EMS Swiss LithoCast Trilogy FT-231, Swiss LithoCast Trilogy FT-232 Instructions For Use Manual

Page 1

INSTRUCTIONS FOR USE

Page 2

2

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

Page 3

3

Please Read this First!

Thank you for purchasing this new EMS product. It meets

the highest quality and safety standards.

We would be pleased to answer your questions and we

welcome your suggestions. We do, of course, provide

support in case of technical problems. Please contact

your EMS authorized service center or your dealer

directly.

We wish you lots of success!

EMS

About this Manual

Please note that the English version of this manual is the

source from which all translations are derived. In case of

any discrepancy , the binding version is the English text.

These operating instructions are to ensure the correct

installation and use of this product. Always keep these

instructions close at hand.

Please read these operating instructions carefully as

they explain important details and procedures. Please

pay special attention to the safety precautions.

To prevent injury to people and damage to property,

please follow the corresponding directives. They are

marked as indicated:

Caution:

Risk of patient or user injury . Risk of damage

to the product or environmental harm.

Note:

Useful additional information and hints.

Intended Use

The product is intended for the fragmentation and removal

of urinary tract calculi in the kidney , ureter, and bladder.

Operating mode

The product can deliver ultrasound and ballistic energies

through a single probe simultaneously, or separately

to fragment stones. The product can extract stone

fragments through the probe while delivering energy or

without delivering energy. The product is able to collect

the stone fragments for analysis.

Intended User

The product must be used by qualied operating room

personnel (with extensive training in urology) in hospitals,

clinics and medical universities to treat affected patients

of any age.

It is intended to be reprocessed by trained reprocessing

personnel, biomedical services, or by an external reprocessing contractor.

Contraindications and Patient Population

Use of the product is contraindicated in patients with any

of the following conditions:

• Active bleeding disorders,

• Solitary functioning kidney,

• Creatinine greater than or equal to 3 µg %,

• During pregnancy,

• Stricture and obstruction problems,

• An implanted electrical stimulator (e.g. pacemaker).

Potential Complications

Potential complications associated with fragmentation of

urinary tract calculi by ballistic and/or ultrasound energy

include:

• Perforation,

• Hemorrhage,

• Lesion,

• Stone migration,

• Pain/colic,

• Macroscopic hematuria,

• Infection,

• Ureteral obstruction.

Page 4

4

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

CONTENTS

1. SAFETY PRECAUTIONS 5

2. COMPONENTS 6

3. INSTALLATION 8

3.1. INSTALLING THE CONSOLE 8

3.2. FILLING THE COOLING SYSTEM 8

3.3. CONNECTING THE CONSOLE TO THE

EQUIPOTENTIAL CONDUCTOR 10

3.4. CONNECTING THE VIDEO CORD

(OPTIONAL) 10

3.5. INSTALLING THE PEDAL 11

3.6. INSTALLING THE STONE CATCHER 11

3.7. INSTALLING THE SINGLE-USE FLUID

MANAGEMENT SYSTEM SET (OPTIONAL)

AND REPLACEMENT POUCH 13

3.8. CONNECTING THE STERILIZED

HANDPIECE TO THE CONSOLE 13

3.9. INSTALLING A PROBE ON THE

HANDPIECE 14

3.10. CONNECTING THE POWER CORD 14

4. GETTING STARTED 15

4.1. STARTING THE DEVICE 15

4.2. ADJUSTING THE PARAMETERS 15

4.3. EQUIPMENT DATA 17

5. TREATMENT 18

5.1. FUNCTIONAL TESTS 18

5.2. PROBE INSERTION 19

5.3. TREATMENT SETTINGS 19

5.4. ADAPTING SUCTION FLOW RATE 21

5.5. STARTING TREATMENT 21

6. POST-TREATMENT PROCEDURE 22

6.1. COMPLETING TREATMENT 22

6.2. DISCONNECTING THE HANDPIECE 23

6.3. RECORDING TREATMENT DATA 24

6.4. DISCONNECTING THE STONE CATCHER 25

6.5. ELIMINATING THE STONE CATCHER

CONTENTS 25

6.6. CONSERVING THE STONE CATCHER

CONTENTS 25

6.7. DISPOSING OF SINGLE-USE

COMPONENTS 25

6.8. SWITCHING OFF THE CONSOLE 25

7. CLEANING, DISINFECTING,

AND STERILIZING 26

7.1. MULTIUSE COMPONENTS 26

7.2. CONSOLE, PEDAL, AND CART 28

8. PRODUCT MAINTENANCE 29

8.1. COOLING LIQUID CIRCUIT MAINTENANCE 29

8.2. REPLACING FUSES 30

8.3. DOWNLOADING LOGFILE 30

9. PRODUCT STORAGE AND SHIPPING 31

9.1. EMPTYING THE COOLING LIQUID CIRCUIT

31

9.2. SHIPPING THE PRODUCT 32

10. PRODUCT DISPOSAL 33

11. EMS TECHNICAL SUPPORT 33

12. TROUBLESHOOTING 34

12.1. MANUAL HANDPIECE UNLOCKING 34

12.2. WEAK SUCTION 34

12.3. PROBE NOT COMPATIBLE WITH THE

ENDOSCOPE 34

12.4. DISPLAYED ERROR MESSAGES 34

13. FORMER ELECTROMAGNETIC

COMPATIBILITY 37

14. NEW ELECTROMAGNETIC

COMPATIBILITY 40

15. TECHNICAL DATA 42

16. SYMBOLS 43

17. APPENDIX 46

17.1. PROBE COMPATIBILITY TABLE 46

17.2. FCC AND IC 46

Page 5

5

1. SAFETY PRECAUTIONS

EMS and the distributor of this product accept no liability for direct or consequential injury or damage resulting from

improper use, arising in particular through non-observance of the operating instructions, or improper preparation and

maintenance.

Instructions for use are explicitly given at installation by an EMS representative.

Before using this product, please carefully read,

understand, and follow the recommendations in the

instruction manual. Failure to observe the operating

instructions may result in the patient or user suffering

serious injury or the product being damaged. This

product may only be applied for its intended use

by qualified personnel and for the applications

described in this manual. If the product is used in

combination with other instruments, please refer to

their instruction manual.

Do not use this product in the presence of ammable

anesthetics or oxidizing gases (such as nitrous

oxide (N2O) and oxygen) or in close proximity

to volatile solvents (such as ether or alcohol), as

explosion may occur.

Before using the product, inspect for any damage.

Do not use if the product is damaged. Use original

EMS spare parts and accessories only.

Do not modify or repair the product yourself. Please

contact an EMS authorized service center.

To avoid risk of contamination, before each use,

always clean, disinfect and sterilize the product

according to the EMS reprocessing instructions.

To avoid injury or damage, make sure that the

fragmentation energy is supplied only upon contact

of the probe with the stone. Do not touch the probe

during activation.

When the mains power switch is in the “0” position,

the product is disconnected from the supply network.

Do not tilt or ip the console without rst having

purged the cooling system. Always empty the

cooling circuit before transport. Please refer to

Emptying the Cooling Liquid Circuit section.

Do not start treatment without ensuring that a

back-up probe is available.

Make sure that the handpiece, handpiece fluid

aspiration connector, and re-usable wrenches are

sterilized before proceeding with installation.

Any serious incident that has occurred in relation to

the product should be reported to the manufacturer

and the competent authority.

Page 6

6

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

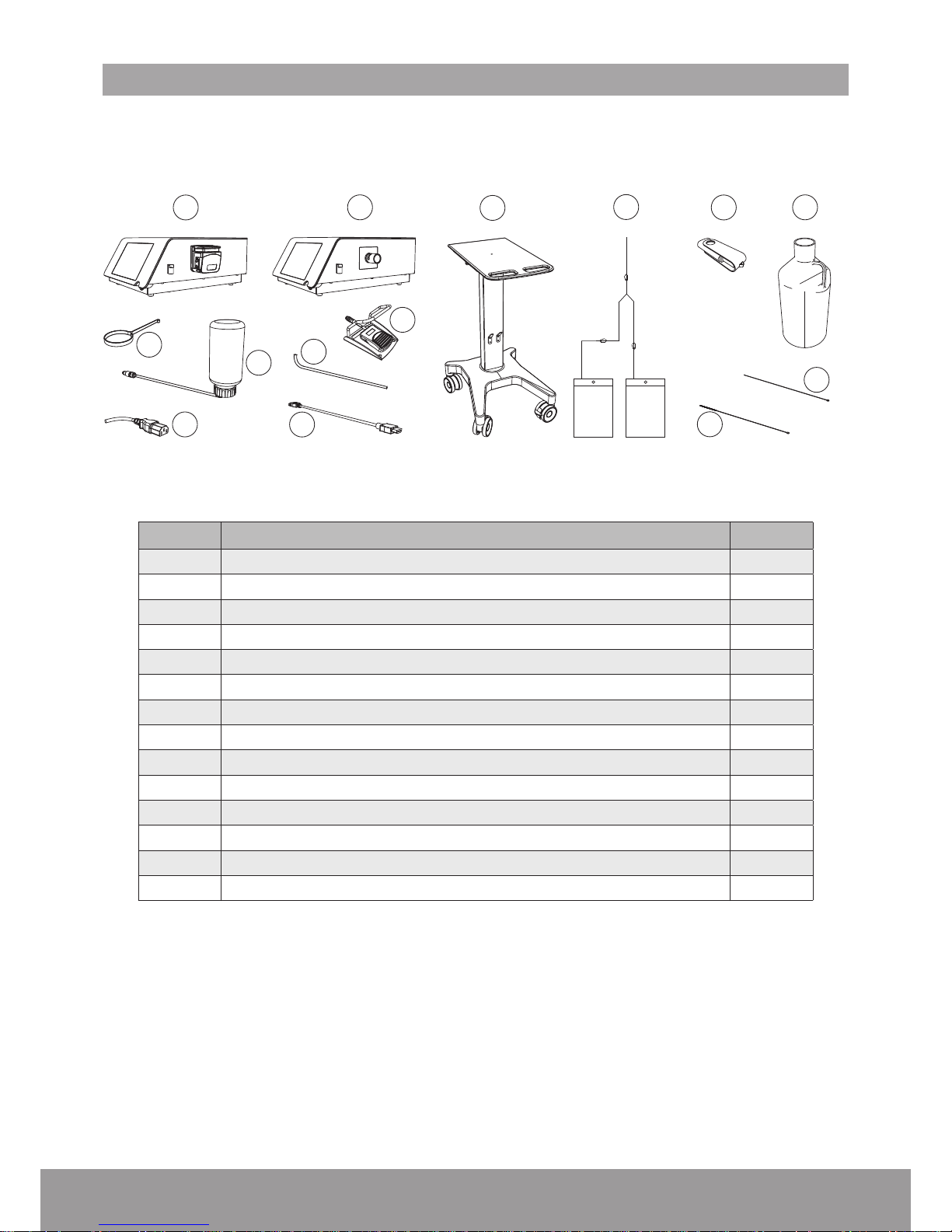

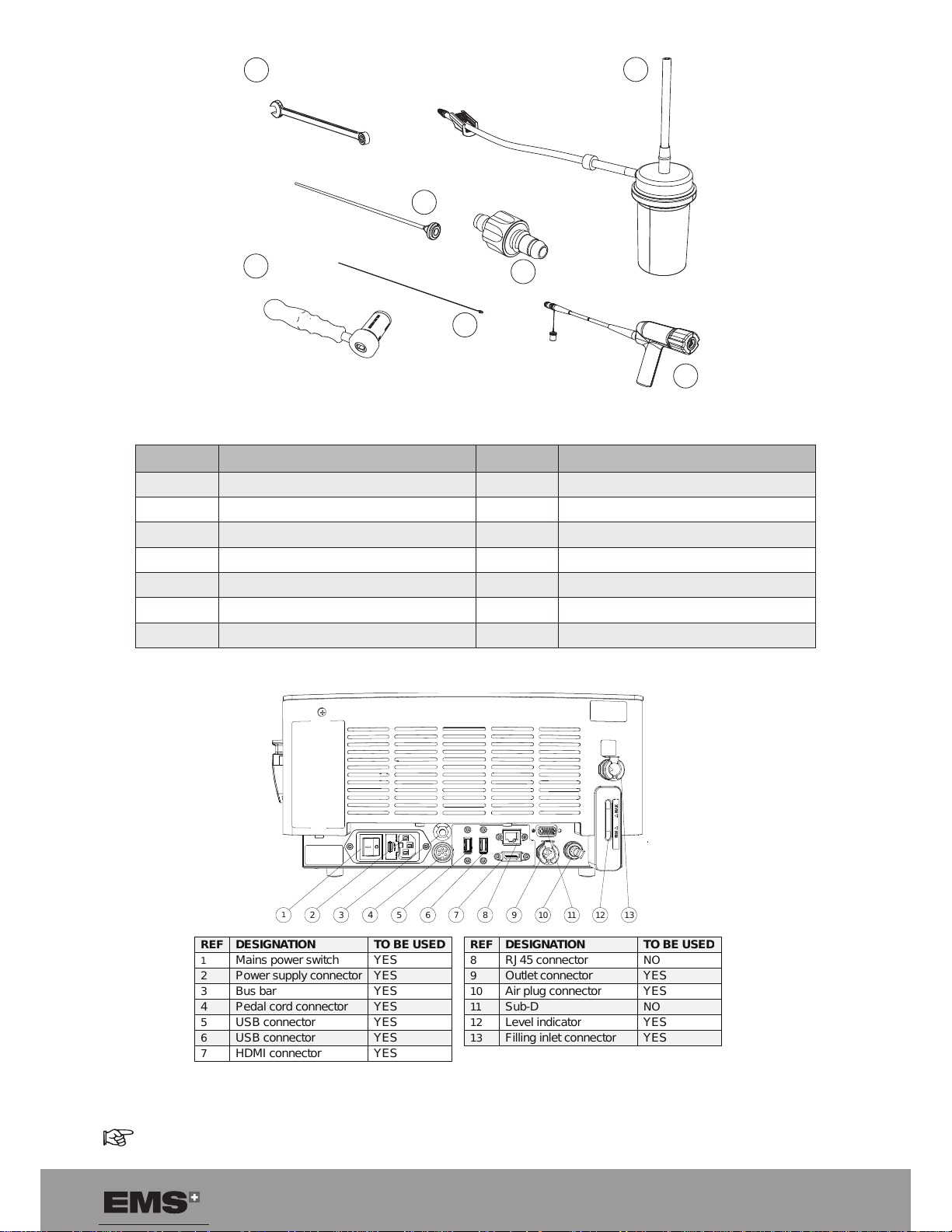

2. COMPONENTS

The components provided for your device will vary, according to your conguration.

