M a n u a l

F o r O p e r a t i o n

UCS 500Nx

The ultra-compact simulator

and its system modules

UCS 500 N5

UCS 500 N7

Modules for Telecom surge

Tsurge5 / Tsurge7

CNT 508 / CNT 516

V 4780 / V4780 S1

UCS500Nx - designed as a modular system - is the most

intelligent solution offering exactly what you need for fullcompliant immunity tests against transient and power fail

phenomena. The distinct operation features, convenient DUT

connection facilities, a clearly arranged menu structure and

display philosophy as well as the pre-programmed standard test

routines make testing easy, reliable and safe. Extendable by a

variety of test accessories the UCS 500Nx is a universal

equipment for abroad range of recommendations even for threephase applications up to 100A

EN/IEC 61000-4-4

EN/IEC 61000-4-5

EN/IEC 61000-4-8

EN/IEC 61000-4-9

EN/IEC 61000-4-11

EN/IEC 61000-4-12

EN/IEC 61000-4-29

EN 61000-6-1

EN 61000-6-2

Version:

5.40 / 13.12.2016

the benchmark for emc

Replaces:

5.39 / 03.08.2016

Filename:

UserManual-UCS 500N5-7-E-V5.40.doc

Printdate:

13.12.16

EM TEST UCS 500 Series

Operating Manual V 5.40 2 / 99

EM Test (Switzerland) GmbH

Sternenhofstrasse 15

4153 Reinach BL1

Switzerland

Phone : +41 61 717 91 91

Fax : +41 61 717 91 99

URL : http://www.emtest.com

Copyright © 2016 EM Test (Switzerland) GmbH

All right reserved.

Information in earlier versions. Specifications subject to change

EM TEST UCS 500 Series

Operating Manual V 5.40 3 / 99

Contents

1. Model Overview ............................................................................................................... 6

1.1. UCS Models........................................................................................................................................ 6

1.2. Standards covered by UCS N Series ................................................................................................. 8

2. Safety information ........................................................................................................... 9

2.1. Protected Earth PE ............................................................................................................................. 9

2.2. FI Fault current protection .................................................................................................................. 9

3. Operating Functions ..................................................................................................... 10

3.1. Front view ......................................................................................................................................... 10

3.2. Rear view .......................................................................................................................................... 12

4. Operation ....................................................................................................................... 15

4.1. Description of the menus .................................................................................................................. 15

4.2. Menu structure .................................................................................................................................. 15

4.3. Main Menu ........................................................................................................................................ 16

4.4. Service .............................................................................................................................................. 17

4.5. Setup ................................................................................................................................................ 19

4.6. Setup procedure for Set voltage ....................................................................................................... 21

5. Test Equipment UCS 500N ........................................................................................... 22

5.1. UCS 500 N5...................................................................................................................................... 22

5.2. UCS 500 N7...................................................................................................................................... 23

6. Technical data ............................................................................................................... 24

6.1. EFT Electrical Fast Transients Burst as per IEC 61000-4-4 ............................................................... 24

6.2. SURGE Immunity requirements as per IEC 61000-4-5 ................................................................... 25

6.3. Power Fail Generator as per IEC 61000-4-11 .................................................................................. 26

6.4. RINGWAVE Immunity requirements as per IEC 61000-4-12 ........................................................... 27

6.5. Telecom Surge Generator as per IEC 61000-4-5 (TSurge module) ................................................ 28

6.6. EUT Supply Specifications ............................................................................................................... 29

6.7. General Specifications ...................................................................................................................... 30

6.8. Environmental conditions ................................................................................................................. 30

6.9. Technical data of special generators ................................................................................................ 31

6.9.1. UCS 500N5.2T ................................................................................................................................. 31

6.9.2. UCS 500N5.5 and UCS 500N5.6 and UCS 500N5.9 for Railways application ................................ 32

6.9.3. UCS 500N5.11 ................................................................................................................................. 33

6.9.4. UCS 500N6.5.................................................................................................................................... 34

6.9.5. UCS 500N6.7.................................................................................................................................... 34

6.9.6. UCS 500N7.1.................................................................................................................................... 35

6.9.7. UCS 500N7.4.................................................................................................................................... 35

7. Maintenance setup and service ................................................................................... 36

7.1. General ............................................................................................................................................. 36

7.2. Test set- up ....................................................................................................................................... 36

7.3. Fuse for the EUT power supply ........................................................................................................ 36

7.4. Insulating- or external transformer for EUT power supply ................................................................ 36

7.5. Calibration and verification ............................................................................................................... 37

7.5.1. Factory calibration ............................................................................................................................ 37

7.5.2. Guideline to determine the calibration period of EM Test instrumentation ...................................... 37

7.5.3. Calibration of Accessories made by passive components only: ...................................................... 37

7.5.4. Periodically In-house verification ...................................................................................................... 37

8. Delivery Groups ............................................................................................................. 38

8.1. Basic equipment ............................................................................................................................... 38

8.2. Accessories and options ................................................................................................................... 38

EM TEST UCS 500 Series

Operating Manual V 5.40 4 / 99

9. EFT Burst as per IEC 61000-4-4 .................................................................................. 40

9.1. Operation .......................................................................................................................................... 40

9.1.1. Quick Start ........................................................................................................................................ 41

9.1.2. Standard test routines ..................................................................................................................... 42

9.1.3. User Test Routines ........................................................................................................................... 43

9.2. Burst generation ............................................................................................................................... 45

9.3. Test level with Burst as per IEC 61000-4-4 Ed.2. ............................................................................ 45

9.4. Coupling/decoupling network ........................................................................................................... 46

9.4.1. Coupling/decoupling network for ac/dc power lines ......................................................................... 46

9.4.2. Capacitive coupling clamp ................................................................................................................ 46

9.5. Burst Test Setup ............................................................................................................................... 46

9.5.1. Test setup with capacitive coupling clamp ....................................................................................... 47

10. Surge Immunity as per IEC 61000-4-5 ......................................................................... 48

10.1. Operation .......................................................................................................................................... 48

10.1.1. Quick Start ........................................................................................................................................ 49

10.1.2. Standard test Routine ....................................................................................................................... 50

10.1.3. User Test Routines ........................................................................................................................... 52

10.1.4. Phase synchronization in 3-phase system ....................................................................................... 54

10.1.5. Pulsed magnetic field as per IEC 61000-4-9 .................................................................................... 56

10.1.6. Setup current limiter for surge current .............................................................................................. 57

10.1.7. Charging time for surge .................................................................................................................... 58

10.2. Surge pulse generation .................................................................................................................... 59

10.3. Coupling/decoupling network ........................................................................................................... 59

10.3.1. Coupling to ac/dc power supply lines ............................................................................................... 59

10.3.2. Coupling to I / O lines ....................................................................................................................... 60

10.4. Test set-up ........................................................................................................................................ 60

11. Voltage Dips as per IEC 61000-4-11 ............................................................................. 61

11.1. Test setup for DIPS and Interruption tests ....................................................................................... 61

11.2. Operation .......................................................................................................................................... 61

11.2.1. Quick Start ........................................................................................................................................ 62

11.2.2. Standard Test Routines .................................................................................................................... 63

11.2.3. User Test Routines ........................................................................................................................... 67

11.3. The Power Fail Test ......................................................................................................................... 68

11.4. Overcurrent ....................................................................................................................................... 69

11.5. The Power Fail Test ......................................................................................................................... 70

11.5.1. Voltage Interruptions ........................................................................................................................ 70

11.5.2. Voltage dips, voltage variations ........................................................................................................ 71

11.6. DC Power networks .......................................................................................................................... 71

11.7. Test setup and accessories .............................................................................................................. 72

11.7.1. Transformer type V4780 ................................................................................................................... 72

11.7.2. Motor variac type MV 2616 ............................................................................................................... 74

11.8. 50/60Hz Magnetic Field as per IEC 61000-4-8 ................................................................................ 76

12. Ringwave Immunity as per IEC 61000-4-12 ................................................................. 78

12.1. Operation .......................................................................................................................................... 78

12.1.1. Quick Start ........................................................................................................................................ 78

12.2. Ring wave pulse generation ............................................................................................................. 80

12.3. Coupling/decoupling network ........................................................................................................... 80

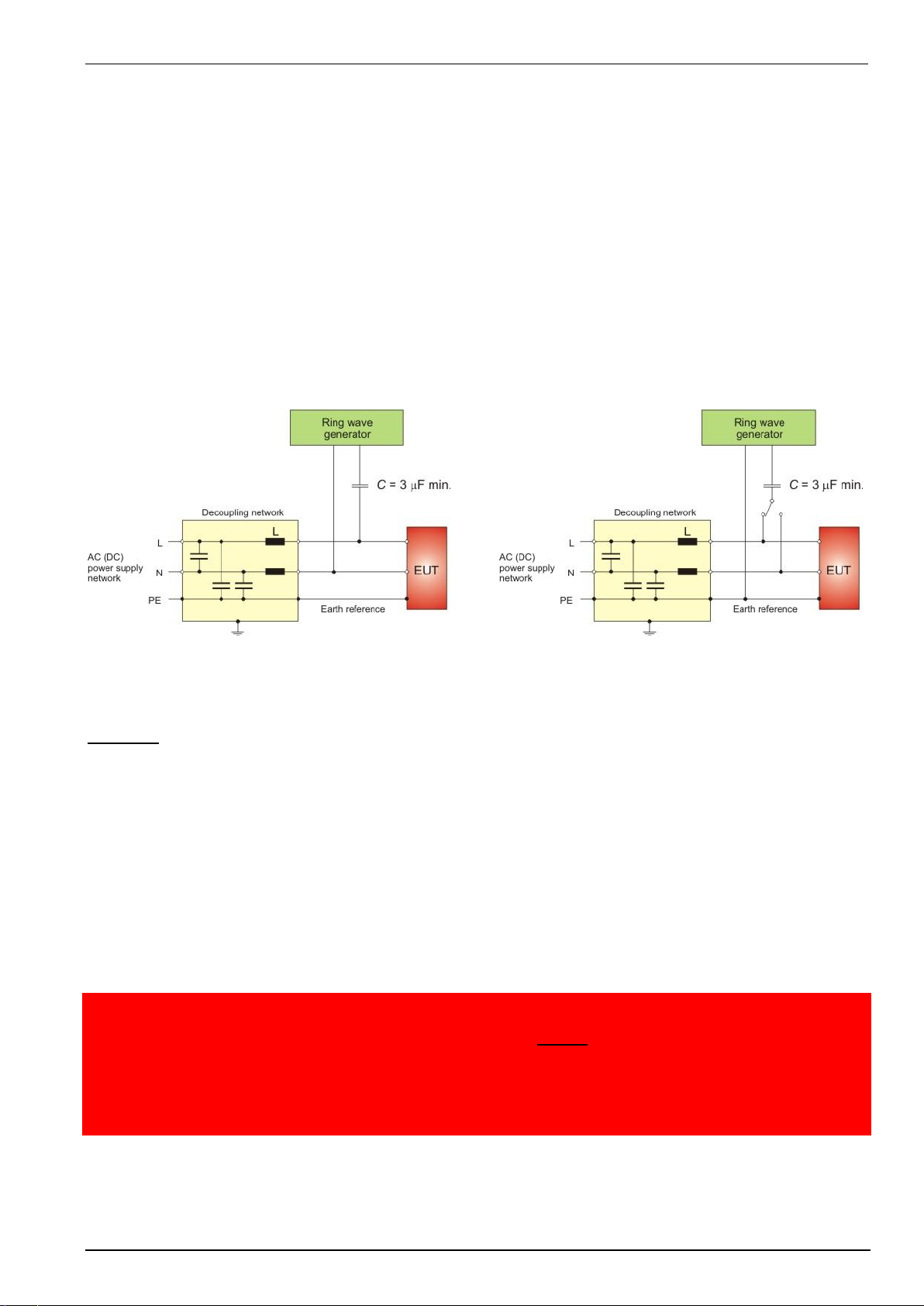

12.3.1. Coupling to ac/dc power supply lines ............................................................................................... 80

12.4. Test set-up ........................................................................................................................................ 80

13. Telecom Surge ............................................................................................................... 81

13.1. UCS 500N5T with Telecom Surge Module ...................................................................................... 81

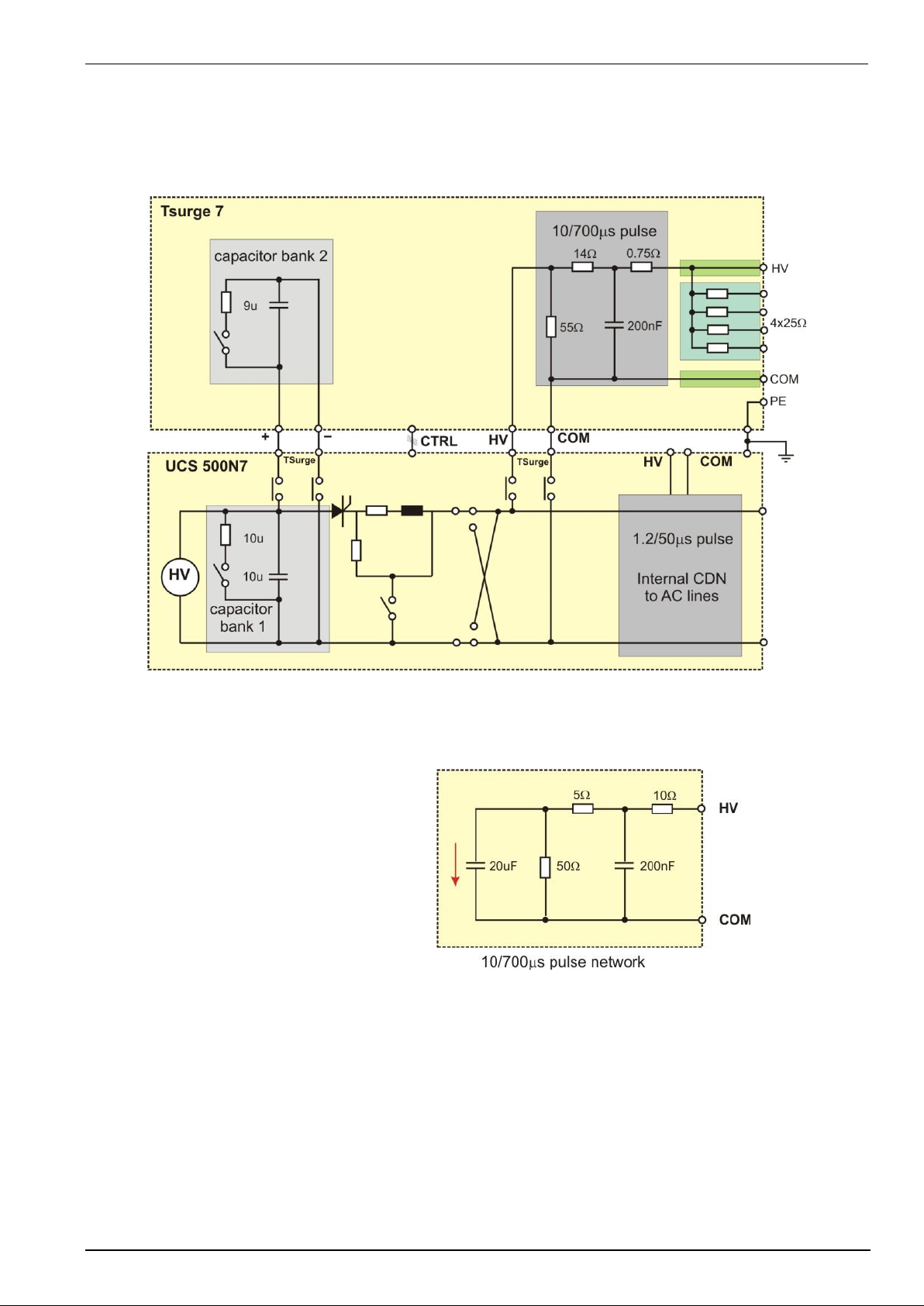

13.2. TSurge7 Module ............................................................................................................................... 81

