Page 1

BUYING GUIDE

FOR INDUSTRIAL

AIR-BLAST CABINETS

Modular design

lets you select

the right pieces

for a perfect fit

EEMMPPIIRREE

PRO-FINISH® SYSTEMS

TM

Page 2

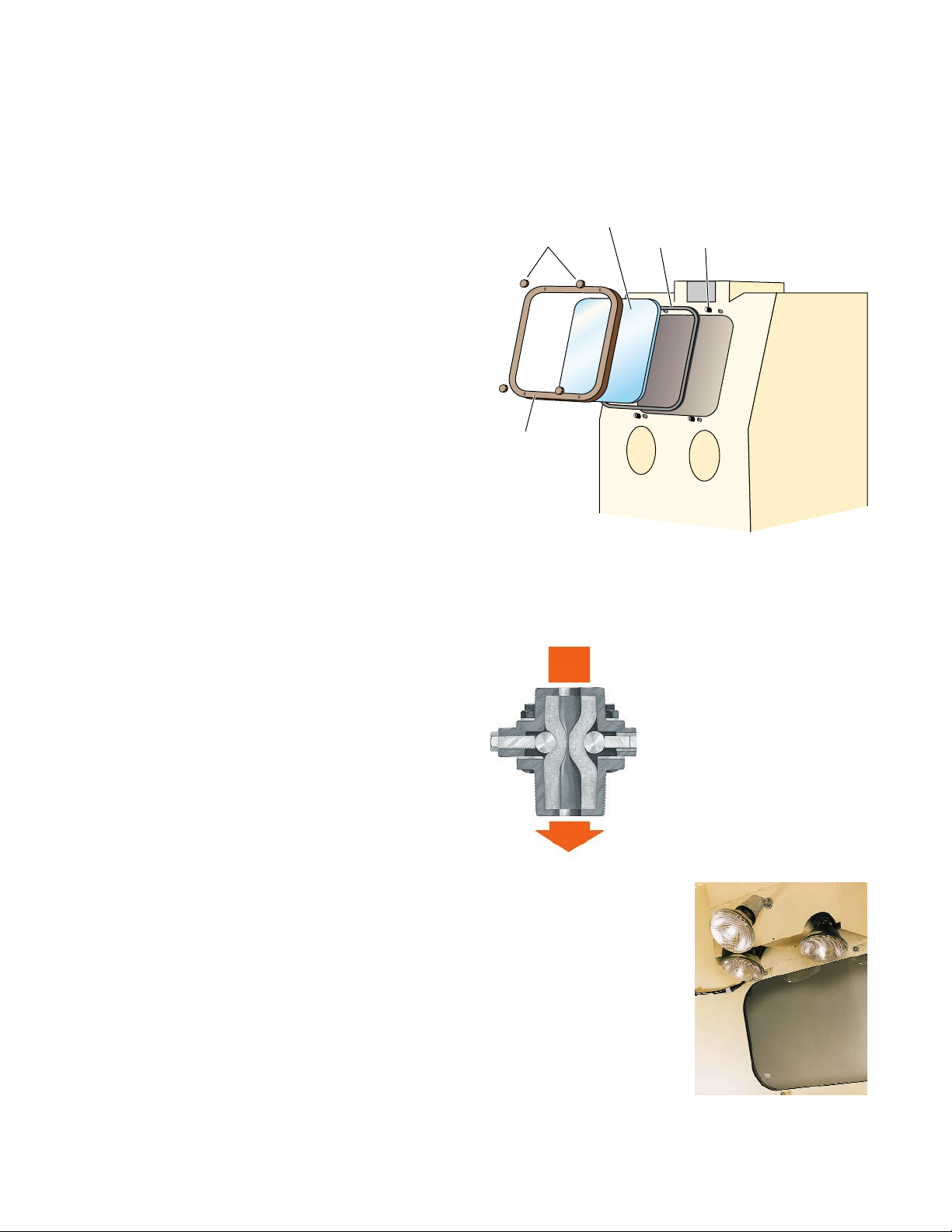

High-intensity flood lights

reduce the chances of over

blasting caused by poor visibility. Lights can be tilted to

focus illumination on areas

being blasted. Two lights are

supplied on 2636, 3648 and

4848 models; three are provided as standard on 6060

and 7272 cabinets.

Sure-Flo®media regulator (Patent No.

4,518,145), used on pressure cabi-

nets, is easy to adjust and assures

precise media regulation, as

well as continuous flow. These

regulators have excellent wear

characteristics and, once the metering tube is worn, it can be easily

replaced more quickly and economically than in any other media

regulator on the market.

-2-

STANDARD PRO-FINISH FEATURES

No other blast cabinet on the market today offers the

many practical benefits included on a Pro-Finish cabinet

as standard equipment. Just look at the features. The

standard components in a Pro-Finish system have been

carefully designed for safety, ease of operation, reduced

maintenance and increased productivity. Throughout,

these cabinets are built to meet the challenges of nonstop industrial blasting.

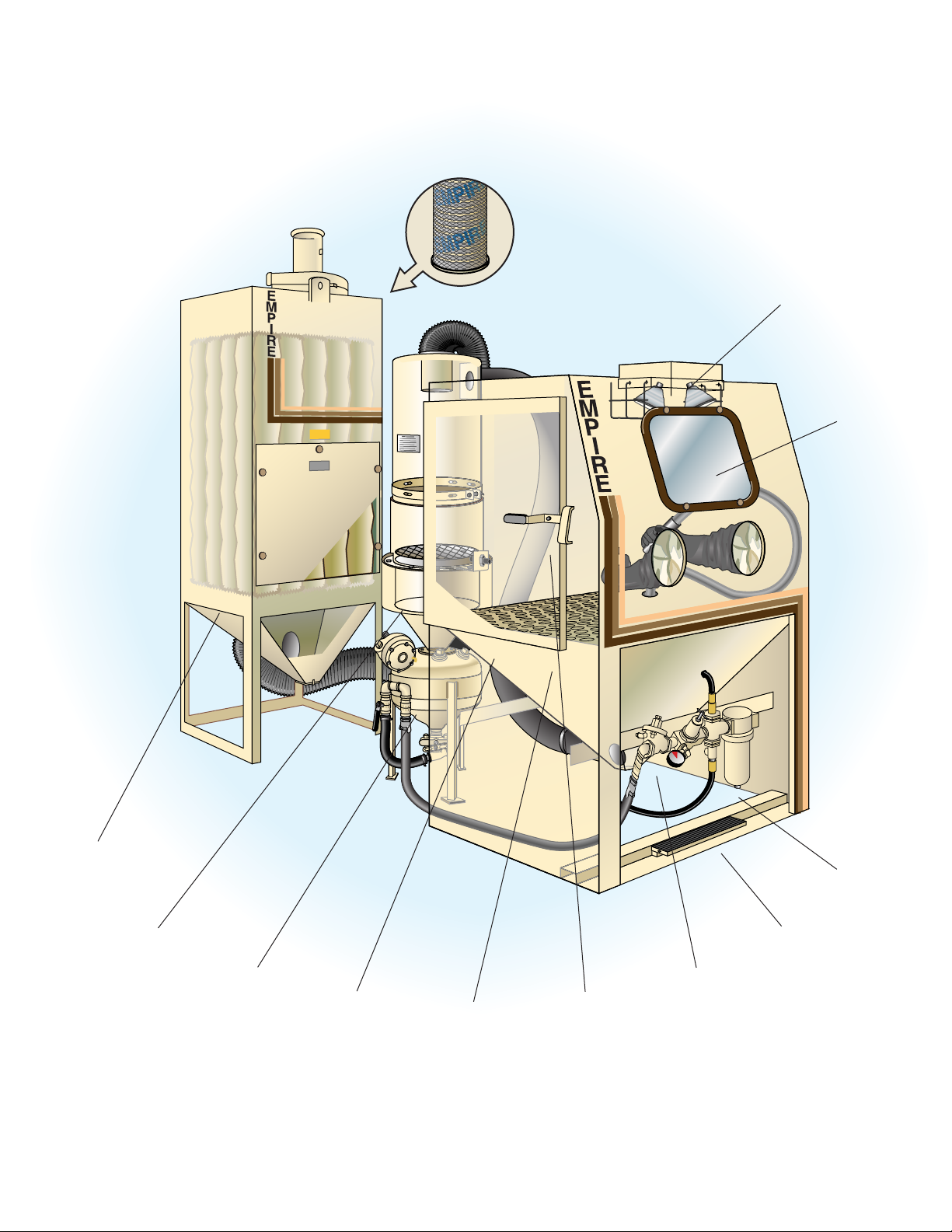

A

Dust collector features an energy-saving air-filtration

system that captures 99% of all particles one micron or

larger so cabinet ventilation can be recirculated. Fan is

mounted on dust collector rather than reclaimer to prevent abrasive wear to the fan housing and impeller.

Cartridge-type dust collectors, offering improved

efficiency and durability, are also available in 600, 900

and 1200 CFM models to simplify cleaning and maintenance.

