Page 1

Page 1R-3088

SUPERB GAS STOVES

R-3088

Assembly Instructions

Effective Date November, 2003

WARNING

If not assembled, operated and maintained in accordance with

the manufacturers instructions, this product could expose you to

property damage, personal injury or loss of life from fire,

explosion or asphyxiation.

Read all warnings below.

W

ARNING

1. The following model numbers are for indoor or outdoor use in

Canada. The following model numbers are for outdoor use only

in United States.

ES-100, ES-200, ES-300,

MS-100, MS-200, MS-300,

ES-S100, ES-S200, ES-S300.

Attention: Portable (20 lb.) cylinder can not be used indoors.

The following model numbers are for outdoor use only in

Canada and United States.

SE-200 and SE-300.

2. Do not leave appliance unattended while in use or hot. Never

move cooker while in use or hot.

3. A fire can occur from overheated oil or grease.

4. Oil may heat faster than expected.

5. Use a thermometer to monitor oil temperature.

6. Do not use appliance on or near combustible surfaces, wood

decks, storage sheds, garages, shrubbery, trees, houses, etc...

7. Do not cover the pot when heating oil or grease.

8. Should grease fire occur, turn off the gas and cover the pot with

the lid.

9. Check every fitting for gas leaks before each use.

10. Never stand over burner while lighting; this could result in serious

injury. Carefully follow lighting instructions.

11. Keep children and pets at a safe distance.

12. Never place empty containers over an open flame.

13. Do not attempt to change valve depth into burner or reassemble

parts.

14. Never store propane tank in an enclosed area. If cooker is stored in

doors after use, disconnect the propane tank for outdoor storage.

15. The Superb regulator and hose assembly must be used, no

substitutions. Other regulators or no regulator used at all could

result in dangerous gas leakage and improper burner performance.

16. Never install or remove the propane tank while cooker is in use or

too hot to touch.

17. Always inspect hose kit before each use. Protect hose from cuts,

heat or abrasions. Never use a hose that indicates signs of cracking

or damage.

18. Never allow hose to contact any part of the cooker while in use or

still hot. Place propane tank from cooker so that the hose length

will not be in the way. Keep all connections and fittings clean,

replace any damaged parts.

19. Never store the propane tank near high heat, open flames, direct

sunlight or where high temperature exist.

Assembly Instructions

REQUIRED TOOLS: Pliers or adjustable wrench and screwdriver.

1. Bolt legs in place by inserting short bolts through holes in corners

of main top, then through slot at top of leg. Screw nuts onto the

bolts. Attach drip pan using four of the short bolts. Insert bolts

through hole in center of leg and through corner of pan. Apply nuts

and tighten securely. Now tighten leg bolts.

2. Install manifold clamps. Insert two long bolts through manifold

clamp holes in the main top. Attach the two manifold clamps loosely

underneath top, using nuts. Place manifold pipe with valves attached

into the clamps. Align the gas valves with center of large opening in

top. The adjusting hood of the valve should face the rear of the

stove. Now tighten the manifold clamps securely. Place the valve

knobs on valve stem, making sure that the control valve is in the off

position. Knob should be in the vertical position. Manifold Pipe

thread is 3/8 male IPS.

3. To install burners: If stove is to be used with LP or bottled gas, the

air shutter (round metal disc) should be partially opened and then

locked in place by tightening the air shutter screw. The hole in open

end of burner slides over the adjusting hood of the gas valve. The

rear part of the burner is attached to hole underneath main top using

long bolts with nuts. Fasten securely.

4. The grates are installed by inserting the two extended legs on grate

into corresponding holes in main top on each side of burner

opening.

5. Always use teflon tape or thread sealer on pipe threads.

FOR MINI-STOVE MODELS (NUMBER MS-100, MS-200, MS-

300))

6. Remove the main top by pulling upward. Install the two manifold

clamps, using the long bolts with nuts, to the bottom front of frame.

Do not tighten clamps.

7. Insert the manifold pipe with valves attached into the clamps; open

end of manifold should extend through hole in left side of frame.

Tighten the manifold clamps. Burners are fastened to burner hangers

already installed. Then assemble in same manner as above.

CHECK FOR GAS LEAKS

After assembly is complete, connect stove to gas supply and check for

gas leaks before lighting. Make sure

proper fittings are used for connection.

(To operate gas valve, push in before

turning.)

1. Turn brass control valve so knob is

in vertical position until it is tight.

(This shuts off flow of gas from the

regulator to the burner.

2. Open LP cylinder valve or gas

supply by 1/4 turn. This allows gas

into the regulator and stops it at the

brass control valve.

