Empire DVCP(32, 36, 42)BP30(N, P)-3DVCP(32 Installation Instructions Manual

INSTALLATION INSTRUCTIONS

INSTALLER:

Leave this manual with the appliance.

CONSUMER:

Retain this manual for future reference.

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death or

property damage.

— Donotstoreorusegasolineorotheram-

mable vapors and liquids in the vicinity of

this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Donottrytolightanyappliance.

• Donottouchanyelectricalswitch;do

not use any phone in your building.

• Leavethebuildingimmediately.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• Ifyoucannotreachyourgassupplier,

calltheredepartment.

— Installation and service must be per-

formed by a qualied installer, service

agency or the gas supplier.

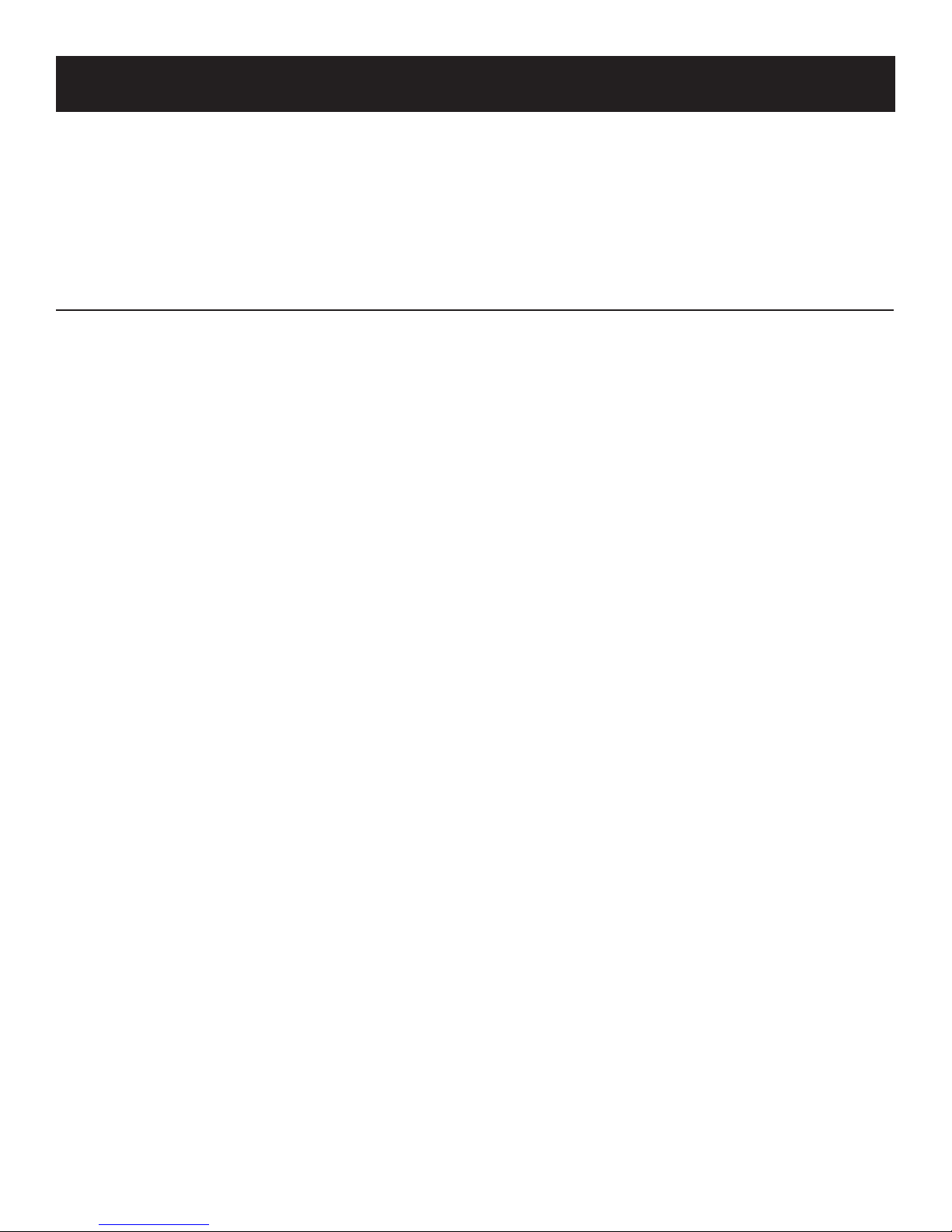

DIRECT VENT

ZERO CLEARANCE GAS

FIREPLACE HEATER SERIES

MILLIVOLT (MV)

DVCP(32,36,42)BP30(N,P)-3

INTERMITTENT PILOT (IP)

DVCP(32,36,42)BP70(N,P)-3

This appliance may be installed in

an aftermarket, permanently located,

manufactured home (USA only) or mobile

home, where not prohibited by state or

local codes.

This appliance is only for use with the type

of gas indicated on the rating plate. This

appliance is not convertible for use with

othergases,unlessacertiedkitisused.

GAS-FIRED

WARNING

HOT GLASS

CAUSE BURNS.

DO NOT TOUCH

UNTIL COOLED.

NEVER

A barrier designed to reduce the risk of burns from the

hot viewing glass is provided with this appliance and shall

be installed for the protection of children and other at-risk

individuals.

ALLOW CHILDREN

TO TOUCH GLASS.

WILL

GLASS

UL FILE NO. MH30033

This replace is design

certied in accordance

with American National

Standard/CSA Standard

ANSI Z21.88/CSA 2.33

and by Underwriters

Laboratories as a Direct

Vent Gas Fireplace

Heater and shall be

installed according to

these instructions.

Page 1

TABLE OF CONTENTS

SECTION PAGE

ATTENTION INSTALLER ..............................................................................................................3

BEFORE YOU START ................................................................................................................ 4-5

CARTON CONTENTS ................................................................................................................... 6

INTRODUCTION ........................................................................................................................... 7

HOMEOWNER REFERENCE INFORMATION ............................................................................. 7

SPECIFICATIONS ......................................................................................................................... 8

ACCESSORIES ............................................................................................................................. 9

FIREPLACE DIMENSIONS ......................................................................................................... 10

FBB10 BLOWER KIT INSTALLATION (OPTIONAL) .............................................................. 11-13

CLEARANCES ............................................................................................................................14

TERMINATION CLEARANCES ................................................................................................... 15

VENT TERMINAL CLEARANCES ............................................................................................... 16

GAS SUPPLY .............................................................................................................................. 17

SAFETY INFORMATION FOR USERS OF LP GAS ................................................................... 18

LOCATING FIREPLACE .............................................................................................................. 19

JUNCTION BOX WIRING INSTALLATION INSTRUCTIONS ......................................................19

MILLIVOLT STANDING PILOT WIRING DIAGRAM .................................................................... 20

IPI ELECTRONIC SYSTEM WIRING DIAGRAM ........................................................................ 21

INSTALLATION .......................................................................................................................22-25

VENT FRAMING .....................................................................................................................26-27

VENT SYSTEM IDENTIFICATION .............................................................................................. 28

SPECIAL VENT SYSTEMS ......................................................................................................... 28

VENTING FIREPLACE - TOP ................................................................................................ 29-32

EXAMPLES - TOP VENT RUN .................................................................................................... 33

HORIZONTAL TERMINATION .....................................................................................................34

VERTICAL TERMINATION .....................................................................................................35-36

DVVK-4F FLEX VENT INSTRUCTIONS ................................................................................37-38

MILLIVOLT STANDING PILOT LIGHTING INSTRUCTIONS ...................................................... 39

MILLIVOLT OPERATING INSTRUCTIONS ................................................................................. 40

MILLIVOLT STANDING PILOT TROUBLESHOOTING ............................................................... 41

INTERMITTENT PILOT LIGHTING INSTRUCTIONS ................................................................. 42

IPI ELECTRONIC SYSTEM OPERATING INSTRUCTIONS....................................................... 43

INTERMITTENT PILOT CONTROL SYSTEM TROUBLESHOOTING ...................................44-45

MILLIVOLT PARTS VIEW - DVCP(32,36,42)BP3 ....................................................................... 46

MILLIVOLT PARTS LIST - DVCP(32,36,42)BP3 ......................................................................... 47

IP PARTS VIEW - DVCP(32,36,42)BP7 ...................................................................................... 48

IP PARTS LIST - DVCP(32,36,42)BP7 ........................................................................................ 49

MAINTENANCE AND SERVICE ............................................................................................50-51

IMPORTANT SAFETY INFORMATION - INSTALLER ................................................................. 52

REQUIREMENTS FOR MASSACHUSETTS .............................................................................. 53

ANNUAL FIREPLACE INSPECTION CHECKLIST ..................................................................... 54

MASTER PARTS DISTRIBUTOR LIST ....................................................................................... 55

HOW TO ORDER REPAIR PARTS .............................................................................................55

WARRANTY ................................................................................................................................ 56

37607-1-0817Page 2

ATTENTION INSTALLER:

Fireplace Installation Checklist

Use this checklist in conjunction with the instructions in this manual.

