September 23nd 2016

DESCRIPTION :

Protection, control and

power supply box

for GMDSS system

Vessels equipped with an AC or DC onboard network

(external regulated filtered charger *)

TYPE : ICA - GMDSS 30 - RAE

(Deported platen A + V)

REFERENCE

: SEEL006715F

SERIAL NUMBER :

MANUFACTURER CODE : F 3645

CUSTOMER :

06715DAF

Page 1 / 14

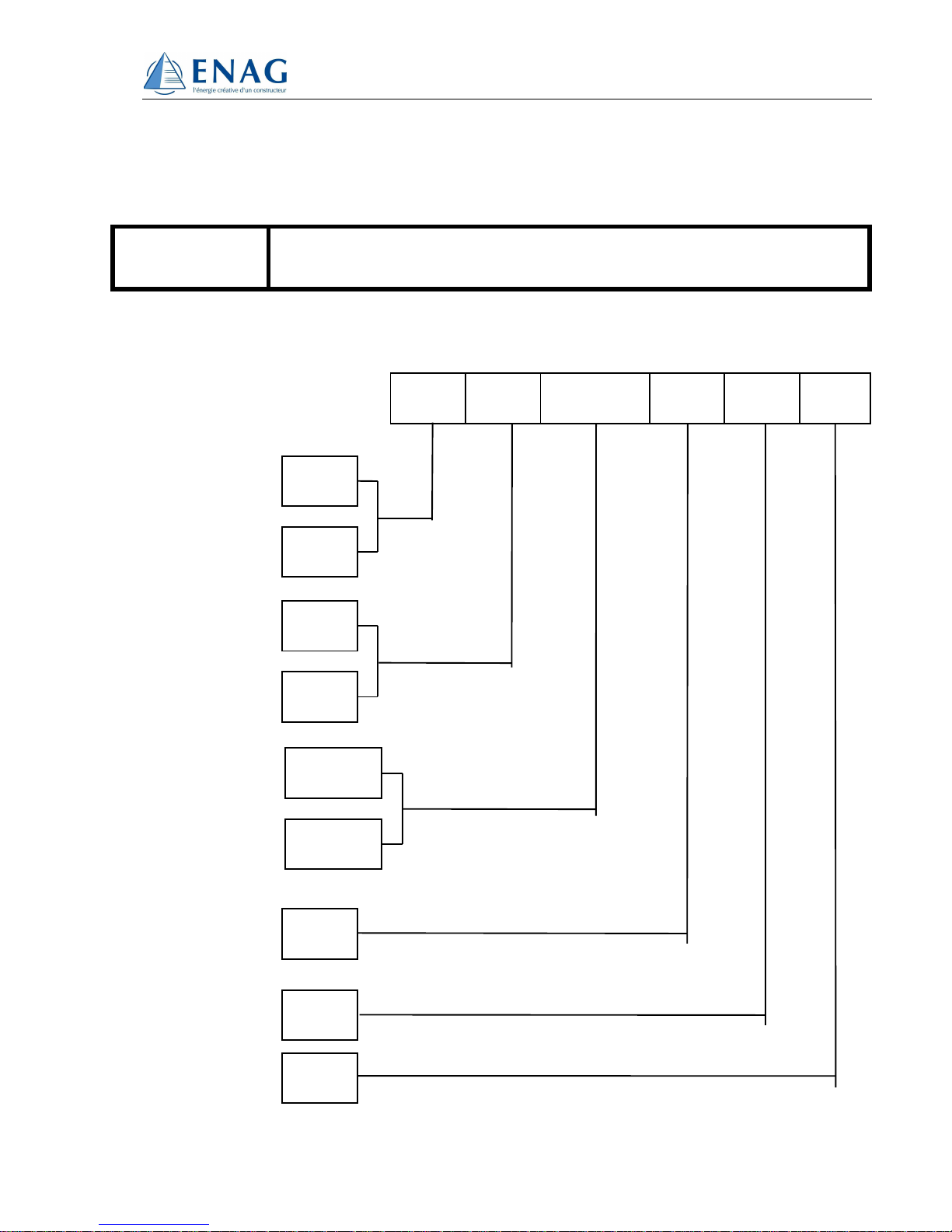

OUTPUT NOMINAL

DC CURRENT

SPECIFIC

SPECIFICATIONS

AUTOMATIC

DETECTION

SYSTEM

IDENTIFICATION

MATERIAL

I

CA - GMDSS 30 - RAE

Material identification procedure

²

I CA GMDSS 30 RAE

RAE

Idn

F

I

INTERNATIONAL

RULES

FRENCH

RULES

TYPE

CC

CA

ALTERNATING

CURRENT

DIRECT

CURRENT

GLOBAL MARITIME

DISTRESS and SAFETY

SYSTEM

SYSTEME MARITIME

de DETRESSE et de

SECURITE en MER

SMDSM

GMDSS

06715DAF

Page 2 / 14

CONTENTS

DESIGNATION PAGE

Cover

Identification

Contents

Generalities

Presentation

Operating Description

Electrical Characteristics

Mechanical Characteristics

Installation - Connection - Settings

Troubleshooting

Maintenance

Appendix

General Guidelines on Equipment Installation

1

2

3

4

5

6

7

7

8

9

10

11

12 to 14

06715DAF

Page 3 / 14

1 - GENERALITIES

ENAG has been specializing in the production of power supplies for the marine

environment for more than 30 years.

ENAG manufactures a complete range of automatic battery chargers.

We can also propose some regulated and filtered power supplies and converters, some

monitoring systems which enable to compose the global supply of the GMDSS system.

This manual is intended for equipment users and installation and maintenance

engineers. The manual must be read thoroughly before any operations are undertaken

on the product and all the users must be informed.

Choice of Appliance

T

he choice of appliance will depend on applicable standards, battery type (technology

used, number of cells, capacity), amount of current consumed by the load centres and

installation and environment constraints.

06715DAF

Page 4 / 14

2 - PRESENTATION

Compact box in conformity with 219 (project from 8/07/98).

It includes :

• 1 main source protected input (On-board main) 219 - 13 - 1

• 1 battery charger

