North America Only

Instruction Manual

February 2015

7 Series Flame Arrestor

Table of Contents

Introduction .................................................................. 1

Specifications .............................................................. 2

Principle of Operation .................................................. 3

Factors Affecting Flame Arrestor Performance ........... 3

Installation ................................................................... 5

Maintenance ................................................................ 6

Recommended Spare Parts ...................................... 10

Parts Ordering ........................................................... 10

Parts List....................................................................10

7 Series

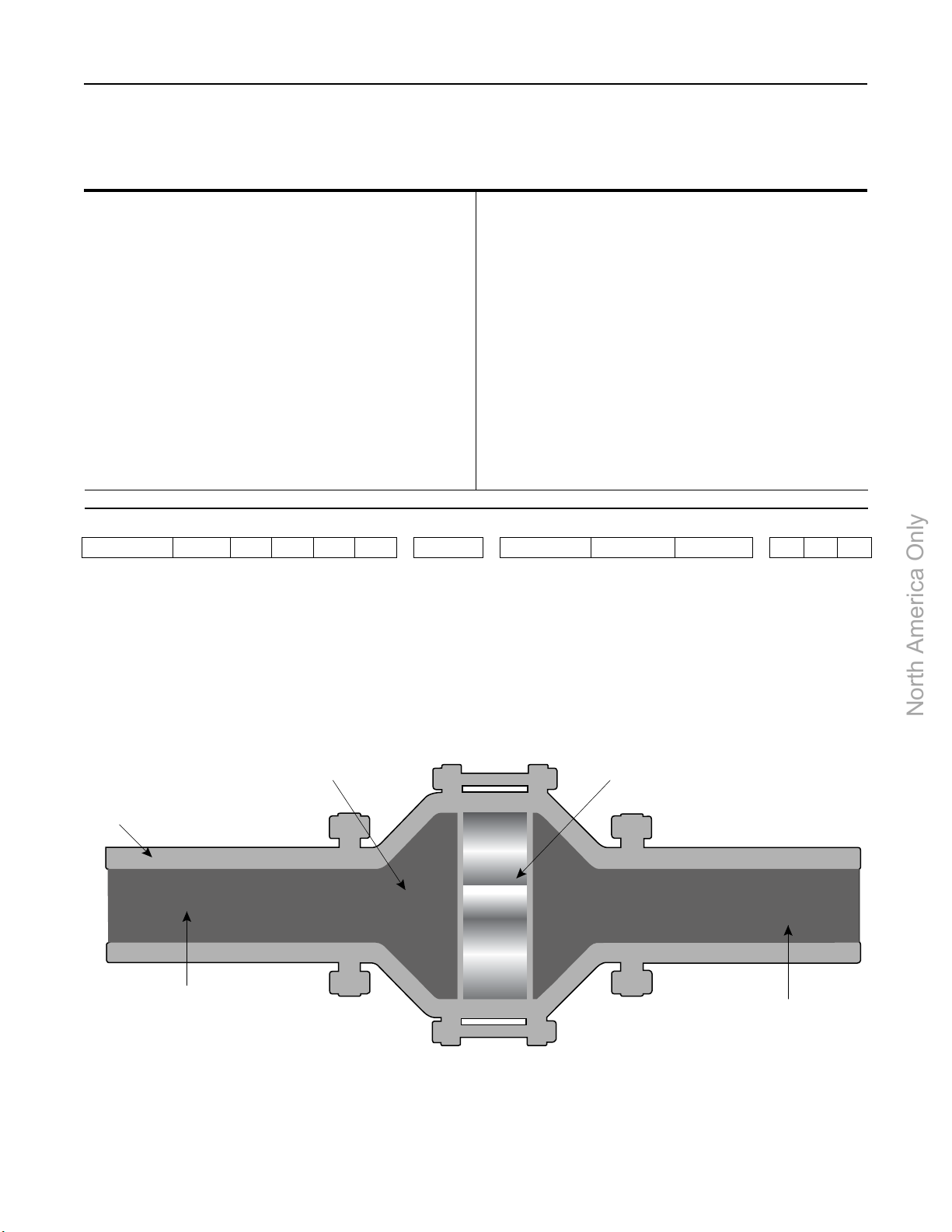

Figure 1. 7 Series Flame Arrestor

!

