Empire Comfort Systems DVC20IN71-1, DVC26IN31-1, DVC20IN31P-1, DVC20IN31N-1, DVC20IN71P-1 Installation Instructions And Owner's Manual

...

GAS-FIRED

INSTALLATION INSTRUCTIONS

AND OWNER’S MANUAL

INSTALLER:

Leave this manual with the appliance.

CONSUMER:

Retain this manual for future reference.

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death or

property damage.

— Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the re department.

— Installation and service must be

performed by a qualied installer,

service agency or the gas supplier.

DIRECT VENT

GAS FIREPLACE HEATER

FIREPLACE

INSERT MODELS

DVC(20,26,28)IN31(N,P)-1

DVC(20,26,28)IN71(N,P)-1

This appliance may be installed into a listed

wood-burning replace in an aftermarket,

permanently located, manufactured home

(USA only) or mobile home, where not

prohibited by state or local codes.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

other gases, unless a certied kit is used.

DANGER

HOT GLASS

CAUSE BURNS.

DO NOT TOUCH

UNTIL COOLED.

NEVER

A barrier designed to reduce the risk of burns from the

hot viewing glass is provided with this appliance and shall

be installed for the protection of children and other at-risk

individuals.

ALLOW CHILDREN

TO TOUCH GLASS.

WILL

GLASS

UL FILE NO. MH30033

This replace is design

certied in accordance

with American National

Standard/CSA Standard

ANSI Z21.88/CSA 2.33

and by Underwriters

Laboratories as a Direct

Vent Gas Fireplace

Heater and shall be

installed according to

these instructions.

Page 1

TABLE OF CONTENTS

SECTION PAGE

Before You Start ......................................................................................................................................... 3

Carton Contents & Hardware Pack ............................................................................................................ 4

Specications ............................................................................................................................................. 5

Homeowner Reference Information ............................................................................................................ 5

Accessories ................................................................................................................................................ 6

Introduction ................................................................................................................................................. 8

Fireplace Insert Dimensions ..................................................................................................................... 10

Minimum Fireplace Opening Dimensions ..................................................................................................11

Mantel and Trim Clearances ......................................................................................................................11

Gas Supply ............................................................................................................................................... 12

Fireplace Preparation ............................................................................................................................... 14

Venting ...................................................................................................................................................... 15

Installation ................................................................................................................................................ 16

Installation Diagram .................................................................................................................................. 17

Vertical Termination .................................................................................................................................. 18

Surround Installation ................................................................................................................................. 19

Alternate ON/OFF Switch Installation ....................................................................................................... 20

Barrier Screen Installation ........................................................................................................................ 22

Blower Information .................................................................................................................................... 23

Log Identication ...................................................................................................................................... 24

Log Placement .......................................................................................................................................... 25

Placement of Glowing Embers and Optional Lava Rock .......................................................................... 32

Operating Instructions .............................................................................................................................. 33

Standing Pilot Lighting Instructions .......................................................................................................... 34

Standing Pilot Wiring ................................................................................................................................ 35

Standing Pilot Troubleshooting ................................................................................................................. 36

IPI System Operating Instructions ............................................................................................................ 37

IPI System Electronic System Wiring Diagram ......................................................................................... 38

Intermittent Pilot Lighting Instructions ....................................................................................................... 39

Intermittent Control System Troubleshooting ........................................................................................... 40

Maintenance and Service ......................................................................................................................... 43

Insert Parts View ...................................................................................................................................... 45

Insert Parts List ......................................................................................................................................... 46

Master Parts Distributor List ..................................................................................................................... 48

How To Order Repair Parts ...................................................................................................................... 48

Important Safety Information .................................................................................................................... 49

Safety Information for Users of LP-Gas .................................................................................................... 50

For the Homeowner ................................................................................................................... 51 - 61

Important Information ............................................................................................................................... 52

Standing Pilot (DVC(20,26,28)IN3 Models) Operating Instructions .......................................................... 55

Standing Pilot (DVC(20,26,28)IN3 Models) Lighting Instructions ............................................................. 56

Intermittent Pilot (DVC(20,26,28)IN7 Models) Operating Instructions ...................................................... 57

Intermittent Pilot (DVC(20,26,28)IN7 Models) Lighting Instructions ......................................................... 58

Important Safety Information .................................................................................................................... 59

Appliance Service History ......................................................................................................................... 60

Warranty ................................................................................................................................................... 61

36561-5-0817Page 2

BEFORE YOU START

WARNING

Read and follow these safety precautions prior to operating this appliance. Failure to follow these precautions may

result in death, injury, or property damage.

Samples and Denitions:

DANGER

Indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

NOTICE: Addresses practices not related to personal injury.

Attention! If the replace insert is installed into a modied

wood-burning, factory-built replace, the replace cannot

be returned to a wood-burning replace. See page 14 for

additional details regarding the allowed modications to a

factory-built replace.

Read all instructions before starting installation and follow them

carefully to insure safety. Failure to follow the instructions will

void the warranty and may cause a re hazard.

The warranty will be voided by, and the warranter disclaims any

responsibility for the following actions:

• Installation of any damaged replace insert or vent system

component.

• Modication of the replace insert or direct vent system.

• Installation other than as instructed by Empire Comfort

Systems Inc.

• Improper positioning of logs, glass door, barrier screen, or

decorative accessories.

• Installation and/or use of any component part not

manufactured or approved by the manufacturer.

Preparation

This replace insert and its components are safe when installed

in accordance with this Installation Manual. Report any parts

damaged in shipment to your dealer. Do not install the replace

insert with damaged, incomplete or substitute parts.

Installation Considerations

• The rebox must be in good working order and sized

according to page 11.

• Gas supply piping – right or left side entrance

• Electrical supply and connections – for blower

• 120V, 60Hz, 1 Amp

• Right side entrance

• Surround Requirements - See Fireplace Insert Dimensions,

page 10 and Accessories, page 6.

• Surround Bottom Cover - For elevated insert installations.

See Accessories, page 6.

• Shroud Requirements - See Accessories, page 6.

• Leveling the Insert - Four leveling bolts are included in

the Hardware Pack. See page 4 for size and page 16 for

installation and use.

1. Read the safety information pages 49 - 50 and 59.

2. Place the sticker located in the instruction envelope onto the

“Homeowner Reference Information” page 5.

3. Show the homeowner where the rating plate and lighting

instruction plate are located.

6. Install and connect the gas lines. See pages 12 and 13.

7. Install the wiring. See pages 35 and 38.

8. Install the venting. See pages 15 - 17.

9. Install the replace insert. See page 16.

10. Light the replace insert. See pages 34 and 39.

11. Troubleshoot issues. See pages 36, and 40 - 42.

12. Show the homeowner how to operate the replace insert.

13. Show the homeowner how do the basic maintenance.

All correspondence should refer to complete Model Number,

Serial Number and type of gas. Fill out the Homeowner

Reference Section on page 5.

Unpacking the replace insert

1. Cut binding straps.

2. Remove the top carton.

3. Carefully remove the carton contents.

4. Use the Carton Contents and Hardware Pack lists on page 4

to verify all components are present.

5. Verify that the replace insert and components have not

been damaged during shipping.

6. Set replace insert in a location near its nal installation

location.

