Page 1

INSTALLATION INSTRUCTIONS

AND OWNER’S MANUAL

INSTALLER:

Leave this manual with the appliance.

CONSUMER:

Retain this manual for future reference.

WARNING

FIRE OR EXPLOSION HAZARD

If the information in this manual is not

followed exactly, a re or explosion may

result causing property damage, personal

injury or loss of life.

— Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the re department.

— Installation and service must be

performed by a qualied installer,

service agency or the gas supplier.

IMPORTANT! Read these instructions

carefully before installing or operating this

gas appliance. These instructions should

be left with the homeowner for future

reference.

RADIANT VENTED BURNER

REQUIRES VENTED LOG SET FOR

INSTALLATION IN SOLID-FUEL

BURNING FIREPLACES

HI / LOW REMOTE MODELS

BFR(2124,30)RN

DANGER

If not installed, operated and maintained

in accordance with the manufacturer’s

instructions, this product could expose

you to substances in fuel or from fuel

combustion which can cause death or

serious illness.

CONGRATULATIONS on the purchase of

your new GAS BURNER! Your Decorative

Gas Burner is designed and intended for

installation in an approved, existing, fully

vented, wood-burning replace, with a gas

hook-up.

This appliance must be installed only in a solid-

fuel burning replace with a working ue and

construction of noncombustible materials.

This unit is NOT for use with solid fuel. Sol-

id fuels shall NOT be burned in a replace

where a decorative appliance is installed.

The vent damper must have a damper clamp

attached to it to keep the damper from

accidentally closing during operation.

GAS-FIRED

Page 2

TABLE OF CONTENTS

SECTION PAGE

Before You Start ............................................................................................................................. 3

Carton Contents And Hardware Pack ............................................................................................ 4

Important Safety Information ....................................................................................................5 - 6

Safety Information For Users of Propane Gas ............................................................................... 7

General Information ....................................................................................................................... 8

Product Specications ................................................................................................................... 9

Introduction .................................................................................................................................. 10

Fireplace Preparation .................................................................................................................. 10

Gas Supply ........................................................................................................................... 11 - 12

Installation ............................................................................................................................. 13 - 14

Door Operation ............................................................................................................................ 15

Hi/Low Lighting Instructions ......................................................................................................... 16

Pilot And Main Burner Flame Characteristics ..............................................................................17

Hi/Low (BFR) Wiring .................................................................................................................... 18

Remote Operation ................................................................................................................19 - 21

Maintenance And Service ............................................................................................................ 22

Troubleshooting ...........................................................................................................................23

BFR Parts List And Exploded View .............................................................................................. 24

Master Parts Distributor List ........................................................................................................ 25

How To Order Repair Parts .......................................................................................................... 25

Warranty ......................................................................................................................................26

Appliance Service History ............................................................................................................ 27

39246-0-0718Page 2

Page 3

BEFORE YOU START

Samples and Denitions:

DANGER

Indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE: Addresses practices not related to personal injury.

1. Read the safety information on pages 5 - 7.

2. Review gas line information on pages 11 and 12.

3. Review the wiring information on page 18.

4. Light the burner and troubleshoot. See pages 16 and 21.

5. Show the homeowner how to operate the burner.

6. Show the homeowner how to do the basic maintenance.

These instructions are intended as a general guide

and do not supersede national or local codes in

any way. Authorities having jurisdiction should be

consulted before installation.

• Follow all local codes regarding installation,

combustion and ventilation air or in the absence

of local codes follow the National Fuel Gas Code

ANSI Z223.1(U.S. installation), or CAN/CGA-B149,

Installation Code (Canada installation) and with

ANSI Z21.60 Decorative Vented Appliances for Solid

Fuel Burning Fireplaces.

• Installation and provision for combustion and

ventilation air must conform to the National Fuel

Gas Code, ANSI Z223.1, or CAN/CGA-B149.1,

Natural Gas Installation Code, or CAN/CGA-B149.2,

Propane Installation Code.

• The installation of appliances designed for

manufactured home (U.S. only) or mobile home

installation must conform with the Standard for

Mobile House, CAN/CSA Z240 MH, in Canada,

or with the Manufactured Home Constructions

and Safety Standard, Title 24 CFR, Part 3280,

in the United States, or when such a standard is

not applicable, Manufactured Home Installations

Standard, ANSI/NCSBCS A225.1/NFPA 501A.

39246-0-0718 Page 3

Page 4

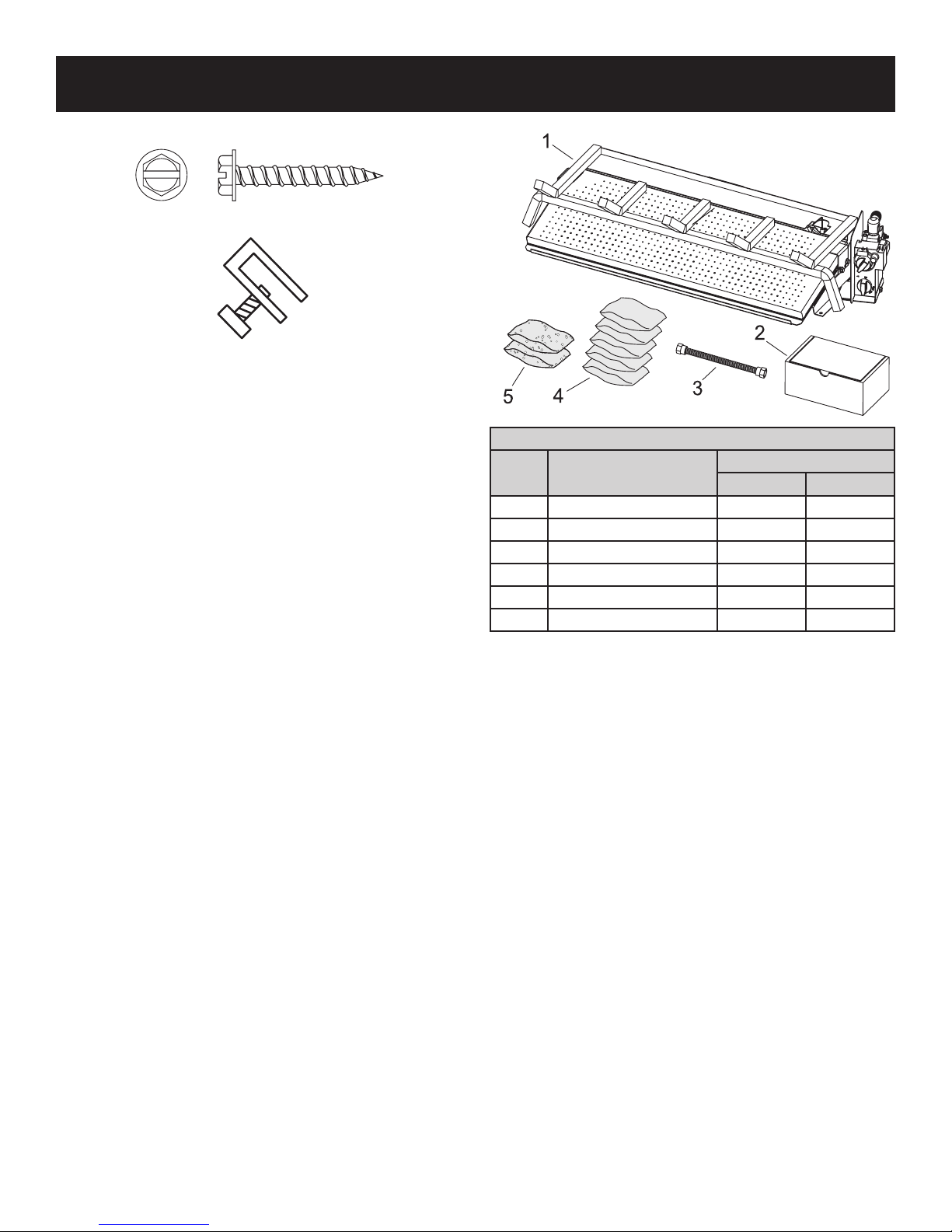

CARTON CONTENTS & HARDWARE PACK

HARDWARE PACK CONTENTS

1/4" X 1 1/4" SLOTTED HEX HEAD ANCHOR SCREW (2)

DAMPER CLAMP (1)

Items not shown to scale.

