Empire Heating Systems GWT-25-3, GWT-35-3, GWT-35-3SG, GWT-35-3RB, GWT-25-3SG Installation Instructions And Owner's Manual

...

INSTALLATION INSTRUCTIONS

AND

OWNER'S MANUAL

GRAVITY VENTED

SINGLE WALL FURNACE

MODEL

GWT-25-3(SG, RB)

GWT-35-3(SG, RB)

Installer: Leave this manual with the appliance.

Consumer: Retain this manual for future reference.

WARNING: If not installed, operated and maintained

in accordance with the manufacturer's instructions,

this product could expose you to substances in fuel

or from fuel combustion which can cause death or

serious illness.

WARNING: If the information in these instructions

are not followed exactly, a re or explosion may result causing property damage, personal injury or

loss of life.

— Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any

other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

re department.

— Installation and service must be performed by a

qualied installer, service agency or the gas supplier.

Page 1

TABLE OF CONTENTS

SECTION PAGE

Important Safety Information ....................................................................................3

Safety Information for Users of LP Gas ...................................................................4

Introduction ..............................................................................................................5

Specications ...........................................................................................................5

Recommended Vent Conguration ..........................................................................6

Gas Supply ...............................................................................................................7

Clearances ..............................................................................................................8

Ventilation and Combustion Air ................................................................................8

Location - All Models ................................................................................................8

Rough-In Instructions ............................................................................................8-9

Finishing Instructions ..........................................................................................9-10

Optional Thermostat Location (SG Models) ........................................................... 11

Lighting Instructions ...............................................................................................12

Vent Safety Shutoff System ...................................................................................13

Proper Main Burner Flame .....................................................................................13

Proper Pilot Flame .................................................................................................13

Troubleshooting ......................................................................................................14

Parts List ................................................................................................................15

How To Order Repair Parts ....................................................................................15

Parts View .............................................................................................................16

Remote Bulb Control Installation Instructions ........................................................17

Optional Blower Installation Instructions ...........................................................18-21

Service Notes ....................................................................................................22-23

Warranty .................................................................................................................24

32038-1-0314Page 2

IMPORTANT SAFETY INFORMATION

THIS IS A HEATING APPLIANCE

DO NOT OPERATE THIS APPLIANCE WITHOUT OUTER CASING INSTALLED.

Due to high temperatures the appliance should be

located out of trafc and away from furniture and

draperies.

• Children and adults should be alerted to the hazards

of high surface temperatures and should stay away

to avoid burns or clothing ignition.

• Young children should be carefully supervised when

they are in the same room as the appliance.

• Clothing or other ammable material should not be

placed on or near the appliance.

• Any safety screen or guard removed for servicing

an appliance must be replaced prior to operating

the appliance.

• Keep burner and control compartment clean.

• Installation and repair should be done by a

QUALIFIED SERVICE PERSON. The appliance

should be inspected before use and at least annually

by a qualied service person. More frequent

cleaning may be required due to excessive lint from

carpeting, bedding materials, etc. It is imperative

that control compartments, burners and circulating

air passageways of the appliance be kept clean.

• DO NOT put anything around the furnace that will

obstruct the ow of combustion and ventilation

air.

• DO keep the appliance area clear and free from

combustible material, gasoline and other ammable

vapors and liquids.

• DO examine venting system periodically and replace

damaged parts.

• DO make a periodic visual check of pilot and burners.

Clean and replace damaged parts.

• DO NOT use this heater if any part has been under

water. Immediately call a qualied service technician

to inspect the heater and to replace any part of the

control system and any gas control which has been

under water.

• This furnace must not be connected to a chimney ue

serving a separate solid-fuel burning appliance.

32038-1-0314 Page 3

SAFETY INFORMATION FOR USERS OF LP-GAS

Propane (LP-Gas) is a ammable gas which can cause res

and explosions. In its natural state, propane is odorless and

colorless. You may not know all the following safety precautions

which can protect both you and your family from an accident.

Read them carefully now, then review them point by point

with the members of your household. Someday when there

may not be a minute to lose, everyone's safety will depend

on knowing exactly what to do. If, after reading the following

information, you feel you still need more information, please

contact your gas supplier.

LP-GAS WARNING ODOR

If a gas leak happens, you should be able to smell the gas because of the odorant put in the LP-Gas.

That's your signal to go into immediate action!

• Do not operate electric switches, light matches, use your

phone. Do not do anything that could ignite the gas.

• Get everyone out of the building, vehicle, trailer, or area. Do

that IMMEDIATELY.

• Close all gas tank or cylinder supply valves.

• LP-Gas is heavier than air and may settle in low areas such

as basements. When you have reason to suspect a gas leak,

keep out of basements and other low areas. Stay out until

reghters declare them to be safe.

• Use your neighbor's phone and call a trained LP-Gas service

person and the re department. Even though you may not

continue to smell gas, do not turn on the gas again. Do not

re-enter the building, vehicle, trailer, or area.

• Finally, let the service man and reghters check for escaped

gas. Have them air out the area before you return. Properly

trained LP-Gas service people should repair the leak, then

check and relight the gas appliance for you.

NO ODOR DETECTED - ODOR FADE

Some people cannot smell well. Some people cannot smell the

odor of the chemical put into the gas. You must nd out if you

can smell the odorant in propane. Smoking can decrease your

ability to smell. Being around an odor for a time can affect your

sensitivity or ability to detect that odor. Sometimes other odors in

the area mask the gas odor. People may not smell the gas odor

or their minds are on something else. Thinking about smelling a

gas odor can make it easier to smell.

The odorant in LP-gas is colorless, and it can fade under some

circumstances. For example, if there is an underground leak, the

movement of the gas through soil can lter the odorant. Odorants

in LP-Gas also are subject to oxidation. This fading can occur if

there is rust inside the storage tank or in iron gas pipes.

The odorant in escaped gas can adsorb or absorb onto or into walls,

masonry and other materials and fabrics in a room. That will take

some of the odorant out of the gas, reducing its odor intensity.

LP-Gas may stratify in a closed area, and the odor intensity could

vary at different levels. Since it is heavier than air, there may be

more odor at lower levels. Always be sensitive to the slightest gas

odor. If you detect any odor, treat it as a serious leak. Immediately

go into action as instructed earlier.

SOME POINTS TO REMEMBER

• Learn to recognize the odor of LP-gas. Your local LP-Gas

Dealer can give you a "Scratch and Sniff" pamphlet. Use it to

nd out what the propane odor smells like. If you suspect that

your LP-Gas has a weak or abnormal odor, call your LP-Gas

Dealer.

• If you are not qualied, do not light pilot lights, perform service,

or make adjustments to appliances on the LP-Gas system. If

you are qualied, consciously think about the odor of LP-Gas

prior to and while lighting pilot lights or performing service or

making adjustments.

• Sometimes a basement or a closed-up house has a musty

smell that can cover up the LP-Gas odor. Do not try to light

pilot lights, perform service, or make adjustments in an area

where the conditions are such that you may not detect the

odor if there has been a leak of LP-Gas.

• Odor fade, due to oxidation by rust or adsorption on walls of

new cylinders and tanks, is possible. Therefore, people should

be particularly alert and careful when new tanks or cylinders

are placed in service. Odor fade can occur in new tanks, or

reinstalled old tanks, if they are lled and allowed to set too

long before relling. Cylinders and tanks which have been

out of service for a time may develop internal rust which will

cause odor fade. If such conditions are suspected to exist,

a periodic sniff test of the gas is advisable. If you have any

question about the gas odor, call your LP-gas dealer. A

periodic sniff test of the LP-gas is a good safety measure

under any condition.

• If, at any time, you do not smell the LP-Gas odorant and you

think you should, assume you have a leak. Then take the same

immediate action recommended above for the occasion when

you do detect the odorized LP-Gas.

• If you experience a complete "gas out," (the container is under no vapor pressure), turn the tank valve off immediately.

If the container valve is left on, the container may draw in

some air through openings such as pilot light orices. If this

occurs, some new internal rusting could occur. If the valve is

left open, then treat the container as a new tank. Always be

sure your container is under vapor pressure by turning it off

at the container before it goes completely empty or having it

relled before it is completely empty.

32038-1-0314Page 4

INTRODUCTION

Introduction

Vented wall furnace is shipped ready to install in a 2" x 4" stud wall,

with studs 16" (406mm) center to center. Always consult your local

Building Department regarding regulations, codes or ordinances

which apply to the installation of a vented wall furnace.

Instructions to Installer

1. Installer must leave instruction manual with owner after installation.

2. Installer must have owner ll out and mail warranty card supplied with furnace.

3. Installer should show owner how to start and operate furnace

and thermostat.

Warning:

Any change to this furnace or its control can be dangerous.

This is a heating appliance and any panel, door or guard

removed for servicing an appliance must be replaced prior

to operating the appliance.

To conserve Gas: Turn off pilot when heater is not in use.

General Information

This series is design certied in accordance with American National

Standard / CSA Standard Z21.86 and CSA 2.32 by the Canadian

Standards Association, as a Vented Wall Furnace and must be

installed according to these instructions.

Any alteration of the original design, installed other than as

shown in these instructions or use with a type of gas not

shown on the rating plate is the responsibility of the person

and company making the change.

Important

All correspondence should refer to complete Model No., Serial No.

and type of gas.

Notice: During initial ring of this furnace, its paint will bake out and

smoke will occur. To prevent triggering of smoke alarms, ventilate

the room in which the furnace is installed.

Installation in Residential Garages

Gas utilization equipment in residential garages shall be installed

so that all burners and burner ignition devices are located not less

than 18" (457mm) above the oor.

Such equipment shall be located, or protected, so it is not subject

to physical damage by a moving vehicle.

Qualied Installing Agency

Installation and replacement of gas piping, gas utilization equipment

or accessories and repair and servicing of equipment shall be

performed only by a qualied agency. The term "qualied agency"

means any individual, rm, corporation or company which either in

person or through a representative is engaged in and is responsible for

(a) the installation or replacement of gas piping or (b) the connection,

installation, repair or servicing of equipment, who is experienced in

such work, familiar with all precautions required and has complied

with all the requirements of the authority having jurisdiction.

State of Massachusetts: The installation must be made

by a licensed plumber or gas tter in the Commonwealth of

Massachusetts.

The installation must conform to local codes or, in the absence of

local codes, with the National Fuel Gas Code ANSI Z223.1/NFPA

54* Natural Gas and Propane Installation Code, CSA B149.1.

*Available from the American National Standards Institute, Inc., 11

West 42nd St., New York, N.Y. 10036.

High Altitudes

For altitudes/elevations above 2,000 feet (610m), input ratings

should be reduced at the rate of 4 percent for each 1,000 (305m)

feet above sea level. Canadian High Altitudes for locations having

an elevation above mean sea level between 2,000 feet (610m) and

4,500 feet (1370m), the manifold pressure is to be decreased from

3.5" w.c. (.871kPa) to 3.0" w.c. (.747kPa) for Natural Gas and from

10.0" w.c. (2.49kPa) to 8.0" w.c. (1.992kPa) for Propane Gas.

