Page 1

INSTALLATION INSTRUCTIONS

GAS-FIRED

AND

OWNER’S MANUAL

INNSBROOK FIREPLACE INSERT

Installer: Leave this manual with the appli-

ance.

Consumer: Retain this manual for future refer-

ence.

DIRECT VENT

GAS FIREPLACE HEATER

MODEL SERIES

DV25IN33L(N,P)-1

DV33IN33L(N,P)-1

DV35IN33L(N,P)-1

UL FILE NO. MH30033

WARNING: If the information in these instructions are not followed exactly, a fire or explosion

may result causing property damage, personal

injury or loss of life.

— Do not store or use gasoline or other flamma-

ble vapors and liquids in the vicinity of this or

any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call

the fire department.

— Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

This appliance may be installed in an aftermarket,

permanently located, manufactured home (USA

only) or mobile home, where not prohibited by

state or local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless a

certified kit is used.

WARNING: If not installed, operated and maintained in accordance with the manufacturer’s

instructions, this product could expose you to

substances in fuel or from fuel combustion which

can cause death or serious illness.

Page 1

Page 2

TABLE OF CONTENTS

SECTION PAGE

Important Safety Information .................................................................................................3

Safety Information for Users of LP Gas .................................................................................4

Introduction ............................................................................................................................5

Specifications .........................................................................................................................6

Fireplace Insert Dimensions ...................................................................................................7

Mantle and Trim Clearances ..................................................................................................8

Gas Supply .............................................................................................................................9

Venting and Installation .................................................................................................. 10-12

Vertical Termination .............................................................................................................13

Alternate ON/OFF Switch Installation .................................................................................14

Surround Panel Installation ..................................................................................................15

Blower Accessory Information .............................................................................................16

Log Placement ......................................................................................................................17

Operating Instructions ..........................................................................................................18

Standing Pilot Lighting Instructions ....................................................................................19

Standing Pilot Wiring ...........................................................................................................20

Standing Pilot Troubleshooting ............................................................................................21

Insert Maintenance and Service ...........................................................................................22

Decorative Accessories .........................................................................................................23

Insert Parts View ..................................................................................................................24

Insert Parts List .....................................................................................................................25

How to Order Repair Parts ...................................................................................................26

Service Notes .................................................................................................................. 26-27

23015-3-0707Page 2

Page 3

IMPORTANT SAFETY INFORMATION

Before enclosing the vent pipe assembly, operate the appliance to ensure it is venting properly.

DO NOT OPERATE THIS APPLIANCE WITHOUT GLASS FRONT PANEL INSTALLED

• Children and adults should be alerted to the hazards

of high surface temperatures and should stay away

to avoid burns or clothing ignition.

• Young children should be carefully supervised when

they are in the same room as the appliance.

• Clothing or other flammable material should not be

placed on or near the appliance.

• Adequate accessibility clearances for servicing and

proper operation should be maintained.

• This appliance must not share or be connected to a flue

serving a separate solid-fuel burning appliance.

• Due to high temperatures the appliance should be

located out of traffic and away from furniture and

draperies.

• The glass front or any part removed for servicing

the appliance must be replaced prior to operating

the appliance. Work should be done by a qualified

service person.

• Keep burner and control compartment clean.

• Vent cap is hot while fireplace is in operation.

• Installation and repair should be done by a

QUALIFIED SERVICE PERSON. The appliance

should be inspected before use and at least annually

by a qualified service person. More frequent

cleaning may be required due to excessive lint from

carpeting, bedding materials, etc. It is imperative

that control compartments, burners and circulating

air passageways of the appliance be kept clean.

• Keep the area around your appliance clear of

combustible materials, gasoline and other flammable

vapor and liquids.

• Under no circumstances should any solid fuels (wood,

coal, paper or cardboard etc.) be used in this appli

ance.

• The flow of combustion and ventilation air must not

be obstructed in any way.

• DO keep the appliance area clear and free from

combustible material, gasoline and other flammable

vapors and liquids.

• DO examine venting system periodically and replace

damaged parts.

• DO make a periodic visual check of pilot and burners.

Clean and replace damaged parts.

• CAUTION: The glass used in your fireplace insert is

ceramic glass. If the glass is cracked or damaged in

any way, it should be replaced only with a complete

glass frame assembly from Empire. See parts list on

Page 25 for ordering.

• DO NOT use this fireplace insert if any part has been

under water. Immediately call a qualified service

technician to inspect the heater and to replace any

part of the control system and any gas control which

has been under water.

-

• DO NOT put anything around the fireplace insert

that will obstruct the flow of ventilation air.

• Maintain clearances in accordance with local

installation codes and the requirements of the gas

supplier.

23015-3-0707 Page 3

• Any safety screen or guard removed for servicing an

appliance must be replaced prior to operating the

appliance.

Page 4

SAFETY INFORMATION FOR USERS OF LP GAS

Propane (LP-Gas) is a flammable gas which can cause fires

and explosions. In its natural state, propane is odorless and

colorless. You may not know all the following safety precau

tions which can protect both you and your family from an

accident. Read them carefully now, then review them point

LP-GAS WARNING ODOR

If a gas leak happens, you should be able to smell the gas because of the odorant put in the LP-Gas.

That’s your signal to go into immediate action!

• Do not operate electric switches, light matches, use your phone.

Do not do anything that could ignite the gas.

• Get everyone out of the building, vehicle, trailer, or area. Do

that IMMEDIATELY.

• Close all gas tank or cylinder supply valves.

• LP-Gas is heavier than air and may settle in low areas such as

basements. When you have reason to suspect a gas leak, keep

out of basements and other low areas. Stay out until firefighters

declare them to be safe.

NO ODOR DETECTED - ODOR FADE

Some people cannot smell well. Some people cannot smell the

odor of the chemical put into the gas. You must find out if you

can smell the odorant in propane. Smoking can decrease your

ability to smell. Being around an odor for a time can affect your

sensitivity or ability to detect that odor. Sometimes other odors

in the area mask the gas odor. People may not smell the gas odor

or their minds are on something else. Thinking about smelling a

gas odor can make it easier to smell.

The odorant in LP-Gas is colorless, and it can fade under some

circumstances. For example, if there is an underground leak, the

movement of the gas through soil can filter the odorant. Odorants

by point with the members of your household. Someday

when there may not be a minute to lose, everyone’s safety

will depend on knowing exactly what to do. If, after read

ing the following information, you feel you still need more

information, please contact your gas supplier.

• Use your neighbor’s phone and call a trained LP-Gas service

person and the fire department. Even though you may not

continue to smell gas, do not turn on the gas again. Do not

re-enter the building, vehicle, trailer, or area.

• Finally, let the service man and firefighters check for escaped

gas. Have them air out the area before you return. Properly

trained LP-Gas service people should repair the leak, then

check and relight the gas appliance for you.

in LP-Gas also are subject to oxidation. This fading can occur if

there is rust inside the storage tank or in iron gas pipes.

The odorant in escaped gas can adsorb or absorb onto or into walls,

masonry and other materials and fabrics in a room. That will take

some of the odorant out of the gas, reducing its odor intensity.

LP-Gas may stratify in a closed area, and the odor intensity could

vary at different levels. Since it is heavier than air, there may be

more odor at lower levels. Always be sensitive to the slightest gas

odor. If you detect any odor, treat it as a serious leak. Immediately

go into action as instructed earlier.

-

SOME POINTS TO REMEMBER

• Learn to recognize the odor of LP-Gas. Your local LP-Gas

Dealer can give you a “Scratch and Sniff” pamphlet. Use it to

find out what the propane odor smells like. If you suspect that

your LP-Gas has a weak or abnormal odor, call your LP-Gas

Dealer.

• If you are not qualified, do not light pilot lights, perform service,

or make adjustments to appliances on the LP-Gas system. If

you are qualified, consciously think about the odor of LP-Gas

prior to and while lighting pilot lights or performing service

or making adjustments.

• Sometimes a basement or a closed-up house has a musty smell

that can cover up the LP-Gas odor. Do not try to light pilot

lights, perform service, or make adjustments in an area where

the conditions are such that you may not detect the odor if

there has been a leak of LP-Gas.

• Odor fade, due to oxidation by rust or adsorption on walls of

new cylinders and tanks, is possible. Therefore, people should

be particularly alert and careful when new tanks or cylinders

are placed in service. Odor fade can occur in new tanks, or

reinstalled old tanks, if they are filled and allowed to set too

long before refilling. Cylinders and tanks which have been

out of service for a time may develop internal rust which will

cause odor fade. If such conditions are suspected to exist, a

periodic sniff test of the gas is advisable. If you have any

question about the gas odor, call your

periodic sniff test of the LP-Gas is a good safety measure

under any condition.

• If, at any time, you do not smell the LP-Gas odorant and you

think you should, assume you have a leak. Then take the same

immediate action recommended above for the occasion when

you do detect the odorized LP-Gas.

• If you experience a complete “gas out,” (the container is under

no vapor pressure), turn the tank valve off immediately. If the

container valve is left on, the container may draw in some air

through openings such as pilot light orifices. If this occurs,

some new internal rusting could occur. If the valve is left

open, then treat the container as a new tank. Always be sure

your container is under vapor pressure by turning it off at the

container before it goes completely empty or having it refilled

before it is completely empty.

LP-Gas dealer. A

23015-3-0707Page 4

Page 5

INTRODUCTION

Instructions to Installer

1. Installer must leave instruction manual with owner after

installation.

2. Installer must have owner fill out and mail warranty card supplied

with the fireplace.

3. Installer should show owner how to start and operate the

fireplace.

This direct vent gas fireplace heater is designed to operate with all

combustion air being siphoned from the outside of the building

and all exhaust gases expelled to the outside of the building. The

information contained in this manual pertains to all models and gas

control systems unless otherwise noted.