13.3. TSurge7 Module ............................................................................................................................... 81

13.4. TSurge Menu .................................................................................................................................... 82

13.4.1. Quick Start ........................................................................................................................................ 82

13.5. Coupling Network ............................................................................................................................. 83

13.6. Test Setup ........................................................................................................................................ 84

13.7. Test pulses TSurge Modules ............................................................................................................ 84

13.7.1. Waveshape Definitions according IEC 61000-4-5 Ed 3.0 ................................................................ 84

13.7.2. Pulse 10 / 700s as per IEC 61000-4-5 ........................................................................................... 85

13.7.3. Pulse 9 / 720s as per FCC ............................................................................................................. 85

EM TEST UCS 500 Series

Operating Manual V 5.40 5 / 99

14. Appendix ........................................................................................................................ 86

14.1. Declaration of CE-Conformity ........................................................................................................... 86

14.1.1. Declaration of Conformity UCS 500N5 ............................................................................................. 86

14.1.2. Declaration of Conformity UCS 500N7 ............................................................................................. 87

14.1.3. Declaration of Conformity UCS 500N5x models for one phenomenon ............................................ 88

14.1.4. Declaration of Conformity UCS 500N5x models .............................................................................. 89

14.1.5. Declaration of Conformity TSurge 7 Module for UCS 500N7 ........................................................... 90

14.1.6. Declaration of Conformity CNT 516.................................................................................................. 91

14.1.7. Declaration of Conformity Tapped Transformer ............................................................................... 92

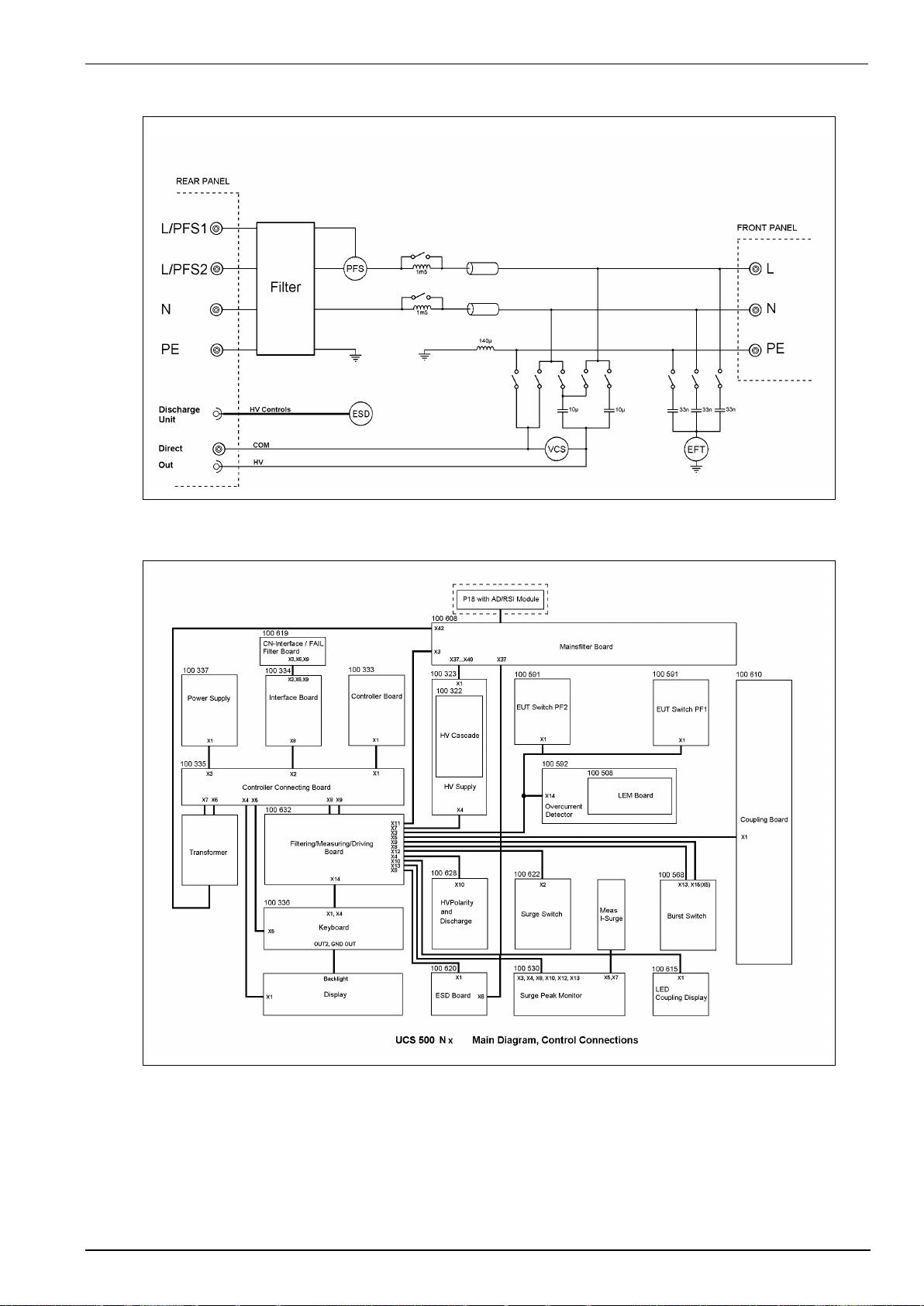

14.2. UCS 500N - General Diagram .......................................................................................................... 93

14.3. Main diagram control connection...................................................................................................... 93

14.4. Main diagram high voltage connection ............................................................................................. 94

14.5. CNT 508N ......................................................................................................................................... 95

14.6. CNT 516 ........................................................................................................................................... 97

14.7. USB interface.................................................................................................................................... 99

EM TEST UCS 500 Series

Operating Manual V 5.40 6 / 99

1.

Model Overview

The following manual is based on the following or later firmware:

- UCS 500N5 : V 5.00xx

- UCS 500N7 : V 8.00xx

- UCS 500N7 : V 9.00xx Supports ANSI A/B coupling method. Requires iec.control V 5.2.3.0 or higher

Devices with the Firmware

- UCS 500N5 : V 4.40uxx

- UCS 500N7 : V 7.40uxx

Have a reduced PFS function of the PFS module. For UCS generators with this firmware version exist a separate

manual with the version 5.09. This manual can be ordered at EM TEST if required.

1.1.

UCS Models

Standard models

Model

U pulse

CDN

Remarks

UCS 500N5

5.5kV

300V 16A 1- ph

UCS 500N5.1

5.5 kV

300V 32A 1- ph

Optional + Tsurge 6HU

UCS 500N5T

5.5 kV

300V 16A 1- ph

EFT, Surge, PFS, TSurge 6HU

UCS 500N5.1T

5.5 kV

300V 32A 1- ph

EFT, Surge, PFS, TSurge 6HU

UCS 500N7

7kV

300V 16A 1- ph

DC 300V / 16A ANSI

UCS 500N7.1

7kV

300V 32A 1- ph

DC 300V / 32A ANSI 9HU

Additional extensions

TSurge5

4kV

Built-in 10/700us pulse module up to 5kV, ITU K22 & IEC 61000-4-5

TSurge7

6kV

External 10/700us pulse module up to 7kV, ITU K22 & IEC 61000-4-5

UCS500N with one built in module

The device includes only one module Surge, Burst or Power Fail. The technical data are identical with the

standard UCS500N5. An extension with additional modules is not possible.

UCS500N5V

5kV

UCS500 with Surge Module

UCS500N5E

5.5kV

UCS500 with EFT Burst Module

UCS500N5P

--

UCS500 with Power Fail Module

Module for UCS500N7

Module

Remarks

EFT/N7

Built-in 5.5kV BURST MODULE

VCS/N7

Built-in 7.0kV SURGE MODULE

PFS/N7

Built-in POWER FAIL MODULE 300 volts/ 16 amps. Mandatory for EUT power switch off

RWG/N7

Built-in Ring Wave Module 6 kV / 100 kHz, Ri =12/30 Ω as per ANSI

(not available for UCS 500N7.1 or UCS 500N7.2)

RWG/N7.1

Built-in Ring Wave Module 6 kV / 100 kHz, Ri =12/30/50 Ω as per ANSI / UL 1741,

No peak current measurement (display indicates = ---).

(not available for UCS 500N7.1 or UCS 500N7.2)

TSurge7

External 10/700us pulse module up to 7.0kV, ITU K22 & IEC 61000-4-5

EM TEST UCS 500 Series

Operating Manual V 5.40 7 / 99

Special models

Model

V

Pulse

CDN

Remarks

UCS 500N5.2

5.5kV

400V 16A 1- ph

UCS 500N5.2T

5.5kV

300V 16A 1- ph

UCS 500 with VCS/5 and Telecom Surge module

UCS 500N5.3

5.5 kV

400V 32A 1- ph

UCS 500N5.3-PFS

5.5 kV

400V 32A 1- ph

UCS500 with Power Fail module 400V AC 32A (L-N)

UCS 500N5.4

5.5kV

300V 16A 1- ph

DC 300V 16A

UCS 500N5.5

5.5 kV

300V 32A 1- ph

EFT/5 and VCS/5

10/40 for supply lines EN 50121-3-2:2007 (Railway)

UCS 500N5.6

5.5 kV

300V 32A 1- ph

EFT/5 VCS/5 and PFS/5

10/40 for supply lines EN 50121-3-2:2007 (Railway)

UCS 500N5.7

5.5kV

300V 16A 1- ph

EFT/5 and VCS/5

UCS 500N5.8

5.5kV

300V 16A 1- ph

EFT/5 and PFS/5; 1ph CDN 300V/16A

UCS 500N5.9

5.5 kV

300V 16A 1- ph

10 /40 for supply lines EN 55121 (Railway)

UCS 500N5.10

5.5kV

690V 16A 1- ph

VCS/5 without built-in coupler

UCS 500N5.11

5.5kV

690V 16A 1- ph

EFT/5, VCS/5 / Tsurge

UCS 500N7.2

7kV

400V 16A 1- ph

EFT/N7, VCS/N7, PFS/N7 (ANSI)

UCS 500N7.3

7kV

300V 16A 1- ph

EFT/N7, VCS/N7, PFS/N7 (ANSI), RWG/N7.x

UCS 500N7.4

7kV

400V 16A 1- ph

EFT/N7, VCS/N7, PFS/N7, (ANSI), RWG/N7.x

UCS 500N7.6

7kV

690V 16A 1- ph

EFT/N7, VCS/N7.x, RWG/N7, without built-in coupler! AC Voltage 690V

UCS 500N7.7

7kV

690V

EFT/N7, VCS/N7.x, without built-in coupler! AC Voltage 690V(p-p)

UCS 500N7.8

7kV

400V 16A 1- ph

EFT/N7, RWG/N7.x (output impedance 12 and 25 ohm); (ANSI)

UCS 500N7.9

7kV

690V

EFT/N7, VCS/N7, RWG/7.x (Ri 12Ω & 50Ω), no built-in coupler, 690V(p-p)

UCS 500N7.10

7kV

690V

VCS/7, no built-in coupler! Application Voltage 690V(p-p)

Other models up to 2009

Model

Name up to 2008

Pulse voltage

CDN

UCS 500 N4.1

UCS 500 M4 S1

4kV

250V 32A single phase

UCS 500 N6

UCS 500 M6B

6kV

250V 16A single phase

UCS 500 N6.1

--

6kV

250V 32A single phase

UCS 500 N6.3

--

6kV

480V 32A single phase

Models up to 2008

Model Pulse voltage

CDN

UCS 500 4kV

250V 16A single phase

upgrade version

UCS 500 M4 4kV

250V 16A single phase

UCS 500 M6 6kV

250V 16A single phase

UCS 500 M6A 6kV

250V 16A single phase

EM TEST UCS 500 Series

Operating Manual V 5.40 8 / 99

Special models

Special models have the index UCS500Nx Sx. The difference to the standard models are: Voltage- and current

ranges. The operation is the same as by the standard UCS equipment’s.

Model Pulse voltage

CDN

UCS 500 M4 S1 4kV

250V 32A single phase

UCS 500 M4 S2 4kV

690V 16A single phase

UCS 500 M4 S3 4kV

690V 32A single phase

UCS 500 M4 S5 4kV

280V 16A single phase

UCS 500 M6 S2 6kV

690V 16A single phase

ANSI

Model

Pulse EUT

Modules

UCS 500 M6B S1

6kV 250V 32A

EFT/6, VCS/6 and PFS/6; 1ph CDN 250V / 32A (ANSI)

module RWG/6 not available

UCS 500 M6B S2

6kV 690V 16A

EFT/6, VCS/6 and PFS/6; 1ph CDN 690V / 16A (ANSI) 480V dc

module RWG/6 not available

1.2.

Standards covered by UCS N Series

A fully equipped UCS 500N covers the following standards

UCS 500

N5

N7

- IEC 61000-4-4

Burst

X

X

- IEC 61000-4-5

Surge

X

X

- IEC 61000-4-8

50/60Hz Magnetic Field

X

X

- IEC 61000-4-9

Pulse Magnetic Field

X

X

- IEC 61000-4-11

Voltage Dips

Voltage Interruptions

Voltage Variations for ac power mains supply

X

X

- IEC 61000-4-12

Ringwave

X

- IEC 61000-4-29

Voltage Interruptions

Voltage Dips for dc power supply systems

X

X

- ANSI

Surge with 2 coupling

X

- ITU and ETS

Telecom Surge

(X)

(X)

- FCC

Part 68

(X)

(X)

EM TEST UCS 500 Series

Operating Manual V 5.40 9 / 99

2.

Safety information

Attention

Before using this equipment, read the operating manual and the

separate delivered safety manual carefully

2.1.

Protected Earth PE

The protective conductor connection is established via the attached power cord and must not be interrupted

under any circumstances.

DANGER

Check before connecting the power supply to the unit that the grounding of the building supply is

installed according to regulations.

In the absence of an earth connection can the frame can be get in the event of a fault, to the mains

voltage potential.

The generator must be properly grounded before connecting on-the EUT supply voltage to the

generator.

2.2.

