M a n u a l

F o r O p e r a t i o n

AutoWave

Portable solution to simulate and

measure Battery Supply Voltage

Variation

FM Version ≥ 5.09.00

The Automotive industry is facing the necessity to investigate

the behavior of the battery voltage variations and their effects to

electronic components connected to the supply network of the

cars, testing emission and immunity.

The two major international standards describing test

procedures to simulate different phenomena’s related to the

battery supply lines are ISO 16750-2 for 12V and 24V supply

voltages and ISO 21848-2 for 42V supply voltage.

ISO 7637-2

ISO 16750-2

ISO 21848-2

SAE J1113

Manufacturer spec as

per GM, Ford, Chrysler,

Mercedes, BMW, VW,

PSA, Renault, Fiat ......

the benchmark for emc

Version:

5.9.1/ 29.02.2016

Replaces:

5.9.0/ 03.02.2016

Filename:

UserManual-AutoWave-E-V5.9.1.doc

Printdate:

29.02.16

EM TEST AutoWave

EM TEST Switzerland GmbH

Sternenhofstrasse 15

4153 Reinach BL1

Switzerland

Phone : +41 61 717 91 91

Fax : +41 61 717 91 99

URL : http://www.emtest.com

Copyright © 2016 EM TEST Switzerland GmbH

All right reserved.

Specifications subject to change

Manual for Operation V 5.9.1 2 / 45

EM TEST AutoWave

Foreword

Thank you for purchasing the AutoWave generator. This user’s manual lists

precautions that must be taken during use, and contains useful information about

the functions and operating procedure of the device. To ensure correct use,

please read this manual thoroughly before beginning operation. After reading the

manual, keep it in a convenient location for quick reference whenever a question

arises during operation.

This manual contains a selection of typical system setup with the correct wiring

diagram.

For information about using and handling with the software AutoWaveControl,

see the manual for this product

Notes

The contains of this manual are subject to change without prior notice as a result

of continuing improvements to the instrument’s performance and functions. The

figures given in this manual may differ from those that actually appear on your

display and screen.

Every effort has been made in the preparation of this manual to ensure the

accuracy of this contents. Should you have any questions or find any errors,

please contact your EM Test representative or send an email to EM Test.

Copying or reproducing all or any part of the contents of this manual without the

permission of EM Test is strictly prohibited.

Trademarks

Microsoft, Windows, Windows NT, Windows Me, Windows XP and Vista are

either registered trademarks or trademarks of Microsoft Corporation in the United

States and/or other countries.

Other company and product names are trademarks or registered trademarks of

their respective companies

For purpose of this manual, the TM and ® symbols do not accompany their

respective names or registered trademark names.

Version

This manual is written for AutoWave Firmware version 5.09.00 and higher

Manual for Operation V 5.9.1 3 / 45

EM TEST AutoWave

Content

1. Model Overview ............................................................................................................... 5

1.1. AutoWave Model and extension modules .......................................................................................... 5

2. Put in service Functions ................................................................................................. 6

2.1. Front view ........................................................................................................................................... 6

2.2. Rear view ............................................................................................................................................ 8

2.3. Put in service .................................................................................................................................... 13

2.3.1. Unpacking ......................................................................................................................................... 13

2.3.2. Installation in a System ..................................................................................................................... 13

2.3.3. Hardware wiring ................................................................................................................................ 14

3. Operation ....................................................................................................................... 24

3.1. Power on ........................................................................................................................................... 24

3.2. Menu structure .................................................................................................................................. 24

3.2.1. Mode Menu ....................................................................................................................................... 24

3.2.2. Setup Menu ...................................................................................................................................... 29

3.2.3. DC Source ........................................................................................................................................ 30

3.2.4. Sample frequency (only with the option record) ............................................................................... 31

3.2.5. Input Range (only with the option record) ........................................................................................ 31

3.2.6. Trigger .............................................................................................................................................. 31

3.2.7. DUT Monitor ..................................................................................................................................... 32

3.2.8. GPIB Address ................................................................................................................................... 32

3.2.9. Ethernet IP- Address ........................................................................................................................ 32

3.2.10. Ethernet Netmask ............................................................................................................................. 32

3.2.11. Ethernet Gateway ............................................................................................................................. 32

3.2.12. Date .................................................................................................................................................. 33

3.2.13. Time .................................................................................................................................................. 33

3.2.14. LCD Contrast .................................................................................................................................... 33

3.2.15. Language .......................................................................................................................................... 33

4. Test Equipment ............................................................................................................. 34

5. Technical data ............................................................................................................... 35

6. Maintenance ................................................................................................................... 37

6.1. General ............................................................................................................................................. 37

6.2. Calibration and Verification ............................................................................................................... 37

6.2.1. Factory calibration ............................................................................................................................ 37

6.2.2. Guideline to determine the calibration period of EM Test instrumentation ...................................... 37

6.2.3. Calibration of Accessories made by passive components only: ...................................................... 37

6.2.4. Periodically In-house verification ...................................................................................................... 37

6.3. Calibration ......................................................................................................................................... 38

6.4. Verification ........................................................................................................................................ 38

7. Delivery Groups ............................................................................................................. 38

7.1. Basic equipment ............................................................................................................................... 38

7.2. Accessories and options ................................................................................................................... 38

7.2.1. Extension Board ............................................................................................................................... 38

7.3. Useful Accessories ........................................................................................................................... 39

7.3.1. Hi-Speed USB 2.0 Fast Ethernet Adapter installation ...................................................................... 39

8. Annex ............................................................................................................................. 40

8.1. Update a new Firmware ................................................................................................................... 40

8.2. Basic Waves ..................................................................................................................................... 42

8.3. Declaration of CE-Conformity ........................................................................................................... 44

8.4. AutoWave - General Diagram .......................................................................................................... 45

Manual for Operation V 5.9.1 4 / 45

EM TEST AutoWave

1.