• 1 separator diode navigation post engine room 219 - 13 - 5

• 1 stand-by source protected input (radio battery) 219 - 13 - 1

• 1 emergency source protected input (service battery with

associated generator if in operation ) 219 - 13 - 1

• 1 automatic reverser without cut-off 219 - 13 - 3

• 1 supervision PCB with active protection,

indicator lights, buzzer, voltmeter and ammeter

Main source over voltage default. Lights + Buzzer 219 -

13 - 4 et 219 - 13 - 6

Emergency and stand-by battery under voltage defaults.

Lights + Buzzer. Automatic battery test 219 - 13 - 4

1 Voltmeter and 1 ammeter 219 - 13 - 3 et 219 - 25 -

4

• Protected outputs :

1 HF transmitter

1 Standard C

1 Telex or 2nd standard C

1 VHF with ASN

1 VHF with ASN

1 Navtex

1 Emergency light or GPS

06715DAF

Page 5 / 14

3 - OPERATING DESCRIPTION

The functioning principle of the GMDSS box is based on Automatic detection System (RAE

system).

Taking into account the “GMDSS” supply logic, the aim is to supply the appropriate power with an

optimal autonomy thanks to radio-communications systems.

Functioning modes :

1 – Main source present

The main generator, directly connected (DC) or through a battery charger (AC), supplies

the loads and maintains the radio battery in good charge state. The whole system

functions in “UPS” mode.

A stand-by battery test (radio battery) is carried out periodically (every 6 hours). It

enables to :

Check that the battery is present

Check that the battery is in good charge state

Lengthen its life duration by carrying out charge and discharge cycles.

The SW1 switch located on the control PCB enables to immediately launch a stand-by

battery test (inspection control).

2 – Main source defective

The main generator does not supply the loads anymore. Two options are possible :

OPTION A : priority to the stand-by source. Use of the control PCB in U4 in the PAL

ref GMDSS24A.

The loads are first supplied without cut-off by the stand-by source (within the limit of

specified voltage), then by the emergency source. That way the emergency source is

protected for an optimum autonomy.

OPTION B : priority to the emergency source. Use of the control PCB in U4 in the

PAL ref GMDSS24B.

