Removal of Left Cover .................................................................................... 5-10

5-5. Removal of the Servo Motor ........................................................................... 5-11

5-6. Compression of Frame Tensioner .................................................................. 5-12

xiv

CadJet T-200 Service Manual

List of Illustrations (cont)

Figure Page

Chapter 5 Assembly/Disassembly (cont)

5-7. Removal of Display Assembly ....................................................................... 5-13

5-8. Service Station Removal ................................................................................ 5-14

5-9. Electronics Cover Removal ............................................................................ 5-16

5-10. Strain Relief Removal/Installation................................................................... 5-17

5-11. Frame Tensioner ........................................................................................... 5-18

5-12. Carriage Belt Clamp ...................................................................................... 5-19

5-13. Carriage PWA Removal/Installation ............................................................... 5-20

5-14. Paper and Encoder Sensor Removal ............................................................. 5-22

5-15. Paper and Encoder Sensor Installation .......................................................... 5-23

5-16. Carriage Bushing Removal ............................................................................ 5-25

5-17. Carriage Bushing Installation ......................................................................... 5-26

5-18. Revealing the Power Supply Screws ............................................................. 5-31

5-19. Inner Platen Parts ......................................................................................... 5-32

5-20. Stabilizer Bracket Removal............................................................................ 5-34

5-21. Disassembly of Plotter Prior to Removing the Inner Platen Parts ................... 5-36

5-22. Removal of Lower Drive Shaft Screws ............................................................ 5-37

5-23. Removing the Foam Block ............................................................................ 5-38

5-24. Lower Drive Shaft Assembly and Stepper Motor Assembly ............................ 5-40

5-25. Removing the Upper Pinch Roller Support ..................................................... 5-45

Chapter 6 Parts List

6-1. Left Side Parts Breakdown .............................................................................. 6-3

6-2. Platen and Above Parts Breakdown ................................................................ 6-5

6-3. Right Side Parts Breakdown ........................................................................... 6-7

6-4. Inner Platen Parts Breakdown ......................................................................... 6-9

6-5. Carriage Assembly Parts Breakdown ............................................................ 6-11

6-6. Service Station Assembly Parts Breakdown .................................................. 6-13

xv

CadJet T-200 Service Manual

List of Tables

Table Page

Chapter 1 General Description

Chapter 2 Theory of Operation

Chapter 3 Maintenance

3-1. Main PWA Connections Table ......................................................................... 3-9

3-2. Carriage PWA Connections Table .................................................................. 3-10

Chapter 4 Troubleshooting

4-1. Troubleshooting Table ...................................................................................... 4-1

Chapter 5 Assembly/Disassembly

Chapter 6 Parts List

1

1-1

General Description

Figure 1-1. CadJet T-200 Inkjet Printer/Plotter.

Introduction

This manual provides service information for the ENCAD®, Inc. 36

inch CadJet T-200 Color Inkjet Printer/Plotters.

It is written for service personnel who possess analog and digital

circuitry experience. Chapter 2, Theory of Operation, should be read

and thoroughly understood before troubleshooting/calibrating the

printers.

The printers support both pre-cut and roll media. Media size is auto-

matically determined and hardclip limits are set accordingly. Pre-cut

General Description 1-2

CadJet T-200 Service Manual

media uses different maximum plotting areas than roll media. See the

Printer Specifications in the User Guide for more details on the media

size printable area.

A Centronics parallel connection is provided to interface with the host

computer. Network connections are made possible through the optional

SEH print server. Commands sent from the host computer can be in

several forms including HP-GL/2, HP-RTL and EN-RTL formats.

Drivers are supplied to support Windows-based PC’s (3.XX, 95/98, and

NT) as well as Macintosh and Power PC computers.

These printers expand upon ENCAD’s tradition of delivering fast, high-

quality color or monochrome graphics for a variety of applications.

ENCAD has made significant advances in designing these printers to

respond to and anticipate our customers’ needs. Principal features are

summarized below.