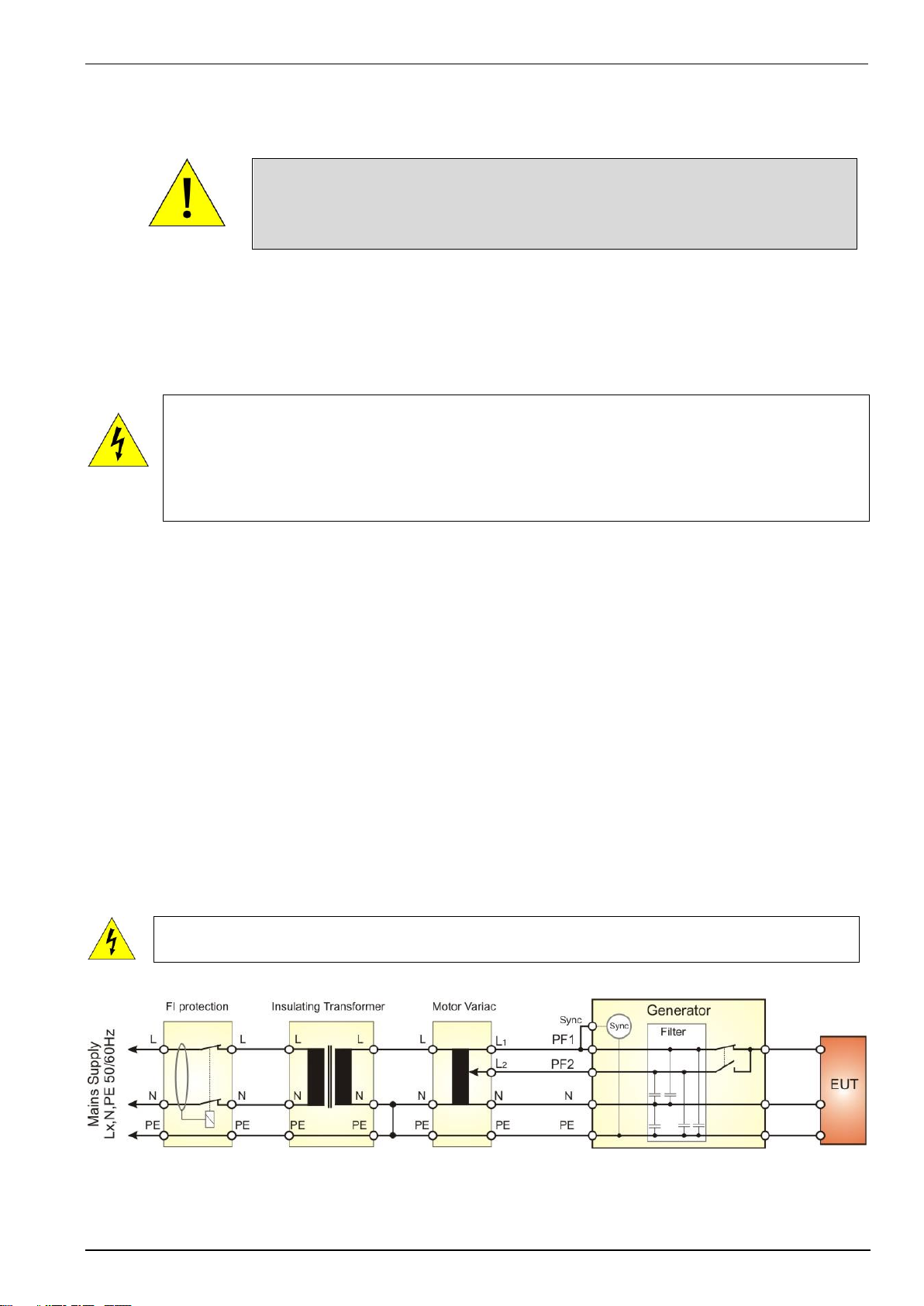

FI Fault current protection

The standards recommend decoupling and filter capacitors to PE for decoupling surge pulses. This is the reason

for tripping fault current protection relays interrupt the mains to the EUT supply. For eliminate the circumstance

use one of the following options:

Remove the fault current protection

This solution does not limit the current to PE. The surge test as other EMC tests with higher currents to PE are

possible. The user must take care to the circuit with no fault current protection. Only trained professional people

are allowed to perform such tests.

Using of insulating transformers

An insulating transformer separates the circuit from the test circuit. The Fault current detector cannot detect the

earth current in the EUT circuit. The synchronization works between line and PE and therefore a connection

between neutral and PE is necessary. Without this N-PE connection the stray capacitance defines the phase

sync.

The fault current safety detection function in the generator circuit is disabled. The user must respect

this circumstance. For a safe operation he must follow the electrical rulers.

Behind the insulating transformer the neutral and PE must be connected for a proper phase synchronization of

the generator. In case of a 3-phase system the user must perform similar.

EM TEST UCS 500 Series

Operating Manual V 5.40 10 / 99

3.

Operating Functions

3.1.

Front view

1 Display

2 Function keys "F1..F7

3 "Test On"

4 Knob (Inc. / Dec

5 Cursor keys "" and ""

6 Exit

7 Escape

8 CRO U (surge)

9 CRO I (surge)

10 CRO Trigger output 5V

11 HV pulse Burst output 50

12 Ground reference

13 Coupling (Burst, Surge and EFT)

14 Channel PF1 and PF2

15 EUT test supply

1 Display

All functions and parameters are displayed (8 lines with max. 40 characters).

2 Function keys "F1 .. F7”

Parameters and functions, displayed in the lowest line, can be selected with the related function key.

3 Test On

By pressing the key "Test On" follows the functions:

- Activate the high voltage power unit; HV is ready to start.

- Switches ON the supply to the EUT test supply (only with built in PFS module).

- The LED indicates the trigger of a burst event.

4 Knob (Inc. / Dec

The knob increments or decrements test parameters with a numeric value or selects from a list of parameters.

5 Cursor keys

Parameters and functions can be changed on-line. The selection of these parameters is realized with the cursor

moving to the left or to the right.

6 Exit

Pressing of the Exit function will cause a reset of the firmware. This is only possible if no test routine is running.

7 ESC

When pressing the ESC button the user moves back one page in the menu.

8 CRO U (surge)

At the BNC output the voltage pulse (surge) of the generator can be measured galvanic separated.

- Impedance measuring instrument: >1MΩ.

- Max. output voltage: 10V 10% at 5 kV / 7kV impulse voltage.

9 CRO I (surge)

At the BNC output the current pulse (surge) of the generator can be measured galvanic separated.

- Impedance measuring instrument: >1MΩ.

- Max. output voltage: 10V 10% at 2.5 kA / 3.5kA output current.

10 BNC - CRO Trigger

At the BNC output the generator trigger can be checked, e.g. the burst duration, the burst repetition rate and the

spike frequency (+5 V rectangular). This output can be generally used as oscilloscope trigger output and is

synchronous to the following events.

- Burst and surge release

- Voltage dip or interruption, start of the event

EM TEST UCS 500 Series

Operating Manual V 5.40 11 / 99

1 Display

2 Function keys "F1..F7

3 "Test On"

4 Knob (Inc. / Dec

5 Cursor keys "" and ""

6 Exit

7 Escape

8 CRO U (surge)

9 CRO I (surge)

10 CRO Trigger output 5V

11 HV pulse Burst output 50

12 Ground reference

13 Coupling (Burst, Surge and EFT)

14 Channel PF1 and PF2

15 EUT test supply

11 HV pulse burst output 50

External coupling devices such as the capacitive coupling clamp and the 3-phase coupling network are

connected to the coaxial 50 ohm output. Also the calibration of the generator is handled at this output.

Note: The burst signal is present on this output at every coupling mode.

12 Ground reference

During test or calibration procedure the burst generator must be grounded to the reference ground plane

13 Coupling mode

The actual coupling mode is indicated by LED

14 Channel PF1/PF2

This LED indicates the channel mode during the power fail test.

15 EUT test supply

For single-phase EUT the coupling/decoupling network is part of the generator. The EUT is powered via the

safety banana plugs at the front panel of the simulator.

EM TEST UCS 500 Series

Operating Manual V 5.40 12 / 99

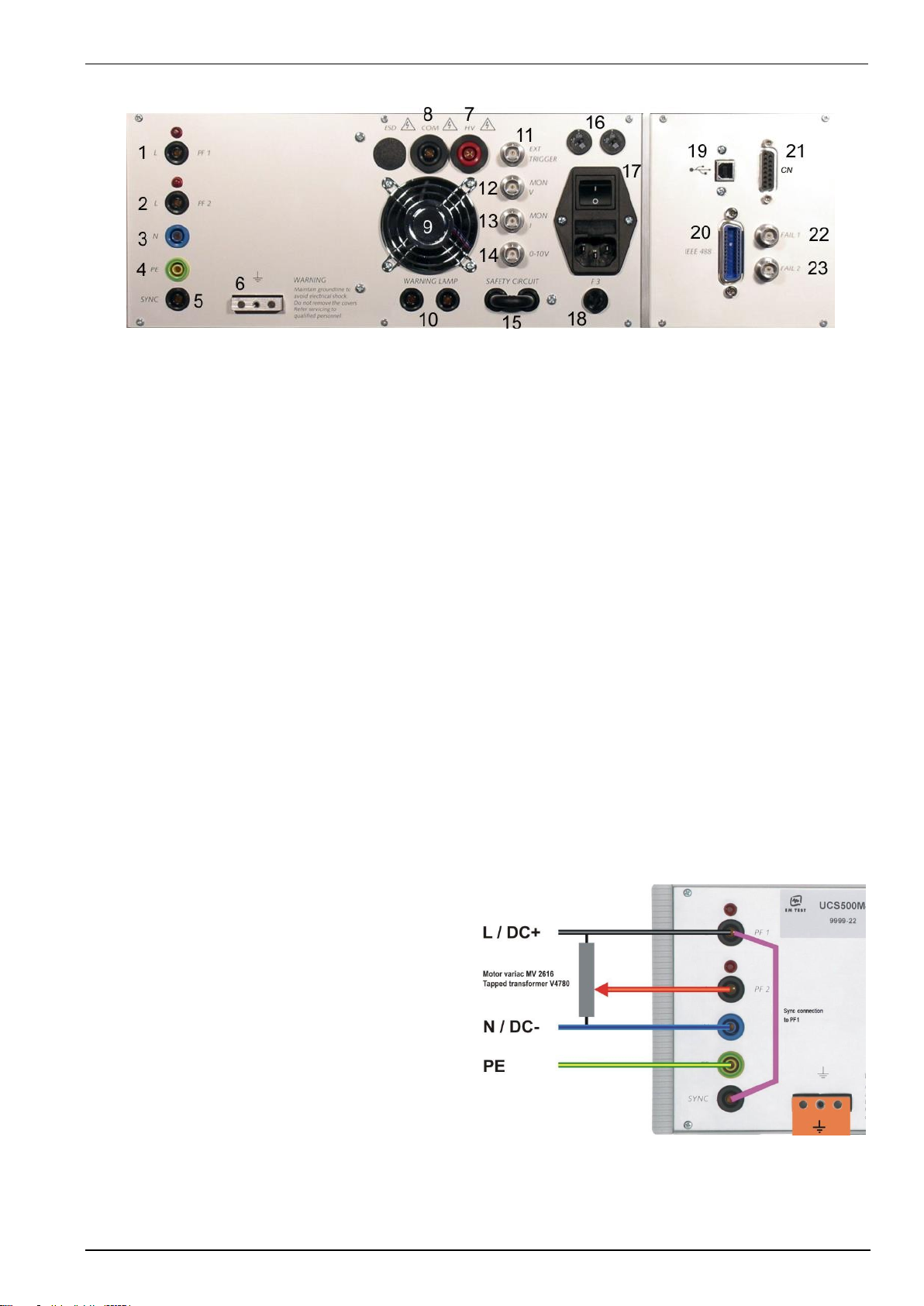

3.2.

Rear view

1 Test supply input; channel PF1 together with

the red lamp for phase indication

2 Test supply input; channel PF2 together with

the red lamp for phase indication

3 Test supply input neutral

4 Test supply input PE

5 Sync input

1 Test supply PF1

The phase of the power supply for the EUT is connected to the banana connector PF1. The phase L is

conducted to the EUT voltage supply via PF1 if channel PF1 is selected in the set-up menu.

To guarantee a correct function of the synchronization the phase shall be connected to this input. The red lamp

than shall be alighted.

2 Test supply PF2

This input is generally used for the reduced dip voltage for testing as per IEC 61000-4-11. At this PF2 input a

variac transformer is connected with a reduced voltage, e.g., 0-250V. A motor driven variac transformer can be

controlled via a 0-10V analogue control output.

To guarantee a correct function of the synchronization the phase shall be connected to this input. The red lamp

than shall be alighted.

3 Test supply neutral (PF1/PF2)

The neutral line of the power supply for the EUT is connected to the banana connector N.

4 Test supply PE (PF1/PF2)

The protective earth line of the power supply for the EUT is connected to the banana connector PE.

5 SYNC input

An ac voltage to which the events shall be synchronized is connected to this input. If no voltage is available the

tests are started automatically in asynchronous mode. Normally this input shall be connected directly to L of the

channel PF1. Umax. Sync = Umax. EUT

Connection EUT supply

AC Supply

The EUT power supply is normally connected to

the UCS plugs PF1, N and PE

A tap of a motor variac transformer or adapting

transformer for power fail testing is connected to

the connection PF2.

The phase synchronization SYNC must be

connected to PF1. By missing this connection all

tests runs in asynchronous mode with no phase

angle adjust for pulse release.

DC Supply

DC+ to PF1, and PF2 for DIPS

DC- to N

additional PE (depends application)

Earth bolt

The earth bolt must be connected to the ground

reference.

EM TEST UCS 500 Series

Operating Manual V 5.40 13 / 99

6 Reference Earth connection

7 HV output for Surge pulse

8 Common output for Surge pulse

9 Ventilation

10 Warning lamp

11 External trigger

12 BNC connector MON U

13 BNC connector MON I

6 Reference earth connection

The generator has to be connected to the reference earth plane of the test set up. The connection at the rear

part of the generator is an alternative to the grounding point at the front panel

7 HV output

The coax plug is the HV HIGH output of the simulator. It is used for external coupling/decoupling networks.

8 COM output

The Com output is the HV LOW output of the simulator. The output is floating

Attention

The direct output of the surge generator is located at the rear panel of the instrument, HV and

COM. It is not allowed to connect these outputs to any other coupling/decoupling network than

manufactured by EM TEST, e.g. the types CNV and CNI. Before to connect any external

networks to this output the operator must contact the manufacturer. Any damages due to this

matter are not covered by warranty.

The direct pulse output shall also not be used to connect the generator directly to any power

conducting lines

The wave shape measured at the direct pulse output must not be within the tolerances specified in

IEC 61000-4-5. The pulse shape shall be verified at the CDN output directly, no matter whether it

is an internal or external CDN.

9 Ventilation

After long term duration tests the generator should keep on running for some minutes to cool down the system.

10 Warning lamp

A voltage free contact is available for external warning indications (warning lamp). The signal is generated after

pressing TEST ON.

11 External trigger

One single event, burst, surge, voltage dip or ESD can be released. Trigger level 5V positive going.

12 BNC connector MON U

At this BNC connector the output power supply voltage for the EUT can be measured. Ratio 100:1 5%.

Impedance measuring instrument: 1M.

13 BNC connector MON I

At this BNC connector the output current for the EUT can be measured, e.g. the nominal current or the peak

inrush current. The rating is 10mV/A 5%. Maximum current = 1000A

Impedance measuring instrument: 1M.