36561-5-0817 Page 3

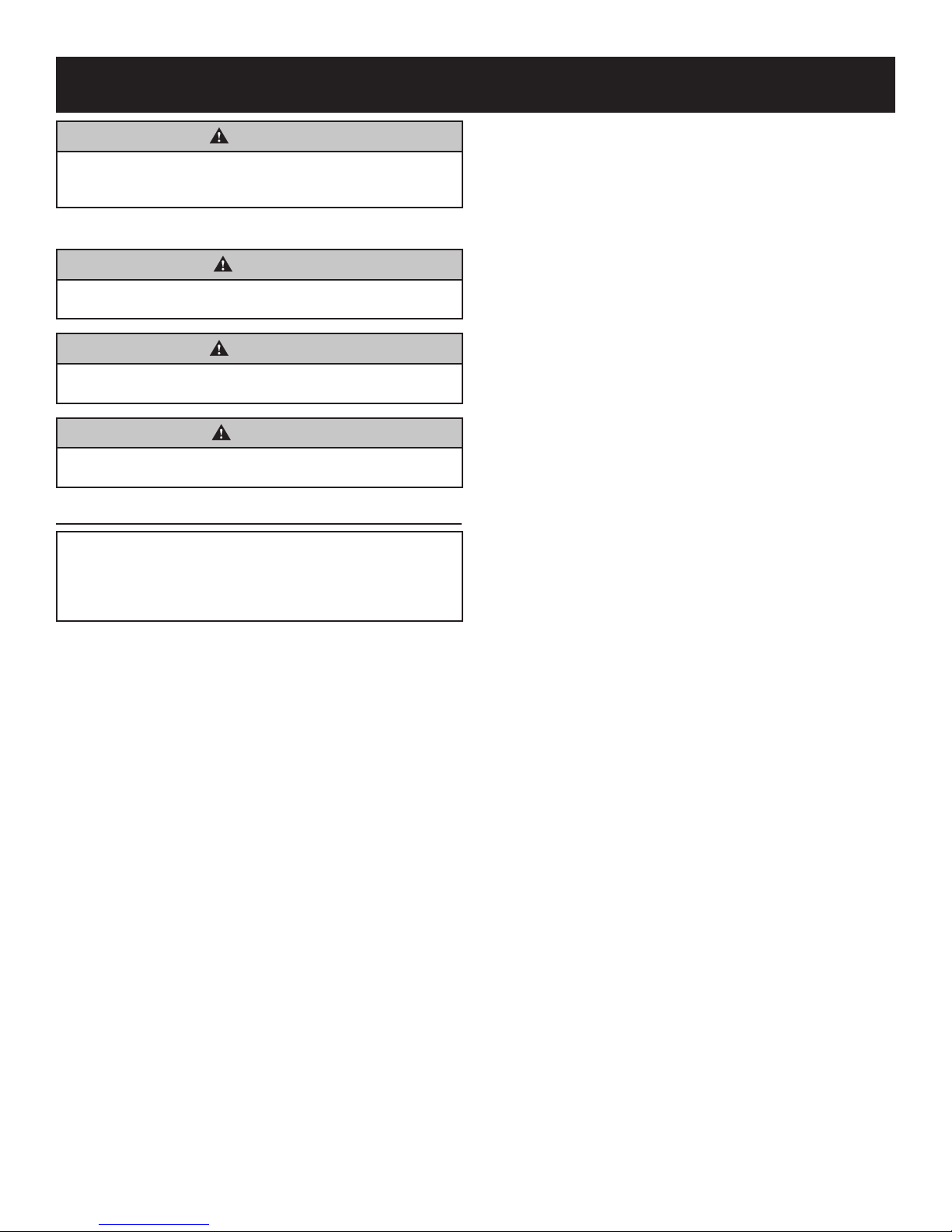

CARTON CONTENTS & HARDWARE PACK

12

13

14

11

1

5

2

3

NOTE: Ships as flat part

REQUIRED when using

a remote receiver

Index

Number

Description

1 Fireplace Insert 1 1 In carton

2 Barrier Screen Assembly 1 1 Front of Insert

3 Warning Label Plate 1 1 In envelope

4 Restrictor Plate 1 1 In envelope

5 Log Set 1 1 Inside Insert rebox

6 Flex Line with Shutoff 1 1 Attached to the gas valve

7 Rockwool Embers 1 1 In envelope

8 AA Batteries 0 4 In envelope

9 Wire Retainer Clips 3 3 In envelope

10 ON/OFF Switch 1 1 In envelope

11 Extension Wire Harness 1 1 In envelope

12 3/16 Allen Wrench 1 1 In envelope

13 5/16-18 Allen Head bolt, 2-1/2 inches long 1 1 In envelope

14 5/16-18 Hex Head bolt, 2-1/2 inches long 4 4 In envelope

15 Shield, Remote Receiver 1 1 In envelope

15

Rockwool

7

8

9

Quantity Supplied

MV IP

4

6

10

Location

36561-5-0817Page 4

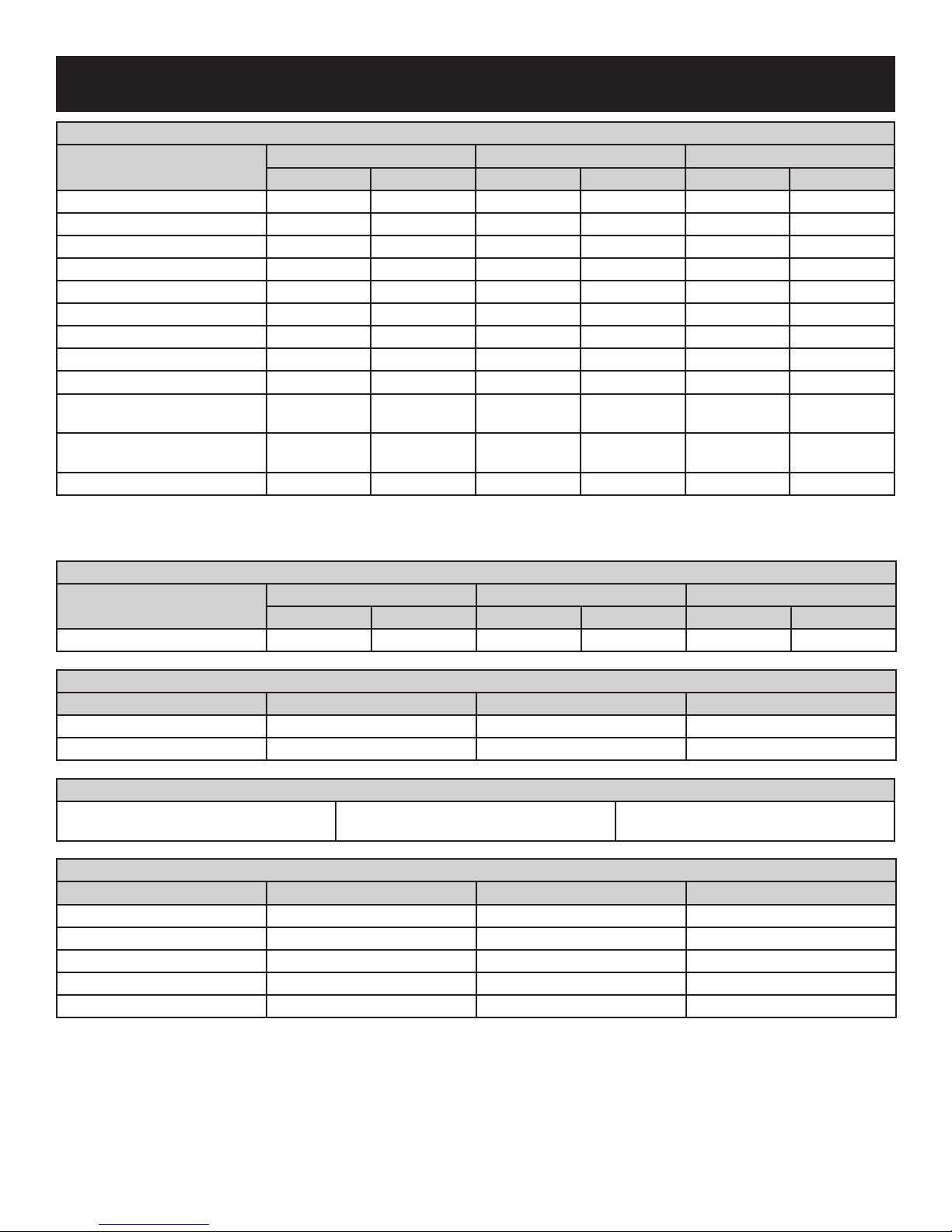

SPECIFICATIONS

DVC20IN(3,7) DVC26IN(3,7) DVC28IN(3,7)

LP N AT LP N AT LP N AT

Input BTU/Hr Maximum 19,500 20,500 26,000 26,000 27,500 28,500

Input BTU/Hr Minimum 15,000 14,500 20,000 17,000 21,000 18,500

KWH (Maximum) 5.37 5.95 7.54 7.54 7.98 8.27

KWH (Minimum) 4.2 4.2 5.8 5.36 6.38 5.36

Orice 1.30mm #44 #53 #40 1.55mm 2.60mm

Air Shutter Opening 1/2 inch open 1/8 inch open 1/2 inch open 3/16 inch open 1/2 inch open 3/16 inch open

Gas Inlet Shutoff Valve (pipe) 1/2 NPT 1/2 NPT 1/2 NPT 1/2 NPT 1/2 NPT 1/2 NPT

NOTICE: Air shutter settings are factory minimum settings. Some venting congurations may require minor air shutter adjustments for

optimum performance.

GAS SUPPLY PRESSURES

GAS TYPE MAXIMUM MINIMUM MANIFOLD

NAT 14 4.5 3.5

LP 14 11 10

HOMEOWNER REFERENCE INFORMATION

We recommend that you record the following information about your replace.

Model Number: _____________________________ Date purchased: ________________________

Serial Number: _____________________________ Location of replace: _____________________

Dealer Name: ______________________________ Dealer Phone: _________________________

Notes: ______________________________________________________________________________

36561-5-0817 Page 5

ACCESSORIES

SURROUNDS (REQUIRED)

DVC20IN DVC26IN DVC28IN

Black Bronze Black Bronze Black Bronze

3 x 6 x 1 DS2063BL DS2063BZ DS2663BL DS2663BZ DS2863BL DS2863BZ

3 x 6 x 1 Bottom Cover C203BL C203BZ C263BL C263BZ C283BL C283BZ

3 x 6 x 2-1/4* DS2063DBL DS2063DBZ - - - -

3 x 6 x 2-1/4 Bottom Cover C203DBL C203DBZ - - - -

6 x 6 x 1 DS2066BL DS2066BZ DS2666BL DS2666BZ DS2866BL DS2866BZ

9 x 6 x 1 DS2096BL DS2096 BZ DS2696BL DS2696BZ DS2896BL DS2896BZ

6 x 6 x 1 Bottom Cover C206BL C206BZ C266BL C266BZ C286BL C286BZ

6 x 6 x 2-1/4* DS2066DBL DS2066DBZ - - - -

9 x 6 x 2-1/4 DS2066DBL DS2066DBZ - - - -

6 x 6 x 2-1/4 or 6 x 9 x 2-1/4

Bottom Cover

6-Inch Cast Iron (Requires

Adator Kit)

Cast Iron Surround Adaptor Kit SAK20 - SAK26 - SAK28

*NOTICE: DVC20IN replace inserts can be installed with either surround. The 6 x 6 x 2-1/4 or 9 x 6 x 2-1/4 inch surround allows the

replace insert to be installed in a 13-5/8 inch deep replace. This option is not available for DVC(26,28)IN replace insert models.

C206DBL C206DBZ - - - -

SC256BL - SC336BL - SC356BL -

-

DECORATIVE FRONT (REQUIRES SURROUND)

DVC20IN DVC26IN DVC28IN

Black Bronze Black Bronze Black Bronze

Lancaster DVF20HBL DVF20HBZ DVF26HBL DVF26HBZ DVF28HBL DVF28HBZ

DOOR FRONTS (REQUIRES SURROUND)

DVC20IN DVC26IN DVC28IN

Transom DFD20DBL DFD26DBL DFD28DBL

Horizon DFD20HBL DFD26DHBL DFD28HBL

SHROUD (REQUIRES SURROUND)

SH1BL Black

LINERS

DVC20IN DVC26IN DVC28IN

Porcelain Black DVP20KR DVP26KR DVP28KR

Banded Brick* DVP20AE DVP26AE DVP28AE

Traditional Aged Brick DVP20DF DVP26DF DVP28DF

Traditional Washed DVP20BW DVP26BW DVP28BW

Herringbone* DVP20SH DVP26SH DVP28SH

* Herringbone Liners available only for American Hearth models; Banded Brick Liners available only for White Mountain Hearth models.

For replace openings up to (in inches)

48H x 36W

36561-5-0817Page 6

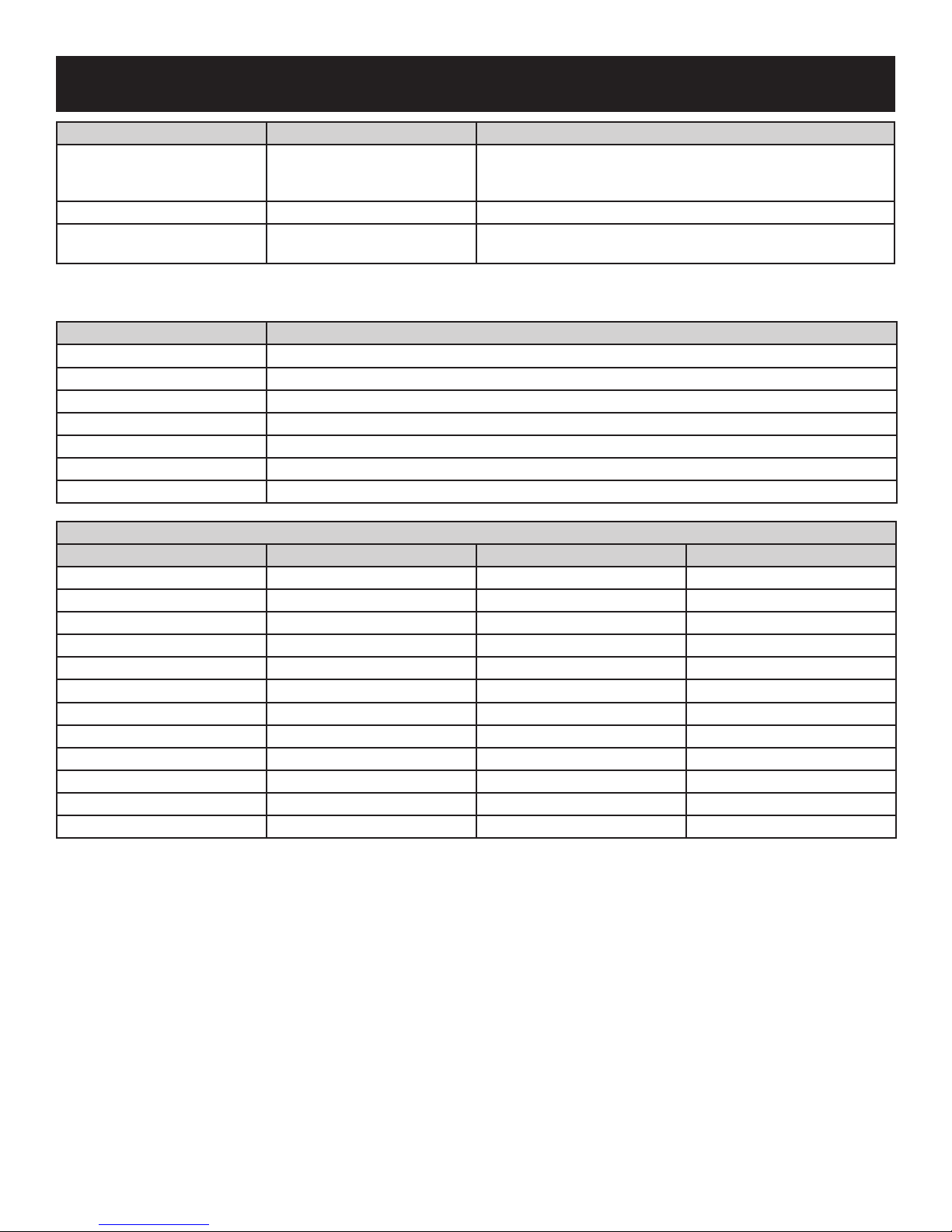

ACCESSORIES

Venting Kits Description Contents

High Wind Round Cap, Flashing, connectors, and clamps.