Locally or Remotely Configured via Host Computer

Take-Up Basket

PowerPC 33 MHz Microprocessor

8 User Configurable Settings

208 Jet Foam Filled Ink Cartridges

Ink Priming System

Snap On Ink Cartridge Caddies for longer print times between refilling

Smart Cartridges

Odometer Function

Electronic Jet Compensation

Fast CAD printing speeds

General Description 1-3

CadJet T-200 Service Manual

Overview

Printers draw according to instructions issued from a “host” computer.

Every printer is engineered to understand a specific set of instructions

and to execute each instruction in a precise manner. In addition, most

printers are designed to execute predetermined characters automati-

cally without a specific line-by-line instruction from the program.

These characters are part of the printer’s permanent memory.

Related Publications

The following publication contains additional information which may

be useful in servicing the ENCAD, Inc. CadJet T-200 Color Inkjet

Printers:

• ENCAD Quick Start Guide for the CadJet T-200,

P/N 217892-xx

• ENCAD CadJet T-200 CD-ROM,

P/N 217893-xx

Copies of these and other ENCAD, Inc. publications may be obtained

by contacting your nearest authorized ENCAD, Inc. dealer or by

contacting ENCAD’s Technical Support and Service Department.

Electrostatic Discharge (ESD) Sensitivity

All PWAs (Printed Wiring Assemblies) associated with the printers

have components sensitive to ESD (electrostatic discharge). Care must

be taken to avoid damage to any of the components by following

current ESD handling procedures and practices.

Always use an approved ESD grounding strap when handling or

working with PWAs.

General Description 1-4

CadJet T-200 Service Manual

Warnings, Cautions and Notes

Warnings, cautions and notes are used when additional information,

instructions or care should be observed. In this manual warnings,

cautions and notes precede the text to which each applies. The defini-

tion of each is provided below.

WARNINGS - Warnings are used to stress that the following steps or

procedures has the potential to cause serious harm or death to service

personnel. Extreme care should be observed when following the proce-

dures and to exercise standard safety procedures. They are indicated

by:

Followed by a paragraph describing the concern.

CAUTIONS - Cautions depict that the following steps or procedures can

cause damage to the equipment if not properly followed. Extreme care

should be observed when following the procedures and to exercise

standard safety procedures. They are indicated by:

CAUTION

Followed by a paragraph describing the concern.

NOTES - Notes are placed before a procedure to inform the service

personnel of specific details to improve quality, to give reminders of

interrelated parts and to provide other helpful information. They are

indicated by:

NOTE

Followed by a paragraph describing the concern.

General Description 1-5

CadJet T-200 Service Manual

Printer Specifications

The specifications and performance characteristics of the CadJet

T-200 Color Inkjet Printers are as follows:

Max Printing Area:

Norm 34.8”

884 mm

Extend 35.61”

904 mm

Language Emulation:

HP-RTL

EN-RTL

HP GL/2

Buffer:

32 MB installed

upgradeable to 128 MB

Power Requirements:

Input Voltage:

90-246 VAC

47-63 Hz

Output Power:

20 W idle

50 W typical

100 W maximum

Accuracy:

Dot Placement: 0.0017

+/- 0.0008

Cut sheet feed accuracy,

edge shift: +/- 0.065

inches as measured over

36 inches

Resolution:

600x600 dpi or

300x600 dpi

Interface:

Centronics parallel

(IEEE 1284)

Network: via 100 Base T

Print Server

Certifications:

Safety

CSA, CSE/NRTL

(equivalent to UL1950)

TUV GS

EN 50 082-1

EN 60 950

UL1950

NOM-019-SCFI-1993

IEC 950

AS/NZS 3260

EMI

FCC Class B

CSA C108.8

EN 55 022 Class B

CISPR 22- Class B

AS/NZS 3548

GB9254-98

General Description 1-6

CadJet T-200 Service Manual

Contents of this Service Manual

Figures are used in this manual to clarify procedures. They are for

illustrative purposes only and may not necessarily be drawn to scale.

Material in this manual may be repeated in various chapters so that

each chapter can “stand alone”. This allows information to be located

without having to refer back and forth between chapters.

Figures and tables are easily located and cross-referenced, and are listed

in the front of the manual under List of Illustrations and List of Tables.

