Emotron VBS48-003-20CNB, VSU48-004-20CNB, VSB23-005-20CNB, VSB23-008-20CNB, VSU48-003-20CNB Instruction Manual

...

Emotron VSB

AC Drive

0.4kW to 3.7kW / 0.54Hp to 5Hp

Instruction manual

English

Thank you for choosing Emotron VSB Series General Purpose AC Motor Drives from CG

machine and identify the fault or seek technical services as soon as possible.

Drives & Automation. This user manual presents a detailed description of Emotron VSB series

with respect to product features, structural characteristics, functions, installation, parameter

setting, troubleshooting, commissioning and daily maintenance, etc. Be sure to carefully read

through the safety precautions before use, and use this product on the premise that personnel

and equipment safety is ensured.

IMPORTANT NOTES

Please assure the intactness of product enclosure and all safety covers before

installation .Operation must conform to the requirements of this manual and local industrial

safety regulations and/or electrical codes.

Contents of this manual may be subject to appropriate modification as a result of product

upgrade, specification change and update of the manual.

In the event of damage or loss of user manual, users may ask local distributors, offices or

our Technical Service Department for a new one.

If any item as stated in this manual is not clear, please contact our Technical Service

Department.

If any anomaly occurs after power up or during the operation, it is essential to stop the

Emotron VSB

Instruction manual - English

400V: Software type/version: 50101/08.01.0085 (main drive and control board)

50201/08.01.0086 (Aux terminal control board)

230V: Software type/version: 50101/08.01.0087 (main drive and control board)

50201/08.01.0088 (Aux terminal control board)

Document number: 01-5577-01 Edition: r0

Date of release: 30-05-2014

© Copyright Crompton Greaves Ltd 2014

Crompton Greaves Ltd retains the right to change specifications and

illustrations in the text, without prior notification. The contents of this document may

not be copied without the explicit permission of Crompton Greaves Ltd.

CONTENTS

Chapter 1 Safety Precautions ................................................... - 1 -

1.1 Safety Considerations .............................................................................................. - 1 -

1.2 Other Considerations ............................................................................................... - 6 -

Chapter 2 Product Information ................................................. - 9 -

2.1 Model Explanation ................................................................................................... - 9 -

2.5 Parts Drawing ........................................................................................................ - 14 -

2.6 Appearance, Mounting Dimensions and Weight ..................................................... - 14 -

2.7 External Dimensions of Keypad ............................................................................. - 16 -

Chapter 3 Installation and Wiring ........................................... - 17 -

3.1 Installation Environment ......................................................................................... - 17 -

3.2 Minimum Mounting Clearances .............................................................................. - 17 -

3.3 Remove & Mount Keypad and Cover ..................................................................... - 18 -

3.4 Selection of Peripheral Devices .............................................................................. - 20 -

3.5 Terminal Configuration ........................................................................................... - 21 -

3.6 Main Circuit Terminals and Wiring .......................................................................... - 22 -

3.7 Control Terminal Wiring .......................................................................................... - 24 -

3.8 Control Terminal Specification ................................................................................ - 26 -

3.9 Control Terminal Usage .......................................................................................... - 27 -

Chapter 4 Operation and Run Instructions ............................ - 36 -

4.1 Operation of Keypad .............................................................................................. - 36 -

4.2 Potentiometer Setting ............................................................................................ - 39 -

4.3 Prompt Message Status ........................................................................................ - 39 -

4.4 Parameter Setting ................................................................................................. - 40 -

4.5 Initial Power up ..................................................................................................... - 41 -

Chapter 5 List of Parameters .................................................. - 47 -

Chapter 6 Specification of Parameters .................................. - 70 -

Group A System Parameter and Parameter Management ......................................... - 70 -

Group b Setting of Running Parameters .................................................................... - 71 -

Group C Input and Output Terminals ............................................................................ - 95 -

Group d Motor and Control Parameters ...................................................................... - 111 -

Group E Enhancement Function and Protection Parameters ......................................- 124 -

Group F Application ....................................................................................................- 131 -

Group H Communication Parameters .........................................................................- 138 -

Group L Keys and Display of Keypad ..........................................................................- 140 -

Group U Monitoring .....................................................................................................- 143 -

Chapter 7 Troubleshooting ................................................... - 148 -

7.1 Fault Causes and Troubleshooting ........................................................................- 148 -

Chapter 8 Maintenance ......................................................... - 155 -

8.1 Routine Inspection ................................................................................................- 155 -

8.2 Regular Maintenance ............................................................................................- 156 -

8.3 Replacement of Vulnerable Parts ..........................................................................- 158 -

8.4 Storage .................................................................................................................- 159 -

Emotron VSB Instruction Manual Chapter 1 Safety Precautions

WARNING

with may result in more faults and/or personal injury even death.

