Page 1

EMS Aviation, Inc.

Sky Connect Aviation Series

Installation Manual

TRACKER

1616-964-12

Date: 7/27/2011

Rev. 2.1

Part Number 1616-964-12

i

Page 2

1616-964-12

Date: 7/27/2011

Rev. 2.1

Aviation Certification Issues

CERTIFICATION – Sky Connect has rights to several Supplemental Type Certificates. Use of

this information is provided with purchase of the equipment. Assistance in certification

efforts to the installers is offered at no charge to the customer or installer. Assistance is

provided on Sky Connect’s scheduling.

Please plan your certification issues with the following in mind; Phone assistance is

provided 8am to 5pm Central Time U.S. based on our available time and work load for the

day.

Certification teams maybe required to perform work on a deadline basis, there will be a fee

for such work at the rate of $150 US per hour. Please contact Sky Connect Technical

Services for assistance.

ii

Page 3

1616-964-12

Date: 7/27/2011

Rev. 2.1

TABLE of CONTENTS

LIST OF REVISIONS.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

INDEX OF ACRONYMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

GENERAL INFORMATION.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

INTRODUCTION.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

SYSTEM DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

TECHNICAL SPECIFICATIONS.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

INSTALLATION PROCESS.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

WIRING DIAGRAM.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

SIM CARD ACTIVATION.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

ANTENNA PLACEMENT PLAN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

INFORMATION NEEDED FOR CONFIGURATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

TRACKER MAPPING SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

WIRING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

CONFIGURATION.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

TRACKER RULES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

INSTALLATION - GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

A DISCUSSION ON SIM CARDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

ITEMS REQUIRED BUT NOT SUPPLIED.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

GENERAL SYSTEM COMPONENTS THAT APPLY TO ALL SYSTEMS. . . . . . . . . . . . . . 3 - 4

SYSTEM COMPONENTS THAT APPLY ONLY TO TRACKER. . . . . . . . . . . . . . . . . . . . . . 3 - 4

GENERAL INSTALLATION INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

TRACKER SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

TRACKER SYSTEM COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

TRANSCEIVER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

CONFIGURATION MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

CONFIGURATION/SIM MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

TRACKER SOP DIALER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

MMU/II (Mission Management Unit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

TRACKER-SOP STRUCTURAL MOUNTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

TRACKER WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

POST INSTALLATION TESTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

TRACKER SETUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 17

TRACKER TESTING.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 17

OPERATION.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 19

iii

Page 4

1616-964-12

Date: 7/27/2011

Rev. 2.1

APPENDIX A Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

INSTALLATION AND SYSTEMS DRAWINGS.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

iv

Page 5

1616-964-12

Date: 7/27/2011

Rev. 2.1

LIST OF REVISIONS

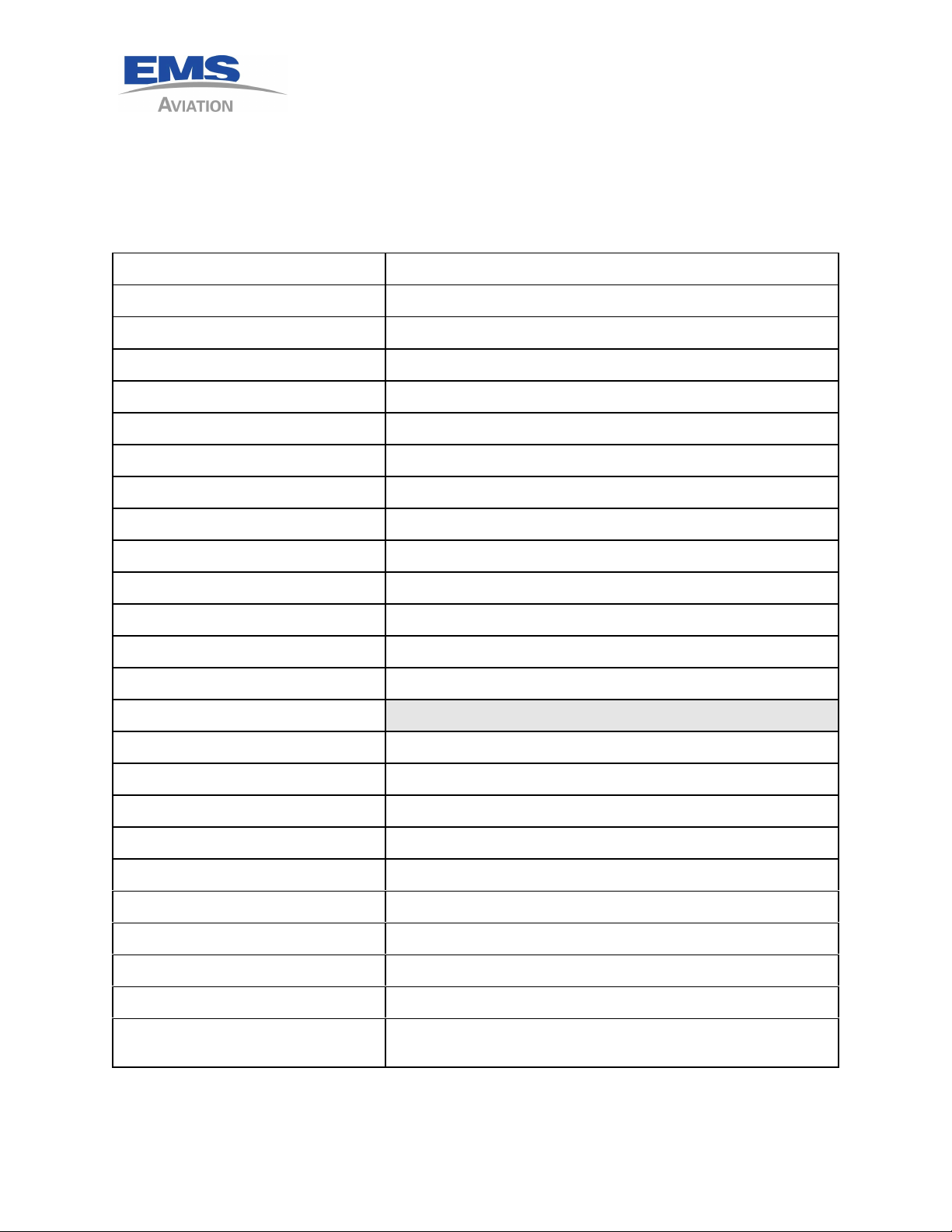

Revision # Description of Change Date Approval

1.0 Removed all POTS unit information and

created a new manual part number for

Tracker only.

1.1 Added Combo antenna, corrected note on

ICSM, revised pin out chart to remove the

400 series references.

1.2 Typos corrected, revised MMU/MMU II

recommended installation wiring

drawing

1.3 Added spec and part numbers for MMU II 12/15/2008 MLF

1.4 Added configuration details on MMU II

and Combo antenna drawing

1.5 Revised to indicate the changes to the

1616-105-01 tray per ECO 10013

2.0 Revised to add description of MMU II

features for Wi-Fi MSet Loads and

Performing Tracker Setup through the

MMU II, Added MMU II Master/Slave

Configuration

3/24/2007 MLF

3/20/2008 MLF

10/3/2008 MLF

1/13/2009 MLF

6/3/2010 MLF

4/7/2011 MLF

2.1 Revised Annuc. #2 description, includes a

picture of the SOP 11 jumper

v

7/27/2011 MLF

Page 6

INDEX OF ACRONYMS

FOI Field Of Interest (a position)

GIS Geographic Information System

IDT Icarus Dial Tone

IMEI International Mobile Equipment Identifier

LBT L Band Transceiver

PBX Private Branch eXchange

POTS Plain Old Telephone System

PUK Personal Unblocking Code

SBD Short Burst Data

1616-964-12

Date: 7/27/2011

Rev. 2.1

SIM Subscriber Identity Module

SMS Short Message Service

For a complete definition of terms see http://www.telestial.com/glossary.htm on the Web.

vi

Page 7

1 GENERAL INFORMATION

1.1 INTRODUCTION

This manual contains information relative to the physical, mechanical, and electrical

installation of the Sky Connect Systems. Operating procedures are also included.

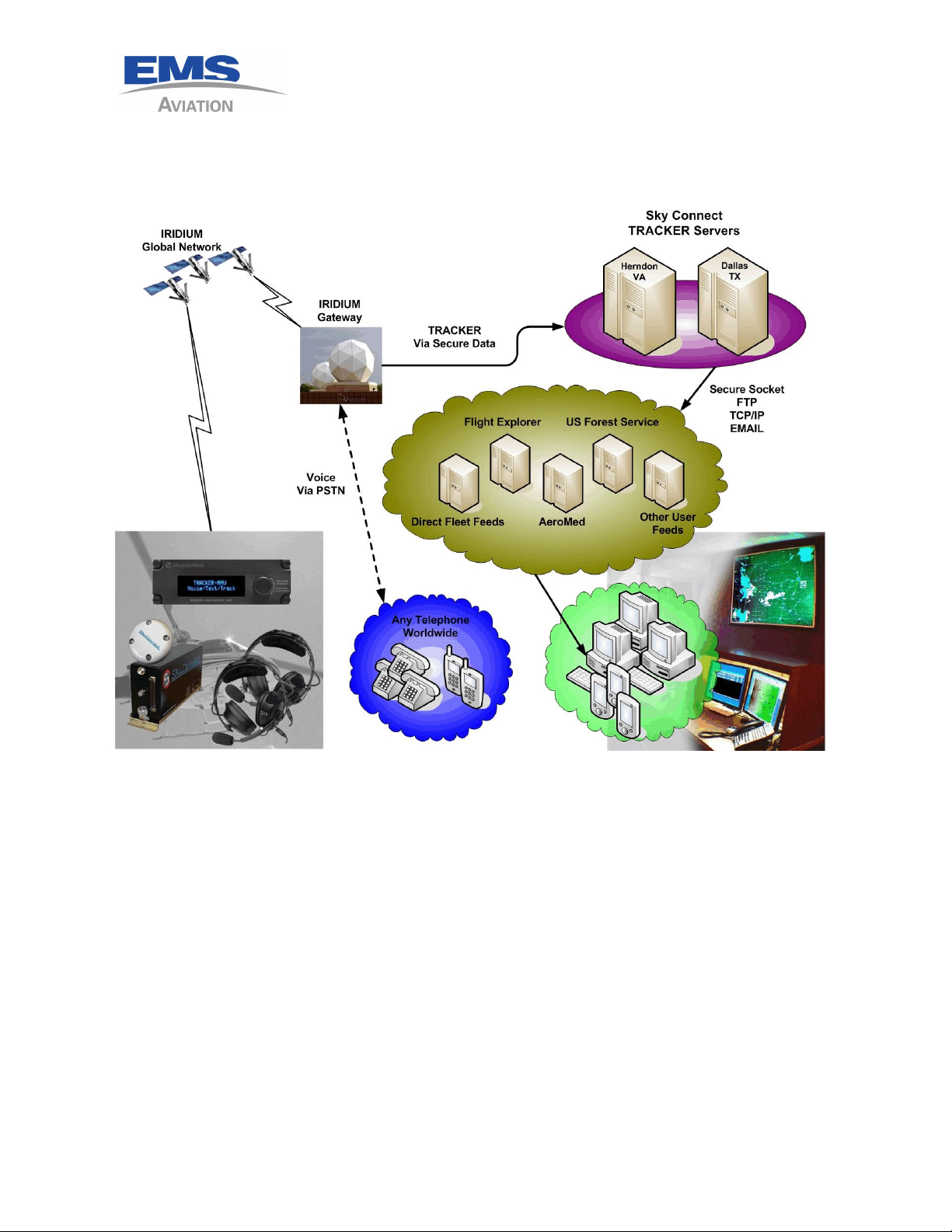

1.2 SYSTEM DESCRIPTION

The Sky Connect series satellite communications device consists of a transceiver, an

L-band antenna, and a dialing/audio/data interface device. The remote mounted

transceiver is the heart of the system, and contains the Iridium satellite LBT (L-Band

Transceiver). The LBT can be thought of as the “phone” in the satellite phone

system and the modem in the data system, as it is the connection used to gain access

to the Iridium network. The LBT allows the two way transfer of voice and data.

