Designer 800 Sewing Machine

Congratulations on purchasing our Empisal Designer 800 Sewing Machine.

Each unit is manufactured to ensure safety and reliability. Before using this appliance

for the first time, please read the instruction manual carefully and keep it for future

reference.

Features of the machine include:

4-step buttonhole

108 stitch functions

Adjustable stitch length: 4mm

Adjustable stitch width: 5mm

Built-in LED light

Thread tension dial

Three needle positions at right, middle or left

Shuttle hook system

Front loading bobbin

Removal extension table

Storage compartment

Thread cutter

Foldable handle

Twin needle facility

Easy changing presser foot

Needle plate with guide lines

Manual reverse lever

Power switch

Soft machine cover included

Measurement guide on machine

Adjustable pressure for presser foot

Self-uncoupling bobbin winder

Accessories included

Versatile utility stitches

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic

safety precautions should always be followed,

including the following:

Read all instructions before using this sewing

machine.

DANGER -To reduce the risk of

electric shock:

1. This appliance should never be left

unattended when plugged in.

2. Always unplug this appliance from the

electric outlet immediately after using and

before cleaning.

WARNING -To reduce the risk of

burns, fire, electric shock, or injury to

persons:

1.

Do not allow to be used as a toy.

Close attention is required when this

appliance is used by or near children.

2.

Use this appliance only for its intended

use as described in this manual. Use only

attachments recommended by the

manufacturer as contained in this manual.

3.

Never operate this appliance if it has a

damaged cord or plug, if it is not working

properly, if it has been dropped or

damaged, or dropped into water. Return

the appliance to the nearest authorized

dealer or service centre for examination,

repair, electrical or mechanical

adjustment.

4.

Never operate the appliance with any air

openings blocked. Keep ventilation

openings of the sewing machine and foot

controller free from accumulation of lint,

dust, and loose cloth.

5.

Keep fingers away from all moving parts.

Special care is required around the sewing

machine needle.

6.

Always use the proper needle plate.

The wrong plate can cause the needle to

break.

7.

Do not use bent needles.

8.

Do not pull or push fabric while stitching. It

may deflect the needle causing it to break.

9.

Switch the sewing machine off ("0") when

making any adjustments in the needle area,

such as threading needle, changing needle,

threading the bobbin, or changing presser

foot, and the like.

10.

Always unplug sewing machine from the

electrical outlet when removing covers,

lubricating, or when making any other user

servicing adjustments mentioned in the

instruction manual.

11.

Never drop or insert any object into any

opening.

12.

Do not use outdoors.

13.

Do not operate where aerosol spray

products are being used or where oxygen

is being administered.

14.

To disconnect, turn all controls to the off

("0") position, then remove plug from

outlet.

15.

Do not unplug by pulling on cord. To

unplug, grasp the plug, not the cord.

SAVE THESE

INSTRUCTIONS

This sewing machine is intended for household

use only.

List of contents

Parts diagram.................................................................................................................................................................................2-3

Accessories.................................................................................................................................................................................... 4

Fitting the snap-in sewing table and spool pin ········································································································· 5

Connecting machine to power source. ··················································································································· 6

Two-step presser foot lever/ Adjusting the presser foot pressure.················································································· 7

Attaching the presser foot holder. ························································································································· 8

Winding the bobbin......................................................................................................................................................................... 9

Inserting bobbin............................................................................................................................................................................... 10

Changing the needle ········································································································································· 11

Threading the upper thread. ································································································································ 12

Thread tension.................................................................................................................................................................................13

Bringing up the lower thread ······························································································································· 14

Reverse sewing/ Removing the work/ Cutting the thread. ··························································································· 15

Matching needle I fabric I thread. ························································································································· 16

How to choose your pattern. ······························································································································· 17

Straight stitching and needle position ···················································································································· 18

Zigzag sewing. ················································································································································· 19

How to sew 4-step buttonholes. ··························································································································· 20

3-step zigzag. ·················································································································································· 21

Stitch selection. ················································································································································ 22

Smocking stitch ················································································································································ 23

Practical stitches ·············································································································································· 24

Darning ·························································································································································· 25

Attaching lace ·················································································································································· 26

Applique ························································································································································· 27

Twin needle.....................................................................................................................................................................................28

Patch work.......................................................................................................................................................................................29

Maintenance ··················································································································································· 30

Trouble shooting guide…………………………………………………………………………………………………………………….31-32

Storing and servicing the machine ························································································································ 33

Warranty.......................................................................................................................................................................................... 34

2

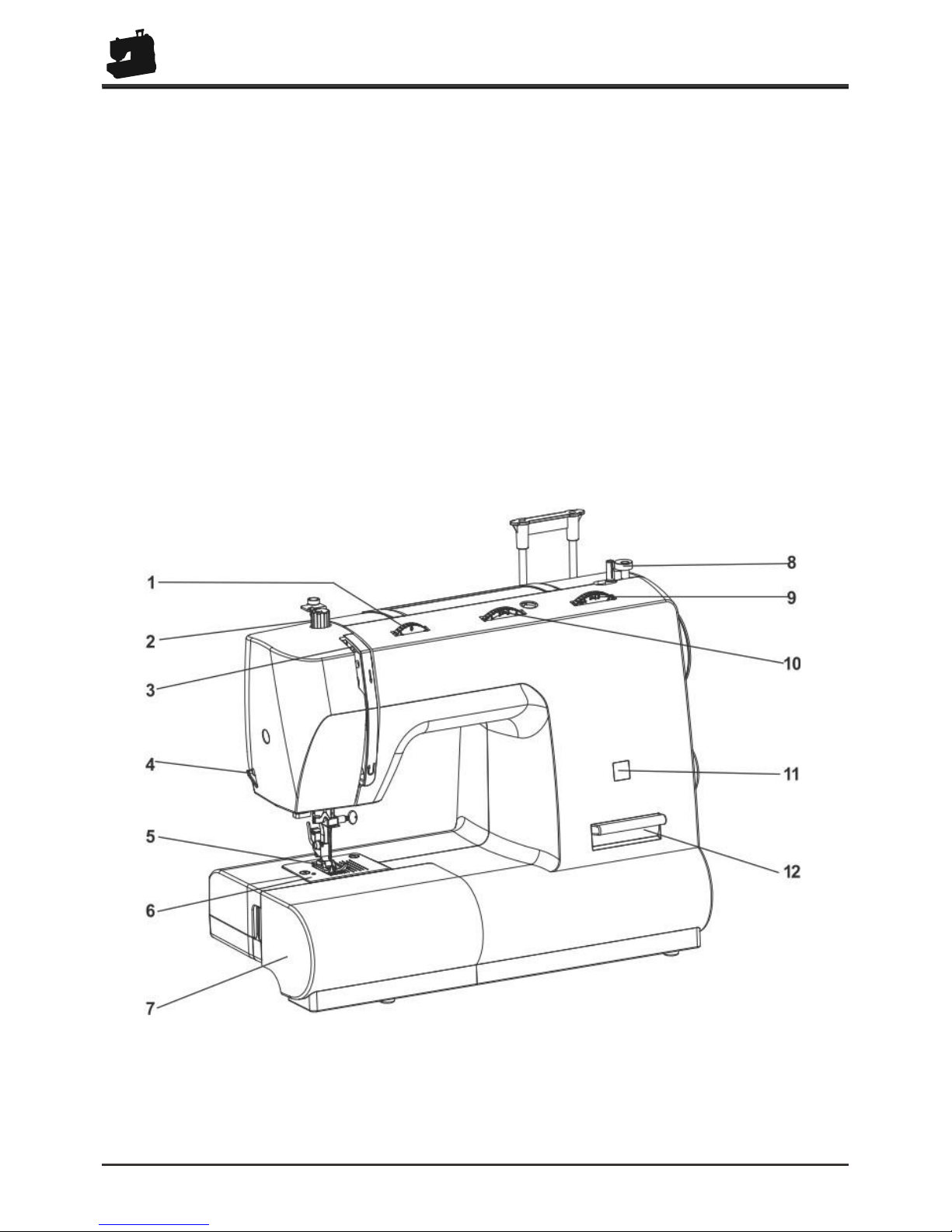

Parts diagram

1.

