Empire Pro-Finish 2636, Pro-Finish 6060, Pro-Finish 3648, Pro-Finish 60120, Pro-Finish 7272 Operating Instructions Manual

...Page 1

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

Operating Instructions

for the

Pro-Finish® Cabinet System

Pressure and Suction

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • •

2101 West Cabot Boulevard

Langhorne, PA 19047-1893

www.empire-airblast.com

Page 2

Empire Abrasive Equipment Company

Model Number: _______________________ Serial Number: ____________________________

Date of Purchase: ____________________ Date of Installation: _______________________

Distributor Purchased From:

Name: __________________________________________________________

Address: ________________________________________________________

Phone: _________________________________________________________

* * * * *

Manufactured by: EMPIRE ABRASIVE EQUIPMENT COMPANY

2101 West Cabot Boulevard

Langhorne, PA 19047-1893

Phone: 215-752-8800, Fax: 215-752-9373

Empire equipment should be properly maintained per the operating instructions. For

peak performance of your equipment, use only genuine Empire replacement parts;

accept no substitutes! The use of non-Empire parts will void the warranty.

PARTS AND SERVICE

1-800-497-4543

To order Empire replacement parts, contact your local authorized Empire distributor.

For the name of your local distributor, call Empire Customer Service, 1-800-497-4543,

or fax us at 215-752-9373, or e-mail us on our website www.empire-airblast.com and

we will call you back.

Never use silica-based abrasives

in Empire blast systems.

CAUTION

Page 2

Page 3

Empire Abrasive Equipment Company

Operating Instructions

for the

Pro-Finish® Cabinet System

Suction and Pressure

Empire Abrasive Equipment Company

3/24/08

Page 3

Page 4

Empire Abrasive Equipment Company

Table of Contents

Table of Contents ................................................................................................4

Introduction........................................................................................................5

1.0 Preparing for Installation ..............................................................................6

1.1 Hand Tools Required ........................................................................................ 6

1.2 Step-by-Step Procedure .................................................................................... 6

2.0 Installation .................................................................................................10

2.1 Installing the Optional Dust Collector ............................................................. 10

2.2 Installing the System...................................................................................... 11

2.3 Electrical Connections.................................................................................... 11

2.4 Installing the Compressed Air Supply ............................................................. 12

3.0 General Equipment Operation .....................................................................13

3.1 Media Selection and Use................................................................................. 13

3.2 Media Loading................................................................................................ 15

3.3 Pneumatic Controls........................................................................................ 15

3.4 Equipment Start-up ....................................................................................... 18

3.5 Equipment Shut-down ................................................................................... 19

3.6 Equipment Adjustments................................................................................. 20

3.7 Helpful Hints for More Efficient Blasting ......................................................... 23

4.0 Maintenance ...............................................................................................24

4.1 Daily Maintenance.......................................................................................... 24

4.2 Weekly Maintenance....................................................................................... 27

4.3 Storage or Temporary Non-Use ....................................................................... 28

5.0 Troubleshooting ..........................................................................................29

5.1 Troubleshooting Chart.................................................................................... 29

5.2 Troubleshooting the Pneumatic Control Circuit............................................... 32

6.0 Recommended Spare Parts ..........................................................................36

7.0 Options and Accessories..............................................................................37

®

8.0 Pro-Finish

8.1 Reclaimers ..................................................................................................... 39

8.2 Pressure Blast Systems .................................................................................. 40

8.3 Suction Blast Systems.................................................................................... 42

8.4 Dust Collectors............................................................................................... 44

8.5 Blowers (Fan & Motor) .................................................................................... 47

8.6 Ducting/Hoses ............................................................................................... 48

8.7 Pipe Strings.................................................................................................... 50

8.8 Pressure Blast Systems .................................................................................. 51

8.9 Basic Cabinet Assembly ................................................................................. 55

9.0 Warranty .....................................................................................................57

Parts .........................................................................................39

Page 4

Page 5

Empire Abrasive Equipment Company

Introduction

®

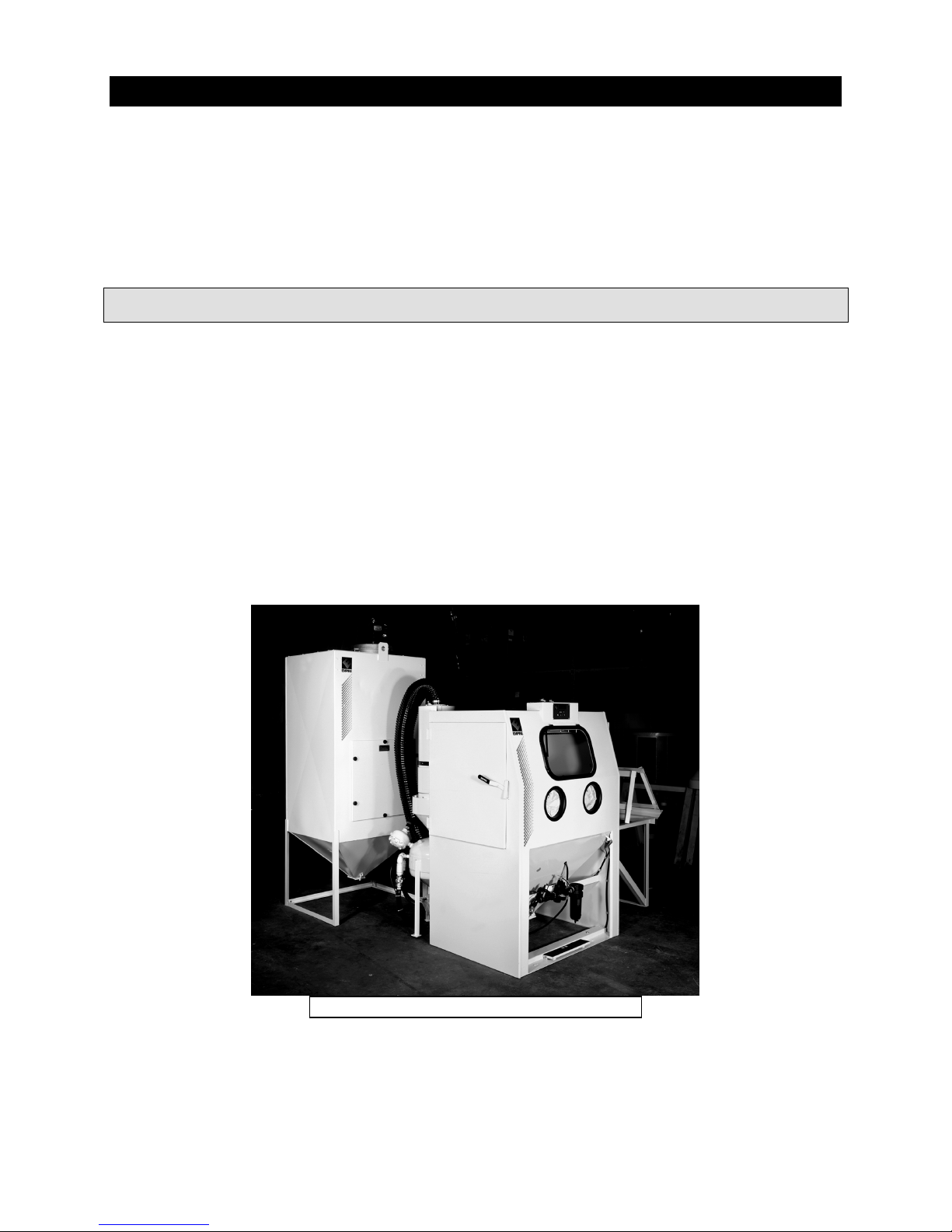

Congratulations on your selection of the Pro-Finish

Cabinet System from Empire

Abrasive Equipment Company. This manual is provided to assist you with the

®

unpacking, assembly, use, and maintenance of your Pro-Finish

Cabinet System.

Please read this manual carefully and keep it in the handy plastic pouch attached to

your system for future reference. If you have any questions about the operation or

maintenance of your equipment, contact your Empire distributor.

Empire: The leader in air-blast technology.

Empire specializes in the design and manufacture of air-blast equipment, and has

continued as an industry leader of more than 50 years. Today, Empire produces the

®

most extensive line of air-blast products in the world. In addition to Pro-Finish

systems, our product line includes ProFormer Cabinets, ECON-O-FINISH™ Cabinets,

Modified Systems, Automated Blast Systems, Blast Rooms, and SuperBlast™ Portable

Blasters.

Empire Abrasive Equipment Company’s reputation as a leader in air-blast technology

is the result of meeting our customer’s demand for quality equipment and systems

that deliver increased productivity. We support our equipment with training, service,

and testing programs. When you need advice, assistance, or equipment on short

notice, our national network of distributors assures that help is nearby.

Figure 1. Pro-Finish

Page 5

®

Cabinet System

Page 6

Empire Abrasive Equipment Company

1.0 Preparing for Installation

1.1 Hand Tools Required

The following tools are recommended for the installation of your Pro-Finish

system:

• 7/16” wrench or socket

• 6” adjustable wrench

• 9/16” wrench or socket

• medium flat-blade screwdriver

• 14” Pipe wrenches

• medium Phillips head screwdriver

• Channel Lock Pliers

1.2 Step-by-Step Procedure

Step 1: Unwrap and remove cabinet

and the components from the pallet.

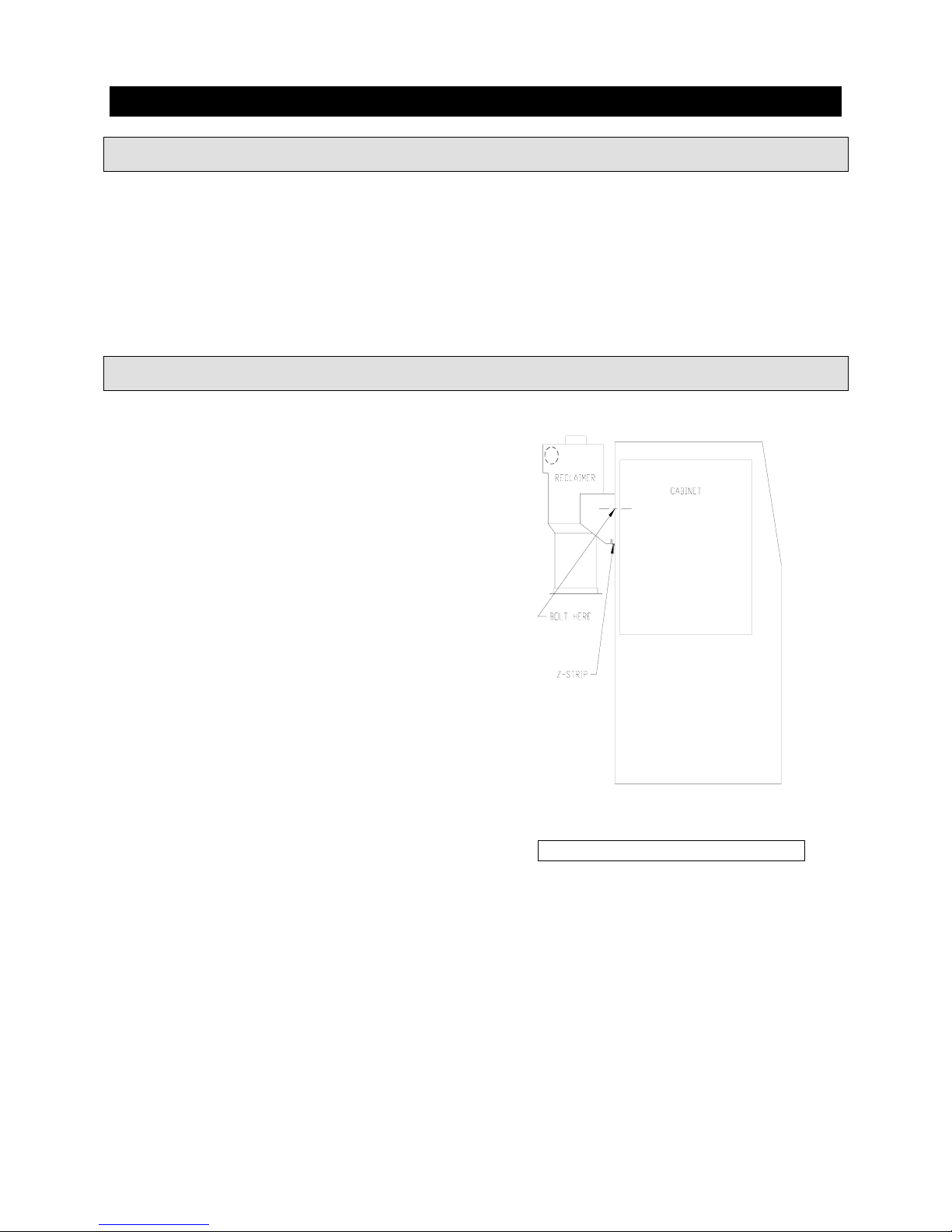

Step 2: Most cabinet systems are

shipped with the reclaimer mounted to

the cabinet. If your system was

shipped with the reclaimer NOT

installed, install the reclaimer as

follows:

a. Lift the reclaimer assembly and

set in place against the rear of

the cabinet so that the slots in

the reclaimer bracket set down

on the “Z-strip”.

b. Push the reclaimer assembly up

against the rear of the cabinet so

that the mounting bolts

protruding from the rear wall of

the cabinet are inserted into the

keyhole slots in the bracket. See

Figure 2.

