Equipment ›Excellence‹

These Assembly and Operating Instructions are an integral part of the product.

> Read Assembly and Operating Instructions carefully before using the product.

> Keep them in a safe place during the product‘s service life.

Translation from the German original edition ©emz 2012 - Subject to modications.

The contents and representations of these Assembly and Operating

Instructions are the intellectual property of emz-Hanauer GmbH & Co.KGaA.

Non-authorized disclosure, reproduction, divulgation or editing of this

documentation, as well as exploitation, utilization or publication, are prohibited.

The rights to the word and design marks ›emz - smart solutions‹ and ›smart Sol plus‹

are the exclusive property of emz-Hanauer GmbH & Co.KGaA.

The rights to any cited brands, names or logos are the property

of their appropriate developers / of the licensees in question.

3

Table of Contents

Table of contents Page

Important fundamental information 4

Symbols used 5

Description 6

Dimensions 7

Technical Data 8

Designation of the components 10

Operation of the controller 11

Display 12

Opening the terminal cover 13

Wall-mounting 14

Connection to power supply 15

Data interfaces 19

Hydraulic systems 20

Functions for boiler control 51

Thermostat functions 54

Soft water station AQA solar 55

Commissioning mode 57

Automatic mode 63

Operation mode 64

Malfunction 78

Replacement of fuse 85

Professional mode 86

Disassembly/Disposal 107

Warranty and liability 108

Error report 109

EC Declaration of conformity 111

Index 112

4

Important fundamental information

These instructions describe installation, commissioning, operation, repair

and disassembly of the differential temperature controller smart Sol plus for

solar thermal plants.

For operation of the entire plant, the technical documentation of all the

components used such as solar collectors, boiler, tank, pumps, mixers

and valves etc. must be complied with.

The controller is handled by the operator of the entire solar

thermal plant, i. e. as a rule by technical non-experts.

Make sure not to use the controller until you have thoroughly read and

understood these Assembly and Operating Instructions and the safety provisions.

Comply with all safety provisions and involve a specialist in case of doubt.

Keep these Assembly and Operating Instructions and all reference

documents so that they are available if required.

When relocating or when selling the device, hand the documents over to your successor.

Important!

The tter installing the controller must inform the plant operator about

operation, functioning and the method of action of the smart Sol plus!

Danger!

The device in operation may only be made accessible to

adults disposing of appropriate knowledge and experience!

Danger!

The controller by no means replaces the safety

components required under plant engineering aspects!

Danger!

Assembly, connection, commissioning, repair and disassembly of

the controller may only be performed by a qualied specialist!

5

Symbols used

When handling the differential temperature controller smart Sol plus

and the entire plant, please make sure that the following safety provisions

in the Assembly and Operating Instructions are complied with!

Note!

Useful information regarding handling of the device and the plant!

Important!

Important information compliance with which is essential!

Danger!

Immediate danger for assets, life and limb!

6

Description

The differential temperature controller smart Sol plusis an independent electronic

controller for surface-mounting which is used for the control of solar thermal plants.

The controller is equipped with a robust three-part plastic housing

which can only be opened by means of tools (screw driver PH2).

Operation is effected by means of only two control elements;

indications appear against a backlit colour display.

Before connection of the electrical system, the controller

must be mounted rmly to a perpendicular, robust surface (wall).

For its own supply and the supply of the outputs, the controller must be connected

to an electrical energy supply system in accordance with the technical data.

Assembly, connection, commissioning, repair and disassembly

of the controller are only admissible in a specialist workshop.

To ensure correct operation, temperature sensors type Pt 1000

must be used - the sensor design does not affect function.

Each temperature sensor has two connectors which are equivalent,

i. e. interchangeable. Thus, polarity reversal is not an issue.

The sensor lines can be extended up to a length of 100 m, to

this effect, a cable cross section of 2 x 1.5 mm2 is recommended.

Note!

The electrical equipment of the device must be installed rmly and

connected to the power supply via a disconnector ensuring complete

isolation from the power supply according to the erection regulations!

Important!

Make sure that only a dry or slightly moistened cloth is used for cleaning

and servicing of the housing, the control elements and the display.

The surfaces must never get into contact with cleaning products

or solvents - mat, brittle or slightly dissolved plastic parts must

be replaced immediately!

A device with damaged housing must not be operated!

7

Dimensions

218 mm 51 mm

109 mm

d

max

5/9 mm

109 mm

140 mm

30 mm

48 mm

218 mm

5 mm

8

Technical Data

Intended Use

The differential temperature controller may be used exclusively as controller for the con-

trol of solar thermal plants. It must be operated within the scope of all the specications

described. Installation and set-up of the controller may only be performed by specialists.

The tter must have read and understood the operating manual.

The tter explains all the relevant functions to the operator.

For operation, it is essential that the housing is closed and free of damage.

Scope of supplies

1 Differential temperature controller smart Sol plus

1 Instruction manual

Differential temperature controller smart Sol plus

Type of mounting Wall-mounting

Housing Plastics, in several parts

Mode of operation Type 1

Type of protection IP 20

Dimensions Width x Height x Depth [mm] 218 x 218 x 51

Weight [g] Basic version 725

Storage/operating temperature [°C] 0-40, non-condensation

Handling via rotary encoder and pushbuttons

Display TFT colour display 70 x 53 mm, backlit

Connection to power supply

Design 3 spring-type terminals PE, N and L

Service voltage [VAC] 85-265

Line frequency [Hz] 50 ±1%

Auxiliary consumption typ. [W] 1.25

Power consumption max. [W] 3.1

Fuse Micro fuse, type 5 x 20 mm, T4A/250 V

Rated pulse voltage [V] 2500

Max. cross sections to be connected

Cable end sleeve: 0.25 to 0.75 mm

2

Single-wire 0.50 to 1.50 mm2

Fine-wired 0.75 to 1.50 mm

2

9

Technical Data

Interfaces TS1 - TS8

Design 2 spring-type terminals each

Assignment as inputs

Admissible temperature probe Temperature sensor Pt 1000

Optional assignment of

TS6-TS8 to the impeller sensor DFZ 1-100 pulses/litre

Optional assignment as PWM signal 100Hz...2kHz or

output on TS7/TS8 analogue output 0...10V, max. 10mA

Interfaces TS9 - TS10

Design 2 spring-type terminals each

Assignment to the impeller sensor DFZ 1-100 pulses/litre

Assignment as output PWM signal 100Hz...2kHz or

analogue output 0...10V, max. 10mA

Active outputs RO1-RO4 :Triac outputs

Design 3 spring-type terminals each, PE, N and L

Output voltage [VAC] 85-265

Output power max. per output [VA] 200

Output current max. per output [A] 1

Switching output REL: Floating change-over contact

Design 3 spring-type terminals

Switching voltage max. [V] 253

Switching capacity max. [VA] 230

Switching current max. [A] 1

Interface for analogue Vortex ow sensors

Design 1 multi-pin connector

5V/24V supply terminals

Design 1 spring-type terminal each

Output voltage [VDC] 5V/24V

Max. current per output [mA] 15

Supply terminals L

Design 1 spring-type terminal each

Output voltage [VAC] 85-265

The total current of all outputs including RO1-RO4 must not exceed 4A!

10

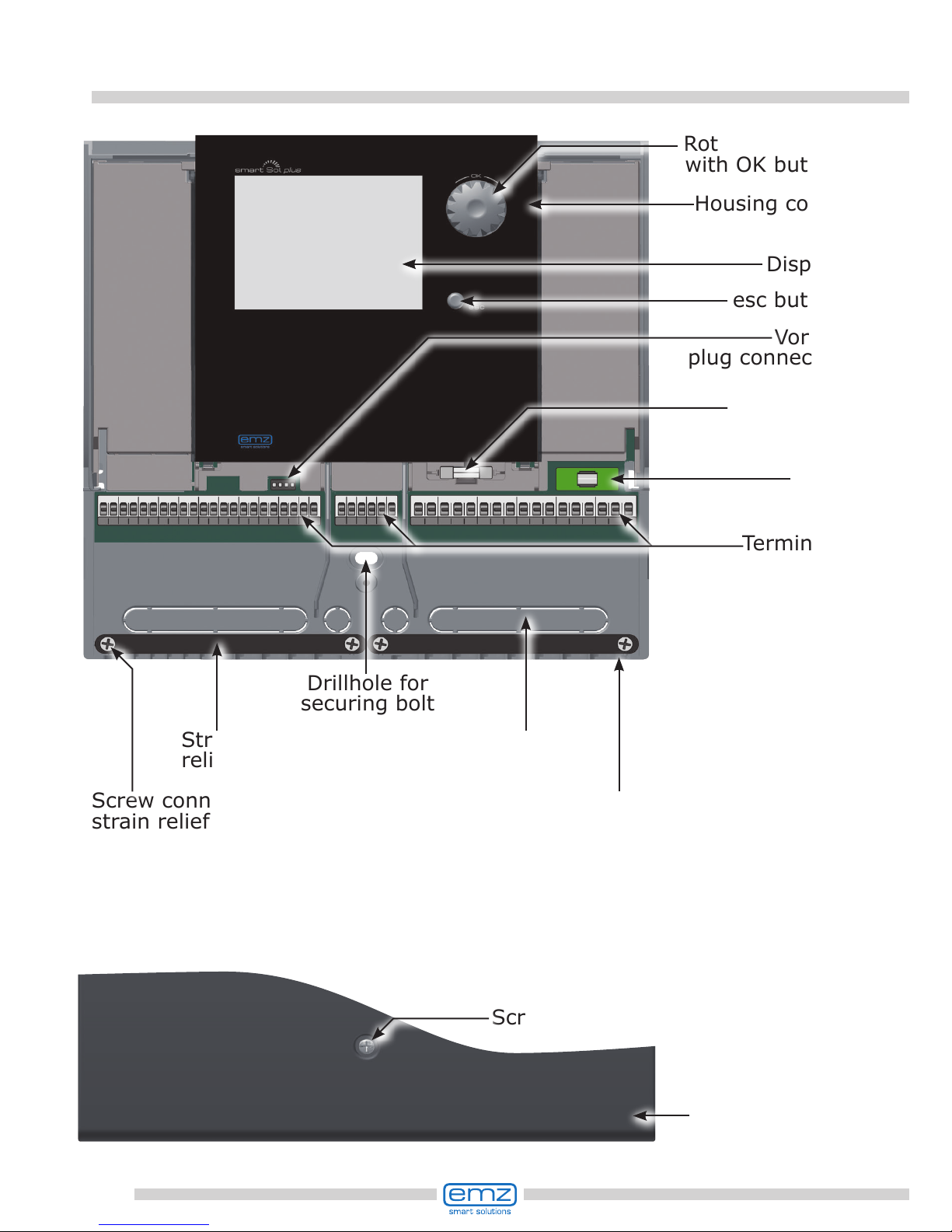

Designation of the components

Housing

base

Drillhole for

securing bolt

Vortex

plug connector

esc button

Display

Rotary encoder

with OK button

Housing cover

Screw fastening of terminal cover

Break-out

segments

Screw connection

strain relief device

Strain

relief device

Terminal cover

Terminals

Fuse

Spare fuse

11

Operation of the controller

The entire set-up and operation of the differential temperature controller

smart Sol plus is effected via only two control elements on the device front.

All settings and interrogations are effected via the rotary encoder.

To nd a required menu item, turn the rotary encoder to ›scroll‹

through the menu - the selectable option appears on a coloured

background on the display.

To conrm the selected menu item, press the rotary encoder.

An appropriate submenu is called up, or selection is activated.

Press the esc button to make the menu return by one level from any subitem.

If no input is made within the preset time (30-255 s),

the controller returns automatically to the initial level.

12

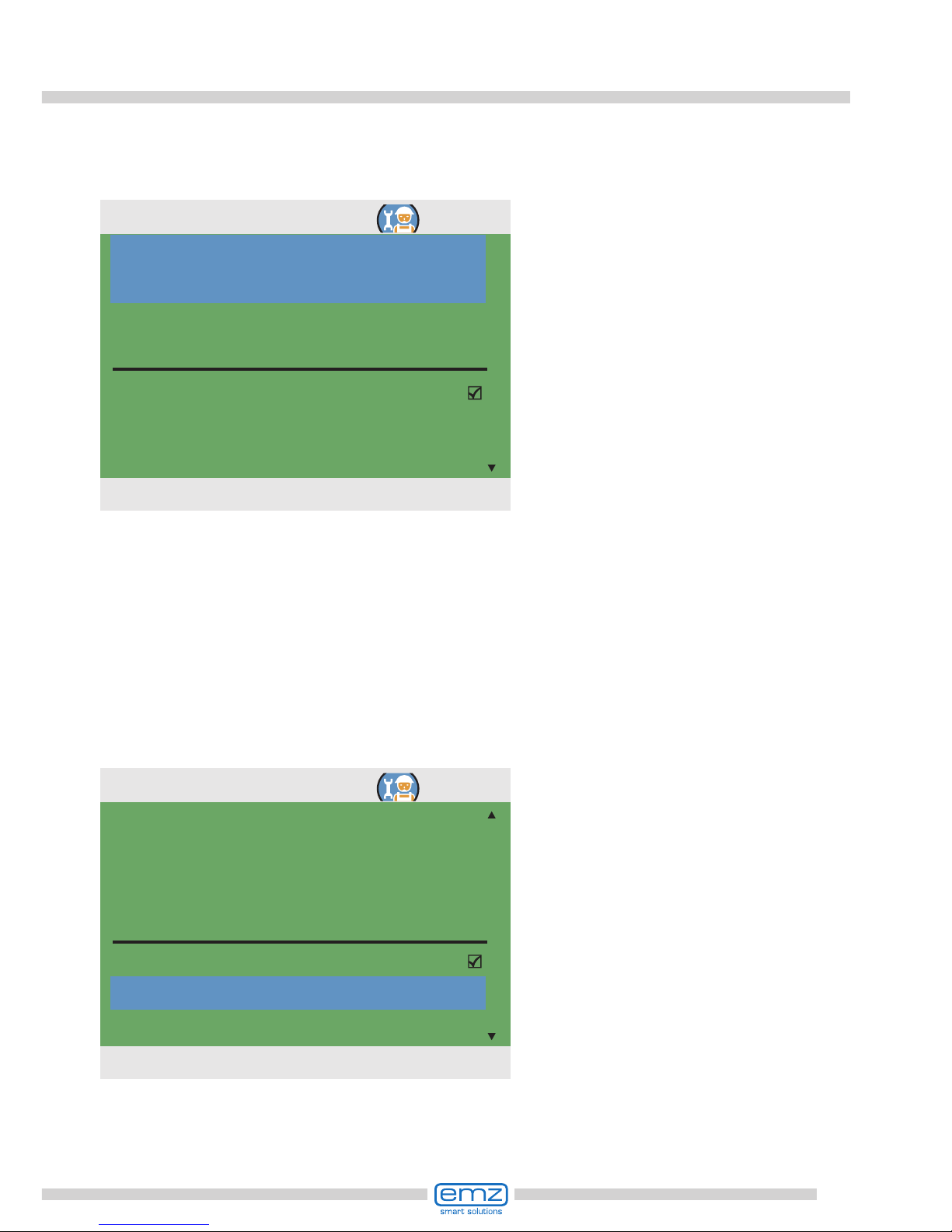

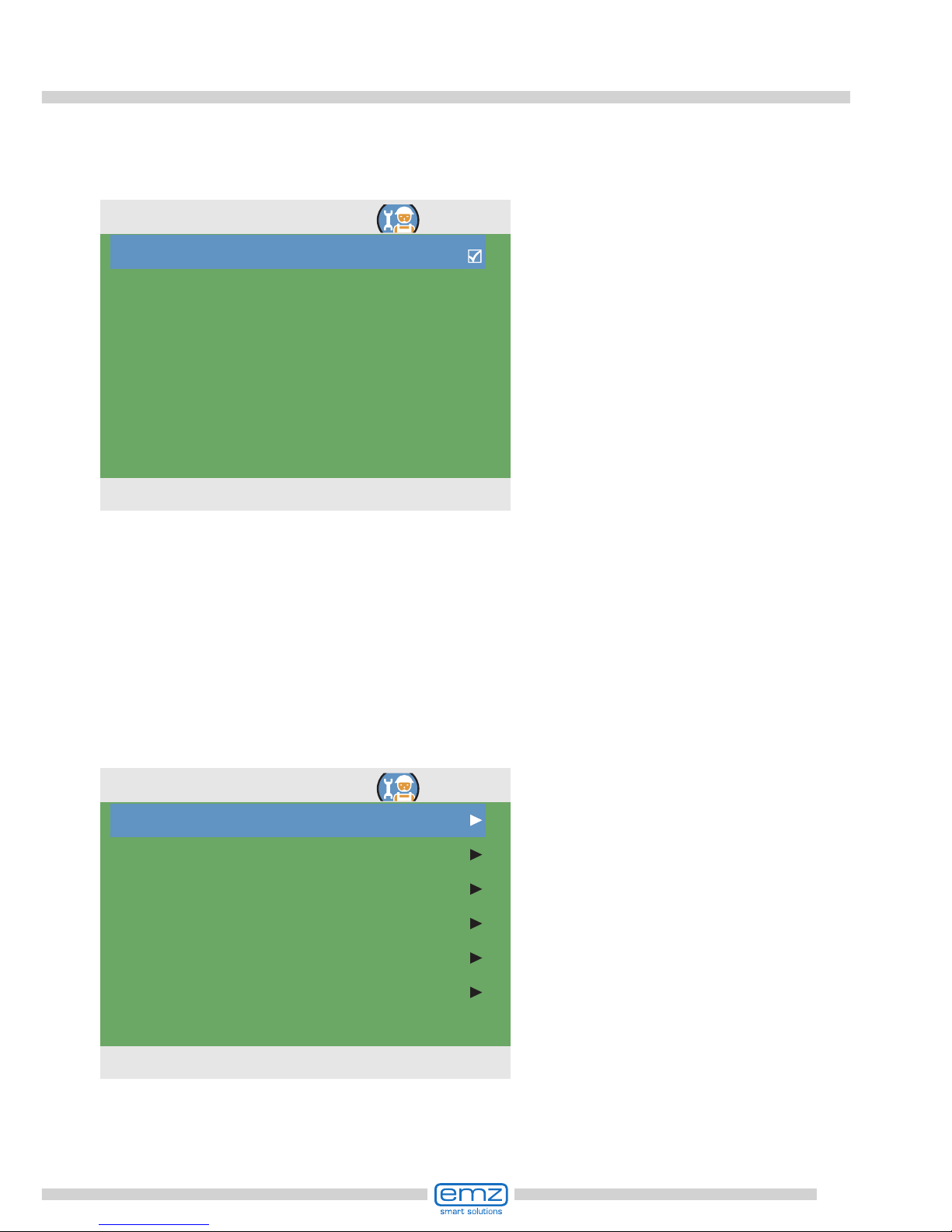

Activation

Start

t ON

T ON

t solar 1

n solar 1

t solar 2

10min

20.0°C

20s

100%

0s

1.3.2 Tube collector

25.08.2012 10:35

System 11

25.08.2012 10:35

Display elements; example: information screen

Display

For indication of the operating mode and for communication in case of set-up, malfunction, modication and evaluation, the differential temperature controller smart Sol plus

is equipped with a coloured full graphics display which is permanently backlit.

The display is active as long as there is supply voltage on the controller.

After a preset time (30 - 255 s), backlighting is dimmed to 10%.

Active system

with current

temperatures

Display elements; example: communication screen

Activatable

menu item

Selection menu

Scroll arrow

Check box

Sub menu arrow

Date and time

Professional mode

Manual mode

Message

Number and name of menu

Date and time

13

Danger!

Mortal danger due to electrocution! Whenever work is performed on the

open terminal cover, all poles of the power supply must be

disconnected reliably and protected against being switched on again!

Opening the terminal cover

1 Release the lock screw.

2 Pull apart the sidewalls

of the terminal cover

at the lower third...

3 ...swivel the terminal

cover forward ...

4 ... push it upwards ...

5 ... and remove it.

Store the terminal cover

carefully and protect

it against damage!

To close the terminal cover,

reverse the opening procedure.

14

Wall-mounting

1 Fasten the top securing bolt so

that a space of 2 to 3 mm is

created between the wall and

the screw head.

2 Move the device so that the

upper fastening port is located

above the screw head ...

3 ... and push it downwards.

4 Fasten the lower securing bolt.

If necessary, use dowel

pins for wall-mounting!

Important!

The device corresponds to protection type IP 20 - make sure the

appropriate prerequisites exist on the envisaged place of installation.

Do not use the housing base as drill template.

A device with damaged housing must not be operated!

15

Connection to power supply

The differential temperature controller smart Sol plus is connected to the

power supply via three groups of spring-type terminals which are

visible once the terminal cover is opened.

To introduce the cables, release the screws on the strain relief device;

if necessary, remove the strain relief device.

In case of ush mounting of the cables, the break-out segments in the housing

base can be removed carefully and the cables routed through these ports.

The central terminal block is the interface to a potential-free change-over contact.

The spring-type terminals for the Power, RO1 to RO4 and REL, and for TS1 to TS10

can accommodate solid wires up to a cross section of 1.5 mm2.

Appropriate stranded wires must be preassembled with cable end sleeves.

For the strain relief device function, TS1 to TS10 and REL require

cable cross sections of at least 5mm, for Power, RO1 to RO4 at least 7mm.

Danger!

Mortal danger due to electrocution! Whenever work is performed

on the open terminal cover, all poles of the power supply must be

disconnected reliably and protected against being switched on again!

