HEATING SYSTEM CONTROLLER FOR HEAT

GENERATION AND DISTRIBUTION

OPERATING AND INSTALLATION

INSTRUCTIONS

emz - THE SMILING COMPANY

These Operating and Installation Instructions are an integral part of the product.

› Read Assembly and Operating Instructions carefully before using the product.

› Keep them in a safe place during the product's entire service life.

Translated from the German original version ©emz 2018 - Subject to modifications.

The contents and representations of these Operating and Installation Instructions are the intellectual

property of emz-Hanauer GmbH & Co.KGaA.

Unauthorized disclosure, reproduction, distribution or editing of this documentation as well as

exploitation, utilization or publication, are prohibited.

The rights to the word and design marks ›emz - smart solutions‹ and ›smart Econ‹ are the exclusive

property of emz-Hanauer GmbH & Co.KGaA.

The rights to any cited brands, names or logos are the property of the respective developers/

licensees.

TABLE OF CONTENTS

Table of contents

Table of contents................................................................................................................................ 3

Important information ......................................................................................................................... 8

Notes on this manual ....................................................................................................................8

Safety information ......................................................................................................................... 8

Conditions of use ..........................................................................................................................9

Intended use ...............................................................................................................................10

Installation and connection ......................................................................................................... 10

Product description .......................................................................................................................... 11

Outdoor temperature-controlled room heating............................................................................ 11

Self-adjustment / heating behavior ............................................................................................. 11

Control of heat generators ..........................................................................................................11

smart EconControl options..........................................................................................................12

Water heating.............................................................................................................................. 12

Anti-legionella function................................................................................................................ 12

Solar heating system .................................................................................................................. 12

smart Econ Transmission technology ......................................................................................... 12

Distance communication via the Internet .................................................................................... 12

Remote maintenance via smart Econ Cloud............................................................................... 12

Cloud access ......................................................................................................................... 13

Information and control .......................................................................................................... 13

Safety..................................................................................................................................... 13

Data protection....................................................................................................................... 13

Device description............................................................................................................................ 14

smart Econ HCW ........................................................................................................................14

smart Econ HCW 1620 Expansion module................................................................................. 14

Connections and interfaces on the smart Econ HCW............................................................ 15

smart Econ Room controller .......................................................................................................15

CAN bus line ............................................................................................................................... 15

Operating the smart Econ room controller ....................................................................................... 16

Heating........................................................................................................................................ 16

Special functions......................................................................................................................... 16

Operating the smart Econ Userinterface.......................................................................................... 17

Control elements......................................................................................................................... 17

Display ........................................................................................................................................17

Prompts during operation................................................................................................................. 18

Overview mode ........................................................................................................................... 18

Menu ........................................................................................................................................... 18

Select menu items ...................................................................................................................... 19

Overview menu ........................................................................................................................... 19

smart Econ - emz-HCW - 180116 3

TABLE OF CONTENTS

›Heat Circuits‹ menu (Overview menu)....................................................................................... 20

›Temperatures‹ menu .................................................................................................................21

›Outputs‹ menu ...........................................................................................................................21

›Diagnosis‹ menu ........................................................................................................................22

Error messages........................................................................................................................... 22

Information ..................................................................................................................................22

Settings during operation .................................................................................................................23

Entering the access code............................................................................................................23

Change values ............................................................................................................................23

Menu structure ............................................................................................................................24

Abbreviations in the menus.........................................................................................................25

Main menu ..................................................................................................................................26

›OPERATING MODES‹ menu ....................................................................................................27

Operating mode ›AUTOMATIC‹.............................................................................................28

Operating mode ›DAY‹...........................................................................................................28

Operating mode ›NIGHT‹.......................................................................................................28

Operating mode ›FROST PROTECTION‹ ............................................................................. 28

Operating mode ›SUMMER‹ .................................................................................................. 28

Operating mode ›FLOOR PAVEMENT HEATING‹................................................................28

Operating mode ›OFF‹...........................................................................................................29

Operating mode ›CHIMNEY SWEEP‹ ...................................................................................29

›TIMER PROGRAMS‹ menu....................................................................................................... 30

Setting heating periods and temperatures ............................................................................. 31

Selecting the day of the week ................................................................................................31

Setting times and temperatures ............................................................................................. 31

›COPY DAY...‹ .......................................................................................................................31

›COPY ALL VALUES...‹ ......................................................................................................... 31

Table for rooms and heating times......................................................................................... 33

Table for rooms and heating times......................................................................................... 34

›HOLIDAY PERIODS‹ menu....................................................................................................... 35

›HEAT CIRCUITS‹ menu ............................................................................................................36

›DOMESTIC HOT WATER‹ menu .............................................................................................. 38

Setting the domestic hot water setpoint temperature.............................................................38

Setting the domestic hot water heating times ........................................................................39

Manual control of domestic hot water heating........................................................................ 40

Setting circulation times .........................................................................................................40

Configure circulation temperatures ........................................................................................41

›GENERAL‹ menu....................................................................................................................... 42

Setting the language of the menu .......................................................................................... 42

Set date and time................................................................................................................... 42

Adjusting the display brightness and buzzer volume ............................................................. 43

›INTERNET‹ menu......................................................................................................................44

4 smart Econ - emz-HCW - 180116

TABLE OF CONTENTS

Installation and connection............................................................................................................... 45

smart Econ Temperature sensor ................................................................................................ 46

smart Econ HCW ........................................................................................................................47

Dimensions smart Econ HCW ............................................................................................... 47

Opening the smart Econ HCW housing ................................................................................. 48

Installation location smart Econ HCW.................................................................................... 48

Installation smart Econ HCW ................................................................................................. 49

Connection smart Econ HCW ................................................................................................ 50

smart Econ Room controller .......................................................................................................51

Node number room controller ................................................................................................51

Dimensions room controller ................................................................................................... 51

Opening the room controller housing..................................................................................... 51

Installation location room controller ....................................................................................... 51

Installation room controller..................................................................................................... 52

Room controller connection ................................................................................................... 52

Connection CAN-Bus.................................................................................................................. 53

Cable routing............................................................................................................................... 53

4-pole CAN bus line ............................................................................................................... 54

Internet-based network .................................................................................................................... 55

Prerequisites ............................................................................................................................... 55

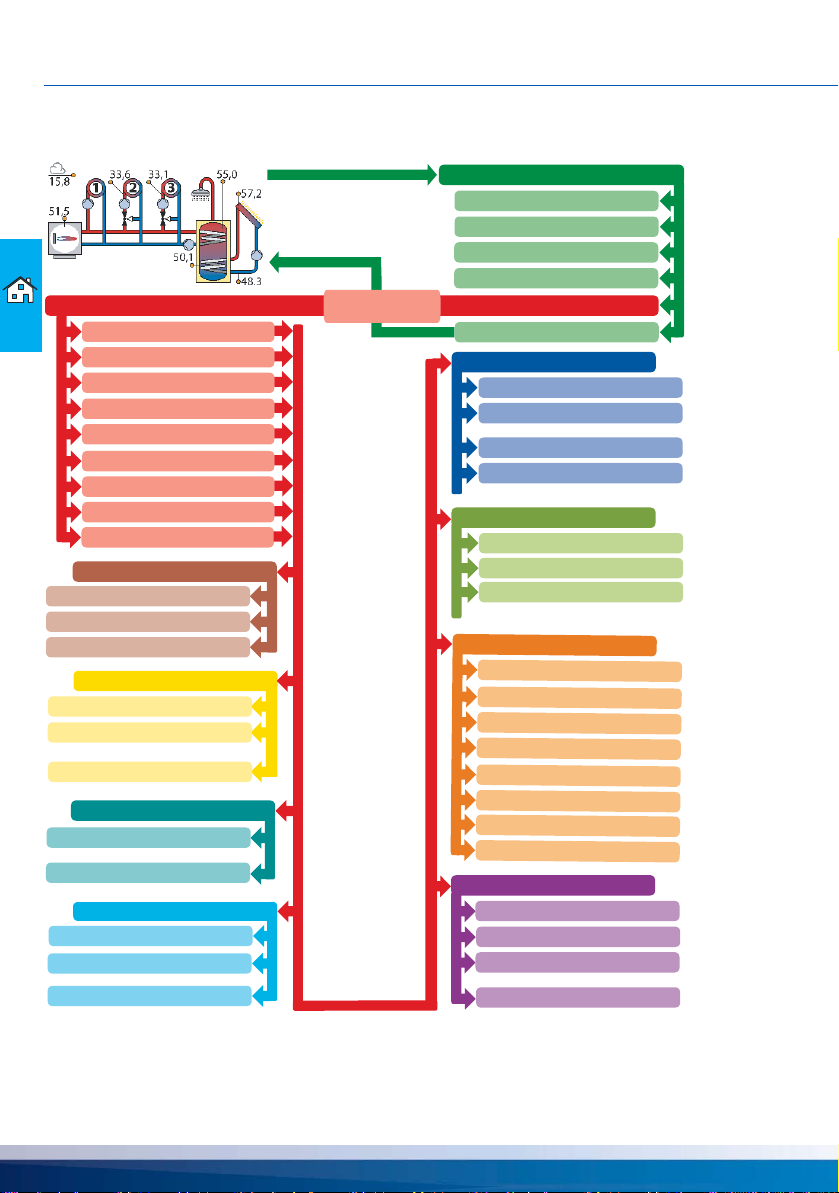

Hydraulic systems and connection diagrams................................................................................... 56

Further hydraulic systems........................................................................................................... 56

Hydraulic symbols....................................................................................................................... 57

Hydraulic system 1: ›HCW 001 Sol‹ (HCW 810) ........................................................................ 58

Hydraulic system 2: ›HCW 002 SF‹ (HCW 810) ......................................................................... 60

Hydraulic system 3: ›HCW 003‹ (HCW 810)............................................................................... 62

Hydraulic system 4: ›HCW 004 Sol‹ (HCW 810) ........................................................................ 64

Hydraulic system 5: ›HCW 005 Sol‹ (HCW 810) ........................................................................ 66

Hydraulic system 6: ›HCW 006 HP‹ (HCW 810)......................................................................... 68