3. Apply gas detector fluid (or soapy

dishwashing solution) on all

connections, especially around the

regulator, valve and POL-cylinder

connection. Any bub-bles that appear indicate a gas leak. If so,

turn off gas and tighten the fitting. If a leak persists, pipe thread

compound may be needed on the threads.

NEVER USE

A FLAME TO CHECK FOR GAS LEAKS.

TO LIGHT

1. When you are sure there are no gas leaks,

turn cylinder valve and brass control valve

to closed position.

(To operate gas valve, push in before

turning.)

2. Re-open LP cylinder valve fully.

3. Re-open brass control valve 1/4 turn.

4. Keeping hands and face away from the top of the burner, light with

a fireplace match or long-nose lighter.

5. Adjust the brass control valve for desired flame height.

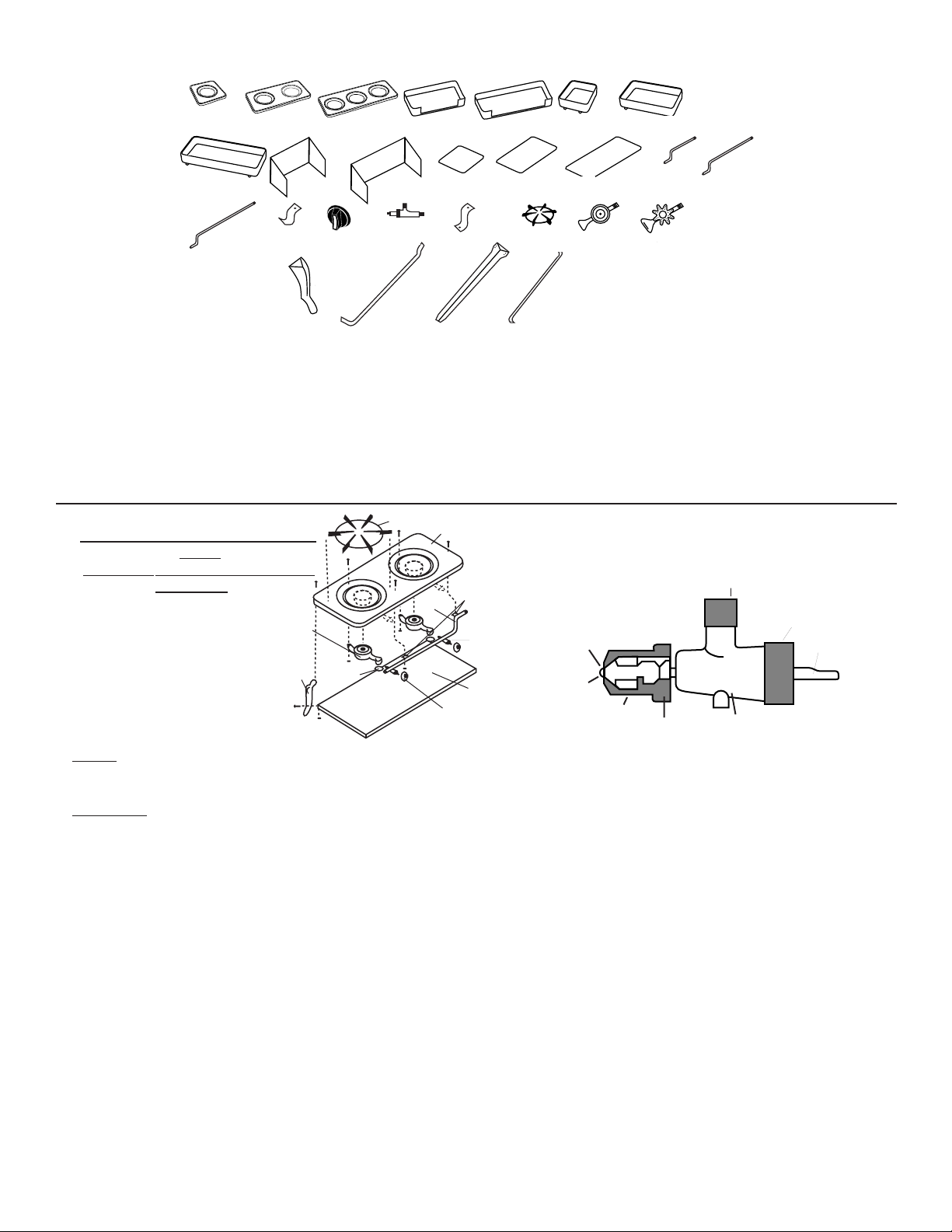

WRENCH TIGHTENED ASSEMBLY

Regulator

POL Connector

Cylinder Service Valve

Handwheel

Pressure

Relief Valve

Empire Comfort Systems, Inc. • 918 Freeburg Avenue • Belleville, IL 62220

OUTFITTERS SERIES

Model Numbers

ES-100, ES-200, ES-300

MS-100, MS-200, MS-300

(9,000 Btu per Burner)

