Page 1

800 243 4844

orders@empireindustries.com

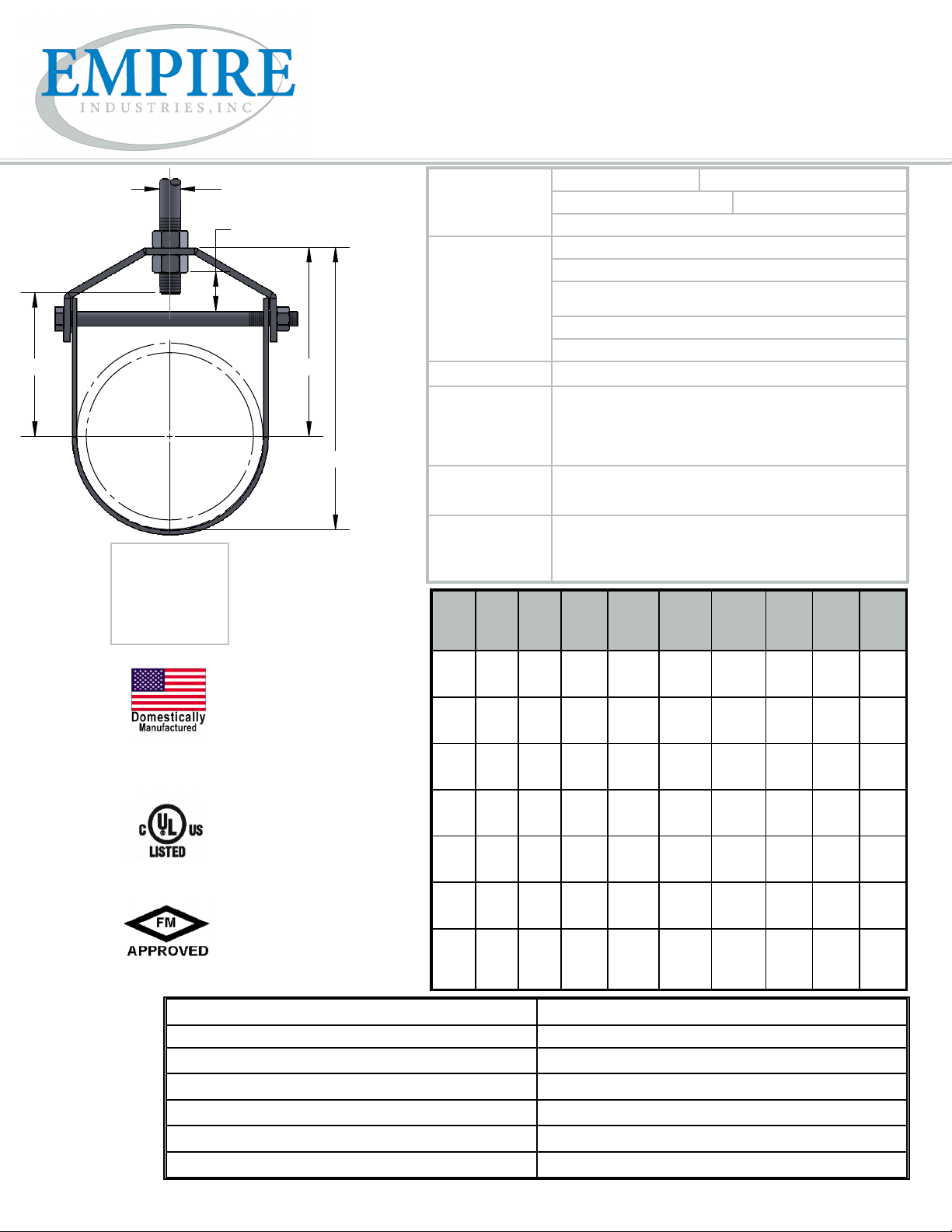

FIG. 11

clevis hanger, standard

C

OF PIPE

L

“E” dimension includes

exposed rod threads

beyond bottom of the

hex nut. Exposed rod

thread dimension is

equal to the diameter of

the rod used.

excluding:

11GI

11GIFL

11HDGI

excluding:

11RR

excluding:

11SS, 11SX & 11RR

A

F

Materials/Finishes Plain Carbon Steel (11B) Electro-Galvanized (11G)

Hot-Dip Galvanized (11HDG) T-304 Stainless (11SS)

T-316 Stainless (11SX)

Variants: Pipe Gard (11PG) - Please contact factory for details.