1.1.

Module

includes

WaveGenerator

- On-Board Supply Simulator with Dual Channel outputs for dc

source control.

- WaveControl software to generate wave shapes based on

segments, point to point matrix.

- Controller with internal hard disk.

Modules

Extension Board

Extension board with

- 2 additional output channels ( Play )

- 2 measuring input channels ( Record )

- Functions to measure, record & play data of on-board supply

systems.

WaveRecorder

Software Module to support, record and replay functions.

Up and download support, waveform editing and report generator

function

The WaveRecorder requires the position Extension Board

Model Overview

AutoWave Model and extension modules

Basic model

Extensions

Manual for Operation V 5.9.1 5 / 45

EM TEST AutoWave

2.

2.1.

1 LED Power

2 LED Running

3 LED Trigger

4 Mode

5 Start

6 Stop

7 Cursor "" ""

8 Setup

9 LED display output channels 1...4

10 LED display input channels 1...2

11 Input channel 1 & 2 ( option )

12 Display

The LED power indicates the power on status.

The LED Running indicates the running play- or

measuring status

The LED Trigger indicates

- Manual, external or remote trigger event

- Start of a sequence

Pressing this button will cyclicly rotate between the main

menus.

- Wave Generator

- Wave Recorder

- Wave Manager

Start and Stop button for measurement and running

arbitrary waves.

START : “Start” or “Continue” a measurement or a

running Arbwave.

STOP : Stops a measurement or a running

Arbwave

2nd STOP : Exit the record or play function

Put in service Functions

Front view

1. LED power

2. LED Running

3. LED Trigger

4. Mode

5. Start / Stop

Manual for Operation V 5.9.1 6 / 45

EM TEST AutoWave

Cursor Key with the following functions

- Scrolling in the menus

- Setting the values up / down

Menu button for the device configuration menu.

See Chapter

3.2.2. Setup

Menu

LED display for indicating the active output channels.

Depends of extension 2 or 4 channels are built in.

Example:

CH 1 : Default channel for the battery power supply.

CH 2 : Auxiliary DC power for dips

CH 3 : Auxiliary channel for Ford specs.

CH 4 : Auxiliary channel for Ford specs.

The LED indicates the state of the measuring channel

CH1 and CH2.

LED Status

OFF : Standby

ON : Recording

Input plugs for the two measuring channels CH1 and

CH2

Maximum input voltage is 200V peak - peak

LCD display 2 x 40 characters

6. Cursor key "" ""

7. Setup

8. LED output active channel CH1 to CH4

9. LED display input channel 1 + 2

10. Measuring input channel 1 + 2

11. Display

Manual for Operation V 5.9.1 7 / 45

EM TEST AutoWave

2.2.

1 Output channel 1...4

2 Framebus IN / OUT

3 CAN port

4 Ethernet port

5 USB port

6 GPIB / IEEE 488 port

7 Fuse F1 DC 3.15A

8 Fuse F2 AC 1A

9 Mains 90V – 250V

10 Trigger IN1 / IN2

11 Trigger OUT1 / OUT2

12 DUT monitor

13 DC supply 12 – 32V

14 Power on switch

BNC output plug to controll external DC sources.

Example:

CH 1 : Default channel for the battery power supply.

CH 2 : Auxiliary DC power for dips

CH 3 : Auxiliary channel for Ford specs.

CH 4 : Auxiliary channel for Ford specs.

Output range:10V

Impedance 50Ω

Daisy Chain bus with Sub D 15 poles male and

female connectors.

This port is used as communication and control bus

between EM Test devices.

Rear view

1. Output Channel 1...4

2. Framebus IN / OUT

Manual for Operation V 5.9.1 8 / 45

EM TEST AutoWave

CAN port 9 pole Sub D female connector

The Philips PCA82C251 CAN transceiver for 24V

system serves as the interface between the CAN

protocol controller and the physical bus. It is primarily

intended for applications (up to 1 Mbaud)

The CAN- BUS is function is inactive

Pin assignment

1: nc

2: CAN_L

3: CAN GND

4: nc

5: CAN SHLD

6: CAN GND B

7: CAN_H

8: nc

9: +VCAN

The network controller supports a 10 / 100BaseTinterface. The device auto-negotiates the use of a

10Mbit/sec or 100Mbit/sec connection.

Pin assignment

1: TXD+

2: TXD

3: RXD+

4: RXD-

USB memory port for data transfer to or from a

memory stick.

The power contacts for USB devices are not protected. They are

suitable to supply connected USB devices with a maximum of

500mA power dissipation. Don’t supply external USB devices

with a higher power dissipation through this interface.

Pin assignment

1: GND

2: +DATA

3: -DATA

4: VCC

Parallel interface GPIB / IEEE 488, IEEE 488

interface with IEEE connector.

Fuse F1 for DC power supply

Fuse type : 3.15 slow blow

Dimension : 5 x 20mm

Fuse F1 for AC power supply

Fuse type : 1A slow blow

Dimension : 5 x 20mm

3. CAN port

4. Ethernet port

5. USB port

6. GPIB / IEEE 488 port

7. Fuse F1

8. Fuse F2

Manual for Operation V 5.9.1 9 / 45

EM TEST AutoWave

The plug is part of the mains filter. ( 90 - 250V / 1A )

Start Stop

Trigger input for event triggering. This trigger inputs

are connected directly to the DSP signal processor.

