EMX Industries, Inc. Tech support: 216-834-0761 1/7

MVP D-TEK_Rev2.0_081319 technical@emxinc.com

MVP D-TEK™

Multi-Voltage Vehicle Loop Detector

Instruction Manual

The MVP D-TEK vehicle loop detector allows for detection of metallic objects entering the field formed

around an induction loop. This detector automatically adjusts to input power from 12 VDC up to 240 VAC

which eliminates the installer’s need to match available power to an appropriately rated vehicle detector.

The MVP D-TEK is made from anodized aluminum and all switches have gold plated contacts that are sealed

for protection. It features full loop diagnostic with frequency counter, 10 sensitivity settings, delay mode,

extend mode, fail safe/fail secure mode, automatic sensitivity boost, pulse and presence operating modes

and two output relays.

Cautions and Warnings

This product is an accessory or part of a system. Install the MVP D-TEK according to

instructions from the gate or door operator manufacturer. Comply with all applicable

codes and safety regulations.

• MVP D-TEK Multi-voltage vehicle loop detector (included)

• HAR-11 11 position harness, 3’ of wire

• LD-11 11 pin DIN rail socket, black, wide base

• LD-11B 11 pin DIN rail socket, black, narrow base

• PR-XX Lite preformed loop (XX – specify size)

• TSTL Test loop, troubleshooting tool

Specifications

Power

12-60 VDC or 12-240 VAC (48-62 Hz)

Draw Current

19.2 mA

Loop Frequency

3 settings (low, medium, high)

Loop Induction

20-2000 μH (Q factor ≥ 5)

Surge Protection

MOV, neon and silicon protection devices

Relay Contact Rating

2 DPST 1A @ 30 VDC

Operating Temperature

-40º to 180ºF (-40º to 82ºC)

Housing Material

Anodized aluminum

Connector

11 pin male connector (JEDEC B11-88)

compatible with DIN rail mount socket or wire harness

Dimensions (L x W x H)

3.25” (83 mm) x 2.56” (40 mm) x 3.65” (90 mm)

Ordering Information

TM

EMX Industries, Inc. Tech support: 216-834-0761 2/7

MVP D-TEK_Rev2.0_081319 technical@emxinc.com

Wiring Connections

Connector Pin

Harness

Description

1

White

Power (12-240 VDC/AC)

2

Black

Power (12-240 VDC/AC)

3

Orange

Relay 2 – NO (normally open contact)

4

Green

Earth Ground

5

Yellow

Presence 1 – COM (common contact)

6

Blue

Presence 1 – NO (normally open contact)

7

Gray

Loop

8

Brown

Loop 9 Red

Relay 2 – COM (common contact)

10

Pink

Presence 1 – NC (normally closed contact)

11

Violet

Relay 2 – NC (normally closed contact)