1616-964-12

Date: 7/27/2011

Rev. 2.1

The LBT is the same in every transceiver of the Sky Connect System though different

modules are added to define the function of the transceiver as a whole. Each Sky

Connect telephone system also has the ability for data transfer at rates up to 10

Kbps (with compression), allowing the user to interface a laptop for in-flight email

capability. The Tracker system offers an optional internal 12 channel G.P.S. module.

Tracker uses the short burst data transfer portions of the Sky Connect suite, though

it can be coupled with any of the phone systems. Any system can exist alone, or

co-exist with another, and upgrades can be done to any system at any time without

incurring additional cost penalties.

The Iridium system can only be occupied by one “call” at a time, whether it is voice,

data, or Short Burst Data. These systems exist simultaneously, but can not be used

simultaneously. Multiple transceivers and antennas are required for multiple

channels of communication. For clarity, two users may be on separate handsets on

the same call, but two users can not be on separate handsets on different calls

without a second transceiver/antenna. Similarly, when a phone call is in progress,

Tracker will be unable to send SBD packets, though as soon as the line is clear, it will

send its stored messages.

1 - 1

Page 8

1616-964-12

Date: 7/27/2011

Rev. 2.1

Figure 1

Tracker & Communication Concept Drawing

1 - 2

Page 9

1616-964-12

Date: 7/27/2011

1.3 TECHNICAL SPECIFICATIONS

1.3.1 TRANSCEIVERS

Part Numbers 1616-XX0-0X all Transceivers are the same with the exceptions listed

in the below table.

ITEM SPEC

Regulatory Compliance: DO-160D, FAA STC on Part 25, 27, and 29 aircraft. FAA-PMA

Temperature Range: Section 4 Cat D2 (-20C to +55C)

Altitude Range: Section 4 Cat D2 (50,000 feet)

Vibration: Section 8 Cat R

Temp Variation: Section 5 Cat C

Power Input: Section 16 Cat B

DC Spike: Section 17 Cat B

Rev. 2.1

Conducted Emissions Section 21 Cat B

Radiated Emissions Section 21 Cat B

Weight 4.05 lbs.

Add Tracker: .05 lbs.

Add G.P.S. .10 lbs

Add Messenger: .05 lbs.

Physical Dimensions:

Length 10.0 Inches

(Width) 2.5 Inches

(Height) 4.5 Inches

Power Requirements (Voltage): 11-32Vdc

Power Requirements (Current) : <1 Amp @ 28Vdc

Transmit Power Average: 1.5 watts

Mounting: Quick release tray, 4-#8 holes, any configuration

Transmission rate: 2.4Kbps voice and data (10Kbps with compression)

Operating Frequency: 1.616-1.6265 GHz

Inputs/Outputs: POTS (Plain Old Telephone Service), RS232, DSC, dc

level. 8 discrete inputs Lo< 1.2 Hi >1.3

1 - 3

Page 10

ITEM SPEC

Connectors: TNC female (Iridium), BNC female G.P.S.,

62 pin High Density D-sub connector

1.3.5.2 SOP DIAL PAD SIX POSITION 1616-051-01/03

SOP 6 Dialer has been discontinued.

1.3.5.3 SOP DIALER ELEVEN POSITION 1616-052-00/02

ITEM SPEC

Weight 8 oz.

Physical Dimensions:

(Depth) 3.375 Inches

(Width) 5.75 Inches

(Height) 1.12 Inches

1616-964-12

Date: 7/27/2011

Rev. 2.1

Power Requirements (Voltage): 6 to 28 volt dimmer connected to two separate busses

Power Requirements (Current) : 100 ma Max.

Inputs: 2 lamp inputs

Outputs: 7 switch grounded outputs

Connectors: DB-15 male

Mounting: Dzus rail

1 - 4

Page 11

1616-964-12

Date: 7/27/2011

Rev. 2.1

1.3.5.4 MISSION MANAGEMENT UNIT 1616-055-00/10/11/12/13

ITEM SPEC

Regulatory Compliance: FAA STC on Part 27, and 29 aircraft. (MMU II only part 29) FAA-

PMA

Weight: 15 oz.

Physical Dimensions:

(Depth) 3.375 Inches(MMU) 5.65 (MMU II)

(Width) 5.75 Inches

(Height) 1.875 Inches

Power Requirements (Voltage): 10-33 VDC

Power Requirements (Current) : 250 ma max.

Inputs: RS-232, Wi-Fi Interface for the use of loading Message Sets into

memory.

Outputs: RS-232, four discrete outputs 100ma sinked to ground

Connectors: 2ea. DB-25 male (keyed)

Mounting: Dzus rail

1.3.5.5 SWITCH PANEL Reserved

1 - 5

Page 12

1.3.5.6 CONFIGURATION MODULE 1616-905-01

This part has been discontinued, see earlier manuals.

1.3.5.7 CONFIGURATION/SIM MODULE 1616-905-02

ITEM SPEC

Regulatory Compliance: FAA STC on Part 27, and 29 aircraft. FAA-PMA

Weight: 16 oz.

Physical Dimensions:

(Length) 2.5 inches (without mating connectors)

(Width) 2.125 inches

(Height) .625 inches

Power Requirements (Voltage): 12VDC (supplied by transceiver)

Inputs: Serial Buss and DPL Buss

Outputs: Serial Buss and DPL Buss

1616-964-12

Date: 7/27/2011

Rev. 2.1

Connectors: One DE9 female and one DB25 male

1 - 6

Page 13

1616-964-12

Date: 7/27/2011

Rev. 2.1

1.3.6 ANTENNAS

1.3.6.1 IRIDIUM LOW PROFILE ANTENNA 1616-880-01 AeroAntenna AT2775-XXX

ITEM SPEC

Regulatory Compliance: TSO C-144, DO-160D

Operating Temp: -55 Deg to +85 Deg C

Weight: .5 Lbs Max.

Physical Dimensions: 3.5 inches in diameter

Frequency: 1595 +/- 30 Mhz

Connectors: TNCF

Altitude: 70,000 feet

Impedance: 50 Ohms

1.3.6.2 IRIDIUM BLADE ANTENNA 1616-880-00 Dayton Grander # L10-780

ITEM SPEC

Regulatory Compliance: FAA STC on Part 27, and 29 aircraft

Weight .7 Lbs Max.

Physical Dimensions:

Length 5.49 Inches

Width 3.09 Inches

Height 3.11 Inches

Speed: 600 Kts.

Impedance: 50 Ohms

1 - 7

Page 14

Date: 7/27/2011

1.3.6.3 SENSOR G.P.S. ANTENNA 1616-880-04

ITEM SPEC

Regulatory Compliance: TSO C-144, DO-160D

Operating Temp: -67 Deg F to +185 Deg F

Weight 5 Oz.

Physical Dimensions: 3.5 inches in diameter X .57 Inches High

Frequency: 1575.42 MHz

Connectors: TNCF

Altitude: 55,000 feet

Impedance: 50 Ohms

Voltage: 4 – 24 VDC

1.3.6.4 ANTCOM COMBO IRIDIUM/GPS ANTENNA 1616-880-13

1616-964-12

Rev. 2.1

ITEM SPEC

Regulatory Compliance: TSO C-144, DO-160D, DO-228, MIL-C-5541

Operating Temp: -67 Deg F to +185 Deg F

Weight 7.84 Oz.

Physical Dimensions: L= 5.026" W= 2.2" H= .71"

Frequency: Iridium= 1610 to 1626.5MHz GPS= 1575.42 +/- 13 MHz

Connectors: TNC both GPS (Blue) and Iridium (Red)

Altitude: 70,000 feet

Impedance: 50 Ohms

Voltage: 2.8 to 28VDC (GPS)

1 - 8

Page 15

2 INSTALLATION PROCESS

INSTALLATION PROCESS OUTLINE

Note: Make a plan to cover the follow items in depth in this manual.

2.1 WIRING DIAGRAM

2.1.1 G.P.S. interface, or use of an internal G.P.S.

2.1.2 Event switches, optional

2.1.3 Diagnostic port, must be installed for configuration

2.1.4 Configuration/SIM module, optional

2.1.5 Selection of Dialers optional

2.2 SIM CARD ACTIVATION

Check to make sure the card is activated, call Sky Connect

You will need to know the following information;

1616-964-12

Date: 7/27/2011

Rev. 2.1

2.2.1 The IMEI # of your unit

2.2.2 Model #

2.2.3 Serial #

2.2.4 Credit Card or billing information for monthly service

2.2.5 Aircraft type and registration number

2.2.6 Complete contact information for customer using the product

2.2.7 Send in activation form to turn on the unit with satellite system, please fill out the

form as accurately as possible to make the process as smooth as possible

2.2.8 The form may be filled out on the web at http://www.skyconnect.aero/1086.xml

2.3 ANTENNA PLACEMENT PLAN

2.3.1 Pay close attention to the length of coax from the antenna to RT

2.3.2 Follow manual instructions on placement near other Sat COM and Comm antennas

2.4 Notebook computer with “tracker setup” program, CD included with RT

2.5 INFORMATION NEEDED FOR CONFIGURATION

2.5.1 How the event switches were wired

2.5.2 What type of switches, MOM, ALT, Press

2.5.3 What phone numbers need to be entered (optional)

2 - 1

Page 16

1616-964-12

Date: 7/27/2011

Rev. 2.1

2.6 TRACKER MAPPING SYSTEM

Decide what mapping system is to be used for tracking the aircraft.