ES-S100, ES-S200, ES-S300

SE-200, SE-300

(10,000 Btu per Burner)

1/4" HEX

FLANGE NUT

1/4" BOLT

GRATE

TOP

BURNER

VALVE

KNOB

BODY

LEG

Model No.

SE-200 w/SLK-28

Page 2

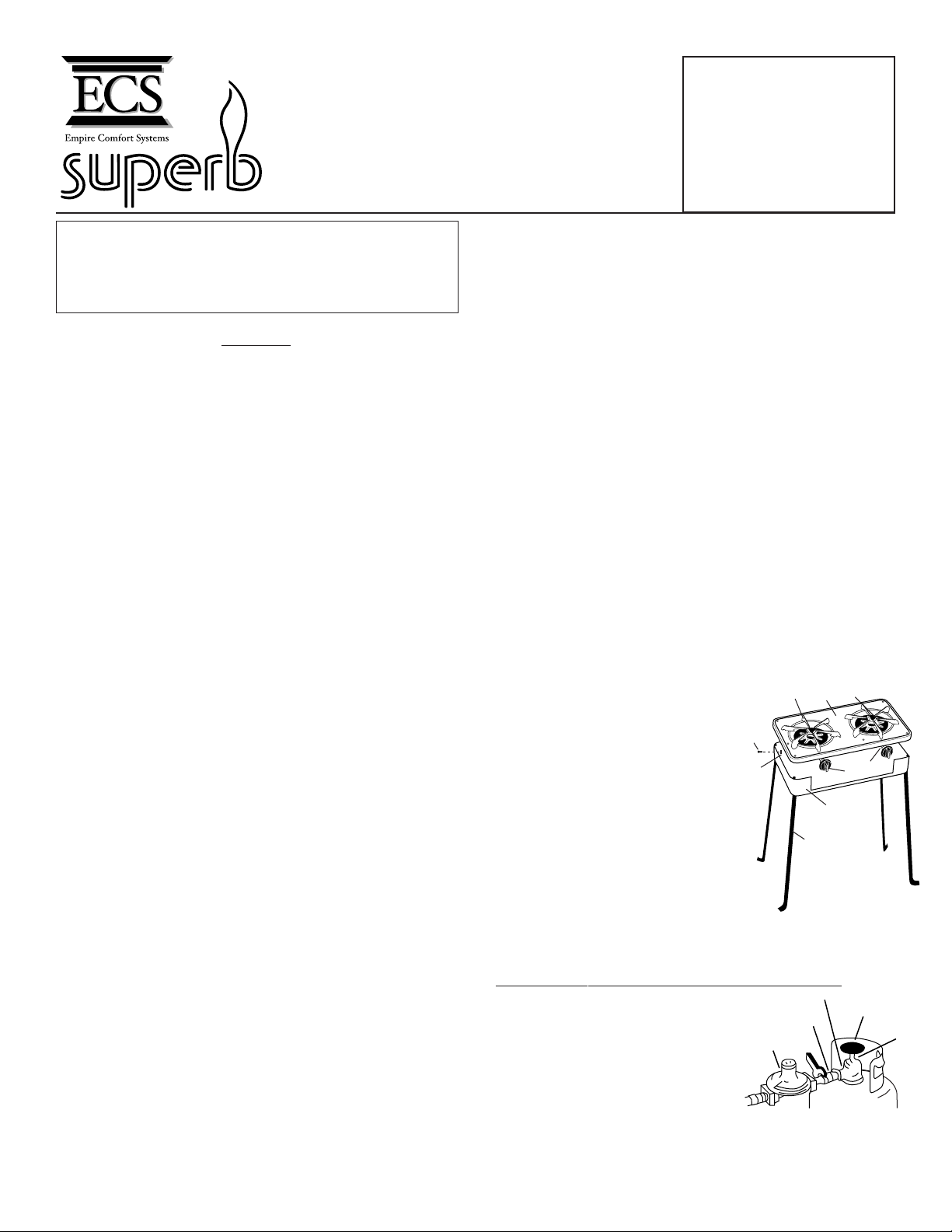

SECTIONAL PARTS FOR GAS STOVE

SP-010 One-Burner Top SP-013 One-Burner Drip Pan SP-028 Burner hanger

SP-011 Two-Burner Top SP-014 Two-Burner Drip Pan R-3339 Grate

SP-012 Three-Burner Top SP-015 Three-Burner Drip Pan SP-055 Round Burner

SP-076 One-Burner Semi-Enclosed Frame* P-220 One-Hole Manifold SP-062 Star Burner