This manual is divided into six chapters as:

Chapter 1 GENERAL DESCRIPTION - Contains a general

description of the ENCAD CadJet T-200 printer. This

includes printer specifications, and related materials. Also

included is a description of the use of Warnings, Cautions

and Notes as used in this manual and chapter contents.

Chapter 2 THEORY OF OPERATION - Functional

descriptions of the overall printer and major assemblies are

contained in this chapter.

Environment:

Operating:

41° to 85° F

(5° to 30° C)

20% to 80% RH

non-condensing

Storage:

-5° to 140° F

(-21° to 60° C)

5% to 80% RH

non-condensing

Weight:

70 lbs(31 kg)

Dimensions:

Height 48” (1210 mm)

Width 54” (1370 mm)

Depth 30” (710 mm)

General Description 1-7

CadJet T-200 Service Manual

Chapter 3 MAINTENANCE - This chapter covers the

scheduled maintenance, cleaning procedures and

alignment/adjustments recommended to perform on the

printers. Diagnostics and a signal flow diagram are also

listed.

Chapter 4 TROUBLESHOOTING - A table containing

problems that could occur and possible causes and repairs

is found in this chapter. This table is not intended to be a

complete listing of troubleshooting procedures. It will

isolate the problem down to the lowest replacable

assembly. If the problem happens to be the wiring

between assemblies, standard troubleshooting techniques

will have to be implemented to correct the problem.

Chapter 5 ASSEMBLY/DISASSEMBLY - Contains detailed

procedures to remove and replace printer parts and

assemblies.

Chapter 6 PARTS LIST - Contains a complete listing of all

field replacable parts and assemblies for the color inkjet

printers. Illustrated parts breakdown drawings are

included to help clarify and identify parts for ordering.

Special kits and adjustment jigs may also be required.

ORIENTATION - Instructions in this manual are based on the

assumption that the service person is facing the front of the printer.

References to top view, back view, and so forth are consistent with

this engineering standard. References to the X Axis and Y Axis

(Paper Axis and Carrier Axis, respectively) follow the standard of

AutoCAD™ absolute coordinates: up and down for X, left to right for

Y.

General Description 1-8

CadJet T-200 Service Manual

Technical Support

ENCAD offers full technical support and service for its various prod-

ucts. If you are unable to find the answer to your question in either the

User’s Guide, Service Manual, or other related publications, check out

ENCAD’s Knowledge Base located on ENCAD’s website support:

ENCAD Website: http://www.encad.com

Additional information is available though our Technical Support and

Service Department’s Help Desk.

ENCAD, Inc.

Technical Support & Service Dept.

6059 Cornerstone Court West

San Diego, CA 92121

Help Desk Telephone: (858) 452-4350 or

(877) ENCAD-TS (362-2387)

Help Desk FAX: (858) 558-4672

International users contact your local ENCAD service provider. See

details on your ENCAD registration card.

2

2-1

Introduction

This chapter explains the mechanical and electrical theory of operation

of the ENCAD CadJet T-200 color inkjet printers.

The CadJet T-200 is a PowerPC 33MHz microprocessor-based digital

printer that receives plotting instructions from a host computer

through the Centronics parallel interface. This interface is either

connected directly to a computer or through a network print server.

