Page 1

0

E N V I R O N M E N T A L M O N I T O R S E R V I C E , I N C .

09/ 15/2 0 1 1 R E V - 1 6

Model 1304 Installation and Operation

Manual

Prepared by: James F. Cognetta

Environmental Monitor Service, Inc.

• PO BOX 4340

Yalesville, CT 06492

Phone 203.935.0102 • Fax 203.634.6663

Sales@emsct.com

Page 2

1

Ship to: ENVIRONMENTAL MONITOR SERVICE

87 Gypsy Lane

Meriden, CT. 06450

Phone 203.935.0102 ext 14

Fax 203.634.6663

E-mail: service@emsct.com

Warnings and Safety Guidelines

Guidelines for user safety and equipment protection

This manual is intended to aid trained and competent personnel in the installation of this equipment. Only a

technician or engineer trained in the local and national electrical standards should perform tasks associated with

the electrical wiring of this device.

Warnings

Under no circumstances will Environmental Monitor Service, Inc. be liable or responsible for any

consequential damage that may arise as a result of installation or use of this equipment.

All examples and diagrams shown in the manual are intended to aid understanding. They do not guarantee

operation.

Environmental Monitor Service, Inc. accepts no responsibility for actual use of this product based on

these examples.

Due to the great variety of possible applications for this equipment, the user must assess the suitability of

this product for specific applications.

Make sure to have safety procedures in place to stop any connect3ed equipment in a safe manner if the

controller should malfunction or become damaged for any reason.

Do not replace electrical parts or try to repair this product in any way.

Only qualified factory trained service personnel trained in is operation should open the device’s housing

or carry out repairs.

The manufacturer is not responsible for problems resulting from improper or irresponsible use of this

device.

You may cause an electric shock, fire or damage the equipment if you ignore any of these safety

precautions.

Page 3

2

1. Limited Warranty

a) Warranty.

i) Except as otherwise provided herein, Seller warrants to Buyer that the Products sold to Buyer are, at

the time of shipment to Buyer from Seller, free from defects in material and workmanship.

ii) This warranty shall be valid for a period of twelve (12) months from the date of shipment to Buyer,

unless a different period is specified herein, or in Seller’s applicable price list in which case the

specified period shall apply. Notwithstanding anything to the contrary contained herein, the warranty

period for spare parts, data processing equipment, including data storage devices, processors,

printers, terminals, communication interfaces, tape drives and all similar devices, and is in all cases

limited to ninety (90) days from the date of shipment to Buyer.

iii) Except in the case of an authorized distributor of Seller, authorized in writing by Seller to extend this

warranty to the distributor’s customers, the warranty herein applies only to Buyer as the original

purchaser from Seller and may not be assigned, sold or otherwise transferred to any third party.

iv) As Buyer's sole and exclusive remedy under this warranty, Seller agrees either to repair or replace, at

Seller's sole option, any part or parts of such Products which, under proper and normal conditions of

use, prove(s) to be defective within the applicable warranty period. Alternately, Seller may at any

time, in its sole discretion, elect to discharge its warranty obligation hereunder by accepting the return

of any defective Product pursuant to the terms set forth herein and refunding the purchase price paid

by Buyer.

b) Exclusions and Limitations.

i) It is recognized that some parts by their nature may not function for the warranty period applicable to

the Product. Therefore, excluded from the warranty herein are ceramic material cells and/or holders,

and other similar parts referenced in the applicable operating manual.

ii) The warranty herein excludes any equipment or accessories which are identified on applicable price

lists, quotations, special promotional materials, or on the face hereof, for which this limited warranty

may be further limited. Included within this category are items produced by third party manufacturers

(as to which Seller passes to Buyer the warranty it has been provided by the manufacturer) and items

which are sold at specially reduced prices with reduced warranty protection (in some cases, extended

warranty protection may be available at an increased price).

iii) This warranty does not cover loss, damage, or defects resulting from: transportation to the Buyer's

facility, improper or inadequate maintenance by Buyer, Buyer-supplied software or interfacing,

unauthorized modification or misuse, operation outside of the environmental specifications for the

Product or improper site preparation or maintenance.

iv) No warranty is made with respect to used, reconstructed, refurbished or previously owned Products,

which will be so marked on the face hereof and, unless otherwise indicated on the face hereof, shall

be sold “As Is”.

v) The warranty herein applies only to Products within the country of original delivery. Products

transferred outside the country of original delivery, either by Seller at the direction of Buyer or by

Buyer’s actions subsequent to delivery, may be subject to additional charges prior to warranty repair

or replacement of such Products based on the actual location of such Products and Seller’s warranty

and/or service surcharges for such location(s).

c) Place of Service. Except when otherwise provided in Seller's current applicable price list, Seller shall

perform all warranty services hereunder at the Seller’s facility, as soon as reasonably practicable after

notification by the Buyer of a possible defect. Seller requires that the Buyer request from the Seller a

Return Authorization Number prior to returning the Product to Seller's production facility, transportation

charges prepaid, when necessary to provide proper warranty service.

d) In the case of onsite warranty. The Seller reserves the right to charge for travel time and all travel

expenses to and from the Seller’s site and Buyers facility. The actual onsite labor time to install, test

replace, adjust etc., to complete the warranty work onsite shall NOT be charged to the Buyer.

Page 4

3

e) Software and Firmware Products. The sole and exclusive warranty applicable to software and firmware

products provided by Seller for use with a processor will be as follows: Seller warrants that such software

and firmware will conform to Seller's program manuals current at the time of shipment to Buyer when

properly installed on that processor, provided however that Seller does not warrant that the operation of

the processor or software or firmware will be uninterrupted or error-free.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. SELLER EXPRESSLY DISCLAIMS THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Page 5

4

Table of Contents

Guidelines for user safety and equipment protection 1

Warnings 1

Warrantee Registration 6

CCuussttoommeerr sseerrvviiccee

7

7

Claims for damaged shipments 8

Shipping discrepancies 8

SSeeccttiioonn 11

9

9

System Description 9

Transmissometer/retro reflector 9

Control Unit 9

Optional Air Purge Weather Cover System 9

Alignment system 9

Cabling 9

Principle of Operation 10

Normal mode of operation 10

Internal calibration system, zero mode 10

Internal calibration system, Span mode10

1304 Opacity Specifications 12

SSeeccttiioonn 22

4

114

Installation Considerations 14

Choose an installation site 14

Accessibility 14

Environment 14

Stack exit 14

Installation – Mechanical 14

Drawing notes 14

Sensors height from Platforms, walk way/ decks, etc,

14

Alignment of stack flanges 15

Installation procedure - stack flanges 15

Sample area 15

Modbus Communication and Addresses 15

Reading Analog output Block Addresses:16

Reading Discrete output Block Addresses: 16

Writing: 16

Communication menu has the following sub categories and

default settings: 16

Changing communication settings: 17

Mounting the air plenum and weather covers

17

Mounting the air plenum and weather

covers 18

Transceiver and retro reflector assembly 19

Air flow switch 21

Control unit 21

SSeeccttiioonn 33

2

222

Before start up 22

Stack exit correlation computation22

Start up service 23

Verifying instrument operation and configuration

23

EDIT Keys 23

Factory O.P.L.R. Display 23

Quick Menu 23

Zero/Span calibration Check 24

SSeeccttiioonn 44

5

225

Instrument operations and adjustments

25

Overview of the systems operation 25

Front Panel LED's 25

Fault Messages 25

Control unit manual controls 26

Alarm set point adjustments 26

Alarm Time Delay Adjustment 26

4-20mA outputs 27

Recorder or other device calibration: 27

Auto cal timer Adjustment 28

Disable internal cal timer 28

Remote calibration cycle initiate 28

Remote calibration cycle acknowledgment28

SSeeccttiioonn 55

0

330

Ajustments 30

Clear on stack zero and span calibration30

Zero reflector adjustment 30

Span filter VALUE 31

Record the zero/span values in the quick menu

31

Off stack zero calibration 32

SSeeccttiioonn 66

3

333

using the on line zero reflector (option)

33

Procedure 33

Page 6

5

Filter correction 33

Course adjustments 35

Micro-turn parts list 35

Filter certification 36

SSeeccttiioonn 77

7

337

Preventive/corrective maintenance37

Preventive/corrective maintenance schedule 37

Trouble Shooting 40

Trouble shooting -continued 41

Spare parts 42

SSeeccttiioonn 88

4

444

Drawings 44

EMS 1001 - Mounting under 6‘ STACK 45

EMS 1002 - Mounting over 6’ stack 46

EMS 1024 - Air purge/Weather cover mech Installation

47

EMS 1078 - PANEL cut out for 1304 control unit

48

EMS 1079 -1304 control unit dimensions 49

EMS 1077 - Terminal identification 1304 control unit

50

EMS 1131 -1304 with recorder system wiring 51

Purge blower electrical and pressure information

52

EMS1101 - Sht 1 of 3 Dual Blower system wiring

53

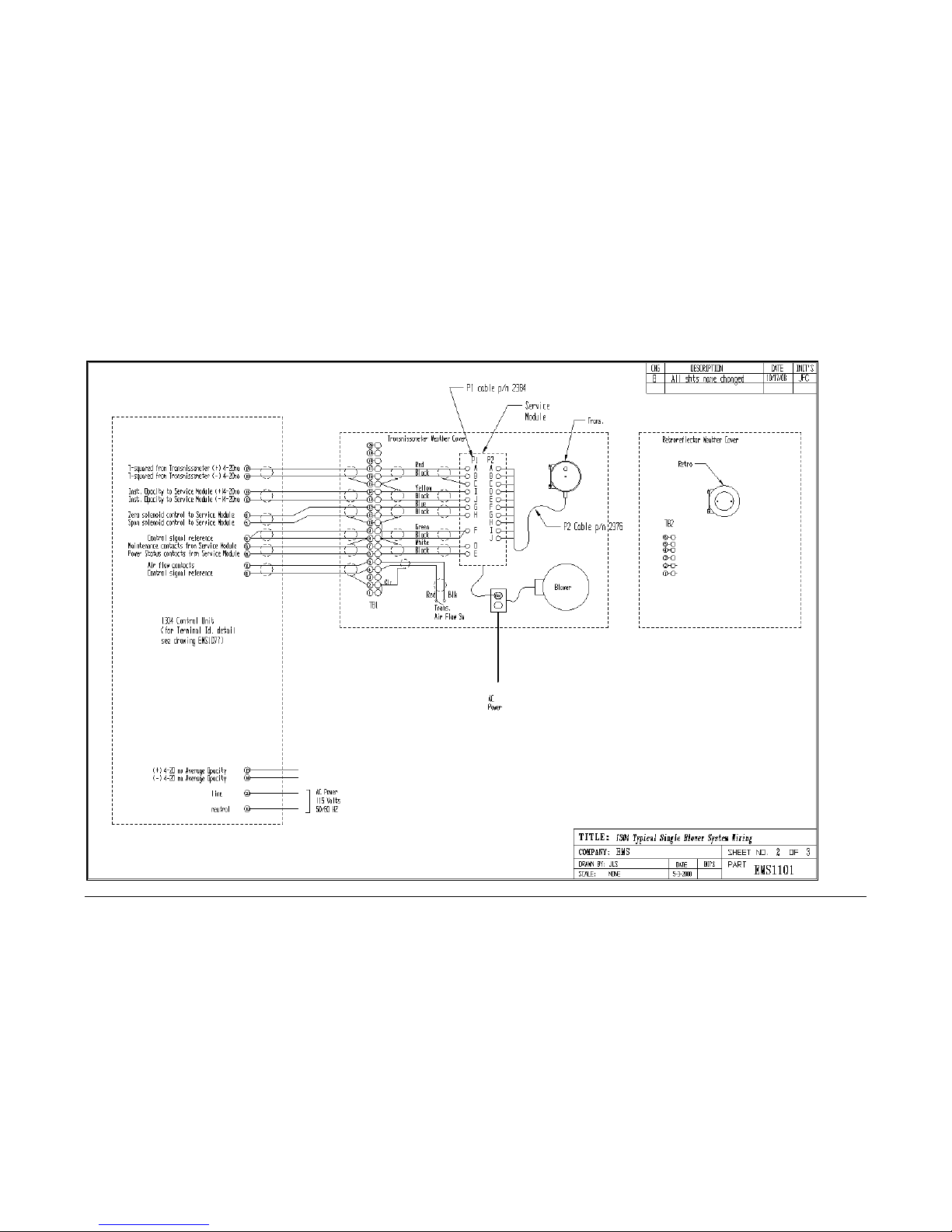

EMS 1101 - Sht 2 of 3 Single Blower system wiring

54

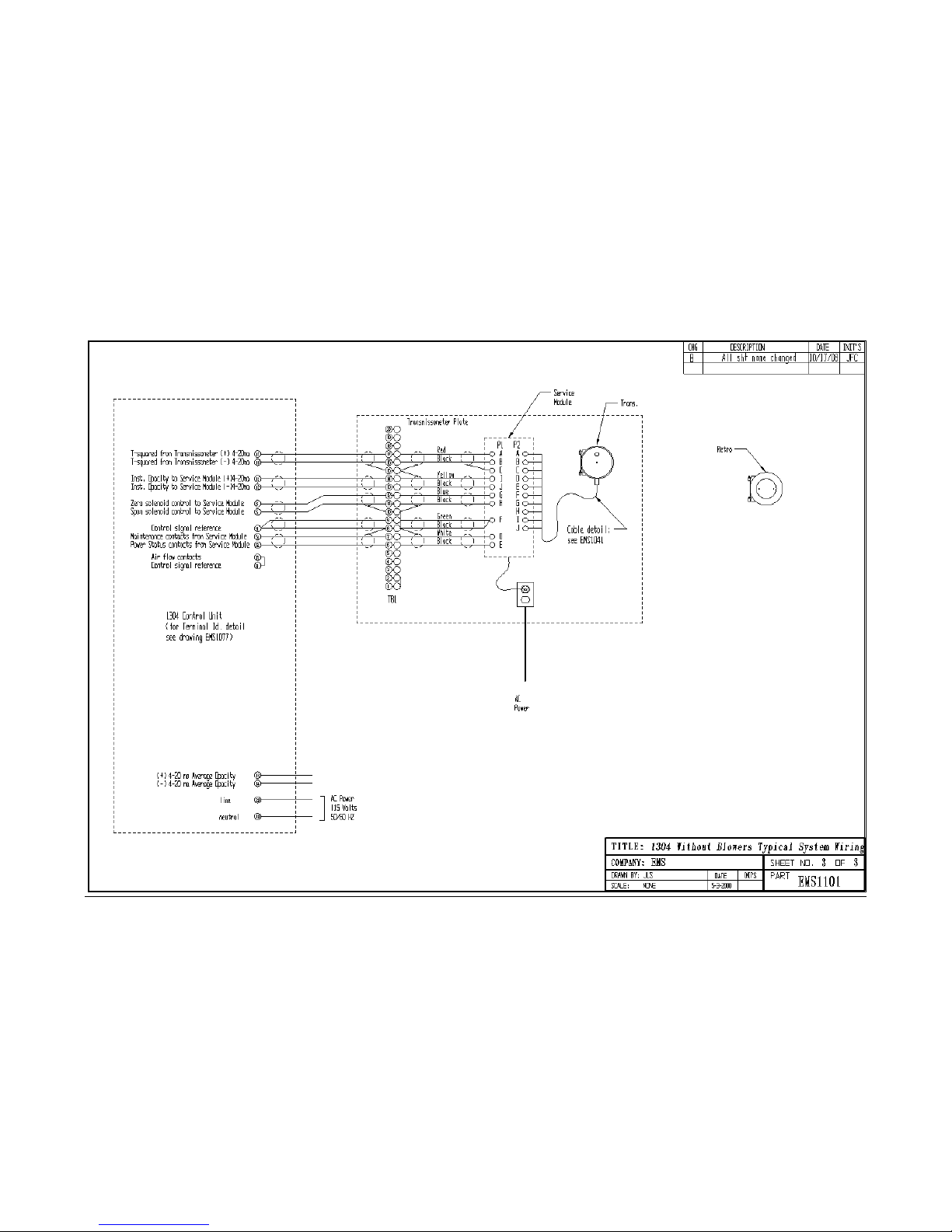

EMS 1101 - Sht 3 of 3 Without Blower system wiring

55

Page 7

6

WARRANTEE REGISTRATION

Read this manual before attempting installation!