WARNING

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion,

re and/or chemical contamination

causing property damage and personal

injury or death.

Enardo ame arrestors must be installed,

operated and maintained in accordance

with federal, state and local codes, rules

and regulations and Emerson Process

Management Regulator Technologies

Tulsa, LLC (EmersonTM) instructions.

Call a quali ed service person to service

the unit. Installation, operation and

maintenance procedures performed

by unquali ed person may result

in improper adjustment and unsafe

operation. Either condition may result in

equipment damage or personal injury.

Only a quali ed person shall install or

service the 7 Series ame arrestor.

Introduction

Scope of the Manual

This Instruction Manual provides speci cations,

installation and maintenance instructions and parts

ordering information for the 7 Series ame arrestor.

Product Description

7 Series ame arrestors are designed to stop the

propagation of con ned low pressure de agration.

The 7 Series is typically used for end-of-line and near-

end-of-line applications when the system operating

pressure is near atmospheric levels and when there is

minimal probability of a ame stabilizing on the ame

arrestor element for an extended period.

Designed with anged connections, this arrestor

allows removal of the ame cell element for easy

cleaning and replacement without removing the

arrestor body from the pipe connection. Standard

housing construction is aluminum, carbon steel or

D103829X012

www.enardo.com

North America Only

7 Series

Specications

The Specications section lists the specications for the 7 Series. Specication is stamped on the nameplate

attached to the ame arrestor.

Available Construction

See Table 1 and Figure 2

Gas Group

B, C and D

Flange Size and Rating

1 to 36 in. / 25 to 900 mm

CL150 FF and RF

Housing Size

Pipe Length

See Table 4

Housing Material

Aluminum, Carbon steel, 304 Stainless steel,

316 Stainless steel and Hastelloy

Cell Material

Aluminum, 304 Stainless steel,

316 Stainless steel and Hastelloy

4 to 72 in. / 100 to 1800 mm

Temperature Rating of Gaskets

(1)

Fiber Gaskets (standard): 450°F / 232°C

Graphite Gaskets (Optional): Higher temperature

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

7 / - -

Blank = Concentric

E = Eccentric

7 Series Housing

Size

04 = 4 in.

through

72 = 72 in.

Figure 2. 7 Series Flame Arrestor Available Constructions and Model Numbering System

Connection

Size

01 = 1 in.

through

36 = 36 in.

NEC Housing

Gas Group

B

C

D

Material

A = Aluminum

C = Carbon steel

4 = 304 SST

6 = 316 SST

H = Hastelloy

E = Exotic

A = Aluminum

4 = 304 SST

6 = 316 SST

H = Hastelloy

®

E = Exotic

Element

Material

Connection

F = Flat face

R = Raised

®

Type

ange

face

ange

®

®

Options

1 = Drain Port

2 = Pressure Tap

3 = Temperature

Probe Tap

4 = Miscellaneous

5 = Protective

Coating

6 = Special

Feature

FLAME STABILIZED ON

ARRESTOR ELEMENT

PIPING

EXPOSED SIDE

Hastelloy® is a mark owned by Haynes International, Inc.

2

Figure 3. Flame Arrestor Operation

FLAME ARRESTOR ELEMENT ABSORBS

AND QUENCHES FLAME FRONT

PROTECTED SIDE

North America Only

7 Series

Table 1. 7 Series Available Construction

7 SERIES IN-LINE FLAME ARRESTOR CARBON STEEL AND STAINLESS STEEL HOUSINGS CONSTRUCTION

Model

70401 1 25 4 100

70402 2 50 4 100

70602 2 50 6 150

70802 2 50 8 200

70603 3 75 6 150

70803 3 75 8 200

70804 4 100 8 200

71006 6 150 10 250

71206 6 150 12 300

71408 8 200 14 350

71608 8 200 16 400

71810 10 250 18 450

72010 10 250 20 500

72212 12 300 22 550

72412 12 300 24 600

In. mm In. mm

Flange Size Housing Size

7 SERIES IN-LINE FLAME ARRESTOR ALUMINUM HOUSING CONSTRUCTION

Model

70802 2 50 8 200

70803 3 75 8 200

70804 4 100 8 200

71006 6 150 10 250

71206 6 150 12 300

71408 8 200 14 350

71608 8 200 16 400

72010 10 250 20 500

72212 12 300 22 550

72412 12 300 24 600

In. mm In. mm

Flange Size Housing Size

stainless steel. The element is available in stainless

steel. Special material and protective coating are

available on request.