Step 3: With the reclaimer in position,

tighten the bolts.

Figure 2. Reclaimer Mounting

Step 4: Attach one end of the conveying

hose to the cabinet hose adapter.

Attach the other end of the hose to the

reclaimer inlet. See Figure 3. Use

supplied hose clamp to make

connections airtight.

®

Cabinet

Page 6

Page 7

Figure 3. Conveying Hose

Installation or Assembly

Steps 5 through 12 apply to pressure

systems only. (Suction systems are

not equipped with a pressure vessel.)

Step 5: Move the pressure vessel into

position as shown in Figure 4.

Figure 4. Pressure Vessel Installation

Step 6: Adjust the leveling bolts on the

pressure vessel legs so that the weight

of the assembly is evenly distributed on

the floor and the hopper flange mates

with the pressure vessel.

Step 7: Install and tighten the six bolts

connecting the storage hopper flange to

the top of the pressure vessel.

Step 8: Connect the quick coupling

ends of the air hose / tubing harness

and to the 1” pipe string on the front of

the cabinet and on the vessel. See

Figure 5.

Figure 5. Air Hose Assembly to Pipe

String Assembly

Step 9: Install the safety pin through

the holes in both halves of each quick

coupling. See Figure 5.

Step 10: Connect the harness ¼” O.D.

control tubing to the exhaust valve and

air valve fittings as shown in Figure 5.

Making sure the connection is tight.

Step 11: Connect the 1” exhaust hose

from the MG-78 exhaust valve to the

hose barb located at the reclaimer inlet.

Step 12: Connect the blast hose quick

coupling as shown in Figure 6 to the

tank coupling below the Sure-Flo Media

Regulator. Install the safety pin.

Page 8

WARNING

Be sure to insert the safety pins into

the two halves of each quick

coupling to lock them together.

Figure 6. Hose/Coupling Connection

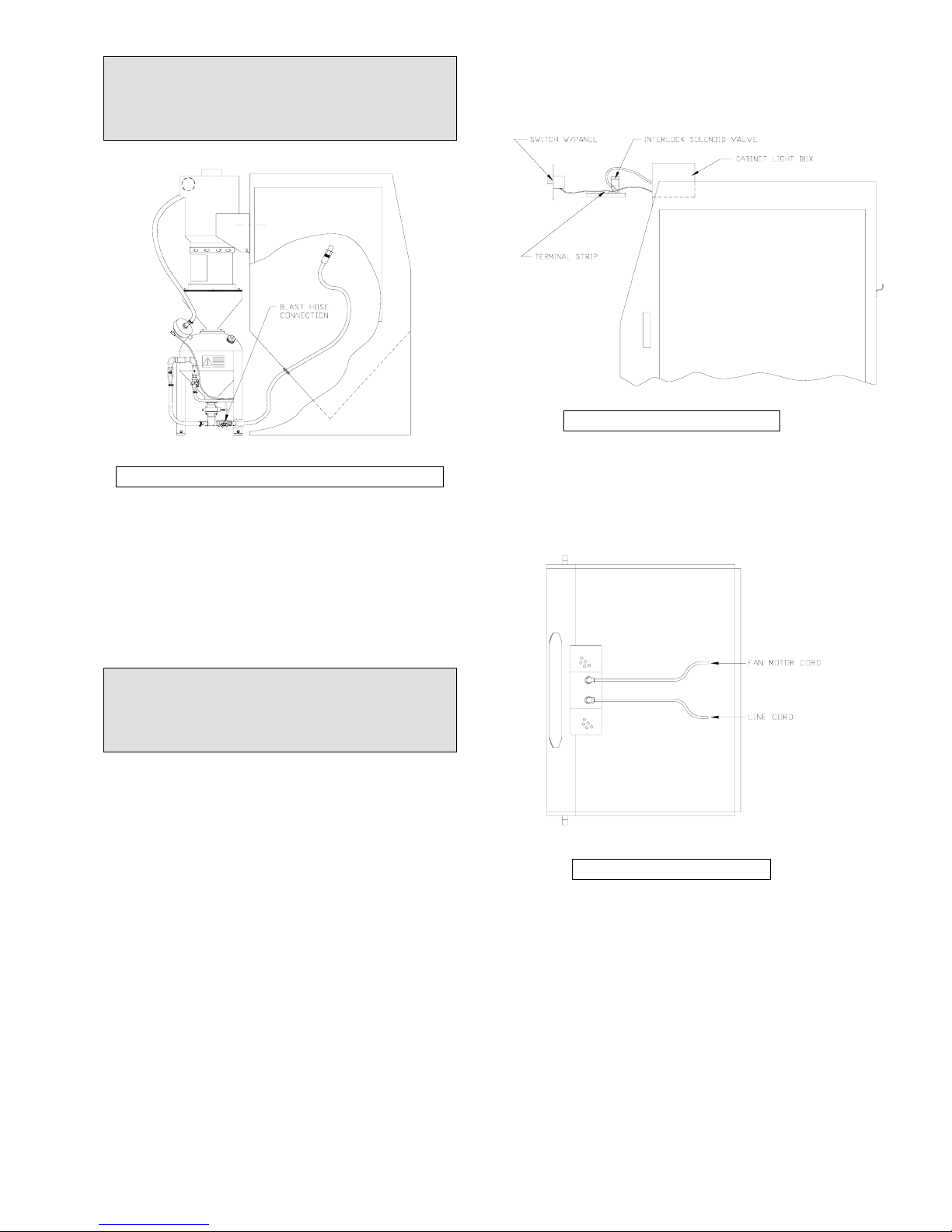

Steps 13 and 18 apply to singlephase systems only.

If your system includes a dust collector,

make the electrical connection between

the fan motor and the cabinet electrical

control box as follows:

WARNING

Be sure that the cabinet supply cord

is disconnected before you start this

procedure.

Step 13: Remove the four screws from

the corners of the control box cover.

Step 14: Slide out the terminal strip

plate as shown in Figure 7.

Figure 7. Terminal Strip

Step 15: Insert the free end of the fan

motor cord into the strain relief on the

top of the electrical box, as shown in

Figure 8.

Figure 8. Strain Relief

Step 16: Pull about 16 inches of cord

into the electrical box.

Page 9

Step 17: Notice that the fan motor cord

wires are numbered. Connect each

wire to the terminal of the same

number.

Step 18: Replace the terminal strip

plate and control box cover. Tighten the

strain relief where the connecting cord

enters the control box.

The single phase electrical schematics

shown in Figure 9 and Figure 10 also

appear on the back of the control box

cover.

Consult the schematic that applies to

the specific type of electrical power that

will be supplied to the cabinet. Your

power supply must match the label

power supply of the cabinet and dust

collector fan motor.

Figure 9 and Figure 10.

Page 10

Empire Abrasive Equipment Company

Step 19: If your system has a fan and

dust bag, fasten the dust bag to the fan

outlet and secure with the clamp

provided.

Step 20: Install the dust hose between

the reclaimer outlet and the dust

Step 21: Secure the hose ends with the

clamps provided.

Step 22: Connect your system to

utilities as described in the Installation

section following.

collector inlet.

2.0 Installation

®

Your Pro-Finish

packages. All equipment must be well grounded and mounted on a level surface. DO

NOT install your Pro-Finish

to wet conditions.

All electrical connections to the Pro-Finish® cabinet should be made by a

qualified electrician and must adhere to the codes, standards, and procedures

specified by the authority having jurisdiction.

The customer is responsible for providing appropriate disconnecting means

adjacent to the equipment for each incoming power circuit.

system may arrive fully assembled or in easily assembled modular

®

system on a wooden floor, a rubber mat, or a floor subject

IMPORTANT

2.1 Installing the Optional Dust Collector

If your system includes a dust collector,

you should install it before your install

the cabinet, because in many

instances, the dust collector is located

behind the cabinet. Install the dust

collector as follows:

Step 1: Place the dust collector on a

level surface behind or adjacent to your

®

Pro-Finish

Cabinet location.

Step 2: Be sure the access door and

pneumatic shaker control on the dust

collector are easily accessible and the

dust hose inlet is directed toward the

cabinet.

Step 3: Allow enough space for the

cabinet doors to open freely. Also allow

enough room to remove the dust from

the dust collector hopper.

Step 4: Stabilize the dust collector by

adjusting its leveling bolts to

compensate for any unevenness in the

supporting floor.

Step 5: A separate ¼” air line is

supplied for the dust collector shaker

mechanism. Attach the free end of this

air line to the dust collector compressed

air inlet connection.

Page 10

Page 11

Empire Abrasive Equipment Company

2.2 Installing the System

Step 1: Place the cabinet on a level

surface. Ensure that there is enough

space around the system for easy

access to components. There should be

enough space for work pieces to be

easily loaded and unloaded through the

cabinet doors.

2.3 Electrical Connections

The standard power supply for the 400

CFM (1 HP) systems is 115-volts/60

cycle/single phase. The standard

electrical supply for 600 CFM (1 ½ HP)

and 900 CFM (2 HP) systems is 230volts/60cycle/single phase. Cabinets

are also available prewired for the

optional power supplies listed in Section

7.0 Options and Accessories. Standard

single-phase systems are supplied with

a line cord (except for systems delivered

to Canada).

