Empire Comfort Systems VFD42FB0F-1, VFD36FB0F-1, VFD36FB0L-1, VFD36FB2DF-1, FD42FB2DF-1 User Manual

...Page 1

INSTALLATION INSTRUCTIONS

GAS-FIRED

The Breckenridge

AND OWNER'S MANUAL

UNIVERSAL FIREBOX FOR ALL

VENT-FREE LOG SETS

Deluxe Vent-Free Universal Fireboxes

ANSI Z21.91 Ventless Fireplace Enclosures for Gas Fired Decorative Type Unvented Room Heaters

WARNING: If the information in these instructions are

not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life.

— Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neigh

bor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed by a quali

fied installer, service agency or the gas supplier.

DO NOT ATTEMPT TO MODIFY OR ALTER THE

CONSTRUCTION OF THE FIREBOX OR ITS COMPONENTS. ANY MODIFICATION OR ALTERATION OF

CONSTRUCTION MAY VOID THE WARRANTY OF

THIS FIREBOX.

CHILDREN AND ADULTS SHOULD BE ALERTED TO

THE HAZARDS OF HIGH SURFACE TEMPERATURE

AND SHOULD STAY AWAY TO AVOID BURNS OR

CLOTHING IGNITION.

YOUNG CHILDREN SHOULD BE CAREFULLY SUPER

VISED WHEN THEY ARE IN THE SAME ROOM AS THE

FIREBOX.

-

-

-

MODELS

VFD32FB0L-1 VFD36FB0L-1 VFD42FB0L-1

VFD32FB2DL-1 VFD36FB2DL-1 VFD42FB2DL-1

VFD32FB2CL-1 VFD36FB2CL-1 VFD42FB2CL-1

VFD32FB0F-1 VFD36FB0F-1 VFD42FB0F-1

VFD32FB2DF-1 VFD36FB2DF-1 VFD42FB2DF-1

VFD32FB2CF-1 VFD36FB2CF-1 VFD42FB2CF-1

Effective Date

December 2006

Installer: Leave this manual with the appliance.

Consumer: Retain this manual for future reference.

FOR USE ONLY WITH A LISTED GAS-FIRED UNVENTED DECORATIVE ROOM HEATER NOT TO

EXCEED 40,000 BTU/H.

DO NOT BUILD A WOOD FIRE.

WARNING: Improper installation, adjustment, alteration,

service or maintenance can cause injury or property damage. Refer to this manual. For assistance or additional information, consult a qualified installer, service agency or the

gas supplier.

Carefully review the instructions supplied with the decorative type unvented room heater for the minimum fireplace

size requirement.

DO NOT INSTALL A VENT-FREE LOG SET IN THIS

FI REB OX, UNLE SS TH IS FI REB OX ME ETS THE

MIN I MUM DI MENSI O NS RE Q UIRE D FOR T HE

INSTALLATION.

Page 123200-0-1206

Page 2

TABLE OF CONTENTS

SECTION PAGE

Important Safety Information .................................................................................................3

Introduction ............................................................................................................................3

Clearances ..............................................................................................................................4

Firebox Installation Instructions ......................................................................................... 4-7

Installing Hood ................................................................................................................... 7-8

Gas Line Connection .............................................................................................................8

Optional Fresh Air Kit Installation Instructions ............................................................... 9-11

Optional Single Speed Blower Installations Instructions ............................................... 12-14

Junction Box Wiring Installation Instructions ......................................................................

15

Maintenance .........................................................................................................................15

Parts List ....................................................................................................................... 16-17

How to Order Repair Parts ...................................................................................................17

Parts View .............................................................................................................................

18

Accessories ..................................................................................................................... 19-20

23200-0-1206Page 2

Page 3

IMPORTANT SAFETY INFORMATION

The installation must conform with local codes or, in

the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1 (latest edition) and to the National

electrical Code, ANSI/NFPA70 (latest edition).

NOTE: Installation and repair should be done by a quali

fied service person. The appliance should be inspected

before use and at least annually by a qualified service

person. More frequent cleaning may be required due to

excessive lint from carpeting, bedding material, etc. It

is imperative that control compartment, burners and

circulating air passageways of the appliance be kept

clean.

This Empire Comfort Systems, Inc. firebox and its

components have been tested and will operate safely when

installed in accordance with this installation manual.

Read all instructions before starting installation, then

follow these instructions carefully during installation

to maximize firebox benefit and safety. Report to your

dealer any parts damaged in shipment.

The Empire Comfort Systems, Inc. warranty will be

voided by, and Empire Comfort Systems, Inc. disclaims

any responsibility for the following actions:

- Installation of any damaged firebox.

- Modification of the firebox or any of the components

parts thereof.

Any safety screen or guard removed for servicing an

appliance must be replaced prior to operating the ap

pliance. Provide adequate combustion and ventilation

air.

The flow of combustion and ventilation air MUST NOT

be obstructed.

Provide adequate clearance around air openings into

the combustion chamber and adequate accessibility

clearance for servicing and proper operation. NEVER

obstruct the front opening of the appliance.

- Installation other than as instructed by Empire

Comfort Systems, Inc.

- Installation and/or use of any component part or

accessory not approved by Empire Comfort Systems,

Inc. in combination or assembly with a Empire

Comfort Systems, Inc. firebox, not withstanding any

independent testing laboratory or other third party

approval of such component part or accessory.

Any such action may create a possible fire hazard.

Consult your local building codes.

Firebox Screen.

The firebox screen must be in place when the firebox is

operating.

-

INTRODUCTION

Instructions to Installer

1. Installer must leave instruction manual with owner after

installation.

2. Installer must have owner fill out and mail warranty card

supplied with firebox.

3. Installer should show owner how to start and operate log set

that is installed into firebox.

Important

All correspondence should refer to complete Model Number,

Serial Number.

Notice: During initial firing of this firebox with a log set installed, its

paint will bake out, and smoke will occur. To prevent triggering of

smoke alarms, ventilate the room in which the unit is installed.

Qualified Installing Agency

Installation and replacement of gas piping, gas utilization

equipment or accessories and repair and servicing of equipment

shall be performed only by a qualified agency. The term "qualified

agency" means any individual, firm, corporation or company

which either in person or through a representative is engaged in

and is responsible for (a) the installation or replacement of gas

piping or (b) the connection, installation, repair or servicing of

equipment, who is experienced in such work, familiar with all

precautions required and has complied with all the requirements

of the authority having jurisdiction.

State of Massachusetts: The installation must be made by

a licensed plumber or gas fitter in the Commonwealth of

Massachusetts. The state of Massachusetts requires that a

flexible appliance connector cannot exceed three feet in

length.

Sellers of unvented propane or natural gas-fired supplemental

room heaters shall provide to each purchaser a copy of 527

CMR 30 upon sale of the unit.