DVKI2P Vertical Vent Kit 17-1/2’

DVK35 Vent Extension Kit

SD46DVACL33 High Wind Vertical Vent Kit

NOTICE: When installing vent caps, special locally made ashings may be required to properly seal the vent system to the existing

chimney termination.

Remote Controls Description

FRBC Millivolt Battery Remote ON/OFF

FRBTC Millivolt Battery Remote Thermostat

TRW Millivolt Wireless Wall Thermostat

TMV Millivolt Reed Switch Wall Thermostat

FWS-1 Millivolt Wall Switch

RVKN Remote Control Variable Flame Height Kit (Nat) (DVC(20,26,28)IN71N only)

RVKP Remote Control Variable Flame Height Kit (LP) (DVC(20,26,28)IN71P only)

GAS CONVERSION KITS

Kit Number Conversion Type Used On Valve Type

36395 LP to NAT DVC20IN3 MV

36396 NAT to LP DVC20IN3 MV

36722 LP to NAT DVC20IN7 IP

36723 NAT to LP DVC20IN7 IP

36397 LP to NAT DVC26IN3 MV

36398 NAT to LP DVC26IN3 MV

36724 LP to NAT DVC26IN7 IP

36725 NAT to LP DVC26IN7 IP

36399 LP to NAT DVC28IN3 MV

36400 NAT to LP DVC28IN3 MV

36726 LP to NAT DVC28IN7 IP

36727 NAT to LP DVC28IN7 IP

Recommended when installing to an existing round replace

chimney pipe.

35 foot ex vent extension section with 2 connectors and 4 clamps

Two 3-inch diameter X 35-feet long lengths of Flex venting, High

Wind Round Termination, ashing, and clamp connectors

36561-5-0817 Page 7

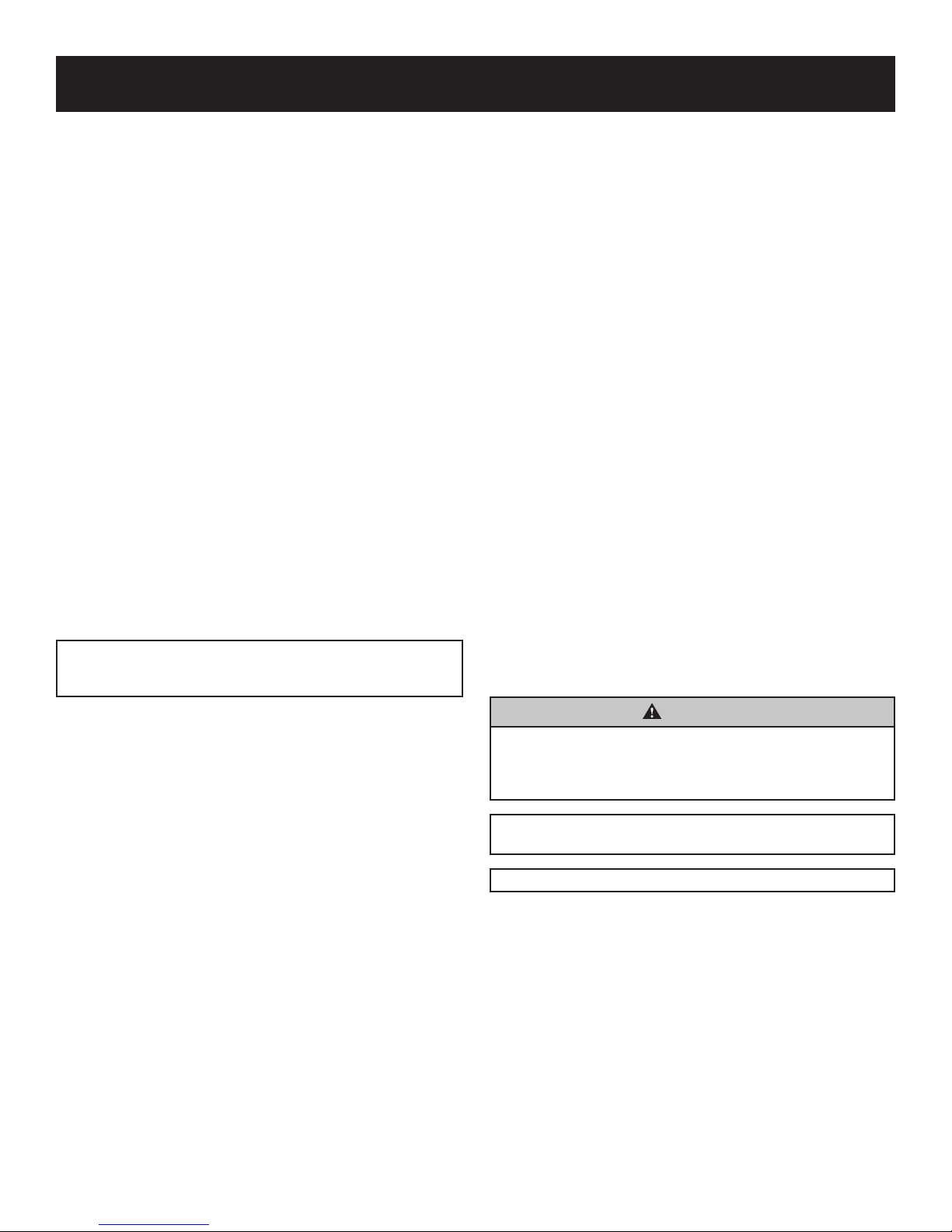

INTRODUCTION

Instructions to Installer

1. Leave this manual with the homeowner.

2. Have the homeowner ll out and mail the Product

Registration Card supplied with the replace insert or online

at www.empirecomfort.com.

3.

Show the homeowner how to start and operate the

replace insert.

4. Manually attach the warning label plate supplied with the gas

replace insert to the inside of the rebox of the replace into

which the gas replace insert is installed.

5. Run replace insert for a minimum 30 to 35 minutes to

burn off oils from manufacturing. Failure to perform this

initial burn-off can cause pilot problems. After burn-off,

clean ame sensor on IP pilot assembly. See page 39 for

sensor location.

Important

All correspondence should refer to complete Model Number,

Serial Number and type of gas.

Qualied Installing Agency

Installation and replacement of gas piping, gas utilization

equipment or accessories and repair and servicing of equipment

shall be performed only by a qualied agency. The term “qualied

agency” means any individual, rm, corporation or company

which either in person or through a representative is engaged

in and is responsible for (a) the installation or replacement of

gas piping or (b) the connection, installation, repair or servicing

of equipment, who is experienced in such work, familiar with all

precautions required and has complied with all the requirements

of the authority having jurisdiction.

Commonwealth of Massachusetts: The installation must be

made by a licensed plumber or gas tter in the Commonwealth

of Massachusetts.

Installation and repair should be done by a qualied service

person. The appliance should be inspected before use and at least

annually by a qualied service person. More frequent cleaning

may be required due to excessive lint from carpeting, bedding

material, etc. It is imperative that control compartments, burners

and circulating air passageways of the appliance be kept clean.

High Altitude

When installing this unit at an elevation above 2000 feet (in

the United States) it may be necessary to decrease the input

rating by changing the existing burner orice to a smaller size.

Generally, input should be reduced 4 percent for each 1000 feet

above sea level. However, if the heating value of the gas has

been reduced, this general rule may not apply. Conrm orice

size with Empire Comfort Systems.

Canadian High Altitude

Altitude: 0-4500 feet (0-1370 m)

When installing this unit at an elevation above 4500 feet (in

Canada), check with local authorities.

Consult your local gas utility for assistance in determining the

proper orice for location.

Well Head Gas Installations

Some natural gas utilities use “well head” gas. This may affect

the Btu output of the unit and promote sooting. Units shall not be

converted to use well head gas.

Building Codes

Consult your local building code agency, prior to installation,

to ensure compliance with local codes-including permits and

inspections.

• The installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas Code

ANSI Z223.1/NFPA 54* Natural Gas and Propane Installation

Code, or CSA B149.1 in Canada. *Available from the

American National Standards Institute, Inc. 11 West 42nd

St., New York, N.Y. 10036.

• The replace insert, when installed, must be electrically

grounded in accordance with local codes or, in absence of

local codes, with the National Electric Code ANSI/NFPA

70 or Canadian Electric code, CSA C22.1, if an external

electrical source is utilized.

Preparation

This direct vent gas replace insert and its components

are tested and safe when installed in accordance with this

Installation Manual. The replace insert must be installed into

a wood-burning replace. Report to your dealer any parts

damaged in shipment, specically check glass condition. Do

not install unit with damaged, incomplete, or substitute parts.

Read all instructions before starting installation and follow these

instructions carefully during installation to ensure maximum

benet and safety. Failure to follow them will void the warranty

and may present a re hazard.

This direct vent gas replace insert is designed to operate with

combustion air siphoned from and all exhaust gases expelled

to the outside of the building. The information contained in this

manual pertains to all models and gas control systems listed on

the front page unless otherwise noted.

These models may be installed in a bedroom or bed-sitting room

in the U.S.A. and Canada.

WARNING

Any change to this replace insert or its controls can be

dangerous. Improper installation or use of the replace

insert can cause serious injury or death from re, burns,

explosions, or carbon monoxide poisoning.

Before enclosing the vent pipe assembly, operate the

appliance to ensure it is venting properly.

Do not operate this appliance without the glass door installed.

• Due to high temperatures, the appliance should be located

out of trafc and away from furniture and draperies.

• Only trim kit(s) supplied by the manufacturer shall be used in

the installation of this appliance.

• Any safety screen, guard, or barrier removed to service an

appliance must be replaced prior to operating the appliance.

• If the barrier becomes damaged, the barrier shall be

replaced with the manufacturer’s barrier for this appliance.

• A barrier designed to reduce the risk of burns from the

hot viewing glass is provided with this appliance and shall

be installed for the protection of children and other at-risk

individuals.

• Only doors certied with the appliance shall be used.

• The glass front or any part removed for servicing the

appliance must be replaced prior to operating the appliance.

36561-5-0817Page 8

INTRODUCTION

Warranty Information

Any alteration of the original design, installed other than as

shown in these instructions or use with a type of gas not shown

on the rating plate is the responsibility of the person and

company making the change.

The warranty will be voided by, and the warranter disclaims any

responsibility for the following actions:

• Installation of any damaged replace insert or vent system

component.

• Modication of the replace insert or direct vent system.

• Installation other than as instructed by Empire Comfort

Systems, Inc.

• Improper positioning of the logs or glass door assembly.

• Installation and/or use of any component part not

manufactured or approved by manufacturer.

• This appliance comes standard with a 120 V/AC cord

assembly to accommodate the blower accessory. An outlet

box may be installed in a bottom back corner of the existing

solid fuel masonry or factory built replace to plug in the cord

assembly, or the supplied power cord may be routed out

onto the hearth to a nearby outlet.

• A 120 V/AC circuit for this product must be protected with

ground-fault circuit-interrupter protection, in compliance

with the applicable electrical codes, when it is installed in

locations such as in bathrooms or near sinks.

• Low voltage and 120 V/AC cannot be shared within the

same wall box.

• Once the appliance installation is completed, the installer

should check that control compartment wiring is secured in

a manner as to not interfere with blower, door latches, valve

controls, or the barrier assembly.