CARTON CONTENTS

BFR(2124,30)RN

INDEX

NO.

1 Burner Assembly 1 1

2 Remote And Receiver Kit 1 1

3 Flexline 1 1

4 Rockwool Mix 5 5

5 Lava Rock 2 2

NS Fiber Heat Sink 1 1

DESCRIPTION

QUANTITY SUPPLIED

BFR2124 BFR30

See Parts Lists on page 22 for ordering replacement parts.

Do not order batteries, bolts, screws, washers or nuts. They are

standard hardware items and can be purchased at any local

hardware store.

39246-0-0718Page 4

Page 5

IMPORTANT SAFETY INFORMATION

Installer: Leave these instructions with the owner. For Installation

In Solid Fuel Burning Fireplaces. Do not burn wood or solid fuels

in a replace where a decorative gas log set is installed. This

appliance is for installation only in a solid fuel burning replace,

masonry replace or manufactured replace.

WARNING

Before installing in a solid fuel burning replace, the chimney

ue and rebox must be cleaned of soot, creosote, ashes

and loose paint by a qualied chimney cleaner.

WARNING

Do not allow fans to blow directly into or at the replace.

Avoid any drafts that alter burner ame patterns.

WARNING

Do not use a blower insert, heat exchanger insert or other

accessory not approved for use with this appliance.

DANGER

Any modication to this gas log set or to controls can be

dangerous. Improper installation or use of the gas log set

can cause serious injury or death from re, burns, explosion or carbon monoxide poisoning.

WARNING

Do not operate this burner with glass doors closed.

• Installation and repair must be done by a QUALIFIED

SERVICE PERSON. The appliance should be inspected

before use and at least annually by a qualied service

person. More frequent cleaning may be required due to

excessive lint from carpeting, bedding materials, etc. It

is imperative that control compartments, burners and

circulating air passageways of the appliance be kept clean.

• Dot not place clothing or other ammable material on or near

the appliance.

• Do not place trash or other articles on the log set during

operation.

• Do not put anything around the replace that will obstruct the

ow of ventilation air.

• Do not use this appliance if any part has been under water.

Immediately call a qualied service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

• Do not use thermostats on vented burner applications

• Keep the appliance area clear and free from combustible

material, gasoline and other ammable vapors and liquids.

• Keep burner and control compartment clean.

• A yearly examination and cleaning of the venting system

of the solid-fuel burning replace must be performed by a

qualied agency.

• Make a periodic visual check of pilot and burners. Clean and

replace damaged parts.

• Alert children and adults to the hazards of high surface

temperatures and caution them to stay away to avoid burns

or clothing ignition.

• Carefully supervise young children when they are in the

same room as the appliance.

• During manufacture, this burner is treated with certain oils,

lms and bonding agents. These substances are not harmful

but may produce smoke and odors as they burn off during

initial operation of the replace. This is normal. Open a

window during the initial bake out period.

•

Proper installation, burner pan location and log placement

is important to achieve optimum look and performance of

your gas log set. Follow the log assembly sequence for

proper operation.

• Do not operate this log set with glass doors in the closed

position. A replace screen must be in place when the log

set is burning. Adequate combustion air must be provided for

proper venting. All ames should go up and out the top of the

rebox into the ue vent. If any ames oat or curl forward

into the room do not operate appliance. Check for an open

ue and adequate combustion air into the room. A damper

clamp must be installed on the rebox damper to maintain

an open ue. See page 10.

• Young children must be carefully supervised when they are

in the same room as the gas log while in operation. Do not

place stockings, clothing or any ammable material above or

near the replace.

• Do not substitute or use materials other than those supplied

for use with the log set.

WARNING

Follow all gas leak check procedures in this manual, prior

to operation.

WARNING

Fuels used in gas or oil-red appliances, and the products

of combustion of such fuels, contain chemicals known to

the State of California to cause cancer, birth defects, and/

or other reproductive harm. This warning is issued pursuant to California Health & Safety Code Sec. 25249.6.

DO NOT ATTEMPT TO DISCONNECT THE GAS OR ANY GAS

FITTING WHILE THIS APPLIANCE IS IN OPERATION.

NEVER leave the decorative gas log set unattended while in

operation.

NEVER allow children to operate this decorative gas log set.

NEVER place hands or ngers on the front-edge of this

decorative gas log set.

NEVER use liquid propane gas in a natural gas unit, or natural

gas in a liquid propane unit.

DO NOT use solid-fuel or lighter uid in any decorative gas log set.

Any safety screen or guard removed for servicing an appliance

must be replaced prior to operating the appliance.

39246-0-0718 Page 5

Page 6

IMPORTANT SAFETY INFORMATION (CONT'D)

WARNING

Do not use this appliance if any part has been under water.

Immediately call a qualied service technician to inspect

the appliance and replace any part of the control system

and any gas control that has been under water.

All units with gas control valves must be lit by a Safety Pilot. The

pilot is located at the right, rear of the unit.

Follow these instructions exactly when lighting the appliance.

BEFORE LIGHTING, smell around the appliance area for gas. Be

sure to smell next to the oor, as propane gas is heavier than air

and will settle to the oor. Use only your hand to rotate the gas

control knob. Never use tools. If the knob will not turn by hand, do

not try to repair it; call a qualied service technician or installer.

Force or attempted repair may result in a re or explosion.

WARNING

All gas burning appliances produce smoke and carbon monoxide gas during operation. These fumes can be harmful if the

appliance is used in any other than a fully vented replace.

WARNING

The Commonwealth of Massachusetts requires that the

chimney ue damper, when used with decorative gas log

sets, be welded open or completely removed. In the Commonwealth of Massachusetts, this appliance must be in-

stalled by a licensed plumber or gastter.

GAS WARNING ODOR

If a gas leak happens, you should be able to smell the gas

because of the odorant put in the propane gas.

That’s your signal to go into immediate action!

• Do not operate electric switches, light matches, use your phone.

Do not do anything that could ignite the gas.

• Get everyone out of the building, vehicle, trailer, or area. Do

that IMMEDIATELY.

• Close all gas tank or cylinder supply valves.

• Propane gas is heavier than air and may settle in low areas

such as basements. When you have reason to suspect a gas

leak, keep out of basements and other low areas. Stay out until

reghters declare them to be safe.

• Use your neighbor’s phone and call a trained propane gas

service person and the re department. Even though you may

not continue to smell gas, do not turn on the gas again. Do not

re-enter the building, vehicle, trailer, or area.

• Finally, let the service man and reghters check for escaped

gas. Have them air out the area before you return. Properly

trained propane gas service people should repair the leak, then

check and relight the gas appliance for you.

WARNING

Improper installation, adjustment, alteration, service or maintenance, can cause property damage, personal injury or loss

of life. Refer to the owner’s information manual, provided with

this appliance. Installation and service must be performed by

a qualied installer, service agency or the gas supplier.