Setup an account with that provider and secure ID and passwords.

Make sure this installation is added to the account that handles the mapping.

It is the responsibility of the owner to add aircraft to the mapping system, Sky

Connect

can NOT do that for you unless it is the Sky Connect Webmap you are using.

2.7 WIRING

2.7.1 Wire system as drawn, you the installer are responsible to the FAA for methods and

practices used during the installation.

2.7.2 Continuity checks.

2.7.3 Power polarity checks.

2.8 CONFIGURATION

2.8.1 Configure RT to work with event switches as connected in wiring

2.8.2 Configure external G.P.S. to talk to Sky Connect RT, Aviation or NMEA RS232 format

data

2.8.3 Enter phone numbers (optional)

2.9 TRACKER RULES ( the ugly 14 rules)

Before the tracker can be used to display data on a map, the rules of operation must

be understood. The following will outline those rules.

2.9.1 The transceiver must send data.

2.9.1.1 In order to send data the transceiver must have an active LBT sending SBD.

This is done from the activation form.

2.9.1.2 The transceiver must have an active SIM card.

2.9.1.3 The transceiver must have been configured for the aircraft type.

2.9.1.4 Helicopters may use collective or squat switches.

2.9.1.5 Airplanes may use squat switches.

2.9.1.6 The transceiver must have the report intervals set.

2.9.1.7 The aircraft must be outside and have a clear view of the sky.

2.9.1.8 The aircraft antenna system must be installed I.A.W. our instructions.

2.9.1.9 To display a complete flight, the aircraft must send Departure, Scheduled

reports, and an Arrival message to define a complete flight. This is done

2 - 2

Page 17

1616-964-12

Date: 7/27/2011

Rev. 2.1

through the proper setting of the squat switch, and or software settings from

the tracker setup configuration software.

2.9.1.10 Our server must be set to pass the data on to the proper map program.

2.9.1.11 Our server must have been set up for the customer (activation form

completed and sent in to our office).

2.9.1.12 The map program must be set to receive the data from our server.

2.9.1.13 The map program must have a profile setup to display the aircraft correctly.

2.9.1.14 If email notification is desired we must have the email addresses (activation

form).

2.10 Sky Connect Tracker Capabilities Notes

The following is a recommendation and suggested options available to the user of

the Sky Connect Tracker Series. We hope not to limit your imagination on how you

can apply the rules of the system, only make some common suggestions.

2.10.1 Event Switch Use

Most important of the options that an end customer can take advantage of

with the tracker is the eight (8) event switches. When one of the switches is

closed or opened, and event report is sent to the ground server alerting the

software to this action. Each event is defined either by the Sky Connect

Server ie Squat switch, or by the end user through the ground mapping

software or the Tracker Configuration software.

Each switch input can be configured to one of the following types of inputs:

2.10.1.1 Toggle Switch - This type of switch selection in the tracker set up software

will send an event report when the switch is closed (set) and when it is again

opened.

2.10.1.2 Press Switch - this is a momentary action switch, and sends one event report

per press.

2.10.1.3 Squat Switch - Has a specific purpose, to report that the aircraft has taken off

(open) or has landed (closed).

2.10.1.4 Dialer - used to dial one of the pre-programmed phone numbers if you are

using the 6 or 11 position dialer panels. Use of the 11 position dialer takes

up 4 of the 8 event switches and limits use for various other inputs.

2.10.1.5 Inhibit - This switch input will prevent the tracker from transmitting the

position data.

The 11 position dialer 1616-052-0X will make use of 7 of the provided 8

2 - 3

Page 18

1616-964-12

Date: 7/27/2011

Rev. 2.1

allowing only one left for the squat switch input if desired.

2.10.2 The predetermined functions of the switches on the 11 position dialer are:

2.10.2.1 Emergency - typically to declare and aircraft emergency.

2.10.2.2 Code - used mostly by EMS operators to declare a patient emergency.

2.10.2.3 Position - mark a position of interest to the pilot or crew.

2.10.2.4 Dialer - 4 event switches are used to dial the programmed numbers.

The MMU does not use any of the event switches so all 8 are available.

2.10.3 Suggested uses for the event switches would be:

2.10.3.1 Connect to an oil pressure switch to automatically send an event report when

oil pressure is lost, to the ground.

2.10.3.2 Connect to a low rotor RPM warning when rotor speed is insufficient, to the

ground.

2.10.3.3 Connect to an over temp/torque light to report this event to the ground.

2.10.3.4 Connect to a relay to let the ground know a circuit breaker has been pulled.

This has been used in the past on lease aircraft to allow the leaser to know

when the pilot has made an attempt to disable the time reporting system,

being the Sky Connect system itself.

Any event the operator would wish to know has occurred in flight, can be recorded

to the ground by the use of a switch closure. The logic can be inverse by the use of a

relay. More than one event can be grouped to one event switch by the use of diodes.

Example: the ground might want to know that an event has occurred that would

require ground maintenance. You might not need to know that a specific event has

occurred immediately, but that something has occurred. Connecting all the engine

events to one input isolated by diodes would report such an event.

Note: Connection of aircraft “required systems” through the tracker (a nonessential

system) will require FAA or other airworthiness approval. Engineering showing

compliance with XX.1309 will have to be completed. Minor or major

change/alteration determination is up to the installer.

2 - 4

Page 19

1616-964-12

Date: 7/27/2011

Rev. 2.1

2.10.4 Server Software Options

Sky Connect Server Software is capable of the following settings.

2.10.4.1 Sending an email when the unit has missed a report. This is determined in

the software by looking at the report rate interval and making the

determination that an interval has passed without a report from the

transceiver. The system waits an additional 5 minutes, and if another report

has not come through to the server, sends an email(s) to an individual or a

table of addresses for missed report alarm, a.k.a. Overdue.

2.10.4.2 Sending an email for EVERY report the unit makes. Some operators use this

to determine if the unit is tracking in lew of a software program.

2.10.4.3 Flight summary reports can be sent by email, with information on the

distance, time and takeoff/landing locations. This email may be sent to one

or many persons in a email table.

2.10.5 Mapping Software Options

There are many mapping programs designed for either a wide customer

base, or designed for very specific operator use. These programs have their

own manuals and should be consulted based on which program you choose.

2 - 5

Page 20

This page intentionally left blank

1616-964-12

Date: 7/27/2011

Rev. 2.1

2 - 6

Page 21

3 INSTALLATION - GENERAL

PRIOR TO INSTALLATION

Perform a visual inspection of the equipment for evidence of damage incurred

during

shipment.

3.1 A DISCUSSION ON SIM CARDS

It is Sky Connect policy to ship all units with a deactivated SIM card. The unit is

tested with a DEMO card before leaving our facility.

With that in mind, please be aware of the following paragraphs.

No testing can occur until a activated SIM card is installed in the transceiver or

CONFIG/SIM Module. The account has to be activated with an Iridium service

provider. Systems are generally shipped with a SIM card installed, with the PIN

code disabled, and the service deactivated. The customer is responsible for this

activation as the customer receives the bills for the phone use. This process can

take minutes, and should be done in advance of the installation/testing.

In the event that the customer provides a SIM card, or desires to provide the card it

must be de-pinned, or the system will get blocked. Contact the manufacturer if you

intend to change SIM cards. Sky Connect recommends against customer

replacement of SIM cards as it affects unit serviceability.

1616-964-12

Date: 7/27/2011

Rev. 2.1

Until the Iridium L-Band Transceiver has been registered on the network, there is

very little you can do to test its operation. A de-pinned activated SIM is required

before this can happen. The SIM card is the identity of the user, and thus must

travel with the user. In this case, the user’s SIM card is installed in the Sky Connect

transceiver.

This process should only need to be accomplished at initial installation. After user

activation, the system will function. Should the unit need to be replaced, or

transferred to another party, or in the event that a SIM card requires replacement,

return unit to Sky Connect or a qualified avionics shop to have the SIM card replaced

in order to keep the SIM card account matched with the user.

3 - 1

Page 22

1616-964-12

Date: 7/27/2011

Rev. 2.1

3.2 ITEMS REQUIRED BUT NOT SUPPLIED;

Table 1

QTY ITEMS USE

1 Daniels Manufacturing Crimper P/N M22520/2-01 P1

1 Daniels Manufacturing Crimper Positioner P/N K41 P1

1 Daniels Manufacturing Crimper Positioner P/N K1S All M24308 connectors

Crimping tools for use on coax connectors All coax connectors

Coax connectors for antenna cable if locally made

Contact insertion/removal tool M81969/1-4 (metal) or

M81969/14-01

(plastic)

Misc. installations supplies such as; wire ties, Adel

clamps, Etc.

If installing a Tracker without the control head (ie

FlightDeck system with a Tracker) and panel

mounted

switches are desired, we offer the following

manufacturer

part numbers with and without LEDs with and

without

NVIS, non NVIS part numbers are not shown call

Vivisun

Vivisun# LED-42-15-KB-36185 (2LA EMER; 3S0

////)

Vivisun# LED-40-18-KB-36189 (2LA CODE; 3J0 ////) Code Switch

Vivisun# LED-42-12-KB-36187 (2LA POSN; 3J0 ////) Position Switch

Vivisun# LED-42-12-KB-36188 (2LA DIAL; 3J0 ////) Dial Switch

Vivisun# LED-40-18-KB-36190 (2JA CALL; 3JA TEXT) Call/Text - Annunciator

Vivisun# 95-42-15-K6-70878 (2LA EMER; 3S0 ////) Emergency Switch

Vivisun# 95-40-18-K6-70956 (2LA CODE; 3J0 ////) Code Switch

Emergency Switch

Vivisun# 95-42-12-K6-70880 (2LA POSN; 3J0 ////) Position Switch

3 - 2

Page 23

1616-964-12

Date: 7/27/2011

Rev. 2.1

QTY ITEMS USE

Vivisun# 95-42-12-K6-70881 (2LA DIAL; 3J0 ////) Dial Switch

Vivisun# 95-40-18-K6-70957 (2JA CALL; 3JA TEXT) Call/Text - Annunciator

3.3 Suggestions for coax connectors and tools (customer supplied);

Table 2

Connector Coax Tool Newark# Industrial#

BNC male RG400/RG142 CTL-1 89F2891 31-4427

BNC male 90 Deg RG400/RG142 CTL-1 39F1443 31-334

TNC female RG400/RG142 220045-2 96F7801 225551-6

TNC female bulkhead RG400/RG142 220045-2 97F8562 225557-6

TNC male RG400/RG142 CTL-1 92B0647 31-4452

TNC male 90deg RG400/RG142 220045-2 90B4658 225554-6

3 - 3

Page 24

3.4 GENERAL SYSTEM COMPONENTS THAT APPLY TO ALL SYSTEMS

Table 3

Product Part Number Description

1616-700-01 Inmarsat Filter

1616-900-99 Sky Connect Series CD ROM

1616-950-XX Aviation Installation Manual, current revision

1616-901-XX Quick Start User Manual, current revision

1616-050-80 SBD Message Traffic

1616-104-01 3 year warranty

S67-1575-109Low Profile Iridium Antenna

1616-429-01 ARINC 429 Converter for converting to RS232

1616-964-12

Date: 7/27/2011

Rev. 2.1

1616-105-02 RT Installation kit which consist of:

1.) 1616-720-07 DD62F00000 – Positronics

connector

2.) 1616-721-01 FC8022D - Positronics contacts

3.) 1616-722-06 D37000Z00 – Positronics hood

3.5 SYSTEM COMPONENTS THAT APPLY ONLY TO TRACKER

Table 4

Description And

Part Number

Tracker and

Tracker with

voice

Components Product

1616-050-0XA -01A Tracker with GPS no voice

-02A Tracker no GPS no voice

-03A Tracker with voice and GPS

-04A Tracker with voice and no GPS

-05A AFF Tracker

1616-880-01 Iridium Antenna AT2775-110GAW-TNCF

1616-880-04 G.P.S. antenna S67-1575-39

1616-880-13 Combo Iridium/GPS antenna

1616-900-01 Installation Kit consist of; tray, Iridium antenna,

connector kit, G.P.S. antenna and Install CD

1616-900-02 Same as above but without G.P.S. antenna

3 - 4

Page 25

1616-964-12

Date: 7/27/2011

Rev. 2.1

Description And

Part Number

Components Product

1616-105-01 Transceiver tray

1616-150-01U Upgrade kit for adding Tracker with G.P.S. to POTS

system

1616-150-02U Upgrade kit for adding Tracker without G.P.S. to

POTS system

S67-1575-39 G.P.S. Antenna 1616-050-01/03/05 only

1616-500-01 SatTalk II Interface

1616-055-XX MMU/II (Mission Management Unit)

1616-055-00 MMU

1616-055-02 MMU NVG lense

1616-055-10 MMU II

1616-055-11 MMU II without POTS audio/no Wi-Fi

1616-055-12 MMU II NVG lense

1616-055-13 MMU II NVG lense without POTS

audio/no Wi-Fi

Originally the -11/13 part numbers did not exist. They

were marked as Mod A (without the POTS interface) and

Mod B (without Wi-Fi)

ALL MMU IIs ORDERED TO BE USED WITH A 1616-050

SHOULD BE A NON POTS 1616-055-11/13 (Mod AB)

units.

1616-905-01 Configuration Module

1616-905-02 Configuration/SIM Module

1616-052-00 11 Position SOP Dialer

1616-052-02 11 Position SOP Dialer NVIS

3 - 5

Page 26

3.6 GENERAL INSTALLATION INSTRUCTIONS

3.6.1 ANTENNA PLACEMENT

The Aero-Antenna AT2775 L-Band antenna should be placed as far as practical from

other transmitting antenna. A minimum of 30 inches is recommended to other

L-Band transmitting antenna. The Iridium antenna is itself a transmitting antenna,

and as such, an eighteen inch minimum spacing to G.P.S. antennae is recommended.

The Iridium antenna requires full view of the sky above. Shadowing and

interference can occur when mounted near vertical stabilizers, and other structures

inherent to aircraft. When used in conjunction with an internal G.P.S. for Tracker, a

separate active Sensor S67-1575-39 G.P.S. antenna is supplied. See Figure 4 for

antenna dimensions.

Note: Inmarsat systems (commonly referred to as Satcom) will greatly interfere

with the performance of the Iridium antenna. This interference may appear

to be intermittent with aircraft position as the Inmarsat transmitting antenna

array is electrically steer able depending on azimuth to satellite. Inmarsat

will disrupt Iridium communications whenever active. Inmarsat should be

disabled when Iridium is in use, alternatively, filters are available for

Inmarsat systems which essentially act as an Iridium bandpass filter. Consult

Sky Connect for more information.

1616-964-12

Date: 7/27/2011

Rev. 2.1

The antenna should be mounted in accordance with the manufacturer’s instructions

and reference FAA AC43.13-2A. The antenna should be properly bonded to the

aircraft ground plane to aid in eliminating unwanted interference. Surface

preparation should include the use of Alodine 1001 or similar. The antennae listed

above, as well as the Sensor S67-1575-109 Iridium antenna are all TSO’d and

approved for mounting on pressurized vessels.

Antenna installations on pressurized vessels require FAA approved design and

engineering data whenever a pressure vessel requires penetration due to

connector/mounting holes. Approved designs can be obtained from aircraft

manufacturers, STC data specific to the antenna, or DERs. Seal antenna in

accordance with FAA AC43.13-2A.

3 - 6

Page 27

3.6.2 ANTENNA CABLE

When routing antenna cable, avoid high current wiring, other transmitting antenna

cables, and sharp bends. Antenna cable should be selected to obtain 3dB max loss at

1.6GHz. The installer is responsible for providing antenna cables. Use the following

chart as an aid to determine the appropriate cable type for your required installed

length. Follow industry practices when assembling the TNC connectors. RG-142

coax cable is recommended in installations up to 20 feet in length, alternative cable

types are listed below.

Pre assembled cable lengths are available from EMTEQ, ECS, and PIC.

Table 5

Cable Length EMTEQ ECS PIC

< 15 feet PFLX195-100 352001 S33141

15-25 feet PFLX240-100 311601 S33141

1616-964-12

Date: 7/27/2011

Rev. 2.1

25-40 feet PFLX340-100 311201 S55122

35-60 feet 310801 S22089

3 - 7

Page 28

3.6.3 TRANSCEIVER STRUCTURAL MOUNTING

The Sky Connect Transceiver should be mounted in accordance with standard

practices found in FAA Advisory Circular 43.13-2A. The Transceiver is approved for

mounting outside the pressure vessel. See Figures 2 and 3 for unit and tray

dimensions.

The structural mount consists of a mating tray, with a self-locking, vibration

resistant, knurled thumbscrew system. The tray should be bolted to a suitable

avionics shelf, using approved #6 hardware, until the tray was changed to Mod level

A, which requires #8 hardware. Please check the Mod Status on the tray prior to

installation to assure you use the correct hardware.

1616-964-12

Date: 7/27/2011

Rev. 2.1

Tray Mod

Level

none 6-32 screw holes are provided, if required, these may be drilled

A 8-32 screw holes are provided. If replacing this tray in place of

The 62 pin High Density D-subminiature connector and 1 to 2 antenna connectors

are all that is required to electrically connect the box once it has been structurally

secured in place.

Hardware to be used

oversize to accommodate 8-32 screws.

an older tray with 6-32 screws, use the 6-32 screws with

washers.

3 - 8

Page 29

3.6.4 TRANSCEIVER ELECTRICAL INSTALLATION

Wiring must be done in accordance with FAA AC43.13-1B, or most current revision.

A crimp tool meeting Mil Spec M22520/2-01 and a positioner are required to ensure

consistent, reliable crimp contact connections for the 62-pin D Subminiature

connector. A 2 amp pull able Circuit Breaker is required for external protection of

the Sky Connect Transceiver. All wiring is 18-22AWG, and should use Mil Spec

22759/16 or 27500/18 wire or wire deemed appropriate to the aircraft type by the

governing aviation regulatory agency. See the appropriate following Sections for

the schematics of your system for wiring examples.

See Table 1 above for recommendations of discreet switches to be installed when

not installing a Sky Connect control head with internal switches.

Note: Sky Connect telephony systems are generally considered non-essential and

should be treated as such when selecting the appropriate bus for power. The

system should be placed behind a nonessential bus. However if the mission of the

aircraft deems the Sky Connect System safety sensitive, the essential buss may be

used. An electrical load analysis may be required when doing so.

1616-964-12

Date: 7/27/2011

Rev. 2.1

3 - 9

Page 30

3.6.5 TRANSCEIVER PIN ASSIGNMENTS

The below Table is a listing of pin assignments and signal flows. This table applies

only to 1616-050-0XA transceivers. For non A models refer to older install manuals.