NOTICE: Information contained in this manual is subject to change without notice and does not represent a

commitment on the part of Environmental Monitor Service, Inc. Environmental Monitor Service, Inc. reserves

the right to make changes in the construction, design, specifications, and/or procedures that may not be reflected

in this manual. This manual is furnished on the express condition that the information herein will not be used for

second source procurement, directly or indirectly detrimental to the interest of Environmental Monitor Service,

Inc.

To register your warrantee and to insure that you receive full coverage for your instrument, please complete and

return this registration within two weeks of receipt of instrument. Please type or print.

Company Name ___________________________________________________________________

Division __________________________________________________________________________

Mailing Address ___________________________________________________________________

City, State Postal Code, Country _______________________________________________________

Telephone & Fax ___________________________________________________________________

Instrument Model. ____________________________________________________________

Serial Number __________________________________________________________________

Maintenance person Name __________________________________________________________

Department Name __________________________________________ Phone __________________

Complete mailing address (if different from above) ________________________________________

What is the industry application for instrument? (i.e. chemical, recovery boiler, cement kiln etc.): ____

________________________________________________________________________________

How will this instrument be used? ____Process Control ___ Combustion control ___ EPA Compliance

Mail to: ENVIRONMENTAL MONITOR SERVICE

Attn: Warrantee Registration

PO Box 4340

Yalesville, CT. 06492 U.S.A.

Page 8

7

Customer service

We strive to provide efficient and expedient service when an instrument or component is returned for repair.

Your assistance can help us to better provide the service you need.

To assure that we process your factory repairs and returned goods efficiently and expeditiously, we need your help.

Before you ship any equipment to our factory please call our Service Response Center at 1-800-864-2814. This

enables us to complete the necessary paperwork and process your equipment correctly when it reaches our dock.

When you call please be prepared to provide the following information:

Your name and telephone number.

Your company name with shipping address.

The number of items being returned.

The part number of each item.

The model number or a description of each item.

The serial number of each item, if applicable.

A description of the problem you are experiencing if factory repair is needed, or the reason you are returning the equipment

(e.g., sales return, warranty return, etc.).

When you call in, our Customer Service Representative will assign an RMA (Return Material Authorization)

number to your shipment and initiate the necessary paperwork to process your equipment as soon as it reaches us.

Please include this RMA number with the equipment you return, preferably both inside and outside the shipping

container. This will assure that your equipment receives the fastest attention possible.

Your assistance in this matter will enable us to serve you better. We appreciate your cooperation and support of

our products and services.

Page 9

8

CLAIMS FOR DAMAGED SHIPMENTS

Inspect all instruments thoroughly on receipt. Check material in the container (s) against the enclosed packing

list. If the contents are damaged and/or the instrument fails to operate properly, notify the carrier and

Environmental Monitor Service immediately.

The following documents are necessary to support claims:

Original freight bill and bill of lading

Original invoice or photocopy of original invoice

Copy of packing list

Photographs of damaged equipment and container

You may want tot keep a copy of these documents for your records also.

Refer to the instrument name/model number, serial number, sales order number, and your purchase order number on all

claims. Upon receipt of a claim, we will advise you of the disposition of your equipment for repair or replacement.

SHIPPING DISCREPANCIES

Check all containers against the packing list immediately on receipt. If a shortage or other discrepancy is found,

notify the carrier and Environmental Monitor Service immediately. WE will not be responsible for shortages

against the packing list unless they are reported promptly.

Page 10

9

Section 1

SYSTEM DESCRIPTION

The Model 1304 Opacity Monitor provides continuous, low maintenance, precision measurement of opacity and

optical density in industrial applications. It is a cost-effective instrument that serves as an aid in operating pollution

and/or process control equipment.

Transmissometer/retro reflector

The Model 1304 is a precision, double-pass, dual beam Transmissometer that consists of a transceiver

(transmitter/receiver) mounted on one side of a stack or duct and a passive reflector mounted on the opposite

side. The light source, photo detectors, and all measurement/reference optics used in opacity measurement are

housed in the transceiver.

The function of the reflector is to return the measurement beam to the detector in the transceiver, creating a

double pass across the process stream. The standard reflector is used for measurement path lengths up to 15 feet.

For longer path lengths, maximum 50 feet, reflectors, optical parts and electronics will vary.

Control Unit

The control unit should be mounted in a control room environment i.e., clean, temperature with max/min of +0o

to +50

o

C (+32

o

to + 122

o

F). The Model 1304 control unit provides instrument control functions, opacity

readings, alarm and fault indicators, analog outputs, and diagnostics with contact closures.

Optional Air Purge Weather Cover System

The transceiver and reflector may be mounted in weather covers. The weather covers are fairly compact to allow

movement around them even on a three-foot walkway or platform. They protect the stack-mounted components

from dirt, moisture; stack temperatures within the specified ambient temperatures limits, and errant air currents

around the stack.

The air purge system constantly circulates air past the optical window. The air flow is directed through the hose to

an air plenum on the stack side of the optical window. The air flow in the air plenum area results in reduced

pressure and increased velocity. This venturi effect tends to continually draw the air around the optical window

into the purge air stream, thereby keeping the lens clean for long periods.

Alignment system

The Model 1304 includes a built-in through-the-lens alignment system. The alignment target can be viewed

through a window on the transceiver. Adjustments to changes in alignment are provided by a 3-point alignment

system, which is integral to the air plenum.

Cabling

The standard cabling used between the stack-mounted units and the control unit is at a minimum 6-pair, #20

AWG, twisted, shielded cable separation distance approximately 2000FT.. More pairs or larger than 20 AWG is

acceptable for longer distances.

Page 11

10

PRINCIPLE OF OPERATION

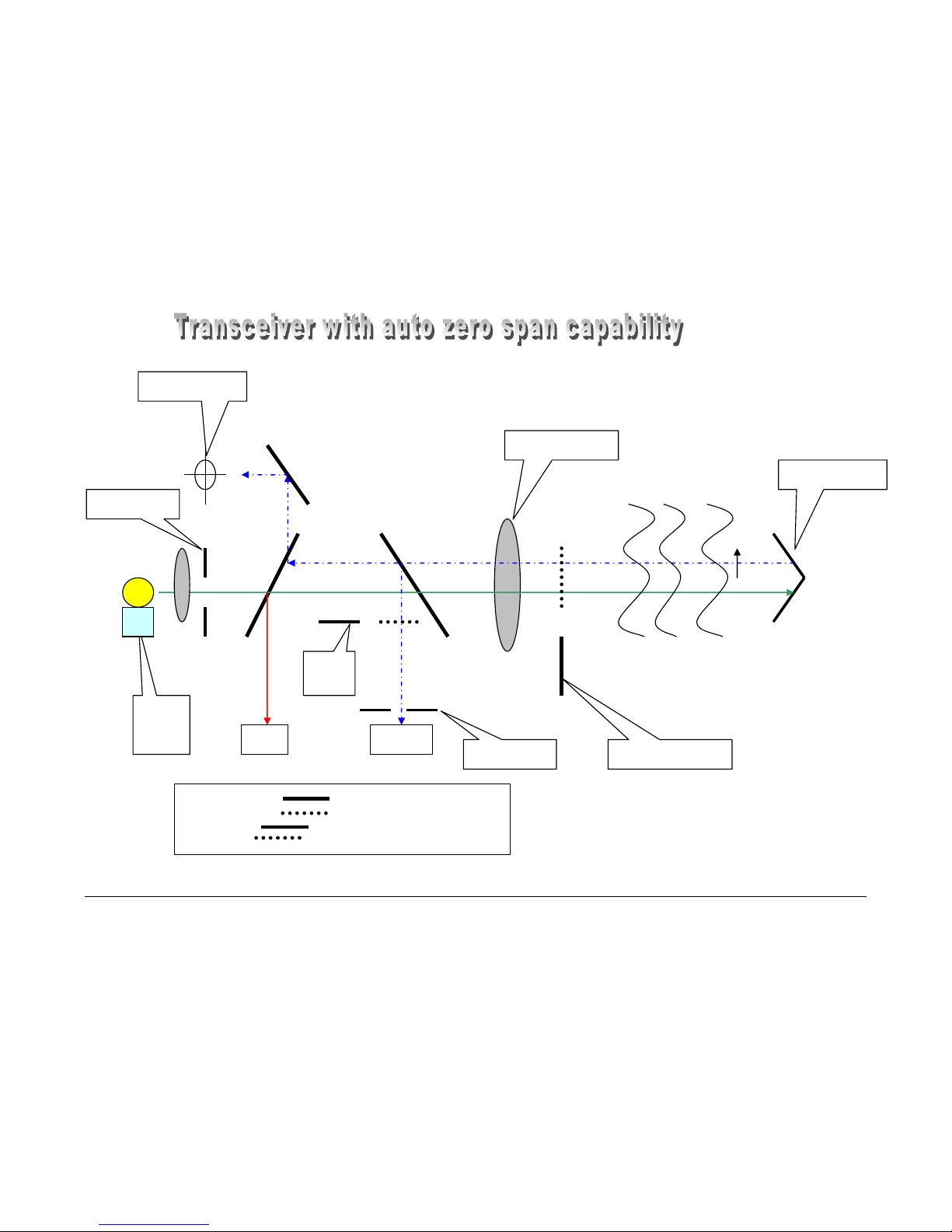

Normal mode of operation

The Dual beam measurement system has a stack mounted Transmissometer sensor system consists of an optical

transceiver mounted on one side of the stack and a retro reflector mounted on the other. To avoid errors due to

ambient light, the lamp (See Drawing) is electronically modulated and projects a collimated beam of light, which is

split into a reference beam, and a measurement beam by an optical Beam splitter. The reference beam is

directed to the reference detector, RD. The measurement beam is projected across the stack to a Retro reflector

that returns the beam back across the stack to a beam splitter and directs the measurement beam to the

measurement detector, MD. A portion of the returning light is also sent to the TTL (Thru the Lens) bulls-eye

target viewed through a window provided at the rear of the Transmissometer. The bulls-eye is used to correct

changes in alignment and is unique in that no moving parts are used!

The ratio of the measurement and reference detectors is used to provide Transmittance 2 (T 2) signal. Because the

same light source is used for both detectors, and a Measurement / Reference ratio is used throughout for the

calculations, the monitor is insensitive to variations in light intensity. Since all measurements are made on a ratio

basis, all resulting computations are independent of the absolute intensity of the light source or contamination of

the optics associated with the collection and focusing of the energy from the lamp. The (T 2) signal is converted to

a current format and sent to the control unit for processing. At the control unit the signal is processed to read 0100% Opacity, provide alarms and outputs.

Internal calibration system, zero mode

Zero and span calibration checks can be initiated manually, automatically or by a PLC or computer. During the

zero calibration mode a calibrated zero reflector is placed in front of the transceiver optical package testing all

optical surfaces and electronic components to assure zero point has not changed.

Internal calibration system, Span mode

In the span mode a Span filter of known Neutral Density is placed in the measurement path and produces a

specific up scale reading in accordance with the latest E.P.A. requirements. The zero and span cycle provides a

continuous check of all the optical components and surfaces, the main lamp, the detector, interconnecting wiring,

control unit and computation analysis.

Page 12

11

Span Filter out:

Span Filter in:

Zero Reflector out:

Zero Reflector in:

RD

MD

Span

Filter

Zero Reflector

Main

Lamp

TTL Bulls-eye

Projection Lens

Retro Reflector

Aperture P

Aperture V

Page 13

12

1304 OPACITY SPECIFICATIONS

Design and performance:

Meets or Exceeds PS-1 Revised and ASTM D6216-03

Peak and Mean Spectral Response

Photopic; 515 to 585 nm, less than 10% of peak response outside 400 to 700 nm

Relative spectral response

<10%

Angle of View

< 4.0 o from optical axis

Angle of Projection

< 4.0 o from optical axis

Calibration Error/accuracy

+/- 1% of full scale

Response time

< 10 second

Zero Drift

< 0.5%

Calibration Drift

< 0.5%

Operational Period

In excess of PS-1 required 336 Hrs.

Zero/Span Calibration

Manual or automatic with zero mirror and neutral density filter

Remote control unit:

120Vac +/- 10% 50/60hz 22va

Numeric Digital Display 5/8 inch (15.9 mm), 4digit LED

Selectable for Instantaneous opacity, Average Opacity. Optional mg/m3

Display resolution

0.1% Opacity

Alphanumeric 8 character LED (0.2") Fault Display

Air purge low, No Stack Power, T2 4-20 Lost/low, Maintenance Mode, Window Dust, Zero Cal

Fail, Span Cal Fail, Manual Cal.

Bargraph

Left/Right: 51 segments LED (5.1") for instant/average opacity. 20 segment LED (2.1") for

window dust and drift in %opacity

Operator Indicating LED’s

Run, Alarm, Operate, Cal in progress

High Opacity Set Point

0-100% of full scale

High Opacity Delay

Adjustable 0-300 Seconds

Hi Opacity Alarm Reset

Automatic

Open Transistor Collector Outputs

Four selectable

Dry Contacts

Two selectable (option: two additional)

Instantaneous Opacity and Average Outputs

4-20 mA grounded reference, 800 ohms max. (two additional optional)

OPLR (Exit Correlation Lx / 2*Lt)

0.2 to 3.0

Cal cycle initiate

Local, remote and timed Adjustable 1 to 24 hours

Enclosure

NEMA 13, IP65, Height: 7.38" x Wide: 3.00: x Depth: 7.75", Weight: 6 lbs.

Ambient Temperature Range

+0o to +50 o C ( +32 o to + 122 o F)

Power Requirements

120 VAC (+/- 15%), 50/60 Hz, 22VA

Network

Protocol: Modbus (ASCII or RTU mode), type RS-485, optically isolated.

Configuration

Speed: 300-38,400 baud, type RS-232

Transceiver Service module:

120/220Vac +/- 10% 50/60hz, Transceiver 65va, Service Module 60va

Display

5/8 inch (15.9 mm), 4-digit LED, selectable for % Opacity and % Transmittance

Local zero/span

Manual on demand

Test jacks

Transceiver to remote control current loop

Diagnostics

Loss of power, Current loop open, maintenance mode.

Transceiver/ Reflector:

Page 14

13

Enclosure

NEMA 4 watertight enclosure

Path Length

2 to 15 feet, 0.6 to 4.6 meters. Longer available

Optical System

Double Pass

Light Source Aging Compensation

Automatic

Light Source Life

> 5 years

Ambient Temperature Limits

-4 o to +131 o F (-20 o to +55 o C)

Process Gas

Up to 750 o F (400 o C), standard (higher available-contact factory)

Alignment Verification

Passive Built-in through-the-lens system

Mounting Flanges

3 inch IPS, 150# pipe flange

Ambient Light Immunity

Solid-state electronic light modulation

Page 15

14

Section 2

INSTALLATION CONSIDERATIONS

Choose an installation site

The primary considerations for choosing a site for the Model 1304 are accessibility, ambient environmental

conditions, and locating the unit to obtain a representative sample of the process. Review the excerpt from the

Federal Register in appendix for suggestions before selecting an installation site. The following general guidelines

should also be considered.

Accessibility

Locate the instrument that provides safe access for periodic maintenance and inspection. A platform or walkway

is required for access to the sensors and weather covers.