Model GWT-25 GWT-35

Input BTU/HR (KW/H) 25,000 (7.3) 35,000 (10.3)

Height 66 1/8" (1679mm) 66 1/8" (1679mm)

Width 16" (406mm) 16" (406mm)

Depth 6" (152mm) 6" (152mm)

Gas Inlet Pipe 1/2" 1/2"

Vent Pipe Type B Oval 4" (102mm) 4" (102mm)

Accessories

Blower Kit GWTB-2 GWTB-2

Rear Register Kit GWTR-1 GWTR-1

Out-of-the-Wall Kit GWTW-2 GWTW-2

Wall Thermostat - Millivolt TMV TMV

Wireless Remote Wall Thermostat TRW TRW

Remote Bulb Thermostat GWRBT GWRBT

Attention: When the GWTW-2, Out-of-the-Wall kit is used the GWTR-1 Rear Register kit cannot be used.

32038-1-0314 Page 5

SPECIFICATIONS

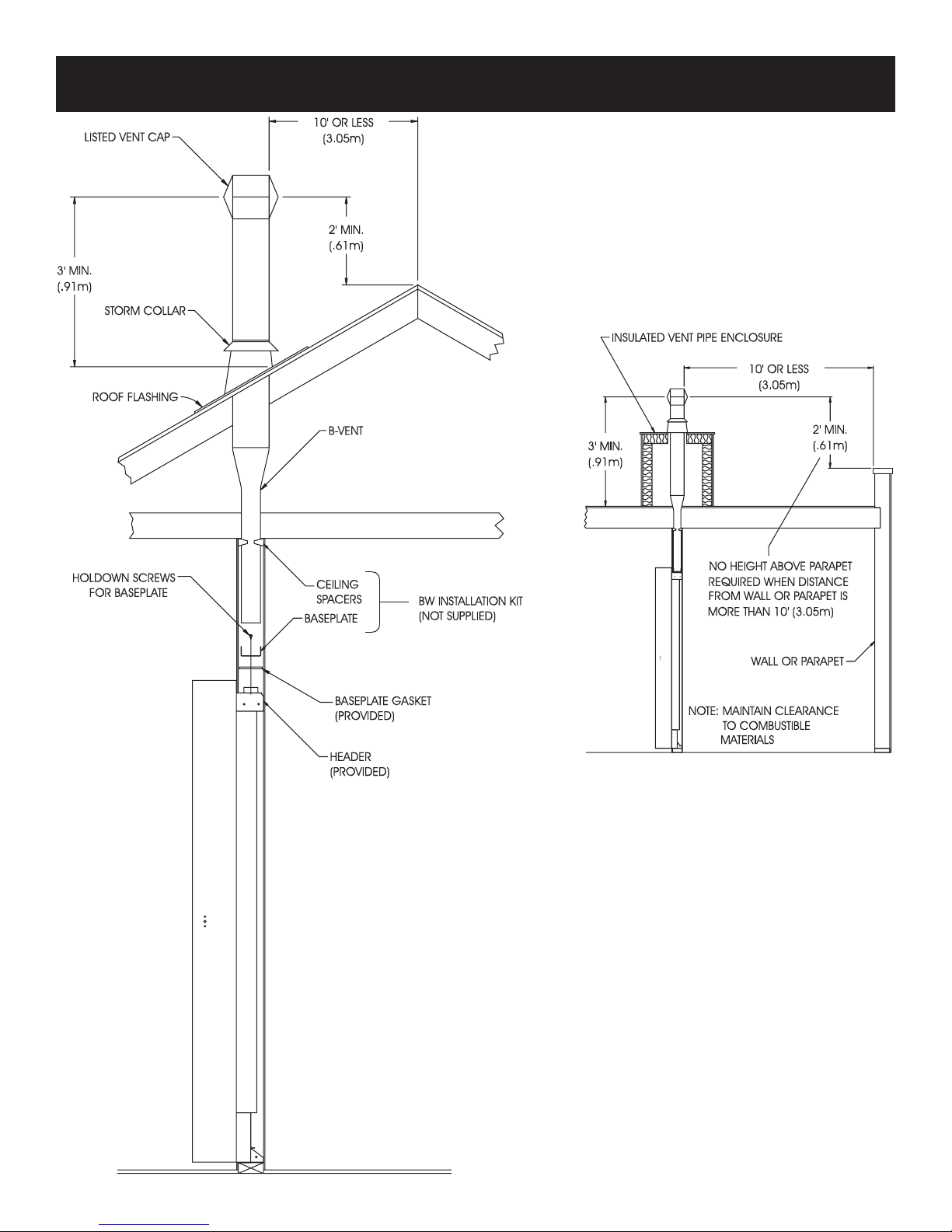

RECOMMENDED VENT CONFIGURATION

Note: No vent equipment supplied with furnace.

4" Oval (all parts purchase locally)

1. Type B-1 oval pipe

2. Single story type B-1 gas vents require a baseplate and one pair of

ceiling plate spacers.

3. Multi-story type B-1 gas vents require a baseplate, one pair of ceiling

plate spacers at the rst oor ceiling and one pair of re stop spacers

at each successive ceiling level.

Type B-W gas vent pipe is available for single story or multistory installations. Type B-W gas vent pipe is to be used

with the Listed base plate, ceiling plate spacers and re stop

spacers.

Insulated Vent Enclosure

Gravity vented wall furnaces installed in buildings with at roofs can have poor

venting. The cold vent pipe will have a delay in proper venting and cause

the wall furnace to shut "off" by the vent safety switch. To prevent delayed

venting as well as condensation of ue products an insulated vent enclosure

is recommended.

Use Type B vent pipe and maintain at least a one inch (25mm) clearance to

combustibles.

Use metal thimble to protect vent pipe as it passes through combustibles.

Baseplate Gasket is factory installed on header. Baseplate attaches to header

with screws. B-vent snaps into and is attached to baseplate. Minimum height

of vent pipe must be six feet (1.8m) above header.

Stud space around gas vents must be free of obstructions and building paper.

Uninsulated Single-Wall Metal Pipe shall not be used outdoors in cold climates

for venting gas utilization equipment.

Attention: The main burner uses room air for combustion. As the gas/air

mixture is injected into the main burner, there is also the ow of dust and lint

particles into the main burner.

Dust and lint accumulation inside the main burner will result in a yellow main

burner ame and possible sooting inside the combustion chamber and vent pipe.

To clean main burner refer to Page 13, "Proper Main Burner Flame."

32038-1-0314Page 6

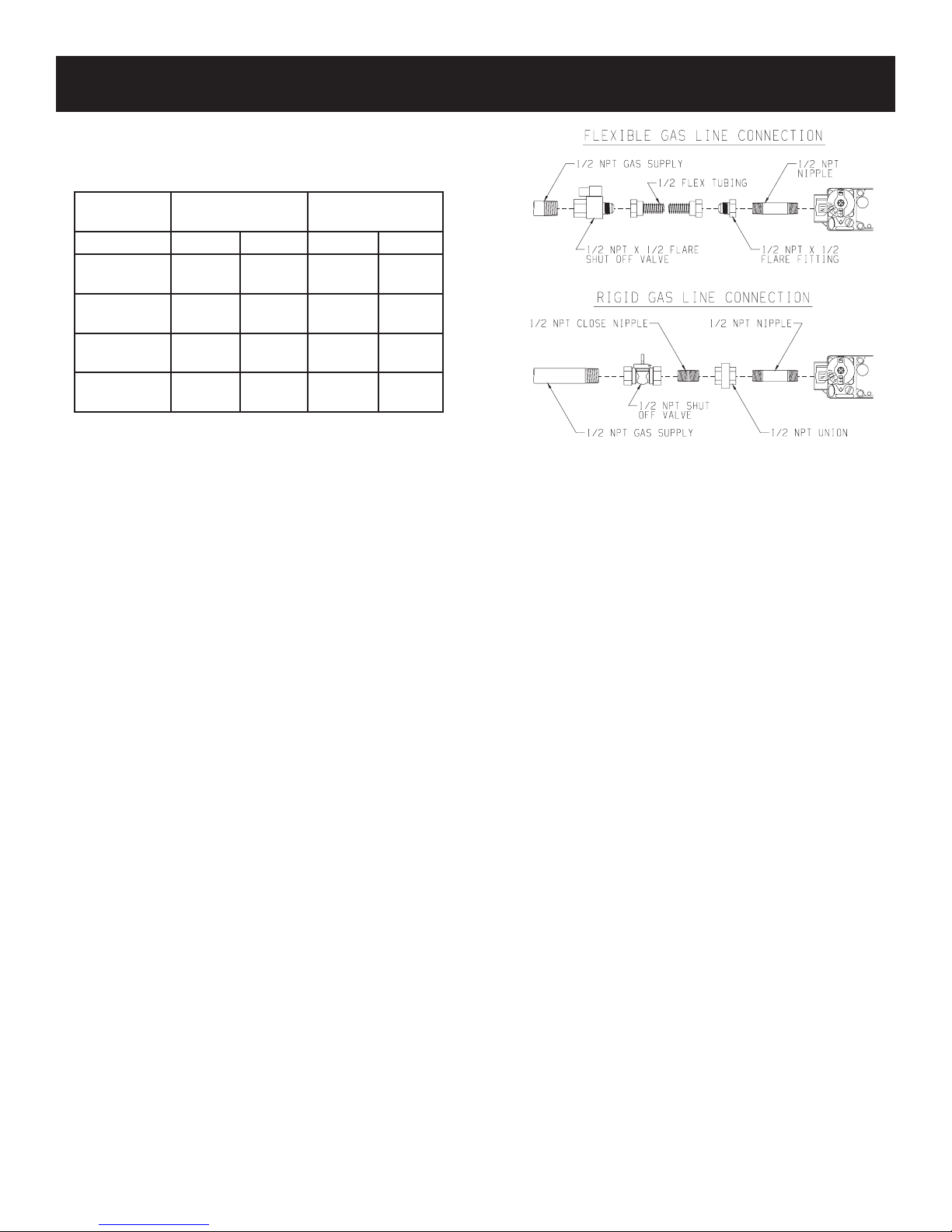

GAS SUPPLY

Check all local codes for requirements, especially for the size and

type of gas supply line required.

Recommended Gas Pipe Diameter

Pipe Length Schedule 40 Pipe

Inside Diameter

Nat. L.P. Nat. L.P.

0-10 feet

0-3 meters

10-40 feet

4-12 meters

40-100 feet

13-30 meters

100-150 feet

31-46 meters

Note: Never use plastic pipe. Check to conrm whether your local

codes allow copper tubing or galvanized.

Note: Since some municipalities have additional local codes, it is

always best to consult your local authority and installation code.

Installing a New Main Gas Cock

Each appliance should have its own manual gas cock.

A manual main gas cock should be located in the vicinity of the unit.

Where none exists, or where its size or location is not adequate,

contact your local authorized installer for installation or relocation.

Compounds used on threaded joints of gas piping shall be resistant

to the action of liqueed petroleum gases. The gas lines must be

checked for leaks by the installer. This should be done with a soap

solution watching for bubbles on all exposed connections, and if

unexposed, a pressure test should be made.

Never use an exposed ame to check for leaks. Appliance must

be disconnected from piping at inlet of control valve and pipe

capped or plugged for pressure test. Never pressure test with

appliance connected; control valve will sustain damage!

A gas valve and ground joint union should be installed in the gas

line upstream of the gas control to aid in servicing. It is required by

the National Fuel Gas Code that a drip line be installed near the gas

inlet. This should consist of a vertical length of pipe tee connected

into the gas line that is capped on the bottom in which condensation

and foreign particles may collect.