Input Signal : Negative slope

Input Function Remarks

Trigger IN 1 : Wave start

Trigger IN 2 : Wave stop ( Vers. >1.30)

Proposal design of external circuit for using positive

edge trigger signal.

External trigger circuit Trigger Input

9. Mains input

10. Trigger IN

Manual for Operation V 5.9.1 10 / 45

EM TEST AutoWave

Trigger outputs for event triggering. This

trigger outputs are generated from the DSP

signal processor.

Max. voltage: 24V ( pull up )

Current : 100mA

NOTE : For use the trigger out the user has

to connect an external DC source

for pull up the trigger signal

Trigger OUT at Start

Trigger OUT at Stop

Trigger OUT at Event

Trigger OUT at Break

Trigger OUT at each Iteration

11. Trigger OUT

Manual for Operation V 5.9.1 11 / 45

EM TEST AutoWave

DUT monitor for any fail detection.

DUT Monitor 1:

DUT Monitor 2:

Function:

Input signal: Negative slope.

NOTE : The signal must be released to high before

you start the next wave. The test will start

and does not stop if the monitor signal is at

low level during the wave start

Settings

The DUT monitor is settable in the AutoWave

software and has the following function

Disabled no function

Stop stops immediately the wave

Notify send a message to DUT Log file

NOTE : The output voltage after a stop event

depends on the setting of the end voltage

parameter:

YES V= Set end voltage

NO V keeps at the actual voltage

Plugs for dc power supply like a car battery. The

output is protected against reverse battery

polarization.

DC input voltage range : 12V – 32V dc

Power ON switch for AutoWave. The system needs

approx. 35 seconds for booting.

12. DUT monitor

13. DC input

14. Power on switch

Manual for Operation V 5.9.1 12 / 45

EM TEST AutoWave

2.3.

2.3.1.

2.3.2.

2.3.2.1.

1. Unlock the two knobs on the front side and pull out the drawer

2. Mount the AutoWave into the four bolts. This fixation will allow the user

to uncase the equipment in a short time for external use.

3. Connect the cables to the AutoWave

Output CH1 to CH4 BNC

Mains 115...230V

Interface IEEE / GPIB

Ethernet if available

Trigger IN / OUT BNC ( if available )

DUT Monitor BNC ( if available )

4. Final work

- check the proper cabling

- insert the drawer

- fix the two knobs

Put in service

Unpacking

Please check if the packing is not damaged. If there is an external damage, make inform your representative.

Installation in a System

The AutoWave is used to control one or more DC sources and / or for measuring and recording of the transient

behavior of a voltage during a sequence.

Installation or mount in a 19” Rack

Manual for Operation V 5.9.1 13 / 45

EM TEST AutoWave

2.3.3.

Connection to

A : Rack with ISO equipment ( IEEE )

B : Stand alone equipment ( Ethernet )

iso.control software uses the IEEE interface. Ethernet is not supported by iso.control

When setting up the test national and international regulations

regarding human safety have to be guaranteed.

It is recommended to connect the simulator to the ground reference

plane of the test set-up.

The generators of the series 200, UCS, LD, PFS and VDS can be

linked together to a fully automotive test set-up.

The set-up communicates via the IEEE/GPIB bus and is controlled by

ISM ISO software.

For setting up the system see the following figures:

Each generator can be operated individually as a single equipment.

Hardware wiring

There are two solutions to connect the computer to the AutoWave.

- IEEE connection

- Ethernet connection

Both interface connections are applicable. Depends of the implementation EM Test propose the

IEEE or Ethernet interface.

iso.control software uses the IEEE interface. Ethernet interface is not supported by iso.control.

Manual for Operation V 5.9.1 14 / 45

EM TEST AutoWave

2.3.3.1.

Setup example with:

AutoWave

UCS 200

VDS 200N

LD200

Devices Wiring

Wiring

Manual for Operation V 5.9.1 15 / 45

EM TEST AutoWave

Setup example with:

AutoWave

UCS 200

VDS 200N

LD200

PFS 200

RDS 200

Note : Do never connect The PFS200 output 0-10V in parallel with any AutoWave output. In this

case the controlled DC source will deliver a wrong output signal. It is not allowed to

connect two output sources in parallel.

Devices Wiring

Supply connections from VDS200 to UCS200 and PFS200 can be wired inside the rack.

Manual for Operation V 5.9.1 16 / 45

EM TEST AutoWave

Setup 3:

example with:

Rack 1

RDS 200

RDS 200

RDS 200

AutoWave

PFS 200N

VDS 200N

Rack 2

LD 200N

UCS 200N

This configuration is suitable for testing Ford AC CI-230 tests with four waves at the

same time. The figure shows the output for:

- General tests at UCS output

- Dips and Drops at PFS 200

- Ford AC CI-230 at RDS and VDS outputs

Note : The default connection between the two racks is

Test Supply Out VDS – Test Supply IN PFS.

Dips and Drops are available on UCS 200 output, when the connection

Test Supply out PFS is used. The disadvantage is the additional voltage drop

inside the UCS 200.

Supply connections from VDS200Nx to PFS200N can be wired inside the rack.

Automotive rack for with 4 DC output for Ford AC CI-230 test

Manual for Operation V 5.9.1 17 / 45

EM TEST AutoWave

Setup 4:

example with:

Rack

MPG 200

LD 200

PFS200

VDS 200N

EFT 200

CNA 200

AutoWave for replace

ARB 2714

Manual for Operation V 5.9.1 18 / 45

EM TEST AutoWave

2.3.3.2.

