Page 1

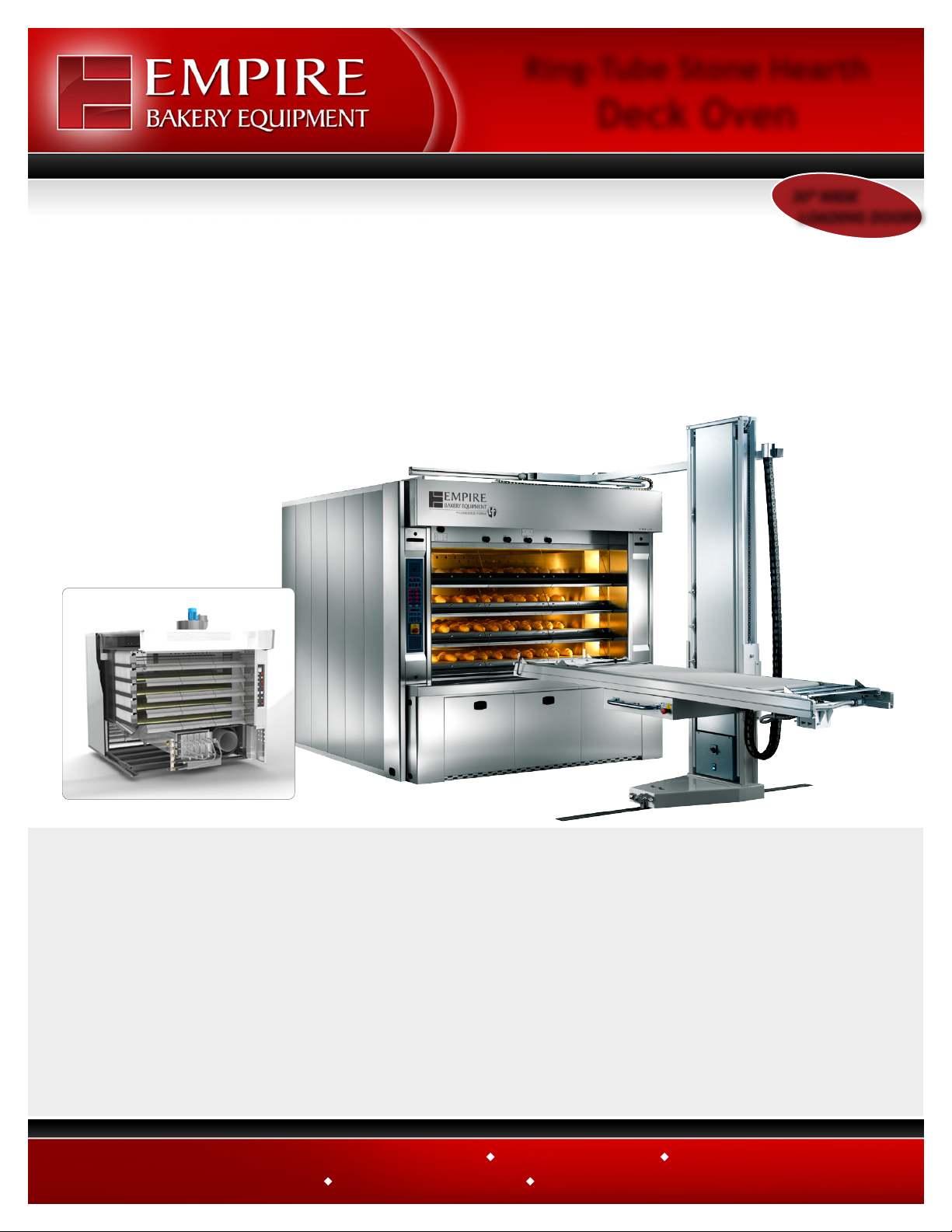

Ring-Tube Stone Hearth

Deck Oven

LFKR/760

30” WIDE

LOADING DOORS

The Pinnacle of Ring Tube Deck Oven Design

Innovation and tradition combine to form Empire’s LFKR Stone Hearth Deck Oven. Sturdy, well insulated Mannesmann steam tube

systems distribute heat quickly and evenly throughout the oven, allowing it to respond rapidly to temperature change. Individual steam

generators strategically positioned in the re box are capable of producing consistent steam for your entire production. Lighter and

smaller than similar ovens in its class, the LFKR allows for easier installation and accessibility in smaller locations. Available in 2, 3 and

4 door models with up to 5 decks, this powerhouse boasts an equivalent pan capacity of up to 74 pans, allowing you to produce nearly

400 loaves of consistent, high quality artisan bread per bake. Best of all, our manual, semi-automatic, and automatic loader/unloader

requires minimum training to master, making the LFKR Stone Hearth Deck Oven extremely easy to operate.