Principle of Operation

Flame arrestor allows gas to pass though it but stops

ame in order to prevent a larger re of explosion.

Arrestor prevents ame by absorbing and dissipating

the heat from ame as it attempts to travel through the

spiral wound crimped ribbon ame cells. These cells

allow maximum ow with maximum protection.

Factors Affecting Flame

Arrestor Performance

Gas Group

!

WARNING

Methanol is classied by the National

Electrical Code (NEC) as a Group-D

vapor. However, our lab tests indicate

that methanol exhibits characteristics

unlike other Group-D vapors under

certain conditions. We therefore

recommend that an arrestor rated

for Group-C vapors be specied for

methanol service.

3

North America Only

7 Series

NATIONAL ELECTRICAL CODE (NEC)

Group B 0.011 0.28 Hydrogen

Group C 0.026 0.65 Ethylene

Group D 0.035 0.90 Propane

GAS GROUP

D 15.4 106

D 15.4 106 5 minutes (all other Group-D)

C 15.4 106 5 minutes

B 15.4 106 2 minutes

Table 2. Maximum Experimental Safe Gap (MESG)

MESG

In. mm

Table 3. 7 Series Flame Arrestor Endurance Burn Time

MAXIMUM INITIAL PRESSURE

psia kPa

30 minutes (Steel and Stainless steel models up to

TEST GAS LIST

ENDURANCE BURN TIME

12 in. and under)

The type of gas in the system determines its gas

grouping and therefore predetermines the type of

arrestor element required. The element must be

designed to accommodate the specic gas group that

could possibly ignite and propagate in the system. The

more explosive gases require the ame cell to absorb

the heat more quickly and efciently. The National

Electrical Code (NEC) groups gases into A, B, C, D

and G.M. categories depending on the Maximum

Experimental Safe Gap (MESG) of the gas.

Maximum Experimental Safe Gap

(MESG)

!

WARNING

Verify that the Flame Arrestor being

installed has the appropriate gas group

rating for your process. This information

is shown on the nameplate attached to

the element housing. Do not remove or

alter this nameplate.

The measurement of the maximum gap between two

equatorial anges on a metal sphere that will prevent

a ame from being transmitted from the sphere to the

surrounding ammable mixture. MESG is dependent

on gas composition. The stoichiometric mixture (the

ideal air/fuel ratio for the most efcient combustion)

is used to determine the minimum MESG for a

given gas. See Table 2 for the MESG per gas group.

Maximum Initial Operating Pressure

This is the pressure of the system at or near static

ow conditions. High pressure deagration can occur

more easily at higher system operating pressures than

at pressures near atmospheric. Elevated pressures

condense the ignitable gas giving the ame more

matter and energy to release thereby boosting the

ame heat intensity. Verify that your system pressure

at or near static ow conditions does not exceed the

maximum pressure shown on the arrestor’s name tag.

Endurance Burn Time

!

WARNING

Unlimited burning should not be allowed

in any ame arrestor, regardless of its

burn time rating. If burning can occur for

a period exceeding 2 minutes starting at

ambient temperature, it is recommended

that a temperature alarm and shutdown

system be installed.

Endurance burn time is the time it takes for a stabilized

ame, at greatest heat saturation conditions, to

heat the arrestor element above the auto-ignition

temperature of the process gas stream resulting in

ame propagation through the arrestor. See Table 3 for

the 7 Series endurance burning time.

4

North America Only

Maximum length of pipe between the

ame arrestor and the ignition source

without bends or other obstructions.

Maximum length of pipe between

the ame arrestor and the ignition

source with a maximum of one 90°

bend. Multiple bends or any additional

obstructions are not recommended.