Customer: _____________________________________

Lot/Address: ___________________________________

_______________________________________________

Model: ________________________________________

Serial # ________________________________________

Date Installed: __________________________________

Fireplace Location: ______________________________

Installer: _______________________________________

Dealer Phone #: _________________________________

_______________________________________________

FIREPLACE INSTALLATION COMMENTS

Veried clearances to combustibles (pg. 14) ........................................................................ o ____________________

Fireplace is leveled and secured .......................................................................................... o ____________________

VENTING/CHIMNEY/PowerFlow™ HEAT DISTRIBUTION

Venting conguration complies to vent diagrams (pg. 29) .................................................... o ____________________

Venting installed, locked, secured in place with correct clearance ....................................... o ____________________

Firestops installed................................................................................................................. o ____________________

Exterior wall/roof ashing installed and sealed..................................................................... o ____________________

Terminations installed and sealed (pgs. 34-36) .................................................................... o ____________________

Light unit and test venting before enclosing the replace .................................................... o ____________________

ELECTRICAL (pgs. 19-21)

Unswitched power (110-120 VAC) provided to the replace ................................................ o ____________________

GAS (pgs. 17-18)

Proper appliance for fuel type............................................................................................... o ____________________

Was a conversion performed? .............................................................................................. oYes oNo

Leak check performed and inlet pressure veried ................................................................ o ____________________

FINISHING (pgs. 23-24)

Non-combustable board installed as required ...................................................................... o ____________________

Veried all clearances meet installation manual requirements ............................................. o ____________________

Mantels and wall projections meet requirements ................................................................. o ____________________

Granite or Clean Face nishing complies with clearance requirements screen ................... o ____________________

Barrier for glass front properly installed ................................................................................ o ____________________

FIREPLACE SETUP

All packaging and protective materials removed (inside & outside of replace) .................. o ____________________

Media installed correctly ....................................................................................................... o ____________________

Firebox glass door cleaned, installed, and secured ............................................................. o ____________________

Accessories installed properly .............................................................................................. o ____________________

Started Fireplace and veried no gas leaks exist ................................................................. o ____________________

Manual envelope and all of its contents removed from inside/outside the

replace and given to party responsible for use and operation ............................................ o ____________________

Provide homeowner with “Scratch & Sniff” odor card .......................................................... o ____________________

Empire recommends the following:

• Keep this checklist visible on the replace until the installation is complete.

• Photograph the installation and copy this completed checklist for your le.

Comments: Further description of the issues, who is responsible (Installer/Builder/Other, etc) and corrective action needed:

___________________________________________________________________________________________________________

Comments communicated to party responsible _____________________by _____________________ on ______________________

37607-1-0817 Page 3

BEFORE YOU START

SampleWarningsandDenitions:

DANGER

Indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE: Addresses practices not related to personal injury.

____________________________________________________

Read all instructions before starting installation and

follow them carefully to ensure safety. Failure to follow

the instructions will void the warranty and may cause a

rehazard.

The warranty will be voided by, and the warranter disclaims

any responsibility for the following actions:

• Installation by anyone other than the dealer or his agent.

• Installation of any damaged replace or component.

• Modication of the replace or direct vent system.

• Installation other than as instructed by Empire Comfort

Systems.

• Improper positioning of logs, glass door, or accessories.

• Installation and/or use of any component part not

manufactured or approved by Empire Comfort Systems.

Installing a television above a replace has become increasingly

popular; however, the area above any replace gets hot and most

TV manufacturers recommend against placing their products

near a heat source.

If you install a television above this replace, Empire Comfort

Systems accepts no responsibility for damage or injuries. Follow

the television manufacturer’s installation instructions, including

any recommendations regarding proximity to heat sources.

If you have a TV above your replace, turn off the replace and

let it cool completely before servicing or touching any buttons on

the TV.

All correspondence should refer to complete Model Number, Serial

Number and type of gas. Fill out the Homeowner Reference Section.

(See Page 3).

Unpacking The Fireplace

1. Cut away shrink-wrap material around the unit.

Retain instruction manual and instruction sheets.

2. Remove non-combustible board from the rear of the

replace, and place in a safe location. It will be needed

for installation.

3. Get help to lift replace.

Television Considerations

37607-1-0817Page 4

BEFORE YOU START (CONTINUED)

Preparation

This replace and its components are safe when installed

in accordance with this manual. Report any parts damaged

in shipment to your dealer. Do not install the replace with

damaged, incomplete or substitute parts.

Installation Considerations

• Gas supply piping – right or left side entrance

• Electrical supply and connections 120V, 60Hz, 1 Amp,

right side entrance

• Allowable replace mounting surfaces:

1. A at, hard, combustible or non-combustible surface

2. A raised platform of combustible or non-combustible

material.

3. The four corners of the replace onto non-combustible

material so that contact is made on all four perimeter

edges on the bottom of the replace – such as on cinder

blocks (where allowed by local codes).

• If the replace is installed directly on carpeting, tile or other

combustible material other than wood ooring, it should be

installed on a metal or wood panel extending the full width

and depth of the replace.

• This replace is designed to be installed in a zero-clearance

enclosure. Combustible material can come in contact with

the side standoff spacers, and the replace can be secured

to combustible framing with the framing brackets provided

with the replace.

Planning the installation

First determine where the replace will be located and what

accessories will be installed.

Your location must allow for:

• Venting – either vertical or horizontal. Choose a vent

conguration, (See Pages 34-36) and make sure the required

access through attics and walls is not blocked by other utilities

such as water lines, sewer vents, gas lines, etc. If access

is blocked, you will need to move the utilities or relocate the

replace.

• Gas supply piping (right or left side of entrance) – (See pipe

size and specs on Page 17).

• Electrical supply requirements

(120V, 60Hz, 1 Amp) (right side entrance)

• Proper framing required for installation of the replace.

See framing dimensions on (See Page 22).

• Finishing the replace – drywall thickness, tile or stone

thickness, and the desired decorative accessories can affect

how you frame the opening and how you attach the nailing

anges to set the proper depth. (See Pages 23 - 24) for

nishing details, before you begin.

Accessories

Most accessories install much more easily before tting the

replace to the opening.

For example, it takes just 10-15 minutes to install the blower side

before it’s framed in. Once the replace is framed in, it takes up

to an hour.

37607-1-0817 Page 5

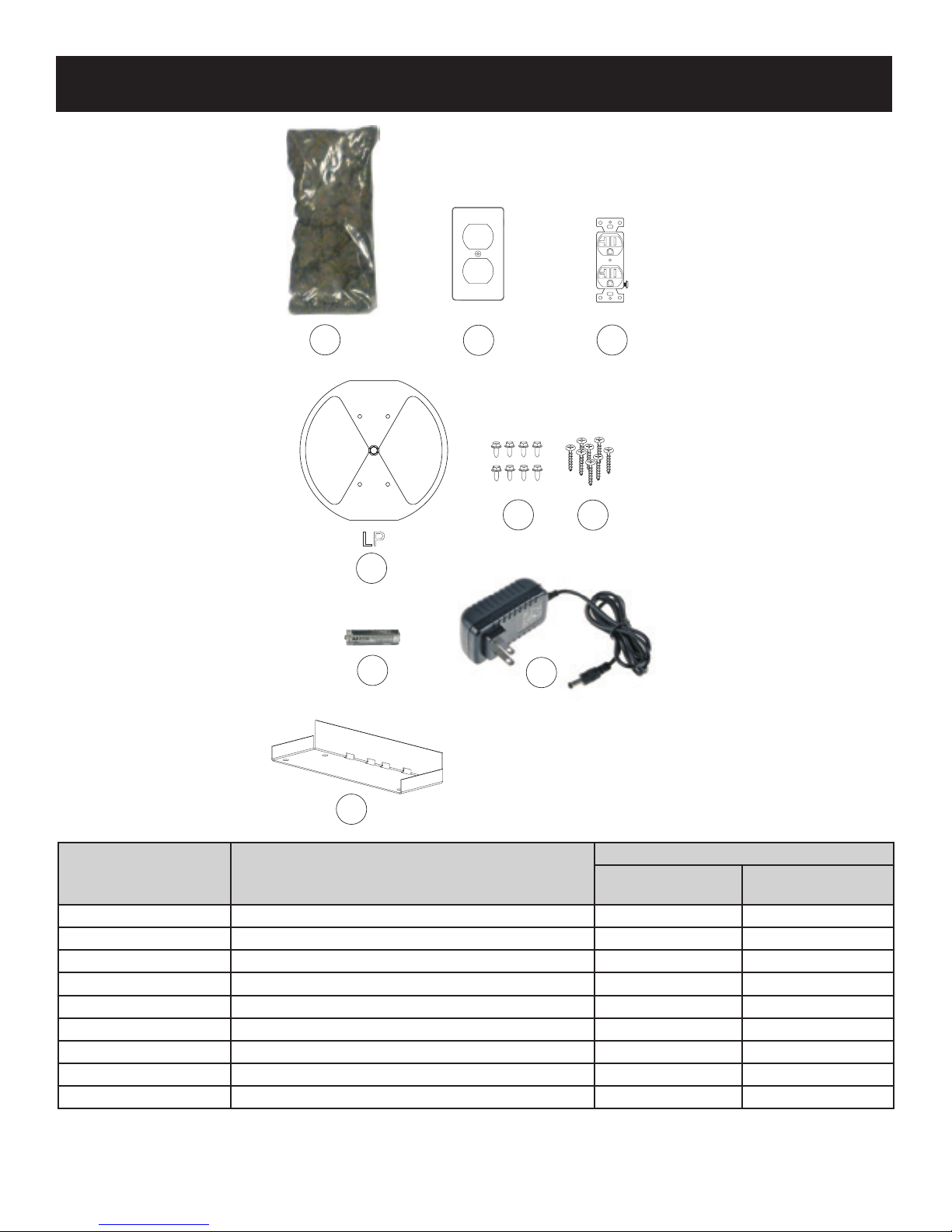

CARTON CONTENTS

1

2

5

3

6

LP

4

7

8

10

9

NOTICE: Items not shown to scale.

INDEX

NUMBER

1 Rock Wool 1 1

2 Receptacle Cover 1 2

3 Receptacle 1 2

4 Flue Restrictor Assembly - (See Page 30) 1 1

5 10 X 1/2 Phillips Screw 12 12

6 #8 X 1 Self-Drilling Drywall Screw 8 8

7 AA Battery 0 4

8 AC Adaptor 0 1

9 Backer Stud 4 4

See Parts Lists on pages 48 - 51 for ordering replacement parts. Do not order batteries, bolts, screws, washers or nuts. They are

standard hardware items and can be purchased at any local hardware store.