1

2

3

4

5

8

9

7

6

10

11

12

14

13

NON STERILE ZONE

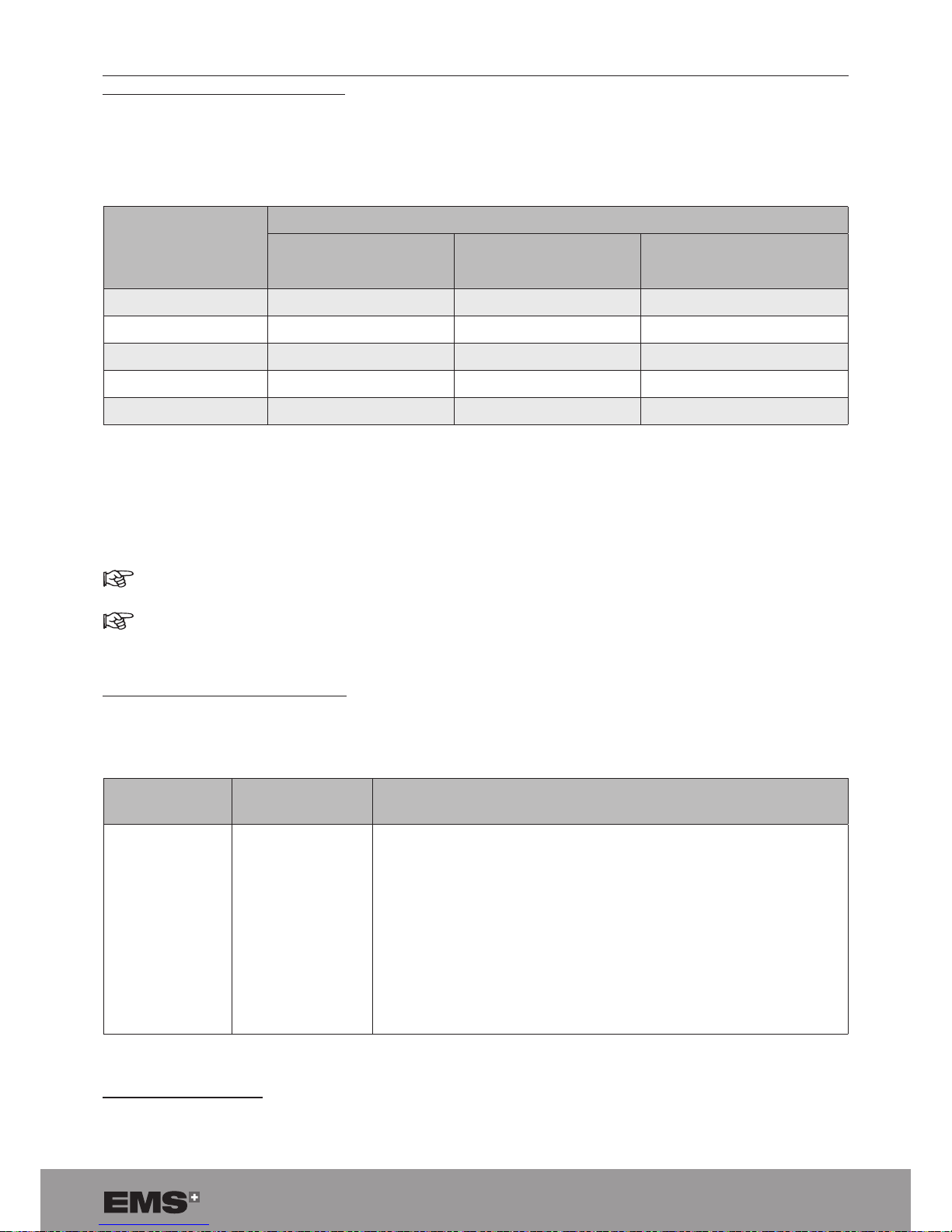

REF DESIGNATION QTY

1 Console (with peristaltic pump) or 1

2 Console (with pinch valve) 1

3 Cart - optional 1

4 Fluid management system - optional 1

5 USB key 1

6 2.5 L Demineralized water 1

7 Stone catcher support 1

8 Cooling system lling kit 1

9 Power cord 1

10 Wired pedal 1

11 Draining tube 1

12 External video cord - optional 1

13 Cleaning brush 1

14 Cleaning rod 1

Figure 1

Page 7

7

15

16

17

18

19

20

21

STERILE ZONE

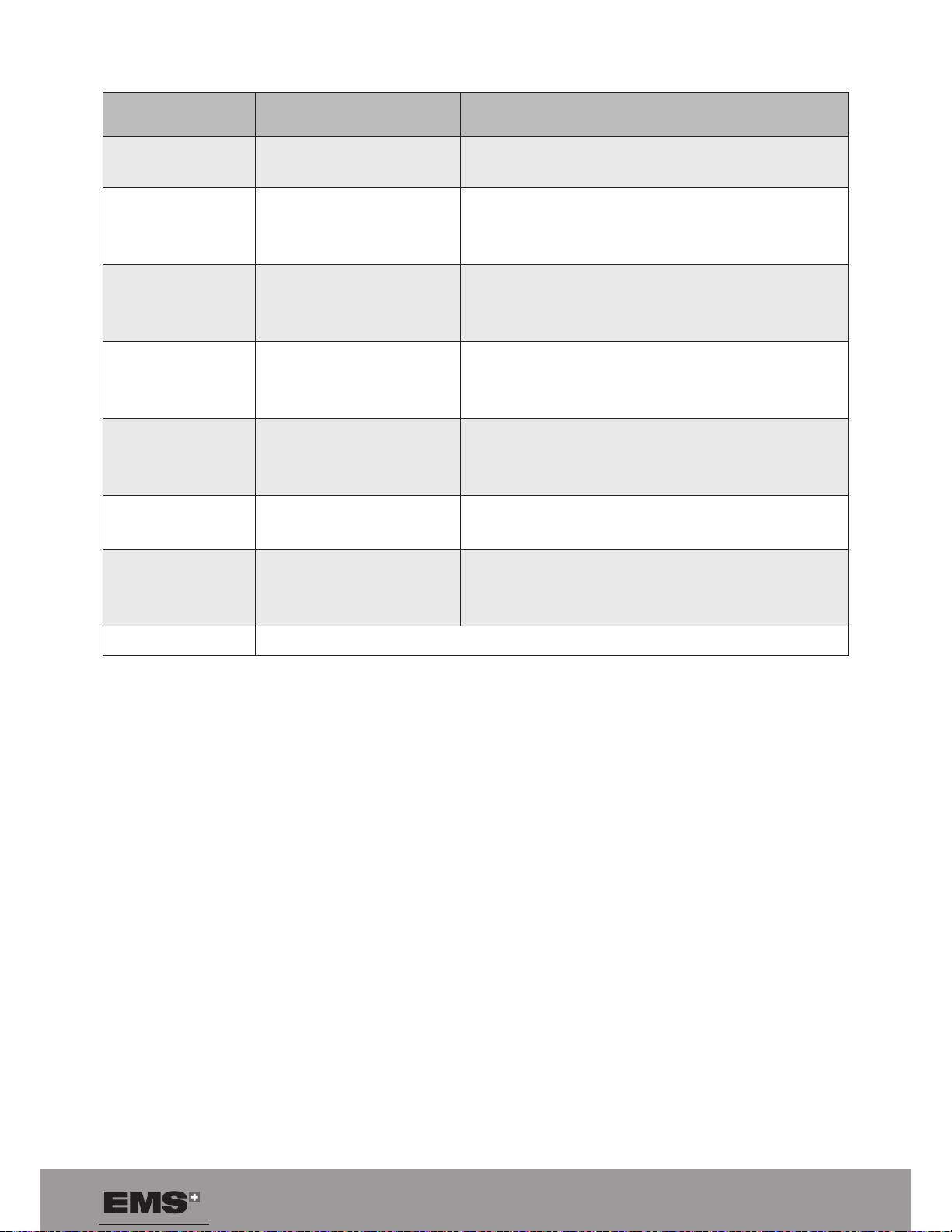

REF DESIGNATION QTY STERILE STATE

15 Standard wrench 1 To be sterilized before use

16 Stone catcher - optional 1 Provided sterile

17 Multiuse torque wrench 1 To be sterilized before use

18 Probe 1 Provided sterile

19 Unclogging rod 2 To be sterilized before use

20 Aspiration plug 1 To be sterilized before use

21 Handpiece 1 To be sterilized before use

Figure 2

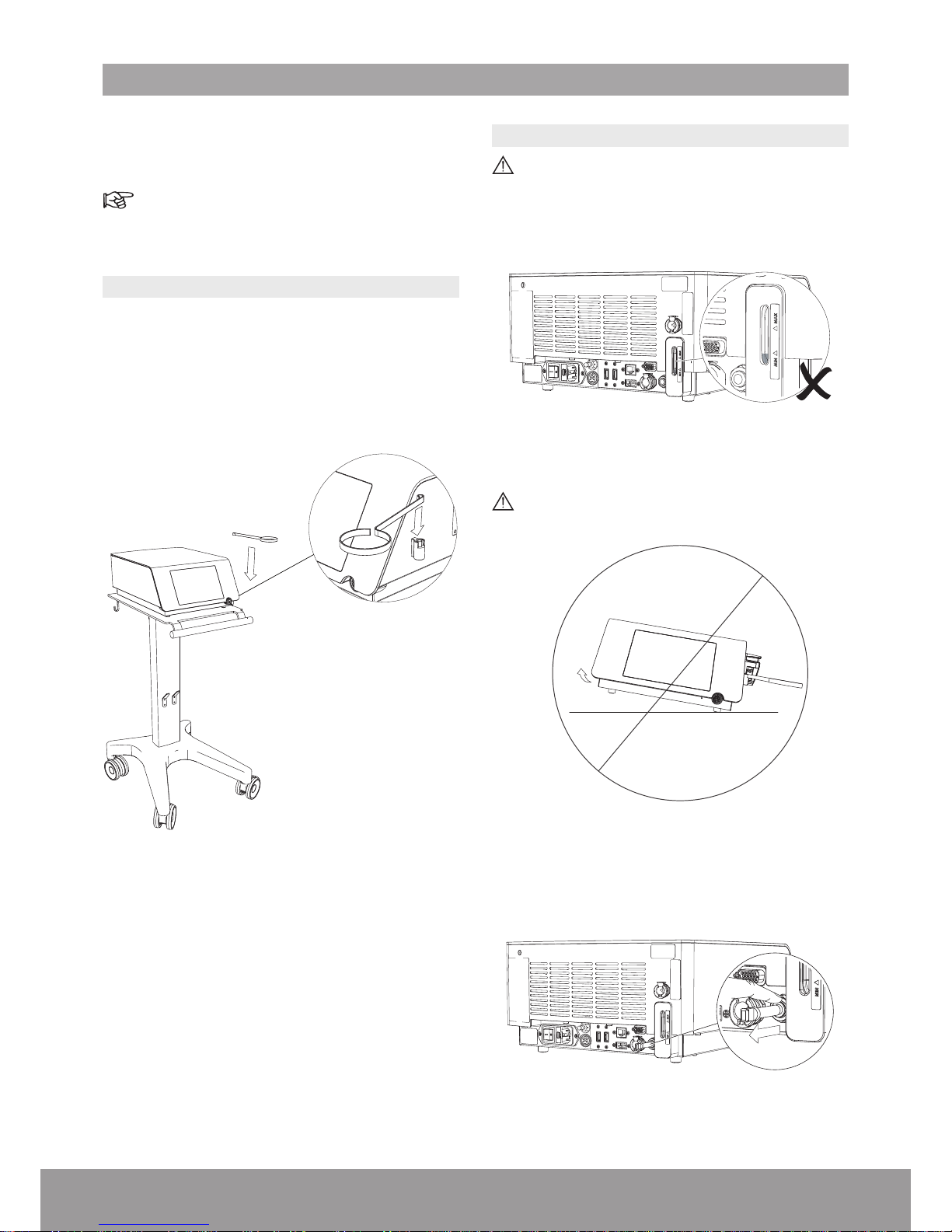

1

2

4

3

568

7

119101312

REF

DESIGNATION

TO BE USED

1

Mains power switch

YES

2

Power supply connector

YES

3

Bus bar

YES

4

Pedal cord connector

YES

5

USB connector

YES

6

USB connector

YES

7

HDMI connector

YES

REF

DESIGNATION

TO BE USED

8

RJ45 connector

NO

9

Outlet connector

YES

10

Air plug connector

YES

11

Sub-D

NO

12

Level indicator

YES

13

Filling inlet connector

YES

Figure 3

Sub-D and RJ-45 (After Sales only).

Page 8

8

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

3. INSTALLATION

Please make sure that you have all the required parts

and tools to complete the installation of your device prior

to starting work

Refer to the Packing List.

Follow the instructions in the indicated order.

