LX10.2

Voltage regulator for generators

Instruction Manual V1.2

Product version V1.1.0.0

Manual V1.2 Page 2 of 20

Warnings And Commissioning information

Revision history

The manual does not cover all technical details of the product. Specifications may be modified by

the manufacturer without notice. For further information, the manufacturer should be contacted.

Manual V1.2 Page 3 of 20

Table of contents

General description

The LX10.2 is designed for use in brushless generators and can be used as a cost effective

universal replacement for a great variety original manufacturers AVR’s.

The LX10.2 can be used for parallel operation with other generators that also control voltage

droop by means of Quadrature Droop Compensation (QDC).

Parallel operation is possible with an additional droop CT, which can be 0.5 or 1A secondary.

Installation, maintenance and adjustment don’t require special application software.

The AVR is protected from the environment by a PUR coating

.

Manual V1.2 Page 4 of 20

Absolute maximum rating

Manual V1.2 Page 5 of 20

Protections

Manual V1.2 Page 6 of 20

Modes of control I

Sensing voltage

Sensing voltage

Generator voltage

Generator voltage

Manual V1.2 Page 7 of 20

Modes of control II

Sensing voltage

Sensing voltage

Sensing voltage

+

Sensing voltage

+

Manual V1.2 Page 8 of 20

Modes of control III

Sensing voltage

Sensing voltage

Max. excitation voltage

(AVR supply voltage x √2 )

Max. excitation voltage

(AVR supply voltage x √2 )

AVR supply

Manual V1.2 Page 9 of 20

Commissioning set up

Commissioning set up

Start

(AVR Active / Generator running ! )

Underspeed protection

Done

Threshold underspeed

Underspeed

Slowly

Until led on

Setpoint underspeed

Underspeed

Very slowly

Until led off

Led not red flickering!

Nominal speed

GM

Note:

It is recommended to turn

the potentiometer a little

further clockwise,

to allow for short

frequency dips.

Indication setpoints

Manual V1.2 Page 10 of 20

Quick reference I

AFD ModeMinimum Rfield

Formula

Minimum field resistance

Factory settings

Sensing voltage

Underspeed frequency

Underspeed slope

Droop

Stability P-action

Stability I-action

Max. out

Dipswitch 1

Dipswitch 2

Dipswitch 3

Dipswitch 4

Dipswitch 5

Dipswitch 6

Dipswitch 7

Dipswitch 8

: 400V

: 45Hz

: Trip slope

: 100%

: 50%

: 50 %

: 100 %

: On

: Off

: Off

: On

: Off

: Off

: Off

: Off

Link: J3-J4, EX-EX

AVR field current.

Max. rating: Intermitted 12A < 10s.

Max. rating: Field forcing 20A < 1s.

Max. out Droop Underspeed Stability Voltage

(Page 6)(Page 6)(Page 6)(Page 8)

Underspeed

Coarse

Fine

- +

- +

Range 230V sensing

+/- 185 .. 290V

Range 400V sensing

+/- 315 .. 505V

+ -0% 100%0% 100% - + - +

I-action

(Integral time)

P-action

(Proportional gain)

Dipswitch

ON

1234

dip

5678

400V sensing voltage.

Phase loss protection disabled.

Remote adjust enabled.

DIP Off On

S-T internally shorted.1

2

3

4

5

6

7

8

Underspeed trip disabled.

Underspeed F/V curve disabled.

Buildup speed 2 sec.

Normal Integral time.

Underspeed trip voltage +/- 27.5% of Unom.

Phase loss protection enabled.

230V sensing voltage.

Underspeed trip enabled.

Buildup speed 5 sec.

Increased Integral time.

Do not place or remove link!

Inputs are for EMRI AFD.

AFD is an option unit

for dual AVR applications.

For more information

see manual AFD.

Underspeed F/V curve enabled.

Underspeed trip voltage +/- 17.5% of Unom.

(Page 5..8)

Trip @

Higher – RPM - Lower

+/- 62Hz +/- 27Hz

Manual V1.2 Page 11 of 20

Quick reference II

Exciter

0 .. 10Adc

Check

Formula

Minimum

Field Resistance

(Page 4, 10)

Max. rating: Intermitted 12A < 10s.