Warning: This unit is not for use with solid fuels.

Appliance Certification

This fireplace is design certified in accordance with American

National Standard/CSA Standard ANSI Z.21-88/CSA 2.33 and by

Underwriters Laboratories as a Direct Vent Gas Fireplace Heater

and shall be installed according to these instructions.

Consult your local building code agency, prior to installation,

to ensure compliance with local codes-including permits and

inspections.

The fireplace insert, when installed, must be electrically grounded

in accordance with local codes or, in absence of local codes, with

the National Electric Code ANSI/NFPA 70 or Canadian Electric

code, CSA C22.1, if an external electrical source is utilized.

These models may be installed in a bedroom or bed-sitting room

in the U.S.A. and Canada.

Qualified Installing Agency

Installation and replacement of gas piping, gas utilization equipment

or accessories and repair and servicing of equipment shall be

performed only by a qualified agency. The term “qualified agency”

means any individual, firm, corporation or company which either in

person or through a representative is engaged in and is responsible

for (a) the installation or replacement of gas piping or (b) the

connection, installation, repair or servicing of equipment, who is

experienced in such work, familiar with all precautions required

and has complied with all the requirements of the authority having

jurisdiction.

State of Massachusetts: The installation must be made by

a licensed plumber or gas fitter in the Commonwealth of

Massachusetts.

The installation must conform with local codes or, in the absence of

local codes, with the National Fuel Gas Code ANSI Z223.1/NFPA

54* Natural Gas and Propane Installation Code, or CSA B149.1

in Canada. *Available from the American National Standards Institute, Inc. 11

West 42nd St., New York, N.Y. 10036.

Warning: ANY CHANGE TO THIS FIREPLACE OR ITS

CONTROLS CAN BE DANGEROUS.

Improper installation or use of the fireplace can cause

serious injury or death from fire, burns, explosions, or

carbon monoxide poisoning.

Any alteration of the original design, installed other than as

shown in these instructions or use with a type of gas not shown on

the rating plate is the responsibility of the person and company

making the change.

Important

All correspondence should refer to complete Model Number, Serial

Number and type of gas.

High Altitude

When installing this unit at an elevation above 2000 feet (in the

United States) it may be necessary to decrease the input rating by

changing the existing burner orifice to a smaller size. Generally,

input should be reduced 4 percent for each 1000 feet above sea

level. However, if the heating value of the gas has been reduced,

this general rule may not apply. Check with local gas utility for

proper orifice size identification.

Canadian High Altitude

Altitude: 0-4500 feet (0-1370 m)

When installing this unit at an elevation above 4500 feet (in Canada),

check with local authorities.

Consult your local gas utility for assistance in determining the

proper orifice for location.

Preparation

This direct vent gas fireplace insert and its components are tested

and safe when installed in accordance with this Installation Manual.

Report to your dealer any parts damaged in shipment, specifically

check glass condition. Do not install unit with damaged, incomplete,

or substitute parts. Read all instructions before starting installation

and follow these instructions carefully during installation to insure

maximum benefit and safety. Failure to follow them will void your

warranty and may present a fire hazard.

The warranty will be voided by, and the warranter disclaims any

responsibility for the following actions:

• Installation of any damaged fireplace insert or vent system

component.

• Modification of the fireplace insert or direct vent system.

• Installation other than as instructed by Empire Comfort Systems,

Inc.

• Improper positioning of the logs or glass door assembly.

• Installation and/or use of any component part not manufactured

or approved by manufacturer.

23015-3-0707 Page 5

Page 6

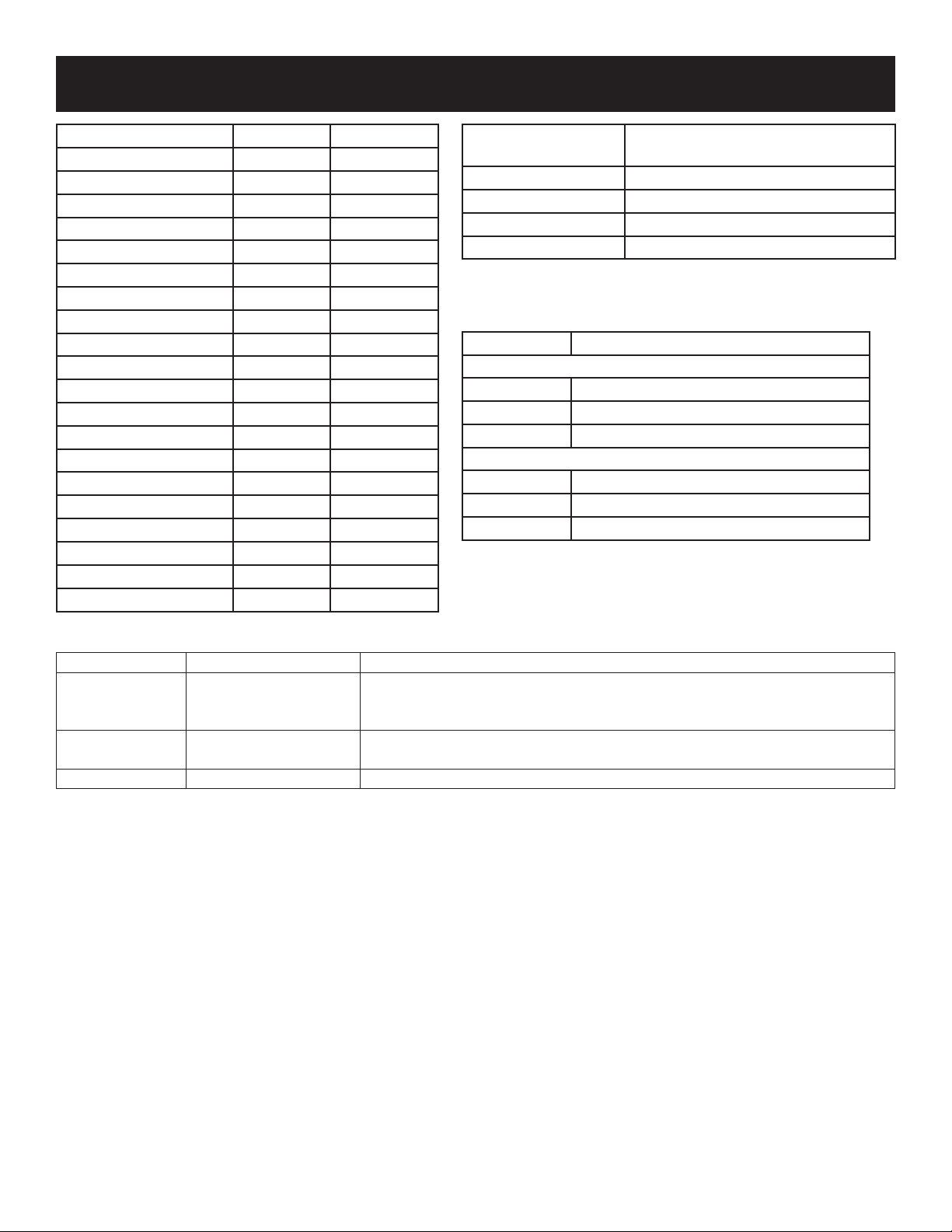

SPECIFICATIONS

DV25IN33L MODELS LP Nat

Input Btu/hr Maximum 25,000 25,000

Btu/hr Minimum 17,000 17,000

KWH (Maximum) 7.30 7.30

(Minimum) 5.00 5.00

Orifice #53 (0.0596) #42 (0.0935)

Air Shutter Opening Full Open 1/8”

DV33IN33L MODELS

Input Btu/hr Maximum 33,000 33,000

Btu/hr Minimum 25,000 25,000

KWH (Maximum) 9.57 9.57

(Minimum) 7.30 6.67

Orifice

Air Shutter Opening Full Open 3/16”

DV35IN33L MODELS

Input Btu/hr Maximum 35,000 35,000

Minimum 27,000 25,000

KWH (Maximum) 10.15 10.15

(Minimum) 7.83 7.30

Orifice #50 (0.070) #33 (0.113)

Air Shutter Opening Full Open 3/16”

LP Nat

#51 (0.067) #34 (0.111)

LP Nat

Remote Control

Accessories

FRBC Millivolt Battery Remote ON/OFF

FRBTC Millivolt Battery Remote T-Stat

TMV Millivolt WIRELESS Wall Thermostat

TRW Millivolt Reed Switch Wall Thermostat

Surround Kits Description

S256BL 6” Wide, black for use on DV25IN models

S336BL 6” Wide, black for use on DV33IN models

S356BL 6” Wide, black for use on DV35IN models

SC256BL 6” Wide, black for use on DV25IN models

SC336BL 6” Wide, black for use on DV33IN models

SC356BL 6” Wide, black for use on DV35IN models

Description

Contemporary

Traditional Cast Iron

Venting Kits Description Contents

DVKI Vertical Vent Kit - 17 1/2’ One piece of 35’ FlexVent (split for 17 1/2’ vent run), Round Cap, Flashing,

connectors, and clamps.

Recommended when installing to an existing round fireplace chimney pipe.

DVVK3FV Vertical Vent Kit - 25’ Two pieces of 25’ FlexVent, Rectangle Cap, Flashing, connectors, and clamps

Recommended when installing to a square or rectangular clay flue.

DVK35 Vent Extension Kit 35’ flex vent extension section with 2 connectors and 4 clamps

Note: When installing vent caps, special locally made flashings may be required to properly seal the vent system to the existing

chimney termination.

