Page 1

AirFlow® S1

AirFlow

®

S1

Water

Airflow

Service manual

ELECTRO MEDICAL SYSTEMS

1

Page 2

AirFlow® S1

2

Page 3

AirFlow® S1

Table of contents

Important note 5

The unit and its components 6

Installation 6

Technical data 7

Description of the unit 7

Description of the electrical parts 8

Description of the hydraulic parts 10

Description of the pneumatic parts 11

Description of the powder parts 12

Trouble shooting 14

Verication of the general condition (internal) 14

Verication of the primary electrical circuit 14

Verication of the secondary electrical circuit 14

Verication of the water circuit 14

Verication of the air circuit 16

Verication of the powder circuit 16

Opening of the unit 15

Disconnecting of the air, water and powder hoses 16

Replacement of the secondary fuses 17

Unsoldering of the electrical wires 17

Replacement of the primary fuses 18

Assembly of the knob 19

Replacement of the transformer 20

Replacement of the thermostats 21

Replacement of the water heater 22

Procedure in case of heating problem 23

Replacement of the water lter cartridge 24

Replacement of the complete water lter 24

Replacement of the water regulator 25

Replacement of the pneumatic module for polisher 26

Replacement of the air lter element 27

Replacement of the air lters 27

Replacement of the electrovalve 28

Replacement of the air regulator 29

Replacement of the powder bowl set 30

Replacement of the pinch valve 31

Spare parts & Update 32

Spair part View 33-35

Function control 36

Safety control 36

EMS reserves the right to modify the technic, accessories, operating instructions or

the contents of the AirFlow® S1 due to technical or scientic improvements.

3

Page 4

AirFlow® S1

4

Page 5

AirFlow® S1

Important note

As manufacturer of electrical/medical devices, our responsibility

extends to the technical safety features of the unit only if mainte-

nance, repairs and modications are carried out by a repair center

trained and authorized by EMS.

All repairs or revisions must be carried out with the original EMS

spare parts.

The EMS quality policy requires a function control for each intervention and a safety control for each intervention requiring the

opening of the unit.

Each intervention of units for repair or revision must be docu-

mented.

For each return addressed to EMS, please clean and disinfect the

AirFlow® as described in the operating instructions and sterilize

the handpiece.

The boards must be wrapped in an antistatic bag.

This unit may not be operated in an explosion hazardous environ-

ment.