1616-964-12

Date: 7/27/2011

Rev. 2.1

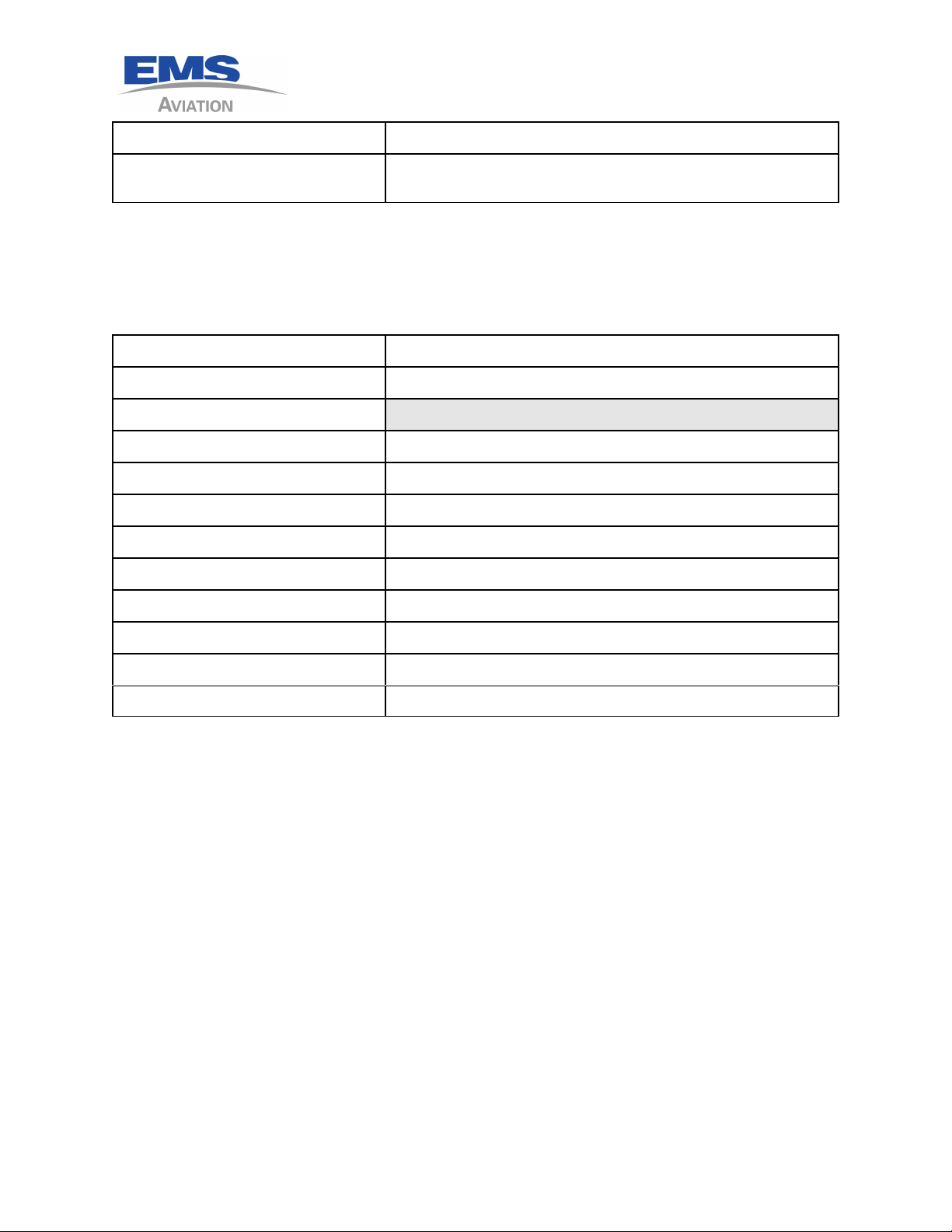

Table 6

Pin Description Flow

1 Ground Input Gnd

2 Reserved do not connect anything to

this pin

3 Comm Audio Lo Gnd

4 DPL Uplink In

5 PC DCD (Data Connections only) Out

6 NC

7 Microphone Audio Hi In

8 Program Stat --Factory Use Do Not

Connect

9 ISCM DPL Ground Gnd

10 Shield/Configure ground Gnd

11 Shield/Configure ground Gnd

12 Configuration Module Power

(3.3V)--Do Not Connect to other

than ICM/ICSM

Out

22 Ground Input Gnd

23 No Connection

24 Program -TX-- Factory Use Do Not

Connect

25 DPL Downlink Out

26 DPL Enable Out

27 PC CTS (Data Connections only) Out

28 Configure SCL In

29 Com Audio Hi Out

30 Diagnostics Gnd Gnd

31 RS232 #1 Gnd Gnd

32 RS232 #2 Gnd Gnd

33 Shield/Configure ground Gnd

34 Program Md0--Factory Use Do Not

Connect

35 Shield/Configure ground Gnd

13 Shield/Configure ground Gnd

14 Shield/Configure ground Gnd

15 Annunciator #1 –Sinks 100ma to

Ground

16 Annunciator #2 – Sinks 100ma to

Ground

17 Annunciator #3 – Sinks 100ma to

Ground

18 Annunciator #4 – Sinks 100ma to

Ground

19 Configure SDA

20 Event switch #1 – Gnd=Active In

21 11-33VDC positive voltage input In

Out

Out

Out

Out

36 PC GND (Data Connections only) Gnd

37 PC S TX (Data Connections only) Out

38 PC DTR (Data Connections only) In

39 PC RTS (Data Connections only) In

40 Program Rx--Factory Use Do Not

Connect

41 No Connection Out

42 11-33VDC positive voltage input In

43 Ground Input Gnd

44 No Connection

45 PC RI (Data Connections only) Out

46 PC DSR (Data Connections only) Out

3 - 10

Page 31

Pin Description Flow

47 Data out Hi – Diagnostics output Out

48 RS232 #2 Hi – Messenger output Out

49 Data in Hi – Diagnostics input In

50 RS232 #2 Hi – Messenger input In

51 PC S RX (Data Connections only) In

52 RS232 #1 Hi – Serial G.P.S. input In

53 Program-md1-- Factory Use Do Not

Connect

54 Program-RST-- Factory Use Do Not

Connect

1616-964-12

Date: 7/27/2011

Rev. 2.1

55 Event switch #8 – Gnd=Active,

configuration. switch style

(mom,alt,dial,sqt)

56 Event switch #7 – same as pin 55 In

57 Event switch #6 – same as pin 55 In

58 Event switch #5 – same as pin 55 In

59 Event switch #4 – same as pin 55 In

60 Event switch #3 – same as pin 55 In

61 Event switch #2 – same as pin 55 In

62 11-33VDC positive voltage input In

View of connector from rear (side contacts insert in)

In

Figure 2

3 - 11

Page 32

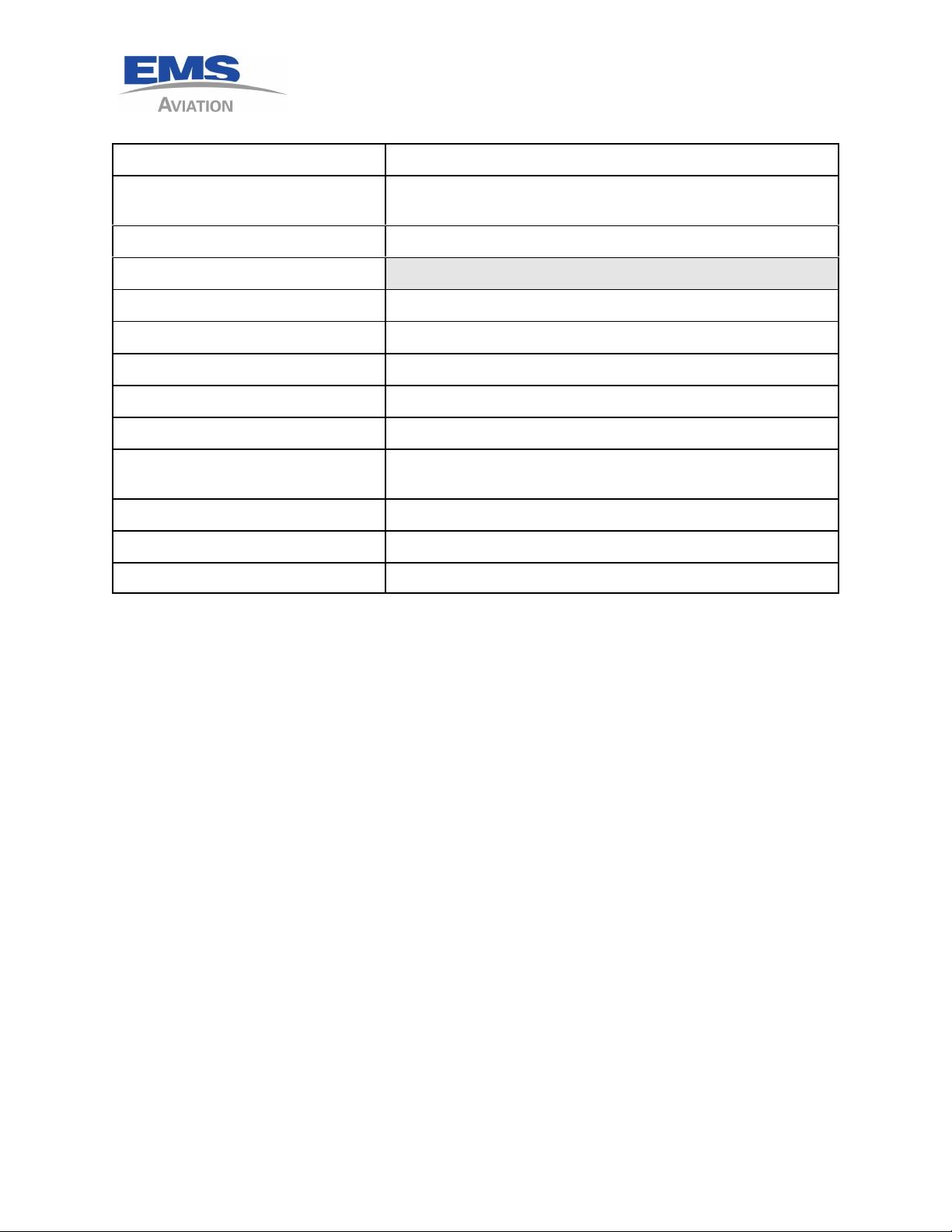

3.6.6 MMU II PIN ASSIGNMENTS

The table below indicates the pin out of the MMU II

J1 - Data J2 - DO NOT CONNECT

1 28 VDC 1

2 Polarized Key 2

3 RS 485 HI 3

4 RS 485 LO 4

5 RS 485 HI 5

6 RS 485 LO 6

7 Unit ID #1 7

8 Unit ID #2 8

9 Unit ID #4 9

10 Unit ID #8 10

11 Spare I/O #1 11

12 Ground 12

13 Ground 13

14 Spare I/O #2 14

15 Message Alert 15

16 Incoming Call 16

17 DTR Out 17

18 Ground 18

19 DSR In 19

20 Ground 20

21 5V Dimmer Input 21

22 14V Dimmer Input 22

23 28V Dimmer Input 23

24 MMU RS232 Input (RX) 24

25 MMU RS232 Output

(TX)

1616-964-12

Date: 7/27/2011

Rev. 2.1

25

3.6.7 Outline Drawings of Equipment

See the appendix for drawings of the equipment.

3 - 12

Page 33

4 TRACKER SYSTEM

INSTALLATION

NOTE: All added features to the Tracker, such as Altitude Trigger, and Change

of Flight Plan feature can increase the cost of operation of the tracker.

Check with your operations department prior to turning on features

that may increase the cost of operation. Once the data is sent over the

system, there will be a charge for the use of the data.

4.1 TRACKER SYSTEM COMPONENTS

4.1.1 TRANSCEIVER

The Tacker transceiver is identical to the unit in Section 3 in physical form.

The Tracker transceiver is not full telephony as the Executive, FlightDeck,

and Classic. The dialing is done through software using the SOP Dialers or

through the MMU when connected.

1616-964-12

Date: 7/27/2011

Rev. 2.1

4.1.2 CONFIGURATION MODULE

The Configuration Module (ICM) part number 1616-905-01, if used should be

installed within 8” to the 62 pin connector and secured to the harness. The

configuration module stores settings external to the transceiver and also

provides a female connector for easy connection to a PC via straight PC cable

for system configuration. The purpose of the module is to alleviate the need

to reprogram to an individual aircraft if units are shifted amongst the fleet.

Removal and replacement of the Sky Connect Transceiver with a different

unit will keep the Users stored settings the same, though a tail number to

serial number configuration mismatch will be logged as a security procedure

via the iridium network. Theft for re-use of the Sky Connect Tracker is

impractical, as not only do we know who you are, but exactly where you are!

Regardless, the configuration procedure only needs to occur once, or when a

configuration module is replaced. An additional use for the configuration

module would be to update all of the phone numbers in a fleets system. This

becomes a time saving device allowing one module to program each aircraft,

only necessitating the update of the individual tail numbers.