Thread tension dial

2.

Presser foot pressure

3.

Thread take-up lever

4.

Thread cutting

5.

Presser foot

6.

Needle plate

7.

Sewing table and accessory box

8.

Bobbin stopper

9.

Stitch length dial

10.

Stitch width dial

11.

Stitch display

12.

Reverse sewing lever

3

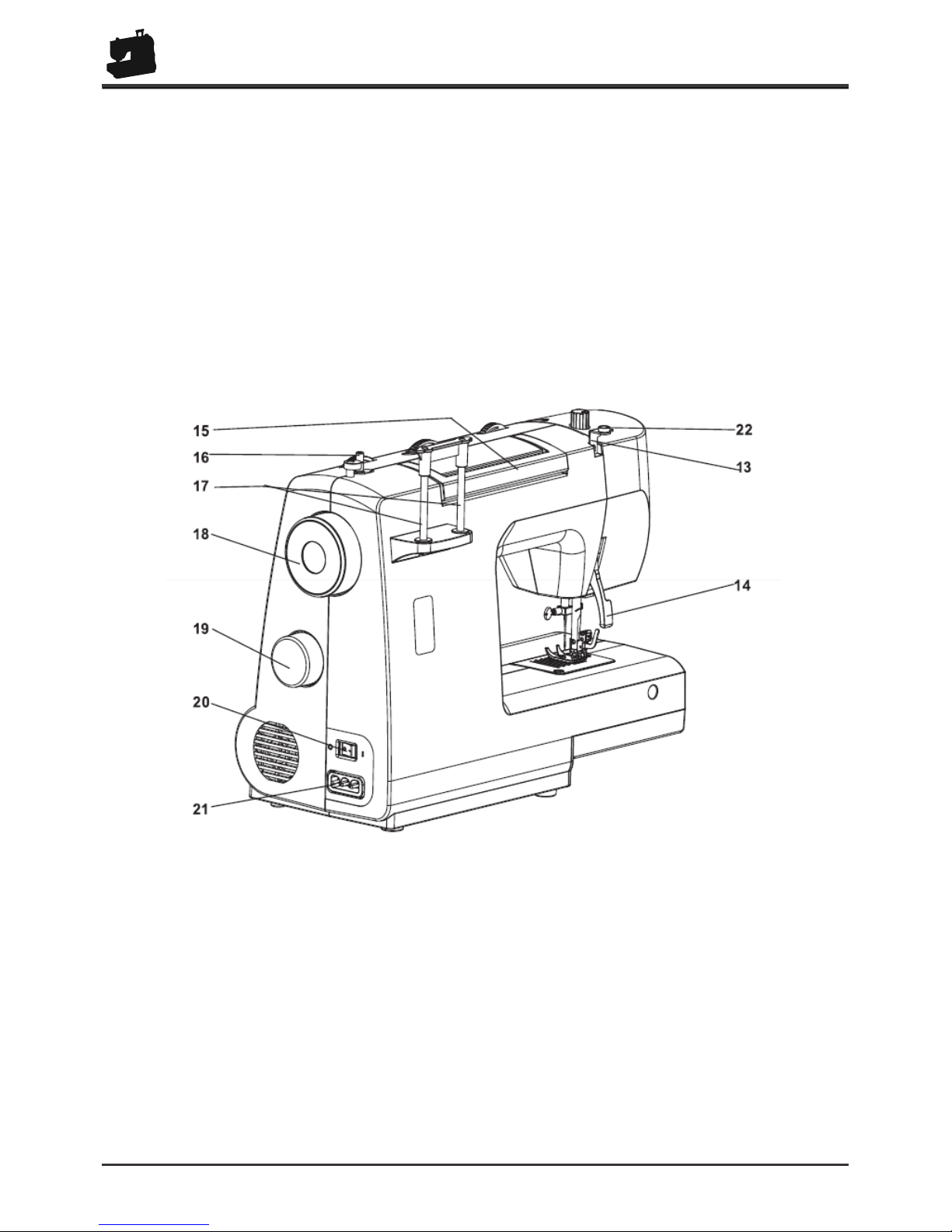

Parts Diagram

13.

Upper thread guide

14.

Presser foot lever

15. Handle

16. Bobbin winder

17. Spool pin

18. Handwheel

19 Pattern selector dial

20.

Power switch

21.

Main plug socket

22.

