Page 1

POWER

FAULT

ISOLATOR

ACTIVE

F

usion

Loop Module

Loop Module

Installation Guide

©2014 EMS Radio Fire & Security Systems Ltd. All rights reserved 1/2 TSD077 Iss 3c 15/04/14 AJM

FCX-532-001

FCX-532-002

Fusion Loop Module

Fusion Loop Module c/w Remote Aerial Facility

POWER

FAULT

ISOLATOR

ACTIVE

F usion

F usion

Loop Module

Part No Product Description

Step 1 Pre Installation

!

The Fusion Loop Module installation must conform to

applicable local installation codes and

should only be

installed by a fully trained competent person.

The following points require consideration upon installation:

Loop Module location. Refer to the design drawings generated

from the radio survey.

Radio performance. Refer to step 3 to ensure the radio

performance is optimised.

Remote aerials.

If using remote aerials with this product, refer

to the Remote Aerial Installation manual for more information.

A maximum of 5 Loop Modules can be connected per loop.

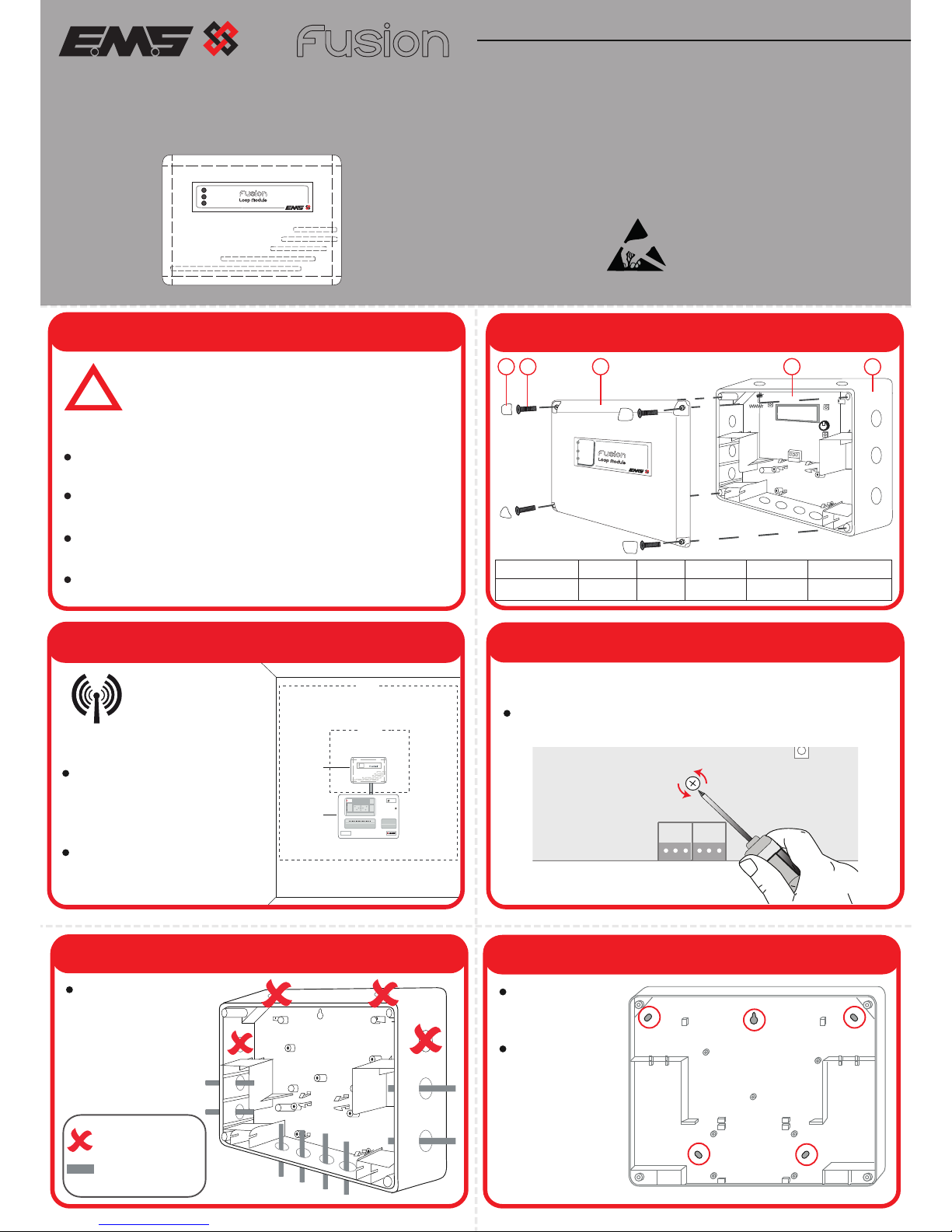

Step 2 Loop Module Components

1

2 3

4

5

4X Corner

covers

4x Lid

Screws

1x Loop

Module Lid

1x Loop

Module PCB

1x Loop Module

Back Box

Part Description

Item No

1 2 3 4

5

FIRE

Fire Alarm Control

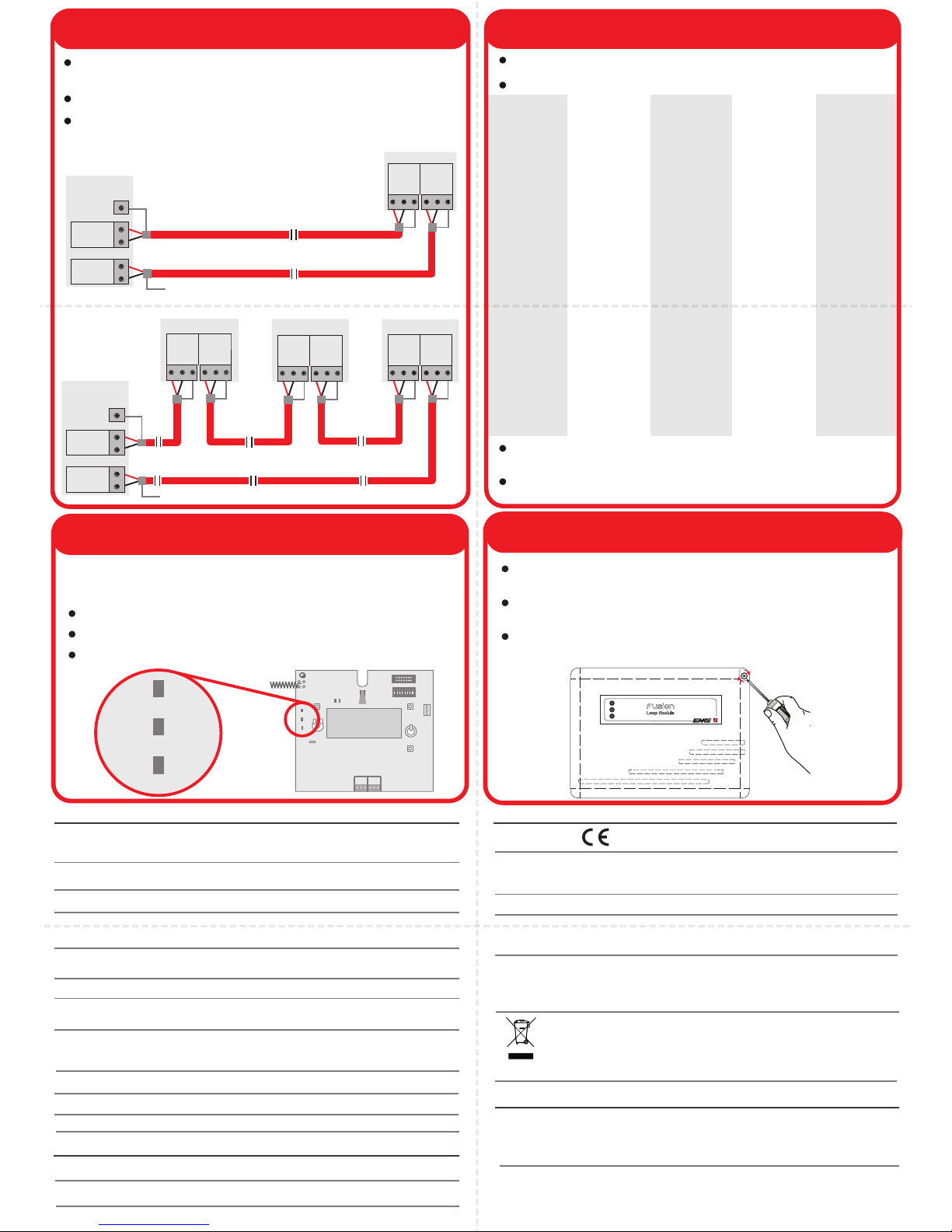

Step 3 Mounting Location Guidelines

Ensure the Loop Module is

not installed within 2m of