DESCRIPTION

QUANTITY SUPPLIED

DVCP(32,36,42)BP3

SERIES

DVCP(32,36,42)BP7

SERIES

37607-1-0817Page 6

INTRODUCTION

The information in this manual pertains to all models and gas

control systems unless otherwise noted.

Instructions to Installer

1. Leave this manual with homeowner.

2. Have the homeowner complete the product registration card

or register online at www.empirecomfort.com

3. Show the homeowner how to start and operate the replace.

Notes to Installer

• This direct-vent replace is designed to:

- Operate with combustion air drawn from outside of the

building.

- Expel all exhaust gases to the outside of the building.

• The installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas Code

ANSI Z223.1/NFPA 54* Natural Gas and Propane Installation

Code, or CSA B149.1 in Canada. * Available from the

American National Standards Institute, Inc. 11 West 42nd

St., New York, N.Y. 10036

• Any alteration of the original design, installation other than

as shown in these instructions, or use with a type of gas not

shown on the rating plate is the responsibility of the person

and company making the change.

• This replace is not for use with solid fuels.

• These replace models may be installed in a bedroom or

bed-sitting room in the U.S.A. and Canada.

WARNING

Any change to this replace can be dangerous. Improper

installation or use can cause serious injury or death from

re,burns,explosionorcarbonmonoxidepoisoning.

FireplaceCertication

This replace is design certied in accordance with American

National Standard/CSA Standard ANSI Z21.88/CSA 2.33 and by

Underwriters Laboratories as a Direct Vent Gas Fireplace Heater

and shall be installed according to these instructions.

Consult your local building code agency, prior to installation,

to ensure compliance with local codes-including permits and

inspections.

The replace, when installed, must be electrically grounded in

accordance with local codes or, in absence of local codes, with

the National Electric Code ANSI/NFPA 70 or Canadian Electric

code, CSA C22.1, if an external electrical source is utilized.

QualiedInstallingAgency

Installation and replacement of gas piping, gas utilization

equipment or accessories and repair and servicing of equipment

shall be performed only by a qualied agency. The term “qualied

agency” means any individual, rm, corporation or company

which either in person or through a representative is engaged

in and is responsible for (a) the installation or replacement of

gas piping or (b) the connection, installation, repair or servicing

of equipment, who is experienced in such work, familiar with all

precautions required and has complied with all the requirements

of the authority having jurisdiction.

Commonwealth of Massachusetts: The installation must be

made by a licensed plumber or gas tter in the Commonwealth

of Massachusetts. Requirements on Page 53.

High Altitude (USA)

When installing this replace at an elevation above 2000 feet

(in the United States) it may be necessary to decrease the input

rating by changing the existing burner orice to a smaller size.

Generally, input should be reduced 4 percent for each 1000 feet

above sea level.

37607-1-0817 Page 7

High Altitude (CANADA)

Altitude: 0-4500 feet (0-1370 meters)

When installing this replace at an elevation above 4500 feet

(in Canada), check with local authorities.

Consult your local gas utility for assistance in determining the

proper orice for your location.

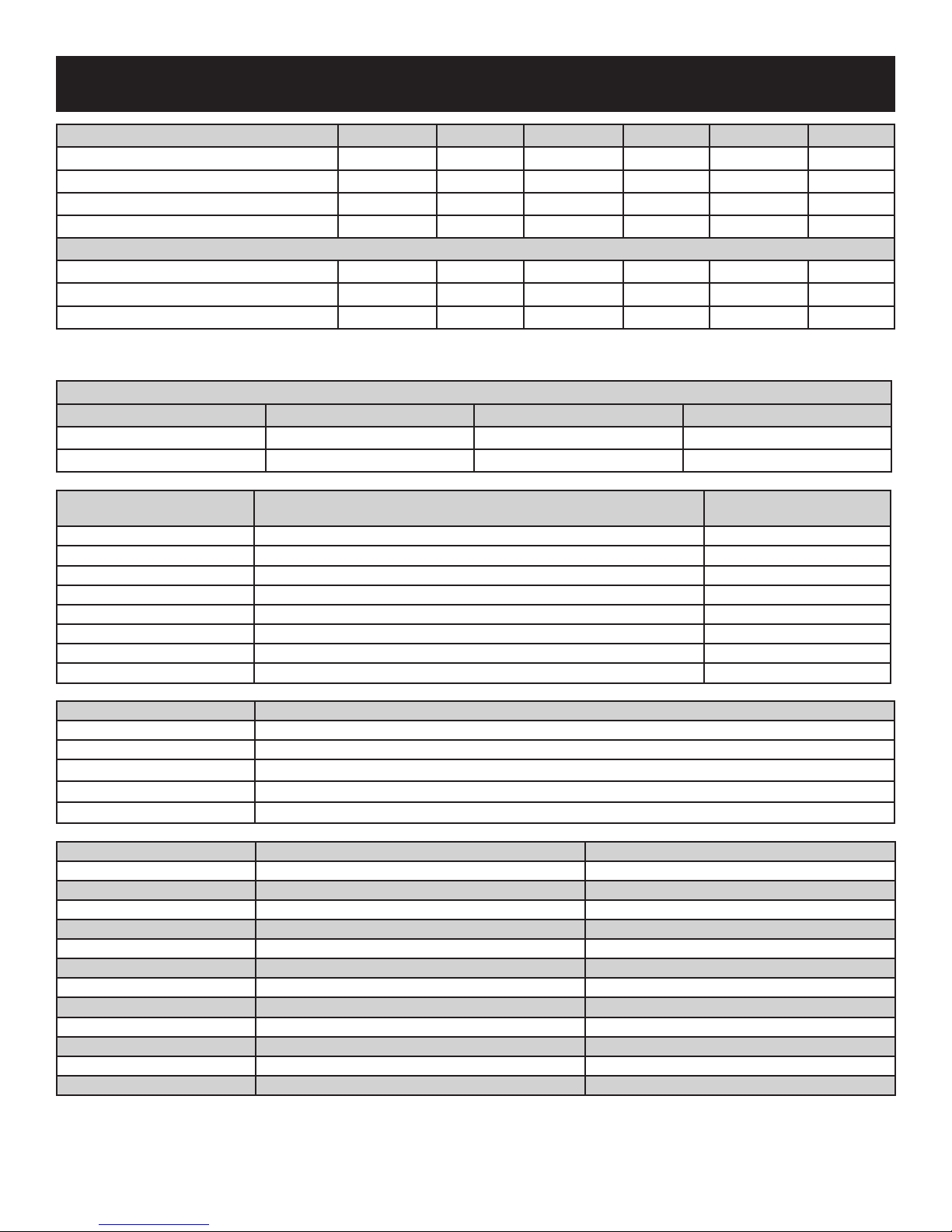

SPECIFICATIONS

DVCP32NAT DVCP32LP DVCP36NAT DVCP36LP DVCP42NAT DVCP42LP

Input BTU/Hr Maximum 24,000 22,000 24,000 24,000 28,500 26,500

Input BTU/Hr Minimum (millivolt only) 18,000 18,000 18,000 19,000 21,000 22,000

KWH (Maximum) 7.03 6.45 7.03 7.03 8.35 7.77

KWH (Minimum) 5.27 5.27 5.27 5.57 6.15 6.3

Orice 42 54 42 1.45mm 39 1.55mm

Air Shutter Opening 3/16-in Full Open 3/16-in Full Open 1/8-in Full Open

Gas Inlet Shutoff Valve (Pipe) 1/2 NPT 1/2 NPT 1/2 NPT 1/2 NPT 1/2 NPT 1/2 NPT

NOTICE:

optimum performance.

Air shutters are factory set for typical venting. Some venting congurations may require minor air shutter adjustments for

GAS SUPPLY PRESSURES

GAS TYPE MAXIMUM MINIMUM MANIFOLD

NAT 14.0-in 4.5-in 3.5-in

LP 14.0-in 10.8-in 10.0-in

Remote Control Options

And Accessories

FRBC Millivolt Battery Remote ON/OFF ALL

FRBTC Millivolt Battery Remote Thermostat ALL

TMW Millivolt Wireless Wall Thermostat ALL

TRW Millivolt Reed Switch Wall Thermostat ALL

FWS-1 Direct Ignition/Millivolt Wall Switch ALL

FRBTP Battery Operated Remote Control with Programmable Thermostat ALL

RVKN-1 Remote Kit, NAT (Stepper Motor) DVCP(32,36,42)BP7N

RVKP-1 Remote Kit, LP (Stepper Motor) DVCP(32,36,42)BP7P

Venting Options Description

DVVK-4TSP Top vent kit (horizontal) - 4-½-in to 6-in (114.3mm to 152mm) wall thickness

DVVK-4TP Top vent kit (horizontal) - 8-in to 12-in (203mm to 305mm) wall thickness

DVVK-4VP Vertical vent kit

DVVK-4F Horizontal ex vent kit (4ft FLEX)

SD46DVA-FCFX7 Flex Adaptor Collar (must be used with ex kits)