Hydraulic system 7: ›HCW 007 Sol-SF‹ (HCW 810)................................................................... 70

Hydraulic system 8: ›HCW 008 Sol‹ (HCW 1620 Base Unit)...................................................... 72

Hydraulic system 8: ›HCW 008 Sol‹ (HCW 1620 Expansion Module)........................................ 74

Hydraulic system 9: ›HCW 009 SF‹ (HCW 1620 Base Unit) ...................................................... 76

Hydraulic system 9: ›HCW 009 SF‹ (HCW 1620 Expansion Module) ........................................ 78

Hydraulic system 10: ›HCW 008 Sol‹ (HCW 1620 Base Unit).................................................... 80

Hydraulic system 10: ›HCW 008 Sol‹ (HCW 1620 Expansion Module)...................................... 82

Hydraulic system 11: ›HCW 011 KAS‹ (HCW 1620 Base Unit) .................................................. 84

Hydraulic system 11: ›HCW 011 KAS‹ (HCW 1620 Expansion Module).................................... 86

Hydraulic system 12: ›HCW 012 Sol‹ (HCW 1620 Base Unit).................................................... 88

Hydraulic system 12: ›HCW 012 Sol‹ (HCW 1620 Expansion Module)...................................... 90

Hydraulic system 13: ›HCW 013 HP‹ (HCW 1620 Base Unit) .................................................... 92

Hydraulic system 13: ›HCW 013 HP‹ (HCW 1620 Expansion Module) ...................................... 94

smart Econ - emz-HCW - 180116 5

TABLE OF CONTENTS

Hydraulic system 14: ›HCW 014 Sol-SF‹ (HCW 1620 Base Unit) ..............................................96

Hydraulic system 14: ›HCW 014 Sol-SF‹ (HCW 1620 Expansion Module) ................................98

Abbreviations for hydraulic components, inputs and outputs .................................................... 100

Function description .......................................................................................................................101

Solar operation..........................................................................................................................101

Collector cooling................................................................................................................... 101

Storage recooling................................................................................................................. 101

Limit temperature .................................................................................................................101

Solar pump anti-lock circuit (ABS) ............................................................................................101

Buffer management function .....................................................................................................101

Heat generator ..........................................................................................................................102

Modulating heat generators (optional) .................................................................................102

Operation of two heat generators......................................................................................... 102

Air-source heat pump and peak load boiler .........................................................................102

Wood-fired boiler and conventional heat generator .............................................................102

Timer program........................................................................................................................... 103

Global day/night temperature....................................................................................................103

Frost protection .........................................................................................................................103

Summer operation..................................................................................................................... 103

Domestic hot water temperature ...............................................................................................103

Domestic hot water priority........................................................................................................ 104

Outdoor temperature-controlled setting .................................................................................... 104

Control loops with mixers ..................................................................................................... 104

Heating curve....................................................................................................................... 104

Using the smart Econ room controller..................................................................................105

Outdoor temperature-guided control without remote setting................................................105

Outdoor temperature-guided control with remote setting.....................................................105

Outdoor temperature-guided control with room influence .................................................... 106

Commissioning...............................................................................................................................107

Device configuration.......................................................................................................................108

Enter access code for the installer ............................................................................................108

Main menu for the installer........................................................................................................ 108

›INSTALLER‹ menu ..................................................................................................................109

›COMMISSIONING‹ menu........................................................................................................ 110

Select hydraulic system .......................................................................................................111

Setting the date, time and daylight saving time.................................................................... 111

Configuring heating circuits/zones .......................................................................................111

Change heating curve .......................................................................................................... 113

Configure request for heat generator ................................................................................... 114

Configure heat pump............................................................................................................ 115

Configure solid fuel boiler..................................................................................................... 116

6 smart Econ - emz-HCW - 180116

TABLE OF CONTENTS

Configure solar system ........................................................................................................ 117

Sensor adjustment ............................................................................................................... 121

Configuring frost protection.................................................................................................. 123

Configuring the room controller ›CONFIG RC‹ .................................................................... 123

›OPERATING HOURS‹ Menu .................................................................................................. 125

›TEST‹ Menu ............................................................................................................................ 126

Test operation...................................................................................................................... 126

Manual switching of outputs................................................................................................. 127

Simulate temperatures......................................................................................................... 127

Simulate room temperatures................................................................................................ 128

Simulate inputs .................................................................................................................... 128

Bus setup............................................................................................................................. 129

›HEAT CIRCUITS‹ menu (Installer) .......................................................................................... 130

Configure heating circuit ...................................................................................................... 131

Configuring room temperature influence on the heating curve

(heating circuits without mixer) ............................................................................................ 132

Configuring the mixer control (heating circuits with mixer) .................................................. 133

Configuring the heating pump.............................................................................................. 134

›DOMESTIC HOT WATER‹ menu (Installer) ............................................................................ 135

Setting the domestic hot water setpoint temperature (Installer)........................................... 136

Configure domestic hot water priority .................................................................................. 137

Configuring the domestic hot water pump ........................................................................... 137

Setting circulation times (Installer) ....................................................................................... 138

Configuring the circulation pump ......................................................................................... 138

Configure circulation temperatures ...................................................................................... 139

›GENERAL‹ menu (Installer) .................................................................................................... 140

›INTERNET‹ menu (Installer).................................................................................................... 143

smart Econ Cloud setup....................................................................................................... 143

Generate new Auth-Code .................................................................................................... 144

Delete user........................................................................................................................... 144

Technical data................................................................................................................................ 145

smart Econ HCW ......................................................................................................................145

smart Econ Room controller ..................................................................................................... 145

smart Econ Temperature sensor .............................................................................................. 145

Solar and boiler temperature sensors.................................................................................. 145

Storage tank and buffer temperature sensor .......................................................................145

Flow/return contact temperature sensor .............................................................................. 146

Characteristic curve and resistance values of PT1000 temperature sensors...................... 146

Disassembly/disposal..................................................................................................................... 147

Warranty and liability...................................................................................................................... 148

Index .............................................................................................................................................. 149

smart Econ - emz-HCW - 180116 7

IMPORTANT INFORMATION

Important information

Notes on this manual

These operating and installation instructions are intended for both system operators and specialist

installers.

The instructions are divided into several sections for a better overview.Each of these sections is

marked with an icon at the edge of each page:

This symbol indicates Sections with general information.

These sections contain important information, safety instructions and descriptions of the

properties of the controller as well as general operating instructions.

These sections are intended for both operators and professional installers.

This symbol indicates sections with information on regular operation.

These sections contain descriptions of how to input individual settings on the controller.

These sections are aimed in particular at system operators.

This symbol indicates sections with information for installation, commissioning, sys-

tem-specific programming and further specialist information for specialist installers.This

information enables specialist installers to set the controller for the proper operation of the

system.

NOTE

Safety information

The assembly and operating instructions indicate possible hazards:

All depictions mentioned are examples and serve for a better

understanding.Content and sequence depend on the selected

system.

Errors and modifications reserved.

DANGER indicates an almost certain danger of serious personal injury or death.

WARNING indicates a possible danger of serious personal injury.

CAUTION indicates a possible danger of slight personal injury.

NOTICE indicates a possible danger of damage to the equipment.

8 smart Econ - emz-HCW - 180116

IMPORTANT INFORMATION

When handling the smart Econ heating system controller and accompanying equipment, please

make sure that the safety provisions in the assembly and operating instructions are complied with!

Conditions of use

These instructions describe the installation, startup, operation, repair and disassembly of the

smart Econ heating system controller.

Observe all technical documentation of all the components used such as boiler, tank, pumps, mixers, and valves, etc. when operating the system.

DANGER

Assembly, connection, startup, repair and disassembly

Danger of death by electrocution!

Whenever working with the terminal cover open, make sure

that all poles of the power supply are completely disconnected

and protected against being switched on again!

The heating system controller is used by the system operator, who in most cases will be a layperson.

NOTE

Make sure not to use the heating system controller until you have thoroughly read and understood

these Assembly and Operating Instructions and the safety provisions.Comply with all safety provisions and contact a specialist in case of doubt.

NOTE

Keep these assembly and operating instructions and all reference documents accessible at all

times.

When relocating or when selling the device, hand the documents over to your successor.

NOTE

The heating system controller replaces by no means the safety

components required under system engineering aspects!

The installer of the heating system controller must instruct the

system operator on the handling, function and principle of

operation of the smart Econ and the components connected to

it!

Only adults with the appropriate knowledge and experience

may access the device during operation./when it is in operation.

smart Econ - emz-HCW - 180116 9

IMPORTANT INFORMATION

NOTE

Intended use

The smart Econ heating system controller may only be used as a controller for thermal systems.

Always observe all described specifications during operation!/when operating the device!

Only specialists may install and set up the heating system controller.

The installer must have read and understood the operating manual.The installer explains all the relevant functions to the operator.

For operation, it is essential that the housing is closed and undamaged.

Installation and connection

Before connecting to the electrical system, the smart Econ HCW Userinterface and the expansion

module must be fixed to a vertical, robust surface (wall), see “Installation and connection” on

page 45.

For its own power supply and that of the outputs, connect the heating system controller to an electrical energy supply system in accordance with the technical data.

Make sure that only a dry or slightly moistened cloth is used for

cleaning and servicing of the housing, the control elements

and the display.

The surfaces must never get into contact with cleaning products or solvents - mat, brittle or slightly dissolved plastic parts

must be replaced immediately!

A device with damaged housing must not be operated!

DANGER

Loose installation or connection

Danger of death by electrocution!

Whenever working with the terminal cover open, make sure

that all poles of the power supply are completely disconnected

and protected against being switched on again!

NOTE

The heating system controller may only be assembled, connected, commissioned, repaired and disassembled by specialists.

The installation and protection regulations for the installation,

commissioning and operation of low-voltage installations in

accordance with EU and national law must be observed.

10 smart Econ - emz-HCW - 180116

PRODUCT DESCRIPTION

Product description

The smart Econ heating system controller was especially developed for single-family houses and

apartment buildings.The goals are the creation of optimum comfort for residents and the greatest

possible ease of use for the system operator.

The smart Econ heating system controller can be operated either via the 4 buttons and the rotary/

push button on the control panel or optionally via existing internet access using a PC, smartphone or

tablet.