23015-3-0707Page 6

Page 7

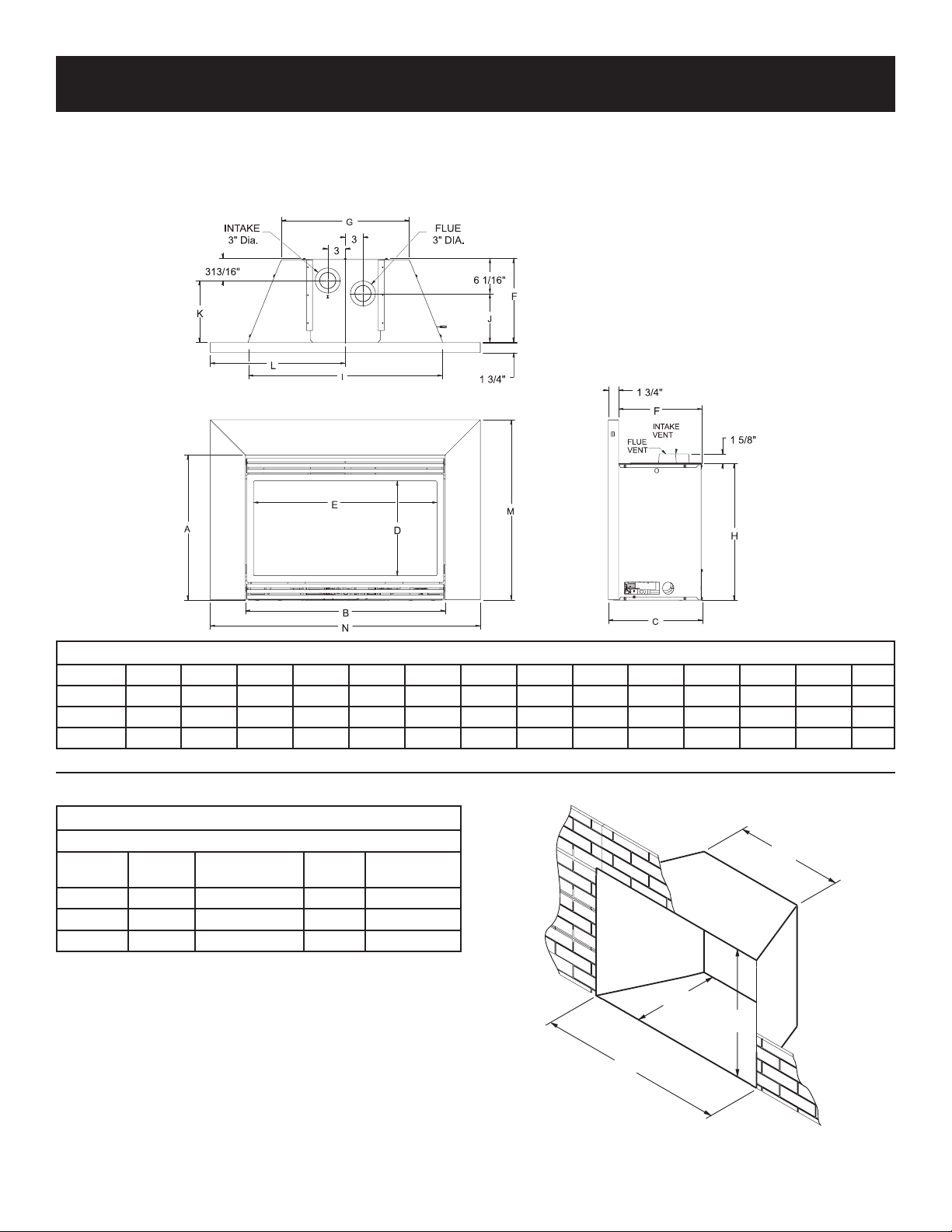

FIREPLACE INSERT DIMENSIONS

A

D

C

B

When planning a fireplace insert installation, it’s necessary to

determine:

• The vent system configuration to be used.

• Gas supply piping.

• Whether optional accessories - devices such as a wall switch

or remote control - are desired.

• Electrical supply requirements for blower.

• Proper opening size of fireplace required for installation of

the fireplace insert.

DV FIREPLACE INSERT DIMENSIONS

MODEL A B C D E F G H I J K L M N

DV25IN 19 3/8” 28 14 1/2” 11 1/8” 25 1/4” 12 3/4” 17” 18 5/16” 27” 6 3/4” 9” 20” 25 3/8” 40”

DV33IN 22 3/8” 31 16 14 1/8” 28 1/4” 14 1/4” 18 3/4” 21 5/16” 30” 8 1/4” 10 1/2” 21 1/2” 28 3/8” 43”

DV35IN 24 3/8” 34 16 16 1/8” 31 1/4” 14 1/4” 21 3/4” 23 5/16” 33” 8 1/4” 10 1/2” 23” 30 3/8” 46”

Figure 1

Fireplace Opening Dimensional Information/Sizing

MINIMUM FIREPLACE OPENING DIMENSIONS

MODEL

NO.

DV25IN 18 3/8” 27 1/2” 12 3/4” 17 1/4”

DV33IN 21 3/8” 30 1/2” 14 1/4” 19”

DV35IN 23 3/8” 33 1/2” 14 1/4” 22”

HEIGHT A*FRONT WIDTH

B

*Note: If the fireplace lintel is wider than 8” (203mm), the

height of the fireplace opening must be increased a few inches to

allow for a gradual offset in the exhaust and/or intake vent pipes.

DEPTH

C

REAR WIDTH

D

Figure 2

23015-3-0707 Page 7

Page 8

MANTLE AND TRIM CLEARANCES

COMBUSTIBLE

MANTEL/TRIM

AREA

12”

10”

1 3/4”

23”

11

”

8”

MINIMUM CLEARANCE TO PERPENDICULAR

COMBUSTIBLE SIDE-WALL

(FROM EDGE

OF DOOR FRAME)

Figure 3

Figure 4

Combustible Material

No greeting cards, stockings or ornamentation of any type

should be placed on or attached to the fireplace. The flow of heat

can ignite combustibles.

23015-3-0707Page 8

Page 9

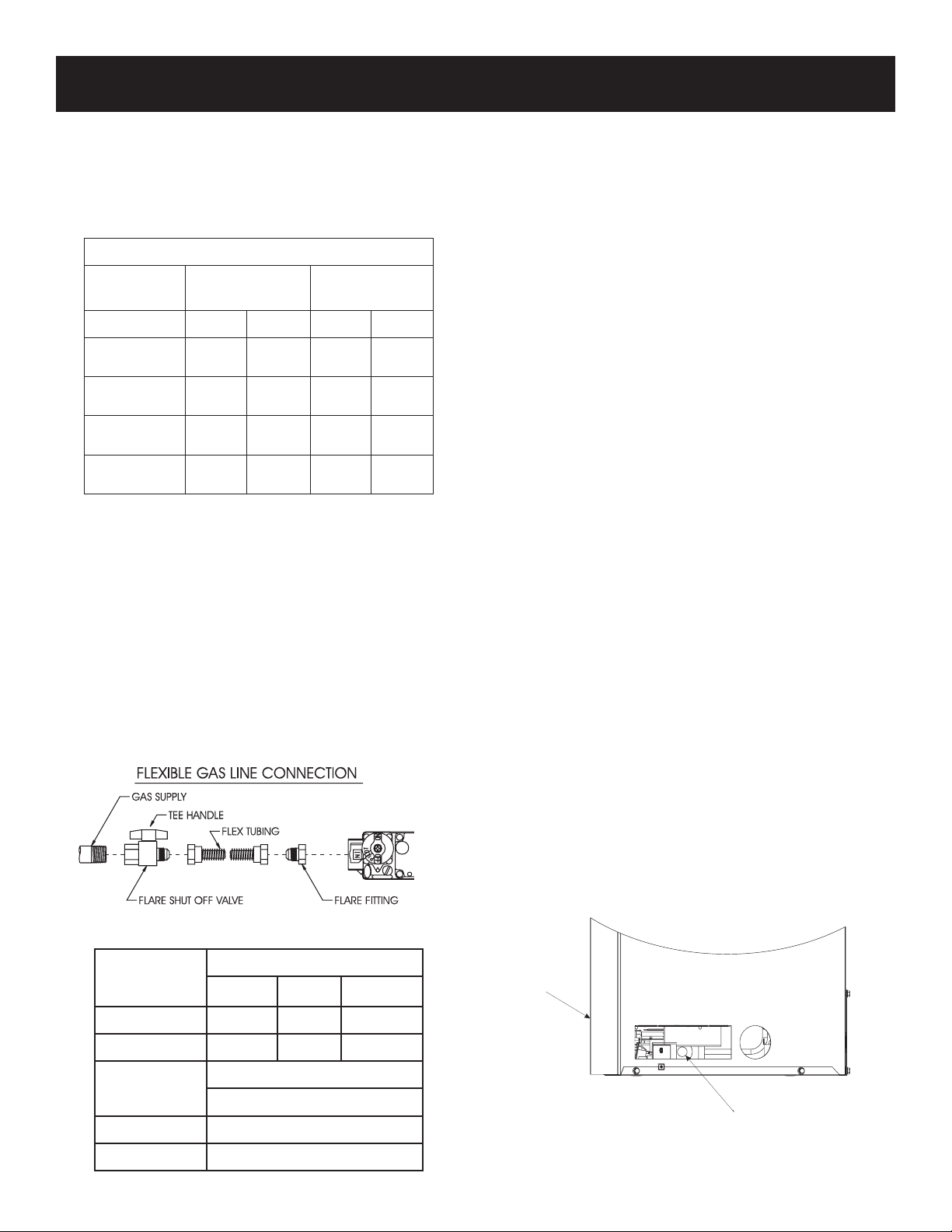

GAS SUPPLY

GAS FLEX LINE WITH

SHUTOFF VALVE

(PROVIDED)

FRONT OF

INSERT

RIGHT SIDE OF INSERT

The gas pipeline can be brought in through the right or left side of

the appliance. The insert has a Flexline with shutoff valve located

on the right side when facing the unit. See Figures 5 and 6. Consult

the current National Fuel Gas Code, ANSI Z223.1 CAN/CGA-B149

(.1 or .2) installation code.