Bobbin thread guide

4

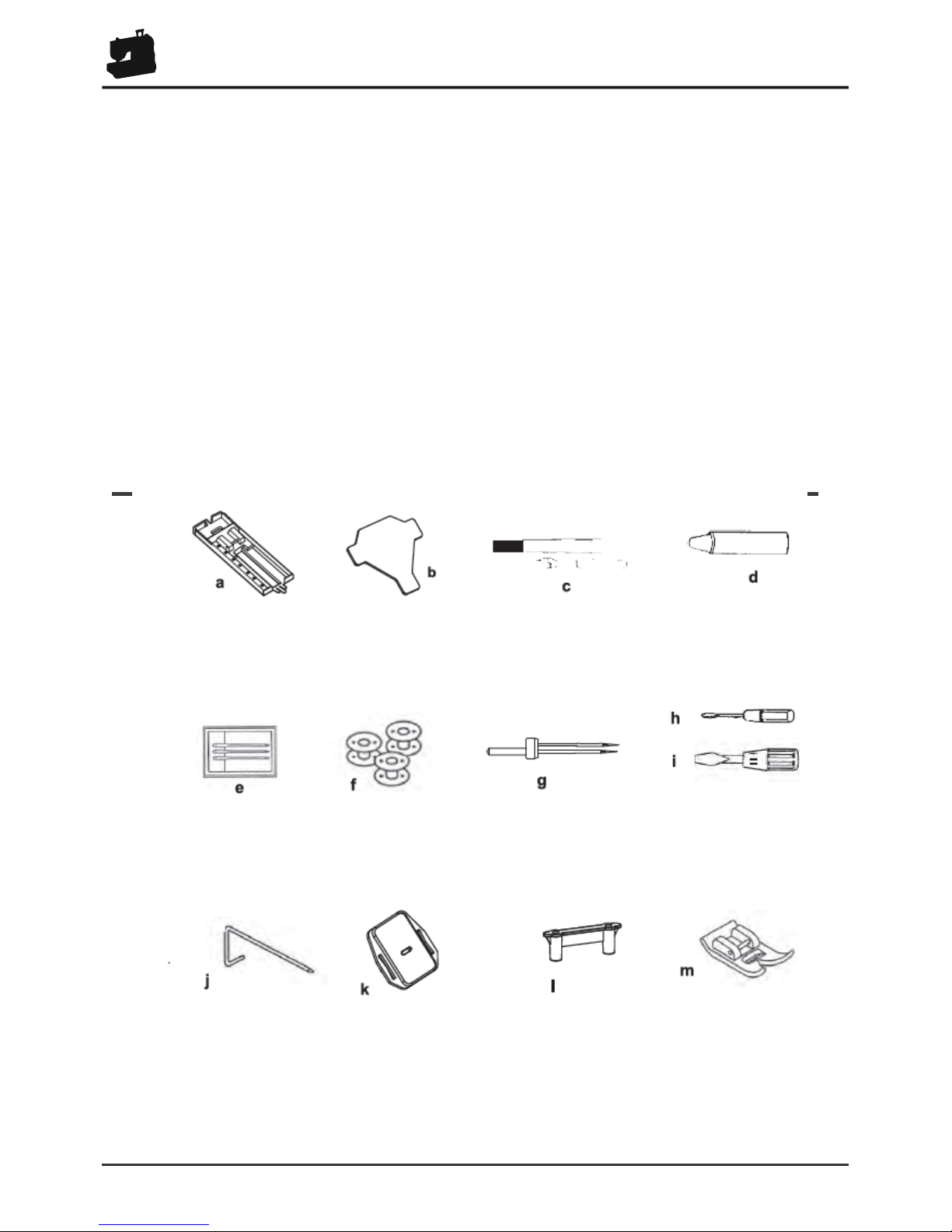

Accessories

Standard accessories

a.

4-step Buttonhole foot

b.

Butterfly shape screwdriver

c.

Seam ripper/brush

d.

Lubricate oil

e.

Needle x 3 pcs

f.

Bobbins x 3 pcs

g.

Twin needle

h.

Screwdriver(small)

i.

Screwdriver(large)

j. Edge/Quilting guide

k. Embroidering plate

I. Spool holder

m.

All-purpose foot

5

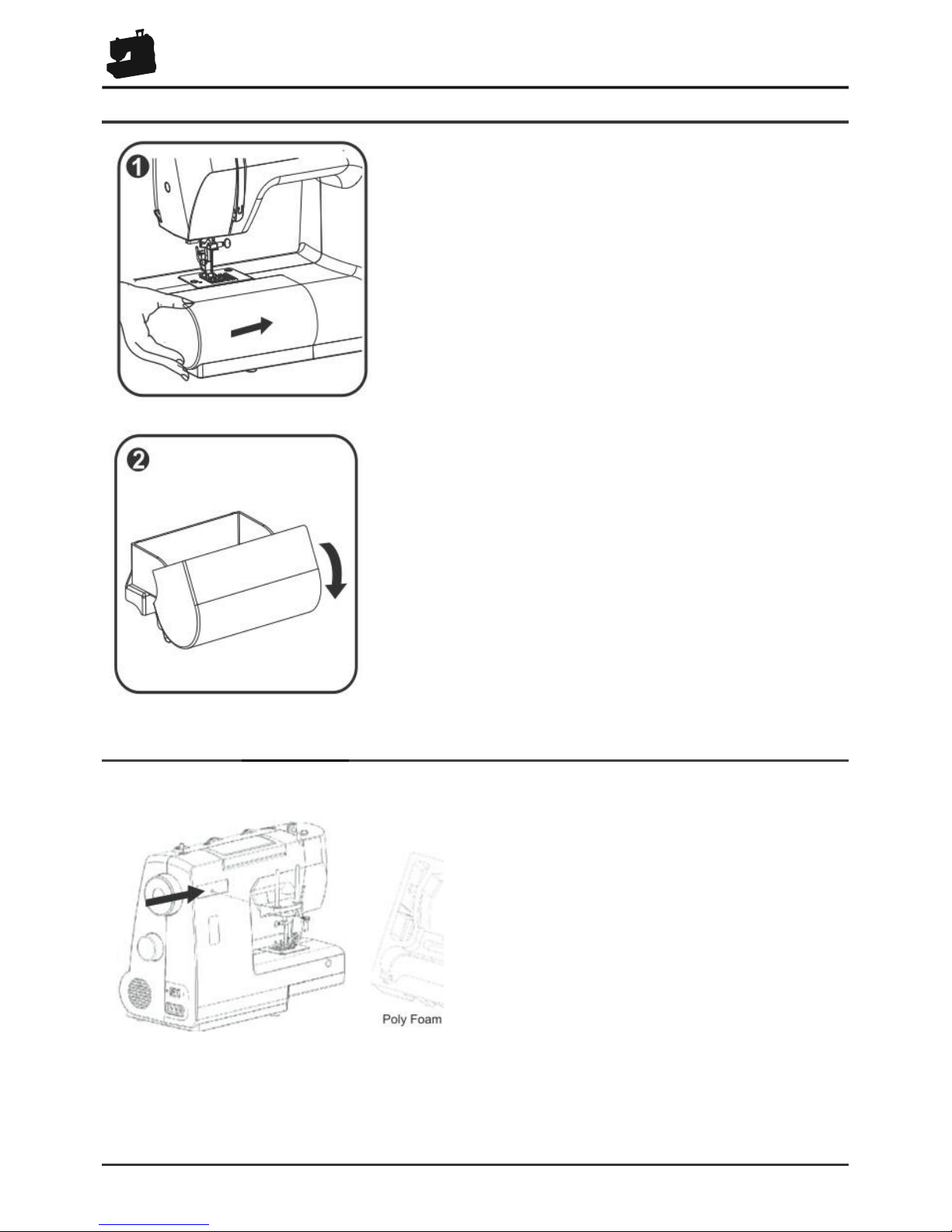

Fitting the snap-in sewing table and spool pin

Fitting the spool pin

Hold the snap-in sewing table horizontal, and push it in the

direction of the arrow. (1)

The inside of the snap-in sewing table can be utilized as an

accessory box.

To open, lift up at the point of the arrow. (2)

Install The Spool pin

1.

Take out the spool pin from

the poly foam.

2.

Loosen the screw M4X18

as shown.

3.

Install the spool pin as

illustrated then tighten the

screw.