other radio or electrical

equipment (not including

the Control Panel).

Ensure the Loop Modules

aerials are not installed

within 0.6m of any metal

work.

POWER

FAULT

0.6m

To ensure the

optimum range

performance of

the Loop Module

is achieved, the following

should be considered:

2m

Control

Panel

Loop

Module

Step 4 PCB Removal

The internal PCB of the Loop Module can be removed to ensure that

damage is not caused during installation.

Remove the central retaining screw prior to unclipping the PCB.

WD

BACK

0V

RX

TX

3V

SCR

+

-

LOOP IN

SCR

LOOP OUT

+

-

Fit the Back Box

to the wall.

All five circled

fixing positions

are available for

use.

Step 6 Fit Loop Module Back Box to the Wall

Step 5 Prepare the Loop Module Back Box

Drill the required

cable entry points

where necessary.

= Do Not Use

= Available Cable

Entry Points

ATTENTION

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE

Page 2

Specification

Operating

Temperature -10°C to 50°C (ambient)

Storage

Temperature 0°C to 35°C

Humidity Up to 95% non-condensing

Operating

Voltage 17 to 28V DC

Power

Requirements 17mA @24V DC

IP Rating IP54

Operating

Frequency 868MHz

Output

Transmitter

Power Variable 0 - 14 dBm

Dimensions 270mm (W) 205mm (H) 75mm (D)

Weight 0.95kg

Location Type A: For indoor use