Setup 5:

example with:

Rack

LD 200N

AMP 200N

AutoWave

UCS 200N

VDS 200N

Wiring examples with AMP 200

Manual for Operation V 5.9.1 19 / 45

EM TEST AutoWave

Setup 7:

example with:

Rack 1

RDS 200

RDS 200

RDS 200

AMP 200N

AutoWave

PFS 200N

VDS 200N

Rack 2

LD 200N

UCS 200N

Setup 8:

example with:

Rack 1

RDS 200

RDS 200

AMP 200N

AutoWave

PFS 200N

VDS 200N

Rack 2

LD 200N

UCS 200N

Manual for Operation V 5.9.1 20 / 45

EM TEST AutoWave

2.3.3.3.

Setup 11:

example with:

Rack

AutoWave

PFM 200N100

VDS 200N

Setup with PFM 200N100

Manual for Operation V 5.9.1 21 / 45

EM TEST AutoWave

2.3.3.4.

Setup 12:

example with:

Rack

AutoWave

PFM 200N100

VDS 200Q 25, Q 50

External : AMP 200

Setup with AutoWave and VDS 200Q and PFM 200N100

Manual for Operation V 5.9.1 22 / 45

EM TEST AutoWave

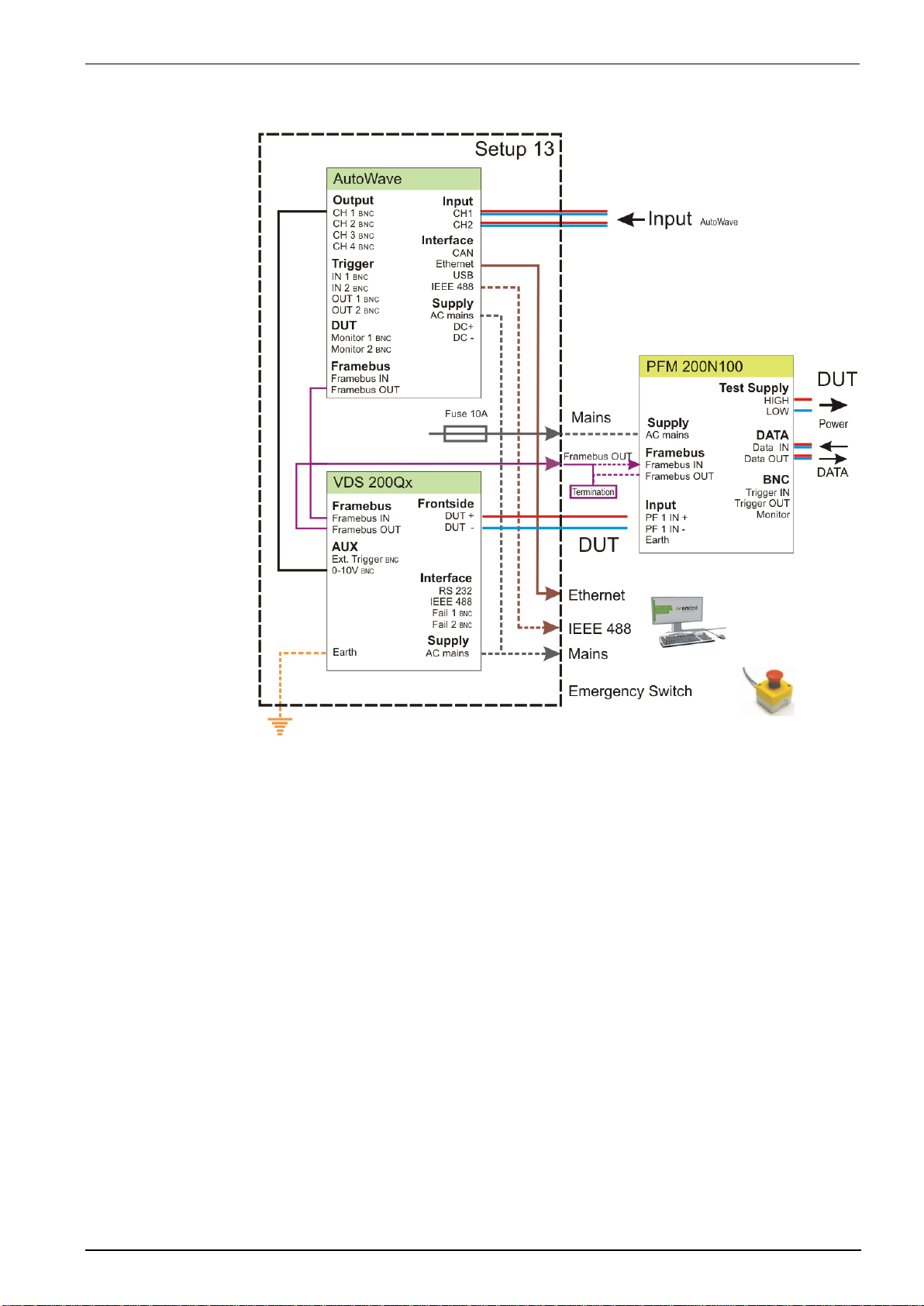

2.3.3.5.

Setup 13:

example with:

Rack

AutoWave

VDS 200Q100

External :

PFM 200N100

Setup with AutoWave and VDS 200Q and PFM 200N100

Manual for Operation V 5.9.1 23 / 45

EM TEST AutoWave

3.

3.1.

After switching on, AutoWave needs approx. 35s for booting. During this

time the display is blank. AutoWave is ready when the display shows

AutoWave and the current version.

The AutoWave is operated by an easy menu control system. Five

function keys are available to select parameters and functions.

3.2.

MODE button : Navigate through the menu WaveGenerator, WaveRecorder and Wave

Manager.

SETUP button : Configuration of the device settings

STOP button : Return to welcome screen ( Startup)

3.2.1.