B

Tunable reclaimers can be adjusted to control media

size. Externally adjustable tuning band requires no tools

and controls the size of fines extracted from the blast

media. Screen prevents oversized particles from causing

clogging and an easy access door permits quick filling.

C

One-cubic-foot pressure vessel minimizes refilling time

and seals automatically for fast, easy startup. Construction is ASME coded only.

D

Rigid, dual-panel doors stand up to abrasives and seal

more tightly than single-panel doors. Flush construction

minimizes media spill when the door is opened.

E

Safety-door switch (Patent No. 4,505,077) prevents

accidental blasting when doors are open. Complies with

OSHA requirements.

F

Self-adjusting door latch assures continued tight sealing as door gasket ages.

G

Simple, pneumatic controls deliver greater reliability

than electric controls employing limit switches and

solenoids that often stick and burn out.

H

Wide foot treadle enables operation with either foot.

I

Moisture separator improves efficiency and reduces

downtime by helping to prevent oil and moisture in supply lines from contaminating media.

J

Large, safety-glass window (14”x22”) can be changed

in a few minutes without tools and has rounded corners

for safe handling.

K

Kleensweep™ creates an air stream across the viewing

window to reduce dust buildup and improve visibility.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Window glass

Knobs

Gasket Bushing

Window

frame

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 3

E

M

P

IR

E

-3-

A

B

C

D

E

F

G

H

I

J

K

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

•••••••••••••••••••••••••••••••

Page 4

-4-

WHY YOU SHOULD CHOOSE

A PRO-FINISH

®

SYSTEM

If your operations involve cleaning with chemicals, acid

etching or dipping, liquid honing, wire brushing,

sanding, deburring, grinding or peening, odds are a ProFinish system will save you time and money.

• These cabinet systems, designed for non-stop blasting,

increase production rates because blasting is faster than

other manual methods.

• Their versatility enables you to perform multiple tasks,

ranging from blending surface flaws to removing foreign matter, such as carbon from pistons, without

affecting tolerances. By simply varying air pressure and

blast media, you can clean or peen and do a lot in

between.

• Modular design, including many standard factory

options, lets you select a system that’s just right for

you—without paying for features and accessories you

don’t need. Pro-Finish also gives you the choice of a

suction or pressure blast system.

• Blasting eliminates the environmental hazards associated with chemical finishing because most modern blast

media are non-caustic and non-toxic. Plus, Pro-Finish

systems put the emphasis on safety in mechanical ways

with features such as blasting interlocks on cabinet

doors, rounded corners on safety-glass viewing windows and guards on sharp floor edges, just to list a few.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

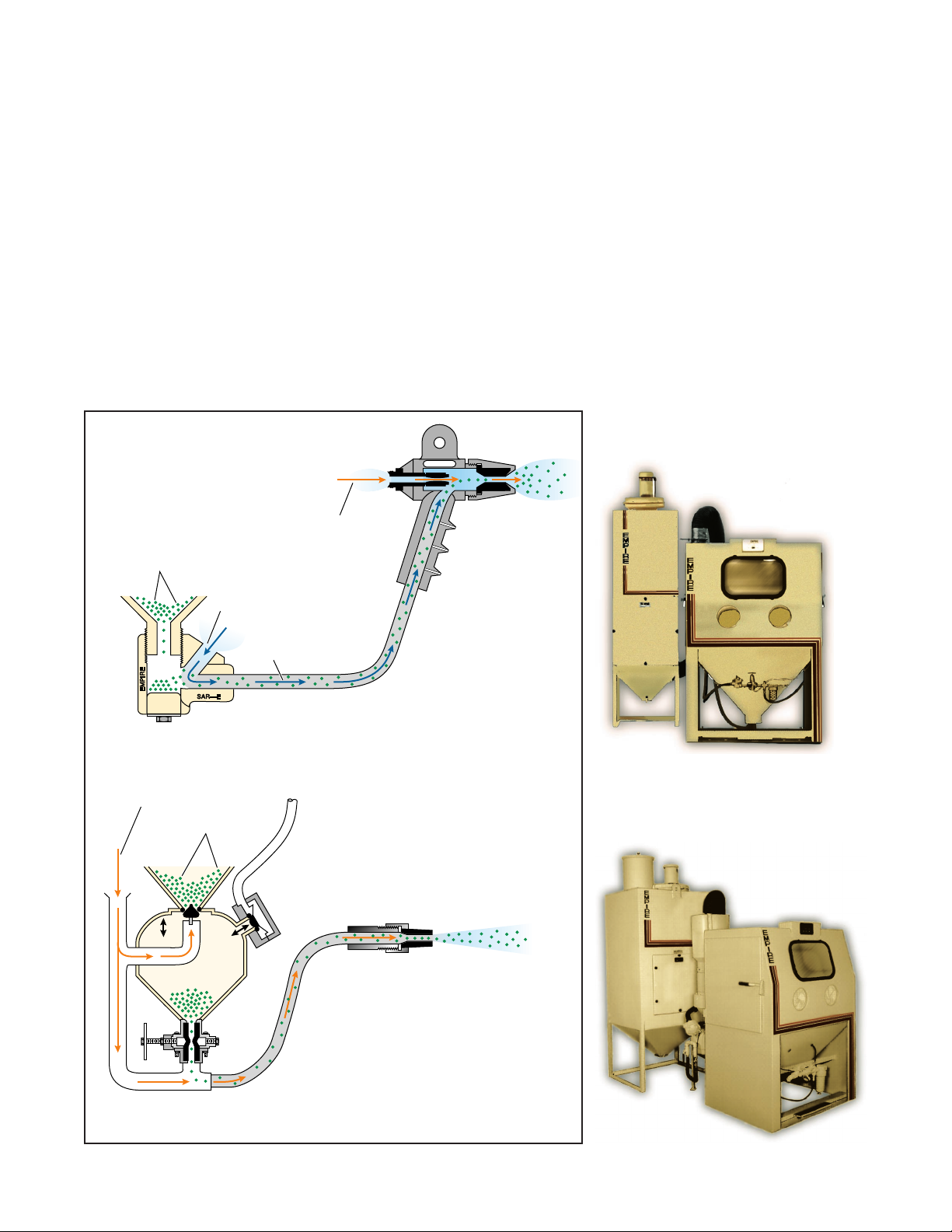

OPERATING PRINCIPLES

EMPIRE

Compressed air

Blast media

Negative pressure

SUCTION SYSTEMS

Compressed air

Blast media

Air flow

PRESSURE SYSTEMS

•••••••••••••••••••••••••••••••

Page 5

-5-

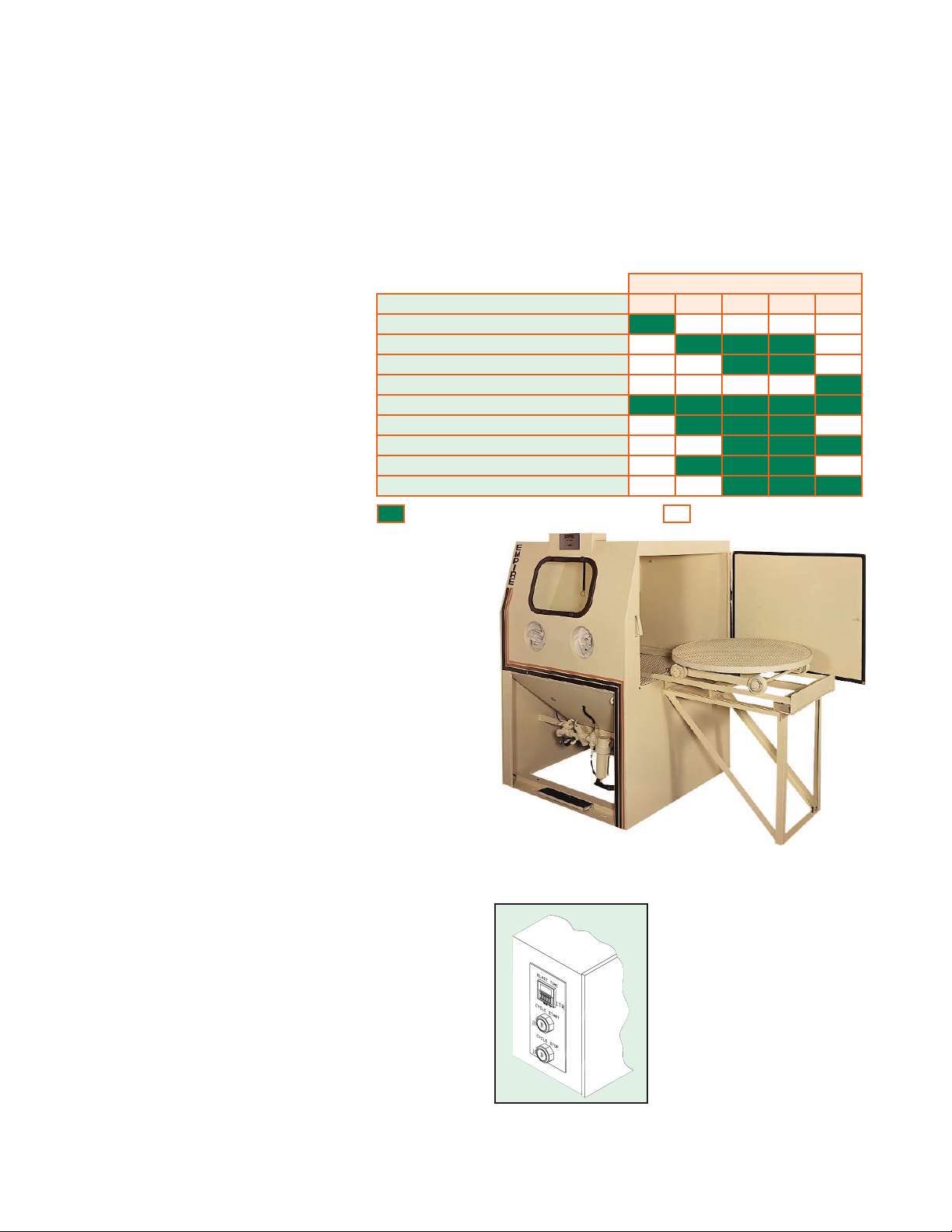

OPPORTUNITIES TO AUTOMATE

Powered movement of blast nozzles and/or workpieces

automates air-blasting operations to varying degrees.