1/2”

12.7mm

1/2”

12.7mm

1/2”

12.7mm

3/4”

19mm

3/8”

9.5mm

1/2”

12.7mm

1/2”

12.7mm

1/2”

12.7mm

Tubing, Type L

Outside Diameter

1/2”

12.7mm

5/8”

15.9mm

3/4”

19mm

7/8”

22.2mm

3/8”

9.5mm

1/2”

12.7mm

1/2”

12.7mm

3/4”

19mm

Figure 1

The use of the following gas connectors is recommended:

— ANS Z21.24 Appliance Connectors of Corrugated Metal Tubing

and Fittings

— ANS Z21.45 Assembled Flexible Appliance Connectors of Other

Than All-Metal Construction

The above connectors may be used if acceptable by the authority

having jurisdiction. The state of Massachusetts requires that a exible

appliance connector cannot exceed three feet in length.

Pressure Testing of the Gas Supply System

1. To check the inlet pressure to the gas valve, a 1/8" (3.175mm)

N.P.T. plugged tapping, accessible for test gauge connection,

must be placed immediately upstream of the gas supply

connection to the appliance.

2. The appliance and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of 1/2 psig (3.5 kPa).

3. The appliance must be isolated from the gas supply piping system

by closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal

to or less than 1/2 psig (3.5 kPa).

Attention! If one of the procedures results in pressures in excess

of 1/2 psig (14" w.c.) (3.5 kPa) on the appliance gas valve, it will

result in a hazardous condition.

Checking Manifold Pressure

Both Propane and Natural gas valves have a built-in pressure

regulator in the gas valve. Natural gas models will have a manifold

pressure of approximately 3.5" w.c. (.871kPa) at the valve outlet

with the inlet pressure to the valve from a minimum of 4.5" w.c.

(1.120kPa) for the purpose of input adjustment to a maximum of

10.5" w.c. (2.614kPa) Propane gas models will have a manifold

pressure approximately 10.0" w.c. (2.49kPa) at the valve outlet

with the inlet pressure to the valve from a minimum of 11.0" w.c.

(2.739kPa) for the purpose of input adjustment to a maximum of

13.0" w.c. (3.237kPa).

A 1/8" (3.175mm) N.P.T. plugged tapping, accessible for test gauge

connection, is located on the outlet side of the gas control.

32038-1-0314 Page 7

CLEARANCES

1. In selecting a location for installation, it is necessary to provide

adequate accessibility clearances for servicing and proper

installation.

2. Clearances to combustible surfaces are 4" (102mm) from sides,

12" (305mm) to top, 1 1/2" (38mm) from oor.

VENTILATION AND COMBUSTION AIR

Wall furnaces shall be installed in a location in which the facilities

for ventilation permit satisfactory combustion of gas and proper

venting under normal conditions. In buildings of conventional frame,

brick, or stone construction without tight storm windows and doors,

inltration is normally adequate to provide air for combustion and

draft hood dilution.

LOCATION - ALL MODELS

NOTE: Minimum distance of 1 1/2" (38mm) must also be maintained

from top surface of carpeting, tile, etc.

Where appliances are installed in conned and unconned spaces

within a building, the building being of unusually tight construction,

air for combustion and ventilation must be obtained directly from

outdoors or from such spaces that freely communicate with the

outdoors. Under these conditions, the conned and unconned

spaces shall be provided with two permanent openings, one near

the top of the enclosure and one near the bottom; each opening

shall have a free area of not less than one square inch (6.45cm2)

per 2,000 BTU (.6KW/H) per hour of total input.

Select a location near the center of the space to be heated. Overow

heat will circulate through doorways into adjacent rooms.

For large homes or spread-out oor plans, two or more furnaces are

recommended. Do not locate furnace where a door could swing

over the outer casing, or where circulation could be retarded by

furniture or cabinets.

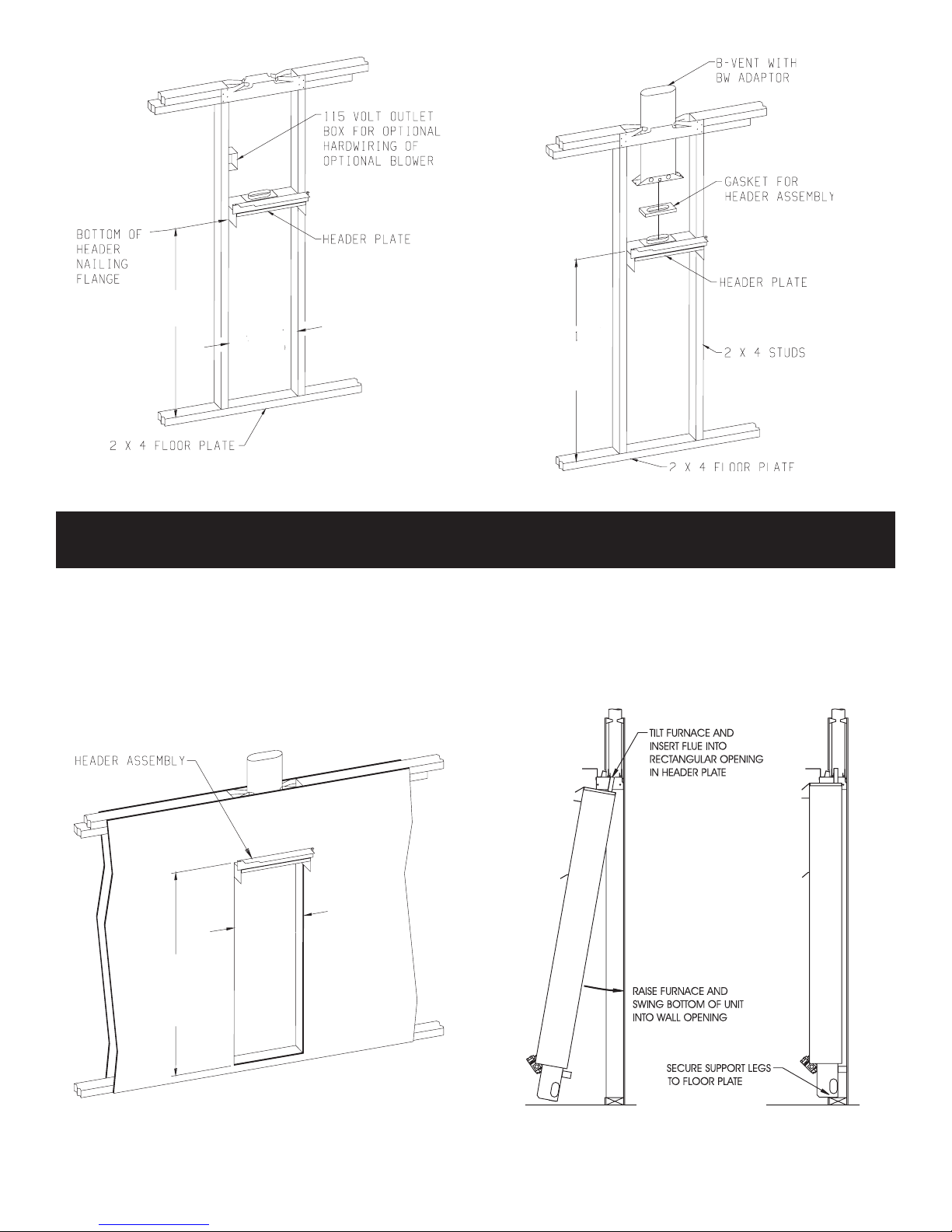

ROUGH-IN INSTRUCTIONS

Provide an opening in the wall 14 1/2" (368mm) wide and 66 1/8"

(168cm) high measured from top of oor plate (See Figure 2 and

Figure 3). Wall depth is to be 2" x 4" framing with 1/4" (6.5mm) to

5/8" (16mm) sheeting. Attach baseplate (not supplied with furnace) to

header plate with sheet metal screws at each end. Attach 4" (102mm)

oval, double wall vent pipe to baseplate. Attach enough vent pipe so

that when installed in wall opening the vent pipe will extend above the

ceiling plate by at least 6" (152mm). Install ceiling spacers according

to manufacturer's instructions. Insert header plate with attached 4"

Do not install in a closet, alcove or small hallway where the furnace

could be isolated by closing doors to the heated space.

When location is selected, check the walls, attic and roof to make sure

there are no obstructions such as pipes, electric wiring, etc., which

would interfere with the installation of the furnace or vent pipe.

NOTE: If Rear Register Kit is to be used, see Rear Register Kit

instructions for location of hole in rear wall. Register outlet

must be cut in wall before furnace is installed.

NOTE: If Optional Blower is to be used, hard wiring must be

completed for the optional blower prior to installation of

header plate.

oval, double wall vent pipe into wall opening. Position header plate

at height shown in Figure 2. Locate rear edge of nailing ange at

the back of the 2" x 4" stud which will center the vent collar in the

wall. Locate the angled edge of header plate ush with the top of

the wall opening. Nail header plate to the wall studs.

32038-1-0314Page 8

62 1/4”

(1581 mm)

14 ½”

(368 mm)

Figure 2

66 1/8”

(1679mm)

WALL

OPENING

FINISHING INSTRUCTIONS

Figure 3

Plastering (Figure 4)

In new construction use only plain (not perforated) gypsum lath

around furnace and vent pipe so that plaster "Keys" will not project

into wall space.

Use wood strips nailed to inside of studs and top of bottom plate.

These must be removed before installation of furnace. Lath and

plaster against top projection of Header Plate.

Do not allow wall nish materials to project into furnace recess.