In the State of Massachusetts, unvented propane and natural

gas-fired space heaters shall be prohibited in bedrooms and

bathrooms.

The installation must conform with local codes or, in the absence

of local codes, with the National Fuel Gas Code, ANSI Z223.1/

NFPA 54.*

*Available from the American National Standards Institute, Inc., 11 West

42nd St., New York, N.Y. 10036.

Page 323200-0-1206

Page 4

45°

6”

3”

MAX.

PERPENDICULAR

SIDE

WALL

FRONT FACE (SIDE)

FIREBOX

(TOP VIEW)

COMBUSTIBLE

MATERIALS ALLOWED

IN SHADED AREAS

FIREBOX

STAND OFF

FINISH

WITH TRIM KIT OR

NON-COMBUSTIBLE MATERIAL

AS DESIRED.

COMBUSTIBLE

FINISHED

WALL

OR MANTEL

2 X 4

HEADER

MANTEL

HOOD

13”

10”

12”

MAX

42”

MIN.

(CEILING TO

TOP O

F HOOD)

11 1/2”

MIN.

FIREBOX

FACE

84”

MIN.

(CEILING TO FLOOR)

CEILING

COMBUSTIBLES

ALLOWED

3/8” COMBUSTIBLE

CLEARANCE REQUIRED

FROM TOP EDGE

OF FIREBOX

10”

22”

8”

20”

6 ½

”

18”

5”

16”

3 ½

”

14”

2”

12 ½”

3/4”

24 ½”

0”

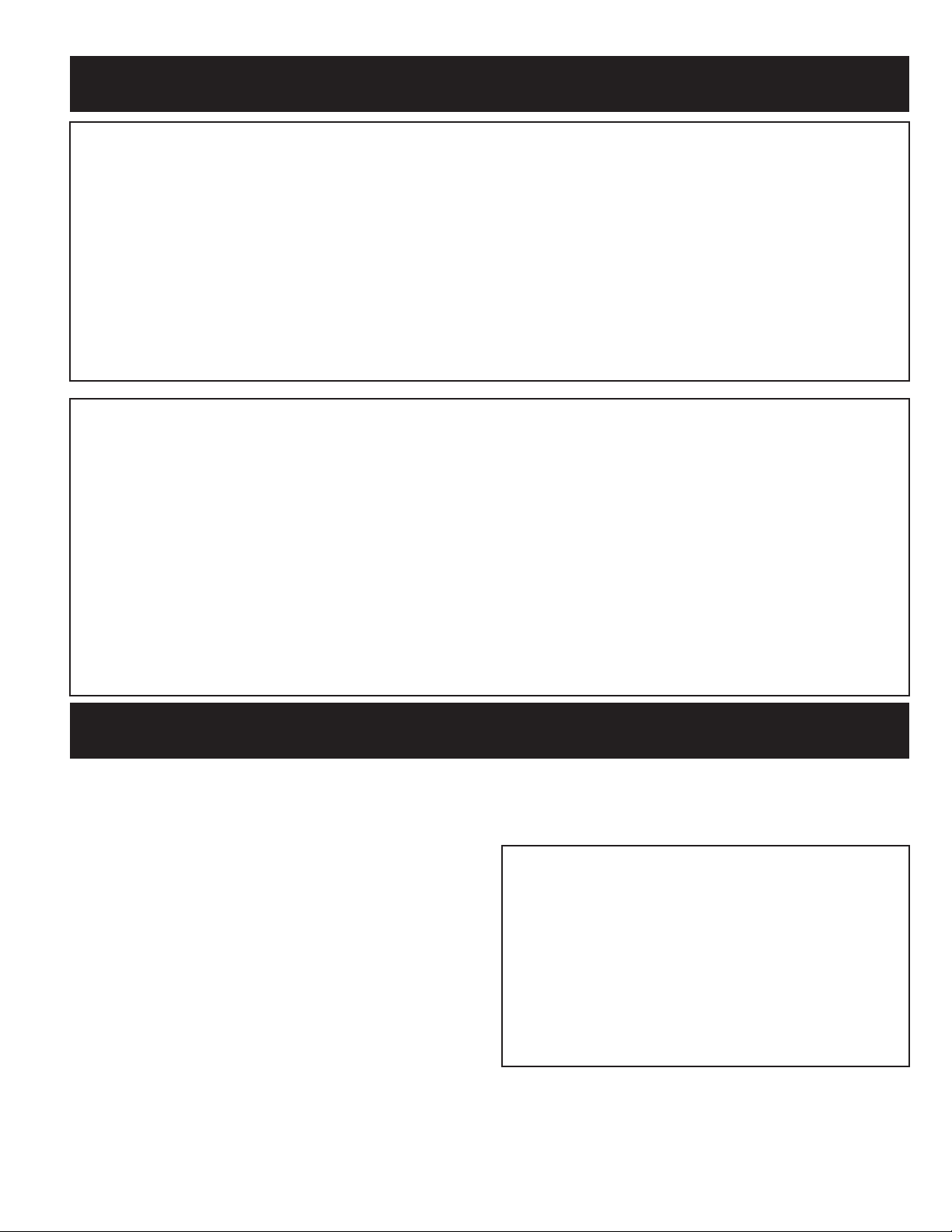

CLEARANCES

Sidewall Clearances: The clearance from the inside of the firebox

to perpendicular combustible side wall should not be less than

6". See Figure 1.

Firebox Side and Back Clearances: The firebox outer casing side

and back flanges are zero clearance to combustibles.

Top Framing and Finishing: Combustible framing may rest on

top of standoffs. Combustible finishing materials may extend

to the top standoff screws on the front edge of the outer wrap.

See Figure 2

.

Figure 1

Ceiling Clearances: The ceiling height should not be less than 42"

from the top of the hood. See Figure 3.

Mantel Clearances: Vent free firebox models must use the hood

supplied with the firebox, or one of the optional hood kits

available for each model. If a combustible mantel is installed,

it must meet the clearance requirements detailed below.

Grate Clearance: The minimum clearance between the front legs

of the grate and front edge of the firebox is 2".

Leave at least 36" clearance from the front of the firebox.

Any vent-free Gas Log Heater must be “For use with approved

ANSI Z21.11.2 unvented room heater.”

Follow and complete the installation instructions of the gas log set

and the requirements of this firebox.

FIREBOX INSTALLATION INSTRUCTIONS

Figure 2

Figure 3

Clearances to combustibles

Check all fittings for leaks before lighting the gas log set.

In planning the installation for the firebox, it is necessary to

determine where the unit is to be installed and whether optional

accessories are desired. Gas supply piping should also be planned

at this time.

A gas shut off must be in this line.