The loads are first supplied without cut-off by the emergency source (within the limit of

specified voltage), then by the stand-by source. That way the stand-by source is protected

for an optimum autonomy.

In case an over voltage of the main generator is detected, the generator is immediately

disconnected and the loads are supplied by the stand-by or emergency source depending

on the option chosen.

3 - Ship alongside the quay, motor stopped

The operator puts the switch on the « OFF » position. The radio is only supplied by the

service battery as long as the battery main switch is not activated.

When the motor is started, the buzzer sound tells the user to put the switch on the “ON”

position. The box is in operation.

06715DAF

Page 6 / 14

4 - TECHNICAL CARACTERISTICS

4.1 ELECTRICAL CARACTERISTICS

• Main supply input: : 230 VAC 50Hz

• Battery charger : 24VDC 30A

• Radio battery input : 24 VDC 30 A

• Service battery input : 24 VDC 30 A

• Protected loads outputs : 1 x 24VDC 30A

6 x 24VDC 7.5A

4.2 MECHANICAL CHARACTERISTICS

• Housing in a metallic box with cable-glands.

• On the front panel, one voltmeter and one battery ammeter, alarm PCB and display

PCB (Leds, buzzer). On/off switch and state light.

• IP 20 protection with natural ventilation

4.2.1 CLIMATIC SPECIFICATIONS

• Te

mperature : - 10°C at + 45°C

• Humidity : 95 % without condensation

4.2.2 APPILCABLE STANDARDS AND RULES

• Merchant Marine Rules Part 219

• SOLAS Rules

• Bureau Veritas approval

• CE Marking

• European directive.