The smart Econ heating system controller is a modern system to control the entire domestic technology of single-family houses and apartment buildings.

As many components of domestic technology can be integrated into one single system, there are

many options for system optimization (e.g. energy efficiency, ease of operation, optimization of comfort and maximum coziness).

Outdoor temperature-controlled room heating

When delivered, the controller is designed for purely outdoor temperature-controlled systems.

Depending on the outside temperature, control valves regulate the flow temperature of the respective control circuit according to the set heating curve.

A smart Econ room controller can also be used for remote adjustment.The room temperature influence can be set as an additional reference variable by connecting the room controller.

To take solar radiation into account, several room controllers can be attached (e.g. to separate the

heating circuits on the north and south side).

Self-adjustment / heating behavior

Optionally, heating behavior can be influenced by using a smart Econ room controller.

The inertia of the room is initially assumed to be "average" and later adapted in a learning phase of

about 3 days, during which the desired progression of the room temperature is compared with the

actual development in the main room.In most cases, the optimum setting is found after 3 days.Of

course, this adjustment can be repeated at any time.

This way, heating operation is optimized in terms of comfort, homeliness and energy consumption

independently of the type of heating (underfloor heating system, wall heating or any combination

thereof).

Control of heat generators

In general, all types of heat generators (gas, oil, solid fuel, district heating, heat pumps, ...) can be

integrated into the smart Econ system control.

The heat generators are either enabled by a smart Econ room controller when heat is required or

controlled according to the heat demand flexibly depending on outdoor temperature or constantly

based on tank temperature etc.

The objective of this is to achieve the longest possible switching intervals to minimize the exhaust

emissions by reducing the number of startups and at the same time to increase the heat generator's

service life.

smart Econ - emz-HCW - 180116 11

PRODUCT DESCRIPTION

smart EconControl options

If a room controller is used, the flow temperature of the associated heating circuit can be raised

briefly for rapid heating if there is a large deviation in the room temperature.The flow temperature is

reduced during setback operation.

If there is no heat demand, the pumps of the relevant heating circuits are switched off.

Water heating

Different preset temperatures can be defined for different times of the day.This allows for energy

savings in general, as the hot water is only controlled to the required temperature in the desired time

range.

Depending on the hydraulic system, two temperature sensors (top and bottom) can be defined (e.g.

switch on when the storage tank becomes "cold" at the top, and switch off when the lower part is

"warm").

A boiler priority circuit is also supported.

Anti-legionella function

To kill germs, the thermal disinfection program is carried out once a week every Monday.The

domestic hot water is heated to 63°C.

Solar heating system

A configurable differential temperature control ensures that the solar heating system generates as

much heat as possible.

You can load several heat consumers (buffer, boiler, swimming pool, etc.) with different temperature

levels.

smart Econ Transmission technology

The components of the heating system smart Econ controller can be networked together.This way,

data is transferred via the fieldbus system CAN (Control Area Network).

“CAN bus line” on page 15

Distance communication via the Internet

The smart Econ heating system controller features an integrated Ethernet interface. that can be

used to connect it to the Internet.The Ethernet makes remote switching possible.The user can also

download the configuration, operating statuses, archive and software updates from the network.The

information messages can be sent directly via e-mail, free access to smart Econ Cloud provided.

“Internet-based network” on page 55

Remote maintenance via smart Econ Cloud

The smart Econ heating system controller can be remotely maintained via the smart Econ Cloud of

the company emz via the Internet. The current operating status of the system can be queried and

the configuration can be changed.

12 smart Econ - emz-HCW - 180116

PRODUCT DESCRIPTION

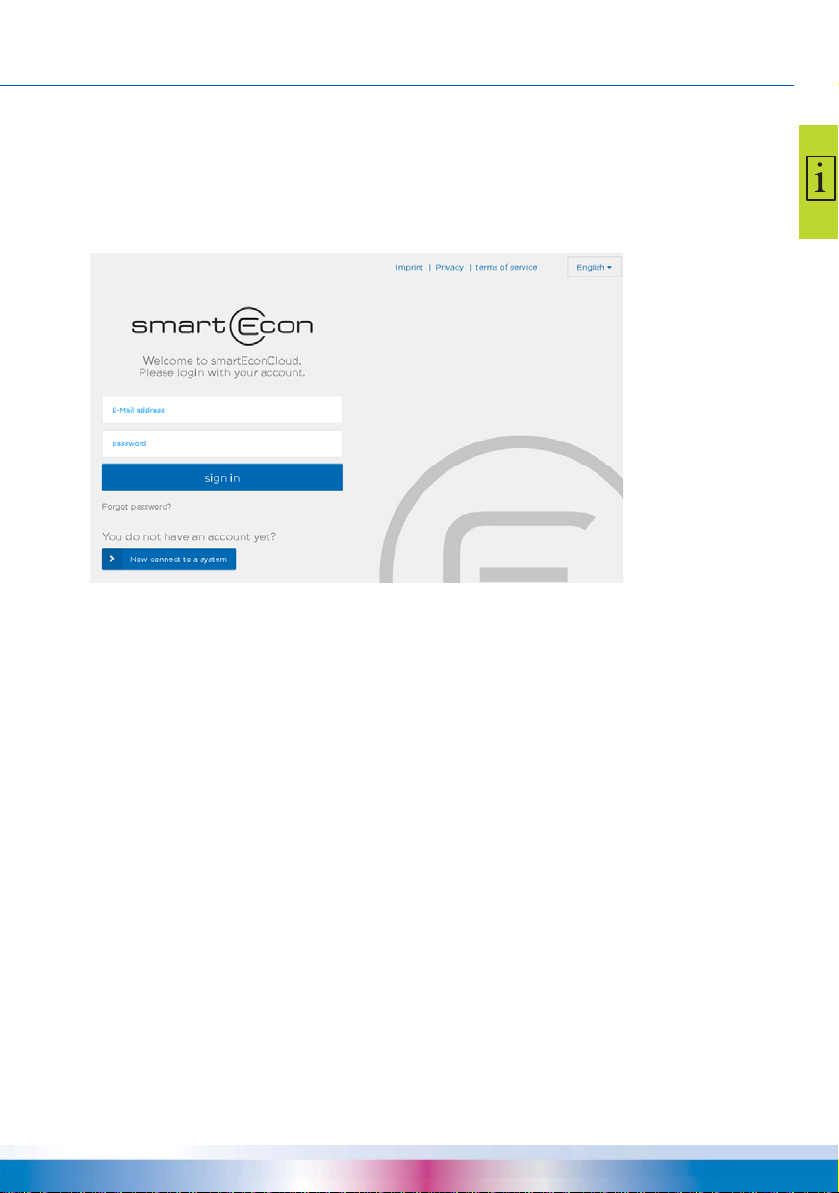

Cloud access

After one-time authentication using the TAN procedure (TAN key/ID code not included) and successful logon, the smart Econ Cloud provides remote access to the controller.Whether PC, Tablet or

Smartphone, the menu interface adapts automatically.

Access via: www.smarteconcloud.com

“smart Econ Cloud setup” on page 143

Information and control

The current status of the controlled pumps, valves and boiler can be read off at a glance from the

graphic system diagram.This is the graphic of the selected system that is also visible on the controller.

In addition to the current system data, the controller’s status messages, error messages and data

archive are available for viewing.In addition, the various operating modes can be selected and individual parameter values of the controller can be changed.

The recordings stored in the controller are processed graphically and can also be displayed together

over a longer period of time.

Safety

Access to the controller is protected in three ways.First, the ID code to be entered at the first login

and a randomly generated 20-digit authentication code - both codes will be checked internally at

each access later on.After logging in, the 6-or-more character, individual user password forms the

third level of protection.

Initial access is activated via a secure TAN procedure.

Data protection

The protection of personal data is our top priority.For identification purposes, no personal data other

than the name and a valid e-mail address is collected from the operator when registering.

smart Econ - emz-HCW - 180116 13

DEVICE DESCRIPTION

Device description

• smart Econ HCW - Heat Control Wall

Compact unit with Userinterface for wall mounting

- HCW 810 with 8 sensor inputs and 10 outputs

- HCW 1620 consisting of the base unit with Userinterface and an expansion module, networked

via CAN bus.Application for complex systems with 16 sensor inputs and 20 outputs

The devices are fitted with a micro-USB and an Ethernet connection at the factory.

Optional accessories:

• smart Econ RC - Room Control

Room unit for room temperature measurement and setpoint temperature adjustment

with party and setback function

• smart Econ Temperature sensor

Type and range depending on the design of the heating system

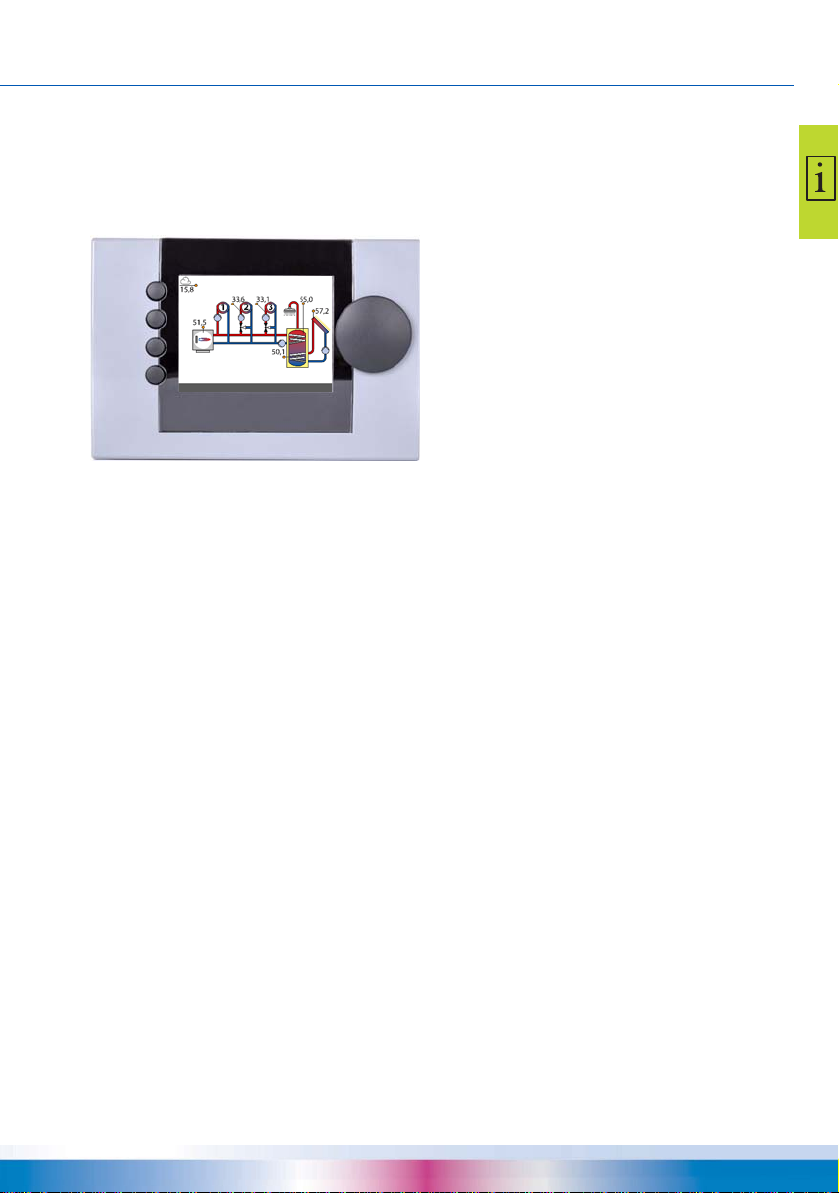

smart Econ HCW

smart Econ HCW integrates the controller and the Userinterface

into one compact housing for wall mounting.

Temperature sensors as well as pumps and valves are connected to the controller.

The smart Econ HCW is connected to the smart Econ Room

controllers via CAN bus.

The display shows the menus for configuration, the temperatures of all the configured temperature sensors, as well as diagnostics and error messages.

The Userinterface provides a combined turn/push button for

operating the menus as well as 4 function keys, see “Control

elements” on page 17.

smart Econ HCW 1620 Expansion module

smart Econ HCW 1620 is composed of the base unit with the

Userinterface and the expansion module.

Temperature sensors as well as pumps and valves are connected to the expansion module in the same way as to the base

unit.

The expansion module is connected to the base unit and the

smart Econ Room controllers via CAN bus.

14 smart Econ - emz-HCW - 180116

DEVICE DESCRIPTION

Connections and interfaces on the smart Econ HCW

The smart Econ HCW has the following connections inside the housing:

• Connections for pumps and mixers (terminal strips)

• Connections for temperature sensors (terminal strips)

• 1 CAN bus interface (terminal strip for 4-wire cable)

• 1 Ethernet interface (LAN) at the back of the housing (Western socket for CAT 5 cable)

An Internet connection can be established via the LAN interface. This allows additional PC operation via the smart Econ Cloud (access optional).

“Internet-based network” on page 55

• 1 USB interface inside the housing (Micro-USB-B)

“Installation and connection” on page 45

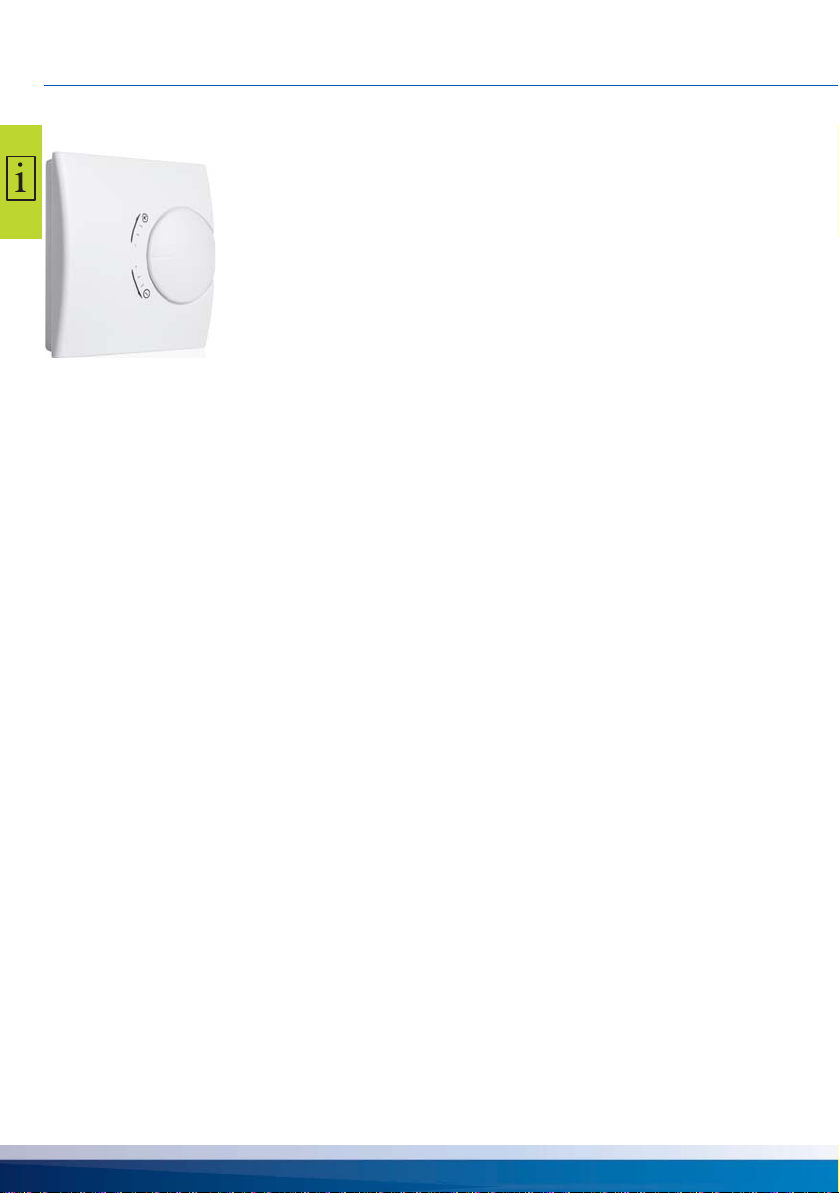

smart Econ Room controller

The smart Econ room controller determines the current room temperature.

The desired room temperature can be readjusted using the setting wheel.In

addition, the operating mode for the assigned heating circuits can be changed

via the end positions of the setting wheel:

In the end position (+) a permanent party mode (always heat)

and in the end position (-) a permanent setback function.

CAN bus line

Connect the individual system components in series with a 4-pole cable, the CAN bus line.

The CAN bus line merely has to be connected from one component to the next, which significantly

reduces the installation effort.

Data is transferred via the fieldbus system CAN (Control Area Network).

smart Econ - emz-HCW - 180116 15

OPERATING THE SMART ECON ROOM CONTROLLER

Operating the smart Econ room controller

Range +3 to -3 The room temperature setpoint is changed by the value set.

End position + Party function for the assigned heating circuits.The highest

room temperature setpoint entered is used, irrespective of the

time program.

End position - Setback function for the assigned heating circuits.The tem-

perature is controlled to the setback temperature entered for

this room.

Heating

• To readjust the desired room temperature, turn the setting wheel to the desired temperature difference.

Example:

The programmed room setpoint temperature is 21 °C.

The room controller is on 2.Step adjusted in direction + .

This results in a desired room temperature of 23 °C.

Special functions

• If you want to heat during the set-back times (party mode), turn the setting wheel to the end position +.

The connected heating circuit changes continuously to day mode until the setting wheel is reset.

• To activate the setback function (e.g. holiday), turn the setting wheel to the end position -.

The connected heating circuit changes to night mode until the setting wheel is reset.

16 smart Econ - emz-HCW - 180116

OPERATING THE SMART ECON USERINTERFACE

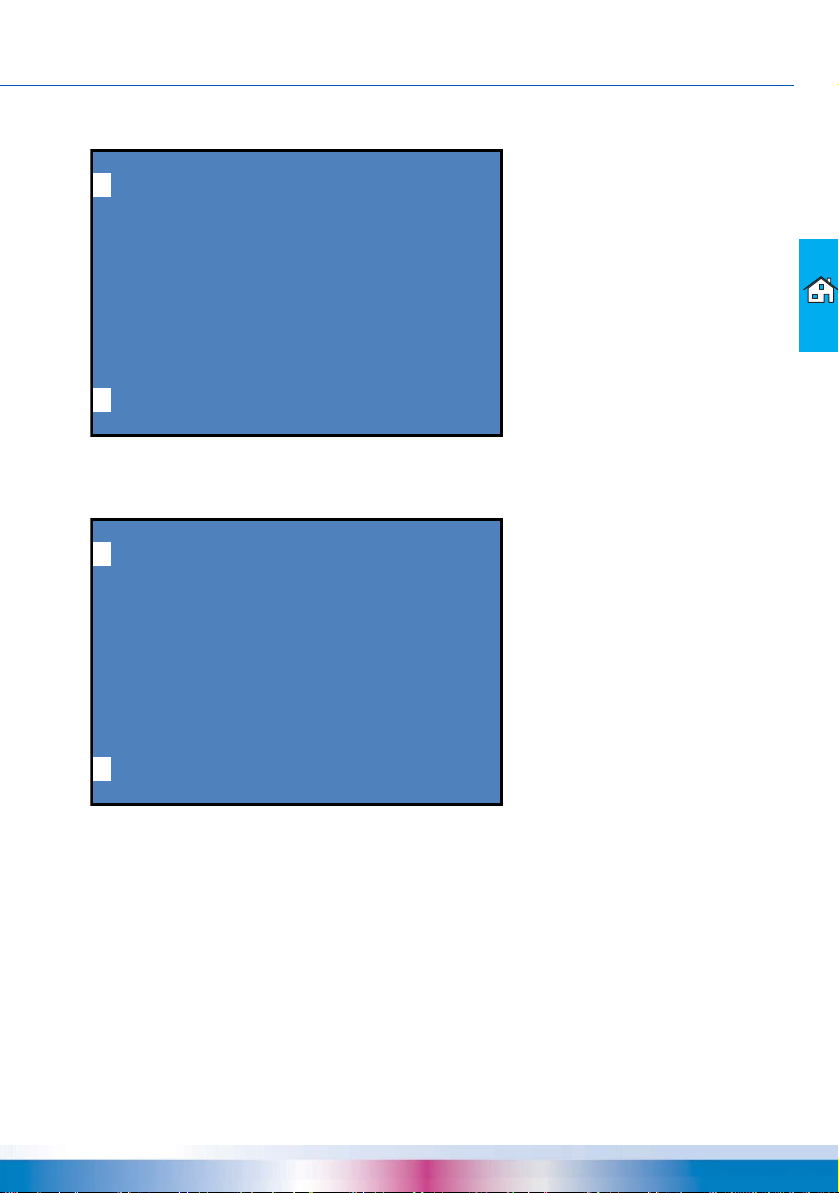

(1)

(2)

(3)

(4)

(5)

(6)

Operating the smart Econ Userinterface

Control elements

The smart Econ Userinterface is set up and operated with a combined turn/push knob (turn knob)

for menu navigation and 4 function buttons.