Environment

Locate the stack-mounted units in an area with ambient temperatures between -4 o to +130o F. (Consult the

factory for other temperature ranges.) Areas that are clean and dry are desirable. Avoid areas with condensation.

Maintenance intervals are directly related to the installation environment. Intervals can vary from 2 to 3 months in

fairly clean environments, to twice a month in dirty environments. Lens cleaning is a function of the ambient

conditions and cleanliness of the purge air.

Locate the instrument to avoid excessive vibration or shock.

Locate the control unit in an easily accessible area with temperatures between +32o to 122o F. To permit the

operator to read and/or change controls, the unit should not be mounted higher than five feet from floor level.

Stack exit

Locate the transceiver more than two stack diameters down from the stack exit is recommended.

INSTALLATION – MECHANICAL

Drawing notes

A review of the drawings and procedures provided will help to produce an error free installation. However, there

are important additional points that must be observed. The beam of the instrument must be kept in the

horizontal plane; the transceiver cannot be rotated more than +/- 10 o from vertical. The weather covers must be

installed vertically plumb.

Installation and wiring diagrams are found at the end of this manual. Please review all drawings prior to starting

installation or wiring. If you have any questions please contact our service department for assistance at 203-9350102 ext. 14

Sensors height from Platforms, walk way/ decks, etc,

A platform or walkway must be available for access to the weather covers. The optimum condition would have

the mounting flanges and weather covers approximately 5 feet up from the floor, but in all cases, a minimum of

12 inches from the bottom of the weather cover to the floor is required to remove the air filters. Railings and

other obstructions should allow the weather cover to swing clear as shown in the installation drawings.

Page 16

15

Alignment of stack flanges

Stack flange alignment is shown on Drawing EMS-1001 and EMS 1002, and is the first step in successful

installation. The final beam alignment adjustments are described in the Beam Alignment Procedure.

Installation procedure - stack flanges

For an opacity monitor, the customer is required to supply and install two 3" I.P.S. flanges at eye level directly

across from each other. The flange faces, mounted on pipe stubs, should be approximately 6" to 8" from the stack

or insulation. On completion of the installation, the flanges must be aligned so that the total deviation of the light

source flange relative to a common centerline, does not exceed +1o and the retro reflector flange does not

exceed +3o .

Flanges should be mounted approximately 5 feet up from the deck of platforms, roof or walk way.

At installations where conditions permit, this may be accomplished by using a piece of 2 1/2" pipe suspended

across the stack protruding far enough to allow slipping the 3" flange pipe assemblies over each end and welding

in place as shown in Drawing section 8.

Any deviation up to the previously specified limits can be adjusted out during the installation and alignment of the

light source and retro reflector with the system's alignment adjustments.

Where installations do not permit the use of the aforementioned method, the following procedure will accomplish

the same results. (See drawing section 8.) An alignment tool can be purchased from the factory to insure accurate

alignment.

Accurately locate one 3 1/2" diameter hole (large enough to accept the 3" pipe) and the other hole approximately

1/2" diameter, directly across from each other. Attach the alignment tool to the flange/pipe assembly and insert

the pipe into the 3 1/2" hole in the stack wall. Align the assembly with the 1/2" diameter hole on the opposite

side by viewing through the alignment tool and weld the pipe in place. Care must be exercised when welding to

maintain alignment.

The 1/2" diameter hole should now be enlarged approximately 3 1/2" to accept the other flange/pipe assembly.

Proceed in the same manner, installing the assembly with the alignment tool attached, and weld in place

maintaining concentric alignment with the 3" pipe previously installed on the opposite wall.

Sample area

To achieve a representative sample, the accepted practice is to have the measurement path of the instrument

directly in the centroidal area of the stack. An area should be chosen where the gases are not stratified in the stack

or duct. (See Federal Register excerpt in section 7)

Where a bend is involved, the path should be chosen to be the plane of the bend. Locations where large amounts

of condensed water may be present should be avoided.

MODBUS COMMUNICATION AND ADDRESSES

Protocol: Modbus (ASCII or RTU mode)

Speed: 1200-38,400 baud

Type: RS-485, optically isolated

RS-485 Modbus connections are 1-3 on the rear panel of the controller. RS-485 cabling may be up to 4000 feet in

length. Belden P/N 3106A cable is recommended.

Page 17

16

Reading Analog output Block Addresses:

0% to 100% instantaneous opacity = 40150 (integer) (xx.xx), 0% to 100% average opacity = 40151 (integer)

(xx.xx), 0 to 10% Window Dust = 40073 (integer) (x.xx)

Reading Discrete output Block Addresses:

Relay 1- Cal in progress, duration 6 minutes (0 = cal, 1 = cal)

Relay 2- High opacity alarm (0= Alarm, 1= Alarm) Note: always 0 during cal cycle.

Cal. Zero Check, duration 3 minutes = 00066 (0 = cal, 1 = cal)

Cal. Span Check, duration 3 minutes = 00065 (0 = cal, 1 = cal)

Cal. Zero Fail Alarm = 00140 (0 = Alarm, 1 = Alarm)

Cal. Span Fail Alarm = 00141 (0 = Alarm, 1 = Alarm)

Lost Of 120VAC Transceiver Power = 00042 (0 = Alarm, 1 = Alarm)

Dust/Zero Shift Alarm = 00075 (0 = Alarm, 1 = Alarm)

High Opacity Alarm = 00097 (0 = Alarm, 1 = Alarm) Note: always 0 during cal cycle.

Common Fault = 00098 (0 = Alarm, 1 = Alarm)

Common fault individual blocks:

Air purge Low = 00043 (0 = Alarm, 1 = Alarm)

No Stack Power = 00042 (0 = Alarm, 1 = Alarm)

T2 4-20mA Lost/Low = 00121 (0 = Alarm, 1 = Alarm)

Maintenance Mode = 00041 (0 = Alarm, 1 = Alarm)

Window Dust = 00075 (0 = Alarm, 1 = Alarm)

Zero Cal Fail = 00140 (0 = Alarm, 1 = Alarm)

Span Cal Fail = 00141 (0 = Alarm, 1 = Alarm)

Manual Cal = 00048 (0 = Alarm, 1 = Alarm)

Writing:

Remote Cal. Initiate (Write) = 45

Communication menu has the following sub categories and default settings:

Com port – 1 (automatic)

Address – 1 (max 32)

Baud – 38.4

Parity - Odd

RTU/ASCII - ASCII

+/- Data - Unsigned

Time out – 30 seconds

Page 18

17

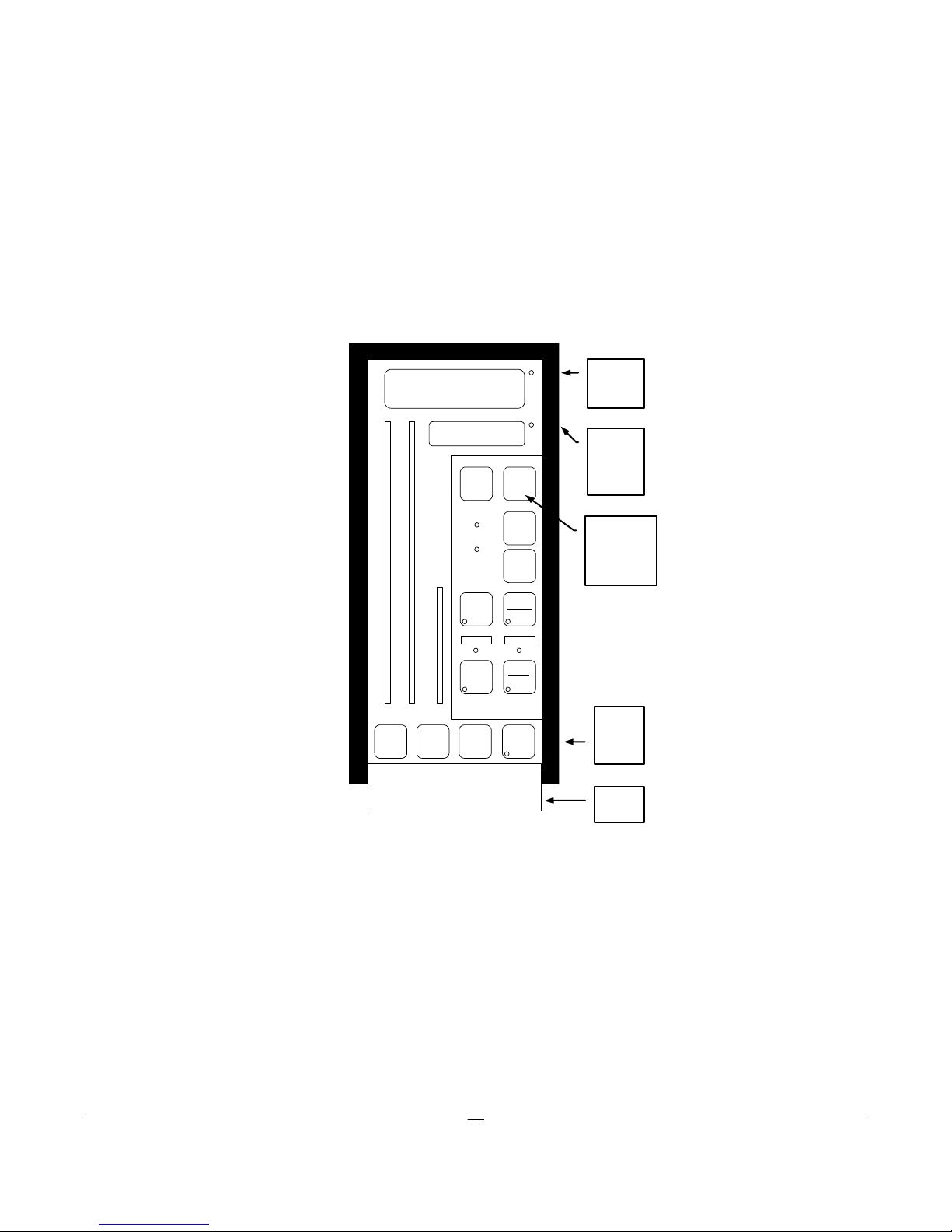

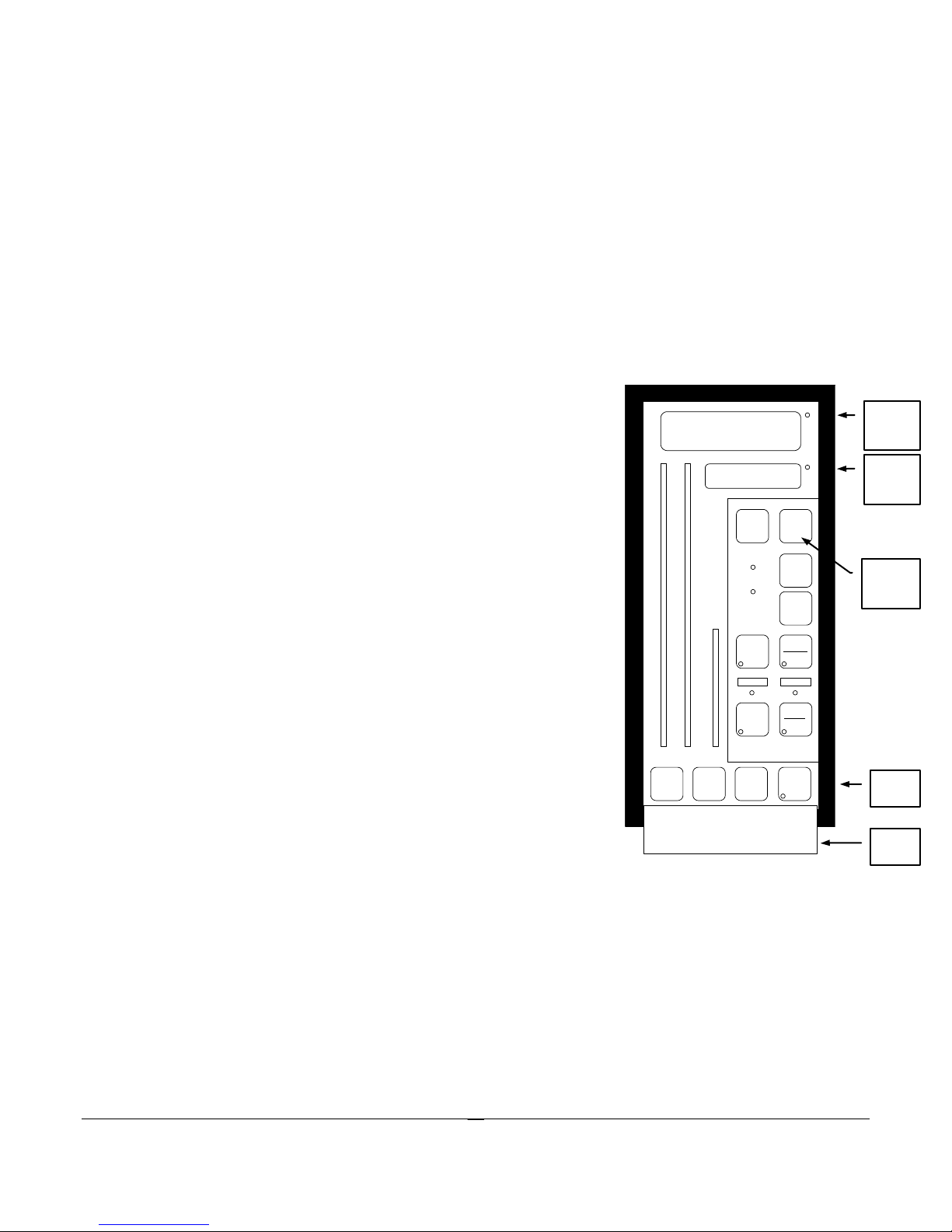

Changing communication settings:

(ESC)

EDIT

ENTER

EDITEDIT

REM

LOC

AUTO

MAN

DIS

ACK

+19999

MESSAGE

PV

SP

OUT

EDIT

Keys

Hinged

Cover

“Edit

Value”

Light

“Scroll

Menu”

light

Moves

Message

Cursor

Press EDIT (ESC) button, Scroll down EDIT to COM MENU, press ENTER, at COM PORT press

ENTER set to 1 for Modbus then press EDIT (ESC) button it will return to COM Port. (Note: controllers will

automatically choose Modbus when the RS 232 port is not in use.)

Press the EDIT to go to Address press ENTER and use the EDIT down or up arrow to go to the address

number assigned to this controller (default is 1), press EDIT (ESC) to return to Address.

Continue as above until all settings are as desired.

Page 19

18

MOUNTING THE AIR PLENUM AND WEATHER COVERS

Hinge Pin

3” 125# Flange

Air Plenum

Middle plate

WARNING! Control unit, Transceiver & Retro serial numbers must match.

After the installation site has been selected and the platform requirements have been met, the mounting flanges

should be installed and aligned as described on Drawings EMS - 1001 and EMS - 1002. Flanges should be

installed with the mounting faces on the vertical plane.

1. Before installing the Transceiver, Retro reflector or any type of

weather cover remove the air plenum from both the Transceiver

and retro reflector. Removal will make the installation easier and

less chance of damage while mechanical attachment of the air

plenums and optional weather covers when provided.

2. If the transceiver and retro reflector have been shipped from the

factory with the air plenum attached, un-clip both hold down

latches, swing open and lift up & off the hinge pins. Place the

Transceiver and retro in a safe place.

3. The air plenum is attached to the customer supplied 3" pipe

flange by four 2 1/2" long 5/8-11 bolts. Working from the 3" flange the correct assembly is; gasket

then air plenum.