39246-0-0718Page 6

Page 7

SAFETY INFORMATION FOR USERS OF PROPANE GAS

Propane Gas is a ammable gas which can cause res and

explosions. In its natural state, propane is odorless and colorless. You may not know all the following safety precautions

which can protect both you and your family from an accident.

Read them carefully now, then review them point by point with

the members of your household. Someday when there may not

be a minute to lose, everyone's safety will depend on knowing

exactly what to do. If, after reading the following information,

you feel you still need more information, please contact your

gas supplier.

NO ODOR DETECTED - ODOR FADE

Some people cannot smell well. Some people cannot smell

the odor of the chemical put into the gas. You must nd out if

you can smell the odorant in propane. Smoking can decrease

your ability to smell. Being around an odor for a time can affect your

sensitivity or ability to detect that odor. Sometimes other odors in

the area mask the gas odor. People may not smell the gas odor or

their minds are on something else. Thinking about smelling a gas

odor can make it easier to smell.

The odorant in propane gas is colorless, and it can fade under

some circumstances. For example, if there is an underground

leak, the movement of the gas through soil can lter the odorant.

Odorants in propane gas also are subject to oxidation. This fading

can occur if there is rust inside the storage tank or in iron gas pipes.

The odorant in escaped gas can adsorb or absorb onto or into

walls, masonry and other materials and fabrics in a room. That will

take some of the odorant out of the gas, reducing its odor intensity.

Propane gas may stratify in a closed area, and the odor intensity

could vary at different levels. Since it is heavier than air, there may

be more odor at lower levels. Always be sensitive to the slightest gas

odor. If you detect any odor, treat it as a serious leak. Immediately

go into action as instructed earlier.

SOME POINTS TO REMEMBER

• Learn to recognize the odor of propane gas. Your local pro-

pane gas dealer can give you a “Scratch and Sniff” pamphlet.

Use it to nd out what the propane odor smells like. If you

suspect that your propane gas has a weak or abnormal odor,

call your propane gas dealer.

• If you are not qualied, do not light pilot lights, perform service,

or make adjustments to appliances on the propane gas system.

If you are qualied, consciously think about the odor of propane

gas prior to and while lighting pilot lights or performing service

or making adjustments.

• Sometimes a basement or a closed-up house has a musty

smell that can cover up the propane gas odor. Do not try to

light pilot lights, perform service, or make adjustments in an

area where the conditions are such that you may not detect

the odor if there has been a leak of propane gas.

• Odor fade, due to oxidation by rust or adsorption on walls of

new cylinders and tanks, is possible. Therefore, people should

be particularly alert and careful when new tanks or cylinders

are placed in service. Odor fade can occur in new tanks, or

reinstalled old tanks, if they are lled and allowed to set too

long before relling. Cylinders and tanks which have been out

of service for a time may develop internal rust which will cause

odor fade. If such conditions are suspected to exist, a periodic

sniff test of the gas is advisable. If you have any question

about the gas odor, call your propane gas dealer. A periodic sniff test of the propane gas is a good safety measure

under any condition.

• If, at any time, you do not smell the propane gas odorant and

you think you should, assume you have a leak. Then take the

same immediate action recommended above for the occasion

when you do detect the odorized propane gas.

• If you experience a complete “gas out,” (the container is under

no vapor pressure), turn the tank valve off immediately. If the

container valve is left on, the container may draw in some air

through openings such as pilot light orices. If this occurs, some

new internal rusting could occur. If the valve is left open, then

treat the container as a new tank. Always be sure your container is under vapor pressure by turning it off at the container

before it goes completely empty or having it relled before it is

completely empty.

39246-0-0718 Page 7

Page 8

GENERAL INFORMATION

Qualied Installing Agency

Installation and replacement of gas piping, gas utilization equipment

or accessories and repair and servicing of equipment shall be per-

formed only by a qualied agency. The term "qualied agency" means

any individual, rm, corporation or company which either in person

or through a representative is engaged in and is responsible for (a)

the installation or replacement of gas piping or (b) the connection,

installation, repair or servicing of equipment, who is experienced in

such work, familiar with all precautions required and has complied

with all the requirements of the authority having jurisdiction.

Commonwealth of Massachusetts: The installation must be

made by a licensed plumber or gas tter in the Commonwealth

of Massachusetts.

The installation and the provisions for combustion and ventilation

air must conform with the National Fuel Gas Code, ANSI Z223.1/

NFPA54* Canadian Installation Code CAN/CGA B149.

*Available from the American National Standards Institute, Inc. 11

West 42nd St., New York, N.Y. 10018.

High Altitude Installation

When installing this unit at an elevation above 2000 feet (in the

United States) it may be necessary to decrease the input rating by

changing the existing burner orice to a smaller size. Generally,

input should be reduced 4 percent for each 1000 feet above sea

level. However, if the heating value of the gas has been reduced,

this general rule may not apply. Check with local gas utility for proper

orice size identication.

For Canadian high altitude applications, this appliance is suitable for

installation at elevations between 0 feet (0m) and 4,500 (1,370m)

without change.

When installing this unit at an elevation above 4500 feet (1,370m)

(in Canada), check with local authorities.

Consult your local gas utility for assistance in determining the proper

orice for location.

39246-0-0718Page 8

Page 9

PRODUCT SPECIFICATIONS

NATURAL GAS

Millivolt

Regulator pressure setting 4.5"

Gas inlet pressure

Model

Gas

Type

Max. 10.5"

Min. 5.0"

Valve

Type

Orice

Manifold

Pressure

(w.c.)

BFR2124RN Natural Hi/Low #22 4.5" 55,000

BFR30RN Natural Hi/Low #12 4.5" 65,000

PROPANE CONVERSION KIT

Burner Model Valve Type Kit Number

BFR2124RN Hi/Low CKV119

BFR30RN Hi/Low CKV120

NOTE: The air shutter setting for all models is 1/16" open.

BTUH

Max.