ATTENTION

equipment.

Chapter 1 Safety Precautions

Safety Precautions

Safety signs in this manual:

WARNING

may result in fire or serious personal injury or even death

ATTENTION: indicates the situation in which the failure to follow operating requirements

may cause moderate or slight injury and damage to equipment.

Users are requested to read this chapter carefully when installing, commissioning and repairing

this product and perform the operation according to safety precautions as set forth in this

chapter without fail. CG Drives & Automation will bear no responsibility for any injury and loss

as a result of any violation operation.

1.1 Safety Considerations

1.1.1 Prior to Ins tallation

: indicates the situation in which the failure to follow operating requirements

.

Do not touch control terminals, circuit boards and any other electronic parts and

components with bare hands.

Do not use the drive whose component(s) is/are missing or damaged. Failure to comply

Check if the product information indicated on the nameplate is consistent with the order

requirements. If not, do not install it.

Do not install the drive in the event that the packing list does not match with real

- 1 -

Emotron VSB Instruction Manual Chapter 1 Safety Precautions

WARNING

to comply may result in equipment damage.

ATTENTION

dissipation. Failure to comply may result in faults or equipment damage.

1.1.2 Installation

Only qualified personnel familiar with adjustable frequency AC drives and associated

machinery should plan or implement the installation. Failure to comply may result in

equipment damage and/or personnel injury even death.

This equipment must be mounted on metal or other flame retardant objects. Failure to

comply may result in fire.

This equipment must be mounted in an area which is away from combustibles and heat

sources. Failure to comply may result in fire.

This equipment must in no case be mounted in the environment exposed to explosive gases.

Failure to comply may result in explosion.

Never adjust mounting bolts of this equipment, especially the ones with red markers. Failure

Handle the equipment gently and take hold of its sole plate so as to avoid foot injury or

equipment damage.

Mount the equipment where its weight can be withstood. Failure to comply may result in

equipment damage and/or personnel injury if falling happens.

Make sure the installation environment conforms to the requirements as stated in

Section 2.4. If not, de-rating is necessary. Failure to comply may result in equipment

damage.

Prevent drilling residues, wire ends and screws from falling into the equipment during

installation. Failure to comply may result in faults or equipment damage.

When mounted in a cabinet, this equipment should be provided with appropriate heat

- 2 -

Emotron VSB Instruction Manual Chapter 1 Safety Precautions

WARNING

RA, RB and RC. Failure to comply may result in equipment damage.

1.1.3 W iring

Only qualified personnel familiar with adjustable frequency AC drives and associated

machinery should plan or implement the wiring. Failure to comply may result in personnel

injury and/or equipment damage.

Wiring must strictly conform to this manual. Failure to comply may result in personnel

injury and/or equipment damage.

Make sure the input power supply has been completely disconnected before wiring.

Failure to comply may result in personnel injury and/or equipment damage.

All wiring operations must comply with EMC and safety regulations and/or electrical

codes, and the conductor diameter should conform to recommendations of this manual.

Failure to comply may result in personnel injury and/or equipment damage.

Since overall leakage current of this equipment may be bigger than 3.5mA, for safety's

sake, this equipment and its associated motor must be well grounded so as to avoid risk

of electric shock.

Be sure to implement wiring in strict accordance with the marks on this equipment’s

terminals. Never connect three-phase power supply to output terminals U/T1, V/T2 and

W/T3. Failure to comply may result in equipment damage.

Install braking resistors at terminals

equipment damage.

Wiring screws and bolts for main circuit terminals must be screwed tightly. Failure to

comply may result in equipment damage.

AC 220V signal is prohibited from connecting to other terminals than control terminals

/B1 and B2 only. Failure to comply may result in

- 3 -

Emotron VSB Instruction Manual Chapter 1 Safety Precautions

ATTENTION

Failure to comply may result in faults.

WARNING

damage.