SP-064 Two-Burner Semi-Enclosed Frame P-219 Two Hole Manifold SP-016 6" Low Leg

SP-063 Three Burner Semi-Enclosed Frame P-221 Three Hole Manifold S-1377 28" High Leg

SP-065 One-Burner Mini-Stove Frame SP-034 Manifold Clamp S-1380 32" High Leg

SP-066 Two-Burner Mini-Stove Frame R-3337 Knob S-1388 Leg Brace for 32" High

SP-067 Three-Burner Mini-Stove Frame R-3445 Gas Valve SW2-1 Two-Burner Windscreen

* Not Shown SW3-1 Three-Burner Windscreen

CAUTION: Orifice HOODS must again be turned down, if the gas

stove is to be used on LP gas after it has once been adjusted for other

gases.

UNDER NO CIRCUMSTANCES SHOULD ANY ALTERATIONS

BE MADE TO THE GAS VALVE AND BURNER ASSEMBLY.

Warranty

Empire Comfort Systems, Inc. makes no claim of fitness of this product for a particular purpose or use and assumes no liability for damages

resulting from the use of the product. Liability of the manufacturer in

any event is limited to the amount of the original purchase price of this

product. This warranty applies only to the use of the product in

accordance with the manufacturer's operating instructions, and remains

in force only so long as the product remains in its original

configuration. This warranty does not apply to products that have been

altered or repaired by outside agents, abused, damaged through neglect,

misuse, or accident, or to products that have been used in any way other

than in accordance with manufacturer's operating instructions. There

are no other warranties, expressed or implied, pertaining to this product

or any other product sold by us. Empire Comfort Systems, Inc. neither

assumes any responsibility in its behalf for operation of this or any

other product manufactured or sold.

W

ARNING: NEVER PUT HANDS OR

FACE

DIRECTLY OVER BURNER WHILE

LIGHTING

You may adjust valve setting at this time.

The flame should show a greenish

blue inner cone with a slight yellow

tip. If necessary, you can make an

adjustment by turning the hood of the

valve in a counterclockwise direction

until the flame performance is

satisfactory. See other side for further instructions regarding valve setting.

DO not

tamper with or attempt repairs on the burners, frames valves, or

LP cylinder. Allow only qualified LP Gas Dealers to make repairs and

adjustments.

Always close

LP cylinder valve after use. Always use and store bottle in

an upright position. Never store or transport these cylinders in an

occupied enclosure.

Adjustment Instructions-Universal Gas Valve

Your portable gas stove is furnished with A.G.A. listed Universal type

Gas Valve. This valve is designed for use with (Liquefied Petroleum

LPG), Natural or Manufactured Gas. When gas plate is installed the

valve should be set for the kind of gas to be used.

The universal valve is adjusted for the various gases by turning the

ADJUSTING HOOD. To turn HOOD use wrench on HOOD SHOULDER. This may be done after gas stove is assembled as HOOD

SHOULDER is easily accessible.

1. This valve is shipped from the factory adjusted for LP gas. If LP gas

is to be used, no adjustments should be necessary. Orifice HOOD

can be open slightly to get desired flame.

2. For use with Natural or Manufactured gas open HOOD until the

proper amount of gas is fed to each burner. When properly adjusted

the flame should have greenish blue inner cones about one-half inch

long. An unnecessary high flame is wasteful and inefficient.

3. The air shutter for each burner should be adjusted so the flame burns

clean without blowing. After you obtain the correct setting or the air

shutter, lock in place by tightening the air shutter screw.