36561-5-0817 Page 9

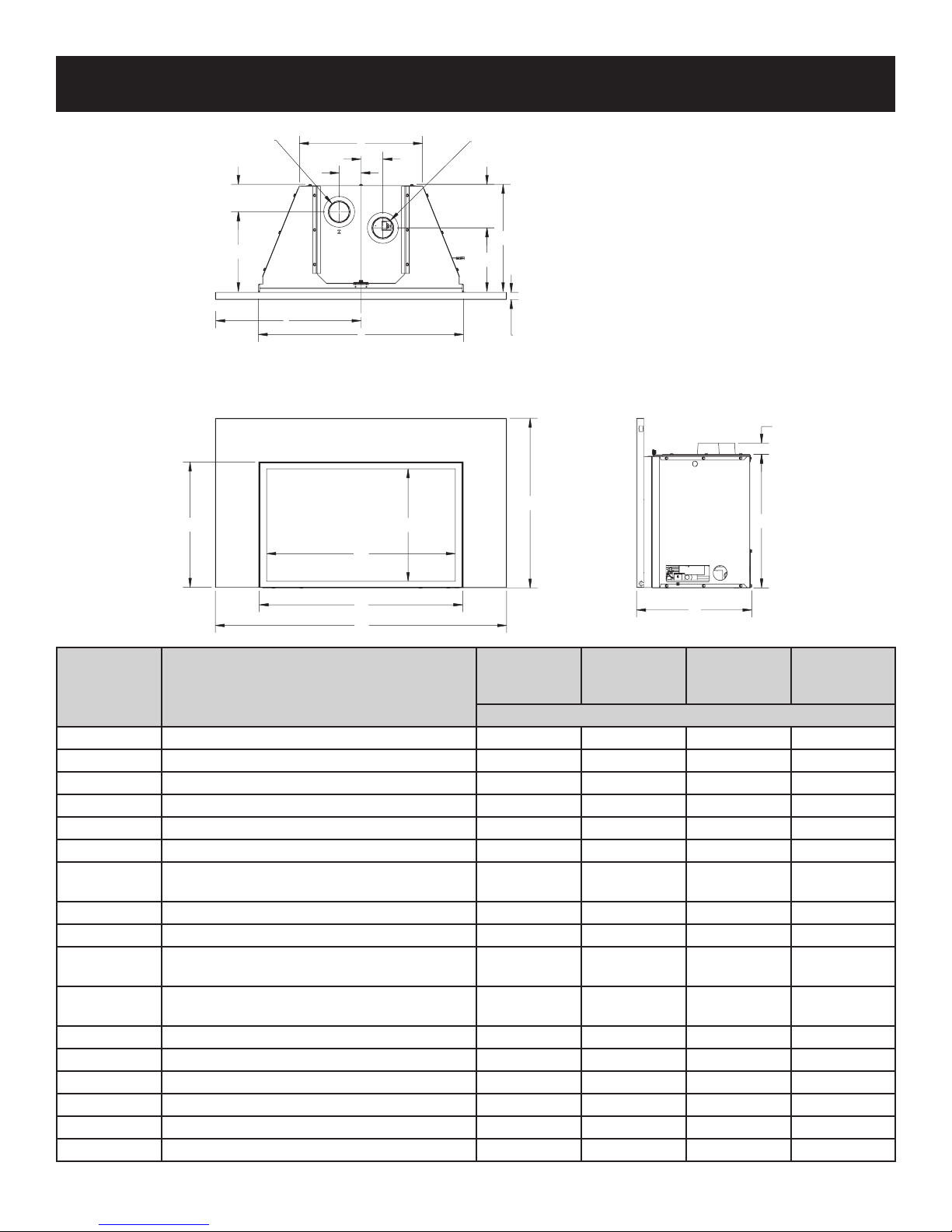

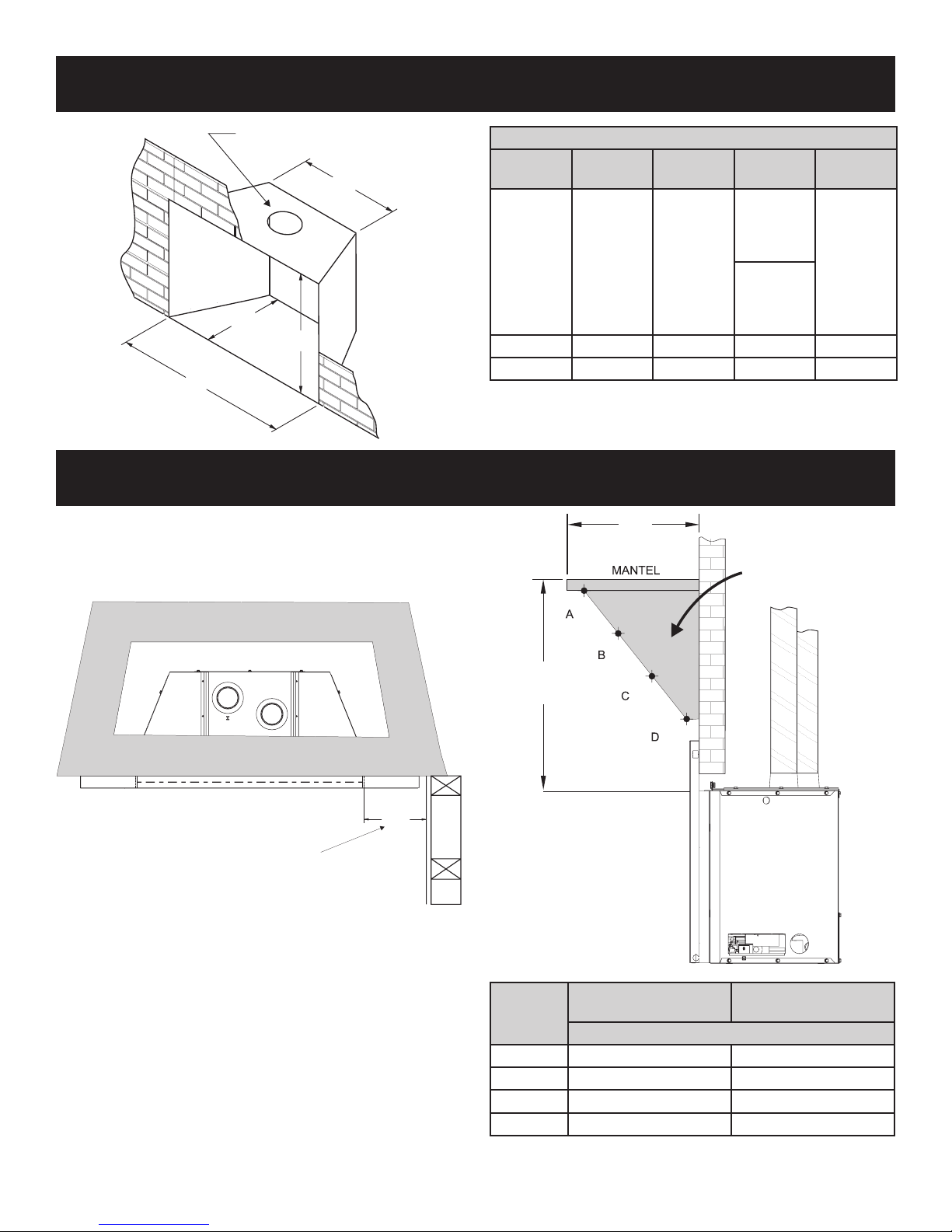

FIREPLACE INSERT DIMENSIONS

INTAKE

3” Dia.

3

4

3/”

K

I

D

G

3”

3”

L

M

N

FLUE

3” Dia.

6”

J

F

O

1

1/”

2

A

H

E

B

DVC20IN

INDEX

LETTER

A Surround Height 23-1/4 23-1/4 26-1/4 28-1/4

DIMENSION DESCRIPTION

with 1-inch

Surround

DVC20IN

with Deep

Surround

Dimensions in Inches

C

DVC26IN DVC28IN

B Surround width with 3-inch wide Surround Legs 34 34 37 40

B Surround width with 6-inch wide Surround Legs 40 40 43 46

C Overall Depth of Insert including Surround 15-7/8 15-7/8 17-5/8 17-5/8

D Barrier Screen Height 17-1/4 17-1/4 20-1/4 22-1/4

E Barrier Screen Width 27-7/8 27-7/8 30-7/8 33-7/8

F

Insert depth - from back of Surround to rear of

insert

14-7/8 13-5/8 16-5/8 16-5/8

G Rear width of Insert 17 17 18-3/4 21-3/4

H Height of Insert 18-1/2 18-1/2 21-1/2 23-1/2

I

I

Centerline of Insert to outside of 3-inch wide

Surround Leg

Centerline of Insert to outside of 6-inch wide

Surround Leg

17 17 18-1/2 20

20 20 21-1/2 23

J Back of Surround to Centerline of Flue Outlet 8-7/8 7-5/8 10-9/16 10-9/16

K Back of Surround to Centerline of Air Inlet 11-3/16 9-15/16 12-7/8 12-7/8

L Front width of Insert cabinet 28-3/16 28-3/16 31-3/16 34-3/16

M Barrier Screen opening height 15-1/2 15-1/2 18-1/2 20-1/2

N Barrier Screen opening width 25-15/16 25-15/16 28-15/16 31-15/16

O Surround depth 1 2-1/4 1 1

36561-5-0817Page 10

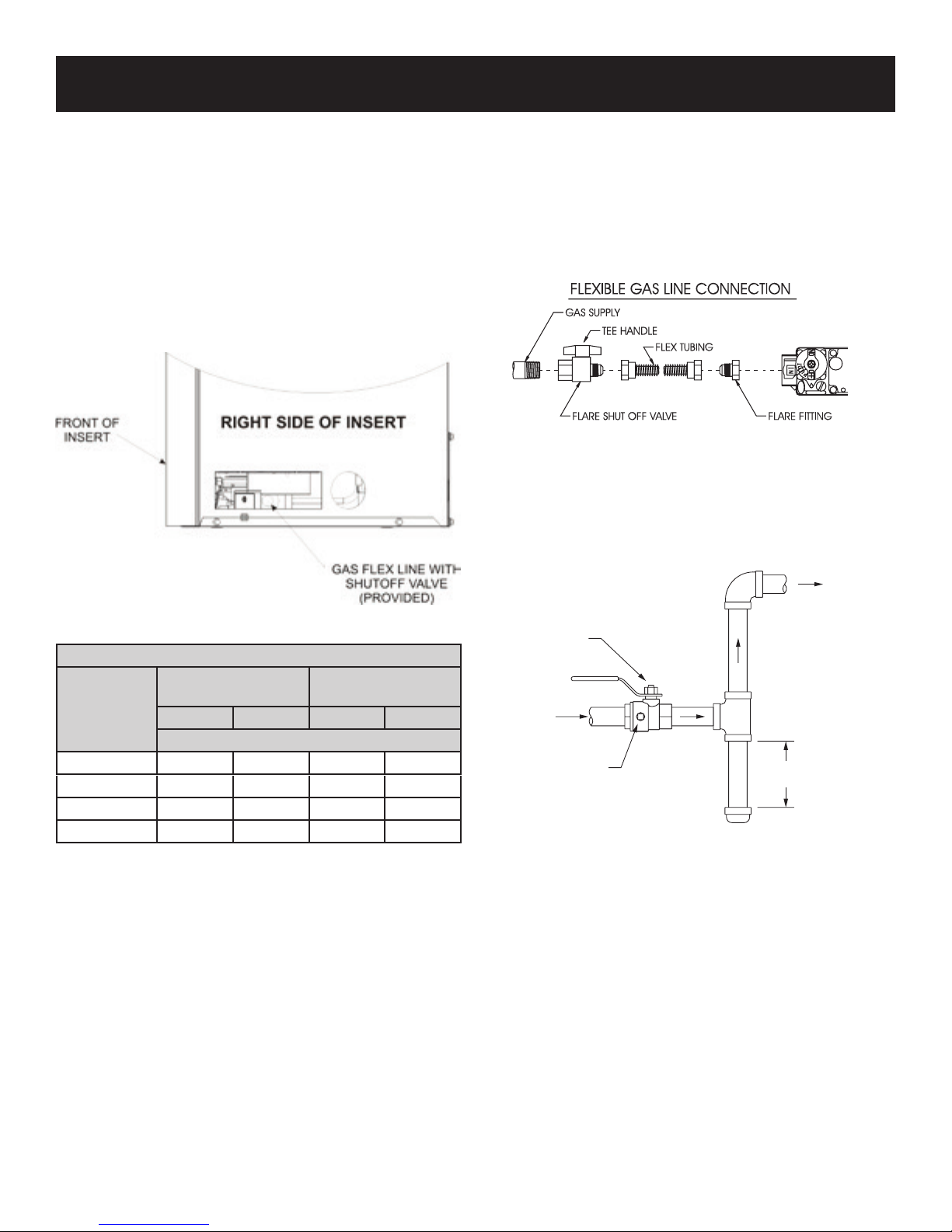

8” MIN. DIA. FLUE

REQUIRED

MINIMUM FIREPLACE OPENING DIMENSIONS

TOP OF INSERT

12”

MAX

17”

MIN

COMBUSTIBLE TRIM

AND MANTELS

ALLOWED IN

SHADED AREA

D

C

A

B

MANTEL AND TRIM CLEARANCES

Combustible Material

No greeting cards, stockings or ornamentation of any type should

be placed on or attached to the replace. The ow of heat can

ignite combustibles.