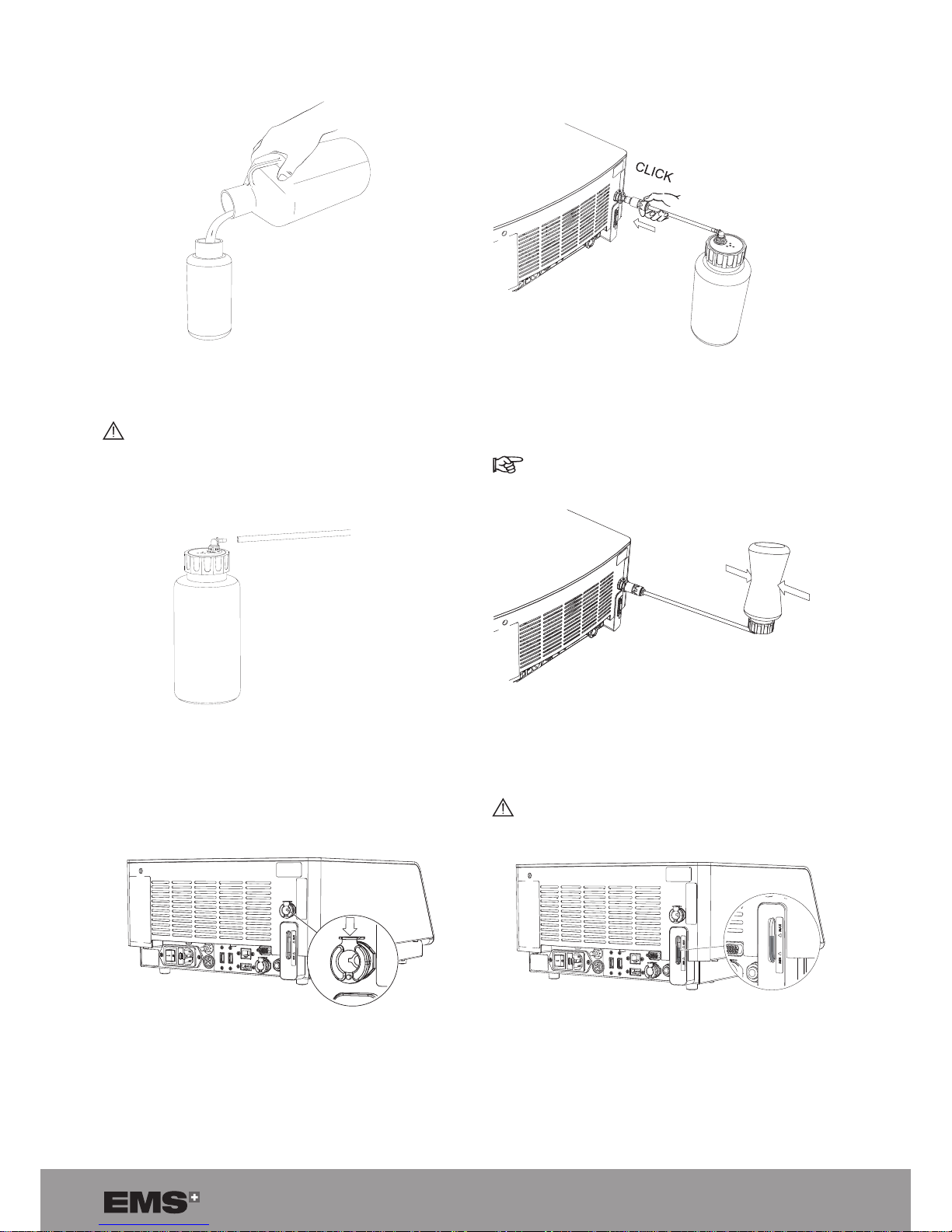

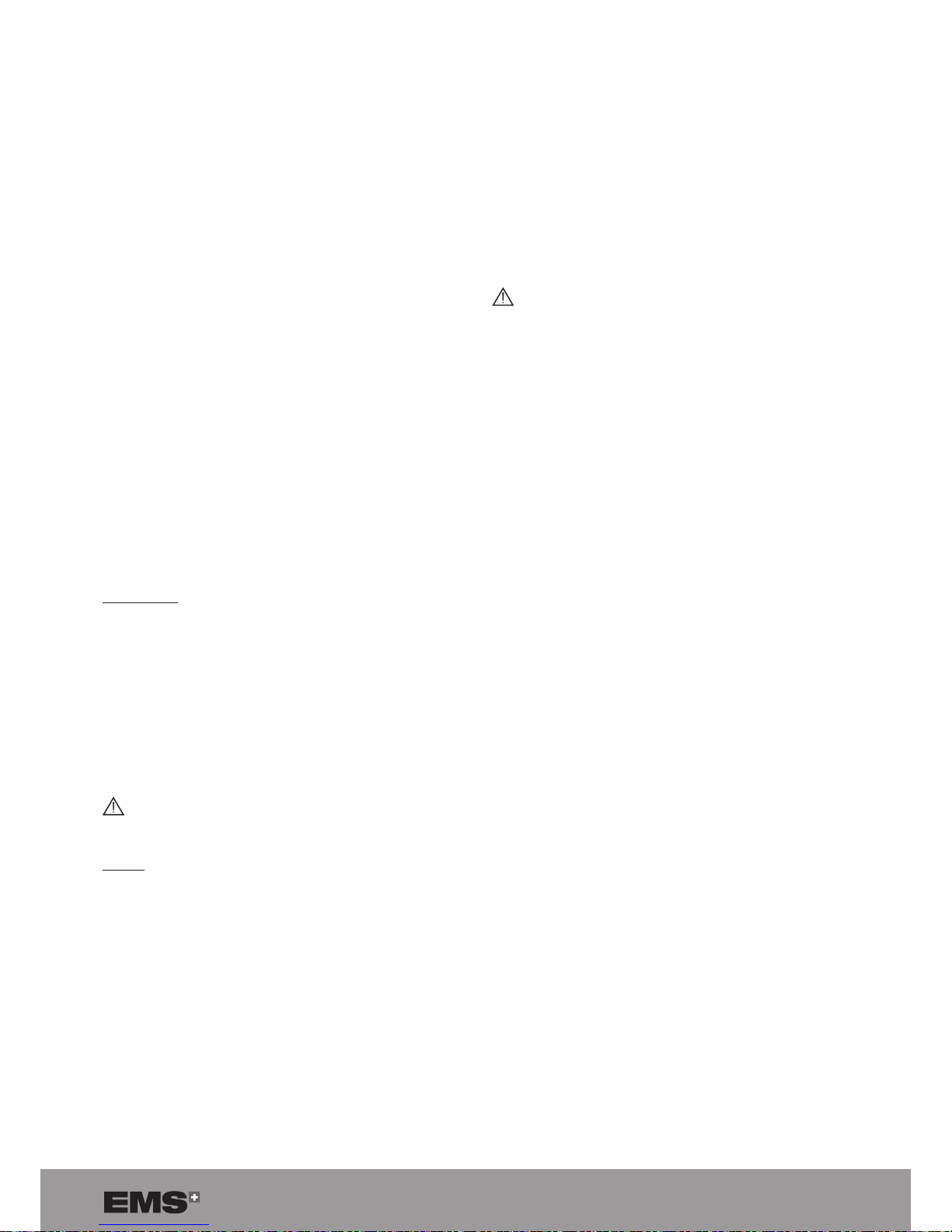

3.1. INSTALLING THE CONSOLE

1. Install the console on a at, stable surface or use the

cart (optional) designed for the console.

2. Remove the protective lm from the console.

3. Install the stone catcher support.

Figure 4

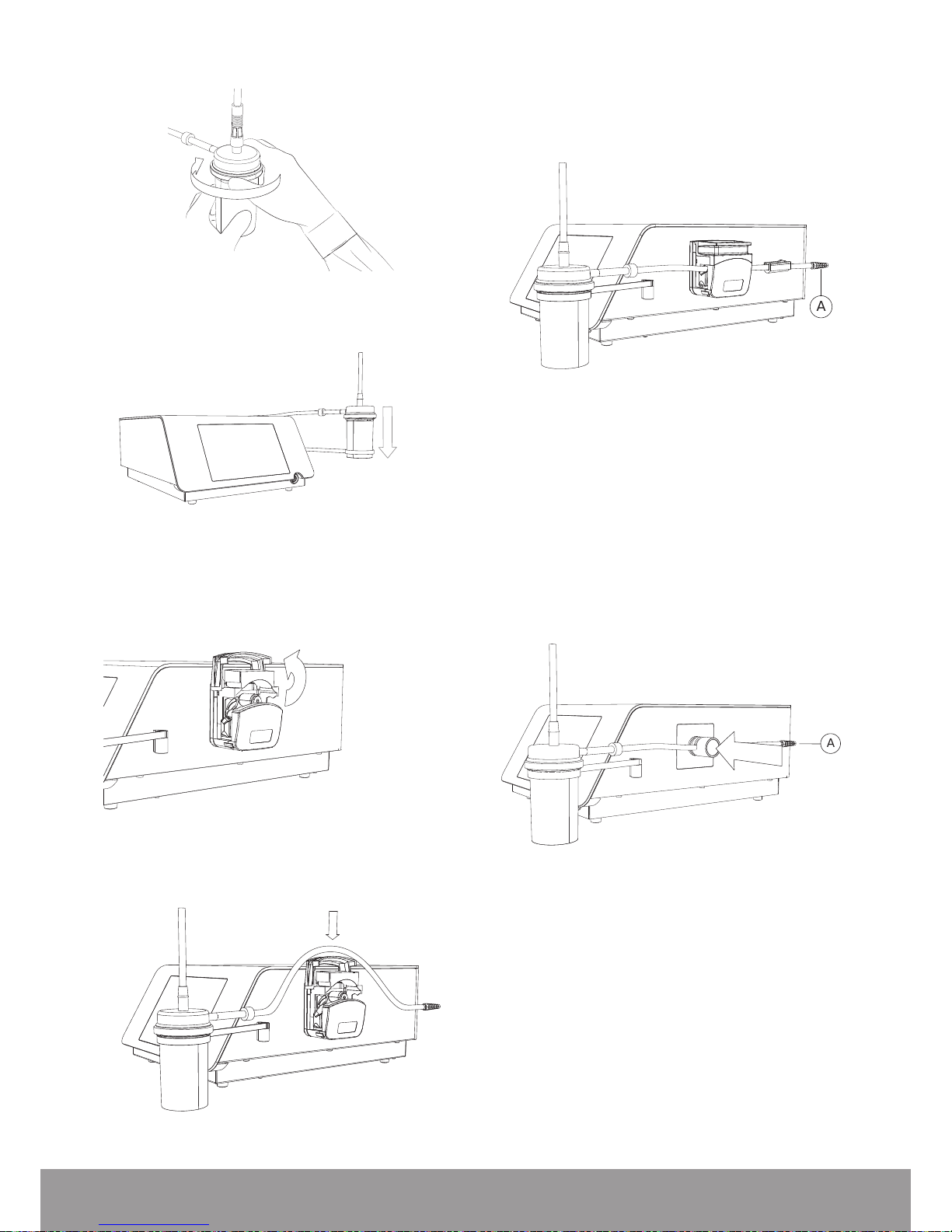

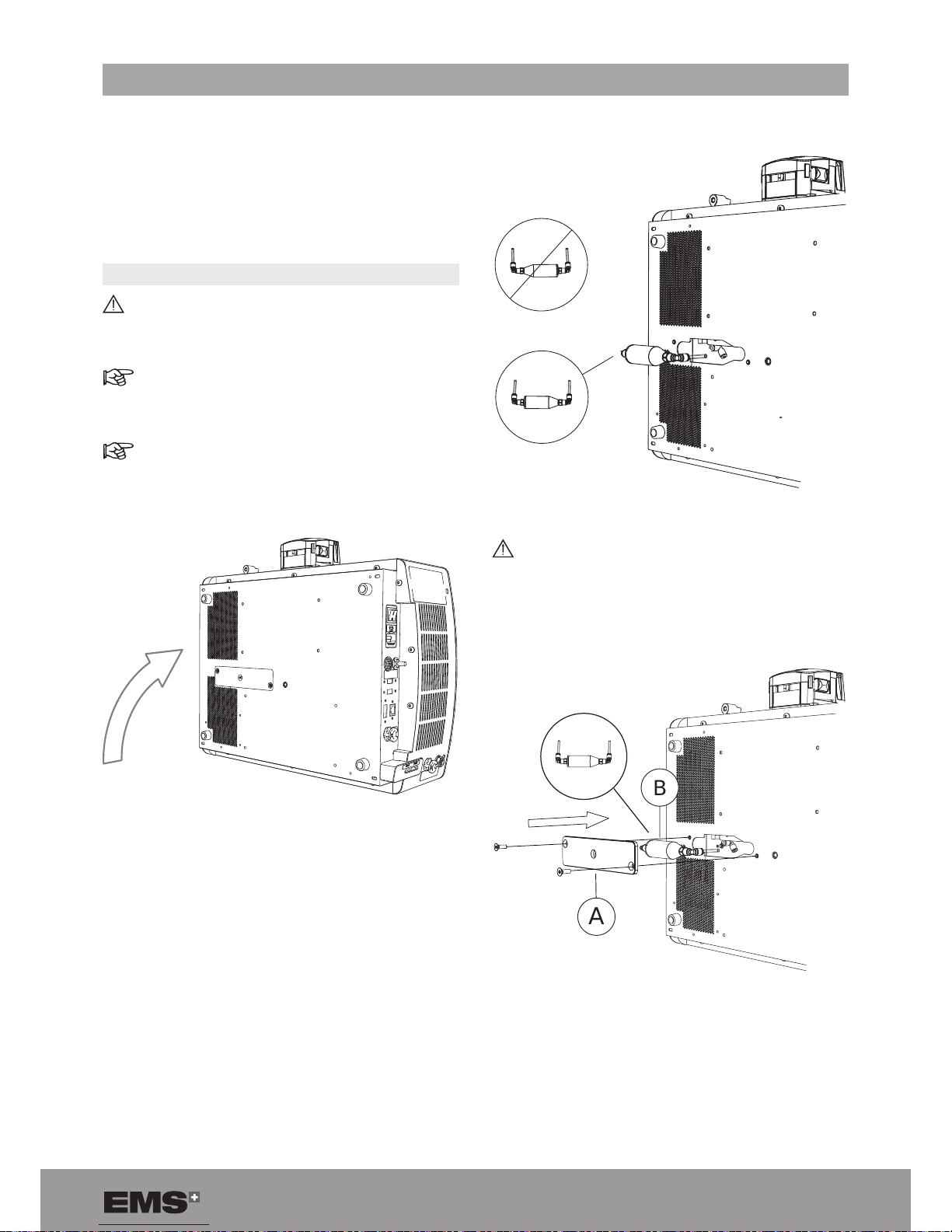

3.2. FILLING THE COOLING SYSTEM

To avoid interruptions during treatment, make sure

that the cooling liquid is above the minimum level

before use. If needed, ll the cooling system as

described below.

Figure 5

Do not tilt the console more than 10 degrees when

there is water in the cooling system.

Figure 6

1. To remove the air vent plug, push the grey ring and

pull the air vent simultaneously.

Figure 7

Page 9

9

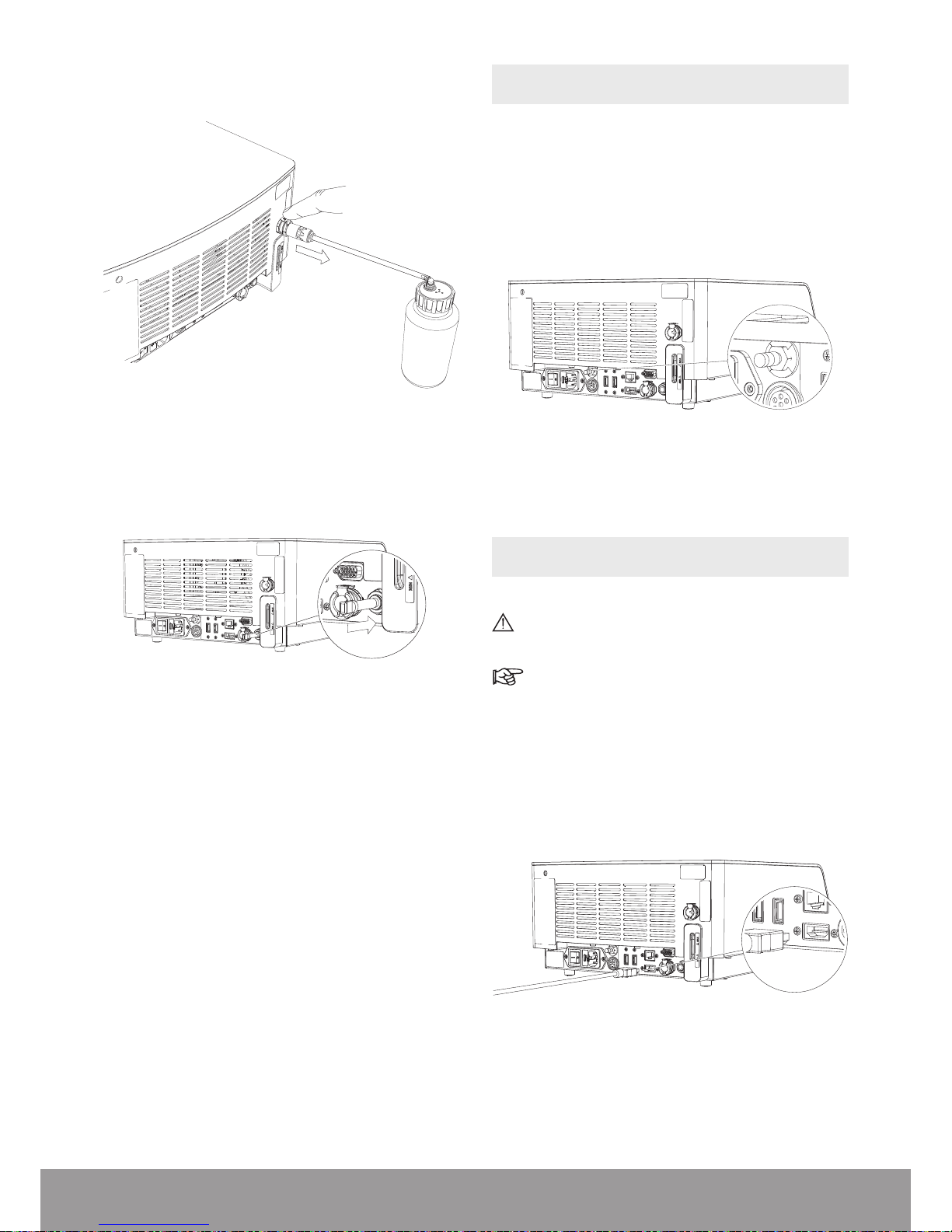

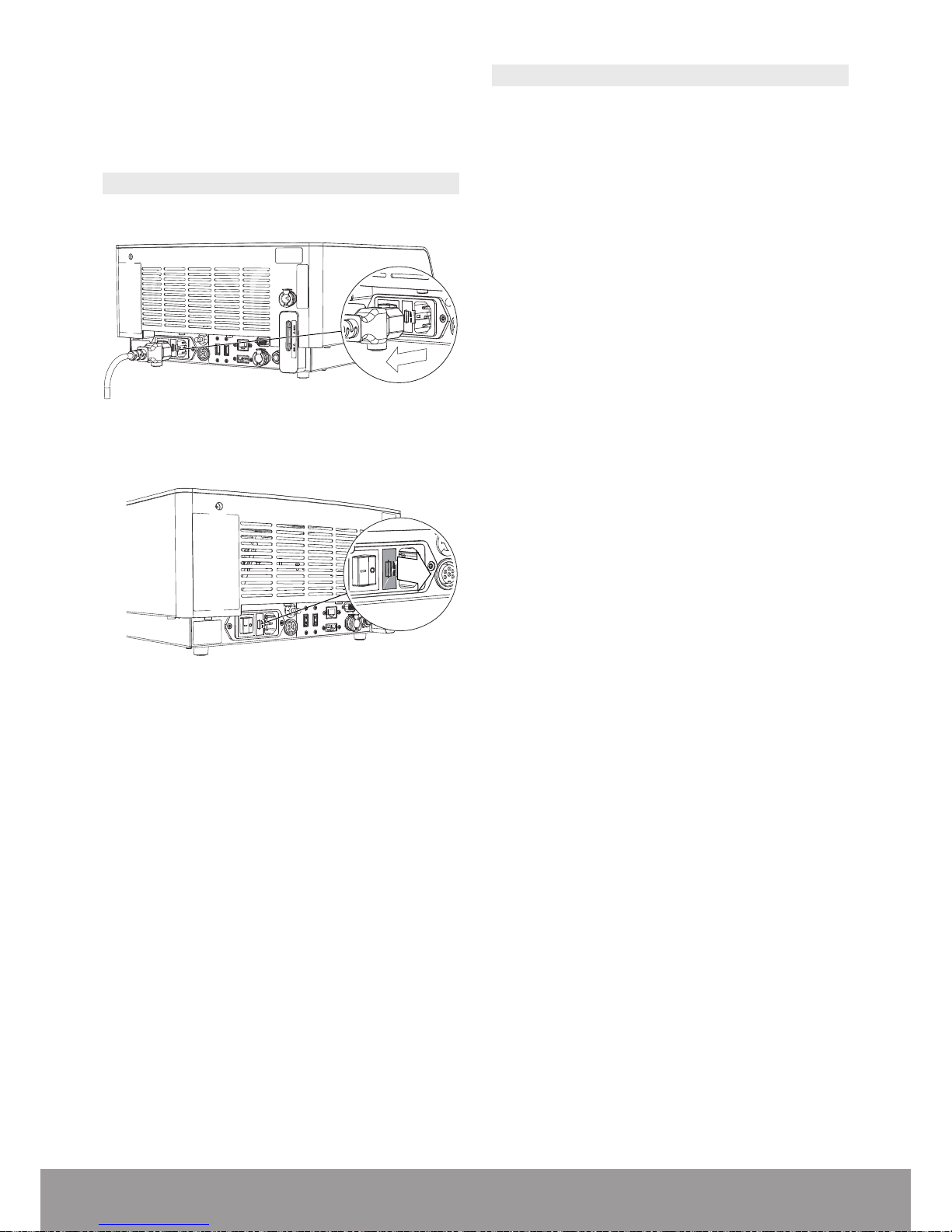

2. Fill the lling bottle and close it.

Figure 8

Only use demineralized water to ll the cooling

system.