CAUTION: MAXIMUM WORKING PRESSURE 1/2 P.S.I. 11-INCH WATER COLUMN

(LOW PRESSURE REGULATOR IS REQUIRED)

R-3088Page 2

LEG

BURNER

AIR

SHUTTER

KNOB

DRIP

PAN

MANIFOLD

CLAMP

GAS

VALVE

MANIFOLD

STOVE

GRATE

SP-010 SP-011 SP-012 SP-064 SP-063 SP-065 SP-066

SP-067

P-221

SP-034

R-3337

R-3445

SP-016

SP-028 R-3339 SP-055

SP-062

SP-013 SP-014 SP-015 P-220 P-219

S-1111

S-1122 S-1133 S-1144 S-1155 S-1166 S-1177

S-1188

S-1266

SW2-1 SW3-1 S-1211 S-1222 S-1233 S-1244 S-1255

S-1277 S-1288 S-1299 S-1300 S-1311

S-1366 S-1377 S-1380 S-1389

S-1322 S-1333

GAS ENTRANCE

ADJUSTING PIN

HOLE IN

ADJUSTING PIN

ADJUSTING HOOD

ADJUSTING HOOD

SHOULDER

DUST COVER

STEM

VALVE BODY

Page 3

Empire Comfort Systems, Inc. • 918 Freeburg Avenue • Belleville, IL 62222

Page 1R-3088-F

RÉCHAUD À GAZ DE SUPERB

R-3088-F

Instructions d'Assemblage

Date d'Entrée en Vigueur, Novembre 2003

AVERTISSEMENT

Si cet appareil n’est pas assemblé, utilisé et maintenu selon les

instructions du fabricant, celui-ci peut provoquer des dommages à la

propriété, des blessures corporelles ou la mort à la suite d’un feu, une

explosion ou une asphyxie.

Lire tous les avertissements ci-dessous.

AVERTISSEMENT

1. Les modèles ayant les numéros suivants peuvent être utilisés soit à

l'intérieur ou à l'extérieur en Canada. Les modèles ayant les numéros

suivants doivent être utilisés à l'extérieur seulement en United States.

ES-100, ES-200, ES-300,

MS-100, MS-200, MS-300,

ES-S100, ES-S200, ES-S300.

Attention: La bouteille portative ne peut pas être utilisée à l'intérieur.

Les modèles ayant les numéros suivants doivent être utilisés à l'extérieur

seulement en Canada et United States.

SE-200 et SE-300.

2. Ne laissez jamais cet appareil sans supervision lorsque vous l’utilisez ou

lorsqu’il est chaud. Ne déplacez jamais cet appareil lorsque vous l’utilisez ou

lorsqu’il est chaud.

3. De l’huile ou de la graisse surchauffée peut provoquer un feu.

4. L’huile peut chauffer plus vite que vous y attendiez.

5. Utilisez un thermomètre pour surveiller la température de l’huile.

6. N’utilisez pas cet appareil sur ou près des surfaces combustibles, patio en

bois, remises, garages, bosquets, arbres, maisons etc...

7. Ne placez pas un couvercle sur le chaudron lorsque vous faites chauffer de

l’huile ou de la graisse.

8. Si un feu de graisse survient, fermez le gaz et mettez le couvercle sur le

chaudron.

9. Avant chaque usage, vérifiez que toutes les connexions n'aient pas de fuite de

gaz.

10. Ne soyez pas au-dessus du brûleur lors de l’allumage; des blessures sérieuses

peuvent survenir. Suivez soigneusement les instructions d’allumage.

11.Gardez les enfants et les animaux à une bonne distance.

12.Ne placez jamais un contenant vide au-dessus d’une flamme .

13.N’essayez pas de changer la profondeur de la valve dans le brûleur ou

d’assembler de nouveau les pièces.

14.Ne jamais entreposez un réservoir de propane dans un endroit clos. Si le

réchaud est entreposé à l’intérieur après l’utilisation, débranchez le réservoir

de propane et entreposez-le à l’extérieur.

15.Vous devez utiliser le régulateur et l’ensemble des tuyaux flexibles de Superb,

aucune substitution. D’autres régulateurs ou aucun régulateur peut provoquer

une fuite de gaz qui sera très dangereuse en plus vous aurez une mauvaise

performance du brûleur

16. N’installez ou n’enlevez jamais le réservoir de propane lorsque le réchaud est

en fonction ou lorsqu’il est trop chaud au toucher.

17. Avant chaque utilisation, toujours vérifiez l’ensemble des tuyaux flexibles.

Protégez les tuyaux flexibles des coupures, de la chaleur ou des éraflures.

N’utilisez jamais un tuyau flexible qui est endommagé.

18. Assurez-vous que les tuyaux flexibles ne touchent aucune partie du réchaud

lorsque celui-ci fonctionne ou lorsqu’il est chaud. Placez le réservoir de

propane de façon à ce que le tuyau flexible soit à l’écart. Assurez-vous q ue

toutes les connexions et les raccords soient propres et remplacez toutes les

pièces endommagées.

19.N’entreposez jamais le réservoir de propane près d’une chaleur intense, d’une

flamme, directement au soleil ou un endroit où la température est très élevée.