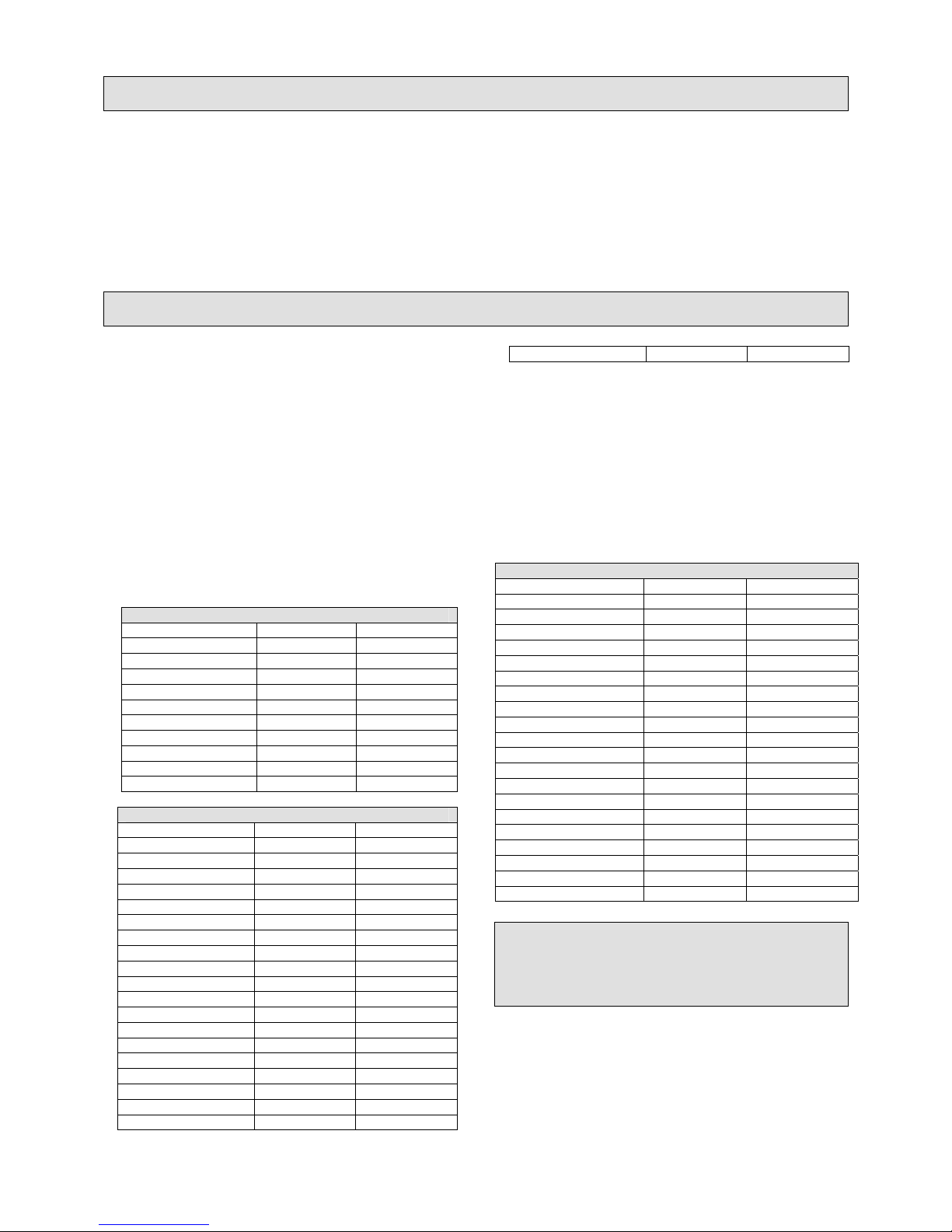

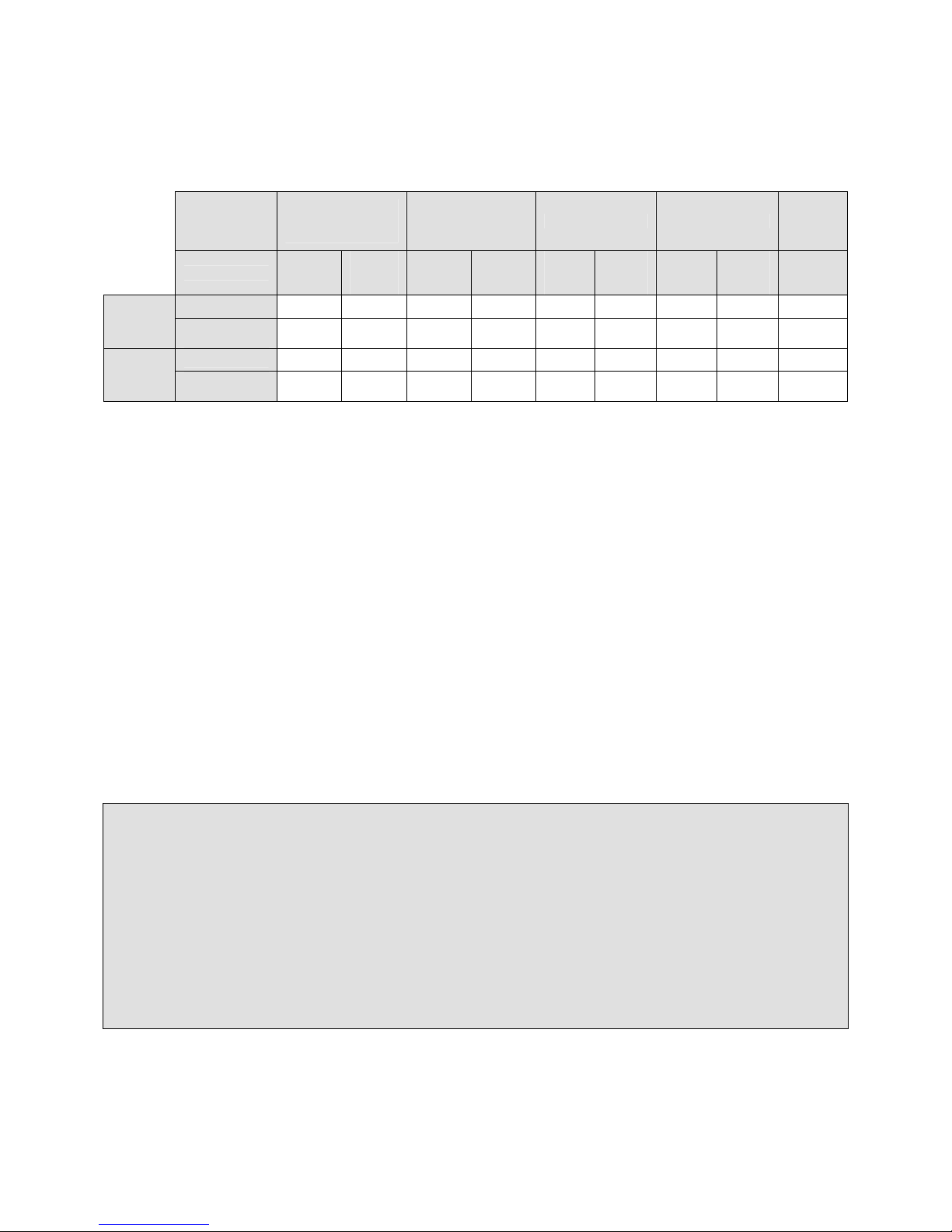

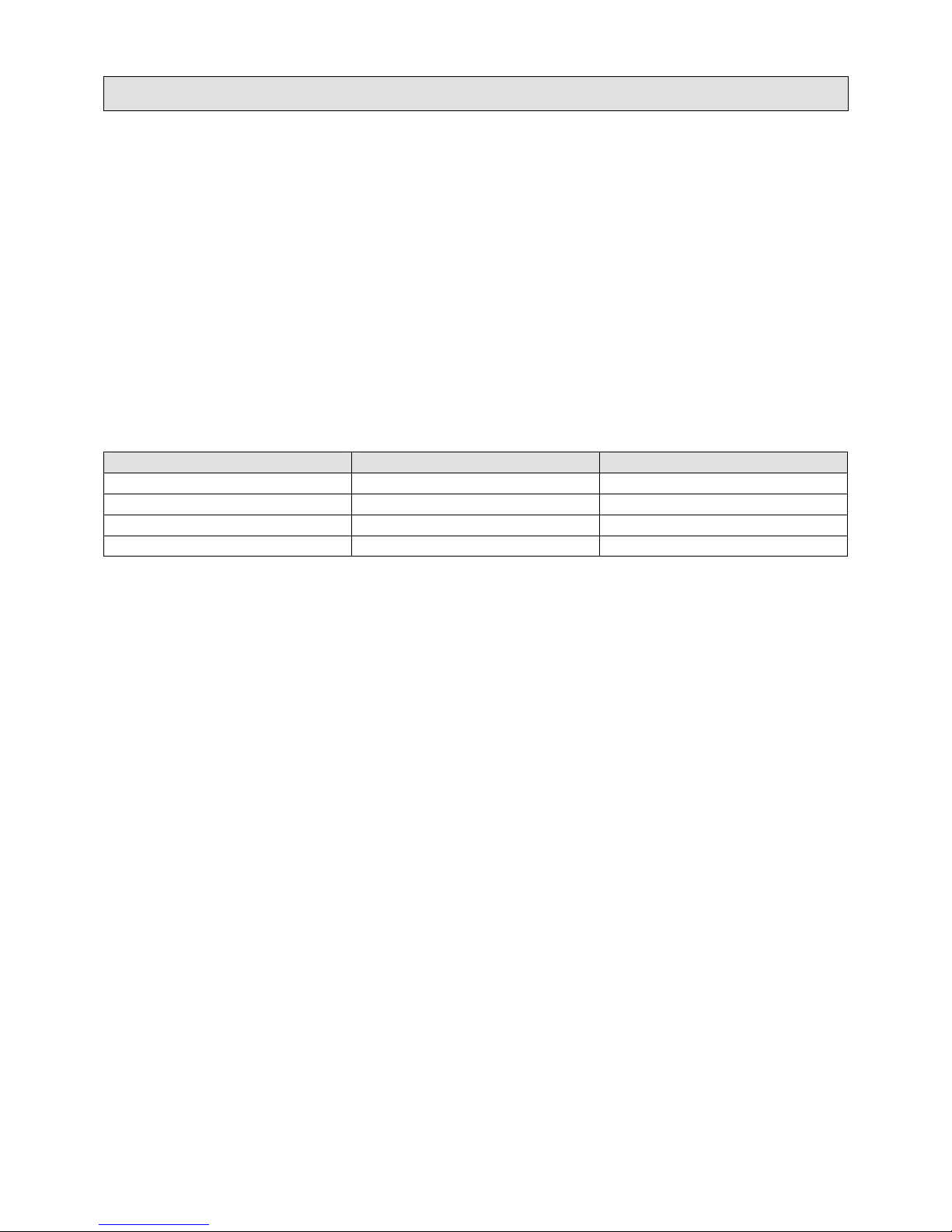

SINGLE-PHASE SINGLE SOURCE

SOURCE MOTOR CURRENT

% 110-120V/60HZ 1 HP 19.0 A

220-240V/60HZ 1 HP 11.0 A

110-120V/50HZ 1 HP 22.2 A

220-240V/50HZ 1 HP 12.6 A

110-120V/60HZ 1 ½ HP 23.0 A

# 220-240V/60HZ 1 ½ HP 13.0 A

220-240V/50HZ 1 ½ HP 15.0 A

110-120V/60HZ 2 HP 27.0 A

@ 220-240V/60HZ 2 HP 15.0 A

220-240V/50HZ 2 HP 17.4 A

SOURCE MOTOR CURRENT

208V/60HZ 1 HP 7.2 A

220-240V/60HZ 1 HP 6.3 A

440-480V/60HZ 1 HP 3.1 A

550-600V/60HZ 1 HP 2.5 A

380/50HZ 1 HP 3.0 A

208V/60HZ 1 ½ HP 9.3 A

220-240V/60HZ 1 ½ HP 8.1 A

440-480V/60HZ 1 ½ HP 4.0 A

550-600V/60HZ 1 ½ HP 3.2 A

380V/50HZ 1 ½ HP 3.9 A

208V/60HZ 2 HP 10.2 A

220-240V/60HZ 2 HP 8.9 A

440-480V/60HZ 2 HP 4.4 A

550-600V/60HZ 2 HP 3.5 A

380V/50HZ 2 HP 4.7 A

208V/60HZ 5 HP 19.9 A

+ 220-240V/60HZ 5 HP 17.3 A

440-480V/60HZ 5 HP 8.6 A

550-600V/60HZ 5 HP 3.9 A

THREE-PHASE SINGLE SOURCE

Step 2: Stabilize the cabinet by

adjusting its leveling bolts to

compensate for any unevenness in the

supporting floor.

380V/50HZ 5 HP 9.5 A

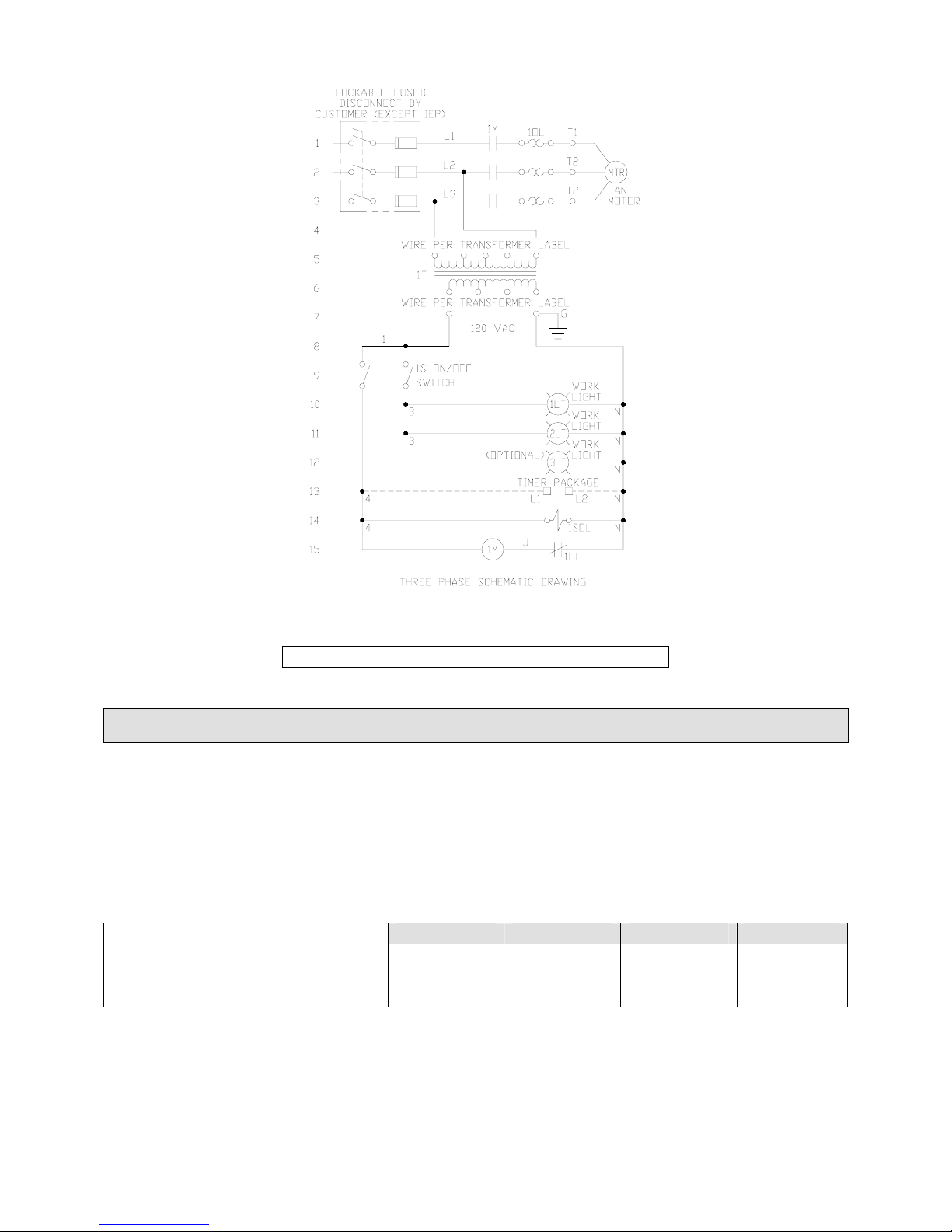

If your system is designed for threephase power, make the electrical

connections as shown in Figure 11.

For both single-phase and three-phase

systems, cabinets equipped with any of

the standard electrical supplies require

a minimum 20 AMP service and

minimum 12 gauge copper wire.

THREE-PHASE DUAL SOURCE

SOURCE MOTOR CURRENT

208V/60HZ 1 HP 4.8 A

220-240V/60HZ 1 HP 4.2 A

440-480V/60HZ 1 HP 2.1 A

550-600V/60HZ 1 HP 1.7 A

380/50HZ 1 HP 1.7 A

208V/60HZ 1 ½ HP 6.9 A

220-240V/60HZ 1 ½ HP 6.0 A

440-480V/60HZ 1 ½ HP 3.0 A

550-600V/60HZ 1 ½ HP 2.4 A

380V/50HZ 1 ½ HP 2.6 A

208V/60HZ 2 HP 7.8 A

220-240V/60HZ 2 HP 6.8 A

440-480V/60HZ 2 HP 3.4 A

550-600V/60HZ 2 HP 2.7 A

380V/50HZ 2 HP 3.4 A

208V/60HZ 5 HP 17.5 A

220-240V/60HZ 5 HP 15.2 A

440-480V/60HZ 5 HP 7.6 A

550-600V/60HZ 5 HP 6.1 A

380V/50HZ 5 HP 8.2 A

NOTE

The approximate single-phase

current draw for all dual source

systems is 3 amps at 110-120 VAC.