Dimensions (in inches)

Model

No.

DVC20IN 18-1/2 28-1/4

DVC26IN 21-1/2 31-1/4 16-5/8 19

DVC28IN 23-1/2 34-1/4 16-5/8 22

Height

A

Front

Width B

Depth

C

14-7/8

with 1-inch

deep

surround

13-5/8

with 2-1/4

inch deep

surround

Rear

Width D

17-1/4

MINIMUM CLEARANCE TO PERPENDICULAR

(FROM EDGE OF THE BARRIER SCREEN FRAME)

Television Considerations

Installing a television above a replace has become increasingly

popular; however, the area above any replace gets hot and most

TV manufacturers recommend against placing their products

near a heat source.

If you install a television above this replace insert, Empire

Comfort Systems accepts no responsibility for damage or

injuries. Follow the television manufacturer’s installation

instructions, including any recommendations regarding proximity

to heat sources.

If you have a TV above your replace, turn off the replace and

let it cool completely before servicing or touching any buttons on

the TV.

36561-5-0817 Page 11

COMBUSTIBLE SIDE-WALL

Figure 1

8”

Index

Letter

A 9-1/4 16

B 7-1/4 13

C 4-1/2 12

D 1-3/4 8

Mantel Depth From

Fireplace Face

Dimensions in Inches

Figure 2

Distance From

Top of Insert

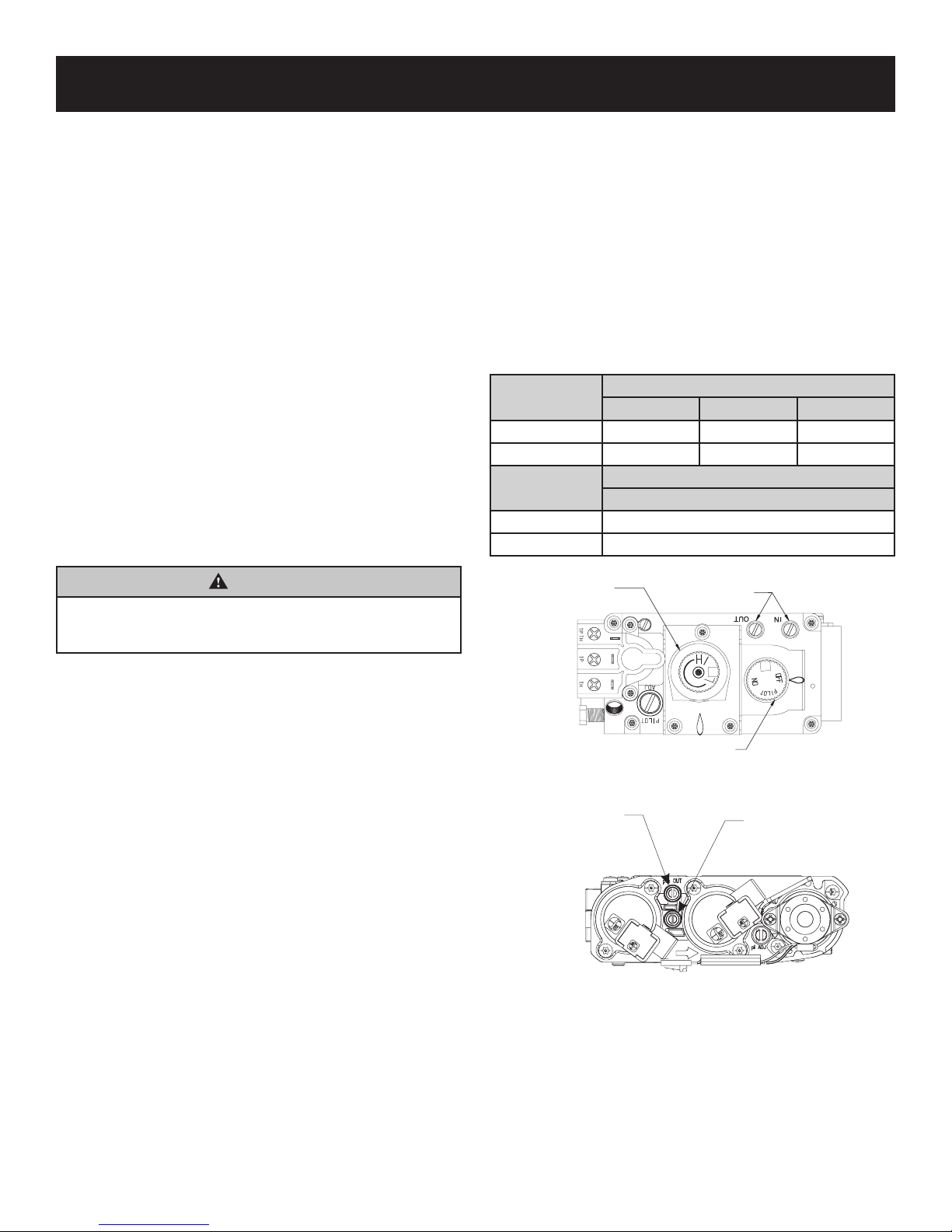

GAS SUPPLY

GAS SUPPL

CONTROL

If the factory-built replace has no gas access hole(s) provided,

an access hole of 1.5 inch (37.5 mm) or less may be drilled

through the lower sides or bottom of the rebox in a proper

workmanship-like manner. This access hole must be plugged

with non-combustible insulation after the gas supply line has

been installed.

The gas pipeline can be brought in through the right or left side of

the appliance. The insert has a Flexline with shutoff valve located

on the right side when facing the unit. See Figures 3 and 4.

Consult the current National Fuel Gas Code, ANSI Z223.1 CAN/

CGA-B149 (.1 or .2) installation code.

NOTICE: Once the gas access hole is drilled through the bottom

of the rebox and through the replace, the replace cannot be

converted back to a solid-fuel burning replace.

Use the following gas connectors:

— ANSI Z21.24 Appliance Connectors of Corrugated Metal

Tubing and Fittings.

— ANSI Z21.45 Assembled Flexible Appliance Connectors of

Other Than All-Metal Construction

The above connectors may be used if acceptable by the authority

having jurisdiction. The Commonwealth of Massachusetts

requires that a exible appliance connector cannot exceed three

feet in length.

Figure 4

Install a gas valve and ground joint union in the gas line upstream

of the gas control to aid in servicing. The National Fuel Gas

Code requires installing a drip leg near the gas inlet. The drip

leg consists of a vertical length of capped pipe installed before

the gas inlet to collect condensation and foreign particles. See

Figure 5.

GAS SUPPLY PLUMBING

TO

VALV E

Figure 3

RECOMMENDED GAS PIPE DIAMETER

Pipe Length

Schedule 40 Pipe

Inside Diameter

NAT Propane NAT Propane

Tubing, Type L

Outside Diameter

(Dimensions in Inches)

0-10ft 1/2 3/8 1/2 3/8

11-40ft 1/2 1/2 5/8 1/2

41-100ft 1/2 1/2 3/4 1/2

101-150ft 3/4 1/2 7/8 3/4

NOTICE: Never use plastic pipe. Check local codes before using

copper tubing or galvanized.

NOTICE: Some municipalities have additional codes. Consult

your local authority and installation code.

MANUAL

SHUT-OFF VALVE

Y

INLET

1/8 NPT PLUGGED

HOLE FOR

TEST GAGE

Figure 5

3”

MINIMUM

36561-5-0817Page 12

CONTROL KNOB

OUTLET

GAS SUPPLY

Installing a New Main Gas Shut-Off Valve

Each appliance must have its own manual gas shut-off valve

located in the vicinity of the replace. Where none exists, or

where its size or location is not adequate, contact your local

authorized installer for replacement or relocation.

Test for leaks. Turn replace off. Compounds used on threaded

joints of gas piping must be resistant to the action of liqueed

petroleum gases. The installer must check all gas connections

for leaks. Perform all leak tests with a leak test solution or soap

solution. Rinse off all solution once testing is complete. Perform a

pressure test on all unexposed connections.

Never use an exposed ame to check for leaks. Never pressure

test with replace connected; control valve will sustain damage.

Disconnect the replace from piping at the control valve inlet and

cap the pipe before pressure testing.

NOTICE: The millivolt gas controls are equipped with a captured

screw type pressure test point, therefore it is not necessary to

provide a 1/8-inch test point upstream of the control.

When using copper or ex connector use only approved ttings.

Disconnect the appliance and its individual shut-off valve from

the gas supply piping system during any pressure testing of that

system at test pressures in excess of 1/2 psig (3.5kPa).

Isolate the appliance from the gas supply piping system by

closing its manual shut off valve during any pressure testing of

the gas supply piping system at test pressures equal to or less

than 1/2 psig (3.5kPa).

WARNING

If one of the procedures results in pressures in excess of

1/2 psig (14-inch w.c.) (3.5 kPa) on the replace gas valve, it

will result in a hazardous condition.

Checking Manifold Pressures

Both Propane and Natural gas valves have a built-in pressure

regulator in the gas valve.

Natural gas models will have a manifold pressure of

approximately 3.5-inch w.c. (.871kPa) at the valve outlet with

the inlet pressure to the valve from a minimum of 4.5-inch w.c.

(1.120kPa) for the purpose of input adjustment to a maximum of

14.0-inch w.c. (3.484kPa).

Propane models will have a manifold pressure of approximately

10.0-inch w.c. (2.49kPa) at the valve outlet with the inlet pressure

to the valve from a minimum of 10.8-inch w.c. (2.68kPa) for the

purpose of input adjustment to a maximum of 14.0-inch w.c.

(3.484kPa).

Gas Supply Pressure (inches w.c.)

Minimum Normal Maximum

Natural Gas 4.5 7.0 14.0

LP (Propane) 10.8 11.0 14.0

Manifold Pressure (inches w.c.)