Recommended Gas Pipe Diameter

Pipe Length Schedule 40 Pipe

Inside Diameter

Nat. L.P. Nat. L.P.

0-10ft

0-3m

11-40ft

4-12m

41-100ft

13-30m

101-150ft

31-46m

1/2"

12.7mm

1/2"

12.7mm

1/2"

12.7mm

3/4"

19mm

3/8"

9.5mm

1/2"

12.7mm

1/2"

12.7mm

1/2"

12.7mm

Tubing, Type L

Outside Diameter

1/2"

12.7mm

5/8"

15.9mm

3/4"

19mm

7/8"

22.2mm

3/8"

9.5mm

1/2"

12.7mm

1/2"

12.7mm

3/4"

1.9 mm

Note: Never use plastic pipe. Check to confirm whether your

local codes allow copper tubing or galvanized.

Note: Since some municipalities have additional local codes, it is

always best to consult your local authority and installation code.

The use of the following gas connectors is recommended:

— ANS Z21.24 Appliance Connectors of Corrugated Metal Tubing

and Fittings.

— ANS Z21.45 Assembled Flexible Appliance Connectors of

Other Than All-Metal Construction

The above connectors may be used if acceptable by the authority

having jurisdiction. The state of Massachusetts requires that a flexible

appliance connector cannot exceed three feet in length.

Figure 5

Installing the Main Gas Cock

Each appliance should have its own manual gas cock.

A manual main gas cock should be located in the vicinity of the

unit. Where none exists, or where its size or location is not adequate, contact your local authorized installer for installation or

relocation.

Compounds used on threaded joints of gas piping shall be resistant

to the action of liquefied petroleum gases. The gas lines must be

checked for leaks by the installer. This should be done with a soap

solution watching for bubbles on all exposed connections, and if

unexposed, a pressure test should be made.

Never use an exposed flame to check for leaks. Appliance must

be disconnected from piping at inlet of control valve and pipe

capped or plugged for pressure test. Never pressure test with

appliance connected; control valve will sustain damage!

NOTE: The millivolt gas controls are equipped with a captured

screw type pressure test point, therefore it is not necessary to provide

a 1/8" test point up stream of the control.

When using copper or flex connector use only approved fittings.

The appliance and it’s individual shut off valve must be disconnected

from supply piping system during any pressure testing of that system

at test pressures in excess of 1/2 psig (3.5kPa).

The appliance must be isolated from the gas supply piping system

by closing its individual manual shut off valve during any pressure

testing of the gas supply piping system at test pressures equal to or

less than 1/2 psig (3.5kPa).

Attention! If one of the procedures results in pressures in excess

of 1/2 psig (14" w.c.) (3.5 kPa) on the fireplace gas valve, it will

result in a hazardous condition.

Checking Manifold Pressures

Both Propane and Natural gas valves have a built-in pressure

regulator in the gas valve. Natural gas models will have a manifold

pressure of approximately 3.5" w.c. (.871kPa) at the valve outlet

with the inlet pressure to the valve from a minimum of 4.5" w.c.

(1.120kPa) for the purpose of input adjustment to a maximum of

14.0" w.c. (3.484kPa). Propane gas models will have a manifold

pressure approximately 10.0" w.c. (2.49kPa) at the valve outlet

with the inlet pressure to the valve from a minimum of 10.8" w.c.

(2.68kPa) for the purpose of input adjustment to a maximum of

14.0" w.c. (3.484kPa).

Gas Supply Pressure (inches w.c.)

Minimum Normal Maximum

Natural Gas 4.5" 7.0" 14.0"

LP (Propane)

Natural Gas 3.5"

LP (Propane)

23015-3-0707 Page 9

10.8" 11.0" 14.0"

Manifold Pressure (inches w.c.)

Normal (HI)

10.0"

Figure 6

Page 10

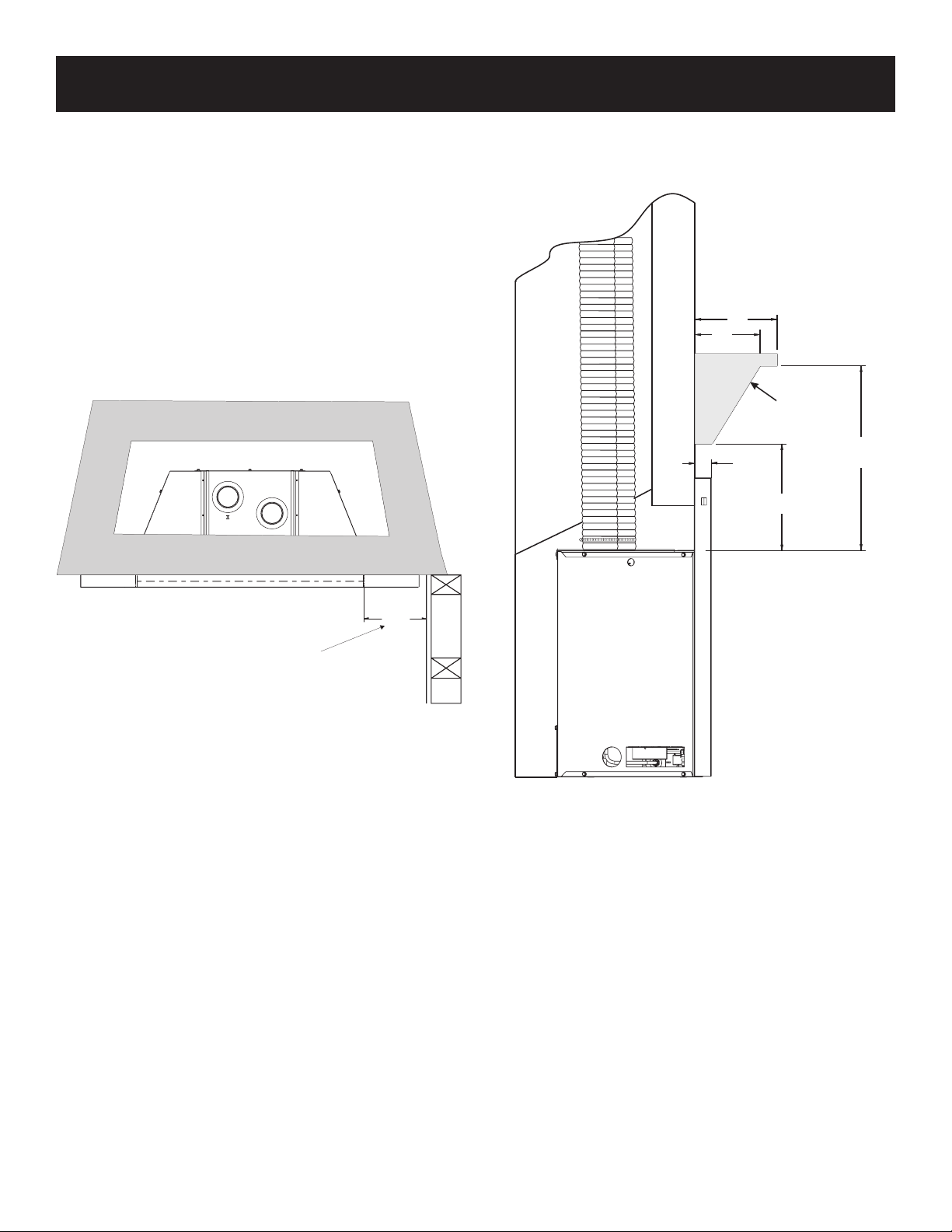

VENTING AND INSTALLATION

1. Before beginning, remove glass door and log package from

unit. Also check to make sure there is no hidden damage to

the unit. Take a minute and plan out the gas, venting and elec-

trical route. It is best to start with the gas line first, followed

by the chimney liner and electrical supply requirements.

2. Minimum fireplace opening requirements are shown in

Figure 2 of this installation manual. The firebrick (refrac-

tory), glass doors, screen rails, screen mesh and log grates

can be removed from a factory built fireplace in order to gain

minimum gas insert opening requirements prior to installing

the gas fireplace insert.

3. This insert requires no hearth extensions. Combustible ma

terial on the floor may be installed up to the insert. Do not

obstruct the lower louver of the insert. The original fireplace

cannot be returned to solid fuel in this condition.

4. The metal floor of the solid fuel firebox may be removed to

facilitate the installation of the insert. CLEARANCE TO

COMBUSTIBLE MATERIAL UNDER THE INSERT IS

1/4”. YOU MUST USE THE LEVELING LEGS TO RAISE

THE INSERT A MINIMUM OF 1/4” IF THE INSERT IS

TO SIT ON COMBUSTIBLE MATERIAL. The side walls

and top structure of the firebox may not be altered with the

exception of removable baffles and dampers. Smoke shields,

shelves and baffles may be removed if attached with me

chanical fasteners. The original fireplace cannot be returned

to solid fuel in this condition.

5. Combustible facing material may be installed over the

original combustible facing material on the solid fuel fire

place. The original specified clearances of a factory-built

fireplace must be maintained, with the exception of the

hearth. Clearances on a masonry fireplace must be main-

tained at 12” from the opening for combustible projections

over 1 1/2”. Clearances for combustible projections under

1 1/2” must be maintained at 6” from the opening per

NFPA211. Plan the surround size accordingly. A surround

must be used with the insert. UNDER NO CIRCUMSTANCE

CAN COMBUSTIBLE MATERIAL BE PLACED BEHIND

THE SURROUND!

6. The insert surround is tested and approved with this gas insert

and may cover existing air circulation vents or grills on the

solid fuel fireplace it is installed into. If the surround does

not cover the entire ventilation grill surface, the exposed grill

area should be left open.