EM TEST UCS 500 Series

Operating Manual V 5.40 14 / 99

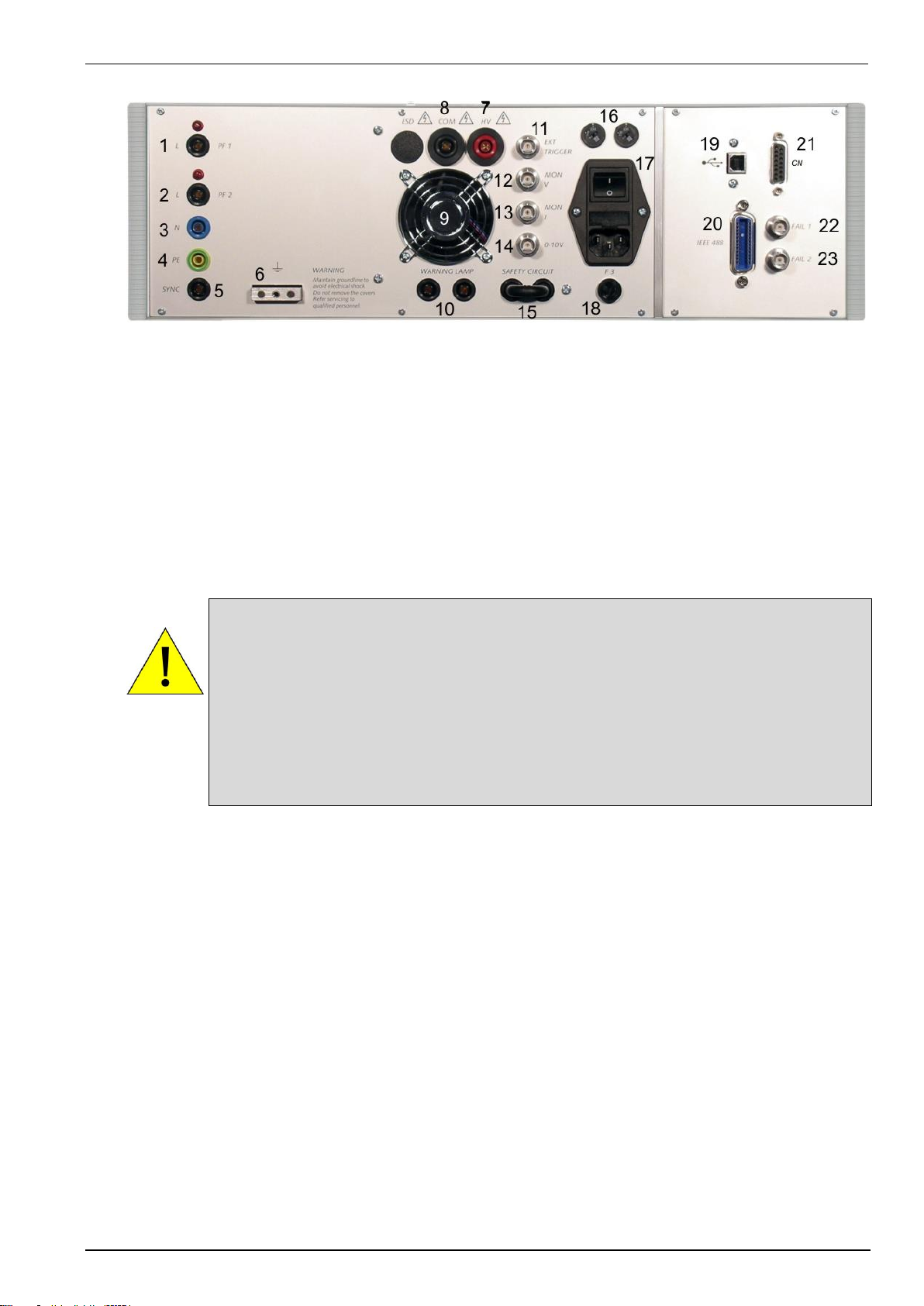

14 Control output 0-10V

15 Security circuit

16 Mains selector 115V / 230V

17 Power on switch

18 Fuse of the high voltage power supply

19 Serial interface USB

20 Parallel interface IEEE

21 Remote control connector

22 FAIL 1

23 FAIL 2

14 Control output 0-10V

The voltage is used to control external power sources. The source is normally connected to the channel PF2

(normally a motor driven variac transformer). The voltage level is selectable via the operating facilities of the

UCS 500N. The voltage level can also be selected within the service menu under the function „setup.

This output is not mounted on UCS500N5E and UCS500N5V.

15 Safety circuit

The test can only be started if the security circuit is closed. If the circuit is opened during a running test the

simulator will be switched off immediately.

14 Mains selector

Selection of 115V / 230V

17 Power on switch

The switch is part of the mains filter. Mains fuses are part of the filter. (230V / 2 A and 115V / 4 A)

18 Fuse of the high voltage power supply

The high voltage power supply is protected by this fuse „F3“. In case that no high voltage is generated but the

control unit works properly this fuse shall be checked.

19 USB interface

USB interface “USB B” connector. For data-transfer a USB interface is available. The internal RS 232 interface

is converted to USB standard. Therefore the user must set the same baud-rate in the device and control

software.

Using the USB interface may cause EMC problems during burst tests at the computer or notebook side of

the communication line. Therefore a high quality USB cable (USB 2.0 standard) shall be used.

20 Parallel interface GPIB / IEEE 488

IEEE 488 interface with IEEE connector

21 Remote control connector CN

External coupling devices are controlled via this remote control connector.

22 Fail detection FAIL 1 EUT control (TEST STOP

Grounding this input will cause a complete stop of the running test procedure. (+15V to ground) The test must

be completely restarted.

23 Fail detection FAIL 2 EUT control (TEST PAUSE

Grounding this input will cause a break for the running test procedure (+15V to ground).The test will be

continued when the input is no more connected to ground.

EM TEST UCS 500 Series

Operating Manual V 5.40 15 / 99

4.

Operation

4.1.

Description of the menus

The simulator is operated by an easy menu control system. Seven function

keys are available to select parameters and functions. All functions are

indicated on the display; max. 8 lines and 40 characters.

The selected parameter is blinking and can be changed by turning the knob (inc./dec.).

: The digit for change can be selected with the cursor ( ).

- Selected values are direct indicated on the screen.

- Status on the bottom lines shows the desired status after pressing the function key.

ESC : ESC will take you back to the previous level in the menu and set the displayed

values. The latest settings are stored automatically and will be recalled when the

menu is selected again.

EXIT : The firmware will reset to the main screen.

EM TEST

UCS 500 N5

Ultra Compact Simulator

V 5.00a02

Burst

Surge

Power Fail

SWN: 001234

The serial number and the version number SWN are

used for traceability reasons. These numbers are listed

in the test reports and calibration certificates. These

numbers also are listed within the test reports

generated by the iec.control software.

Start-up display example UCS 500N5. The models type is displayed after startup.

4.2.

Menu structure

Level 0...4

Level 0

Level 1

Level 2

Level 3

Level 4

MAIN MENU

F1 BURST IEC 61000-4-4

F2 SURGE IEC 61000-4-5/9

F3 PFS IEC 61000-4-11/8/29

F7 SERVICE

Burst IEC 61000-4-4

F1 Quick Start

F2 Standard routines

F3 User test routines

Quick Start

F1 Start

F2 Change

F3 Continue

Start

Start the test routine

Change

Select all parameters

Continue

Continue the test routine

Surge IEC 61000-4-5/9

Standard routines

Preprogrammed test routines as

per standard requirements

Standard routines

F1 : F4 IEC 61000-4-4 Level 1-4

F5 Generic Standard EN 61000-6-1

F6 Generic standard EN 61000-6-2

F7 Manual standard routine

Standard routines F1..F3

F1 Start

F2 Change

F3 Continue

Power Fail IEC 61000-4-8/11/29

User test routines

Preprogrammed test routines for

evaluation and design support

F1 Synchronous to the mains

F2 Random burst release

F3 Change V after T by U

F4 Frequency sweep I

F5 Frequency sweep II

F6 Frequency sweep III

F7 Change polarity after T

User test routines F1..F3

F1 Start

F2 Change

F3 Continue

Service

F1 Addresses

F3 Setup

F4 Change standard levels

Setup

F1 Change language

F2 LCD backlighting

F3 Interfaces

F4 ESD/keyboard beeper

F5 Running time clock

F6 Set voltage

F7 Magnetic field factors

Change language Gern or English

LCD backlighting On, Off or Auto

Interfaces Select all parameters

ESD/keyboard beeper (on, off)

Running time clock

Display of the TEST ON time

Set voltage (ext. motor variac)

Magnetic field factors

Correction factors for magnetic field

antenna and current transformer

Change standard level

Change standard level

F1 All parameters to standard level

F2 IEC 61000-4

F3 EN 61000-6-1

F4 EN 61000-6-2

Change standard levels

F1 IEC 61000-4-4 Burst

F2 IEC 61000-4-5 Surge

...

EM TEST UCS 500 Series

Operating Manual V 5.40 16 / 99

4.3.

Main Menu

MAIN MENU

F1 : Burst IEC 61000-4-4

F2 : Surge IEC 61000-4-5/9

F3 : Power Fail IEC 61000-4-11/8/29

F4 : Ringwave IEC 61000-12

F5 : TSurge

F7 : Service

F1

F2

F3

F4

F5

F6

F7

F1 Burst test

With function key F1 the user can select Burst Test as per IEC 61000-4-4. The test pulses are fast transients with

a pulse shape of 5/50ns.

Attention: The generator covers the new specifications given in the draft revision IEC 61000-4-4 edition 2. This means a new spike

frequency which is selectable between 5 kHz and 100 kHz. The burst duration is automatically matched between 15ms

and 0.75ms. The common mode coupling is new with all couplings at the same time.

F2 Surge test

With function key F2 the user can select Surge Test as per IEC 61000-4-5. The test pulses are high energy pulse

with a voltage shape of 1,2/50s and a short circuit current shape of 8/20s.

In addition the test procedure for Pulse Magnetic Field testing as per IEC 61000-4-9 is included in this menu.

F3 Power Fail test

With function key F3 the user can select the Power Fail Test as per IEC 61000-4-11.

The simulator will generate voltage dips and voltage variations with preselectable parameters. IEC 61000-4-11 is

valid for ac power supply systems. For dc supply system in future IEC 61000-4-29 shall be recommended.

In addition the test procedure for 50/60Hz Magnetic Field Testing as per IEC 61000-4-8 is included within the

menu.

The Power fail menu includes a Voltage Variation test as per IEC 61000-4-11 as test procedure. The simulator

will generate voltage variations in the second range.

Attention: The generator covers already the new specifications given in FDIS IEC 61000-4-11: 2004. This means the introduction of

a new 80% test level as well as a new function for the Voltage Variation test.

F4 Ringwave as per IEC 61000-4-12 (UCS500 N7)

With function key F4 the user can select the Ring Wave Test as per IEC 61000-4-12 or ANSI/IEEE. The test

pulses are single-shot with an oscillating and decaying waveshape.

F5 Telecom Surge Test

With the Option TSurge a Telecom Surge pulse 10/700s as per IEC 61000-4-5, ITU, ETS or FCC part 68 Pulse

B is available.

F7 Service

Setup and servicing routines are available.

EM TEST UCS 500 Series

Operating Manual V 5.40 17 / 99

4.4.

Service

SERVICE

F1 : Addresses

F3 : Set-up

F4 : Change standard levels

F7 : Status

F1

F2

F3

F4

F5

F6

F7

F1 Addresses

The addresses of the EM TEST (Switzerland) GmbH

and the EM TEST GmbH are shown. The addresses

of all EM TEST sales agencies are listed on the web

site of EM Test under :

www.emtest.com

F3 Set-up

The software will clearly explain the set-up procedure.

F4 Change standard levels

The stored standard test levels can be changed within this menu.

SERVICE Change standard levels

F1 : Reset all standard levels

F2 : IEC 61000-4

F3 : EN 61000-6-1

F4 : EN 61000-6-2

F1

F2

F3

F4

F5

F6

F7

The user can change the stored standard levels

F1: Set all parameters acc. to standard. The stored standard test levels can be changed within this menu.

The settings are actualized to the standards dated in summer 2004.

F2: IEC 61000-4

F1: IEC 61000-4-4 Burst

F2: IEC 61000-4-5 Surge

F3: IEC 61000-4-8 Magnetic field AC

F4: IEC 61000-4-9 Magnetic field Surge

F5: IEC 61000-4-11 Power Fail AC

F6: IEC 61000-4-29 Power Fail DC

F3: EN 61000-6-1 Generic

F1: EN 61000-6-1 Generic Burst

F2: EN 61000-6-1 Generic Surge

F3: EN 61000-6-1 Generic Power Fail

F4: EN 61000-6-2 Generic

F1: EN 61000-6-1 Generic Burst

F2: EN 61000-6-1 Generic Surge

F3: EN 61000-6-1 Generic Power Fail

EM TEST UCS 500 Series

Operating Manual V 5.40 18 / 99

F7 Status

Status information of the equipment.

UCS500N5 UCS500N7

Page 1

UCS500N5

V5.00

005000

Built in

Modules

Model

Version

SW Number

Burst

Surge

Power Fail

Ringwave

Int. 1Ph

Operating

00000035.53 hrs

Test time

00000015.53 hrs

DI-Status 0000

SCR-Status 0000

Information of

operating

Status information

Page 2

Keyboard Beep

Countdown Beep

Backlighting

off

off

5 min

RS 232

IEEE

19200

15

Setup information

Interface information

DAC adjust

+0, +0

+0, +0

+0, +0

Voltage

V 264

Vn 230

CH PF1

H-field

Af

Tf

If

DAC Adjust

Parameter

Set voltage

H-filed

parameter

EM TEST UCS 500 Series

Operating Manual V 5.40 19 / 99

4.5.

Setup

Firmware V 6.01ax (UCS 500N5) V9.04ax (N7x)

SETUP

SETUP

F1 : Change language / Sprache ändern

F1 : Change language / Sprache ändern

F2 : LCD backlighting

F2 : LCD backlighting

F3 : Interfaces

F3 : Interfaces

F4 : Beep

F4 : Beep

F5 : Timer

F5 : Timer

F6 : Set voltage

F6 : Set voltage low / high

F7 : Magnetic field correction factors

F7 : Magnetic field correction factors

F1

F2

F3

F4

F5

F6

F7 F1

F2

F3

F4

F5

F6

F7

F1 Change language

The user can chose between two languages, German and English.

F2 LCD backlighting

With the use of F2 the backlighting can be switched on or off.

Additionally the Auto Off function can be programmed to switch off the backlighting after a defined time that the

equipment has not been in operation (1 - 30minBecause of the limited lifetime of LCD displays, approx. 10,000h

this function should always be activated.

F3 Interfaces

This menu will help the user to define the status of the integrated serial and parallel interfaces, e.g. the baud rate

of the RS 232 or the address of the IEEE interface.

F4 Beep

F1 is the selector for the keyboard beeper ON/OFF mode. (Short beep at every keyboard hit)

F3 is the selector for the countdown-beeper ON/OFF mode. (Short beep before surge pulse releasing )

To indicate that a running test is finished the beeper sounds always 3 times (not changeable).

F5 Operating time

Pressing of F5 will show the different operating time and status of the test equipment.

Operating time: Total time where the UCS is powered on.

Testing Time: Total time during a running test.

DI – Status: Service information about internal digital inputs.

SCR – Status: Service information about surge switch operation

F6 Set voltage low/high Firmware V 6.01ax (UCS 500N5) V9.04ax (N7x)

This Firmware version offers two separate voltage settings for user that needs to test equipment for 115 V and

230V mains supply. Thanks to the two settings, the user can keep the Motorvariac in the 230V position

Using a MV 2616 with voltage selector switch:

- Set the voltage selector to the 230V position for low and high mains voltage supply.

- Use the Firmware with low and high settings and use the MV 2616 for any supply in the 230 V position.

The operator can specify the following parameters:

F1: Setup Main Voltage to low 115 V. Motorvariac parameter settings for lower main voltage. (115 V)

F2: Setup Main Voltage to high 230 V Motorvariac parameters for higher main voltage. (230 V)

F3: Motorvariac high (low) Selection and indicate of the active “Main Voltage” setting. The

selected setting is used in the power Fail tests for motorvariac

control

The procedure for low and high parameters voltage setting is the same as described in F6 Set Voltage below.

F6 Set voltage

For control of an external power supply source an analogue control voltage can be programmed (0-10V dc).