Exciter Field

AVR supply

Transformer

Max. rating: 20..300Vac

PMG

Max. rating: 20..300Vac

Stator

Max. rating: 20..300Vac

Auxilary windings

Max. rating: 20..300Vac

LH1 LH2 LH3 LH4 EX EX

Link

Link

Link

- +

Sensing

U-V-W

clockwise

(Page 12..15)

W

V

U

N

230V

Remote adjust

1kΩ

-

+

Max. value : 10K

Max. : -10V..+10V

S T

Isolated supply

(-10V .. +10V)

Rx (10kΩ ..100kΩ)

Dipswitch 1 off Dipswitch 1 off

S T

0..10kΩ

Rx

Current selection

Input X1-X2

CT 0.5A

(Droopkit)

Input X1-X2

CT 1A

(Droopcat)

J1 J2

J1 J2

J1-J2 : Open J1-J2 : Link

Current sensing

J1 J2

J1 J2

J1-J2 : Open

J1-J2 : Link

V phase

0.5A

V phase

1A

X1 X2 X1 X2

400V

Manual V1.2 Page 12 of 20

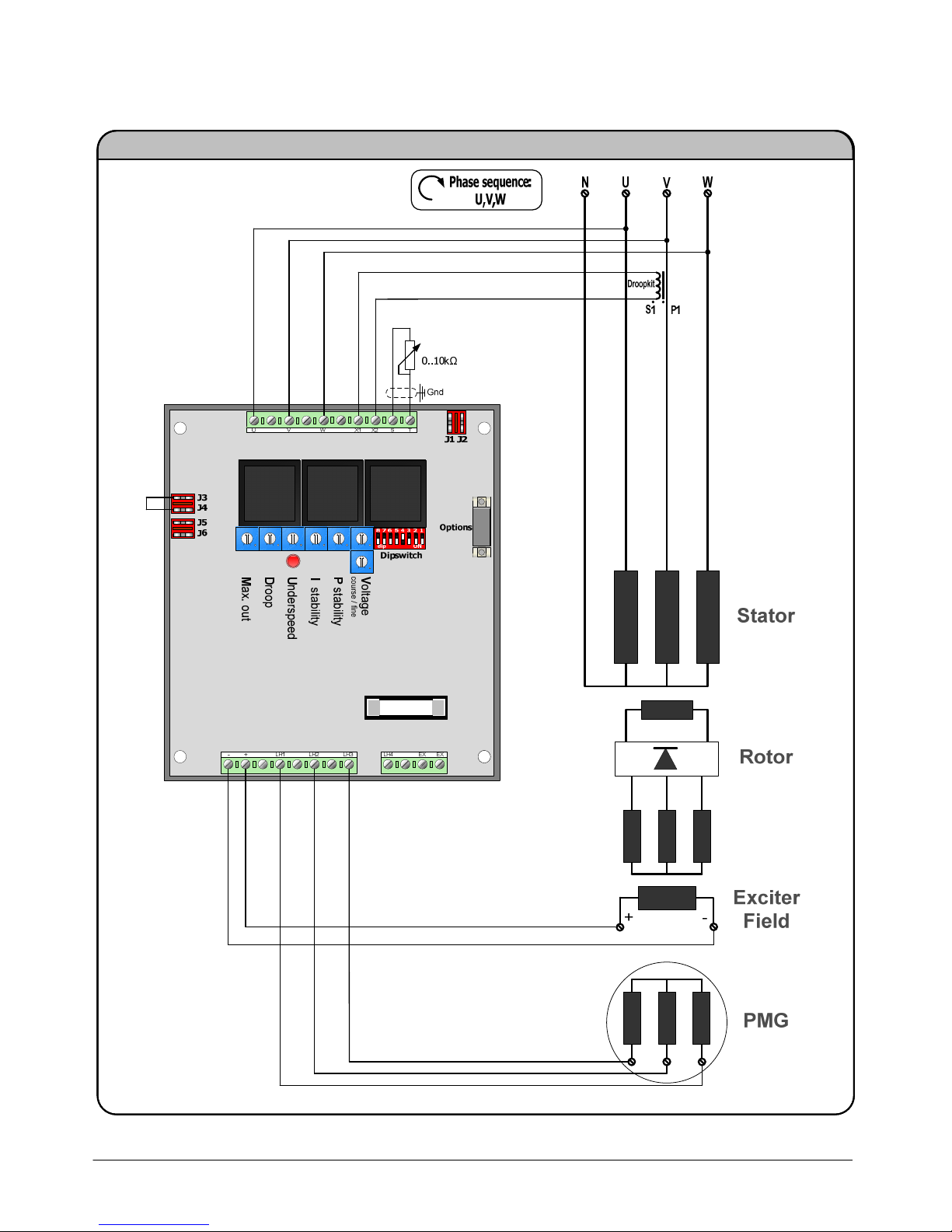

Wiring diagram I

AVR with PMG

Manual V1.2 Page 13 of 20

Wiring diagram II

AVR with auxilary windings (self excited)