5

Page 6

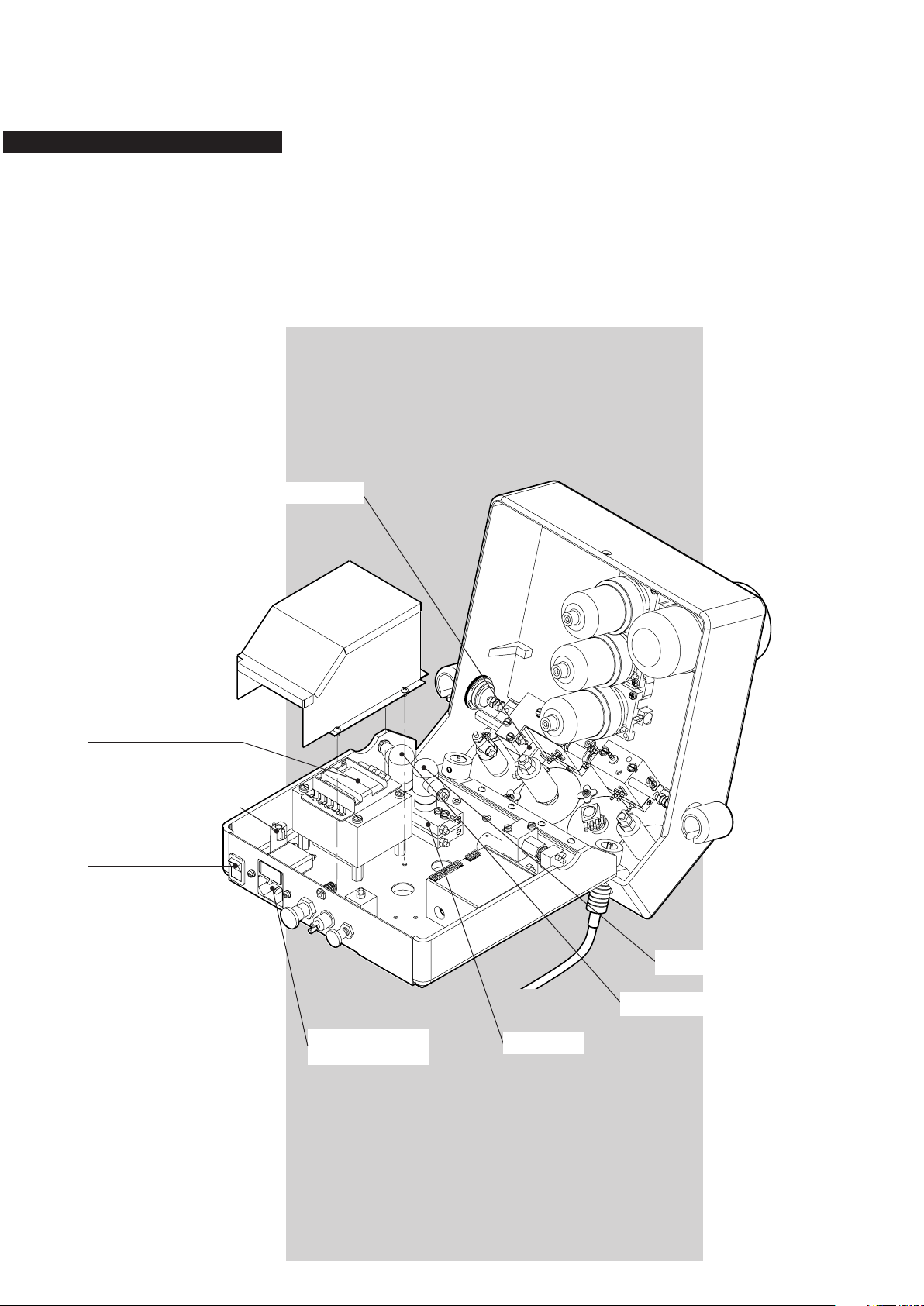

AirFlow® S1

Water

Airow

AirFlow

®

S1

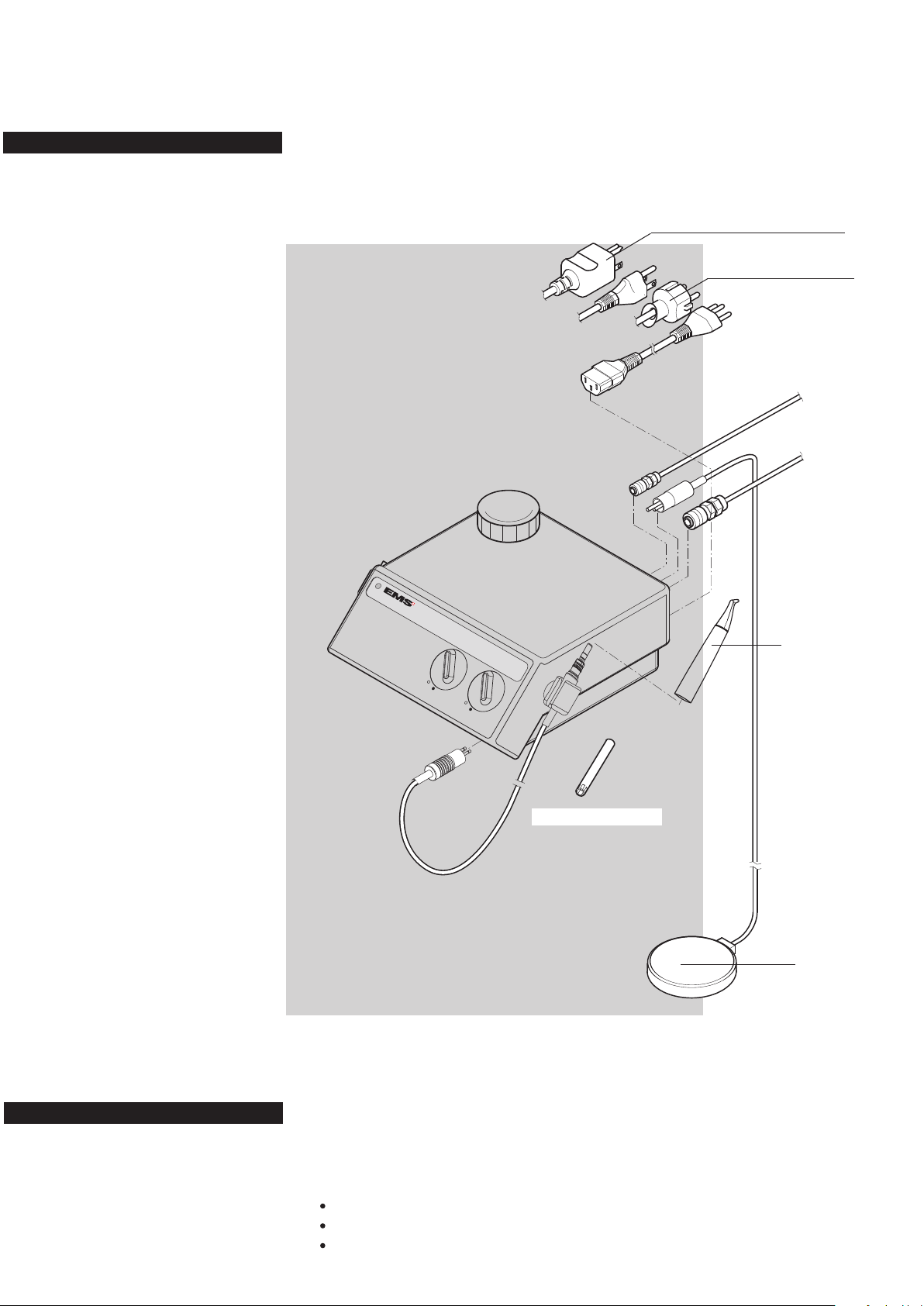

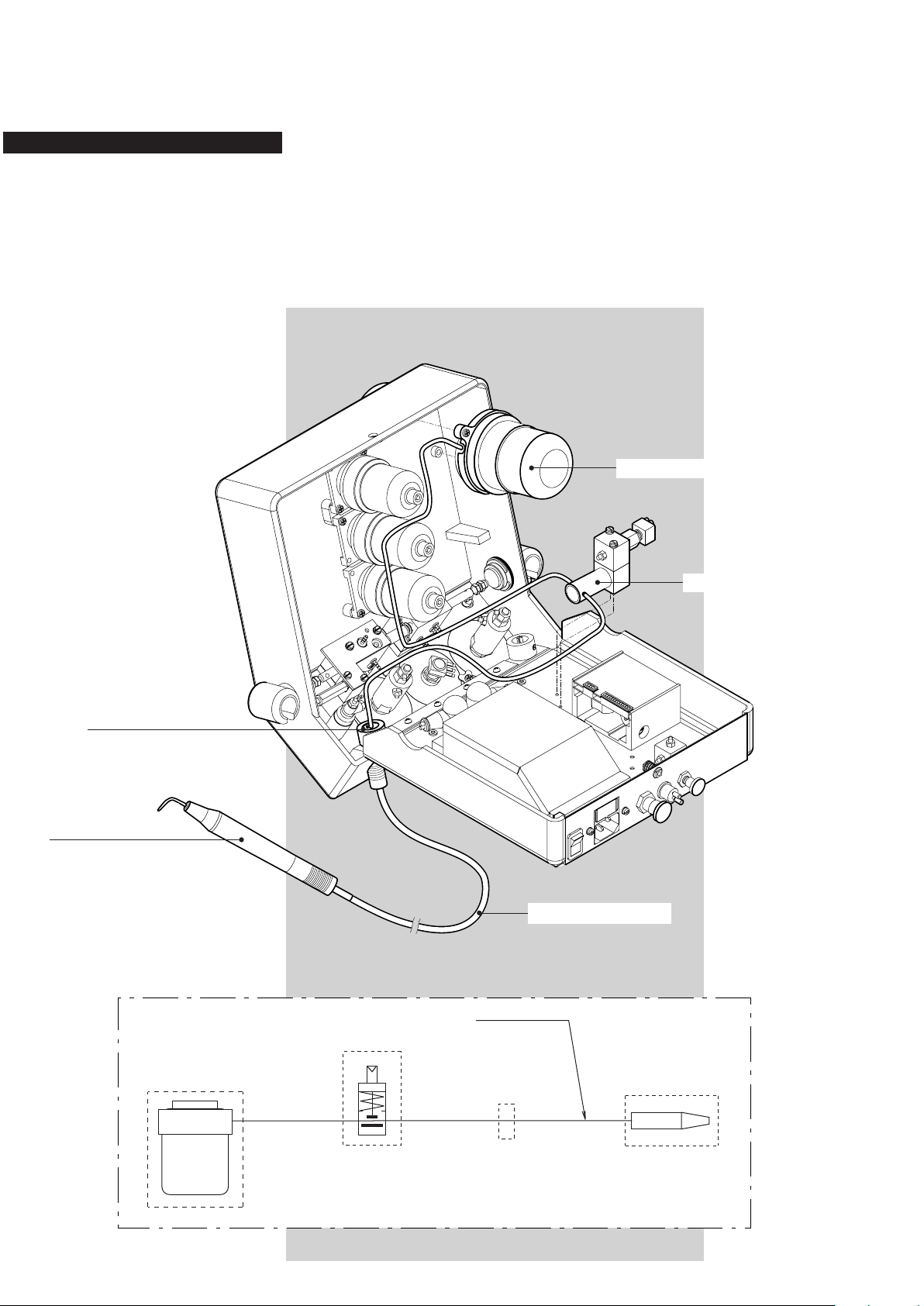

The unit and its components

Installation

Mains 100 - 110 V AC

Mains 220 - 240 V AC

Water pressure

1 - 5 bar

Compressed air

4.5 - 7 bar

Polisher handpiece

Spanner for water lter

Footswitch

6

Installation

The following connections are required to operate the

unit :

A water supply of between 1 and 5 bars

A compressed air supply of between 4.5 and 7 bars

An electrical supply.

Page 7

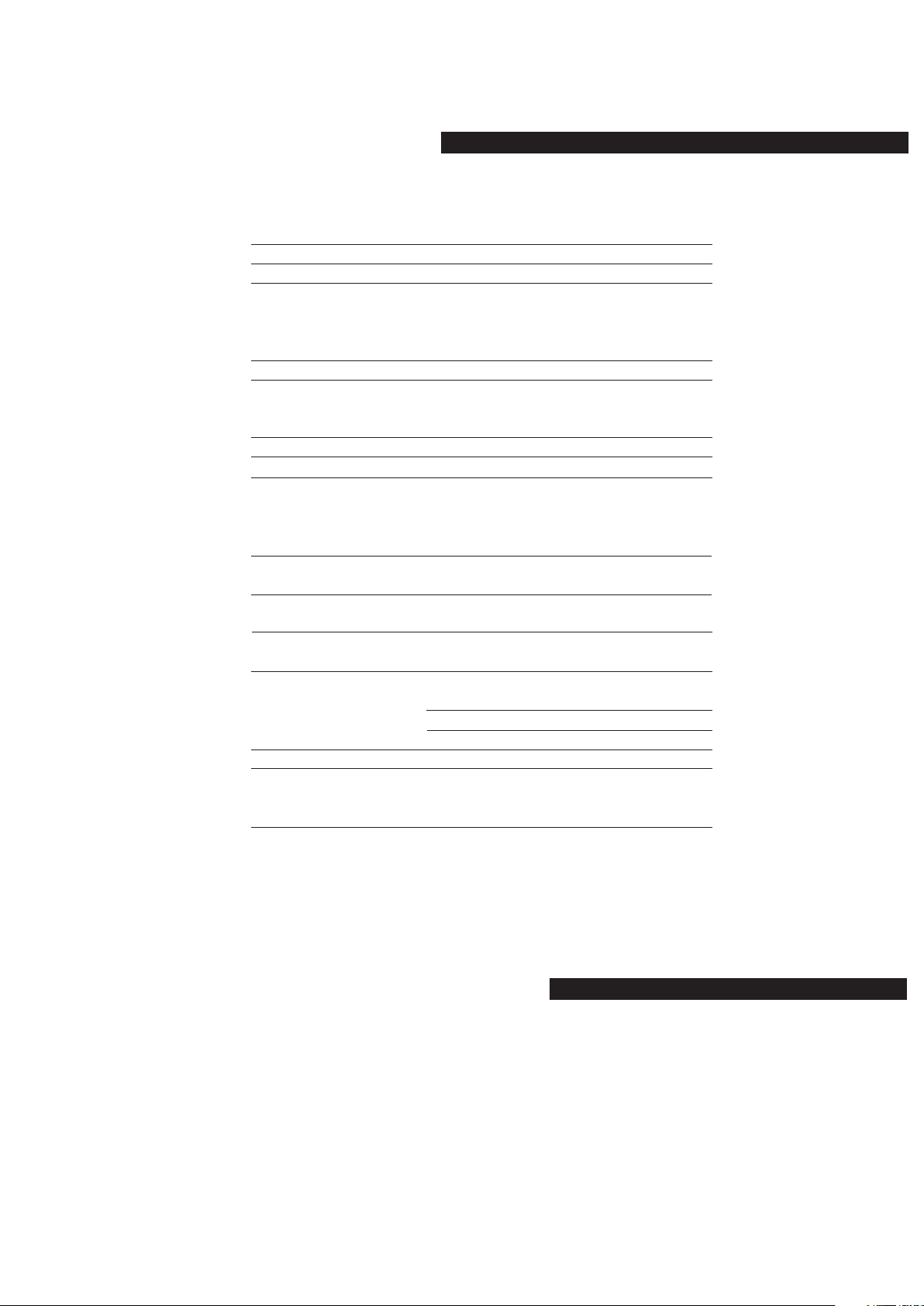

Technical data

Technical data

Manufacturer: EMS SA - 1260 Nyon, Switzerland

Models: AirFlow® S1

Classication: EN 60601-1 Class I

Type B

IP 20

93/42 CEE: Class IIa

Mode of operation: Continuous operation

Supply voltage: 100 V AC / 110 V AC

220 V AC

240 V AC

Main frequency: 50 - 60 Hz

Power consumption: max. 75 VA / for CSA units 115 VA*

Fuses Primary: ø 5 x 20 mm, 250 V

for 100V AC/110V AC, T 1 A, time-lag

for 220V AC/240V AC, T 0.5 A, time-lag

Secondary: ø 5 x 20 mm, 250 V, T 2.5A, time-lag

Compressed air supply: 4.5 to 7 bar (450 to 700 kPa) >15 Nl/min

(66 to 102 Psi)