The operator can specify the following parameters:

F1: Max. variac voltage V [ V ] Maximal output voltage at 100% position of the external motor variac or dc

controlled voltage source. The analogue reference value for the max. voltage is 10 V.

F2: Mains supply voltage V [ V ] of the device under test. This voltage shall be specified by the operator and

depends on the type of equipment under test. The variac normally is automatically set to this output voltage.

F3: Default channel. The operator select the default channel PF1 or PF2 from which the EUT is powered.

EM TEST UCS 500 Series

Operating Manual V 5.40 20 / 99

F7 Magnetic field correction factors

F1: Coil factor Af A/m Range [0.200...9.99 step 0.01 ]

F2: Transformer factor Tf A/V Range [0.020...9.999 step 0.001 ]

F3: Impedance factor If A/V Range [0.200...1.00 step 0.01 ]

These values are delivered together with the necessary options to conducted magnetic field testing.

- Coil factor depends on the type of antenna which is used for the test.

- Transformer factor depends on the type of transformer which is used for the test.

- Impedance factor depends on the type of surge generator which is used for the test. A generator with a

source impedance of 2 needs an impedance factor of approx. If = 0.5

EM TEST UCS 500 Series

Operating Manual V 5.40 21 / 99

4.6.

Setup procedure for Set voltage

The UCS 500 is able to control an external voltage source with a 0-10V analogue dc signal.

The 10V level corresponds to the max. output voltage of the connected voltage source. For the correct setting it

is necessary to know the max. output voltage of the source. For setting for ac or dc source the same procedure is

necessary.

Setup for adjust the external voltage variac to the UCS 500Nx

The voltage setting is a regulating procedure where one

winding of the motor-variac is approx. 1.9V. Additionally

the control needs some mechanical tolerance for stop

the step motor. Therefore the selected voltage is

normally in a tolerance of 3V

The motor-variac control has an internal deadband

where the voltage will not be adjusted.

The following procedure will guide the user through the Set Voltage procedure.

The setting for Umax and Un are listed in the boxes below. After each setting the user has to press the ESC

button for make the setting.

Step

Umax.

Un

CH

Remarks

A --

--

PF2

Set the UCS 500 to PF2 mode for measure the variable voltage

B

100

100

PF2

The variac moves to his max. voltage. ( 10V dc at the 0-10V output)

Read Umax. voltage from the voltmeter. ( MV2616 approx. 257V)

C

Umax

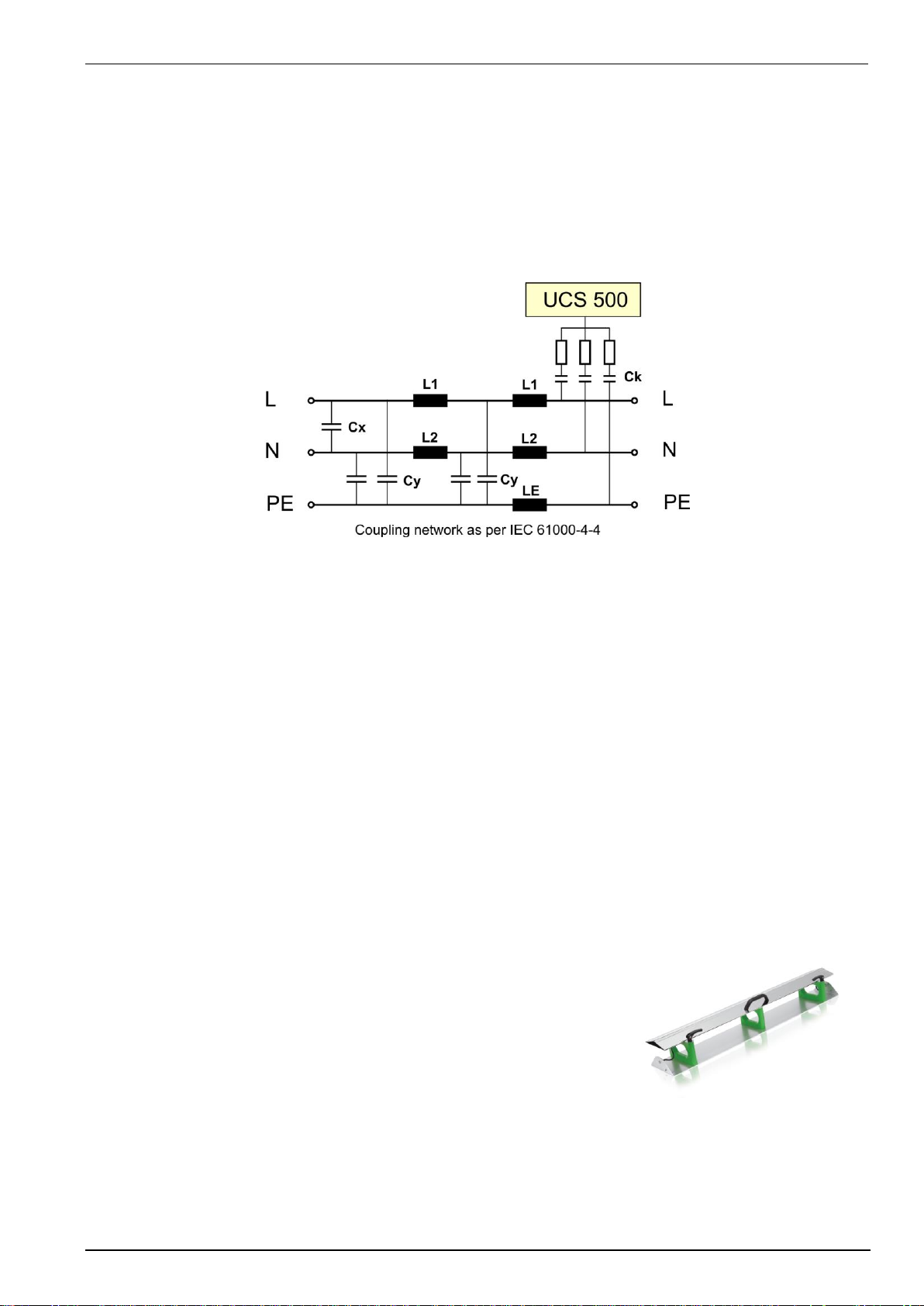

230

PF2

Enter Umax. and set Un to 230V ( 115V)