Terminal block

RO1-RO4/Power

Terminal

block REL

Terminal block

TS1-TS10

16

Connection to power supply

Connection of a pump to REL

Connection diagram for a pump to REL:

Connection of a switching valve to RO1-RO4

Connection diagram for a switching Connection diagram for a switching

valve without power supply to RO4: valve with power supply to RO4:

Connection of a switching valve to REL

Connection diagram for a switching Connection diagram for a switching

valve without power supply to REL: valve with power supply to REL:

Valve

L

N

PE

Valve

L‘

N

L

Valve

L

L‘

N

Valve

L‘

N

PE

Pump

L‘

N

PE

17

Connection to power supply

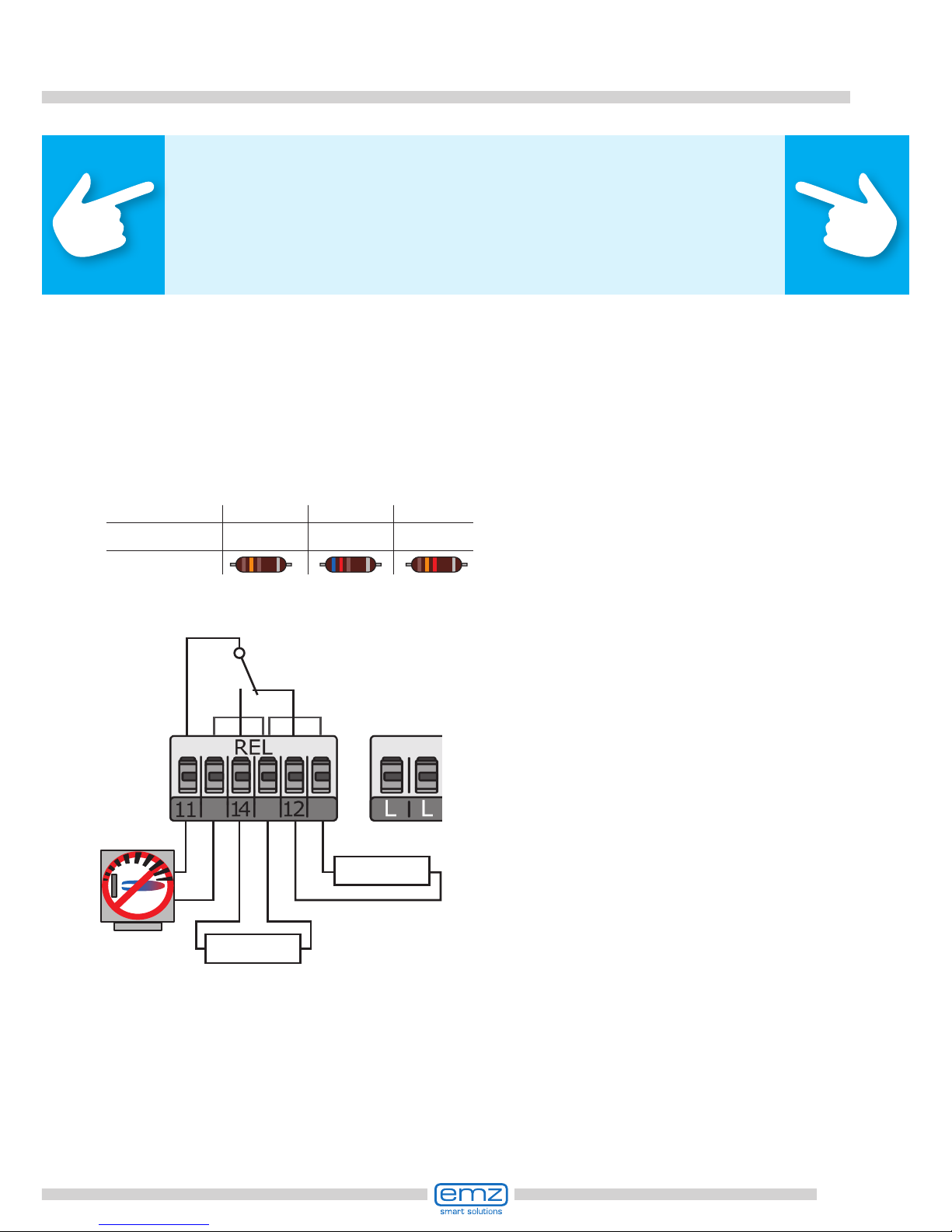

High-efciency pump:

A high-efciency pump can be connected via RO1 to RO4.

The appropriate control signal is issued at TS7 to TS10.

Thus, TS7 to TS10 is no longer available as input.

The control signal may be an analog voltage 0 - 10V or a PWM signal.

For further details, please refer to the pump specication.

For denition and settings, the professional mode under 1.2.9 has been provided.

RO1 to RO4:

230V supply of the

high-efciency pump

TS7-TS10: PWM-control signal

for the high-efciency pump

Left-hand terminal GND

Right-hand termin.: Signal

Volumetric ow sensor:

Measurement of solar radiation (heat quantity):

The solar yield is calculated from the ow rate and the differential temperature.

The differential temperature is the difference in the temperature of the collector

sensor and the solar circuit return line sensor. There are various technical options:

a) Use of a vortex volumetric ow sensor with 2 analog signals for ow rate and

temperature. The vortex sensor can be inserted directly at the plug connector provided

behind the TS terminals. All plant layouts (systems) permit solar radiation.

Pin assignment

b) Impeller sensor (incrementation input)

An impeller sensor can be connected to TS6 to TS8 and must be adjusted during

installation. The temperature sensor for the solar return line must be set

in the menu ›1.1.4 Heat quantities‹.

Solar yield measurement with impeller sensors is possible for all systems.

18

Connection to power supply

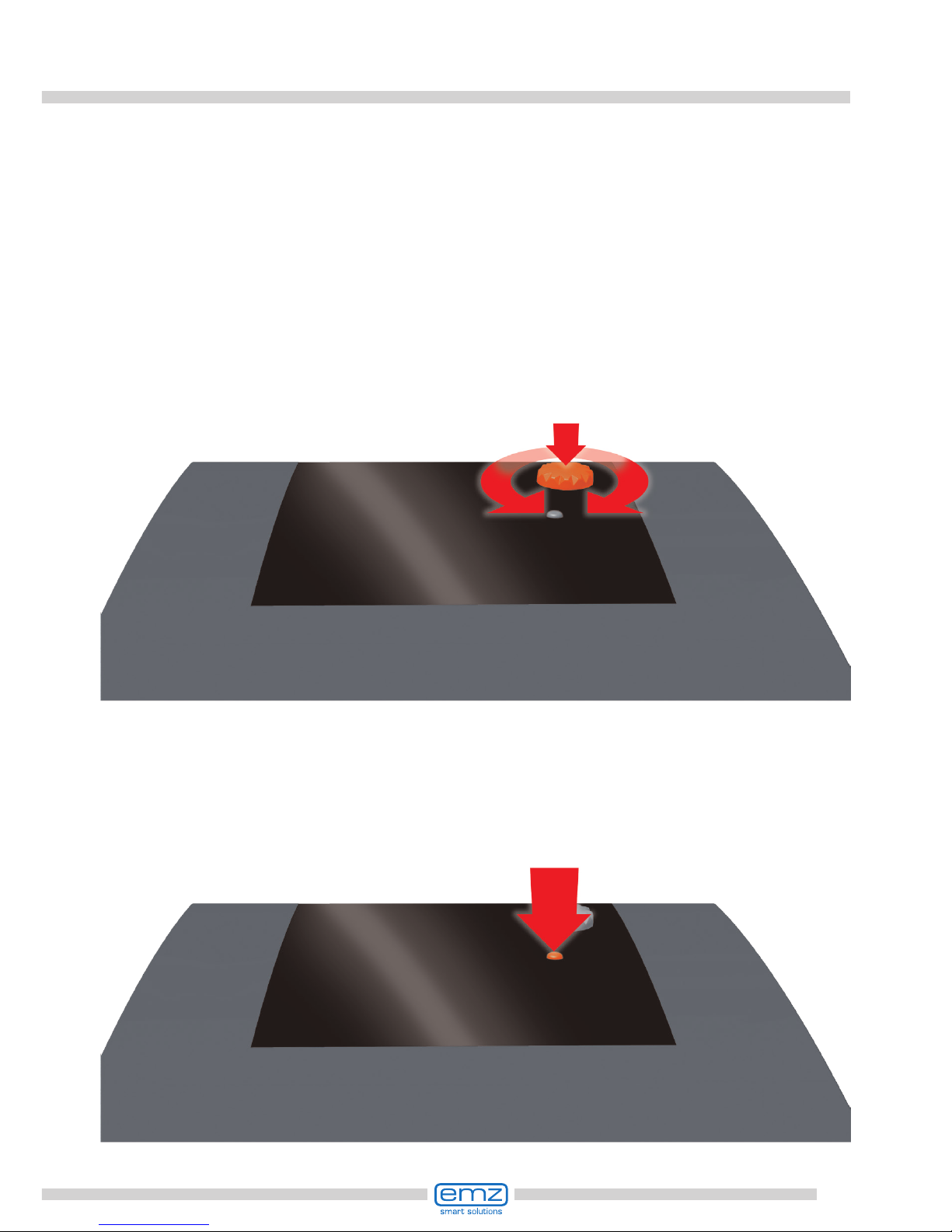

For connection, press the actuation pushbutton

of the spring-type terminal using a screwdriver and

insert the wire to its stop in the appropriate port.

Release the actuation pushbutton and

pull the cable slightly to ensure that it

is safely clamped.

Important!

Before closing the terminal cover, make

sure the strain relief device is tightened safely.

Check once more that all cables are in good

condition and connected correctly.

The strain relief device can only ensure solid

clamping if the cables are not stripped to a length

of over 35 mm.

Insulation of the individual wires must be

removed over a length of 9 - 10 mm to ensure

safe electric contact in the spring-type terminal.

Stranded wires must be provided with cable end sleeves!

9-10 mm

max.

35 mm

19

Data interfaces

The solar controller has the following data interfaces:

The cut-outs at the left of the housing base accommodate a

USB port as well as a slot for a storage medium (SD card).

These interfaces are used, for example, for reading of er-

ror messages or log data or loading of software updates.

The USB port provides access to the SD card.

Only SD cards approved by emz must be used.

The controller automatically detects the SD card.

Prior to removing the SD card

›Rem.SD card safely‹ must be

selected in ›1.2 Settings‹,

otherwise data loss may occur.

20

Hydraulic systems

Boiler with disable

recharge feature,

efciency optimization

Boiler with disable

recharge feature

time-/temperaturecontrolled, in combination

Boiler, e. g. using fossil

fuels/ solid fuels/

heat pump etc.

Hydraulic

heat exchanger

Temperature probe

Switching valve

Solar collector panel

Secondary yield

Solar collector panel

Main yield

Swimming pool

Warmwasserspeicher/

Pufferspeicher mit

Wärmetauschern

Warm water /

buffer tank without

heat exchanger

Heating pump

Return line

Supply line

Note!

Dene structure and design of the plant already when planning

the entire solar thermal system and align the design with the

one of the hydraulic systems of the controller!

If you want to complete an existing system or replace

the existing controller, please make sure that

smart Sol plus is compatible with the existing conguration!

The sensors are connected to TS1 to TS10, the order not being

signicant; pumps and valves are connected to RO1 to RO4 / REL - The

interfaces are assigned to the functions in question on commissioning.

21

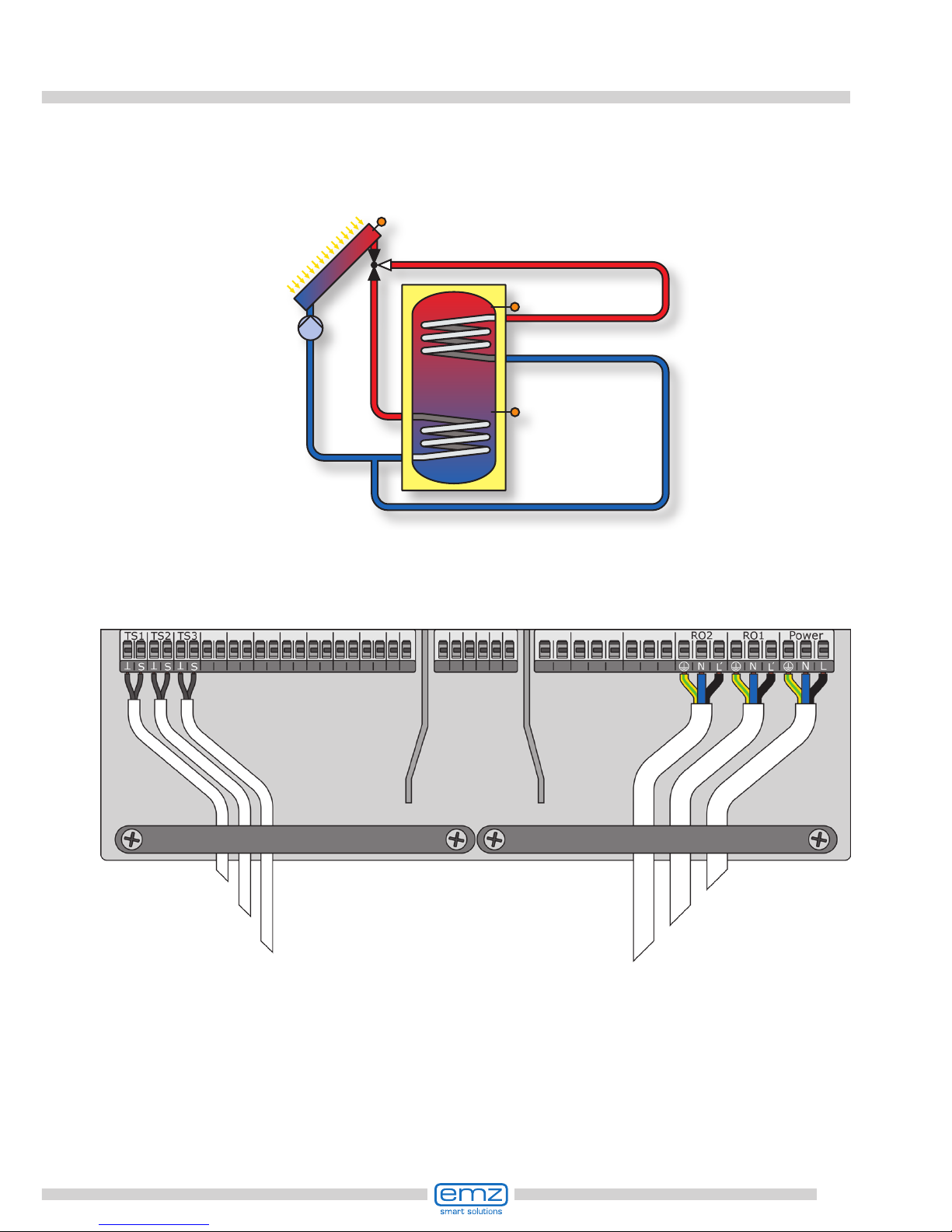

Hydraulic system 1

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

RO1

TS1

TS2

Tank 1

T1

Collector

sensor 1

Solar

circuit

pump 1

Tank

sensor 1,

bottom

22

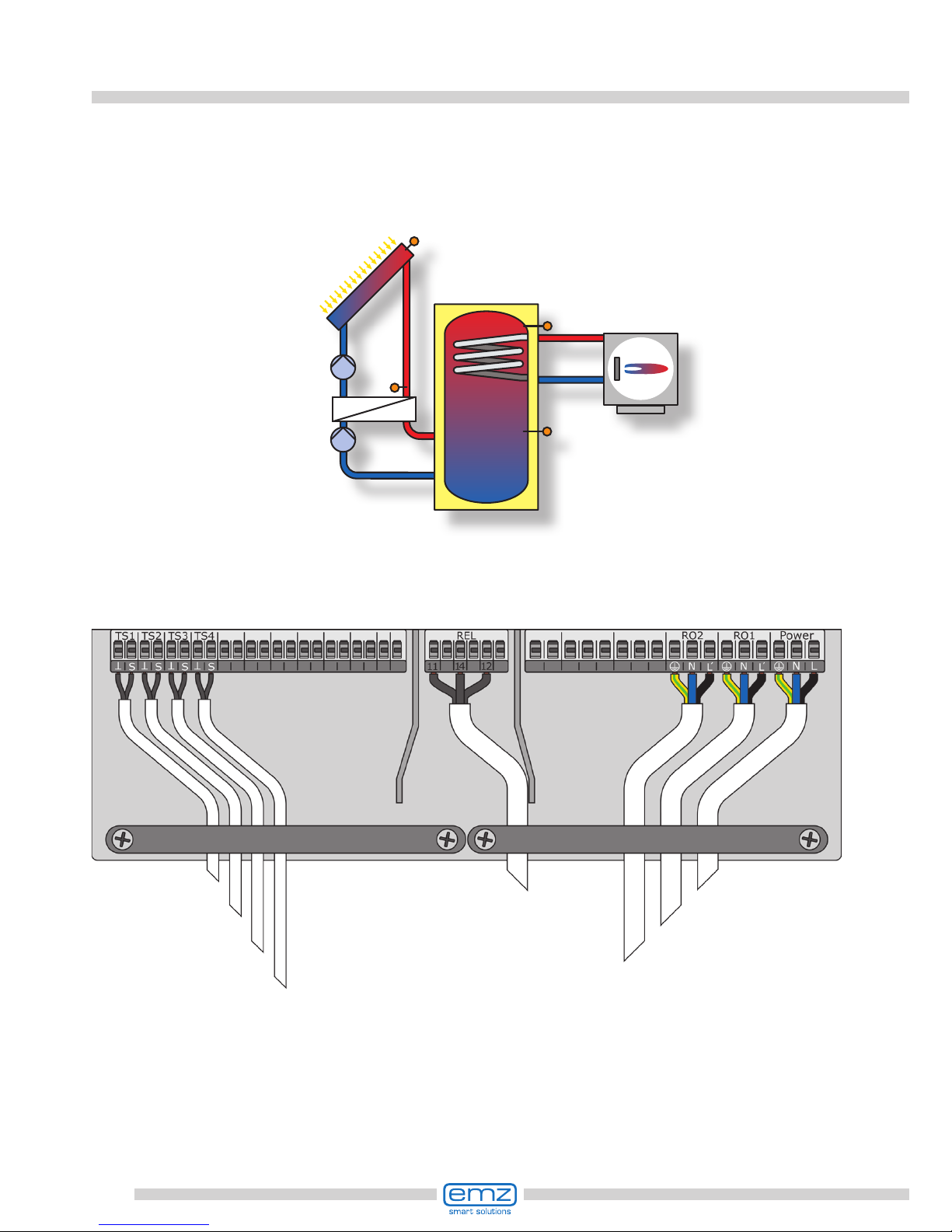

Hydraulic system 2

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top

RO1

TS1

TS2

TS3

Tank 1

T1

Collector

sensor 1

Solar

circuit

pump 1

Tank

sensor 1,

bottom

Tank sensor 1,

top

Heating boiler

connection

according to

page 51-53

23

Hydraulic system 3

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top Charging area valve

TS3

TS2

TS1

RO2

RO1

Tank 1

T1

Collector sensor 1

Solar

circuit

pump 1

Tank

sensor 1,

bottom

Tank sensor 1,

top

Charging area valve

24

Hydraulic system 4

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top Charging area valve

TS3

TS2

TS1

RO2

RO1

Tank 1

T1

Collector

sensor 1

Solar

circuit

pump 1

Tank

sensor 1,

bottom

Tank sensor 1,

top

Charging

area

valve

25

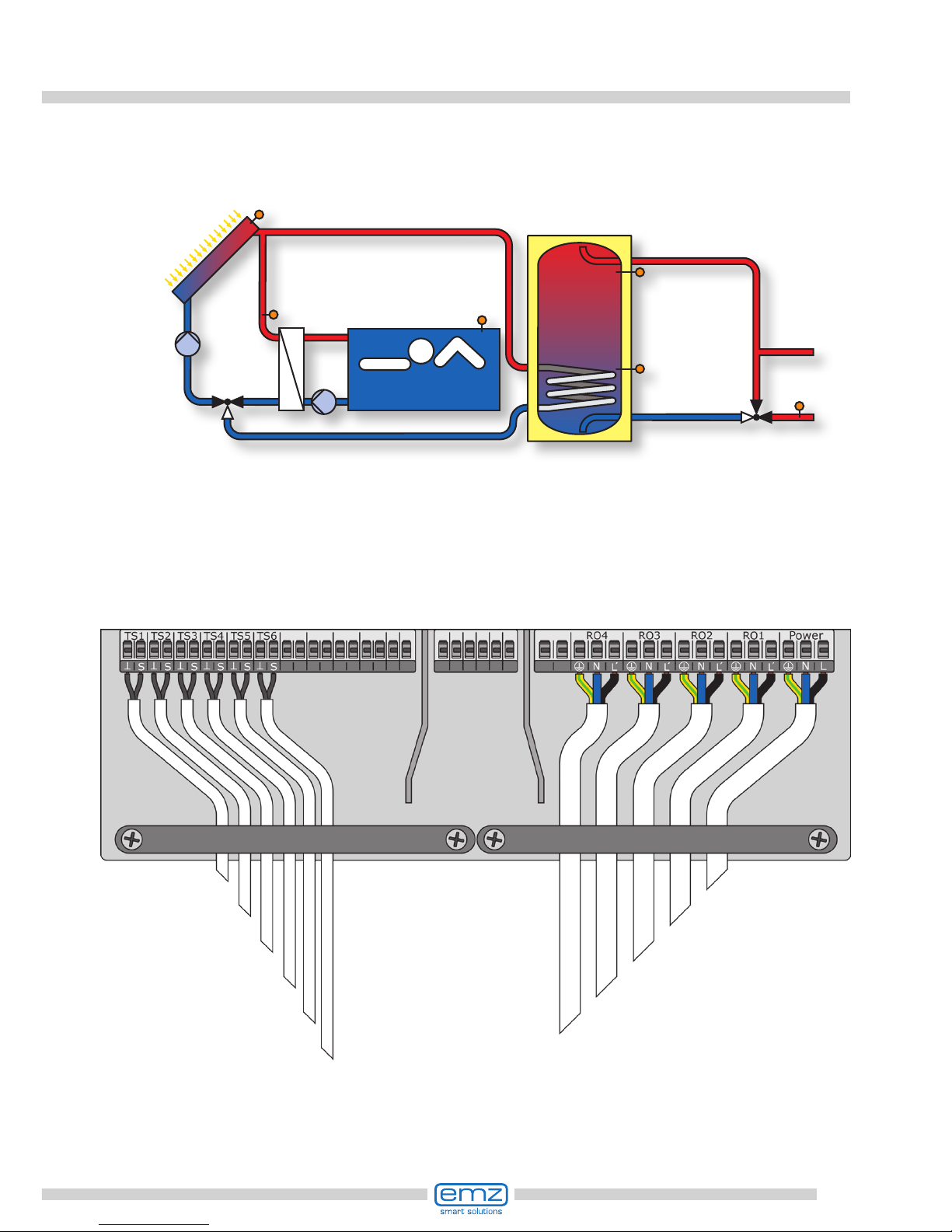

Hydraulic system 5

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Heat exchanger sensor Heat exchanger pump