23200-0-1206Page 4

Page 5

The firebox can be mounted on any of these surfaces:

COMBUSTIBLE MATERIALS ALLOWED

NON-COMBUSTIBLE

FINISHING MATERIAL

TO FIREBOX OPENING

FLUSH

FACE

MODELS

LOUVERED

FIREBOX

MODELS

COMBUSTIBLE MATERIALS ALLOWED

1. A flat hard combustible or non-combustible surface.

2. A raised platfor m of combustible or non-combustible

material.

3. Recessed into the floor as illustrated by Figure 4 (flush face),

and Figure 5 (louvered models).

4. Supported under all (4) corners of the firebox so that contact

is made on all four perimeter edges on the bottom of the unit

(Example: Four (4) concrete masonry blocks).

If the firebox is installed directly on carpeting, tile or other

combustible material other than wood flooring, it should be installed

on a metal or wood panel extending the full width and depth of

the unit.

At this point, you should have decided what components to include

in your installation, and where the firebox is to be located. If this

has not been done, stop and consult your dealer for assistance

with

this planning.

Planning Your Installation

Please note that the optional BVA1 Fresh Air kit available for use

with the Vent Free Firebox must be installed at the time of the initial

installation. Refer to pages 9, 10, and 11 for detailed instructions

for the air kit.

Accessory kits such as the FBB5 Blower kit, Trim kits, Mantles,

Full Cabinet Mantels, plus other Decorative Frame, Hood, and

Door accessory kits may be installed after the firebox is secured

to the framed opening.

Refer to the instructions provided with each of the optional

accessory kits for proper installation and operation.