Rate

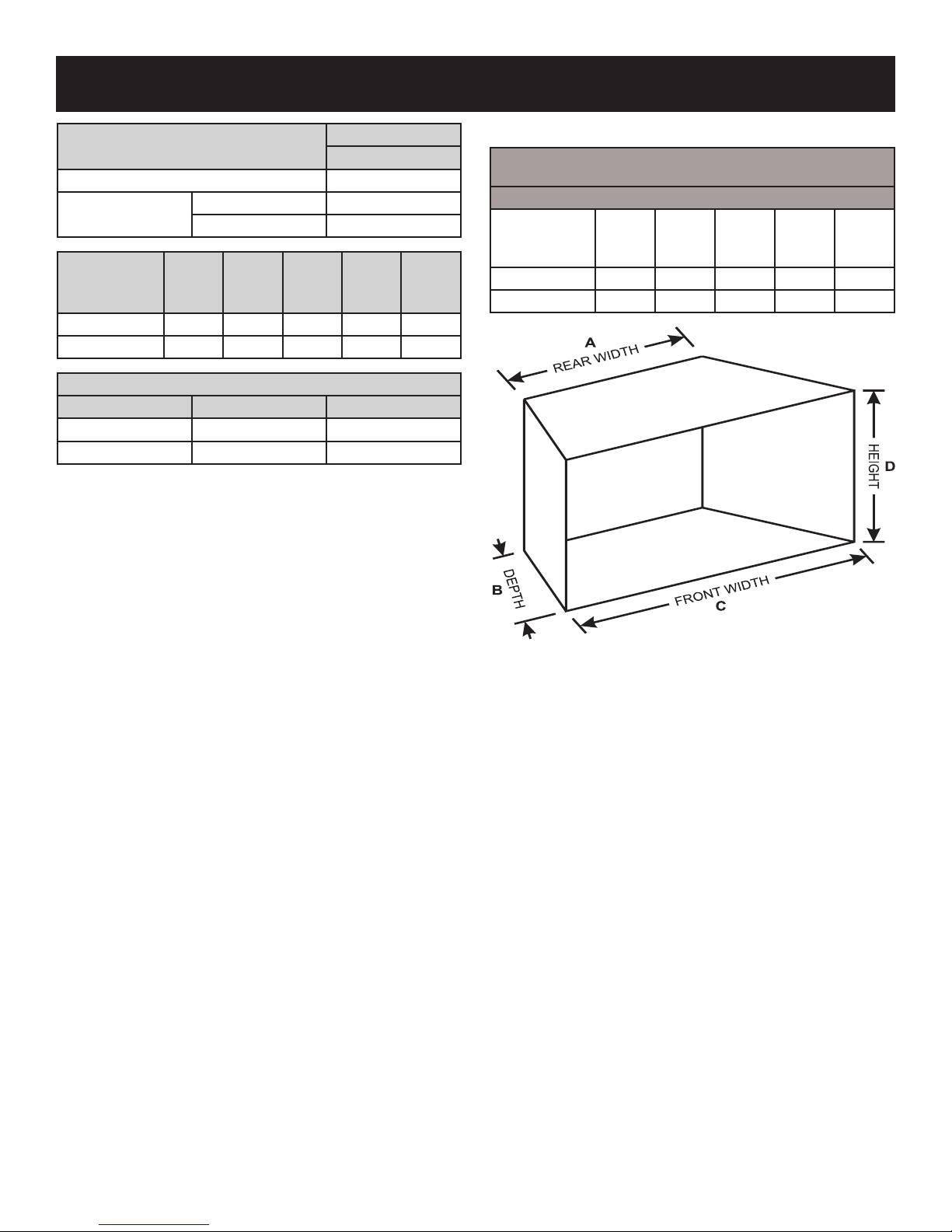

Determining the Correct Burner Size for Your Fireplace

MINIMUM FIREPLACE DIMENSIONS

FACTORY BUILT FIREPLACES

Chimney Height Minimum of 6 Feet

Burner

Model

Rear

WidthADepth

B

Front

WidthCHeight

D

BFR2124RN 26 16 30 20

BFR30RN 30 16 36 20

Minimum

Vent

in Sq.

Inches

49

49

Figure 1

39246-0-0718 Page 9

Page 10

INTRODUCTION

Introduction

Always consult your local Building Department regarding regulations, codes or ordinances which apply to the installation of a

vented decorative gas log set in a solid-fuel burning replace.

This appliance is only for use with the type of gas indicated on

the rating plate.

Instructions to Installer

1. Installer must leave instruction manual with owner after

installation.

2. Installer must have owner ll out and mail warranty card

supplied with the replace.

3. Installer should show owner how to start and operate the

replace.

WARNING

Any change to this appliance or its controls can be dangerous. Improper installation or use of the appliance can cause

serious injury or death from re, burns, explosion or carbon

monoxide poisoning.

General Information

Any alteration of the original design, installed other than as

shown in these instructions or use with a type of gas not

shown on the rating plate is the responsibility of the person

and company making the change.

Important

All correspondence should refer to complete Model No., Serial

No. and type of gas. This information can be found on the data

plate supplied with the burner.

NOTICE: During initial use of the logs you will detect an odor as

the logs are cured. This is normal.

WARNING

A replace screen must be in place when this appliance is

in operation. The screen shall allow for introduction of combustion air.

WARNING

When this decorative gas appliance is used in a replace

equipped with glass doors, the glass doors should remain

open during log set operation. This will maximize the radiant

heat provided to the surrounding area, and minimize overheating of any valve installation. The glass doors may be

closed when the log set is not in use.

FIREPLACE PREPARATION

• Remove all contents from the burner carton.

• Check the contents of the carton against the parts list in this

manual. Report any missing or damaged parts to your dealer.

• Turn off gas supply to replace or rebox.

• Have the replace oor and chimney professionally cleaned to

remove ashes, soot, creosote or other obstructions.

Have this cleaning performed annually after installation.

•

Seal any fresh air vents or ash clean-out doors located on oor

or wall of replace. If not, drafting may cause pilot outage or

excessive sooting. Use a heat-resistant sealant. Do not seal

chimney ue damper.

Installing Damper Clamp

Remove all ashes or other debris from the replace. If the replace

is equipped with an ash dump be sure to seal the door with furnace

cement or high temperature silicone. Be sure to check the damper

for proper operation and verify that the ue passageway is open.

Attach damper clamp to the vent damper and tighten hold down bolt.

Place the clamp over the lip of the damper and tighten the hold

down bolt until the clamp is securely attached to the damper. This

will prevent the damper from accidentally closing.

Figure 2

39246-0-0718Page 10

Page 11

GAS SUPPLY

Check all local codes for requirements, especially for the size and

type of gas supply line required.

RECOMMENDED GAS PIPE DIAMETER

Pipe

Length

0-10 feet 1/2-in 3/8-in 1/2-in 3/8-in

10-40 feet 1/2-in 1/2-in 5/8-in 1/2-in

40-100 feet 1/2-in 1/2-in 3/4-in 1/2-in

100-150 feet 3/4-in 1/2-in 7/8-in 3/4-in

NOTICE: Never use plastic pipe. Check to conrm whether your

local codes allow copper tubing or galvanized.

NOTICE: Since some municipalities have additional local codes, it

is always best to consult your local authority and installation code.

Installing a New Main Gas Shut-Off Valve

Each appliance should have its own manual gas shut-off valve.

In the Commonwealth of Massachusetts the gas shut-off valve must

be a T handle type.

A manual main gas shut-off valve should be located in the vicinity

of the unit. Where none exists, or where its size or location is not

adequate, contact your local authorized installer for installation or

relocation.

Compounds used on threaded joints of gas piping shall be

resistant to the action of liqueed petroleum gases. The gas lines

must be checked for leaks by the installer. Testing for leaks on

all exposed connections should be done with leak detection test

solution. After testing is complete, all solution should be cleaned

off. On unexposed connections, a pressure test should be made.

Never use an exposed ame to check for leaks. Appliance must

be disconnected from piping at inlet of control valve and pipe

capped or plugged for pressure test. Never pressure test with

appliance connected; control valve will sustain damage!

A gas valve and ground joint union should be installed in the gas

line upstream of the gas control to aid in servicing. It is required by

the National Fuel Gas Code that a drip line be installed near the gas

inlet. This should consist of a vertical length of pipe tee connected

into the gas line that is capped on the bottom in which condensation

and foreign particles may collect.

The use of the following gas connectors is recommended:

— ANSI Z21.24 Appliance Connectors of Corrugated Metal Tubing

and Fittings

— ANSI Z21.45 Assembled Flexible Appliance Connectors of

Other Than All-Metal Construction

Schedule 40 Pipe

Inside Diameter

Natural Propane Natural Propane

Tubing, Type L

Outside Diameter

Figure 3

The above connectors may be used if acceptable by the authority

having jurisdiction. The Commonwealth of Massachusetts requires

that a exible appliance connector cannot exceed three feet in length.