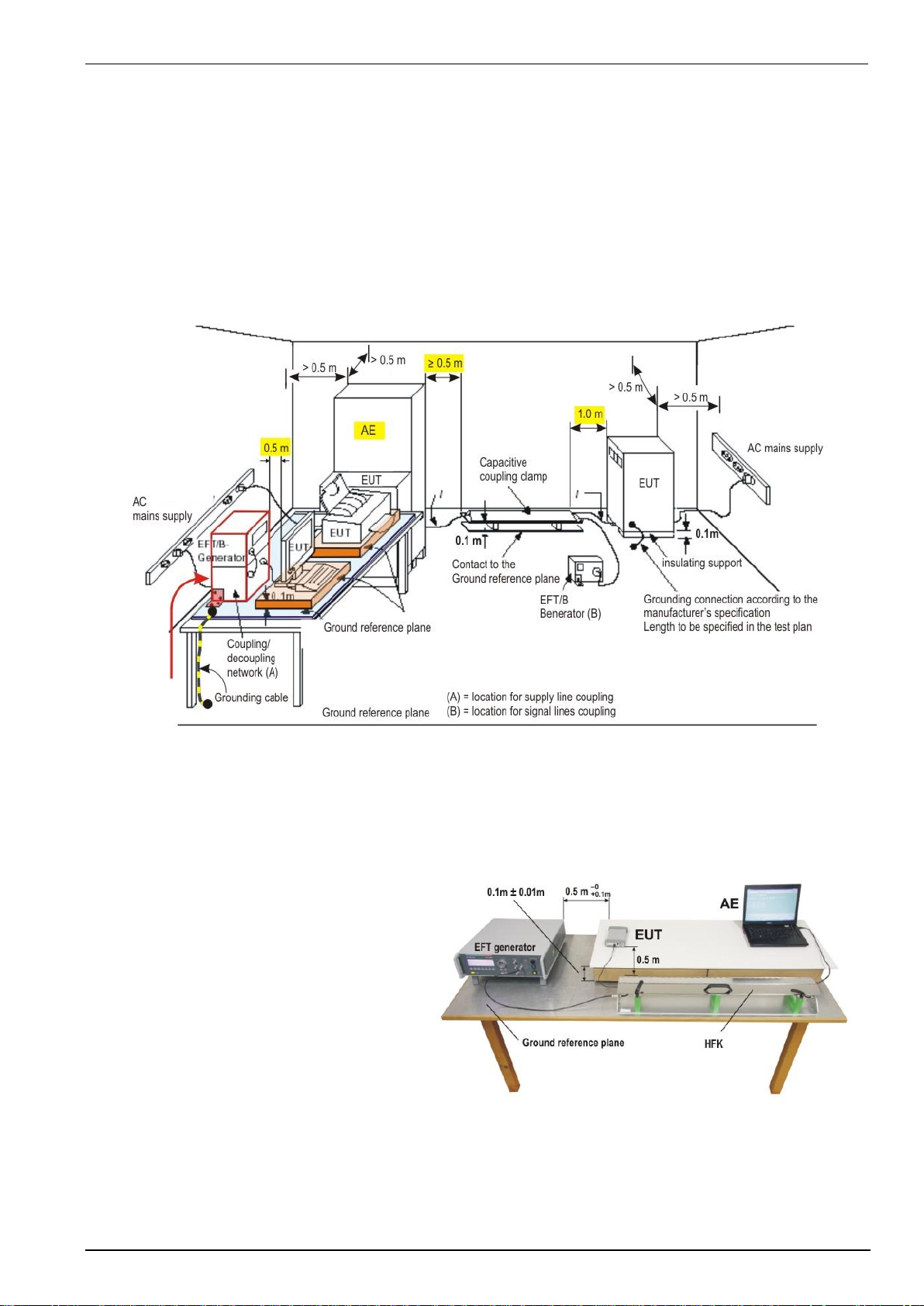

D

Umax

100

PF2

Check the 100V at the voltmeter. Tolerance 3V

E Umax

0

PF2

Check the 0V at the voltmeter. Tolerance < 2V

F

Umax

100

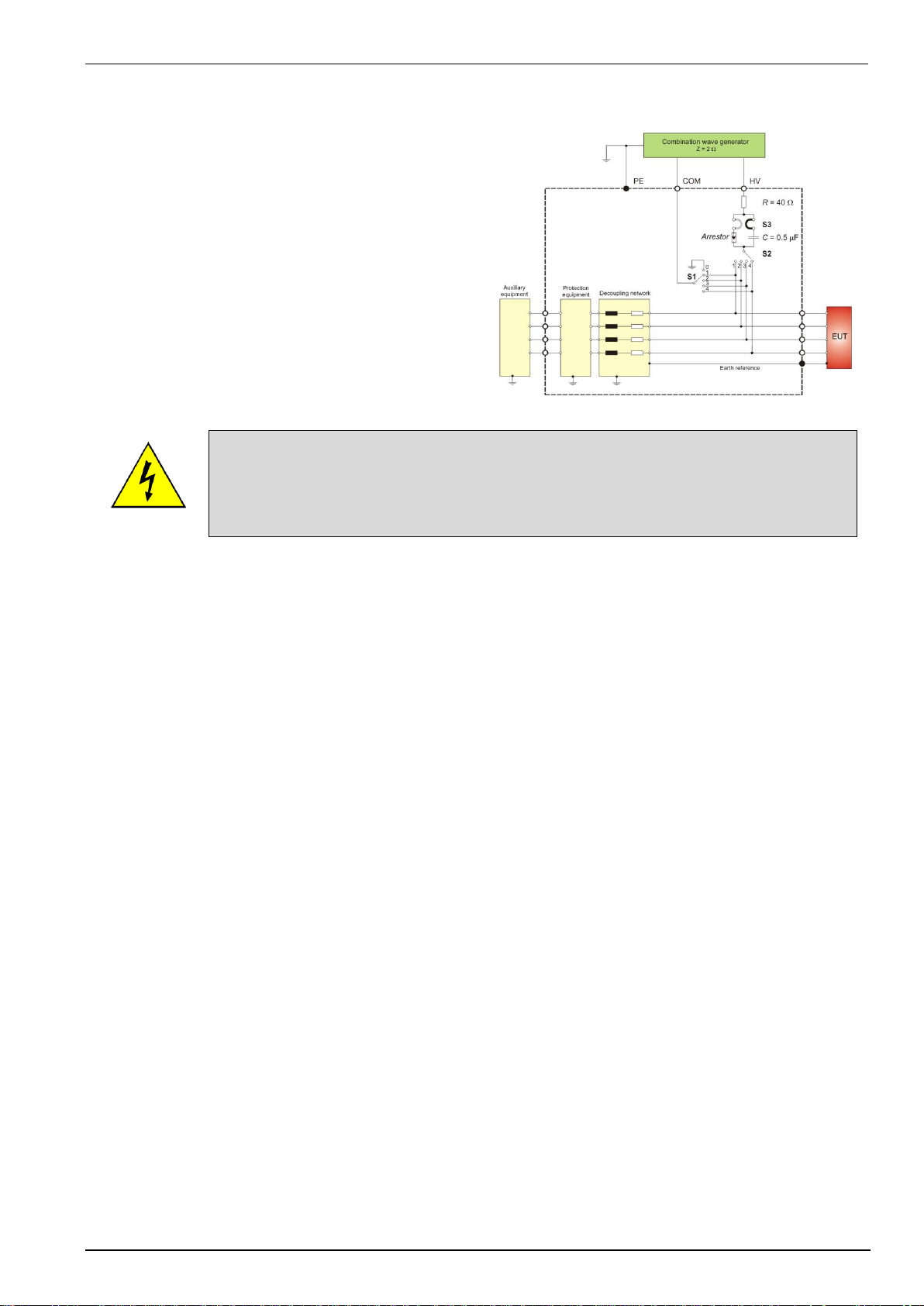

PF2

Check the 100V at the voltmeter. Tolerance 3V

G

Umax

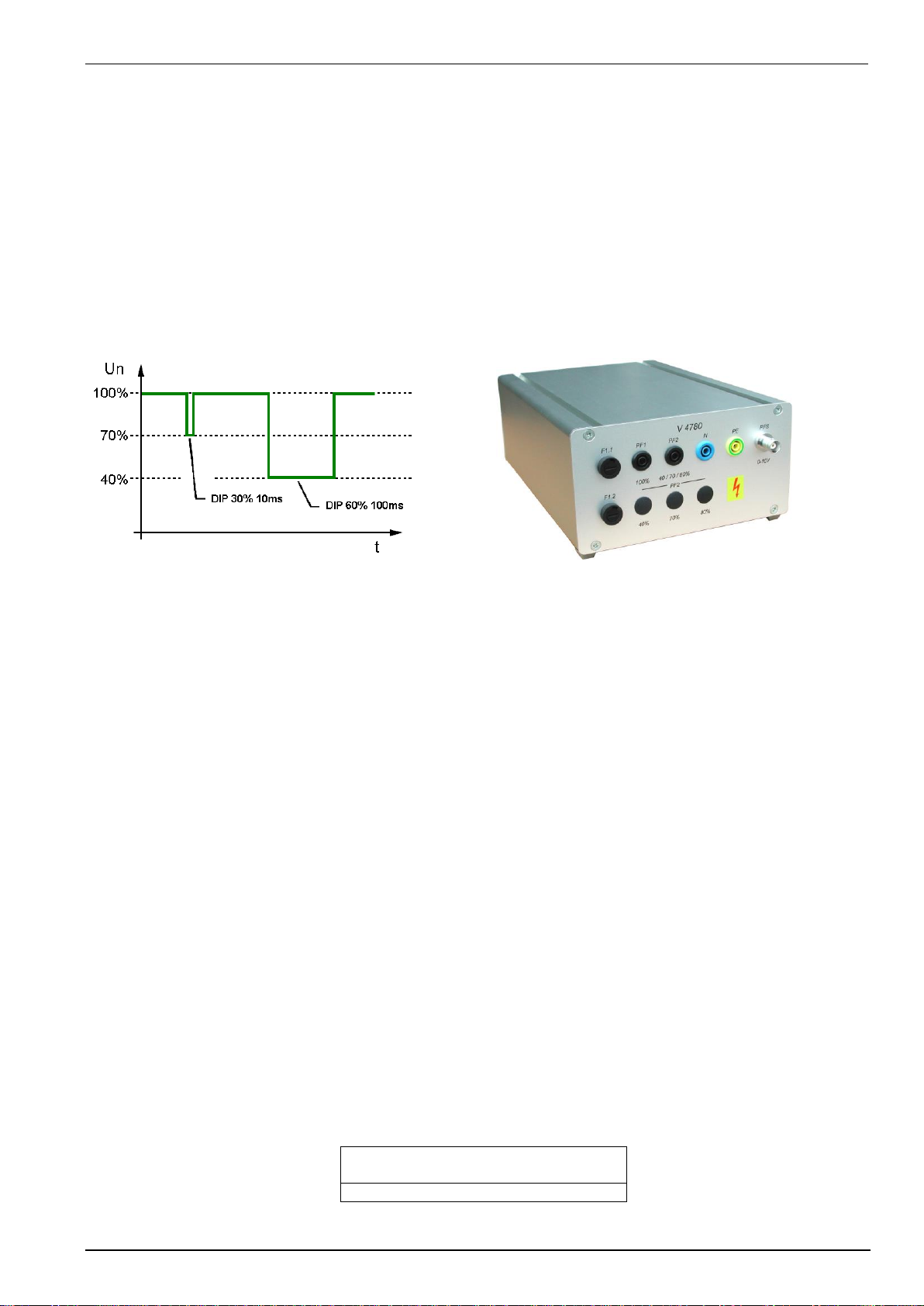

230

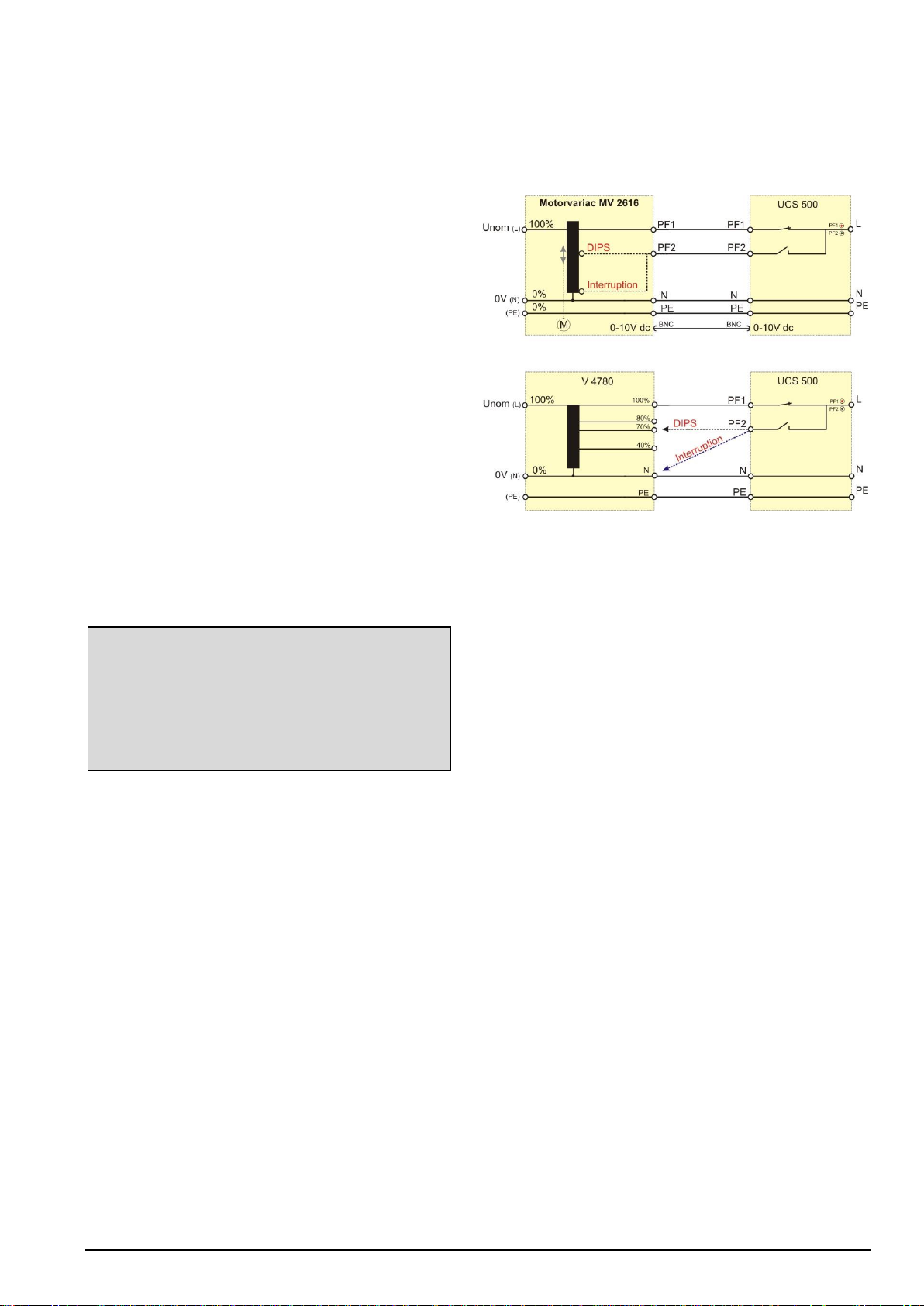

PF2

Check the 230V at the voltmeter. Tolerance 3V

If the output voltage is not inside the tolerance or you like to make a better adjustment:

- Change the Umax voltage and restart the check procedure from step C to G.

EM TEST UCS 500 Series

Operating Manual V 5.40 22 / 99

5.

Test Equipment UCS 500N

The simulator UCS 500N is separated in different main parts. The control unit is screened to all other parts.

5.1.