Manual V1.2 Page 14 of 20

Wiring diagram III

AVR with transformer (self excited)

Manual V1.2 Page 15 of 20

Wiring diagram IV

AVR with generator phase supply (self excited)

Manual V1.2 Page 16 of 20

Tips and Suggestions I

Manual V1.2 Page 17 of 20

Tips and Suggestions II

Field flash with isolated battery (AVR)

Manual V1.2 Page 18 of 20

Tips and Suggestions III

Field flash with isolated battery (Exciter field)

Manual V1.2 Page 19 of 20

General installation information

Absolute Maximum Ratings

- The Absolute Maximum Ratings are those limits for the device that, if exceeded, will likely damage the device. Exceeding the

absolute maximum ratings voids any warranty and/or guarantee.

Mounting

Mounting of the product should be done in such a way that:

- the absolute maximum ambient temperature rating of the product will never be exceeded.

- maximum cooling (direction of cooling ribs and direction of airflow) is achieved.

- Mounting no humid air can flow through the product or condensation occurs.

- dust or other materials or residue will not remain in or on the product.

- the maximum vibration is not exceeded.

- personal contact with persons is impossible.

Wiring

- Diameter size of the wiring should be enough to carry the expected current. Wire insulation should be enough to withstand

the expected operating voltages and temperatures.

- To improve EMC emission and immunity, care should be taken for the lay out of the wiring. This in respect to all wiring in the

installation.

- Keep current carrying wires as short as possible.

- Keep wires carrying a total sum of zero Ampere close to each other, or in one single cable, E.g. U, V, W, or X (+) and XX (-),

or Phase and neutral, or S and T.

- Avoid current carrying conductors next to sensing or control wiring. Especially current controlled by SCR’s or PWM controlled

transistors.

- If sensitive sensing signal cables need to be laid across distance along other cabling, shielded cable is preferred. Keep the

shield as long as possible and the wiring outside the shield as short as possible. Do not solder or shrink the shield to a

regular wire. Connect the original shield to ground at one side with an as large as possible contact surface.

Additional installation information

- When the product is supplied by means of a transformer, it should never be an auto-transformer. Auto-transformers react as

voltage sweep up coil and may cause high voltage peaks.

- Standard fit capacitors or over-voltage suppressers across X (+) and XX (-), or exciter field terminals inside the generator

should be removed.

- When the product is supplied by means of a transformer, it should be able to carry at least the maximum expected current.

Advisable is, to have a transformer which can carry twice the maximum expected current. Inductive loads make voltage sacks

and peeks into the secondary voltage of a transformer, from which the device may malfunction.

- It is not recommended to apply switches in dc outputs. It is preferred to use switches in the ac supply inputs of devices. In

case it is unavoidable to have switches in the dc output of a device, action must be taken to avoid over voltage damage to the

device due to contact arcing. Use a voltage suppressor across the output.

- It is not recommended to apply switches or fuses in the sensing lines. Defects can cause high voltage situations due to over-

excitation.

- When using a step down transformer in medium or high voltage generators, the transformer should be three phase (if three

phase sensing), and the transformer should be suitable for acting as a sensing transformer. If the transformer is unloaded,

connect a resistor to avoid voltage waveform distortion.

- The phase relation from the generator to the AVR is important. Also when voltage transformers and/ or current transformers

are installed.

- When using a step down or insulation transformer in the droop circuit, phase relation from the generator to the AVR is

important.

- CT’s wiring, connected to the AVR should never be grounded.

- Always disconnect electronic products, circuits and people before checking the insulation resistance (Megger check).

- Due to differences in generators impedance’s, EMC behavior is not predictable. Therefore the commissioner / installer should

be aware of proper and correct installation.

- Large, highly inductive, exciter stator windings can cause destructive high voltage peaks. Adding a resistor from 10 to 20

times the exciter stator field resistance reduces voltage spikes. If necessary filter can be fitted additionally. (e.g. snubber, RCnetwork)

- Upon problems during commissioning, faulty behavior or defects in the generator, consult the fault finding manual at our web

site

- Some advises may be overdone or seem extraordinary, but since the electrical rules are the same everywhere, these advises

are given.