A gas valve and ground joint union should be installed in the gas

line upstream of the gas control to aid in servicing. It is required

by the National Fuel Gas Code that a drip leg be installed near the

gas inlet. See Figure 4. This should consist of a vertical length of

pipe tee connected into the gas line that is capped on the bottom

in which condensation and foreign particles may collect.

39246-0-0718 Page 11

Figure 4

Page 12

GAS SUPPLY (CONT'D)

Pressure Testing of the Gas Supply System

1. To check the inlet pressure to the gas valve, use the test gauge

connection described below.

2. The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1/2 psig (3.5 kPa).

3. The appliance must be isolated from the gas supply piping system

by closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal

to or less than 1/2 psig (3.5 kPa).

CAUTION

If one of the procedures results in pressures in excess of 1/2

psig (14-in w.c.) (3.5 kPa) on the appliance gas valve, it will

result in a hazardous condition.

Checking Manifold Pressure

Millivolt Natural Gas models will have a manifold pressure of ap-

proximately 3.5-in w.c. (.871kPa) at the pressure regulator outlet

with the inlet pressure to the pressure regulator from a minimum

of 5.0-in w.c. (1.120kPa) for the purpose of input adjustment to a

maximum of 10.5-in w.c. (2.615kPa). Manual Natural Gas models

will have a manifold pressure of approximately 5.3-in w.c. (1.12kPa)

at the pressure regulator outlet with the inlet pressure to the pressure

regulator from a minimum of 6.0-in w.c. (1.74kPa) for the purpose

of input adjustment to a maximum of 10.5-in w.c. (2.615kPa).

Manual

*NOTICE: A test gage connection is located downstream of the

gas appliance pressure regulator for measuring gas pressure. The

connection is a 1/8 inch 3mm) N.P.T. plugged tapping.

Millivolt

*NOTICE: The gas control is equipped with a captured screw-type

test gauge connection.

39246-0-0718Page 12

Page 13

INSTALLATION

Gas supply system must be installed in accordance with the U.S.

National Fuel Gas Code.

This appliance and its individual shut off valve must be disconnected from the gas supply piping system during any system

pressure test in excess of 1/2 PSI (3.5 KPA).

Use a system manual shut off valve to shut off the gas supply to

this gas appliance before continuing with installation procedures.

DANGER

To avoid injury and property damage, DO NOT obstruct the

ow of combustion and ventilation air when installing or

operating the appliance.

IMPORTANT

Seal any fresh air vents or ash clean-out doors located on the

oor or wall of the replace. If this is not performed, drafting

may cause pilot outage or excessive sooting. Use a heat-

resistant sealant. DO NOT seal the chimney ue damper.

IMPORTANT

BEFORE YOU BEGIN - Check the gas pressure at the

replace stub to ensure proper minimum gas pressure (see the

specications beginning on page 9 of this manual).

ANCHOR SCREWS

Figure 5

BFR MODEL FRONT AND REAR

IMPORTANT

BEFORE YOU BEGIN - Ensure that the rebox meets the

minimum specications of the appliance (see the specications

beginning on page 9 of this manual).

IMPORTANT

This appliance when rst installed and used may produce

odors. This is normal. Open a window when operating the

appliance for the rst time.

IMPORTANT

This appliance must be installed only in a solid-fuel burning

replace, which contains a working ue and is constructed of

non-combustible materials.

You must secure the gas burner to the replace oor. If not, the

entire unit may move when you adjust the controls. Movement

of unit may cause shifting of the gas logs which leads to

excessive sooting and improper burning. See Figure 5.

Special care is required if you are installing the unit into a

sunken replace. You must raise the replace oor with non-

combustible material to allow access to gas log controls.

This will ensure adequate air ow and guard against sooting.

Raise the replace oor using noncombustible materials.

ASSEMBLY PROCEDURE:

1. Place the burner in the replace or rebox. Make certain the

entire ember burner is inside the front edge of the replace

or rebox.

2. An anchor hole is provided in each burner leg. After cen-

tering the burner, mark the hole positions on the replace/

rebox oor. Drill two 5/32 inch diameter holes approximately

1-1/2 inches deep for masonry screws or 1/8 inch hole for

sheet metal screws.

3. Anchor to the replace/rebox oor using the screws provided. Refer to Figure 5.

Figure 6

39246-0-0718 Page 13

Page 14

INSTALLATION (CONT'D)

WARNING

Failure to position the parts in accordance with all included

pictures, diagrams and drawings, or failure to use only

parts specically approved with this appliance may result

in property damage or personal injury.

4. Spread the rock wool over the burner. The rock wool should

be broken into uffy quarter-sized pieces.

Figure 7

5. Place the lava rock around the burner assembly.

WARNING

Apply loose material (rockwool and lava rock) per instruction

manual. DO NOT apply extra material not supplied with this

appliance. All previously applied loose material (rock wool)

must be removed prior to reapplication.

CAUTION

DO NOT place rockwool or lava rock in the area of the

safety pilot assembly.

STOP!

The LKF Fiber Log Set and LPR2430 Refractory Log Set are the

only two log sets which are approved for use on these burners.

DO NOT substitute a different log set or deviate from the log

placement sequence.

Refer to the instructions packaged with your Decorative Gas Logs.

6.

Remove all contents from the Decorative Gas Log carton.

7. Check the contents of the carton against the parts list in the

manual. Report any missing or damaged parts to your retailer.

8. Remove any and all protective wrapping from the gas logs.

9. Arrange the decorative gas logs on the burner according to

the instructions.

NOTICE: The Commonwealth of Massachusetts requires that the

chimney ue damper, when used with decorative gas log sets, be

welded open or completely removed.

Figure 8

Figure 9

6. Place remote receiver in the front right corner of rebox and

cover with lava rock as shown in Figure 9.

39246-0-0718Page 14

Page 15

DOOR OPERATION

CAUTION

Operate the replace with the bifold glass doors in

only the fully open position.

NOTE: Always close the mesh rescreens when operating

the replace with the glass doors fully open.

CORRECT DOOR POSITION WHEN

OPERATING THE FIREPLACE

FULLYOPEN DOORS

Figure 10

INCORRECT DOOR POSITION WHEN

OPERATING THE FIREPLACE

PARTIALLYOPEN DOORS.

WARNING

DO NOT operate the replace with the doors partially open or closed. Operating the replace with the

doors partially open or closed creates a hazardous

situation.

• Partially open doors can cause sooting on front

of the replace.

• Closed doors can cause the glass to overheat

and shatter.

Figure 11

39246-0-0718 Page 15

Page 16

HI / LOW LIGHTING INSTRUCTIONS

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING

If you do not follow these instructions exactly, a re or explosion may result causing property damage,

personal injury or loss of life.

A. This appliance has a pilot which must be lighted by hand.

When lighting the pilot, follow these instructions exactly.

B. BEFORE LIGHTING smell all around the appliance area

for gas. Be sure to smell next to the oor because some

gas is heavier than air and will settle on the oor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the re

department.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or

turn by hand, don't try to repair it; call a qualied service

technician. Force or attempted repair may result in a re

or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualied service technician to

inspect the appliance and to replace any part of the control

system and any gas control which has been under water.

LIGHTING INSTRUCTIONS

WARNING

• Any glass doors shall be opened when the appliance is in operation.

• A replace screen must be in place when the appliance is operating and the screen shall have an opening(s) for

introduction of combustion air.

1. STOP! Read the safety information or other side of plate.

2. Push in gas control knob slightly and turn clockwise

to "OFF". Do not force.

3. Turn gas ow adjustment knob clockwise either

manually or with remote control to "OFF".