Electro-Galvanized, Imported: 1/2” - 12” (11GI)

Electro-Galvanized, 3/16” thick Felt-Lined, Imported: 1/2” - 8”

(11GIFL)

Hot-Dip Galvanized, Imported: 2”-3”, 4”-6”, 8”-12” (11HDGI)

Clevis Standard with Reduced Rod (11RR)

B E

Service: Designed for the suspension of non-insulated, stationary pipe lines.

Approvals: U.L. - U.L.C. listed (sizes 2-1/2” - 8” excluding 7”) and FM approved

(3/4” - 2” galv only. 2-1/2” - 8” plain and galv.). Complies with

Federal Specication WW-H-171-E (Type# 1), A-A-1192 A (Type#

1) and Manufacturers’ Standardization Society MSS SP-58 and SP-69

C

(Type# 1). Approvals do not apply to 11RR.

Ordering: Specify gure number, material, nish type and pipe size.

For 11RR, Specify gure number, material, nish type, pipe size and

rod size.

Notes:

For sizes 20” and larger a spacer sleeve is added over the cross

bolt. Upper locknut must be tightened securely to assure proper

hanger performance. Stainless steel hangers are recommended for applications where protection from a corrosive environment is required.

PIPE

PIPEODBO LT A B C E F WGT

SIZE

1/2

3/4

1

1-1/4

1-1/2

2

2-1/2

3

3-1/2

4

5

6

7

8

10

12

14

16

18

20

24

30

0.840

1.050

1.315

1.660

1.900

2.375

2.875

3.500

4.000

4.500

5.563

6.625

7.625

8.625

10.750

12.750

14.000

16.000

18.000

20.000

24.000

30.000

1/4

1/4

1/4

1/4

1/4

1/4

5/16

5/16

5/16

3/8

1/2

1/2

1/2

5/8

3/4

3/4

7/8

1

1

1-1/4

1-1/4

1-1/4

3/8

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

5/8

5/8

3/4

3/4

3/4

7/8

7/8

1

1

1

1-1/4

1-1/4

1-1/4

1-11/16

1-11/16

2-1/16

2-1/2

2-7/8

3-5/16

4-1/2

4-3/4

5-7/8

5-15/16

5-11/16

6-13/16

7-13/16

8-1/16

10

11-9/16

12-9/16

13-15/16

16

17-1/2

19-3/4

24-1/8

2-1/16

2-9/16

2-11/16

3-3/16

3-11/16

4-7/16

5-7/8

6-1/2

7-15/16

8-3/16

8-7/16

10-1/8

11-5/8

12-7/16

15-7/16

18

19-9/16

21-15/16

25

27-1/2

31-3/4

39-1/8

5/16

1-5/16

1-1/4

1-11/16

2-1/16

2-1/2

3-3/8

3-11/16

4-13/16

4-9/16

4-5/16

5-3/16

6-3/16

6-1/4

8

9-9/16

10-9/16

11-15/16

13-7/8

15-1/8

17-3/8

21-1/2

EACH

(LBS)

7/16

7/16

5/8

7/8

1-1/16

1-1/4

1-15/16

1-3/4

2-9/16

2-1/8

1-7/16

1-3/4

2

1-7/8

2-1/4

2-13/16

2-9/16

2-13/16

3-3/4

3-3/4

4

4-3/4

0.18

0.18

0.22

0.26

0.34

0.38

0.86

0.96

1.14

1.26

2.04

2.80

3.24

4.46

8.06

10.34

14.80

21.00

24.40

47.00

54.00

69.50

MAX

REC

LOAD

(LBS)

730

730

730

730

730

730

1130

1130

1350

1430

1430

1940

2000

2000

3600

3800

4200

4600

4800

4800

4800

6000

PROJECT INFORMATION APPROVAL STAMP

Project: Notes:

Address:

Contractor:

Engineer:

Date:

Approved Approved as Noted Not Approved

Loading...

Loading...