Basic display, overview mode

(1) Function key 1 / Abort (^)

(2) Select function key 2 / digit left (<)

Function keys 1 and 2 can be used for switching functions.

(3) Select function key 3 / digit right (>)

Function button for quick access and software switch

(4) Help function: INFO key for function explanations (i)

(If available, the operating options of the function keys are shown on the display.)

(5) Combined Turn/push button with OK button function for menu navigation

(6) Display

You input settings and queries using the turn/push button:

“Select menu items” on page 19

“Change values” on page 23

Display

The smart Econ Userinterface has a graphic display which is permanently illuminated to indicate the

operating status and to communicate in case of setup, malfunction, change and evaluation.

If no action is taken on the control elements of the Userinterfacefor a longer period (approx. 5 min),

the menu switches back to the hydraulic system and the brightness of the display is dimmed

(“Adjusting the display brightness and buzzer volume” on page 43).

To access the main menu, the access code must be entered (again).

smart Econ - emz-HCW - 180116 17

PROMPTS DURING OPERATION

04.04.18 10:35:10 Server: online AUTOMATIC

Hea t Cir c u its

Temperatures

Outputs

Diagnostics

MENU

BACK

26.02.2018 14:23:03 Server: online AUTOMATIC

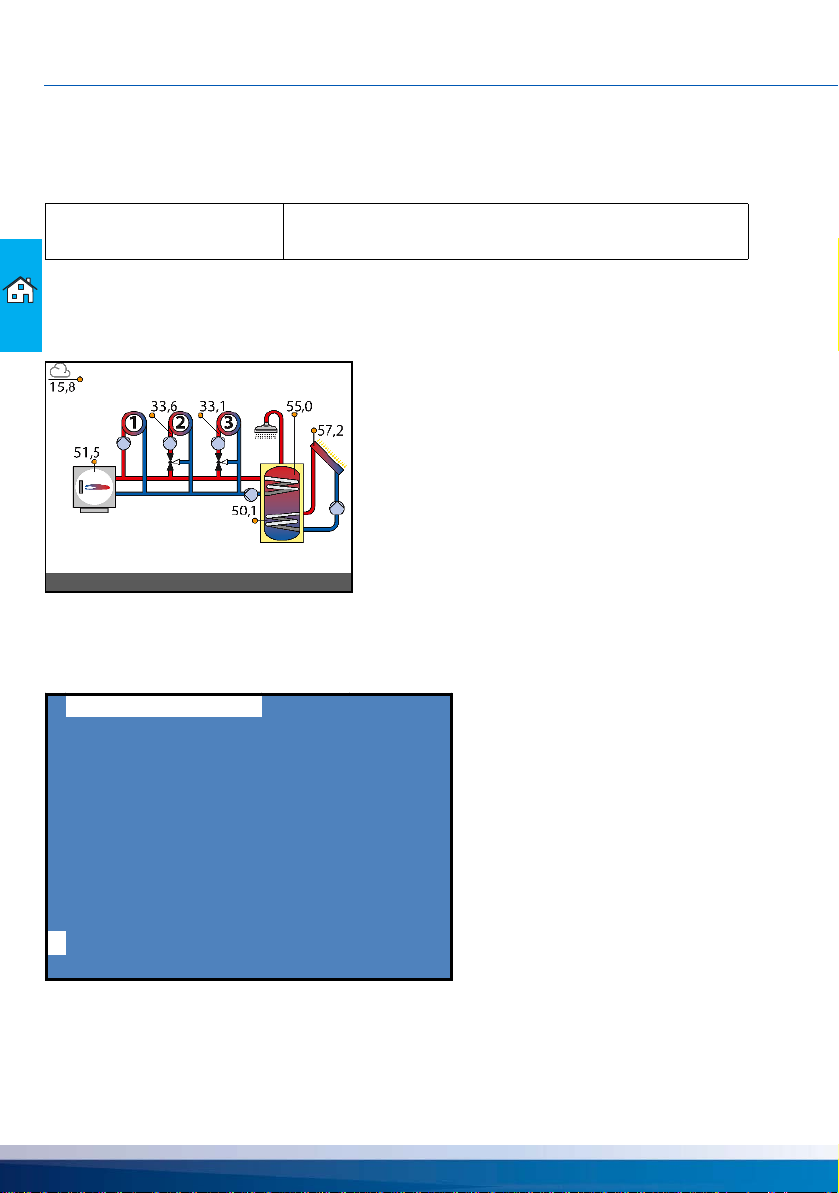

Prompts during operation

Using the smart Econ Userinterface, you can check the current system status and adjust the settings.

NOTE

Overview mode

In overview mode, the configured system diagram, sensor temperatures and the operating statuses

of connected components are displayed.

(Example)

Press the rotary/push button to access the menu.

Menu

Check the display screen of the smart Econ on a regular basis

to be able to eliminate any malfunctions promptly!

i

The menu shows the available options for displaying the controller’s temperatures and operating

statuses.

The selected menu item is highlighted.

18 smart Econ - emz-HCW - 180116

PROMPTS DURING OPERATION

Hea t Cir c u its

Temperatures

Outputs

Diagnostics

MENU

BACK

26.02.2018 14:23:03 Server: online AUTOMATIC

Certain menus are divided into several pages, which you can select with the rotary/push button.

The menu item ›BACK‹ always appears in the last line of the last page.

The menu can also be exited by simply pressing the rotary/push button.

On the bottom line, you can see the date and time on the left, status messages in the middle and the

current operating mode on the right.

On the left, the current function of the function keys (1)-(4) is displayed.

See “Control elements” on page 17

Select menu items

• To select the required menu item, scroll through the menu by turning the rotary/push button - the

respective selectable option appears highlighted on the display.

• Pressing the rotary/push button ("OK") confirms the selected menu item.

The respective submenu is opened or the corresponding selection is activated.

• Select ›BACK‹ to jump back one level from any subitem in the menu.

•By pressing the INFO button or by selecting ›INFO‹, you can access help information on the

selected menu item.

Overview menu

i

The overview menu contains the most important information for you to get a quick overview of the

system status.

• Select a submenu.

“›Heat Circuits‹ menu (Overview menu)” on page 20

“›Temperatures‹ menu” on page 21

“›Outputs‹ menu” on page 21

“›Diagnosis‹ menu” on page 22

• Use ›MENU‹ to change settings.

See “Main menu” on page 26

• Select ›BACK‹ to return to the overview mode.

smart Econ - emz-HCW - 180116 19

PROMPTS DURING OPERATION

Hea t Cir c u its

HEAT CIRCUIT 1

*** ON 06:00- 22.00

HEAT CIRCUIT 2

OFF

HEAT CIRCUIT 3

ON 00:00-24.00

BACK

26.02.2018 14:23:03 Server: online AUTOMATIC

›Heat Circuits‹ menu (Overview menu)

i

The ›Heat Circuits‹ menu displays the operating states of all heating circuits in the configured system.

• If the controller is in day mode, the duration programmed for day mode appears to the right of the

current operating status.

If the party function is activated, the time period 00:00 - 24:00 is displayed; no time is displayed in

the setback and frost protection modes.

• If the controller is not in day mode, e.g. outside the programmed time period or if the operating

mode does not permit day mode, nothing appears at this point.

• The ›ON‹/›OFF‹ status indicates whether the heating circuit is ready for operation.

Example: HC 1 =›AUTOMATIC‹, HC 2 =›NIGHT‹, HC 3 =›DAY‹.

NOTE

In the event of a fault, e.g. a defective sensor, three asterisks

*** appear under the relevant heating circuit

20 smart Econ - emz-HCW - 180116

PROMPTS DURING OPERATION

Temperatures

flow heat c irc. 3 <2/22> 36.7

flow heat c irc. 4 <2/24> 44.1

----------------------------damped out-temp. 1.2

BACK

26.02.2018 14:23:03 Server: online AUTOMATIC

Outputs

pump heat circ. 1 <1/36> ON

pump heat circ. 2 <1/38> ON

pump heat circ. 3 <2/36> OFF

pump heat circ. 4 <2/38> OFF

pump dhw <1/34> OFF

pump circ. <2/40> ON

BACK

26.02.2018 14:23:03 Server: online AUTOMATIC

›Temperatures‹ menu

i

The ›Temperatures‹ menu displays the measured or calculated temperature values of the configured system.

The <number> after the input designations shows the number of the connection contact to which the

respective sensor is connected.

Example: ›flow heat circ. 1 <1/20>‹

Designations without <number> are calculated temperature values without connection contact.

Example: ›damped out-temp.‹

›Outputs‹ menu

i

The ›Outputs‹ menu displays the operating statuses ›ON‹/›OFF‹ of the controlled controller outputs

in the configured system.

The <number> after the output designations indicates the number of the switched connection con-

tact.Designations without <number> are logical switching states without connection contact.

smart Econ - emz-HCW - 180116 21

PROMPTS DURING OPERATION

Diagnostics

setpoint-HC 2 21.0

setpoint-HC 3 21.0

setpoint-HC 4 21.0

request heat gen. OFF

DHW PRIORITIY 0.0

i

BACK

26.02.2018 14:23:03 Server: online AUTOM ATIC

Message

MALFUNCTION!