6

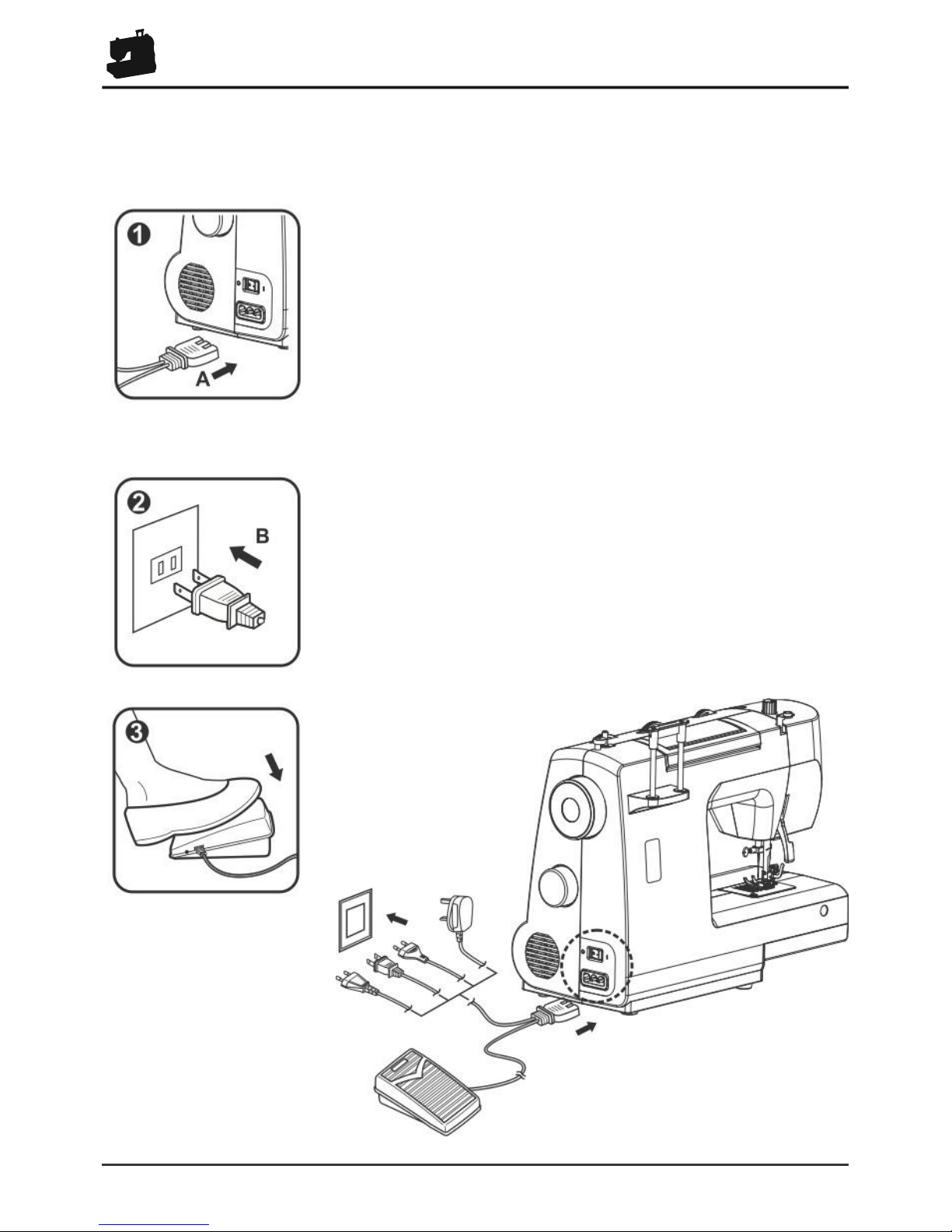

Connecting machine to power source

Caution:

Always make sure that the machine is unplugged from the power

source and the main switch is on "OFF" when the machine is not in

use and before inserting or removing parts.

-

This machine is equipped with a polarized plug which must be

used with an appropriate electrical outlet.

-

Connect the machine to a power source as illustrated (1&2).

-

The power switch is located above the terminal box. Your

machine will not operate unless this switch is on" I ". (1}

-

The sewing light turns on automatically when the main switch is on

"I".

-To start the machine, press the foot control (3}.The speed

of the machine is regulated by the amount of pressure

exerted on the foot control.

Attention:

Consult a qualified electrician if in doubt as to connect machine to

power source. Unplug power cord when machine is not in use.

Only the supplied foot control should be used with this

machine, use of any other control will void the warranty.

7

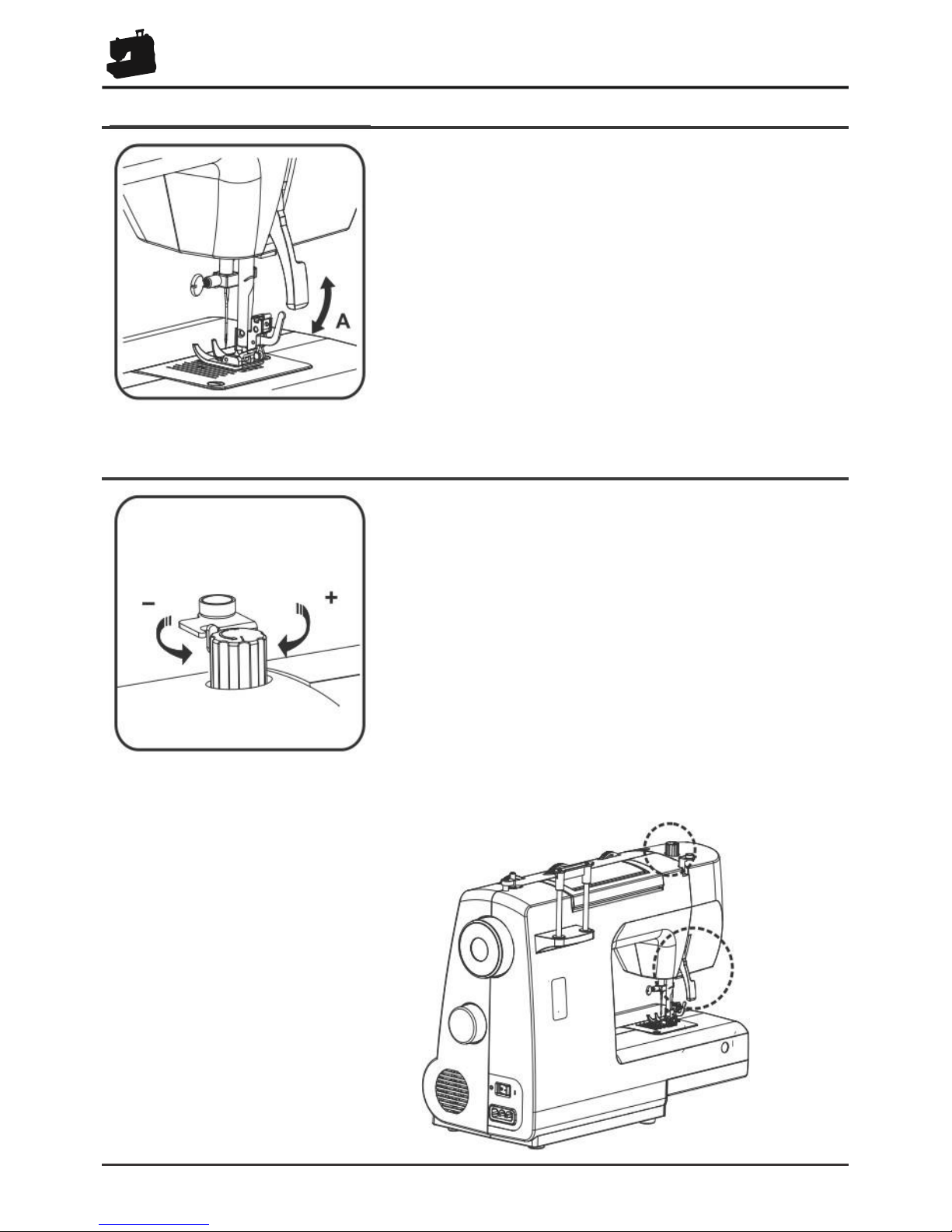

Two-step presser foot lever

When sewing several layers or thick fabrics, the presser

foot can be raised to a second stage for easy positioning of

the work. (A)

Adjusting the presser foot pressure

The presser foot pressure of the machine has been pre-set

and requires no particular readjustment according to the

type of fabric (light-or-heavy weight).