Features

♦ State-of-the-Art Insulated Ring Tube Design

♦ Available in 2, 3 & 4 Door Designs, up to 5 Decks

♦ Stone Hearth Baking Surface

♦ Individual Steam Generators for Each Deck

♦ Counter Balanced Doors made of Tempered Glass

♦ Digital Thermostat & Automatic Steam Timers

1C Enterprise Place, Hicksville, NY 11801-5356 Ph: (516) 681-1500 Fx: (516) 681-1510

1-800-878-4070 www.empirebake.com Email: info@empirebake.com

♦ Extra Wide 30” Loading Doors

♦ 24 Volt Control System

♦ Pan Capacity Based on Standard 18” x 26” Pan

♦ Compact, Front Mounted Oven Controls

♦ Available with Manual, Semi-Automatic, and

Automatic Loaders

Page 2

Technical Data

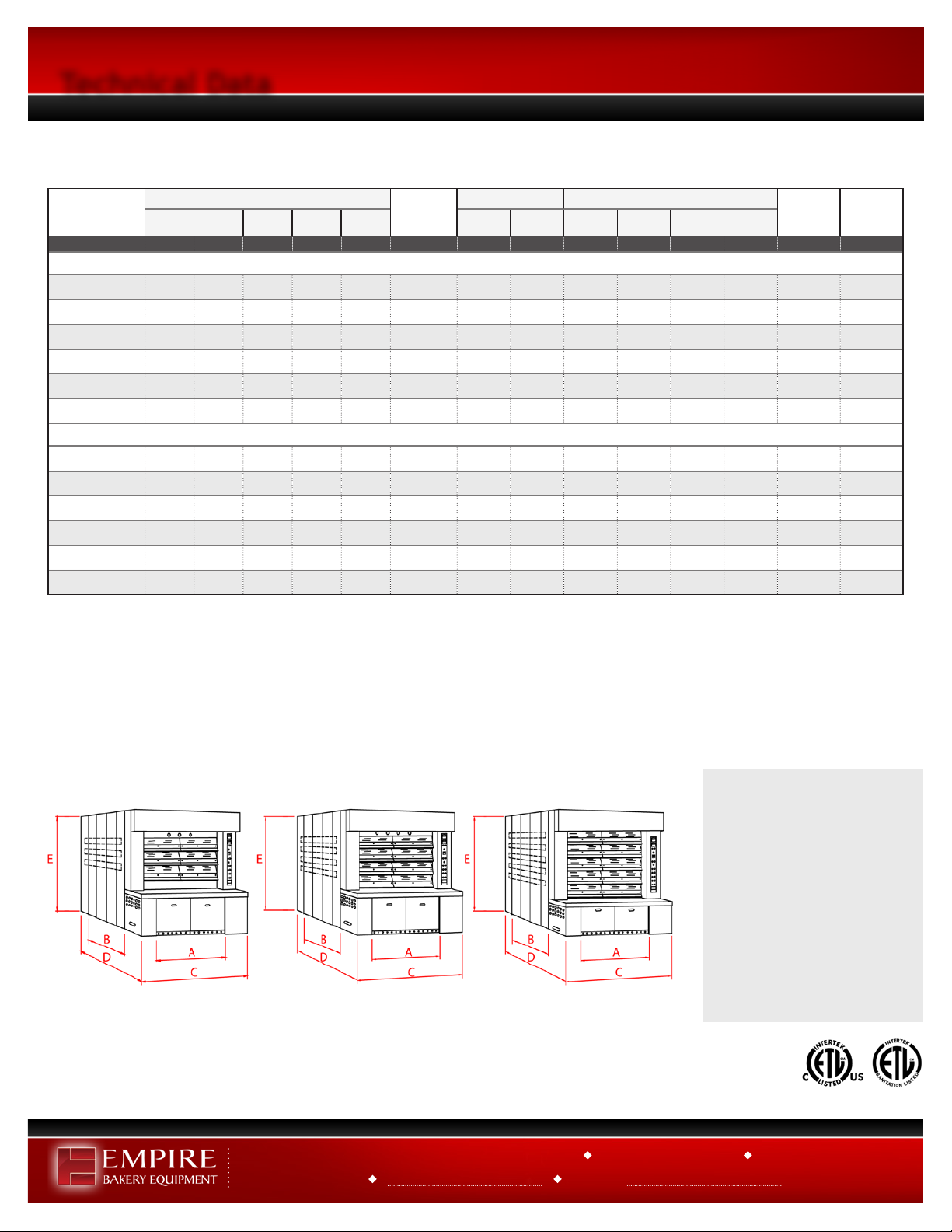

LFKR-0912

Model

Overall Dimensions

WIDTH

DEPTH

(C)

in in in in in lbs in in ft² BTU/hr Kw

(D)

HEIGHT

(E)

DEPTH

w/ Loader

HEIGHT

w/ Fan*

Net Wt

Deck Dimensions Deck Capaciy

WIDTH

DEPTH

(A)

Surface

(B)

Area

Actual Pan

Capacity

Equivalent

Pan Cap.

Approx 1Lb

Loaves

Thermal

Power

Installed

Electrical

3 Deck** (Usable Deck Heights, from top: 9.06”, 7.87”, 7.87”)*

LFKR-320/760 81.9 116.5 90.6 232.9 104.6 8,157 59.8 63.0 78.5 18 24.2 133 198,000 1.5

LFKR-321/760 81.9 132.3 90.6 263.2 104.6 9,259 59.8 78.7 98.1 24 30.2 166 218,000 1.5

LFKR-322/760 81.9 148.0 90.6 296.3 104.6 10,803 59.8 94.5 117.8 30 36.2 199 238,000 1.5

LFKR-330/760 111.8 116.5 90.6 232.9 104.6 10,362 89.8 63.0 117.8 27 36.2 199 278,000 1.5

LFKR-331/760 111.8 132.3 90.6 263.2 104.6 12,566 89.8 78.7 147.2 36 45.3 249 298,000 1.5

LFKR-332/760 111.8 148.0 90.6 296.3 104.6 13,889 89.8 94.5 176.6 45 54.3 299 317,000 1.5