NOTE: Surround panel kits have been tested and approved to

cover existing air circulation vents or grills.

NOTE: Cutting of sheet metal parts of a fireplace in order to

install the fireplace insert is prohibited.

WARNING: Only the surround as supplied may be used

to cover integral grills on the solid fuel-burning fireplace.

No other components such as shrouds, sheet metal plates,

etc. may be used to seal off vents.

7. To assure top performance, safety and efficiency, inserts must

be installed with an approved flue liner as per CAN/CGA

B-149 or National Fuel Code ANSI Z223 and these instructions.

Note: The following statement is also provided on a separate

label plate in the instruction packet. Prior to installation of

the fireplace insert, the installer must mechanically secure this

warning plate to the inside of the fireplace for future reference

as required.

WARNING: The solid fuel fireplace has been converted

for use with gas only and cannot be used for burning wood

-

-

-

or solid fuels unless all original parts have been replaced

and the fireplace has been reapproved by the authority

having jurisdiction.

8. The solid fuel fireplaces’ flue damper must be fully locked

in the open position or removed for installation of the gas

fireplace insert.

9. The fireplace and fireplace chimney must be cleaned and in

good working order and constructed of noncombustible materials.

10. Make sure that all chimney cleanouts fit properly so air can

not leak into the chimney.

11. Install the insert without the surround panels attached and

make all gas, venting, and electrical connections.

If the factory built fireplace does not have gas access holes

provided, an access hole of 1 1/2” diameter (37.5mm) or

less may be drilled through the lower sides or bottom of

the firebox in a proper workmanship like manner. This

access hole must be plugged with a non-combustible insu

lation after the gas supply line has been installed.

12. To complete the installation, install surround panel assembly.

Please refer to instructions included with the surround panel

kit.

Ensure there are no obstructions to side air passages of

decorative trim once installed on insert.

INSTALLING THE VENT SYSTEM

Vent System Installation Precautions

Before starting installation of vent kits, the installer should read

these instructions and the Vent Kit Instructions to ensure that a

proper vent installation is completed. Consult your local Building

Codes before beginning the Installation.

WARNING: THIS GAS INSERT AND VENT ASSEMBLY

MUST BE VENTED DIRECTLY TO THE OUTSIDE

AND MUST NEVER BE ATTACHED TO A CHIMNEY

SERVING A SEPARATE SOLID FUEL BURNING

APPLIANCE. EACH GAS APPLIANCE MUST USE

A SEPARATE VENT SYSTEM. COMMON VENT

SYSTEMS ARE PROHIBITED.

-

-

23015-3-0707Page 10

Page 11

VENTING AND INSTALLATION

Vent System Approvals

Figure 8 shows the vent termination caps and systems approved

for use with these models. Approved vent system terminations

are labeled for identification. 3-inch diameter listed flexible

aluminum or stainless steel gas vent is used for both the incoming

combustion air and exhaust vent pipes. NO OTHER VENTING

SYSTEMS OR COMPONENTS MAY BE USED. Detailed

installation instructions are included with each vent termination

kit and should be used in conjunction with this manual.

Horizontal Venting

The vent system on this model CANNOT be terminated

horizontally.

Vertical Venting

The inlet and exhaust vent pipes MUST be connected to the

proper collars on the unit

will not operate. The intake vent collar is identified by a stamped

“I” on the top collar sliding vent plate assembly.

WARNING: MAJOR U.S. BUILDING CODES SPECIFY

MINIMUM CHIMNEY AND/OR VENT HEIGHT

ABOVE THE ROOF TOP. THESE MINIMUM HEIGHTS

ARE NECESSARY IN THE INTEREST OF SAFETY.

SEE FIGURES 8 THROUGH 10 FOR MINIMUM

HEIGHTS, PROVIDED THE TERMINATION CAP IS

AT LEAST 2-FEET FROM A VERTICAL WALL AND

2-FEET BELOW A HORIZONTAL OVERHANG.

Note: This also pertains to vertical vent systems installed on the

outside of the building.

WARNING: THE EXHAUST PIPE MUST ONLY

BE CONNECTED TO THE EXHAUST STARTING

COLLAR OF THE UNIT AND TO THE EXHAUST

COLLAR OF THE TERMINATION CAP.

THE INLET AIR PIPE MUST ONLY BE CONNECTED

TO THE INLET AIR STARTING COLLAR OF THE

UNIT AND TO THE INLET AIR COLLAR OF THE

TERMINATION CAP. BOTH THE INLET VENT AND

THE FLUE VENT MUST BE CONNECTED FROM

THE INSERT TO THE VENT TERMINATION CAP.

NOTE: The minimum vertical vent rise is 12 feet and the

maximum vertical vent rise is 35 feet. These dimensions are

measured from the starting collars of the unit to the end of the last

section of vent pipe. See Figure 8.

NOTE: The damper of the masonry chimney may need to be

removed to allow installation of the flexible-vent pipe.

When installing into a zero clearance, factory built wood-burning

fireplaces, the use of the DVKI Round Vertical Termination Kit

should allow you to mount the vent adaptor and cap to the exposed

round chimney pipe easily.

AND to the termination cap or the unit

Connecting the Vent Pipe

Caution: Sharp edges. Always use gloves when installing.

Install the 3-inch flexible vent pipes down through the chimney.

Attach the pipe-to-cap adaptor to the termination cap and the

top of the flexible vent pipe, then install the cap to the top of the

chimney.

Remove the vent slide plate assembly from the top of the insert.

See Figure 7. Trim off excess venting then attach and secure

the bottom ends of the flex pipes to the starting collars with the

adjustable band clamps provided. Slide the gas insert into place,

and position any excess flex vent pipe back up into the chimney.

Begin installation of the insert into the fireplace opening. Align

the vent slide plate assembly with the guides located on top of

the insert. Work the insert inch by inch into the fireplace cavity

as you pull forward on the vent slide plate assembly. Do not use

excessive force on the vent slide plate. Once the vent slide plate

is close to seating, install the vent bolt through the center hole

of the insert top flange, and into the vent slide plate nut. Using

a wrench or socket, tighten the bolt until the vent slide plate is

seated forward completely.

Positioning, Leveling, and Securing Insert

1. Place the insert into position.

Note: The front flanges of the insert (without surround panels)

should be set at approximately 1”(inch) in front of the face of the

fireplace.

2. Level the insert from side to side and front to back.

3. If necessary, use the leveling bolts included in the instruction

pack. Screw the legs into the nuts installed in the bottom of

the insert. Turn legs in until insert is level.

CAUTION: TO AVOID DOWNDRAFTS AND/OR COLD AIR

PROBLEMS, IT IS RECOMMENDED TO SEAL OFF THE

AREA BETWEEN THE TERMINATION CAP AND THE TOP

OF THE SOLID-FUEL CHIMNEY OPENING INTO WHICH

THE VENT CAP HAS BEEN INSTALLED.

Figure 7

23015-3-0707 Page 11

Page 12

RECTANGULAR

TERMINATION CAP

(DVVK3FV KIT)

VENT CLAMPS

INTAKE VENT

FLUE EXHAUST VENT

OPTIONAL ON/OFF

SWITCH LOCA

TION

10’ MINIMUM

35’ MAXIMUM

VENT CLAMPS

NOTE: LONG EXTENSION

TUBE FOR INLET VENT

CONNECTION.

RETAINER SCREWS MAY

BE INSTALLED THROUGH

THE VENT CLAMPS TO

ENSURE POSITIVE SECUREMENT

OF VENTING.

SCREWS ADDED THROUGH

VENT CLAMPS TO RETAIN

VENTING TO COLLARS

RECOMMENDED.

USE HIGH TEM

P

SEALANT ON VENT

CONNECTIONS

USE HIGH TEMP

SEALANT ON VENT

CONNECTIONS

ROUND

TERMINATION CAP

(DVKI KIT)

ROUND CO-LINEAR TO

CO-AXIAL ADAPTOR

BLOWER ACCESS

COVER PLA

TE

BLOWE

R

POWER CORD

OPTIONAL

LOW VOLTAGE

WIRES

OPTIONAL ON/OFF

SWITCH LOCATION

VENTING AND INSTALLATION

Figure 8

23015-3-0707Page 12

Page 13

VERTICAL TERMINATION

MIN.

12"

MIN.

24"

24"

MIN.

C

L

Determining Minimum Vent Height Above the Roof.

WARNING: Major U.S. building codes specify minimum

chimney and/or vent height above the roof top. These minimum

heights are necessary in the interest of safety. These specifica

tions are summarized in Figure 9.

ROOF PITCH H (Min.)

Flat to 6/12 12" (305 mm)

6/12 to 7/12 15" (381 mm)

Over 7/12 to 8/12 18" (457 mm)

Over 8/12 to 16/12 24" (610 mm)

Over 16/12 to 21/12 36" (914 mm)

Figure 9

Note that for steep roof pitches, the vent height must be increased.

In high wind conditions, nearby trees, adjoining roof lines, steep

pitched roofs, and other similar factors can result in poor draft,

or down-drafting. In these cases, increasing the vent height may

solve this problem.

Vertical Through the Roof Applications

The Gas Fireplace Insert has been approved for:

a) Vertical installations up to 35 feet in height (top of insert to

-

cap).

b) Two sets of 45 degree elbow offsets (bends in flexvent) within

the vertical installation. From 0 to a maximum of 8 ft. of vent

pipe can be used between elbows.

c) Wall straps must be used to support offset pipe every 4'.

This application will require that you first determine the roof pitch

and use the appropriate venting components.

General Maintenance

Conduct an inspection of the venting system semi-annually.

Recommended areas to inspect are as follows:

1. Check areas of the venting system which are exposed to the

elements for corrosion. These will appear as rust spots or

streaks and, in extreme cases, holes. These components should

immediately be replaced.