7 Series

Table 4. 7 Series Pipe Length Rules

GAS GROUP “B” GAS GROUP “C” GAS GROUP “D”

4 ft. / 1.2 m., open ended pipe 6 ft. / 2 m., open ended pipe 20 ft. / 6 m.

Not Recommended With a Bend. 6 ft. / 2 m., open ended pipe 20 ft. / 6 m.

Pipe Lengths

Extended lengths of pipe allow the ame to advance

into more severe states of ame propagation such as

high pressure deagration or detonations. 7 Series

Flame Arrestors should be installed in accordance with

the Table 4.

Bends and/or Flow Obstructions

CAUTION

For maximum safety, avoid bends

and ow obstructions within 10 pipe

diameters on the protected side of the

ame arrestor.

Bends in piping, pipe expansions and/or contractions,

valves, orice plates or ow obstructing devices of

any kind contribute to turbulent ow. Turbulent ow

enhances mixing of the combustible gases, greatly

increasing the combustion intensity. This can result in

increased ame speeds, higher ame temperatures

and higher ame front pressures than would occur in

normal ow conditions.

Installation

!

WARNING

Always make sure that the system is

at atmospheric pressure and there is

no ignitable gas that could ash when

either installing or maintaining the unit.

Connection

Enardo ame arrestors are normally provided with

CL150 raised or at face anges. Other ange

patterns are available upon request. Make sure the

companion anges installed in adjacent piping match

the anges on the ame arrestor.

Standard compressed ber gaskets that withstands

temperatures of 450°F / 232°C are standard. Graphite

gaskets with higher temperature ratings are available

as an option.

Positioning

CAUTION

The ame arrestor is tted with lugs

for lifting the element assembly during

servicing operations. These lugs are

not intended for lifting the entire unit

during installation. Damage to the ame

arrestor may result from improper

lifting. Heavy units should be lifted

using appropriately rated Nylon (PA)

straps rigged on the outside of the

tension studs.

The ame arrestor should be positioned such that the

element is accessible for removal. The tension studs

are supplied with jacking nuts on one half of the bolting

circumference. Install the unit so that the jacking nuts

(on the inside of the studs) are positioned on the

opposite side from the direction that the element

assembly will be removed.

Models that have drain plugs are designed for

horizontal installation and should be installed with the

drain plugs aligned at the bottom of the unit. Models

that have pressure taps are designed to allow pressure

gauges to be installed on both sides of the ame cell

assembly to determine blockage. The pressure taps

should be aligned at the top to allow easy viewing

of the gauges. Units that are equipped with optional

internal cleaning systems should be connected to a

source of cleaning media such as water, steam or

other suitable solvent.

Flow Direction

The Enardo ame arrestor is bi-directional and can be

installed either vertically or horizontally. Consideration

should be given to non-symmetrical assemblies that

5

North America Only

7 Series

include features such as clean-out ports, temperature

monitoring device or other options that might have

a preferred installation direction to suit the needs of

the customer.

Piping Expansions and Reductions

Adjacent to Flame Arrestors

!

WARNING

No instrument, tubing or other device

whatsoever shall circumvent the

ame arrestor in such a manner to

allow a ame path to exist around

the ame element of the arrestor.

When instrumentation is installed in

such a manner that it creates a path

circumventing the ame element of an

arrestor, measures must be taken to

prevent passage of ame through the

instrumentation device and/or system.

Instrumentation must be capable

of withstanding the maximum and

minimum pressures and temperatures to

which the device may be exposed.

An Enardo ame arrestor may be installed in any

vapor control line that is smaller than or equal

to the nominal pipe diameter of the arrestor’s

connection anges.

When it is necessary to increase the diameter of the

piping on the downstream side of the ame arrestor,

a length of pipe at least 120 pipe diameters must

be installed between the ame arrestor and the

expansion. A pipe diameter is considered as the inside

diameter of pipe having a nominal size equal to the

ame arrestor’s connecting anges.