1st line : Menu or submenu title

2nd line : Actual Menu Function

Operation

Power on

Menu structure

There are two buttons to navigate through the menus.

Mode Menu

Figure 4.1 shows the handling of the Mode menu which rotates cyclic by pressing the Mode button.

WaveGenerator

Easy waveform generation of all automotive standards.

Generation of all kind of voltage profiles via software.

Replay of waveforms from imported data or plot files.

Check of the DUT under real world conditions.

WaveRecorder

Recording the voltage variation in the lab setup.

Replay of the measured data via an adequate dc source or amplifier.

Check of the DUT under real world conditions.

Wave Manager

File exchange to/ from a memory stick for data transfer to an external computer.

Deleteing of waveforms

Figure 4.1 Mode Menu

Manual for Operation V 5.9.1 24 / 45

EM TEST AutoWave

3.2.1.1.

The output active LED indicates the output channel(s) of the selected

file.

Note : Files with multiple waves indicates all used output channels. The

software AutoWave delivers the detailed information about the

wave on each channel.

Select a file

1. Select with the buttons the desired file.

2. Press buttons to play and stop the file.

Start, Break and Continue

Functions

- Selecting files

- Play files

status blinking : Running

off : Ready to start

A selected wave will be repeated according to the selected number of “Events”. The time counter begins after

each restart at zero.

Key functions

Menu Wave Generator

Manual for Operation V 5.9.1 25 / 45

EM TEST AutoWave

Start, Break and Restart same file

Start, Stop and

return to WaveGenerator menu

Manual for Operation V 5.9.1 26 / 45

EM TEST AutoWave

3.2.1.2.

Channel selection

Recording

Functions

Recording the voltage variation in the lab setup.

Replay of the measured data via an adequate dc source or amplifier.

Check of the DUT under real world conditions.

Menu Wave Recorder

Manual for Operation V 5.9.1 27 / 45

EM TEST AutoWave

3.2.1.3.

Function selection

Select a file and

- Delete

- Copy

- Load

Functions

- Copy file to USB Memory stick

- Load file from USB Memory stick

- Delete file

Menu Wave Manager

Manual for Operation V 5.9.1 28 / 45

EM TEST AutoWave

3.2.2.

Setup Menu

In the setup menu all settings of the AutoWave can be done manually. The following figures show the

configuration of the different parameters.

How to navigate in the Setup menu

Figure 4.2 shows the handling of the Setup menu. The small buttons inside the circle shows how to step through

the menu or parameter list. The setup menu “Sample Frequency and Input Range“ occurs only when the option

record is built in.

Figure 4.2 Setup Menu

Manual for Operation V 5.9.1 29 / 45

EM TEST AutoWave

3.2.3.

Channel Selected output channel for setting the parameters

Source Source design for polarity output

Input U Max. input signal to control the power supply from

AutoWave ( individual each channel)

Output U Max. output signal of the power source to the DUT

Vset Manually setting DC output voltage of each channel.

(Vset ≤ Output)

Channel CH1, CH2, CH3, CH4

Source Unipolar , Bipolar

Input U Voltage range [ 0V ... 10.00V ] step 0.01

Output U Voltage range [ 0V...999.99V ] step 0.01

Examples for VDS

Unipolar

10.00V

30.00V or 60.00V

Toggle between the two edit modes with the button MODE

DC Source

Parameter to control the connected voltage source. This setting must be done for each channel CH1...CH4 with

a connected voltage source. AutoWave calculates automatically the correct output signal for controlling the

source.

Mode of value setting

The user has a choice of two modes to edit values for voltage and frequency parameters.

The “normal” mode is the usual one, and is done in two steps:

- first step to setup the integer part

- second step to setup the fractional part.

The “all step editor” mode selects each digit from left to right and the value is parsed sequentially.

“Normal” Mode

30.00VSETUP30.00V SETUPnext value to setup

Available keys:

STOP: Ends the editing, discarding any changes

LEFT: Decrease the value with acceleration

RIGHT: Increase the value with acceleration

SETUP: Move from integer part to fractional part and then validate the setting

MODE: Change editing mode to “All Step Edition”

Note: In this mode, when you are setting the integer part, the fractional is set to zero.

“All Step Editor” Mode

30.00VSETUP30.00V SETUP 30.00VSETUP30.00VSETUPnext value to setup

Available keys:

STOP: Ends the editing, discarding any changes

LEFT: Decrease the value with acceleration

RIGHT: Increase the value with acceleration

SETUP: Move the edited digit step by step from the left to right position / validate the setting

MODE: Change editing mode to “Normal”

Note: in this mode, any acceleration on LEFT or RIGHT key is disabled.

Manual for Operation V 5.9.1 30 / 45

EM TEST AutoWave

3.2.4.

Sampling frequency

Default 5kS/s

Sampling Frequency [kHz] depends on the number of channels

Single channel Dual channel

CH1 or CH2 CH1 and CH2

500kHz - 250kHz - 100kHz 100kHz

50kHz 50kHz

25kHz 25kHz

10kHz 10kHz

5kHz 5kHz

2.5kHz 2.5kHz

1kHz 1kHz

500Hz 500Hz

250Hz 250Hz

100Hz 100Hz

50Hz 50Hz

25Hz 25Hz

10Hz 10Hz

5Hz 5Hz

3.2.5.

Input Range bipolar input. Each channel can be set individually.

Channels : CH 1, CH2

Default : 100V

Ranges for both channels

5V

10V

20V

50V

100V

3.2.6.

Enable: Function of Trigger IN is enabled.

- Trigger IN 1, IN 2

Default : Enabled

Disable: Function of Trigger IN is disabled.