Description Models Used On

Conversion Kits Description Used On

31768 Conversion Kit, DV (Natural to Propane) DVCP32BP30

31769 Conversion Kit, DV (Propane to Natural) DVCP32BP30

31770 Conversion Kit, DV (Natural to Propane) DVCP36BP30

31771 Conversion Kit, DV (Propane to Natural) DVCP36BP30

31772 Conversion Kit, DV (Natural to Propane) DVCP42BP30

31773 Conversion Kit, DV (Propane to Natural) DVCP42BP30

32874 Conversion Kit, DV (Natural to Propane) DVCP32BP70

32875 Conversion Kit, DV (Propane to Natural) DVCP32BP70

32876 Conversion Kit, DV (Natural to Propane) DVCP36BP70

32877 Conversion Kit, DV (Propane to Natural) DVCP36BP70

32878 Conversion Kit, DV (Natural to Propane) DVCP42BP70

32879 Conversion Kit, DV (Propane to Natural) DVCP42BP70

37607-1-0817Page 8

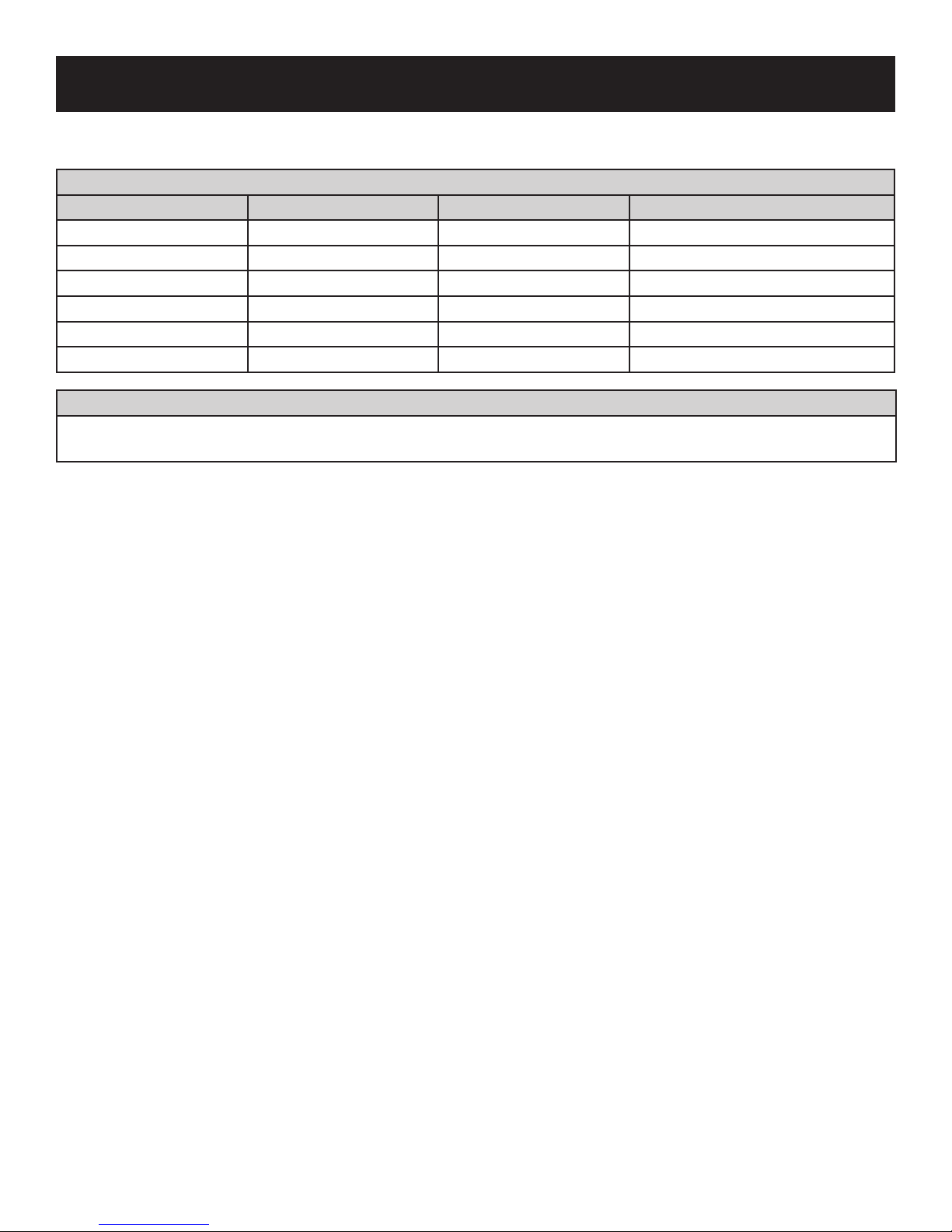

ACCESSORIES

The following accessories are available from your Empire Comfort Systems dealer. If you need additional information beyond what your

dealer can furnish, contact Empire Comfort Systems Inc., 918 Freeburg Ave., Belleville, Illinois 62220-2623 or info@empirecomfort.com.

OPTIONAL

DVCP32 DVCP36 DVCP42 Description

DVP32FAB DVP36FAB DVP42FAB Liner, Aged Brick, Ceramic Fiber

DVP32FCB DVP36FCB DVP42FCB Liner, Cottage Brick, Ceramic Fiber

DVP32FRB DVP36FRB DVP42FRB Liner, Rustic Brick, Ceramic Fiber

DVP32LKR DVP36LKR DVP42LKR Liner, Black Reective

FBB10 FBB10 FBB10 Blower, Auto Variable-Speed

LK6 LK6 LK6 Lighting Kit, 120 V

REQUIRED

This unit requires Ceramic Fiber Logs to complete the replace interior. Contact your Empire Comfort Systems Dealer (See Page 55)

for further information. Do not operate the replace without the Ceramic Fiber Logs installed.

37607-1-0817 Page 9

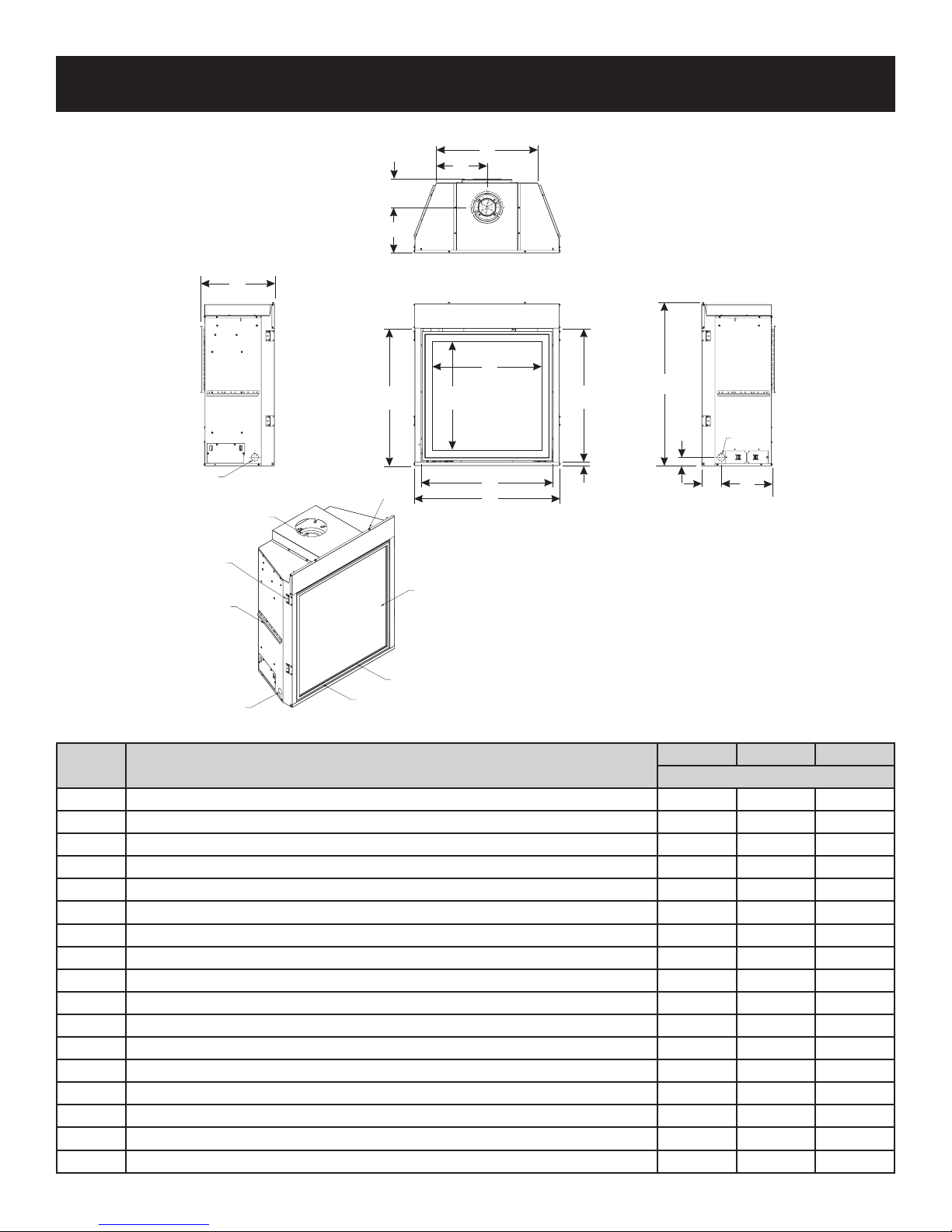

FIREPLACE DIMENSIONS

VENT COLLAR

NAILING

FLANGES

BARRIER SCREEN ASSEMBLY

&

GLASS FRAME ASSEMBLY

GAS LINE

ACCESS

RATING PLATEAND

LABELS INSIDE

GAS CONTROL AND

SWITCHES INSIDE

A

K

L

LEFT VIEW

FRONT VIEW

TOPVIEW

RIGHT VIEW

P

M

GAS LINE

ACCESS

N

O

SIDE STANDOFF

TOPSTANDOFF

G

I

J

C

GAS LINE

ACCESS

INDEX

LETTER

DIMENSION DESCRIPTION

A The maximum height of replace face (excluding standoffs) 38-1/4 38-1/4 40-1/4

B The maximum width of the replace face (excluding nailing anges) 34-7/16 37-7/16 43-7/16