4. Wait ten (10) minutes to clear out any gas. Then smell for

gas, including near oor. If you smell gas, STOP! follow "B"

in the safety information on other side. If you do not smell

gas, go to the next step.

5. Find pilot - the pilot is attached to the rear-right of the burner.

6. Turn gas control knob counterclockwise to "IGN".

7. Depress and turn gas control knob counterclockwise

to "PILOT". A spark is produced when gas

control knob is turned between "IGN" and "PILOT".

Repeatedly depress and turn gas control knob between

"IGN" and "PILOT" until pilot is ignited. Continue to hold

the control knob in for about one (1) minute after pilot is lit.

Release knob and it will pop back up. Pilot should remain

lit. If it goes out repeat steps 2 through 7.

• If knob does not pop up when released, stop and

immediately call your service technician or gas supplier.

• If the pilot will not stay lit after several tries, turn the

gas control knob to "OFF" and call your service.

TO TURN OFF GAS TO APPLIANCE

8. Attention! Gas control has an INTERLOCK latching device.

When the pilot is initially lit and the safety magnet is

energized (pilot stays on) the INTERLOCK latching device

becomes operative. If the gas control is turned to the "OFF"

position or gas ow to the appliance is shut off, the pilot

cannot be relighted until the safety magnet is de-energized

(approximately 60 seconds). There will be an audible "click"

when the safety magnet in the gas control is de-energized.

Pilot can now be relighted. Repeat step 2 through 7.

9. Turn gas control knob counterclockwise to "ON".

10. Turn gas ow adjustment knob counterclockwise

either manually or with remote control between

"OFF" and "ON" to adjust ame height.

1. Set the ON/OFF switch to "OFF".

2. Push in gas control knob slightly and turn clockwise

to "OFF". Do not force.

39246-0-0718Page 16

Page 17

PILOT AND MAIN BURNER FLAME CHARACTERISTICS

Pilot Flame Pattern

Figure 12 shows a correct pilot ame pattern. The correct ame

will be blue and will extend beyond the thermocouple/thermopile.

The ame will surround the thermocouple/thermopile just below

the tip. A slight yellow ame may occur where the pilot ame and

main burner ame meet.

After use, cleaning of the pilot burner may be required for the proper

ame. The pilot orice can be cleaned with high pressure air or

by placing under running water. Pilot orice must be dry before

replacement. Use canned air to clean inside the pilot after the pilot

orice has been removed.

To Remove Pilot Orice

1. Disconnect the pilot supply line at the pilot burner.

2. Remove pilot orice from pilot burner. It may be necessary to

tap on pilot burner in order to remove the pilot orice.

Pilot Flame Pattern

Figure 12

If pilot ame pattern is incorrect -

• See Troubleshooting, page 21.

Main Burner Flame Pattern

The main burner ame will be yellow with a blue base.

Main Burner Flame Ignition and Extinction

When the main burner is ignited it will take a few seconds for the

full ame pattern to develop.

When the main burner is extinguished it will take a few seconds for

the ames to disappear. It is normal to have the ames burn down

near the rock wool, as the remaining gas is burned.

39246-0-0718 Page 17

Page 18

HI / LOW (BFR) WIRING

NOTICE: Thermostats are not approved on vented decorative

appliances.

Label all wires prior to disconnection when servicing controls. Wiring

errors can cause improper and dangerous operation. Verify proper

operation after servicing.

The gas valve does not require 24 or 110 volts. See pages 19 - 21

for remote control instructions.

It is important to use wire of a proper gauge for the length of the wire:

RECOMMENDED WIRE GAUGES

Maximum Length Wire Gauge

1' to 10' 18

10' to 25' 16

25' to 35' 14

Remote Receiver

Use the following steps to place the remote receiver adjacent to

the gas valve.

Attention:

1. The remote receiver cannot be placed behind the gas valve and

burner assembly.

2. When facing the appliance, the remote receiver must be placed

in the right side rebox, toward the front.

Wiring Diagram

Figure 13

NOTICE: Do not let remote control receiver come in contact with

burner assembly.

Refer to remote control installation and operating instructions for

more details on remote control.

39246-0-0718Page 18

Page 19

REMOTE OPERATION

APPLICATION

GV34 is a servo motor operated valve with remote control

allowing for innite adjustment from low re to hire re.

GENERAL NOTES

Radio Frequency Remote

868 MHz for Europe; 915 MHz for U.S. (FCC ID:

UX5-R300) and for Canada (IC: 4943-R300).

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and

(2) This device must accept any interference received,

including interference that may cause undesired operation.

Changes or modications not expressly approved by the

party responsible for compliance could void the user's

authority to operate the equipment.

Batteries Remote Handset:

2 X 1.5V "AAA"

(quality alkaline

recommended)

Batteries Receiver:

4 X 1.5V "AA"

(quality alkaline

recommended).

Battery

Replacement

Battery

replacement is

recommended

at the beginning

of each heating

season. Do not

use metal tools to

remove batteries.

Using a metal tool

could cause a short

that may damage

the receiver.

Location Of

Receiver

See page 14.

STANDARD HANDSET FEATURES

AM

PM

°F

°C

Figure 14:

R300 Standard

Model, Patented

LCD Icon Features And Description

Sleep Mode Icon. After 8 hours of no

signal between the handset and the

receiver, valve runs to pilot and Sleep

Mode icon is displayed.

Ambient Temperature Display: Indicates

the current room temperature. °F or °C

Child Safety Lock: When ON (icon

showing), the right button must be pushed

twice within 0.5 seconds to increase the

ame height.

Battery Life Indicator: 4 bars indicates a

fully charged battery.

Clock Mode: Set to 12 or 24 hour clock.

Communication Indicator: Indicates the

handset is transmitting to the receiver.

INITIAL SETUP

SETTING THE ELECTRONIC CODE

Radio Frequency Remote

A code is selected automatically for all Mertik Maxitrol

electronics from among 65,000 random codes available.

On initial and subsequent receiver battery changes, the

receiver has to learn the code of the handset.

Figure 15:

R300 Standard

Model Icons

39246-0-0718 Page 19

• Power up Handset

• Power up Receiver (LED blinks).

• While blinking, press any button.

• When the Receiver LED stops blinking, the code is set.

NOTE: These remote handset and receiver are not

interchangeable with previous versions. For all lighting

instructions please refer to appliance manufacturer's

instructions.

Page 20

REMOTE OPERATION (CONT'D)

WARNING

Read through this entire warning before attempting

initial setup / programming.

A red number/icon indicates the icon is blinking. This

will help determine which menu item is being set or

programmed.

When programming a menu item, use the right (up)

button ONLY. Pressing the left (down) button will

cause the programming menu to skip to the next

menu item. If you accidentally skip to the next menu

item, you must cycle through all the menu items to

return to the item you were programming.

When adjusting a menu item, the number will scroll

up only (1, 2, 3...) and will cycle back to the beginning

number.

15 seconds of inactivity will cause the remote to

automatically go to operation mode. Follow Step 1.

INITIAL SETUP - PROGRAMMING MODE to return to

programming mode. Any changes will be saved each

time you exit programming mode.

INITIAL SETUP - PROGRAMMING MODE

INITIAL SETUP - PROGAMMING MODE (CONT'D)

SETTING THE MINUTES

:

SETTING CHILD SAFETY LOCK

This concludes your basic programming. The remote will

automatically save your changes and go to operation

mode after 15 seconds of inactivity.

STANDARD HANDSET OPERATION

FLAME HEIGHT ADJUSTMENT

4. Press

• Press (down) button to set

5. Set Child Safety Lock either ON or

• Press (up) button to set Child

Minutes. 00-59.