- Trigger IN 1, IN 2

Sample frequency (only with the option record)

Sample frequency for data recording. The max. sampling frequency is limited by the number of used measuring

channels.

Input Range (only with the option record)

Setting the measuring input range of the two input channels

Trigger

Setting of the trigger status

Manual for Operation V 5.9.1 31 / 45

EM TEST AutoWave

3.2.7.

The DUT Monitor 1 and DUT Monitor 2 control the behavior during a

test or record. The following settings are offered for the two DUT monitor

inputs

Default : Disabled

Settings DUT Monitor ( open collector input)

- Disable: Input has no function

- Notify: Message will be written on a file

- Stop: Wave stops and continue according the user decision

3.2.8.

Standard : IEEE 488

Address : 1...30

Default : 18 Default address for iso.control software

3.2.9.

Selectable range : 0.0.0.0 to 255.255.255.255

Default Address : 10.0.0.2

3.2.10.

Selectable range : 0.0.0.0 to 255.255.255.255

Default Netmask : 255.0.0.0

3.2.11.

Selectable range : 0.0.0.0 to 255.255.255.255

Default Gateway : 10.0.0.1

DUT Monitor

Open collector input for event control during a test or record.

GPIB Address

GPIB Address for using the AutoWave with the software iso.control

Ethernet IP- Address

Set Ethernet IP Address of the target AutoWave

Set Ethernet Netmask of the target AutoWave

Ethernet Netmask

Set Ethernet Gateway of the target AutoWave

Manual for Operation V 5.9.1 32 / 45

Ethernet Gateway

EM TEST AutoWave

3.2.12.

Day : 1...31

Month : 1...12

Year : 2000...2200

Note: When pressing Setup to exit the Date setup, the display returns after

few seconds delay to the Configuration display

3.2.13.

Format : HH.MM:SS ( H : Hour M : Minute S :Second )

Mode : 24 hours / day

Note: When pressing Setup to exit the Time setup, the display returns

after few seconds delay to the Configuration display

3.2.14.

3.2.15.

English : Default setting

German : Change to German language

The time is used for mark the stored files.

Date

Time

The LCD Contrast is selectable between the value 70 to 100.

Selection of the desired language.

LCD Contrast

Language

Manual for Operation V 5.9.1 33 / 45

EM TEST AutoWave

4.

Test Equipment

PC 104 Computer

The computer is a PC 104 board with AMD SC520 processor and 32 MB SDRAM

DSP Board

The DSP board is based on the DSP 56303 100 MHz from Motorola which includes two output channels with a

resolution of 16 bits / 500kHz

Extension Board

The extension board is a mezzanine card that includes:

- 2 input channels 16 bits / 500kHz

- 2 output channels 16 bits / 500kHz

Power supply

The AutoWave can be operated on two different power supply system.

- AC mains power

- DC supply from car battery

AC input

The AC mains power input is a wide range AC input that allows to operate the AutoWave in every country of the

world. With the voltage input range from 90V ... 250V and 47Hz ... 63Hz it is not necessary to use an adapter

transformer.

DC Input

The DC input is used for mobile operation in a car. The input is designed for 12V and 24V systems

Internal Battery (optional)

An internal battery pack is used for buffer voltage dips. In case of dropouts below approx. 3V, the device will

switch off and reboot when the DC voltage is higher than 10V. The Autowave does not operate with the

internal buffer battery.

Manual for Operation V 5.9.1 34 / 45

EM TEST AutoWave

5.

AutoWave

Number of output channels

2 channels;

2 additional channels can be added as an option (ExtBoard)

Output voltage

10V, unipolar or bipolar

Resolution

16 Bit

Frequency range

DC ... 50kHz ( 10samples per sinus period at 500kSample/sec )

Output Range

10V

Output Type

Single Ended

Resolution

16 bit

Differential linearity error

8 LSB (DAC)

Integral linearity error

4 LSB (DAC)

Accuracy

(0.5% + 5mV)

Maximum Sampling Rate

500kS/s (Accuracy: 50ppm) for one channel

Transition Time

< 5s Tested with 1kHz Square wave (20Vpp / without Offset).

Output Impedance

50

Max Output Current

10mA Output short circuit protected.

Wave Forms

Segment types

DC voltage

Sine

Sine sweep ( log, linear )

Damp Sine

Sine Ramp

Square wave

Profile

Triangular

Sawtooth

Ramp up / Ramp down

Step

Exponential

Calculated based on mathematical formula

Segment duration

Unlimited

Segments per wave form

20-30 depends on the complexity of the segment

WaveRecorder

Number of input channels

2 channels (ExtBoard for AutoWave required)

Input voltage ranges

5V, 10V, 20V, 50V and 100V;

unipolar or bipolar

Resolution

16 Bit

Accuracy

better than 0.2%

Frequency range

DC ... 50kHz

Sampling rate (selectable)

5S/s...500kS/s (one channel)

5S/s...100kS/s (two or four channels)

Storage

File size max. 1 GByte

Technical data

Manual for Operation V 5.9.1 35 / 45

EM TEST AutoWave

Display and Controls

Display

Text LCD 2 lines, 40 characters

LED indicators

Power On

Active channel 6 (2 inputs, 4 outputs)

Trigger

Running status

Operation

6 function keys

Trigger and DUT Monitoring

Trigger

2 inputs, 2 outputs

DUT monitoring

2 inputs, configurable

Control

Computer

PC 104 computer

AMD Microprocessor 100MHz

32MB RAM

Operating system

Linux, with Real time extension

DSP Signal processor

Motorola DSP 56303

Data storage

Hard disk 40GB ( standard )