% = 400 CFM (-4)

# = 600 CFM (-6)

@ = 900 CFM (-9)

+ = 1200 CFM (-12)

Page 11

Page 12

Empire Abrasive Equipment Company

Figure 11. Three-Phase Schematic Diagram

2.4 Installing the Compressed Air Supply

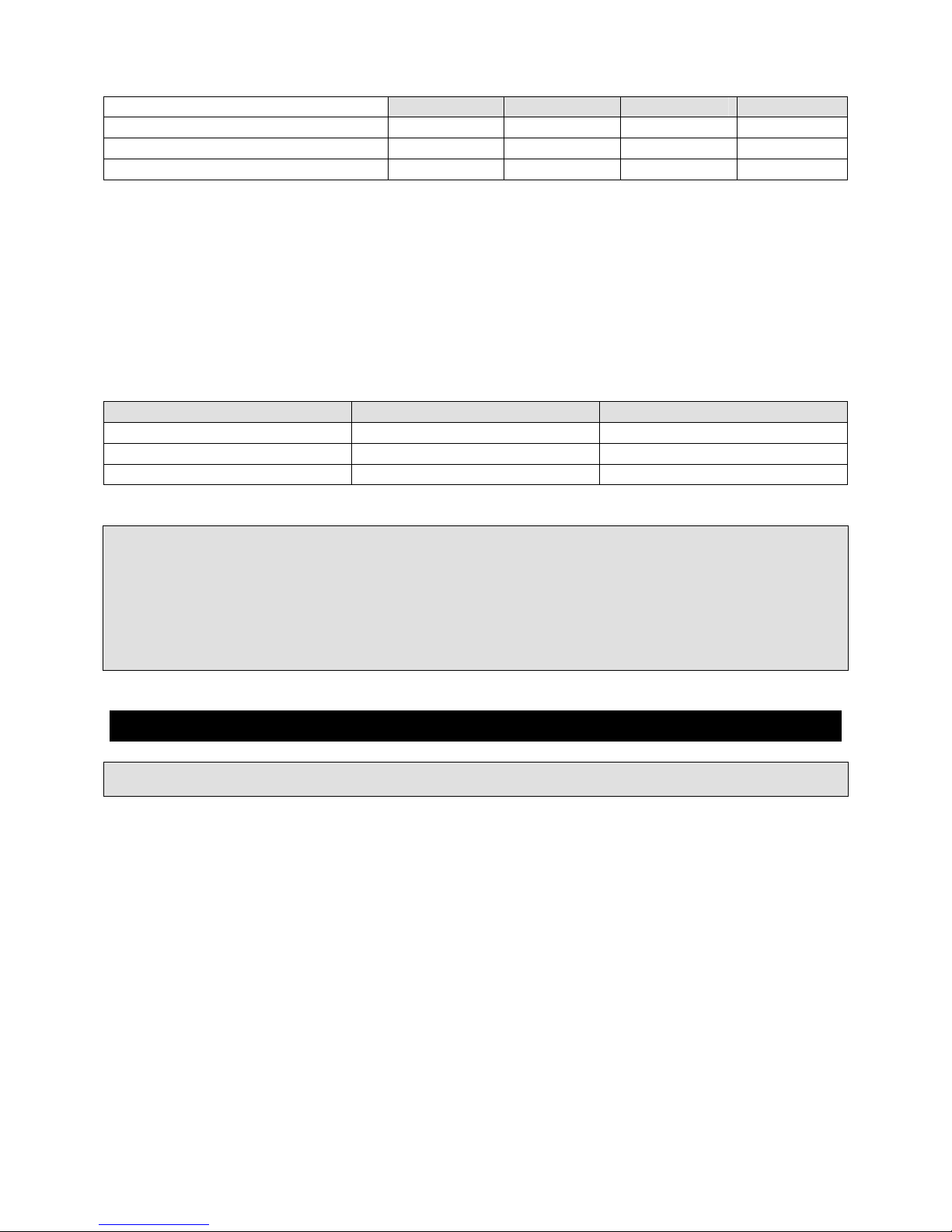

Step 1: Using the following two charts

to determine the proper air volume

®

needed for your Pro-Finish

system.

The volume of air required for efficient

operation of your system depends on

AIR REQUIREMENTS (SCFM) FOR SUCTION BLAST

40 psi 60 psi 80 psi 100 psi

¼” nozzle, 1/8” air jet 12 17 21 26

5/16” nozzle*,5/32” air jet 19 27 34 42

7/16” nozzle, 7/32” air jet 38 52 66 80

* Standard nozzle

the size of the nozzle you are using and

the desired blast pressure. The chart

lists the minimum air requirements in

SCFM for various nozzles and

pressures.

Page 12

Page 13

Empire Abrasive Equipment Company

AIR REQUIREMENTS (SCFM) FOR PRESSURE BLAST

40 psi 60 psi 80 psi 100 psi

1/8” nozzle 10 14 17 20

3/16” nozzle* 22 30 38 45

¼” nozzle 41 54 68 81

* Standard nozzle

Step 2: Use the chart below to

determine the size of the air line needed

for your cabinet. Even when the

compressor is properly sized, the air

line that connects it to your cabinet

must be large enough to avoid a large

pressure drop, which can cause

inefficient blasting.

Example: Your systems includes:

(a) A 125 foot long air line which

requires a 1” line (according to

the table).

(b) An air volume of 80 CFM, which

requires a 1-1/4” line size

Choose the larger line size (1-1/4”).

Line Size (in) Length of Air Line (ft) Air Volume (SCFM)

¾ Up to 95 13 to 38

1 95 to 190 38 to 59

1-1/4 190 to 350 59 to 85

IMPORTANT

To operate properly, your Pro-Finish® system requires clean, dry air. Moisture or

oil in the compressed air supply can contaminate the abrasive, which can

prevent it from flowing freely and cause inefficient blasting. Though your

system is equipped with a general purpose filter to remove small amounts of

condensed water and oil from compressed air supply, this filter is not designed

to clean grossly contaminated air.

3.0 General Equipment Operation

3.1 Media Selection and Use

Proper media selection strongly

influences the efficiency of your

blasting operation. Your choice of

media depends on the kind of job to be

done (cleaning, deburring,

smoothing sharp edges, paint removal,

preparation for coatings, etc.) The size

of the media depends on the results

you need.

Fine media results in more impacts per

second over a given area. Therefore,

fine media is preferred for easy blasting

jobs, such as the removal of light rust

from steel.

Large media results in fewer impacts,

but each impact has more force, so that

large media is more suitable for difficult

jobs, such as removal of mill scale.

Page 13

Page 14

Sometimes large and find media may be

combined for optimum results.

The chart below lists the range of media

®

recommended for each Pro-Finish

Blast System. Certain media, such as

sand and slag, are not to be used in Pro-

®

Finish

cabinets, both for health

reasons and because they pulverize on

impact and cannot be recirculated.

Media Type

Media Size

Suction

Pressure

R – Recommended. * Recommended optional vibrating screen for mesh sizes 200 to 300 or when high humidity is a problem.

NR – Not Recommended. ** Recommended optional vibrating screen and aerated media regulator for mesh sizes 200 to 300.

W/Reclaimer R R* R R* NR R NR R R

W/O

Reclaimer

W/Reclaimer R R** R R** NR R NR R R

W/O

Reclaimer

Aluminum Oxide

or

Garnet

46 to

80

Mesh

R NR NR NR R R R R NR

R NR NR NR R R R R NR

100 to

300

Mesh

Glass Beads Steel Grit Steel Shot

25 to

180

Mesh

200 to

300

Mesh

G-16

to

G-50

G-80

to

G-200

S-390

to

S-170

S-110

to

S-70

Walnut

Shells

or

Plastic

Any

Size

Spherical media, such as glass beads,

are used for general purpose cleaning

and finishing where a satin-like finish

is desired with little dimensional

change. Glass beads are effective when

used with pressures in the 20 to 60 PSI

range. Above 60 PSI, excessive bead

breakdown will occur.

Angular aggressive media, such as

aluminum oxide, steel grit, and garnet

generally provide faster cleaning and

produce a less-polished finish

compared to glass beads. Aluminum

oxide and steel grit are suitable for use

breaks down quickly at pressures

greater than 40 PSI.

Walnut shells or plastic are sometimes

used for delicate parts, paint removal,

or when a polished finish is required.

Pressures from 20 to 100 PSI may be

used with these media, depending on

the application.

When changing from one type of media

to another, clean the cabinet interior

and media hoses thoroughly to avoid

cross contamination.

at pressures up to 100 PSI. Garnet

CAUTION

If your application requires aggressive media, such as aluminum oxide, garnet, or

steel grit, it is recommended that you use optional heavy duty ducting,

reclaimer lining, and DI-CARB or BORON nozzles to prevent premature wear.

Empire strongly recommends using boron carbide nozzles when blasting with

Aluminum oxide, which is the most abrasive media.

If these options are not included with your system, they can be added. Optional

Rubber curtains for interior cabinet surfaces are also available. Consult your

Empire distributor for details.

Page 15

Empire Abrasive Equipment Company

3.2 Media Loading

Cabinets With Reclaimers:

Step 1: With the cabinet switch OFF,

load media through the reclaimer

Glass Beads Aluminum Oxide Steel Shot or Grit

Suction 10 lb. 15 lb. 25 lb. 5 lb.

Pressure 75 lb. 100 lb. 200 lb. 30 lb.

Cabinets Without Reclaimers:

Step 1: With the cabinet switch ON,

load media through the cabinet door.

Glass Beads Aluminum Oxide Steel Shot or Grit

Suction 75 lb. 100 lb. 200 lb. 30 lb.

IMPORTANT

Be careful not to overfill pressure systems. Overfilling will cause malfunction

and premature wear. See Subsection 4.1 Daily Maintenance.

access door. Total capacity for each

media and system is shown below:

Walnut Shells or

Plastic

Total capacity for each media is shown

below:

Walnut Shells or

Plastic

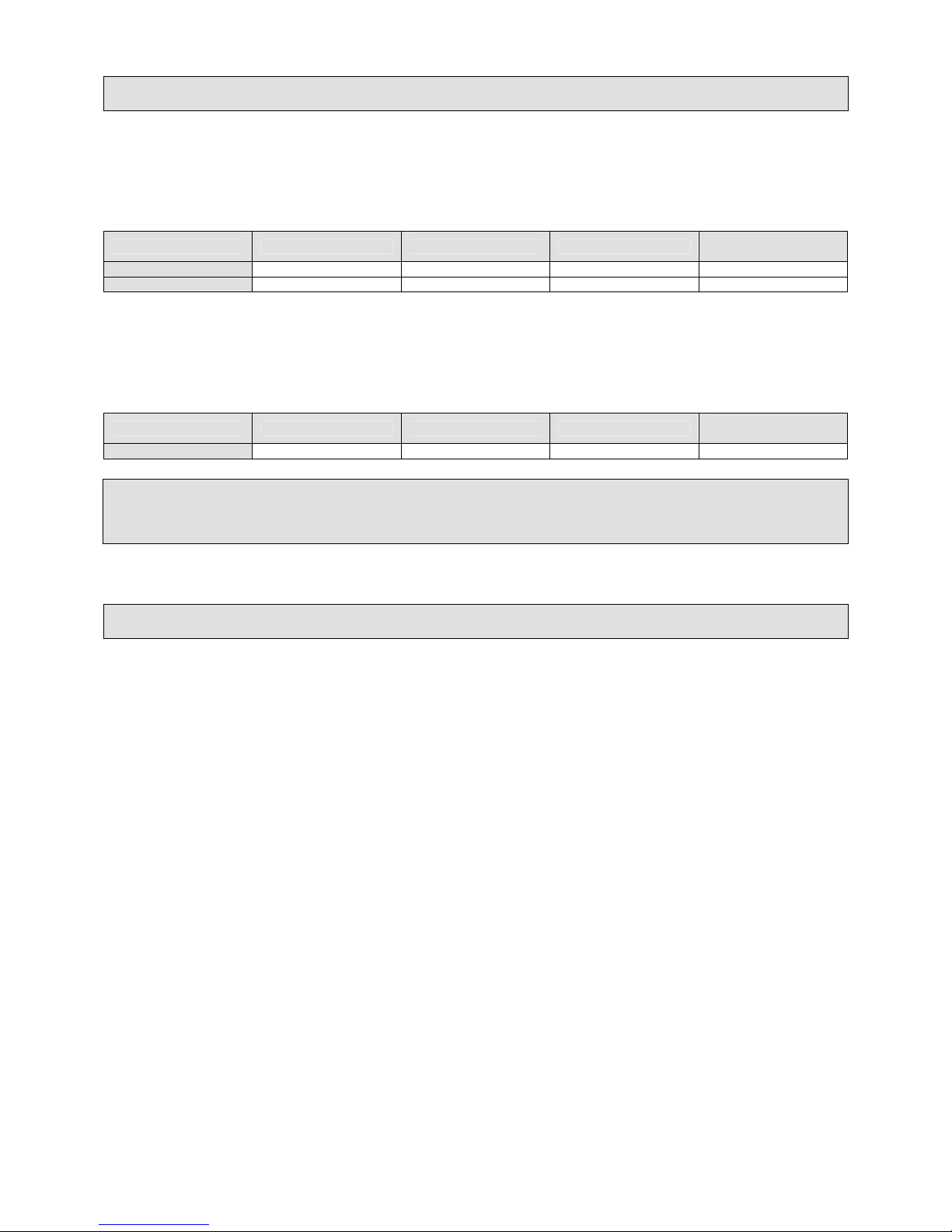

3.3 Pneumatic Controls

The Pro-Finish

pneumatic control circuit to protect

workers, workers environment, and

activate the blast.