However, if you need to adjust the presser foot pressure, turn the

presser foot pressure dial as shown to the left.

For sewing very thin fabric, loosen the pressure by

turning the dial counter clockwise, and for heavy

fabric, tighten by turning it clockwise.

8

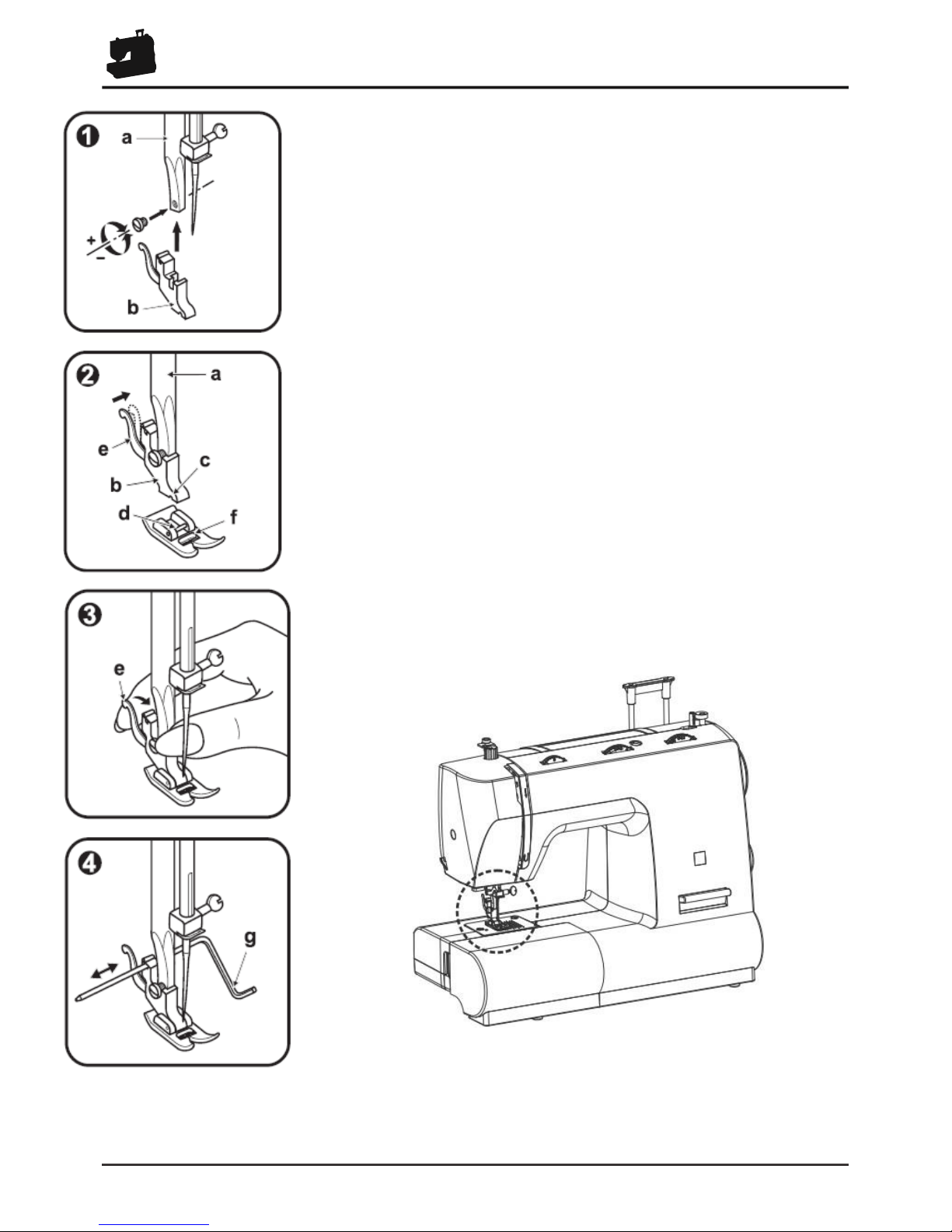

Attaching the presser foot holder

•Attention:

Turn the power switch to "OFF" before carrying out any of the operations

below.

Raise the needle to its highest position and raise the presser foot

lever. Attach the presser foot holder (b) to the presser foot bar (a). (1)

Attaching the presser foot:

Lower the presser foot holder (b) until the cut-out (c) is directly above

the pin (d). (2)

Lower the presser foot holder (b) and the presser foot (f) will engage

automatically.

Removing the presser foot:

Raise the presser foot.

Release the pressure foot by raising lever (e) located at the back of the

foot holder. {3)

Attaching the seam guide:

Attach the seam guide (g) in the slot as illustrated. Adjust the

distance as required for hems, pleats, etc..... (4)