Maintenance

3. Inspect the ame cell with a calibrated pin gauge

to ensure maximum crimp size openings do not

exceed the following values for their respective

gas group:

• Explosion Group D – 0.051 in. / 1.3 mm

• Explosion Group C – 0.038 in. / 0.965 mm

• Explosion Group B – 0.017 in. / 0.432 mm

4. If any damage is noted, or crimp openings

exceed maximum size allowable, replace the

element assembly.

5. Keep the element openings clean to prevent

loss of efciency in absorbing heat. Remove the

element assembly and clean the elements to

prevent the openings from becoming clogged

with particulate matter. Clean the element with a

suitable cleaning media (solvent, soap, water or

steam) then blow dry using compressed air. Be

careful not to damage or dent the cell openings

as this would hamper the effectiveness of the unit.

Do not clean the arrestor elements by rodding to

remove blockages, as this practice will damage

the elements and seriously impair the arrestor’s

performance. If the arrestor element cannot be

cleaned satisfactorily, replace it.

6. For best cleaning results, use a high pressure

sprayer with spray wand (1500 to 3000 psig /

103 to 207 bar) to clean the entire element

surface. Hold the spray nozzle perpendicular

to the surface being cleaned to maximize spray

media penetration into the element. Alternately

spray each side of the element surface until clean.

7. The cleaning interval should be governed by the

amount and type of particulate in the system to

which it is installed and must be determined by

the user. To determine the maintenance interval,

the user should check the element in the rst few

months of operation to nd how quickly particulate

accumulates in the cells.

8. After cleaning, thoroughly inspect the element for

damage. If damaged, replace it.

!

WARNING

Flame cells must be inspected for

damage immediately following a

deagration and/or stabilized burn.

1. Carefully remove the element assembly from

the arrestor and place it on a soft surface such

as plywood.

2. Inspect the ame cell visually for any signs of

corrosion or other damage.

6

Note

Under no circumstance should the

element bank be disassembled from its

shell for cleaning or replacement. The

element section must be replaced as a

complete assembly.

Cleaning of units equipped with this

system may be accomplished in several

ways including periodic cleaning using

manually operated valves, by use of

North America Only

7 Series

an automated cycle timing method

or by having the cleaning operation

initiated whenever the pressure loss

across the arrestor element exceeds a

predetermined value.

Element Assembly, Disassembly and

Reassembly Instructions

!

WARNING

Isolate gas supply and bring system

to atmospheric pressure to prevent

ignitable gas from ashing while

performing maintenance.

1. Loosen all jacking (inside) nuts on tension studs

between conical sections of the ame arrestor.

2. Tighten the inside jacking nuts on the tension

studs forcing the two conical sections apart. When

the two ange faces have separated, remove the

tension studs that do not have inside jacking nuts

so that the element assembly can be removed.

The inside jacking nuts are installed on all tension

studs that facilitate jacking the unit apart. The

inside jacking nuts are not installed on tension

studs that are taken out, for ease of removal.

CAUTION

Element assemblies are heavy and will

require the use of adequate equipment

and manpower to prevent injury.

3. Thoroughly clean the gasket sealing faces being

careful not to damage the sealing surface. For

reassembly, lightly grease one side of a new

gasket and place it in the machined recess of each

interior ange on the two conical sections.

4. Replace the ame element assembly with a new

assembly or properly cleaned and inspected

existing unit.

5. Loosen the jacking nuts on the tension rods until

the ame cell assembly seats onto the gaskets.

6. Replace all tensioning studs and hand tighten the

outer nuts. Check to be sure that all the jacking

nuts are completely loose and not making contact

with the ange face.

Torquing Instruction

CAUTION

Excessive or uneven torquing can

cause permanent damage to gaskets

and housing.

Tools/Supplies Required

• Torque wrench appropriate for the specied torque

• Socket wrenches of the proper size to t the hex

nuts being tightened

• Molydisulde based lubricating paste,

Molykote® G-n or equivalent

• Brush suitable for applying lubricant to the studs

• Wiping rags necessary for the clean up of

excessive lubricant

Procedure

1. Use studs and nuts that are free of visible

contamination and corrosion.

2. Apply lubricant to the threads of the stud

protruding outboard of the interior anges and

to the face of the hex nuts which will contact

the ange.