Water supply: Cold water 1 to 5 bar (100 to 500 kPa)

(15 - 73 Psi)

Operating conditions: +10

30% to 75% relative humidity

Storage and transport

conditions: -10oC to +40oC (+14F to 104F)

10% to 95% relative humidity

Air pressure: 500 hPa to 1060 hPa

Weight: Approx. 3.6 kg (8.1 lbs)

Dimensions: Height: 120 mm

Width: 250 mm

Length: 250 mm

o

C to +40oC (+50F to 104F)

* For units sold in the USA and Canada

Description of the unit

The powder unit of the AirFlow® S1 is primarily intented for removing soft deposits and discolourations from all visible areas of teeth

as well as from ssures and interdental spaces.

The AirFlow® S1 is driven by a pneumatic footswitch.

7

Page 8

AirFlow® S1

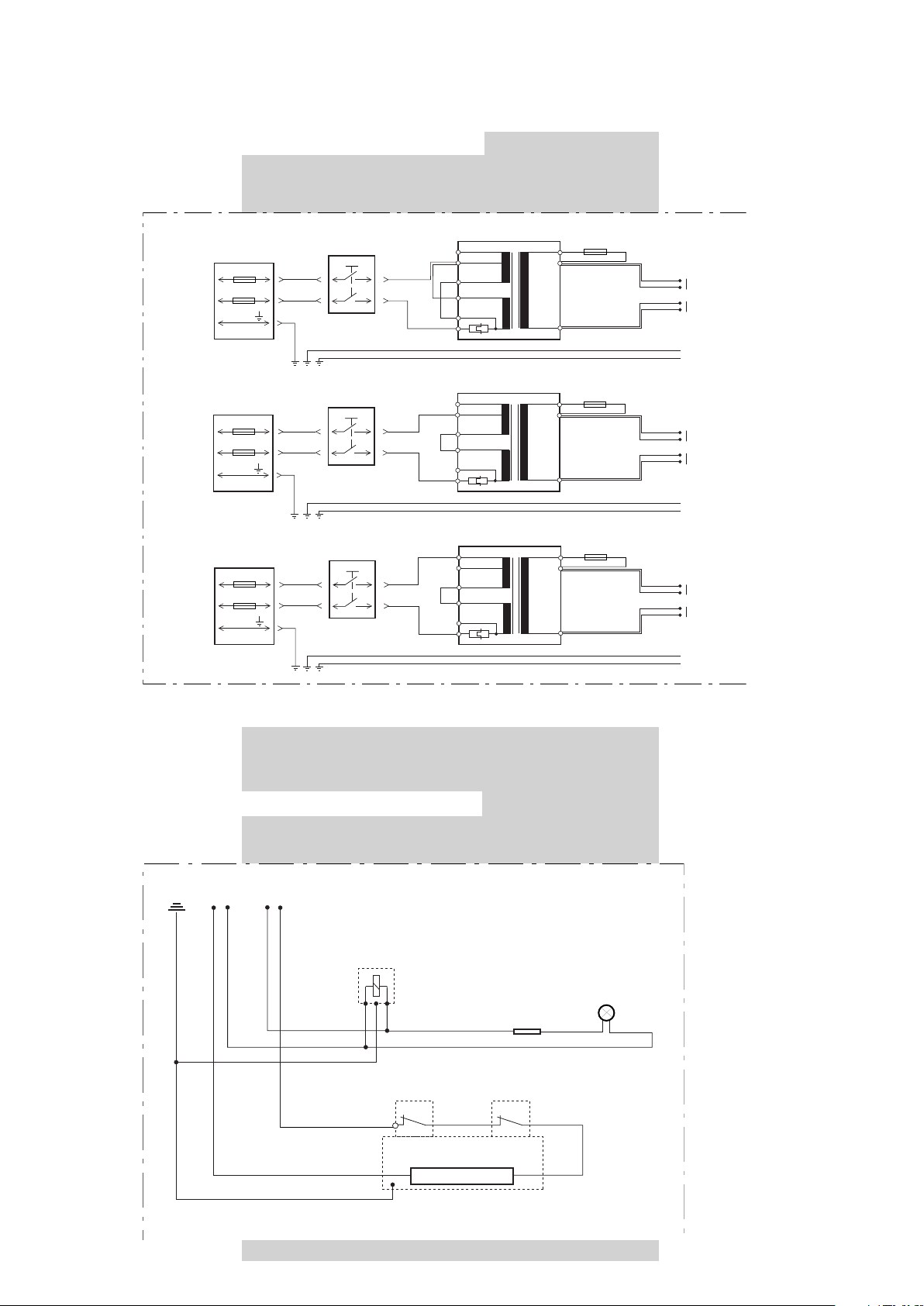

Description of the electrical parts

This unit is equipped with a mains socket with fuses incor-

porated. The main switch ON/OFF is placed on the back

side of the unit.

The mains voltage (high voltage of 110, 220 or 240 V AC)

is converted into 24V AC (low voltage), by an internal trans-

former, to supply all the electrical components of the unit.