Step 1: Turning the system ON/OFF

Switch to ON, energizes the interlock

Solenoid valve, permits air to enter the

control air line to the foot treadle,

illuminates cabinet lights and start the

fan motor.

Step 2: The operator steps on the foot

treadle opening a three way control air

valve. Air enters the door interlock

supply tubing continuing to the door

air jets. If the part load/unload doors

are closed, latched, and door air jets

are sealed, the control air lines

pressurize and open the main blast air

valve (and the pressure systems

exhaust valve to close). The opening of

the main air valve starts the blast.

®

system uses a patented

Step 3: When the operator removes his

foot from the foot treadle, the three way

air valve close, shutting off air to the

controls, and exhausting all down

stream air. The control air line

pressure bleeds from the door interlock

supply tubing, main blast air valve (and

the pressure system exhaust valve).

This permits the main blast air valve to

close (and the pressure system exhaust

valve to open) stopping the blast.

Step 4: When a part load/unload door

is opened, the pad covering the door

interlock air jet is unseated. When the

foot treadle is pressed with a door open,

control air bleeds from the door air jet

opening, preventing the control circuit

from pressurizing. The main blast air

valve will not open, and blasting will

not occur.

Page 15

Page 16

Empire Abrasive Equipment Company

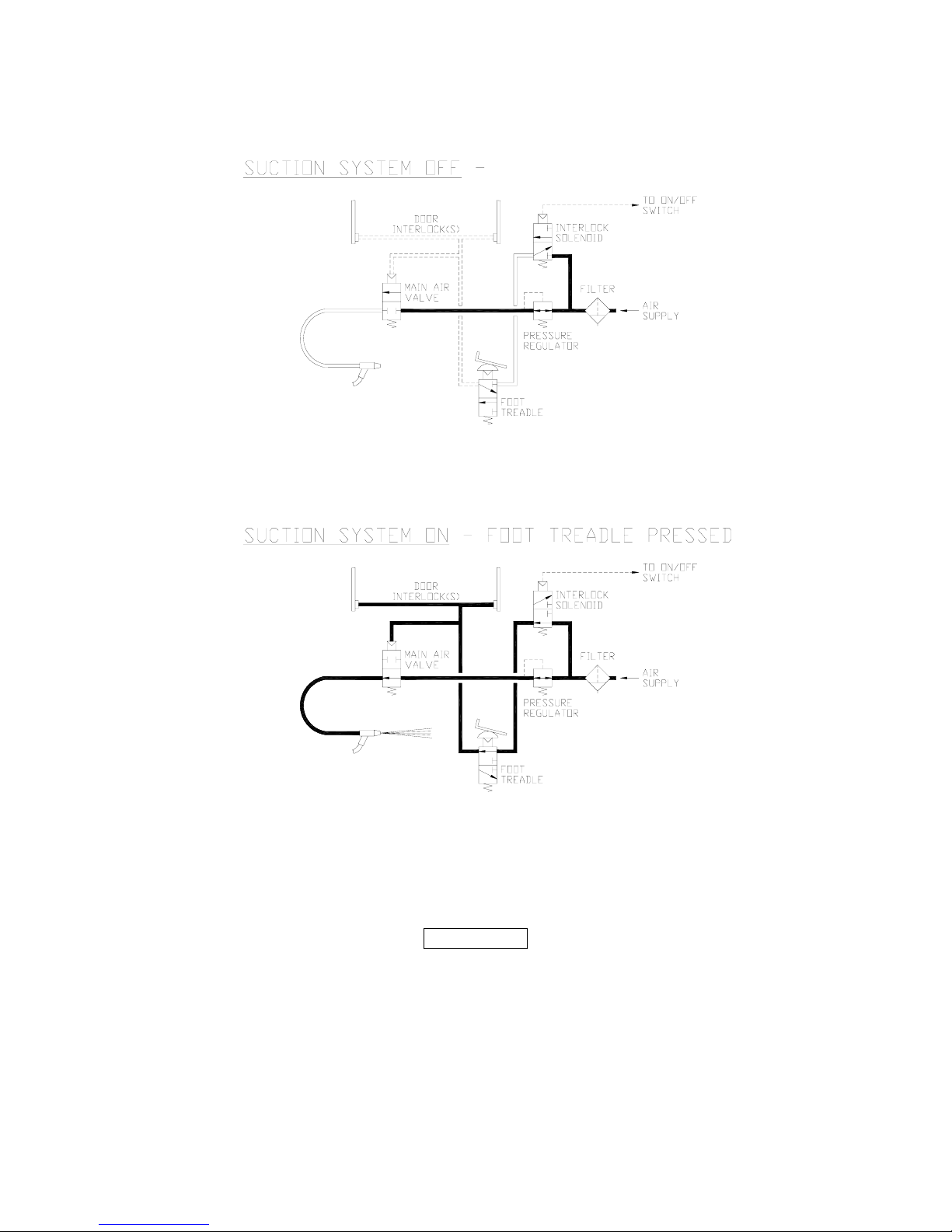

The following schematic diagrams illustrate the pneumatic control circuits for suction

systems (Figure 12A) and pressure systems (Figures 12B). For each system type, the

cabinets are shown in blasting and non-blasting modes (shaded pipe is pressurized).

Figure 12A.

Page 16

Page 17

Empire Abrasive Equipment Company

Figure 12B.

Page 17

Page 18

Empire Abrasive Equipment Company

3.4 Equipment Start-up

Step 1: After checking that all pipe and

hose connections are tightly fastened,

turn on the plant compressed air and

open the (user furnished) manual (ball)

valve(s) controlling air flow to the

system.

Step 2: Turn the cabinet power switch

ON.

Step 3: Place parts to be blast-treated

in the cabinet. The parts must be free

of oil, grease, and moisture.

Suction Blast Pressure Blast

Glass Beads 30-60 PSI 20-60 PSI

Aluminum Oxide 30-100 PSI 20-80 PSI

Steel shot or grit 80-100 PSI 20-80 PSI

Walnut shells or plastic 20-100 PSI 20-80 PSI

Step 7: Hold the gun or nozzle at a

distance that produces the fastest

action. This distance may vary from 3

to 18 inches, depending on the work

piece and the desired finish. Avoid

pumping the foot treadle, as this will

decrease your efficiency and cause

premature wear of components.

Step 4: Close the cabinet door(s).

Step 5: Set the blast air pressure

regulator at the desired pressure.

Recommended operating pressure

ranges for various media are listed in

the table below. Do not exceed 125 PSI

blast pressure.

Step 6: Grip the suction gun or

pressure nozzle assembly firmly and

step on the foot treadle. After a few

seconds the abrasive flow will stabilize

and you will be ready for blasting.

The size of the effective blasting pattern

varies with the type and length of the

nozzle, air pressure, and the nature of

the work piece. Use the following chart

and diagram as a guide, but be aware

that the approximate pattern diameters

can only be determined by considering

each case individually.

Page 18

Page 19

Empire Abrasive Equipment Company

Blast Pattern Diameter at Distance Listed

Nozzle ID A B C

¼ ¾ 1 ¼ *

Suction Blast

5/16 1 1 ½ *

7/16 1 1/8 1 ¾ *

1/8 ¾ 1 ¼ 2 ¼

Pressure Blast

3/16 1 1 ½ 2 3/8

¼ 1 1/8 1 ¾ 2 1/2

Suction Blast at a distance of greater than 12” is usually not effective.

3.5 Equipment Shut-down

Step 1: Turn cabinet power switch

OFF.

Step 2: Shut off the plant air supply.

Page 19

Page 20

Empire Abrasive Equipment Company

3.6 Equipment Adjustments

Ventilation Flow Reclaimer Adjustment (for systems with reclaimers):

®

All Pro-Finish

adjusted to control the average size of

media retained by the reclaimer. The

reclaimer is supplied with a “tune-able”

secondary air adjustment. When the

band is properly adjusted reusable

media will be returned to the media

storage hopper. Unwanted dust and

broken down media (fines) will be

removed from the system and conveyed

to the dust collector. See Figure 5

Empire’s reclaimer design has vertical

slots with a solid tuning band. The

original Pro-Finish

horizontal slots in both the reclaimer

and tuning band.

Fine tuning adjustments of both

reclaimers are similar. Just remember

to move the band in the direction of the

reclaimer slots; horizontal slots rotate

the band, vertical slots slide band up or

down.

The tuning band is joined at both ends

by a bolt and wing nut that must be

loosened before the band can be

adjusted. The slot pattern around the

reclaimer body has one slot omitted.

The joined ends of the tuning band

must be located over the area of the

omitted slot.

Dust collectors require a coating of

dust on the filter cartridges to

achieve maximum filter efficiency,

also known as “seasoning”. The

filters are seasoned when the static

pressure reading on the collector

gauge is 2 or greater.

Step 1: Start with no reclaimer slots

visible. Adjust the band in one

direction until 1/16” of opening is

created between the band and

reclaimer slots.

reclaimers can be

®

reclaimers have

NOTE

HELPFUL HINT

Place a reference pencil mark on

reclaimer body (and a corresponding

reference mark on the tuning band if

horizontal slots).

Step 2: Operate the blast system for at

least one hour.

Step 3: Turn the cabinet power switch

OFF.

Step 4: Inspect the dust collector waste

drum for reusable media.

Step 5: If no media is found in the

waste, adjust the tuning band to expose

1/16” more reclaimer body slot area.

Step 6: Make a new reference mark on

the reclaimer body.

Step 7:

Repeat Steps 2 through 7 until a

small amount of media is found in the dust

collector waste. Adjustment is complete.

NOTE

As a new system is used, the filters

become coated with dust, “seasoned”

and the airflow in the recovery

system will decease to the normal

operating rate. This will affect

previous reclaimer tuning band

adjustments.

If visibility becomes poor inside the

cabinet when blasting, there is too

much dust mixed with the blast media.

The reclaimer tuning band should be

re-adjusted. Follow Step 2 though 7.

NOTE

For systems with large quantities of

dust mixed with blast media, all dust

and media should be removed from

the system and new media installed.

Page 20

Page 21

Step 8: If more than a small amount of

media is found in the dust collector

waste, additional reclaimer tuning band

adjustment may be required. Follow

Steps 9 through 13.

Step 9: Adjust the tuning band back to

the previous reference mark on the

reclaimer body, reducing the opening

between the reclaimer and the band.

Step 10: After operating the blast

Step 11: If no media is found in the

waste, adjust the tuning band to expose

1/16” less reclaimer body slot area.

Step 12: Make a new reference mark

on the reclaimer body.

Step 13: Repeat Steps 8 through 13

until a small amount of media is found

in the dust collector waste. Adjustment

is complete.

system for at least one (1) hour, turn

the cabinet power switch OFF. Inspect

the dust drum waste for reusable

media.