14 ½”

(368 mm)

66 1/8”

(1679mm)

WALL

OPENING

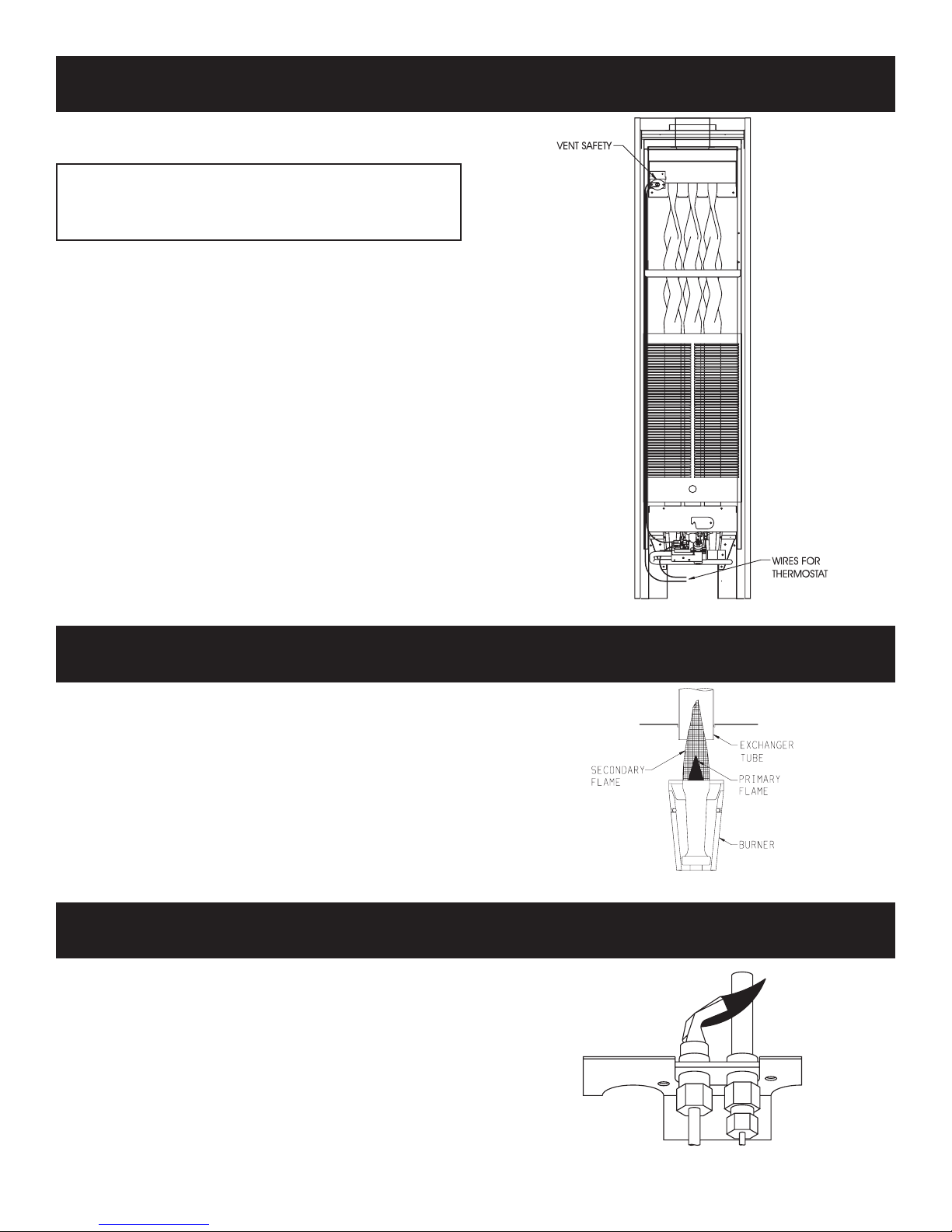

Installing Furnace (Figure 5)

Clear the recess of all debris, and remove any wood plaster-grounds.

Stand the furnace on oor in front of wall opening.

Insert furnace ue into rectangular opening in header plate and

raise furnace carefully (see Figure 5). Swing bottom of furnace into

wall opening with back of legs ush with rear of oor plate. Secure

furnace support legs to the oor plate.

Figure 4

32038-1-0314 Page 9

Figure 5

FINISHING INSTRUCTIONS (continued)

IMPORTANT — Avoid securing too tightly and disturbing the inner

casing. Do not try to force furnace into a wall opening which is

smaller than specied dimension.

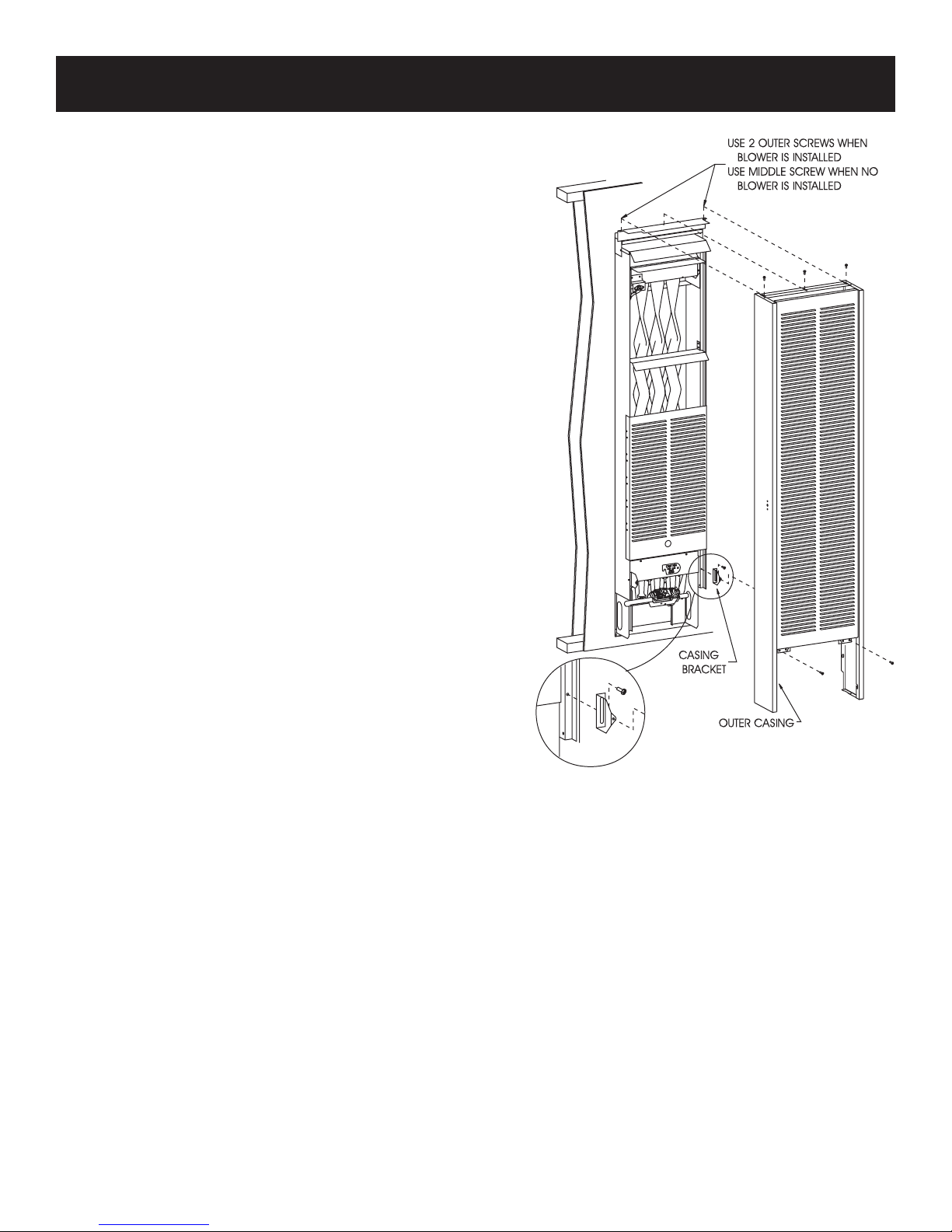

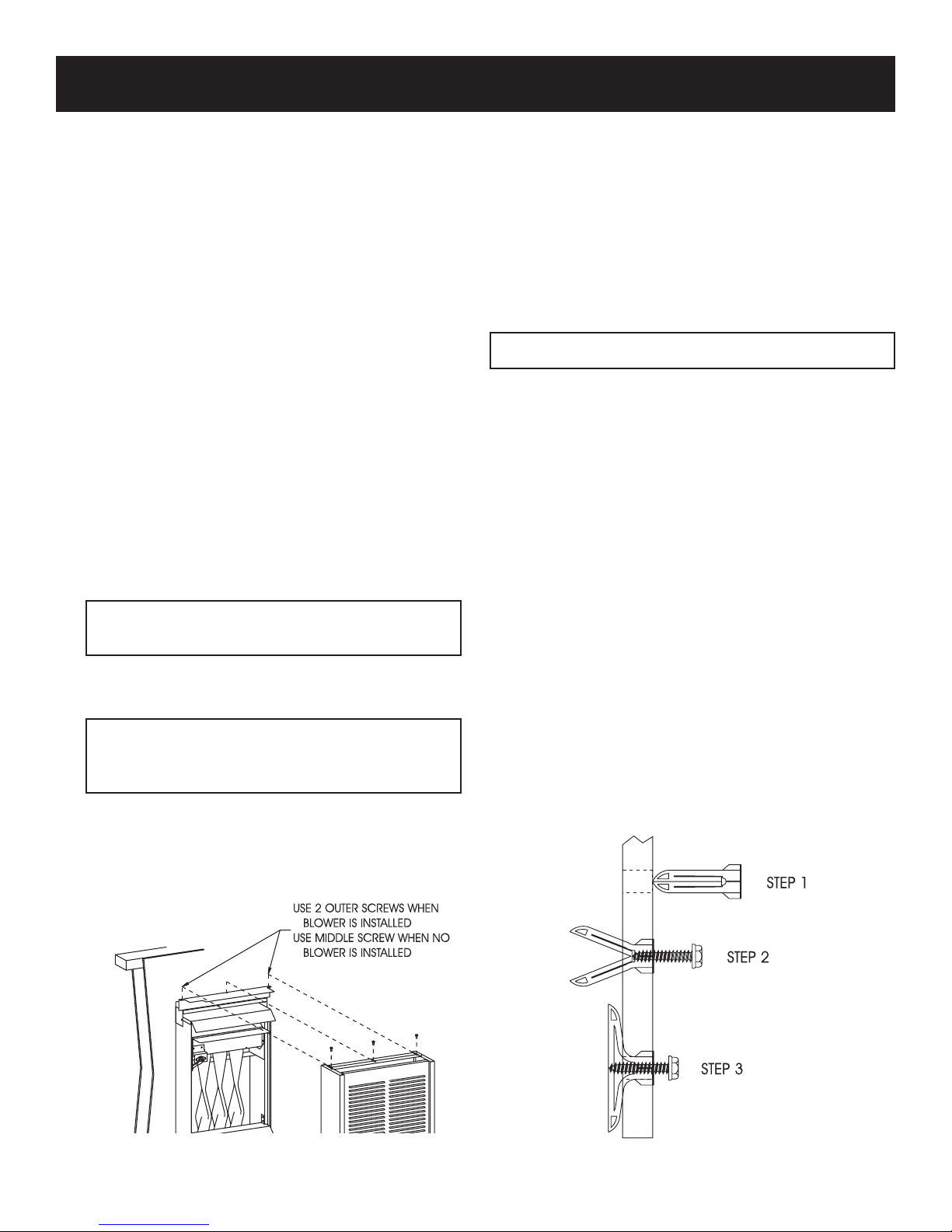

OUTER CASING (Figure 6)

1. Align 1 3/4" slot on casing bracket with bottom screw hole on

inner casing. Attach casing bracket to inner casing with one (1)

10 x 1/2" screws for each casing bracket. Do not completely

tighten screws at this time.

2. Place outer casing onto header.

Attention: Use center clearance hole on outer casing top for

attachment to header with one (1) 8 x 3/8" Phillips screw when

optional blower is not installed.

Attention: Use outside clearance holes on outer casing top

for attachment to header with two (2) 8 x 3/8" Phillips screws

when optional blower is installed.

3. Align clearance holes on outer casing bottom with screw holes

on casing brackets by adjusting slots on casing brackets.

4. Complete tightening casing bracket screws from Step 1 to inner

casing at this time.

5. Attach outer casing to casing brackets with two (2) 10 x 1-1/2"

screws.

INSTALLING CONTROL DOOR

Attach two washers supplied in hardware package to pivot pins

located at bottom of control door. Install control door to outer casing assembly.