C The maximum depth of the replace 17-1/2 17-1/2 17-1/2

D The height of the replace opening 31-3/8 31-3/8 33-3/8

E The width of the replace opening 31 34 40

F The interior depth of the replace (not shown) 11-1/2 11-1/2 11-1/2

G The rear exterior width of the replace 23-15/16 26-15/16 32-15/16

I Width from the left side of the replace to the centerline of vent 12 13-1/2 16-1/2

J Depth from back of replace to centerline of top vent 6-3/4 6-3/4 6-3/4

K Height from the bottom of the replace to the left gas line opening 2 2 2

L Depth from the front of the replace to the left gas line opening 4-5/8 4-5/8 4-5/8

M Depth from rear of replace to gas line opening 12-5/16 12-5/16 12-5/16

N Viewing area height 24-7/8 24-7/8 26-3/8

O Viewing area width 27-1/2 30-1/2 36-1/2

P Depth from front of replace to centerline of vent 10-3/4 10-3/4 10-3/4

Q Distance from oor to bottom replace opening 7/8 7/8 7/8

R Distance from oor to top replace opening 32-1/4 32-1/4 34-1/4

R

D

E

B

Q

DVCP32 DVCP36 DVCP42

(Inches)

37607-1-0817Page 10

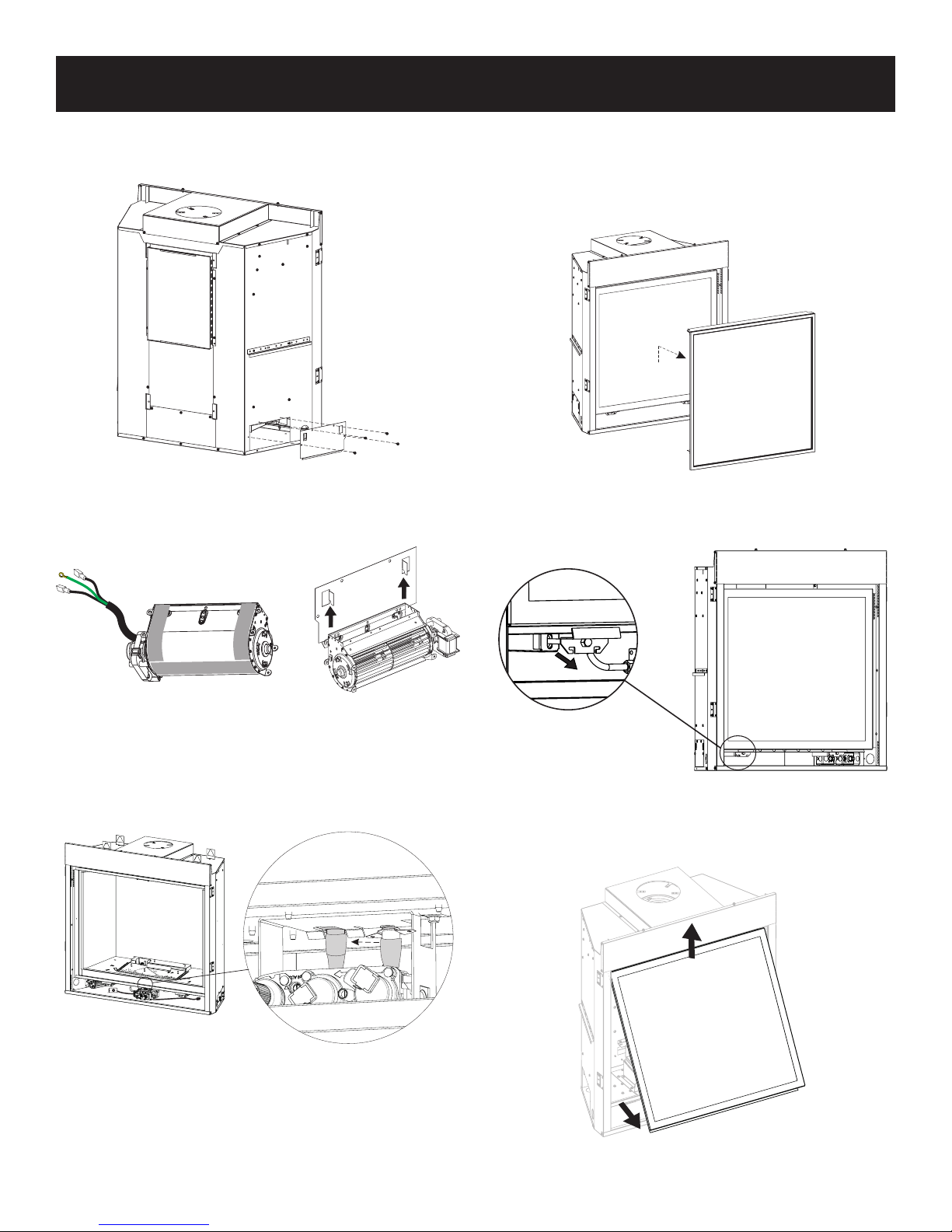

FBB10 BLOWER KIT INSTALLATION (OPTIONAL)

Back side of Blower

showing Velcro

BEFORE FIREPLACE IS INSTALLED IN WALL

1. With power turned off, remove plate and four screws from left

panel. See Figure 1.

Figure 1

2. Install the blower onto the pre-bent brackets on the blower

plate. Ensure the Velcro connects to secure the blower in

place. See Figure 2.

AFTER FIREPLACE IS INSTALLED IN WALL

NOTICE: Do not handle barrier screen or door with your bare

hands! (Always Wear Gloves)

1. Turn off power and gas. Lift barrier screen and pull away

from the unit. See Figure 4.

Figure 4

2. Pull outward to release both latches at bottom of rebox

assembly. See Figure 5.

Figure 2

3. Route wiring through opening created in Step 1.

4. Secure blower assembly into place per step 2 with velcro.

5. Install thermo disc by snapping into valve bracket burner

assembly. See Figure 3.

Figure 3

6. Connect power source into outlet on the bottom right side of

the replace.

Figure 5

3. Disengage Glass Frame by pulling outward in a swinging

motion. Place Glass Frame aside in a safe out-of-the-way

location. See Figure 6.

Figure 6

37607-1-0817 Page 11

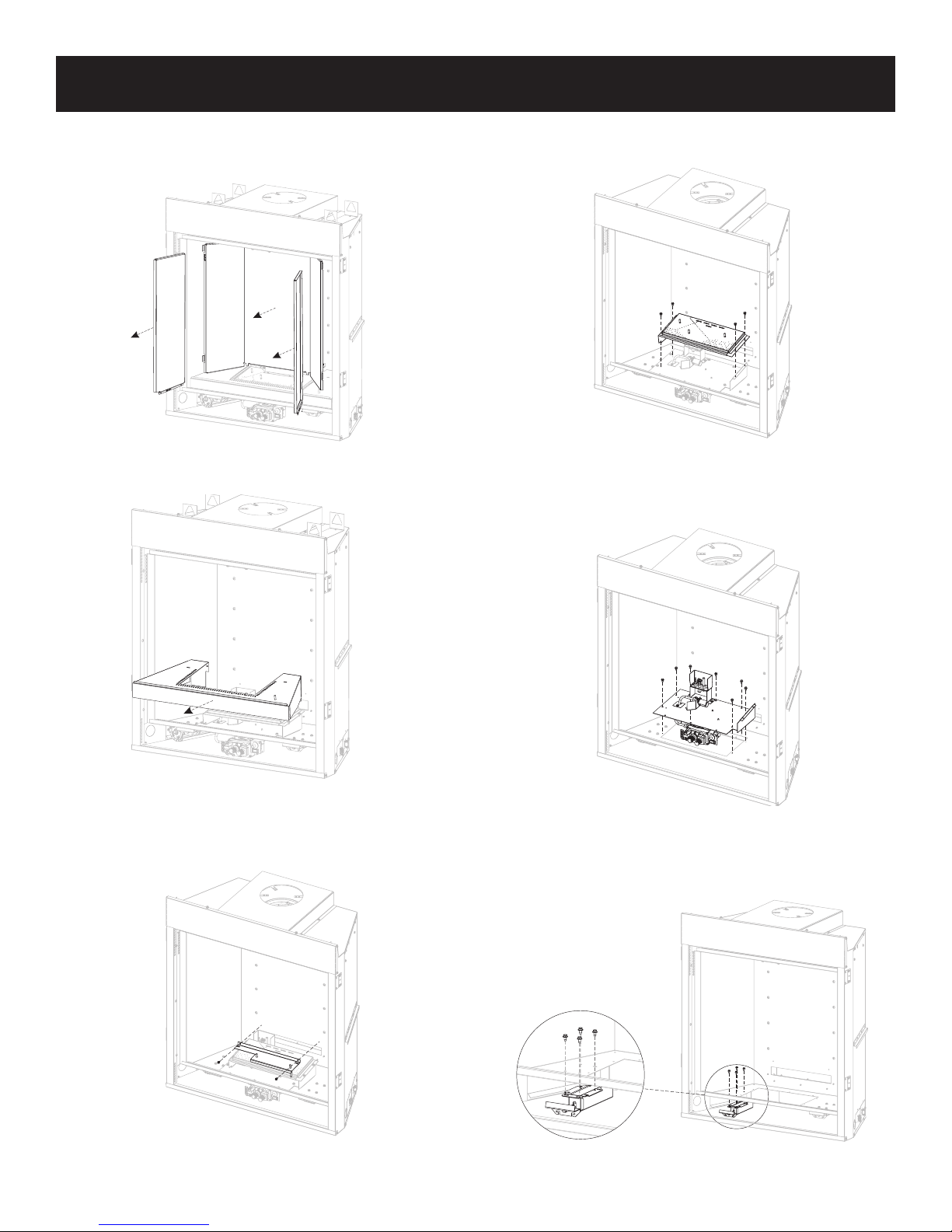

FBB10 BLOWER KIT INSTALLATION (OPTIONAL) (CONT’D)

4. Remove log set and decorative media. Remove brackets

and liners if installed. Retain bracket and screws for

reassembly. SeeFigure7.(Reectivelinersshown)

Figure 7

5. Remove burner cover by lifting off. See Figure 8.

7. Remove the four screws securing burner and slide to right

then lift burner off. Retain burner and screws for reassembly.