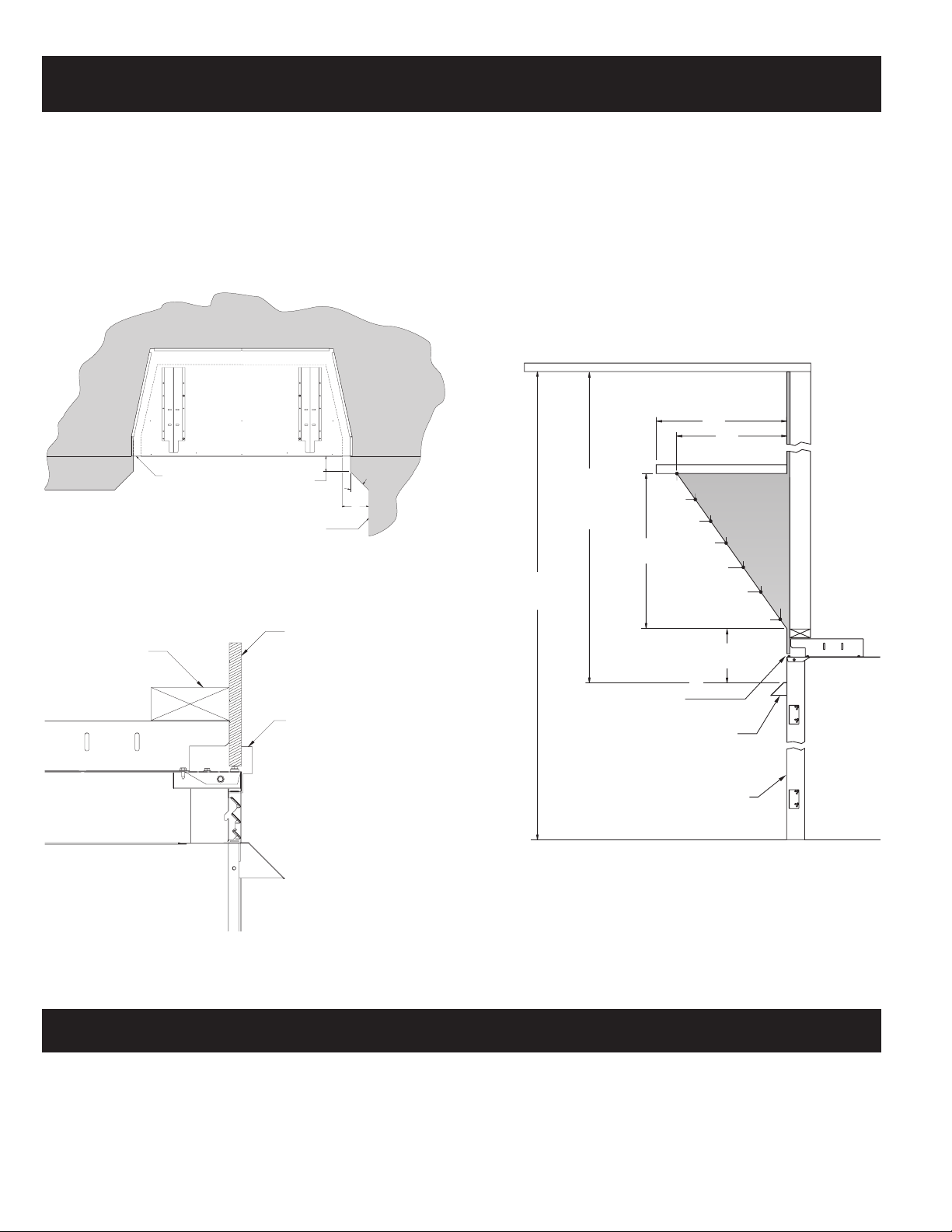

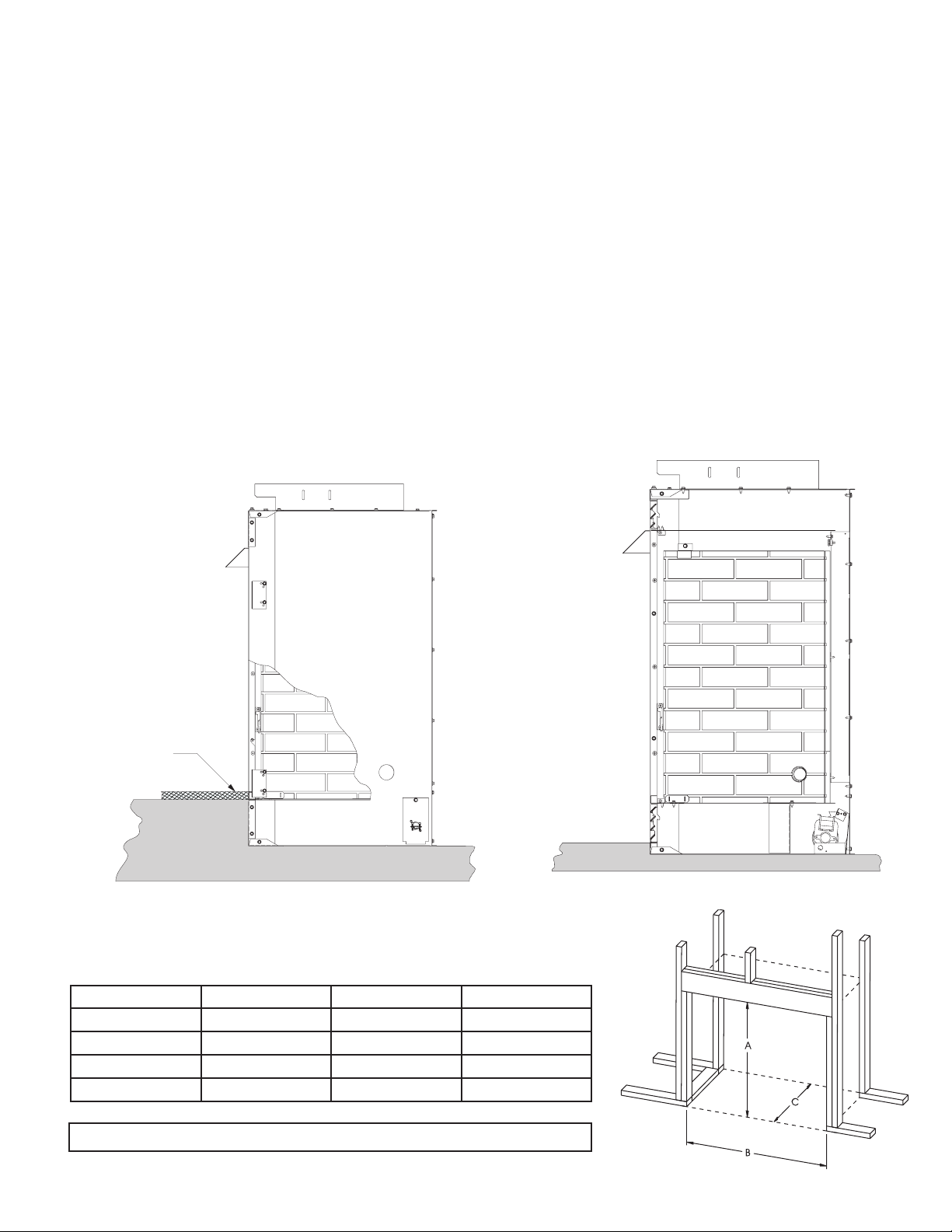

Firebox Framing

Firebox framing can be built before or after the firebox is set

in place. Framing should be positioned to accommodate wall

covering and firebox facing material. The firebox framing should

be constructed of 2 x 4 lumber or heavier. The framing headers

may rest on the top of the firebox standoffs. Refer to Figures 6

and 7 for firebox framing dimensions.

Model Framing Height Framing Width Framing Depth

Attention: Add 3-3/4" to "A" Dimension when using flush mantel base.

Framing dimension A includes a three inch clearance for standoffs on firebox.

Figure 4

Deluxe Vent-Free Firebox Framing Dimensions (in inches)

"A" "B" "C"

VFD32FB 36 1/8" 35" 17"

VFD36FB 38 1/8" 40" 19 3/8"

VFD42FB 38 1/8" 44" 19 3/8"

Figure 5

Figure 6

Page 523200-0-1206

Page 6

H

J

K

I

A

G

F

B

E

H

I

A

G

F

B

E

C

D

L

M

DELUXE

LOUVERED

DELUXE

FLUSH

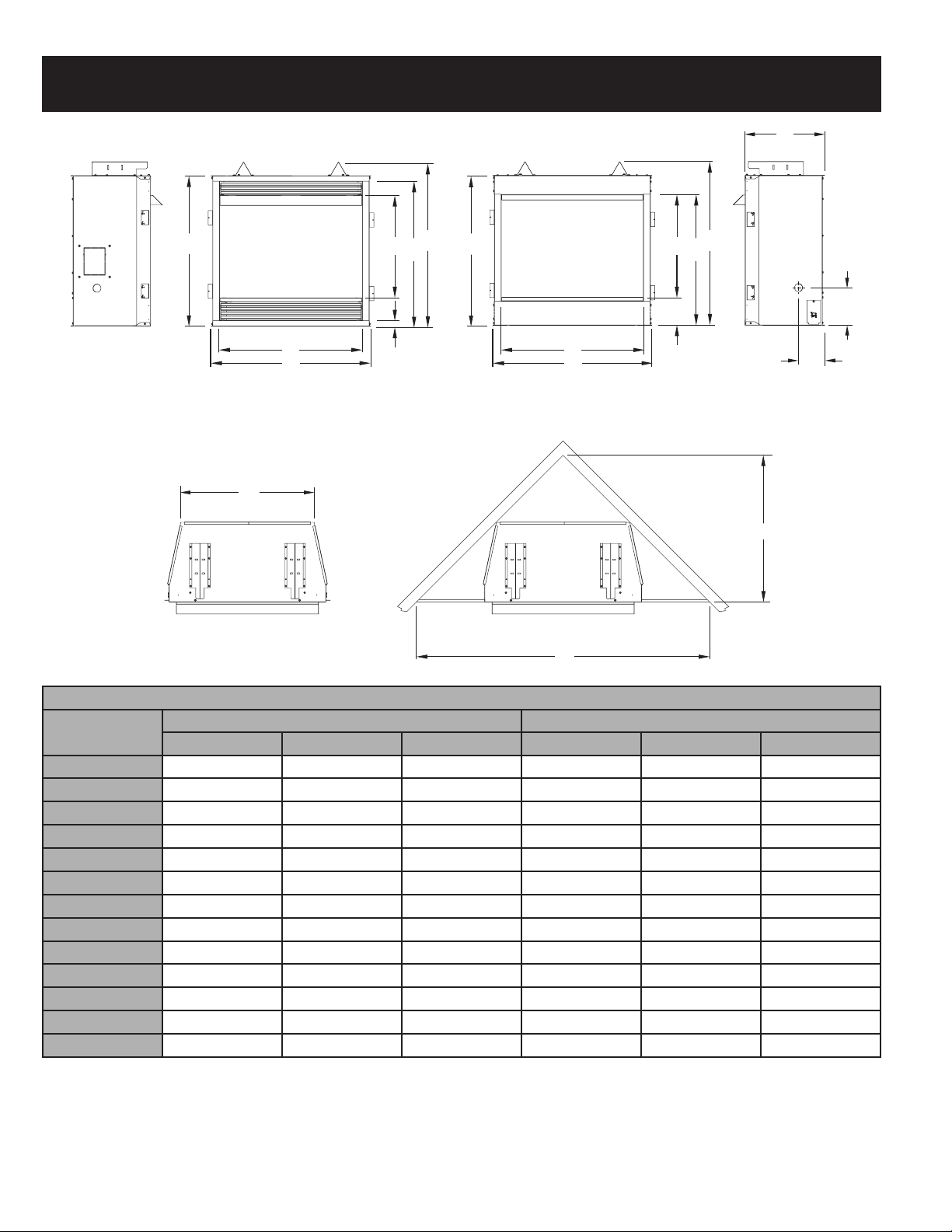

FIREBOX INSTALLATION INSTRUCTIONS (continued)