For instance, using a powered turntable in combination

with oscillating nozzles makes many blast-finishing processes virtually automatic when a timer package is

added to control duration and on/off functions. Some

techniques for automating Pro-Finish cabinets—easily

and economically—are described below.

Turntables

Turntables, offered in both manual and

pneumatically powered models, facilitate

the handling of heavy parts and provide

opportunities for automation. Turntables

can be wheeled into or out of cabinets on a

dolly or track, or fixed inside cabinets.

Most stationary designs feature a low-profile,

giving operators easy “over-the-top” access

without wasting interior cabinet space.

Turntable sizes range from 18 to 48 inches

in diameter with load capacities of up to

1,500 pounds. (Turntables with higher

capacities are also available.) Powered

turntables, with speed ranges from 8-to-20

rpm, can be controlled by a manual on/off valve or tied

into an optional timer circuit for purposes of automation.

Gun Oscillators, Timers & Other Accessories

Gun oscillators, suitable for larger Pro-Finish cabinets,

can be used with powered turntables and multiple nozzles to reduce the number of guns required, therefore

reducing compressed-air consumption. The oscillator

will blend multiple passes of the nozzle, creating a more

uniform finish. Production rates increase as the benefits

of manual coverage and multi-gun blasting are combined.

A radially sweeping oscillator, powered by an air

cylinder, strokes as many as four blast guns through a

range of up to 18 inches. Stroke length, stroke speed and

on/off functions can also be controlled automatically.

Timers are employed to control the on/off functions

of blast guns, oscillators and turntables. Our 60-minute

spring timer is powered mechanically and works well

in most automated applications. Empire’s precision

reset timer, powered by a synchronous motor, always

clicks down from the same preset time. This feature,

along with large graduations on the timer dial, assure

more accurate control of blast durations.

When using timers with pressure systems, an adequate media supply must be available for the duration of

the blast process. Consequently, a larger pressure vessel

and/or media-level indicator should be considered.

Automatic door clamps lock the cabinet during

blasting. For environments in which passive dust emissions present a safety concern, a timer is added to allow

for adequate dust evacuation before the cabinet doors

are opened. When “close-to-clean-room” standards are

required, delay switches are supplied.

Turntables speed up parts handling and open

avenues to automation.

Precision reset timer

controls blast duration and

helps deliver consistent

results.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

24” Powered with Dolly & Track (1000 lb)

36” Powered with Dolly & Track (1000 lb)

TYPE OF TURNTABLE 2636 3648 4848 6060 7272

18” Manual with Dolly & Track (300 lb)

24” Manual with Dolly & Track (1000 lb)

36” Manual with Dolly & Track (1000 lb)

48” Manual with Dolly & Track (1500 lb)

18” Manual, Fixed inside (300 lb)

24” Powered, Fixed inside (300 lb)

36” Powered, Fixed inside (300 lb)

CABINET MODEL

Not available with this modelAvailable with model number shown above

•••••••••••••••••••••••••••••••

Page 6

Pressure (PSI) 30 40 50 60 70 80 90 100

1/4” nozzle, 3/32” air jet 6 7 8 10 11 12 13 15

1/4” nozzle, 1/8” air jet 10 12 15 17 19 21 23 26

5/16” nozzle, 5/32” air jet* 15 19 23 27 31 37 38 42

7/16” nozzle, 7/32” air jet 31 38 45 52 59 66 73 80

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

SUCTION CABINETS

Suction-Blast Air Requirements (SCFM) Suction-Blast Spray Diameters

-6-

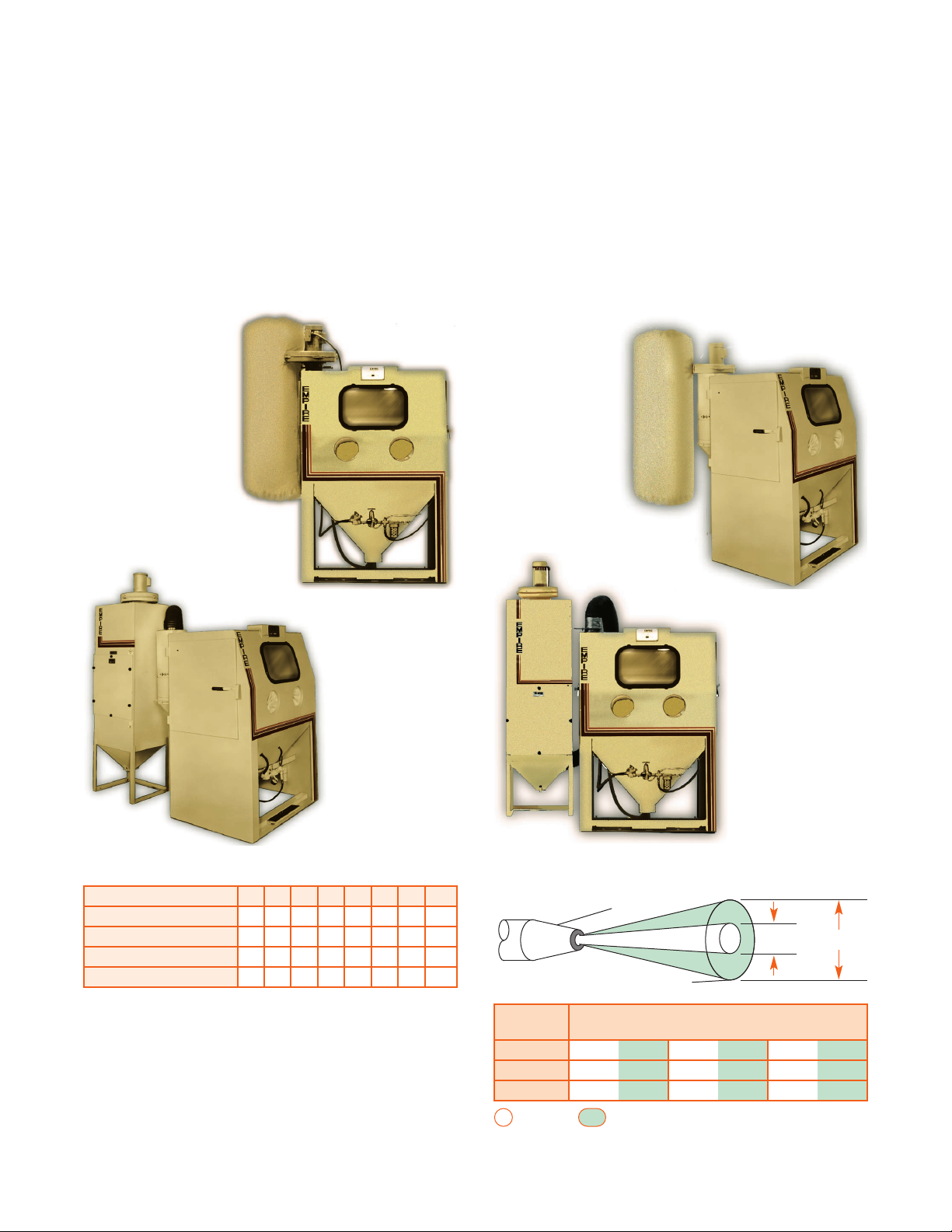

Pro-Finish suction cabinets cost less and are simpler

than pressure cabinets. They also blast continuously

without the need to stop for media refills, and they simplify the use of multiple nozzles. The results are usually

comparable to those achieved with a pressure system

although production rates are not as high. When initial

cost and maintenance are primary concerns, the suction

system is a good choice.

Pro-Finish suction systems come in five sizes and

can be specified with a collector or dust bag on smaller

units.

A media reclaimer is optional. Nevertheless, when using

media that can be recovered, a reclaimer is advisable

because it normally pays for itself quickly in terms of

reduced waste and high-quality, repeatable results.