3. Assemble the nuts to the studs such that the

amount of thread extending outboard beyond the

nut is approximately equal on both ends.

4. Tighten the nuts to the torque values shown

in Table 5 following the designated sequence,

repeating the sequence as shown. Flange pattern

tightening sequences are shown in Figure 4.

Bolt Lubrication

Lubrication will affect required torque of clean

fasteners in good condition more than any other factor.

In fact, 90% of applied torque goes to overcome

friction while only 10% actually stretches the bolt.

Table 5 assumes that only machine oil is used as a

lubricant. Table 6 shows a list of several common

lubricants and their effect on torque required to stretch

bolts to 50% of their yield strength. Most are available

from local bearing distributors.

Molykote® G-n is a mark owned by Dow Corning Corporation.

7

North America Only

7 Series

4

2

8

4

PATTERN 1

1

10

6

2

PATTERN 4

1

1

3

6

4

2

3

5

8

1

4

6

2

5

3

7

PATTERN 2 PATTERN 3

1

16

1

5

3

7

9

12

58

4

10

6

2 11

9

3

7

PATTERN 5

12

8

4

14

10

6

2 15

PATTERN 6

5

9

13

3

7

11

28 1

24

24

20

1

16

12

8

4

18

14

10

6

2 19

5

9

13

17

3

7

11

15

16

12

8

4

22

18

14

10

1

20

6

5

9

13

17

21

3

7

11

15

19

23

2

4

26

20

16

12

8

22

18

14

10

6

2

5

9

13

17

21

25

3

7

11

15

19

23

27

PATTERN 7 PATTERN 8 PATTERN 8

Figure 4. Flange Pattern Tightening Sequence

8

North America Only

7 Series

Table 5. Tightening Steps and Torque Values

7 SERIES FLAME ARRESTORS WITH ALUMINUM

END SECTIONS ONLY

Model Pattern

(2)

TIGHTENING STEPS AND TORQUE (LBF-FT / N•m)

Step 1 Step 2

(1)(2)

70802-A, 70803-A, 70804-A 1 Snug 25 / 34

71006-A, 71206-A, 71408-A 2 Snug 25 / 34

71608-A 3 Snug 25 / 34

72010-A 3 Snug 50 / 68

72212-A, 72412-A, 72414-A,

72614-A, 72616-A

5 Snug 50 / 68

73016-A 7 Snug 50 / 68

73216-A 8 Snug 50 / 68

7 SERIES FLAME ARRESTORS WITH STEEL OR

STAINLESS STEEL END SECTIONS ONLY

Model Pattern

70401, 70401.5, 70602, 70603,

70604, 70802, 70803, 70804

(2)

Step 1 Step 2 Step 3 Step 4 Step 5

1 Snug 20 / 27 50 / 68

TIGHTENING STEPS AND TORQUE (LBF-FT / N•m)

71006, 71206 2 Snug 20 / 27 50 / 68

71408 2 Snug 25 / 34 60 / 81

71608 3 Snug 25 / 34 50 / 68 80 / 108

71810 3 Snug 25 / 34 50 / 68 90 / 122

72010 3 Snug 25 / 34 50 / 68 75 / 102 100 / 136

72212 4 Snug 25 / 34 50 / 68 85 / 115

72412 4 Snug 35 / 47 70 / 95 100 / 136 130 / 176

72614, 72616 4 Snug 35 / 47 70 / 95 100 / 136 140 / 190

72814 5 Snug 35 / 47 70 / 95 100 / 136 125 / 169

73016 5 Snug 35 / 47 70 / 95 100 / 136 130 / 176

73216 6 Snug 35 / 47 70 / 95 105 / 142

73420 6 Snug 35 / 47 70 / 95 115 / 156

7 SERIES FLAME ARRESTORS WITH STEEL OR

STAINLESS STEEL END SECTIONS ONLY

Model Pattern

(2)

Step 1 Step 2 Step 3 Step 4 Step 5

TIGHTENING STEPS AND TORQUE (LBF-FT / N•m)

73620 6 Snug 35 / 47 70 / 95 100 / 136 120 / 163

74020, 74024, 74824 7 Snug 35 / 47 70 / 95 130 / 176

77036 8 Snug 35 / 47 70 / 95 130 / 176 200 / 271

1. Use machine oil as lubricant. See Bolt Lubrication section (Table 6) and torque correction factors for other lubricants.