Figure 6

32038-1-0314Page 10

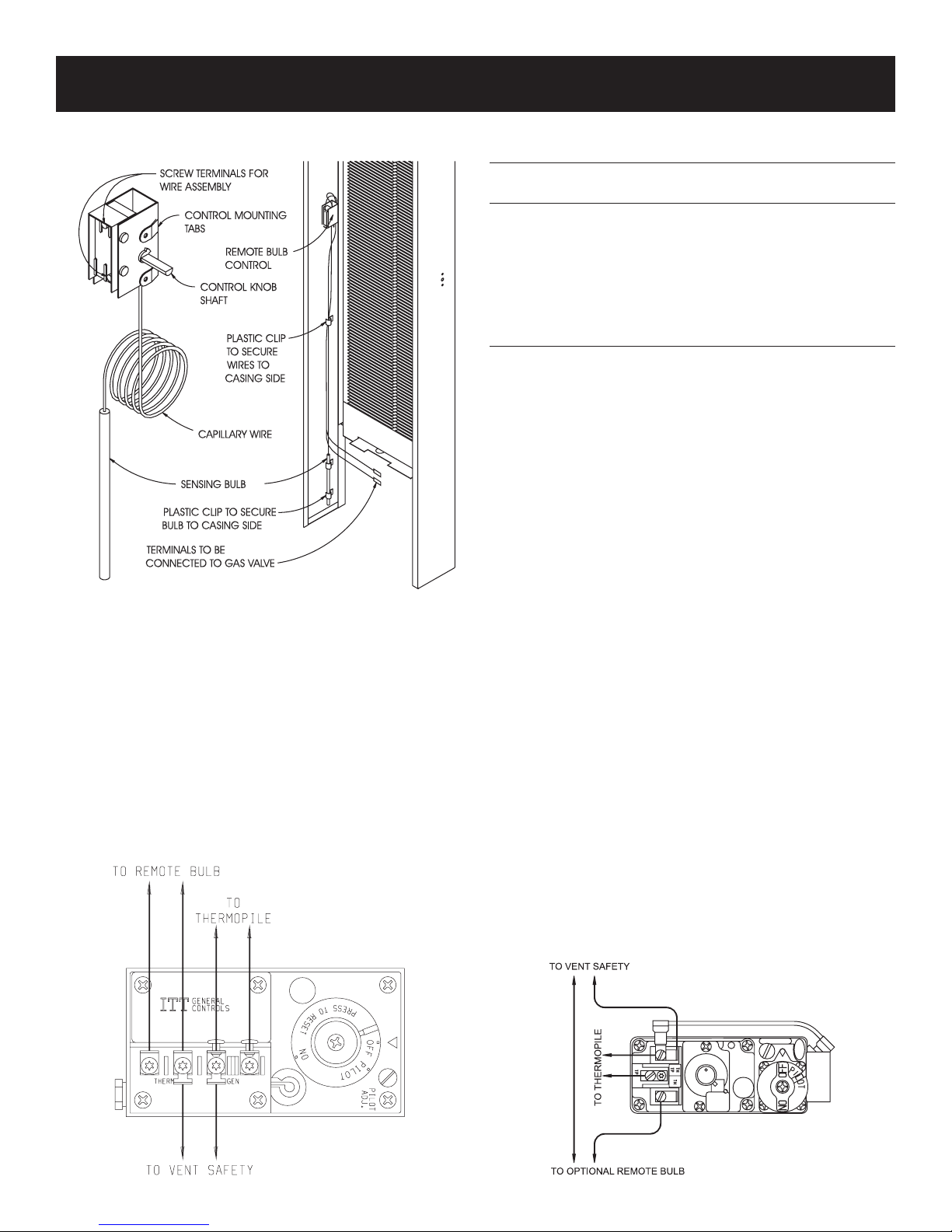

OPTIONAL THERMOSTAT LOCATION (SG MODELS)

CAUTION — Do not run wire behind anges of Header Plate or in

any location where it might be damaged.

Millivolt wall thermostats are specially designed for use on self-

generating systems. They should never be used on line or low

voltage A.C. circuits.

Interior Wall — The thermostat should be installed on an inside

wall away from the furnace but in the same room.

It is important to use wire of a gauge proper for the length of the

wire:

RECOMMENDED WIRE GAUGES

Maximum Length Wire Gauge

1' to 10' 18

10' to 25' 16

25' to 35' 14

Proper operation depends on a good pilot ame. The ame must

cover the top of the thermopile. Cleaning of the pilot orice and

burner may be required due to spiders.

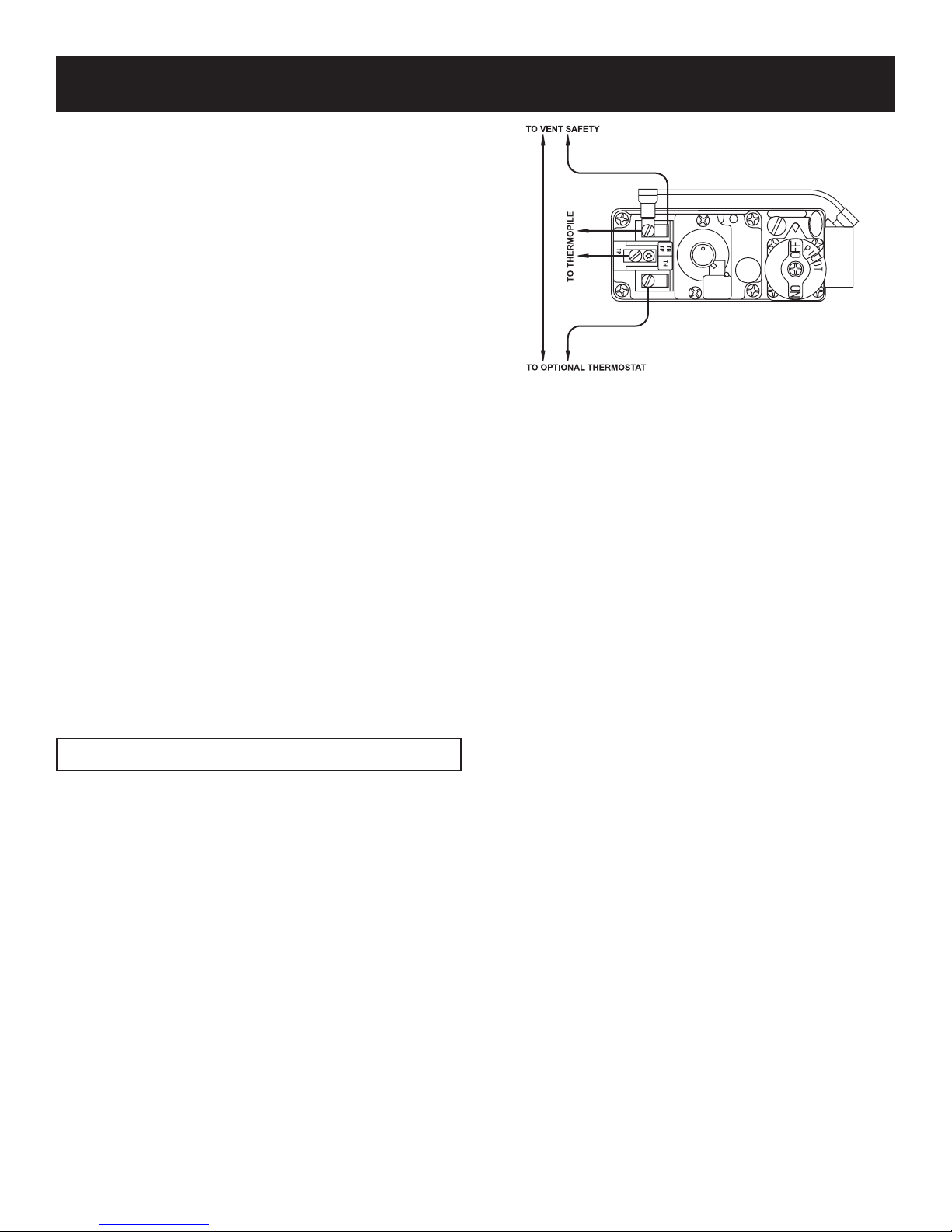

System Check (Figure 7)

A millivolt meter is required to check the system. Millivolt readings

should be:

• Across the thermopile terminals, 400-450 millivolts with

thermostat OFF.

• Across the thermopile terminals, 150-250 millivolts with

thermostat ON.

• Across the thermostat wires at the valve, less than 30 millivolts

with thermostat ON.

• Across the thermostat wires at the thermostat, less than 5

millivolts with thermostat ON. (Dirty pilot or low pressure will

reduce readings.)

Connect thermostat wires to gas valve as shown in Figure 7.

Figure 7

To conserve Gas: Turn off pilot when heater is not in use.

32038-1-0314 Page 11

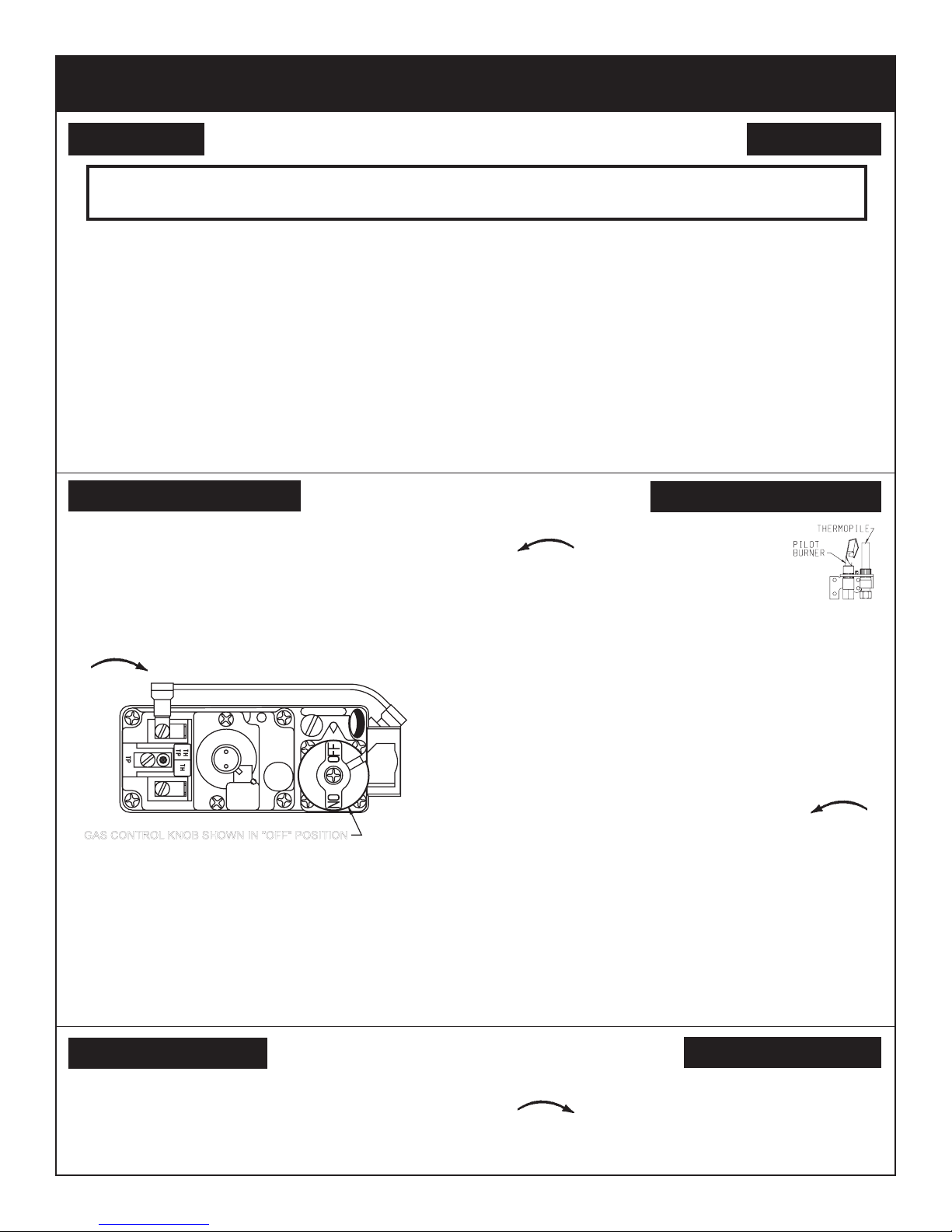

GAS CONTROL KNOB SHOWN IN "OFF" POSITION

LIGHTING INSTRUCTIONS

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a re or explosion may result

causing property damage personal injury or loss of life.