Transformer

Secondary fuse

Main switch

Electrovalve

8

Mains socket

and primary fuses

Thermostat 47°C

Thermostat 60°C

Water heater

Page 9

AirFlow® S1

Blue

24 V AC

Green LED

Resistance

+-

Electrovalve

Blue

Blue

Blue

Blue

Blue

Thermostat

Red

47˚C

Thermostat

60˚C

Red

Water heater

Green/Ye llow

Red

Red Red

Red

Red

Red

Black

Secondary fuse

T 2.5A

Transformer

*

Main switch

Mains socket

T 1A

Primary fuses

T 1A

Yellow/

Green

ON/OFF

11

1

2

4

3

5

6 240 V

130 V

220 V

110 V

8

9

Red

Black

Secondary fuse

T 2.5A

Transformer

*

Main switch

Mains socket

Yellow/

Green

ON/OFF

11

1

2

4

3

5

6 240 V

130 V

220 V

110 V

8

9

Red

Black

Secondary fuse

T 2.5A

Transformer

*

Main switch

Mains socket

Yellow/

Green

ON/OFF

11

1

2

4

3

5

6 240 V

130 V

220 V

110 V

8

9

110 V AC

220 V AC

240 V AC

Red

Red

Red

Red

Red

Black

Black

Black

T 0.5A

Primary fuses

T 0.5A

T 0.5A

Primary fuses

T 0.5A

Blue

24 V AC

Red

Blue

Red

Blue

24 V AC

Red

Blue

Red

Blue

24 V AC

Red

Blue

Red

Yellow/Green

Yellow/Green

Yellow/Green

Yellow/Green

Yellow/Green

Yellow/Green

Primary circuit (high voltage)

*For the transformers without thermal protection (no pin 1), connect the black wire on pin 2.

Secondary circuit (low voltage)

9

Page 10

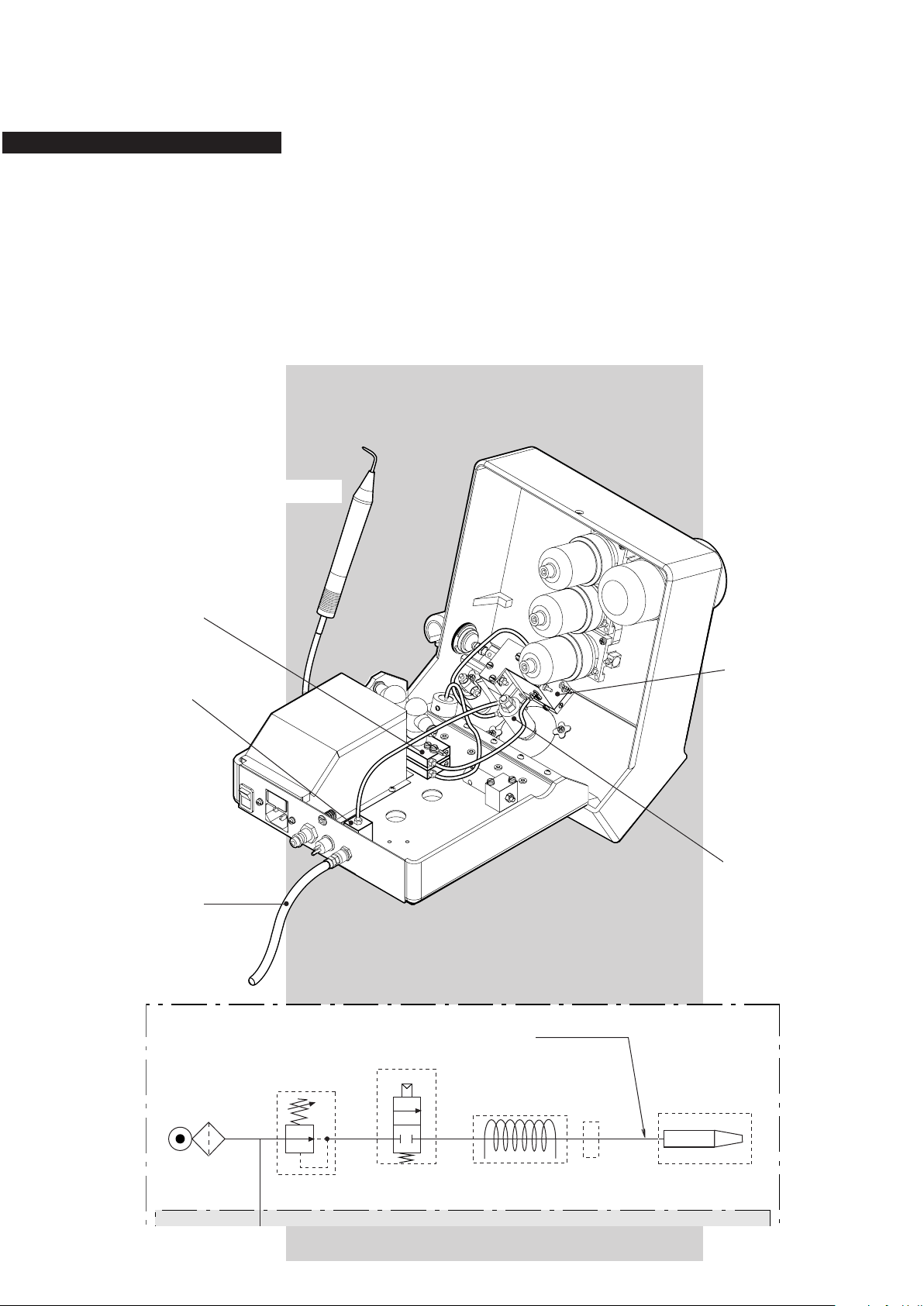

AirFlow® S1

Polisher

handpiece cord

Additional connections available for AirFlow® S2

Water filter on

AirFlow® S1

Pneumatic

module for

polisher

Water heater

Polisher

connector

Polisher handpiece

Water

regulator

Description of the hydraulic parts

AirFlow® S1 is equipped with a water lter at the entrance

of the water supply. Water circuit is made by blue hoses.

On the AirFlow® unit, the water passes through a water

lter then though a water regulator allowing the regulation

of the ow, and goes into the pneumatic module driven by

the electrovalve, the heater and the polisher handpiece via

the handpiece cord.