3. Connect the lling tube to the lling bottle.

Figure 9

4. Make sure that the metal locking part is in the down

position.

Figure 10

5. Push the lling tube into the lling inlet connector

until it engages.

Figure 11

6. Invert the lling bottle and squeeze it to ll the tank.

In case of over-lling, please refer to Emptying

the Cooling Liquid Circuit section.

Figure 12

Make sure that the level of water in the tank is

between the min. and max. indicators.

Figure 13

Page 10

10

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

7. Push the metal locking part down to remove the lling

tube.

Figure 14

8. Re-insert the air vent plug up to the stop.

Figure 15

3.3. CONNECTING THE CONSOLE TO THE

EQUIPOTENTIAL CONDUCTOR

When applicable and according to your in-house protocol,

connect the equipotential conductor at the rear of the

console with the bus bar.

The equipotential conductor provides a connection

between the unit and the potential equalization bus bar

of the electrical installation when necessary.

Figure 16

The equipotential cable is not supplied with the console.

3.4. CONNECTING THE VIDEO CORD

(OPTIONAL)

Only connect products compliant with IEC 60950

or equivalent.

The console must be OFF before connecting the

video cord.

1. Connect the video cord to the HDMI connector at

the rear of the console and to a video monitor that

supports “Picture-in-Picture.”

2. Follow the instructions provided for the video monitor

to select the video input.

Figure 17

Page 11

11

3.5. INSTALLING THE PEDAL

1. Connect the pedal cord to the corresponding connector

at the rear of the console.

Pay attention to the pedal cord connector indexation.

Figure 18

2. Make sure that the pedal cord connector is in the

correct position and screw the securing nut.

Figure 19

The pedal can be placed in a protective bag (not

supplied).

3. Make sure that the pedal is in an accessible location

before starting treatment.

3.6. INSTALLING THE STONE CATCHER

Case 1: Use of an in-house aspiration system.

1. Screw the aspiration plug to the handpiece.

Figure 20

2. Connect the in-house aspiration system on the

aspiration plug.

3. Follow the instructions provided for the in-house

aspiration system.

Case 2: Use of a sterile, single-use Stone Catcher

provided by EMS (optional)

1. Screw the sterile connector of the stone catcher into

the handpiece.

Figure 21

Page 12

12

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

2. Tighten the Stone Catcher lid.

Figure 22

3. Insert the stone catcher into the stone catcher support.

Figure 23

4. Proceed according to your device:

• For Peristaltic Pump Device

1. Open the pump.

Figure 24

2. Place the stone catcher output tube into the pump.

Figure 25

3. Close the pump.

4. Connect the stone catcher output tube end with the

conical connector (A) to the optional uid management

system or to your uid disposal system.

A

Figure 26

5. Make sure that the output tube is not twisted or under

tension when placed in the peristaltic pump device

head.

• For Pinch Valve Device

1. T o insert the stone catcher output tube into the pinchvalve, push the pinch valve device and insert simultaneously the tube.

A

Figure 27

2. Connect the stone catcher output tube end with the

conical connector (A) to an external vacuum source.

Page 13

13

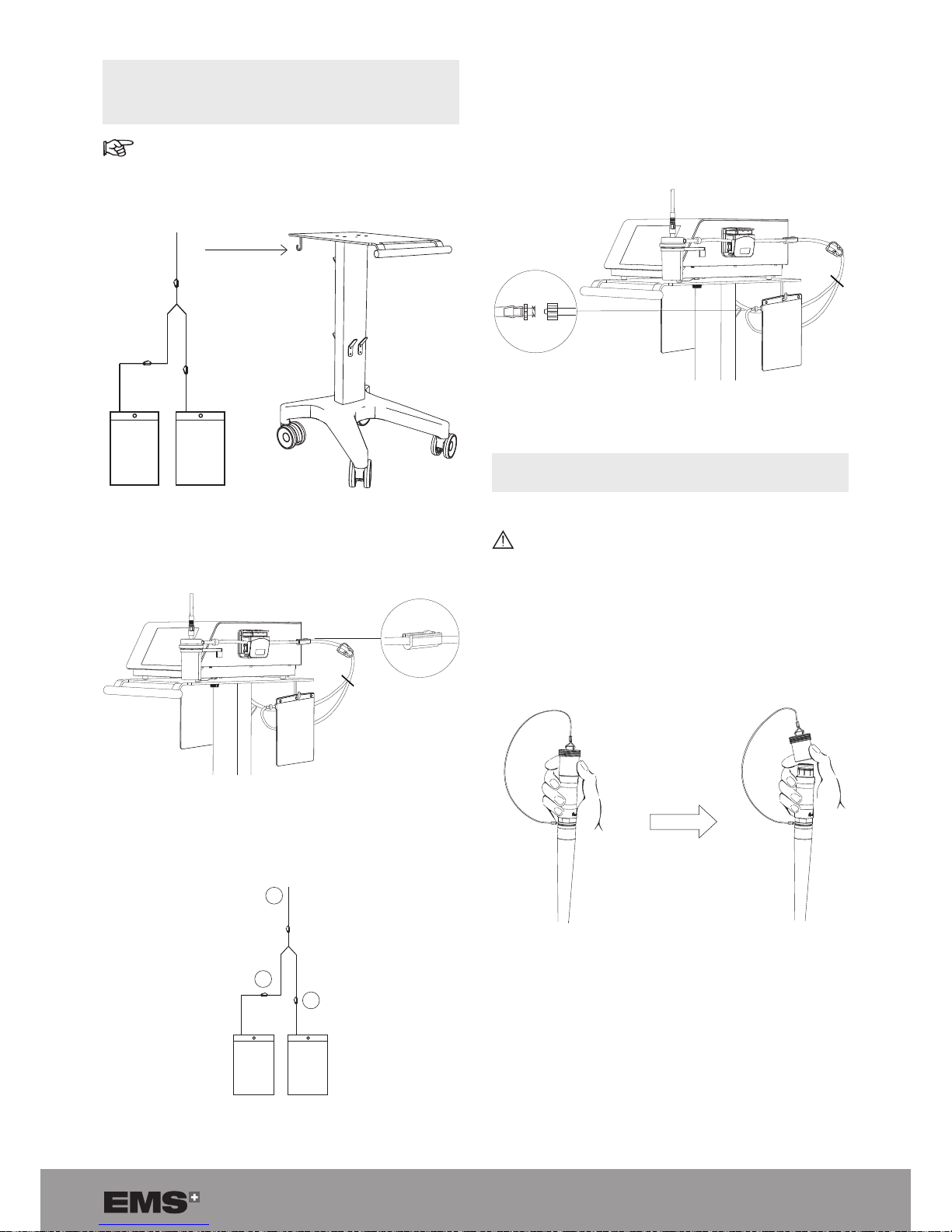

3.7. INSTALLING THE SINGLE-USE FLUID

MANAGEMENT SYSTEM SET (OPTIONAL) AND

REPLACEMENT POUCH

For the peristaltic pump device only

1. Suspend the two uid pouches, on the cart or on an

IV pole, at a level that is lower than the console.

Figure 28

2. Connect the uid management system input tube (A)

to the stone catcher output tube connector.

Figure 29

3. Close clamp (B) of one pouch to ll the rst pouch.

Clamp (C) stays open.

A

B

C

Figure 30

4. When the open pouch is lled, open the closed clamp

(B) rst.

5. Close the open clamp (C) (adjacent to the lled pouch).

6. The lled pouch can be exchanged for a new empty

pouch, using the Luer-lock connection.

Figure 31

3.8. CONNECTING THE STERILIZED HANDPIECE

TO THE CONSOLE

Make sure that the handpiece connector is dry before connecting it to the console.

1. T o remove the protective cap from the handpiece cord,

hold the metal part of the handpiece cable connector

and push up on the cap using your thumb and index

nger.

Figure 32

Page 14

14

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

2. Remove the protective cap from the console.

Figure 33

3. Connect the handpiece to the console.

Figure 34

4. Pay attention to the orientation of the handpiece

connector.

The red dot must be on top for proper alignment.

5. Make sure that the handpiece cord does not touch

the oor and is not compressed or squeezed in any

way that might impede circulation of the cooling liquid.

6. The handpiece connection to the console is maintained

by a mechanical lock. During use, the lock icon (orange

handpiece activation icon) remains illuminated.

Do not exceed the maximum number of usage cycles for the handpiece as specied in the Technical Data section.

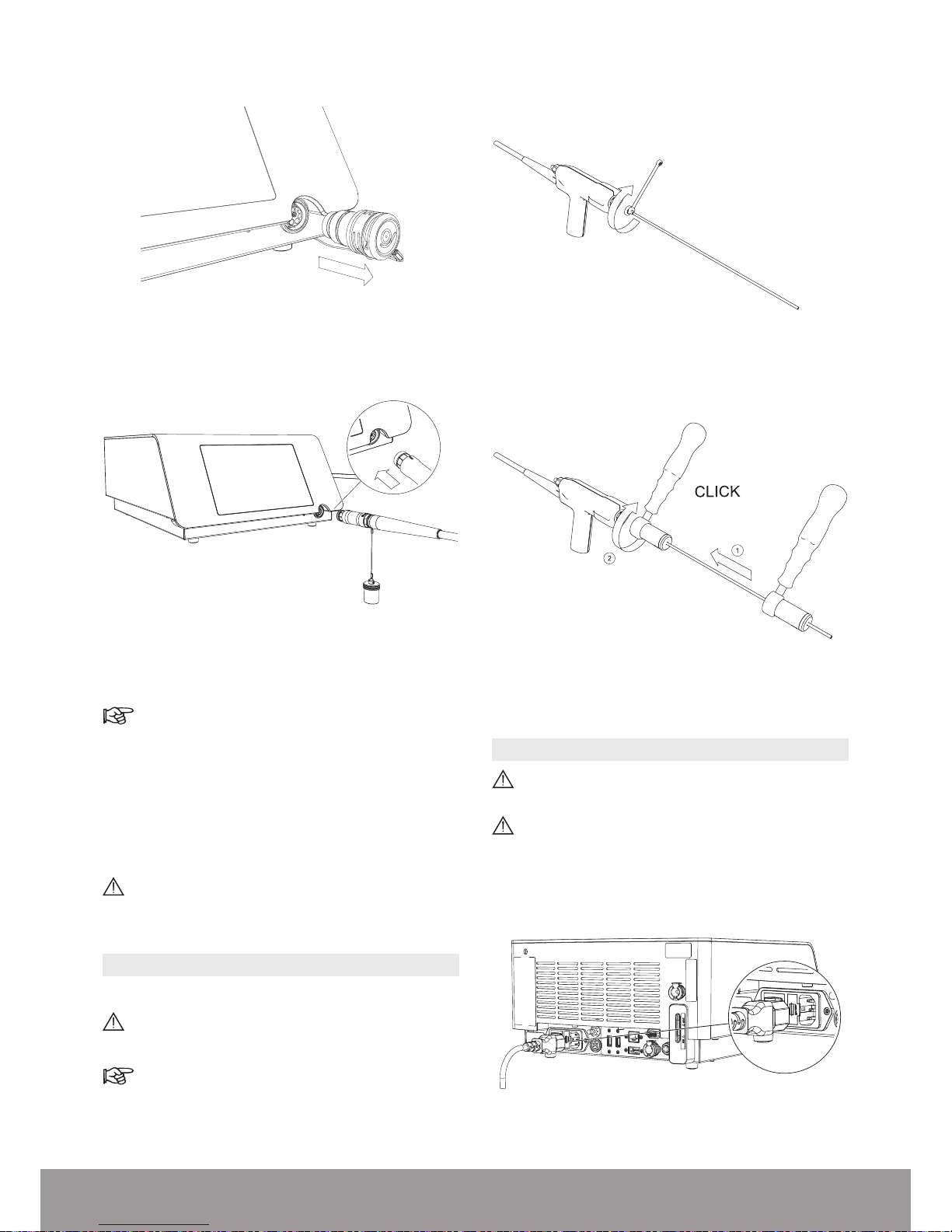

3.9. INSTALLING A PROBE ON THE HANDPIECE

1. Select the appropriate probe.

Risk of contamination: do not use after the expiration

date on the package label.

Refer to the Probe Compatibility Table section.

2. Use the wrench to rmly tighten the appropriate probe

on the handpiece.

Case 1: Standard wrench

Figure 35

Case 2: Multiuse Torque wrench

Figure 36

3.10. CONNECTING THE POWER CORD

Connect only to a FI protected mains power supply

(FI = Residual current protection).

T o prevent damage to the console, make sure that

its rated voltage meets the local line voltage.

Connect the power cord to the power socket at the rear

of the console.