Since all adjustable frequency AC drives from CG Drives & Automation have been

subjected to hi-pot test before delivery, users are prohibited from implementing such a

test on this equipment. Failure to comply may result in equipment damage.

Signal wires should to the best of the possibility be away from main power lines. If this

cannot be ensured, vertical cross-arrangement shall be implemented, otherwise

interference noise to control signal may occur.

If motor cables are longer than 100m, it is recommended output AC reactor be used.

1.1.4 Running

Drives which have been stored for more than 2 years should be used with voltage

regulator to gradually boost the voltage when applying power to the drives. Failure to

comply may result in equipment damage.

Be sure to confirm the completion and correctness of the drive wiring and close the

cover before applying power to the drive. Do not open the cover after applying power.

Failure to comply may result in electric shock hazard.

After applying the power, never touch the drive and peripheral circuits no matter what

state the drive is under, otherwise there will be electric shock hazard.

Prior to the running of the drive, check there is no person in surrounding area who can

reach the motor so as to prevent personal injury.

Only qualified technicians familiar with adjustable frequency AC drives are allowed to

perform signal test during operation. Failure to comply may result in equipment damage

and/or personal injury.

Never change the drive parameters at will. Failure to comply may result in equipment

- 4 -

Emotron VSB Instruction Manual Chapter 1 Safety Precautions

ATTENTION

output and/or contactor. Failure to comply may result in equipment damage.

WARNING

maintenance, and

accordance with above-noted rules.

ATTENTION

turned off.

Make sure the number of phases of power supply and rated voltage are consistent with

product nameplate. If not, contact the seller or CG Drives & Automation.

Check there are no short circuits in peripheral circuits connected with the drive, and

make sure the connection is tight. Failure to comply may result in equipment damage.

Make sure the motor and associated machinery are within allowable range of service

prior to operation. Failure to comply may result in equipment damage.

Never touch fans, heat sink and braking resistor with bare hands. Failure to comply may

result in equipment damage and/or personal injury.

It is not allowed to start & stop the driver frequently via direct switching power on or off.

Failure to comply may result in equipment damage.

Make sure the drive is in a non-output status before switch-on/switch-off of the drive

1.1.5 Maintenance

Only qualified technicians are allowed to implement the

troubleshooting.

Never implement the maintenance, and troubleshooting before power supply has been

turned off and discharged completely. Failure to comply may result in equipment

damage and/or personal injury.

To avoid an electric shock hazard, wait at least 10 minutes after the power has been

turned off and make sure the residual voltage of the bus capacitors has discharged to

0V before performing any work on the drive.

After the replacement of the drive, be sure to perform the same procedures in strict

Do not touch the electric components with bare hands during maintenance, and

troubleshooting. Failure to do this may result in component damage due to ESD.

All pluggable components can be inserted or pulled out only when power has been

- 5 -

Emotron VSB Instruction Manual Chapter 1 Safety Precautions

1.2 Other Considerations

1.2.1 Input Power Supply

This series of drives are not applicable to applications out the range of operating voltage as set

forth in this manual. If necessary, please use booster to rise or drop the voltage to regulated

voltage range.

1.2.2 Surge Protection

This series of drives are furnished with surge suppressor that has certain resistance to lightning

induction. However, users in areas with frequent occurrence of lightning need to mount an

external surge suppressor in front of the drive power input side.

1.2.3 Operation of Contactor

As to the configuration of peripheral devices recommended by this manual, it is necessary to

mount a contactor between the power supply and this drive input side. Such a contactor should

not be used as a control device for start and stop of the drive, as frequent charging &

discharging shall reduce the service life of internal electrolytic capacitors.

When it is necessary to mount a contactor between the drive output and the motor, it

should be ensured the drive is in a non-output status before switch-on/switch-off of such a

contactor. Failure to comply may result in drive damage.

1.2.4 O utput F ilter

Since the drive output is PWM high frequency chopping voltage, mounting filter devices such

as an output filter and an output AC reactor between the motor and the drive shall effectively

reduce output noise, avoiding interference to other surrounding equipments.

If the length of cable between the drive and the motor exceeds 100m, an output AC reactor

is recommended to use with the purpose of preventing drive fault as a result of overcurrent

caused by excessive distributed capacitance. An output filter is optional depending on field

requirements.

Be sure not to mount phase-shifting capacitor or surge absorber at output side of the drive

since this may result in drive damage as a result of over-temperature.