2. Remove the cap and shine a flashlight down the vent. Remove

any bird nests or other foreign material.

3. Check for evidence of excessive condensate, such as water

droplets forming in the flex venting and subsequently dripping

out at joints or seams. Condensate can cause corrosion of caps,

pipe and fittings. It may be caused by having excessive lateral

runs, or having exterior portions of the system exposed to cold

weather.

4. Inspect joints to verify that no pipe sections or fittings have been

disturbed and, consequently, loosened. Also, check mechanical

supports, such as wall straps or plumbers’ tape for rigidity.

Figure 10

When terminating the vent cap near an exterior wall or overhang,

maintain minimum clearances as shown in Figure 10.

23015-3-0707 Page 13

Page 14

ALTERNATE ON/OFF SWITCH INSTALLATION

WIRING FROM

MILLIVOL

T GAS

VALV

E

ON/OFF

SWITCH

ASSEMBLY

Right Side Installation

Left Side Installation

ON/OFF

SWITCH

ASSEMBL

Y

WIRING THE FIREPLACE

Note: Electrical wiring must be installed by a licensed electrician.

CAUTION: DISCONNECT REMOTE CONTROLS IF YOU ARE ABSENT FOR EXTENDED TIME PERIODS. THIS WILL PREVENT

ACCIDENTAL FIREPLACE OPERATION.

Installation of Alternate Surround Panel ON/OFF Switch

An ON/OFF switch and wire assembly are provided. They are included

in the instruction packet.

Do not cut wire or insulation on metal edges.

Note: Refer to surround panel installation section on page 15 for additional information on attachment.

Contemporary Surrounds

1. Find the coiled low voltage wire assembly and ON/OFF switch lo

cated in the instruction packet.

2. Attach the flag terminal ends to the “TH/TP” and “TH” terminals on

the front terminal block of the gas valve. See Figure 13.

3. Run the low voltage alternate switch wires up the back of the right

or left surround panel. Then secure the wires with wire clips pro

vided. See Figure 11.

-

Figure 12

Note: For right side leg installation, reverse switch position in

bracket.

3. Run the low voltage alternate switch wires up the back of the right

-

or left cast surround leg. Then secure them with the wire clips pro

vided.

4. Install the switch bracket with screws as shown in Figure 12 to the

back of the cast surround leg.

5. Install ON/OFF switch, and connect low-voltage wires from gas

valve.

6. Attach cast surround panel assembly to the insert. Place the cast

surround assembly against the face of the insert and align the lower

retaining tabs with the notches on the insert sides. Lift the cast sur

round assembly slightly until the bottom return flange (top panel)

is positioned over the top flange on the insert. This secures the cast

surround assembly to the insert without screws.

-

-

Figure 11

Insert ON/OFF switch into side panel then attach wire assembly

from valve terminals.

4. Remove the switch knockout on the side surround panel, then install

the ON/OFF switch.

5. Connect the low voltage wires from the gas valve to the

ON/OFF switch.

6. Attach the surround panel assembly to the insert. Place the surround

panel assembly against the face of the insert and align the lower

retaining tabs with the notches on the insert sides. Lift the surround

panel assembly slightly until the bottom return flange (top panel)

is positioned over the top flange on the insert. This secures the surround panel assembly to the insert without screws.

Traditional Cast Iron Surrounds

1. Find the coiled low voltage wire assembly and ON/OFF switch lo

cated in the instruction packet.

2. Attach the flag terminal ends to the “TH/TP” and “TH” terminals on

the front terminal block of the gas valve. See Figure 13.

Figure 13

-

23015-3-0707Page 14

Page 15

SURROUND PANEL INSTALLATION

NOTE: INSTALL SURROUND PANELS

SO THAT THE TOP PANEL

RETURN FLANGE SLIDE’

S

OVER THE TOP FLANGE ON

THE INSER

T

1” Ref.

SURROUND PANEL ASSEMBLY

ENGAGE SIDE PANEL

HOOKS W

ITH THE

NOTCHES PROVIDED O

N

THE SIDE FLANGE

S

INSTALLING THE TRIM SURROUNDS

Combustible materials MUST NEVER overlap onto the front

face.

WARNING: WHEN FINISHING THE FIREPLACE

INSERT, NEVER OBSTRUCT OR MODIFY THE AIR

INLET/OUTLET LOUVERS ON THE FIREPLACE IN

SERT IN ANY MANNER.

-

Figure 15

Figure 14

23015-3-0707 Page 15

Page 16

BLOWER ACCESSORY INFORMATION

The appliance, when installed must be electrically connected

and grounded in accordance with local codes or, in the absence

of local codes, with the current CSA C22.1 Canadian Electrical

Code.

U.S. Installations, follow local codes and the National Electrical

Code, ANSI/NFPA No. 70.

Should this blower require servicing, the power supply must be

disconnected. For rewiring of any replacement components, refer to Figures 16 and 17 and the parts list on page 25.

BLOWER ACCESSORY

Operation

The fireplace insert is equipped with a factory installed blower accessory

that includes a fan control switch, plus a rheostat (speed control).

The speed control knob is located behind the lower louver at the right

side of the insert.

From a cold start, the temperature activated fan control switch will

normally take 5-10 minutes to heat up and energize the blower.

Once the blower is energized, adjust the blower speed control as desired,

then replace the lower louver.

When the insert is shut off, it may take 30-40 minutes for the heated unit

to dissipate (cool down) enough for the blower to shut off automatically.

Note: The blower shut off times will vary on blower speed and BTU

input level setting control by adjustment of the HI/LO knob located on

the gas valve.

Blower removal instructions

Servicing or removal of the blower system must be performed by a

qualified service person.

If the blower assembly (Item 45, page 24) must be replaced, the following

steps are recommended for removal:

Figure 16

1. Turn off gas and disconnect the electrical supply.

2. Remove the glass door assembly.

3. Remove the log set.

4. Remove the front surround panel assembly by lifting upward and

outward to detach.

5. Remove the 5/16” x 2-1/2” center bolt that retains the Vent Slide

plate assembly.

6. Remove the insert from the fireplace cavity by pulling forward on

the insert, and at the same time, sliding the vent plate rearward until

disengaged.

7. As the insert is moved outward, the gas line may need to be

disconnected at the insert shut off valve. If so, make sure the main

gas line is shut off that supplies gas to the insert.

8. Once the insert is pulled out, the blower assembly can be removed

by locating the (6) screws on the lower back of the insert that retains

the blower base plate.

9. When the screws are removed, gently pull the blower assembly

outward.

10. Disconnect the two ¼” wire terminals from the motor.

11. Remove the (4) screws that retain the blower assembly to the base

plate, and set blower aside.

12. Install the replacement blower, and re-install the insert by reversing

above steps.

Figure 17

23015-3-0707Page 16

Page 17

LOG PLACEMENT

BACK

LOG

LEFT

TWIG

RIGHT

TWIG

RIGH

T

CENTER

LOG

RIGHT FRONT

LOG

LEFT FRONT

LOG

LEFT

CENTER

LOG

Before you begin: This fireplace insert is supplied with a set of seven ce

ramic fiber logs. Do not handle these logs with your bare hands. Always

wear gloves to prevent skin irritation from ceramic fibers. After handling

logs, wash your hands gently with soap and water to remove any traces

of fiber.

The positioning of logs is critical to safe and clean operation of this

fireplace. Sooting and other problems may result if the logs are not

properly and firmly positioned in the fireplace. Refer to Figure 18 and

Figure 19 and corresponding WARNING when completing following

log placement steps.

1. Remove top louver, grasp louver, lift and pull forward.

2. Lower bottom louver, lift and hinge forward.

3. Release two glass frame spring clamps at bottom of the glass door

assembly.

4. Swing the bottom of the glass door outward approximately 10-15

degrees, then grasping the edges, gently lift upward to remove the

door assembly, and set aside.

5. Remove the foam packaging that contains the log set from inside the

firebox.

6. Carefully unpack the logs and twigs. Spread them out for easy

identification.

7. Begin with the front left and front right logs. Place these so that

they are centered left to right on the front log support ledge. The flat

bottoms will rest on top of the front log support ledge, and they must

be position all the way forward and touching the back of the grate

tangs. Important: The front right log has a small knot as shown in

Figure 18.

8. Next install the large rear log. It will be centered left to right and

placed all the way to the back of the firebox, on top of the rear log

support. Note: DV25IN models incorporate two small tabs in the

rear log support that keep the back log positioned correctly. DV33IN

models have one small tab in the rear log support to ensure the back

log is in the correct position. The DV35IN models will have two

tabs bent forward in the rear log support to ensure proper left to right

positioning of the log, plus one small tab near the center that keeps

the back log from shifting forward.

9. Locate the center left log. It will have two locator pin holes on the

bottom flat surface. Align the two holes with the two left pins on

the burner assembly. Make sure this log is not raised up off of the

burner. The flat bottom surface must be completely resting flat on

the top of the burner surface.

10. Install the center right log. It will also have two locator pin holes on

the bottom flat surface. Align these two holes with the two right pins

on the burner assembly. Make sure this log is not raised up off of

the burner. The flat bottom surface must be completely resting flat

on the top of the burner surface.

11. Add the right twig by placing the locator pin hole on the bottom of

the twig with the pin on top of the center right log. The tip of the

right twig will rest on top of the rear log near the right end.

12. Add the left twig by placing the locator pin hole on the bottom of

the twig with the pin on top of the center left log. The long branch

of the left twig will rest in a small groove on top of the rear log. This

groove is near the left end of the rear log.

Note: Decorative Rock is not included with the Fireplace Insert,

however it may be purchased separately and placed only on the firebox

floor.

Do Not place decorative rock or rock wool on the logs or burner

assembly.

-

13. Replace the glass door assembly onto the fireplace insert.

14. Secure the glass door with the two spring clamps located under the

firebox.