The male connector on the ICM connects via 6 wires to the 62 pin connector

of the Tracker system. The female connector is the configuration port for

both the ICM and the Tracker itself. If the configuration module is in place

during programming, settings are saved to the transceiver and to the ICM. If

4 - 1

Page 34

the ICM is connected at startup, the configuration is read from the ICM. If it is

not present at startup, the system uses its internal memory which is

re-flashed by the ICM at startup when connected.

4.1.3 CONFIGURATION/SIM MODULE

The Configuration/SIM Module (ICSM) part number 1616-905-02, has the

same functionality as the Configuration Module but allows for the installation

of the SIM card into the module instead of the transceiver. With this setup no

card need be installed in the transceiver at all. This allows for the swapping

of the unit, and the SIM card to remain with the aircraft. No changes to the

aircraft’s phone number. A secondary advantage would be if the customer

changed voice providers, the ICSM could be opened and the card installed,

eliminating maintenance to the transceiver itself.

NOTE: While the 9 pin female connector on the ICM/ICSM is

designed to be connected directly to a PC for programming,

the PC should not be connected directly to the 9 or 25 pin

female connector used to connect to the ICM/ICSM’s male

connector. Only pins 2, 3, and 5 are used for configuration,

the remainder of the pins are used internally and damage

can be done to the Tracker and the PC if these lines are

connected to a PC inadvertently. See wiring diagrams.

1616-964-12

Date: 7/27/2011

Rev. 2.1

4 - 2

Page 35

4.1.4 TRACKER SOP DIALER

There are two SOP Dialers, a six position and a eleven position. The

six position is a very basic design with lighting for the switches but

not for the panel. There is no NVIS version of this unit. The eleven

position dialer has a back lit face plate and the dimming feature to

the panel lights and the annunciators can be separate or together.

1616-964-12

Date: 7/27/2011

Rev. 2.1

Figure 12

SOP 11 Dialer

4.1.5 MMU/II (Mission Management Unit)

This unit is a computer controlled dialer and is very flexible in

operation. It communicates with the transceiver over an RS-232

port. This unit can be programmed in the aircraft with new

message sets. There are several versions of the MMU/II, but the

basic operation of all of them are the same. See the operators

manual for a complete description of features.

Stores phone numbers to be called

Stores text messages

MMU II has a keypad for direct dialing without storing a

number

Possible NVG versions

Wi-Fi loading of Message Sets (if Wi-Fi equipped)

4 - 3

Page 36

1616-964-12

Date: 7/27/2011

Rev. 2.1

Figure 10

MMU II

Figure 11

MMU

4 - 4

Page 37

4.2 TRACKER-SOP STRUCTURAL MOUNTING

The Tracker SOP A has eliminated the use of the SatTalk 2 audio controller, and only

the RT and the SOP Dialer or MMU need be considered for mounting.

If you are using the original version of the SOP system (P/N 1616-050-03/-04), the

Sat Talk 2 audio controller normally is installed using a flange mounting plate that is

supplied and may be attached to the bottom of the audio controller using the

existing screws that secure the bottom plate. Using the flange plate, the controller is

mounted using four #6 screws in a 6.25” by 2.5” pattern. Alternatively, a bracket

can be fashioned to strap the controller in place.

The SOP Dial pad is a Dzus mounted unit. The dimensions are 5.75" x 1.125" with an

overall depth of 2.8”, and depth behind panel of 2.1".

The MMU is a Dzus mounted device. Dimensions are 5.75" x 1.9" with a depth

behind the panel of 5.5"

1616-964-12

Date: 7/27/2011

Rev. 2.1

4.3 TRACKER WIRING

Follow the installation drawing 1616-910-XX for the interconnection of the Tracker

system into the aircraft. As always pay close attention to the notes that apply to that

drawing. Wiring of the Tracker system is mission specific. Tracker can be entirely

standalone, or tied to multiple aircraft systems. The Tracker system is designed to

be extremely flexible with open architecture. Switched input options are limited

only by the customer and the specific capabilities of the GIS software used for

aircraft tracking.

The SatTalk 2 for the Tracker-SOP system requires approximately 80 ma at any

voltage between 10 and 32 VDC and must be protected by an external fuse or circuit

breaker. Tracker SOP “A” and MMU does not use the SatTalk 2.

Note: this applies to both the 6 and 11 position SOP

Dialers. These units need a lighting supply to make the

annunciators turn on, so plan this part of the installation

carefully. If you have a dimmer buss that does not supply

full voltage when the dimmer is off, then a two stage

dimmer will need to be designed to allow for Bright/Dim

operation.

4 - 5

Page 38

1616-964-12

Date: 7/27/2011

Rev. 2.1

The SOP dialer should be powered through either a bright/dim switch, or through a

rheostat. If not connecting the dialer to a dimmer buss, connect to 14/28 VDC

through a circuit breaker. The dialer is entirely passive and can be dimmed through

a range of 4-11VDC. If two or more dialers are to be installed, they may be wired in

parallel with the addition of isolation diodes on the dialer lines, A1, A2, and A4. See

wiring drawings for details.

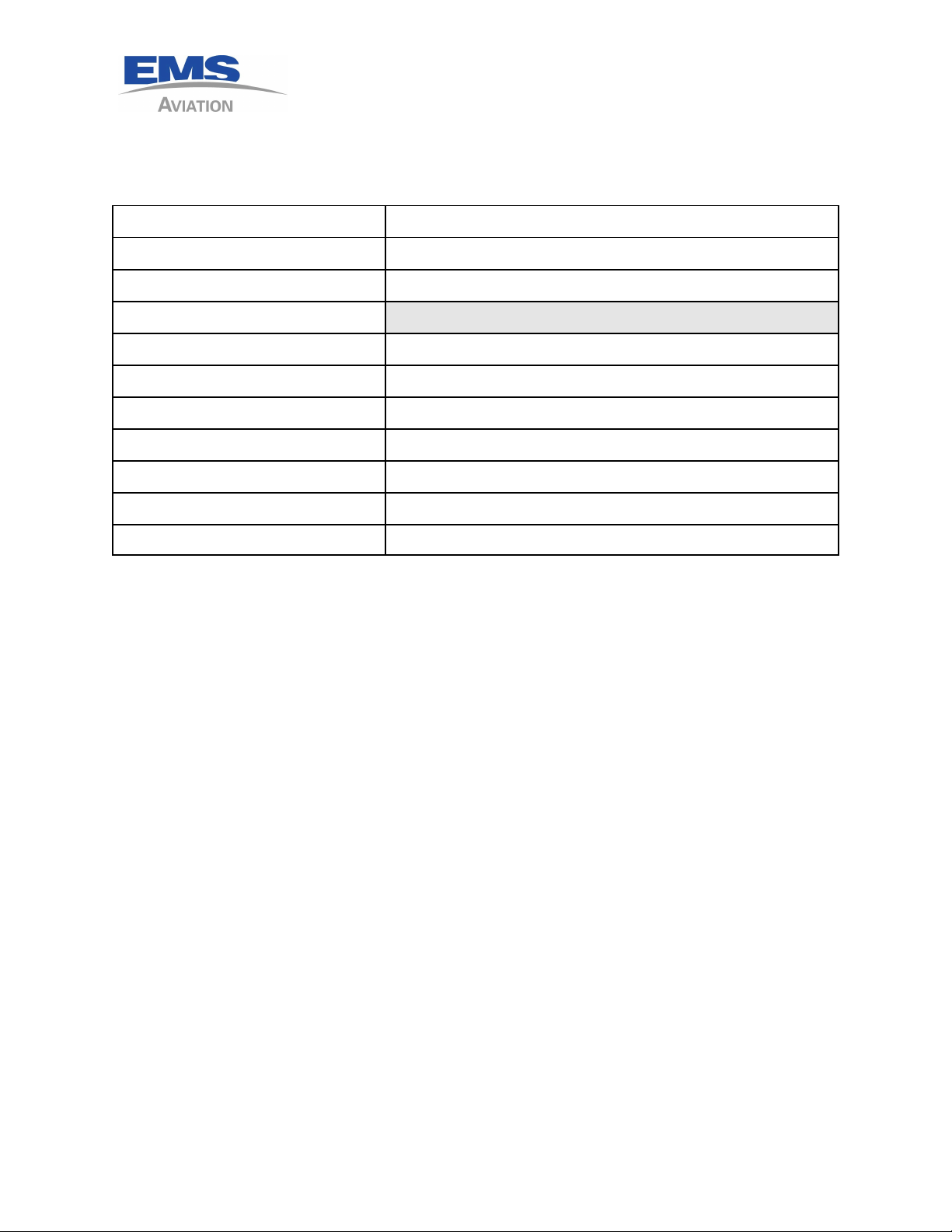

The 11 Position Dialer has the annunciators dimmed from a separate source as the

back lighting on the face plate. By default, they are wired separately, but can be

connected together either externally or internally by adding a shorting bar across

header J2.

J2 jumper

shown installed

The MMU S/N 001 to 100 lighting is controlled from the lighting buss, but the unit

does not draw current from the buss. The control is used to “follow” the dimmer

buss voltage and when this voltage gets within 20% of the low end of the scale, the

unit will illuminate to full brightness for day light use. This is designed for aircraft

that loose dimmer voltage when the dimmer is turned off. S/N 101 and later, due to

a change in the display, the only dimming allowed is through the face plate knob and

menu.

MMU and MMU II - P1 are wired identical with the exception listed above on the

dimmer. MMU II also dims through a menu using the knob. MMU II P2 is identical

to the connector on the PTA12-X00. Either a MMU or a PTA-12 can be removed and

the correct dash number MMU II be installed in its place.

See paragraph below, for installations that use a MMU and a GPS that does not

supply altitude data, the serializer may be input through the diagnostics port. This

should be done using the 9 pin connector as on the drawings, so the serializer may

be disconnected when time to connect a PC.

The best way to load a MSet into the MMU II is through the connector P/J19 as

shown in the installation drawings. This is a pigtail that is to be provided to the

customer so the MSet can be loaded without removing the MMU II from the

aircraft. Please make sure this connector is provided in all the installations.

4 - 6

Page 39

1616-964-12

Date: 7/27/2011

Rev. 2.1

When using an external GPS receiver, in order for the Tracker to include aircraft

altitude in the data that is sent to the ground, a Garmin GPS receiver (430/530/480,

etc) must be used in order to get altitude data from the navigation RS-232 data

stream.

For GPS receivers such as the KLN-90B, KLN-900, etc which DO NOT supply altitude

in their serial stream, a source of serial altitude data in the Icarus (Garmin) format

at 9,600 baud must be supplied to the Tracker. There are multiple sources available

for serial altitude data in this format including certain Garmin transponders,

encoders with a serial output, and the Icarus 3000U serializer. Please consult

technical support for further details.