REFERENCE

LETTER

DELUXE

LOUVERED FLUSH

VFD32 VFD36 VFD42 VFD32 VFD36 VFD42

A 35 5/8" 37 5/8" 37 5/8" 35 5/8" 37 5/8" 37 5/8"

B 34 1/2" 39 1/2" 43 1/2" 34 1/2" 39 1/2" 43 1/2"

C 17 7/16" 19 13/16" 19 13/16" 17 7/16" 19 13/16" 19 13/16"

D 29" 33" 37" 29" 33" 37"

E 33" 35" 35" 33" 35" 35"

F 31" 36" 40" 31" 36" 40"

G 22 3/8" 24 3/8" 24 3/8" 22 3/8" 24 3/8" 24 3/8"

H 1 1/4" 1 1/4" 1 1/4" 6 1/8" 6 1/8" 6 1/8"

I 31 1/2" 33 1/2" 33 1/2" 28 9/16" 30 9/16" 30 9/16"

J 8 3/8" 8 3/8" 8 3/8" 8 3/8" 8 3/8" 8 3/8"

K 5 3/4" 5 3/4" 5 3/4" 5 3/4" 5 3/4" 5 3/4"

L 31 13/16" 36 3/16" 38 3/16" 31 13/16" 36 3/16" 38 3/16"

M 63 3/8" 72 3/8" 76 3/8" 63 3/8" 72 3/8" 76 3/8"

Figure 7

Firebox Dimensions

23200-0-1206Page 6

Page 7

ATTACH (4)

FRAMING BRACKETS

TO

SIDES OF FIREBOX

PRIOR TO INSTALLING

UNIT TO FRAMED OPENING

A

C

A

C

B

C

B

C

B

FIREBOX OPENING

CHECK TO SEE

THA

T BOX IS SQUARE

PRIOR TO AT

TACHING TO

FRAMING

FIREBOX INSTALLATION INSTRUCTIONS (continued)

Locating Firebox

Place firebox in framing opening. Use the four (4) framing brackets

provided on the firebox to attach firebox to framing. Different hole

locations can be used for finishing materials with thicknesses of

3/8", 1/2" and 3/4". Attach these materials with screws provided,

two (2) per framing bracket. See Figure 8.

Framing brackets should fit directly against framing material. Use

at least one (1) nail per bracket to secure in place.

Check squareness of the firebox prior to securing to framed opening.

See Figure 9.

Figure 8

INSTALLING HOOD

A black hood that is furnished with each firebox (or optional hood)

MUST be installed before the firebox is used. Failure to do so may

create a possible fire hazard. The hood is located behind upper

louver, or inside the firebox on flush face units. If brass, stainless

steel, or hammered pewter hoods are desired, they can be purchased

as an option. Attachment is the same as the standard black hood.

Flush Face Models

1. On flush face models, loosen the two screws (A) holding firebox

top to face panel, then slide the hood flange between the firebox

top and face panel and re-tighten the screws.

2. Install one (1) screw at each end of the hood as shown (C).

Louvered Models

1. If you have a louvered model, remove upper louver.

2. Place the top hood flange on top of the firebox, then install three

screws through the firebox top from below and screw into the

pilot holes in the hood flange (B).

3. Install one (1) screw at each end of the hood as shown (C).

4. Re-install louver.

Caution: The hood must be installed prior to operation of appliance.

See Figure 10

Figure 9

Flush Face Models

Louvered Models

Figure 10

Page 723200-0-1206

Page 8

GAS ACCESS HOLES

INSTALLING HOOD (continued)

Extended Hoods

If your non-combustible facing material is over 1" in thickness that will be used to finish this firebox, an extended hood is available that

will extend out 2" farther out into the room. Contact your local dealer for details.

VB4H32BL Standard Black VB4H36BL Standard Black VB4H42BL Standard Black

VB4H32BR Polished Brass VB4H36BR Polished Brass VB4H42BR Polished Brass

VB4H32SS Stainless Steel VB4H36SS Stainless Steel VB4H42SS Stainless Steel

VB4H32HP Hammered Pewter VB4H36HP Hammered Pewter VB4H42HP Hammered Pewter

Finishing

All joints (top, bottom and sides), where the wall or decorative facing material meets the firebox surround should be sealed with a noncombustible material.

Hearth extensions are recommended, but not required for these fireboxes.

GAS LINE CONNECTION

The firebox is designed to accept a 3/8-inch gas line for an approved

vent-free gas logset. Have the line installed by a qualified service

person in accordance with all building codes. Consult local building

codes to properly size the gas supply line leading to the 3/8-inch

hook-up at the unit. The state of Massachusetts requires that a

flexible appliance connector cannot exceed three feet in length.

Gas access holes are provided on both sides of the firebox.

Figure 11. On models with ceramic brick panels installed, carefully

remove the indented knockout in the ceramic brick panel using a

drill or utility knife. See Figure 12.

When installing optional ceramic fiber side panels into firebox,

lay panel on a flat surface. Remove the gas line knockout (round

depression) in the appropriate side panel using a drill or utility

knife.

After the brick panel knockout is removed, the firebox wrap may

have a round metal knockout that must be removed also. Use a

screwdriver to punch out the metal knockout.

Check gas type. Use only the gas type indicated on the gas log

set rating plate. If the gas listed on the plate is not your type of

gas supply, DO NOT INSTALL. Contact your dealer for proper

model.

Always use an external regulator for all LP fireboxes to reduce the

supply tank pressure to a maximum of 14" w.c. This is in addition

to the regulator fitted to the log set.

WA R N I N G : C O N N E C T I O N D I R EC T LY T O A N

UNREGULATED L.P. TANK CAN CAUSE EXPLOSION.

Install only a ANSI Z21.11.2 vent-free log set into this firebox.

See

Figure 11

Figure 12

23200-0-1206Page 8

Page 9

OPTIONAL FRESH AIR KIT INSTALLATION INSTRUCTIONS

TO INSTALL BVA-1 FRESH AIR KIT,

REMOVE RECTANGULAR CUT-OUT WITH

SHEET METAL CUTTERS

FOR DELUXE AND PREMIUM FIREBOXES

The optional BVA1 Fresh Air Kit is designed to introduce outside

air to the fireplace or firebox as desired.

It must be installed prior to, or at the time of fireplace or firebox

installation to framing.

The Fresh Air kit must be installed prior to the installation of wallboard or other finishing materials around the unit.