See Figure 10.

Figure 10

8. Remove ten screws and lift burner assembly. Disconnect

gas line. Retain screws and burner assembly for reassembly.

See Figure 11.

Figure 8

6. Remove log support by removing the two screws securing

the metal plate to log support. Retain log support and screws

for reassembly. See Figure 9.

Figure 9

Figure 11

9. Remove the four screws securing the left latch assembly

to the underside of the rebox. Retain screws and latch

assembly for reassembly. See Figure 12.

Figure 12

37607-1-0817Page 12

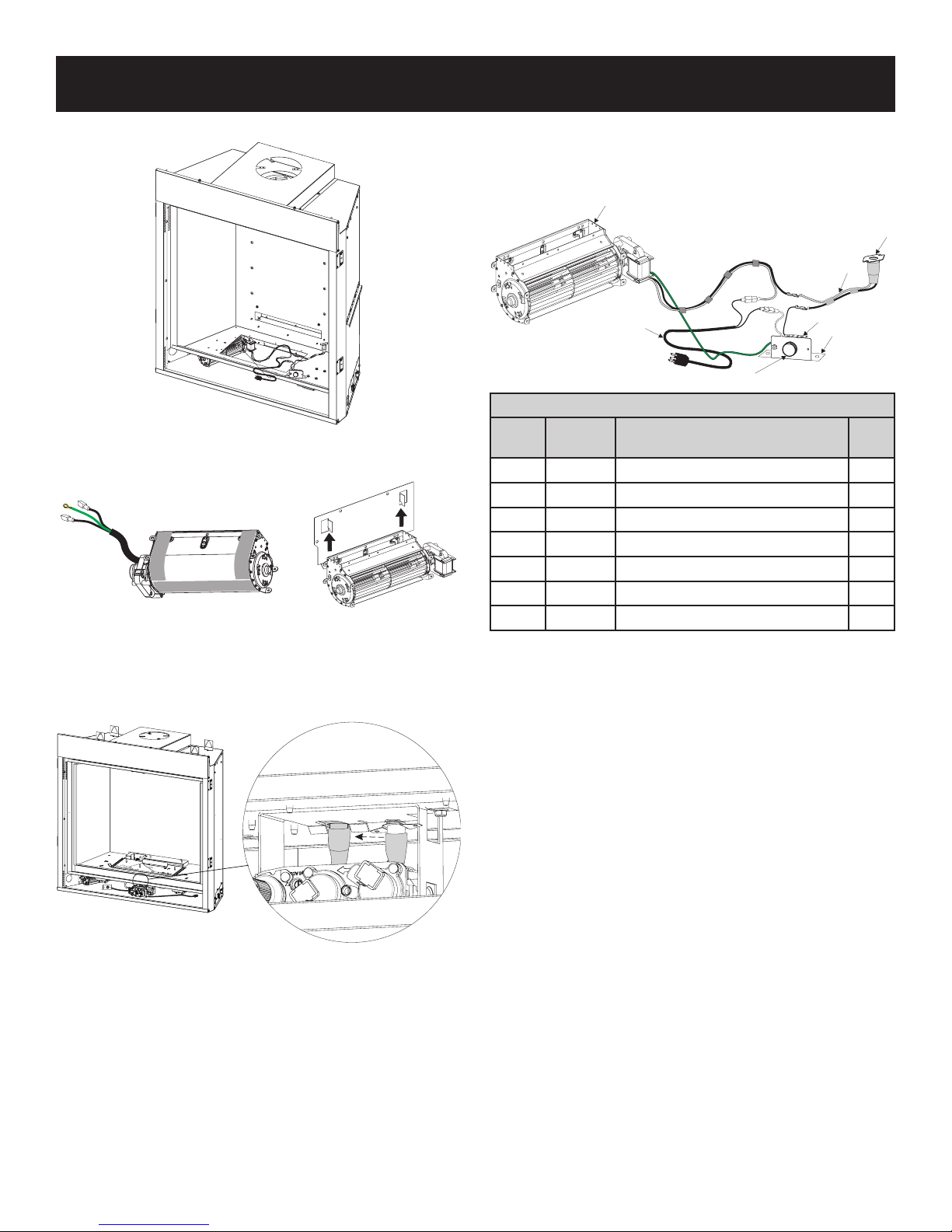

Back side of Blower

showing Velcro

FBB10 BLOWER KIT INSTALLATION (OPTIONAL) (CONT’D)

2

10. Install blower through rebox cutout. See Figure 13.

Figure 13

11. Install the blower onto the pre-bent brackets on the blower

plate. Ensure the Velcro connects to secure the blower in

place. See Figure 14.

21. Turn on power.

22. Reinstall the glass frame removed in steps 2 and 3. See

Figures 5 and 6.

23. Replace barrier screen removed in step 1. See Figure 4.

1

7

3

4

5

6

BLOWER ASSEMBLY PARTS LIST

INDEX

NO.

PART

NO

DESCRIPTION QTY

1 R2804 Blower Assembly 1

2 R7649 Fan, Control L120-20 1

3 R2099 Cord Set, 30-Inches 1

4 R4192 Rheostat, Knob 1

5 R4186 Rheostat, 3.0 AMP 115 VAC 1

6 10088 Rheostat Box Bracket 1

7 R11768 Wire Harness, Fan Control 1

Figure 14

12. Reinstall the latch assembly removed in step 9. See Figure 12.

13. Install thermo disc by snapping into valve bracket burner

assembly. See Figure 15.

Figure 15

14. Reconnect gas line and turn gas on. Check for leaks.

15. Reinstall the burner assembly and ten screws removed in

step 8. See Figure 11.

16. Reinstall the burner and four screws removed in step 7.

See Figure 10.

17. Reinstall the log support and secure it with metal plate and

two screws removed in step 6. See Figure 9.

18. Replace burner cover removed in step 5. See Figure 8.

19.

Replace liner and bracket if removed in step 4. See Figure 7.

20. Replace log set and decorative media.

Figure 16

37607-1-0817 Page 13

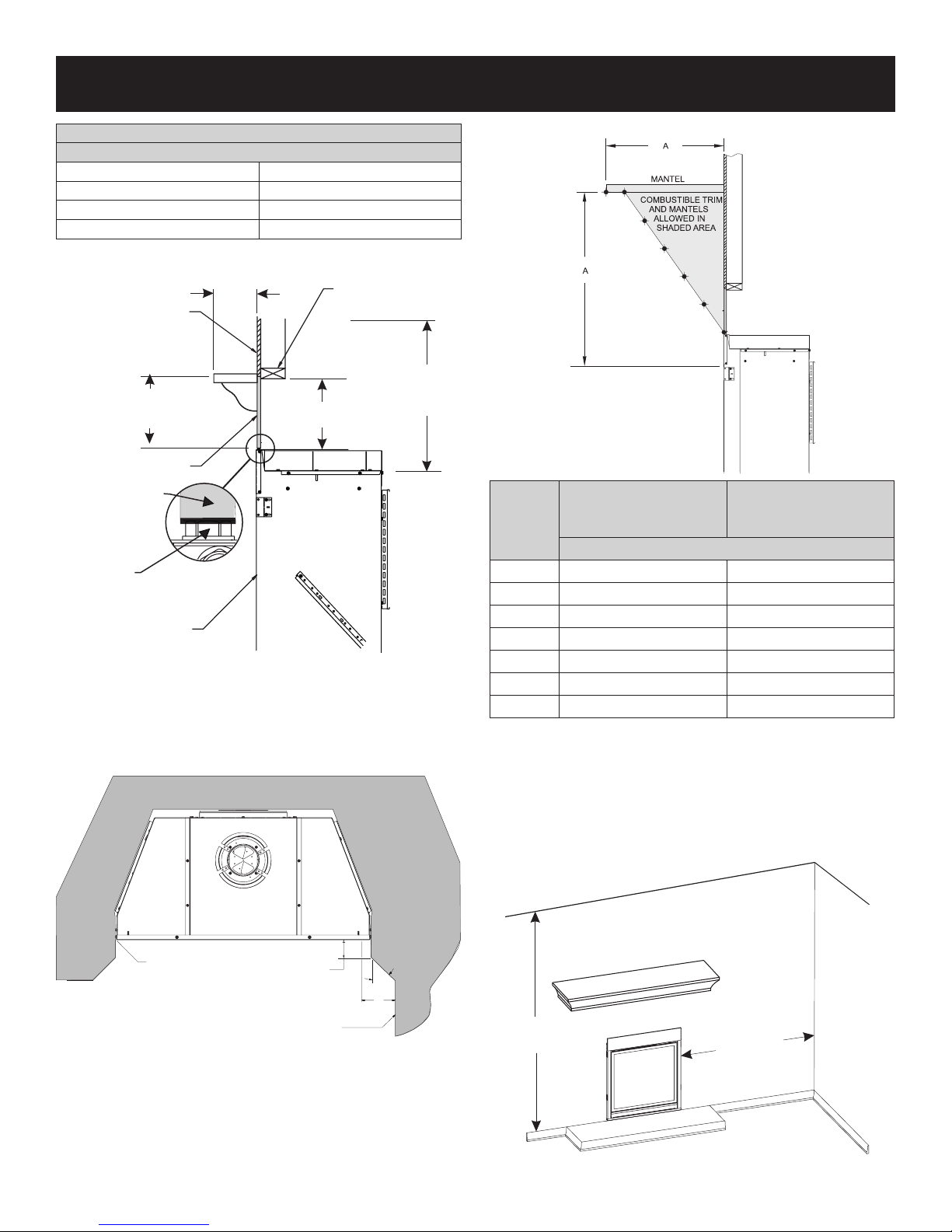

CLEARANCES

SEE MANTLE CHART FOR

MAXIMUM MANTEL DEPTH

GLASS FRONT

FINISHED WALL

(NON-COMBUSTIBLE)

SEE MANTEL CHART

FOR MINIMUM HEIGHT

OF MANTLE ABOVE UNIT

2"x4" HEADER

MINIMUM TO

CHASE TOP

24”

FINISHED WALL

(COMBUSTIBLE)

9”

(NON-COMBUSTIBLE)

BOARD

SCREW HEAD

FIREPLACE

(TOP VIEW)

PERPENDICULAR

SIDE WALL

45°

6

3

MAX.