Pro-Finish suction cabinets are available with many

factory options that contribute to ease of operation,

reduced maintenance and greater productivity.

Plus, Pro-Finish’s modular design lets you upgrade to

a pressure system in the field at any time, enabling you

to build on your original investment.

SRB (Suction

with reclaimer

and bag)

SC (Suction with

collector)

*Unless otherwise specified, this nozzle is supplied.

4 SCFM = 1 compressor horsepower.

SRC (Suction

with reclaimer

and collector)

SB (Suction with bag)

GUN

ID 6” 12” 18”

1/4” 1-3/8” 2-5/8” – 2-3/4” – 1”

5/16”* 1-1/2” 3-1/2” 1-3/4” 4-1/2” – 3-3/4”

7/16” 2” 3-3/4” 2” 4-1/2” – 3-3/4”

Gun

Spray Diameter

Distance from Workpiece

Hot Spot Brush-off

Hot Spot Brush-off *Standard nozzle

•••••••••••••••••••••••••••••••

Page 7

-7-

SUCTION BLAST OPTIONS

Multiple blast guns add to the speed and versatility of

Pro-Finish suction cabinets. A total of four guns can be

employed to facilitate the automated blasting of parts

with irregular profiles. In addition to short-handle guns,

the multiple-gun option includes individual shut-off

valves, a one-inch pipe string, required hoses, and holders for gun positioning. Multi-gun packages include a

4.5-cubic-foot media storage hopper with easy access for

loading and media inspection.

Fixed gun holder is adjustable to position gun in any

orientation so operator can use both hands to manipulate

workpieces within the blast stream.

Rotating basket, which attaches to cabinet door,

automates batch finishing of small workpieces. The basket attachment includes its own drive motor and

60-minute timer. In addition, it is removable, which

helps in unloading of parts and permits the cabinet to be

used for manual blasting of larger workpieces.

The basket attachment is typically used with suction

cabinets, but may be fitted to a pressure system having

adequate media supplies. It will handle 15 pounds or 200

cubic inches of “flowable” parts and can be specified

with an abrasion-resistant coating for longer service life.

Empire also produces dedicated basket-blasting

machines in a variety of models and sizes.

Kleen package consists of trays mounted under the

cabinet-door opening and a return hose on the suction

media regulator. Door trays prevent dust, which clings to

the cabinet doors, from dropping onto the floor when the

doors are opened. If the blast nozzle plugs, the pressurized media will not spill out of the media-regulator air

intake. Instead, it is routed to the blast cabinet.

Kleen-package door trays are also available with pressure blast cabinets.

Kleen Package

(Diagram)

Fixed gun holder frees operator to manipulate parts.

4.5-cubic-foot media storage

hopper provides a large supply

of abrasives to support up to

four blast guns.

“Two-in-One”

basket turns Pro-

Finish cabinet into

a dual-purpose

machine capable

of finishing small

parts automatically.

Door trays

Return hose

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

•••••••••••••••••••••••••••••••

Page 8

Pressure (PSI) 20 30 40 50 60 80 100 120

1/8” nozzle 6 8 10 13 14 17 20 25

3/16” nozzle* 15 18 22 26 30 38 45 55

1/4” nozzle 27 32 41 49 55 68 81 97

5/16” nozzle 42 50 64 76 88 113 137 152

3/8” nozzle† 55 73 91 109 126 161 196 220

PRESSURE CABINETS

Pressure-Blast Air Requirements (SCFM)

Pressure-Blast Spray Diameters

-8-

Because pressure cabinets deliver blast media at higher

velocities than suction systems, a Pro-Finish pressure

cabinet is ideal for turning out work fast. In many applications, these pressure cabinets will perform jobs

four-times faster than suction systems. In addition, they

use compressed air more efficiently and provide more

precise blasting control at both high and low operating

pressures. For really demanding tasks, like removing

tight mill scale or finishing hard-to-reach surfaces, a

pressure system is normally the only practical choice.

Pro-Finish pressure cabinets come in six sizes with

dust collectors and media reclaimers provided as standard

equipment. (Less expensive dust bags can be specified

with some models—see specifications on pages 16 and

17.)

With Empire reclaimers, Pro-Finish pressure cabinets

not only reduce operating costs associated with the purchase and disposal of media, but also assure consistent

results shift after shift. Plus, they are available with

options designed to meet almost any production need.

*Unless otherwise specified, this nozzle is supplied.

†This nozzle supplied on FaStrip cabinets.

4 SCFM = 1 compressor horsepower

Compressors should be sized to the next larger nozzle to allow for

nozzle wear.

PRC (Pressure with reclaimer and collector)

PRB (Pressure with reclaimer and bag)

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Nozzle

Hot Spot Brush-off

Spray Diameter

Nozzle Distance from Workpiece

ID 6” 12” 18”

1/8” 3/4” 1” 1” 1-1/2” – 1-1/8”

3/16”* 1-1/4” 1-3/8” 1-1/2” 2” 1-5/8” 2-1/2”

1/4” 1-1/4” 1-1/2” 1-7/8” 2-1/4” 2-1/8” 2-3/4”

†

3/8”

1-5/8” 1-3/4” 2” 2-1/4” 2-1/4” 3”

Hot Spot Brush-off *Standard nozzle †FaStrip nozzle

•••••••••••••••••••••••••••••••

Page 9

-9-

PRESSURE BLAST OPTIONS

Fine-tuning controls, incorporating Empire’s automatic

Sure-Flo

®

media regulator, enable the operator to adjust

the richness of the air-to-grit mixture from the front of

the cabinet while he works. As a result, dialing in the

optimum air-to-grit ratio for a particular job is greatly

simplified. To further assist the operator, an indicator

displays relative grit richness within the blast stream.

In applications where media are changed frequently—or where contamination can cause periodic clogging

of the girt valve—a push-button choke is available on

the same control panel.

Fixed-orifice media regulator is attached below the

Sure-Flo valve in applications, such as shot peening,

where very precise metering is required.

Low media-level sensor and indicator warns the

operator when the media supply in the pressure vessel is

low. The indicator/sensor consists of an electronic probe

in the pressure vessel that activates a signal light mounted on the front of the cabinet.

3.5-cubic-foot pressure vessel triples the amount of

blasting that can be accomplished between media refills.

This larger vessel is especially valuable when using a

large blast nozzle or a second nozzle. This option also

includes a three-cubic-foot media-storage hopper,

mounting brackets and longer hoses.

Two pressure-blast nozzles can be supplied with

Pro-Finish systems to increase coverage and reach multiple faces on parts such as screw threads or root

sections. Finishing speed is double that of an ordinary

high-production pressure system. The two nozzles can

be turned on and off individually with manual valves.

Two holders are included for nozzle positioning.

Fixed-nozzle holder, which bolts anywhere on the

cabinet wall, can be adjusted to position the nozzle in

any orientation, leaving both of the operator’s hands

free to maneuver workpieces.

NOTE: Some option combinations are not available.

For information, please consult Empire or your local

Empire distributor.

Fine-tuning controls let operator adjust air/grit ratio

from front of cabinet for optimum results.

Fixed-nozzle

holder frees

operator to

manipulate

parts.

3.5-cubic-foot,

ASME pressure vessel

extends operating intervals

between media

refills.

Two pressure-blast nozzles

increase blast coverage and

finishing speed.

Sight glasses permit viewing into

pressure vessel—

even when

pressurized—for

quick, accurate

checks on media

level.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

•••••••••••••••••••••••••••••••

Page 10

-10-

STANDARD PRO-FINISH OPTIONS

Pro-Finish cabinets are available with a wide range of

factory options designed to reduce maintenance and

improve operating efficiency. In addition, these cabinets

can be automated to further enhance productivity and

consistency. Nearly every option is easily retrofitted to

existing systems.

Extended-Wear Components

Empire’s extended-wear components increase service

life in an aggressive or high-production environment.

These components are normally very cost-effective

because they reduce downtime as well as expenses for

repairs and maintenance. Also, they are sold individually

so you can tailor features to your specific application

and budget.

The addition of rubber curtains increases cabinet

life. These free-hanging liners, made of black 1/8” neoprene and held in place with rubber knobs for easy

replacement, actually last longer than steel in an abrasive environment. White rubber is also available to

brighten the cabinet interior. Beyond protecting the cabinet, these curtains resist discoloration much longer than

white paint on steel.

Window protectors can be provided in clear plastic

or a perforated screen to reduce clouding and pitting.

Matting is offered for turntables and cabinet floors to

pad parts and prolong the life of steel-support surfaces.

Pro-Finish systems with reclaimers offer a number of

protective options:

• Heavy-duty, media-conveying duct made of

smooth-wall, wire-reinforced PVC for long service

• Inlet wear-plate (easily replaceable) to protect the

most vulnerable part of the reclaimer

• Urethane coating that extends the service life of

interior wear surfaces by five times

• Ultra-wear lining, as an alternative, that increases

normal service life by a factor of ten

Di-Carb

®

nozzles (tungsten carbide) are available for

use with steel abrasives and glass beads, as are boron

carbide nozzles for applications involving aluminum

oxide, silicon carbide and garnet.