Tools needed: Gloves, Metal snips, Vise-Grip, ¼” Nut Driver,

Standard Screwdriver

Caution: Sharp edges

Air Door Installation for Vent Free Firebox Models:

VFD(32,36,42)FB

1. Begin by removing the rectangular cutout located on the left

side of the firebox. Use gloves and sheet metal snips to create the opening for the Air Door assembly to install into. See

Figures 13 and 14.

Figure 15

4. Next, with the vise grip attached, feed the long control rod

through the small rectangular opening at the left side of the

firebox face. Carefully position the rod and bracket so that

the bracket can be secured to the inside opening of the firebox

with two screws. See Figure 16. Do not remove vise grips at

this time.

Figure 13

Figure 14

2. Move the left hand curtain screen to the center of the firebox

opening.

3. Grasp the long control rod lever with control bracket (items 7

and 8 in Fresh Air Kit Parts List) securely with a vise grips

as shown in Figure 15.

Figure 16

5. Working from the side cutout opening, place the slightly

opened air door assembly into the cutout opening as shown

in Figure 17.

Figure 17

6. While holding the door assembly in your left hand, grasp the

vise grip (attached to the long control rod). Rotate and move

the control rod around until the inside end of the rod is mated

Page 923200-0-1206

Page 10

with the hole in the front flange of the movable air door. See

OUTSIDE AIR

ROD BRACKET

OPEN

FRESH AIR ROD

(CONTROL LEVER)

LEFT SIDE VIEW

OF FIREBOX OPENING

OUTSIDE AIR

ROD BRACKET

OPEN

FRESH AIR ROD

(CONTROL LEVER)

TO

P CUTAWAY

VIEW

DAMPER

ASSEMBL

Y

OUTER

CASING

FRESH

AIR

ROD

OUTSIDE

AIR

ROD

BRACKET

1

2

8

4

7

6

5

3

Figure 18.

Figure 18

when rotated upward, and can be locked open by pulling forward into the notch at the top of the control lever bracket.

10. To close, simply disengage by letting the lever rotate downward. The air door will remain closed by magnetic action.

See Figure 21.

Figure 19

7. Once the control rod is fed through the air door hole, gently

lift the outer air door plate assembly inward and upward until

the mounting holes in the plate line up with the pilot holes in

the side wrap.

8. Install (4) screws to retain the Air Door assembly. See Fig-

ure 20.

9. Remove vise grip from control rod, then check the operation

of the Air Door. The control lever should open the air door

Figure 20

Figure 21

FRESH AIR KIT PARTS LIST

INDEX

NO.

PART

NO. DESCRIPTION

1 10124 OUTSIDE AIR HOOD 1

2 18476 OUTSIDE AIR TUBE ASSEMBLY 1

3 R8196 WASHER, SILICONE (BV) 1

4 19548 DAMPER ASSEMBLY 1

5 R8047 TUBULAR CLIP (BV) 1

6 R8189 ROD, FRESH AIR (BV) 1

7 R8703 ROD, AIR CONTROL (FB) 1

8 20473 BRACKET, OUTSIDE AIR ROD (FB) 1

QUANTITY

SUPPLIED

23200-0-1206Page 10

Page 11

OUTSIDE

HOOD

4” DIA. AIR DUCT

CONNECTOR

(INSTALLER SUPPLIED)

OUTSIDE PLATE/VENT

SCREEN ASSEMBLY

AIR DOOR

ASSEMBLY

FIREBOX OR

FIREPLACE

Figure 22

Completion of Air Kit installation

1. Determine the length of 4” Dia. rigid or flex duct connector

(installer supplied) you will need from the firebox/fireplace

to the exterior surface of the outside wall, where the air kit

hood will be installed. Add a few extra inches to the length

to allow for easier attachment of the outside duct connection

prior to securing the outside rain cap hood to the building.

2. Secure the 4” dia. duct to the Air Door assembly collar on the

firebox/fireplace with band clamps or screws.

3. Run the other end of the duct through the exterior wall cutout.

4. From the outside of the building, connect the duct to the

collar on the outside air vent assembly with band clamp or

screws to secure.

5. Mate the outside rain cap hood over the air vent, seal with

caulk as necessary, then secure with screws provided to the

exterior wall surface. See Figure 22 and 23.

6. Figure 24 illustrates the various options for installation of the

air duct run possibilities.

CAULKING

RAIN CAP

DUCT TERMINATION

WALL

Caulk and Install Duct Termination

Figure 23

Figure 24

Page 1123200-0-1206

Page 12

OPTIONAL SINGLE SPEED BLOWER INSTALLATION INSTRUCTIONS

REMOVE BOTTOM LOUVER TO

INSTALL BLOWER ASSEMBL

Y

REMOVE COVER PLATE TO

INSTALL BLOWER ASSEMBL

Y

Attention: Install blower assembly before connecting gas inlet

supply line.

Wiring

The appliance, when installed, must be electrically grounded in

accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSI/NFPA 70, if an exter-

nal electrical source is utilized. This appliance is equipped with

a three-prong [grounding] plug for your protection against

shock hazard and should be plugged directly into a properly

grounded three-prong receptacle. Do not cut or remove the

grounding prong from this plug. For an ungrounded receptacle,

an adapter, which has two prongs and a wire for grounding, can

be purchased, plugged into the ungrounded receptacle and its wire

connected to the receptacle mounting screw. With this wire completing the ground, the appliance cord plug can be plugged into

the adapter and be electrically grounded.

Caution: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing.

Note: Junction box on right side of firebox must be pre-wired at

time of firebox installation for use with blower assembly. A

standard wall ON/OFF wall switch or optional SCV1 Variable Speed Control Kit should be installed to activate power to the Firebox, and control the operation of the FBB5

Blower assembly. It is recommended that installation of the

wiring be performed by a qualified electrician. See Figure

25.

1. If installed, turn OFF gas supply to firebox/gas log.

2. If applicable, turn OFF electric supply to firebox.

CAUTION: ALL WIRING SHOULD BE DONE BY

A QUALIFIED ELECTRICIAN AND SHALL BE IN

COMPLIANCE WITH ALL LOCAL, CITY AND STATE

BUILDING CODES. BEFORE MAKING THE ELECTRICAL CONNECTION, MAKE SURE THAT MAIN POWER

SUPPLY IS DISCONNECTED. THE APPLIANCE, WHEN

INSTALLED, MUST BE ELECTRICALLY GROUNDED

IN ACCORDANCE WITH LOCAL CODES, WITH THE

NATIONAL ELECTRICAL CODE ANSI/NFPA 70 (LATEST EDITION).

A factory installed junction box is located on the lower right

side of the firebox. Wiring must be fed to the junction box

and attached to the receptacle that is provided. From right

side of the firebox, remove the screw securing the junction

box assembly. Leave approximately 6” of wire in the junction

box for connection.

Attach black wire to one side of the receptacle and white wire

to opposite side of receptacle. The ground wire should be at

tached to the green (ground) screw.