RO2

TS1

RO1

TS2

TS3

Tank 1

T1

Collector

sensor 1

Solar

circuit

pump 1

Tank

sensor 1,

bottom

Heat ex-

changer

sensor

Heat

exchanger

pump

26

Hydraulic system 6

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top Heat exchanger pump

Heat exchanger sensor

RO2

TS1

RO1

TS2

TS4

Tank 1

T1

Collector

sensor 1

Solar

circuit

pump 1

Tank

sensor 1,

bottom

Heat ex-

changer

sensor

Heat

exchanger

pump

TS3

Tank sensor 1,

top

Heating boiler

connection

according to

page 51-53

27

Hydraulic system 7

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Bypass sensor Bypass valve

RO1

TS1

TS3

RO2

TS2

Tank 1

T1

Collector

sensor 1

Solar

circuit

pump 1

Tank

sensor 1,

bottom

Bypass valve

Bypass

sensor

28

Hydraulic system 8

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top Bypass valve

Bypass sensor

RO1

TS1

TS4

RO2

TS2

Tank 1

T1

Collector

sensor 1

Solar

circuit

pump 1

Tank

sensor 1,

bottom

Bypass valve

Bypass

sensor

TS3

Tank sensor 1,

top

Heating boiler

connection

according to

page 51-53

29

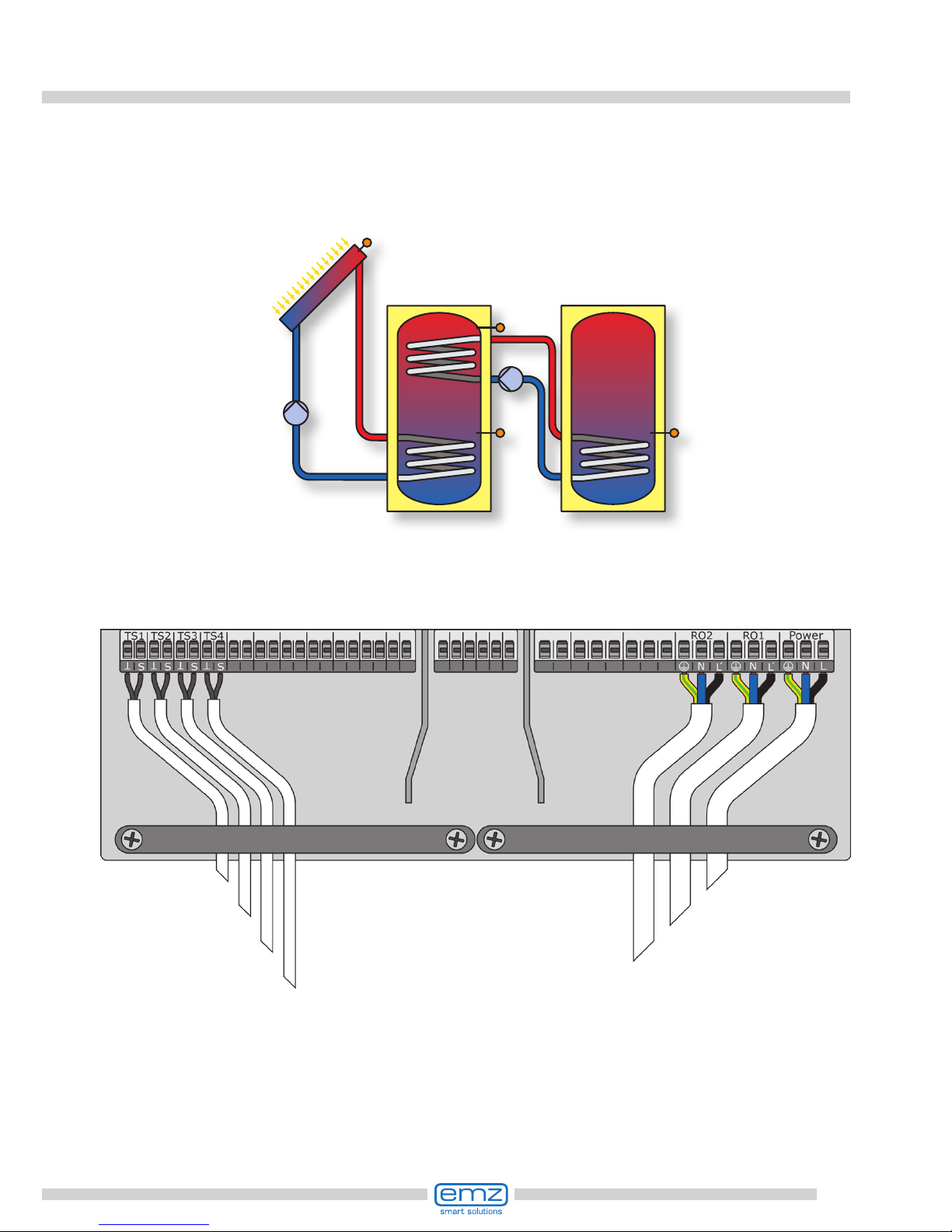

Hydraulic system 9

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top Transfer pump

Tank sensor 2, bottom

TS4

RO1

TS1

TS3

TS2

RO2

Tank 1

T1

Tank 2

T2

Collector

sensor 1

Solar

circuit

pump 1

Tank

sensor 1,

bottom

Transfer

pump

Tank sensor 1,

top

Tank

sensor 2,

bottom

30

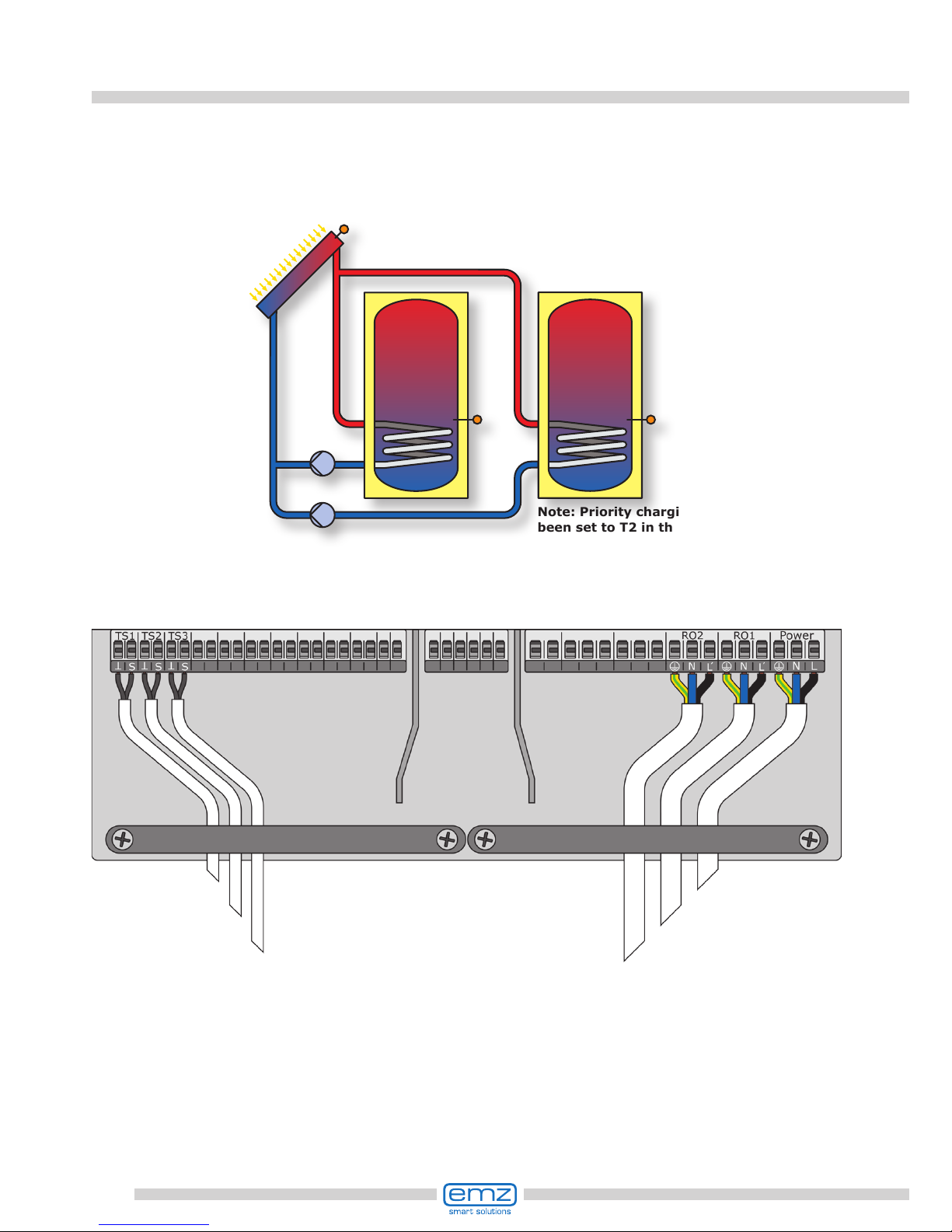

Hydraulic system 10

Note: Priority charging has

been set to T2 in the factory.

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 2, bottom Solar circuit pump 2

TS2

TS1

TS3

RO1

RO2

Tank 1

T1

Tank 2

T2

Collector

sensor 1

Solar circuit

pump 1

Tank

sensor 1,

bottom

Solar circuit pump 2

Tank

sensor 2,

bottom

31

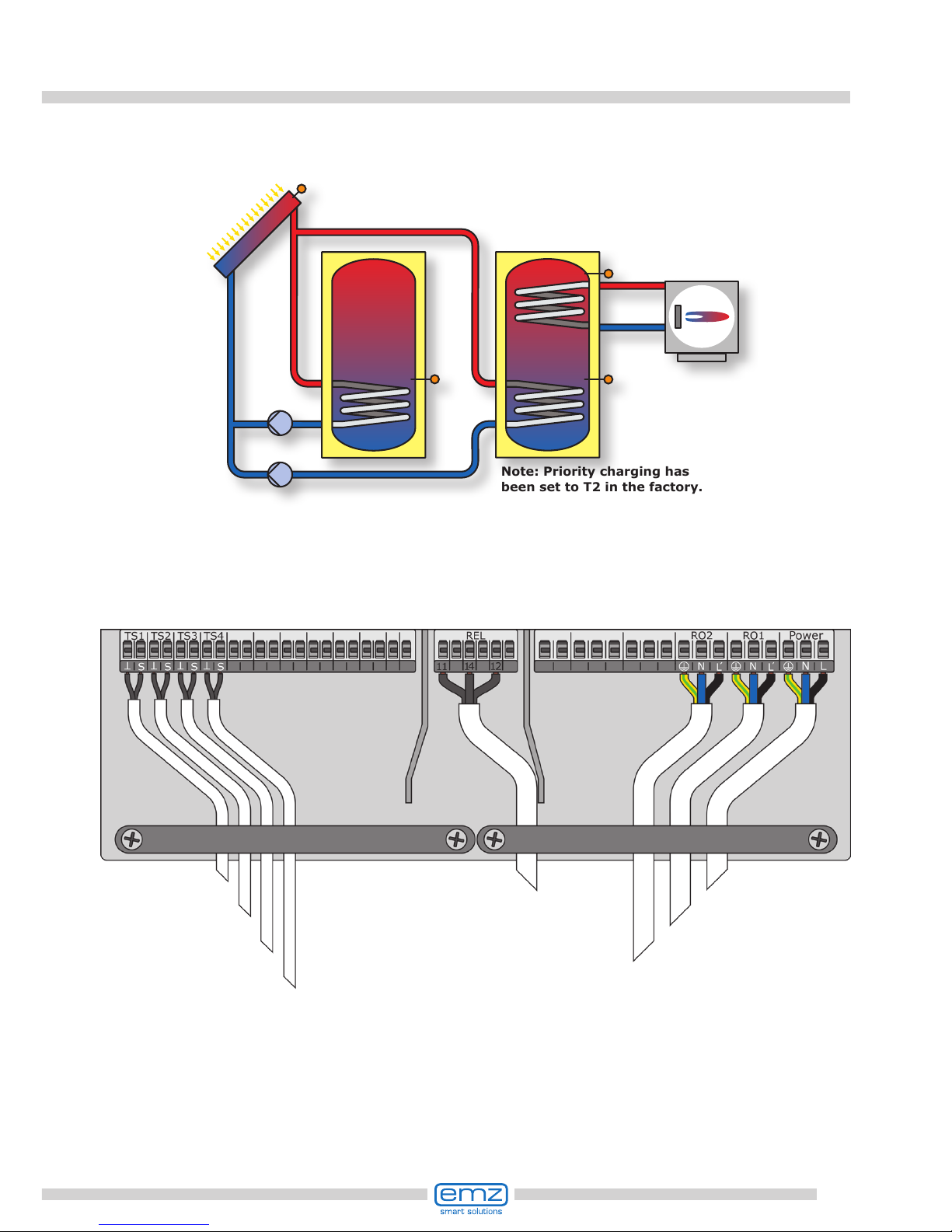

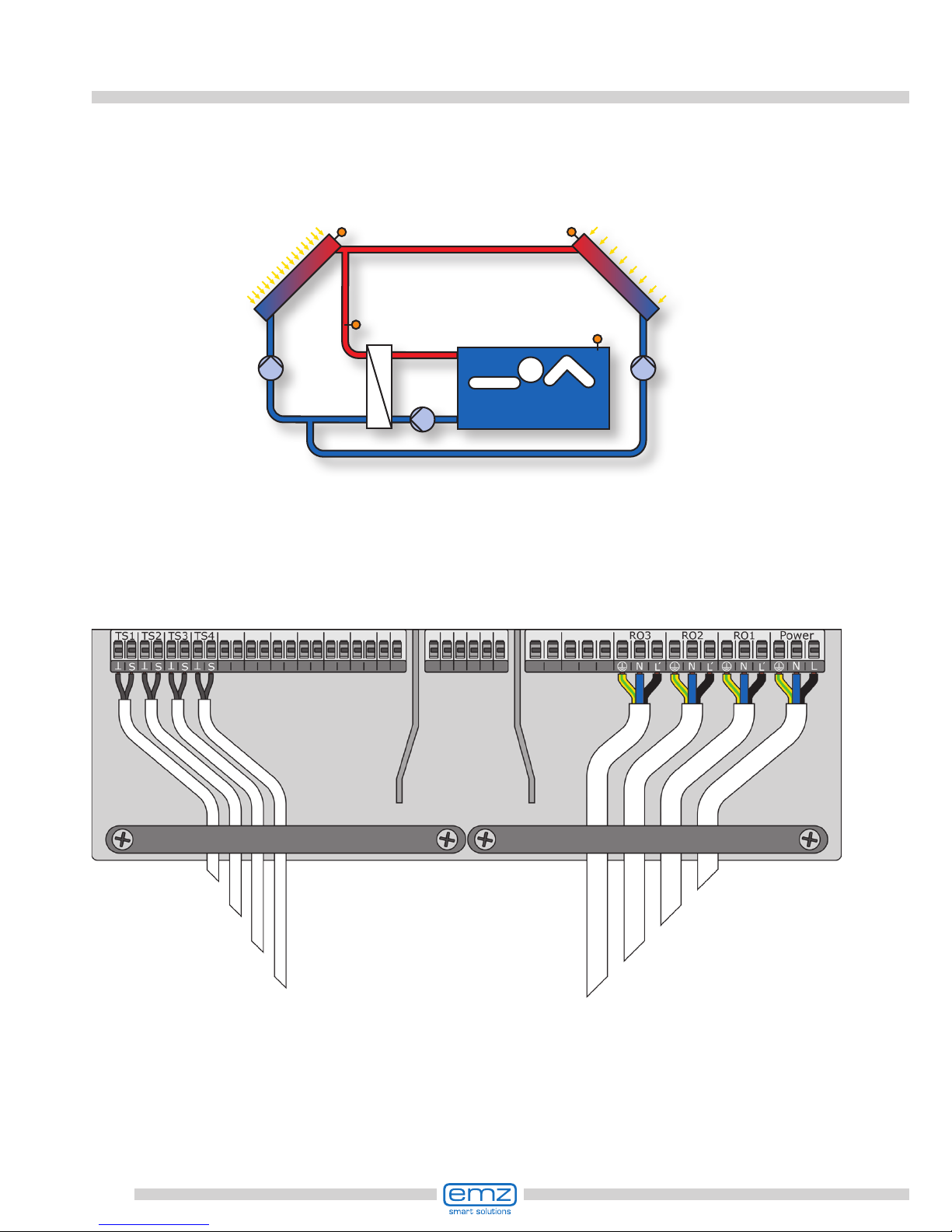

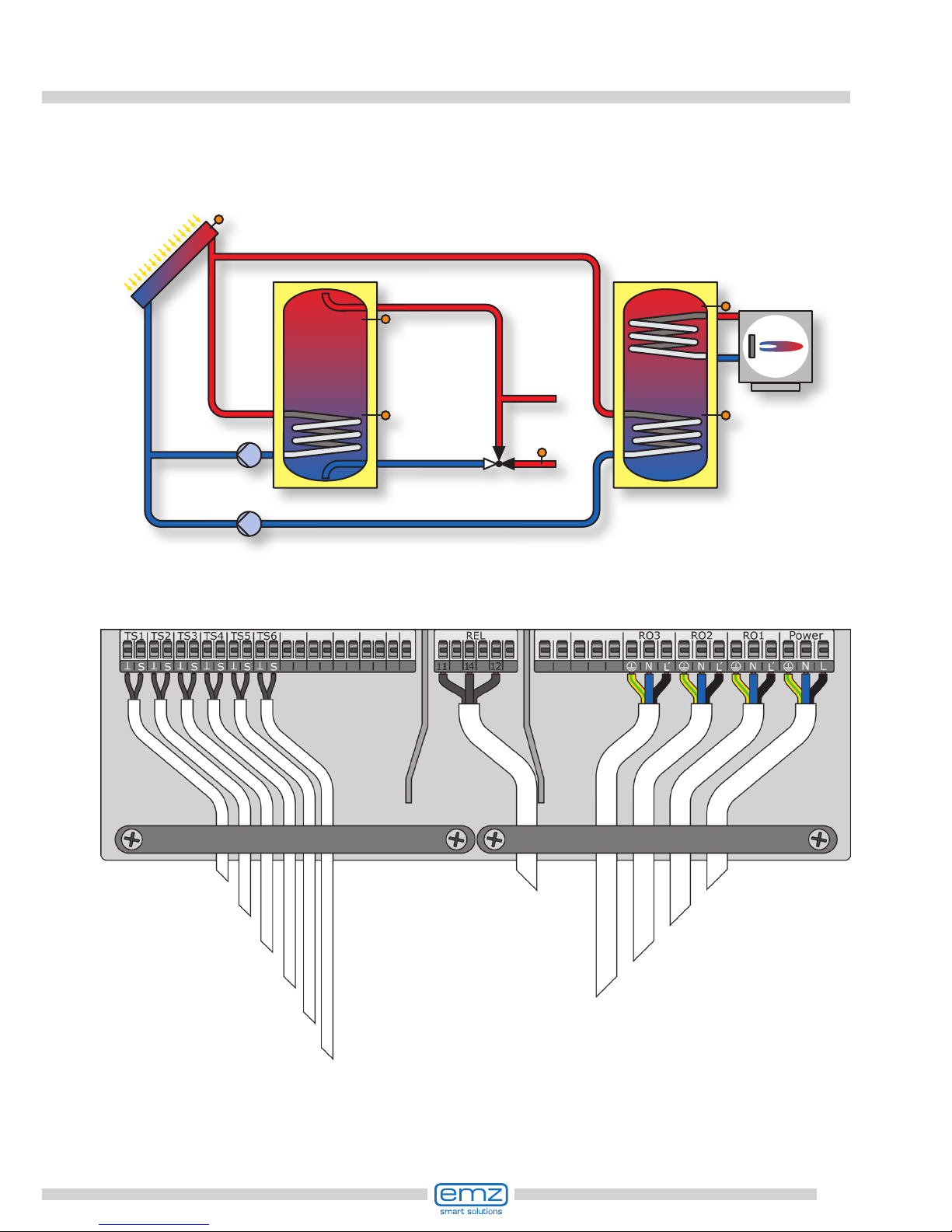

Hydraulic system 11

Note: Priority charging has

been set to T2 in the factory.

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top Solar circuit pump 2

Tank sensor 2, bottom

TS2

TS1

TS4

RO1

RO2

Tank 1

T1

Tank 2

T2

Collector

sensor 1

Solar circuit

pump 1

Tank

sensor 1,

bottom

Solar circuit

pump 2

Tank

sensor 2,

bottom

TS3

Tank sensor 2,

top

Heating boiler

connection

according to

page 51-53

32

Hydraulic system 12

Note: Priority charging has

been set to T2 in the factory.

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 2, bottom Tank switching valve

TS2

RO1

TS1

RO2

TS3

Tank 1

T1

Tank 2

T2

Collector

sensor 1

Solar circuit

pump 1

Tank

sensor 1,

bottom

Tank switching valve

Tank

sensor 2,

bottom

33

Hydraulic system 13

Note: Priority charging has

been set to T2 in the factory.