4. If you have weather covers remove the two (2)-weather cover hood hinge pins located on the upper

right and left hand corner of the hood. The air plenum and weather cover are attached to the 3" pipe

flange by four (4) 2 1/2" long 5/8-11 bolts. Working from the 3" flange the correct assembly is;

gasket, weather cover mounting plate, gasket, mating flange & air plenum. Place the 5/8-11 bolt

through the top hole of the middle plate. Place a flat washer between the middle plate and mating

flange and pass the bolt through. Slip a split lock washer over the bolt and secure with a nut. Repeat

for the remaining three mounting bolts.

5. Any wiring or air hoses can be connected now.

Page 20

19

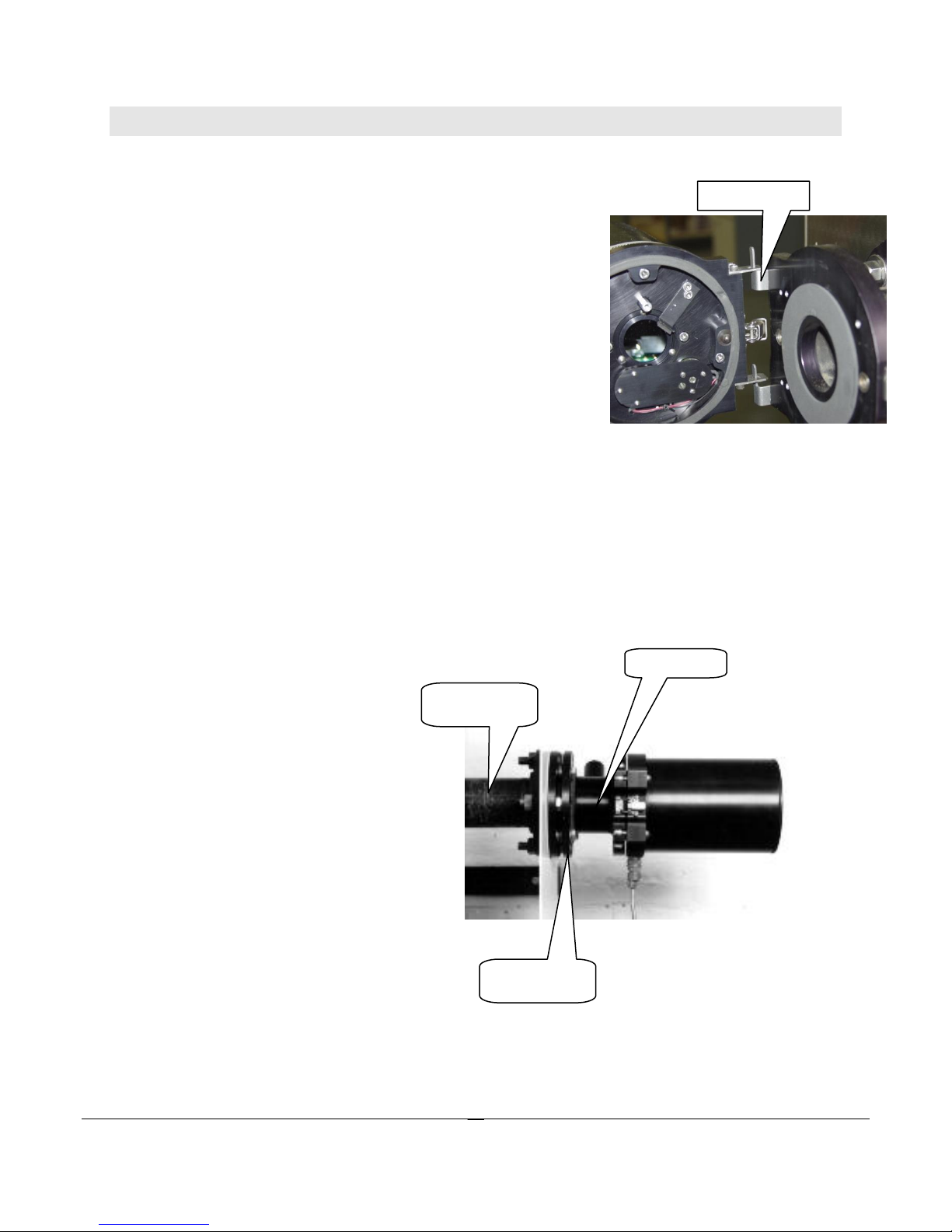

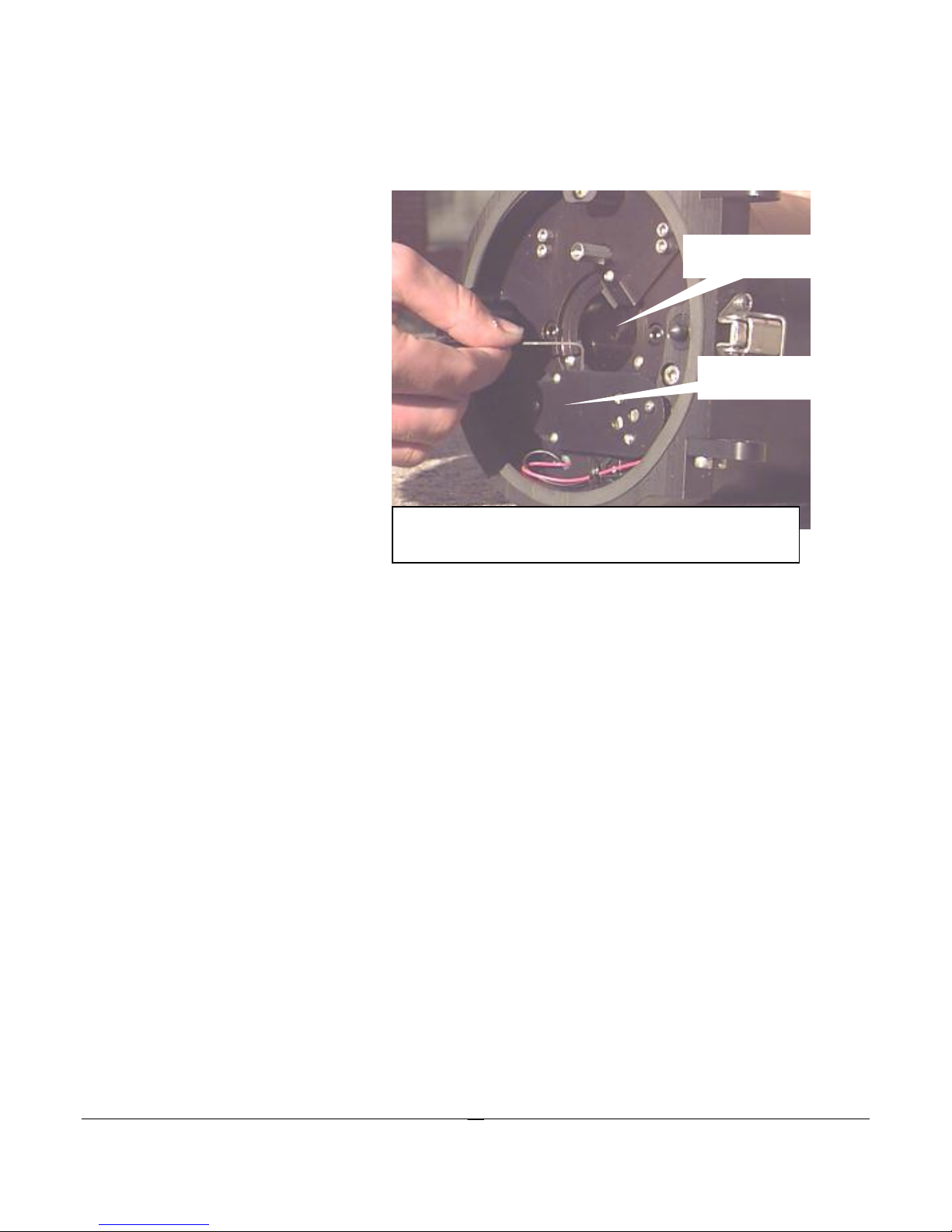

Transceiver and retro reflector assembly

Lift side Upper

Hinge Pin

Left side Lower

Hinge Pin

1. Attach the Transceiver and Retro reflector to

the air plenum assembly by placing them on

the hinge pins.

2. Close transceiver & retro and secure in place

with the two hold down latches.

3. The air-purge blowers should be powered up

at this time to prevent stack particulate from

accumulating in the nipple and air-purge

housing.

Caution: If installed location has a positive pressure

the air-purge system must be used continuously during installation to prevent process gases from contaminating

optical surfaces or over heating instrument electronics. If the system is shut off for more than momentary

interruptions, the instrument may be damaged. Failure to provide continuous air-purge may void the warranty.

All wiring from the control unit to the transceiver should be completed at this time.

NOTE: THE AIR PLENUM ASSEMBLY FOR BOTH TRANSCEIVER AND RETRO MUST BE

INSTALLED AS BELOW, I.E. THE PINS ON THE LEFT SIDE POINTING UP!

Page 21

20

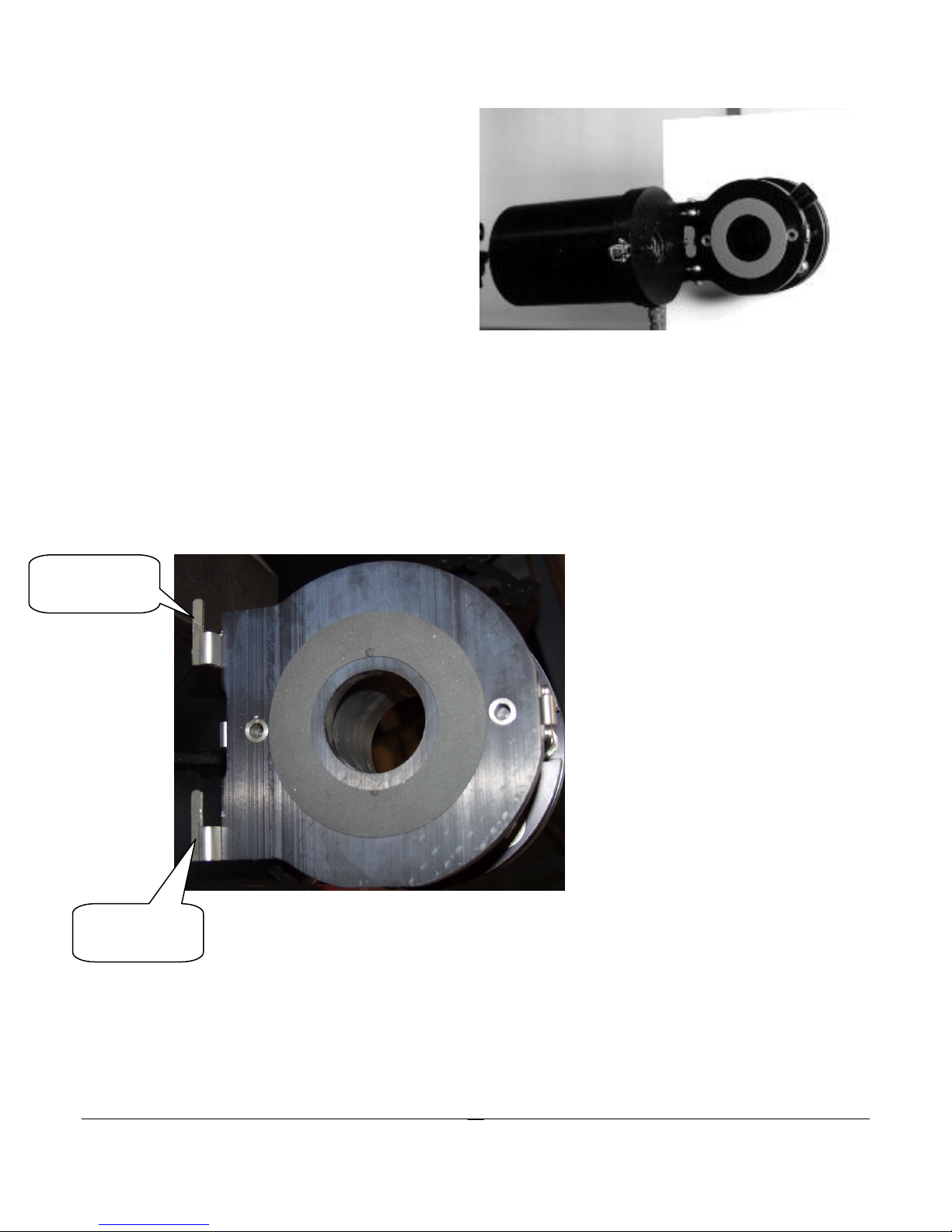

Beam alignment procedure

Figure 1, Service module

Figure 2, Alignment of the transceiver

Adjusting bolts

Note: Alignment can not be done unless the power is applied to the stack mounted service module. The control

unit does not have to be connected or powered. For alignment accuracy, the stack should be at normal

temperature.

Maintenance module switches should be in the normal operating positions:

Zero/Operate - Operate

Span/Operate - Operate

Normal/Test - Normal

service module.

through the viewing port located on the rear of the transceiver and observing whether the beam

image is in the center of the cross hair (bulls-eye).

Opacity/T

1. If not already on, turn on the power to all air purge systems and

2. Align the Reflector mating flange so it is plumb and parallel to the 3"

2

- Opacity

150# mounting flange. Use the 3 adjusting nuts on the air purge plenum

flange until this is accomplished. The adjusting nuts have nylon locking inserts

to prevent loosing by vibration.

3. Move to the Transceiver, and determine monitor alignment by looking

Page 22

21

Air flow switch

If you have an airflow alarm when the system is powered check the airflow switch. With the blower running and

the source under normal conditions disconnect the leads of the switch and place an ohmmeter across them. The

switch should be closed, less than 2 ohms, if flow is enough to over come stack pressure and blower inlet is clear.

Cover the air cleaner inlet and verify the switch opens. Replace the leads the test is complete.

Control unit

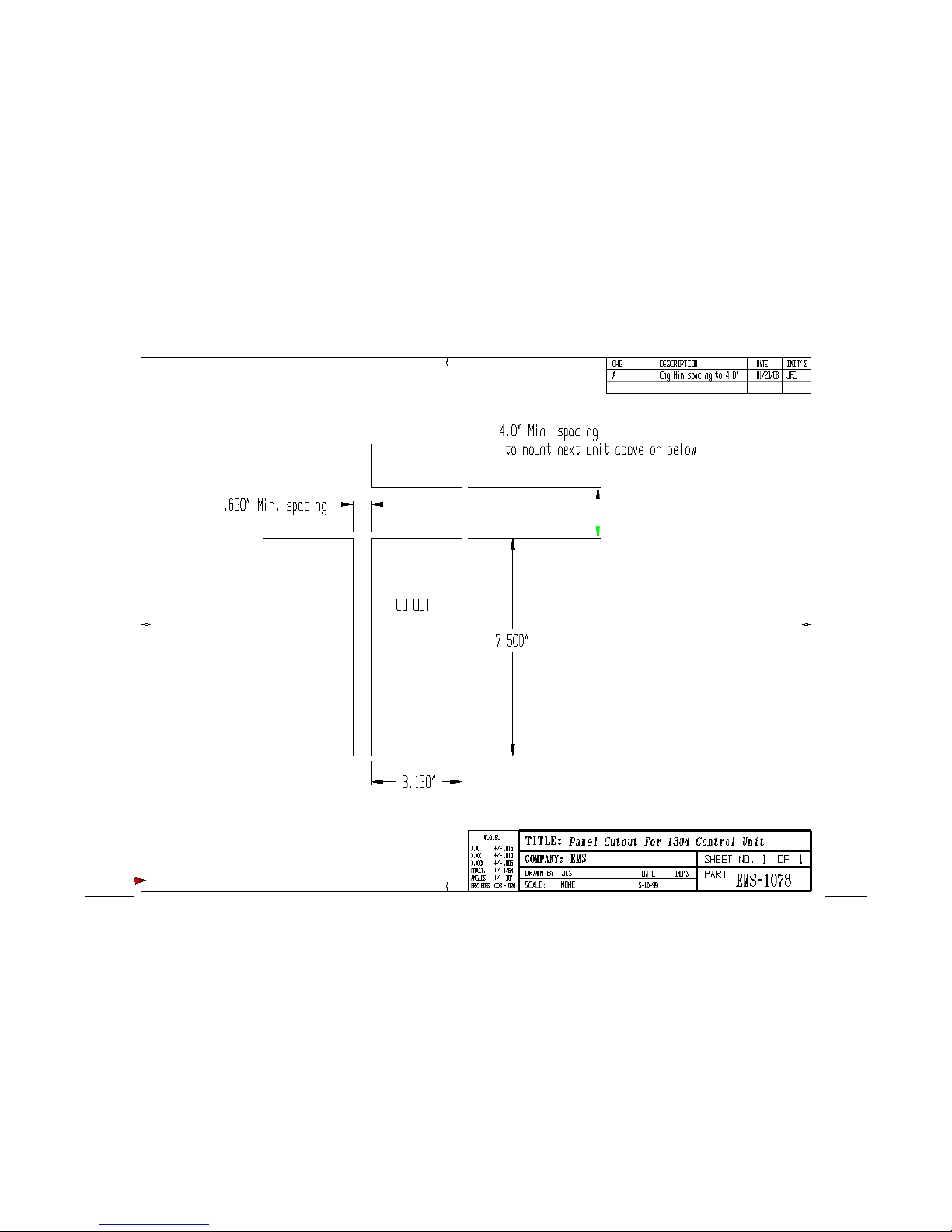

Mount the control unit at eye level for best viewing of the display.