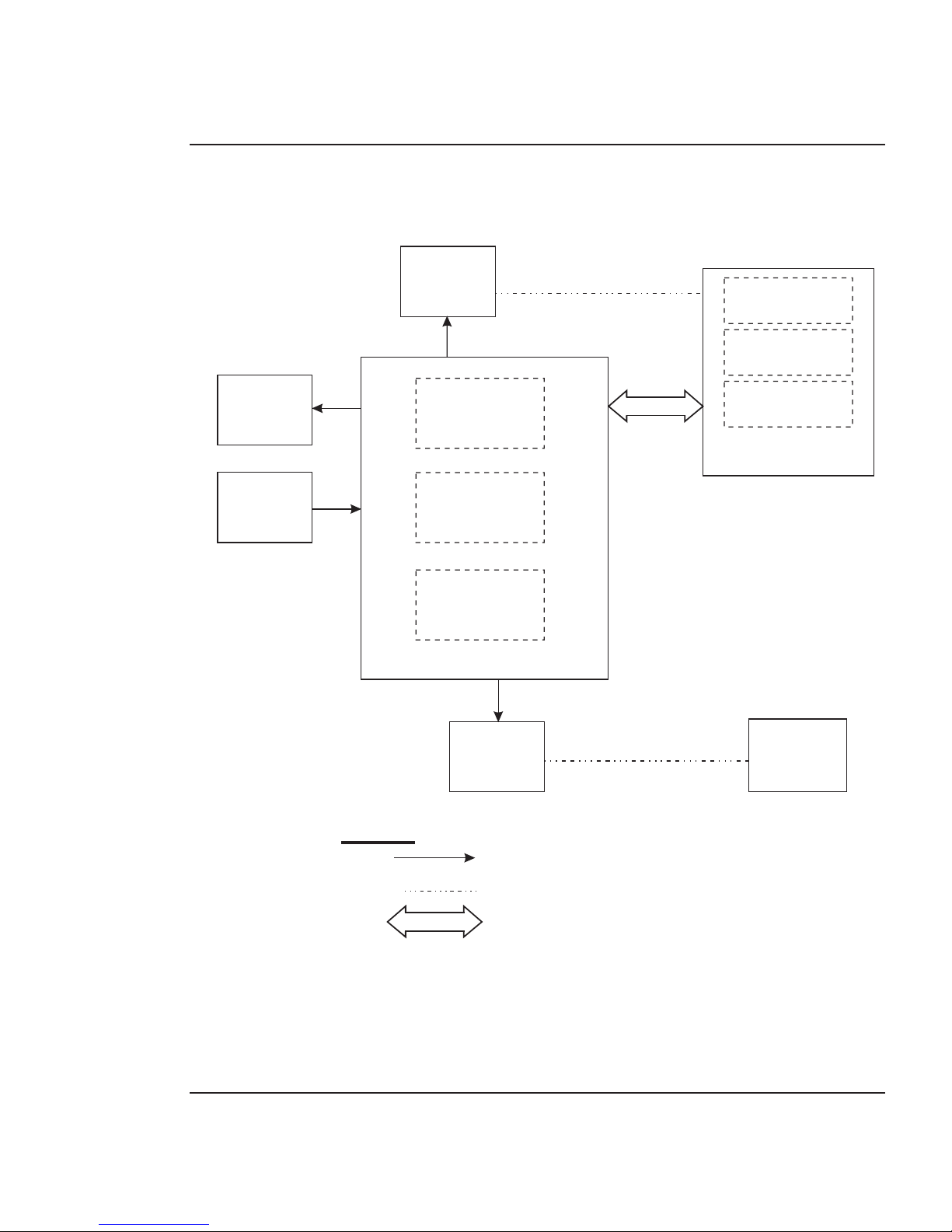

CadJet T-200 Printers General Block

Diagram

Figure 2-1 illustrates the major functional areas of the printers.

The CadJet T-200 printers consist of two mechanical assemblies:

1. Paper (Media) Axis Drive

2. Carriage Axis Drive

and four main electrical assemblies:

1. MPWA (Main Printed Wiring Assembly)

2. Carriage Assembly

3. Display Assembly

4. Power Supply

Theory of Operation

Theory of Operation 2-2

CadJet T-200 Service Manual

CARRIAGE AXIS DRIVE

ELECTRICAL CONNECTION

MECHANICAL CONNECTION

MAIN DATA BUS

MPWA

DISPLAY

CIRCUITS

STEPPER

MOTOR

SERVO

MOTOR

MICRO-

PROCESSOR

MEMORY

CIRCUITS

GATE

ARRAY

CARRIAGE

ASSEMBLY

CARRIAGE

PWA

PAPER

SENSOR

LOWER

DRIVE

ASSEMBLY

LEGEND

ENCODER

SENSOR

PAPER AXIS DRIVE

POWER

SUPPLY

Figure 2-1. General Block Diagram.