Annunciators (optional)

Annunciator #1 - This is the status light of the tracker. This light if connected

will;

A.) Flash the version of the tracker software as a portion of the POST

(power on self test)

B.) Indicate the condition of the tracker. Steady light with a flicker on

the report interval. Or flash an SOS pattern when the tracker is seeing

a problem condition.

Annunciator #2 - This light will indicate by flashing, an incoming call or flash

with the ring of an out going call. Once the call is picked up or answered, this

output remains low (to ground) for the duration of the call. When the call is

terminated, the output will go to a high.

Annunciator #3 - The Link light will indicate to the operator the condition of

the satellite RF level being picked up by the transceiver. Any level of signal

lower than 4 the light be illuminated. Phone calls can be made, but may be

dropped at this level, tracking will not reliably occur.

Annunciator #4 - Lights to indicate a system failure. First flash the software

version in sync with annunciator #1. Then illuminates until the system is

registered on the Iridium network. Once registered, it extinguishes and only

lights again if a system fault is detected.

4 - 7

Page 40

MMU/MMU II Annunciators - The MMUs have their own annunciator that

will illuminate a light for the following reasons;

Incoming Message - To provide a heads up indication to the pilot if the MMU

is installed out of the scan view of the pilot, the “Incoming MSG” light will

blink slowly for five seconds.

Incoming Call - As above the “Incoming Call” light will flash with the ring of

the phone to allow the pilot to know there is an incoming call if the audio

monitor switch is off.

4.4 POST INSTALLATION TESTING

No testing can occur until a valid SIM card is installed in a transceiver, the PIN code

turned off, and the account has been activated with an Iridium service provider.

Systems are generally shipped with a SIM card installed, with the PIN code disabled,

and the service inactive. The customer is responsible for this activation as the

customer receives the bills for the phone use. This process can take some time, and

should be done in advance of the installation/testing.

1616-964-12

Date: 7/27/2011

Rev. 2.1

4.4.1 MMU II CONFIGURATION

Entering Installer Configuration mode is one CCW pushed-in detent of the rotary

knob while pressing the ‘*’ key from either the Ready page, or from the initial MMU

splash display page. The following parameters may be set in Configuration mode:

4.4.1.1 Config Version - Internal use, for informational purposes. This description is

valid for Config Version 2.

4.4.1.2 WiFi Channel - Select the WiFi channel the MMU should use, or “No” to

deselect WiFi. Note: to shutoff WiFi completely, you must select and save a

value of “No” and then power-cycle the MMU. (only appears for MMUs with

WiFi capability)

NOTE: Wi-Fi usage on the aircraft in flight requires the aircraft to have a EMI test

against interference from TPEDs (Transmitting Personal Electronic Devices).

This would be any device carried on to the aircraft that would emit 802.11 Wi-Fi

signals. The MMU II itself transmits approx. 10mw of 802.11 signal. TPEDS

can produce as much as 4 watts of 802.11 signal when searching for a hot spot. IF

you are to use TPEDS, the EMI test must be complied with on your aircraft with

your suit of avionics as installed.

4 - 8

Page 41

1616-964-12

Date: 7/27/2011

Rev. 2.1

4.4.1.3 WiFi Transmit Power - Select the power level for the MMU to operate WiFi.

For aircraft use, this should typically be 6. (only appears for MMUs with WiFi

capability)

4.4.1.4 Brightness Control - Select one of the following:

1.) Manual – the user always controls display and keypad brightness

2.) Dimmer Bus – the MMU samples a connection to a dimmer bus and

adjusts display and keypad brightness accordingly

3.) Light Sensor – the MMU samples ambient light and adjusts display and

keypad brightness accordingly. The sensor is located just above the keypad

“*” key.

4.4.1.5 Sensor/Dimmer Low End - This value aligns with the dimmer bus voltage or

light sensor for the dimmest setting of the display and keypad brightness. For

the light sensor, this value is in LUX. (only appears when brightness control

on light sensor or dimmer bus)

4.4.1.6 Sensor/Dimmer High End - This value aligns with the dimmer bus voltage or

light sensor for the brightest setting of the display and keypad brightness.

For the light sensor, this value is in LUX. (only appears when brightness

control on light sensor or dimmer bus)

4.4.1.7 Dial/In-call Mechanism - Determines the handling of the messenger port as

well as the mechanism used for establishing phone connections. Choose from

the following:

1.) None – generally, not used.

2.) DTMF/DTMF – for POTS installations with a TRKR on the messenger port.

Incoming and outgoing calls and in-call DTMF are made via POTS.

3.) AT/AT – Incoming and outgoing calls as well as in-call DTMF are made via

commands to the TRKR.

4.) AT/DTMF – Incoming and outgoing calls are made via commands to the

TRKR. In-call DTMF tones are generated.

5.) Reserved – generally, not used.

6.) POTSnoTRKR – Connection to a TRKR not required; no messaging

required. Incoming and outgoing calls are made via POTS. The messenger

port may optionally be connected, for example to MSET Manage for MSET

upload.

4 - 9

Page 42

1616-964-12

Date: 7/27/2011

Rev. 2.1

4.4.1.8 DTMF Total Time - This is the time for a tone from the start of one digit to the

start of the next. The default value of 1016 works for most applications. To

determine the duration in seconds, multiply the value by 246 uSecs. For

example, the default value of 1016, times 246 uSecs, is 0.25 seconds. (only

appears when Dial/In-call mechanism enables DTMF)

4.4.1.9 DTMF Interval Time - This is the duration of the pause between digit tones.

The default value of 407 works for most applications. To determine the

duration in seconds, multiply the value by 246 uSecs. For example, the

default value of 407, times 246 uSecs, is 0.1 second. (only appears when

Dial/In-call mechanism enables DTMF)

4.4.1.10 DTMF Output Volume - The volume level of DTMF PWM digit tones, a value

from 0 to 127. Default value is 30.

4.4.1.11 Phones Volume - The volume level of the phones, a value from 0 to 127.

Default value is 50.

4.4.1.12 Sidetone Level - The sidetone level, a value from 0 to 127. Default value is 0.

4.4.1.13 Microphone Volume - The microphone volume, a value from 0 to 127. Default

value is 60.

4.4.1.14 Ringer Volume - The ringer volume, a value from 0 to 127. Default value is 50.

4 - 10

Page 43

1616-964-12

Date: 7/27/2011

Rev. 2.1

4.4.1.15 Volume Tap - Select from the following options:

1.) Not Enabled – neither offhook nor flash are enabled

2.) Offhook – allow taking phone offhook from ringer volume page

3.) Flash – allow flashing of the line (go onhook for 90 ms) from phone

volume page

4.) Offhook & Flash – allow both of these options

4.4.1.16 Messenger Protocol - Select the protocol version to be used between MMU

and the TRKR box. For proper operation until noted otherwise, Version 1

protocol should be enabled.

To exit from Configuration mode, push-n-turn the knob one detent to “Exit Settings

Mode”, and then tap the knob back to the “MMU Ready” display.

A mechanism known as “pocket-config” is available to change volumes and levels

while in-call. To enable pocket-config, you must first enter Configuration mode, and

then exit Configuration mode (it does not matter if any settings are changed; only

that you were at one time in this mode). Once that is performed, pocket-config is

then enabled any time while in-call. While pressing one of the following keypad

keys, turn the knob to select:

1.) DTMF Output Volume

2.) Phones Volume

3.) Sidetone Level

4.) Microphone Volume

5.) Ringer Volume

6.) Ringer Sample – the ringer will be heard with a test ring.

4 - 11

Page 44

4.4.2 MMU II Master vs. Slave Configuration

This configuration will allow two MMU IIs to be used connected to one transceiver.

The function here, since the RS485 has not yet been implemented, would be to allow

two MMU IIs to connect and carry on a phone conversation as in a party line

situation. The Slave will not be able to indicate signal strength as that is a function

of the RS232 control line and not implemented as part of this feature... yet.

Full operation of the MMU II in a master slave relationship will require

implementation of the RS485 control bus. This is not yet released and when it is all

slaves will function as the master does in an installation.

To configure two MMU IIs to communicate over POTS line with one transceiver,

follow the below procedure.

Perform the following configuration and testing with reference to the MMU II

Operators Guide, and the Pilot’s Guide for description of function and use of the

knobs and menus.

1616-964-12

Date: 7/27/2011

Rev. 2.1

4 - 12

Page 45

4.4.2.1 Master Unit Configuration

Step Procedure

M1 Apply Power to the Master MMU II

M2 When the Screen displays the MMU Version and MSet

hold the * button (Upper Right) and press the KNOB in while

making a turn one click counter-clockwise, then release both the

knob and the * button.

M3 The MMU II will now display the BRIGHTNESS CTL page.

M4 Rotate the Knob (do not press in) clockwise until the DIAL/In-Call

Mech: page appears.

M5 Ensure that the display is set at DTMF/DTMF

1616-964-12

Date: 7/27/2011

Rev. 2.1

M6 If not, TAB the knob and the selection will begin to flash.

M7 Rotate the knob until the DTMF/DTMF is displayed. Press the

knob and hold. The screen will display “Value Saved SUCCESS”.

M8 Rotate the Knob (do not press in) clockwise until the Volume Tap:

appears.

M9 If required, TAP knob and select Offhook & KeyIn.

M10 Press the knob and hold. The screen will display “Value Saved

SUCCESS”.

M11 Press the knob in and rotate clockwise one click. Release.

M12 The screen should display Exit Settings Mode.

M13 Press the knob in and release. The screen will now display MMU

Ready page.

M14 Master MMU II Configuration complete.

M15 Cycle Power to the Master MMU II.

4 - 13

Page 46

4.4.2.2 MMU II Slave Configuration

Step Procedure

S1 Apply Power to the Slave MMU II Controller.

S2 When the Screen displays the MMU Version and MSet version,

press and hold the * button (Upper Right) and press the main

KNOB in and turn one click counter-clockwise, then release both

the knob and the * button.

S3 Rotate the Knob (do not press in) clockwise until the DIAL/In-Call

Mech: page appears.

S4 The display probably is set at DTMF/DTMF.

S5 Press the knob and release. The selection will begin to flash.

1616-964-12

Date: 7/27/2011

Rev. 2.1

S6 Rotate the knob until the Pots/NoTrkr is displayed.

S7 Press the knob and hold. The screen will display “Value Saved

SUCCESS”.

S8 Rotate the Knob (do not press in) clockwise until the Volume Tap:

page appears.

S9 The display probably is set at NOT ENABLED.

S10 Press the knob in and release. The selection will begin to flash.

S11 Rotate the knob until the selection Offhook displayed.

S12 Press the knob and hold. The screen will display “Value Saved

SUCCESS”.

S13 Press the knob in and rotate clockwise one click. Release.

S14 The screen should display Exit Settings Mode.