Normal (HI)

Natural Gas 3.5

LP (Propane) 10.0

HI/LO

REGULATOR

PRESSURE

TAPS

36561-5-0817 Page 13

PRESSURE

TAP

Figure 6 - Millivolt Valve

INLET

PRESSURE

TAP

Figure 7 - IP Valve

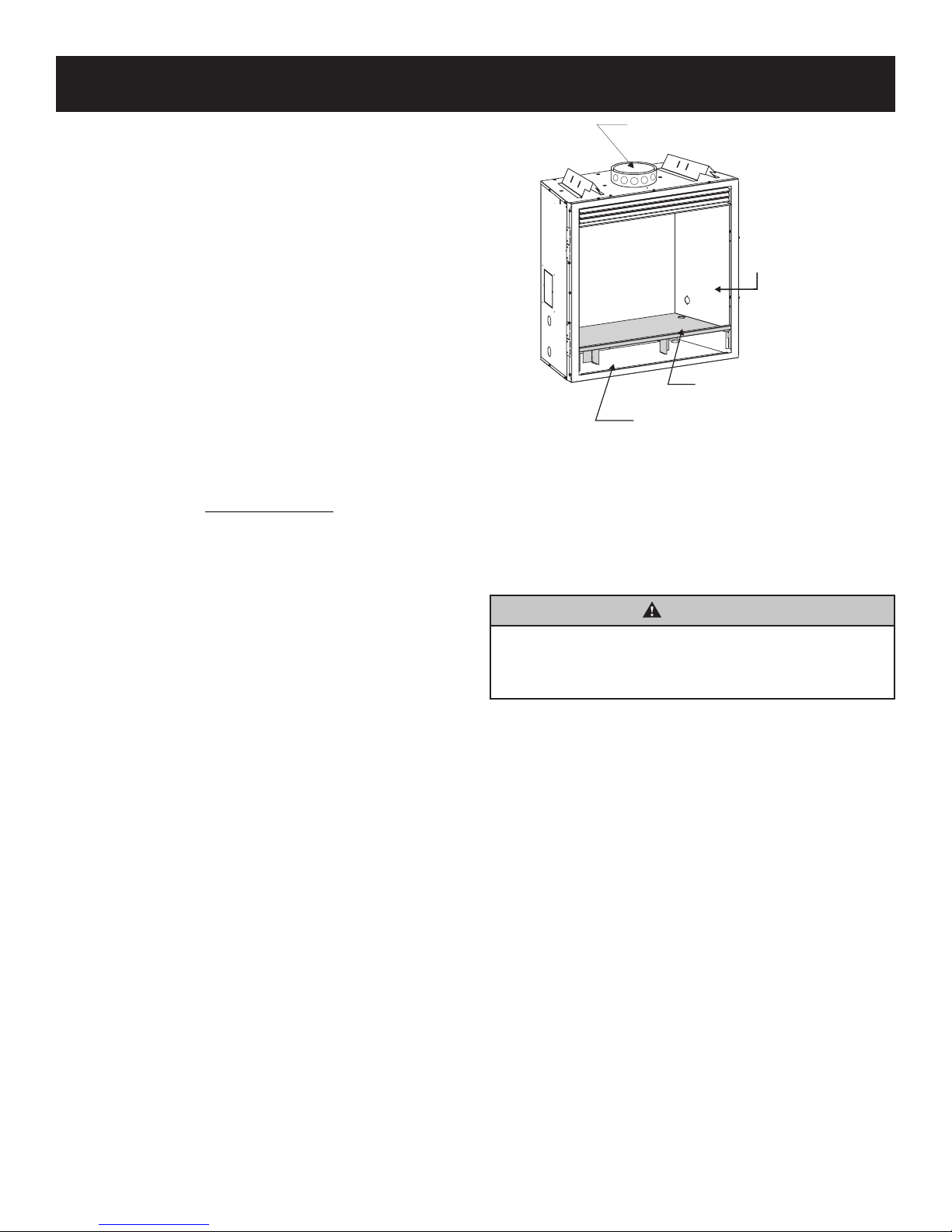

FIREPLACE PREPARATION

ACHED

8” DIAMETER FLUE (MIN.)

GENERIC FACTORY-BUILT WOODBURNING FIREPLACE SHOWN

Before You Start

Before installing, read these instructions and the Vent Kit

Instructions to ensure proper installation. Consult local Building

Codes before beginning the Installation.

NOTICE: Cutting the sheet metal parts of an existing

replace in order to install the replace insert is prohibited.

1. The replace and replace chimney must be cleaned, in

good working order. The approved chimney for the factorybuilt replace or masonry chimney must be used to run

venting through.

NOTICE: Do not handle barrier screen or door assembly with

your bare hands! (Always Wear Gloves)

2. Remove the barrier screen, glass door and log package from

replace insert. Check to make sure there is no damage to

the replace insert or its components.

3. Plan out the gas, venting and electrical route. Start with the

gas line, followed by the chimney preparation and electrical

supply requirements.

4. The minimum replace opening requirements are shown in

Page 11 of this installation manual. The rebrick (refractory),

glass doors, screen rails, screen mesh and log grates can

be removed from a factory built replace to gain minimum

gas insert opening requirements prior to installing the gas

replace insert. See Figure 8.

5. Remove or lock the replace ue damper in the fully open

position prior to installing the gas replace insert.

6. Make sure that all chimney cleanouts t properly so air

cannot leak into the chimney.

7. The replace insert does not require any additional hearth

extension. However, the original hearth materials installed

with the replace must be retained. If the original materials

have been damaged or removed, a new one must be

installed. Hearth materials must consist of a non-combustible

material such as brick, tile, slate, marble, or other noncombustible surface extending the width of the replace and

out a minimum of 16 inches in front. Wood ooring, vinyl, or

carpet are not allowed directly in front of the replace insert.

NOTICE: The original replace cannot be returned to

solid fuel use without returning the hearth extension to the

specication required for a solid fuel replace.

8. The metal oor of the solid fuel rebox may be removed to

install the insert. If the rebox oor is removed, the insert

must be raised off the oor of the replace at least 1/4 inch

to protect the combustible surface under the original

replace. Clearance to combustible material under the insert

is 1/4-inch. Combustible material must not be placed inside

the original area. The side walls and top structure of the

rebox may not be altered with the exception of removable

bafes and dampers. Fire screens, refractory liners (sides

and oor), smoke shields, shelves and bafes may be

removed if attached with mechanical fasteners. The original

replace cannot be returned to solid fuel in this condition.

See Figure 8.

INTERIOR BAFFLES,

SMOKE SHIELDS, AND

SHELVES MAYBE

REMOVED IF ATT

WITH MECHANICAL

FASTENERS

FIREBOX FLOOR

FIREBOX FLOOR

CAN BE REMOVED

CAN BE REMOVED

FIREPLACE FLOOR

CAN NOT BE REMOVED

Figure 8

NOTICE: The following statement is also provided on a

separate warning label plate in the instruction packet. Prior

to installation of the replace insert, the installer must

mechanically secure this warning label plate to the inside of

the replace for future reference as required.

WARNING

This solid fuel replace has been converted for use with gas

only and cannot be used for burning wood or solid fuels

unless all original parts have been replaced and the replace

has been reapproved by the authority having jurisdiction.

Clearances

• Maintain the original specied exterior clearances of the

factory-built replace and vent system.

• Maintain mantel and trim clearances on a masonry replace

at 12 inches above the opening for combustible projections

over 1-1/2 inch.

• Clearances for combustible projections under 1-1/2 inch

must be maintained at 6 inches above the opening per

NFPA211. Plan the surround size accordingly. A surround

must be used with the insert. Under no circumstance can

combustible material be placed behind the surround or

behind the insert!

36561-5-0817Page 14

VENTING

Vent System Installation Precautions

Before installing vent kits, read these instructions and the Vent Kit

Instructions to ensure installation. Consult local Building Codes

before beginning the Installation.

To ensure top performance, safety and efciency, inserts must be

installed with an approved ue liner as per CAN/CGA B-149 or

National Fuel Code ANSI Z223 and these instructions.

WARNING

This gas insert and vent assembly must be vented directly to

the outside and must never be attached to a chimney serving

a separate solid-fuel burning or gas-venting appliance.

Vent System Approvals

Figure 10 shows the vent termination cap and system approved

for use with these models. Approved vent system terminations

are labeled for identication. Use 3-inch diameter, exible

aluminum or stainless steel gas venting for both the incoming

combustion air and exhaust vent pipes. No other venting

systems or components may be used. Detailed installation

instructions are included with each vent termination kit and

should be used in conjunction with this manual.

Horizontal Venting

The vent system on this model CANNOT be terminated

horizontally.

NOTICE: The minimum vertical vent rise is 10 feet and the

maximum vertical vent rise is 35 feet. These dimensions are

measured from the starting collars of the unit to the end of the

last section of vent pipe. See Figure 10.

NOTICE: The damper of the masonry chimney may need to be

removed to install the exible-vent pipe.

When installing into a zero clearance, factory built wood-burning

replace, the DVKI2P Round Vertical Termination Kit should allow

you to mount the vent adaptor and cap to the exposed round

chimney pipe.

NOTICE: The vent cap must be in open, free air. It cannot be

installed under an existing cap shared by other ues.

Vertical Venting

The inlet and exhaust vent pipes MUST be connected to the

proper collars on the unit AND to the termination cap or the unit

will not operate. The intake vent collar is identied by a stamped

“I” on the top collar sliding vent plate assembly.

WARNING

Major U.S. building codes specify minimum chimney and/or

vent height above the roof top. These minimum heights are

necessary in the interest of safety. See Figures 11 and 12 for

minimum heights, provided the termination cap is at least 2

feet from a vertical wall and 2 feet below a horizontal overhang.

NOTICE: The above warning also pertains to vertical vent

systems installed on the outside of the building.

WARNING

The exhaust pipe must only be connected to the exhaust

starting collar of the unit and to the exhaust collar of the

termination cap.

The inlet air pipe must only be connected to the inlet air

starting collar of the unit and to the inlet air collar of the

termination cap. Both the inlet vent and the ue vent must

be connected from the insert to the vent termination cap.

36561-5-0817 Page 15

INSTALLATION

Connect the Vent Pipe & Install the Fireplace Insert

CAUTION

Sharp edges. Wear gloves when installing.

1. Install the 3-inch exible vent pipes down through the

chimney.

2. Attach the pipe-to-cap adaptor to the termination cap and the

top of the exible vent pipe, then install the cap to the top of

the chimney.

CAUTION

Seal off the area between the termination cap and the top

of the solid-fuel chimney opening into which the vent cap

is installed to avoid downdrafts and/or cold air problems.