2. See Figure 4.

Table 6. Torque Correction Factors for Common Lubricants

DESCRIPTION COEFFICIENT OF FRICTION MULTIPLY TORQUE VALUE IN TABLE 5 BY

Machine Oil f = 0.15 1.00

API SA2 Grease f = 0.12 0.80

®

Never-Seez

Never-Seez

Molykote

Molykote® G-n is a mark owned by Dow Corning Corporation.

Never-Seez® is a mark owned by Bostik, Inc.

(Ni base) f = 0.11 0.73

®

(Cu base) f = 0.10 0.67

®

G-n Paste f = 0.06 0.40

9

North America Only

7 Series

Recommended Spare Parts

For installations that require frequent maintenance and

minimum downtime, it is recommended that the user

purchase a spare element assembly and several spare

element gaskets. The spare element assembly can

be installed immediately and the dirty assembly can

then be cleaned and be stored as a spare for the next

maintenance interval.

Note

Element gaskets should be replaced

each time the cell assembly is loosened

and removed to insure a gas tight seal.

Parts List

Table 7. Part Numbers for Replacement Element Assembly Gaskets (for Cast Aluminum End Sections)

MODEL

70802-A, 70803-A and 70804-A 7008102 7049202

71004-A 7008135 7049235

71206-A 7008136 7049236

71408-A 7008124 7049224

71608-A 7008107 7049207

1. Two (2) required per assembly.

Standard Gasket

(Compressed Fiber)

Parts Ordering

When corresponding with your local Sales Ofce about

this equipment, always reference the equipment serial

number stamped on the nameplate.

When ordering replacement parts, specify the

complete 7-character part number of each required

part as found in the following parts list.

(1)

PART NUMBER

High Temperature Gasket

(Graphite Coated 316 Stainless Steel)

Table 8. Part Numbers for Replacement Element Assembly Gaskets (for All Fabricated End Sections)

MODEL

70400 7008153 7049253

70600 7008134 7049234

70800 7008123 7049223

71000 7008135 7049235

71200 7008136 7049236

71400 7008124 7049224

71600 7008107 7049207

71800 7008108 7049208

72000 7008109 7049209

72200 7008110 7049210

72400 7008111 7049211

72600 7008112 7049212

72800 7008113 7049213

73000 7008114 7049214

73200 7008115 7049215

73400 7008116 7049216

73600 7008117 7049217

73800 7008152 7049252

74000 7008118 7049218

74800 7008133 7049233

77000 7083300 - - - - - -

1. Two (2) required per assembly.

Standard Gasket (Compressed Fiber)

(1)

PART NUMBER

High Temperature Gasket

(Graphite Coated 316 Stainless Steel)

10

North America Only

7 Series

Table 9. Replacement Element Assemblies Part Numbers (Group D Gas)