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 2, top Tank switching valve

Tank sensor 2, bottom

TS2

RO1

TS1

RO2

TS4

Tank 1

T1

Tank 2

T2

Collector

sensor 1

Solar circuit

pump 1

Tank

sensor 1,

bottom

Tank switching valve

Tank

sensor 2,

bottom

TS3

Tank sensor 2,

top

Heating boiler

connection

according to

page 51-53

34

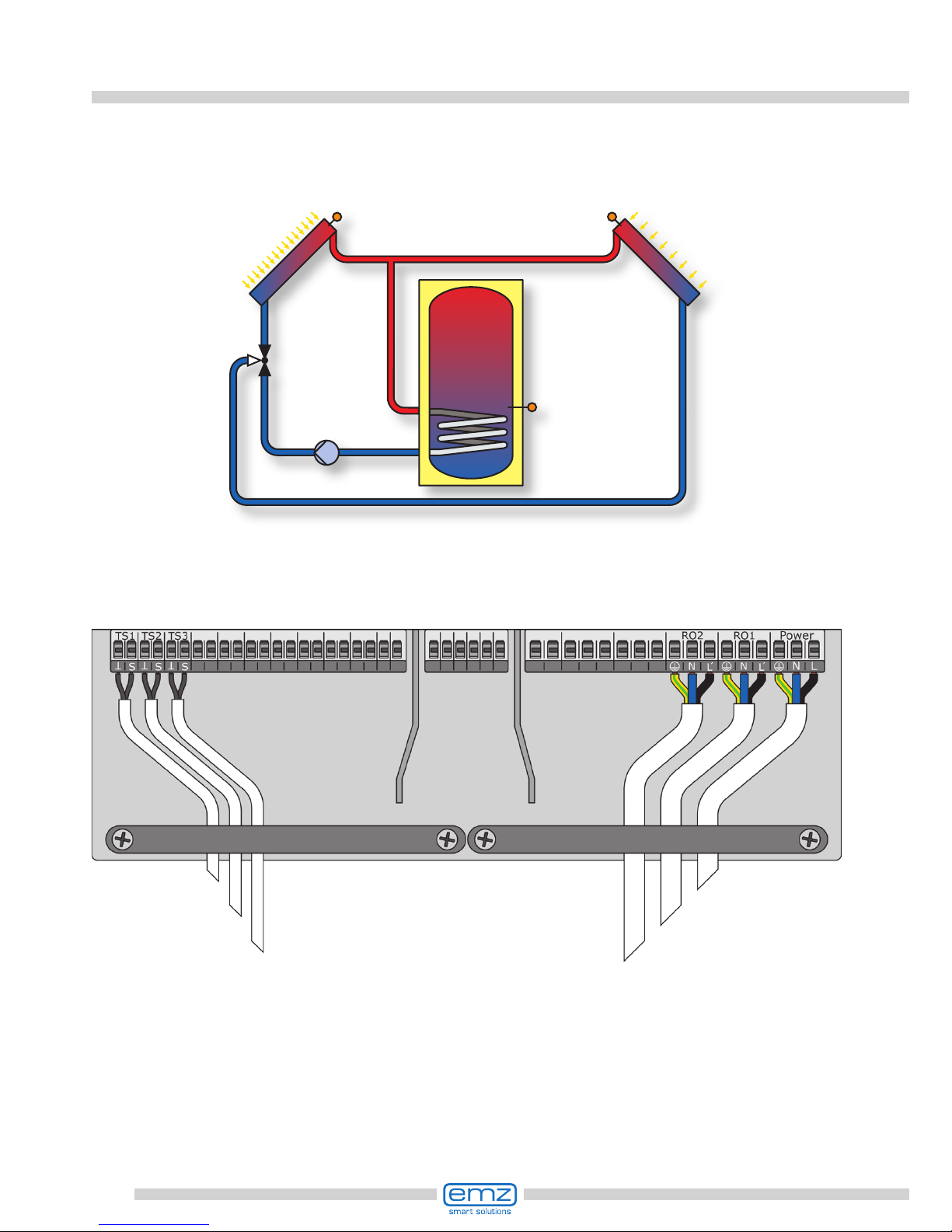

Hydraulic system 14

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Collector sensor 2 Solar circuit pump 2

TS2

TS1

TS3

RO1

Tank 1

T1

Collector

sensor 1

Solar circuit

pump 1

Tank

sensor 1,

bottom

Collector

sensor 2

RO2

Solar circuit

pump 2

35

Hydraulic system 15

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top Solar circuit pump 2

Collector sensor 2

TS3

TS2

TS1

TS4

RO1

Tank 1

T1

Collector

sensor 1

Solar circuit

pump 1

Tank

sensor 1,

bottom

Collector

sensor 2

RO2

Solar circuit

pump 2

Tank sensor 1,

top

Heating boiler

connection

according to

page 51-53

36

Hydraulic system 16

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Collector sensor 2 Three-way valve

TS2

TS1

TS3

RO1

Tank 1

T1

Collector

sensor 1

Solar circuit

pump 1

Tank

sensor 1,

bottom

Collector

sensor 2

RO2

Three-way valve

37

Hydraulic system 17

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top Three-way valve

Collector sensor 2

TS3

TS2

TS1

TS4

RO1

Tank 1

T1

Collector

sensor 1

Solar circuit

pump 1

Tank

sensor 1,

bottom

Collector

sensor 2

RO2

Tank sensor 1,

top

Three-way valve

Heating boiler

connection

according to

page 51-53

38

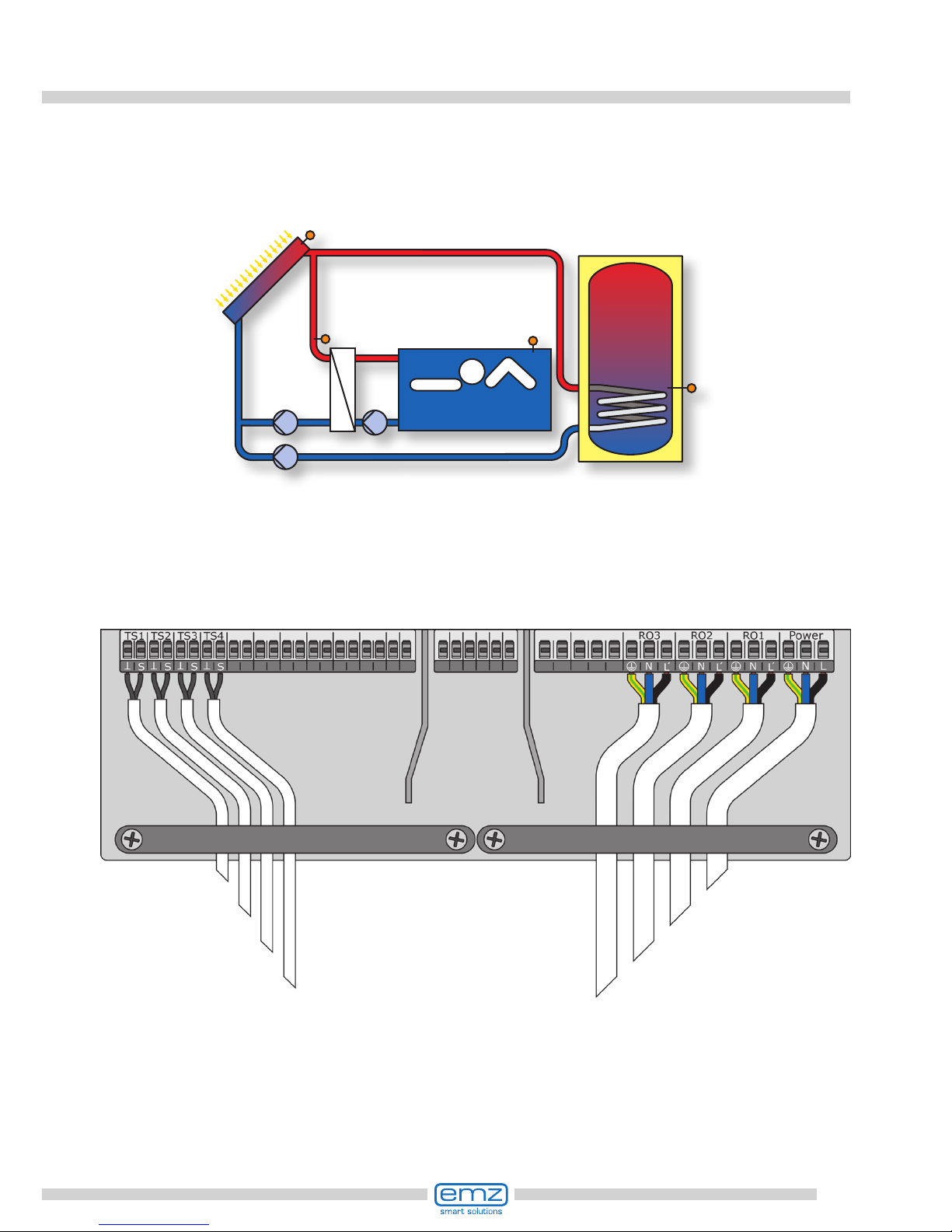

Hydraulic system 18

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 2, bottom Tank switching valve

TS2

RO1

TS1

RO2

TS3

Tank 1

T1

Tank 2

T2

Collector sensor 1

Solar circuit

pump 1

Tank

sensor 1,

bottom

Tank switching valve

Tank

sensor 2,

bottom

Note: Priority charging has

been set to T2 in the factory.

39

RO1

Solar

circuit

pump 1

RO2

Three-way valve

Tank 1

T1

Tank 2

T2

Tank 3

T3

TS1

Collector sensor 1

TS2

Tank

sensor 1,

bottom

TS3

Tank

sensor 2,

bottom

TS4

Tank

sensor 3,

bottom

RO3

Three-way valve

Hydraulic system 19

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 2, bottom Three-way valve

Tank sensor 3, bottom Three-way valve

40

Hydraulic system 20

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top

Return line sensor

TS3

TS2

TS1

RO1

Tank 1

T1

Collector

sensor 1

Solar circuit

pump 1

Tank

sensor 1,

bottom

Tank

sensor

1, top

TS4

Return line

sensor

Three-way valve,

return temperature

increase

RO3

Three-way valve,

return temperature increase

41

Hydraulic system 21

Collector

sensor 1

Connection to

power supply

Heat exchanger

sensor

Solar circuit pump 1

Swimming pool sensor Heat exchanger pump

Collector sensor 2 Three-way valve

TS3

TS2

TS1

RO1

1 Collector sensor 2

Solar circuit

pump 1

TS4

Swimming

pool sensor

Heat

exchanger

sensor

Heat exchanger pump

RO3

RO2

Three-way valve

42

Hydraulic system 22

Collector

sensor 1

Connection to

power supply

Heat exchanger

sensor

Solar circuit pump 1

Swimming pool sensor Solar circuit pump 2

Collector sensor 2 Heat exchanger pump

TS3

TS2

TS1

RO1

1 Collector sensor 2

Solar circuit

pump 1

TS4

Swimming

pool sensor

Heat

exchanger

sensor

Heat exchanger pump

RO3

RO2

Solar circuit

pump 2

43

Hydraulic system 23

Collector

sensor 1

Connection to

power supply

Heat exchanger

sensor

Solar circuit pump 1

Swimming pool sensor Solar circuit pump 2

Tank sensor 1, bottom Heat exchanger pump

TS3

TS2

TS1

RO1

Collector sensor 1

Solar circuit

pump 1

Tank

sensor 1,

bottom

TS4

Swimming

pool sensor

Heat

exchanger

sensor

Heat exchanger pump

RO3

Tank 1

T1

RO2

Solar circuit pump 2

Note: Priority charging has

been set to T1 in the factory.

44

Hydraulic system 24

Collector

sensor 1

Connection to

power supply

Heat exchanger

sensor

Solar circuit pump 1

Swimming pool sensor Heat exchanger pump

Tank sensor 1, bottom Three-way valve, buffer tank 1

TS3

TS2

TS1

RO1

Collector sensor 1

Solar circuit

pump 1

Tank

sensor 1,

bottom

TS4

RO3

Swimming

pool sensor

Heat

exchanger

sensor

Heat exchanger pump

Three-way valve,

buffer tank 1

RO2

Tank 1

T1

Note: Priority charging has

been set to T1 in the factory.

45

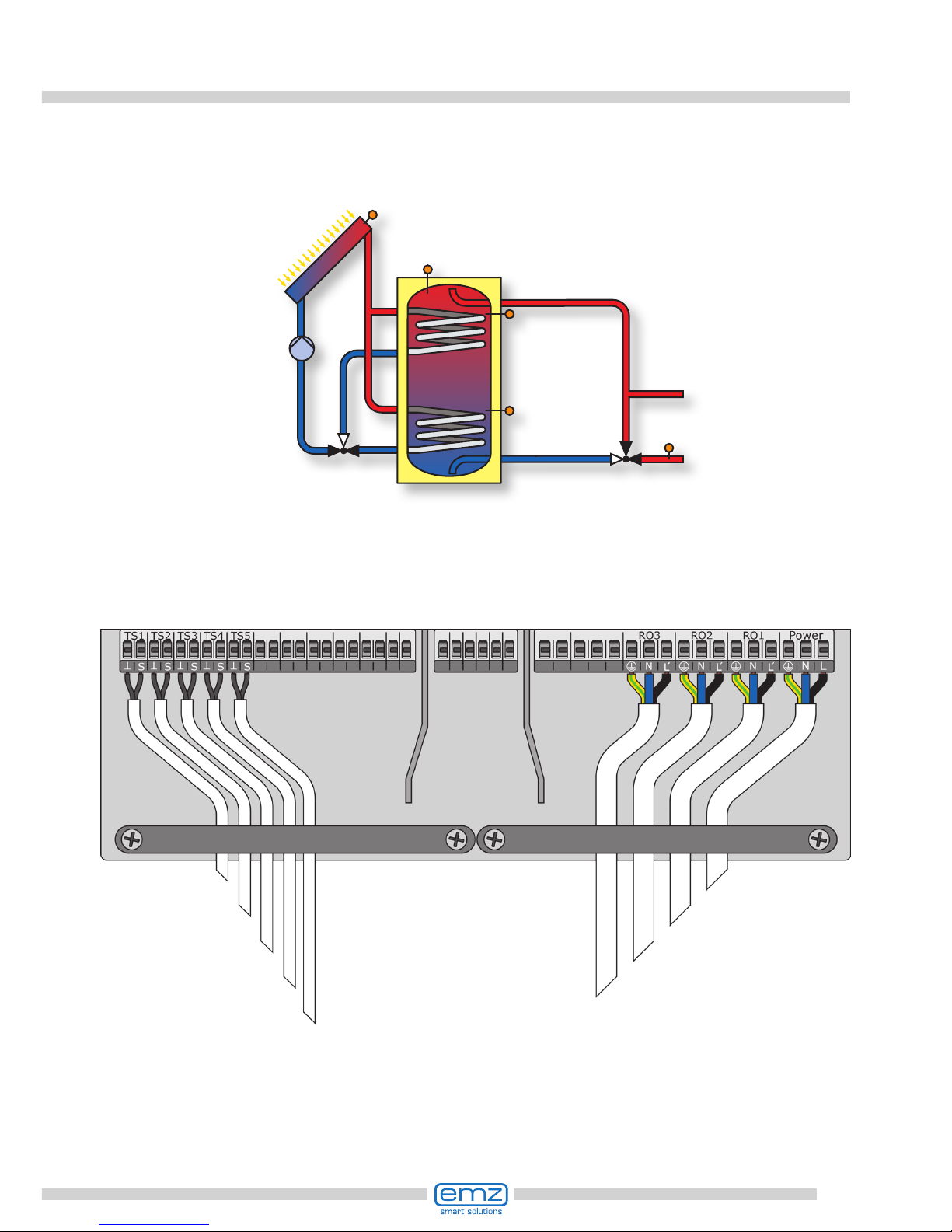

Hydraulic system 25

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top Charging area valve

Tank sensor return line Three-way valve,

return temperature increase

Return line sensor

TS3

TS1

RO1

Tank 1

T1

Collector sensor 1

Solar

circuit

pump 1

Tank sensor 1,

top

TS2

Tank sensor 1,

bottom

Return

line sensor

Three-way valve, return

temperature increase

RO3

RO2

Charging area valve

TS5

Tank sensor

return line

TS4

46

Hydraulic system 26

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top Solar circuit pump 2

Collector sensor 2 Three-way valve,

return temperature increase

Return line sensor

TS3

TS1

TS4

RO1

Tank 1

T1

Collector

sensor 1

Solar circuit

pump 1

Collector

sensor 2

Tank sensor 1,

top

RO2

Solar circuit

pump 2

TS2

Tank sensor 1,

bottom

TS5

Return

line sensor

Three-way valve, return

temperature increase

RO3

Heating boiler

connection

according to

page 51-53

47

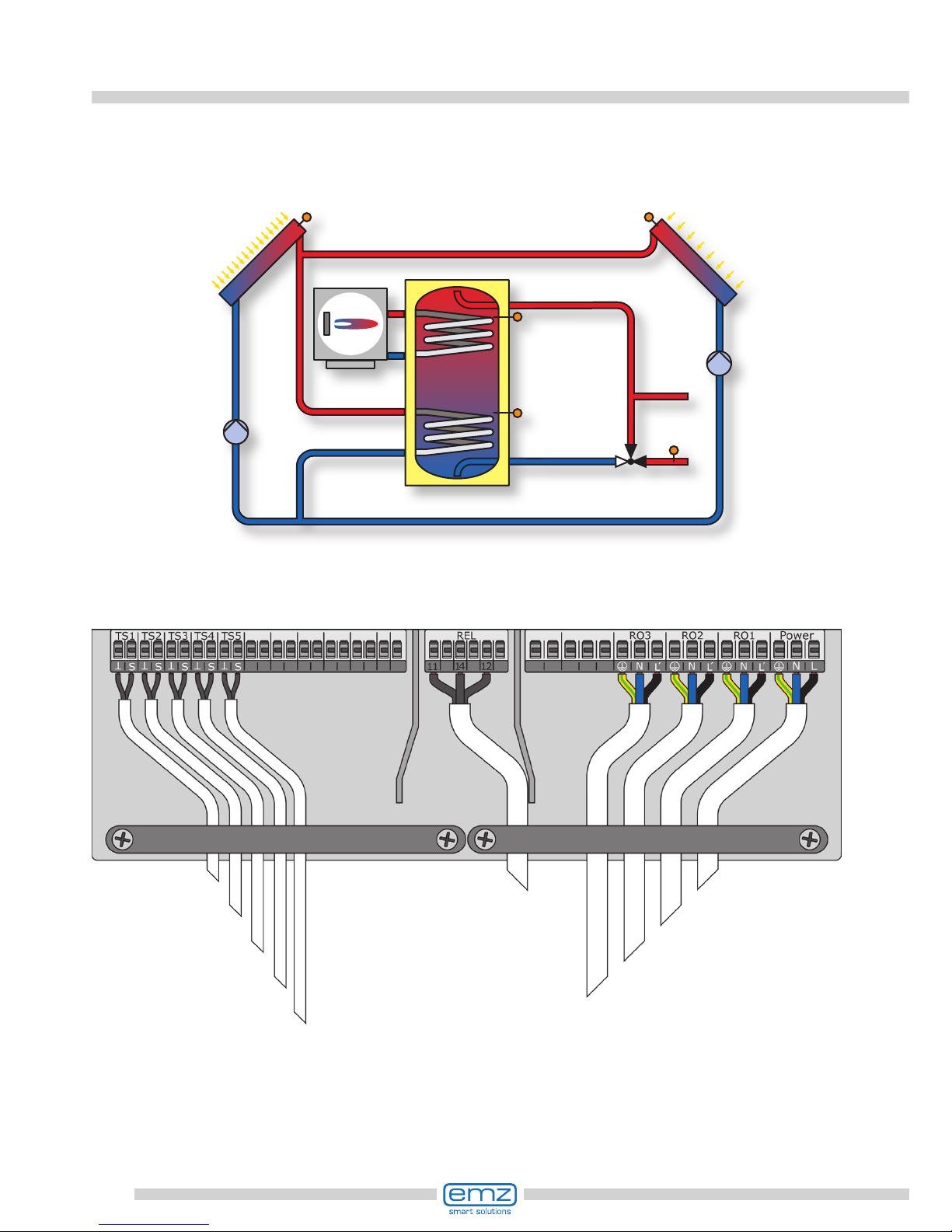

Hydraulic system 27

Collector

sensor 1

Connection to

power supply

Heat exchanger

sensor

Solar circuit pump 1

Swimming pool sensor Heat exchanger pump

Tank sensor 1, bottom Three-way valve, buffer tank 1

Tank sensor 1, top Three-way valve,

return temperature increase

Return line sensor

TS5

Tank sensor 1,

top

TS4

Tank sensor 1,

bottom

Return line

sensor

Three-way valve, return

temperature increase

RO4

TS6

TS3

TS2

TS1

RO1

Collector sensor 1

Solar circuit

pump 1

RO3

Swimming

pool sensor

Heat

exchanger

sensor

Heat exchanger pump

Three-way valve,

buffer tank 1

RO2

Tank 1

T1

Note: Priority charging has

been set to T1 in the factory.

48

Hydraulic system 28

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top Three-way valve

Collector sensor 2 Three-way valve,

return temperature increase

Return line sensor

TS3

TS1

TS4

RO1

Tank 1

T1

Collector

sensor 1

Solar circuit

pump 1

Collector

sensor 2

Tank sensor 1,

top

RO2

TS2

Tank sensor 1,

bottom

TS5

Return

line sensor

Three-way valve, return

temperature increase

RO3

Three-way valve

Heating boiler

connection

according to

page 51-53

49

Hydraulic system 29

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top Solar circuit pump 2

Tank sensor 2, bottom Three-way valve,

return temperature increase

Tank sensor 2, top

Return line sensor

TS3

TS1

RO1

Tank 1

T1

Collector

sensor 1

Solar

circuit

pump 1

Tank sensor 1,

top

TS2

Tank sensor 1,

bottom

TS6

Return line

sensor

Three-way valve, return

temperature increase

RO3

RO2

Solar

circuit

pump 2

Tank 2

T2

TS5

Tank sensor 2,

top

TS4

Tank sensor 2,

bottom

Note: Priority charging has

been set to T2 in the factory.

Heating boiler

connection

according to

page 51-53

50

Hydraulic system 30

Collector

sensor 1

Connection to

power supply

Tank sensor 1,

bottom

Solar circuit pump 1

Tank sensor 1, top Tank switching valve

Tank sensor 2, bottom Three-way valve,

return temperature increase

Tank sensor 2, top

Return line sensor

TS3

TS1

RO1

Tank 1

T1

Collector

sensor 1

Solar circuit

pump 1

Tank sensor 1,

top

TS2

Tank sensor 1,

bottom

TS6

Return

line sensor

Three-way valve, return

temperature increase

RO3

RO2

Tank switching

valve

Tank 2

T2

TS5

Tank sensor 2,

top

TS4

Tank sensor 2,

bottom

Note: Priority charging has

been set to T2 in the factory.

Heating boiler

connection

according to

page 51-53

51

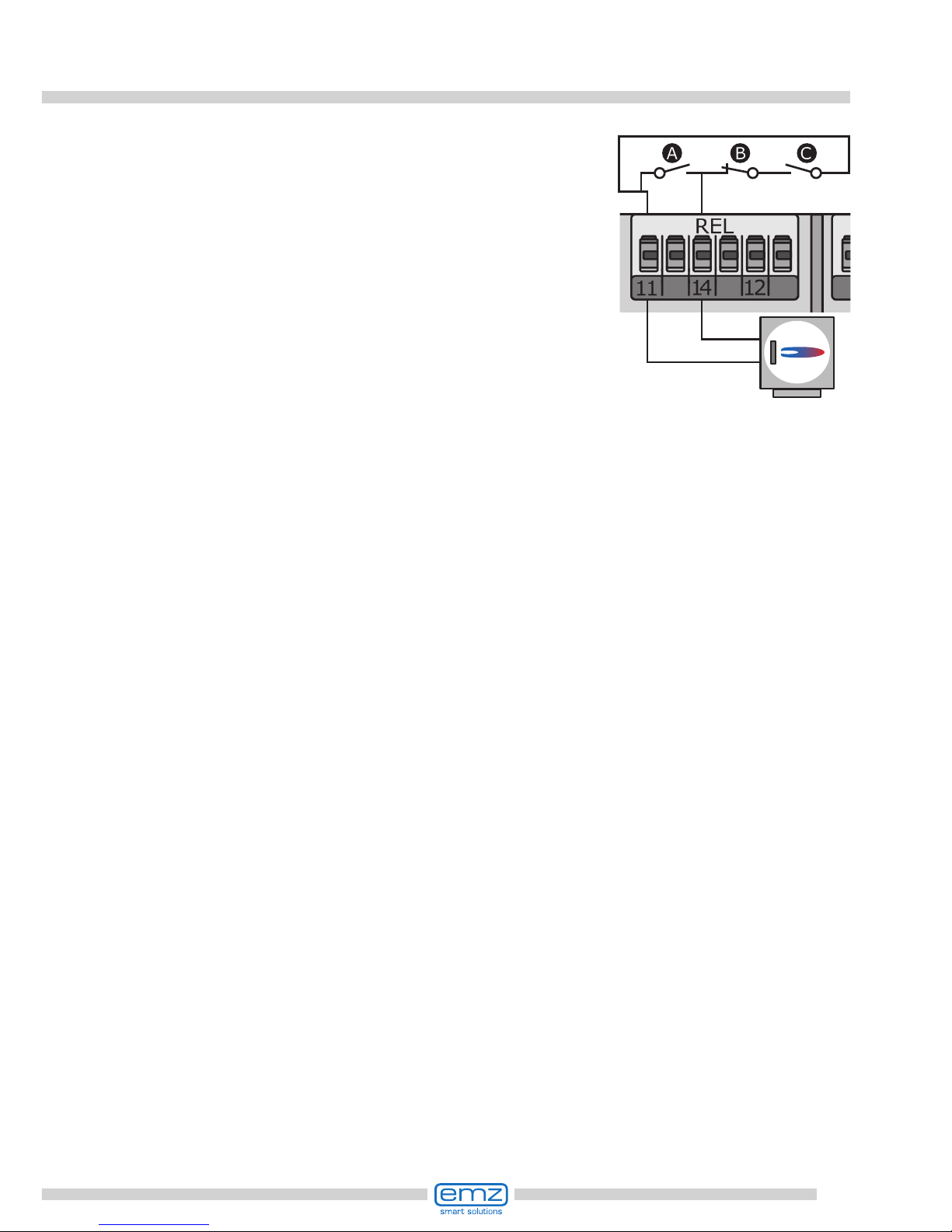

Functions for boiler control

The functions for boiler control are accomplished

via the potential-free relay contact which is connected

accordingly to the relevant interface of the heating boiler.