Cut out for panel mounting is shown in the drawing section. Insert the

control unit through the cut out hole. Insert the panel mounting hardware

in the slots provided in the top and bottom of the control unit from the

rear. Tighten the screws until the control unit is securely held in place.

Wire the control unit per drawing section and Energized power.

NOTE: Controller requires a step down transformer for 220Vac 50/60hz

operation.

Page 23

22

Lt

Lx

OPLR

Section 3

50.0

120*2

120

OPLR

BEFORE START UP

You must complete the following before start up is attempted.

1. Measure and record flange -to-flange distance to verify it is the same as final check out sheet.

2. If you are using a recorder, DAS, etc., DO NOT CONNECT THEM NOW. Outputs and inputs from

other sources should be left off until system has been completely checked according to the following

instructions. After system operation has been verified connect and test external connections.

3. Read the instructions first to familiarize yourself with the instrument before attempting start up.

4. The air purge and Weather cover system, Transceiver, Retro reflector, Service module must be

installed and power applied.

5. Control unit must be installed and wired to the service module and customers equipment as

applicable.

6. All wiring and mechanical installations must be complete per drawings provided in this manual. All

wiring must be checked and power applied to both the control unit and the stack maintenance

module.

7. Beam Alignment procedure has been completed.

STACK EXIT CORRELATION COMPUTATION

1. The stack exit correlation is especially important to verify. If possible all dimensions should be verified

by actual measurements.

2. Measure and record inside stack dimensions at the measuring point and at the stack exit, and compute

the Optical Path Length Ratio (O.P.L.R.) Check that the calculated and the O.P.L.R. found in the

Factory OPLR Check step found further in this section are with in +/- 2%.

Lx = Stack exit inner diameter, Lt = Inner diameter of the effluent path

Example: A stack with a 120" stack exit I.D. and a 120" pathlenght

Page 24

23

START UP SERVICE

(ESC)

EDIT

ENTER

EDITEDIT

REM

LOC

AUTO

MAN

DIS

ACK

+19999

MESSAGE

PV

SP

OUT

EDIT

Keys

Hinged

Cover

“Edit

Value”

Light

“Scroll

Menu”

light

Moves

Message

Cursor

Environmental Monitor Service, Inc. is available to assist you, call our service department at (203) 935-0102 or fax

(203) 634-6663 for details and to schedule start up.

Verifying instrument operation and configuration

Alignment procedure must be completed as outlined in Section 2.

Power applied to both the control unit and the sensors for a minimum of 30 Minutes before any adjustments are

attempted.

Observe the front panel LED's and confirm the red Operate and the green RUN LED's are on. Press the ACK

button to confirm NO ALM’S message is displayed. Press the DIS button until OPACITY % is displayed.

EDIT KEYS

All data entry, editing, and diagnostics are accomplished with four EDIT

keys behind the hinged cover.

FACTORY O.P.L.R. DISPLAY

Under the flip down door, press the EDIT (ESC) button (the red Edit

(ESC) LED will light). The message display will read QUICK MENU. Press

the ENTER key, then the EDIT key or hold and scroll down until the

Display reads “OPLR Read Only”. Press the ENTER key the OPLR is

displayed. This is a read only block and cannot change the OPLR of the

system. It is intended for a convenient place to record the OPLR. The OPLR

is factory set and cannot be changed in the field. If an OPLR change is

required contact the factory for return authorization number and shipping

instructions.

QUICK MENU

Alarm Set Point In % opacity

Alarm Time Delay In Seconds

Auto Cal Cycle Time In hours

Zero Cal Value In % opacity

Span Cal Value In % opacity

OPLR Read Only XX.XX

Page 25

24

ZERO/SPAN CALIBRATION CHECK

The zero calibration has been set at the factory by placing the instrument on an optical bench using the flange-toflange dimensions specified by the customer and recorded in the customers final test report. This zero value is

critical as it can offset smoke measurement plus or minus if not correctly set. The measurement reflector contains

an aperture that is chosen during the factory calibration and is fixed. The Transceiver is aligned with the beam

centered on the retro reflector and the electronics is adjusted to produce a zero opacity value.

The calibration zero reflector is then adjusted to provide a low value typically 1-2% and the span filter up scale

value is recorded. The values are entered in the Quick Menu under "Zero Cal Value" and " Span Cal Value".

When the system enters a manual or auto cal check cycle the current zero and span values are checked against the

stored values. If either the zero or span current value exceeds the stored value by +/- 2% opacity the fault system

will energize.

To verify initiate a manual cal cycle by pushing the AUTO/MAN key. The Alarm LED will light and the

Left/Right Bargraph will blink, this is normal because a manual cal is considered a fault condition. Pressing the

ACK key will cause the ALARM LED and the bargraphs to stop blinking. The message display will read

MANUAL CAL ALARM. Push the DIS key to return to display opacity.

After the cal cycle is complete pushing the ACK key should clear any alarms. If no alarms are present the system is

working properly.

Page 26

25

Section 4

INSTRUMENT OPERATIONS AND ADJUSTMENTS

Overview of the systems operation

The Model 1304 Opacity monitor system consists of transceiver, retro reflector, service module and the control

unit. The maintenance module has a digital display for reading opacity from the control unit and T2 from the

transceiver. It also has connections for attaching a meter for trouble shooting or calibration when necessary. Other

switches are provided for initiating zero and span modes during service or maintenance. If any switch causes the

system to read other than stack opacity the Control unit Fault Alarm system will be energized notifying the

operator. A fault output signal (open transistor collector) is also energized for use with other alarms or DAS

system, which need to know opacity readings are not representative of the actual stack opacity and a fault

condition exists.

Only two conditions are considered normal operation; 1- Reading smoke, 2- Computer or internal clock

initiated calibration check cycle.

Front Panel LED's

ALARM - Red LED is blinking when a Fault is detected. Manual Cal.

RUN - Green LED is on during normal operation and blinking if system is in S/M mode. The primary reason for

S/M mode is to prevent 4-20mA outputs from changing when user is modifying block ware.

OPERATE - Red LED is on during normal operation.

AUTO/MAN - Red LED is on during calibration check mode.

ZERO - Red LED is on when zero cal cycle is in progress, out during span or normal operation.

SPAN - Red LED is on when span cal cycle is in progress, out during zero or normal operation.

HIGH OPACITY - Red LED is on if opacity exceeds set point for more than the time delay (typically 30 seconds).

REM/LOC - Red LED always out this is not used.

Fault Messages

Air purge low - Airflow to the transceiver and/or retro reflector is not sufficient.

No Stack Power - Indicates loss of service module power loss or other related power or component failure from

the service module.

T2 4-20 Lost/low- Transceiver 4-20mA current loop is out of specification or missing.

Maintenance Mode - Indicates a maintenance mode switch on the service module is in a position and the system

is not displaying or outputting the smoke reading.

Window Dust - Dirt has accumulated on the transceiver lens and/or the zero mirror in excess of the > 5% limit

and must be cleaned.

Zero Cal Fail - During calibration check the zero reading has exceeded the > 2% opacity set point.

Span Cal Fail - During calibration check the span reading has exceeded the > 2% opacity set point

Manual Cal - A manual calibration check from the control unit front panel AUTO/MAN key was pressed.

Page 27

26

Control unit manual controls

(ESC)

EDIT

ENTER

EDITEDIT

REM

LOC

AUTO

MAN

DIS

ACK

+19999

MESSAGE

PV

SP

OUT

EDIT

Keys

Hinged

Cover

“Edit

Value”

Light

“Scroll

Menu”

Light

Moves

Message

Cursor

ACK - Acknowledges fault alarms and displays the fault message.

DIS - Changes display each time it is pressed; Opacity %, Average Opacity, dust/zero shift, hours to next cal.

AUTO/MAN - initiates a maintenance cal cycle and resets calibration cycle timer clock.

Alarm set point adjustments

Under the flip down door, press the EDIT (ESC) button (the red Edit

(ESC) LED will light). The message display will read QUICK MENU.

Press the ENTER key, then the EDIT key 1 time until the Display

reads ALARM SET POINT. Press the ENTER key twice, the Edit

Value Light will flash. Press and hold the EDIT or EDIT key

until the desired set point in % opacity value is displayed, i.e. 20.00 is

20.00% opacity. Press the EDIT key 4 times to return to normal

operation.

Alarm Time Delay Adjustment

Under the flip down door, press the EDIT (ESC) button (the red Edit

(ESC) LED will light). The message display will read QUICK MENU.

Press the ENTER key, then the EDIT key 2 times until the Display

reads ALARM TIME DELAY. Press the ENTER key twice, the Edit

Value Light will flash. Press and hold the EDIT or EDIT key until

the desired time in seconds is displayed, i.e. 15 is 15 seconds delay. Press

the EDIT key 4 times to return to normal operation.

Page 28

27

4-20mA outputs

(+) Recorder/DAS (-)

14

11+

13

12-

Sensor location

terminal TB 1

EMS1304 Control

unit rear panel

terminals

Reference Drawing # 1131

The Model EMS1304 comes with two 4-20mA outputs. The ranges are set during final test to the information

supplied by the customers.

Maximum output Loop compliance is 800 Ohms.

AOUT1 (instantaneous opacity, zero/span when in check mode) is connected at Control unit terminals 11 & 12

and supplies the opacity signal to a recorder or DAS and too the service module 14 & 13 (on TB1, - 1101) for

display at the sensor location.

AOUT 2 (average opacity, zero/span when in check mode) is connected at Control unit terminals 13 & 14.

No calibration is necessary; however if you want to check that other devices such as recorders or DAS are

responding correctly use the following procedure.

Recorder or other device calibration:

On the control unit front panel press the AUTO/MAN key for a maintenance zero and span cycle. Both outputs

will correspond to the opacity display value.

Page 29

28

Auto cal timer Adjustment

Under the flip down door, press the EDIT (ESC) button (the red Edit (ESC) LED will light). The message

display will read QUICK MENU. Press the ENTER key, then the EDIT key 3 times or scroll down until the

Display reads AUTOCAL CYCL TMR. Press the ENTER key twice, the Edit Value Light will flash. Press and

hold the EDIT or EDIT key until the desired set point in hours is displayed, i.e. 24.00 equals 24 hour

intervals. Press the EDIT key 4 times to return to normal operation.

Disable internal cal timer

(Version “K” dated 11/28/2007 and up)

Set the cal cycle adjustment for 24.1 hours this will disable the internal clock from initiating a calibration check

cycle. The count down is still displayed but it has no effect. To start a calibration cycle in this mode use the

remote calibration cycle initiate.

Remote calibration cycle initiate

To have an external device cause the monitor to begin calibration cycle, connect a N.O. dry contact to terminal 8L

& 9. A momentary closure will initiate a 3-minute zero and a 3-minute span check cycle. Total time of calibration

check is 6 minutes.

Remote calibration cycle acknowledgment

Cal in progress - By dry contacts on terminal 4U (common) and 5U (NC). This contact remains closed until cal is

completed, i.e. both zero & span.

Page 30

29

Service module

The service module is used to pass signals to and from the transceiver and control unit, display opacity via digital

meter, initiate maintenance zero and span cycles and insertion of external current meter in the transceiver to

control unit 4-20mA loop.

OPACITY / T2 - This switch selects the display of the stack digital meter. In the Opacity mode the digital displays

% Opacity from the control unit. In the T2 mode it is the signal out of the transceiver in % Transmittance 2.

OPERATE / ZERO - This switch controls the zero mirror solenoid. In the operate position the mirror is not in the

measuring path and is considered normal operation. When the mirror solenoid is energized the mirror is placed in

the measurement path and is considered a maintenance condition, i.e. signal is not representative of the stack

smoke. The control unit will indicate a Fault.

Energizing and observe the digital meter to test the systems response to zero % opacity.

Energize in conjunction with the span filter to observe the up scale span % opacity calibration

point.

OPERATE / SPAN - This switch controls the span filter solenoid. In the operate position the span filter is not in

the measuring path and is considered normal operation. When the span filter solenoid is energized the span filter

is placed in the measurement path and is considered a maintenance condition, i.e., signal is not representative of

the stack smoke. The control unit will indicate a Fault.

Energize in conjunction with the zero mirror to observe the up scale span calibration point.

NORMAL / TEST - This switch controls the EXTERNAL mA METER connections. In the normal mode the

terminals are shorted. In the test mode the terminals are open and the current loop from the transceiver is

interrupted allowing the use of an external current meter to be placed in series with the transceiver current output.

When this is in the test mode position it is considered a maintenance condition and fault condition. If no current

meter is in the test jacks the loop current the control unit will indicate full scale and the control unit will indicate a

Fault.

Page 31

30

Section 5

Figure 3

PT-1 Zero

Figure 1

AJUSTMENTS

Clear on stack zero and span calibration

A clear stack condition must exist to perform this calibration. Power must have been on for no less than 30

minutes. Do not attempt these adjustments in inclement weather. After the cover is removed from the transceiver

normal levels of day light in the area will not effect the calibration.

To complete this procedure the following items are required: EMS Micro-turn

200 on-line test kit (p/n 1232) with a high filter of at least 0.8 O.D.

1. Swing both the retro and transceiver open and clean the protective

windows (see Figure 4). Return both to the closed position.

2. Verify alignment, returning beam is centered on the TTL target.

3. On the transceiver remove the screw below the target viewing window

and pulling the housing straight back until it clears the optical plate.

4. On the Service Module (Figure 3) make sure the normal/test switch is

in the normal position.

5. NOTE: All adjustments are on the 222-1667 PC Board (see figure 1).

6. Adjust the 20 turn Zero potentiometer on board 222-1667 marked "PT

-1", CW for an up scale reading >15%, then slowly CCW for 0-1%

opacity.

7. Install the EMS Micro-turn 200 on-line test

reflector on the transceiver and screw the device to the

transceiver with the mounting screw. With the

thumbwheel adjust the on-line reflector for the same

opacity as in previous step and lock it in place.

8. Place the highest value filter (for best results at

least a 0.8 O.D.) in the slot provided. Adjust the Span

potentiometer on board 222-1667 marked "PT -3" for

the filters correlated value on the service module

opacity display equals to the correlated value.

See section six (6) for filter correlation

formulas.