Install the recepticle into the junction box. Attach cover

plate.

Attention: If installed, do not damage gas inlet supply line

when blower assembly is inserted into firebox. In some cases,

removal the gas inlet supply line may be necessary.

3. Determine which type of firebox you have prior to installa

tion. See Figures 26 and 27.

Deluxe Louvered

Models

Figure 26

Deluxe Flush Face

Models

-

-

Figure 25

Figure 27

23200-0-1206Page 12

Page 13

4. Insert blower assembly into interior, bottom of firebox. Posi-

REAR COVER PANEL MAY BE

REMOVED TO INSTALL BLOWER

REINSTALL COVER AFTER

BLOWER

IS INSTALLED

FAN CONTROL

SWITCH LOCATION

FAN CONTROL WIRES

BLOWER POWER CORD

tion blower assembly so that you align the notch on back of

blower assembly with the center screw on firebox back, then

push the blower assembly against firebox back. The blower

wheel must be centered with the back wall of the firebox. The

magnets on the back and bottom of blower assembly will sufficiently hold blower assembly in place.

Note: For field installation of blower assembly, it may be easier to

remove rear cover panel to install blower. This eliminates

the need to remove brick liner panels, but the blower would

have to be installed prior to installing the firebox into a

wall or chase. See Figure 28.

Figure 28

5. Once the blower assembly is in position, locate the plug but

ton in the top right rear corner of the firebox. Remove the

plug with a standard screwdriver and discard plug.

6. Next, find the fan control switch and wire assembly. Feed the

wires through the hole at the top of the firebox, and secure the

fan control switch with (2) #6 screws provided. See Figure

29.

8. One fan control wire will have a 1/4” female terminal that

must be attached to the open terminal on the blower motor.

See Figure 32, Connection A.

9. The other fan control wire has a 1/4” male terminal. Attach

this terminal to the open terminal on the blower power cord.

See Figure 32, Connection B

10. Route the wires away from moving parts of the blower assembly and retain wires together near the blower motor using

the plastic purse clip provided.

11. To complete the installation, plug the power cord into the

junction box receptacle at the right rear corner of the firebox

outer wrap. See Figure 30.

12. If room permits, the power cord can be located from the outside of the unit looking through the junction box access hole

(with the junction box removed), then plug up the power cord

before reinstalling the pre-wired junction box.

13. Once all connections are made electrically, it is recommended that you test the blower fan control operation by turning

on power to the blower (Caution: 110 Volt). Then apply heat

to the fan control switch inside the firebox with a lighter or

match until blower is activated. Once blower is activated,

check for proper operation. Do not place hands near blower

assembly or other wiring while power is on.

14. Replace blower access plate and/or reinstall the brick liner

panels if provided.

15. This completes the installation of the optional FBB5 Blower

kit accessory.

Note: This blower is equipped with a heat activated fan control

switch. Blower will operate when the firebox warms up,

and will turn off automatically when the firebox cools

down.

Figure 29

7. The fan control wires will slide down between the firebox

and outer wrap near the blower assembly. See Figure 29.

Figure 30

Page 1323200-0-1206

Page 14

Blower Motor

1

2

A

B

110 VOLT AC

JUNCTION BOX

WHITE

FA

N

SWITCH

BLACK

FAN/MOTOR

ASSEMBL

Y

The blower motor does not have oiling holes. Do not attempt to

oil the blower motor.

Blower Wheels

The blower wheels will collect lint and could require periodic

cleaning. If the air output decreases or the noise level increases,

it indicates a dirty blower wheel. Remove fan and clean blower

wheels.

Warning: Unplugging of blower accessory will not stop the

heater from cycling. To turn off gas to the heater (millivolt

model): push in gas control knob slightly and turn clockwise

to “OFF.” Do not force. To turn off gas on direct ignition

model, turn gas line valve to “OFF.”

Figure 31

1 FBB5 BLOWER ASSEMBLY COMPLETE

2 R8199 FAN CONTROL SWITCH

Figure 32

23200-0-1206Page 14

Page 15

JUNCTION BOX WIRING INSTALLATION INSTRUCTIONS

CAUTION: ALL WIRING SHOULD BE DONE BY A QUALIFIED ELECTRICIAN AND SHALL BE IN COMPLIANCE

WITH ALL LOCAL, CITY AND STATE BUILDING CODES. BEFORE MAKING THE ELECTRICAL CONNECTION,

MAKE SURE THAT MAIN POWER SUPPLY IS DISCONNECTED. THE APPLIANCE, WHEN INSTALLED, MUST BE

ELECTRICALLY GROUNDED IN ACCORDANCE WITH LOCAL CODES OR, IN THE ABSENCE OF LOCAL CODES,

WITH THE NATIONAL ELECTRICAL CODE ANSI/NFPA 70 (LATEST EDITION)

A factory installed junction box is located on the lower right

hand side of the firebox. Wiring must be fed to the junction

box and attached to the receptacle that is provided. Remove the

knockout in the installed junction box to accept wiring into the

junction box. Install a UL listed cable clamp (not supplied) in the

knockout hole. Leave approximately 6" of wire in the junction

box for connection.

Attach black wire to one side of the receptacle and white wire to

opposite side of receptacle. The ground wire should be attached

to the green (neutral) screw.

Install the receptacle into the junction box. Attach cover plate.

Figure 33

MAINTENANCE

Keep the control compartment, logs and burner area surrounding the

logs clean by vacuuming or brushing area at least twice a year.

THE LOGS CAN GET VERY HOT – HANDLE ONLY WHEN

COOL.

Always turn off gas to the pilot before cleaning. For relighting,

refer to lighting instructions located on the log set.

Never obstruct the flow of the combustion and ventilation air. Keep

the front of the firebox clear of all obstacles and materials.

Screens must be closed during operation.