9

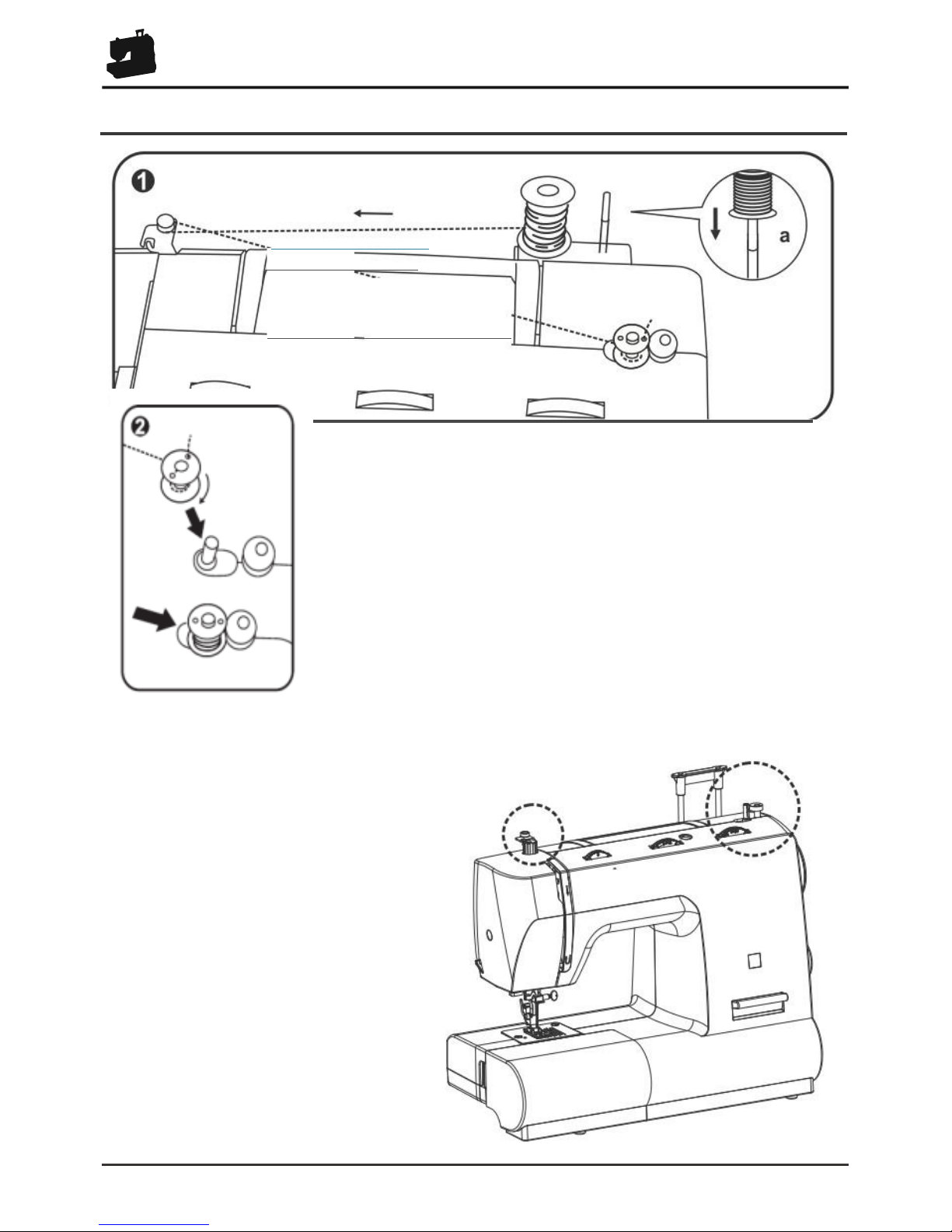

Winding the bobbin

..................

·--- ----...........

Place an empty bobbin on the bobbin winder spindle.

Take the thread from the spool through the bobbin winder

tension disc. (1)

Wind the thread a few times by hand around the empty bobbin

in a clockwise direction. Push the bobbin to the right towards

the bobbin winding position. (2)

Press the foot control gently. The bobbin will stop winding

when it is full. Push the bobbin to the left to "sewing position"

and remove it.

•

Please Note:

When the bobbin winder spindle is in

"bobbin winding" position, the machine

will not sew and the hand wheel will not

turn. To start sewing, push the bobbin

winder spindle to the left (sewing

position).

a. Spool pin

Inserting the bobbin

■ Attention:

Turn power switch to "OFF" before inserting or removing the bobbin.

When inserting or removing the bobbin, the needle must be fully raised.

Open the hinged cover. (1)

Hold the bobbin case with one hand. Insert the bobbin so that the thread

runs in a clockwise direction (arrow). (2)

Pull the thread through the slot, down and to the left until it enters the

delivery eyelet (rectangular opening) under the tension spring. (3)

Hold the bobbin case by the hinged latch. (4)

Insert the bobbin case fully into the shuttle race and release the latch.

Make sure that the metal finger fits into the notch at the top of the race

cover. (5)

10

Changing the needle

■ Caution:

Turn power switch to "OFF" before

inserting or removing the needle.

Replace the needle at the first sign of

thread breakage or skipped stitches.

Select the correct type and size of needle

for the fabric to be sewn. Turn the balance

wheel towards you until the needle is at its

highest position. Loosen the needle clamp

screw (A) and tighten again after inserting

the new needle. (1)

The flat side of the needle shaft should be

facing away from you (B). Push the

needle up (C) into the needle clamp as far

as it will go (D).

Tighten the needle clamp screw firmly.

The sewing needle must always be

straight and sharp for smooth sewing.

Replace the needle (2) if it is bent (A),

blunt (B) or the point is damaged (C).

11

12

Threading the upper thread

Caution:

Before threading, turn power switch

to "OFF".

Raise the needle bar to its highest

position. Follow exactly the numbered

threading sequence illustrated below.

If you skip a step or fail to properly

engage the thread in any of the

thread guides, the machine will not

sew properly. (1-5)

Continue to draw the thread down

and into the needle bar thread guide.

Insert the thread through the eye of

the needle from front to back. Leave

about 10 cm (4") of thread loose

behind the needle. (6)

a. Spool pin

b. Spool holder

13

Thread tension

Note:

The bobbin thread tension has

been adjusted at the factory and

readjustment is usually not

required.

Lower thread tension

To test the bobbin thread tension,

remove the bobbin case and bobbin

from the machine and hold the

bobbin case suspended by the

thread. Shake it once or twice. If the

tension is correct, the thread will

unwind by about an inch or two. If

the tension is too tight, it will not

unwind. If the tension is too loose,

the thread will unwind for more than

two inches.

To adjust, turn the small screw on

the side of the bobbin case. (1)

Upper thread tension

Basic thread tension setting: "4". (2)

To increase the tension, turn the dial up to a higher number. To reduce the tension, turn the dial to

a lower number.

A.

Normal thread tension.

B.

Thread tension too loose.

C.

Thread tension too tight.

14

Bringing up the lower thread

Hold the upper thread with the left hand.

Turn the handwheel towards you with your

right hand until the needle goes down and

comes up again to its highest position. (1)

-Lightly draw the needle thread forming a

loop with the bobbin thread. The upper

thread should have caught the lower

thread in a loop.

-

Pull the needle thread toward you and

the lower thread will come up from the

bobbin in a large loop. (2)

Pull about 15 cm. (6") of both threads

away from you under the presser foot.

15

Reverse sewing

Removing the work

Reverse sewing is used for locking the end of seams and where

reinforcement is needed. At the end of seam, press down the

reverse sewing lever and touch the foot control lightly. Sew a few

reverse stitches. Release the lever and the machine will sew

forwards again (A).

Turn the handwheel towards you to bring the thread take up lever

to its highest position. Raise the presser foot and draw the fabric

away from you.

Cutting the thread

Hold the threads behind the presser foot. Using both hands, guide

them to the slit (B) at the rear of the presser bar and press down

to cut the thread. You can also use the thread cutter on the side of

the machine.

16

Matching needle I fabric I thread

NEEDLE, FABRIC, THREAD SELECTION GUIDE

NEEDLE SIZE

FABRICS

THREAD

9-11(65-75)

Lightweight fabrics-thin cottons, voile,

serge, silk, muslin, Oiana, interlocks,

cotton knits, tricots, jerseys, crepes,

woven polyester, shirt & blouse

fabrics.

Light-duty thread in cotton,

nylon or polyester.

12(80)

Medium weight fabrics-cotton, satin,

kettleclote, sailcloth, double knits,

lightweight woollens.

Most threads sold are medium

size and suitable for these

fabrics and needle sizes. Use

polyester threads on synthetic

materials and cotton on natural

woven fabrics for best results.

Always use the same thread on

top and bottom.

14(90)

Medium weight fabrics-cotton duck,

woollen, heavier

knits,

terrycloth,

denims.

16{100)

Heavyweight fabrics-canvas, woollens,

outdoor tent and quilted fabrics,

denims, upholstery material (light to

medium).

18(110)

Heavy woollens, overcoat fabrics,

upholstery fabrics, some leathers and

vinyls.

Heavy duty thread, carpet

thread. (Use heavy foot

pressure -large numbers.)

IMPORTANT: Match needle size to thread size and weight of fabric

NEEDLE, FABRIC SELECTION

NEEDLES

EXPLANATION

TYPE OF FABRIC

HA x 1

15 x 1

Standard sharp needles.

Sizes range thin to large.

9 (65) to 18 (110)

Natural woven fabrics-wool, cotton, silk, etc.

Qiana. Not recommended for double knits.

15 x

1/705H

(SIN)

Semi-ball point needle,

scarfed 9 (65) to 18 (110)

Natural and synthetic woven fabrics, polyester

blends. Knits-polyesters, interlocks, tricot,

single and double knits. Can be used instead

of 15 x 1 for sewing all fabrics.