26.02.2018 14:23:03

›Diagnosis‹ menu

The ›Diagnostics‹ menu displays the current states and values of all components and thus of the

entire heat generation process.

The values displayed are logical switching states and calculated values that display the target state

of the control loops.

Error messages

In the event of a fault, an alarm message appears on the display.

Information

i

You can display further information by pressing the function key marked ›i‹.

22 smart Econ - emz-HCW - 180116

SETTINGS DURING OPERATION

Hello user

PLEA S E ENTER YOUR CODE

0000

Settings during operation

Entering the access code

To prevent settings from being changed accidentally, it is necessary to enter an access code for the

smart Econ heating system controller.

In the overview menu (page 19) you can call up the main menu:

• Select ›MENU‹.

You have to enter the access code.

<

>

• Enter the access code for the end user (Code: 0000), if necessary.

See Change values below

• Press the turn knob to confirm.

The main menu is now available. “Main menu” on page 26

Depending on the access code, the corresponding menu items appear.

NOTE

Change values

• Select the value to be changed (e.g. code or temperature) by turning the rotary/push button (highlighted).

• Press the rotary/push button to change the value.

• Use the function keys 2 (<) and 3 (>) to select the digit of the number to be changed (underlined).

Example code: 0000

• Press and turn again to increase or decrease the value.

Example code: 0004

• Press the rotary/push button to confirm the value.

• Repeat the procedure for further digits of the number, if necessary.

The Userinterface does not display any submenus that are not

needed by the selected hydraulic system or the activated

options.

smart Econ - emz-HCW - 180116 23

SETTINGS DURING OPERATION

...

...

...

...

...

...

...

HEIZKREIS 1

SETTINGS

DHW PRIORITY ON/OFF *

TIMER DHW

HEAT CIRCUITS

DOMESTIC HOT WATER **

GENERAL

INTERNET

Overview

Heat Circuits

Temperatures

MENU

INTERNET

serial number

CODE

DHCP

IP-Address

OPERATING MODES

AUTOMATIC

CHIMNEYSWEEP

TIMER PROGRAMS

DOMESTIC HOT WA

TER **

Outputs

Diagnostics

BACK

Enter Code

INSTALLER *

COMMISSIONING

OPERATING HOURS

TEST

HEIZKREIS n

MENU

(Example)

LANGUAGE

DATE + TIME

DELETE ERROR MESSAGE

GENERAL

LANGUAGE *

INSTALLER *

OPERATING MODES

HOLIDAY PERIODS

SETTINGS PUMP DHW *

TIMER CIRCULATION

SETTINGS PUMP CIRC. *

MIN DHW-TEMP CIRC

MAX RF-TEMP CIRC

HEAT CIRCUIT 1

HEAT CIRCUIT n

HOLIDAY PERIODS

ENTIRE UNIT

TIMER PROGRAMS

HEAT CIRCUITS **

global day temp.

HEAT CIRCUIT 1

HEAT CIRCUIT n

global eco temp.

DAY

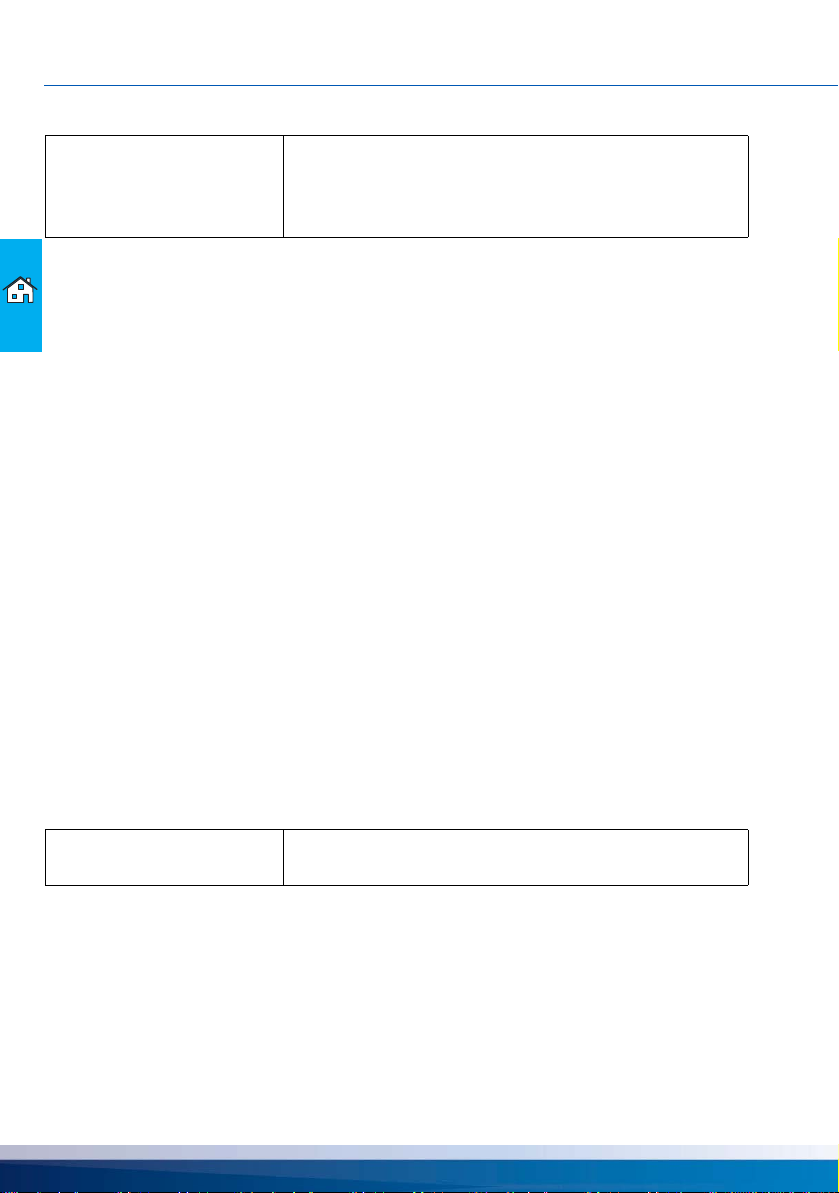

Menu structure

* Menu items are only available for the installer, see page 108

** Menu depends on the selected system.

24 smart Econ - emz-HCW - 180116

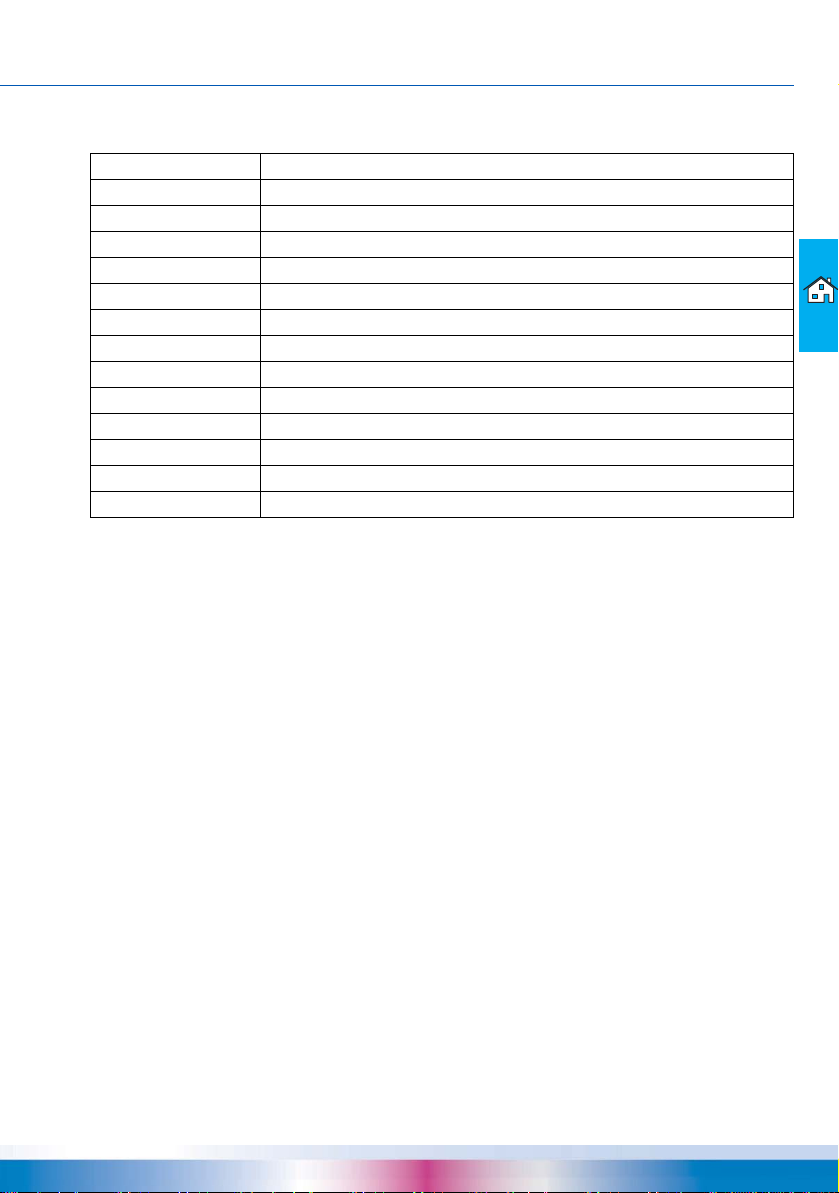

Abbreviations in the menus

Abbreviation Description

ABS Anti-blocking system

CIRC Circulation

DHW Domestic hot water

FL Flow line

HC Heat Circuit

HG Heat generator

HP Heat pump

OT Outside temperature

P Pump

RC Room controller

RL Return line

SFB Solid fuel boilers

SOL Solar

SETTINGS DURING OPERATION

smart Econ - emz-HCW - 180116 25

SETTINGS DURING OPERATION

Main menu

^

OPER A TING MODES

TIMER PROGRAMS

HOLIDA Y PERIODS

HEAT CIRCUITS

DOMESTIC HOT WA TER

GENERA L

i

INT ERN ET

BACK

Main menu

The ›Main menu‹ is displayed after selecting the access code for the end user (Code: 0000).See

“Entering the access code” on page 23

Here you can input settings.