NOTE: Use right (up) button only.

Numbers scroll up (1, 2, 3...) to 59

then cycle back to 00.

and scroll to the next menu item.

OFF.

Safety Lock ON (icon showing) or

OFF.

(up) button to set

• Press

• Press (down) to scroll through menu items.

• Press (up) to adjust menu items.

SETTING °F OR °C

SETTING 12 HOUR OR 24 HOUR MODE

SETTING THE HOUR

(until screen blinks) to enter Programming Mode.

(both buttons) and hold for 5 seconds

1. Press (up) button to choose

either °F or °C.

• Press (down) button to set

and scroll to the next menu item.

2. Press (up) button to choose

either “12” or “24”.

• Press (down) button to set

and scroll to the next menu item.

3. Press (up) button to set the

AM

Hour, 1-12 or 0-23.

NOTE: Use the (up) button only.

Numbers scroll up (1, 2, 3,...) to 12

or 23 then cycle back to 1 or 0.

• Press (down) button to set

and scroll to the next menu item.

PAGE 3

• To turn the main burner ON or to increase the ame

height, press the (up) button.

• To decrease the ame height, press the (down)

button or turn main burner OFF.

39246-0-0718Page 20

Page 21

REMOTE OPERATION (CONT'D)

SLEEP MODE

After 8 hours of no signal between the handset and the

receiver valve runs to pilot and the Sleep Mode icon is

displayed.

TURN OFF GAS TO APPLIANCE

Access the gas control.

Turn the main valve knob clockwise to the PILOT

position. Push in knob; turn and release. Continue turning

to the OFF full clockwise position.

Replace appliance accessibility cover (if applicable).

MANUAL VALVE OPERATION

1. STOP! Read the safety information included before

proceeding.

2. Turn main valve knob to the OFF full clockwise

position.

3. Turn the MANUAL knob to the full clockwise

position.

4. Wait ve (5) minutes to clear out any gas. Verify that

no gas is in the area around the appliance, including

near the oor. If you detect gas STOP! Follow

Warnings (see pg. 16) under “What to do if you

smell gas”. If no gas is present, proceed to step 5.

5. Turn main valve knob slightly counterclockwise

towards the IGN position unitl it stops, then

press down and continue turning counterclockwise

to the pilot position. Continue to hold down

knob for 10 seconds after pilot burner has been lit. If

pilot does light, steps 1 and 2 may be repeated.

NOTE: If the pilot does not stay lit after several tries,

turn main valve knob to the PILOT position. Push in

knob; turn and release. Continue turning to the OFF

full clockwise position and proceed to step 7.

6. Upon lighting, release knob and turn main valve knob

fully counterclockwise to ON position.

7. If the appliance will not operate, follow the

instructions “Turn Off Gas to Appliance”.

MANUAL FLAME HEIGHT OPERATION

The motorized valve is equipped with a slip clutch allowing

manual adjustment of the main burner by turning the

manual knob. When turning the manual knob, do not force.

STANDBY PROCEDURE

Turn main valve knob clockwise to Pilot position,

allowing only pilot gas to ow.

39246-0-0718 Page 21

Page 22

MAINTENANCE AND SERVICE

Maintenance

The Decorative Gas Log Set should be thoroughly inspected at

least once a year by a qualied technician.

At the beginning of each season, check for:

• Chimney ue or vent pipe is drawing properly, and that vent

pipe connections are tight.

• Blockages at the chimney or vent termination.

• Creosote and soot build-up in chimney and/or vents (clean if

necessary).

• Inspect the pilot and burners.

• Remove dust, cobwebs, pet hair or other debris from the

replace.

• Check for gas leaks. See page 11.

The burner system has been adjusted for proper operation at the

factory. No adjustment is necessary, other than altitude de-rate or

pilot ame.

WARNING

NEVER enlarge valve orices or burner ports.

Sooting

Some sooting of your log set is normal, adding to the appearance

of burned wood. If excessive sooting accumulates, clean the logs

using either of the following options::

A.

When the logs are cold, remove logs from burner, brush the

soot off with a brush. Do not use water or soot cleaners.

B. When the logs are cold, remove logs from burner. Take

logs outside and remove soot with an air hose. Refer to

Installation Instructions supplied with logs for re-installation information.

Cleaning

Keep the control area, logs and burner area surrounding the logs clean.

THE LOGS CAN GET VERY HOT— HANDLE ONLY WHEN COOL.

Always keep the appliance area clear and free from combustible

materials, gasoline, and other ammable vapors and liquids.

Never obstruct the ow of combustion and ventilation air. Keep the

front of the appliance clear of all obstacles and materials.

Inspecting Venting System

A vented replace venting system is designed and constructed

to develop a positive ow adequate to remove ue gases to the

outside atmosphere.

Any foreign objects in the venting system, may cause ue gases

to ow into the room.

Periodic examination and/or cleaning of the venting system of the

solid-fuel burning replace must be done by a qualied service

person. Visually inspect the damper and ue area for excessive

soot build-up. This soot (carbon) may be removed by brushing with

a soft bristle brush.

39246-0-0718Page 22

Page 23

TROUBLESHOOTING

PROBLEM OBSERVED POSSIBLE CAUSE CORRECTIVE MEASURE

Gas odor during setup Gas Leak

Gas odor before rst ignition Gas Leak

No gas to pilot Make sure gas is on, in pilot position

Thermocouple not hot Depress valve knob for at least 1 minute

Pilot will not ignite, or will not

stay lit

Delayed ignition

Burner does not light but pilot

remains on

Burner lights but does not

stay lit while pilot remains on

Burner & pilot light but will not

stay on

Incorrect burner ame

Backre of burner

Appliance produces unwanted

odors

Logs appear to smoke

Whistle noise from appliance

Improper pilot ame adjustment See Pilot Characteristics - adjust ame

Loose connections on the thermocouple Check gas connections

Faulty pilot or thermocouple Replace Safety Pilot

Faulty valve Replace Valve

Low gas pressure Check gas supply pressure

Clogged or dirty burner ports Clean burner ports

Blocked orice Check orice opening

Faulty valve Replace valve

Low gas pressure Check gas supply pressure

Clogged or dirty burner ports Clean burner ports

Blocked orice Check orice opening

Faulty pilot or thermocouple Replace safety pilot

Faulty valve Replace valve

Low gas pressure Check gas supply pressure

Faulty valve Replace valve

Faulty pilot or thermocouple Replace Safety pilot

Clogged or dirty burner ports Clean burner ports

Low gas pressure Check gas supply pressure

Not enough fresh air for pilot Open door or window - ventilate

Faulty valve Replace valve

Faulty pilot or thermocouple Replace safety pilot

Clogged or dirty burner ports Clean burner ports

Remote control overheating Move away from ame

Remote control batteries failing Replace batteries

Incorrect gas supply or pressure Check gas supply pressure

Blocked orice Check orice opening

Clogged or dirty burner ports Clean burner ports

Faulty valve Replace valve

High altitude Adjust orice size for altitude

Blocked orice Check orice opening

Clogged or dirty burner ports Clean burner ports

Low gas pressure Check gas supply pressure

Vapors from paint, hair spray, glues, etc. Ventilate room

Initial burn-off of manufacturing chemicals Ventilate room

Vapors from manufacturing chemicals Ventilate room

Logs curing See “Curing of Refractory Logs”

Air in gas line Bleed lines

Control knob not in fully open position Open control knob to full position

Spiral gas ex line Replace gas feed line

What To Do If You Smell Gas

• Do not try to light any appliance. • Do not touch any

electrical switch; do not use any phone in your building. •

Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions. • If you cannot reach

your gas supplier, call the re department.