Theory of Operation 2-3

CadJet T-200 Service Manual

Paper (Media) Axis Drive

LOWER ROLLER SHAFT ASSY

PINCH ROLLERS

STEPPER MOTOR

REDUCTION GEAR

Figure 2-2. Paper (Media) Axis Drive.

The Paper (Media) Axis Drive moves the plotting media in a direction

perpendicular to the length of the printer. This friction drive utilizes a

micro-step drive technology and consists of a stepper motor, reduction

gears, lower drive shaft assembly, and pinch rollers. This can be seen

in Figure 2-2.

The reduction gear meshes the stepper motor to the lower drive shaft

assembly which allows the media to advance or retract. The purpose of

the pinch rollers is to apply pressure to the media onto the drive shaft

assembly to reduce the chance of slipping.

Misaligned pinch wheels is a main cause of skewing the media. When

skewing occurs, pinch roller alignment may be required.

Theory of Operation 2-4

CadJet T-200 Service Manual

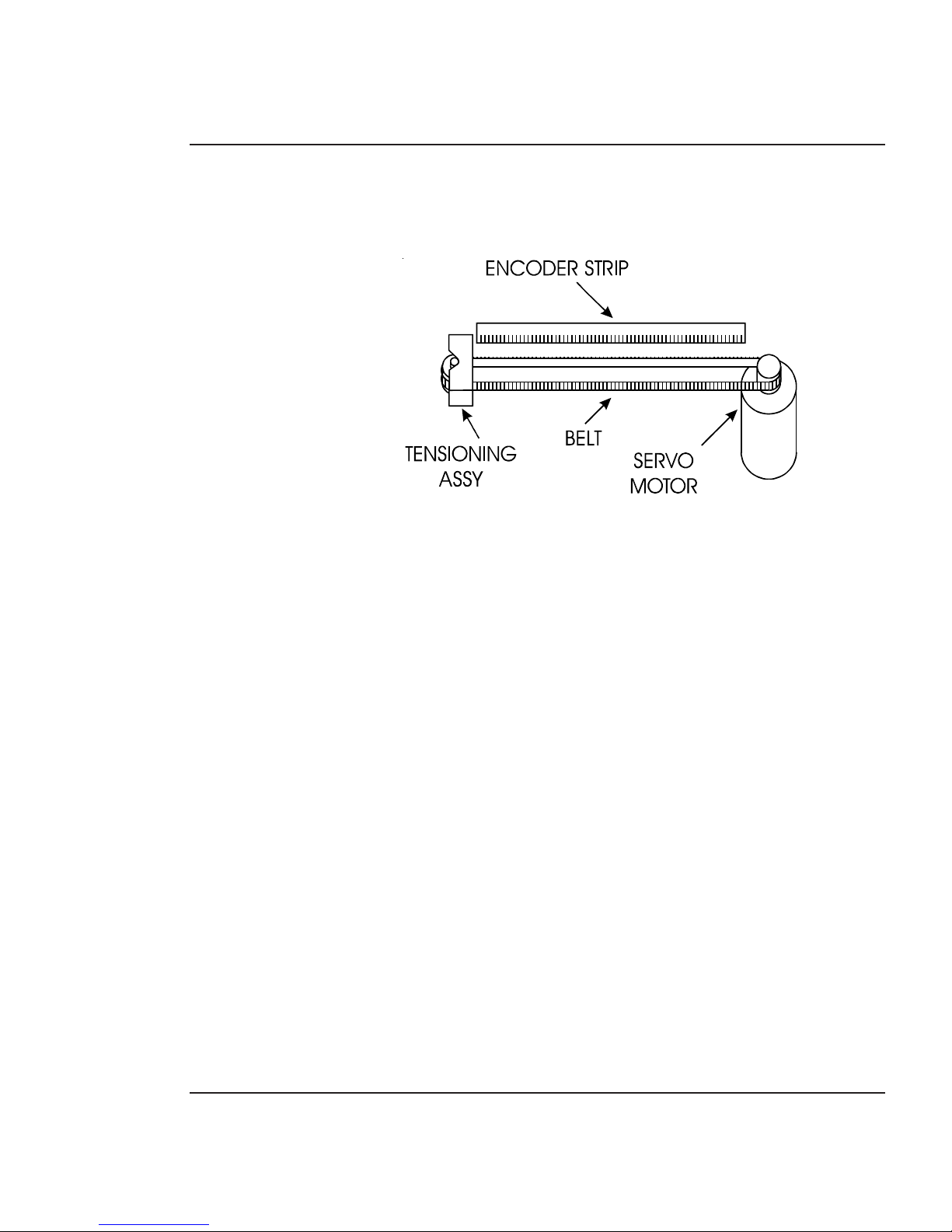

The Carriage Axis Drive

Figure 2-3. Carriage Axis Drive.

The Carriage Axis Drive moves the printer’s carriage assembly along

the length of the printer. The drive consists of a servo motor, linear

encoder strip, drive belt, and tensioning assembly. These items are

illustrated in Figure 2-3.

The servo motor, drive belt, and tensioning assembly are the compo-

nents that actually drive the carriage assembly. The servo motor drives

the belt back and forth allowing the attached carriage assembly to be

repositioned as required. The tensioning assembly is spring controlled

and allows the proper amount of tension on the belt.

The linear optical encoder strip is used to obtain the printers accuracy

along the axis of the printer. It is made with 150 parallel lines per inch

etched into it. By utilizing two optical encoder sensors that are slightly

off set from each other, and reading the leading and trailing edges of the

lines, a resolution of 600 dpi can be obtained.

The stepper and servo motors are controlled from the main printed

wiring assembly by the microprocessor.