Instructions d'Assemblage

OUTILS NÉCESSAIRES: Pince ou clé à molette et tournevis.

1. Boulonnez les pieds en insérant les boulons courts dans les trous situés à

chaque coin de la pièce principale du dessus, puis dans la fente à la partie

supérieure des pieds. Vissez les écrous sur les boulons. Fixez l'attrape-goutte

en utilisant quatre des boulons courts. Introduisez les boulons dans le trou au

centre du pied et au coin de l'attrape-goutte. Mettez les écrous et serrez-les

bien. Maintenant serrez les boulons des pieds.

2. Installez les brides du tuyau à gaz. Introduisez deux longs boulons dans les

trous des brides du tuyau à gaz situés sur la pièce principale du dessus.

Attachez sans serrer, sous la pièce principale du dessus, les deux brides du

tuyau à gaz en utilisant des écrous. Placez dans les brides le tuyau à gaz avec

les valves attachées. Aligner les soupapes à gaz avec le centre de la grande

ouverture du dessus. Le capot d'ajustement de la soupape doit s'orienter vers

l'arrière du réchaud. Maintenant, serrez bien les brides du tuyau à gaz. Placez

les boutons de la soupape sur la tige de la soupape, en vous assurant que la

soupape de commande soit à la position "off" (arrêt). Le bouton doit être en

position verticale. Le filet du tuyau à gaz est 10mm mâle IPS.

3. Pour installer les brûleurs; si le réchaud est utilisé avec du gaz propane ou du

gaz en bouteille, le volet d'air (disque rond en métal) doit être partiellement

ouvert et puis verrouillé en place en serrant la vis du volet d'arrivée d'air. Le

trou dans l'extrémité ouverte du brûleur glisse sur le capot d'ajustement de la

soupape de gaz. La partie arrière du brûleur est boulonnée au trou situé sous

la pièce principale du dessus à l'aide de longs boulons et écrous. Serrez-les

bien.

4. Les grilles s'installent en introduisant les deux pieds prolongés de la grille

dans les trous correspondants de la pièce principale du dessus sur chaque côté

de l'ouverture du brûleur.

5. Utilisez toujours du ruban en teflon ou un scellage pour tuyau sur les filets des

tuyaux.

POUR LES MODÉLES MINI-RÉCHAUD (NUMBÉROS MS-100, MS-200,

MS-300)

6. Enlevez la pièce principale du dessus en la tirant vers le haut. Installez les

deux brides du tuyau à gaz à l'avant-bas du bâti, en utilisant les longs boulons

et écrous. Ne serrez pas les brides.

7. Introduisez dans les brides le tuyau à gaz avec les soupapes attachées;

l'extrémité ouverte du tuyau à gaz devrait s'allonger à travers le trou dans le

côté gauche du bâti. Serrez les brides du tuyau à gaz. Les brûleurs sont fixés

aux supports du brûleur qui sont déjà installés. Puis, continuez l'assemblage de

la même manière que ci-dessus

VÉRIFIER LES FUITES

Lorsque l'assemblage est complété, brancher le réchaud à l'alimentation de gaz et

vérifier qu'il n'y ait pas de fuite de gaz avant d'utiliser votre réchaud. Assurez-vous

que les bons adaptateurs soient utilisés pour les connexions. (Pour manipuler la

soupape de gaz, poussez avant de tourner.)

1. Tourner la soupape de commande en cuivre pour que le bouton soit en position

verticale jusqu'à ce qu'il soit serré. (Ceci ferme l'entrée du gaz du régulateur

au brûleur.)

2. Ouvrir de 1/4 de tour la soupape de la bouteille

PL ou l'alimentation de gaz. Ceci permet

l'entrée du gaz dans le régulateur et l'arrête

à la soupape de commande en cuivre.

3. Recouvrir d'un liquide pour détecter le gaz

(ou une solution d'eau et de savon à

vaisselle) toutes les connexions,

spécialement autour du régulateur,

soupape et connexion de la bouteille

POL. S'il y a une bulle, ceci indique qu'il y a

une fuite de gaz. Si c'est le cas, fermez

l'arrivée de gaz et reserrez les connexions.

Si la fuite persiste, vous devrez utiliser un

composé sur les filets des tuyaux.

N'UTILISEZ JAMAIS UNE FLAMME POUR

VÉRIFIER UNE FUITE DE GAZ.

ALLUMAGE

1. Lorsque vous êtes certain qu'il n'y a pas de

fuite de gaz, tournez la soupape de la

bouteille et la soupape de commande en

cuivre en position fermée, (Pour

manipuler la soupape de gaz, poussez

avant de tourner.)