Interfaces

GPIB Address 1...30

Ethernet

USB (for memory stick and ext. hard disc) I max. 500mA

CAN bus (for trigger)

Frame bus (internal system bus)

Storage battery

Lithium battery

Type: CR2032 3V, 235mAh 20.0 x 3.2 mm

Buffer battery ( option )

Rechargeable battery 12V, 2000mAh NiMH

Environmental Hard disk

Temperature

operating

5...40°C

storage

-20...60°C

gradient

20°C / hour

Humidity

10%...90% non-condensing

Vibration

Operating

1.0G

Non Operating

5.0G

Shock

Operating

225G ( 2ms)

Non Operating

900G ( 1ms)

General Data

Safety design

per IEC 1010, EN 61010

Power supply

AC: 90V ... 250V , 47Hz...63Hz

DC: 12V ... 32V, filtered and buffered

Fuses

F1 : 3.15 A slow blow ( DC )

F2 : 1.00 A slow blow ( AC )

Power requirement

40W max.

Dimension (W x H x D)

380 x100 x 390 mm

Weight

6kg

= => not relevant data for the standards can be changed by the manufacturer <= =

Manual for Operation V 5.9.1 36 / 45

EM TEST AutoWave

6.

6.1.

6.2.

6.2.1.

The EM Test equipment are calibrated in the factory and marked with a calibration

mark. The used measuring instruments are traceable to the Swiss Federal Office of

Metrology.

The calibration date is marked. The validity of the calibration is to the responsibility

of the user’s quality system. Neither the certificate of calibration nor the

corresponding label mark any due date for re-calibration.

Example: Calibration mark

6.2.2.

6.2.3.

6.2.4.

Maintenance

General

The AutoWave is absolutely maintenance-free.

Replacement of storage battery

Lithium battery : after approx. 10 years (indicates by memory lost of setting)

Internal battery pack (option) : NiMH type (Replace after .3..6 years necessary)

Calibration and Verification

Factory calibration

Every EM TEST generator is entirely checked and calibrated as per international standard regulations before

delivery. A calibration certificate is issued and delivered along with a list of the equipment used for the

calibration proving the traceability of the measuring equipment. All auxiliary equipment and accessories are

checked to our internal manufacturer guidelines.

The calibration certificate and the certificate of compliance (if available) show the date of calibration.

Guideline to determine the calibration period of EM Test instrumentation

Our International Service Departments and our QA Manager are frequently asked about the calibration interval

of EM TEST equipment.

EM TEST doesn’t know each customer’s Quality Assurance Policy nor do we know how often the equipment is

used and what kind of tests are performed during the life cycle of a test equipment. Only the customer knows all

the details and therefore the customer needs to specify the calibration interval for his test equipment.

In reply to all these questions we like to approach this issue as follows :

EM TEST make use of a solid state semiconductor switch technique to generate high voltage transients. A

precious advantage of this technique is the absolute lack of periodical maintenance effort. In consequence

thereof a useful calibration period has to be defined based on two criteria :

- The first one is the customer’s Quality Assurance Policy. Any existent internal regulation has to be applied at

highest priority. In the absence of such internal regulation the utilization rate of the test equipment has to be

taken into consideration.

- Based on the experience and observation collected over the years EM TEST recommend a calibration

interval of 1 year for frequently used equipment. A 2-years calibration interval is considered sufficient for

rarely used test generators in order to assure proper performance and compliance to the standard

specifications.

Calibration of Accessories made by passive components only:

Passive components do not change their technical specification during storage. Consequently the measured

values and the plots stay valid throughout the storage time. The date of shipment shall be considered as the

date of calibration.

Periodically In-house verification

Please refer to the corresponding standard before carrying out a calibration or verification. The standard

describes the procedure, the tolerances and the necessary auxiliary means. Suitable calibration adapters are

needed. To compare the verification results, EM Test suggests to refer to the waveshape and values of the

original calibration certificate.

Manual for Operation V 5.9.1 37 / 45

EM TEST AutoWave

6.3.

6.4.

7.

7.1.

7.2.

7.2.1.

Extension Board

- 2 output channels 16 Bit CH3 , CH 4 10V

- 2 input channels 16 Bit 100V

Calibration

For periodical calibration the AutoWave has to return back to the manufacturer

Verification

A verification can be done with the following procedure:

Output channel

Setting a defined voltage to the output channel and verification with a DMM ( 5½ digit )

Measuring: 0.00V

5.00V

10.00V

Delivery Groups

Basic equipment

Arbitrary generator type AutoWave

Mains cable

Calibration certificate

Manual on USB memory stick

Safety manual

Accessories and options

Extension Board

Manual for Operation V 5.9.1 38 / 45

EM TEST AutoWave

7.3.

7.3.1.

Product Features:

• True 10/100Mbps Network Connectivity

• Auto 10/100Mbps Speed Detection

• Backwards Compatible with USB 1.1

Useful Accessories

The Accessories in this paragraph are not part of the EM Test delivery list. EM Test suggest to buy this

devices from a local dealer.

Hi-Speed USB 2.0 Fast Ethernet Adapter installation

For user where no Ethernet connector is available, EM Test suggest to buy an USB - Ethernet adapter on the

IT-market. This USB – Ethernet adapter is not part of the EM Test delivery.

EM Test proposes and tested the following device:

D-Link : DUB-E100

For communication with the AutoWave via Ethernet a Hi-Speed USB 2.0 Fast Ethernet Adapter type DUB-E100

is available. This connection is used if the AutoWave is not installed in a rack with other EM Test equipment.