HOUSING

MATERIAL

FLAME

CELL

MATERIAL

MODEL PART NUMBER

70400 7011741 7011742 7002246 7002261 7002275 7048509 7002201

70600 7011734 7011735 7048514 7048515 7002279 7048516 7002266

70800 7011704 7011712 7002253 7002203 7002217 7002211 7002202

71000 7011705 7011713 7002254 7002204 7002291 7002214 7002292

71200 7011706 7011702 7002256 7002239 7002233 7002283 7002293

71400 7011707 7011714 7002263 7002228 7002223 7002262 7002268

71600 7011708 7011715 7002248 7002247 7002234 7002280 7002297

71800 7011736 7011737 7002252 7002251 7002289 7002250 7048518

72000 7011709 7011716 7002213 7002249 7048519 7002218 7002296

72200 7011710 7011717 7002240 7002207 7048520 7048510 7048521

72400 7011711 7011718 7002258 7002265 7002232 7002264 7002276

72600 7011703 7011738 7048522 7048523 7048524 7048525 7048526

72800 7011726 7011739 7048505 7048527 7048528 7002281 7048529

73000 7011721 7011740 7002243 7002270 7048530 7048531 7048532

73200 7011732 7011733 7002230 7048533 7048534 7048535 7048536

73400 7011743 7011744 7048537 7002226 7048538 7048539 7048540

73600 7011745 7011746 7048541 7002241 7048542 7048543 7002274

73800 7011747 7011748 7048544 7048545 7048546 7048547 7048548

74000 7011749 7011750 7048549 7002273 7048550 7048551 7002209

74800 7011751 7011752 7048552 7002288 7048553 7048554 7048555

Aluminum Aluminum Carbon Steel Carbon Steel

Aluminum

304 Stainless

Steel

Aluminum

304 Stainless

Steel

304 Stainless

Steel

304 Stainless

Steel

Carbon Steel

316 Stainless

Steel

316 Stainless

Steel

316 Stainless

Steel

Table 10. Replacement Element Assemblies Part Numbers (Group C Gas)

HOUSING

MATERIAL

FLAME CELL

MATERIAL

MODEL PART NUMBER

70400 7011753 7011754 7048556 7048557 7048502 7048558 7048559

70600 7011755 7011756 7048560 7048561 7048562 7048563 7002231

70800 7011729 7011731 7048507 7002255 7002295 7002206 7048564

71000 7011757 7011758 7048506 7002259 7048501 7048565 7048566

71200 7011759 7011760 7048567 7002260 7048569 7048570 7048571

71400 7011761 7011762 7048572 7048573 7048574 7048575 7002245

71600 7011763 7011764 7048576 7048577 7048578 7048504 7048579

71800 7011765 7011766 7048580 7048581 7048582 7048583 7048584

72000 7011767 7011768 7048585 7002299 7048586 7048587 7048588

72200 7011769 7011770 7048589 7048590 7048591 7048592 7048593

72400 7011771 7011772 7048594 7048595 7048596 7048597 7002244

Aluminum Aluminum Carbon Steel Carbon Steel

Aluminum

304 Stainless

Steel

Aluminum

304 Stainless

Steel

304 Stainless

Steel

304 Stainless

Steel

Carbon Steel

316 Stainless

Steel

316 Stainless

316 Stainless

Steel

Steel

11

North America Only

7 Series

Table 11. Replacement Element Assemblies Part Numbers (Group B Gas)

HOUSING

MATERIAL

FLAME CELL

MATERIAL

MODEL PART NUMBER

70400 7011773 7011774 7048598 7048513 7002212 7048512 7002210

70600 7011775 7011776 7048599 7056501 7056502 7056503 7056504

70800 7011725 7011777 7056505 7002216 7002286 7048511 7002215

71000 7011778 7011779 7056506 7002205 7056507 7002290 7056509

71200 7011780 7011781 7056510 7002257 7002282 7056511 7002298

71400 7011782 7011783 7056512 7048508 7056513 7056514 7056515

71600 7011784 7011785 7056508 7056516 7056517 7056518 7056519

71800 7011786 7011787 7056520 7056521 7056522 7056523 7056524

72000 7011727 7011788 7056525 7056526 7056527 7056528 7056529

72200 7011789 7011790 7056530 7056531 7056532 7056533 7056534

72400 7011791 7011792 7056535 7056536 7056537 7056538 7056539

Aluminum Aluminum Carbon Steel Carbon Steel

Aluminum

304 Stainless

Steel

Aluminum

304 Stainless

Steel

304 Stainless

Steel

304 Stainless

Steel

Carbon Steel

316 Stainless

Steel

316 Stainless

Steel

316 Stainless

Steel

Emerson Process Management

Regulator Technologies Tulsa, LLC

9932 East 58th Street

Tulsa, OK 74146-6411

Tel: +1 918 662 6161

Fax: +1 918 662 0004

For further information visit www.enardo.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Enardo is a mark owned by Regulator Technologies Tulsa, LLC,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management Regulator Technologies Tulsa, LLC does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use

and maintenance of any Emerson Process Management Regulator Technologies Tulsa, LLC product remains solely with the purchaser.

©Emerson Process Management Regulator Technologies Tulsa, LLC, 2015, Rev. F; All Rights Reserved

Loading...

Loading...