A. This appliance has a pilot which must be lighted by

hand. When lighting the pilot, follow these instructions

exactly.

B. BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the oor because some

gas is heavier than air and will settle on the oor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above.

2. Set the thermostat to lowest setting (if applicable).

3. Turn off all electric power to the appliance (if applicable).

4. Remove control access panel (control door).

5. Push in gas control knob slightly and turn clockwise

to "OFF."

NOTE: Knob cannot be turned from "PILOT" to "OFF" unless

knob is pushed in slightly. Do not force.

6. Wait ten (10) minutes to clear out any gas. Then smell

for gas, including near the oor. If you smell gas, STOP!

Follow "B" in the safety information above. If you don't

smell gas, go to the next step.

7. Find pilot - follow metal tube from gas control. The pilot

is mounted on front of main burner.

• If you cannot reach your gas supplier, call the re

department.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or

turn by hand, don't try to repair it; call a qualied service

technician. Force or attempted repair may result in a re

or explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualied service technician to inspect

the appliance and to replace any part of the control system

and any gas control which has been under water.

8. Turn gas control knob counterclockwise

to "PILOT."

9. Push in control knob all the way and

hold in. Immediately light the pilot with

a match. Continue to hold the control

knob in for about one (1) minute after

the pilot is lit. Release knob and it will pop back up. Pilot

should remain lit. If it goes out, repeat steps 5 through

9.

• If knob does not pop up when released, stop and im-

mediately call a qualied service technician or gas

supplier.

• If the pilot will not stay lit after several tries, turn

the gas control knob to "OFF" and call your service

technician or gas supplier.

10. Turn gas control knob counterclockwise to

"ON."

11. Replace control access panel (control door).

12. Turn on all electric power to the appliance (if applicable).

13. Set thermostat to desired setting (if applicable).

TO TURN OFF GAS TO APPLIANCE

1. Set the thermostat to lowest setting.

2. Turn off all electric power (if applicable) to appliance if

service is to be performed.

3. Remove control access panel (control door).

4. Push in gas control knob slightly and turn clockwise

to "OFF." Do not force.

5. Replace control access panel (control door).

32038-1-0314Page 12

VENT SAFETY SHUTOFF SYSTEM

This appliance must be properly connected to a venting system.

This appliance is equipped with a vent safety shutoff system.

Warning: Operation of this wall furnace when not connected

to a properly installed and maintained venting system or

tampering with the vent safety shutoff system can result in

carbon monoxide (CO) poisoning and possible death.

This furnace is equipped with a manual reset vent safety switch.

The manual reset vent safety switch will cause gas ow to the main

burner to "shut off" due to improper venting or a blocked ue.

To reset the manual reset vent safety switch:

1. Remove outer casing.

2. Depress manual reset button. The manual reset vent safety

switch is located on the draft diverter.

3. Replace outer casing.

If the manual reset vent safety switch continues to "shut off" the gas

ow to the main burner a qualied service person must be contacted

to inspect for improper venting, blockage in the vent pipe or the

manual reset vent safety switch for being defective.

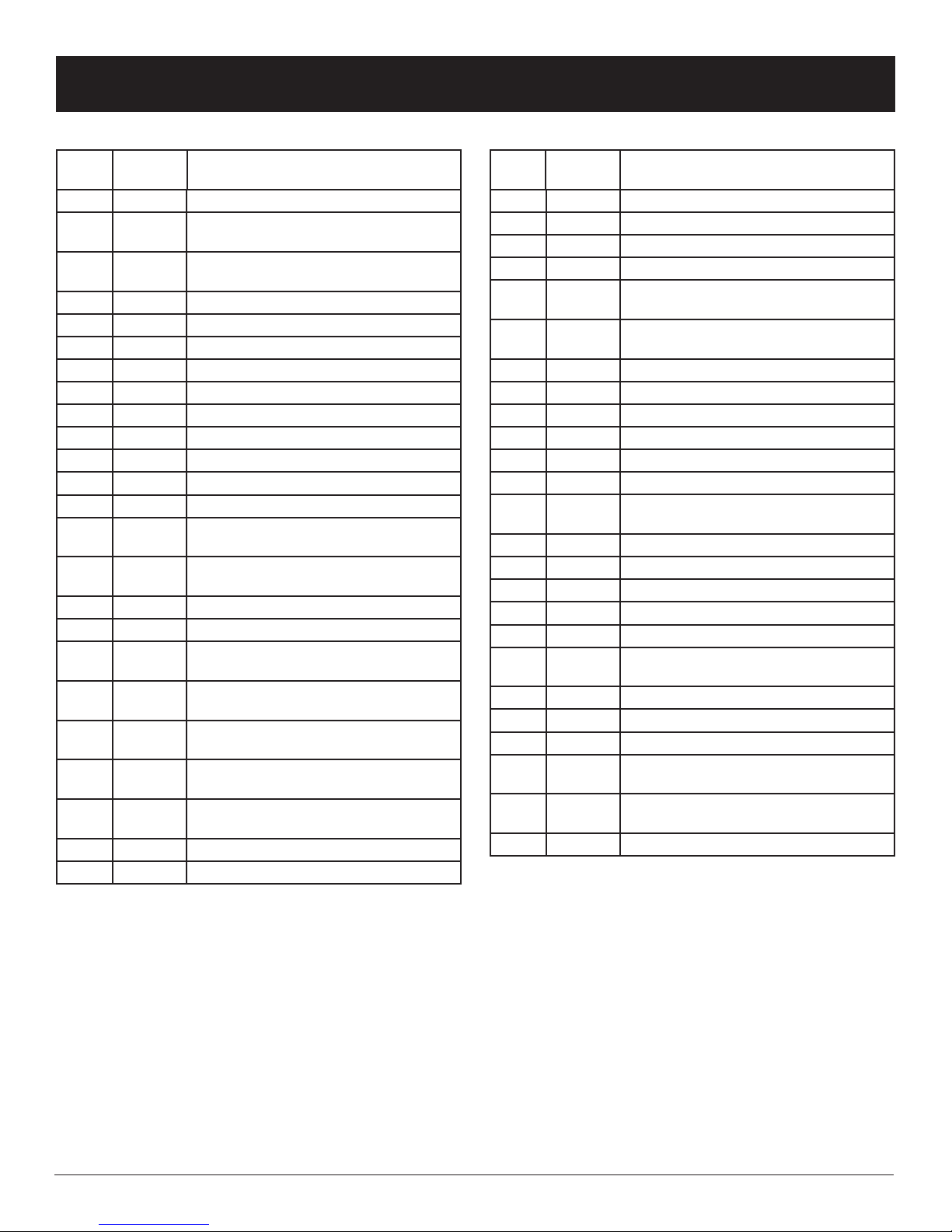

PROPER MAIN BURNER FLAME

The correct ame will be a short blue inner ame with a much larger

light blue outer ame. The burner does not have a primary air

adjustment. The ame will be proper if the factory-set pressure and

orice are used. After the furnace has begun operating, cleaning

of the burner may be needed for proper ame, examine at least 2

times per season.

To clean burner ports, disconnect the gas supply to the valve. Remove

the burner assembly from the combustion chamber. Remove pilot

burner from main burner and then remove the main burner. Force

water into the ports and blow dry with vacuum cleaner air, or low

pressure compressed air.

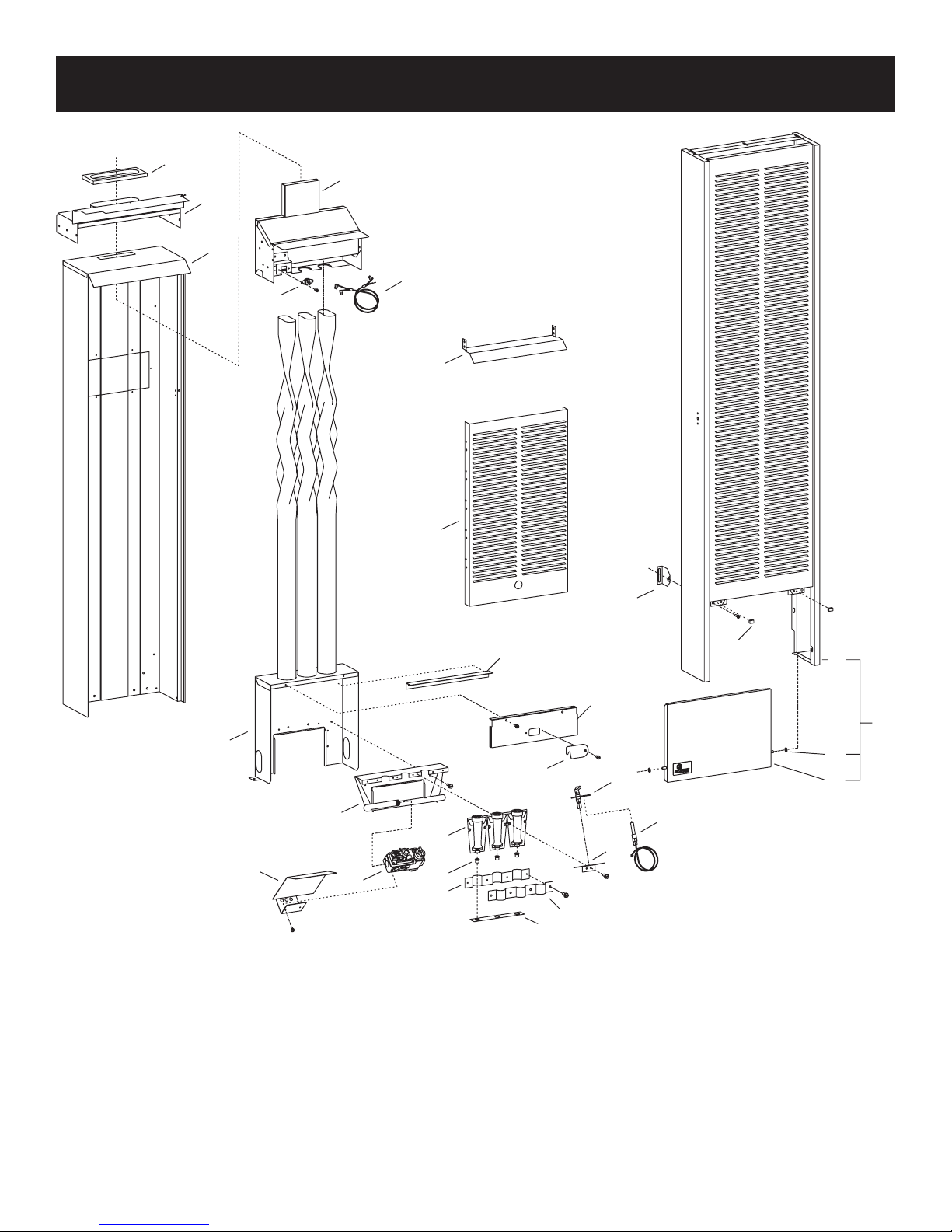

PROPER PILOT FLAME

The correct ame will be blue, extending past the thermopile. The

ame will surround the thermopile just below its tip.