9. Remove the filter and adjust the Zero potentiometer PT-1 for 0-1%.

10. Insert the High filter again adjust PT-3 for its value, repeat steps until the values come within 0.5 %

Opacity.

11. Remove the on-line test reflector and replace the transceiver cover and secure the transceiver in place.

You must complete "Zero Reflector Adjustment" procedure next.

Zero reflector adjustment

1. After clear or off stack zero has been performed the zero reflector needs to be adjusted.

2. Find and record the zero offset value found in the QUICK MENU under "Zero Cal Value", see

"Zero/Span Calibration Checks" in section 3 for procedure to access the quick menu.

Page 32

31

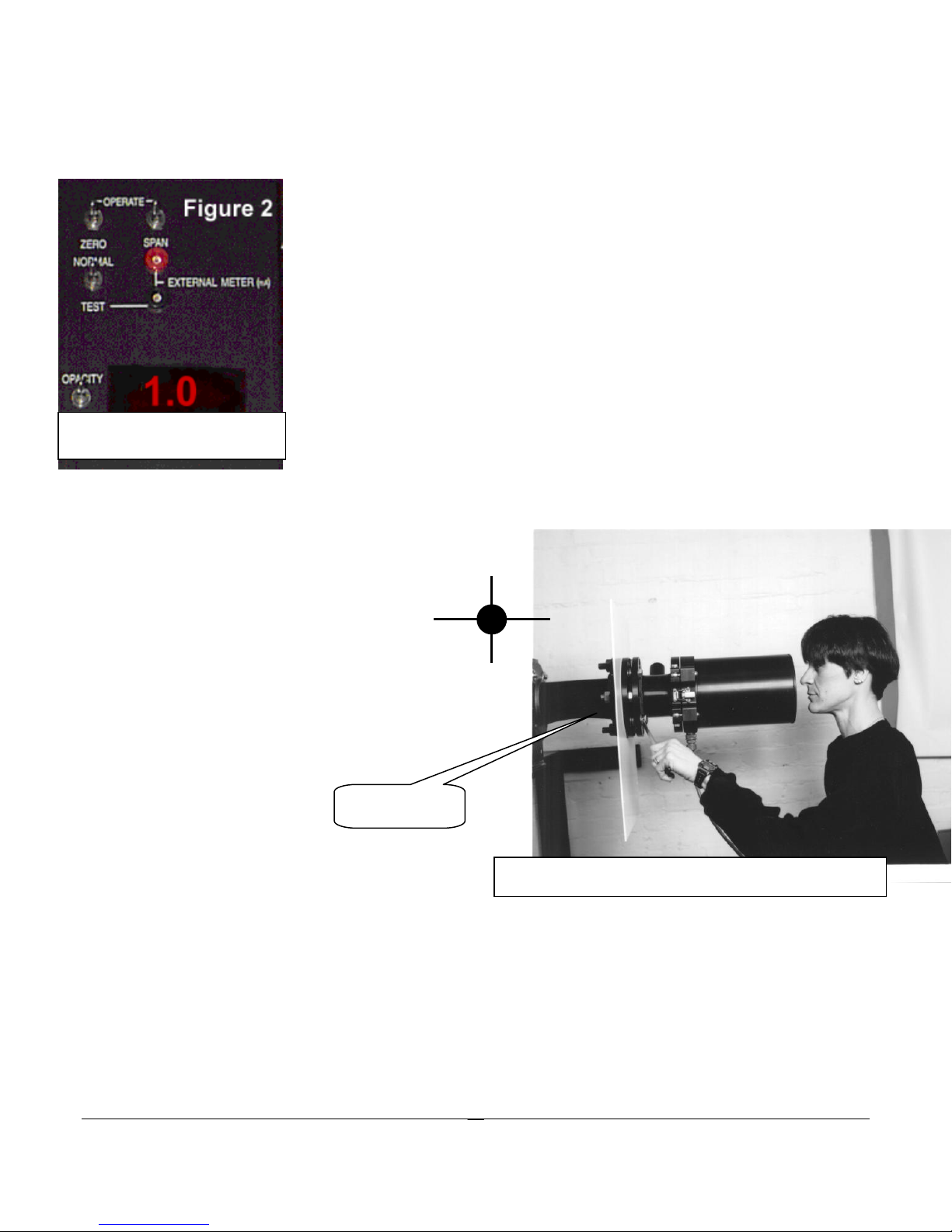

3. Place the Opacity/ T

Figure 4

Protective Window

Zero Reflector

2

switch on the service module in the Opacity position to observe the correlated

opacity on the digital display.

4. Swing open the transceiver and initiate a zero with the zero switch on the service module to raise the

zero reflector into place. Observe and record the zero value after 30 seconds. Return the mirror to

normal resting position by

returning the zero switch to

operate position.

5. Insert a 1/16" Alan wrench

into the adjustment set screw

located on the top of the zero

reflector (see figure 4). Turn

set screw clock-wise 1/8 turn.

6. Remove the Alan wrench and

initiate a zero utilizing the zero

switch on the service module and

after 15 seconds observe the

reading is moving toward the

desired value. (if value is away

from desired repeat step 4 turn set

screw C.C.W.)

7. Repeat steps 4 & 5 each time

making small 1/8-turn increments

until the desired value is reached. Cycle 2-3 times more waiting 15 to 20 seconds between cycles to

assure unit repeats desired value +/- 0.5% Opacity. Record the final value, you will need to enter it

into the "ZERO CAL VALUE" in the QUICK MENU.

8. Swing transceiver into operate position and secure in place.

Span filter VALUE

1. With the zero switch in zero, place the span switch in span. Span is not adjustable, final value is a

function of filter value, transceiver calibration and OPLR. Record the final value; you will need to

enter it into the "SPAN CAL VALUE" in the QUICK MENU.

2. Return both zero and span switches to operate, normal/test to normal, T2/Opacity to Opacity.

Record the zero/span values in the quick menu

1. At the control unit, under the flip down door, press the EDIT (ESC) button (the red Edit (ESC)

LED will light). The message display will read QUICK MENU. Press the ENTER key, then the

EDIT key 4 times or hold and scroll down until the Display reads ZERO CAL VALUE. Press the

ENTER key twice, the Edit Value Light will flash. Press and hold the EDIT or EDIT key

until the zero value recorded in the previous steps is displayed. Press ENTER then Press the EDIT

key 3 times to return to normal operation.

2. Press the EDIT (ESC) button (the red Edit (ESC) LED will light). The message display will read

QUICK MENU. Press the ENTER key, then the EDIT key 5 times or hold and scroll down

until the Display reads SPAN CAL VALUE. Press the ENTER key twice, the Edit Value Light will

flash. Press and hold the EDIT or EDIT key until the span value recorded in the previous

steps is displayed. Press ENTER then Press the EDIT key 3 times to return to normal operation.

Page 33

32

3. This completes the calibration.

Off stack zero calibration

This procedure may be used if: A clear stack condition is not possible and the zero appears to be incorrect or if

the flange to flange distance on site are different than the original factory set up.

1. Remove the transceiver and retro reflector from the hinge pins, remove the service module and install

the system on E.M.S. test stands and at the correct flange to flange distance plus 11 inches. The

additional 11 inches compensates for air plenum spacing, as the air plenums are not used for the off

stack zero calibration. If EMS test stands are not available, an alternate method is to use 3" pipe

flanges with air plenums installed, contact the factory for air plenum availability. Set the spacing

between the 3" flanges exactly the same as Flange-to-Flange measurement.

2. Clean transceiver and retro windows.

3. Connect the control unit with the control to service module test cable kit (p/n 1469) and apply power

to the system.

4. The retro reflector must be level.

5. Follow instruction for "Clear on stack zero and span calibration".

Page 34

33

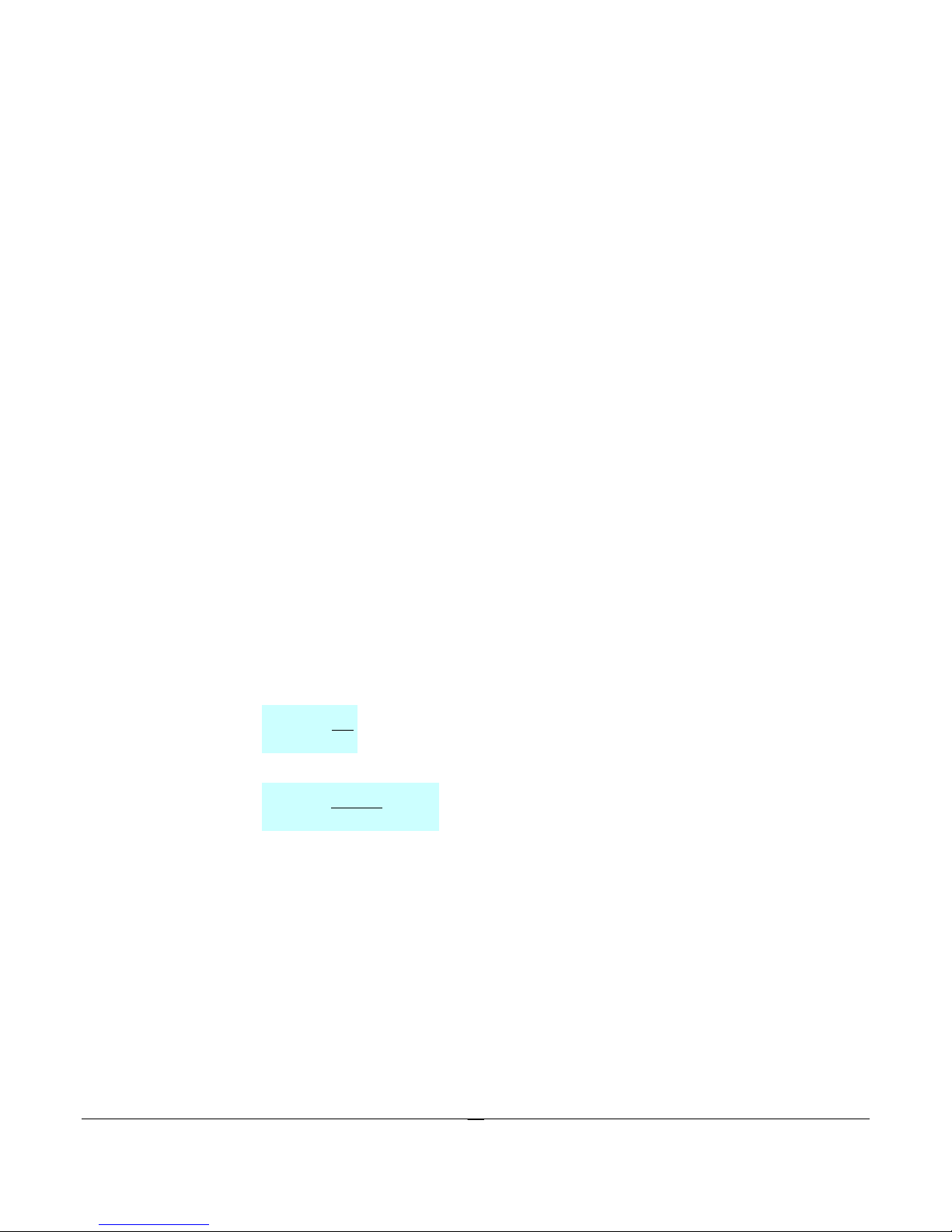

Section 6

Large Knob

Figure 5, Micro-Turn 200

Reflector plate

Mounting screw

USING THE ON LINE ZERO REFLECTOR (OPTION)

The "Micro-turn" 200 on - line test and audit system P/N 1232 may be used for:

Opacity audit

Linearity checks and adjustments

System accuracy verification

Service on line or off stack

The "Micro-turn" 200 on - line test and audit system P/N 1232 contains a test reflector, three neutral density

filters, filter certification certificates and carrying case. The Micro-turn 200 on-line test reflector is inserted over the

transceiver lens.

Procedure

The Micro-turn 200 on-line test reflector is inserted over the transceiver lens. The filters provided are marked in

single-pass opacity, this is the same as double-pass with a correlation factor (OPLR) of "0.50" for other correlation

factors turn to CHANGING OPLR section for instructions.

1. Hold the Micro-turn in a position so as to see the reflector. Turn the fine adjustment (large knob) in a

direction, which will open the iris to expose more of the reflector. This direction will cause the

monitor to lower opacity and by turning in the opposite direction, closing the iris, will raise the

opacity.

2. Loosen clamps on the transceiver and swing it open and

clean the lens, use alcohol with a clean lint free paper and

leave no film on the lens.

3. Place the Micro-Turn 200 with the reflector facing

toward the Transmissometer (away from the stack) on

the two alignment pins and screw the device to the

transceiver with the mounting screw.

4. Using the fine adjustment (large knob) start by raising the

opacity level above zero, and then slowly turn the knob in

the opposite direction to just reach "ZERO". If you

cannot reach zero or you cannot come above zero see

"course" adjustment section of this manual.

5. Place the EMS Neutral Density Slides in the slot provided on the top of the

device just behind the mounting screw. The system should read the same

value written on the label +/- 2% or better.

Filter correction

If you have an OPLR (correlation factor) other than 0.5 your slides will read differently. To calculate what the slide

will read with another OPLR use the formula:

Page 35

34

2100*

100

1

11

5.0

2

OP

Op

M

%5.54100*

100

1.23

11

5.0

5.1

Where:

OP1 = Standard filter Value in %

M2 = OPLR for your instrument

OP2 = Standard Filter value at your OPLR in %

Example:

Standard filter value is 23.1% what will it read at OPLR of 1.5?

Filter re-calibration is available from EMS and if not regulated by EPA regulations in your State to a more

frequent schedule we suggest you re-calibrate at the minimum of once a year. If you have filters from other

manufacturers we can also calibrate them as well (call for pricing). Filters are tested per USA Code of Federal

Regulations 40CFR60 Appx. B, Performance Specification 1, Section 7.1.3 Attenuation Calibration.

Page 36

35

Course adjustments

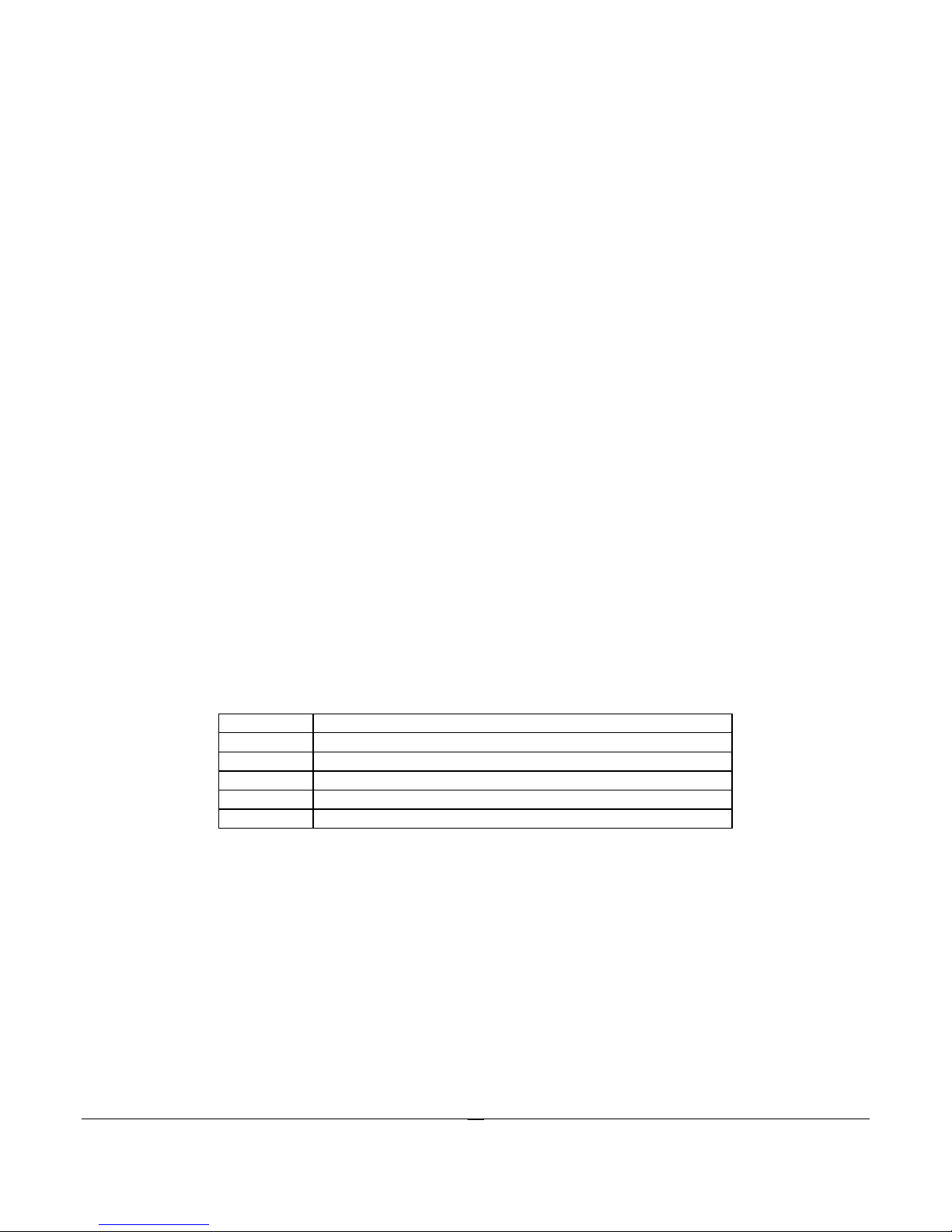

Part Number

Description

1395

2" square Neutral Density Filter (certified & Traceable to NIST).