The individual functions are assigned

the following priorities:

A Anti-legionella priority 1

B recharge suppression priority 2

C reheating priority 3

Boiler

Anti-legionella function

The anti-legionella functions checks if the minimum heating for reduction of legionella

has been achieved in the tank due to heating activity or solar heat within a set interval.

f no sufcient heating has been achieved by these means the controller starts a reheat

cycle, specically for reduction of legionella.

The tter must set the parameters based on the applicable general directives and local

requirements. The time of the disinfection cycle can be determined freely.

Reheat function

The temperature sensor in the upper tank area supplies the values for reheating.

For oil or gas operated systems, reheating takes place via the heating boiler.

For solid-fuel boilers, reheating takes place via the heat present in the drinking water

tank. To this effect, the temperature within the tank must be within preset limits.

The temperature control is interlinked with six time blocks.

Reheating is activated as soon as the temperature falls below

the set value by the hysteresis value in the current time block.

When the set value is exceeded the reheating cycle stops.

Disable recharge

The efciency of a solar plant increases as the recharge of the tank from the

boiler decreases. Consequently, „disable recharge“ means that

recharging of the water tank is blocked by the boiler.

Time-controlled disable recharge

Recharge is blocked by the boiler for specic phases via a time program.

Within the preset period of time (for ex. 7 to 19 h), recharge is blocked completely

by the boiler without requiring the minimum temperature to this effect.

52

Functions for boiler control

Time-/temperature-controlled disable recharge

If a minimum temperature in the tank is exceeded, disable recharge is activated.

This function can be activated in parallel to the time program.

If the preset minimum temperature (e. g. 45°C) in the tank

is exceeded, recharge of the tank is disabled by the boiler.

If, however, the minimum temperature is no longer reached, recharge is enabled

by the boiler no matter whether the time program blocks recharge or not.

Efciency-optimized recharge suppression

If the calculated minimum temperature in the buffer tank is exceeded, the

disabled recharge feature is activated. The installer can specify two weighting

factors in menu 1.4.3 for the calculation of this minimum temperature:

Factor 1 Parameter values from 1-10 whereby:

Solar yield 1 = more solar yield, less recharge by the boiler

:

10 = less solar yield, more recharge by the boiler

Factor 2 Parameter values from 1-10 whereby:

Comfort 1 = lower comfort, less recharge by the boiler

:

10 = higher comfort, more recharge by the boiler

t

T

Factor 1 = 7

Factor 2 = 7

t

T

Factor 2 = 1

Factor 1 = 5

t

T

Factor 2 = 5

Factor 1 = 1

A exible minimum

temperature is thus

calculated once per

day which disables the

recharge by the boiler.

This exible minimum

temperature is between

›T min. tank‹ and ›T target‹.

Q

t

Solar energy history

t

T

T min. tank (e.g.35°C)

T targ. (e.g. 45°C)

Recharge active

Recharge suppressed

53

Functions for boiler control

Sensor type Pt 100 Pt 500 Pt 1000

R Terminal 12 130 Ω 620 Ω 1,3 kΩ

Colour code

Boiler

R (T=70°C)

Tank sensor

top

Note!

For boilers without control input, the functions for boiler control

can be accessed by the simulation of temperature values.

To enable reheating or anti-legionella functions, the corresponding

boiler temperature must be increased at the boiler control.

The differential temperature controller smart Sol plus

regulates the boiler control functions by a xed value

resistance simulating a charged buffer tank for the boiler.

The resistance value depends on the type of sensor the heating

is adjusted to - this information is provided in the boiler manual.

Connection provided at the

REL terminal block, as illustrated.

54

T OFF

ROx

T

t

T ON

Temperature thermostat ›Cooling‹:

T ON > T OFF The output is activated once the

›T ON‹ temperature is reached, and deactivated

once the ›T off‹ temperature is reached.

T ON

ROx

T

t

T OFF

Temperature thermostat ›Heating‹:

T OFF > T ON The output is deactivated once the

›T OFF‹ temperature is reached, and activated

once the ›T ON‹ temperature is reached.

Thermostat functions

ROx

8:00 9:00

t

T OFF

ROx

T

t

T ON

8:00 9:00

The controller’s free outputs can be used as thermostats for various applications.

Settings must be made to this effect in professional mode under ›1.3.1 Thermostat‹.

Control signals can be dened as temperature thermostat, timer,

timer thermostat or temperature comparator.

Timer-Thermostat

Combination of timer and thermostat.

Once at least one of these criteria is met,

the output is activated.

Temperature comparator

Any temperature difference to a reference

sensor will trigger a control signal:

The output is activated once ›dT ON‹ is reached,

and deactivated once ›dT OFF‹ is reached.

Timer function:

The output is activated

within a selected time frame.

dT OFF

dT ON

ROx

TSx

T

t

Reference sensor

55

RO1

TS1

TS2

TS3

Speicher 1

SP1

Soft water station AQA solar

In the main menu, information transmitted by the soft water station can

be retrieved under ›1.8 AQA solar‹.

In a specic equipment version (with an extension module), the differential

temperature controller smart Sol plus can be connected to the soft water station

AQA solar of BWT Wassertechnik GmbH, Schriesheim.

AQA solar is a decalcication plant based on an ion exchanger, which ensures that

the water lines and heat exchangers in your home are not damaged by scaling.

In case of very intense temporary heating of the drinking water, especially with

thermal solar systems, decalcication is very useful to maintain efciency.

Setup and operation of the equipment combination smart Sol plus and AQA solar

is described in separate documentation and/or the operating manual of BWT.

Integration of the soft water station

is possible in all hydraulic systems of

the smart Sol plus, and is displayed,

e. g.:

For connection, the terminals

›Tx‹, ›Rx‹ and ›Gnd‹ above

the interface terminals TS1 to TS10

are provided on the extension modules.

Soft water

Flow rate

Soft water delivery

recent regeneration

Salt consumption

421l/h

317m3

24.08.2012 09:00

66g

1.8 AQA solar

25.08.2012 10:30

56

57

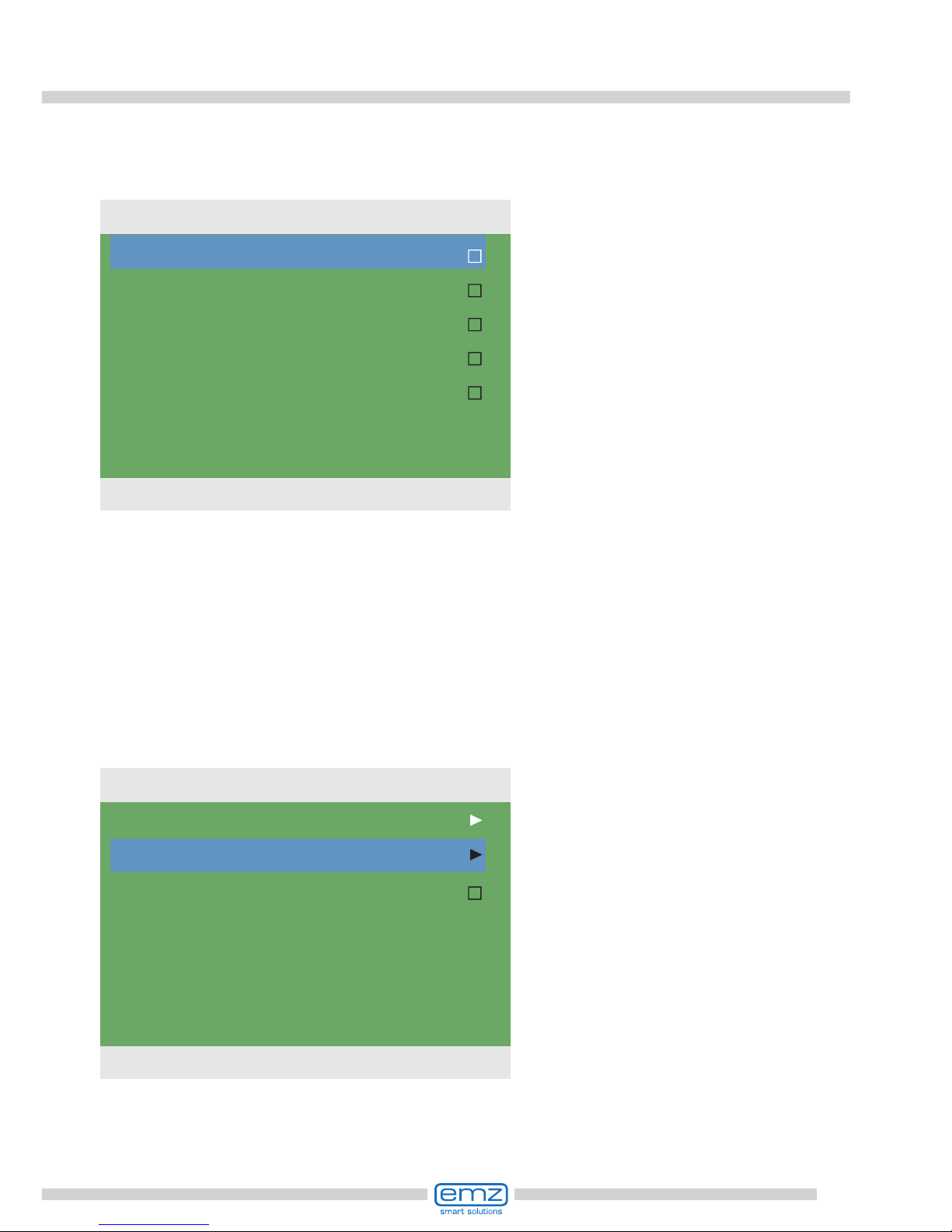

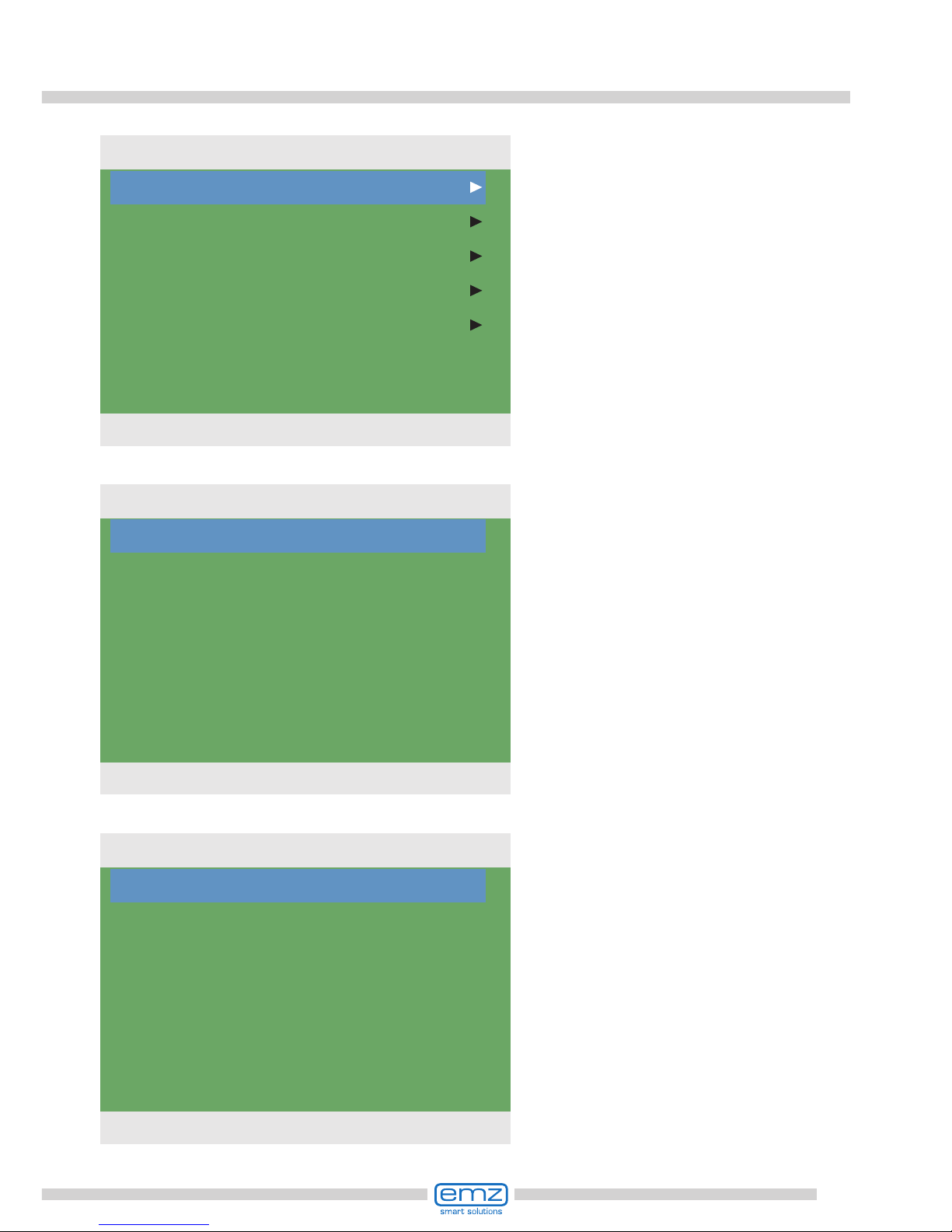

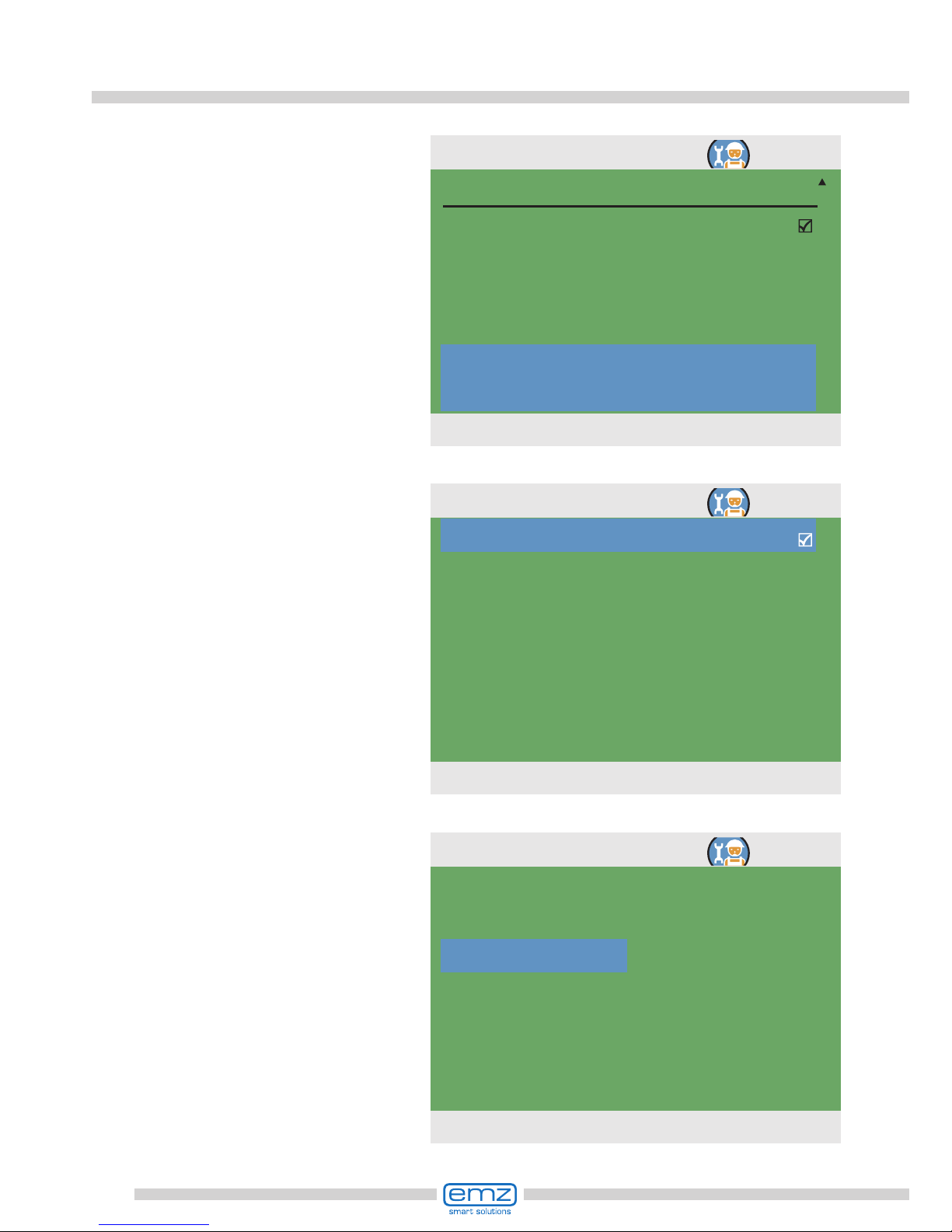

Commissioning mode

›0.1 Language‹ appears after

a short booting sequence.

Various languages are available in

this version of the smart Sol plus.

Activate the required version and

acknowledge by pressing ›Next‹.

This is an explanation in terms of an example of commissioning of the

differential temperature controller smart Sol plus; details vary along

with the hydraulic conguration and the software version.

Commissioning is communicated in plain text; the user must make a

selection, acknowledge and - if applicable - jump to the next menu item.

The differential temperature controller smart Sol plus accompanies you during the

entire conguration and interrogates everything it must know for optimum operation.

Now, the power supply of the controller must

be switched on - the display screen appears.

Important!

For commissioning, the controller must be assembled

correctly, all inputs and outputs must be connected

and ready for operation, the strain relief device must

be screw-fastened and the terminal cover closed!

Deutsch

English

Français

Italiano

Česky

Español

Polski

0.1 Language

25.08.2012 09:12

58

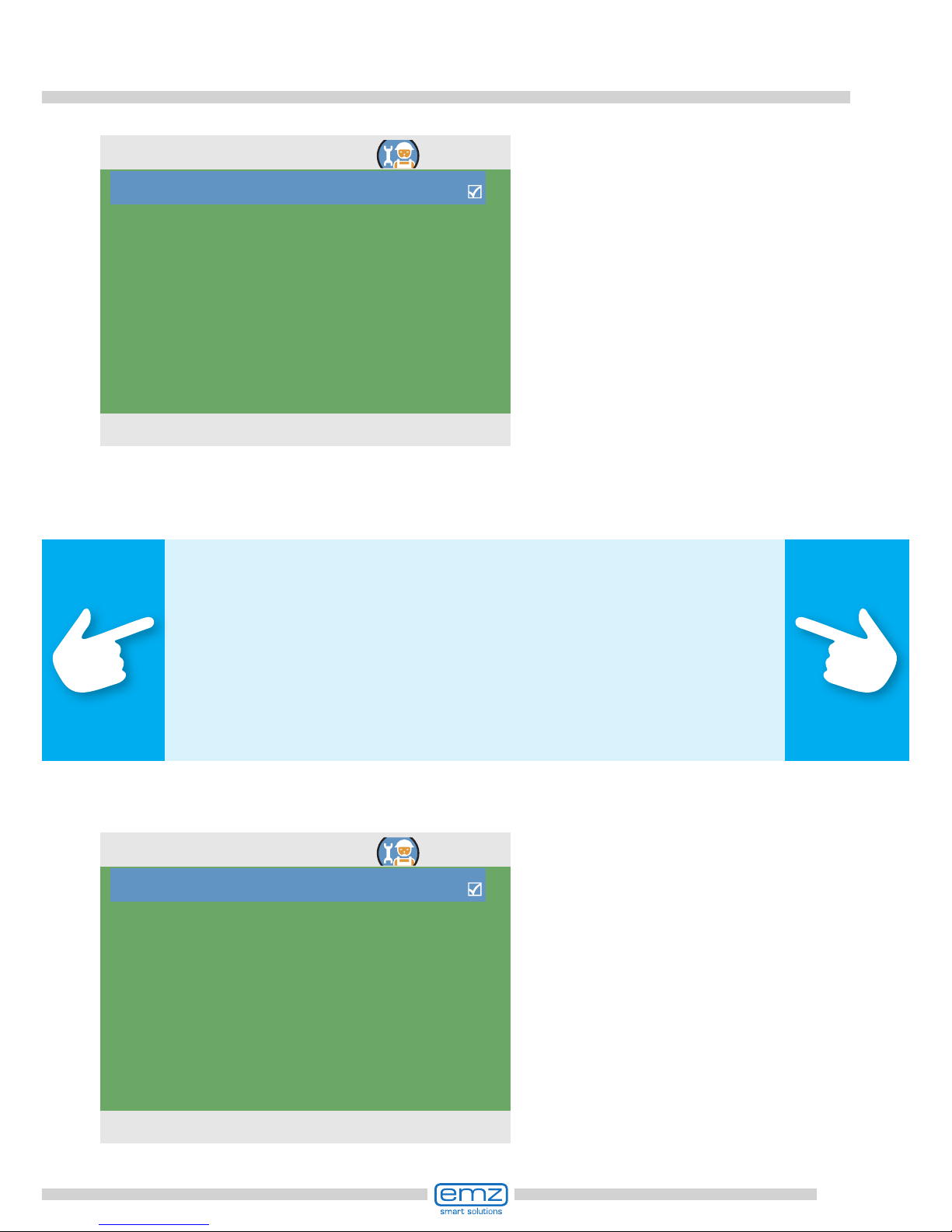

Commissioning mode

›0.3 Inputs‹ appears.

Select and activate the input interfaces TS1 to TS8 used and assign the

selected function to them by scrolling.

Once all inputs have been assigned

correctly, acknowledge by pressing

›Next‹.

Important!

At the interfaces TS6 / TS7 / TS8 an impeller sensor

can be selected as owmeter via ›Impeller‹.

›0.2 Time/date‹ appears.

Press ›OK‹ - the hour is highlighted in

colour.

Turn the rotary encoder until the

correct gure appears, and

acknowledge via the ›OK‹ button.

The controller accepts the value

and jumps to the minute setting.

In this way, all values for time and

date

can be entered.

If the differential temperature controller is installed at a location where

daylight-saving time exists, the time

shift can be activated here.

Acknowledge by pressing ›Next‹.

Date

Time

Automat. Clock Change

25.08.2012

09:12

Next

0.2 Time/Date

25.08.2012 09:12

TS1

TS2

TS3

TS4

77.6°C

Collector 1

46.7°C

Tank1 bottom

42.2°C

Tank2 bottom

61.4°C

0.3 Inputs

25.08.2012 09:12

59

Commissioning mode

›0.5 Outputs‹ appears.