15 x 1/705 HS

(SUK)

Full ball point needle 9

(65) to 18 (110)

Sweater knits, Lycra, swimsuit fabric, elastic.

130 PCL

Leather needles. 12 (80)

to 18

(110)

Leather, vinyl, upholstery. (Leaves smaller

hole than standard large needle.)

Note:

1. Twin needles, can be purchased for utility and decorative work.

2. When sewing with twin needles, the stitch width dial should be set at less than "2.5".

3. European needles show sizes 65, 70, 80 etc. American and Japanese needles show size 9, 11,

12 etc.

4. Replace needle often (approximately every other garment) and I or at first thread breakage or

skipped stitches.

17

How to choose your pattern

For straight stitch select pattern "A"

with pattern selector dial (4). Adjust

the stitch length with the stitch

length dial (2). You may choose any

needle position, by turning the stitch

width dial (1).

For zigzag stitch, select pattern "B"

with pattern selector dial (4). Adjust

the stitch length (2) and stitch width

{1) according to the fabric being

used.

To obtain any of the patterns on the

upper row, turn the stitch length dial

to "S2", select the pattern desired

with pattern selector dial, and adjust

the stitch width with the stitch width

dial.

To obtain any of the patterns on the

second row, turn the stitch length

dial to "S 1", select the pattern

desired with pattern selector dial,

and adjust the stitch width with the

stitch width dial.

To obtain any of the other patterns

shown in the third row on the stitch

selection panel, select the letter

above the stitch with the pattern

selector dial. Adjust the stitch length

and the stitch width with the control

dials according to the result desired.

1. Stitch width dial

2. Stitch length dial

3. Stitch display

4. Pattern selector dial

5. Reverse sewing lever

18

Straight stitching and needle position

Turn the pattern selector dial so that

the stitch display shows the straight

stitch position.

Generally speaking, the thicker the

fabric, thread and needle, the

longer the stitch should be.

Choose your needle position, from

left position to right needle position

by changing the stitch width dial (1)

from "0" to "5".

1.

Stitch width dial

2.

Stitch length dial

3.

Stitch display

4.

Pattern selector dial

5.

Reverse sewing lever

19

Zigzag sewing

Turn the pattern selector dial to "8".

Function of stitch width dial.

The maximum zigzag stitch width for zigzag stitching

is "5"; however, the width can be reduced on any pattern. The width

increases as you move zigzag dial from "0" - "5". For twin needle

sewing, never set the width wider than "3.5". (1)

Function of stitch length dial while zigzagging

The density of zigzag stitches increase as the setting of stitch length

dial approaches "0". Neat zigzag stitches are usually achieved at "3.5"

or below. (2)

Satin stitch

When the stitch length is set between "0" - "1", the stitches are very

close together producing the "satin stitch" which is used for making

buttonholes and decorative stitches.

Sewing thin fabrics:

When sewing very thin fabrics, it is suggested that you use interfacing

on the backside of the fabric.

20

How to sew 4-step buttonholes

Prepare

Take off the all-purpose foot and attach the buttonhole foot.

Measure diameter and thickness of button and add 0.3 cm

(1/8") for bar tacks; mark buttonhole size on fabric.

Place fabric under the foot, so that marking on the buttonhole

foot aligns with starting marking on fabric. Lower the foot, so

that the buttonhole centre line marked on the fabric aligns with

the centre of the buttonhole foot.

Adjust the stitch length dial between "0.5-1" to set stitch density.

Note:

Density varies according to the fabric.

Always test sew a buttonhole on the fabric you are using to sew

the buttonhole.

Follow the 4-step sequence changing from one step to

another with the stitch pattern selector dial. Take care not to

sew too many stitches in steps 2 and 4. Use seam ripper and

cut buttonhole open from both ends towards the middle.

21

3-step zigzag

Sewing on lace and elastic, darning, mending, reinforcing edges. Set

the machine as illustrated. Pattern selector on "C".

Place patch in position. The stitch length can be shortened to produce

very close stitches. (1)

When mending tears, it is advisable to use a piece of backing fabric to

reinforce. The stitch density can be varied by adjusting the stitch length.

First sew over the centre and then overlap on both sides. Depending on

the type of fabric and damage, sew between 3 and 5 rows. (2)

Stitch selection

Triple straight stitch: (1/3) Pattern selector on "A". For

hardwearing seams.

Turn the stitch length dial to "S1".

The machine sews two stitches forwards and one stitch

backwards. This gives triple reinforcement.

Triple zigzag: (2/4) Pattern selector on "8".

For hardwearing seams, hems and decorative seams.

Turn the stitch length dial to "S1".

Adjust the stitch width dial to between "3" and "5". Triple

zigzag is suitable for firm fabrics like denim, corduroy, etc.

22

Smocking stitch

Seams, hems, T-shirts, underwear, etc. Set

the machine as illustrated.

This stitch can be used for all types of jersey as well as for woven

fabrics. (1)

Sew at 1 cm (1/4") from the fabric edge and trim the surplus fabric.

(2)

Pattern selector on "C".

Turn the stitch length dial to "S1".

23

24

Practical stitches

Set the machine as illustrated.

Turn the switch width dial and stitch length dial to suit the fabric.

Shell hem (A)

For decorative edges.

Suitable for edges on sheer, fine and stretch fabrics. The larger stitch

should go just over the edge of the fabric to create the shell effect.

Crescent stitch (B)

For a delicate edge finish along the edge of fabric.

Stitch length should be set from "0.5'' - "1.0".

Rampart (C)

For flat joining seams, sewing on elastic and visible hems. This

stitch can be used for firm, thicker fabrics.

25

Darning

Turn stitch length dial to the desired length.

Turn stitch selector to straight stitch, centre needle position.

Position the fabric to be darned under the presser foot together with the under

laying fabric to be used.

Lower the presser foot and alternately sew forward or reverse

using the lever.

Repeat this motion until the area to be darned is filled with rows of stitching.

For reverse sewing instructions, see page 16.

26

Attaching lace

Turn stitch length dial to the desired length.

- Turn the stitch selector to straight stitch, centre needle position.

- Fold in the edge of the fabric (approximately 6 mm 1/4").

- Place the lace under the folded edge of the fabric allowing it to under

lap the fabric slightly as required by the pattern of the lace.

- Sew on the edge of the fabric fold.

- You can add a decorative touch by using the satin stitch to sew the

lace.

27

Applique

- Turn stitch length dial to the desired length.

- Turn pattern selector dial to zigzag.

- Select a narrow zigzag width.

- Cut out the applique design and baste it to the fabric.

- Sew slowly around the edge of the design.

• Trim excess material outside the stitching. Make sure not to cut any stitches.

- Remove the basting thread.

- Tie top and bottom thread under the applique to avoid unravelling.

28

Twin needle

- Turn stitch length dial to the desired stitch length.

- Turn stitch selector to straight stitch, centre needle position, width setting "2.5".

- Make sure that the two threads used to thread the twin needle

- are of the same weight. You can use one or two colours.

- Insert the twin needle in the same way as single needle. Flat side of needle

should face away from you.

- Follow instructions for single needle threading. Thread each needle separately.

- Please note:

- When sewing with twin a needle, always proceed slowly, and make sure to

maintain a low speed to ensure quality stitching.

- When using twin needle on zigzag make sure the stitch width dial is set

between" 0 "and "2.5". Do not use twin needle at setting

........

........

........

........