1626

Iris 49 x 34mm

1163

1/4-20 x 21/2" Adjustment Knob

1164

Lock nut

1. Opacity is below zero and you can not reach zero after you have turned the adjustment knob as far

as it will go into the Micro-turn housing perform the following procedure:

2. Hold the Micro-turn in your hand so you can see the iris and retro reflector. Turn the fine adjustment

knob so that the iris is closed as far as it will go. CAUTION: do not force the knob at the first sign of

binding STOP.

3. Next loosen the course adjustment set screw.

4. Turn the fine adjustment knob in the opposite direction as far as it will go than tighten Allen set screw

located on the bottom of the COM block. Be sure not to tighten more than 1/16 of a turn to prevent

damage to the iris ring.

5. After the setscrew is tight again try to reach zero, repeat if necessary.

6. Opacity is above zero and you can not bring it up after you have turned the adjustment knob as far

as it will go into the Micro-turn housing perform the following procedure:

7. Hold the Micro-turn in your hand so you can see the iris and retro reflector. Turn the adjustment

knob so that the iris is open as far as it will go. CAUTION: do not force the knob at the first sign of

binding STOP.

8. Next loosen the course adjustment set screw.

9. Turn the fine adjustment knob in the opposite direction as far as it will go than tighten Allen set screw

located on the bottom of the COM block. Be sure not to tighten more than 1/16 of a turn to prevent

damage to the iris ring.

10. After the setscrew is tight again try to reach zero, repeat if necessary.

11. You have tried above and you cannot reach zero or zero is unstable, contact the factory for assistance.

Micro-turn parts list

Page 37

36

Filter certification

QA/QC testing by EMS of the filters at an interval of not more than 6 months is recommended. Filter

certification, replacement or additional Neutral Density Filters are available from EMS.

EMS Neutral Density Filters for Micro-turn 200 are calibrated on a Perkin-Elmer Lambda Series 6 / PECSS

Spectrophotometer per Federal Environmental Protection Agency specifications. These specifications are

contained in the Code of Federal Regulations 40 CFR 60, Appendix B, Performance Specification 1, Attenuator

Calibration. The filters are scanned over the visible region from 380 to 780 nanometers in one nanometer steps

and the resulting transmittances of the filter are weighted to the Source C Human Eye Response by multiplying

each value by its associated response factor. The corrected values of transmittance are converted to % Opacity

and the value is recorded on the filter and associated chart.

Page 38

37

Section 7

PREVENTIVE/CORRECTIVE MAINTENANCE

Preventive/corrective maintenance schedule

Daily:

Check Zero/Span marks are within specification (+/- 2%)

Check for fault conditions

Monthly or as required:

Clean transceiver and retro windows

Check alignment, correct if necessary

Check air filters replace if necessary

Quarterly:

All daily and monthly checks

Perform COM Audit per EPA regulation 40 CFR, 60 App. B, PS-1.

Replace air filters

Check all air hoses and clamps for tightness and wear, correct as necessary

Check weather cover gaskets for leakage

Check all bolts for tightness

Check all electrical connections are secure

Check air blower for excessive noise

Assure that airflow switch is operating properly

Page 39

38

Yearly:

Clear stack or off stack zero

All quarterly checks

Remove transceiver and retro, clean air plenum

Replace any worn hoses and gaskets

Check all system operations

General

Corrective and preventive maintenance schedules should be adjusted according to site specific conditions to

ensure the maximum availability of accurate measurement data. Routine checks should be implemented to:

Observe and correct the operation of the air-purge system giving particular attention to keeping the optical path

within the mounting flanges clear of dirt build-up.

Observe and correct the operation of peripheral accessory equipment such as recorders, computers, etc.

Observe and correct the stack zero measurement whenever a clear stack condition exists. Care should be exercised

to ensure that both transmittance and opacity measurements are at their prescribed values.

Verify that instrument operating manuals are available and that maintenance logs are properly maintained and

reviewed.

Every 3-5 Years:

EMS recommends periodical, depending on the severity of the sensor locations 3-5 years between overhaul of our

opacity system to keep them working at their optimal level. Overhauls become necessary do to the fact that over

time dust, out gassing of electronic parts, removing protective covers, etc., manifest itself as overall optics

degradation causing more frequent adjustments and poor performance of the opacity monitor.

To schedule call EMS service department 203.935.0102 ext 14 or email; service@emsct.com

Page 40

39

Control unit preventive maintenance

Preventive maintenance consists of cleaning the instrument regularly and inspecting it occasionally for broken or

damaged parts. Regular maintenance will improve the reliability of your instrument and prevent breakdowns.

Cleaning - Accumulations of dirt and dust on components act as an insulating blanket preventing efficient heat

dissipation. Dust on circuit boards and wires can cause arcing and short circuits, resulting in damage to

components or even instrument failure. Clean your instrument with clean high-pressure air before this happens!

The control unit chassis provides protection from dust and dirt and should be in place during normal operation of

the instrument.

Exterior - Dust the chassis with a soft cloth. Dust the front panel with a soft paintbrush. Dirt clinging to the

surface can be removed with a soft cloth dampened with a mild detergent and water solution. Avoid using

abrasive cleaners, as they will scratch the housing and front panel.

Interior - Dust in the interior of the control unit should be removed before it builds up enough to cause arcing

and short circuits during periods of high humidity. Dust is best removed from the interior by the type of canned

air used for computer cleaning. Dirt clinging to the surfaces can be removed with a soft paintbrush.

Visual Inspection - Inspect the interior occasionally for broken connections, improperly seated semiconductors,

damaged or improperly installed circuit boards, heat damaged components, etc. If heat damaged components are

found, care must be taken to find the cause of the excessive heat and measures must be taken to prevent

recurrence of the damage.

Semiconductor Checks - Periodic checks of the semiconductor devices in this instrument are not recommended.

The best check of semiconductor performance is actual operation of the instrument.

Weather cover/blower preventive maintenance

Periodically - Check and inspect all hoses and wire connections inside the weather covers.

Air Filter - Remove and inspect replace the filter cartridge as necessary. EMS p/n 2122

Page 41

40

Trouble Shooting

Problem

Possible Cause

Remedy

Control unit reads 100%, both bargraphs are

blinking, Alarm LED is on, Fault message

T2 4-20mA lost/low, service module meter

in T2 reads -20 or higher.

Transceiver current loop

to the control unit is open

Operate/test switch must be in

Operate.

Check wiring for open from

Terminal 17 & 18 on control unit to

terminal 17 & 16 at service module

location.

Alignment is good but control unit reads

high opacity or erratic in normal, zero &

span mode, service module meter in opacity

reads high or erratic.

1- Reference voltage TP-2

on signal processor 1667

is lower than 9.3V

2- Main lamp out

1- Adjust lamp drive PT-2 on the

power modulator 1668 until

Reference voltage TP-2 on signal

processor 1667 is 10.0 Volts.

2- Replace main lamp assembly

Control unit reads High, zero/span values

are OK

1- Smoke

2- Alignment is out

1- Correct process

2- Adjust alignment until centered

on target.

High dust alarm and /or cal fail cal message

Transceiver window

and/or zero mirror is dirty

Clean window and or zero mirror

Control unit reads High, zero/span values

are OK, alignment is good

Dirt built up in flanges

Swing open transceiver & Retro.

Clean flanges with push rod.

Air purge fault message

No or low air flow

Replace air blowers as necessary

Replace air filters as necessary

Tighten hose clamps as necessary

No stack power fault message

Service module lost power

or failed

Check power, check SM fuse.

Replace as needed

Page 42

41

Trouble shooting -continued

Problem

Possible Cause

Remedy

Maintenance Mode message

Maintenance switch or

maintenance function is

on

1- Control unit zero/span

key was pressed.

2- Service module

zero/operate switch in

zero, span/operate switch

in span

3- Service module

test/operate switch in test

Return all to operate or

neutral positions and press

ACK key to clear alarms.

Control unit blank

Control unit fuse open

Replace and check for

shorts in the power supply

or individual boards.

Page 43

42

SPARE PARTS

Level 1 - General maintenance supplies recommended for all users.

Level 2 - Back up critical printed circuit boards and parts suggested permitting rapid return to service

if corrective maintenance is needed. Level 2 is recommended in addition to Level 1 for those users

requiring maximum instrument availability.

Level 3 - If you cannot operate your facility without a monitor in operation. Level 3 is recommended

in addition to Level 1

TERMS: NET 30 Days, F.O.B. Factory with credit approval. Quotes valid for 30 days.

All prices in US Dollars

LINE

P/N

DESCRIPTION

Call for

price

LEVEL 1

1 per 4 inst. Or 1 per plant

1239

Main Lamp Pre-Focused Assembly - 1300

series

1 per 4 inst. Or 1 per plant

1466

13xx series opacity transceiver/retro latch,

spring & gasket repair kit

1 per 4 inst. Or 1 per plant

1258

Standard air purge Blower, Min 5CFM @ 36

inches H2O, Max 36CFM @ 2 Inches H2O

1 per 4 inst. Or 1 per plant

1885

Air flow switch assembly for air purge blower

2 per inst.

2122

8 Pack Air filter replacement element (ID 1.5

OD 4.5 HT 5.875 Black)

1 per plant

1232

Micro-turn 200 on-line test reflector kit for

EMS 13xx transceivers with 3 Neutral Density

filters in hard carrying case.

LEVEL 2

1 per 4 inst. Or 1 per plant

2555

1304 CPU board

1 per 4 inst. Or 1 per plant

2556

Backup Memory Module, 8kx8 EEPROM

1 per 4 inst. Or 1 per plant

2372

1304/1303 Zero reflector iris assembly with

rotary solenoid, reflector tape and zero arm.

1 per 4 inst. Or 1 per plant

2357

Service Maintenance Module Assembly with

Digital display, local zero/span and test jacks.

1 per 4 inst. Or 1 per plant

2152

1303/1304 Rotary solenoid for Zero reflector

1 per 4 inst. Or 1 per plant

1668

Power/modulator board for 13XX Transceiver.

1 per 4 inst. Or 1 per plant

2554

Opacity Remote Control Unit model PCC-III.

LEVEL 3

Page 44

43

Qty as needed

1366

Spare Model 1304 control unit, service

module, transceiver & retro 3-15 Ft.

1 per plant

1234

Opacity test stands for series 13xx transceiver

& retro

1 per plant

1078

EMS 3" pipe Flange Alignment tool

1 per plant

1073

1304/1303 control unit to service module 10'

test cable

Prices: For price and delivery Call 203.935.0102 ext 11, Fax 203.634.6663 or email