Natural gas pilots require adjusting when the inlet gas pressure is

above 5" w.c. (1.245kPa). Remove the pilot cover screw on the

control valve and turn the adjustment screw clockwise to reduce

ame. Replace pilot cover screw to eliminate gas leaking at that

control valve opening.

LP gas (propane) will not require adjustment.

After use, cleaning may be required for the proper ame.

Examine the pilot ame before and during each heating season.

Figure 8

Figure 9

Figure 10

32038-1-0314 Page 13

TROUBLESHOOTING

GENERAL All furnaces have been re-tested to check for proper

operation. This includes main burner ame, pilot ame, and gas

control operation. If the furnace fails to function on initial installation,

it is advisable to re-check the following:

1. Inlet gas pressure.

2. Type of gas being used and that shown on the rating plate.

The Service Department at Empire Comfort Systems, Inc. may be

contacted to assist in servicing furnace.

Servicing the Pilot and Main Burner, Pilot Orice, Thermopile

and Main Burner Orice

Disconnect the gas supply at the inlet to the control valve. Remove the

burner assembly to which the above components are attached.

Pilot Does Not Light

With air in the gas line, such as when the furnace is rst installed

or was "OFF" all summer, the pilot ame may be too lean to ignite

on the rst few trials. Turn the gas control knob to PILOT position

and depress the gas control knob. Hold the gas control knob down

to bleed the line;

1. Use lighter rod to light pilot with a match.

If Pilot Does Not Light By Any Means

1. Check gas control knob for being in the "Pilot" position.

2. Check pilot adjustment for being full open (counterclockwise

to open).

3. If gas is available in the supply tubing, the pilot orice and/

or pilot burner is probably restricted by a spider web. Clean

pilot assembly and relight.

If Pilot Does Not Remain "On" After Releasing Gas Control

Knob

1. Follow instructions and hold gas control knob down longer

and harder.

2. Determine if pilot ame extends past thermopile; if not, adjust

pilot ame or clean pilot burner.

3. Replace thermopile if millivolt reading is less than 300 millivolts

when wall thermostat or remote bulb is turned OFF. Replace

gas control if magnet dropout millivolt reading is over 100

millivolts.

Pilot Outage During Normal Operation

1. Check input by manifold pressure gauge or gas meter.

2. Check millivolt output when furnace is in operation. If millivolt

output decreases during furnace operation gas control may

be defective.

Main Gas Valve Does Not Open When Thermostat Is Turned

"On"

1. Check millivolt output of thermopile.

2. Thermostat wires may be broken.

3. Thermostat may be defective.

32038-1-0314Page 14

MASTER PARTS DISTRIBUTOR LIST

To Order Parts Under Warranty, please contact your local Empire dealer. See the dealer locator at www.empirecomfort.com. To

provide warranty service, your dealer will need your name and address, purchase date and serial number, and the nature of the

problem with the unit.

To Order Parts After the Warranty Period, please contact your dealer or one of the Master Parts Distributors listed below. This

list changes from time to time. For the current list, please click on the Master Parts button at www.empirecomfort.com.

Please note: Master Parts Distributors are independent businesses that stock the most commonly ordered Original Equipment

repair parts for Heaters, Grills, and Fireplaces manufactured by Empire Comfort Systems Inc.

Dey Distributing

1401 Willow Lake Boulevard

Vadnais Heights, MN 55101

Phone: 651-490-9191

Toll Free: 800-397-1339

Website: www.deydistributing.com

Parts: Heater, Hearth and Grills

East Coast Energy Products

10 East Route 36

West Long Branch, NJ 07764

Phone: 732-870-8809

Toll Free: 800-755-8809

Fax: 732-870-8811

Website: www.eastcoastenergy.com

Parts: Heater, Hearth and Grills

HOW TO ORDER REPAIR PARTS

Victor Division of F. W. Webb Company

200 Locust Street

Hartford, CT 06114

Phone: 860-722-2433

Toll Free: 800-243-9360

Fax: 860-293-0479

Toll Free Fax: 800-274-2004

Websites: www.fwwebb.com & www.victormfg.com

Parts: Heater, Hearth and Grills

Able Distributors

2501 North Central Avenue

Chicago, IL 60639

Phone: 773-889-5555

Toll Free: 800-880-2253

Fax: 773-466-1118

Website: www. abledistributors.com

Parts: Heater

Parts Not Under Warranty

Parts can be ordered through your Service Person, Dealer, or a Master Parts Distributor. See this page for the Master Parts Distributors list. For best results, the service person or dealer should order parts through the distributor. Parts can be shipped directly to the

service person/dealer.

Warranty Parts

Warranty parts will need a proof of purchase and can be ordered by your Service Person or Dealer. Proof of purchase is required for

warranty parts.

All parts listed in the Parts List have a Part Number. When ordering parts, rst obtain the Model Number and Serial Number from the

name plate on your equipment. Then determine the Part Number (not the Index Number) and the Description of each part from the following illustration and part list. Be sure to give all this information . . .

Appliance Model Number Part Description

Appliance Serial Number Part Number

Type of Gas (Propane or Natural)

Do not order bolts, screws, washers or nuts. They are standard hardware items and can be purchased at any local hardware store.

Shipments contingent upon strikes, res and all causes beyond our control.

32038-1-0314 Page 15

PARTS LIST

ATTENTION: When ordering parts, it is very important that part number and description of part coincide.

Index

No.

Part No. Description Index

1 WFA115 HEADER GASKET

2 GWT172 HEADER ASSEMBLY

(INCLUDES NO. 1, GASKET) (USA)

2 15740 HEADER ASSEMBLY

(INCLUDES NO. 1, GASKET) (CANADA)

3 GWT182 INNER CASING ASSEMBLY

4 GWT065 DIVERTER ASSEMBLY- GWT-25-2

4 GWT066 DIVERTER ASSEMBLY - GWT-35-2

5 R3239 VENT SAFETY SWITCH - GWT-25-2

5 R3045 VENT SAFETY SWITCH - GWT-35-2

6 R3038 ECO LEAD ASSEMBLY

7 GWT020 FRONT SHIELD

8 GWT077 HEAT SHIELD

9 26463 EXCHANGER ASSEMBLY - GWT-25-2

9 26464 EXCHANGER ASSEMBLY- GWT-35-2

10 GWT070 BURNER BRACKET ASSEMBLY -

GWT-25-2

10 GWT073 BURNER BRACKET ASSEMBLY -

GWT-35-2

11 R5245 GAS VALVE - NAT

11 R5246 GAS VALVE - LP

12 R3031 BURNER (GWT-25-2 – 3 REQUIRED)

(GWT-35-2 – 4 REQUIRED)

13 P8855 BURNER ORIFICE - GWT-25-2 NAT

(3 REQUIRED)

13 P8865 BURNER ORIFICE - GWT-25-2 LP

(3 REQUIRED)

13 P8854 BURNER ORIFICE - GWT-35-2 NAT

(4 REQUIRED)

13 P8865 BURNER ORIFICE - GWT-35-2 LP

(4 REQUIRED)

14 GWT169 AIR SHUTTER REAR- GWT-25-2 LPG

14 GWT012 AIR SHUTTER REAR - GWT-35-2 LPG

Part No. Description

No.

15 GWT054 AIR SHUTTER BOTTOM - GWT-25-2 LP

15 GWT049 AIR SHUTTER BOTTOM - GWT-35-2 LP

16 GWT168 AIR SHUTTER FRONT - GWT-25-2 LP

16 GWT011 AIR SHUTTER FRONT - GWT-35-2 LP

17 GWT010 BURNER COMPARTMENT FRONT -

GWT-25-2

17 GWT008 BURNER COMPARTMENT FRONT -

GWT-35-2

18 DV064 COVER PLATE

19 R3035 PILOT - LP

19 R3034 PILOT - NAT

20 GWT021 PILOT BRACKET

21 R1054 THERMOPILE

22 GWT186 CASING BRACKET

23 GWT177 CASING FRONT ASSEMBLY

(INCLUDES #24)

24 R3763 MAGNET (2 REQUIRED)

25 GWT087 CASING DOOR ASSEMBLY (USA)

25 15739 CASING DOOR ASSEMBLY (CANADA)

26 R885 NYLON WASHER (2 REQUIRED)

27 23906 VALVE SHIELD

28 23385 CASING ASSEMBLY COMPLETE

(INCLUDES #23, #25, & #26)

29 29011 EXCHANGER TUBE SUPORT

N/S GWT121 PILOT TUBING- GWT-25-2

N/S GWT076 PILOT TUBING- GWT-35-2

N/S R1089 PILOT ORIFICE

(HONEYWELL .009 LP ONLY)

N/S R1081 PILOT ORIFICE

(HONEYWELL .014 NAT ONLY)

N/S GWT190 HARDWARE PACKAGE

USE ONLY MANUFACTURER'S REPLACEMENT PARTS. USE OF ANY OTHER PARTS COULD CAUSE INJURY OR DEATH.

32038-1-0314Page 16

28

PARTS VIEW

1

2

3

5

4

6

7

8

22

29

17

9

27

10

11

18

12

13

14

16

15

19

21

20

24

23

26

25

32038-1-0314 Page 17

OPTIONAL REMOTE BULB CONTROL INSTALLATION

INSTRUCTIONS

MODELS

GWT-25 RB, GWT-35 RB, GWT-50 RB

INSTRUCTIONS

Note: At the option of the owner, the remote bulb control may be

located on the left or right side of the outer casing.

1. Remove remote bulb control from the shipping carton.

2. Remove outer casing assembly from shipping carton.

Note: If wall furnace is already installed, remove outer casing from

unit and lay on oor with front side down.

3. Attach wire assembly to remote bulb control.

4. Carefully unwind capillary wire on remote bulb control.

5. Remove (3) hole plugs from left or right side of outer casing

where remote bulb control is to be installed.

6. Mount remote bulb control to inside of outer casing with (2) No.

6-32 x 1/4" (6mm) screws.

Index Part

No. Number Description

1 GW-130 Remote Bulb Control Kit

2 R-1224 Remote Bulb Control

3 R-2499 Wire Assembly

4 R-1162 Control Knob

5 R-1720 Plastic Clip (3 Required)

6 R-1223 Instructions

7 R-1578 No. 6-32 x 1/4" (6mm) Screw (2 Required)

Caution: Remote bulb wire routing is important. Wires should be in

proper location to avoid damage from being overheated.