2. Ouvrez complètement la soupape de la

bouteille PL.

3. Ouvrez de nouveau la soupape de

commande en cuivre de 1/4 de tour.

4. En gardant vos mains et votre visage à distance du dessus du brûleur, allumer

à l'aide de longues allumettes ou d'un allumoir à étincelles.

5. Ajustez la soupape de commande en cuivre pour obtenir la hauteur de la

flamme désirée.

1/4" HEX

FLANGE NUT

1/4" BOLT

GRATE

TOP

BURNER

VALVE

KNOB

BODY

LEG

WRENCH TIGHTENED ASSEMBLY

Regulator

POL Connector

Cylinder Service Valve

Handwheel

Pressure

Relief Valve

Numéros des Modèles

ES-100, ES-200, ES300

MS-100, MS-200, MS-300

(9,000 Btu par Brûleur)

ES-S100, ES-S200, ES-S300

SE-200, SE-300

(10,000 Btu par Brûleur)

Modèle No.

SE-200 avec/SLK-28

Brûleur

Grille

Dessus

Bouton

6.5mm

Bâti

Bouton

Soupape

Pied

Écrou a

bride

hexagonal

6.4mm

Régulateur

Raccord POL

Volant

Soupape

du

Sûreté

Soupape de Service du Cylindre

Assemblage à l'Aide d'une Clé

OUTFITTERS SERIES

Page 4

PIÈCES POUR LE RÉCHAUD AU GAZ

SP-010 Dessus avec un brûleur SP-013 Attrape-goutte pour un brûleur SP-028 Support du brûleur

SP-011 Dessus avec deux brûleurs SP-014 Attrape-goutte pour deux brûleurs R-3339 Grille

SP-012 Dessus avec trois brûleurs SP-015 Attrape-goutte pour trois brûleurs SP-055 Brûleur rond

SP-076 Bâti semi-fermé pour un brûleur* P-220 Tuyau à gaz avec un trou SP-062 Brûleur en étoile

SP-064 Bâti semi-fermé pour deux brûleurs P-219 Tuyau à gaz avec deux trous SP-016 Petit pied de 152mm

SP-063 Bâti semi-fermé pour trois brûleurs P-221 Tuyau à gaz avec trois trous S-1377 Long pied de 709mm

SP-065 Bâti mini-réchaud pour un brûleur SP-034 Brides pour tuyau à gaz S-1380 Long pied de 813mm

SP-066 Bâti mini-réchaud pour deux brûleurs R-3337 Bouton S-1388 Entretoise pour long pied de 813mm

SP-067 Bâti mini-réchaud pour trois brûleurs R-3445 Soupape à gaz SW2-1 Paravent pour deux brûleurs

* Pas Représenté SW3-1 Paravent pour trois brûleurs

ATTENTION: L'orifice du capot doit encore une fois être renversé, si le

réchaud au gaz doit être utilisé avec le gaz PL après qu'il est été ajusté pour un

autre gaz.

EN AUCUNE CIRCONSTANCE, AUCUN CHANGEMENT DOIT ÊTRE

FAIT À LA SOUPAPE DE GAZ ET À L'ASSEMBLAGE DU BRÛLEUR.

GARANTIE

Empire Comfort Systems, Inc. n'a aucune prétention quant au rendement de ce

produit dans un dessein ou une utilisation particulière et n'assume aucune

responsabilité pour dommages causés par l'utilisation de ce produit. La

responsabilité du manufacturier se limite, en toute circonstance, au prix de vente

au détail original de ce produit. Cette garantie n'est valide que lors d'une

utilisation conforme aux instructions d'utilisation du manufacturier, et sera

maintenue aussi longtemps que ce produit demeurera sous sa forme originale.

Cette garantie ne s'applique pas aux produits qui ont été altérés ou réparés par

un agent non-autorisé, abusés, endommagés suite à une négligence, un emploi

abusif, un accident ou tout autre produit dont l'emploi n'a pas été conforme, de

quelque manière que ce soit, aux instructions d'utilisation du manufacturier. Il

n'existe aucune autre garantie exprimée ou sous-entendue, se rattachant à ce

produit ou tout autre produit vendu par nous. Empire Comfort Systems, Inc.

n'assume aucune responsabilité en son nom pour l'utilisation de ce produit, ou

de tout autre produit manufacturé ou vendu.

AVERTISSEMENT: NE JAMAIS AVOIR LE

VISAGE OU LES MAINS AU-DESSUS

DU BRÛLEUR LORS DE L'ALLUMAGE.