UCS 500 N5

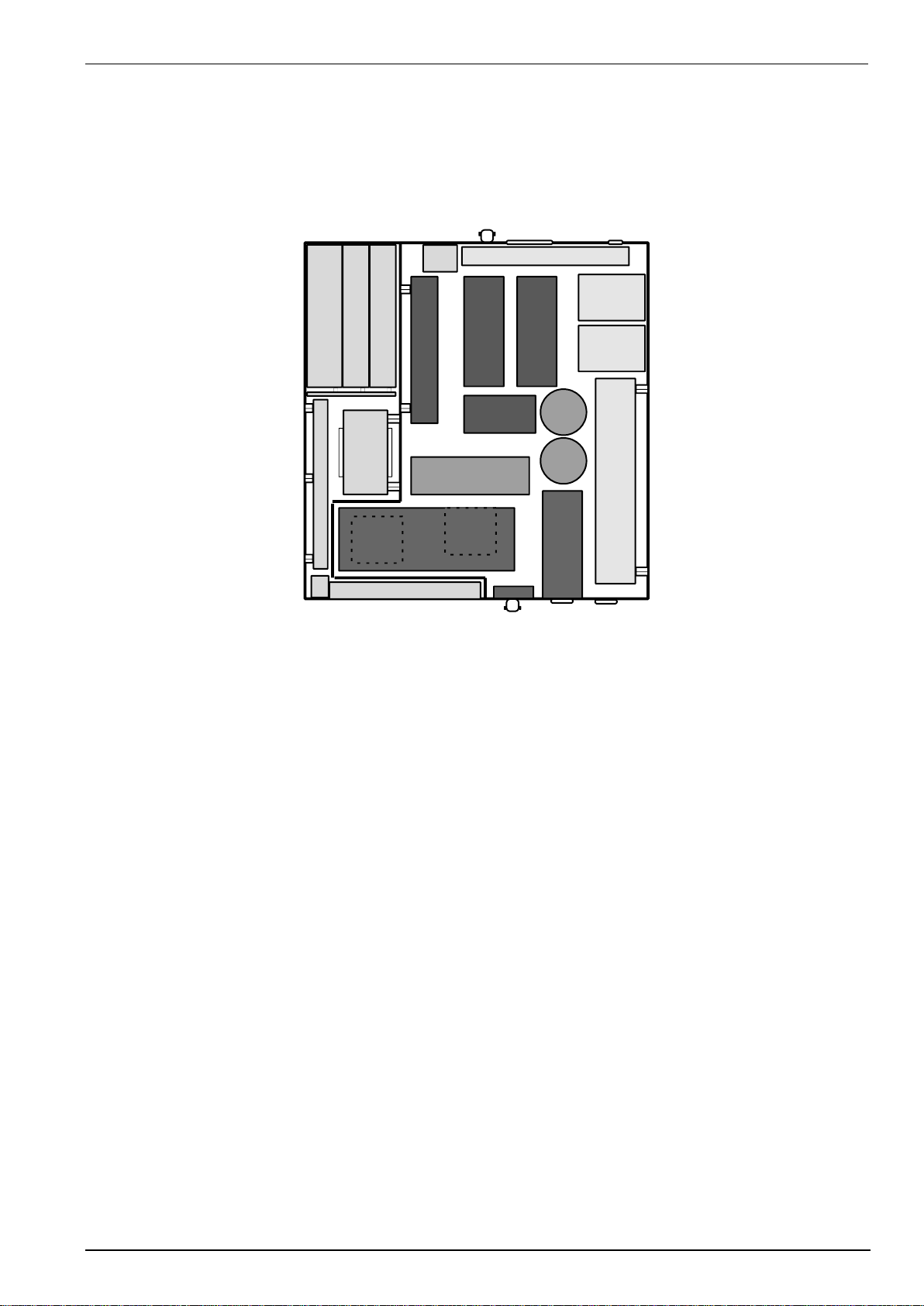

123

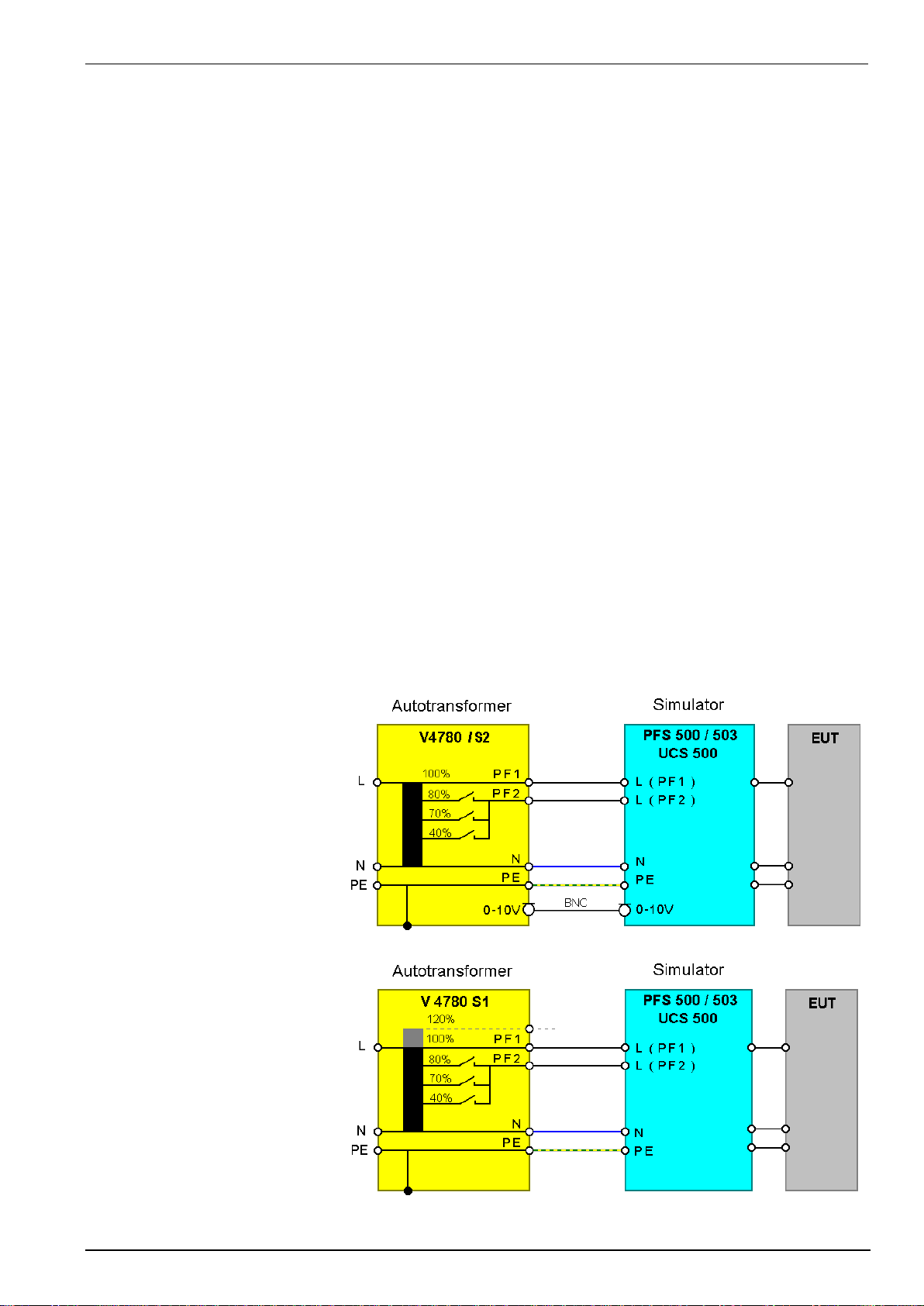

7

5

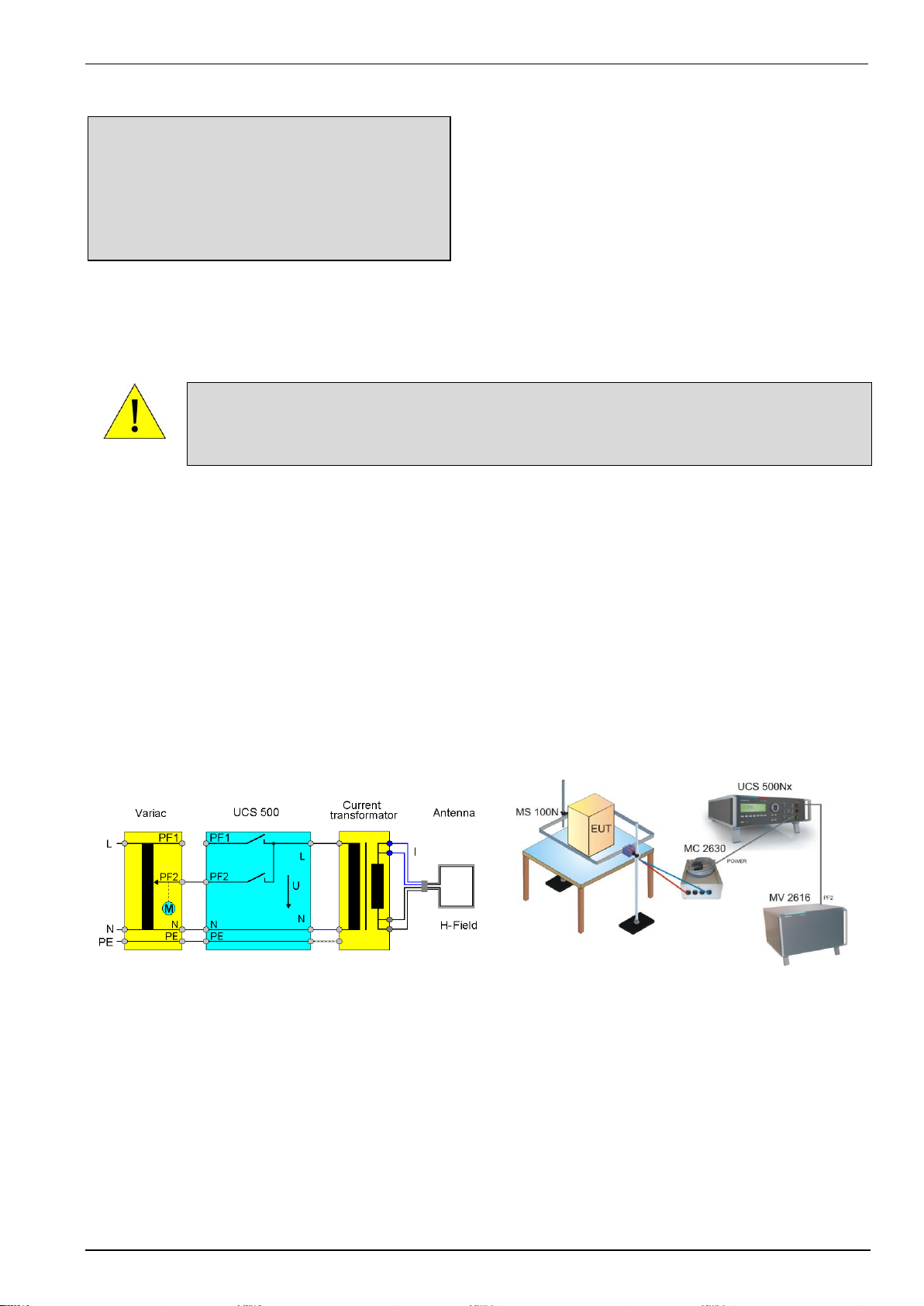

6

Front panel

Back panel

20

4

161619

19

6

18

9

10

11

13

15

17

14

14

8

21

22

23

21

12

Control unit

1 Power supply board

2 Interface board

3 Controller board

4 Power supply transformer

5 Filter board / connecting board

6 Keyboard / LCD- display

7 General power supply input, filter

8 Ventilation

High voltage unit

9 High voltage power supply

10 Storage capacitor

11 HV- board

12 ESD controller board

13 Surge switch-board

14 Coupling capacitors for surge mode

15 High voltage switch for burst mode

16 Power switches for voltage dip mode PF1, PF2

17 Current sensor

Coupling/decoupling unit

18 Filter board

19 Decoupling chokes

20 Coupling/decoupling network

21 Measuring and control output

22 Input for the power mains supply of the EUT

23 Output for the EUT supply

EM TEST UCS 500 Series

Operating Manual V 5.40 23 / 99

5.2.

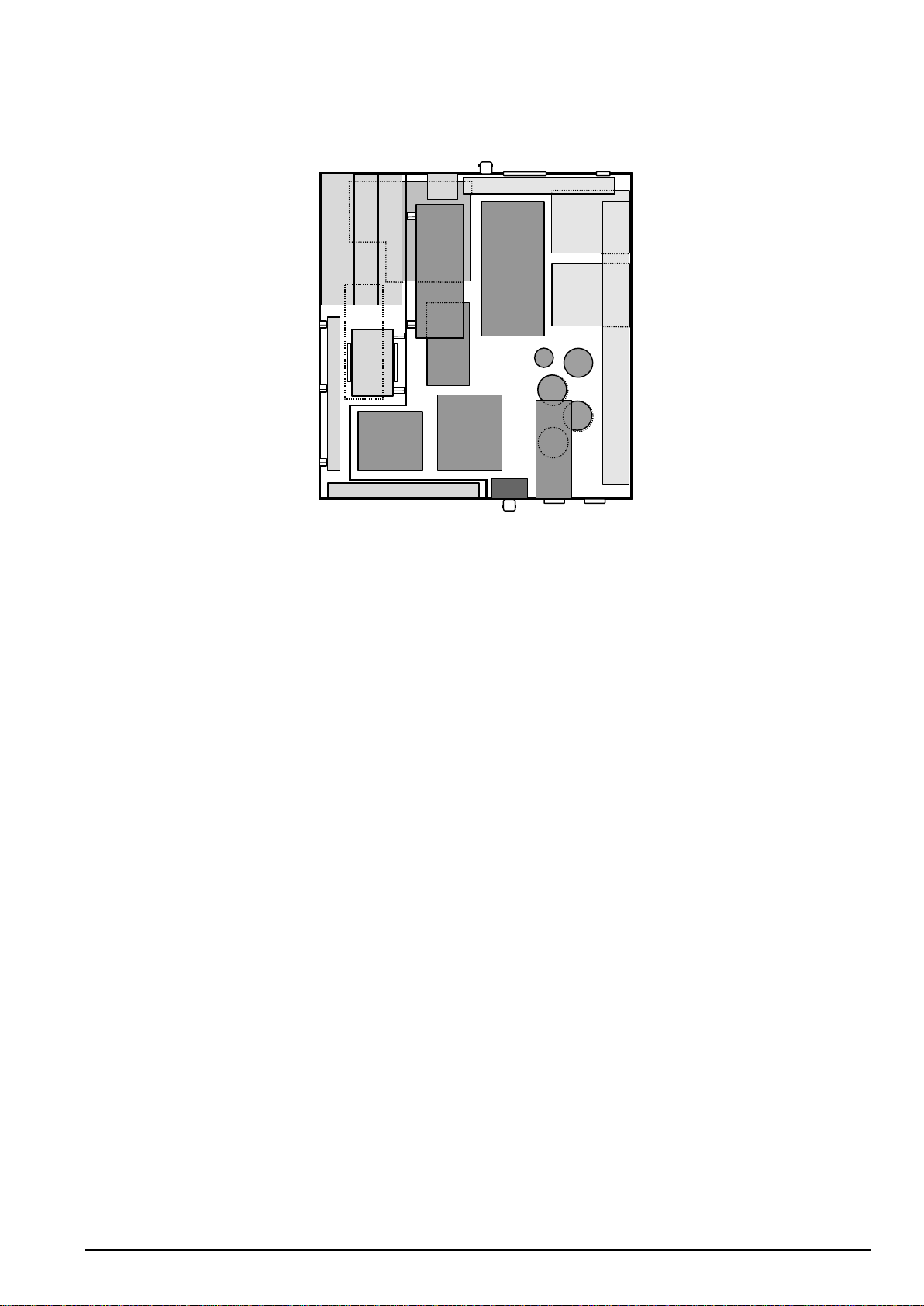

UCS 500 N7

123

Frontpanel

Rearpanel

11

1

2

3

4

5

1

6

7

9

10

11

12

13

14

15

16

17

18

19

202021

22

23

8

7

Control unit

1 Power supply board

2 Interface board

3 Controller board

4 Power supply transformer

5 Filter board / connecting board

6 Keyboard / LCD- display

7 Measuring and control outputs

8 General power supply input, filter

9 Ventilation

High voltage unit

10 High voltage power supply

11 Surge/Burst storage capacitor

12 Ringwave storage capacitor

13 HV switching board

14 Burst module

15 Surge module

16 Ringwave module

17 Power Fail module

Coupling/decoupling unit

18 Surge/Ringwave coupling capacitors

19 Coupling network

20 Decoupling chokes

21 Filter board for the EUT supply

22 Input for the EUT supply

23 Output for the EUT supply

EM TEST UCS 500 Series

Operating Manual V 5.40 24 / 99

6.

Technical data

6.1.

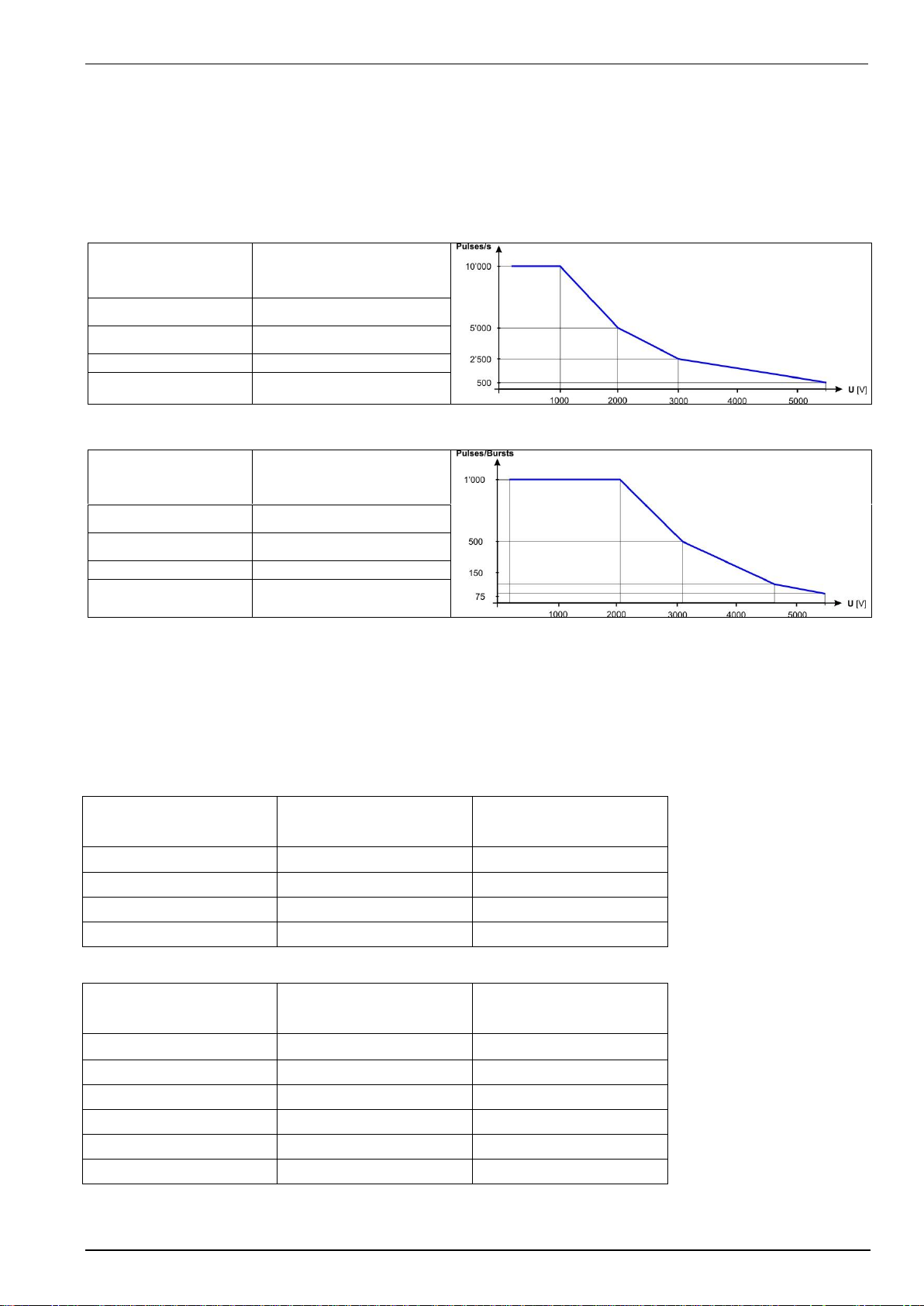

EFT Electrical Fast Transients Burst as per IEC 61000-4-4

Test Level

Model N5

Model N7

Open circuit *

200V - 5500V ± 10% Step 20V

200V – 5500V ± 10% Step 50V

Wave shape into a 50 load

100V – 2750V

100V – 2750V

Rise time tr

5ns ± 30%

5ns ± 30%

Pulse duration td

50ns 30%

50ns 30%

Wave shape into a 1000 load

200V – 5500V

200V – 5500V

Rise time tr

5ns ± 30%

5ns ± 30%

Pulse duration td

35ns - 150ns

35ns – 150ns

Source impedance

Zq = 50 ± 20%

Zq = 50 ± 20%

Polarity

Positive / negative

positive / negative

Trigger

Trigger of bursts

AUTO, MANUAL, EXTERN

Synchronization

0 - 360° (16 - 500Hz)

Asynchronous = 0° a reference signal is connected to the Sync input.

Burst duration td

0.10ms – 999ms

Burst repetition rate tr

10ms – 9999ms

Spike frequency f

0.1kHz – 1000kHz Range Step

< 10 kHz 0.1 kHz

10 – 100 kHz 1.0 kHz

100 – 250 kHz 10.0 kHz

> 250 kHz 50.0 kHz

Test duration T

0:01 min - 99:59 min

Output

Direct via 50 coaxial connector

To connect ext. coupling devices

To connect ext. coupling devices

Coupling network

To L, N, PE all combinations

To L, N, PE all combinations

DUT power mains supply

AC 300 V / 16 A / 50/60 Hz

AC 300 V / 16 A / 50/60 Hz

DC 300 V / 160 A

DC 300 V / 16 A

Test routines

Quick Start

Immediate start, all parameters adjustable during a running test

Standard test as per

IEC 61000-4-4 level 1

IEC 61000-4-4 level 2

IEC 61000-4-4 level 3

IEC 61000-4-4 level 4

EN 61000-6-1 Generic

EN 61000-6-2 Generic

IEC 61000- 4-4 Manual operated standard test routine

User test routines

Synchronous burst release

Random burst release

Change level V after T by steps of dV

Frequency sweep in one single burst

Frequency sweep with constant pulses

Frequency sweep, constant burst duration

Change polarity after T

* With Burst pulses as per. IEC 61000-4-4 Ed2 : 2004 the max. output voltage can be limited.

EM TEST UCS 500 Series

Operating Manual V 5.40 25 / 99

6.2.

SURGE Immunity requirements as per IEC 61000-4-5

Test Level

Model N5

Model N7

Open circuit voltage

160 V – 5000 V ± 10% Step 20 V

250 V – 7000 V ± 10% Step 50 V

Short circuit current

80 A – 2500 A ± 10%

125 A – 3500 A ± 10%

Wave shape open circuit

coupling

18 F line to line 9 F line to ground

18 F line to line 9 F line to ground

Front time tr

1,2 s ± 30% 1,2 s ± 30%

1,2 s ± 30% 1,2 s ± 30%

Pulse duration (16A model)

50 s +10 μs/-10 μs 50 s +10 μs/-25 μs

50 s +10 μs/-10 μs 50 s +10 μs/-25 μs

Pulse duration (32A model)

50 μs +10 μs/-15 μs 50 μs +10 μs/-30 μs

50 μs +10 μs/-15 μs 50 μs +10 μs/-30 μs

Wave shape short circuit

coupling

18 F line to line 9 F line to ground

18 F line to line 9 F line to ground

Front time tr

8 s ± 20% 2.5 s ± 30%

8 s ± 20% 2.5 s ± 30%

Pulse duration

20 s ± 20% 25 s ± 30%

20 s ± 20% 25 s ± 30%

Polarity

Pos., Neg., Alt

Pos., Neg., Alt

Repetition rate

max. 1Hz (1s* - 999s)

max. 0.5Hz (2s* - 999s)

Events preselection

1 - 30'000 or endless

1 - 30'000 or endless

Counter

1 - 1000000

1 - 1000000

Trigger

Trigger of pulses

AUTO, MAN, EXTERN

AUTO, MAN, EXTERN

Synchronization

0 - 360° (16 - 500Hz)

0 - 360° (16 - 500Hz)

Synchronization

Asynchronous = 0° a reference signal is connected to the Sync input.