Figure 37

Page 15

15

4. GETTING STARTED

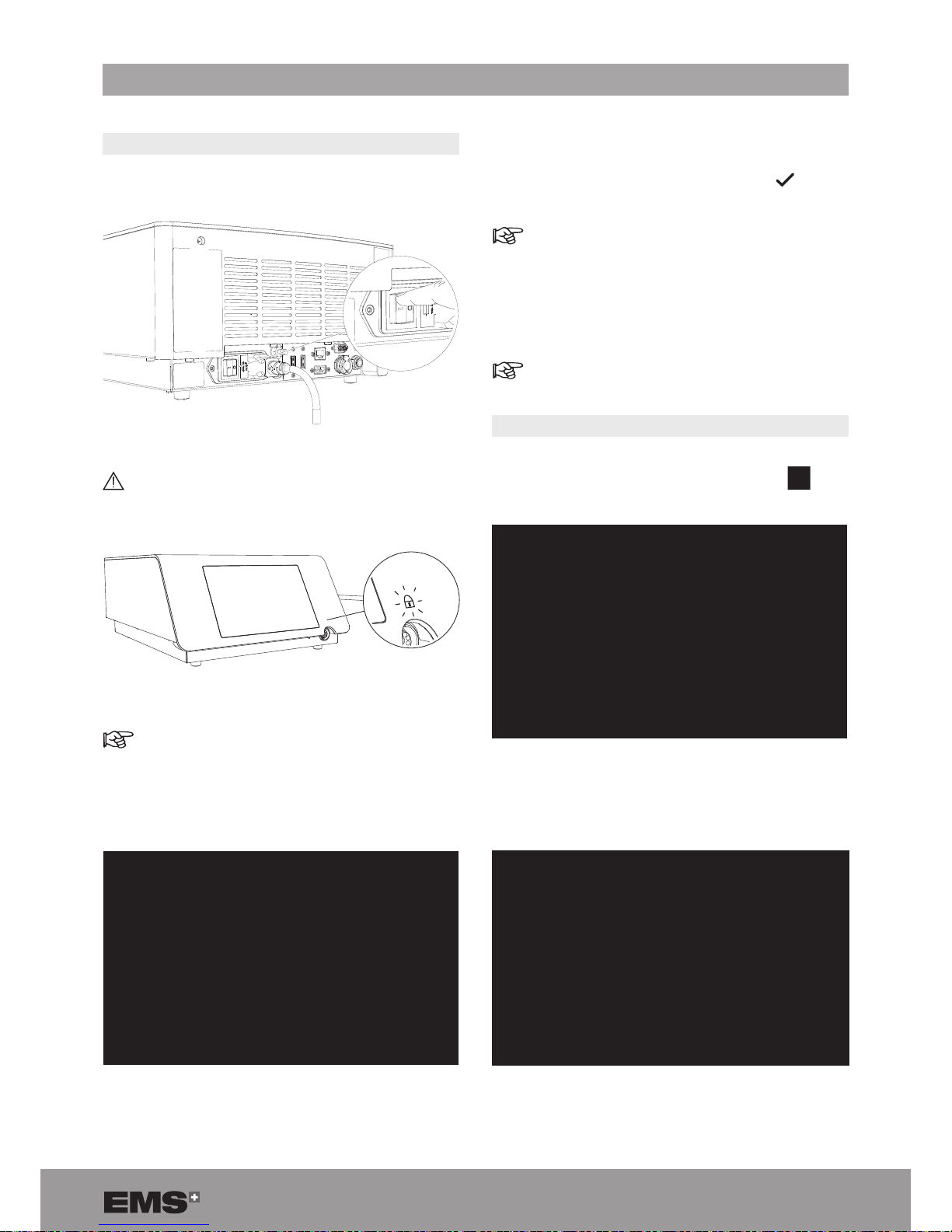

4.1. STARTING THE DEVICE

1. Use the mains power switch located on the rear panel

to switch on the console.

Figure 38

Do not disconnect the handpiece while the lock

icon is switched on (in orange), since this may

result in damage.

Figure 39

When the handpiece is connected when starting

the device, the lock icon will be orange and the

purge will start.

2. Wait until the STAND BY screen appears.

Figure 40

3. The console automatically performs a series of

diagnostic tests.

4. The console displays a green check mark for each

successfully completed diagnostic test.

In case of error messages, refer to the troubleshooting information provided on the screen or to the

Troubleshooting section.

5. The console is ready for use when all diagnostic tests

have been successfully completed.

The touch screen can be operated when wearing

surgical gloves.

4.2. ADJUSTING THE PARAMETERS

1. To access the PARAMETERS screen from the

STAND BY screen, press PARAMETERS .

Figure 41

2. Congure the parameters as needed.

Figure 42

Page 16

16

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

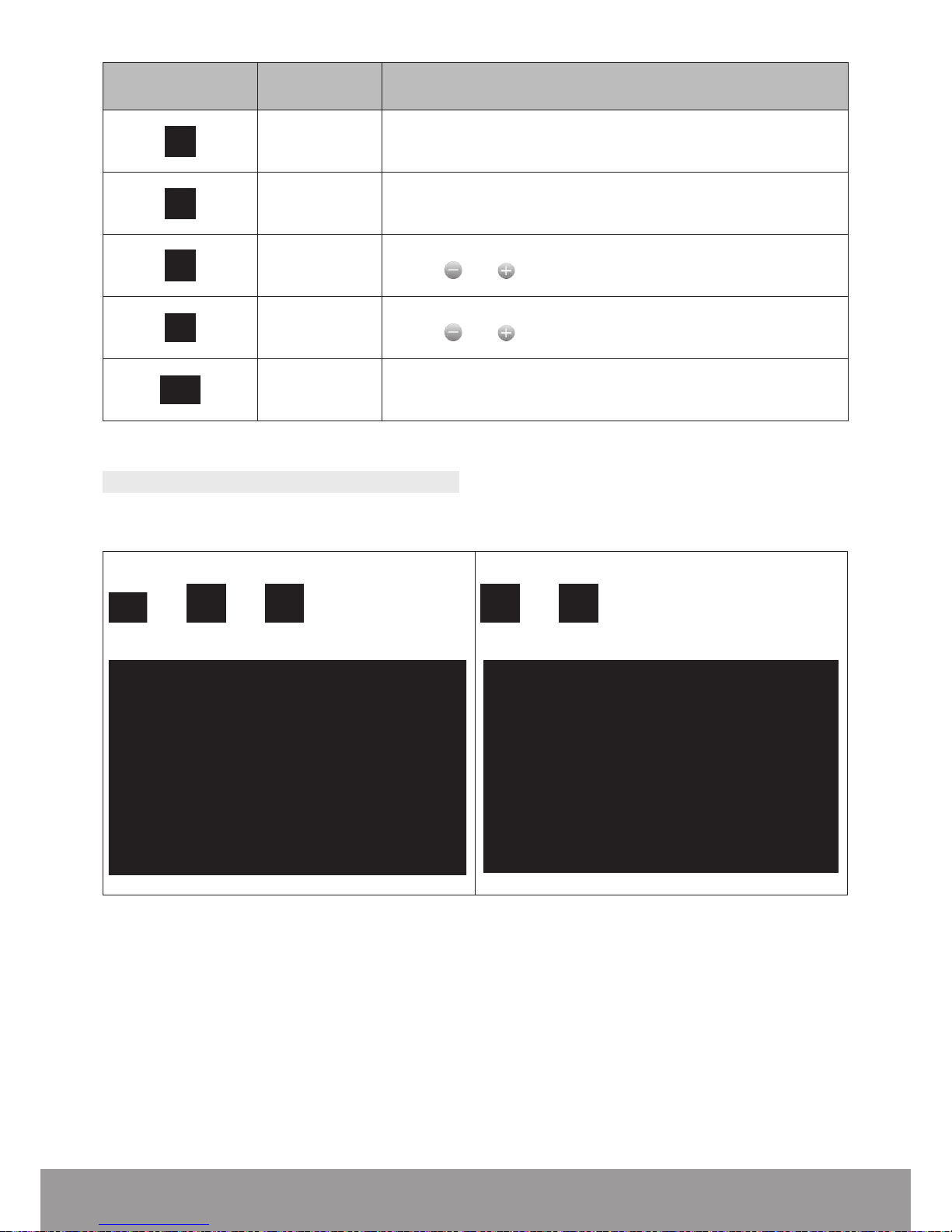

Click this pictogram Meaning Action

Log le

download

To download the log le and save it on a USB drive.

Several screens will appear.

Choose a

language

To select the display language.

Refer to the Setting the Language section.

Brightness

Use the

and buttons to adjust the display brightness.

Volume

Use the

and buttons to adjust the volume.

Back To conrm and return to the previous screen.

Table 1

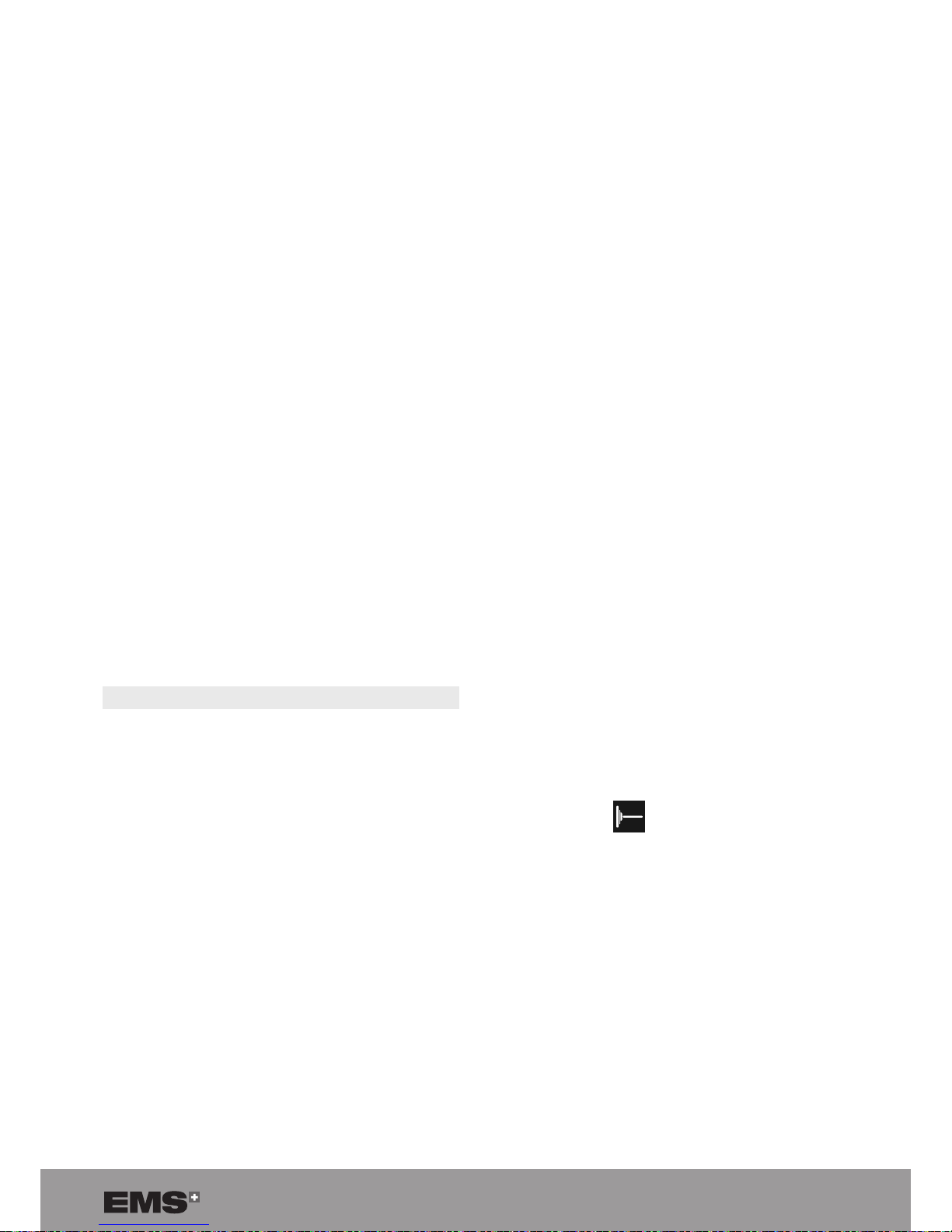

4.2.1. Choosing the Language

1. To access the language selection menu, press:

From the READY screen

ð ð

From the STAND BY screen

ð

Table 2

Page 17

17

2. Click the language you want to select.

Figure 43

3. To conrm the selected language, click OK.

Figure 44

4.3. EQUIPMENT DATA

1. From the STAND BY screen, select the equipment

pictogram to consult its equipment data.

Figure 45

2. Select Console

to view the installed software

version number, product serial number , and cumulated

treatment statistics.

Figure 46

3. Select Handpiece

to view the handpiece serial

number and cumulated treatment statistics.

Figure 47

4. Select Probe to view the probe reference

number, batch number, probe dimensions, and

cumulated treatment statistics.

Figure 48

Page 18

18

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

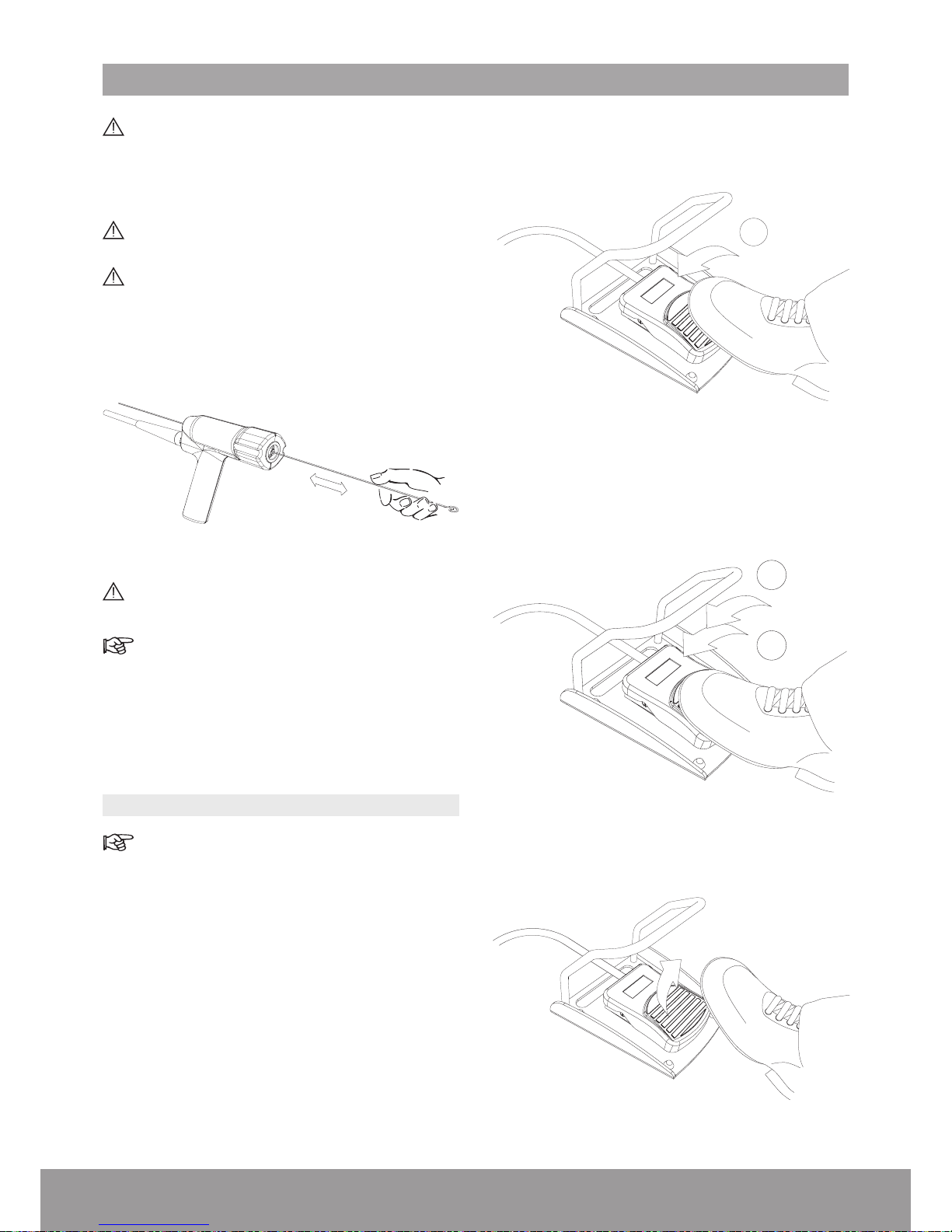

5. TREATMENT

T o avoid the risk of electric shock, this product must

only be connected to a mains power supply with

protective earth. No modication shall be made on

this product. The mains power switch of the product

must be accessible at any time.

Do not use the product in surgery after any product

update without rst performing functional tests.

Fragments blocked in the lumen of the probe and

the handpiece may lead to loss of suction and

heating of the probe. If blockage occurs, stop lithotripsy . Use the unclogging rod to remove fragments

from the probe and from the handpiece lumen

before continuing.