1.2.5 Insulation of the motor

In view of the fact that the drive output is PWM high frequency chopping voltage accompanied

by higher harmonics, the noise, temperature rise and vibration of the motor is higher compared

with sinusoidal voltage. Particularly this debases motor insulation. Therefore, the motor should

be subjected to insulation inspection before initial use or reuse after being stored for a long

- 6 -

Emotron VSB Instruction Manual Chapter 1 Safety Precautions

period of time. The motor in regular service should also be subjected to regular insulation

inspection so as to avoid the drive damage as a result of motor insulation damage.

1.2.6 Derating

Due to the thin air in high-altitude areas, the radiating performance of the drive with forced air

cooling may degrade while the electrolyte of electrolytic capacitors is more volatile, which can

result in reduction in product life. Drive should be derated when used in an area at the altitude

above 1000 meters. It is recommended to derate 1% for every 100m when the altitude is above

1000 meters.

- 7 -

Emotron VSB Instruction Manual Chapter 1 Safety Precautions

- 8 -

Emotron VSB Instruction Manual Chapter 2 Product Information

Chapter 2 Product Information

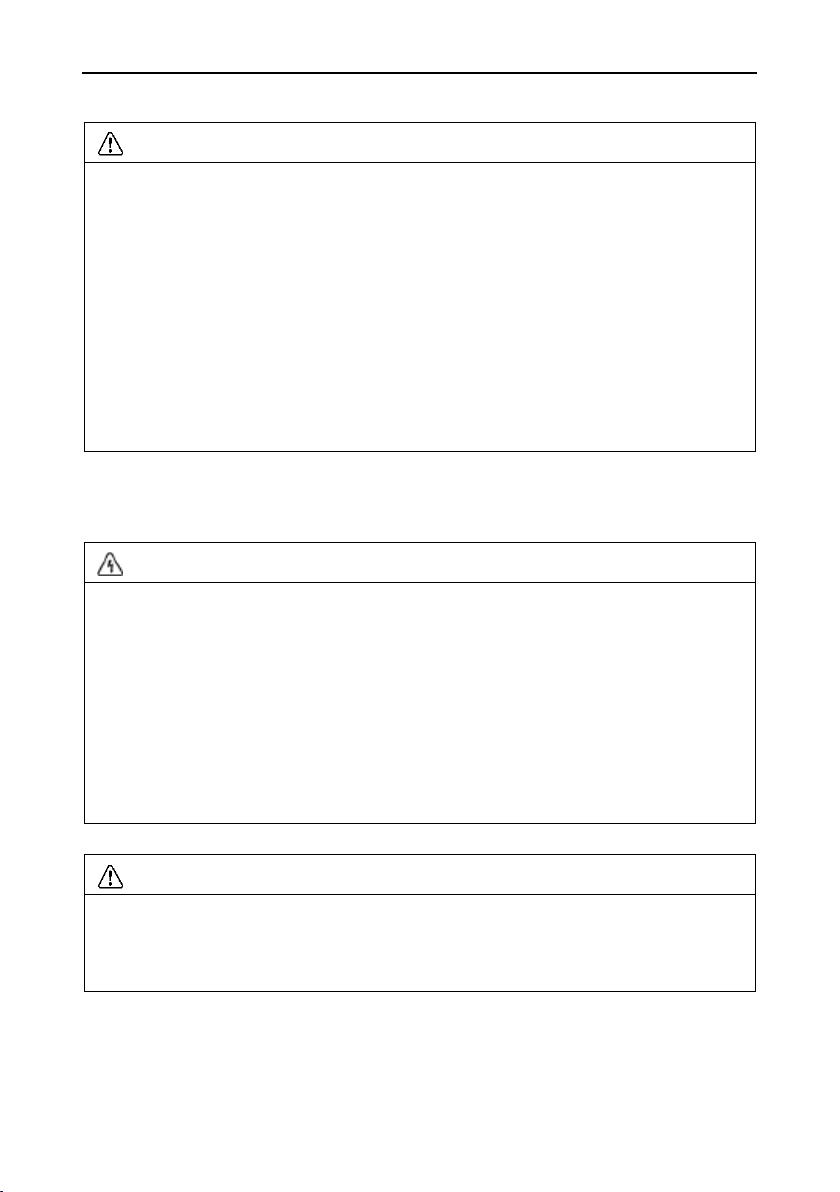

2.1 Model Explanation

Model shown on product nameplate indicates the series name, applicable type of power supply,

power class and hardware, etc. via the combination of numbers, symbols and letters.