Incorrect routing of remote bulb control wires may result

in damage to wires and incorrect operation of remote

bulb control. Follow these instructions and refer to the

drawing for proper wire routing.

7. If remote bulb control is located on the right side of the outer

casing, carefully bend or loop capillary wire around control. This

will enable the sensing bulb to be positioned at the bottom of

the unit.

8. Secure sensing bulb on the inside, at the bottom, of the outer

casing with (2) plastics clips.

9. Feed the wire assembly down along the inside of the outer

casing.

10. Use third plastic clip to secure wire assembly and capillary

wire to the casing. (Approximately 24" (610mm) from bottom

of unit.)

11. Attach control knob to remote bulb control.

12. Install furnace according to instructions in the Installation Instructions and Owner's Manual.

Note: If wall furnace is already installed, secure outer casing to

unit.

13. Attach wire assembly to gas valve at the "TH" and "TH/TP"

terminals on the Robertshaw valve.

Attach wire assembly to gas valve at the "THERMO" terminals

on the ITT valve. If the wire assembly has two 1/4" (6mm)

female connectors, the connectors should be cut off the wire

assembly. Strip and bare the wires and attach wires to the

"THERMO" terminals.

Note: This remote bulb control is connected to the gas valve

the same way as a wall thermostat. Any references made to

the thermostat in the lighting instructions would also apply to

the remote bulb control.

32038-1-0314Page 18

OPTIONAL BLOWER INSTALLATION INSTRUCTIONS

GWTB-2 FOR MODELS

GWT-25 (SG, RB), GWT-35 (SG, RB), GWT-50 (SG, RB)

Installing Blower Using Three-Prong Plug

1. Install furnace according to Installation Instructions and Owner's

Manual.

2. Refer to Drawing for measurements to locate (2) mounting

holes on wall surface above furnace.

On Solid Wall

3. After locating mounting holes, attach (2) #10 x 1 1/2" screws

provided in blower kit into wall. Do not completely tighten

screwheads to wall, leave a 7/16" gap between screwheads

and wall.

On Sheet Rock Wall

3. After locating mounting holes, drill (2) 5/16" diameter holes into

wall. Insert the (2) plastic expansion anchors into holes. Insert

(2) #10 x 1 1/2" screws provided in blower kit into (2) plastic

expansion anchors. Do not completely tighten screwhead

to plastic expansion anchors, leave a 7/16" gap between

screwheads and plastic expansion anchors. Refer to Figure

2.

4. At the top of outer casing remove (1) screw from center

clearance hole that attaches outer casing to header assembly.

Also, remove (2) screws that attach bottom of outer casing to

inner casing.

5. Pull the outer casing forward approximately 1 inch away from

wall surface.

6. Remove (4) 8 x 3/8" screws that attach blower front to blower

housing.

Caution: When removing blower front be careful not to

damage motor coil wires. Damaged coil wires will disable

blower function.

7. Position blower housing on top of header assembly and route

three-prong cord set between left side of outer casing and inner

casing.

Caution: Blower cord set routing is important. Cord set

should be in proper location to avoid being overheated.

Incorrect routing of cord set may result in damage to cord

set.

8. Replace the outer casing to the wall surface.

9. Attach outer casing to header assembly. Attention: The center

clearance hole will not be used. The two outside clearance

holes will be used to attach outer casing to header assembly,

(1) screw from Step 4 and (1) screw supplied in hardware

package. Refer to Figure 1.

10. Attach outer casing to inner casing with (2) screws from Step

4.

11. Align key hole slots on back of blower housing with the (2)

screws attached to wall. Position blower housing ush with

wall surface and on top of outer casing. Complete tightening

blower housing screws from Step 3 to wall.

12. Attach caps and plugs from blower housing and blower front.

13. Attach blower front to blower housing with (4) 8 x 3/8" screws

from Step 6.

14. Installation of optional blower assembly is completed.

Caution: When installing blower housing onto wall be careful

motor coil is not damaged.

Installing Blower With Hard Wiring

1. When facing the wall opening, install 120V electrical outlet

junction box inside wall opening on left wall stud approximately

12 inches above header plate.

2. Refer to Drawing for measurements to locate access hole for

electrical wiring on wall surface.

3. After locating access hole, drill a 1/2" hole into wall.

4. Route enough eld wiring from 120V electrical outlet junction

box through 1/2" access hole in wall for connection to blower

housing.

5. Install furnace according to Installation Instructions and Owner's

Manual.

6. Refer to Drawing for measurements to locate (2) mounting

holes on wall surface above the furnace.

On Solid Wall

7. After locating mounting holes, attach (2) #10 x 1 1/2" screws

provided in blower kit into wall. Do not completely tighten

screwheads to wall, leave a 7/16" gap between screwheads

and wall.

On Sheet Rock Wall

7. After locating mounting holes, drill (2) 5/16" diameter holes into

wall. Insert (2) plastic expansion anchors into holes. Insert

(2) #10 x 1 1/2" screws provided in blower kit into (2) plastic

expansion anchors. Do not completely tighten screwhead

to plastic expansion anchors, leave a 7/16" gap between

screwheads and plastic expansion anchors. Refer to Figure

2.

Figure 1

32038-1-0314 Page 19

Figure 2

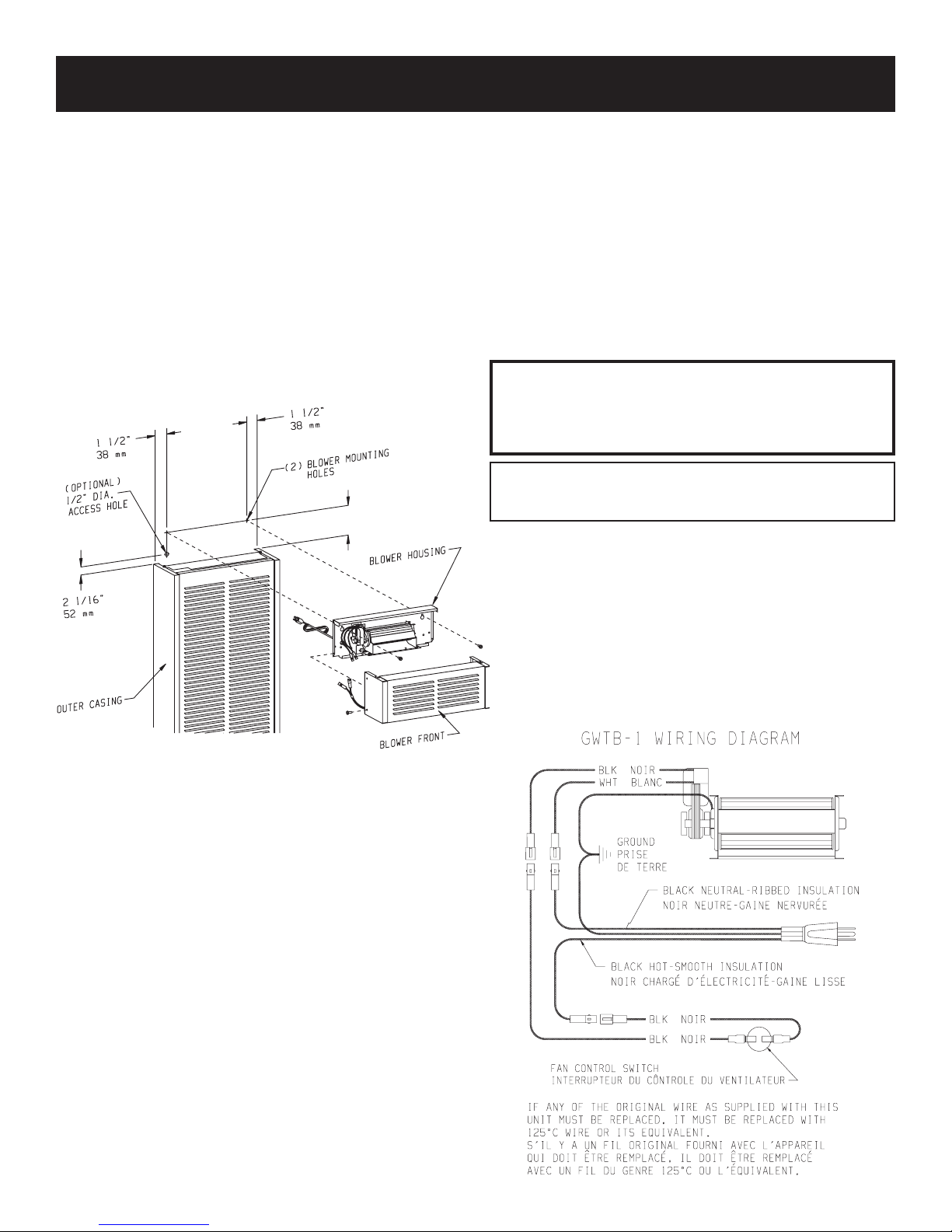

OPTIONAL BLOWER INSTALLATION INSTRUCTIONS

8. Remove three prong cord set from blower housing.

9. Remove (4) 8 x 3/8" screws that attach blower front to blower

housing.

10. Position blower housing on top of header assembly.

11. Route 120V eld wiring into blower housing through cord set

hole on back of blower housing.

12. Refer to wiring diagram to make wiring connections inside blower

housing. Be sure to follow all local and National electrical codes

when making eld wiring connections.

13. Align key hole slots on back of blower housing with (2) screws

attached to wall. Position blower housing ush with wall surface

and on top of outer casing. Complete tightening blower housing

screws from Step 7 to wall.

14. Attach caps and plugs from blower housing and blower front.

15. Attach blower front to blower housing with (4) 8 x 3/8" screws

from Step 9.

16. Installation of optional blower assembly is completed.

13”

(330 mm)

4 7/16”

(112.6 mm)

Wiring

The appliance, when installed, must be electrically grounded in

accordance with local codes or, in the absence of local codes, with

the National Electrical Code, ANSI/NFPA 70 or Canadian Electrical

Code, CSA C22.1, if an external electrical source is utilized. This

appliance is equipped with a three-prong [grounding] plug for

your protection against shock hazard and should be plugged

directly into a properly grounded three-prong receptacle. Do

not cut or remove the grounding prong from this plug. For an

ungrounded receptacle, an adapter, which has two prongs and a

wire for grounding, can be purchased, plugged into the ungrounded

receptacle and its wire connected to the receptacle mounting screws.

With this wire completing the ground, the appliance cord plug can

be plugged into the adapter and be electrically grounded.

WARNING:

Unplugging of blower accessory will not stop the heater

from cycling. To shut heater off: Turn temperature dial or

thermostat to lowest setting. Turn knob on gas control to

"OFF", depressing slightly. Do not force.

CAUTION: Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing.

Oiling

The blower motor does not have oiling holes. Do not attempt to oil

the blower motor.

Figure 3

Fan Control

The automatic fan control is located on the bottom of the blower

assembly. The fan control is a nonadjustable, automatic type. The

fan control will require between 3 and 7 minutes of main burner

operation before the fan control "closes" and activates the blower.

The blower will continue to run between 3 and 7 minutes after the

main burner shuts off, before the fan control "opens" and deactivates

the blower.

GWTB-2 WIRING DIAGRAM

32038-1-0314Page 20

Loading...

Loading...