EMS. Technology House, Herne Bay, Kent, CT6 8JZ, United Kingdom

Manufacturer

Year of

manufacture See devices serial number label

2002/96/EC (WEEE directive):

Products marked with this symbol cannot be disposed of as unsorted

municipal waste in the European Union. For proper recycling, return this

product to your local supplier upon purchase of equivalent new

equipment, or dispose of it at designated collection points. For more

information see www.recyclethis.info

Contact Information

EMS. Technology House, Herne Bay, Kent, CT6 8JZ, United Kingdom

t: +44 (0) 1227 369570

f: +44 (0) 1227 369679

e: enquiries@emsgroup.co.uk

www.emsgroup.co.uk

Regulatory Information

EMS General

European Union

directives

1999/5/EC (R&TTE directive):

Hereby EMS Radio Fire & Security Systems declares that this device is in

compliance with the essential requirements and other relevant provisions

of Directive 1999/5/EC.

Approved to

EN54-17:2005

EN54-18:2005

E

N54-25:2008

©2014 EMS Radio Fire & Security Systems Ltd. All rights reserved 2/2 TSD077 Iss 3c 15/04/14 AJM

Certification

Certification

body 0359

CPR Certificate 0359-CPR-0222

Step 10 Reassemble the Loop Module

Ensure that the Loop Module PCB is correctly inserted and the

PCB retaining screw is refitted.

Refit the Loop Module lid, ensuring all four lid screws and

corner covers are fitted.