Manual V1.2 Page 20 of 20

Contact

EMRI Electronics B.V.

Manufacturer

Morsestraat 10

6716 AH, Ede, Netherlands

Tel: +31 (0)318 620 427

Fax: +31 (0)318 634 615

Website: www.emri.nl

E-mail: info@emri.nl

I

CELAND,

Hafnarfjordur

Rafeining ehf

Tel: +354 565 3049

Fax: +354 565 3048

Website: www.rafeining.is

E-mail: rafeining@rafeining.is

POLAND,

Gdynia

An-Elec Sp. z o.o.

Tel: +48 58 668 44 00

Fax: +48 58 668 44 66

Website: http://an-elec.pl

E-mail:

info@an

-

elec.pl

INDIA,

Faridabad

Power Solutions

Tel: +911 29404 1409

Fax:: +911 29404 1410

Website: www.psolindia.com

E-mail: ramesh.powersolutions@gmail.com

SOUTH AFRICA,

Roodepoort

Yneldo Electronics

Tel: +27(0)117637053

Fax: +27(0)117634212

Website: www.yneldo.com

E-mail:

yneldo@yneldo.com

POLAND,

Szczezin-Mierzyn

Marel Serwis

Tel: +48 91 48 58 388

Fax: +48 91 48 79 948

Website: www.marel.szczecin.pl

E-mail: handel@marel.szczecin.pl

CHILE,

Santiago

Lucio Vicencio y CIA.LTDA

Tel: +1-281-334-2904

Fax:: +1-832-221-5642

Website: www.luciovicencio.cl

E-mail:

lucio

vincencioltda@gmail.com

NORWAY,

Bergen

Frydenbø Electric A/S

Tel: +47 55 34 91 00

Fax: +47 55 34 91 10

Website: www.frydenbo.no

E-mail: firma.fel@frydenboe.no

SINGAPORE,

Singapore

Cyclect Electrical Engineering

Tel: +65 6868 6013

Fax: +65 6863 6260

Website: www.cyclect.com.sg

E-mail: heng.p@cyclect.com.sg

THAILAND,

Bang Lamung

Semtec Maritime/Genetech Co.Ltd

Tel: +66 38301262

Fax: +1-832-221-5642

Website: semtecmaritime.com/

Email

:

ron@northstarusa.co

UNITED

ARAB

EMIRATES,

Sharjah

KDU Technical Services

Tel: +971-6-5575480

Fax: +971-6-5575490

Website: www.kdutech.ae

E-mail:

kdutech@kdutech.ae

SWEDEN,

Kungälv

Elektrisk Drivteknik EDT AB

Tel: +46-705-28 20 60

Tel: +46-709-50 47 90

Website: www.edtab.se

E-mail:

info@edtab.se

GREECE,

Piraeus

Stavros Kassidiaris S.A.

Tel: +30 210 4636000

Fax: +30 210 4624471

Website: www.kassidiaris.gr

E-mail: info@kassidiaris.gr

CANARY ISLANDS,

Las Palmas

Zamakona Yards

Tel: +34 928467521

Fax: +34 928461233

Website: www.zamakonayards.com/

E-mail:

jbetanco

r@zamakonayards.com

UNITED STATES,

Fort Lauderdale - Florida

North Star USA inc.

Tel: +1 800 571-4453

Fax: +1 3052985727

Website: www.northstarusa.co/

Email:

ron@northstarusa.co

UNITED KINGDOM,

Stockton on Tees

MJR Controls

Tel: +44 1642 762 151

Fax: +44 1642 762 502

Website: www.mjrcontrols.com

Email:

chris.milner@mjrcontrols.com

UNITED STATES,

Kemah - Texas

Ramtec Marine Systems LLC

Tel: +1-281-334-2904

Fax: +1-832-221-5642

Website: www.ramtec-marine.com

Email:

waling@ramtec

-

marine.com

REPUBLIC OF PANAMA,

Panama

PASRAS S.A.

Tel: +507 3140095

Fax: +507 3140094

Website: www.pasras.com

E-mail: info@pasras.com

ROMANIA,

Constanta

SAMTEC SRL

Tel: +40 241 517 047

Fax: +40 241 517 047

Website: www.samtec.ro

E-mail: samtec_srl@yahoo.com

Loading...

Loading...