Empire or your local Empire distributor can assist

you in selecting the extended-wear components most

beneficial in your air-blasting operations.

Media Control and Conditioning Options

For more efficient cycling of fine media, a vibrating

screen can be added to the reclaimer on Pro-Finish suc-

tion systems. On pressure systems, Empire’s automatic

Sure-Flo media regulator, in combination with the

MG-78 CR exhaust valve, can also be included to

assure smooth, consistent operation. These devices overcome problems associated with very fine abrasives

(200-300 mesh range), low-density media (e.g., plastics

and walnut shells), and high humidity.

In addition, Empire’s automatic Sure-Flo regulator

conserves energy by retaining compressed air within the

pressure vessel between shut-down and start-up.

Automatic Sure-Flo media regulator promotes

consistent media flow and reduces energy costs.

Empire MH-2 blast

guns or pressure

nozzles are available with tungsten

carbide or silicon

carbide to reduce

wear with certain

types of media.

Rubber curtains,

available in white to

enhance visibility,

protect the cabinet

interior and are

easy to replace.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

•••••••••••••••••••••••••••••••

Page 11

ADDITIONAL CABINET OPTIONS

DUST COLLECTOR OPTIONS

-11-

Pneumatically powered vertical-lift doors save floor

space and facilitate loading and unloading of parts when

used in combination with rolling turntable dollies. Several safety features assure the door will not close

accidentally. A pneumatic sensor is also provided to

prevent blasting whenever the door is open in accordance with OSHA standards.

Engineered for smooth operation, Pro-Finish verticallift doors are guided in plastic tracks. The door is fully

sealed with gaskets to keep media inside the blast cabinet. Rubber lining and heavy-duty construction provide

long service life.

Rubber safety mats, with holes to catch spilled particles, are placed around the blast cabinet to keep

adjacent work areas clean and prevent injuries from

falls, especially when slippery spherical media is used.

The mats also dissipate static electricity, provide a comfortable surface on which to stand, and improve the

appearance of the work area.

Cabinet sound attenuator, mounted over the air

inlet, suppresses blasting noise from the cabinet by

absorbing sound waves and directing them away from

the operator.

Static strap, worn on the operator’s wrist, dissipates

static electrical charges, preventing shocks to the operator that may occur when humidity in the working

environment is low.

System security key-lock, prevents use of the cabinet by unauthorized personnel. By retaining the key,

supervisors are better able to keep track of why, when

and by whom the system is being used.

Fan sound attenuator reduces the noise level of ProFinish dust collectors below 85 db(A) in accordance

with OSHA standards. These sound attenuators include

a cover that can be adjusted to prevent light media from

being carried through the system to the dust collector.

Automatic bag shaker signals a powered cylinder to

automatically shake accumulated dust from the bags

every time the machine is turned off. Several minutes of

shaking cleans bags thoroughly, which extends their service life and improves visibility within the cabinet.

Automation of this process also frees the operator for

more productive tasks.

Manometer keeps the operator up to date regarding

the cleanliness of the dust bags by registering the pressure drop across the bags whenever the fan is running.

Automatic pulse-check cleaner on CDC cartridgetype collectors assures thorough and timely cleaning for

optimum performance.

Fan sound attenuator on Pro-Finish dust collectors

reduces noise levels below 85 db (A) in accordance

with OSHA standards.

Vertical-lift doors work

smoothly and seal tightly

to prevent media leaks.

Plus, they are the safest in

the industry.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

•••••••••••••••••••••••••••••••

Page 12

Empire offers a number of standard Pro-Finish variations for specialized air-blasting jobs.

Ergo-Blast systems, for instance, increase productivity by improving operator performance during extended

periods of continuous blasting. These cabinets are

ergonomically designed for sit-down operation and

include other features to reduce fatigue. As a result,

machine operators concentrate on the job at hand when

working for hours on repetitive tasks rather than trying

to find the best position to relieve a sore back. By

removing everyday distractions, Ergo-Blast cabinets

maximize production.

ERGO-BLAST CABINETS

ECONO-FINISH®CABINETS

FaStrip®CABINETS

-12-

Pro-Finish FaStrip cabinets are specifically designed for

use with low-density media, such as plastics, that provide fast coverage without eroding substrates. Paint

stripping, for example, can be performed quickly and

economically without the use of hazardous chemicals.

FaStrip cabinets deliver plastic or organic media from

a large venturi nozzle coupled to a grounded, flexible

blast hose. A large, vibrating screen within the reclaimer

and Empire’s exclusive automatic Sure-Flo media regulator, working in tandem with the MG-78 CR exhaust

valve, keeps light media flowing smoothly. A magnetic

separator is also included in the system to extract ferrous

particles that can damage delicate substrates.

Ergo-Blast cabinets

improve operator efficiency.

FaStrip cabinets

remove old coatings

quickly without

damaging

delicate substrates.

Magnetic separator

extracts ferrous

debris and can be

removed easily for

cleaning.

See pages 15, 16 and 17 for available Ergo-Blast

models, part numbers, general specifications, shipping weights and dimensions.

See pages 15 and 17 for available FaStrip models,

part numbers, general specifications, shipping

weights and dimensions.

Ergo-Blast Features

• Knee-hole indentation for sitting operation

• Elevated foot rest for treadle control

• Elevated, padded arm rest that pivots

• Top-entry nozzle to take weight off operator’s hand

• Cabinet sound attenuator

• Door trays to catch stray dust

• Available in FaStrip models

FaStrip Features

• Automatic Sure-Flo saves air, smooths media flow

• MG-78 CR exhaust valve improves media control

• Magnetic separator removes ferrous particles

• Vibrating reclaimer screen removes large debris

• Available in Ergo-Blast configurations

These economical cabinets

offer exceptional value

when used in light-duty

service. Despite their

low cost, Econo-Fin-

ish cabinets can be

specified with media

reclaimers as well as

dust-collection

options approved by

OSHA.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

•••••••••••••••••••••••••••••••

Page 13

-13-

DUAL-STATION CABINETS

PRESSURE CONVERSION KITS

THE PRO-FINISH 7272

This cavernous cabinet will accept large parts, yet it is

less expensive than a blast room, and it eliminates the

need for operators to suit-up in protective clothing. In

addition, the 7272 cabinet makes blasting surprisingly

easy because the operator’s gloves can be positioned at

two different levels to accommodate variations in operator or workpiece height. Thanks to a dual-cone bottom,

the floor height is quite low, enabling the operator to

reach work surfaces without having to continually reposition parts in the blast enclosure.

Manufactured from 11-gauge plate steel with continuously welded seams, this rugged cabinet has a floor

capacity of 1500 pounds. The blast hose enters from the

top to relieve operator strain, and a serpentine mediareturn hose eliminates problems associated with the use

of “Y” branches.

The unit shown is equipped with a powered door and

parts-loading option consisting of a turntable dolly that

rolls over tracks on the door’s interior. Because the door

is closed upward by a pneumatic piston, this assembly

reduces vertical space requirements and provides an

excellent seal. Double-winged doors are also available

on 7272 cabinets without turntables.

In addition to 3696 and 60120 dual-station cabinets,

both of which offer two operating systems, Empire now

provides the 3674: a cabinet connecting two work stations to a single operating system. The 3674 handles

larger parts at a lower cost. Each work station in the unit

includes its own viewing window and set of sealed

gloves, but the two stations share one blast hose and

nozzle/gun assembly. The blast controls, as well the

nozzle/gun connections, are arranged to give the operator full access to larger parts from either work station.

The 3674 cabinet is offered with suction or pressure

operating systems (3674 SRC-9 and 3674 PRC-9,

respectively) and a FaStrip model (FS 3674 PRC-9).

Suction cabinets equipped

with reclaimers can be converted easily to more efficient

pressure-blast systems in the

field. All the pressure components, including a one-inch

pipe string, are provided in

the conversion kit. The steps

are simple. Bolt the pressurevessel assembly onto the

reclaimer, route the blast hose,

connect control lines, and

you’re ready to enjoy the benefits of pressure blasting.

Suction cabinets produced

by other manufacturers can

also be converted to an

Empire pressure system. Ask

Empire or your local Empire

distributor for details.

Pressure-conversion kits upgrade suction cabinets

to pressure operation in the field.

3674

cabinets

handle

larger parts

at lower

costs.

This 7272 “finishing center” with two work stations and

baffled, circular vestibules for loading pipe is just one

example of the modifications Empire performs routinely. We can produce cabinets equipped to process

hard-to-handle parts. Plus, we can add as much—or as

little—automation as you

need to reduce labor costs

and boost production

rates. In many cases, one

of our modified

cabinets finishes

way ahead of an

automated sys-

tem or blast

room on your

bottom line.

MODIFIED PRO-FINISH CABINETS

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

•••••••••••••••••••••••••••••••

Page 14

-14-

PRO-FINISH MEDIA RECLAIMERS

PRO-FINISH DUST COLLECTORS

Media reclamation can be one of the most critical

aspects of air-blasting processes. In addition to media

costs, reclaimer performance affects operating speed

and quality. Failure to remove dust and fines has an

adverse effect on consistency and productivity. If oversized particles are returned to the blast system, for

example, clogging and/or inconsistent results often

occur.