39246-0-0718 Page 23

Page 24

BFR PARTS LIST AND EXPLODED VIEW

WARNING

Failure to position the parts in accordance with these

diagrams or failure to use only parts specically

approved with this appliance may result in property

damage or personal injury.

INDEX NO. PART NO. DESCRIPTION USED ON

1 11788 Decorative Rock BFR2124 BFR30

2 15496 Rock Wool, .75 oz BFR2124 BFR30

3 38633 Valve Bracket, Hi/Low BFR2124 BFR30

4

5 P253 Fitting, Orice, 90° Angle BFR2124 BFR30

6

7 R12602 Valve, NAT Maxitrol GV34 BFR2124 BFR30

8 R11977 Venturi Gasket BFR2124 BFR30

9 R11978 Venturi BFR2124 BFR30

10 R12052 Pilot w/ Thermopile - NG BFR2124 BFR30

11 R12059 Nipple, 3/8 X 3/8 X 1 Black Iron BFR2124 BFR30

12 R12217

13 R12219

14

15 R6207 Elbow 5/16 X 3/8 90 BFR2124 BFR30

16 39028 Electrode Bracket BFR2124 BFR30

17 R2809 Damper Clamp BFR2124 BFR30

18 R1155 Electrode BFR2124 BFR30

19 R7624 Air Shutter BFR2124 BFR30

20 R12635 Remote And Receiver BFR2124 BFR30

21

NS

38340 Tube Assembly, 2124 BFR2124

38665 Tube Assembly, 30 BFR30

P273 Orice, #22 BFR2124

P325 Orice, #12 BFR30

Fitting, 1/2 Flare X 3/8 NPT Internal Threads

Flex Line, Non-Whistling 16 Inch X 1/2 Flare

R12624 Grate Weldment, 24 BFR2124

R12625 Grate Weldment, 30 BFR30

39114 Burner Assembly BFR2124

39115 Burner Assembly BFR30

38898 Fiber Heat Sink BFR2124

38899 Fiber Heat Sink BFR30

BFR2124 BFR30

BFR2124 BFR30

39246-0-0718Page 24

Page 25

MASTER PARTS DISTRIBUTOR LIST

To Order Parts Under Warranty, please contact your local Empire dealer. See the dealer locator at www.empirecomfort.com. To provide warranty service, your dealer will need your name and address, purchase date and serial number, and the nature of the problem with the unit.

To Order Parts After the Warranty Period, please contact your dealer or one of the Master Parts Distributors listed below. This list changes

from time to time. For the current list, please click on the Master Parts button at www.empirecomfort.com.

Please note: Master Parts Distributors are independent businesses that stock the most commonly ordered Original Equipment repair

parts for Heaters, Grills, and Fireplaces manufactured by Empire Comfort Systems Inc.

Dey Distributing

1401 Willow Lake Boulevard

Vadnais Heights, MN 55101

Phone: 651-490-9191

Toll Free: 800-397-1339

Website: www.deydistributing.com

Parts: Heater, Hearth and Grills

East Coast Energy Products

10 East Route 36

West Long Branch, NJ 07764

Phone: 732-870-8809

Toll Free: 800-755-8809

Fax: 732-870-8811

Website: www.eastcoastenergy.com

Parts: Heater, Hearth and Grills

HOW TO ORDER REPAIR PARTS

F. W. Webb Company

200 Locust Street

Hartford, CT 06114

Phone: 860-722-2433

Toll Free: 800-243-9360

Fax: 860-293-0479

Toll Free Fax: 800-274-2004

Websites: www.fwwebb.com & www.victormfg.com

Parts: Heater, Hearth and Grills

Parts Not Under Warranty

Parts can be ordered through your Service Person, Dealer, or a Master Parts Distributor. See this page for the Master Parts Distributors list. For best results, the service person or dealer should order parts through the distributor. Parts can be shipped directly to the

service person/dealer.

Warranty Parts

Warranty parts will need a proof of purchase and can be ordered by your Service Person or Dealer. Proof of purchase is required for

warranty parts.

All parts listed in the Parts List have a Part Number. When ordering parts, rst obtain the Model Number and Serial Number from the

name plate on your equipment. Then determine the Part Number (not the Index Number) and the Description of each part from the

following illustration and part list. Be sure to give all this information . . .

Appliance Model Number Part Description

Appliance Serial Number Part Number

Type of Gas (Propane or Natural)

Do not order bolts, screws, washers or nuts. They are standard hardware items and can be purchased at any local hardware store.

Shipments contingent upon strikes, res and all causes beyond our control.

39246-0-0718 Page 25

Page 26

WARRANTY

Empire Comfort Systems Inc. warranties this hearth product to be free from defects at the time of purchase and for the periods specied

below. Hearth products must be installed by a qualied technician and must be maintained and operated safely, in accordance with the

instructions in the owner’s manual. This warranty applies to the original purchaser only and is not transferable. All warranty repairs must

be accomplished by a qualied gas appliance technician.

Limited Lifetime – Refractory Logs

Should any part fail because of defective workmanship or material during the normal life of this product, Empire will repair or

replace at Empire’s option.

Limited Five-Year Parts Warranty – Burners, Grates, Ceramic Fiber Logs

Should any part fail because of defective workmanship or material within ve years from the date of purchase, Empire will repair

or replace at Empire’s option.

Limited Two-Year Parts Warranty – Valves

Should the valve fail because of defective workmanship or material within two years from the date of purchase, Empire will repair

or replace at Empire’s option.

Limited One-Year Parts Warranty – Remote Controls, Accessories, and Parts

Should any remote control, thermostat, accessory, or other part fail because of defective workmanship within one year from

the date of purchase, Empire will repair or replace at Empire’s option.

Duties of the Owner

The appliance must be installed by a qualied installer and operated in accordance with the instructions furnished with the

appliance. A bill of sale, cancelled check, or payment record should be kept to verify purchase date and establish warranty

period. Ready access to the appliance for service.

What Is Not Covered

Damages that might result from the use, misuse, or improper installation of this appliance.

Travel, diagnostic costs and freight charges on warranted parts to and from the factory.

Claims that do not involve defective workmanship or materials.

Unauthorized service or parts replacements.

Removal and reinstallation cost.

Inoperable due to improper or lack of maintenance.

How To Get Service

To make a claim under this warranty, please have your receipt available and contact your installing dealer. Provide the dealer

with the model number, serial number, type of gas, and purchase verication. The installing dealer is responsible for providing

service and will contact the factory to initiate any warranted parts replacements. Empire will make replacement parts available

at the factory. Shipping expenses are not covered.

If, after contacting your Empire dealer, service received has not been satisfactory, contact: Consumer Relations Department,

Empire Comfort Systems Inc., PO Box 529, Belleville, Illinois 62222, or send an e-mail to info@empirecomfort.com with

“Consumer Relations” in the subject line.

Your Rights Under State Law

This warranty gives you specic legal rights, and you may also have other rights, which vary from state to state.

39246-0-0718Page 26

Page 27

APPLIANCE SERVICE HISTORY

Date Dealer Name Service Technician Name Service Performed/Notes

39246-0-0718 Page 27

Page 28

Empire Comfort Systems Inc.

Belleville, IL

If you have a general question

about our products, please e-mail

us at info@empirecomfort.com.

If you have a service or repair

question, please contact your dealer.

www.empirecomfort.com

39246-0-0718Page 28

Loading...

Loading...