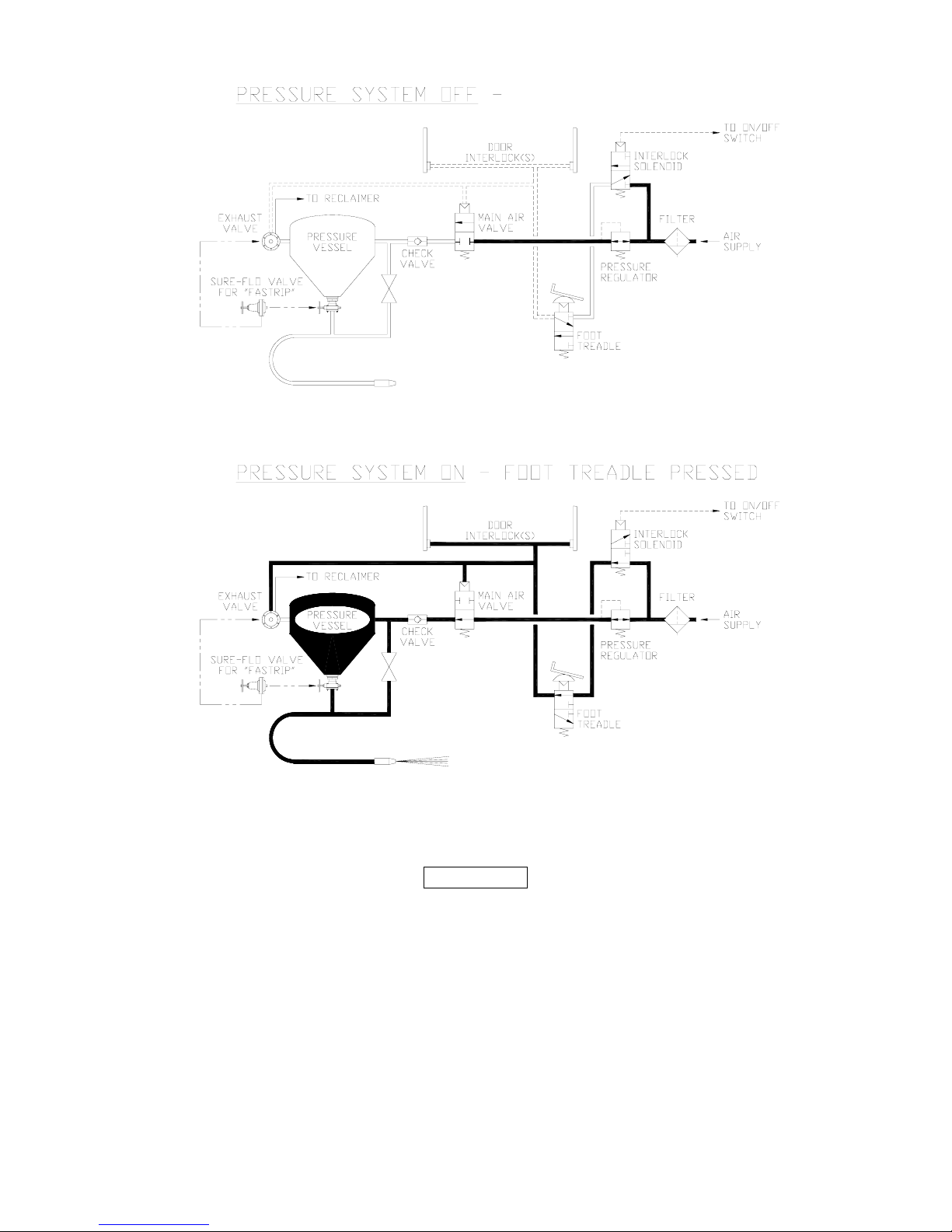

The schematic diagrams in Figure 13 illustrate:

(1) the basic operation of the system.

(2) the air and media flow before and after blasting.

Figure 13. Operating Principles

Page 22

Empire Abrasive Equipment Company

IMPORTANT

An insufficient volume of secondary air entering the reclaimer will cause dust to

accumulate with the “good” media in the storage hopper or pressure vessel.

This accumulation leads to inefficient blasting. Conversely, too much secondary

air will cause useful media to be carried to the dust collector and be wasted.

To avoid these conditions, adjust the tuning band to meet your specific blasting

requirements. When your system is new, it will be necessary to readjust the

tuning band periodically until the filters are “seasoned”.

WARNINGS

Explosive Dust: Explosive dust is generated from blast media, removed coatings

and substrates. An extreme concentration of dust may combust if ignited by

spark or flame. As a precaution, clean the system and empty the dust collector

often. Change media that has excessive dust concentration.

Emptying the Dust Collector: Always wear an appropriate dust mask when

emptying the dust collector and changing filters. Empty the dust collector daily.

Ventilation Flow Adjustment Systems Without Reclaimers:

For these systems, ventilation air is

drawn directly from the cabinet. The

slide gate on the cabinet ventilation

outlet should be adjusted to give the

maximum flow of ventilation air without

carrying good media from the cabinet.

The proper adjustment of the gate can

be found through trial and error. Fine

media cannot be used in systems of

this type without having some of it

carried over to the dust collector or bag.

NOTE

If your media requirements change, you can easily add a reclaimer to your ProFinish® system.

Media Flow (Suction Systems):

®

Pro-Finish

equipped with the SAR-2 media

regulator to control the flow of media to

the Suction Blast Gun. The regulator is

located at the bottom of the Storage

Hopper assembly.

The amount of media entering the hose

is controlled by how far the media hose

is inserted into the regulator. For

normal operation, approximately ½ of

the air inlet port is blocked by the

media hose. This may vary slightly

suction blast systems are

when changing media size nozzle size,

and/or blast pressure.

To find a uniform media flow, loosen

the thumbscrew and slide the media

hose into the SAR-2 regulator to

increase and withdraw the hose to

decrease media flow at the nozzle. To

determine if media is flowing, look

through the media regulator air inlet

while the gun is operating. Listen for

the sound of the blast to be smooth and

constant.

Page 22

Page 23

Empire Abrasive Equipment Company

Media Flow (Pressure Systems):

Pro-Finish

supplied with the patented Sure-Flo®

grit valve. Adjust the media flow

through this valve by turning the Thandle. Start with the valve fully

closed by turning the T-handle

®

pressure cabinets are

clockwise until you notice resistance.

Then turn the T-handle counterclockwise in 1/4 turn or 1/8 turn

increments until you observe the

desired flow.

clockwise until you notice resistance.

3.7 Helpful Hints for More Efficient Blasting

The efficiency of your blasting operation

depends on four factors:

1) Equipment selection

2) Media selection

3) Operating procedures

4) Maintenance

With the help of your Empire

Distributor and/or Empire factory

representative, you now own equipment

that will properly meet your blasting

requirements.

You can select the proper media,

operating procedures, and maintenance

steps by following the recommendations

in this manual. If you need more

information about any aspect of your

machine’s operation or the blasting

process, contact your local distributor

or the factory.

The following measures will also help

you improve the efficiency of your

blasting operation:

Step 1: To accomplish more in less

time, use the largest nozzle practical for

your operation. Of course, nozzle

diameter may be limited by the amount

of compressed air available, but an

increased volume of compressed air is

often justified by reduced labor costs.

Also, if you are blasting small parts, it

doesn’t make sense to use a big nozzle,

as most of the blast pattern will be

overspray.

Step 2: For faster cleaning, use the

highest pressure practical for your

operation. Maximum pressure for a

given operation is limited by type of

media (e.g. glass beads can break down

rapidly above a certain pressure) and

amount of material which must be

removed from the workpiece.

Step 3: If you are blasting small parts,

it may be more efficient to manipulate

the part with tow hands and use an

optional fixed nozzle holder.

Step 4: Never underestimate the

importance of clean, dry air. More

operational problems are traceable to

the lack of clean dry air than any other

single factor. If the supply air is not

clean and dry, media quickly becomes

contaminated, causing flow problems,

which wastes media and leads to

excessive operator downtime.

Page 23

Page 24

Empire Abrasive Equipment Company

4.0 Maintenance

4.1 Daily Maintenance

Step 1: Check the condition of the media.

If the media is contaminated or broken

down into dust, thoroughly clean the

inside of the cabinet and recovery system

and reload with new media.

Step 2: Adjust the reclaimer tuning band

if you observe a dusty condition. See

section 3.6 Equipment Adjustments.

Step 3: Clean the filter bag or shake the

dust collector bags after every 2-4 hours

of operation.

A. For a single dust bag, remove the

bottom bag clip and shake the

accumulated dust through the bag

bottom into an appropriate

container.

B. For systems equipped with a

(baghouse) dust collectors, turn off

the cabinet power switch and

remove the dust from the bags by

pressing the bag-shake button 15

to 20 times.

C. Cartridge collector (CDC), empty

the dust drum when 2/3 full.

Dispose of the waste properly.

Step 4: Check light bulbs and gloves

Step 5: Remove debris from the

reclaimer screen.

Step 6: Open the manual drain on the

general-purpose filter in the cabinet

pipe string and drain any accumulated

moisture and oil. Close the drain.

Step 7: Check the media level. For

optimal operation, the media level

should not drop below one-half the

recommended capacity.

A. The media level in suction can

be observed in the media storage

hopper.

C. The media level in pressure

systems can be observed by

looking through the sight glasses

or the reclaimer door down into

the top of the vessel. When the

vessel is de-pressurized, the

sealing plunger must be visible.

Add media until just visible at

the sealing plunger.

Step 8: All quick coupling connections

must be equipped with safety pins.

Inspect all couplings and blast hoses

daily for splits, bubbles, soft spots, etc.

Screws should be flush with coupling

surfaces. Tighten screws, if necessary.

Page 24

Page 25

Empire Abrasive Equipment Company

The following drawings show media flow through a typical pressure system and are

provided to help you understand how to maintain the media at the proper level.

Pictured at right is a fully charged system

with the vessel depressurized (no

blasting). Note that the media fills the

pressure vessel but that there is not

media in the storage hopper.

Before Blasting

When blasting starts, the vessel

pressurizes, the media impacts the part

being blasted, and reusable media is

hopper will transfer into the pressure

vessel.

recovered and accumulates in the

storage hopper. Continuous blasting

time is limited by the type and amount

of abrasive in the in the vessel when

blasting starts (normally 8 to 15

minutes with a fully charged 1 cubic

foot vessel, depending on nozzle size

and blast air pressure). Each time the

operator stops blasting, the vessel depressurizes and the sealing plunger

drops. Media in the storage hopper

flows into the vessel. If blasting is

stopped long enough (usually 1-2

minutes), all media in the storage

During Blasting

Page 25

Page 26

Empire Abrasive Equipment Company

Thus, you can determine the amount of

media in the vessel in either of two

ways: (1) note how much continuous

blast time you can achieve with a fully

charged vessel and compare this with

your current continuous blast time; or

(2) stop blasting, open the reclaimer

door, and visually determine the media

level by looking into the top of the

vessel.

Overfilling pressure vessels will cause

improper operation and premature

wear. Allow sufficient time after

blasting for the pressure vessel to refill

(2 minutes). When the pressure vessel

is filled, check to see if any media has

remained in the storage hopper,

indicating that the vessel is overfilled,

the sealing plunger may not seat tightly

when you start blasting.

See Section 4.3 Storage or Temporary

Non-Use for instructions on how to

empty the pressure vessel.

Refer to Section 3.2 Media Loading for

instructions to add media.

After Blasting

Pressure Vessel Overfilled

Page 26

Page 27

Empire Abrasive Equipment Company

4.2 Weekly Maintenance

Step 1: Repeat the daily maintenance

procedures.

Step 2: Inspect all media-carrying

hoses for wear by feeling along the

length of the hose for soft spots. Hoses

with soft spots should be replaced.

Step 3: Check the nozzle for wear.

When the nozzle is worn 1/8” oversize,

replace it. A drill bit can be inserted

into the nozzle to check its size.

Step 4: On suction systems, check the

air jet for wear.

Step 5: Loosen the set screw in the side

of the gun body and remove the air jet.

See Figure 14.

Step 6: If the air jet shows wear, rotate

it 90° and reinsert it into the gun.

Step 7: Re-tighten the set screw.

IMPORTANT

If an air jet is allowed to wear

completely through, it will cause

premature wear of the gun body and

nozzle.

Step 8: Check the nozzle adapter and

gun body for wear. Replace if

necessary.

Step 9: Check the window gaskets for

leaks. Replace if necessary.

Step 10: Check your spare parts

inventory. Ensure that you have an

adequate supply of replacement items.

Figure 14. Air Jet

Page 27

Page 28

Empire Abrasive Equipment Company

4.3 Storage or Temporary Non-Use

If your Pro-Finish® system will not be

used for several days (or more), follow

these steps to remove media and

prevent media from caking inside the

system:

Step 1:

• Suction systems:

Empty media from the cabinet and

storage hopper. To remove the media

from the storage hopper: remove the

rubber plug from the bottom of the

SAR-2 regulator.

• For pressure systems:

A) Reduce blast pressure to 40 PSI.

B) Close the choke (ball) valve on

the pressure vessel pipe string.

(see Figure 15).

Remove the blast nozzle and washer

from the blast hose.

C) Pressurize the vessel as if to

blast.

These steps will cause the media to flow

from the open end of the blast hose in a

controlled manner. The media can now

be directed into a suitable container or

receptacle.

After the pressure vessel is empty:

D) Open the choke valve.

E) Replace the nozzle washer and

nozzle.

F) Return the blast pressure setting

to normal.

Step 2: Drain the general purpose

filter. Close the drain valve.

Figure 15. Closed Choke Valve

Page 28

Page 29

Empire Abrasive Equipment Company

5.0 Troubleshooting

5.1 Troubleshooting Chart

Trouble Probable Cause Remedy

1. Good media

carried to dust

collector.

New bags. Continue use until bag “cake” forms

Systems with reclaimers:

tuning band is open too

far.

Insufficient media in

suction hopper allows

secondary air to enter.

Systems without

reclaimers: slide gate is

open too far.

Media too fine. Use more coarse media.

(approximately eight hours of

operation).

Adjust tuning band.

Add media to recommended media

level.

Adjust slide gate.

2. Media escaping

to the work area

from dust collector.

3. Poor visibility

during blasting.

Pressure systems: Worn

Replace plunger and/or sealing ring.

plunger or sealing ring

leaking air into reclaimer.

Hole in dust bag(s)or loose

bag(s).

Reclaimer not adjusted

properly.

Replace leaking bag(s)or refasten

bag(s).

Adjust reclaimer air inlet settings

See 3.6 Equipment Adjustments

Clogged dust bag(s). Shake dust bag or dust collector bags.

“Blinded” filters (reduced

air flow due to age of bag).

Over a period of years dust may

penetrate the dust bag to the extent

that normal air flow is restricted even

when bags are shaken regularly.

When this condition is reached,

replace the filters.

Fan rotation backwards. Reverse the fan rotation.

Media has high dust

content.

Replace media and adjust reclaimer

tuning band.

Recovery hose blocked. Remove hose, inspect and remove

obstruction.