FRONT FACE (SIDE)

COMBUSTIBLE

MATERIALS ALLOWED

IN SHADED

AREAS

G

F

E

D

C

B

CLEARANCE TO COMBUSTIBLES

(Inches)

Back 0

Side 0

Floor 0

Top Framing Edge See Below

Figure 17

Combustible Material

No greeting cards, stockings or ornamentation of any type should

be placed on or attached to the replace. The ow of heat can

ignite combustibles.

Mantel Chart

FIREPLACE OPENING

INDEX

LETTER

DISTANCE FROM TOP

EDGE OF FIREPLACE

(VERTICAL)

DISTANCE FROM

FIREPLACE FRONT

(HORIZONTAL)

(Inches)

A 18 12

B 6 0

C 9 2-1/4

D 11 3-3/4

E 14 6

F 16-3/4 8

G 18 10

Figure 19

Clearances

Clearance from bottom edge of replace to ceiling is 72-inches.

Clearance from side of replace to adjacent sidewall is 6-inches.

Refer to framing dimensions on page 22.

NOTICE: 72 inch minimum applies when unit is installed in wall

above oor level.

Figure 18

72”

(183cm)

6” (152mm)

Figure 20

37607-1-0817Page 14

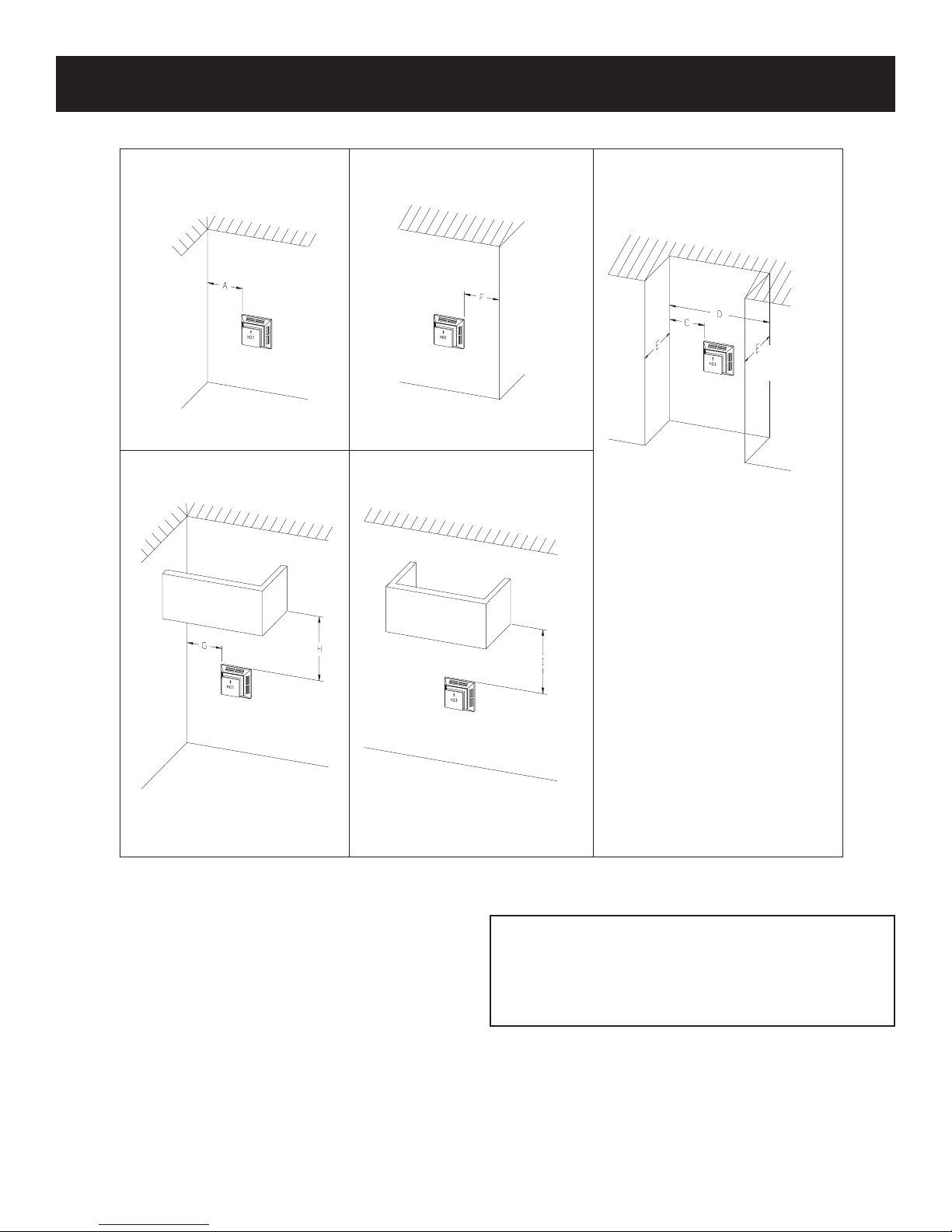

TERMINATION CLEARANCES

RECESSED LOCATION

OUTSIDE CORNER

INSIDE CORNER

“A”=COMBUSTIBLE 9-in (229mm)

= NONCOMBUSTIBLE2-in (51mm)

“F”=COMBUSTIBLE 6-in (152mm)

= NONCOMBUSTIBLE 6-in (152mm)

BALCONY

WITH PERPENDICULAR SIDE WALL

BALCONY

WITH NO SIDEWALL

“C”=CLEARANCE FROM CORNER

IN RECESSED LOCATION

COMBUSTIBLE 9-in (229mm)

NONCOMBUSTIBLE 2-in (51mm)

“D”=MINIMUMWIDTHFOR BACK WALL

OF A RECESSED LOCATION

COMBUSTIBLE 38-in (965mm)

NONCOMBUSTIBLE 24-in (610mm)

“E”=MAXIMUM DEPTHOF48-in (1219mm)

FOR RECESSED LOCATION

“G”=COMBUSTIBLE 9-in (229mm)

= NONCOMBUSTIBLE 2-in (51mm)

“H”=COMBUSTIBLE18-in (457mm)

= NONCOMBUSTIBLE 12-in (305mm)

“I” = COMBUSTIBLE 12-in (457mm)

= NONCOMBUSTIBLE 12-in (305mm)

Termination clearance for buildings with combustible and noncombustible exteriors.

Vertical Sidewall Installations

Important! Minimum clearance between vent pipes and

combustible

materials is 3 inches (76 millimeter) on top, and 2

inches (25 millimeter) on bottom and sides.

Important! When vent termination exits through foundation less

than 20 inches (508 millimeter) below siding outcrop, the vent

pipe must extend outward so that the horizontal vent termination

is located ush to, or beyond the outcrop siding.

Information on Various Venting Routes and Components

Important: Locate the replace in such a way that minimizes the

number of offsets and horizontal vent length.

Venting system must maintain a balance between the

combustion air intake and the ue gas exhaust. Limitations to

vent congurations apply.

37607-1-0817 Page 15

Figure 21

ATTENTION: Vinyl Soft, Vinyl Ceiling, Vinyl Overhang

Disclaimer

Clearances are to heat resistant material (i.e. wood, metal). This

does not include vinyl. Empire Comfort Systems Inc. will not be held

responsible for heat damage caused from terminating under vinyl

overhangs, vinyl ceilings or vinyl ventilated/unventilated softs.

VENT TERMINAL CLEARANCES

Canadian Installations1 US Installations2 Canadian Installations1 US Installations2

A= Clearance above

grade, veranda, porch,

deck, or balcony

B= Clearance to window or

door that may be open

C= Clearance to

permanently

closed window

D= Vertical clearance

ventilated soft located

above the terminal within

a horizontal distance of

2 feet (61 cm) from the

center line of the terminal

E= Clearance to

unventilated

soft

F= Clearance to

outside corner

G= Clearance

inside corner

H= Clearance to each side

of center line extended

above meter/regulator

assembly

ATTENTION:VinylSoft,VinylCeiling, VinylOverhang

Disclaimer

Clearances are to heat resistant material (i.e. wood, metal). This

does not include vinyl. Empire Comfort Systems Inc. will not be

held responsible for heat damage caused from terminating under

vinyl overhangs, vinyl ceilings or vinyl ventilated/unventilated softs.