Theory of Operation 2-5

CadJet T-200 Service Manual

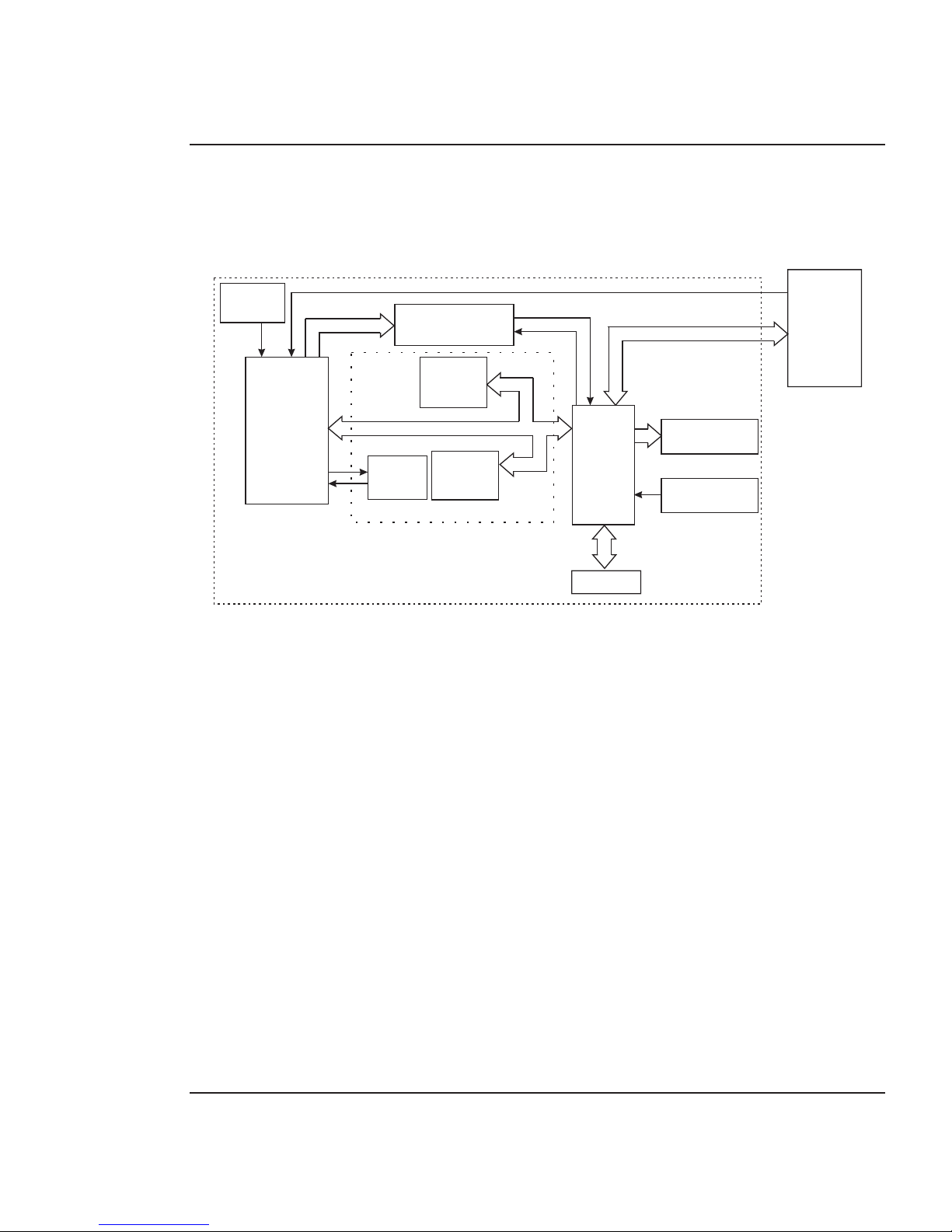

Main Printed Wiring Assembly (MPWA)

SERIAL

EEPROM

MICRO-

PROCESSOR

(CPU)

OSC

Y1

STEPPER MOTOR

CONTROLLER

FLASH

EEPROM

DYNAMIC

RAM

GATE

ARRAY

SERVO MOTOR

CONTROLLER

CARRIAGE

PWA

PARALLEL

DATA BUS

MEMORY CIRCUITS

CONTROL

PANEL

Figure 2-4. Main Printed Wiring Assembly.

The Main Printed Wiring Assembly (MPWA) consists of seven func-

tional areas:

1. Microprocessor (CPU)

2. Gate Array

3. Memory Circuits

4. Stepper Motor Controller

5. Servo Motor Controller

6. Control Panel

7. Interface Circuits: Parallel

Theory of Operation 2-6

CadJet T-200 Service Manual

Microprocessor

The microprocessor (an IBM PowerPC) is the central processor unit

which supervises system functions, executes the printer firmware,

manipulates data, and controls input/output data busses. It has two

built-in serial ports, a two channel DMA (Direct Memory Access)

controller, a timer module, clock generator, and an on-board chip select

generator. One serial port connects to the Mini-DIN connector which

can be used to communicate with the host computer; the other serial

port interfaces to the Control Panel. One DMA channel supplies data to

the gate array for jet firing; the other DMA channel is used to receive

data through the parallel port via the gate array, or the serial port

when using a high speed serial mode. One timer generates a servo

interrupt every millisecond; the other is used for timing the Stepper

Motor.

The system is timed by a 33MHz system clock from an oscillator (Y1).

The chip select generator is programmed to generate chip selects at the

appropriate addresses, with the appropriate data size (byte, word) and

with the appropriate number of wait states.