Pro-Finish reclaimers provide precise control of

media recycling. These reclaimers can be adjusted to

control the recovery of fine, medium or coarse working

materials while removing unwanted particles from the

blasting process. As a result, you enjoy reduced media

costs as well as consistent, high-quality results.

All Pro-Finish reclaimers deliver 99% efficiency,

include a screen to prevent over-sized particles from

clogging, provide an easy-open access door for quick

cleaning and filling, and feature 12-gauge construction

RECLAIMER GLASS ALUMINUM STEEL STEEL

CFM BEADS OXIDE GRIT SHOT

400 ALL 46 120 S-70

600 ALL 36 80 S-110

900 ALL 36 80 S-110

1200 ALL 30 40 S-170

Media/Reclaimer Compatibility

Chart shows the maximum media sizes recoverable with single-gun/nozzle

systems. Multiple guns, larger nozzles, operation at altitudes above 5000

feet, or use of a 50-Hz electrical supply may require a larger reclaimer and

dust-collector blower. Larger sizes may be used. Consult factory.

Available in both bag- and cartridge-type designs, ProFinish dust collectors improve working conditions while

reducing maintenance and operating costs. By capturing

99% of all particles one micron or larger, these efficient

dust collectors permit filtered air to be recirculated into

the plant, thus providing significant savings on heating

and air conditioning.

Other features of Pro-Finish dust collectors include:

• Fan blade on clean-air side for long life

• 14-gauge, reinforced construction

• Raised clean-out opening for fast waste removal

• Top-clean air discharge for operator comfort

• Easy push-button control for thorough cleaning

• Cartridge models for simplified maintenance

RECLAIMER OPERATING PRINCIPLES

All Pro-Finish media reclaimers are

tunable. By adjusting a fine-tuning

band on the reclaimer, the amount of

air introduced into the system can be

controlled to assure precise separation

of functional media from dust and other

unwanted debris.

As spent media, dust and debris

are pulled by air flow to the reclaimer

inlet, incoming air and media spiral in a

downward vortex, throwing larger particles against the outer reclaimer wall.

An air stream forms an upward counter

vortex through the center tube, which

carries out dust while heavier particles

drop into the storage hopper below for

reuse. A screen catches any oversized

debris.

Dust and undersized debris are

drawn from the reclaimer into the bottom of the dust collector. Sudden

expansion forces heavier dust particles

to the bottom. Remaining fine dust is

pulled to the surface of the dust filters.

Clean air can then be discharged to the

work area.

NOTE: The CFM of all Pro-Finish

reclaimers is rated at nominal static

working pressure of 6” water, with

the exception of the 1200 CFM

model, rated at 10” static pressure.

Competitive units may appear to

achieve higher CFM due to ratings

based on inadequate working static

pressure.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Silencer

Kleensweep

Air flow

Debris

Compressed air

Cabinet Dust collector

Path of noise

Bag shake

Reclaimer

Tuning

ports

Blast

media

Blast system

Clean air

discharge

Dust

•••••••••••••••••••••••••••••••

Page 15

MODEL DCM-80A DCM-200 DCM-200A DCM-200B CDC-6 CDC-9 CDC-12

Dimensions (DxWxH) 21”x26”x98” 34”x39”x107” 34”x39”x105” 34”x39”x116” 34”x39”x115” 34”x39”x115” 34”x39”x118”

With Sound Attenuator

29”x31”x107” 40”x41”x112” 40”x39”x112” 40”x39”x127”———

& Automatic Bag Shaker

With Sound Attenuator

& Photohelic Package

————34”x48”x120” 34”x48”x120” 34”x48”x123”

CABINET MODEL SIZE 2636 3648 3674 4848 6060 7272

A) Door opening depth (ID) 20” 29” 29” 41” 50” 64”

B) Door opening height (ID) 22” 32” 32” 32” 40” 58”

C) Height from turntable to top of door opening

Stationary manual turntable 17” 27”— 27” 35”—

Rolling manual turntable 15” 25” 25” 25” 33” 44”

Rolling powered turntable — 21” 21” 21” 29” 38”

Low-profile turntable 20” 30”— 30” 38”—

D) Exterior height 72” 75” 75” 75” 80” 84”

E) Height from enclosure floor to glove-entry midpoint 10” 10” 10” 10” 10” 25” to 29”

F) Height from cabinet base to enclosure floor 34” 34” 34” 34” 34” 28”

G) Cabinet depth (exterior) 26” 36” 36” 48” 60” 72”

H) Cabinet width (exterior) 36” 48” 74” 48” 60” 72”

Floor area 42 ft

2

59 ft

2

90 ft

2

80 ft

2

87 ft

2

163 ft

2

Access points

******

PRO-FINISH DIMENSIONS

-15-

Standard Cabinets

( See “SIDE VIEW” for A, B, C, D, E, and F. See “PLAN VIEW” for G, H, floor area and access points.)

Dust Collectors

Dust Bags

NOTES TO CABINET DIMENSIONS

• System shown includes cabinet, reclaimer, dust collector, turntable and some popular options. (Other configurations and options will affect

dimensions, which are approximate and subject to change.) • Dust collector, reclaimer and options can be rearranged within limits to suit

particular installations. • Floor areas shown indicate basic reclaimer/dust-collector sizes and include operator access points as well as

turntable and platform. • Height includes reclaimer and dust-collection hose.

SIDE

VIEW

PLAN VIEW

A

B

C

E

F

G

H

*

*

*

*

D

Dimensions (DxWxH): 24”x30”x83”

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

•••••••••••••••••••••••••••••••

Page 16

MODEL PART NUMBER DUST BLOWER SHIPPING

NUMBER NUMBER OF DOORS COLLECTION MOTOR

WEIGHTT

2636 SB 102010 1 standard Dust bag 1 hp 421 lbs

2636 SC 102011 1 standard DCM-80A 1 hp 671 lbs

2636 SRB-4 102000 1 standard Dust bag 1 hp 451 lbs

2636 SRC-4 102001 1 standard DCM-80A 1 hp 701 lbs

2636 SRC-4 (ERGO) 120001 1 standard DCM-80A 1 hp 800 lbs

3648 SB 103010 2 standard Dust bag 1 hp 539 lbs

3648 SC 103011 2 standard DCM-80A 1 hp 789 lbs

3648 SRB-4 103000 2 standard Dust bag 1 hp 565 lbs

3648 SRC-4 103001 2 standard DCM-80A 1 hp 819 lbs

3648 SRC-4 (ERGO) 121001 2 standard DCM-80A 1 hp 920 lbs

3648 SRC-6 103021 2 standard DCM-200 1-1/2 hp 1266 lbs

3648 SRC-6 (CDC) 103051 2 standard CDC-6 1-1/2 hp 1575 lbs

3648 SRC-6 (ERGO) 121021 2 standard DC-200 1-1/2 hp 1365 lbs

3648 SRC-6 (CDC, ERGO) 121051 2 standard CDC-6 1-1/2 hp 1665 lbs

3674 SRC-9 128021 2 standard DCM-200A 2 hp 1760 lbs

3674 SRC-9 (CDC) 128051 2 standard CDC-9 2 hp 2060 lbs

3696 SB/TWIN 106010 2 standard (2) Dust bags (2) 1 hp 1078 lbs

3696 SC/TWIN 106011 2 standard (2) DCM-80A (2) 1 hp 1578 lbs

3696 SRB-4/TWIN 106000 2 standard (2) Dust bags (2) 1 hp 1138 lbs

3696 SRC-4/TWIN 106001 2 standard (2) DCM-80A (2) 1 hp 1638 lbs

3696 SRC-4/TWIN (ERGO) 124001 2 standard (2) DCM-80A (2) 1 hp 1840 lbs

3696 SRC-6/TWIN 106021 2 standard (2) DCM-200 (2) 1-1/2 hp 2632 lbs

3696 SRC-6/TWIN (CDC) 106051 2 standard (2) CDC-6 (2) 1-1/2 hp 3232 lbs

3696 SRC-6/TWIN (ERGO) 124021 2 standard (2) DCM-200 (2) 1-1/2 hp 2850 lbs

3696 SRC-6/TWIN (CDC, ERGO) 124051 2 standard (2) CDC-6 (2) 1-1/2 hp 3450 lbs

4848 SC 104011 2 standard DCM-200 1-1/2 hp 1376 lbs

4848 SRC-6 104001 2 standard DCM-200 1-1/2 hp 1423 lbs

4848 SRC-6 (ERGO) 122001 2 standard DCM-200 1-1/2 hp 1525 lbs

4848 SRC-6 (CDC, ERGO) 122051 2 standard CDC-6 1-1/2 hp 1825 lbs

4848 SRC-9 104021 2 standard DCM-200A 2 hp 1458 lbs

4848 SRC-9 (ERGO) 122021 2 standard DCM-200A 2 hp 1566 lbs

4848 SRC-9 (CDC, ERGO) 122052 2 standard CDC-9 2 hp 1860 lbs

6060 SC 105011 2 standard DCM-200A 2 hp 1669 lbs

6060 SRC-9 105001 2 standard DCM-200A 2 hp 1736 lbs

6060 SRC-9 (CDC) 105051 2 standard CDC-9 2 hp 2036 lbs

60120 SC/TWIN 107011 2 standard DCM-200A 2 hp 3338 lbs

60120 SRC-9/TWIN 107001 2 standard DCM-200A 2 hp 3472 lbs

60120 SRC-9/TWIN (CDC) 107051 2 standard CDC-9 2 hp 4072 lbs

7272 SRC-9 127001 1 standard DCM-200A 2 hp 2700 lbs

7272 SRC-12 127023 1 standard DCM-200B 5 hp 2800 lbs

SUCTION CABINET SPECIFICATIONS

-16-

NOTES TO SPECIFICATIONS:

All cabinet sizes feature 14-gauge steel construction with the exception of 7272 cabinets which are

11-gauge. Cabinets with a single door open on the right-hand side. (An additional left-hand door is optional.) For information on electricals,

reclaimer sizing and dust collection, see “APPLICATION CONSIDERATIONS” on page 18.