DIN Rail Socket OR 11 Wire Harness

EMX Industries, Inc. Tech support: 216-834-0761 3/7

MVP D-TEK_Rev2.0_081319 technical@emxinc.com

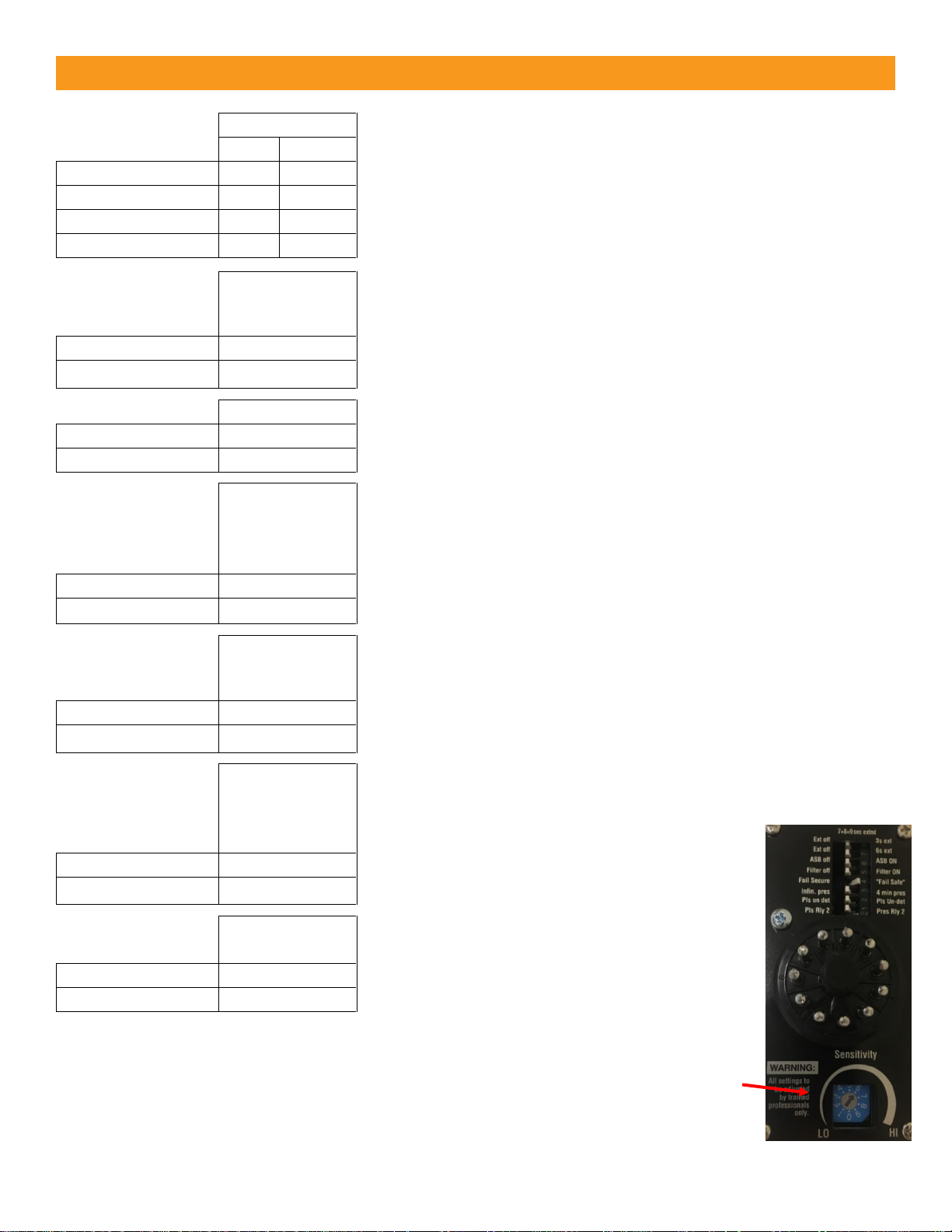

Settings & Display

Extend Detect

DIP Switch

Extend Detect mode extends the detection after the vehicle

leaves the loop for the extension time specified by DIP switch 7

and 8. When the vehicle is no longer detected and the operator

enters the extended detection time period, the red LED will flash.

8 7 No Extension

off

off

3 Second Extension

on

off

6 Second Extension

off

on

9 Second Extension

on

on

Automatic

Sensitivity Boost

DIP Switch 6

Automatic Sensitivity Boost mode increases the sensitivity to

maximum when detection occurs. This allows for the continual

detection of high bed vehicles that might otherwise not be

detected. The sensitivity returns to normal after the vehicle exits

the loop.

ASB On

on

ASB Off

off

Filter

DIP Switch 5

Filter mode inputs a momentary delay into the detection circuit to

verify that a vehicle is present in the loop for a minimum time

period before activation occurs.

Filter On

on

Filter Off

off

Fail Safe/

Fail Secure

DIP Switch 4

Fail Safe mode activates the presence output in the event of a

loop failure. Fail Secure mode will not activate the presence

output in the event of a loop failure and the detector will not

change states on power loss or power up. In Fail Secure mode

relay 2 will trigger if a loop fault occurs. Do not use Fail Secure

for reversing loop applications.

Fail Safe

on

Fail Secure

off

Presence

DIP Switch 3

4 Minute presence mode causes the output to reset after 4

minutes. Infinite presence mode causes the output to remain in

detection mode as long as the vehicle remains near the loop.