Water heater

Water lter

Water supply

Polisher handpiece

Pneumatic module for

polisher

Water regulator

10

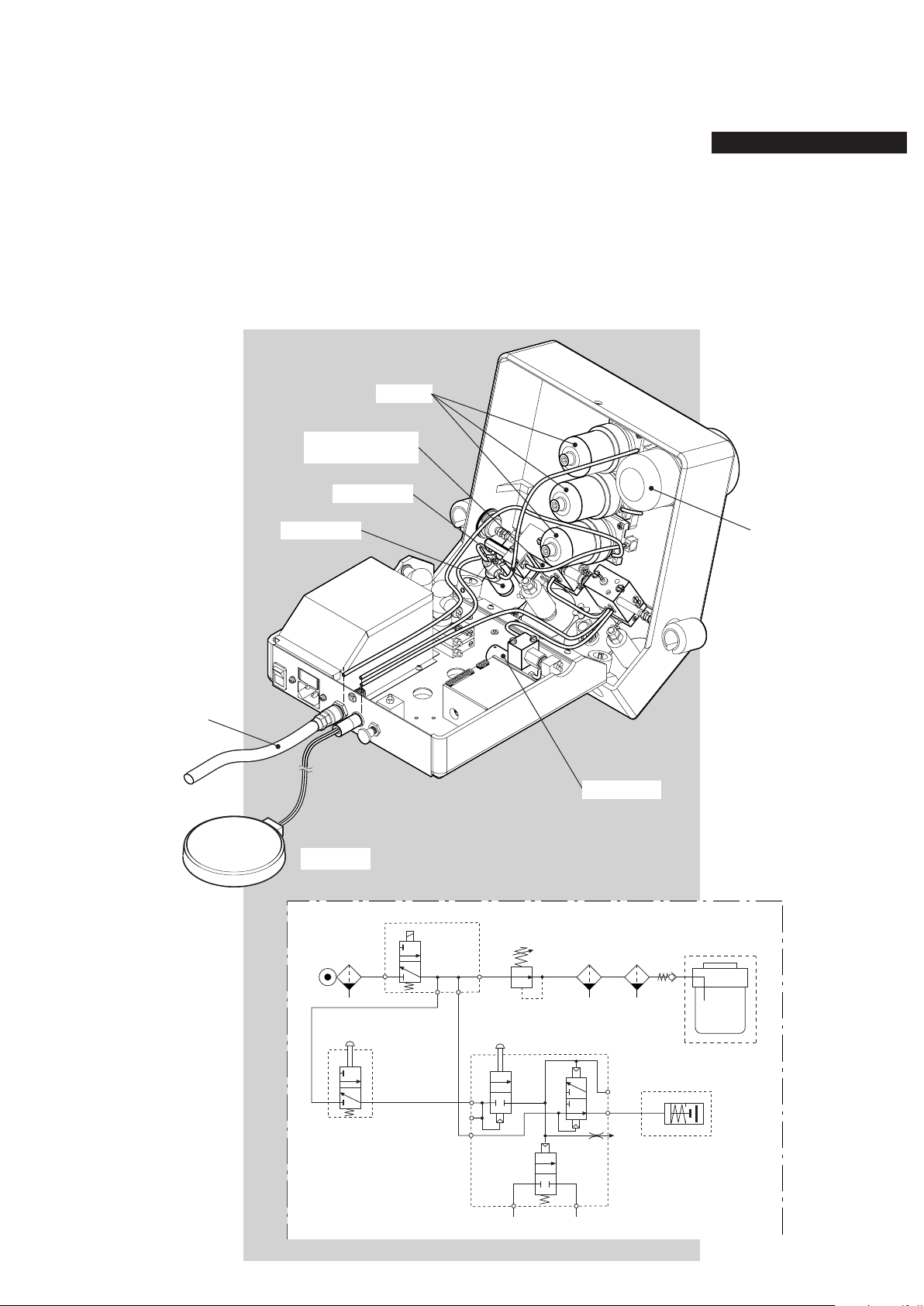

Page 11

AirFlow® S1

See water circuit

Pneumatic module for polisher

Electrovalve

Pinch valve

Footswitch

Powder bowl set

Air filterAir filterAir filter

Air regulator

Description of the pneumatic parts

AirFlow® S1 unit is driven by a pneumatic footswitch. Internal air

circuit is made by yellow hoses.

It is equipped with an air lter at the entrance of the air supply.

The air passes through a regulator allowing the regulation of the

ow, and goes into the a set of two air lters before its entrance

into the powder bowl.

The pneumatic module for polisher, the pinch valve and the water

circuit are driven by the air circuit.

Air lter

Pneumatic module

for polisher

Air supply

Electrovalve

Air regulator

Footswitch

Powder bowl set

Pinch valve

11

Page 12

AirFlow® S1

Polisher

handpiece cord

Powder bowl set

Pinch valve

Polisher

connector

Polisher handpiece

Description of the powder parts

The powder circuit is used on the AirFlow® system. The

powder circuit is made by a transparent hose.

The powder comes from the powder bowl and passes

through the pinch valve allowing the stop of the ow, and

goes into the polisher handpiece via the handpiece cord.

Powder bowl set

Polisher connector

Polisher handpiece

Pinch valve

Polisher handpiece cord

12

Page 13

Notes

Remarks and observations

13

Page 14

AirFlow® S1

Trouble shooting

-

-

°

°

14

≤ ≤

≤ ≤

≤ ≤

≤ ≤

* Replacement do not need the opening of the unit

Page 15

Opening of the unit

83

Remove the screw (83) and open the upper casing by

lifting up from the closed position.

The assembly of the upper part and the lower part of the

unit is made by the hinge (86).

86

15

Page 16

AirFlow® S1

* Replacement do not need the opening of the unit

Disconnecting of the air, water and powder hoses

In all cases, remove rst the external collar and after the

conical part of the uniclamp (92).

Remove the hose (66, 70 or 85) from the tubing of the element.

66

70

85

92

16

Page 17

Replacement of the secondary fuse

FUSE

T

2.5

AMPS

Turn the fuse holder head (82) on the anticlockwise and

extract the fuse (81).

Replace the fuse following the specications mentioned

on the sticker.

Sticker

82

81

Unsoldering of the electricawires

In all cases, before to unsolder the wires on the

electrical connexion, remove the insulated sleeving.

Connector

Insulated sleeving

17

Page 18

AirFlow® S1

FUSES

100-110V

T 1 A

220-240V

T 500mA L

I

O

Replacement of the primary fuses

Open the unit (see page 15).

Apply a lateral slight pressure with a small screwdriver on

the fuse holder (78) and extract the fuses (77).