Figure 49

Do not let the handpiece remain in contact with the

patient during treatment.

During treatment, an auditory information pulse

will be emitted.

This section provides guidance for using the product.

It does not provide detailed instructions for performing

lithotripsy procedures.

5.1. FUNCTIONAL TESTS

If a function or component is not working as

explained below, refer to the Troubleshooting

section.

1. From the STAND BY screen, press the START

button to access the READY screen.

2. Insert the probe into a sterile receptacle of physio-

logical uid.

3. Use the 2-mode foot pedal.

4. Press the pedal halfway (STEP 1) to activate suction

and make sure that suction is working properly (uid

moving through the suction tube).

1

Figure 50

5. Press the pedal completely (STEP 2) to activate both

suction and energies and make sure that the quality

meter is in the green zone and the uid is moving

through the suction tube.

1

2

Figure 51

6. Remove foot from the pedal to stop the functional

test.

Figure 52

Page 19

19

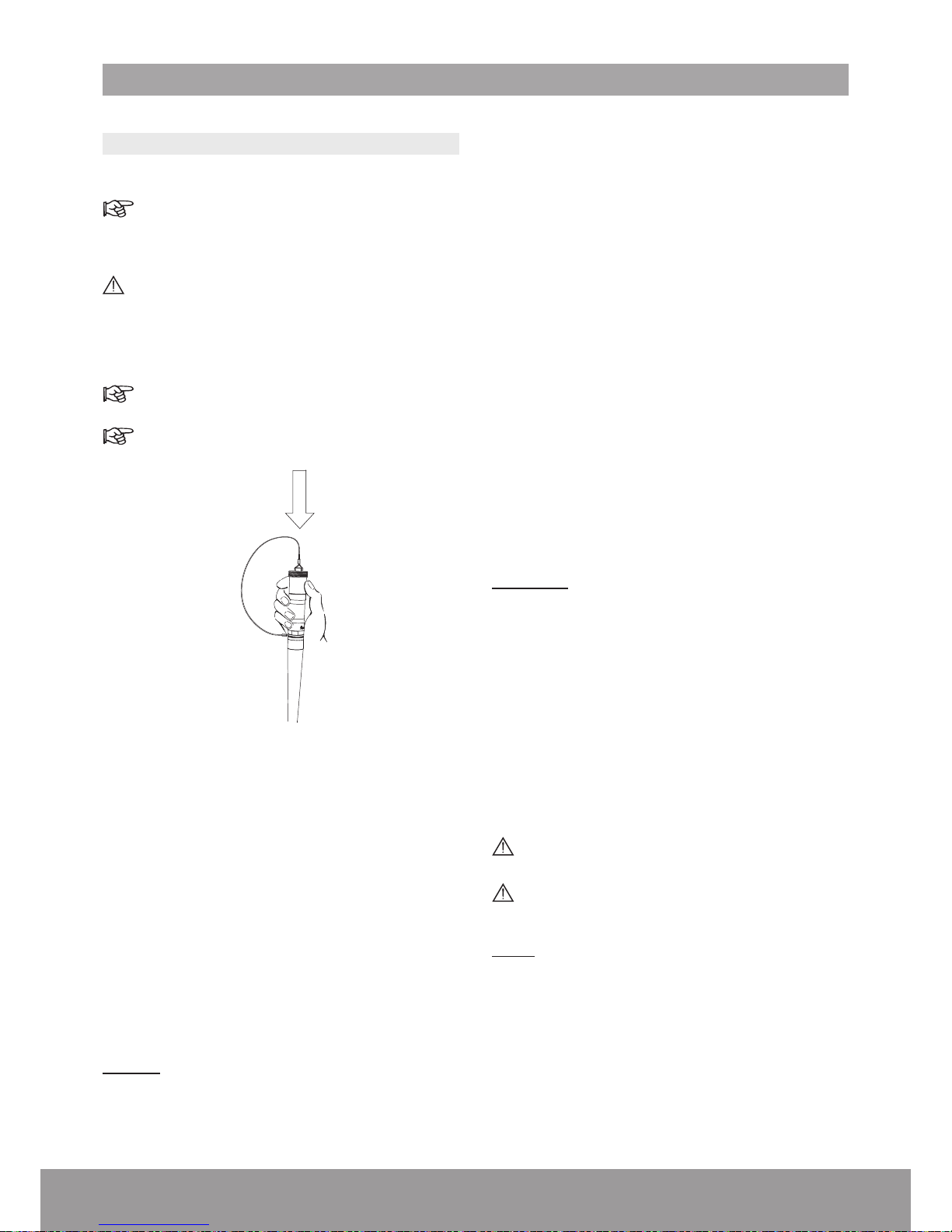

5.2. PROBE INSERTION

Do not touch the probe during activation.

If a probe breaks distally, use sterile grasping

forceps to remove probe pieces from the urinary

tract.

1. Throughout the entire treatment, keep the probe tips

under endoscopic vision.

To avoid bending the probe, make sure that the

probe and the endoscope are aligned.

The probe tip should be extended 10 - 20 mm

beyond the endoscope tip.

2. Introduce and position the probe inside the endoscope.

3. The probe shall be in contact with the stone.

4. Make sure that the operation is performed with

continuous endoscopic vision.

5.3. TREATMENT SETTINGS

1. The probe is automatically recognized by the

handpiece to congure the console parameters for

each probe type.

2. The READY screen will display factory settings or the

settings used for the previous treatment.

• For peristaltic pump device

Figure 53

• For pinch valve device

Figure 54

3. All probe and handpiece usage information are

automatically recorded in the console (number of

uses, time of use, etc.).

4. According to the type of treatment, two pre-settings

are available:

• Hard Stones Treatment,

• Soft Stones Treatment.

5. You can also set each parameter manually.

Refer to the following sections:

- Custom Settings,

- Hard Stones Treatment Settings,

- Soft Stones Treatment Settings.

5.3.1. Custom Settings

1. From the ST AND BY screen, press the START button.

Figure 55

Page 20

20

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

2. If required, adjust any settings manually as described in the following table:

PICTOGRAMS MEANING ACTION

ON/OFF button

Use the ON/OFF button to activate or deactivate the functionality in

question.

Impact

Impact power

Use the

and buttons to adjust the impact power in percent

from 10% to 100% (in 10% increments).

Impact frequency

Use the

and buttons to adjust the frequency of impact

pulses from 1 Hz to 12 Hz (in 1 Hz increments).

Ultrasound

Ultrasound power

Use the and buttons to adjust the ultrasound power from

10% to 100% (in 10% increments).

Suction

Suction ow rate

Use the and buttons to adjust the suction ow rate from

10% to 100% (in 10% increments).

This control is only active for consoles with an integrated

peristaltic pump device.

Treatment Efciency

Indicator

To provide instant visual feedback about the efciency of the

treatment.

• Green: the treatment works properly.

• Orange: the treatment is not efcient.

Menu To return to the STAND BY screen from the READY screen.

Table 3

5.3.2. Hard Stones Treatment Settings

1. T o use the hard stones pre-settings, press the HARD

STONES TREATMENT button from the STAND BY

screen.

Figure 56

2. The READY screen will appear and display the hard

stone treatment pre-settings.

3. If required, adjust any settings manually as described

in the table above.

5.3.3. Soft Stones Treatment Settings

1. To use the soft stones pre-settings, press the SOFT

STONES TREATMENT button from the STAND BY

screen.

2. The READY screen will appear and display the soft

stones treatment pre-settings.

3. If required, adjust any settings manually as described

in the table above.

Page 21

21

5.4. ADAPTING SUCTION FLOW RATE

An excessively high suction level can impair the

endoscopic vision, collapse an organ, or damage

the mucosa.

To adapt the suction ow rate:

• For peristaltic pump device only

1. Use the suction ow rate control as described

in Table 3.

Do not use the roller clamp of the stone catcher to

adapt the suction ow rate.

• For pinch valve device only

1. Adjust the roller clamp of the stone catcher.

2. The pinch valve device default state is closed.

It opens when the pedal is pressed halfway

(STEP 1).

3. The roller clamp on the suction tube controls

the suction ow rate independently of the ow

pressure.

5.5. STARTING TREATMENT

1. Go to the READY screen to start the treatment.

2. Press the pedal halfway (STEP 1) to activate the

suction.

3. Press the pedal completely (STEP 2) to activate both

suction and the energies.

4. Release STEP 2 to deactivate energies.

5. Release STEP 1 to deactivate suction.

Refer to the Functional T ests section for pedal use.

After 1 minute of inactivity , the system automatically

executes a purge and stops cooling the circuit. It

is reactivated when you push the pedal.

Page 22

22

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

6. POST-TREATMENT PROCEDURE

6.1. COMPLETING TREATMENT

1. Remove the probe from the endoscope.

Figure 57

Do not disconnect the probe and the handpiece

at this stage.

2. Switch off IMPACT and ULTRASOUND from the

READY screen before starting this procedure.

3. Tilt the stone catcher.

Figure 58

4. Press the pedal halfway (STEP 1) for a few seconds

to empty the suction circuit and reduce the level of

water in the stone catcher.

1

Figure 59

To accelerate the emptying procedure, the stone

catcher can be disconnected from the handpiece.

5. The suction tubes must be cleared.

6. Loosen the probe from the handpiece, using one of

the following methods.

Figure 60

Page 23

23

Figure 61

Figure 62

Wait until the lock icon switches off. The handpiece

cannot be disconnected when the lock icon is on.

6.2. DISCONNECTING THE HANDPIECE

Make sure that the console is still on during this

procedure.

Make sure that the lock icon is off.

Figure 63

1. Pull back the metallic part of the handpiece connector

to disconnect the handpiece.

Figure 64

If the mechanical disconnection of the handpiece

is not possible when the console is switched off,

refer to the Troubleshooting section.

2. Plug the cap on the handpiece connector in the front

panel.

Figure 65

Page 24

24

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

6.3. RECORDING TREATMENT DATA

1. Select History

to view the statistics for the last 5 treatment sessions.

From the READY screen:

ð

From the STAND BY screen:

Table 4

2. Information on the previous treatment sessions will be displayed.

Figure 66

3. Press NEXT PAGE to display more previous treatment data.

Figure 67

Page 25

25

6.4. DISCONNECTING THE STONE CATCHER

1. Disconnect the stone catcher from the handpiece

and from the uid management system or from your

vacuum system.

Figure 68

6.5. ELIMINATING THE STONE CATCHER

CONTENTS

If the stone fragments are not to be kept for analysis,

dispose of them. Refer to the Product Disposal section.

6.6. CONSERVING THE STONE CATCHER

CONTENTS

If the stone fragments are to be kept for analysis, close

the receptacle with the yellow transport closing cap,

supplied with the stone catcher.

Figure 69

6.7. DISPOSING OF SINGLE-USE COMPONENTS

Dispose of single-use components (probe, Stone Catcher

and fluid management system) in accordance with

hospital protocol.

6.8. SWITCHING OFF THE CONSOLE

Make sure that the lock icon is switched off

before turning off the console.

• Set the mains power switch to 0.

Figure 70

Page 26

26

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

7. CLEANING, DISINFECTING, AND STERILIZING

7.1. MULTIUSE COMPONENTS

Step A: Preparation at the Point of Use

Safe storage and transportation to the reprocessing

area to avoid any damage to the instrument and

contamination to the environment and the people

involved in the reprocessing process.

After contamination, the sample is allowed to dry

for 1 hour at room temperature.

Step B: Pre-cleaning

For the handpiece, place the protective cap onto

the handpiece connector before cleaning.

Do not remove the protective cap until reprocessing is completed.

Figure 71

1. Wipe the product with a damp cloth.

2. Immerse the product in cold tap water for 5 minutes.

3. Use a syringe with 50mL of deionized water to ush

the lumen three times

4. Rinse the product with a water jet pistol (with a

minimum pressure of 3.8 bar) for 30 seconds.

Step C: Cleaning, disinfection and drying process

Step C1. Manual Cleaning, disinfection and drying

process

Cleaning

EMS recommends using Neodisher® MediClean as the

cleaning agent as it has been used for the validation

study.

• Wipe the product with a damp cloth to remove

gross contamination.

• Flush the lumen of the product three times for

5 seconds using a water jet pistol.

• Immerse the product in cold tap water for 5 minutes.

Make sure that all surfaces are moistened.

• Brush all accessible surface with a soft Bristol

nylon brush until all visible residues are removed;

• Immerse the product in 0.5% cleaning solution

for 5 minutes. Make sure that all surfaces are

moistened.

• EMS recommends using Neodisher® MediClean

at 40°C.

• Rinse the product with a water jet pistol for

60 seconds, while paying special attention to each

gap, slit, or hidden surface.

• Rinse the product under cold tap water.

• Dry the product by blowing air for 20 seconds.

Disinfection

The following test devices, materials & machines have

been used for the validation study:

• Disinfection agent: Cidex® OPA.

• Immerge the product in a disinfectant solution for

10 minutes. Care that all surfaces are moistened.

• EMS recommended to use Cidex OPA at 20°C.

• Rinse the product with a water jet pistol for

60 seconds, while paying special attention to each

gap, slit, or hidden surface.

• Rinse the product under cold tap water.

Disinfection must be performed no later than 1 hour

after the cleaning phase.

Sterilization must be performed after disinfection.

Drying

Dry the outside of the instrument with a lint-free towel.

Dry the lumen of the products with ltered compressed

air (max. pressure 3 bar).

The instrument must never be heated >138°C.

Page 27

27

Step C2. Automated Cleaning, disinfection and drying

process

Automated Cleaning, disinfection and drying validation

has been performed using a Miele 7735CD washing

machine, and the cleaning agent Neodisher® Mediclean.

EMS recommends using Neodisher® Mediclean for their

products.

For this step, a Washer/Disinfector machine must have

suitable baskets to hold small, fragile products and rinsing

connections for the attachment to product lumina.

The program of the Washer/Disinfector machine shall be

able to perform the following steps.

Place the instrument in a suitable rack and start the

program. The Vario TD programs have been shown to

be effective:

• 2 min pre-washing with cold water (<40°C). Drain;

• 5 min washing with 0.5% detergent at 55°C. Drain;

• 3 min neutralising with warm water (>40°C). Drain;

• 2 min intermediate rinsing with warm water

(>40°C). Drain.

Special instructions of the manufacturer for the Washer/

Disinfector must be followed.

Disinfection (if required by national laws)

Automated Thermal Disinfection in a Washer/Disinfector

taking into consideration national requirements in regards

to A0-Value (see EN 15883) e.g. 93°C for 3 minutes.

A machine cleaning and disinfection method should

always be used for cleaning/disinfection because of the

increased effectiveness of this method.

Sterilization must be performed after disinfection.

Drying

Drying of outside of instrument through drying cycle of the

Washer/Disinfector. If needed, additional manual drying

can be performed using a lint-free towel and filtered

compressed air (max. pressure 3 bar).

The instrument must never be heated >138°C.

Step D. Functional Testing, Maintenance

If stains are still visible on the product after cleaning/

disinfection, the entire cleaning/disinfection procedure

must be repeated. Products with visible damage, chips/

akes, corrosion or bent out of shape must be disposed

of (no further use is permissible).

Step E. Packaging for sterilization

Prior to sterilization, the products must be placed in a

suitable sterilization container or sterilization packaging:

Compliant with EN ISO 11607 or EN 868.

Step F. Sterilization

Sterilization of instruments by applying a fractionated

pre-vacuum process (according ISO 13060 and

ISO 17665) taking into consideration the respective

country requirements.

Do not exceed the maximum number of sterilization

cycles, please refer to the instruction manual.

Step F1. Prevacuum sterilization

Parameters for the pre-vacuum cycle:

• 3 prevacuum phases

• Sterilization temperature of 132°C for 3 minutes

• Drying time: minimum 20 min

• Do not exceed a sterilization temperature of 138°C

and a holding time of 20 min.

Step K. Storage

Storage of sterilized instruments in a dry , clean and dust

free environment at modest temperatures of 5°C to 40°C.