Do not use 4 Minute presence mode for reversing loop

applications.

4 Minute

on

Infinite

off

Relay 2

Pulse Mode

DIP Switch 2

When in pulse mode (DIP switch 1 is off),

DIP switch 2 determines when the pulse occurs.

When DIP switch 2 is on, Pulse on Un-Detect,

relay 2 will pulse when the vehicle exits the loop.

When DIP switch 2 is off, Pulse on Detect, relay 2

will pulse when the vehicle enters the loop.

Pulse on Un-Detect

on

Pulse on Detect

off

Relay 2

Pulse/Presence

DIP Switch 1

DIP Switch 1 toggles between assigning the

relay 2 outputs to Presence or Pulse mode.

Presence

on

Pulse

off

Sensitivity Setting

The 10-position rotary switch allows for adjustment of the detection level.

The sensitivity threshold increases from position 0 (lowest setting) through

9 (highest setting). Typical applications require a setting of 3 or 4. The rotary adjustment

must be set to a specific/whole number. There are no half settings.

EMX Industries, Inc. Tech support: 216-834-0761 4/7

MVP D-TEK_Rev2.0_081319 technical@emxinc.com

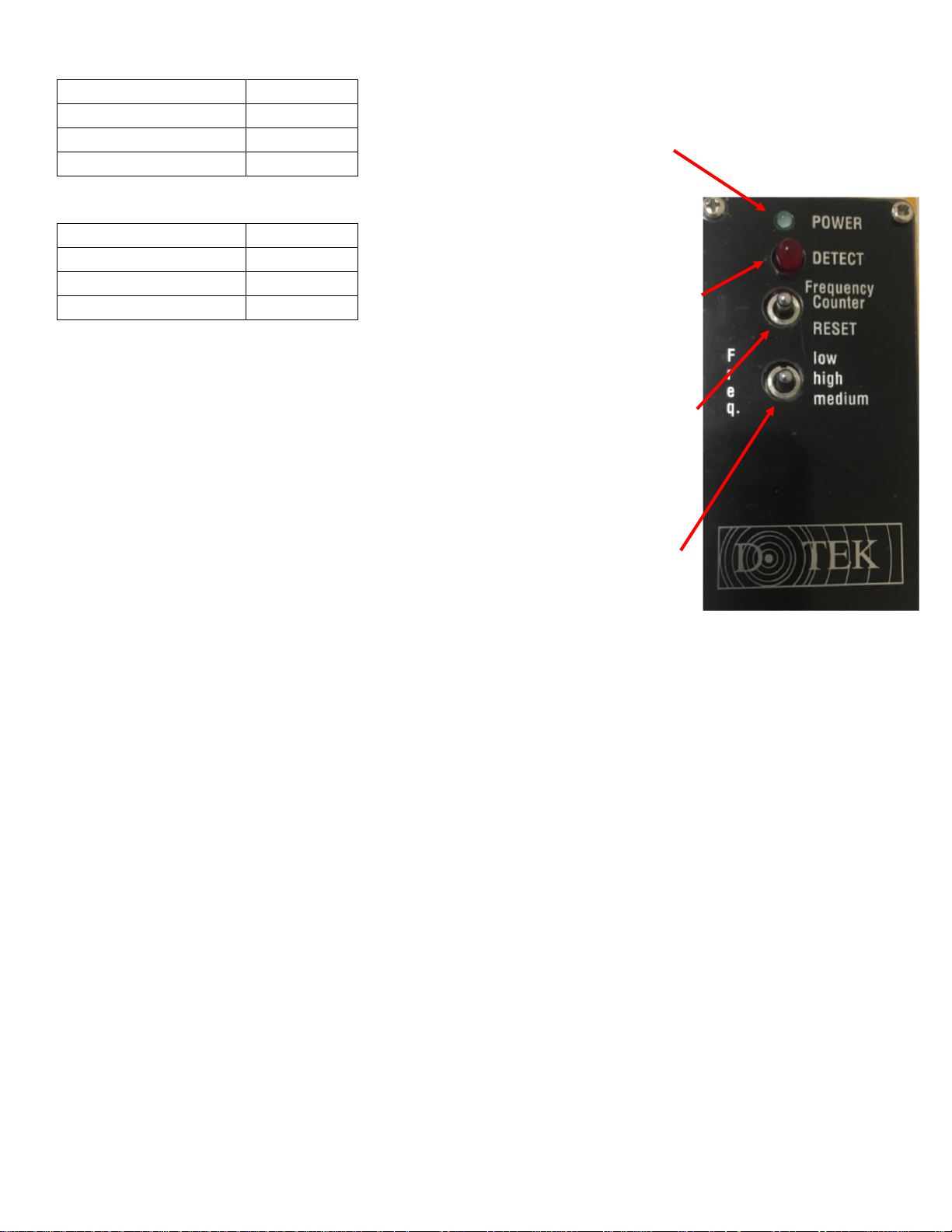

Power Green LED

The green LED is on when the device is

powered up and operating correctly.

No Power

off

Power

on

Previous Loop Fault

slow flash

Shorted or Open Loop

fast flash

Detect Red LED

The red LED is on when a vehicle

presence is detected and off when no

presence is detected. The red LED will

flash during extended detection and

when the frequency counter switch is

momentarily flipped up.

No Detection

off

Detection

on

Extended Detection

flash

Frequency Count

flash

Frequency Counter/ Reset Switch

Momentarily flipping the switch down calibrates the detector to the local

inductance field, DIP switch settings and frequency setting. Momentarily flipping

the switch up to check the operating frequency will cause the red LED to flash.

Each flash represents 10kHz. (For example, 5 flashes = 50KHz operating

frequency.) Counts from 3 to 13 confirm that the detector has tuned to the loop.

Frequency Switch

The frequency switch is used to assign the loop operation frequency.

The primary purpose of the frequency setting is to allow the installer the ability

to set different operating frequencies for multi-loop installations and is

recommended to prevent crosstalk/interference from multiple loops.

To check the operating frequency, refer to the frequency counter/reset switch.

Momentarily flip the RESET switch down after changing the frequency to calibrate

the detector to the local inductance field.