Product Description:

The D-Link DUB-E100 is a Hi-Speed USB 2.0 10/100Mbps Fast Ethernet Adapter specifically designed to plug

into an available Universal Serial Bus (USB) port on a desktop or laptop PC under Microsoft Windows XP, Me,

2000 or 98SE. Based on USB 2.0, the DUB-E100 extends the transfer speed of earlier USB Fast Ethernet

adapters to true 10/100Mbps connectivity.

As a USB device, the D-Link DUB-E100 eliminates the need to use an ISA, PCI, or PC Card slot to add LAN

connectivity to a PC desktop or laptop computer. Installation and use are further simplified by living the USB's

out-of-the-box installation approach to connecting computer peripherals. You will not need to open the case of

your computer, nor will you be required to set IRQ's. The D-Link DUB-E100 represents the simplest way to

connect your computer to an Ethernet based network.

The D-Link DUB-E100 provides a standard RJ-45 connector for a quick and simple method of connecting to an

Ethernet 10Mbps or Fast Ethernet 100Mbps based LAN via a network hub or switch. The built-in USB 2.0 cable

connects directly to your computer or laptop.

Power for the DUB-E100 is provided directly by the USB bus, eliminating the need for an external power

adapter. It also supports USB's energy saving suspension and resumes functions to minimize power

consumption, which is specifically useful for laptop/notebook users.

Manual for Operation V 5.9.1 39 / 45

EM TEST AutoWave

8.

8.1.

A : After the installation or update of the

AutoWaveControl software.

A message box may automatically appear if

AutoWaveControl software detects an older

firmware on the AutoWave.

1. Press the OK button to enter the Device

update window.

B : When the user has different firmware

versions to operate with the AutoWave.

1. Press the Update button in the device

setup for enter the Device update window.

Actual Firmware Version field :

Firmware version being installed in the

AutoWave.

Select the Firmware field :

Firmware versions in the computer for

download into the AutoWave.

2. Press the Download button to download

the new firmware into the AutoWave.

Annex

Update a new Firmware

To update the Firmware start the program AutoWaveControl. A firmware update is recommended :

Manual for Operation V 5.9.1 40 / 45

EM TEST AutoWave

After “download the AutoWave display shows

AutoWave REMOTE

AuitoWave.tgz stored

The message “File Stored” confirms the

successful download of the new firmware to

AutoWave.

3. Press the Reboot button for Booting the

AutoWave.

During the booting process the AutoWave

will install the new firmware version

A bar graph shows the booting progress.

After a successful update the actual firmware

of the AutoWave is displayed in the field

“Actual Firmware Version”.

4. Press the OK button to return to the

Device Setup Window.

Manual for Operation V 5.9.1 41 / 45

EM TEST AutoWave

8.2.

Segment name

Picture

Description

DC

Constant DC voltage at V1 level during the selected

duration t1.

Ramp

Voltage ramp where the time t1 goes from 0% to 100% or

10% to 90%

Square

Square function with defined voltage parameters V1 and V2

offset and the square duration of V1 and V2.

Triangle

sawtooth

Step

Sine

Sine Sweep

Sine wave with frequency sweep over the duration t1. The

sine starts with the frequency f1 and ends with the

frequency f2. The frequency can sweep up or down with the

frequency.

Sine ramp

Switching

Damped sine

Description:

Damped sine with asymptote end voltage on Vp2 offset

level = V1-Vp1

Exponent

Description:

This function simulates a fall or rise of an exponential

impulse waveshape. It simulates a typical fall or rise of a

capacitive impulse waveshape.

Basic Waves

The AutoWave generates the waves like an arbitrary generator as PointWaves, where all samples are stored in

a file. As an advantage the AutoWave firmware generates the waves as segmented waves from a parameter

list. This has the advantage to save a lot of memory and to create waves who can not be realized by

PointWaves.

The following waves are programmed inside the AutoWave:

Manual for Operation V 5.9.1 42 / 45

EM TEST AutoWave

Profile

Square Ramp

Manual for Operation V 5.9.1 43 / 45

EM TEST AutoWave

8.3.

Manufacturer :

EM TEST Switzerland GmbH

Address:

Sternenhofstr. 15

CH 4153 Reinach

Switzerland

Product‘s name:

AutoWave

EN 61010-1 : 2011

Safety requirements for electrical equipment for measurement, control, and

laboratory use.

EN 61326-1 : 2013

Electrical equipment for measurement, control and laboratory use Class A

EN 61000-3-2 : 2014

Limits for harmonic current emissions

EN 61000-3-3 : 2013

Limitation of voltage changes, voltage fluctuations and flicker in public lowvoltage supply systems.

European representative

Manufacturer

AMETEK CTS Germany GmbH

EM TEST (Switzerland) GmbH

Lünenerstr. 211

Sternenhofstr. 15

D 59174 Kamen

CH 4153 Reinach

Tel: +49 (0) 2307 / 26070-0

Tel: +41 61-7179191

Fax: +49 (0)2307 / 17050

Fax: +41 61-7179199

By

N. Holub

General manager

A. Burger

Design and Research

Place

Kamen, Germany

Reinach BL , Switzerland

Date

25. February 2016

25. February 2016

Declaration of CE-Conformity

declares, that under is sole responsibility, the product’s listed below, including all their options, are conformity with

the applicable CE directives listed below using the relevant section of the following EC standards and other

normative documents.

Low Voltage Directive 2014/35/EU

Standard to which conformity is declared:

EMC Directive 2014/30/EU

Standard(s) to which conformity is declared:

Manual for Operation V 5.9.1 44 / 45

EM TEST AutoWave

8.4.

AutoWave - General Diagram

Manual for Operation V 5.9.1 45 / 45

Loading...

Loading...