12-in (30cm) 12-in (30cm) I= Clearance to service

6-in (15cm) for appliances ≤ 10,000 Btuh

(3kW), 12-in (30cm) for

appliances > 10,000

Btuh (3kW) and ≤

100,000 Btuh (30kW),

36-in (91cm) for appliances > 100,000 Btuh

(30kW)

12-in (30cm) 12-in (30cm)

24-in (61cm) 24-in (61cm)

12-in (30cm) 12-in (30cm)

6-in (15cm) 6-in (15cm)

9-in (23cm) 9-in (23cm)

3ft (91cm) within a

height 15ft (4.5m)

above the meter/regulator assembly

6-in (15cm) for appliances ≤ 10,000 Btuh

(3kW), 9-in (23cm) for

appliances > 10,000

Btuh (3kW) and ≤

50,000 Btuh (15kW),

12-in (30cm) for appliances > 50,000 Btuh

(15kW)

3ft (91cm)

regulator vent outlet 3ft (91cm) 6ft

J= Clearance to nonme-

chanical air supply

inlet to building or the

combustion air inlet to

any other appliance

K= Clearance to a

mechanical air

supply inlet

L= Clearance above

paved sidewalk or

paved driveway

located on public

property

M= Clearance under

veranda, porch

deck, or balcony

1 In accordance with the current CSA B149.1, Natural Gas and Propane

Installation Code

2 In Accordance with the current ANSI Z223.1/NFPA 54, National Fuel Gas

Code

† A vent shall not terminate directly above a sidewalk or paved driveway that

is located between two single family dwellings and serves both dwellings

‡ Permitted only if veranda,, porch, deck, or balcony is fully open on a mini-

mum of two sides beneath the oor.

* For clearances not specied in ANSI Z223.1/NFPA 54 or CSA B149.1, one

of the following shall be indicated:

Clearance in accordance with local installation codes and the requirements of the

gas supplier.

6-in (15cm) for appliances ≤ 10,000 Btuh

(3kW), 12-in (30cm) for

appliances > 10,000

Btuh (3kW) and ≤

100,000 Btuh (30kW),

36-in (91cm) for appliances > 100,000 Btuh

(30kW)

6ft (1.83m)

7ft (2.13m) † 7ft (2.13m) †

12-in (30cm) ‡ 12-in (30cm) ‡

6-in (15cm) for appliances ≤ 10,000 Btuh

(3kW), 9-in (23cm) for

appliances > 10,000

Btuh (3kW) and ≤

50,000 Btuh (15kW),

12-in (30 cm) for appliances > 50,000 Btuh

(15kW)

3ft (91cm) above if

within 10ft (3m)

horizontally

Figure 22

37607-1-0817Page 16

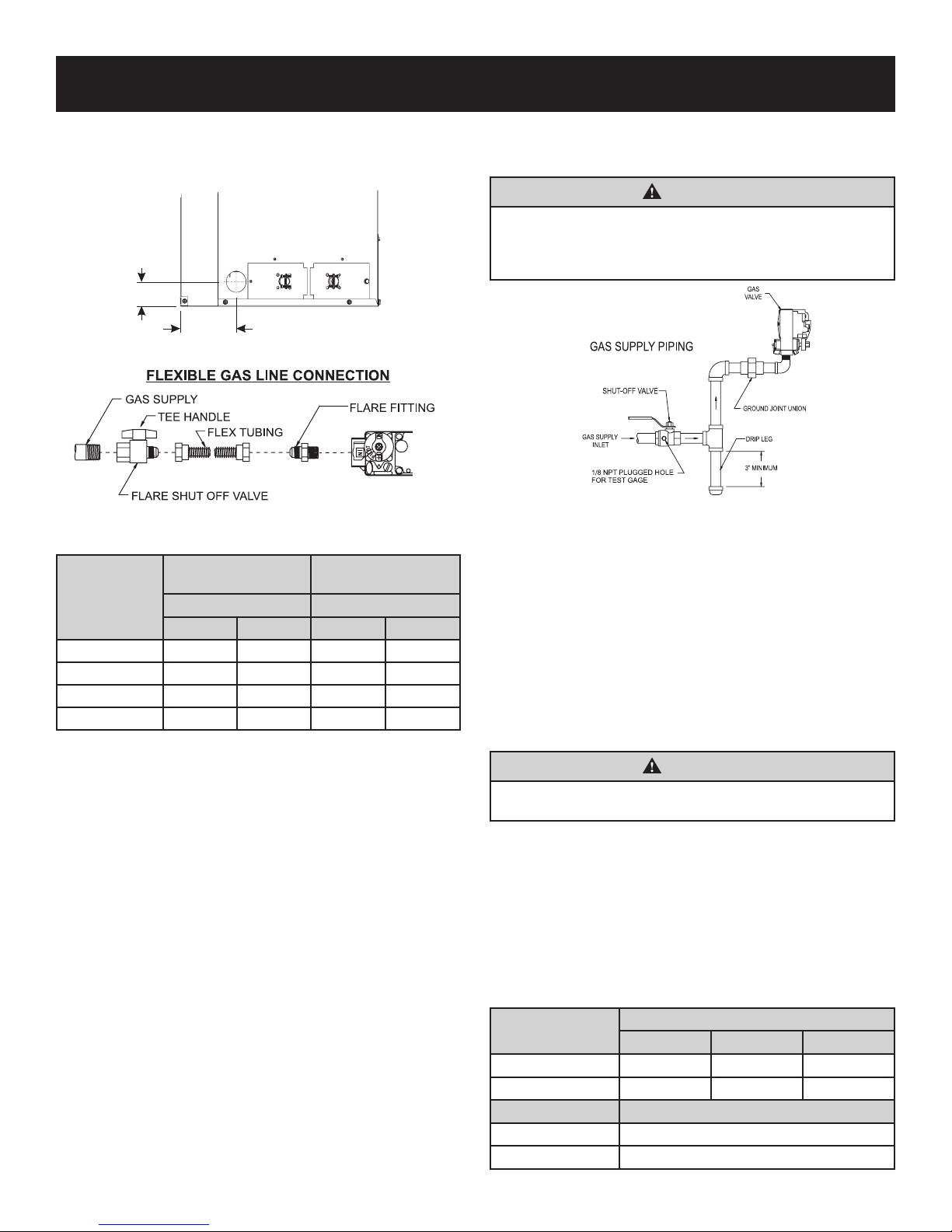

GAS SUPPLY

The gas pipeline can be brought in through the right or left side of

the appliance. Consult the current National Fuel Gas Code, ANSI

Z223.1 CAN/CGA-B149 (.1 or .2) installation code.

RIGHT SIDE OF FIREBOX

2”

4 5/8”

Figure 23

Figure 24

Recommended Gas Pipe Diameter

Schedule 40 Pipe

Pipe Length

0-10 feet 1/2 3/8 1/2 3/8

10-40 feet 1/2 1/2 5/8 1/2

40-100 feet 1/2 1/2 3/4 1/2

100-150 feet 3/4 1/2 7/8 3/4

NOTICE: Never use plastic pipe. Check to conrm whether your

local codes allow copper tubing or galvanized.

NOTICE: Because some municipalities have additional local codes,

consult your local authority and installation code.

The use of the following gas connectors is recommended:

— ANSI Z21.24 Appliance Connectors of Corrugated Metal Tubing

and Fittings.

— ANSI Z21.45 Assembled Flexible Appliance Connectors of

Other Than All-Metal Construction

The above connectors may be used if acceptable by the authority

having jurisdiction. The Commonwealth of Massachusetts requires

that a exible appliance connector cannot exceed three feet in length.

A gas valve and ground joint union should be installed in the gas

line upstream of the gas control to aid in servicing. It is required

by the National Fuel Gas Code that a drip leg be installed near the

gas inlet. See Figure 25. This should consist of a vertical length of

pipe tee connected into the gas line that is capped on the bottom

in which condensation and foreign particles may collect.

Installing a New Main Gas Supply Valve (Check Local Code)

Each appliance should have its own manual gas supply valve.

A manual main gas supply valve should be located in the vicinity of the

unit. Where none exists, or where its size or location is not adequate,

contact your local authorized installer for installation or relocation.

Compounds used on threaded joints of gas piping shall be resistant

to the action of liqueed petroleum gases.

Inside Diameter

(Inches) (Inches)

Nat LP Nat LP

Tubing, Type L

Outside Diameter

The gas lines must be checked for leaks by the installer. This should

be done with a soap solution watching for bubbles on all exposed

connections, and if unexposed, a pressure test should be made.

WARNING

Neveruseanexposedametocheckforleaks.Appliance

must be disconnected from piping at inlet of control valve and

pipe capped or plugged for pressure test. Never pressure test

withapplianceconnected;controlvalvewillsustaindamage!

Figure 25

NOTICE: The millivolt gas controls are equipped with a captured

screw type pressure test point, therefore it is not necessary to provide

a 1/8 inch test point up stream of the control.

On direct ignition valves, hex plugs may be replaced with hose ttings

for pressure checks, then reinstalled before operating replace.

When using copper or ex connector use only approved ttings.

The replace and its individual shut off valve must be disconnected

from supply piping system during any pressure testing of that system

at test pressures in excess of 1/2 psig (3.5kPa).

The replace must be isolated from the gas supply piping system

by closing its individual manual shut off valve during any pressure

testing of the gas supply piping system at test pressures equal to

or less than 1/2 psig (3.5kPa).

WARNING

Pressures in excess of 1/2 psig (14 inches w.c.) (3.5kPa) on

thereplacegasvalve,maydamagethevalve.

Checking Manifold Pressures

Both Propane and Natural gas valves have a built-in pressure regulator.

Natural gas models will have a manifold pressure of approximately 3.5

inches w.c. (.871kPa) at the valve outlet with the inlet pressure to the

valve from a minimum of 4.5 inches w.c. (1.120kPa) for the purpose

of input adjustment to a maximum of 14.0 inches w.c. (3.484kPa).

Propane gas models will have a manifold pressure approximately 10.0

inches w.c. (2.49kPa) at the valve outlet with the inlet pressure to the

valve from a minimum of 10.8 inches w.c. (2.68kPa) for the purpose

of input adjustment to a maximum of 14.0 inches w.c. (3.484 kPa).

Gas Supply Pressure (inches w.c.)

Minimum Normal

Natural Gas 4.5 7.0

LP (Propane) 10.8 11.0

Manifold Pressure (inches w.c.)

Natural Gas 3.5 - Normal (HI)

LP (Propane) 10.0 - Normal (HI)

Maximum

14.0

14.0

37607-1-0817 Page 17

Loading...

Loading...