Select and activate the output interfaces RO1 - RO4 / REL used and

assign them to the selected function

by scrolling.

Once all outputs have been assigned

correctly, acknowledge by pressing

›Next‹.

›0.4 Volumetric ow‹ appears.

If TS6 / TS7 / TS8 has already been

assigned to ›Impeller‹, ›Impeller‹ will

appear here in terms of sensor system. The number of pulses per litre

still has to be selected.

If different features (or no features)

are assigned to TS6 / TS7 / TS8, a

vortex sensor or a ow rate detector

can be selected via pump

activation. To this effect, the vortex

volumetric ow sensor installed or the

max. pump ow rate still have to be

dened.

Acknowledge by pressing ›Next‹..

Important!

A high-efciency pump can be connected to TS7 to TS10.

The WILO ST 25/7 PWM is preassigned.

Vortex UI12

Flow rate

connected to

Grundfos 1-12l/min

RO2

Next

0.4 Volumetric flow

25.08.2012 09:13

RO1

HE-control signal

RO2

RO3

RO4

REL

Solar pump 1

---

---

---

---

---

Next

0.5 Outputs

25.08.2012 09:13

60

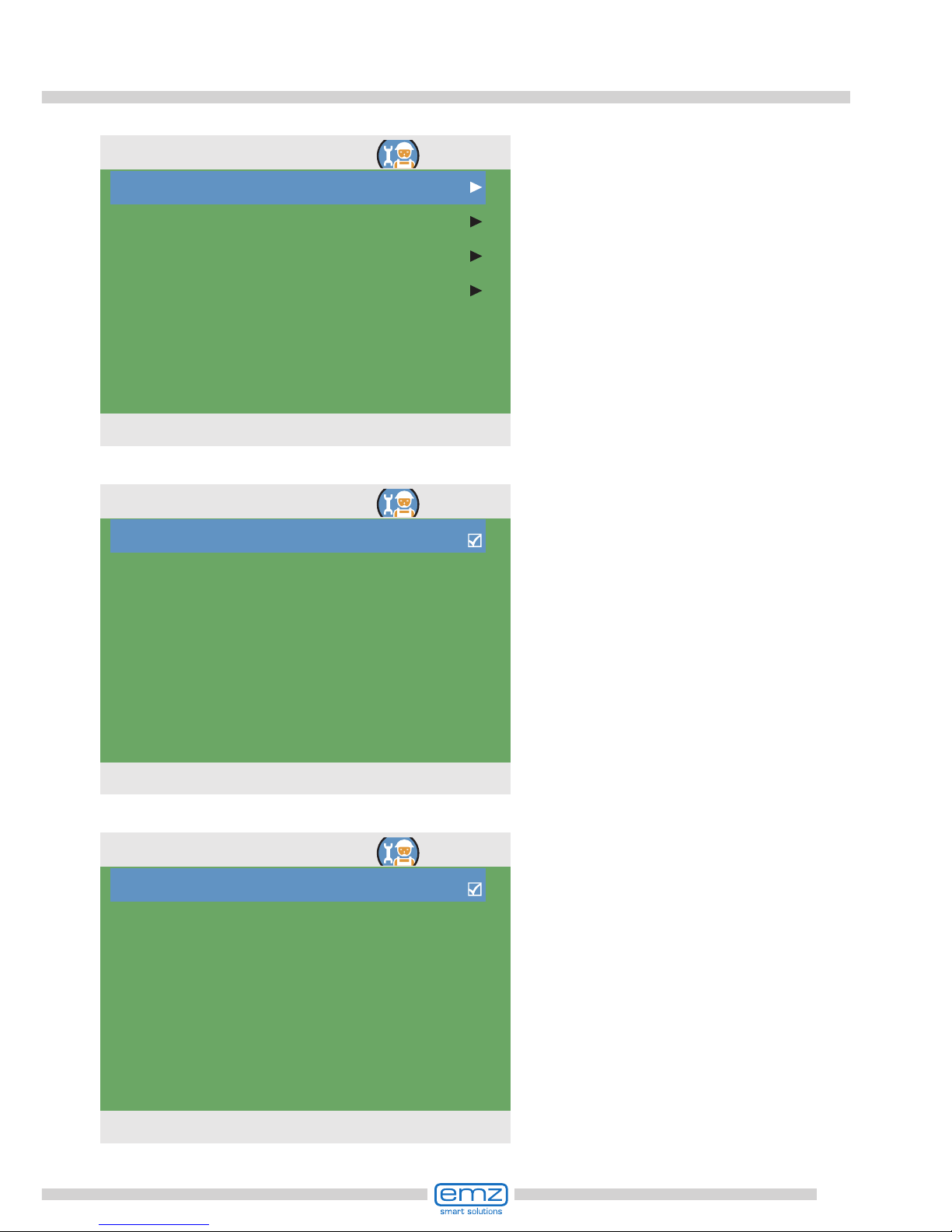

Commissioning mode

›0.7 Checklist‹ appears.

Here, the submenus Test outputs and

Holiday function are made available.

By selecting ›SP 1 (top), a scrollbox

is displayed in which an appropriate

input (TS1 - TS8) can be assigned.

Select Test outputs and activate

by pressing the OK button.

Now, the controller offers the hydraulic systems which are possible due to

the assigned inputs and the selected

outputs.

By turning the rotary encoder, the

required system can be selected

(here system 1 of 3 possible ones)

and acknowledged via the button

›OK‹.

Note!

Here, access to all plant layouts is possible for testing purposes

via the option ›Show all‹. However, for correct operation, one of

the plant layouts suggested by the controller must be selected.

System 1/3

25.08.2012 09:13

Test outputs

Holiday function

Tank 1 top

Next

0.7 Checklist

25.08.2012 09:14

61

Commissioning mode

›0.7 Checklist‹ reappears.

As the plant, when not in use, is only

supplied with heat, but no heat is

withdrawn, it may be subject to

overheating and damage.

Thus, a ›holiday function‹ was

programmed which minimizes

heat input.

Here, the holiday function can be set -

call up by pressing the ›OK‹ button.

›0.8 Test outputs‹ appears.

Here, the outputs can be activated

manuallyvia the ›OK‹ button to test

the function of the activated output or

of the connected unit.

If not all pumps and valves are working properly, the plant elements in

question and the cabling must be

veried and repaired.

Acknowledge by pressing ›Next‹.

RO1

RO2

RO3

RO4

REL

Next

0.7.1 Test outputs

25.08.2012 09:14

Test outputs

Holiday function

Tank 1 top

Next

0.7 Checklist

25.08.2012 09:14

62

Commissioning is complete.

As of this point, the smart Sol plus

controls the solar thermal plant

automatically.

›0.7 Checklist‹ reappears.

Acknowledge by pressing ›Next‹.

›0.9 End‹ appears.

By ›Next‹, the controller

changes over to ›Automatic mode‹.

Various options can be selected

for the holiday function.

At lower ambient temperatures

(e. g. at night), tank recooling tries

to dissipate heat via the collectors.

The soft charge circuit is designed so

that the heat input into the tank is as

low as possible.

The appropriate switch-ON and OFF

temperatures must be varied as

required.

Acknowledge by pressing ›Next‹.

Commissioning mode

Tank recooling

Soft charge

T-ON

T-OFF

120.0°C

100.0°C

Next

0.7.2 Holiday function

25.08.2012 09:14

You have completed

commissioning!

Next

0.9 End

25.08.2012 10:15

System 11

25.08.2012 09:16

63

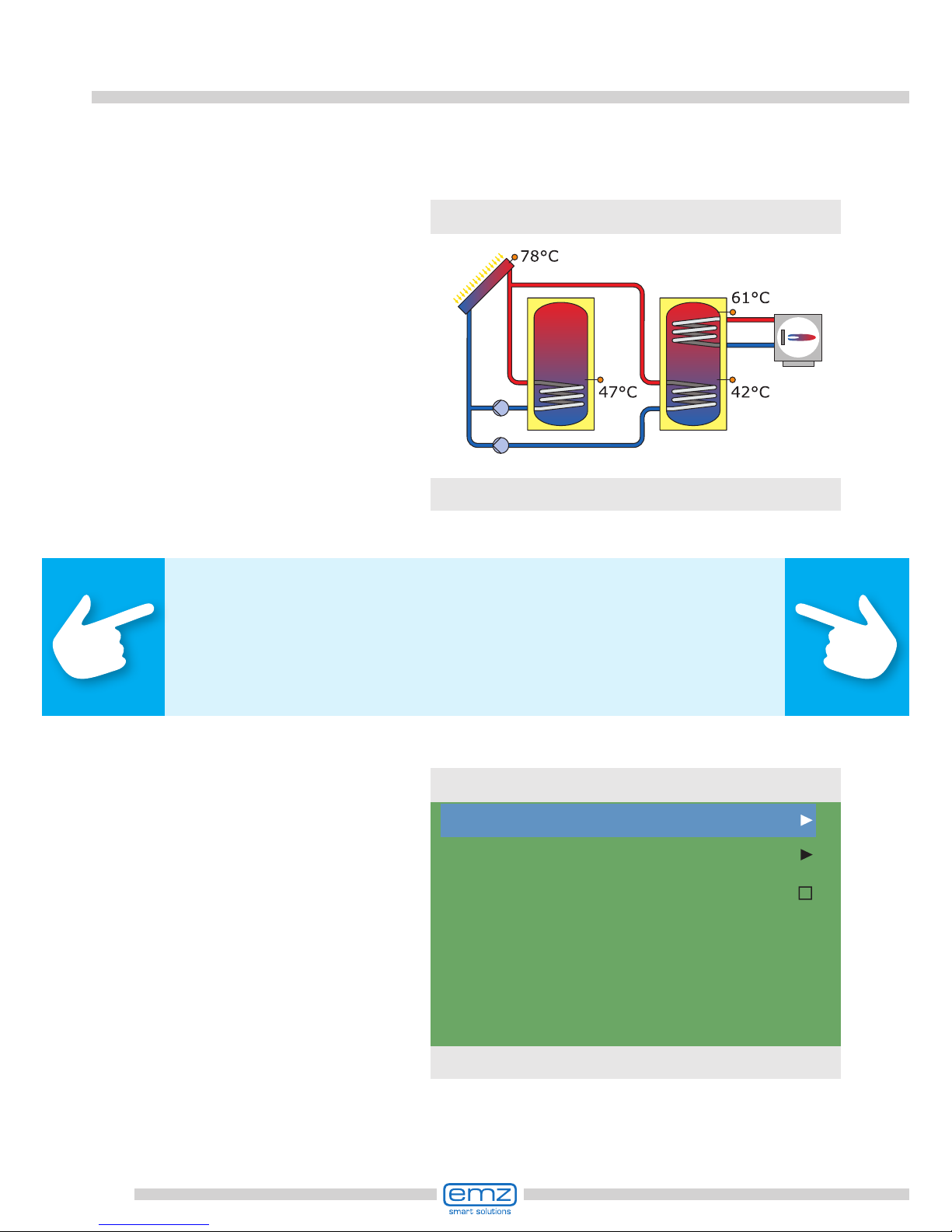

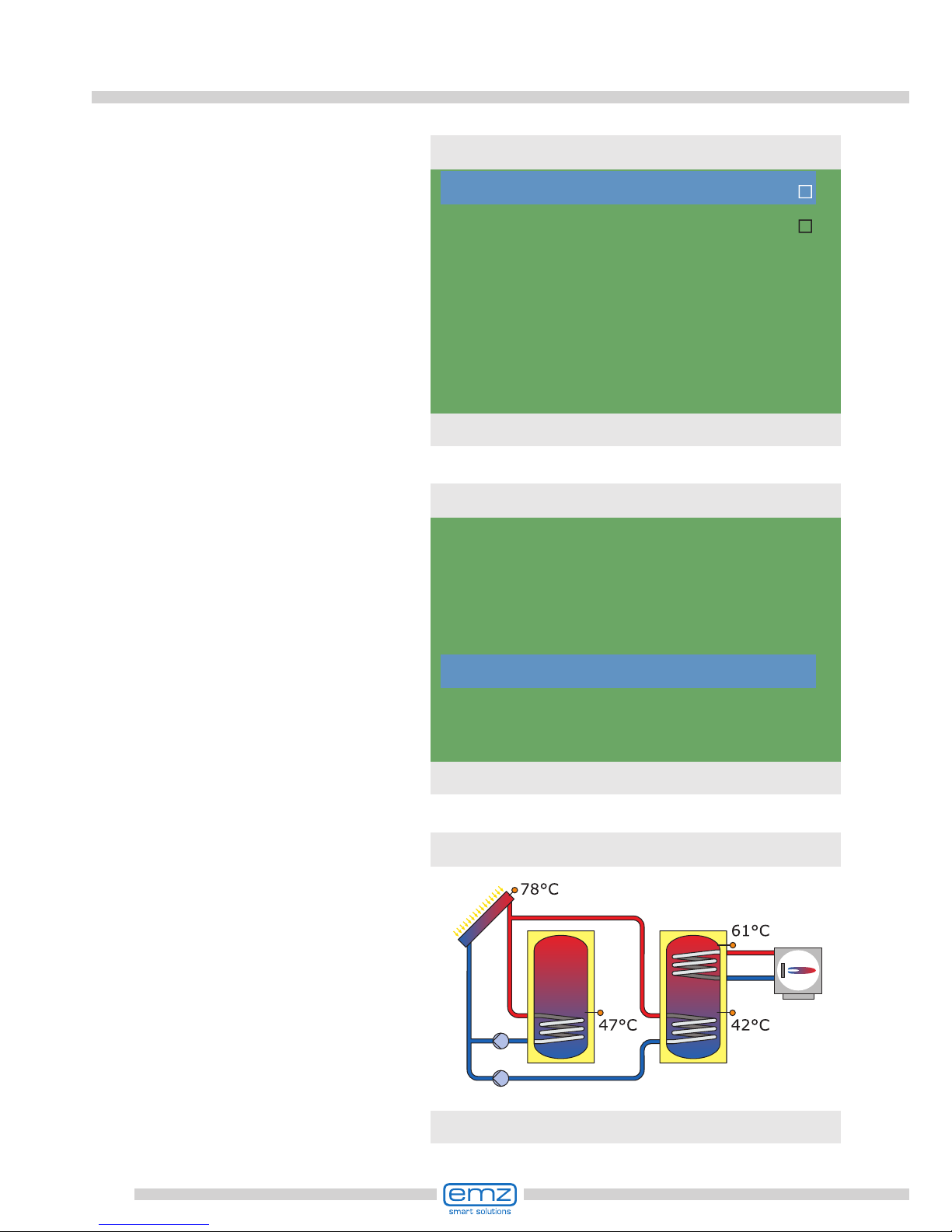

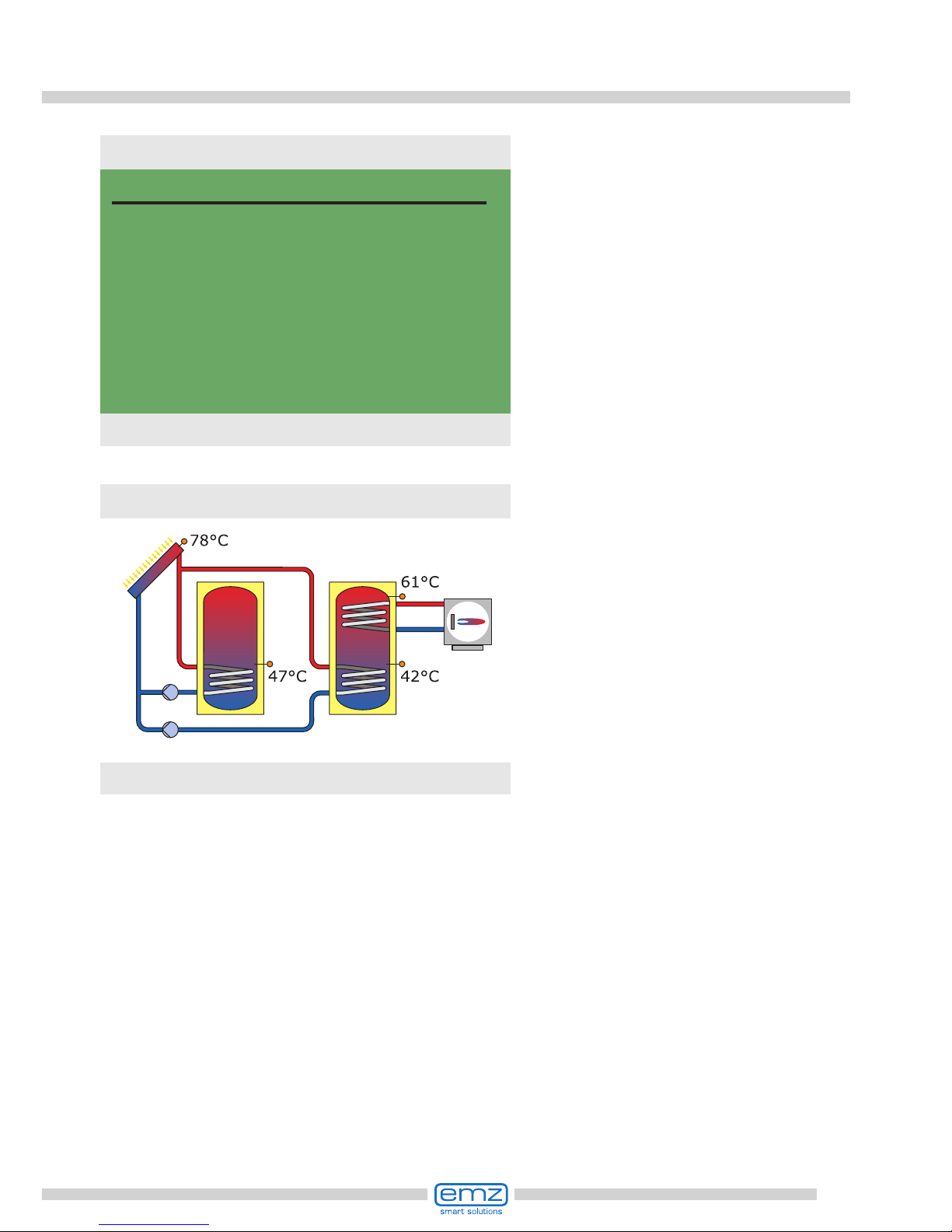

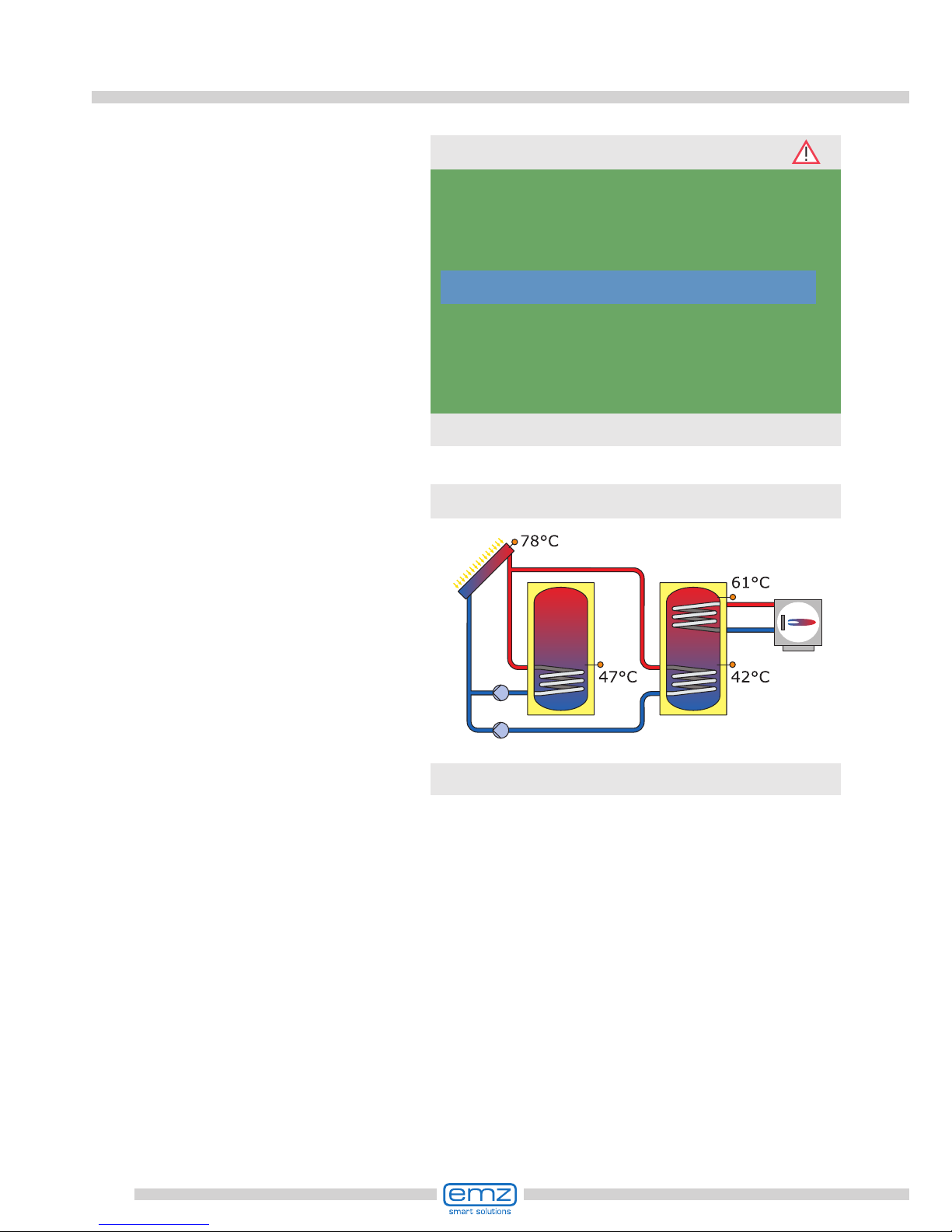

Automatic mode

In automatic mode, the screen

displays the date, the time and

the active hydraulic system.

The current temperature is displayed

for each temperature sensor.

The pump activity is displayed

on the display as animation.

There is no need for intervention

by the tter or operator.

Note!

Check the display screen of the smart Sol plus on a regular

basis to be able to eliminate any malfunctions promptly!