POWER

FAULT

ISOLATOR

ACTIVE

Care must be taken to ensure the LEDs are not damaged by

the light pipe when refitting the Loop Module Lid.

F usion

Loop Module

Loop Module 1

Loop Module 2

Loop Module 3

Loop

In

Loop

Out

+

-

Control

Panel

Step 7 Connection Wiring

Multiple Loop Modules (max 5)

Loop Module 1

Single Loop Module

+

-

Screen

Scr

LoopInLoop

Out

Scr

+-+

-

Scr

LoopInLoop

Out

Scr

+-+

-

Scr

LoopInLoop

Out

Scr

+-+

-

Scr

LoopInLoop

Out

Scr

+-+

-

Loop cables should only be passed via the access points

available.

Flame retardant cable glands must be used.

Cable lengths should be kept to a minimum to ensure cables are

away from the PCBs aerials.

RX

RF1 RF2

Step 9 Applying Power

Apply power to the Control Panel. The normal LED states for the

Loop Module are as below:

Healthy LED - Green LED will be on.

Fault LED - Yellow LED will be off.

Sys Fault LED - Yellow LED will be off.

TX

RADIO

WD

RESET

HELP

RX

ON

1 2 3 4 5 67 8

BACK

POWER

FAULT

ISOLATE

0V

RX

TX

3V

SCR

+

-

LOOP IN

SCR

LOOP OUT

+

-

1 2 3 4 5 6 7

POWER

FAU LT

ISOLATE

addr

DIL

switch

setting

1…….…8

addr

DIL

switch

setting

1…….…8

addr

DIL

switch

setting

1…….…8

addr

DIL

switch

setting

1…….…8

addr

DIL

switch

setting

1…….…8

1 10000000 11 11010000 21 10101000 31 11111000 41 10010100

2 01000000 12 00110000 22 01101000 32 00000100 42 01010100

3 11000000 13 10110000 23 11101000 33 10000100 43 11010100

4 00100000 14 01110000 24 00011000 34 01000100 44 00110100

5 10100000 15 11110000 25 10011000 35 11000100 45 10110100

6 01100000 16 00001000 26 01011000 36 00100100 46 01110100

7 11100000 17 10001000 27 11011000 37 10100100 47 11110100

8 00010000 18 01001000 28 00111000 38 01100100 48 00001100

9 10010000 19 11001000 29 10111000 39 11100100 49 10001100

10 01010000 20 00101000 30 01111000 40 00010100 50 01001100

51 11001100 61 10111100 71 11100010 81 10001010 91 11011010

52 00101100 62 01111100 72 00010010 82 01001010 92 00111010

53 10101100 63 11111100 73 10010010 83 11001010 93 10111010

54 01101100 64 00000010 74 01010010 84 00101010 94 01111010

55 11101100 65 10000010 75 11010010 85 10101010 95 11111010

56 00011100 66 01000010 76 00110010 86 01101010 96 00000110

57 10011100 67 11000010 77 10110010 87 11101010 97 10000110

58 01011100 68 00100010 78 01110010 88 00011010 98 01000110

59 11011100 69 10100010 79 11110010 89 10011010 99 11000110

60 00111100 70 01100010 80 00001010 90 01011010 100 00100110

101 10100110 106 01010110 111 11110110 116 00101110 121 10011110

102 01100110 107 11010110 112 00001110 117 10101110 122 01011110

103 11100110 108 00110110 113 10001110 118 01101110 123 11011110

104 00010110 109 10110110 114 01001110 119 11101110 124 00111110

105 10010110 110 01110110 115 11001110 120 00011110 125 10111110

126 01111110

Step 8 Configuration

The address number is set using the onboard 8 way switch.

Available selections are shown in the table below.

The Loop Modules programming is configured using the Loop

Modules menu structure.

Refer to the Engineers Guide (Doc Ref: TSD062) for full

programming details.

Loop

In

Loop

Out

+

-

Control

Panel

+

-

Screen

Screen Not Connected

Screen Not Connected

Loading...

Loading...