Cabinet air inlet plugged. Blow filter clean with air line.

Dust collector door leaks

air.

Blast nozzle or air jet too

large.

Tighten door, replace gasket if

necessary.

Replace worn nozzle with

recommended size: maximum ¼”

diameter pressure, maximum 7/32”

air jet for suction.

Page 29

Page 30

Trouble Probable Cause Remedy

3. Poor visibility

during blasting

(continued).

4. No air or media

flow from nozzle.

5. Poor production

rate.

6. Static charge

build-up and

discharge annoys

the operator.

7. Blast air flow,

but intermittent or

no media flow.

Empire Abrasive Equipment Company

Operating air pressure too

high.

Compressed air line shut

Decrease pressure to within

recommended range.

Open all air valves from compressor.

off.

Cabinet Doors not tightly

closed.

Close cabinet doors sealing door

interlock.

Regulator adjusted to zero. Adjust regulator.

Nozzle clogged. Disassemble and clean nozzle.

Door interlock air hose

leaking.

Replace hose (if problem continues

see 5.2 Troubleshooting Pneumatic

Control Circuit).

Low blast air pressure. Increase pressure within the specified

range.

Nozzle too small (the

smaller the nozzle, the

smaller the blast pattern).

Install a larger nozzle (and air jet on

suction systems) to accommodate

your production needs.

Improper media. See 3.1 Media Selection and Use.

Improper media flow. See 3.6 Equipment Adjustments.

Low media level. Add media to maintain recommended

level.

Parts to be blasted are oily

or wet.

Parts to be processed must be

absolutely dry and free of oil, grease,

etc.

Media has high dust

content (Blast media

breaks down and must be

replaced on a regular

Remove old media from system and

replace with new. Adjust reclaimer

tuning band. See 3.6 Equipment

Adjustments.

basis).

Low quality blast hose

(poor conductor of static

charge).

Replace blast hose with one of high

quality. Static charges are created

and build up by the air and media

moving at high velocity through the

blast hose.

System grounded

Earth ground the system.

improperly.

Part insulated, resting on

rubber mat.

Low compressed air and

ambient humidity.

Place part on metal surface, i.e.

cabinet floor or turntable top.

Install Empire Anti Static Strap, part

510411.

Blast air pressure too low. Adjust and maintain pressure within

recommended range.

Clogged nozzle. Disassemble and clean nozzle.

Damp media (If media

stays formed in a ball after

squeezed in the palm of

the hand, it is too damp to

Remove damp media from system and

replace with new, dry media. Check

compressed air supply filters. Do not

blast wet or oily parts.

flow properly).

Page 30

Page 31

Trouble Probable Cause Remedy

j

7. Blast air flow,

but intermittent or

no media flow

(continued).

Empire Abrasive Equipment Company

Suction System:

Improper air jet nozzle

combination.

Nozzle orifice size must be twice the

air jet orifice size 1/8”diameter air jet

requires minimum ¼” diameter

nozzle.

Suction System:

Media hose improperly

installed.

ust media hose in media regulator.

Ad

Check media hose at entry to the

suction gun body, hose clamp nut, o-

ring, and hose must create an air

tight seal

Suction System:

Clogged media hose.

Remove media hose from media

regulator at the bottom to the media

storage hopper, bring that end of the

hose through an open door and into

the cabinet. Remove the nozzle from

the suction gun, insert the blow-off

gun nozzle in the open end of the

media hose, and blow accumulated

media and/or debris out through the

suction gun.

Pressure System:

Adjust media regulator.

Sure-Flo media regulator

closed.

Pressure System:

Leaking sealing plunger

Check for compressed air leaks and

repair.

and/or exhaust valve

Pressure System:

Sure-Flo media regulator

obstructed.

Open Sure-Flo media regulator to full

open, close the choke valve, remove

blast nozzle, set blast pressure at 70-

80 PSIG and attempt to blast. All air

will be forced through the media

regulator clearing the obstruction. If

media flow problems persist, shut off

and lock out compressed air supply,

disassemble media regulator and

clear obstruction.

Page 31

Page 32

Empire Abrasive Equipment Company

5.2 Troubleshooting the Pneumatic Control Circuit

Hand Tools Required:

The following tools are required to

troubleshoot the pneumatic control

circuit:

• Pressure tester (P/N 140382)

• 7/16” open end wrench

• Flat-blade screwdriver

Step-by-Step Procedures:

Refer to the control circuit schematics

shown in Figure 7 and the

troubleshooting procedures listed on

the pages following the figures.

Figure 11. Pneumatic Circuit - Suction

Figure 12. Pneumatic Circuit - Pressure

Page 32

Page 33

Empire Abrasive Equipment Company

Problem: Lights and blower work, but blast will not activate.

Step 1: Verify that the main air supply

is on and that the cabinet is receiving

air blast and regulator is set at proper

pressure. Check for obvious control air

leaks:

• Are the doors tightly closed?

• Are the door air jet seals in good

condition?

With the main switch ON and foot

treadle pressed, listen for air leaks.

Repair any air leaks that you find.

Step 2: Turn the cabinet switch ON

and OFF.

If you hear a slight air hiss when the

switch is turned OFF, proceed to Step3.

If you do not hear an air hiss, the

absence of the blast could be the result

of either of the following (Refer to Figure

11 or Figure 12, as appropriate for your

system):

A. There is a leak between A and

the foot treadle valve C. Check

for leaks in the tubing between A

and the interlock solenoid B.

Disconnect electrical power to

the cabinet.

Remove the Empire nameplate to

verify that tubing ends are firmly

connected.

Check for air leaks between B

and C.

B. The interlock solenoid B is faulty.

If no air leaks are found using

the procedure outlined in Step

2A, replace the interlock

solenoid.

Step 3: With the power switch ON, step

on and off the foot treadle several

times. You should hear a slight hiss of

air at the foot treadle when you release

it.

If you hear the hiss, the blast, problem

is being caused either by:

• a tubing leak, or

• a faulty main air valve or

pressure system exhaust valve

If you do not hear an air hiss, the

absence of the blast is being caused by

one of the following:

A. The foot treadle tab does not fully

press the foot treadle valve. To

verify this condition, remove the

treadle by taking out the bolt at

each end.

With the cabinet switch ON,

manually press the foot treadle

valve plunger.

If the blast is activated, you can

correct the problem by adjusting

the foot treadle tab, as follows:

• Loosen the two screws on

top of the foot treadle.

Slide the tab forward so

•

that it fully contacts the

foot treadle plunger.

B. The foot treadle is faulty. To

assess the condition of the foot

treadle, remove the air line D

downstream of the foot treadle.

If no air escapes when the foot

treadle valve is manually

pressed, the valve is faulty and

should be replaced.

Page 33

Page 34

Empire Abrasive Equipment Company

C. There is an air leak downstream

from the foot treadle valve. If

neither Step 3A nor Step 3B

reactivate the blast, disconnect

the tubing at D and connect a

test gauge to the tubing.

Manually press the foot treadle

valve.

If the gauge does NOT read full line

pressure when the foot treadle is

pressed, either the tubing upstream

of the door interlock or the foot

treadle valve is faulty and must be

repaired or replaced.

If the gauge reads full line pressure

when the foot treadle valve is

pressed, the problem is a leak

downstream from (in either the door

interlock D or control tubing).

Step 4 describes the procedure to correct a

line leak.

Step 4: To repair a leak in the tubing

downstream from the foot treadle, proceed

as follows:

Connect a pressure test gauge to the

tubing at E.

With the switch ON, press the foot treadle.

If the test gauge indicates full pressure

when the foot treadle is pressed, but the

blast is not activated, the main air valve is

faulty and must be replaced.

If the test gauge does not indicate full

pressure, the problem is being caused by a

leak between D and E at the door interlock.

Check the tubing for leaks. For pressure

systems, perform Step 5, as necessary.

Step 5: (Pressure systems only) To

determine if the exhaust valve or the

exhaust valve control line (E to F) is

leaking, proceed as follows:

If the control tubing between E and F is

intact and has no leaks, connect the test

gauge to the tubing at F.

If the blast activates when the foot treadle

is pressed, the problem is a leaking

exhaust valve or a ruptured diaphragm in

the exhaust valve. Repair or replace the

exhaust valve.

Page 34

Page 35

Empire Abrasive Equipment Company

Problem: Excessive delay between stepping on the foot treadle and blast

activation.

(This delay should be between ½ and 1 second for suction systems and 1 to 2 seconds

for pressure systems.)

Remove the tubing at E and connect a test

gauge to the tubing.

With the cabinet switch ON, press the foot

treadle.

If the gauge pressurizes slowly to full line

pressure, the problem is restricted flow.

This condition could be caused by either A

or B below:

A. The foot treadle tab does not fully

press the foot treadle valve plunger.

To verify this condition, remove the

treadle by taking out the bolt at

each end.

With the cabinet switch ON,

manually press the foot treadle

valve plunger.

If the blast activates in normal time,

you can correct the problem by

adjusting the foot treadle tab as

follows:

• Loosen the two screws on top of

the foot treadle.

• Slide the tab forward so that it

fully contacts the foot treadle

plunger.

B. The control air line is kinked or

crimped. Check the condition of the

control air lines.

If the test gauge pressurizes to a

pressure significantly lower than

full line pressure, there is a leak

in the control circuit. Proceed as

follows:

Trace leaks by moving the test

gauge upstream until full

pressure is observed. Check D

and E.

Full pressure at D indicates

leaking door interlocks.

Low pressure at D indicates a

leak between:

D and C, or

C and B, or

B and A.

On pressure systems only:

• If the test gauge at F

pressurizes rapidly to full line

pressure, the exhaust valve

has a leak or a ruptured

diaphragm.

Page 35

Page 36

Empire Abrasive Equipment Company

6.0 Recommended Spare Parts

The following chart lists the parts you should maintain in inventory to ensure

®

continuous operation of your Pro-Finish

Qty Part No. Description Pressure Suction

1

1

2 532701 Floodlights X X

20’ 524441 Door gasket X X

1 290182 Exhaust valve X

25’ 520792 ½” blast hose X

10 520802 5/8” blast hose X

10 524052

10 524101 QC washer X

1 517221 Foot treadle valve X X

2 pair 509891 Rubber gloves X X

1 524451 Window gasket X X

1 510401 Window safety glass X X

1 519001 Interlock solenoid X X

2

1 523942 Sealing ring X

1 510431 Plunger, for 1 cu. ft. pressure vessel X

1

1 753551 MH-2 Gun Body X

2

6’ 520822 Exhaust hose X

2 520252 Tubing fittings X

1 523592 Sure-Flo metering tube, ¾” X

501331

501341

401351

501272

501282

501292

515521

515525

522351

516101

505651

505661

505671

505691

¼” Di-carb nozzle (suction) or

5/16” Di-carb nozzle (suction) or

7/16” Di-carb nozzle (suction)

1/8” Di-carb nozzle (pressure) or

3/16” Di-carb nozzle (pressure) or

¼” Di-carb nozzle (pressure)

NW-5 nozzle washer for ceramic

nozzles

Filter/Bag for DCM Collectors or

Filter/Cartridge for CDC Collectors

4 x 8 return hose or

6 x 11 Recovery hose

3/32” air jet or

1/8” air jet or

5/32” air jet or

7/32” air jet

system.

X

X

X

X X

X X

X

Page 36

Page 37

Empire Abrasive Equipment Company

7.0 Options and Accessories

A variety of standard accessories are

®

available for any Pro-Finish

system.

These accessories can be either factory

installed or customer installed with a

minimum of cabinet modification.

Category Options Description

1. Optional Electricals 220-240/50/1

2. Turntables - Stationary

or Tracks

3. Fine-Tuning Controls Pressure blast systems incorporating Empire’s automatic Sure-Flo

4. Fine-Tuning with Choke In applications where media is changed frequently, or where

5. Fixed-Orifice Media

Regulator

6. Low Media-Level Sensor

and Indicator (Factory

Installed Option)

7. Harsh Media and

Extended Wear

Components

8. Fixed Gun (or Nozzle)

Holder

208/60/3

220-240/60/3

380/50/3

440-480/60/3

550-600/60/3

Available with Manual, turntables facilitate the handling of heavy

In applications such as shot peening, in which very precise

The low media-level sensor and indicator warns the operator when

Empire’s extended wear components increase service life in an

Inlet wear plate An easily replaceable inlet wear plate protects the most vulnerable

Reclaimer

urethane coating

Reclaimer UltraWear lining

Di-Carb®

(tungsten carbide)

nozzles

Boron carbide

Nozzles

Rubber curtains Cabinet life is increased with the use of rubber curtains. Free-

Window

protectors

Matting To pad parts and prolong the life of steel support surfaces, mats

Suction blast systems

Voltage/Frequency/Phase of power available.

parts. The turntable dolly travels on a track, or is fixed inside the

cabinet. Most stationary designs feature a low profile that provides

operators with easy “over-the-top” access and does not waste

interior cabinet space. Turntable size 24” diameter with standard

capacities ranging from 300 to 1000 pounds.

media regulator, allow the operator to adjust the richness of the

air-to-media mixture from the workstation at the front of the

cabinet. As a result, dialing in the optimum air-to-media ratio for

a particular job is greatly simplified. To further assist the operator,

an indicator gauge displays relative media richness.

contamination can cause periodic clogging of the media regulator,

a push-button choke is available with fine tuning.

metering of media is required, a fixed-orifice media regulator is

attached below the Sure-Flo media regulator.

the media supply in the pressure vessel is low. The

indicator/sensor consists of an electronic probe in the vessel that

activates a signal light mounted on the front of the cabinet.

aggressive or high-use environment. These components are

normally very cost-effective because they reduce downtime, repair

interval, and maintenance costs. Extended wear components are

sold individually so you can tailor features to your application

needs and budget

area of the reclaimer.