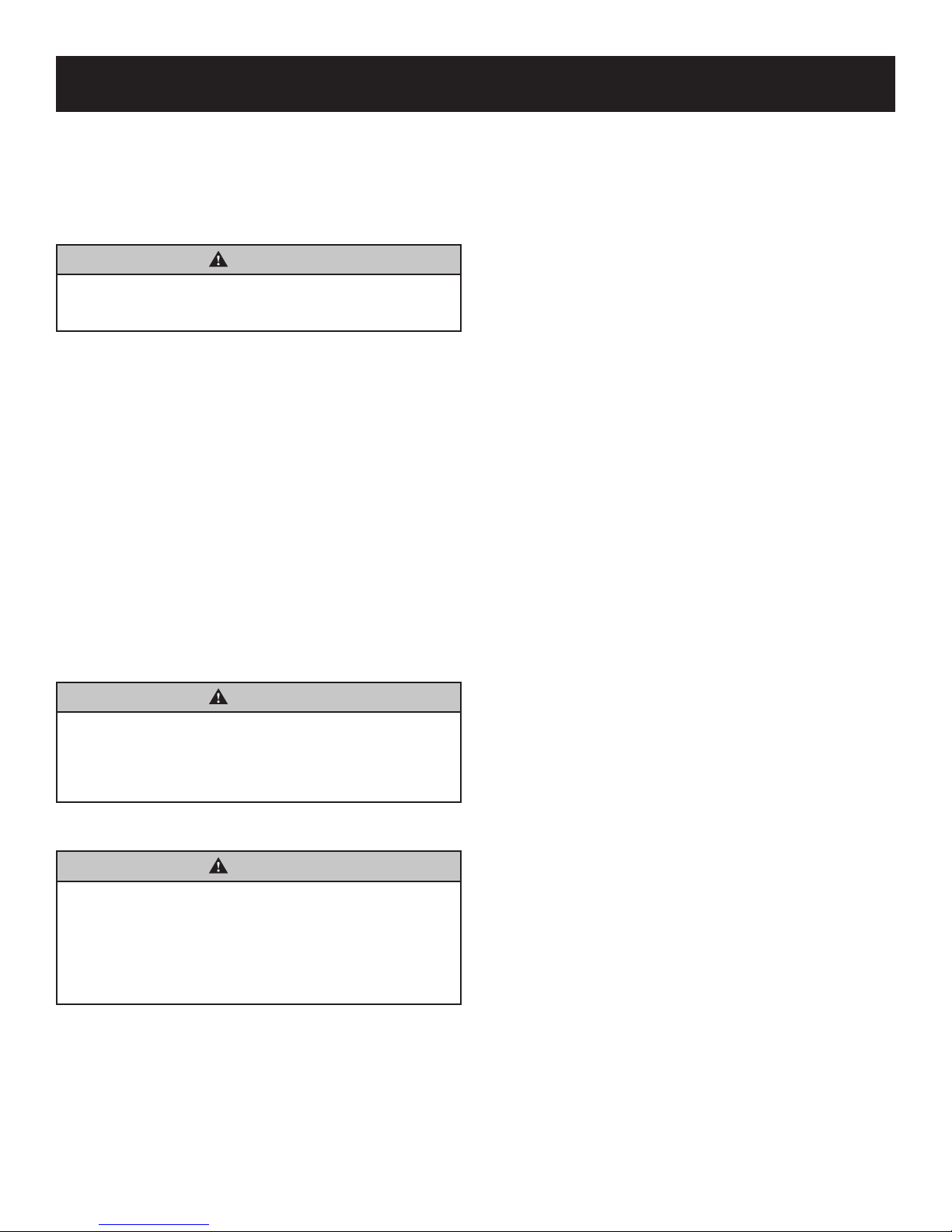

3. Remove the vent slide plate assembly from the top of the

insert. See Figure 9.

9. Level the insert from side to side and front to back.

10. If necessary, use the leveling bolts included in the instruction

pack. Screw the legs into the nuts installed in the bottom of

the insert. Turn legs in until insert is level.

NOTICE: If desired, attach metal strapping or brackets

(not provided) from the replace cavity to the insert outer

jacket to secure the replace insert to the replace hearth or

opening.

11. Once the replace insert is level and the vent slide plate is

close to seating, install the black button head 5/16-18 x 2

1/2 inch long bolt through the center hole of the insert top

bracket, and into the vent slide plate nut.

12. Use the provided allen wrench to tighten the bolt until the

vent slide plate is seated forward completely.

13. Install surround assembly. Refer to instructions included with

the surround kit.

NOTICE: All manufacturer supplied surrounds, shrouds, and

decorative front options have been tested and are approved for

use with the replace insert and may cover existing air circulation

vents or grills on the solid fuel replace it is installed into.

Do not seal the ventilation openings on the insert with trim panels

or surrounds.

WARNING

Only surrounds, shrouds, and decorative front components

supplied by the manufacturer may be used to cover

integral grills on the solid-fuel burning replace. No other

components such as sheet metal plates may be used to

seal off vents.

Figure 9

4. Trim off excess venting then attach and secure the bottom

ends of the ex pipes to the starting collars with the

adjustable band clamps provided.

5. Slide the gas insert into place without the surround panels

attached, and position any excess ex vent pipe back up

into the chimney. Do not leave an excess of pipe that could

cause a restriction in the intake or exhaust system.

6. Make all gas and electrical connections.

7. Align the vent slide plate assembly with the guides located

on top of the insert.

8. Work the insert inch by inch into the replace cavity as you

pull forward on the vent slide plate assembly. Do not use

excessive force on the vent slide plate.

NOTICE: The front anges of the insert (without the surround)

should be set at approximately 1-inch) in front of the face of the

replace.

36561-5-0817Page 16

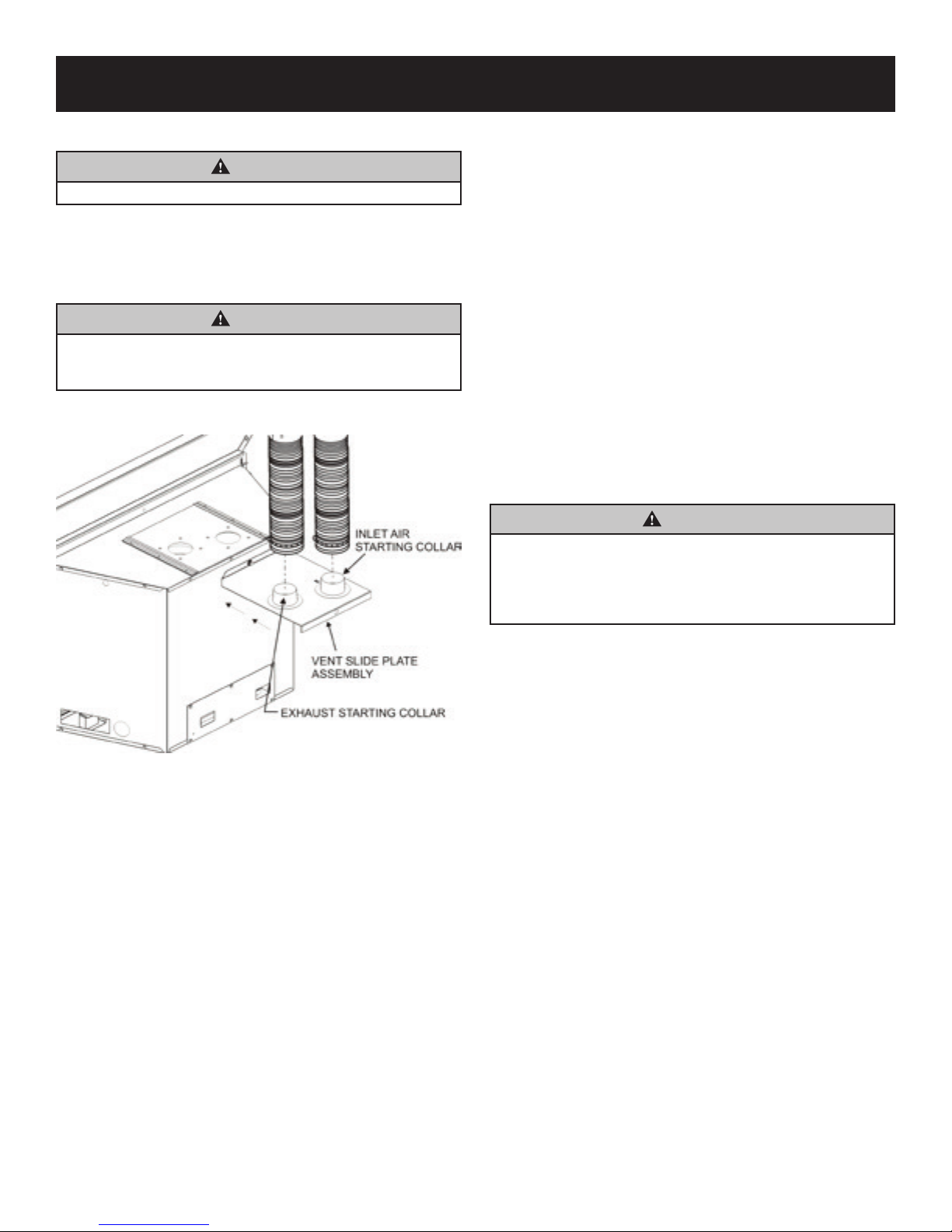

INSTALLATION DIAGRAM

ROUND

TERMINATION CAP

DVKI2P KIT

(INCLUDES CO-AXIAL

ADAPTER AND FLASHING)

DVKI2P FLASHING SHOWN. IF A

LARGER OR DIFFERENT CONFIGURATION

IS REQUIRED, A FIELD-BUILT VERSION

(BUILT TO LOCAL CODES) IS ACCEPTABLE.

INSTALL RETAINER SCREWS

THROUGH THE VENT CLAMPS

TO SECURE VENTING

NOTE: LONG EXTENSION

TUBE FOR INLET

CONNECTION

VENT CLAMPS

USE HIGH-TEMP

SEALANT ON VENT

CONNECTIONS

OPTIONAL ON/OFF

SWITCH LOCATION

INSTALL SCREWS THROUGH

VENT CLAMPS TO SECURE

THE VENTING TO THE COLLARS

INTAKE VENT

10’ MINIMUM

35’ MAXIMUM

FLUE EXHAUST VENT

VENT CLAMPS

USE HIGH-TEMP

SEALANT ON VENT

CONNECTIONS

OPTIONAL

LOW-VOLTAGE

WIRES

36561-5-0817 Page 17

BLOWER

POWER CORD

Figure 10

BLOWER ACCESS

PLATE

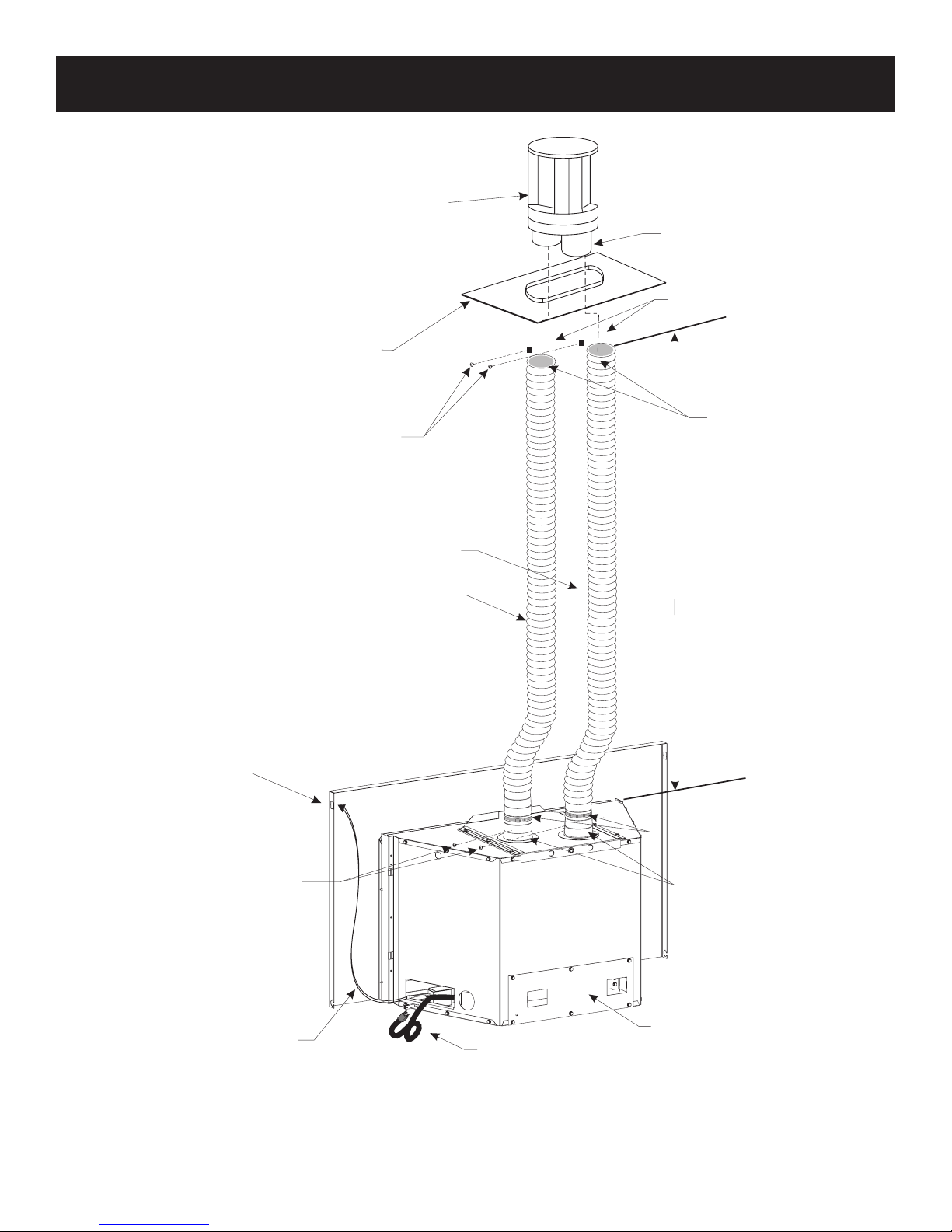

VERTICAL TERMINATION

Determining Minimum Vent Height Above the Roof.