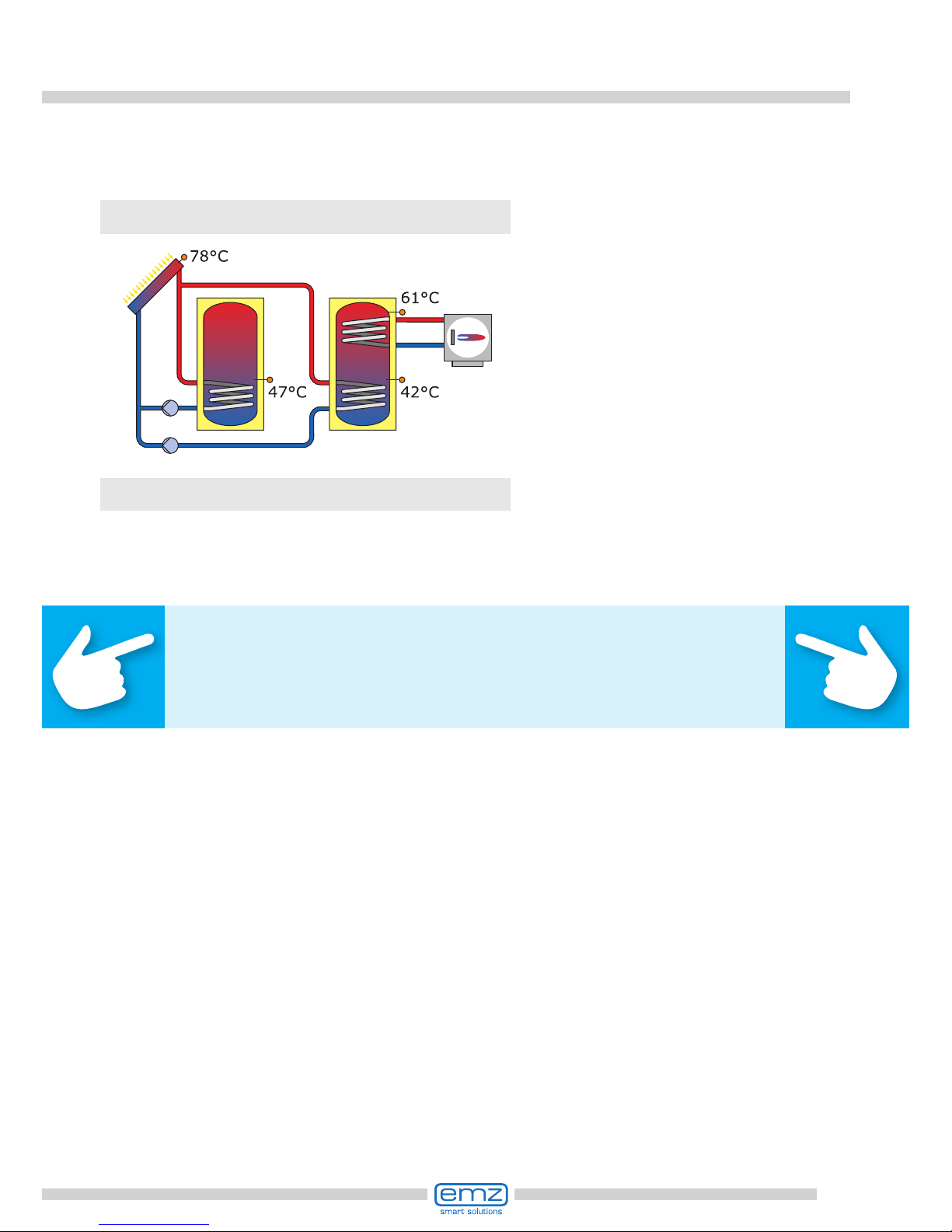

System 11

25.08.2012 09:17

64

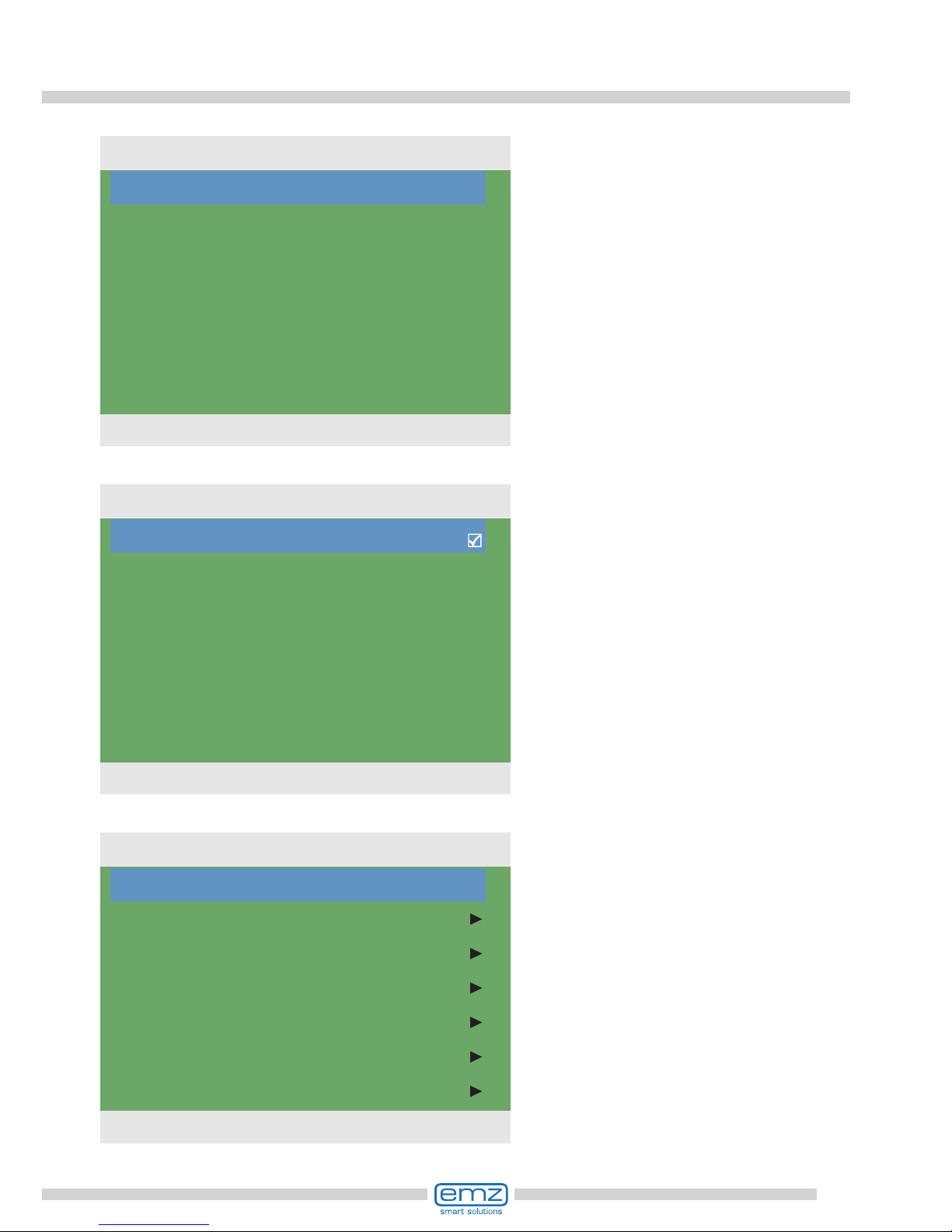

Operation mode

On the controller, the user can make

various settings and obtain information about states and processes.

To this effect, press the button

›OK‹ in automatic mode.

›1 Main menu‹ appears.

A list of subitems appears

By scrolling ...

...the lower part of

the menu is displayed.

Once the rst subitem

›Evaluation‹ is selected, ...

System 11

25.08.2012 10:19

Evaluation

Settings

Basic functions

Efciency functions

Protective funct.

Monitoring

Login

1 Main menu

25.08.2012 10:19

Settings

Basic functions

Efciency functions

Protective funct.

Monitoring

Login

About smartSol

1 Main menu

25.08.2012 10:19

65

Operation mode

...›1.1 Evaluation‹ appears.

Another selection level appears.

Once the rst subitem

›Measured values‹ is selected, ...

...›1.1.1 Measured val...‹ appears.

Here, the temperatures and

dates concerning the controller

are displayed.

If additional tank sensors have

been dened on commissioning,

these measurands also appear here.

Return to ›1.1 Evaluation‹.

Once the second subitem

›Service hours‹ is selected, ...

...›1.1.2 Service hours‹ appears.

The operating time of the activated

plant components is displayed in

hours.

By actuating the menu item ›Reset‹,

all counters are reset to zero.

The values are saved once per day,

so that one day max. is „lost“ in

case of failure of the power supply.

Return to ›1.1 Evaluation‹.

Once the third subitem

›CO2 savings‹ is selected, ...

Measured values

Service hours

CO2 savings

Heat quantities

Error list

1.1 Evaluation

25.08.2012 10:20

Collector temperature1

Tank 1 bottom temp.

Tank 2 bottom temp.

Tank 1 top temp.Solar

Solar pump 1

Solar pump 2

Boiler

78.2°C

47.0°C

42.1°C

61.4°C

80%

34%

OFF

1.1.1 Measured values

25.08.2012 10:20

Solar pump 1

Solar pump 2

Boiler

Reset

112h

94h

361h

1.1.2 Service hours

25.08.2012 10:21

66

Operation mode

...›1.1.3 CO2 savings‹ appears.

Here, assessment of the saved carbon

dioxide can be activated, read and

reset.

By selecting ›Fuel‹...

...›Edit‹ appears.

Here, the fuel types natural gas or

fuel oil can be selected for a calculation of CO2.

Return to ›1.1 Evaluation‹.

Continue with ›Heat quantities‹.

›1.1.4 Heat quantities‹ appears.

Up to four heat counters can be

congured for the collection of

the generated energy quantity.

The evaluation period can be selected

via the ›Diagram‹ - ›Week‹, ›Month‹

or ›Year‹

Press ›Reset‹ to reset

the counter to 0.

Activation

CO2 Savings (calc.)

Reset

Fuel

447 kg

Natural gas

1.1.3 CO2 savings

25.08.2012 10:21

Fuel

Restore last value

Factory settings

Natural gas

Edit

25.08.2012 10:15

Heat qty. 1

Heat qty. 2

Heat qty. 3

Heat qty. 4

Diagram

Reset

1.1.4 Heat quantities

25.08.2012 10:22

Week

67

Operation mode

The evaluation appears

as a bar graph.

Selecting a submenu,

e.g. ›Heat qty. 1‹...

150

125

100

75

50

25

0

7d [kWh]

1.1.4 Heat quantities

25.08.2012 10:22

...will access ›1.1.4.1 heat qty. 1‹

Activation will start a counter

which calculates heat yield.

›Volume ow‹ denes the volume

ow sensor to be used.

Return and feed sensors are assigned.

In addition to the operation mode’s

functions, the sensors in the return

and supply lines are assigned.

›Efcient tank-charge‹ denes

whether this heat quantity is

used for efcient buffer charge.

›Add to overall HQ‹ adds each

heat quantity to the overall counter.

Continue with ›Error list‹.

Activation

Heat quantity (calculated)

Volume ow

Return line sensor

Supply line sensor

0 kWh

---

---

---

1.1.4.1 heat qty. 1

25.08.2012 10:22

Return line sensor

Supply line sensor

Glycol type

Efcient tank-charge

Add to overall HQ

---

---

Water

1.1.4.1 heat qty. 1

25.08.2012 10:22

68

Operation mode

›1.1.5 Error list‹ appears.

Here, a table of the last errors

occurred appears for information.

By selecting a fault ...

... the error message

appears in plain text.

If necessary, take the

appropriate measures.

Return to ›1 Main menu‹.

Continue with ›Settings‹.

›1.2 Settings‹ appears.

Another selection level appears.

Once the rst subitem

›Date/Time‹ is selected, ...

M33: 4:31 03.07

M32: 6:44 03.07

M05: 7:01 03.07

---

---

---

---

1.1.5 Error list

25.08.2012 10:22

M05:

Sensor short-circuit

on TS3!

Press ESC to return

1.10 Error list

25.08.2012 10:22

Date/Time

Language

Display

Remove SD card safely

Factory settings

1.2 Settings

25.08.2012 10:23

69

Operation mode

...›1.2.1 Date settings‹ appears.

Here, date and time can be set in

case of deviation or an extended

period of deenergizing.

If the differential temperature controller is installed at a location where

daylight-saving time exists, the time

shift can be activated here.

Select the subitem

›Date‹ or ›Time‹ by pressing ›OK‹.

One group of gures each is activated

and can be varied via the rotary encoder; whenever ›OK‹ is pressed, the

activation

jumps to the next group.

Return to ›1.2 Settings‹.

Continue with ›Language‹.

›1.2.2 Language‹ appears.

Here, the user can change over

to another available language.

Continue with ›Display‹.

Date

Time

Automat.Clock Change

25.08.2012

10:23

1.2.1 Date setting

25.08.2012 10:23

Date

Time

Automat.Clock Change

25.08.2012

10:23

1.2.1 Date setting

25.08.2012 10:23

Deutsch

English

Français

Italiano

Česky

Español

Polski

1.2.2 Language

25.08.2012 10:23

70

Operation mode

Before the SD card can be removed,

›Remove SD card safely‹ must have

been selected.

The last menu item is

›Factory settings‹.

By selecting and pressing the

button ›OK‹, followed by ›esc‹,

the preset values are deleted and

replaced by the factory settings.

Return to ›1 Main menu‹.

Continue with ›Basic functions‹.

›1.3 Basic functions‹ appears.

Another selection level appears.

Once the rst subittem

›Thermostat‹ is selected, ...

›1.2.7 Display‹ appears.

›Brightness‹ serves to adjust the

backlighting of the display in steps

of 5% from 10% to 100%.

›Blanking time‹ is used to determine

the time after which, in case of inactivity, backlighting is reduced from the

set value to 10%. Adjustable in the

range from 30 to 255 seconds.

Return to ›1.2 Settings‹.

Brightness

Blanking time

100%

180s

1.2.7 Display

25.08.2012 10:23

Date/Time

Language

Display

Remove SD card safely

Factory settings

1.2 Settings

25.08.2012 10:24

Thermostat

Tube collector

Holiday function

Delta T control

Fixed T control

Post Heating Request

Increase return T

1.3 Basic functions

25.08.2012 10:25

71

Operation mode

...›1.3.1 Thermostat‹ appears.

The controller‘s free outputs can

be used as thermostats for various

applications.

In professional mode, presettings

must be made to this effect - your

tter will explain the appropriate

function to you, if necessary.

By selecting a subitem ...

...the appropriate activation

screen is displayed.

Return to ›1.3 Basic functions‹.

Continue with ›Tube collector‹.

›1.3.2 Tube collectors‹ appears.

This option is to be activated in case

vacuum tube collectors are used.

Return to ›1.3 Basic functions‹.

Continue with ›Holiday function‹.

Thermostat RO3

Thermostat RO4

1.3.1 Thermostat

25.08.2012 10:25

Activation

1.3.1 Thermostat RO3

25.08.2012 10:25

Activation

1.3.2 Tube collector

25.08.2012 10:25

72

Operation mode

›1.3.3 Holiday funct...‹ appears.

Here, you enter the time of your next

holiday. “Holiday” means that the

heating/

warm water plant is not used in summer.

In this case, the controller will adapt

control for the specied period so that

overheating of the plant is prevented.

First select the subitem ›Start‹,

then ›End‹ by pressing ›OK‹.

›Edit‹ appears.

Here, the dates of your absence are

entered. Return to ›1.3 Basic functions‹.

Continue with ›Delta T control‹.

›1.3.5 dT control‹ appears.

Here, parameters of the

controller can be changed.

The factory settings of the

smart Sol plus can be used

for almost all plants.

Ask a tter before making

changes at this point.

Return to ›1.3 Basic functions‹.

Continue with ›Fixed T control‹.

Start of holiday

End of holiday

19.07.2013

02.08.2013

1.3.3 Holiday function

25.08.2012 10:26

Start of holiday

Restore last value

Factory settings

19.07.2013

Edit

25.08.2012 10:26

dT-ON 1

dT-OFF 1

8.0k

4.0k

1.3.5 dT control

25.08.2012 10:27

73

Operation mode

›1.3.6 Fixed temp.c...‹ appears.

Here, the temperature values for

the collector panels are entered which

are to be achieved via control of the

pump delivery rate in question.

The factory settings of the

smart Sol plus can be used

for almost all plants.

Return to ›1.3 Basic functions‹.

Continue with ›Increase return T‹.

›1.3.10 Post Heatin...‹ erscheint.

The reheating control reacts to the

values of the top tank sensor. If the

temperature falls below ›t charge‹

minus the hysteresis, the control

activates the reheating cycle via the

heating boiler. When the set value

is reached the reheating cycle is

stopped.

Return to ›1 Main menu‹.

Continue with ›Efciency functions‹.

›1.3.8 Increase retu...‹ appears.

Parameters for return ow

temperature increase can

be dened here.

Ask a tter before making

changes at this point.

Return to ›1 Main menu‹.

Continue with ›Post Heating Request‹.

T-xed 2

70.0°C

1.3.6 Fixed temp.cont...

25.08.2012 10:27

Activation

T ON

T OFF

T min

8.0K

4.0K

15.0°C

1.3.8 Increase return ...

25.08.2012 10:27

Hysteresis

Time block 1

Time block 2

Time block 3

Time block 4

Time block 5

Time block 6

10.0K

1.3.10 Post Heating R...

25.08.2012 10:27

74

Operation mode

›1.4 Efciency funct...‹ appears.

Another selection level appears.

Once the rst subitem

›disable recharge‹ is selected, ...

›1.5 Protective funct.‹ appears.

Another selection level appears.

Continue with ›Collector defrost.‹.

... ›1.4.3 disable recha...‹ appears.

This option must be activated if

recharging of the warm water tank

is to be switched off as a function of

time or temperature.

To this effect, the tter must

make the appropriate presettings.

Return to ›1 Main menu‹.

Continue with ›Protective functions‹.

Disable recharge

1.4 Efficiency functions

25.08.2012 10:28

Activate time program

Activate T-min

Activat.Tmin oat

1.4.3 Disable recharge

25.08.2012 10:28

Collector defrosting

Tank cooling

Soft charge

1.5 Protective funct.

25.08.2012 10:29

75

Operation mode

›1.5.2 Defrosting‹ appears.

›Defrosting‹ can be used

to heat frozen collectors.

At the same time, the tank is cooled!

This is a one-time action which

must be repeated as required.

Return to ›1.5 Protective functions‹.

Continue with ›Tank cooling‹.

›1.5.5 Cooling funct.‹ appears.

This option must be activated if,

during a heat wave, the heat input

exceeds the energy withdrawal.

In this case, the controller cools the

tank via the collectors, e. g. at night.

Return to ›1.5 Protective functions‹.

Continue with ›Soft charge‹.

›1.5.6 Soft charge‹ appears.

This option should be activated if an

extended spell of hot, sunny weather is to be expected. Thus, the heat

input in the tank is reduced.

Return to ›1 Main menu‹.

Continue with ›Monitoring‹.

Activation

1.5.2 Defrosting

25.08.2012 10:29

Activation

1.5.5 Cooling funct.

25.08.2012 10:29

Activation

1.5.6 Soft charge

25.08.2012 10:29

76

Operation mode

›1.6 Monitoring‹ appears.

Here, the error list can be called up.

The required information

appears on the display.

Return to ›1 Main menu‹.

Continue with ›Login‹.

›1.8 AQA solar‹ appears.

This menu is only occupied if the soft

water station ›AQA solar‹ made by

BWT is integrated in the fresh water

heating.

For appropriate information,

please refer to the documentation

by BWT / regarding AQA solar.

Return to ›Main menu‹.

Continue with ›About smart Sol‹.

›1.7 Login‹ appears.

Here, the tter can enter his/her ac-

cess code to perform further settings

and changes.

Return to ›1 Main menu‹.

Continue with ›AQA solar‹.

Error list

1.6 Monitoring

25.08.2012 10:29

Access code

0

1.7 Login

25.08.2012 10:29

Soft water

Flow rate

Soft water delivery

recent regeneration

Salt consumption

421l/h

317m3

24.08.2012 09:00

66g

1.8 AQA solar

25.08.2012 10:30

77

Operation mode

›1.9 About‹ appears.

Here, the software and hardware

version of the controller, the

serial number and the date of

commissioning appear.

This information is required for

repairs and for version management.

If no entry is made within the

preset time (30 - 255 s) on the

smart Sol plus, the display returns

to ›System‹.

›esc‹ is used to return to the home

screen from every menu.

smartSol

SW version

HW version

Serial number

Commissioning

11.42

3.01

16009

24.08.2012

1.9 About

25.08.2012 10:30

System 11

25.08.2012 10:31

78

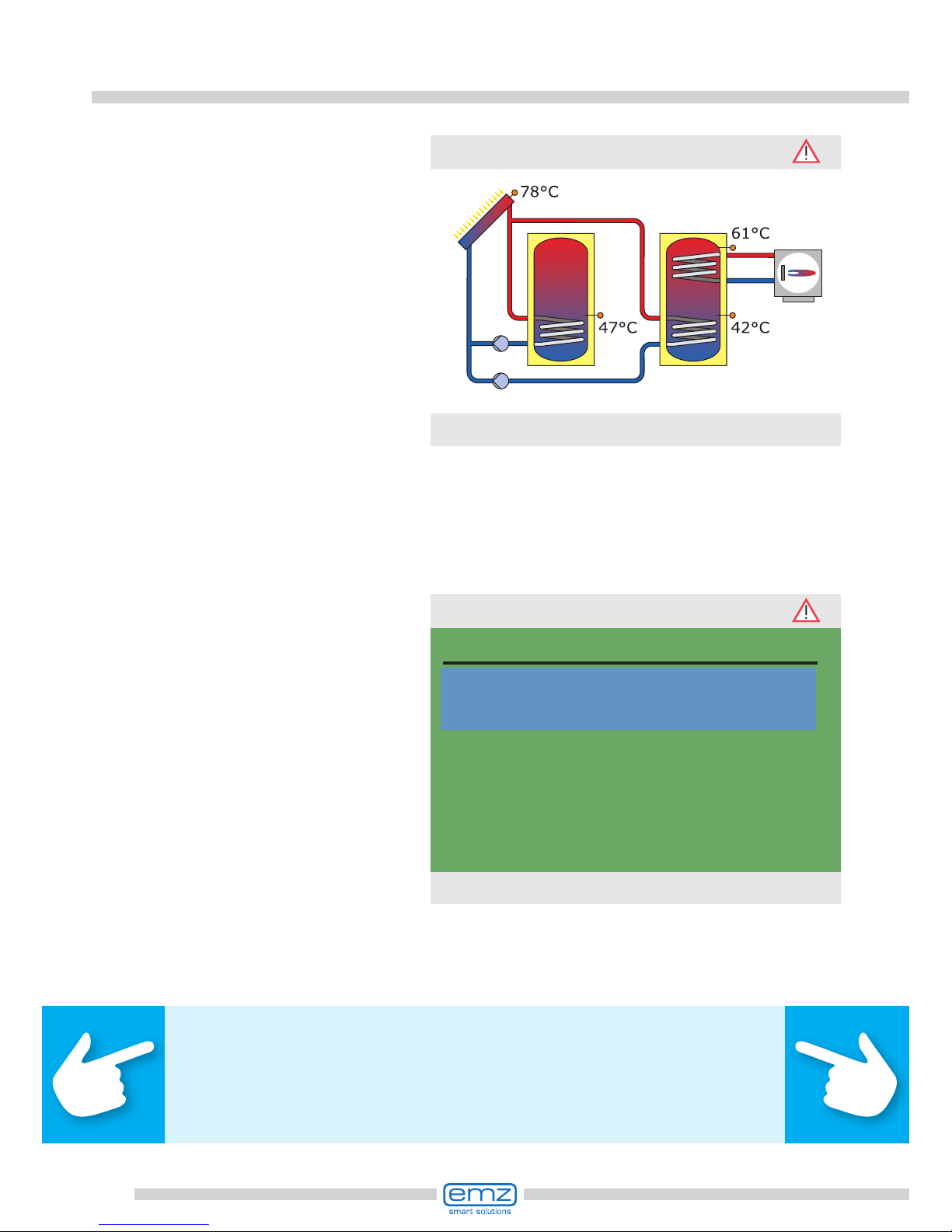

Malfunction

The screen on top right shows

the ›Attention‹ symbol which

points out a notication or an

operating malfunction.