The urethane coating extends the service life of interior wear

surfaces by five times.

The Ultra-Wear lining increases normal service life by a factor of

ten.

Di-Carb nozzles are for use with steel abrasives and glass beads.

Boron carbide nozzles are for use with aluminum oxide, silicon

carbide, and garnet media.

hanging curtains are made of black 1/8” neoprene and held in

place with rubber knobs for easy replacement. These curtains

actually last longer than steel. White curtains are available to

brighten the cabinet interior, and it doesn’t degrade with use, as

does white paint on steel.

Window protectors can be provided in clear plastic or as a

perforated screen to reduce frosting and pitting of the cabinet

window.

are offered for turntable tops and cabinet floors.

The fixed gun holder is adjustable to position any gun in any

orientation so the operator can use both hands to manipulate work

pieces in the blast stream.

Pressure blast systems

If your production requirements change,

you can add the options you need to

update your system.

Page 37

Page 38

Empire Abrasive Equipment Company

Category Options Description

9. Fine Media Kits Vibrating screen

10. Magnetic Reclaim

Separator

11. Dust Collector Option

NOTE: For more

information about

options, contact your

Empire distributor or

the factory.

and (for pressure

systems only)

aerated media

regulator

Magnetic reclaim separator reduces possible damage to delicate

Photohelic

Controlled pulse

jet cleaning

The fixed nozzle holder, which bolts anywhere on the cabinet wall,

can be adjusted to position the nozzle in any orientation, leaving

both of the operator’s hands free to manipulate work pieces.

A vibrating screen in the reclaimer (plus an aerated media

regulator for pressure systems) overcome flow problems associated

with very find abrasives (200 to 300 mesh range), lightweight blast

media (plastics, walnut shells, etc.), and high humidity.

substrates by removing steel and other ferrous contaminants from

the blast media as it passes through the reclaimer. The separator

consists of an industrial magnet that can be removed through the

reclaimer door for cleaning.

Automatically pulse the filters as required.

Page 38

Page 39

8.0 Pro-Finish® Parts

8.1 Reclaimers

Empire Abrasive Equipment Company

Item

1

2 — — 766741 766751 Removable top

3 — 751501 — — Outlet flange (6")

4 — 524361 — — Gasket, outlet flange (1 required)

5 760721 — — — Door, reclaimer

6 524331 — — — Gasket, reclaimer door

7 524371 — — — Gasket, reclaimer to storage hopper

8 524342 — — — Gasket, tuning band

9 767581 — — — Tuning Band (steel part only)

10 551782 — — — Bolt, 1/4" -20 x 2"

11 552392 — — — Wing nut, 1/4" -20

12 509581 — — — Latch and keeper (requires welding)

13 544122 — — — Plug, 1" NPT (Suction systems only)

14 522611 — — —

15 551842 — — — Bolt, 3/8" -16 x 1" (8 required)

16

17

18 760711 — — — Screen, flat, 5/16"; 13" OD

Additional parts used with Reclaimers

19 — — — Wearplate assembly

All

Sizes

— 140438 — —

— 140439 140440 140441

552542 — — — Nut, 3/8" -16 (1 gun suction systems) 8 required

522762 Lock Washer 3/8

739041 — — — Screen, fine, 11-1/2" OD 8 Mesh

739051 — — — Screen, coarse, 11-1/2" OD 4 Mesh

400

Only

600

Only

900-

1200

Only

Description

Reclaimer Body Assembly with

1 HP 115V/60Hz/1ph blower and bag

Reclaimer Body Assembly

(includes items 1-12)

Exhaust hose assembly for std. 1 cu. ft. pressure vessel (Pressure

system only)

Page 39

Page 40

Empire Abrasive Equipment Company

8.2 Pressure Blast Systems

Parts for Blast Hose Assembly – Standard 1/2”

Item

1 504912 NA-2 Nozzle Adapter

2 505232 NC-1/2 Nozzle Coupling

3

4 505222 QC-1/2 Quick Coupling with washer + screw package item 4,5.6

5 505782 UF-100 Tank Coupling, 1" FPT with AHCW

6 524101 AHCW Coupling Washer (10 pack)

525102 AHCW Coupling Washer (25 pack)

7 523931

8 554242

9 510511 Safety pin

10 564822 Tag, safety, screw/coupling

11 520792 PBH-1/2 Blast Hose (Maximum length: 50')

Part

Number

524041 NW-5 Nozzle Washer, Ceramic nozzles, 5/8" ID (110 pack)

524052 NW-2 Nozzle Washer, Di-Carb/Boron, 1/2" ID (10 pack)

Model

Number

(1" x 13/8")

(#8 x

3/8")

Description

Grommet, blast hose

Screws (4 pack)

Page 40

Page 41

Empire Abrasive Equipment Company

Blast & Air Hoses

Item Bulk

1

2

— 140301 140302 140303 140304 140654 Air hose assembly, 1" ID

520912 — — — — — Air hose, 1" ID

(43") (5') (6') (7') (9') (Air hose length)

— 522551 522541 521672 522561 516281

— 522541 516271 522561 — —

520792 — — — — — Blast hose, 1/2" ID

(7.5') (9') (10') (13') (16') (Blast hose length, std cabinet)

(9') (12') (13') — — (Blast hose length, ERGO)

(Maximum blast hose length: 50’)

2636

Only

3648

3696

Only

4848

Only

6060

60120

Only

7272

Only

Exhaust Hose

Item Part Number Description

3

4 520181 Hose barb, 1" NPT x 1" ID hose (1 each end)

5 520512 Hose clamp, 2" (1 each end)

522611 Exhaust hose (with 1" NPT barb ends), 67" for standard 1 cu. ft. vessel

140691 Exhaust hose (with 1" NPT barb ends), 9 ft. for optional 3 cu. ft. vessel

520822 Exhaust hose (1" ID blast hose) (Maximum length: 50')

Pressure Vessel

Item Part Number Description

6

7

8 760741 Hopper, 1-cubic foot

9 524371 Gasket, reclaimer to hopper)

10 523942 Sealing ring, rubber, 2-1/8" ID

11 510431 Plunger, sealing, PVC coated

12 546072 Plunger guide (1/2" NPT x 3-1/2" nipple)

13 545702 Tee, 1" x 1” x 1/2" NPT

14 517503 Check valve, 1" NPT

15 518492 Ball valve, 1" NPT

16 520581 Hose clamp for 1" ID hose (1 each end)

17 520912 Hose, 1" ID (specify 1.5' for 1 cu. ft.; 3.5' for 3 cu. ft.)

18 545822 Tee, 1" x 2" x 1' NPT

19 546192 Nipple, 1" NPT x close, HD

20

140300 Pressure vessel assembly, 1 cu. ft., Includes shaded items shown.

760811 Pressure vessel only, 1 cu. ft.

504041 Pressure vessel only, 1 cu. ft., with 1" NPT port for level probe

551742 Leveling bolt, 3/8" – 16 x 2", 1 cu. ft. (3 per assembly)

551982 Leveling bolt, 1/2" – 13 x 2-3/4", 3 cu. ft. (3 per assembly)

567332 Label, WARNING “Do not disassemble…”

567312 Label, WARNING “Flange above…”

Description

Blast hose assembly,

1/2" ID (items 16-24)

Blast hose assembly, 1/2" ID,

ERGO

Page 41

Page 42

Empire Abrasive Equipment Company

8.3 Suction Blast Systems

Components

Item

1

2 546332 Nipple, 1-1/4" NPT x 3"

3 544142 Plug, 1-1/4" NPT

4 760441 Outlet adapter, cabinet, 1-1/4"NPT for SAR-2 (no reclaimer)

5 524381 Gasket, cabinet outlet

6 524371 Gasket, reclaimer to hopper (2 required with magnet)

7 520502 Hose clamp, 1/2" air hose (2 per hose)

8 523921 Grommet, air hose, 3/4" x 1-1/16"

9 523931 Grommet, blast hose, 1" x 1-3/8"

Part

Number

760751 Hopper, 1 – gun suction

140487 Hopper, Multi-gun (4 outlet)

Description

Blast & Air Hoses

Item Bulk

— 522831 522841 522851 522861 516261 Air hose assembly, 1/2" ID

10

11

— 522861 522861 516261 — — Air hose, 1/2" ID, ERGO

520861 — — — — — Air hose, 1/2" ID

(7.5') (7') (8') (10') (12') (Air hose length, std cabinet)

(10’) (10’) (12’) — — (Air hose length, ERGO)

— 522571 522581 522591 522601 521201

— 522591 522601 522601 — — Blast hose section, 5/8" ID, ERGO

520802 — — — — — Blast hose, 5/8" ID

(6') (8') (9') (13') (16') (Blast hose length, std cabinet)

(9') (11.5') (13') — — (Blast hose length, ERGO)

(Maximum blast hose length: 50')

2636

Only

3648

3696

Only

4848

Only

6060

60120

Only

7272

Only

Description

Blast hose section, 5/8"

ID

Page 42

Page 43

Empire Abrasive Equipment Company

SAR-2 Media Regulator

Item Part Number Description

12 290156 SAR-2 Media Regulator, complete, 1-1/4" FPT

13 753351 Regulator body, SAR-2

14 510121 Plug, clean out

15 551042 Thumb screw, 1/4"-20 x 1"

PARTS for MH-2 Guns

Item Part Number Description

1

2

3 520402 Hose barb, 1/2" FPT x 1/2" hose

4 505621 Connector, MH-2

5 523912 O-Ring, 1/2" ID x 5/8" OD (2 required)

6 526171 Sleeve, rubber, for air jet

7

8 523881 O-Ring, 1-1/16" ID x 1-5/16" OD

9 520081 Nut, hose clamp, MH-2

10 551702 Set screw, 1/4"-20 x 3/8"

11 511251 Spring, suction gun assist

12 544862 Coupling, 1/2" NPT (BB4-1 A only)

13 543532 Elbow, 1/2" NPT street (BB4-1 A only; 2 per gun)

14 — For replacement nozzles please contact your local Empire Distributor

753551 Gun body, MH-2 LONG handle

753561 Gun body, MH-2 SHORT handle

505651 Air jet, 3/32" (orange)

505661 Air jet, 1/8" (yellow)

505671 Air jet, 5/32" (green)

505681 Air jet, 3/16" (blue)

505691 Air jet, 7/32" (white)

505701 Air jet, 1/4" (red)

505641 Nozzle adapter, plastic (standard)

504931 Nozzle adapter, steel

Page 43

Page 44

Empire Abrasive Equipment Company

8.4 Dust Collectors

Components

Item

1 515521

2

3 523551 Gasket, top plate, 1/8" x 1/4" (DCM-80A uses 8 ft; others use 12 ft.)

4 524351 Gasket, clean out door, dust collectors

5 525711 Gasket, access door, dust collectors 5/8" x 5/8" (103” section)

525061 Gasket, 5/8"x 5/8"

6 760851 Access door, dust collector

7 510461 Knob, 3/8"-16, (6 required)

8 551852 Bolt, 3/8"-16 x 1-1/4", (6 required)

9 551742 Bolt, leveling, 3/8"-16 x 2", (4 required)

10

11 517221 Valve, pushbutton, 1/8" NPT & #10-32, “3P”

12 521101 Barbed fitting, 1/4" tube x #10-32, 1 per assembly

13 520432 Adapter, 1/4" tube x 1/8" MPT, 90º (for air cylinder)

14 521081 Adapter, 1/4" tube x 1/4" MPT (inlet)

15 510541 Tubing, 1/4" O.D.** (8 ft. needed)

16 523161 Hose with fittings, 1/4" x 16 ft. dust collector

17

18 523541 Rubber bumper, 8 required

19 509581 Latch and keeper (requires welding)

20 761801 Adapter, 10" ID x 6" OD, DCM-200

21 551522 Screw, #10-32 x 1/2", 2 required

22 566712 Caulk, tube

23 567401 Decal, Instruction/Warning

24 564305 Decal, Empire logo

25

ADDITIONAL PARTS used with Dust Collectors

26 — Blowers & blower motors

27 — Ducting and adapters

28 — Silencers (optional)

29 — Manometer (optional)

30 — Automatic bag shaker (optional)

Part

Number

Dust bags

QTY: DCM-80A & DCR-80 (12), DCM-200 & DCM-200A (30)

760841 Top plate DCM-80A

760901 Top plate DCM-200 & DCM-200A

515981 Air cylinder, standard collector and auto shaker

515771 Air cylinder, auto-pneumatic bag shaker only

760861 Bag Rack Weldment (DCM-80A)

760921 Bag Rack Weldment (DCM-200A)

564301 Decal, orange dot strip

564471 Paint, 6 oz. aerosol, Beige

Description

Page 44

Page 45

Empire Abrasive Equipment Company

Large Dust Bag

Item

A 515841 Dust bag, 4" inlet, 30 sq. ft.

B 520461 Closure clamp

C 520531 Clamp, 4" adjustable

D — Blower

E — Slide gate

F — Deflector (baffle)