WARNING

Major U.S. building codes specify minimum chimney height

above the roof top. These specications are summarized in

Figure 11.

LOWEST

VENTCAP

WOOD BURNING

CHIMNEY

ROOF PITCH X/12

H (Min.) Minimum height from

roof to lowest discharge opening

ROOF PITCH

Flat to 6/12 12

6/12 to 7/12 15

Over 7/12 to 8/12 18

Over 8/12 to 16/12 24

Over 16/12 to 21/12 36

Figure 11

DISCHARGE

OPENING

H (Min.)

(in inches)

Vertical Applications

The Gas Fireplace Insert has been approved for vertical

installations up to 35 feet in height (top of insert to cap).

General Maintenance

Conduct an inspection of the venting system semi-annually.

Recommended areas to inspect are as follows:

1. Check areas of the venting system which are exposed to

the elements for corrosion. These will appear as rust spots

or streaks and, in extreme cases, holes. These components

should immediately be replaced.

2. Remove the cap and shine a ashlight down the vent.

Remove any bird nests or other foreign material.

3. Check for evidence of excessive condensate, such as water

droplets forming in the ex venting and subsequently dripping

out at joints or seams. Condensate can cause corrosion of

caps, pipe and ttings. It may be caused by having excessive

runs, or having exterior portions of the system exposed to

cold weather.

4. Inspect joints to verify that no pipe sections or ttings

have been disturbed and, consequently, loosened. Check

mechanical supports.

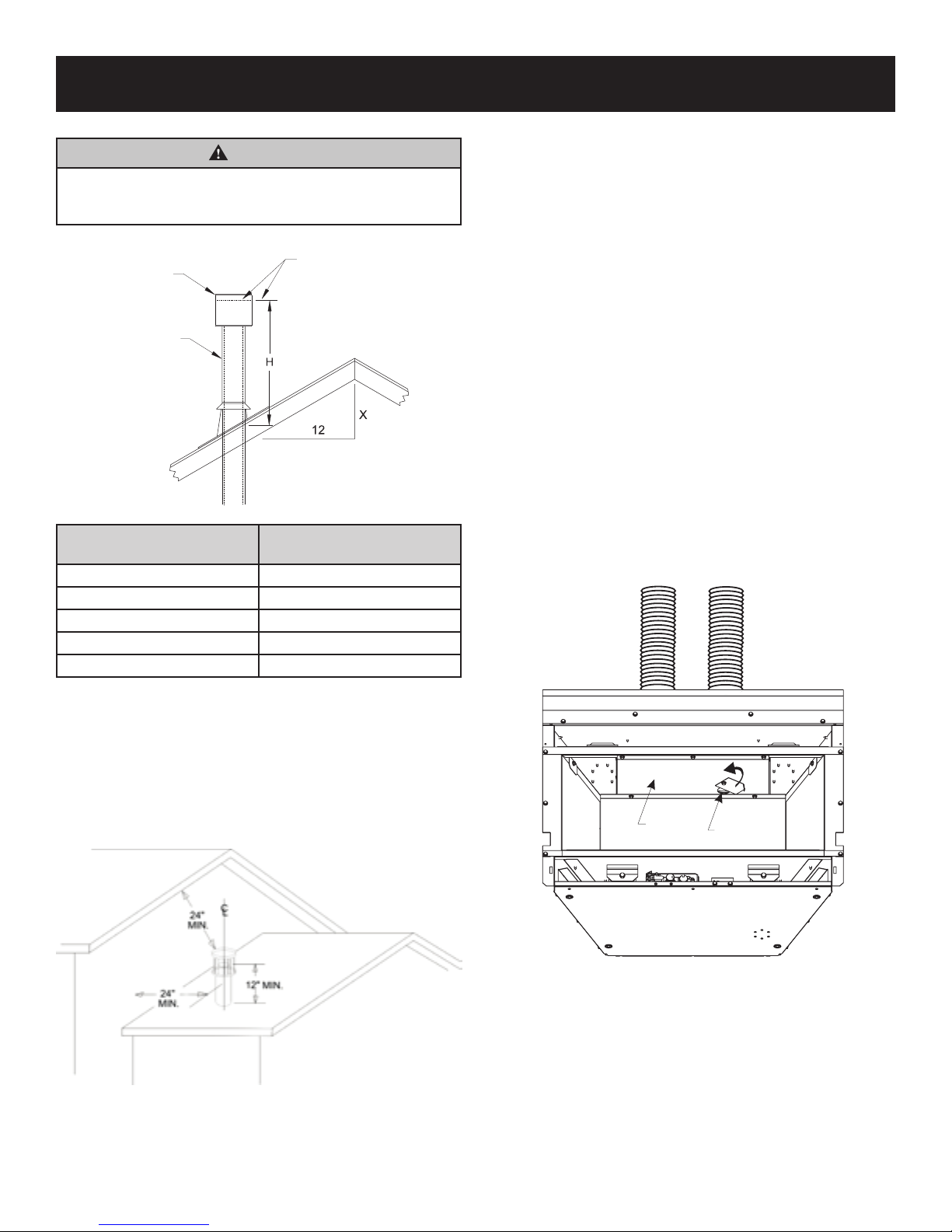

Tall Vent Heights

Poor combustion may occur during initial and cold start-ups.

Open the ue bafe vent to improve performance. To adjust,

rotate the ue bafe vent enough to encourage better draft for

improved combustion.

NOTICE: For steep roof pitches, the vent height must be

increased. In high wind conditions, nearby trees, adjoining roof

lines, steep pitched roofs, and other similar factors can result in

poor draft, or down-drafting. In these cases, increasing the vent

height may solve this problem.

When terminating the vent cap near an exterior wall or overhang,

maintain minimum clearances as shown in Figure 12.

Figure 12

FIREBOX

BAFFLE

Figure 13

FLUE

BAFFLE

VENT

36561-5-0817Page 18

VERTICAL TERMINATION

ON/OFF SWITCH

Optional Inlet Air Restrictor Plate Installation

An optional air restrictor plate is included in the instruction

packet. Install the optional air restrictor if the replace insert

installation requires 20 to 35 feet vertical venting, or is in highwind area.

1. Remove the barrier screen, glass door, log set and liner

panels (if applicable) and set aside.

2. Remove the back log support bracket by removing the two

screws securing it to the log support and set aside.

3. Remove the log support by removing the three screws

securing it to the rebox back and set aside.

4. Loosen the two bottom screws that secure the inlet air duct

collar at the rear of the rebox. See Figure 14.

5. Place the inlet air restrictor plate over the air intake opening.

Align the plate with the loosened screws, shift the plate on

the keyhole slots, then retighten the two screws. See Figure

14 for locating the inlet air duct opening.

6. Reinstall the back log support and three screws removed in

step 3.

7. Reinstall the rear log support bracket and two screws

removed in step 2.

8. If applicable, reinstall liner panels, log set, glass door, and

barrier screen.

Figure 14

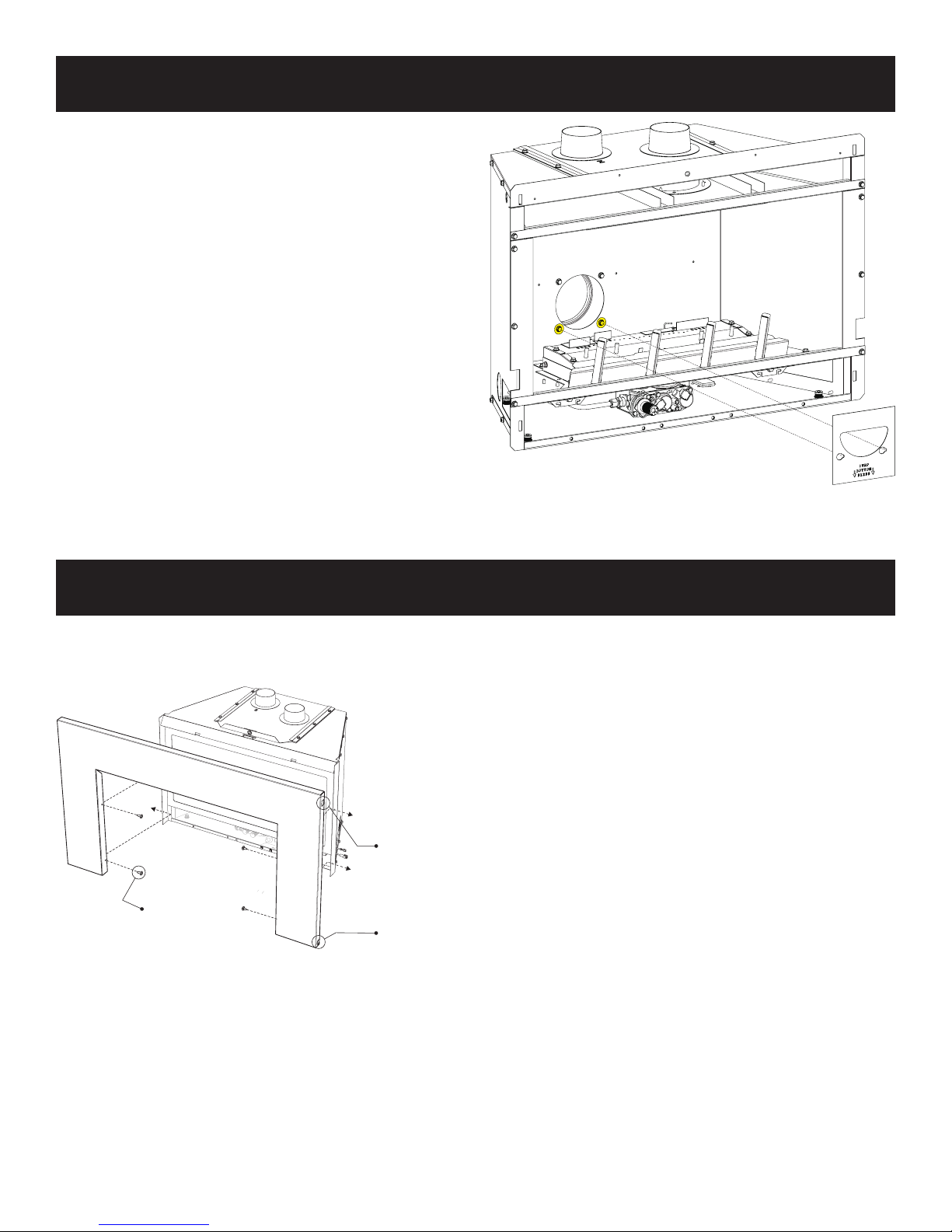

SURROUND INSTALLATION

1. Secure the surround to the replace insert anges with four #8

x 1/2-inch truss head screws (two each side). See Figure 15.

KNOCKOUT

#

1

8/TRUSS HD

x

2

SCREWS (4)

Figure 15

POWER CORD

KNOCKOUT

36561-5-0817 Page 19

Loading...

Loading...