EMX Industries, Inc. Tech support: 216-834-0761 5/7

MVP D-TEK_Rev2.0_081319 technical@emxinc.com

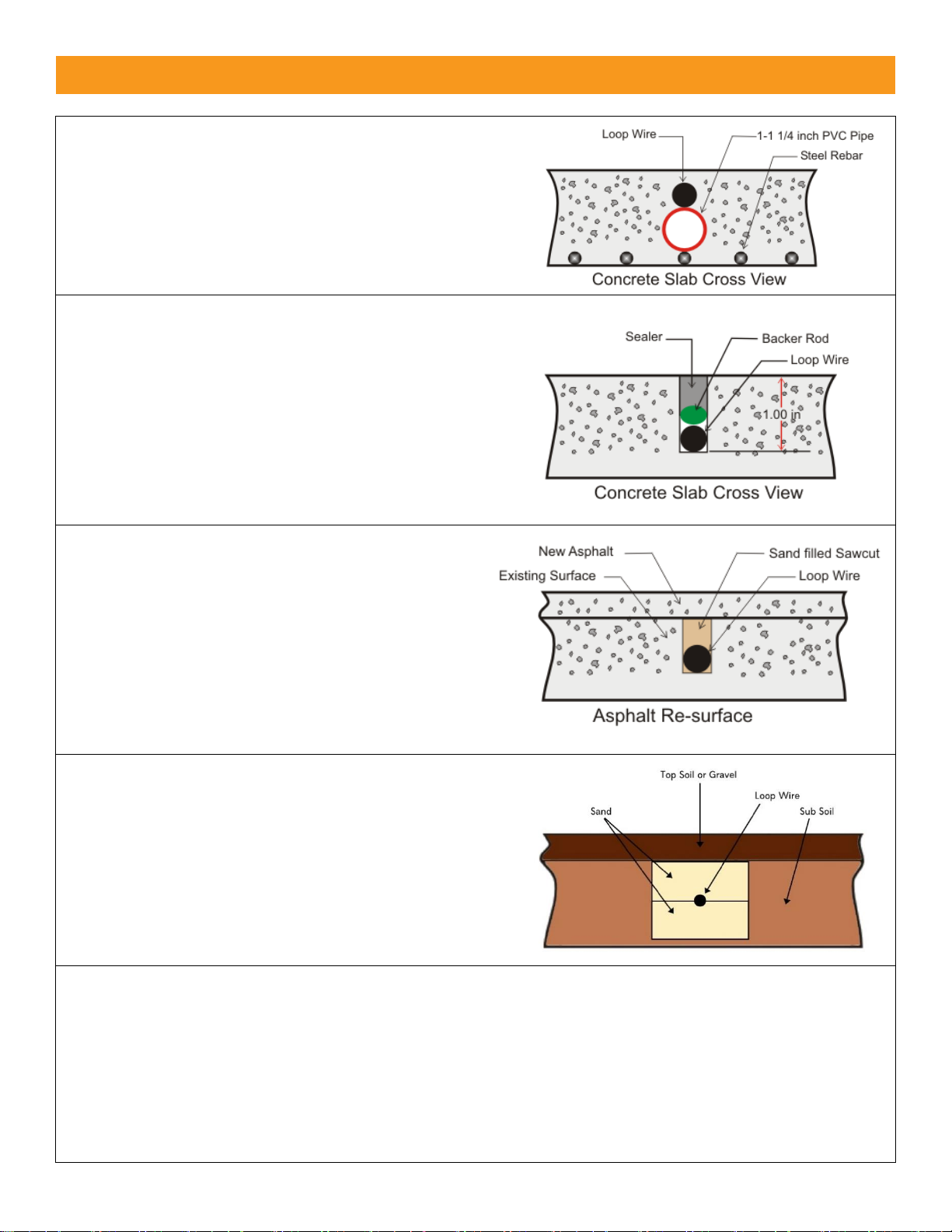

Loop Installation

NEW SLAB POUR

Ty-wrap 1-1/4” PVC pipe to the top of the rebar in the

size and configuration of the loop (ex. 4’ x 8’).

Then ty-wrap the loop to the top of the PVC frame.

This stabilizes the loop during the pour and separates

it from the rebar.

SAW CUT EXISTING SURFACE

Cut 1” deep into the existing surface, place a 45° cut at

the corners to prevent sharp edges from damaging the

loop wire. Notch out for the “T” connection where the

lead wire connects to the loop. Remove all debris from

the finished cut with compressed air. Place the loop

into the saw cut. Place backer material into the

saw cut over the loop wire and pack tightly. Place a

high-quality sealer over the saw cut to seal the surface.

RESURFACE ASPHALT

Saw cut the existing surface ¾” deep and place a 45°

cut at the corners to prevent sharp edges from

damaging the loop wire. Remove all debris from the

finished cut with compressed air. Place sand over

the loop wire to the surface and pack tightly.

Lay new asphalt.

GRAVEL OR SOIL INSTALLATION

While this is not a recommended installation for

most loops, it has been used successfully with

proper preparation. Remove gravel or top soil until

reaching a stable base. Dig ~ 6-8” deep by ~ 6-8” wide.

Fill halfway with sand and pack tightly. Place the loop

into the trench and finish filling to level with sand.

Pack tightly and replace gravel or soil over top.

GENERAL INSTALLATION GUIDELINES

• Use EMX lite preformed loops for quick, reliable installations.

• It is not recommended to install a loop near power lines (overhead or underground) or low voltage lighting.

If necessary near these power sources, place at a 45° angle. Make the loop shape a diamond, not a square.

• Never install a loop near inductive heaters.

• If using a non-preformed loop, lead-in wire (wire from loop to detector) must be twisted a minimum of

6 turns per foot to avoid the effects of noise or other interference.

• Detection height is approximately 70% of the shortest side of the loop.

For example: detection height for a 4’ x 8’ loop = 48” x .7 = 33.6”

EMX Industries, Inc. Tech support: 216-834-0761 6/7

MVP D-TEK_Rev2.0_081319 technical@emxinc.com

Installation

1. Configure DIP switch according to preferences. Refer to Settings & Display section for more

information.