Replace the fuses following the specications mentioned

on the sticker at the rear of the unit.

18

78

77

Sticker

Page 19

Assembly of the knob

The regulators and taps sent for After Sales Support

are ADJUSTED and TESTED to function correctly.

Don’t modify the adjustment before assembly.

Preparation of the regulator holder

Cut the three external pins coming from the moulding.

Lay down a lm of silicone paste on the contact surface

between the knob and the holder.

Assembly instructions

Put the knob (68) and the elastic washer (69) into the knob

holder of the regulator in such a way that the stop of the

knob is as close as possible to the stop of the knob holder

(on the left). Do not turn the axis of the regulator. The knob

should be able to turn in a clockwise direction (thus open-

ing the regulator).

Turn the knob anticlockwise (0o-15o) to join the 2 stops. The

regulator is now at minimum position.

69

Silicone paste

Regulator axis

68

Stop on the regulator

holder

Stop on the knob

Put the assembly into the upper casing of the unit (from

inside), the spot of the knob should be opposite to the spot

on the casing .

Spot of the knob

Spot on the casing

19

Page 20

AirFlow® S1

Replacement of the transformer

Remove the three screws (90) of the metal housing of the

transformer (64).

Remove the housing of the transformer and extract the

bushing (93).

Remark: note the order of connection for each wire.

Unsolder all the electrical cables of the transformer (65).

Remove the four screws (83) and the washers (74) of the

transformer.

Put in place a new transformer.

65

90

64

93

20

74

83

Page 21

Replacement of the thermostats

This procedure is identical for the thermostat 60oC (28)

and for the thermostat 47oC (29) screwed on the top of the

water heater (30).

Remove the thermostat protection (27).

Unsolder the two cables on the thermostat.

Unscrew the thermostat using the two pins for electrical

connection.

Put in place a new thermostat.

27

28

29

30

21

Page 22

AirFlow® S1

Replacement of the water heater

Remove the three screws (90) of the metal housing of the

transformer (64).

Remove the housing of the transformer and extract the

bushing (93).

Unsolder the electrical wires on pin 11 of the transformer

(65) and extract the electrical wire of the water heater from

the bushing.

Remove the thermostat protections (27) and unsolder the

four electrical wires on the thermostats (28) and (29).

Extract the electrical wire of the water heater from the ther-

mostat protection.

Remove the two uniclamps (92) and disconnect the blue

water hoses (70) from the water heater (30).

Unscrew the ground connection (31).

Remove the two screws (25) and the two washers (26).

Put in place a new water heater.

The water heater is mounted

on two insulating cannons (32).

28

30

64

90

25

26

27

31

29

92

70

32

22

93

65

Page 23

Procedure in case of heating problem

Switch the power ON and verify (by hand) the increase of

temperature of the water heater (30). If the heater stays cold,

use the following procedure to identify if the problem is due

or not to the thermostats.

Shunt (A) the thermostat 47oC (29) and control the increase

of temperature of the heater.

If the heater starts to be warm, it means that the

thermostat 47oC is out of order and it must be re placed by a new one (see page 21).

If no increase of temperatue appears, try to rearm

the thermostat 60oC (28) by pushing the pin down.

In case of the pin stays up, it means that the

rearmament system is out of order and the ther mostat 60oC must be replaced by a new one (see

page 21).

In case of the pin stays down (good rearmament),

and if the heater doesn’t work, shunt the thermos-

tats 47oC (A) and 60oC (B) at the same time.

At this step, if no heating is produced, control the electrical

supply of the water heater (see page 9).

Pin

28

29

30

Shunt B

Shunt A

23

Page 24

AirFlow® S1

Replacement of the water lter cartridge

Unscrew the cap of the water lter (38) on the back side

of the unit.

Unscrew the water lter cartridge using the hexagonal

spanner (10).

Change the water lter spare parts set (39).

Replacement of the complete water lter

Dismantle the uniclamp (92) and disconnect the blue water

hose (70) from the water lter.

Unscrew the external nut of the water lter and put in place

a new complete water lter (38).

38

External nut

92

70

24

10

39

Water lter cap

Page 25

Replacement of the water regulator

Dismantle the two uniclamps (92) and disconnect the blue

water hoses (70) from the regulator.

Remove the two screws (90) and the elastic washers (89)

of the knob.

Extract the water regulator (91) and the knob (68) from

inside of the casing.

Remove the knob from the water regulator.

Put in place a new water regulator (see page 19).

70 92

91

90

89

68

25

Page 26

AirFlow® S1

Replacement of the pneumatic module for

polisher

Remove the two screws (63) and the washers (26).

Release the electrovalve (23) and its plate (21).

Extract the selector rod (22) from the module.

Remove the ve uniclamps (92) and disconnect the three

yellow air hoses (66) and the two blue water hoses (70)

from the pneumatic module for polisher (62).

Put in place a new pneumatic module for polisher.

22

92

21

23

70

63

26

62

92

66

26

Page 27

Replacement of the air lter element

Unscrew the air lter bowl (59).

Unscrew the air lter element (60).

Change the air lter element and the O-ring.

Replacement of the air lters

This procedure is identical for :

- the air lter with horizontal L coupling (58),

- the air lter with check-valve (55),

- the air lter with vertical L coupling (54).

Remove the two screws (61).

Dismantle the two uniclamps (92) and disconnect the

yellow air hoses (66) from the air lter.

Put in place a new air lter.

61

59

92

66

O-ring

60

58

61

54

55

27

Page 28

AirFlow® S1

Replacement of the electrovalve

Remove the two screws (63) and the washers (26).

Release the plate support (21) of the electrovalve and re-

move the two plastic screws (20).

Disconnect the three electrical connectors from the elec-

trovalve.

Disconnect the four uniclamps (92) and the yellow air hoses

(66) from the electrovalve (23).

Put on a new electrovalve in replacement.

Place the seal (included with the electrovalve set)

between the electrovalve and the plate support.

92 66 20

Seal

23

21

63 26

28

Page 29

Replacement of the air regulator

Remove rst the two screws (63) and the washers

(26) of the pneumatic module for polisher to allow

a free access to the xation of the air regulator.

Dismantle the two uniclamps (92) and disconnect the yellow

air hoses (66) from the regulator.