Page 28

28

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

7.2. CONSOLE, PEDAL, AND CART

1. Turn off the console.

Figure 72

2. Disconnect the power supply connector before

cleaning.

Figure 73

3. Remove the protective bag from the pedal, if applicable.

4. Plug the cap on the handpiece connector in the front

panel

Figure 74

5. Use a cleaning wipe with proven efcacy (e.g., enzol

2%) to clean the surfaces.

The housing of the console is not waterproof.

6. To disinfect use 70% isopropyl alcohol or other

EPA-recognized surface disinfectant. Be sure to

carefully follow the instructions provided by the disinfection solution manufacturer.

Page 29

29

8. PRODUCT MAINTENANCE

Should legal provisions in your country specify maintenance intervals, these must be observed. The console

and handpiece may need to be returned for periodic

servicing.

For the spare parts described below, please refer to the

order form or contact your EMS authorized service center.

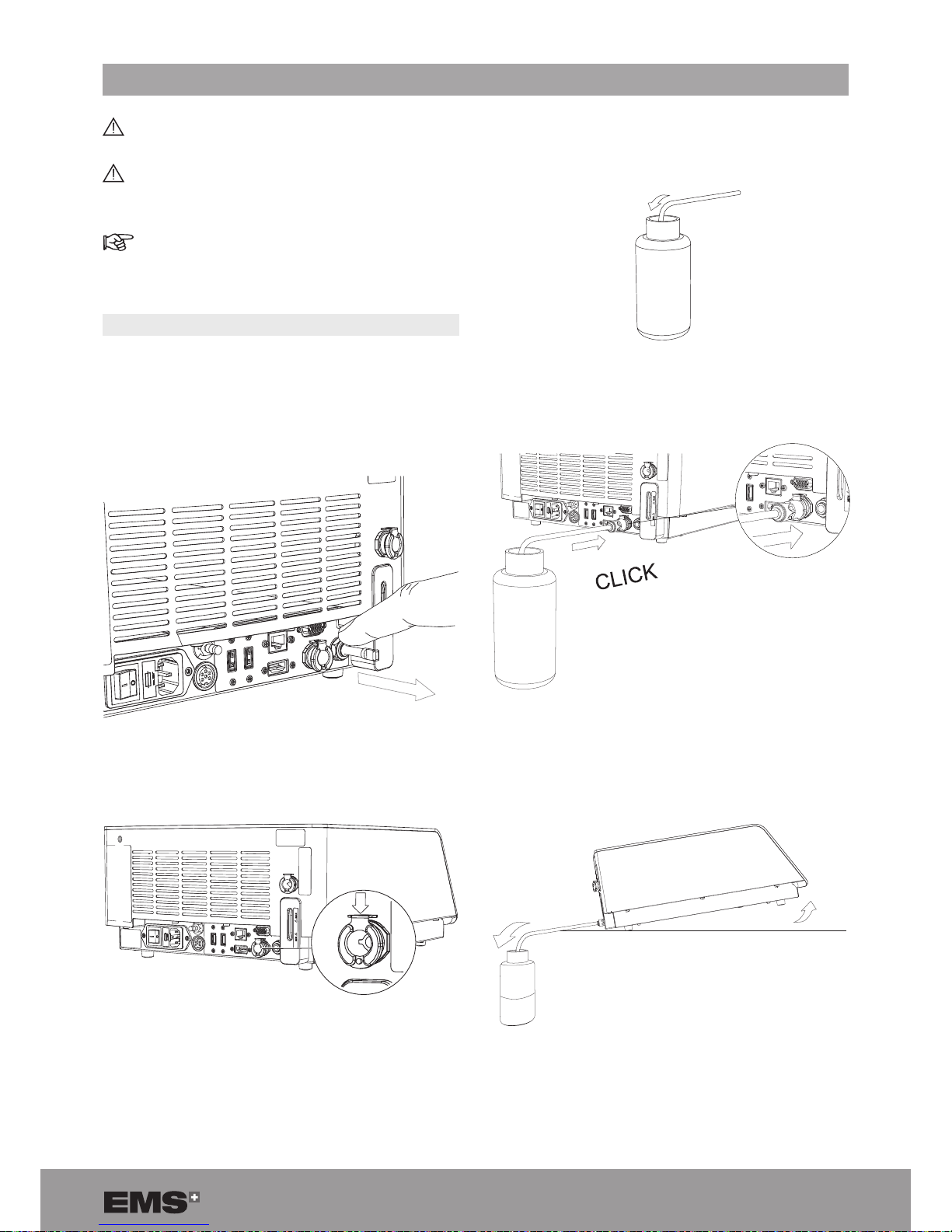

8.1. COOLING LIQUID CIRCUIT MAINTENANCE

The cooling liquid and the water lter must be

replaced every year. Regular maintenance is

required for product to function properly.

This procedure is applicable for pump and pinch

valve version.

1. Empty the cooling liquid circuit.

Refer to the Product Storage and Shipping section

for instructions on emptying the cooling liquid

circuit.

2. Place the console at on its side.

Figure 75

3. Use the Torx tool size 20 to remove the water lter

cover (A).

4. Push the colored ring with your left hand and simulta-

neously pull the plug to remove the lter tube.

5. Replace the water lter.

Figure 76

Connect the tubes to the corresponding color.

The grey ring is on the left and the green ring is

on the right.

6. Re-install the water lter (B) and cover (A).

B

A

Figure 77

Page 30

30

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

7. Replace the console on a at surface.

8. Refill the cooling system. Refer to the Filling the

Cooling System section.

8.2. REPLACING FUSES

1. Disconnect the power cord at the rear of the console.

Figure 78

2. Remove the fuse drawer located in the power socket.

Figure 79

3. Replace defective fuses with the fuse type specied

on the identication plate at the rear of the console.

4. Re-insert the fuse drawer.

5. If the fuses fail again, please contact your EMS autho-

rized service center.

8.3. DOWNLOADING LOGFILE

An EMS service center may request this procedure.

1. Plug the USB key provided by EMS at the rear of the

console.

2. From the STANDBY screen, select PARAMETERS

3. Press LOGFILE DOWNLOAD.

4. Follow the procedure displayed on the screen.

Page 31

31

9. PRODUCT STORAGE AND SHIPPING

Do not tilt or invert the console without rst having

emptied the cooling liquid circuit.

Always empty the cooling liquid circuit before

longterm storage (2 weeks or more) or shipping to

avoid damage to the console.

Storage and transport conditions are specied in

the Technical Data section.

9.1. EMPTYING THE COOLING LIQUID CIRCUIT

1. Unplug all cables at the rear of the console.

2. Place the console on a at, stable surface.

3. To remove the air vent plug, push the grey ring with

your left hand and simultaneously pull the plug.

Figure 80

4. Make sure that the metal locking device is in the

down position.

Figure 81

5. Put the draining tube in a receptacle that is more than

600 ml in volume.

Figure 82

6. Connect the draining tube (supplied with the product)

to the outlet.

Figure 83

7. Tilt the console until the connector is in contact with

the at, stable surface to fully empty the cooling liquid

circuit.

Figure 84

Page 32

32

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

8. Unlock the metal locking part to disconnect the

draining tube.

Figure 85

9. Re-insert the air vent plug.

9.2. SHIPPING THE PRODUCT

Before shipping the product, follow the instructions

provided in the Cleaning, Disinfecting and Sterilizing section.

T o avoid damage, pack the product and all accessories in the original packaging. Make sure to insert

the air vent plug prior to packing and shipping the

product.

Page 33

33

10. PRODUCT DISPOSAL

The product must not be discarded in

domestic household waste.

Should you wish to denitively dispose

of the product, please comply with the

applicable regulations in your country.

Keep the original packaging until the product is to be

disposed of permanently.

Waste Electrical and Electronic Equipment belonging

to customers located in the European Union may be

shipped to EMS for recycling in accordance with the

WEEE regulations. The costs of recycling, exclusive of

shipping fees, are covered by EMS.

11. EMS TECHNICAL SUPPORT

Please contact your EMS authorized service center for

any product servicing or repairs. You must complete the

appropriate EMS form in order to be issued a Return

Material Agreement (RMA) number.

EMS declines responsibility for the safety of the product

and declares the warranty null and void if service or

repair is carried out by an unauthorized third party or if

non-genuine spare parts are used.

It is mandatory to return your product in its original

packaging. By following these packaging guidelines,

your product shall be protected against damage during

shipment. T o protect the personnel of the EMS authorized

service center and for safety reasons during transport and

shipment, all products and accessories returned to the

factory for repair or servicing must be cleaned, disinfected

and sterilized in accordance with the instruction manual.

Repair can be refused for products or accessories

received in a contaminated condition.

When sending your product directly to the EMS authorized service center, please include the name of the

distributor to simplify processing.

Page 34

34

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

12. TROUBLESHOOTING

Ensure that the product and the accessories have

been used in accordance with the conditions

specied by EMS.

Only contact an EMS service center if none of the

following instructions works.

To improve our quality of service, please provide the

following information:

• Product reference number,

• Software revision,

• Batch number/serial number,

• Service history of the product (e.g., previous issues

or repairs).

12.1. MANUAL HANDPIECE UNLOCKING

Only use the manual handpiece unlocking

procedure when disconnection has failed.

Refer to the Disconnecting the Handpiece section.

1. Turn off the console.

2. Keep the console in its at position.

3. Insert a needle (2mm diameter) until you reach the

stop.

4. Push the needle to the right to unlock the handpiece.

The handpiece is unlocked.

1

2

Figure 86

5. Remove the handpiece.

12.2. WEAK SUCTION

1. Make sure that the stone catcher tube is correctly

inserted in the peristaltic pump/pinch valve.

2. Make sure that the stone catcher roller clamp is not

closed.

3. Check that no clogging occurs in the handpiece or

probe.

4. Make sure that there are no leaks in the suction circuit.

5. Replace the liquid collection pouch if it is full.

6. Make sure that the stone catcher cover is fully

tightened up to the stop.

7. Make sure that the stone catcher is correctly tightened

on the handpiece.

• For Pinch Valve Device

1. Make sure that the pinch valve opens when the pedal

is pressed down.

• For Peristaltic Pump Device

1. Increase the suction from the READY screen.

2. Open the cover of the pump to check that the rollers

on the head of the pump turn.

3. Make sure that there are no leaks in the collection

system.

12.3. PROBE NOT COMPATIBLE WITH THE

ENDOSCOPE

1. Refer to the Probe Compatibility Table section to

check the diameter and/or length of the probes with

respect to the dimensions of the endoscope.

2. Check the physical integrity of the probe.

3. Replace the probe.

12.4. DISPLAYED ERROR MESSAGES

In case of a malfunction or an operating error, the

faulty component is automatically highlighted in

the STAND BY screen.

In case of critical error, the system stops and

automatically reverts to the STAND BY screen.

Page 35

35

Figure 87

1. Press the highlighted faulty component and follow

the interactive menu to identify the exact origin of

the error.

2. Follow the recommended action that is displayed.

3. If the solutions proposed fail to solve the problem,

please contact your EMS authorized service center.

Do not, in any case, return a product before troubleshooting of the error has been performed.

4. The following table provides more detailed information

about failures: error number and associated error

messages.

• Console

E001 - The cooling pump is not detected and handpiece cooling might not be available. Please restart device.

Please contact your EMS authorized service center if the error persists.

E002 - The cooling valve is not detected and handpiece cooling might not be available. Please restart device.

Please contact your EMS authorized service center if the error persists.

E008 - Conguration les of the console are corrupted and informations might be incorrect. Please contact your

EMS authorized service center.

E009 - Console internal communication error. Please restart device. Please contact your EMS authorized service

center if the error persists.

E010 - Pedal not detected. Please verify that the connector of the pedal is connected to the console. Please

contact your EMS authorized service center if the error persists.

E016 - No suction system has been detected. Please restart device or contact your EMS authorized service center

if the error persists.

E017 - T wo suction systems seem to be connected. Please restart device or contact your EMS authorized service

center if the problem persists.

E018 - The console temperature is high. Treatment is still possible but verify the console is placed in a correctly

ventilated place

E019 - The console temperature is too high. System needs to cool down. Please keep it powered while temperature

returns to safe level.

E020 - Console internal communication error. System trying to recover . Please restart device or contact your EMS

authorized service center if the error persists.

E024 - Console internal communication error. Please restart device or contact your EMS authorized service center

if the error persists.

Page 36

36

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

E025 - Console temperature error. Please wait for the console to cool down. Please contact your EMS authorized

service center if the error persists.

E026 - Shockwave module critical error. Please restart the device. Please contact your EMS authorized service

center if the error persists.

E027 - Ultrasound module critical error. Please restart the device. Please contact your EMS authorized service

center if the error persists.

E031 - The console temperature sensor was not detected. Please restart the device. Please contact your EMS

authorized service center if the error persists.

E032 - Fan was not detected. Please restart the device. Please contact your EMS authorized service center if

the error persists.

E034 - Handpiece lock not detected. Please restart the device. Please contact your EMS authorized service

center if the error persists.

E038 - The console temperature sensor was not detected. Please restart the device. Please contact your EMS

authorized service center if the error persists.

Table 5

• Handpiece

E003 - The handpiece temperature is rising and could be harmful. Please let the system cool down. V erify cooling

tank water level and handpiece cord sealing. Please check that after handpiece disconnection that the handpiece

cooling circuit is dry. Please contact your EMS authorized service center if the error persists.

E004 - The handpiece temperature is high. Treatment is still possible but verify cooling tank level.

E005 - Handpiece not detected. Please verify that the handpiece is connected to the console. Replace the

handpiece if the error persists.

E037 - The handpiece temperature sensor was not detected. Please restart the device. Please contact your EMS

authorized service center if the error persists.

Table 6

• Probe

E011 - Probe has exceeded the usage limit. The probe use policy is validated for a maximum number of usage

cycles. Continue treatment at your own responsibility.

E012 - Probe not detected. Please check that the probe is correctly installed on the handpiece. Please contact

your EMS authorized service center if the error persists.

E013 - Unknown probe. Please verify that the probe is a valid one or undamaged. Please contact your EMS

authorized service center if the error persists.

E035 - Probe settings can’t be automatically loaded. Please change probe. Please contact your EMS authorized

service center if the error persists.

Table 7

Page 37

37

13. FORMER ELECTROMAGNETIC COMPATIBILITY

The SWISS LITHOCLAST® TRILOGY should not be used adjacent to or stacked with another SWISS LITHOCLAST®

TRILOGY . If adjacent or stacked use is necessary, the SWISS LITHOCLAST® TRILOGY should be observed to verify

normal operation in the conguration in which it will be used.

Guidance and manufacturer’s declaration – electromagnetic emissions

The SWISS LITHOCLAST® TRILOGY is intended for use in the electromagnetic environment specied below. The

customer or the user of the SWISS LITHOCLAST® TRILOGY should ensure that it is used in such an environment.

Emissions Test Compliance Electromagnetic Environment – Guidance

RF emissions

CISPR 11

Group 1 The SWISS LITHOCLAST® TRILOGY

uses RF energy only for its

internal function. Therefore, its RF emissions are very low and are not

likely to cause any interference in nearby electronic equipment.

RF emissions

CISPR 11

Class B The SWISS LITHOCLAST® TRILOGY

is suitable for use in all establish-

ments, including residential establishments and those directly connected

to the public low-voltage power supply network that supplies buildings

used for domestic purposes.

Harmonics emissions

IEC 61000-3-2

Class A

Voltage uctuations /

icker emissions

IEC 61000-3-3

Complies

Table 8

Guidance and Manufacturer’s Declaration – Electromagnetic Immunity

The SWISS LITHOCLAST® TRILOGY is intended for use in the electromagnetic environment specied below. The

customer or the user of the SWISS LITHOCLAST® TRILOGY should ensure that it is used in such an environment.