Page 1523200-0-1206

Page 16

PARTS LIST

PART NUMBER

ITEM

1 17149 17149 17149 17149 17149 17149 TOP STANDOFF

2 17169 17169 17169 N/A N/A N/A UPPER LOUVER

3 10554 10554 10554 10554 10554 10554 FRAMING BRACKET

4 17170 17170 17170 N/A N/A N/A LOWER LOUVER

5 17162 17162 17162 17162 17162 17162 JUNCTION BOX ASSEMBLY

6 R3492 R3492 R3492 R3492 R3492 R3492 RECEPTICLE

7 R3491 R3491 R3491 R3491 R3491 R3491 COVER, JUNCTION BOX

8 N/A 20447 20448 N/A 20447 20448 BRACKET, TOP BRICK RE-

9 N/A 19401 19401 N/A 19401 19401 BRACKET, BOTTOM BRICK

10

11 BRICK PANEL BACK

12 BRICK PANEL LEFT

13 20020 20020 20020 20486 20486 20486 HOOD

14 R7051 R7051 R7051 R7051 R7051 R7051 ROD, SCREEN

15 R8137 R8137 R8137 R8137 R8137 R8137 SCREEN CURTAIN

16 R8727 R8727 R8727 R8727 R8727 R8727 HOLE PLUG

17 19990 19990 19990 19990 19990 19990 BLOWER COVER PLATE

ITEM

1 17247 17247 17247 17247 17247 17247 TOP STANDOFF

2 18807 18807 18807 N/A N/A N/A UPPER LOUVER

3 10554 10554 10554 10554 10554 10554 FRAMING BRACKET

4 18808 18808 18808 N/A N/A N/A LOWER LOUVER

5 17162 17162 17162 17162 17162 17162 JUNCTION BOX ASSEMBLY

6 R3492 R3492 R3492 R3492 R3492 R3492 RECEPTICLE

7 R3491 R3491 R3491 R3491 R3491 R3491 COVER, JUNCTION BOX

8 N/A 20447 20448 N/A 20447 20448 BRACKET, TOP BRICK RE-

9 N/A 19401 19401 N/A 19401 19401 BRACKET, BOTTOM BRICK

10

11 BRICK PANEL BACK

12 BRICK PANEL LEFT

13 20145 20145 20145 21087 21087 21087 HOOD

14 R7052 R7052 R7052 R7052 R7052 R7052 ROD, SCREEN

15 R8148 R8148 R8148 R8148 R8148 R8148 SCREEN CURTAIN

16 R8727 R8727 R8727 R8727 R8727 R8727 HOLE PLUG

17 19990 19990 19990 19990 19990 19990 BLOWER COVER PLATE

N/A R8665 VBP32SA N/A R8662 VBP32SA

PART NUMBER

N/A R8668 VBP36SA NA R8668 VBP36SA

DESCRIPTIONVFD32FB0L VFD32FB2DL VFD32FB2CL VFD32FB0F VFD32FB2DF VFD32FB2CF

TAINER

RETAINER

BRICK PANEL RIGHT

DESCRIPTIONVFD36FB0L VFD36FB2DL VFD36FB2CL VFD36FB0F VFD36FB2DF VFD36FB2CF

TAINER

RETAINER

BRICK PANEL RIGHT

23200-0-1206Page 16

Page 17

PART NUMBER

ITEM

1 17247 17247 17247 17247 17247 17247 TOP STANDOFF

2 17187 17187 17187 N/A N/A N/A UPPER LOUVER

3 10554 10554 10554 10554 10554 10554 FRAMING BRACKET

4 17188 17188 17188 N/A N/A N/A LOWER LOUVER

5 17162 17162 17162 17162 17162 17162 JUNCTION BOX ASSEMBLY

6 R3492 R3492 R3492 R3492 R3492 R3492 RECEPTICLE

7 R3491 R3491 R3491 R3491 R3491 R3491 COVER, JUNCTION BOX

8 N/A 20447 20448 N/A 20447 20448 BRACKET, TOP BRICK RE-

9 N/A 19401 19401 N/A 19401 19401 BRACKET, BOTTOM BRICK

10

11 BRICK PANEL BACK

12 BRICK PANEL LEFT

13 19984 19984 19984 19984 19984 19984 HOOD

14 R7053 R7053 R7053 R7053 R7053 R7053 ROD, SCREEN

15 R8148 R8148 R8148 R8148 R8148 R8148 SCREEN CURTAIN

16 R8727 R8727 R8727 R8727 R8727 R8727 HOLE PLUG

17 19990 19990 19990 19990 19990 19990 BLOWER COVER PLATE

N/A R8671 VBP42SA N/A R8671 VBP42SA

DESCRIPTIONVFD42FB0L VFD42FB2DL VFD42FB2CL VFD42FB0F VFD42FB2DF VFD42FB2CF

TAINER

RETAINER

BRICK PANEL RIGHT

HOW TO ORDER REPAIR PARTS

Parts can be ordered through your service person or dealer. For best results, the service person or dealer should order parts through the distributor.

Parts can be shipped directly to the service person/dealer.

All parts listed in the Parts List have a Part Number. When ordering parts, first obtain the Model Number from the name plate on your equipment.

Then determine the Part Number (not the Index Number) and the Description of each part from the following appropriate illustration and list. Be sure

to give all this information.

Firebox Model Number Part Description

Firebox Serial Number Part Number

Do not order bolts, screws, washers or nuts. They are standard hardware items and can be purchased at any local hardware store.

Shipments contingent upon strikes, fires and all causes beyond our control.

Page 1723200-0-1206

Page 18

PARTS VIEW

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

16

17

17

23200-0-1206Page 18

Page 19

1

2

1

2

8

4

7

6

5

3

ACCESSORIES

Accessory Description Model Numbers

Fan Kit

Designed to provide forced air flow. FBB5

Variable Speed Control Kit

Brick Liners

Fresh Air Kit

Wall mounted variable speed control for use with

FBB5 blower

SCV-1

VBP32SA

Deluxe Firebox

VBP36SA

VBP42SA

Deluxe and Premium Fireboxes BVA-1

Frame Kits

Standard 3-Piece Frame Kits

Brass, Stainless Steel, or Hammered Pewter

Contact dealer for all available

optional frame kits

Extruded Aluminum Frame Kits

Brass, Stainless Steel, or Hammered Pewter

Standard Hood Brass hood = BR

Stainless Steel = SS

Hammered Pewter = HP

Contact dealer for all available

optional hood accessories

Page 1923200-0-1206

Page 20

Extended 4" Hoods

Louvers

Bottom Trim Strip

ACCESSORIES (continued)

Extended hoods that extend out 2" farther than the standard

hoods, to accommodate thicker surround materials.

Available as optional kits in Brass, Hammered Pewter, and

Stainless Steel finishes.

Styles include Slat, Mission, Arch, and Leaf Patterns.

Available as optional kits in Brass, Hammered Pewter, and

Stainless Steel finishes.

Contact dealer for all available

optional hood accessories

Contact dealer for all available

optional louver accessories

Decorative Door Kits

Decorative Frame Kits

Available as optional kits in Brass, Hammered Pewter, and

Stainless Steel finishes.

Available as optional kits in Brass, Hammered Pewter, and

Stainless Steel finishes.

Available as optional kits in Brass, Hammered Pewter, and

Stainless Steel finishes.

Contact dealer for all available

optional trim accessories

Contact dealer for all available

optional frame kit accessories

Contact dealer for all available

optional decorative door kit

accessories

Empire Comfort Systems, Inc.

918 Freeburg Ave. Belleville, IL 62220

PH: 618-233-7420 or 800-851-3153

FAX: 618-233-7097 or 800-443-8648

info@empirecomfort.com

www.empirecomfort.com

23200-0-1206Page 20

Loading...

Loading...