Remove the two screws (90) and the elastic washers (89)

of the knob.

Extract the air regulator (67) and the knob (68) from inside

of the casing.

Remove the knob from the air regulator. Put in place a new

air regulator (see page 19).

66

92

67

68

90

89

2663

29

Page 30

AirFlow® S1

Replacement of the powder bowl set

Unscrew the cap for powder bowl (56) from outside of the

unit.

Remove the two screws (34) and the washers (26).

Dismantle the two uniclamps (92) and disconnect the yellow

air hose (66) and the transparent powder hose (85) from

the powder bowl set (35).

Put in place a new powder bowl set with the two O-rings

(33 and 37).

92 66

92

85

34 26 37 33

35

36

57

56

30

Page 31

Replacement of the pinch valve

Remove the two screws (25) and the washers (26).

Dismantle the two uniclamps (92) and disconnect the trans-

parent powder hose (85) from the polisher connector (48).

Remove the transparent powder hose passing through the

pinch valve hole.

Dismantle the uniclamp (92) and disconnect the yellow air

hose (66) from the pinch valve (24).

Put in place a new pinch valve and a new powder hose.

92

48

85

25

26

24

92

66

31

Page 32

AirFlow® S1

-The Spare parts catalogue #1 dent refer to FM-058/*

- AF Handpiece EL-085 + EL-086 + EM-061

are Discontinued

Spare parts & Update

Replace by EQ-160

-The solnoide valv EQ-024 replace by EQ-159

-The powder tube BG-006 replace by EQ-207

32

Page 33

AirFlow® S1

22

23

20

21

24

25

26

27

28

29

63

26

62

25

26

61

59

60

58

59

38

39

42

43

44

35

36

34

30

37

26

40

41

33

31

32

52

53

54

55

57

56

45

46

47

48

49

51

50

33

Page 34

AirFlow® S1

90

93

65

64

26

72

26

73

74

72

66

67

71

68

69

70

69

92

91

90

89

83

104

88

79

78

77

76

75

80

81

82

84

87

86

85

74

83

83

34

Page 35

AirFlow® S1

Pos. Designation Order No.

20 Plastic screw for electrovalve DD-037

21 Plate for electrovalve BE-003

22 Selector rod EQ-023

23 Electrovalve EQ-159

24 Pinch valve + holder EH-034

25 Screw for heater & pinch valve DD-030

26 Washer M3 DF-017

27 Thermostat protection AP-001

By position

28 Thermostat 60oC CF-004

29 Thermostat 47oC CF-006

30 Water heater EK-015

30 Water heater CSA* EK-107

31 Screw for heater ground DD-025

32 Insulating cannon for heater CH-041

33 O-ring for powder bowl BC-006

34 Screw for powder bowl DD-609

35 Powder bowl set EH-007

36 Powder bowl AB-002B

37 O-ring for powder bowl BC-017

38 Water lter complete EG-004

39 Water lter spare parts set EQ-029

40 Screw front panel connector DD-003

41 Washers for handpiece holder EQ-011

42 Locking set EQ-010

43 Air inlet connector EQ-005

44 Protection cap air connector AQ-016

45 Protection caps for footswitch AQ-013

connectors

46 Footswitch inlet connector EH-022

47 Protection cap water connector AQ-015

48 Polisher connector EG-013

49 O-ring for polisher connector BC-035

50 Set of 4 stoppers EQ-015

51 Green control light CH-031

52 Resistance 470 Ohms CJ-010

53 Push button AD-056

54 Air lter - vertical L coupling EQ-064

55 Air lter with check-valve EQ-066

56 Cap for powder bowl + O-ring EQ-019A

57 O-ring for Air-Flow cap BE-009

Pos. Designation Order No. Pos. Designation Order No.

58 Air lter - horizontal L coupling EQ-065

59 Air lter bowl + O-ring EQ-020

60 Kit Air lter element + O-ring EQ-152

61 Screw for air lters DD-608

62 Pneumatic module for polisher EH-006

63 Screw for polisher module DD-032

64 Metal housing for transformer AL-004

65 Transformer CC-008A

66 Yellow air hose BG-004

67 Air regulator + holder EH-014

68 Knob AB-011H

69 Elastic washer for knobs DF-042

70 Blue water hose BG-005

71 Handpiece holder right AA-041E

72 Nut ground conn.- mains socket DE-006

73 Nut for ground connection DE-002

74 Washer M4 DF-018

75 Mains socket CH-034

76 Screw for base and mains socket DD-026

77 Fuse T 1A (100/110 V AC) CE-033

77 Fuse T 0.5A (220/240 V AC) CE-027

78 Fuse holder CE-019

79 Main switch CE-013

80 Fuse holder CE-009

81 Fuse T 2.5A CE-025

82 Fuse holder head CE-010

83 Screw for ground, transfo & locking DD-035

84 Screw for ground DD-027

85 Powder tube replacement kit EQ-207

86 Hinge AQ-028A

87 Screw for hinge DD-607

88 Hinge plate AL-005

89 Elastic washer for knob screw DA-009

90 Screw for knobs & metal housing DD-602

91 Water regulator + holder EG-076

92 Uniclamp BG-001

93 Bushing for transformer housing CG-007

104 Upper case AA-038J

105 Front Label DQ-332

35

Page 36

AirFlow® S1

Function control

Use the “Trouble shooting” to control the functioning of the unit

after each repair.

Indicate on the data sheet the serial number of the unit, the result

of the controlled points and the part exchanged.

Date and sign the data sheet and transmit a copy to the After Sales

Service in Nyon for information.

Uae the Deat Sheet fonction control ZA-176.

Safety control

The EMS quality policy requests a safety control for each repair

requiring the opening of the unit.

Use the safety control procedure of the SAV FM-010.

36

Page 37

Notes

Remarks and observations

37

Page 38

Notes

Remarks and observations

Page 39

Page 40

SWITZERLAND

EMS SA, Ch. de la Vuarpillière 31, CH-1260 Nyon

Tel. +41 22 99 44 700, Fax +41 22 99 44 701

e-mail: welcome@ems-ch.com

website: www.emsdent.com

FM-003/EN Ed.2013/01

Loading...

Loading...