Resolution

1°

1°

Measurements

CRO

5 V Trigger

5 V Trigger

CRO Û

10 Vp at 5 kV

10 Vp at 7.0 kV

CRO Î

10 Vp at 2.5 kA

10 Vp at 3.5 kA ; 1 Digit 50 A

Accuracy CRO U , CRO I

± 10%

± 10%

CRO Û/I Z measuring instrument

> 1 MΩ

> 1 MΩ

Peak voltmeter

5000 V

7000 V

Peak current meter

2500 A : Display 1 Digit 20 A

3500 A : Display 1 Digit 50 A

Current limiter setting

10 A...3000 A step 10 A

10 A...4000 A step 10 A

Output N5

N7

Direct

HV-Banana connector, Zi = 2

X X

Coupling network

L – N with Z = 2

X X

L-PE, N-PE, L+N-PE with Z = 12

X X

L-PE, N-PE, L+N-PE with Z = 2

na X

DUT supply

AC 300V / 16A / 50/60 Hz

X X

DC 300V / 16A

X X

Test routines

Quick Start

Immediate start, all parameters adjustable during a running test

Standard test routines as per

IEC 61000-4-5 level 1

IEC 61000-4-5 level 2

IEC 61000-4-5 level 3

IEC 61000-4-5 level 4

EN 61000-6-1 Generic

EN 61000-6-2 Generic

IEC 61000-4-5 Manual operated standard routine

User test routines

Change polarity after n pulses

Change coupling mode after n pulses

Change voltage level V after n pulses by V

Change phase angle A after n pulses by A

Magnetic field test

test routine as per IEC 61000-4-9

test level 100, 300 and 1000A/m

cont. adjustable within Quick Start

* depends on charging voltage

EM TEST UCS 500 Series

Operating Manual V 5.40 26 / 99

6.3.

Power Fail Generator as per IEC 61000-4-11

EUT supply

Model N5

Model N7

Channel PF1 and PF2

AC voltage/current

max. 300V/16A

max. 300V/16A

Mains frequency

50/60 Hz

DC voltage/current

max. 300V/16A

max. 300V/16A

Inrush current

more than 500A

Protection

Electronic fuse for continuous overcurrent / inrush currents

Electronic control of overheating

PF1 and PF2 are safe against short circuit

max. current channel PF1

nominal current continuous

max. current channel PF2

nominal current with intermittently 10s (50% duty cycle)

Trigger

Events trigger

AUTO, MAN, EXTERN

Repetition rate

0.01s – 9’999s Accuracy 0.05% + phase sync

Duration of events

0.02ms – 9’999s Accuracy 0.05%

Events preselection

1 - 30'000 or endless

1 - 30'000 or endless

Counter

1 - 1000000

1 - 1000000

Synchronization

0 - 360° (16 - 500Hz)

Asynchronous = 0° if a reference signal is connected to the Sync input.

Max Sync input voltage

Max. 300V or same as EUT voltage specs.

Resolution

1°

Measurements

DUT supply

AC/DC voltage in the LCD display, divider ratio 1:100 +/- 10%

BNC output MON U

Measurement of the EUT supply divider ratio 1:100 5%

BNC output MON I

Measurement of the EUT current and the inrush current

10mV/A 5%, max. 1000A

CRO TRIGGER

positive going flank

0-10V Control Output

0-10V DC for external voltage source

Test routines

Quick Start

Immediate start, all parameters adjustable during a running test

Standard test routines

as per IEC 61000-4-11 ac power ports

as per IEC 61000-4-29 dc power ports

as per IEC 61000-6-1 Generic

as per IEC 61000-6-2 Generic

Manual operated standard test routine

User test routines

Voltage variation, external variac control

Change phase angle W after n events by dA

Change events duration td after n events by dtd

Inverse mode

Magnetic field test

test routine according to IEC 61000-4-8

test level 1, 3, 10 and 30A/m with MC 2630 and a variac

test level 100, 300 and 1000A/m with MC26100

Magnetic field tests per IEC 61000-4-8 and -9

The test routines for handling the magnetic field tests are included in the internal UCS 500N firmware. All functions to

control external options as voltage/current sources or magnetic field antennas are included. In addition the following

hardware is required:

Option required for Magnetic Field Test per IEC 61000-4-9

- Magnetic field antenna (square 1mx1m coil MS 100)

- Adapter for connecting the square coil to the surge output.

Option required for Magnetic Field Test 50/60Hz per IEC 61000-4-8

- External variac (MV2616) and magnetic field antenna (square 1mx1m coil MS 100)

- External current transformer (MC2630) to test 1, 3, 10 and 30 A/m levels

- External current transformer (MC26100) to test level 100, 300 and 1000 A/m levels (short term).

EM TEST UCS 500 Series

Operating Manual V 5.40 27 / 99

6.4.

RINGWAVE Immunity requirements as per IEC 61000-4-12

The Ringwave module is available for the UCS500 N7 generator.

Test level

Open circuit voltage

6000 V ± 10 %

Wave shape voltage

Rise time first peak T1

0,5 µs ± 30 %

Oscillation frequency 1/T

100kHz ± 10 %

Decaying of Pk1 to Pk2

40 % - 110 %

Decaying of Pk2 to Pk3

40 % - 80 %

Decaying of Pk3 to Pk4

40 % - 80 %

Decaying other peaks

no requirements for other peaks

Short circuit current 12 Ω

500 A ± 10 %

Short circuit current 30 Ω

200 A ± 10 %

Short circuit current 50 Ω

120 A ± 10 % option RWG / N7.1 module, no peak current measurement

Wave shape current

Rise time first peak tr T1

< 1 μs

Oscillation frequency 1/T

100 kHz ± 10 %

Decaying

no requirements

Polarity

positive / negative / alternating

Repetition rate

250 V – 4000 V max. 1 Hz (1s - 999s)

> 4000 V max. 0.1 Hz (10s – 999s)

Events preselection

1 - 30'000 or endless

Counter

1 – 1’000’000

Trigger

Trigger of pulses

AUTO, MAN, EXTERN

Synchronization

0 - 360°

Resolution

1°

Output

Direct

HV-banana connector; Zi = 12 Ω / 30 Ω / (50 Ω; option RWG/N7.1)

Coupling network

L-N, L-PE, N-PE, L+N-PE

DUT power mains supply

AC 300 V / 16 A / 50/60 Hz

DC 300 V / 16 A

Measurements

CRO

5 V Trigger

CRO Û

10 Vp at 7.0 kV

CRO Î

Output signal is not suitable for Ringwave current measurement

Peak voltmeter

0 – 7000 V

Peak current meter

Displayed value only as trend suitable, accuracy > 20%

Test routines

Quick Start

Immediate start, all parameters adjustable during a running test

EM TEST UCS 500 Series

Operating Manual V 5.40 28 / 99

6.5.

Telecom Surge Generator as per IEC 61000-4-5 (TSurge module)

UCS 500N5T (includes TSurge module) TSurge7 (external)

As per ITU and ETS recommendations

Output voltage open circuit

160V – 5’000V 10% 250V – 7’000V 10%

Pulse 10/700s

Front time TF (rise time tr)

10s 30% (1.0s 30%)

Pulse duration td

700s 20%

As per FCC part 68 Pulse B

Output voltage open circuit

160V – 5’000V 10% 250V – 7’000V 10%

Front time TF

9s 30%

Pulse duration td

720s 20%

Output current short circuit

4 – 100A 6 – 175A

Rise time tr

5s 30%

Pulse duration td

320s 20%

As per IEC 61000-4-5

Pulse 10/700s

Open circuit output voltage

160V – 5’000V 10% 250V – 7’000V 10%

Rise time tr

10s 30%

Pulse duration td

700s 20%

Short circuit output current

4 – 100A 6 – 175A

Rise time tr

5s 20%

Pulse duration td

320s 20%

Coupling

As per ITU

For 2 wire T1 and T2 with 25 each

As per FCC part 68

For 2 wire T1 and T2 with 25 each

As per IEC 61000-4-5

For 4 wire T1,T2,T3,T4 with 100 each

External networks are required for other applications (options)

General

Energy storage capacitor

20F

Polarity

Positive, negative or alternating

Counter select

1 – 30,000 or endless

Dimensions

Housing

19“, 3HU, 450x500x155mm (ext. TSurge6.1 module)

Weight

approx. 11.85kg

Accessories Included

HV cable set

Connect the TSurge module to UCS 500N7

Control cable

To control TSurge via UCS 500N7

EUT adapter

socket depends on the country of use

EM TEST UCS 500 Series

Operating Manual V 5.40 29 / 99

6.6.

EUT Supply Specifications

Standard models

Model

CDN

Remarks

UCS 500N5

300V 16A 1- ph

DC 300V / 16A

UCS 500N5.1

300V 32A 1- ph

DC 300V / 32A

UCS 500N7

300V 16A 1- ph

DC 300V / 16A ANSI

UCS 500N7.1

300V 32A 1- ph

DC 300V / 32A ANSI

DC current specification for all UCS500N model: Imax. = 16A dc (where not otherwise specified)

EUT Fuse

The UCS 500Nx models have no internal fuse for the EUT supply.

The user is responsible to adapt a suitable fuse for the EUT outside the UCS 500Nx

EM TEST UCS 500 Series

Operating Manual V 5.40 30 / 99

6.7.

General Specifications

Mains supply

230V/115V, 50/60Hz

Power consumption

110W

Fuse

230V : 2 AT slow blow

115V : 4 AT slow blow

Safety

Safety circuit

External interlock capability

Warning lamp

voltage free contact max. 250V 5A

Design

per IEC 1010, EN 61010

Interfaces

Serial

USB (compatible to USB 1.1 and 2.0)

Parallel IEEE

Address 1-31

Analog output

0-10V DC, to control an external power supply

UCS 500N5

UCS500N7

Dimensions

19" / 3 HU

19" / 6 HE

Weight

app. 25 kg

ca.. 30 kg

6.8.

Environmental conditions

Temperature

10 °C to 35 °C

Humidity

30 % to 70 %; non condensing

Atmospheric pressure

86 kPa (860 mbar) to 106 kPa (1 060 mbar)

=> Not relevant data for the standards can be changed by the manufacturer <=

EM TEST UCS 500 Series

Operating Manual V 5.40 31 / 99

6.9.

Technical data of special generators

This chapter describes differing technical data from special generators

6.9.1.

UCS 500N5.2T

Module

Built in modules

Surge, T-Surge

CDN

internal 1ph 16 A AC/DC

EUT:

Single Phase 300V 16 A

Dimensions and weight

Dimension

445 x 500 x 420 mm

Weight

Approx. 35 kg

Housing

6HU

EM TEST UCS 500 Series

Operating Manual V 5.40 32 / 99

6.9.2.

UCS 500N5.5 and UCS 500N5.6 and UCS 500N5.9 for Railways application

Standards:

- EN 50121-3-2: 2015

- EN 50121-4: 2015

- EN 50121-5: 2015

Module : Burst

Surge

EUT

UCS 500N5.5: 300V 32A

UCS 500N5.6: 300V 32A

UCS 500N5.9: 300V 16A

Module

Built in modules

UCS 500N5.5: Burst, Surge

UCS 500N5.6: Burst, Surge, Power Fail

UCS 500N5.9: Burst, Surge, Power Fail

Surge Coupling

L - N, L - PE, N - PE, L + N - PE

Surge impedance Ri

2, 10, 40 Must be set manually by a bridge

REMARK : The complete Ri impedance is the addition of the 2

generator impedance und the manually set impedance

(10, 40).

Coupling\ Ri

2

12

42 / 0.5 µF

L - N

ok

ok

ok

L - PE

N - PE

no pulse

ok

ok

L + N - PE

no pulse

ok

ok

Dimensions and weight

Dimension

450 x 550 x 285 mm

Weight

34.2kg

Housing

6HU

EM TEST UCS 500 Series

Operating Manual V 5.40 33 / 99

6.9.3.

UCS 500N5.11

Module : Burst

Surge

TSurge ( optional)

EUT: 690V 16A

Module

Available Module

Burst, Surge, TSurge

Surge coupling

L - N, L - PE, N - PE, L + N - PE

Dimensions and weight

Dimension

445 x 500 x 420 mm

Weight

37.6kg

Housing

9HU

EM TEST UCS 500 Series

Operating Manual V 5.40 34 / 99

6.9.4.

UCS 500N6.5

Module : Surge

Ring wave

CDN External CNV503B7 6kV 32A

EUT: Three Phase

3x440V 32A

Module

Built in modules

Surge, Ringwave, TSurge

Coupling

external CNV503B7 and TSurge

Dimensions and weight

Dimension

450 x 550 x 285 mm

Weight

26.0kg (UCS500N6.5) 38.0kg ( CNV503B7) 12.1kg( TSurge)

Housing

6HU

6.9.5.

UCS 500N6.7

Modules : Surge

Power Fail

Ringwave

EUT: Single Phase

Coupling Network 40A

Module

Built in modules

Surge, Power Fail, Ringwave

Surge decoupling inductance

0.6mH internal dU at 40A 50Hz 230V approx. 15V

Dimensions and weight

Dimension

663 x 550 x 600mm

Weight

94 kg

Housing

Minirack 12HU / rolls 50mm

EM TEST UCS 500 Series

Operating Manual V 5.40 35 / 99

6.9.6.

UCS 500N7.1

Modules : EFT

Surge

Power Fail

T-Surge (option)

EUT: Single Phase 300V 32A

Module

Built in modules

EFT, Surge, Power Fail

Optional module

T-Surge

Remark

Ringwave not possible

Dimensions and weight

Dimension

445 x 500 x 420mm

Weight

approx. 37.6 kg

Housing

9HU

6.9.7.

UCS 500N7.4

Modules : EFT

Surge

Power Fail

Ringwave

EUT: Single Phase 400V 16A

Module

Built in modules

EFT, Surge, Power Fail, Ringwave

Optional module

T-Surge

Remark

Ringwave not possible

Dimensions and weight

Dimension

445 x 500 x 420mm

Weight

42.8 kg

Housing

9HU

=> Not relevant data for the standards can be changed by the manufacturer <=

EM TEST UCS 500 Series

Operating Manual V 5.40 36 / 99

7.

Maintenance setup and service

7.1.

General

The generator is absolutely maintenance-free by using a solid state semiconductor switch to generate transients

7.2.

Test set- up

When setting up the test national and international regulations

regarding human safety have to be guaranteed.

It is recommended to connect the simulator to the ground reference

plane of the test set-up.

The generators of the series 500, UCS, VCS, CSS, TSS and CNI, can

be linked together to a fully automotive test set-up.

The set-up communicates via the IEEE / GPIB bus and is controlled by

software. For setting up the system see the following figures:

Each generator can be operated individual as a single equipment.

7.3.

Fuse for the EUT power supply

The EM Test pulse generators have no built in fuse for the EUT power supply. It is in the scope of responsibility

of the user to protect the EUT external for the rated current.

The design of the external fuse must be match the following rules:

- fuse dimension must be equal or smaller than the rated EUT current of the connected test

generator

- fuse must be designed for protect the connected EUT device under test in malfunction

Example of external fuse

Fuse in the building is designed for

32A. A Fuse box with 16A fuse

protection is installed between the

building supply and the test

generator.