06715DAF

Page 7 / 14

5 - INSTALLATION - CONNECTION - SETTINGS

TROUBLESHOOTING

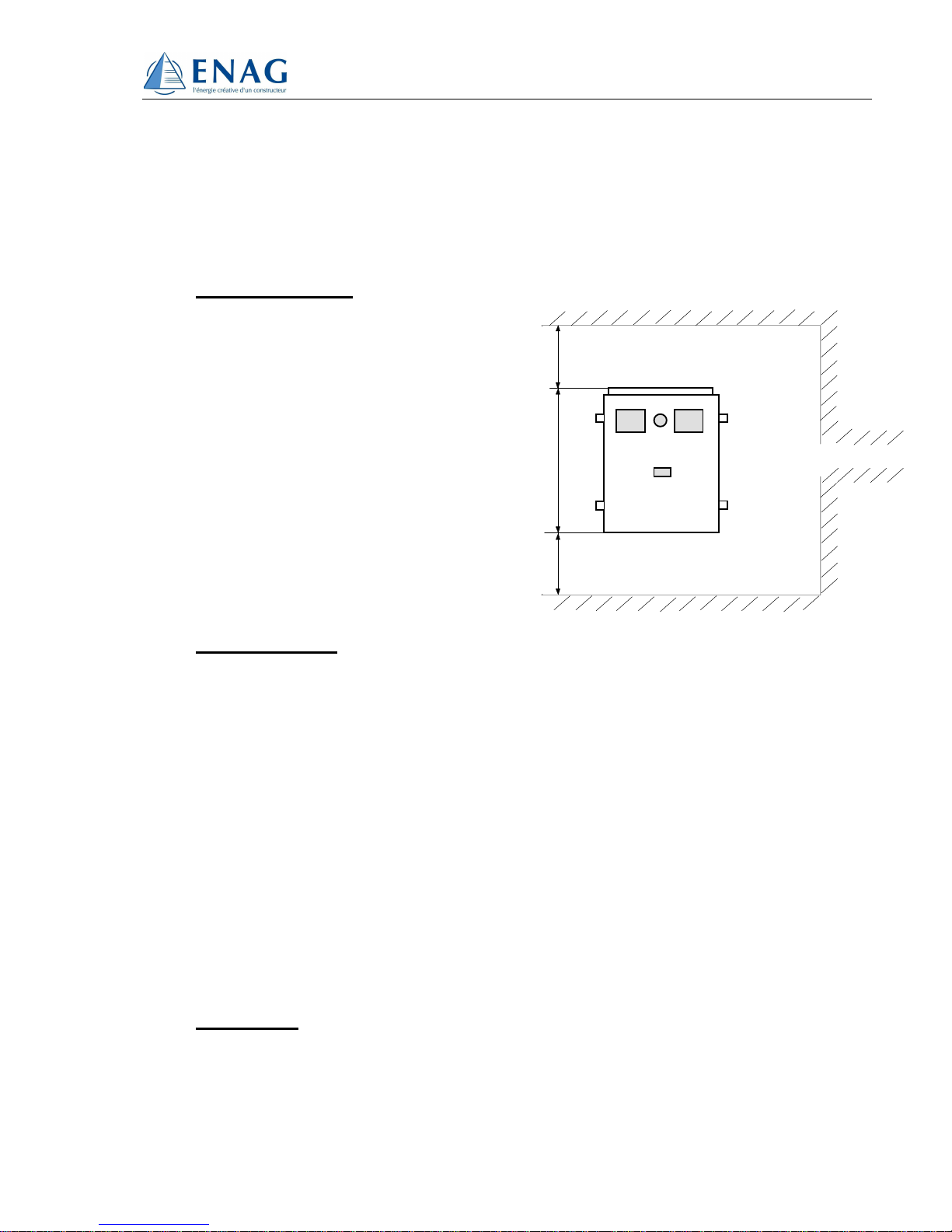

5.1 INSTALLATION

As

the appliance is cooled by natural

convection, a minimum allowance

must be left for installation as shown.

Mounting centre distance and space

requirement: see enclosed drawing.

The situation of the charger must be

adapted to its protection rating.

5.2 CONNECTION

The cable fixation is done on the connecting bar.

A shielded cable connection attenuates electromagnetic disturbance and reduces

the susceptibility of the appliance. This type of cable is recommended in all

installations.

The ground terminal or lug of the appliance must be connected by a short, wide

strap to the installation ground. See cables fixation plan.

The ground strap of the shielded cables must be linked to the appliance ground

inside the case.

Separate the supply, load and control cables.

5.3 SETTINGS

See enclosed drawing.

L=100

L=100

Ceiling

Floor

06715DAF

Page 8 / 14

5.4 TROUBLESHOOTING

5.4.1 Switch on 0

The led functioning on emergency battery remains switched off.

Check the presence of voltage at the input terminals, the state of the F5 and F6

fuses.

The voltmeter does not show the stand-by battery vol

tage.

Check the presence of voltage at the input terminals, the state of the F3 and F4

fuses.

.

5.4.1 Switch on 1

The led main source presence remains switched off.

Check the presence of voltage at the input terminals, the state of the F1 and F2

fuses.

The led main source presence is lit and the led functioning on main source remains

switched off.

IF OPTION A : priority to the stand-by source. Use of the control PCB in U4 on the

PAL REF GMDSS24A

- The led functioning on stand-by source is lit.

Check the voltage of the main source.

Check the stand-by battery test is not running.

- The led functioning on emergency source is lit.

Check the voltage of the main source and the stand-by source.

IF OPTION B : priority to the emergency source. Use of the control PCB in U4 on the

PAL REF GMDSS24B

- The led functioning on emergency source is lit.

Check the voltage of the main source.

- The led functioning on stand-by source is lit.

Check the stand-by battery test is not running.

Check the voltage of the main source and the emergency source.

06715DAF

Page 9 / 14

The led stand-by battery default is lit.

If the red led on the control PCB is lit, this means that a stand-by battery test has

been carried out and that the result is negative. This led will remain lit until the next

test.

If the red led on the control PCB is not lit, this means that an over voltage on the

stand-by battery has been detected.

In both cases, check the stand-by battery.

Contact the ENAG Technical Department who will indicate any further tests to be carried

out according to the measuring and testing means available to the operator.

In case of failure persistence, please contact the ENAG factory. The material must be

di

smounted and sent to the factory where the internal electronic circuits are checked on an

appropriate test bench.

6 - MAINTENANCE

Switch off the power.

If the appliances are situated in a dusty atmosphere, clean them periodically with a

vacuum cleaner as a build-up of dust prevents heat dissipation.