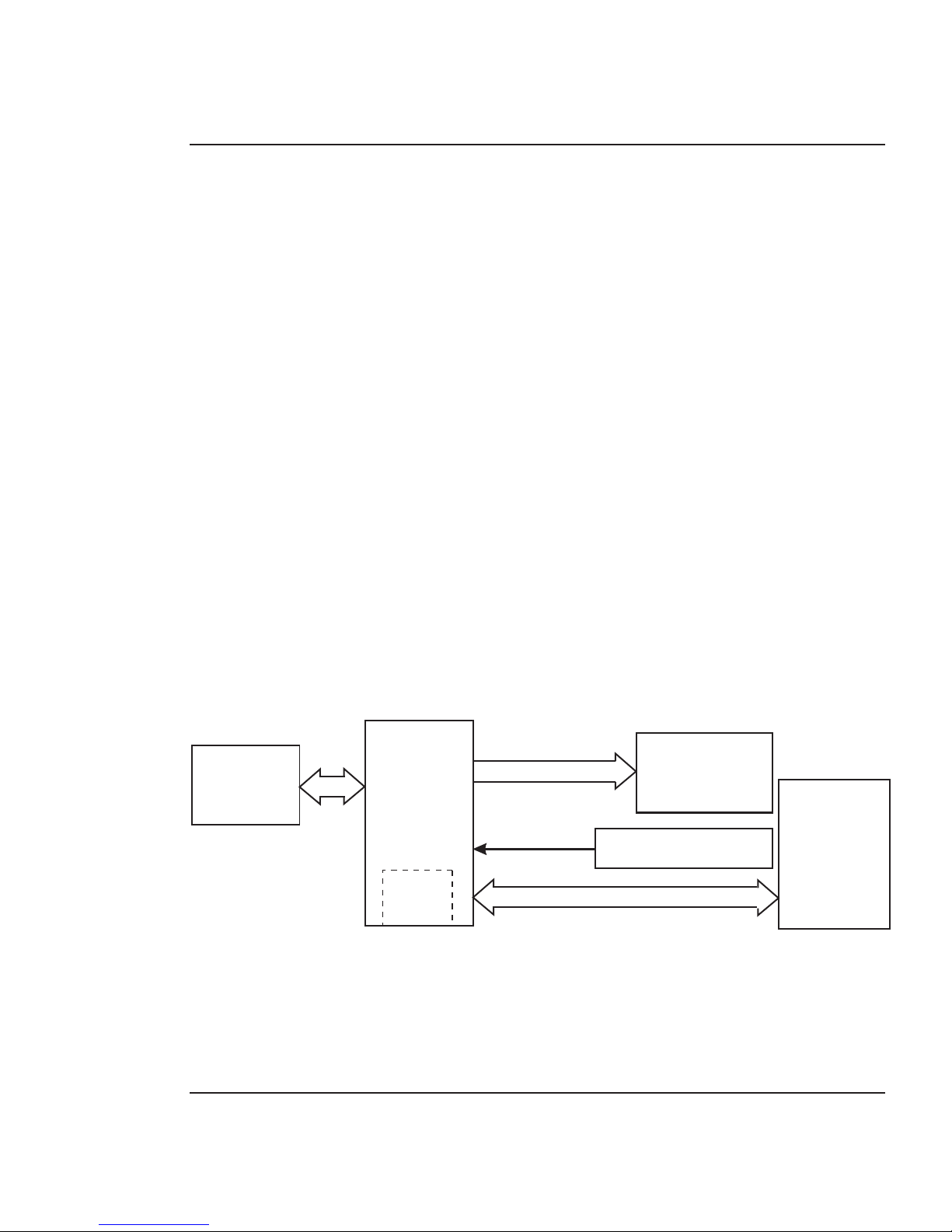

Gate Array

PARALLEL

PORT

GATE

ARRAY

SERVO

CONTROLLER

TO

CARRIAGE

PWA

STATIC

RAM

MICROSWITCHES

Figure 2-5. Gate Array.

Theory of Operation 2-7

CadJet T-200 Service Manual

The gate array contains the hardware logic for dot firing, monitoring

changes in the Carriage Assembly position, controlling DMA through

the parallel port, receiving commands from the microswitches and

generating the PWM (Pulse Width Modulation) waveforms for the

servo controller.

The gate array is a Xilinx device. It is a static RAM-based field

programmable gate array. This means that the logic that it imple-

ments is determined by configuration information in internal RAM

storage. Each time power is turned on, this information must be

downloaded from the system ROM. This type of gate array allows for

the flexibility of upgrading the logic by simply downloading the new

system software.

Memory Circuits

Memory is used to retain large amounts of information. This infor-

mation is stored in the device memory in the form of binary bits.

Printer memory consists of Flash, DRAM, and EEPROM.

Maximum installable memory is as follows:

DRAM = 32 MB

Flash = 1 MB

Serial EEPROM = 1KB

Flash EEPROM

Flash EEPROM is Electrically Erasable, Programmable, Read Only

Memory used to store instructions and data constants which the

microprocessor can access and interpret, with no loss of information

when power is off.

Loading...

Loading...