Select via ›OK‹.

If ›Safety function‹ appears in

the display, this is a message,

no malfunction.

In this case, there is no deciency,

but limits have been exceeded.

The controller indicates that a

protective function has been

triggered.

The message is only active until

normal operation has been restored.

Note!

If a malfunction message appears in the display, the operator

can dene the possible causes by means of the Service Wizard

so that he/she can provide the tter with precise information.

System 11

25.08.2012 10:32

Safety function

Solar circuit

emergency cut-off

1.10 Service Wizard

25.08.2012 10:32

79

Malfunction

›1.10 Service Wizard‹ appears.

The malfunction appears in plan text

- here:

›M02: Breakage of sensor on TS1!‹.

If an analysis/repair is not

required at present, press ›Menu‹

to return to the main menu.

Danger!

Mortal danger due to electrocution!

For troubleshooting on the plant, disconnect all poles of the power

supply reliably and protect it them against being switched on again!

The differential temperature controller smart Sol plus communicates malfunction

processes in plain text. The Service Wizard indicates the possible causes of

malfunctions on the basis of the detected symptoms and thus supports

immediate and comfortable detection of deciencies.

There may be various deciencies in a solar thermal system, which require

a wide variety of approaches. The controller communicates every step to

the operator or tter via the screen, so that there is no need to describe

all malfunctions in detail in this operating manual.

Here, a malfunction message with troubleshooting process is presented as an example.

M02:

Breakage of

sensor on TS1!

Menu Next

1.10 Service Wizard

25.08.2012 10:33

80

Malfunction

The controller here provides the troubleshooting instruction to check the

connection cable.

Perform the measure in accordance

with the recommendation.

Acknowledge by pressing ›Next‹.

For this malfunction, the following

causes are assumed:

›Cable/connection‹ or ›Sensor‹ -

select the rst menu item and

conrm by pressing ›OK‹.

The Service Wizard helps detect

possible causes of malfunctions.

Acknowledge by pressing ›Next‹.

M02:

Breakage of

sensor on TS1!

Menu Next

1.10 Service Wizard

25.08.2012 10:33

Possible reasons:

Cable/connection

Sensor

Exit

1.10 Service Wizard

25.08.2012 10:33

Please check the

connection cable

to the sensor.

Next

1.10 Service Wizard

25.08.2012 10:33

81

Malfunction

Repair information appears.

Perform the appropriate repair work.

Exit the ›Service Wizard‹

by pressing ›Exit‹.

More detailed instructions

are available if required.

Acknowledge by pressing ›Next‹.

The troubleshooting

result is interrogated.

Continue via ›Yes‹ for the case that

the malfunction has been determined.

Disconnect it

and measure

its resistor.

Next

1.10 Service Wizard

25.08.2012 10:33

Could you detect

a short-circuit /

cable break?

No Yes

1.10 Service Wizard

25.08.2012 10:33

Please replace

the cable.

Exit

1.10 Service Wizard

25.08.2012 10:33

82

Malfunction

Appropriate instructions appear

for each source of faults.

Perform the measure in accordance

with the recommendation.

Continue with ›Explanation‹.

If the cause of the malfunction

has not yet been determined,

troubleshooting can be continued.

Continue with ›No‹.

Select all the sources of malfunctions

listed, and conrm via ›OK‹.

Could you detect

a short-circuit /

cable break?

No Yes

1.10 Service Wizard

25.08.2012 10:33

Possible reasons:

Cable/connection

Sensor

Exit

1.10 Service Wizard

25.08.2012 10:34

Please check

the sensor for

plausible values.

Explanation

1.10 Service Wizard

25.08.2012 10:34

83

Malfunction

After description of the troubleshooting measure, the result determined by

you is interrogated...

A part of the information and

instructions may be provided

in close detail, so that ...

...the texts may well

take several screens.

Disconnect it

and measure

its resistor.

Next

1.10 Service Wizard

25.08.2012 10:34

With PT 1000 sensors

0°C to 100°C

correspond to

a resistor of

1000 to 1385 Ohm.

Is your measured

value within

1.10 Service Wizard

25.08.2012 10:34

correspond to

a resistor of

1000 to 1385 Ohm.

Is your measured

value within

Yes

No

1.10 Service Wizard

25.08.2012 10:34

84

Malfunction

... and the appropriate logical

conclusion is made, the repair

work displayed.

After elimination of the malfunction,

the plant screen without the

›Attention‹ symbol appears

again on the display,

automatic mode is continued.

Sensor is faulty and

must be replaced.

Exit

1.10 Service Wizard

25.08.2012 10:34

System 11

25.08.2012 10:38

85

Replacement of fuse

To remove the device fuse, open the terminal cover.

Above the right-hand group of terminals, the fuse base and a spare fuse are

located. Pull the upper part of the support and the spare part out.

The fuse link is clamped in the formed piece and is removed together with the plastic

holder.

Now, push the micro-fuse laterally out of its holder.

The fuse link is installed by reversing the above order.

Make sure to procure yourself immediately a new spare fuse!

Danger!

Mortal danger due to electrocution! Before opening

the terminal cover, disconnect the power supply reliably!

Danger!

Risk of re due to overload or short-circuit!

Only use fuse links type 5 x 20 mm, T4A!

86

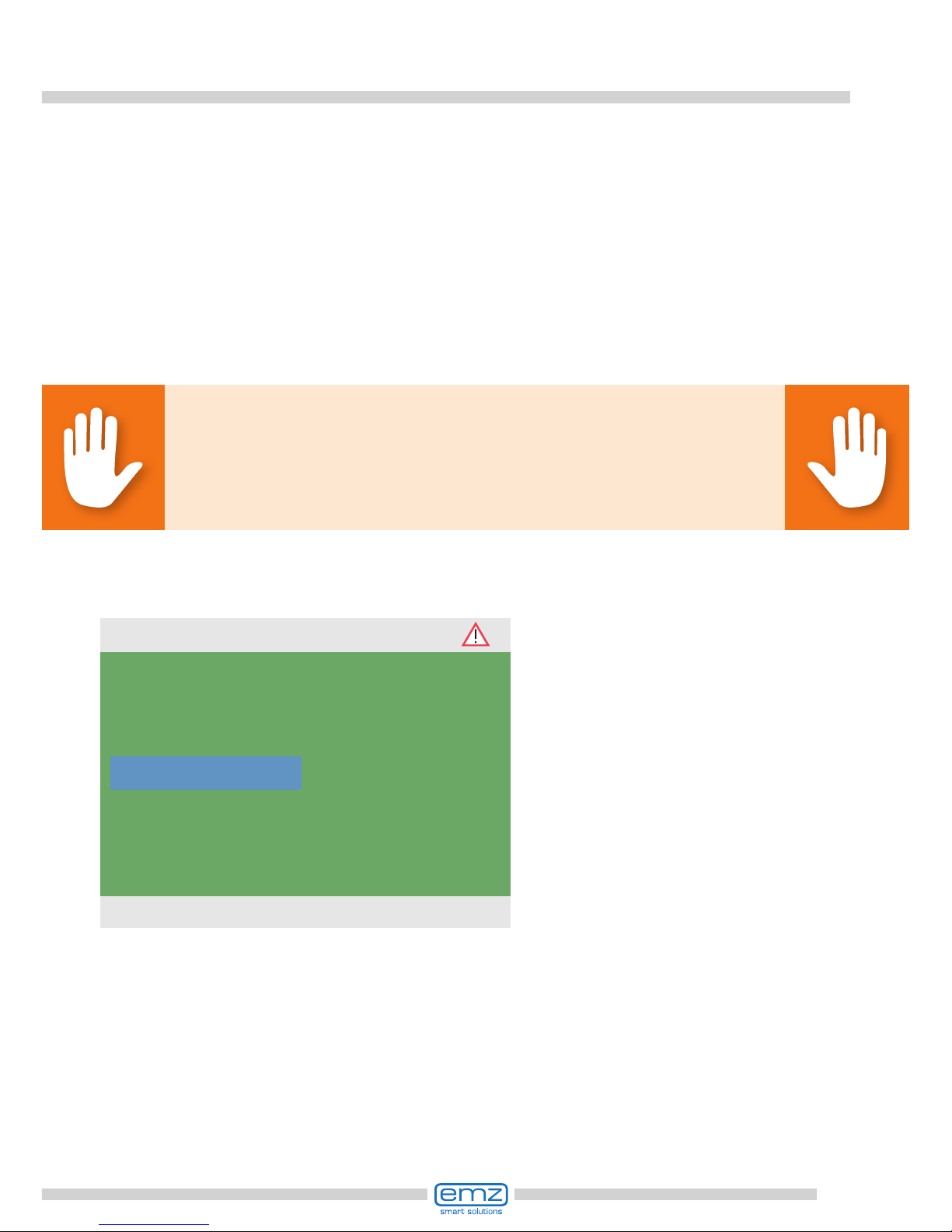

Professional mode

Important!

In professional mode, settings are made which require detailed

knowledge of the heating and solar plant.

Moreover, solid specialist knowledge regarding control

engineering, hydraulics and solar thermal water heating is required!

If a single parameter is changed, this may affect the safety,

function and efciency of the entire plant!

Leave the settings in professional mode to a

specialist workshop, the tter or heating installer!

Modications by non-experts tend to result in damage to

the plant, rather than to an improvement of its efciency!

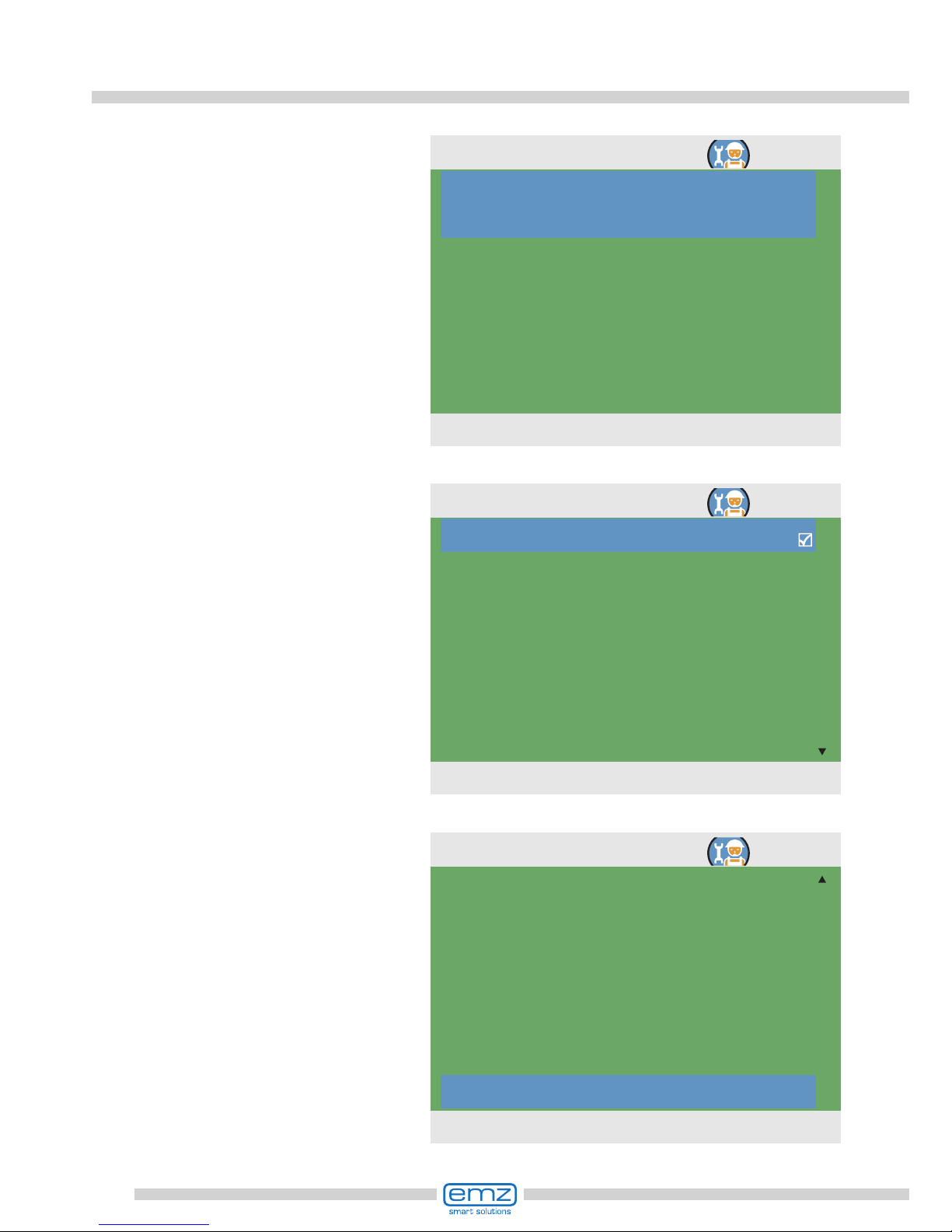

To enter the professional mode, select

›1.7 Login‹ from the main menu,

activate and ...

... enter the access code.

The access code to

professional mode is ›365‹.

The fact that the tter must be

available for his/her customers

on 365 days per year may serve

as a mnemonic trick.

Access code

0

1.7 Login

25.08.2012 10:29

Access code

Restore last value

Factory settings

365

Edit

25.08.2012 10:31

87

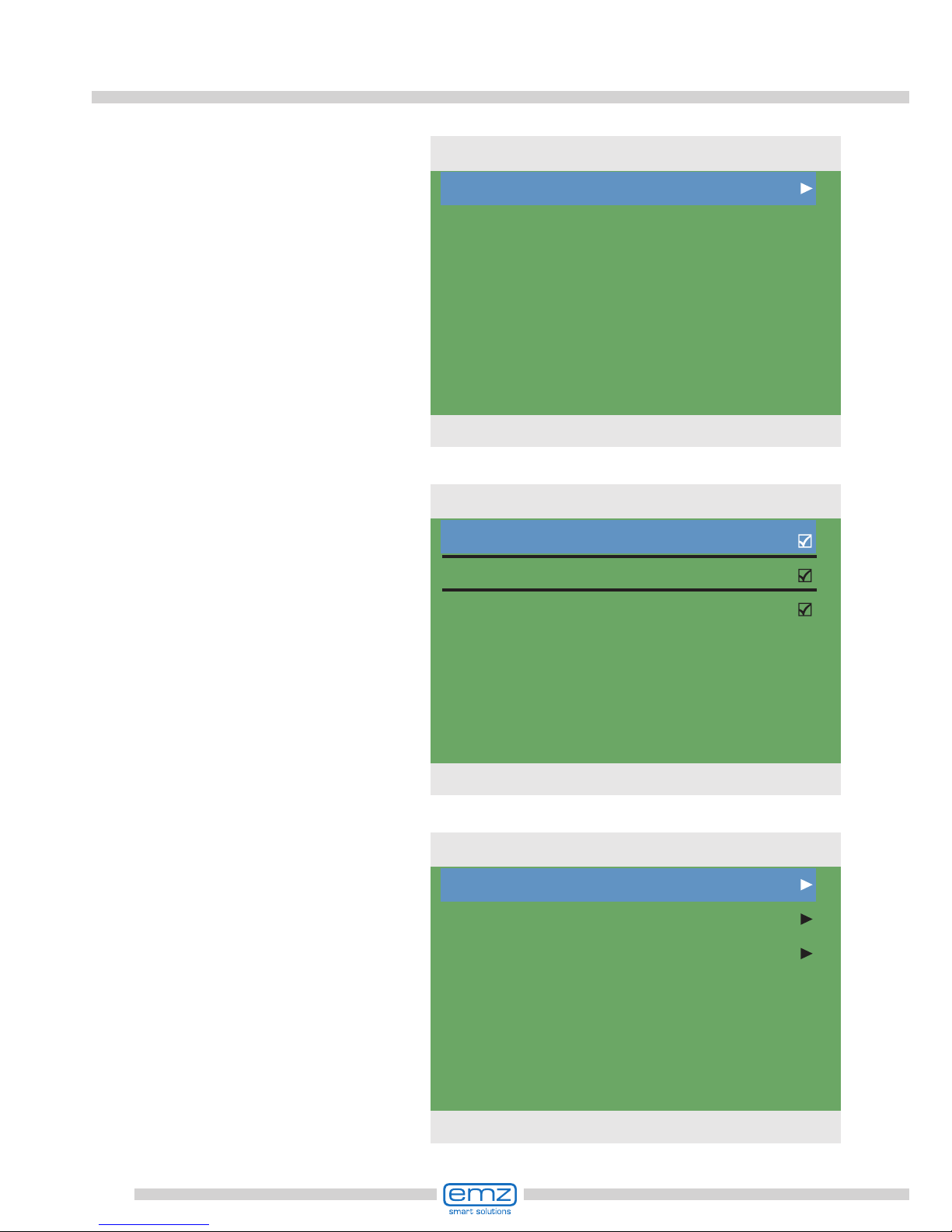

Professional mode

After having returned to ›1 Main

menu‹,the screen shows a list of

subitems as in operation mode.

The menu ›1.1 Evaluation‹ is

identical to the operating mode.

The following items appear under

›1.2. Settings‹ next to the operation

mode menus:

- ›Temp. limitation‹

- ›Max.temp.shutoff‹

- ›Min. temperature‹

- ›Priority charging‹

Call up menu item ›Temp. limitation‹.

Evaluation

Settings

Basic functions

Efciency functions

Protective funct.

Monitoring

Login

1 Main menu

25.08.2012 10:32

Measured values

Service hours

CO2 savings

Heat quantities

Error list

1.1 Evaluation

25.08.2012 10:32

Date/Time

Language

Display

Tank temp.limitation

Max.temp.shutoff

Min.temperature

Remove SD card safely

1.2 Settings

25.08.2012 10:33

88

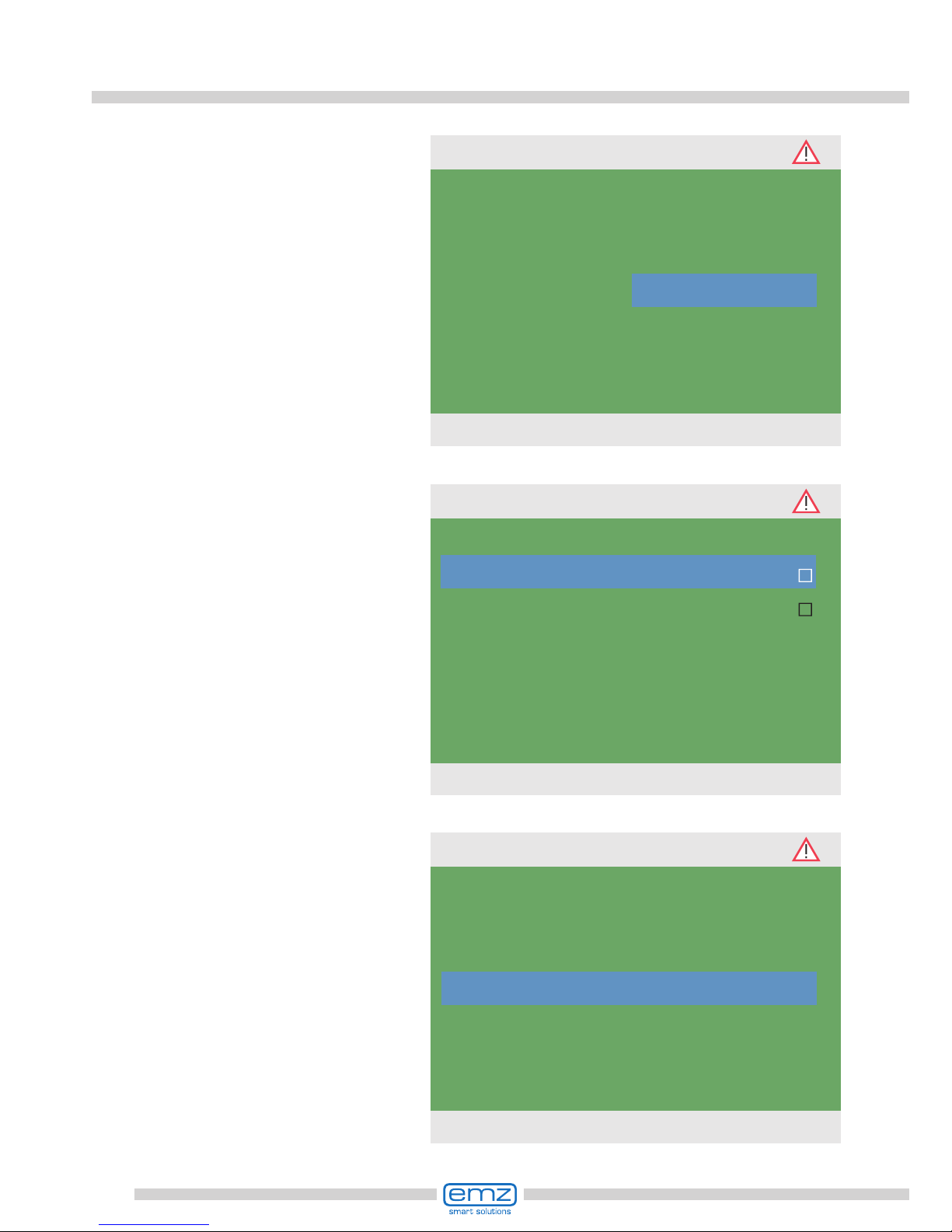

Professional mode

If the temperature in tank 1 exceeds

the value T limit 1, or if the temperature in tank 2 exceeds the value

T limit 2, the solar circuit pump is

switched off unconditionally.

The pump is not switched on again

until the actual temperature falls below the value T limit by the hysteresis

›Hyst‹.

Example: T limit =60°C minus Hyst=5K => Reclosing temperature 55°C.

Continue via the menu

item ›Max.temp.shutoff‹.

Maximum temperature of the tanks 1

and 2, to avoid excessively hot water

in the tank; the tank in question is

only charged to its ›T max‹.

In case of collector overheating, the

tank can be charged up to ›T-limit‹.

Continue via the menu item

›Min. temperature‹.

To increase efciency on charging

the tanks, the minimum temperature

to be present at the collector in

question is entered via ›T min. Coll‹.

The relevant hysteresis value

represents the difference

between the switch-ON

and switch-OFF temperature.

Continue via the