2. Connect the 11 pin DIN rail socket or wire harness to the MVP D-TEK and connect an appropriate

power supply by pins 1 and 2 (white and black wire). Pin 4 (green wire) must be connected to earth

ground for effective surge protection.

3. Connect the loop wires to pins 7 and 8 (gray and brown wire).

4. Connect the operator wires to the DIN rail socket or wire harness, per one of the monitoring

methods below and according to the instructions provided by the operator manufacturer.

Relay 1 (Presence)

• Connect COM to pin 5 (yellow wire)

• Connect NO to pin 6 (blue wire)

• Connect NC to pin 10 (pink wire)

Relay 2 (Pulse/Presence)

• Connect COM to pin 9 (red wire)

• Connect NC to pin 11 (violet wire)

• Connect NO to pin 3 (orange wire)

• For Pulse, DIP switch 1 must be in off position

• For Presence, DIP switch 1 must be in on position

5. Adjust sensitivity setting to desired level to assure detection of all vehicle traffic. The sensitivity

level increases from position 0 (lowest setting) through 9 (highest setting). Typical applications

require a setting of 3 or 4. Any time the sensitivity setting changes, momentarily flip the

RESET switch down to calibrate the MVP D-TEK to the loop.

• To test the sensitivity, without moving the sensing loop, drive a vehicle near the loop.

Position the vehicle over the loop where the detection point is desired and change the

sensitivity settings to the lowest setting where detection occurs.

• The rotary adjustment must be set to a specific/whole number. There are no half settings.

6. If using multiple loops or suspect crosstalk/interference from the environment, perform

a frequency count on each detector to confirm that the operation frequencies are different.

• Momentarily flip up the frequency count switch and count the number of flashes of the

red LED. Each flash represents 10kHZ. Counts from 3 to 13 confirm that the detector is

tuned to a loop.

• If multiple loops and detectors are utilizing the same or very similar frequency,

change the frequency switch to a different low/high/medium setting on one of the

devices. For example: Move one MVP D-TEK to the low frequency setting and the second

MVP D-TEK to the high frequency setting.

7. Momentarily flip the RESET switch down to calibrate the MVP D-TEK to the loop.

TIP:

EMX Industries, Inc. Tech support: 216-834-0761 7/7

MVP D-TEK_Rev2.0_081319 technical@emxinc.com

Troubleshooting

Symptom

Possible Cause

Solution

Green LED not on

No power

Check the power supplied to the MVP D-TEK on

pins 1 (white wire) and 2 (black wire). Voltage should

read between 12-240 VDC/AC.

Green LED

fast flash

Loop wire shorted or not

connected

Check the loop resistance with a multimeter to confirm

a reading between 0.5 ohms and 5 ohms. If reading is

outside of this range, replace the loop. The reading

should be steady.

Check loop connections to terminals

Momentarily flip the RESET switch down

Green LED

slow flash

Loop wire was previously

shorted or open

Check the loop resistance with a multimeter to confirm

a reading between 0.5 ohms and 5 ohms. If reading is

outside of this range, replace the loop. The reading

should be steady.

Momentarily flip the RESET switch down

Red LED on

constantly (stuck

in detection

mode)

Faulty loop

Poorly crimped

connection or loose

connection

Perform a megger test from loop lead to ground,

it should be more than 100 megaohms.

Check loop connections to terminals. Verify splices are

properly soldered and sealed against moisture.

Detector detects

intermittently

when no vehicle

is on the loop

Faulty loop

Poorly crimped

connection or loose

connection

Cross-talk between

multiple loop detectors

Loop not securely

installed to prevent

movement of loop in

pavement.

Perform a megger test from loop lead to ground,

it should be more than 100 megaohms.

Check loop connections to terminals. Verify splices are

properly soldered and sealed against moisture.

Set multiple loops to different frequencies

Verify that loop is securely installed in pavement and

that site is in good condition preventing movement of

loop wires.

EMX Industries, Inc. products have a warranty against defects in materials and workmanship for a period

of two years from date of sale to our customer.

Warranty

Loading...

Loading...