15. Re-install the upper and lower louver assemblies by aligning the end

tabs with the slots provided in the outer face flanges of the insert.

Figure 18

Warning: Failure to position the parts in accordance with this dia

gram or failure to use only parts specifically approved with this

appliance may result in property damage or personal injury.

Figure 19

Note: Center the front two logs on the front log support ledge. Then make

sure they are positioned all the way forward and touching the back edges

of the grate tang uprights. The bottom of the two front logs are flat and

must sit on top of the front log support ledge.

-

23015-3-0707 Page 17

Page 18

OPERATING INSTRUCTIONS

750 Millivolt System

The standing pilot (750 millivolt system) is a continuous burning

pilot. The pilot remains ON even when the main burner is OFF.

When you ignite the pilot, the thermopile produces millivolts

(electrical current) which energizes the magnet in the gas valve.

After 30 seconds to 1 minute time period you can release the gas

control knob and the pilot will stay ON. Allow your pilot flame to

operate an additional one (1) to two (2) minutes before you turn the

gas control knob from the PILOT position to the ON position. This

time period allows the millivolts (electrical current) to build-up to

a sufficient level allowing the gas control to operate properly.

1. Follow the SAFETY and LIGHTING INSTRUCTIONS for

standing pilot controls found in this manual and on labels found

in control compartment behind the door assembly.

CAUTION: During the initial purging and subsequent lightings,

never allow the gas valve control knob to remain depressed in

the “pilot” position without pushing the piezo ignitor button

at least once every second.

2. During the operating season, leave the control valve knob in the

“ON” position. This will allow the pilot flame to remain lit. Turn

the burner flame on or off with the fireplace REMOTE/OFF/ON

switch, wall switch or remote controls.

NOTE: The gas control valve allows you to increase or decrease the

height of the main burner flame. The control valve has a pressure

regulator with a knob as shown in Figure 20. Rotate the knob

clockwise to “HI” to increase the flame height and counterclockwise

to “LO” to decrease the flame height.

3. When the operating season is over, turn the

switch to “OFF” and the control valve to “OFF”. The system,

including the pilot light, will be shut down.

REMOTE/OFF/ON

Initial Lighting

Upon completing the gas line or turning the gas valve on after it

has been in the “OFF” position, a small amount of air will be in the

lines. When first lighting the fireplace, it will take a few minutes

for the lines to purge themselves of this air. Once the purging is

complete, the fireplace will light and operate satisfactorily.

Subsequent lightings of the appliance will not require such purging

if the gas valve is not turned to “OFF.”

Pilot Flame (Figure 21)

The thermopile/thermocouple (standing pilot) tips should be

covered with flame.

Figure 21

Figure 20

The OWNER should carefully read and follow these operating

instructions at all times. Lower the door assembly to view the gas

controls for the fireplace.

23015-3-0707Page 18

Page 19

STANDING PILOT LIGHTING INSTRUCTIONS

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

A. This appliance has a pilot which must be lighted by hand.

When lighting the pilot, follow these instructions exactly.

B. Before lighting smell all around the appliance area for gas.

Be sure to smell next to the floor because some gas is heavier

than air and will settle on the floor.

What To Do If You Smell Gas

• Do not try to light any appliance.

• Do not touch any electrical switch;

• Do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

LIGHTING INSTRUCTIONS

1. Stop! Read the safety information above.

2. Set REMOTE/OFF/ON switch to OFF.

3. Turn off all electric power to the appliance (if applicable).

4. Lower bottom louver assembly.

5. Push in gas control knob slightly and turn clockwise

to "OFF."

Note: Knob cannot be turned from "PILOT" to "OFF" unless

knob is pushed in slightly. Do not force.

6. Wait ten (10) minutes to clear out any gas. Then smell for gas,

including near the floor. If you then smell gas, STOP! Follow

"B" in the safety information above. If you do not smell gas,

go to the next step.

7. Find pilot - Follow metal tube from gas

control. The pilot is behind the burner

on the right side.

8. Turn gas control knob counterclockwise

to "PILOT."

• If you cannot reach your gas supplier, call the fire depart

ment.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by hand,

don't try to repair it; call a qualified service technician. Force

or attempted repair may result in a fire or explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

9. Push in control knob all the way and hold in. Repeatedly push

the piezo ignitor button until the pilot is lit. Continue to hold

the control knob in the for about one (1) minute after the pilot is

lit. Release knob, and it will pop back up. Pilot should remain

lit. If it goes out, repeat steps 5 through 9.

• If the control knob does not pop up when released,

STOP and IMMEDIATELY call a qualified service technician

or gas supplier.

• If the pilot will not stay lit after several tries, turn the

gas control knob to "OFF" and call your service technician

or gas supplier.

10. Turn gas control knob counterclockwise to "ON."

11. Close bottom louver assembly.

12. Turn on all electric power to the appliance (if applicable).

13. Set REMOTE/OFF/ON switch to desired setting.

-

TO TURN OFF GAS TO FIREPLACE

1. Set REMOTE/OFF/ON switch to OFF.

2. Turn off all electric power to the appliance if service is to be

performed (if applicable).

3. Lower bottom louver assembly.

23015-3-0707 Page 19

4. Push in gas control knob slightly and turn clockwise

to "OFF." Do not force.

5. Close bottom louver assembly.

Page 20

STANDING PILOT WIRING

For Standing Pilot Ignition Wiring

Appliance Requirements

WARNING: DO NOT CONNECT 110-120 VAC TO THE

GAS CONTROL VALVE OR THE APPLIANCE WILL

MALFUNCTION AND THE VALVE WILL BE DE

STROYED.

STANDING PILOT WIRING DIAGRAM

Optional Wall Switch

Position the wall switch in the desired position on a wall. Run a

maximum of 25 feet (7.8m) or less length of 18 A.W.G. minimum

wire and connect it to the fireplace valve pigtails.

-

WARNING: DO NOT CONNECT THE 110-120 VAC

TO THE WALL SWITCH OR THE CONTROL VALVE

WILL BE DESTROYED.

CAUTION: LABEL ALL WIRES PRIOR TO DISCONNEC

TION WHEN SERVICING CONTROL. WIRING ERRORS

CAN CAUSE IMPROPER AND DANGEROUS OPERATION.

VERIFY PROPER OPERATION AFTER SERVICING.

-

23015-3-0707Page 20

Page 21

STANDING PILOT TROUBLESHOOTING

With proper installation and maintenance, your new Direct Vent Gas Fireplace will provide years of trouble-free service. If you do

experience a problem, refer to the Trouble Shooting Guide below. This guide will assist a qualified service person in the diagnosis

of problems and the corrective action to be taken.

1. Spark ignitor will not light pilot after repeated triggering

of piezo ignitor button.

a. Defective ignitor (no spark electrode)

—Check for spark at electrode and pilot; if no spark and

electrode wire is properly connected, replace ignitor.

b. No gas or low gas pressure.

—Check remote shut off valves from fireplace. Usually

there is a valve near the main. There can be more than one

(1) valve between the fireplace and main.

—Low pressure can be caused by a variety of situations

such as a bent line, too narrow diameter of pipe, or low line

pressure. Consult with plumber or gas supplier.

c. No LP in tank.

—Check LP (propane) tank. Refill tank.

2. Pilot will not stay lit after carefully following lighting

instructions.

a. Defective thermocouple.

—Check that pilot flame impinges on thermocouple. Clean

and/or adjust pilot for maximum flame impingement.

—Ensure the thermocouple connection at the gas valve is

fully inserted and tight (hand tight plus 1/4 turn). Faulty

thermocouple if reading is below specified minimum of 15

millivolts.

—Disconnect the thermocouple from the valve, place one

millivolt meter lead wire on the end of the thermocouple

and the other millivolt meter lead wire on the thermocouple

copper wire. Start the pilot and hold the valve knob in. If

the millivolt reading is less than 15 millivolt, replace the

thermocouple.

b. Defective valve.

—If thermocouple is producing more than 15 millivolts,

replace faulty valve.

3. Pilot burning, no gas to burner, valve knob “ON”, REMOTE/

OFF/ON switch “ON.”

a. REMOTE/OFF/ON switch, wall switch, remote control or

wires defective.

—Check REMOTE/OFF/ON switch and wires for proper

connections. Place jumper wires across terminal at switch.

If burner comes on, replace defective switch. If OK, place

jumper wires across switch wires at gas valve-if burner

comes on, wires are faulty or connections are bad.

b. Thermopile may not be generating sufficient millivolts.

—If the pilot flame is not close enough physically to the

thermopile, adjust the pilot flame.

—Be sure the wire connections from the thermopile at the

gas valve terminals are tight and the thermopile is fully

inserted into the pilot bracket.

—Check the thermopile with a millivolt meter. Take the

reading at TH-TP & TP terminals of the gas valve. The meter

should read 350 millivolts minimum, while holding the valve

knob depressed in the

PILOT position, with the pilot lit, and

the REMOTE/OFF/ON switch in the OFF position. Replace

the faulty thermopile if the reading is below the specified

minimum.

—With the pilot in the ON position, disconnect the thermopile

leads from the valve. Take a reading at the thermopile leads.

The reading should be 350 millivolts minimum. Replace the

thermopile if the reading is below the minimum.

c. Defective valve.

—Turn valve knob to ON. Place REMOTE/OFF/ON switch

to ON. Check with millivolt meter at thermopile terminals.

Millivolt meter should read greater than 200 millivolts. If the

reading is okay and the main burner does not ignite, replace

the gas valve.

d. Plugged main burner orifice.

—Check main burner orifice for blockage and remove.

4. Frequent pilot outage problem.

a. Pilot flame may be too high or too low, or blowing (high),

causing pilot safety to drop out.

—Clean and adjust flame for maximum flame impingement on

the thermocouple. Follow lighting instructions carefully.