S15 Press the knob in and release. The screen will now display MMU

Ready page.

S16 Slave MMU II Configuration complete.

4 - 14

Page 47

4.4.2.3 Master/Slave Testing

Step Procedure

T1 Apply Power to the EMS Sky Connect Transceiver and the both the

Master and Slave MMU II Controllers.

T2 Operation of the Master MMU II should be as normal.

T3 Place an incoming call to the aircraft. The external Call

Annunciator should flash (if installed). The MMU II displays

should display – Incoming Call

T4 On the Slave MMU II Controller, press the knob to answer the call.

The Call should be answered after a slight delay, and the Call

Connected / Duration screen appears and the timer starts and

the external CALL annunciator (if installed) illuminates steady.

1616-964-12

Date: 7/27/2011

Rev. 2.1

T5 Mic and Phone audio should be available to the Slave MMU II

Controller

T6 Press the knob to end the test call.

T7 Initiate a call from the Slave MMU II Controller.

T8 The call should dial as normal. The external CALL annunciator (if

installed) will be illuminated during the call

T9 END of Test

4 - 15

Page 48

4.5 Loading of Message Sets

Loading the Message Sets into the MMU II may be done in one of two ways.

A.) Serial port of a PC connected to the pigtail of the MMU II harness via a 9 pin

serial port cable.

B.) Wi-Fi port on the MMU II (if so equipped)

The MSet Mange software has provisions to select either of the above options.

The best way to load a MSet into the MMU II is through the connector P/J19 as

shown in the installation drawings. This is a pigtail that is to be provided to the

customer so the MSet can be loaded without removing the MMU II from the

aircraft. Please make sure this connector is provided in all the installations.

1616-964-12

Date: 7/27/2011

Rev. 2.1

4 - 16

Page 49

4.6 TRACKER SETUP

See the software manual to configure the unit to work as the customer desires.

NOTE: This is a very important step in installing the system correctly,

DO NOT SKIP CONFIGURING THE TRACKER.

Tracker Setup using the MMU II as a setup device.

If you are installing a MMU II in the system, the MMU II maybe used as a terminal to

allow Tracker Setup without a PC connected to the transceiver. Follow the

procedures below to use the MMU II for this purpose.

4.7 TRACKER TESTING

In order to fully test Tracker, you will need access to a PC running Sky Connect

Tracker-Map, or an approved GIS display system. In the event that this is not

available to you, contact Sky Connect Technical Support where we can remotely aid

in your testing. Refer to Appendix A for additional troubleshooting advice.

1616-964-12

Date: 7/27/2011

Rev. 2.1

The installer can verify the proper wiring of every onboard component with a

combination of the Tracker Setup program and the “all in one” annunciator light.

The installer can be assured that their portion of the job is acceptable if the onboard

unit consistently indicates that it is sending and completing messages.

6 or 11 position dialer - this is indicated by a fast pulse as messages are sent at

programmed intervals, followed by a solid green indication.) It is the customer’s

responsibility to choose the manner in which they display their “tracked” aircraft,

not the installers.

MMU - this is indicted when the “READY” page is displayed with the current signal

strength.

Note: Only one Iridium source can occupy the network at one time. If a Sky

Connect voice option is installed and in use, the Tracker will store and send

position reports when the line is free. Configurations will exist to give

Tracker priority, thus discontinuing an in-progress call.

Using ground power, turn on the Aircraft master, avionics master, or what ever is

required to fully power all elements of the installed Sky Connect components. If a

G.P.S. is interfaced, it must be operating and have acquired satellites. The aircraft

must have an unimpeded view of the sky. Operating next to a hangar can cause

occasional brief signal interruption of both G.P.S. and Iridium functions. If using an

4 - 17

Page 50

1616-964-12

Date: 7/27/2011

Rev. 2.1

internal G.P.S., allow the unit to run for up to 15 minutes on the initial startup to

allow the internal G.P.S. to acquire almanac data. Allow one minute for the system

to register on the iridium network.

Within this registration time, Tracker will generate a start up message which will be

sent via the Iridium network to our switching network, and then to the mapping

system. At this time, (approximately 24 seconds after the message was generated) a

data block will be available to your Tracking Provider. With some software systems

there may be a delay up to 1 ½ minutes before the aircraft is seen on your GIS.

Giving the G.P.S. a destination waypoint, and if possible some speed, will send

additional parameters to the mapping system for display, including Destination,

Speed, Altitude, Flight Plan, etc.

IMPORTANT - Using the TRACKER SETUP program, you can test

most of the features of the installation with the exception of the

full network test. Any contact closures that were installed for use

with Tracker can be tested at this time as well. No messages will

be sent while the Tracker Setup program is connected and

running. Messages will resume, roughly one minute after the

Tracker Setup program is terminated.

From the main page, you can verify the G.P.S. position, speed, and altitude. The units

IMEI # and G.P.S. input type are displayed when known. The Iridium Signal strength

(0-5) and Modem status are displayed and updated in real time.

From the Switch configuration page you can select the type and rate of each switch

input, but you can also test to verify the input. The Setup program samples the

incoming switches every ten seconds to see if they are active. The switch status will

display as on if a ground is applied to the corresponding pin, and off if the line is

floating.

Each closure will also generate a specific event at the PC running the mapping

system software. The program must have an “assignment” for the event triggers to

accomplish their task. The assignment for contact closure #2, for example, can be

assigned on the mapping system PC terminal to annunciate “Mission Aborted.” The

important element here is that the contact closure number is accurate to the specific

switch being tested. Purposes for these switches are defined by the end user. For

more clarity on this programming, refer to the mapping system operation manual.

Should you desire to use our Tech Support for these tests, you will need to have

available the Transceiver Serial Number, IMEI#, aircraft flight ID, and installed

options/configuration. With power applied, Tracker will continue to generate

4 - 18

Page 51

position report updates at its programmed interval. Once registered on the

network, Tracker interval reports are billed per hour of use including during the

testing process.

Note: Programmed interval directly affects customer billing.

Consult with end user regarding all available configuration options

before accomplishing.

4.8 OPERATION

4.8.1 TRACKER

The Sky Connect Tracker system consists of the transceiver and L-band

antenna, as well as an additional module in the transceiver. The Tracker can

be added to any system but works autonomously of them. The Tracker can

utilize a feed from most panel mounted G.P.S. systems, or its own internal

G.P.S. (when equipped with separate active G.P.S. antenna). This feed of

aviation data provides Tracker with aircraft flight parameters such as

latitude, longitude, speed, direction, altitude, and flight plan information if

available.

1616-964-12

Date: 7/27/2011

Rev. 2.1

The Tracker utilizes Short Burst Messaging over the Iridium network to send

this flight information packet to ground terminals for the monitoring of fleet

aircraft. Regular reporting intervals of twelve seconds to greater than 30

minutes can be set for the triggering of a flight information packet. Three

separate rates can be selected based on flight status.

In addition to interval reporting, changes in flight parameters, proximity to

waypoint, or “events” can trigger reports. Events can be triggered by contact

closures, such as a squat switch, or an emergency button. DC level inputs

may require external diode protection. While no external switching or

annunciation is required for the Tracker system to operate, it can contain up

to eight external event switches, and four status annunciators. It is

recommended that at least one annunciator be installed in a suitable location

which would provide verification of a completed message transaction. This

annunciator would alert the user to the system status and a reception (or

lack thereof) of the flight information packet at the Iridium Gateway.

4 - 19

Page 52

1616-964-12

Date: 7/27/2011

Rev. 2.1

Examples of Event Switch usage would be;

Engine Oil Pressure

Low Rotor RPM

Engine Out

Engine Fire

Engine Chip

Gear Box Chip

Any of the above that will trigger a switch closeure, a ground to turn on a

lamp, can be used to trigger an event report from the Tracker. Relays may be

used to isolate “required” systems from “non required” or simply diodes.

The options and variation here are far too complex and vary to cover all of

them in a STC project. This type of interface will have to be approved by your

local airworthiness authority, and NOT from this manual as it is only

intended to be offered as a guide as to how to use these features.

4 - 20

Page 53

4.8.2 TRACKER SOP A

Tracker SOP A is a new version of the original Tracker SOP but without the

need for the SatTalk II audio controller component. The audio operations of

the SatTalk 2 are now included in the Tracker SOP “A” transceiver. This

brings the operational characteristics of the Tracker SOP “A” model to the

same as any remote mounted Comm transceiver. This unit can be operated

with or without an audio panel, and needs no external amplification of the

phone audio.

Most audio panels only support ½ duplex, or push-to-talk communications.

For obvious reasons, this is somewhat limiting for phone conversations. The

reason Full Duplex audio panels are recommended for proper operation is to

retain the full transmission capabilities of your on board communications

transceivers. In a full duplex system, Comm 3 is devoted to the Satellite

phone, while Comm 1 and 2 are the VHF Transceivers. When a call is

initiated, Comm 3 is selected and communications happen as they would on a

phone; without the need to push-to-talk. Meanwhile, the pilot is still able to

monitor his on board radios, and if necessary, key the Mic to allow

conversations on the VHF Transceiver.

1616-964-12

Date: 7/27/2011

Rev. 2.1

In a half duplex audio panel, keying on any transceiver line will cause the

muting of all other sources of incoming audio. Safety of flight can be

compromised in this fashion by muting an incoming call from ATC while

holding down the key to communicate on the phone.

It is strongly recommended that a Full Duplex audio panel such as the PS

Engineering PMA7000B or NAT AMS50 be used when interfacing the SatTalk

II (or the SOP Model “A”) as a transceiver.

4.8.3 SOP DIALER

With both SOP Dialer panels it is recommended that if you do not have a

dimmer circuit that maintains voltage with the dimmer off, that you connect

the lights to a two stage dimmer circuit.

4.8.3.1 SIX POSITION

The six position dialer has been dis continued. Refer to older install manuals

for information on this unit.

4 - 21

Page 54

4.8.3.2 SOP 11 (ELEVEN POSITION DIALER)

See this section for a visual of the 11 position dialer.

1. 11 programmable positions.

2. The rotary knob serves as the dial button by pushing in on the

knob. To hang up, push a second time.

3. The dimmer feature of the unit works on a true 6 to 28VDC

range.

4. It has a separate input for the dimming of the annunciator

lights than the face plate. This is internally selected by a

jumper.

5. The face plate is back lit.

6. There is a “Phone”, indicator to indicate a visual on the ringing.

7. This unit has a Tracker light to indicate the operation of the

tracker.

8. Toggle switch operation are indicated by seperate lights to

show they are on or off.

1616-964-12

Date: 7/27/2011

Rev. 2.1

4.8.4 MMU/II

See the MMU/II Operator’s Manual for a detail description of the MMU/II.

The MMU/II communicates with the transceiver over an RS-232 port. This is