MEANING OF MODEL NUMBERS AND LETTER CODES:

The first two numbers indicate nominal cabinet depth in inches.

The next two or three numbers show nominal cabinet width. Letters following model numbers mean the following: S = Suction; P = Pressure; B = Bag; C = Collector; R = Reclaimer. Numerals following letter codes show reclaimer-ventilation capacity in hundreds of CFM at 6”

S.P. (1,200 CFM units are rated at 10” S.P.) “TWIN” indicates a two-cabinet system. (Example: a 60120 TWIN consists of two 6060 cabinets) Letter codes in parentheses translate as follows: CDC = Cartridge Dust Collector; ERGO = Ergo-Blast model; FS = FaStrip model.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

•••••••••••••••••••••••••••••••

Page 17

MODEL PART NUMBER DUST BLOWER SHIPPING

NUMBER NUMBER OF DOORS COLLECTION MOTOR

WEIGHTT

2636 PRB-4 102100 1 standard Dust bag 1 hp 664 lbs

2636 PRC-4 102101 1 standard DCM-80A 1 hp 914 lbs

2636 PRC-4 (ERGO) 120101 1 standard Dust bag 1 hp 1015 lbs

3648 PRB-4 103100 2 standard Dust bag 1 hp 782 lbs

3648 PRC-4 103101 2 standard DCM-80A 1 hp 1032 lbs

3648 PRC-4 (ERGO) 121101 2 standard DCM-80A 1 hp 1130 lbs

3648 PRC-6 103121 2 standard DCM-200 1-1/2 hp 1479 lbs

3648 PRC-6 (CDC) 103151 2 standard CDC-6 1-1/2 hp 1779 lbs

3648 PRC-6 (ERGO) 121121 2 standard DCM-200 1-1/2 hp 1585 lbs

3648 PRC-6 (FS) 103129 2 standard DCM-200 1-1/2 hp 1500 lbs

3648 PRC-6 (CDC, ERGO) 121151 2 standard CDC-6 1-1/2 hp 1885 lbs

3648 PRC-6 (CDC, FS) 103159 2 standard CDC-6 1-1/2 hp 1800 lbs

3648 PRC-6 (ERGO, FS) 121921 2 standard DCM-200 1-1/2 hp 1600 lbs

3648 PRC-6 (CDC, ERGO, FS) 121951 2 standard CDC-6 1-1/2 hp 1900 lbs

3674 PRC-9 128121 2 standard DCM-200A 2 hp 1970 lbs

3674 PRC-9 (CDC) 128151 2 standard CDC-9 2 hp 2290 lbs

3674 PRC-9 (FS) 128129 2 standard DCM-200A 2 hp 2300 lbs

3674 PRC-9 (CDC, FS) 128159 2 standard CDC-9 2 hp 2600 lbs

3696 PRB-4/TWIN 106100 2 standard (2) Dust bags (2) 1 hp 1379 lbs

3696 PRC-4/TWIN 106101 2 standard (2) DCM-80A (2) 1 hp 1879 lbs

3696 PRC-4/TWIN (ERGO) 124101 2 standard (2) DCM-80A (2) 1 hp 2975 lbs

3696 PRC-6/TWIN 106121 2 standard (2) DCM-200 (2) 1-1/2 hp 2773 lbs

3696 PRC-6/TWIN (CDC) 106151 2 standard (2) CDC-6 (2) 1-1/2 hp 3373 lbs

3696 PRC-6/TWIN (ERGO) 124121 2 standard (2) DCM-200 (2) 1-1/2 hp 2900 lbs

3696 PRC-6/TWIN (FS) 106901 2 standard (2) DCM-200 (2) 1-1/2 hp 2750 lbs

3696 PRC-6/TWIN (CDC, ERGO) 124151 2 standard (2) CDC-6 (2) 1-1/2 hp 3500 lbs

3696 PRC-6/TWIN (EGRO, FS) 124921 2 standard (2) DCM-200 (2) 1-1/2 hp 2950 lbs

4848 PRC-6 104101 2 standard DCM-200 1-1/2 hp 1636 lbs

4848 PRC-6 (CDC) 104151 2 standard CDC-6 1-1/2 hp 1936 lbs

4848 PRC-6 (ERGO) 122101 2 standard DCM-200 1-1/2 hp 1735 lbs

4848 PRC-6 (CDC, ERGO) 122151 2 standard CDC-6 1-1/2 hp 2035 lbs

4848 PRC-9 104121 2 standard DCM-200A 2 hp 1671 lbs

4848 PRC-9 (CDC) 104152 2 standard CDC-9 2 hp 1971 lbs

4848 PRC-9 (ERGO) 122121 2 standard DCM-200A 2 hp 1775 lbs

4848 PRC-9 (FS) 104129 2 standard DCM-200A 2 hp 1650 lbs

4848 PRC-9 (CDC, ERGO) 122151 2 standard CDC-9 2 hp 2075 lbs

4848 PRC-9 (CDC, FS) 104159 2 standard CDC-9 2 hp 1950 lbs

4848 PRC-9 (ERGO, FS) 122921 2 standard DCM-200 A 2 hp 1750 lbs

4848 PRC-9 (CDC, ERGO, FS) 122951 2 standard CDC-9 2 hp 2050 lbs

6060 PRC-9 105101 2 standard DCM-200A 2 hp 1949 lbs

6060 PRC-9 (CDC) 105151 2 standard CDC-9 2 hp 2250 lbs

6060 PRC-9 (FS) 105129 2 standard DCM-200A 2 hp 1975 lbs

6060 PRC-9 (CDC, FS) 105159 2 standard CDC-9 2 hp 2275 lbs

60120 PRC-9/TWIN 107101 2 standard DCM-200A 2 hp 3713 lbs

60120 PRC-9/TWIN (CDC) 107151 2 standard CDC-9 2 hp 4313 lbs

7272 PRC-9 127101 1 standard DCM-200A 2 hp 2900 lbs

7272 PRC-9 (FS) 127901 1 standard DCM-200A 2 hp 3000 lbs

7272 PRC-12 127123 1 standard DCM-200B 5 hp 3000 lbs

7272 PRC-12 (FS) 127923 1 standard DCM-200B 5 hp 3100 lbs

PRESSURE CABINET SPECIFICATIONS

(See facing page for meaning of model numbers and notes.)

-17-

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

•••••••••••••••••••••••••••••••

Page 18

APPLICATION CONSIDERATIONS

-18-

To specify the proper equipment for your application,

you should set specific objectives and choose the equipment and materials to achieve these goals.

If you are replacing existing equipment or adding

blast cabinets to meet growing needs, you are probably

familiar with the benefits of air-blasting, the best media

to use, and the type of system you want. However, if

you have a new blasting application, you and your

Empire distributor should review the following outline

before making a final selection.

Cabinet Sizing

Prior to selecting a cabinet, determine the critical characteristics of your workpiece. These factors should

include: part size (will the workpiece fit into the cabinet?), accessibility of surfaces to be blasted, orientation

requirements, desired operating procedures (manual or

automatic), and masking considerations. Normally, a

sketch of the part within the cabinet is helpful in determining the most functional cabinet size.

Surface Requirements

To achieve desired results, there is no substitute for actual sample blasting, through which real-world parameters

can be defined. The key factors in achieving the “right”

surface characteristics are: coverage, duration, pressure

and media—all of which are interrelated. Nevertheless,

the best final results normally start with the “right”

media. General descriptions and characteristics of the

most commonly used blast media are provided on the

back cover of this catalog.

Generally, fine media do faster work on lighter jobs.

Heavy media impact harder for deeper etching or

increased “arc heights,” but may lodge in small recesses.

Before making a final choice about media, determine

how many times the material can be recycled and how

reclamation affects your operating costs.