À ce moment vous pouvez ajuster le

réglage de la soupape. La flamme devrait

montrer l'intérieur d'un cône d'une couleur

vert bleu avec un bout légèrement

jaunâtre. Si nécessaire, vous pouvez

faire un ajustement en tournant le capot

de la soupape dans la direction antihoraire

jusqu'à ce que la performance de la

flamme soit satisfaisante. Voir de l'autre

côté pour de plus amples instructions

regardant le réglage de la soupape.

Ne pas altérer ou essayer de réparer les brûleurs, le bâti,

les soupapes ou la bouteille PL. Seulement les vendeurs qualifiés de gaz PL

devraient faire les réparations et les ajustements.

Toujours fermer la soupape de la bouteille PL après chaque emploi. Toujours

utilisez et remisez la bouteille en position debout. Ne jamais remiser ou

transporter la bouteille à l'intérieur d'un espace habité.

Instructions pour l'ajustement de la soupape à gaz universelle.

Votre réchaud portatif à gaz est muni d'une soupape à gaz de type Universelle

approuvée A.G.A. Cette soupape est désignée pour être utilisée avec (pétrole

liquifié), Naturel ou gaz manufacturé. Lorsque la plaque signalétique de gaz est

installé, la soupape doit être réglée pour le genre de gaz qui sera utilisé.

La soupape universelle est ajustée pour les différents gaz en tournant LE CAPOT

D'AJUSTEMENT. Pour tourner le CAPOT utiliser une clé sur l' ÉPAULEMENT

DU CAPOT. Ceci peut être fait lorsque vous avez fini d'assembler le réchaud

étant donné que l'ÉPAULEMENT DU CAPOT est facilement accessible.

1. Cette soupape est ajustée pour le gaz PL lorsqu'elle est expédiée de l'usine.

Si le gaz PL est utilisé, aucun ajustement sera nécessaire. L'orifice du

CAPOT peut être légèrement ouvert pour obtenir la flamme désirée.

2. Pour utiliser avec le gaz Naturel ou Manufacturé, ouvrez le CAPOT jusqu'à

ce qu'une bonne quantité de gaz arrive à chaque brûleur. Lorsque la flamme

est convenablement ajustée, l'intérieur du cône sera vert bleu et d'une

longueur d'environ 13mm. Il n'est pas nécessaire d'avoir une flamme très

haute, ce sera du gaspillage et inefficace.

3. Le volet d'arrivée d'air pour chaque brûleur devra être ajusté de façon à ce

que la flamme brûle proprement sans s'éteindre. Lorsque vous obtenez le bon

ajustement pour le volet d'arrivée d'air, verrouillez en place en serrant la vis

du volet d'arrivée d'air.

ATENTION: PRESSION DE FONCTIONNEMENT MAXIMUM 1/2 P.S.I. 2.74KPA

(RÉGULATEUR DE BASSE PRESSION EST OBLIGATOIRE)

R-3088-FPage 2

LEG

BURNER

AIR

SHUTTER

KNOB

DRIP

PAN

MANIFOLD

CLAMP

GAS

VALVE

MANIFOLD

STOVE

GRATE

Grille Dessus du

Réchaud

Volet

d'arrivée

d'air

Brûleur

Pied

Bouton

Attrapegoutte

Grille

Brides pour

tuyau à gaz

Tuyau à gaz

BROCHE D'AJUSTEMENT

ENTRÉE DE GAZ

TROU DANS LA BROCHE

D'AJUSTEMENT

CAPOT D'AJUSTEMENT

ÉPAULEMENT DU CAPOT

D'AJUSTEMENT

CORPS DE LA SOUPAPE

COUVERCLE À POUSSIÈRE

TIGE

S-1111

S-1266

S-1188

S-1277 S-1288 S-1299 S-1300 S-1311

S-1366 S-1377 S-1380 S-1389

S-1322 S-1333

SW2-1 SW3-1 S-1211 S-1222 S-1233 S-1244 S-1255

S-1122 S-1133 S-1144 S-1155 S-1166 S-1177

SP-010 SP-011 SP-012 SP-064 SP-063 SP-065 SP-066

SP-067

P-221

SP-034

R-3337

R-3445

SP-016

SP-028 R-3339 SP-055

SP-062

SP-013 SP-014 SP-015 P-220 P-219

ADJUSTING PIN

HOLE IN

ADJUSTING PIN

ADJUSTING HOOD

ADJUSTING HOOD

SHOULDER

GAS ENTRANCE

DUST COVER

STEM

VALVE BODY

Loading...

Loading...