4 Deck** (Usable Deck Heights, from top: 8.27”, 6.69”, 6.69”, 6.69”)*

LFKR-420/760 81.9 116.5 90.6 232.9 104.6 10,582 59.8 63.0 104.7 24 32.2 177 258,000 1.5

LFKR-421/760 81.9 132.3 90.6 263.2 104.6 11,684 59.8 78.7 130.8 32 40.3 221 278,000 1.5

LFKR-422/760 81.9 148.0 90.6 296.3 104.6 13,669 59.8 94.5 157.0 40 48.3 266 298,000 1.5

LFKR-430/760 111.8 116.5 90.6 232.9 104.6 13,448 89.8 63.0 157.0 36 48.3 266 298,000 1.5

LFKR-431/760 111.8 132.3 90.6 263.2 104.6 15,653 89.8 78.7 196.3 48 60.4 332 337,000 1.5

LFKR-432/760 111.8 148.0 90.6 296.3 104.6 17,857 89.8 94.5 235.5 60 72.5 399 377,000 1.5

NOTES:

Increased deck heights available as an option. Use of a PSA loader will reduce deck clearance by 2”.

*

Each deck has a door width of 30”

**

Equivalent pan capacity is a reference used to estimate the number of breads that can be baked at one time and is calculated by dividing the total

***

baking surface by the area of a standard bun pan (3.25 sq. ft.)

NOTE: Specications are subject to revision and conrmation. Drawings are for illustration only, not for construction use.

1C Enterprise Place, Hicksville, NY 11801-5356 Ph: (516) 681-1500 Fx: (516) 681-1510

1-800-878-4070 www.empirebake.com Email: info@empirebake.com

Fuel:

Oil, Natural Gas, Propane

Electrical:

220V/3 Ph 16 Amp Service

+ 110V 10 Amp line (burner)

Plumbing:

Drain Line - 1/2”

Water Connection - 1/2” cold water

Venting:

Burner Exhaust - 8”

Steam Exhaust - 10”

*Steam Exhausts at 1,167 cfm

Ventilation:

Please refer to our technical bulletins regarding

combustion, steam ventilation and makeup air. All

installations must adhere to all applicable codes.

Loading...

Loading...