.............

...

........

........

........

........

........

........

........

29

Patchwork

These stitches are used to join two pieces of fabric while leaving a space

between their edges.

1. Fold over the edges of the two pieces of fabric for the hem and baste the

edges to a thin piece of paper leaving a small space between them.

2. Set the Pattern selector on "G".

Turn the stitch length dial to "S1".

3. Stitch along the edge, pulling both threads slightly when beginning to sew.

* Use thicker than normal thread for sewing.

4. After sewing, remove the basting and the paper. Finish by tying knots on

the reverse side at the beginning and the end of the seams.

30

Caution:

Always make sure that the machine is unplugged from

power source and the main switch is on "0" before inserting

or removing any parts and before cleaning.

Remove the stitch plate:

Turn the hand wheel until the needle is fully raised. Open

the hinged front cover and unscrew the needle plate screw

with the screw driver. (1)

Cleaning the feed dog:

Remove the bobbin case and use the brush supplied to

clean the whole area. (2)

Cleaning and lubricating the hook:

Remove the bobbin case. Snap the two hook retaining

arms (a) outwards. Remove the hook race cover (b) and

the hook (c) and clean with a soft cloth. Lubricate at the

points (d) (1-2 drops) with sewing machine oil. Turn the

hand wheel until the hook race

(e) is in the left position. Replace the hook (c).

Replace the hook race cover and snap back the two hook

retaining arms. Insert the bobbin case and bobbin and

replace the stitch plate.

Important: Fabric fluff and threads must be removed

regularly. Your machine should be serviced at regular

intervals at one of our service agencies.

Maintenance

31

Troubleshooting guide

Problem

Cause

Correction

Upper thread breaks

1. The machine is not threaded

correctly

2. The thread tension is too tight

3. The thread is too thick for the

needle

4. The needle is not inserted

correctly

5. The thread is round wound the

spool holder pin

6. The needle is damaged

1. Rethread the machine

2. Reduce the thread tension

(lower number)

3. Select a larger needle

4. Remove and reinsert the

needle (flat side towards the

back)

5. Remove the reel and wind

thread onto reel

6. Replace the needle

Lower thread breaks

1. The bobbin case is not inserted

correctly

2. The bobbin case is threaded

wrongly 3 .The lower thread tension

is too tight

1. Remove and reinsert the

bobbin case and pull on the

thread. The thread should pull

easily

2 .Check both bobbin and bobbin

case

3. Loosen lower thread tension

as described

Skipped stitches

1. The needle is not inserted

correctly

2. The needle is damaged

3. The wrong size needle has been

used

4. The foot is not attached correctly

1. Remove and reinsert needle

(flat side towards the back)

2. Insert a new needle

3. Choose a needle to suit the

thread and fabric

4. Check and attach correctly

Needle breaks

1. The needle is damaged

2 .The needle is not correctly

inserted

3. Wrong needle size for the fabric

4. The wrong foot is attached

1. Insert a new needle

2. Insert the needle correctly (flat

side towards the back)

3. Choose a needle to suit the

thread and fabric

4. Select the correct foot

Loose stitches

1. The machine is not correctly

threaded

2. The bobbin case is not correctly

threaded

3. Needle/ fabric/ thread

combination is

wrong

4. Thread tension wrong

1. Check the threading

2. Thread the bobbin case as

illustrated

3. The needle size must suit the

fabric and thread

4. Correct the thread tension

Seams gather or pucker

1. The needle is too thick for the

fabric

2. The stitch length is wrongly

adjusted

3. The thread tension is too tight

1. Select a finer needle

2. Readjust the stitch length

3. Loosen the thread tension

Uneven stitches, uneven feed

1. Poor quality thread

2. The bobbin case is wrongly

threaded

3. Fabric has been pulled

1. Select a better quality thread

2. Remove bobbin case and

rethread and

insert correctly

3. Do not pull on the fabric while

sewing, let it be taken up by the

machine

The machine is

noisy

1. The machine must be lubricated

2. Fluff or oil have collected on the

hook

or needle bar

3. Poor quality oil has been used

4. The needle is damaged

1. Lubricate as described

2. Clean the hook and feed dog

as described

3. Only use good quality sewing

machine oil

4. Replace the needle

The machine jams

1. Thread is caught in the hook

1. Remove the upper thread and

bobbin case, tum the hand wheel

backwards and forwards by hand

and remove the thread remands.

Lubricate as described

32

STORING THE MACHINE

Store the machine in its box or in a clean, dry place. Never

wrap the power cord around the machine.

SERVICING THE MACHINE

If the unit is not operating correctly, please check the following:

You have followed the instructions correctly.

The wall socket is switched on.

That the mains power supply is ON.

That the plug is firmly in the mains socket.

If the machine still does not work after checking the above:

- Consult the retailer for possible repair or replacement. If the retailer fails to

resolve the problem and you need to return the machine, make sure that:

The unit is packed carefully back into its original packaging.

Proof of purchase is attached.

A reason is provided for why it is being returned.

If the supply cord is damaged, it must be replaced by the manufacturer or an authorised service

agent, in order to avoid any hazard. If service becomes necessary within the warranty period, the

machine should be returned to an approved Home of Living Brands (Pty) Limited service centre.

Servicing outside the warranty period is still available, but will, however, be chargeable

33

PLEASE AFFIX YOUR PROOF OF PURCHASE/RECEIPT HERE

IN THE EVENT OF A CLAIM UNDER WARRANTY

THIS RECEIPT MUST BE PRODUCED

W A R R A N T Y

1. Home of Living Brands (Pty) Ltd (“Home of Living Brands”) warrants to the original

purchaser of this product (“the customer”) that this product will be free of defects in

quality and workmanship which under normal personal, family or household use and

purpose may manifest within a period of 1 (one) year from the date of purchase

(“warranty period”).

2. Where the customer has purchased a product and it breaks, is defective or does not

work properly for the intended purpose, the customer must notify the supplier from whom

the customer bought the product (“the supplier”) thereof within the warranty period. Any

claim in terms of this warranty must be supported by a proof of purchase. If proof of

purchase is not available, then repair, and/or service charges may be payable by the

customer to the supplier.

3. The faulty product must be taken to the supplier's service centre to exercise the

warranty.

4. The supplier will refund, repair or exchange the product in terms of this warranty subject

to legislative requirements. This warranty shall be valid only where the customer has not

broken the product himself, or used the product for something that it is not supposed to

be used for. The warranty does not include and will not be construed to cover products

damaged as a result of disaster, misuse, tamper, abuse or any unauthorised modification

or repair of the product.

5. This warranty will extend only to the product provided at the date of the purchase and not

to any expendables attached or installed by the customer.

6. If the customer requests that the supplier repairs the product and the product breaks or

fails to work properly within 3 (three) months of the repair and not as a result of misuse,

tampering or modification by or on behalf of the customer, then the supplier may replace

the product or pay a refund to the customer.

7. The customer may be responsible for certain costs where products returned are not in

the original packaging, or if the packaging is damaged. This will be deducted from any

refund paid to the customer.

HOME OF LIVING BRANDS (PTY) LTD (JOHANNESBURG)

JOHANNESBURG TEL NO. (011) 490-9600

CAPE TOWN TEL NO. (021) 552-5161

DURBAN TEL NO. (031) 792-6000

www.homeoflivingbrands.com

34

Loading...

Loading...