5. The pilot and main burner extinguish while in operation.

a. No LP (Propane) in tank.

Check LP (Propane) tank. Refill fuel tank.

b. Inner vent pipe leaking exhaust gases back into system.

—Check for leaks.

c. Glass too loose, gasket leaks in corners after usage.

—Be certain glass assembly is installed correctly.

d. Horizontal vent improperly pitched.

—The horizontal vent cap should slope down only enough

to prevent any water from entering the unit. The maximum

downwards slope is 1/4 inch.

e. Bad thermopile or thermocouple.

—Replace if necessary.

f. Improper vent cap installation.

—Check for proper installation and freedom from debris or

blockage.

6. Glass soots, and/or soot deposits collected on logs.

a. Flame impingement on logs incorrect.

—Check and adjust log position. See Page 17. Contact

Empire Comfort Systems, Inc.

b. Debris around throat of main burner.

—Inspect the opening at the base of the main burner. It is

imperative that NO material be placed in this opening.

7. Flame burns blue and lifts off main burner.

a. Insufficient oxygen being supplied.

—Check to make sure vent cap is installed properly and free

of debris. Make sure that vent system joints are tight and

have no leaks.

—Check to make sure that no material has been placed at

the main burner base.

23015-3-0707 Page 21

Page 22

INSERT MAINTENANCE AND SERVICE

Although the frequency of servicing and maintenance will depend

on use and the type of installation, you should have a qualified

service technician perform an appliance checkup at the beginning

of each heating season. Specific guidelines regarding each

appliance maintenance task are listed below.

IMPORTANT: TURN OFF THE GAS BEFORE SERVICING

YOUR APPLIANCE.

Cleaning Burner and Controls

Frequency: Once annually.

By: Qualified service technician.

Task: Brush or vacuum the control compartment, fireplace logs

and burner areas surrounding the logs.

Checking Flame Patterns, Flame Height

Frequency: Periodically.

By: Qualified service technician/Home owner.

Task: Make a visual check of your fireplace’s flame patterns.

Make sure the flames are steady - not lifting or floating. The

thermopile/thermocouple (standing pilot) tips should be covered

with flame. See Figure 21.

Checking Vent System

Frequency: Before initial use and at least annually thereafter,

more frequently if possible.

By: Qualified service technician/Home owner.

Task: Inspect the external vent cap on a regular basis to ensure

that no debris is interfering with the flow of air. Inspect entire vent

system for proper function.

Cleaning Logs

Use a soft brush attachment on a vacuum cleaner to gently remove

dust or soot deposits from logs and burner.

Cleaning Glass Door

Frequency: After the first 3 to 4 hours of use. As necessary after

initial cleaning.

By: Home owner.

Task: Remove and clean glass after the first 3 to 4 hours of use.

After the initial cleaning, clean as necessary. Film deposits on the

inside of the glass door should be cleaned off using a household

glass cleaner.

NOTE: DO NOT handle or attempt to clean the door when it

is hot and DO NOT use abrasive cleaners.

Glass Door Replacement

Do not operate the fireplace insert if the high-temperature ceramic

glass is cracked or broken.

Do not attempt to replace the ceramic glass panel. A complete

replacement glass door assembly should be ordered as listed in

the Parts List on page 25, if needed.

Do not use substitute materials for replacement of glass door

components.

Do not abuse the glass door by striking the glass.

Do not abuse the glass door by slamming or forcing the door

shut.

When installing the glass door assembly, place the top door flange

over the firebox top, center left to right, then gently swing the

door bottom inward and secure with the two (2) spring loaded

door latches.

23015-3-0707Page 22

Page 23

Decorative Mission Louver

Decorative Leaf Louver

Decorative Arch Louver

STD Louvers 45 Deg

STD Contemporary Surround

Cast Iron Traditional Surround

Bottom Cover

DECORATIVE ACCESSORIES

The following accessory parts can be obtained from your Empire Comfort Systems dealer. If you need additional information beyond

what your dealer can furnish, contact Empire Comfort Systems Inc., Nine Eighteen Freeburg Ave., Belleville, Illinois 62220.

• Black

• Gold Finish

• Hammered Pewter

• Brushed Stainless

• Black • Black • Black (Standard)

• Black

• Gold Finish

• Hammered Pewter

• Brushed Stainless

• Black

• Gold Finish

• Hammered Pewter

• Brushed Stainless

• Gold Finish

• Hammered Pewter

• Brushed Stainless

• Black

Used to finish off bottom of insert and surround

panels when installed in a fireplace without a flush

hearth extension. Can be used with traditional cast

iron or contemporary surround kits.

23015-3-0707 Page 23

Page 24

INSERT PARTS VIEW

23015-3-0707Page 24

Page 25

INSERT PARTS LIST

PART NUMBER

INDEX NO. DV25IN33L(N,P) DV33IN33L(N,P) DV35IN33L(N,P) DESCRIPTION

1 22950 22950 22950 GUIDE, FLUE CONNECTOR

2 23309 23211 23211 VENT SLIDE PLATE ASSEMBLY

3 R9188 R9188 R9188 GASKET, TOP

4 R9192 R9196 R9199 BRICK PANEL, BACK

5 R9195 R9198 R9201 BRICK PANEL, RIGHT

6 R9194 R9197 R9200 BRICK PANEL, LEFT

7 20448 20448 20448 BRICK LINER BRACKET

8 22951 22972 22972 FIREBOX BAFFLE

9 22958 22976 22990 LOG SHELF

10 23303 23006 23320 GLASS DOOR & FRAME ASSEMBLY

11 23329 17169 17127 LOUVER ASSEMBLY

12 23158 23160 23160 LOG SUPPORT, FRONT

13 23315 23024 23024 GRATE TANG / BRACKET ASSEMBLY

14 R3435 R3435 R3435 WIRE ASSEMBLY

15 R3436 R3436 R3436 SWITCH, REMOTE/OFF/ON

16 R2708 R2708 R2708 IGNITER, PIEZO

17 23159 23161 23504 LOG SUPPORT, REAR

18 23521 23521 23521 FLAME SHIELD, RIGHT

19a R7612 R7612 R7612 PILOT ASSEMBLY, SIT (NAT)

19b R7611 R7611 R7611 PILOT ASSEMBLY, SIT (LP)

20 R9189 R9189 R9189 GASKET, PILOT

21 R5676 R5676 R5676 AIR SHUTTER

22 P253 P253 P253 FITTING, ORIFICE ANGLED

23a P286 P270 P244 ORIFICE, MAIN BURNER (NAT)

23b P214 P210 P245 ORIFICE, MAIN BURNER (LP)

24 23311 23017 23017 BURNER ASSEMBLY

25 22959 22959 22959 VALVE BRACKET

26 22739 22738 22738 TUBING ASSEMBLY

27 22973 22973 22973 SHIELD, VALVE

28a R7577 R7577 R7577 VALVE, SIT GAS (NAT)

28b R7578 R7578 R7578 VALVE, SIT GAS (LP)

29 22953 22953 22953 PIEZO BRACKET

30 16223 16223 16223 SPRING RETAINER ASSEMBLY

31 N/A 23690 23690 FLAME SHIELD, LEFT

32 M163 M163 M163 GASKET, FLUE CONNECTOR

33 23009 23009 23009 FLUE CONNECTOR ASSEMBLY

34 R9257 R9219 R9219 LOG, RIGHT FRONT

35 R9258 R9220 R9220 LOG, RIGHT CENTER

36 R9260 R9252 R9252 TWIG, RIGHT

37 R9261 R9253 R9253 TWIG, LEFT

38 R9255 R9217 R9217 LOG, BACK

39 R9259 R9251 R9251 LOG, LEFT CENTER

40 R9256 R9218 R9218 LOG, LEFT FRONT

41 R9268 R9268 R9268 WIRE ASSEMBLY - SWITCH

42 R2522 R2522 R2522 SWITCH, ON / OFF

43 18879 18879 18879 RHEOSTAT ASSEMBLY (SPEED CONTROL)

44 R7649 R7649 R7649 CONTROL, FAN

45 R9211 R9211 R9211 BLOWER ASSEMBLY (MOTOR W/HOUSING)

46 22954 22954 22954 BRACKET, BLOWER

47 R2204 R2204 R2204 CORD SET

48 R7591 R7591 R7591 FLEXLINE W/SHUTOFF VALVE

USE ONLY MANUFACTURER’S REPLACEMENT PARTS. USE OF ANY OTHER PARTS COULD CAUSE INJURY OR DEATH.

23015-3-0707 Page 25

Page 26

HOW TO ORDER REPAIR PARTS

Parts can be ordered only through your service person or dealer. For best results, the service person or dealer should order parts

through the distributor. Parts can be shipped directly to the service person/dealer.

All parts listed in the Parts List have a Part Number. When ordering parts, first obtain the Model Number from the name plate on your

equipment. Then determine the Part Number (not the Index Number) and the Description of each part from the following appropriate

illustration and list. Be sure to give all this information .

Fireplace Number Part Description

Fireplace Serial Number Part Number

Type of Gas (Propane or Natural)

Do not order bolts, screws, washers or nuts. They are standard hardware items and can be purchased at any local hardware store.

Shipments contingent upon strikes, fires and all causes beyond our control.

Empire Comfort Systems, Inc. Nine Eighteen Freeburg Ave. Belleville, Illinois 62222-2623

SERVICE NOTES

23015-3-0707Page 26

Page 27

SERVICE NOTES

23015-3-0707 Page 27

Page 28

Empire Comfort Systems, Inc.

918 Freeburg Ave. Belleville, IL 62220

PH: 618-233-7420 or 800-851-3153

FAX: 618-233-7097 or 800-443-8648

info@empirecomfort.com

www.empirecomfort.com

23015-3-0707Page 28

Loading...

Loading...