service@emsct.com

Page 45

44

Section 8

DRAWINGS

Page 46

45

EMS 1001 - Mounting under 6‘ STACK

Page 47

46

EMS 1002 - Mounting over 6’ stack

Page 48

47

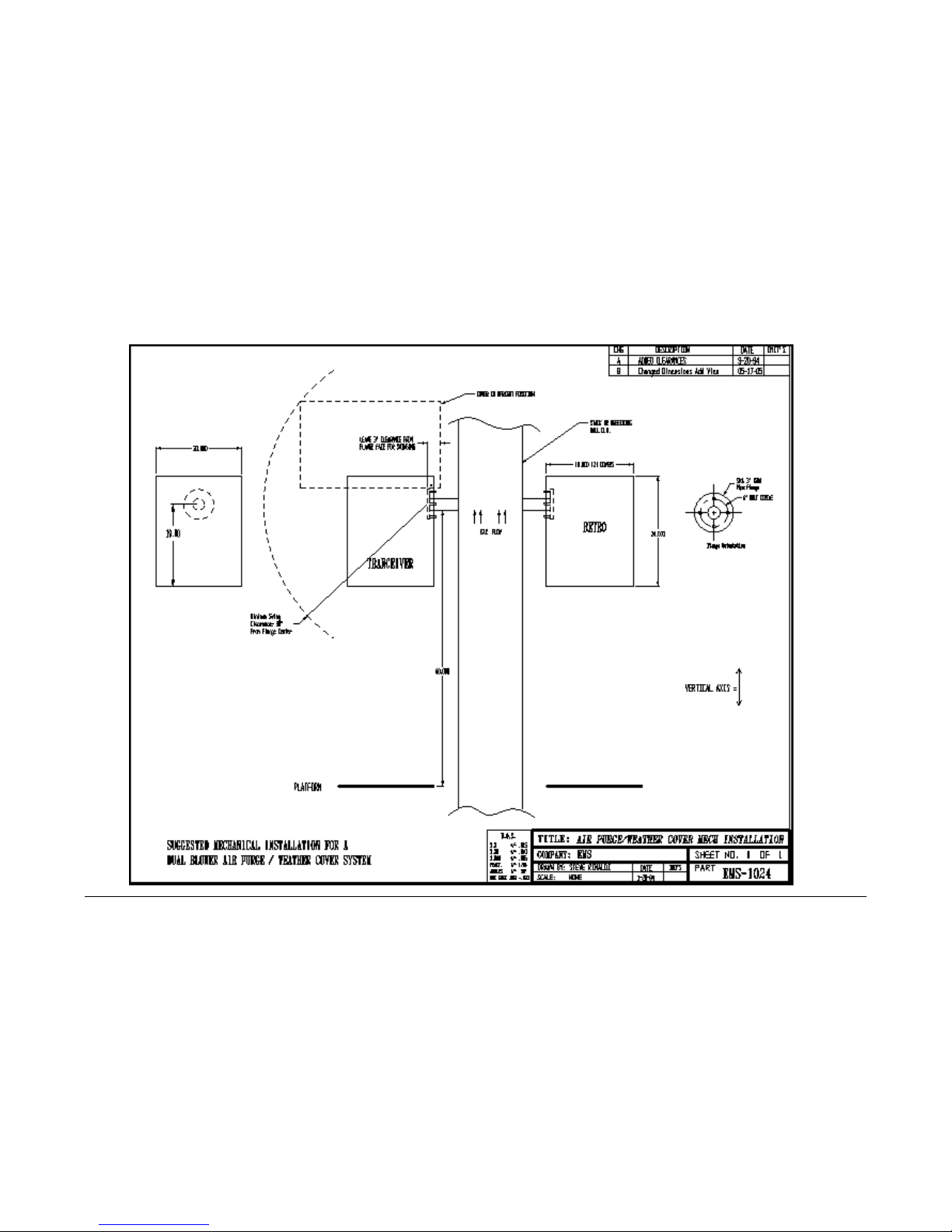

EMS 1024 - Air purge/Weather cover mech Installation

Page 49

48

EMS 1078 - PANEL cut out for 1304 control unit

Page 50

49

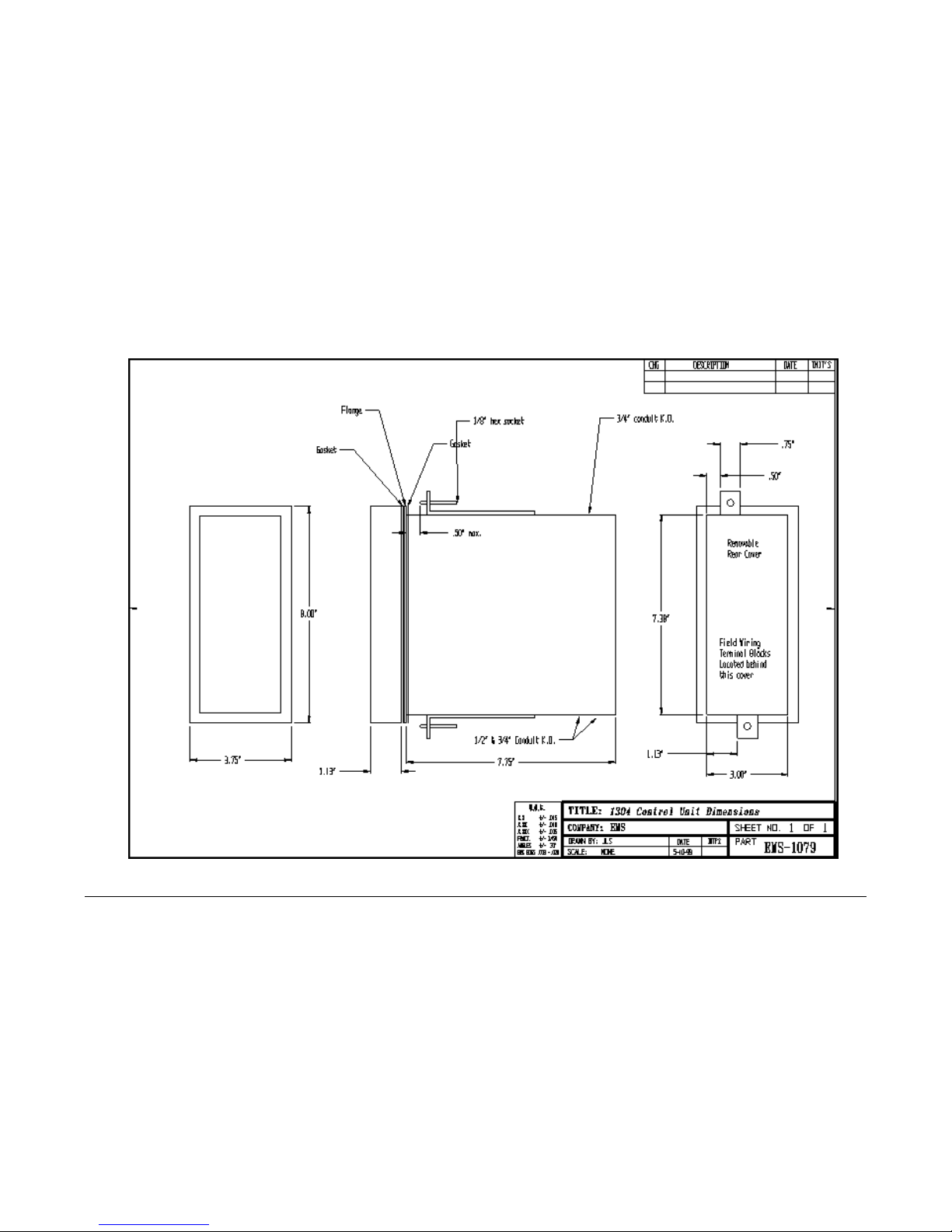

EMS 1079 -1304 control unit dimensions

Page 51

50

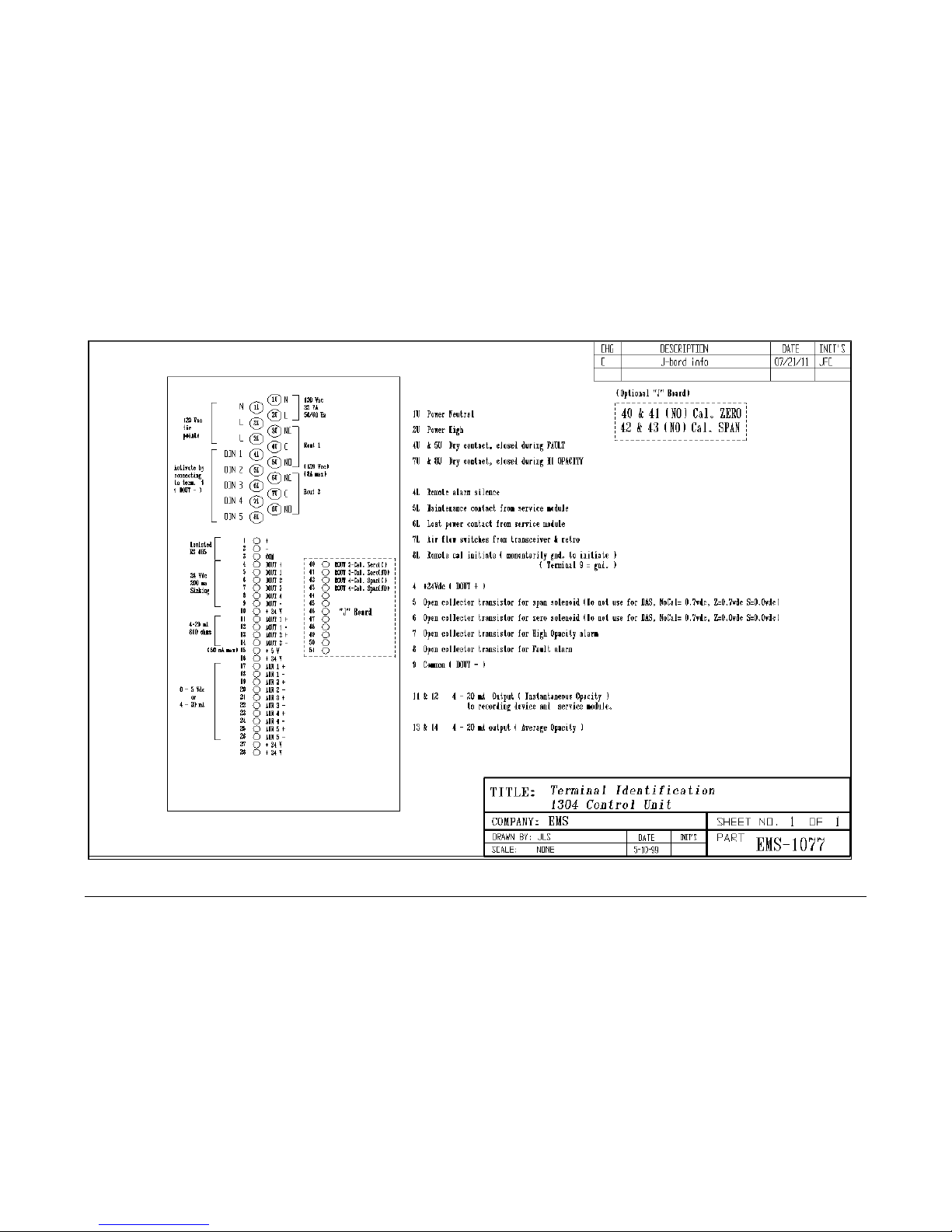

EMS 1077 - Terminal identification 1304 control unit

Page 52

51

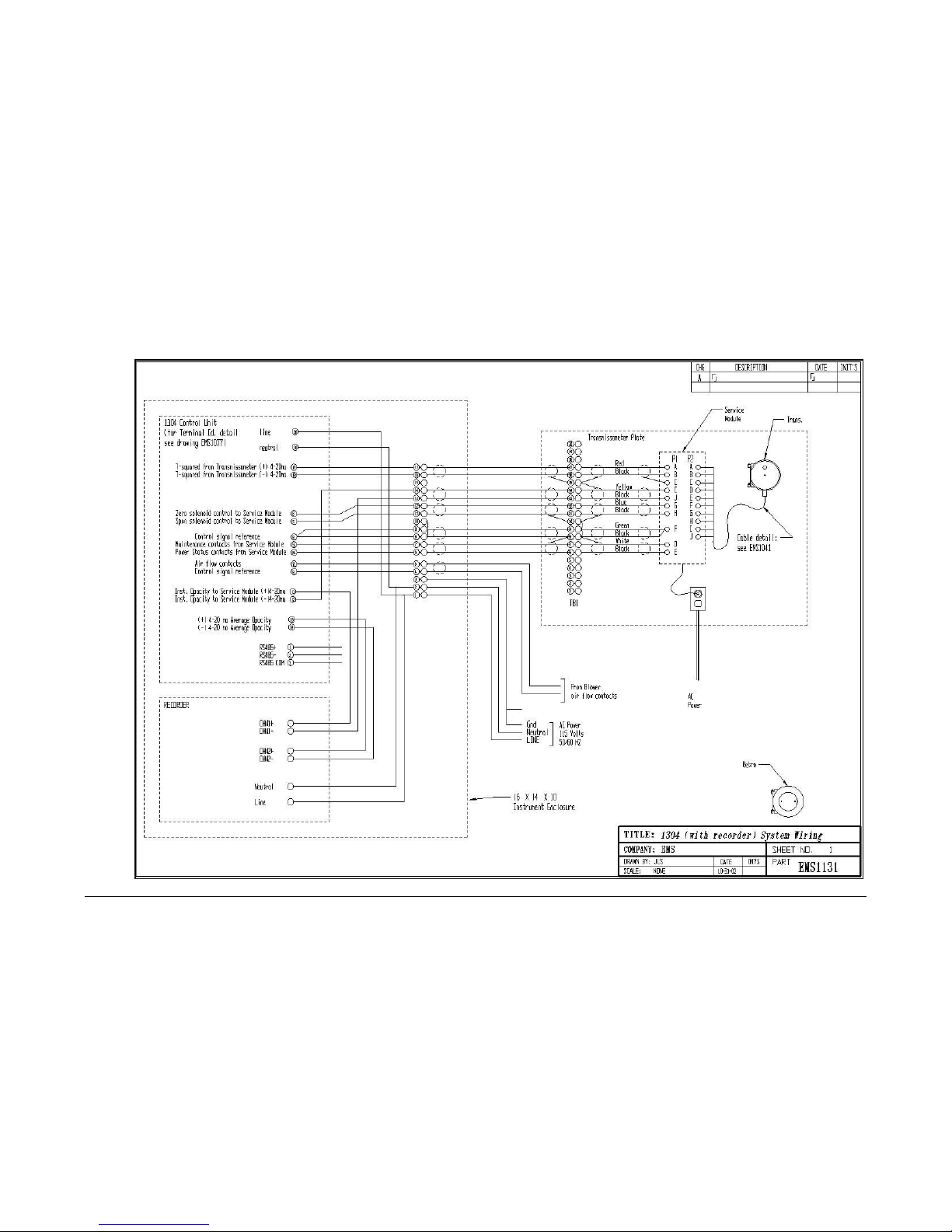

EMS 1131 -1304 with recorder system wiring

Page 53

52

PURGE BLOWER ELECTRICAL AND PRESSURE INFORMATION

Single Phase

110VAC

50/60Hz

220VAC

50/60Hz

Start Amps

9.0

4.5

Run Amps

4.5-5.7

2.2-2.8

H.P.

0.5

0

5

10

15

20

25

30

35

40

45

50

153045

60

Inch H2O

CFM

Blower Performance

Pressure

Page 54

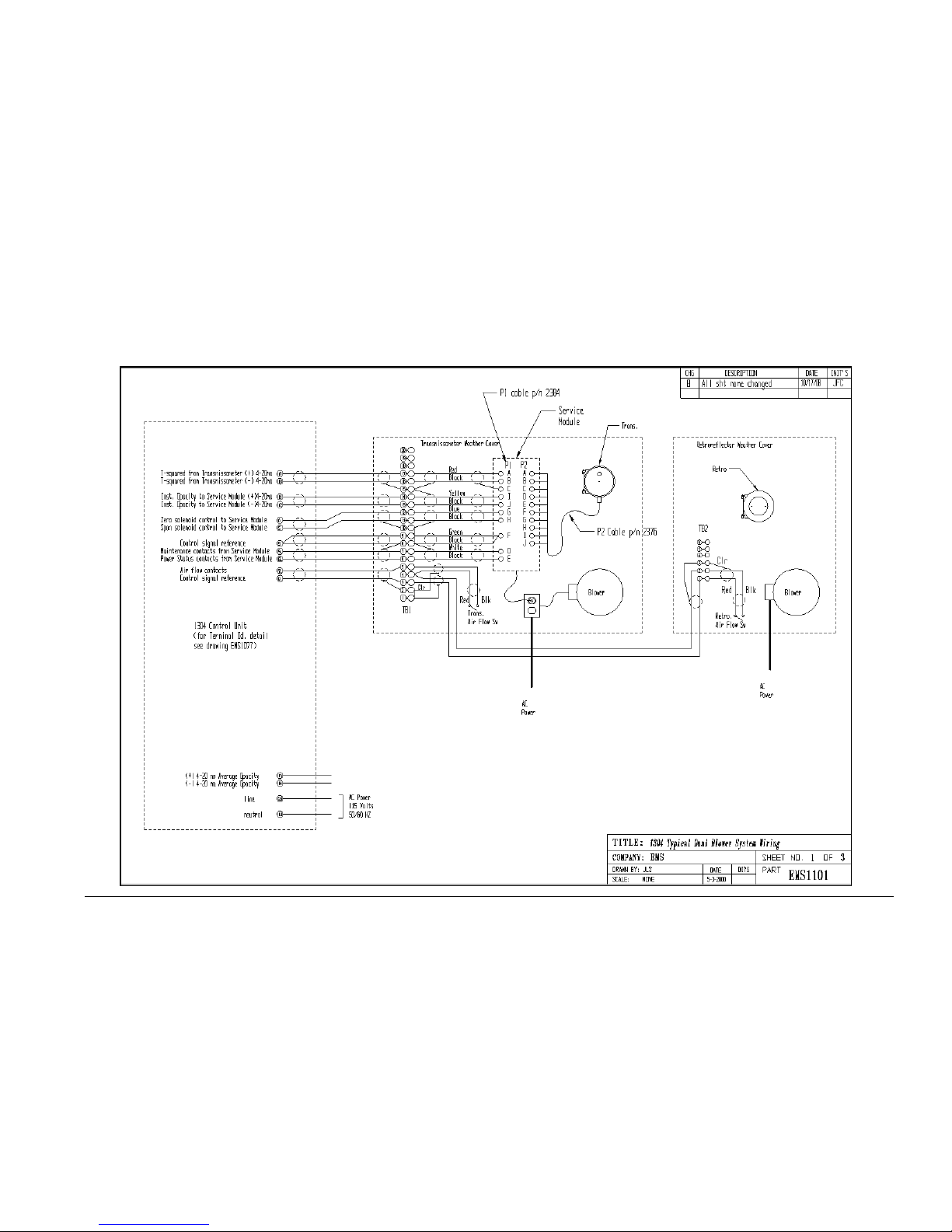

53