An annual check on the main nuts and screws may prove

necessary in highly

disturbed environments (strong vibrations, wide temperature variations, etc.).

A full technical inspection by a qualified inspector is recommended every year.

06715DAF

Page 10 / 14

APPENDIX

Dimensions (alimentation box) N° 06715 05

Dimensions (deported platen) N° 06715 15

Terminal N° 04933 04

Implantation N° 04933 09

Implantation cover N° 06715 10

Electrical drawing N° 06715 06

Spare parts list N° 06715 RF

Cables fixation N° 04933 11

Setting plan (control PCB) N° 04834 05

Connection N° 06715 16

Synoptic N° 04809 09

Synoptic N° 04809 10

06715DAF

Page 11 / 14

Guidelines on equipment installation

By

virtue of European directive 89/336/EC, the equipment must conform to electromagnetic

compatibility criteria Date of application: January 1st, 1996.

The

two main demands in terms of electromagnetic compatibility are:

Emission: Protection of the environment against disturbance by conduction and radiation.

Immunity: Absence of susceptibility in a disturbing atmosphere.

Installation

General Rules

The equipment must be installed according to the recommendations of the user manual. The

main rules are as follows:

Use shielded cables with a correct section in order to power the appliance and the

load centres within acceptable tolerance limits.

(Definition criteria: nature and length of the cables, ambient temperature, voltage

drop, type of tracking, etc.).

Make sure the equipment is correctly ventilated for good heat dissipation

(installation space, ambient temperature, etc.).

Choose the location in accordance with the protection rating of the appliance.

06715DAF

Page 12 / 14

Emc-related installation guidelines

Cables:

Use shielded cable for all connections (*). The shielding must be grounded on the

transmitter side and the receiver side.

Keep the cables and shielding connections as short as possible.

Feed the cables as close as possible to the ground (“loose” cables or loops are to be

avoided - fasten the cables down to the ground).

Separate the supply and load cables.

Separate the power and control cables (minimum 200 mm).

The cables should only supply power to the appliance. A branch connection or bridge to

supply another appliance are to be prohibited.

(*) This is a recommendation but is not compulsory. The installation electrician will consider

the EMC environment and decide whether or not to use shielded cable.

Metal casing

The cases or cabinets for the appliances or containing the equipment must be metallic or

have a conductive coating.

The ground bolt or lug of the casing should be connected to the main ground by the

shortest strap possible. The bolt connected to the main ground must have a good electrical

contact (scratch off the paint and weld the bolt).

The ground being the reference point of the potential, the various current-bearing parts of

the equipment environment must be made equipotential by linking them together (where

possible, metal shielding and troughs are grounded with the shortest straps).

06715DAF

Page 13 / 14

Additional attenuator systems

The coils of contactors, relays, solenoid valves and electromagnets must be

equipped with overvoltage arresters (RC circuits, varistor or diode on direct current,

RC circuits or varistor on alternating current).

Additional filters may be mounted according to applicable standards. Disturbance

a

ttenuation enables the specified levels to be attained. The filters must be mounted

as near as possible to the appliance.

Remember that filters increase the leakage current.

As a general rule, we recommend consulting the manufacturer before installing a

filter, particularly on the load and control cable side.

SEEL006715D N° 06715RAD PAGE 1 / 1

Ind :

Designation :

DATE : NATO CODE :

D

ICA - GMDSS 30 - RAE (Deported platen A + V)

23/09/2016 F3645

Nb Rep Designation Partnumber Manufacturer Item code

2 F17-F18 Fuse 10Agg 10x38 13310 LEGRAND 30001307

PL2 POWER CARD

8 F1 à F8 Fuse ATO 15A-32V 257015 LITTELFUSE 30011476

6 F9 - F14 Fuse ATO 7,5A-32V 25707,5 LITTELFUSE 30013145

2 F15-F16 Fuse 5x20 D1-0,31A CEHESS 30005209

PL1 CHARGER CARD

2 F1 Fuse 6,3x32 15A 250V ( POWER SUPPLY 230VAC ) 326015 LITTELFUSE 30013200

SPARE PARTS LIST

Loading...

Loading...