Immunity Test

IEC 60601

Test Level

Compliance level

Electromagnetic Environment –

Guidance

Electrostatic

discharge (ESD)

IEC 61000-4-2

± 6 kV contact

± 8 kV air

± 6 kV contact

± 8 kV air

Floors should be wood, concrete or ceramic

tile. If floors are covered with synthetic

material, the relative humidity should be at

least 30%.

Electrical fast

transient / burst

IEC 61000-4-4

± 2 kV for power supply

lines

±1 kV for input/output lines

± 2 kV for power

supply lines

Not applicable

Mains power quality should be that of a typical

commercial or hospital environment.

Surge

IEC 61000-4-5

± 1 kV line(s) to line(s)

± 2 kV line(s) to earth

± 1 kV line(s) to line(s)

± 2 kV line(s) to earth

Mains power quality should be that of a typical

commercial or hospital environment.

Power frequency

(50/60 Hz)

magnetic eld

IEC 61000-4-8

3 A/m 3 A/m Power frequency magnetic elds should be

at levels characteristic of a typical location in

a typical commercial or hospital environment.

Voltage dips,

short interruptions and

voltage variations on power

supply input

lines

IEC 61000-4-11

<5% UT (>95% dip in UT)

for 0.5 cycle

40% UT (60% dip in UT)

for 5 cycles

70% UT (30% dip in UT)

for 25 cycles

<5% UT (>95% dip in UT)

for 5 s

<5% UT (>95% dip in

UT) for 0.5 cycle

40% UT (60% dip in

UT) for 5 cycles

70% UT (30% dip in

UT) for 25 cycles

<5% UT (>95% dip in

UT) for 5 s

Mains power quality should be that of a typical

commercial or hospital environment. If the

user of the SWISS LITHOCLAST® TRILOGY

requires continued operation during power

mains interruptions, it is recommended that

the SWISS LITHOCLAST® TRILOGY be

powered from an uninterruptible power supply

or a battery.

Table 9

Page 38

38

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

Portable and mobile RF communications equipment should be used no closer to any part of the SWISS LITHOCLAST®

TRILOGY, including cables, than the recommended separation distance calculated from the equation applicable to

the frequency of the transmitter.

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

3 Vrms

150 kHz –

80 MHz

3 V/m

80 MHz –

2.5 GHz

10 Vrms

10 V/m

Recommended separation distance

d = 0.35 √P

d = 0.35 √P 80 MHz – 800 MHz

d = 0.7 √P 800 MHz – 2.5 GHz

where P is the maximum output power rating of the transmitter

in watts (W) according to the transmitter manufacturer and d is

the recommended separation distance in meters (m).

Field strengths from xed RF transmitters, as determined by an

electromagnetic site survey,

a

should be less than the compliance

level in each frequency range.

b

Interference may occur in the vicinity of equipment marked with

the following symbol:

Table 10

At 80 MHz and 800 MHz, the higher frequency range applies.

These guidelines may not apply to all situations. Electromagnetic propagation is affected by absorption and

reection from structures, objects and people.

a

Field strengths from xed transmitters, such as base stations for radio (cellular/cordless) telephones and land

mobile radios, amateur radios, AM and FM radio broadcast and TV broadcast cannot be predicted theoretically with

accuracy. To assess the electromagnetic environment due to xed RF transmitters, an electromagnetic site survey

should be considered. If the measured eld strength in the location in which the SWISS LITHOCLAST® TRILOGY is

used exceeds the applicable RF compliance level above, the SWISS LITHOCLAST® TRILOGY should be observed

to verify normal operation. If abnormal performance is observed, additional measures may be necessary , such as

re-orienting or relocating the SWISS LITHOCLAST® TRILOGY.

b

Over the frequency range 150 kHz to 80 MHz, eld strengths should be less than 10 V/m.

UT is the A/C mains voltage prior to application of the test level.

Page 39

39

Recommended separation distances between portable and mobile RF communications equipment and the

SWISS LITHOCLAST® TRILOGY

The SWISS LITHOCLAST® TRILOGY is intended for use in an electromagnetic environment in which radiated RF

disturbances are controlled. The customer or the user of the SWISS LITHOCLAST® TRILOGY can help prevent

electromagnetic interference by maintaining a minimum distance between portable and mobile RF communications

equipment (transmitters) and the SWISS LITHOCLAST® TRILOGY as recommended below , according to the maximum

output power of the communications equipment.

Rated maximum

output power of

transmitter [W]

Separation distance according to frequency of transmitter [m]

150 kHz to 80 MHz

d = 0.35 √P

80 MHz to 800 MHz

d = 0.35 √P

800 MHz to 2.5 GHz

d = 0.7 √P

0.01 0.04 m 0.04 m 0.07 m

0.1 0.13 m 0.13 m 0.22 m

1 0.4 m 0.4 m 0.7 m

10 1.3 m 1.3 m 2.2 m

100 4 m 4 m 7 m

Table 11

For transmitters rated at a maximum output power not listed above, the recommended separation distance (d) in

meters (m) can be estimated using the equation applicable to the frequency of the transmitter, where power (P) is the

maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer.

At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

These guidelines may not apply to all situations.

Electromagnetic propagation is affected by absorption and reection from structures, objects and people.

Compliant cables and accessories

The use of accessories and cables other than those specied or sold by EMS as replacement parts may result in

increased emissions or decreased immunity of this product.

Cables and

accessories

Maximum length Complies with

Handpiece cord

Pedal

2.9 m

2.9 m

CISPR 11 Class B / Group 1: RF electromagnetic disturbance

IEC 61000-4-2 Electrostatic discharge (ESD)

IEC 61000-4-3 Electromagnetic elds radiated by radio-frequencies

IEC 61000-4-4 Electric fast transient / burst

IEC 61000-4-5 Surge

IEC 61000-4-6 Disturbances induced by radio-frequency elds

IEC 61000-4-8 Power frequency magnetic eld (50/60 Hz)

IEC 61000-4-11 Voltage dips, short interruptions and voltage variations

Table 12

Essential performance

The SWISS LITHOCLAST® TRILOGY has neither life sustaining functions nor diagnostic of life supporting functions.

Page 40

40

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

14. NEW ELECTROMAGNETIC COMPATIBILITY

Electromagnetic compatibility according to IEC 60601-1-2:2014

Guidance and manufacturer’s declaration – electromagnetic emissions

The Swiss LithoClast® Trilogy is intended for use in the electromagnetic environment specied below. The

customer or the user of the Swiss LithoClast® Trilogy should assure that it is used in such an environment.

EMISSIONS TEST COMPLIANCE ELECTROMAGNETIC ENVIRONMENT - GUIDANCE

RF emissions

CISPR 11

Group 1

The Swi s s LithoClast® Trilogy uses RF energy only for its internal

function. Therefore, its RF emissions are v ery low and are not

likely to cause any interference in nearby electronic equipment.

RF emissions

CISPR 11

Class A

The emissions characteristics of the Swiss LithoClast® Trilogy

make it suitable for use in hospitals only.

Harmonic emissions

IEC 61000-3-2

Not applicable

Voltage uctuation / icker

emissions

IEC 61000-3-3

Not applicable

Table 13

Guidance and manufacturer’s declaration – electromagnetic immunity

The Swiss LithoClast® Trilogy is intended for use in the electromagnetic environment specied below. The

customer or the user of the Swiss LithoClast® Trilogy should assure that it is used in such an environment.

IMMUNITY TEST

IEC 60601

TEST LEVEL

COMPLIANCE LEVEL

ELECTROMAGNETIC

ENVIRONMENT - GUIDANCE

Electrostatic discharge

(ESD)

IEC 61000-4-2

± 8 kV contact

± 15 kV air

± 8 kV contact

± 15 kV air

Floors should be wood, concrete

or ceramic tile. If oors are

covered with synthetic material,

the relative humidity should be at

least 30%.

Radiated RF

IEC 61000-4-3

3 V/m

80 MHz to 2.7 GHz

10 V/m

80 MHz to 2.7 GHz

Portable and mobile RF communications equipment should be used

no closer than 30 cm to any part

of the Swiss LithoClast® Trilogy,

including cables.

Proximity elds from RF

wireless communica-

tions equipment

IEC 61000-4-3

See next table See next table

Conducted RF

IEC 61000-4-6

3 V rms

150 kHz to 80 MHz

6 V rms

in ISM and amateur radio

bands

3 V rms

150 kHz to 80 MHz

6 V rms

in ISM and amateur radio

bands

Power frequency

(50/60 Hz) magnetic

eld

IEC 61000-4-8

30 A/m 30 A/m

Power frequency magnetic elds

should be at levels character-

istic of a typical location in a

typical commercial or hospital

environment.

Table 14

UT is the A/C mains voltage prior to application of the test level.

Page 41

41

Proximity elds from RF wireless communications equipment

TEST FREQUENCY

(MHZ)

MODULATION

IEC 60601

TEST LEVEL

385

Pulse modulation

a

18 Hz

27 V/m

450

FM

± 5 kHz deviation

1 kHz sine

28 V/m

710

754

780

Pulse modulation

a

217 Hz

9 V/m

810

870

930

Pulse modulation

a

18 Hz

28 V/m

1720

1845

1970

Pulse modulation

a

217 Hz

28 V/m

2450

Pulse modulation

a

217 Hz

28 V/m

5240

5500

5785

Pulse modulation

a

217 Hz

9 V/m

a

50% duty cycle square wave signal

Table 15

Page 42

42

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

15. TECHNICAL DATA

MANUFACTURER E.M.S. Electro Medical Systems S.A., CH-1260 Nyon, Switzerland

MODEL SWISS LITHOCLAST® TRILOGY

POWER SUPPLY 100 – 240 VAC, 50 – 60 Hz, 500 VA

EN 60601-1 CLASSIFICA TION System: EN 60601-1: Class I

Probe: EN 60601-1: Class I BF

MDD 93/42 EEC

CLASSIFICATION

Class IIb: device, handpiece

Class IIa: probes

Class I: uid management system, pedal, torque wrench, cart

Class Is: Stone catcher

IEC 60529 IP

CLASSIFICATION

Console (IP21)

Handpiece (IPX8)

Pedal (IPX8)

PRIMARY FUSE 6.3A, T (slow), 250 VAC (=T6.3A250V)

Dimensions: Ø5 X 20 mm

CONSOLE Weight: 13.5 kg

Dimensions: height – 135 mm, width – 360 mm, depth – 420 mm

OPERATING CONDITIONS Temperature: +10°C to +30°C

Relative humidity: 30% to 75%

Atmospheric pressure: 700 hPa to 1060 hPa

Max. altitude: 3000 m

TRANSPORT AND STORAGE

CONDITIONS

Temperature: 1°C to +40°C

Relative humidity: 10% to 90%

Atmospheric pressure: 70 kPa to 106 kPa

PRODUCT USAGE PERIOD Console lifetime: 7 years

Sterile accessories shelf-life: 2 years

Handpiece lifetime: 2 years or 100 usage cycles

Torque wrench lifetime: 3 years, or 6000 clicks/300 sterilizations

COOLING LIQUID Demineralised water

MAXIMUM

TRANSPORTABLE

WEIGTH ON THE CART

40kg

Page 43

43

16. SYMBOLS

Manufacturer logo

Product name

Origin of the product

CE symbol refers to directive 93/42/EC, including EN 60601-1 and EN 60601-1-2

DEKRA INMETRO identication for products in conformance with Brazilian electrical

standards

GOST R marking for products in conformance with Russian standards

Lock icon

Applied part, type BF

Manufacturer

Year of manufacture

Catalogue number

Disposal of Old Electrical & Electronic Equipment (Applicable in the European Union

and other European countries with separate collection systems)

Equipotential plug

Page 44

44

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

Serial number

Refer to the instruction manual

Device requiring protective earth

Input

Fuse

Risk of electric shock

Emptying

Filling

Foot pedal connection

Do not allow ngers to come into contact with moving parts

Flow direction

Minimum tank level indicator

Maximum tank level indicator

Page 45

45

Degree of protection against water permeability

USB connector

HDMI connector

Thermal disinfection

135°C

Sterilizable at up to 135°C in the autoclave

2

STERILIZE

Do not re-sterilize

Do not re-use

Do not use if package is damaged

Refer to instruction manual

Content

STERILE EO

Sterilized using ethylene oxide

Use by

Danger

Table 16

Page 46

46

SWISS LITHOCLAST BLAST - FB-610/EN 23-JUNE-2017 / EMS CONFIDENTIAL

17. APPENDIX

17.1. PROBE COMPATIBILITY TABLE

Different probe sizes are available to allow effective treatment with the most popular endoscopic systems for percutaneous nephroscopy, rigid and semi-rigid ureteroscopy and cystoscopy:

PROBE DIAMETER

AND LENGTH

MINIMUM ENDOSCOPE

WORKING CHANNEL

SIZE

MAXIMUM ENDOSCOPE

WORKING CHANNEL

LENGTH

TAG RING COLOR

Ø 1.1 mm x 425 mm 4 Fr 400 mm RED

Ø 1.1 mm x 520 mm 4 Fr 500 mm RED

Ø 1.1 mm x 625 mm 4 Fr 600 mm RED

Ø 1.5 mm x 425 mm 5 Fr 400 mm ORANGE

Ø 1.5 mm x 520 mm 5 Fr 500 mm ORANGE

Ø 1.9 mm x 341 mm 6 Fr 320 mm YELLOW

Ø 3.4 mm x 340 mm 10.5 Fr 320 mm GREEN

Ø 3.4 mm x 445 mm 10.5 Fr 420 mm GREEN

Ø 3.9 mm x 350 mm 12 Fr 330 mm BLUE

Ø 3.9 mm x 440 mm 12 Fr 420 mm BLUE

Table 17

* US and suction not available

17.2. FCC AND IC

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired operation.

Any changes or modications not expressly approved by Electro Medical Systems for compliance could void the user’s

authority to operate this equipment.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

FCC RF exposure statement:

Important note: This device complies with FCC and Industry Canada radiation exposure limits set forth for general

population. This device must not be co-located or operating in conjunction with any other antenna or transmitter.

IC Statements:

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the following

two conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may cause undesired operation of the device.

Under Industry Canada regulations, the radio transmitter(s) in this device may only operate using an antenna of a

type and maximum (or lesser) gain approved for the transmitter by Industry Canada. To reduce potential radio interference to other users, the antenna type and its gain should be so chosen that the equivalent isotropically radiated

power (e.i.r.p.) is not more than that necessary for successful communication.

Page 47

47

Page 48

EMS Electro Medical Systems SA EMS worldwide ofces (medical)

EMS-SWISSQUALITY.COM

SUISSE

Ch. de la Vuarpillière 31

1260 Nyon

SWITZERLAND

Tel. +41 22 99 44 700

Fax +41 22 99 44 701

e-mail: welcome@ems-ch.com

Manufacturer

EMS Electro Medical Systems SA

Ch. de la Vuarpillière 31

1260 Nyon

SWITZERLAND

FRANCE

EMS France Sarl

23, Av. Louis Bréguet

Immeuble Santos Dumont, Bâtiment D

F-78140 Vélizy Villacoublay

Tél. +33 1 34 58 03 80

Fax +33 1 34 58 03 90

e-mail: info@ems-france.fr

ITALY

EMS Italia S.r.l

Via Faravelli 5

I-20149 Milano

Tel. +39 02 3453 8075

Fax +39 02 3453 1724

e-mail: medical@ems-italia.it

USA/CANADA

EMS Corporation

11886 Greenville Avenue #120

Dallas, TX 75243, USA

Tel. +1 972 690 83 82

Fax +1 972 690 89 81

e-mail: info@ems-na.com

GERMANY

EMS Medical GmbH

Schatzbogen 86

D-81829 München

Tel. +49 89 43 57 29 990

Fax +49 89 43 57 29 90 66

e-mail: info@ems-medical.de

SPAIN

EMS Electro Medical Systems España SL

Bernardino Obregón 14 bis

E-28012 Madrid

Tlf. +34 91 528 99 89

Fax +34 91 539 34 89

e-mail: administracion@ems-espana.com

© Copyright EMS SA FB-610/6_rev A-01 ed.2017/06

Loading...

Loading...