Production Rate

The many variables affecting production rates include:

blast system type (suction or pressure); blast media

(type, size and quality); blast pressure; distance and

angle of guns/nozzles in relation to the workpiece; part

size; and operator capabilities. Again, sample blasting is

the only true test, but if higher production rates are your

objective, take a look at Pro-Finish pressure systems and

Ergo-Blast configurations for manual work—or consider

automation options.

Reclaimer and Dust Collector

Most Pro-Finish systems are available with two ventilation

options. Dusty, heavy-use or multiple-gun applications

usually require additional ventilation for optimum operator visibility and extended equipment life. Dense media

require larger blowers for adequate conveying. (See

“Media/Reclaimer Compatibility” table on page 14.)

Systems with exposed dust bags or without reclaimers

are not recommended for production applications.

Utilities

Your Pro-Finish system requires electricity and compressed air. Be sure the system you select interfaces

properly with the electrical sources in the plant where it

will be installed. Standard pre-wiring for 1 horsepower

motors is: 115V, 60Hz, 1 phase, 20 amp; for 1-1/2

horsepower motors: 230V, 60Hz, 1 phase, 15 amp; for 2

horsepower motors: 230V, 60Hz, 1 phase, 17 amp; for 5

horsepower motors: 230V, 60Hz, 3 phase, 20 amp. These

numbers represent full-amp draws for the dust collector

and basic cabinet. Three-phase electrical upgrades can be

supplied complete with control transformer for onesource power connection. Three-phase upgrades are also

available with more economical dual source. Because

field re-wiring can be costly, it is not advisable.

Options

Tailor the system to your application by choosing standard options. If harsh media is selected, you will want to

protect your equipment with Empire’s extended-wear

components. For light or fine media (200 mesh or less),

or humid conditions, consider a vibrating screen and

automatic Sure-Flo regulator. When using plastics or

walnut-shells, FaStrip cabinets are recommended.

Review all standard factory options as they relate to

material handling, productivity and serviceability with

an eye toward getting maximum value from your ProFinish system. Because these systems are modular, you

can select only the equipment needed. Further upgrading

in the field is normally a simple procedure.

Automation

You can customize a Pro-Finish cabinet to run without

an operator by incorporating a powered turntable and

gun holder. More sophisticated approaches include multiple blast guns, oscillators and a timer package.

Almost every automated Pro-Finish application is different so care should go into visualizing how the part

will be processed. If an out-of-round workpiece is rotated on a turntable, areas that come closer to a stationary

blast source will experience greater intensity. In addition,

recessed regions may be missed and interior surfaces may

be hard to reach with standard equipment.

Multiple guns/nozzles not only provide faster cycles

through increased coverage, but also “see” more facets

on multi-sided parts. Consequently, most automated systems employ multiple guns or nozzles.

Manual touch-up is offered with Pro-Finish systems

involving automation because, unlike the human eye,

mechanical devices cannot sense where extra blasting

might be required. Touch-up can also eliminate the effect

of “barberpoling,” which occurs when blast oscillation is

slightly faster than part rotation.

One of the final “components” to choose in your automated Pro-Finish system is the cabinet. Picture how

much room is needed inside the working enclosure—not

only for the workpiece, but also for the guns/nozzles,

hoses and all moving mechanisms. Be careful not to

undersize the cabinet.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

•••••••••••••••••••••••••••••••

Page 19

-19-

EMPIRE: A LEADER IN AIR-BLAST

TECHNOLOGY FOR OVER 50 YEARS

Empire has specialized in designing and manufacturing

abrasive-blasting products for over fifty years. Today,

we produce the most extensive line of air-blast equipment in the industry.

In addition to Pro-Finish

®

cabinets, our product line

includes Econo-Finish

®

cabinets, fully automated blast

systems, blast rooms and portable blasters. We also have

the capability to modify our Pro-Finish cabinets for

many specialized applications—normally with a minimum of custom engineering.

We’ve earned our reputation as a leader in air-blast

technology by developing products that meet customer

needs for increased productivity and improved product

quality—and by supporting our equipment with responsive training, service and testing programs.

When you require advice, assistance or equipment on

short notice, our national network of stocking distributors assures that help is nearby.

To arrange a first-hand look at our operations, please

give us a call.

Empire Abrasive Equipment Company, headquartered in Langhorne, Pennsylvania, specializes in the

development of air-blast systems and equipment.

BEST-EQUIPPED TEST LAB AND DEMONSTRATION CENTER IN THE WORLD

A TRACK RECORD OF “FINISHING FIRST”

Our test lab and demonstration center in Langhorne, PA, is the world’s largest. It enables us to simulate many

production conditions in order to determine the best mix of media and machinery for your application.

The variables we can adjust include media type, blast systems (suction or pressure), operating

pressures, dwell times, impact angles and other factors related to fixturing and parts handling.

We can simulate the blast parameters you prescribe or we can develop recommendations on the

best combination of media and equipment when you supply “before and after” sample parts.

Shifter forks

etched with ALOX

Cylinder surface

profiled with ALOX

Collar deburred

with glass beads

Copier tube etched

with silicon carbide

Parts BEFORE and AFTER

air-blasting with EMPIRE

machines

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Page 20

PFBG-4015MPro-Finish Buying Guide

NOTES:

Above information is intended as a general reference guide. Consult your authorized Empire distributor for specific media specifications.

1) Sodium bicarbonate must be treated with a flow agent.

2) Do not use silica sand in a hand cabinet.

3) See "Media/Reclaimer Compatibility" chart on page 14 for mesh sizes that are compatible with reclaimer systems.

WARRANTY: THREE YEAR LIMITED

Consult Empire for details. For other literature or

more information, consult your local Empire distributor, your Empire regional sales manager, or Empire

company headquarters.

Dimensions and specifications will vary with options

and accessories purchased. SPECIFICATIONS ARE

SUBJECT TO CHANGE WITHOUT NOTICE.

SILICA SAND IS NOT TO BE USED IN ANY EMPIRE

BLAST EQUIPMENT.

EMPIRE PRODUCTS

• A full range of cabinets—economy to custom

• Basket blasters for batch processing

• Automated blast systems

• Pneumatic blast & recovery systems

• FaStrip

®

plastic & wheat-starch decoating systems

• Blast rooms

• Outdoor portable systems

• A full line of parts and accessories

PRO-FINISH SURFACE-TREATMENT, CLEANING AND FINISHING CAPABILITIES

The selections of finishes are virtually unlimited and so are the applications.

Finishing Cleaning & Removal Surface Treatment & Prep

• Add matte or satin finish, • Chemical impurities • Coatings • Strengthen • Add fatigue resistance

or decorative frost • Paint • Sealants and adhesives • Improve wear properties • Reduce design

• Remove glare or • Carbon deposits • Scale weights, porosity, friction or susceptibility to

imperfections • Blend marks • Excess brazing • Casting corrosion • Improve lubrication

• Hone and burnish materials • Flashing • Burrs • Expose flaws for inspection • Etch for

• Mark identifications • Rust • Oxidation bonding and adhesion • Cut

MEDIA GUIDE

Printed in the USA on recycled paper

Information subject to change without notice.

Glass Ceramic Stainless Steel Steel Aluminum Silicon Crushed Plastic Agri

Bead Shot Cut Wire Shot Grit Oxide Carbide Garnet Glass Media Shell

Finishing YES YES YES YES YES YES YES YES YES NO NO

Cleaning/Removal YES YES YES YES YES YES YES YES YES YES YES

Peening YES YES YES YES NO NO NO NO NO NO NO

Surface Profiling (Etch) NO NO YES NO YES YES YES YES YES YES YES

Working Speed MED MED MED MED MED-HIGH HIGH VERY-HIGH HIGH HIGH MED-HIGH LOW-HIGH

Recyclability HIGH-LOW HIGH HIGH VERY-HIGH VERY-HIGH MED-HIGH MED-LOW MED MED-LOW MED LOW

Probability of Metal Removal VERY LOW VERY LOW VERY LOW VERY LOW MED MED-HIGH MED-HIGH MED LOW-MED VERY LOW VERY LOW

Hardness, MOH Scale 5.5 7 6-7.5 6-7.5 8-9 8-9 9 8 5.5 3-4 1-4.5

(Rockwell RC) (57-63) (35-55) (20-66) (40-66)

Bulk Density (lb/cu. ft.) 100 150 280 280 230 125 95 130 100 45-60 40-80

Mesh Size 30-440 8-46 20-62 8-200 10-325 12-325 36-220 16-325 30-400 12-80 MANY

Typical Blast Pressures (psi) 20-55 20-90 20-90 20-90 20-90 20-90 20-90 30-80 20-50 20-60 10-40

Shapes: ▲Angular; ●Spherical

●●●●▲▲▲▲▲▲

or

●▲

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

TM

EMPIRE

2101 West Cabot Boulevard, Langhorne, PA 19047-1893

Call: (215) 752-8800

Fax: (215) 752-9373

ABRASIVE EQUIPMENT

E-Mail: Airblast@empire-airblast.com

Visit: www.empire-airblast.com

Loading...

Loading...