• “›OPERATING MODES‹ menu” on page 27

• “›TIMER PROGRAMS‹ menu” on page 30

• “›HOLIDAY PERIODS‹ menu” on page 35

• “›HEAT CIRCUITS‹ menu” on page 36

• “›DOMESTIC HOT WATER‹ menu” on page 38

• “›GENERAL‹ menu” on page 42

• “›INTERNET‹ menu” on page 44

Note: Additional menu items available for the installer.

“Main menu for the installer” on page 108

26 smart Econ - emz-HCW - 180116

SETTINGS DURING OPERATION

PLEA SE SELECT

ENTIRE UNIT

HEAT CIRCUIT 1

HEAT CIRCUIT 2

HEAT CIRCUIT 3

BACK

PLEA SE SELECT MODE

AUTOMATIC

DA Y

NIGHT

FROST PROTECTION

SUMMER

FLOOR PAVEMENT HEATING

OFF

CHI MNEY S WEEP

BACK

›OPERATING MODES‹ menu

^

i

(Example, depending on the selected system)

In the ›OPERATING MODES‹ menu, first select whether the setting is to apply to the entire system

or only to the individual heating circuit.

^

i

In the menu ›PLEASE SELECT MODE‹ you then define the operating mode for the selected section

of the system.The following modes are possible:

• Operating mode ›AUTOMATIC‹

• Operating mode ›DAY‹

• Operating mode ›NIGHT‹

• Operating mode ›FROST PROTECTION‹

• Operating mode ›SUMMER‹

• Operating mode ›FLOOR PAVEMENT HEATING‹

• Operating mode ›OFF‹

• Operating mode ›CHIMNEY SWEEP‹

smart Econ - emz-HCW - 180116 27

SETTINGS DURING OPERATION

NOTE

Operating mode ›AUTOMATIC‹

System control according to the time programs entered and the chosen ambient temperature setpoints (“›HEAT CIRCUITS‹ menu” on page 36).

The user can make changes with the smart Econ room controller's setting wheel, see “Operating the

smart Econ room controller” on page 16.

As this is set directly at the smart Econ room controller, each user can control the entire heating system for the respective area without requiring any special knowledge of the heating installation or its

control system.

Operating mode ›DAY‹

Time programs are not considered.The highest room temperature setpoint entered for the respective heating circuit is used.

Operating mode ›NIGHT‹

The time programs are not considered, the temperature is always controlled to the room temperature setpoint entered for setback operation.The temperature is also controlled to this setback room

temperature on individual programmed holidays as well as on the last holiday of a holiday period.

See “›HOLIDAY PERIODS‹ menu” on page 35

Operating mode ›FROST PROTECTION‹

Time programs are not considered.The temperature is always controlled to the frost protection room

temperature.

Except for the last day, the temperature is also set to this value during a holiday period.

See “›HOLIDAY PERIODS‹ menu” on page 35

You can change the frost protection temperature directly in the settings of the ›FROST PROTECTION‹ operating mode and it applies to the entire system.

With the exception of the operating modes ›FROST PROTECTION‹ and ›OFF‹, no messages are displayed indicating that

the selected operating mode is active.

The selected operating mode is displayed in the footer.

NOTE

Operating mode ›SUMMER‹

The space heating is off, all other functions (water heating, solar heating system, etc.) are

active.The heating circuit pumps and mixers are switched on briefly once a week to prevent them

from getting stuck when they are not being used regularly during the summer.

Operating mode ›FLOOR PAVEMENT HEATING‹

Note: The ›FLOOR PAVEMENT HEATING‹ mode is only available for heating circuits with mixers.

The frost protection function is always active in all operating

modes except the ›OFF‹ operating mode.

28 smart Econ - emz-HCW - 180116

SETTINGS DURING OPERATION

To be able to properly dry heated screed, the material is heated according to a standardized flow

temperature curve (irrespective of the room temperature).

Note: ›FLOOR PAVEMENT HEATING‹ can be activated with the access code for the end user, but

cannot be set.

Progress of the drying process

day 012345678910

Temperature 20° 25° 30° 35° 40° 40° 40° 40° 40° 30° 20°

Change at midnight every day, regardless of the activation time.

Operating mode ›OFF‹

In this operating mode, all current temperatures and other input information are displayed but no

switching functions are activated.

All components of the system must be switched to inactive!

Operating mode ›CHIMNEY SWEEP‹

In this operating mode, the heating can be switched on immediately at any room temperature.The

boiler is heated up to the highest setpoint entered.

smart Econ - emz-HCW - 180116 29

SETTINGS DURING OPERATION

TIMER PROGRAMS

HEAT CIRCUIT 1

HEAT CIRCUIT 2

HEAT CIRCUIT 3

BACK

TIMER PROGRAMS

HEAT CIRCUIT 1

----------ROOM SETPOINTS

BACK

›TIMER PROGRAMS‹ menu

^

i

(Example, depending on the selected system)

In the ›TIMER PROGRAMS‹ menu, first select the heating circuit to which the setting is to apply.

^

i

Then select ›ROOM SETPOINTS‹.

30 smart Econ - emz-HCW - 180116

SETTINGS DURING OPERATION

HEAT CIRCUIT 1

COPY A LL V A LUES

Monday COPY DAY

from 06:00 - 22:00 hrs => 21 degr

from 00:00 - 00:00 hrs => 21 degr

from 00:00 - 00:01 hrs => 21 degr

economy mode => 15 degr

everything clear NO? => <INFO>!

BACK

^

i

Setting heating periods and temperatures

You can define up to three heating periods for each room and day of the week.

You can define a room temperature for each set period.

In between these periods, the system regulates itself to the setback temperature.

If you set the time from 00:00 to 00:00, the system will not be controlled at this time.

You can enter the times in steps of 10 minutes, the temperatures in steps of 1/10 degree.

Selecting the day of the week

The default setting is ›Monday‹ .

Select the day (shaded) with the turn knob and press the knob. The day will begin to flash.Turn the

turn knob to the left or right and press it to select a different day.

Setting times and temperatures

“Change values” on page 23

›COPY DAY...‹

With the turn knob, select ›COPY DAY...‹ (highlighted) and press the turn knob.A submenu in which

you can select the day of the week is opened.

Example: Tuesday should be the same as on Monday.

Select ›Tuesday‹, press the turn knob, ›COPY DAY...‹, press the turn knob, select ›Monday‹, press

the turn knob.

›COPY ALL VALUES...‹

With the turn knob, select ›COPY ALL VALUES...‹ (highlighted) and press the turn knob.A selection

of additional rooms is displayed.Turn the turn knob again to select a room and press to confirm and

copy all times and temperatures from this room.

smart Econ - emz-HCW - 180116 31

SETTINGS DURING OPERATION

Example:

›HEAT CIRCUIT 1‹ has been defined,

›HEAT CIRCUIT 2‹ should have the same heating times and temperatures.

Select ›HEAT CIRCUIT 2‹, press the turn knob, ›COPY ALL VALUES...‹, press the turn knob, select

›HEAT CIRCUIT 1‹, press the turn knob.

On the following pages, you will find blank forms for rooms in which you can enter the name of the

room, three heating temperature levels with the corresponding heating periods as well as the setback temperature (in between) for your system.

32 smart Econ - emz-HCW - 180116

SETTINGS DURING OPERATION

Table for rooms and heating times

Room:

Day of the week Temperatures and periods

°C °C °C

Monday :- : :- : :- :

Tuesday :- : :- : :- :

Wednesday :- : :- : :- :

Thursday :- : :- : :- :

Friday :- : :- : :- :

Saturday :- : :- : :- :

Sunday :- : :- : :- :

In between: °C (setback temperature)

Room:

Day of the week Temperatures and periods

°C °C °C

Monday :- : :- : :- :

Tuesday :- : :- : :- :

Wednesday :- : :- : :- :

Thursday :- : :- : :- :

Friday :- : :- : :- :

Saturday :- : :- : :- :

Sunday :- : :- : :- :

In between: °C (setback temperature)

smart Econ - emz-HCW - 180116 33

SETTINGS DURING OPERATION

Table for rooms and heating times

Room:

Day of the week Temperatures and periods

°C °C °C

Monday :- : :- : :- :

Tuesday :- : :- : :- :

Wednesday :- : :- : :- :

Thursday :- : :- : :- :

Friday :- : :- : :- :

Saturday :- : :- : :- :

Sunday :- : :- : :- :

In between: °C (setback temperature)

Room:

Day of the week Temperatures and periods

°C °C °C

Monday :- : :- : :- :

Tuesday :- : :- : :- :

Wednesday :- : :- : :- :

Thursday :- : :- : :- :

Friday :- : :- : :- :

Saturday :- : :- : :- :

Sunday :- : :- : :- :

In between: °C (setback temperature)

34 smart Econ - emz-HCW - 180116

SETTINGS DURING OPERATION

PLEA SE SELECT

^

ENTIRE UNIT

HEAT CIRCUIT 1

HEAT CIRCUIT 2

HEAT CIRCUIT 3

HEAT CIRCUIT 4

BACK

i

HOLIDA Y PERIODS

^

ENTIRE UNIT

new holiday f rom 00.00

until 00.00

BACK

i

›HOLIDAY PERIODS‹ menu

(Example, depending on the selected system)

In the ›HOLIDAY PERIODS‹ menu, first select whether the setting is to apply to the entire system or

only to the individual heating circuit.

• Enter the start and end dates for the holiday.

“Change values” on page 23

Notes:

To delete a holiday period, enter the date 00.00.

More than 10 holiday periods can be set for the entire system,

for a single heating circuit, however, only one.

On these holidays, the room temperature is controlled to the frost protection room temperature.

See “Operating mode ›FROST PROTECTION‹” on page 28.

On the last day of a holiday period, the room temperature is controlled to the setback temperature.

If a programmed holiday period has passed, the entry is automatically deleted.

smart Econ - emz-HCW - 180116 35

SETTINGS DURING OPERATION

HEAT CIRCUITS

global day temp. (°C): 22.0

global eco temp. (°C): 18.0

HEAT CIRCUIT 1

HEAT CIRCUIT 2

HEAT CIRCUIT 3

HEAT CIRCUIT 4

BACK

HEAT CIRCUIT 2

SETTINGS ROOM 2

MIXER HEAT CIRC. 2

BACK

›HEAT CIRCUITS‹ menu

^

i

(Example, depending on the selected system)

The ›HEAT CIRCUITS‹ menu shows the global set points and a selection of heating circuits.

• Change the global values applicable to all heating circuits, if necessary.

›global day temp.(°C)‹ = Global setpoint day room temperature for heating periods

›global eco temp.(°C)‹ = Global setpoint night room temperature for setback periods

• Select a heating circuit, e.g. ›HEAT CIRCUIT 2‹ .

Make the settings for the other heating circuits accordingly.

^

i

• Select ›SETTINGS ROOM 2‹ in the ›HEAT CIRCUIT 2‹ menu.

(Example, depending on the selected system)

36 smart Econ - emz-HCW - 180116

SETTINGS DURING OPERATION

SETTINGS ROOM 1

^

NA ME SETTINGS ROOM 1

current set point (°C) 0

use global day temp.: NO

use global eco temp.: NO

ROOM SETPOINTS 0

BACK

i

• Change the name of this temperature sensor if necessary.

• Change the setpoint temperature for this heating circuit, if necessary.

“Change values” on page 23

For further settings, see “›HEAT CIRCUITS‹ menu (Installer)” on page 130

smart Econ - emz-HCW - 180116 37

SETTINGS DURING OPERATION

DOMESTIC HOT WATER

SETTINGS

TIMER DHW

TIMER CIRCULA TION

MIN DHW- TEMP CIRC

MA X RF- TEMP CIRC

BACK

SETTINGS

^

desired value 50

BACK

›DOMESTIC HOT WATER‹ menu

^

i

In the ›DOMESTIC HOT WATER‹ menu you can define the set temperature, the heating times and,

if necessary, the circulation times.

For further settings, see “›DOMESTIC HOT WATER‹ menu (Installer)” on page 135

Setting the domestic hot water setpoint temperature

• Select ›SETTINGS‹ in the ›DOMESTIC HOT WATER‹ menu.

i

• Change the ›desired value‹ (in °C) if necessary.

“Change values” on page 23

38 smart Econ - emz-HCW - 180116

SETTINGS DURING OPERATION

TIMER DHW

^

WEEK L Y PROGRA M

SWITCH TO MA NUA L/ A UTO

BACK

TIMER DHW

^

COPY A LL V A L UES

Monday

sw itch on f rom 06:00 - 22:00 hrs

sw itch on f rom 00:00 - 00:00 hrs

sw itch on f rom 00:00 - 00:00 hrs

Weekly program ENABLED

everything clear NO? => <INFO>!

BACK

Setting the domestic hot water heating times

• To set the heating times, select ›TIMER DHW‹ in the ›DOMESTIC HOT WATER‹ menu.

i

• You can change the heating times via ›WEEKLY PROGRAM‹.

i

• You can define up to three heating times and temperatures for each day of the week.

No heating is used for all times in between.

If you set the time from 00:00 to 00:00, the system will not be controlled at this time.

You can enter the times in steps of 1 minute, the temperatures in steps of 1/10 degree.

“Selecting the day of the week” on page 31

“›COPY DAY...‹” on page 31

“›COPY ALL VALUES...‹” on page 31

• You activate or deactivate the time switch via ›Weekly program: APPROVED‹.

smart Econ - emz-HCW - 180116 39

SETTINGS DURING OPERATION

SCHA LTUHR WW

^

AUTOMATIC (TIMER PROGRAMS)

ALWAYS ON

ALWAYS OFF

BACK

TIMER CIRCULA TION

^

WEEK L Y PROGRA M

BACK

Manual control of domestic hot water heating

• To manually control the heating, select ›SWITCH TO MANUAL/AUTO‹ in the ›TIMER DHW‹

menu.

i

• Select the desired heating mode.

Setting circulation times

• To set the circulation times, select ›TIMER CIRCULATION‹ from the ›DOMESTIC HOT WATER‹

menu.

i

• You can change the circulation times via ›WEEKLY PROGRAM‹ in the same way as for “Setting

the domestic hot water heating times” on page 39.

40 smart Econ - emz-HCW - 180116

SETTINGS DURING OPERATION

MIN DHW- TEMP CIRC

^

limit value 38.0

BACK

MAX RF- TEMP CIRC

^

limit value 38.0

BACK

Configure circulation temperatures

• Select ›MIN DHW-TEMP CIRC‹ in the ›DOMESTIC HOT WATER‹ menu.

i

• Change the ›limit value‹ if necessary.

Minimum storage tank temperature for release of circulation

Circulation setpoint temperature: 38.0 °C (setting range: 0.0 - 95.0)

“Change values” on page 23

• Select ›MAX RF TEMP CIRC‹ in the ›DOMESTIC HOT WATER‹ menu.

i

• Change the ›limit value‹ if necessary.

Maximum temperature in the return line of the circulation

Temperature for stopping the circulation: 38.0 °C (setting range 0.0 - 85.0)

“Change values” on page 23

If the temperature in the return line of the circulation is higher than the set limit value, the circulation

pump is switched off.(The circulation system is flushed.)

smart Econ - emz-HCW - 180116 41

SETTINGS DURING OPERATION

GENERA L

LANGUAGE English T

DA TE + TIME

DELETE ERROR MESSA GE

serial number 12345

softw are version v1.4

firmw are version v1.5

display activ intens ity 80

display dimmed intensity 40

Beeper-Level MAX

--------------------------------------------

DATE + TIME

^

w eek day Wednesday

DA Y 1 7

month 1

year 2018

hour 14

minute 25

second 0

off set -1

BACK

›GENERAL‹ menu

^

i

In the ›GENERAL‹ menu you can view information about Userinterface and change general settings.

For further settings, see “›GENERAL‹ menu (Installer)” on page 140

Setting the language of the menu

• Change the language via ›LANGUAGE‹ if necessary.

“Change values” on page 23

Set date and time

• Select ›DATE + TIME‹ in the ›GENERAL‹ menu.

i

• Set the current date and time.

›offset‹: The time zone can be set here.

“Change values” on page 23

Note: The date and time must be reset after a long power failure.

42 smart Econ - emz-HCW - 180116

SETTINGS DURING OPERATION

dis play activ intensity 80

display dimmed intensity 40

Beeper-Level MAX

--------------------------------------------

Adjusting the display brightness and buzzer volume

i

In the ›GENERAL‹ menu you can adjust the brightness of the LCD display and the volume of the

buzzer:

• ›display active intensity‹: Brightness during operation

• ›display dimmed intensity‹: Brightness in standby mode

• ›Beeper-Level‹: Alarm volume in case of error messages

“Change values” on page 23

smart Econ - emz-HCW - 180116 43

SETTINGS DURING OPERATION

INTERNET

serial number 12345

CODE: xxxxxxxxxxxxxxxxxxxx

renew AUTH-CODE? NO

delete user-data? NO

DHCP Y ES

IP-Address 192.168.1.100

Subnet mask 255.255.255.0

Gateway 192.168.1.1

DNS1 0.0.0.0

DNS2

›INTERNET‹ menu

^

i

0.0.0.0

In the ›INTERNET‹ menu you can view and change the network settings of the Userinterface.

“Change values” on page 23

For further settings, see “›INTERNET‹ menu (Installer)” on page 143

44 smart Econ - emz-HCW - 180116

Installation and connection

INSTALLATION AND CONNECTION

DANGER

Electrical hazard

Danger of death by electrocution!

Before performing any work on the terminals, make sure you

completely disconnect all poles of the power supply and

secure them against being switched on again!

NOTE

Externally secure the consumers that are connected to the

potential-free relay outputs according to their power consumption.

The fuse in the controller only protects the electronic components!

The total load of all pumps or mixers connected to a controller

must not exceed 6 A.

Use flexible connecting cables (stranded wires) only!

smart Econ - emz-HCW - 180116 45

INSTALLATION AND CONNECTION

smart Econ Temperature sensor

Universal sensor elements are available for measuring temperatures.

“smart Econ Temperature sensor” on page 145

These can:

• be plugged into preconfigured thermowells [universal sensors] (supply temperature, boiler temperature, etc.)

• be attached to pipelines [pipe-mounted sensor] (storage tank temperature, flow temperature, etc.)

• be used as smart Econ outside temperature sensor in a weather-resistant housing

If required, you can alternatively use other temperature sensor versions (outside sensor, air duct

sensor, wall mounting room sensor, flush mounting room sensor).

Temperature sensor polarity Terminal

red even terminal number (e.g. 10)

white uneven terminal number (e.g. 11)

The temperature sensors are protected against reverse polarity.If a temperature sensor was connected incorrectly, this will be automatically detected and signaled during startup.Interruptions in the

circuit are also detected and signaled.

Note: If the display shows "polarity reversal", this may also be due to a short circuit in the signal

lines.

NOTE

Only connect temperature sensors and contacts.

Never apply voltage!

46 smart Econ - emz-HCW - 180116

smart Econ HCW

Dimensions smart Econ HCW

220

110 110

INSTALLATION AND CONNECTION

58

218

(dimensions in millimeters)

140

49.6

smart Econ - emz-HCW - 180116 47

INSTALLATION AND CONNECTION

Opening the smart Econ HCW housing

1 Release the lock screw.

2 Swing terminal cover forward ...

3 ... push it upwards ...

4 ... and remove it.

Store the terminal cover carefully and protect it

against damage!

To close the terminal cover, reverse the opening

procedure.

Installation location smart Econ HCW

• In an easily accessible place

• Usual installation height: Display at user eye level

When used for temperature measurement:

• The device must not be exposed to external heat.(Waste heat from electrical appliances, waste

heat from lighting, heated walls, via radiators, etc.)

48 smart Econ - emz-HCW - 180116

Installation smart Econ HCW

INSTALLATION AND CONNECTION

NOTE

Do not use the housing base as drill template.