Fig. 2-1 Nameplate information

Fig. 2-2 Product model explanation

- 9 -

Emotron VSB Instruction Manual Chapter 2 Product Information

A

Ω

A

A

kW*

A

VSB23-003-20CNB

2.6

5.5/3.2

0.4

16

>200

VSB23-005-20CNB

4.5

9.2/6.3

0.75

25

>200

VSB23-008-20CNB

7.5

14.5/9

1.5

32

>100

VSB23-011-20CNB

11

23/15

2.2

40

>75

150% 1 min. every 10 min.

120% 1 min

A

Ω

A

A

kW*

A

VSU48-003-20CNB

2.5

3.5

0.75

16

>150

VSU48-004-20CNB

3.8

6.2

1.5

16

>100

VSU48-006-20CNB

5.5

9.2

2.2

16

>75

VSU48-009-20CNB

9

14.9

3.7

40

>75

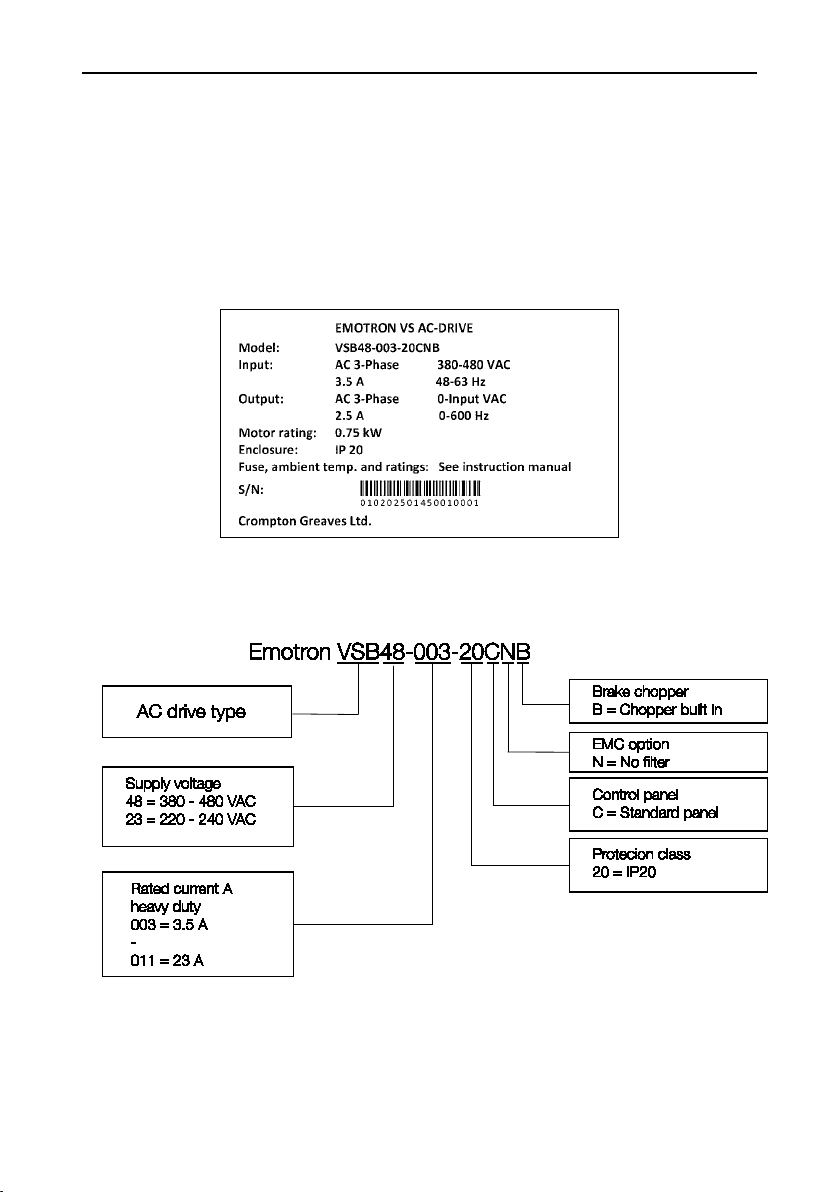

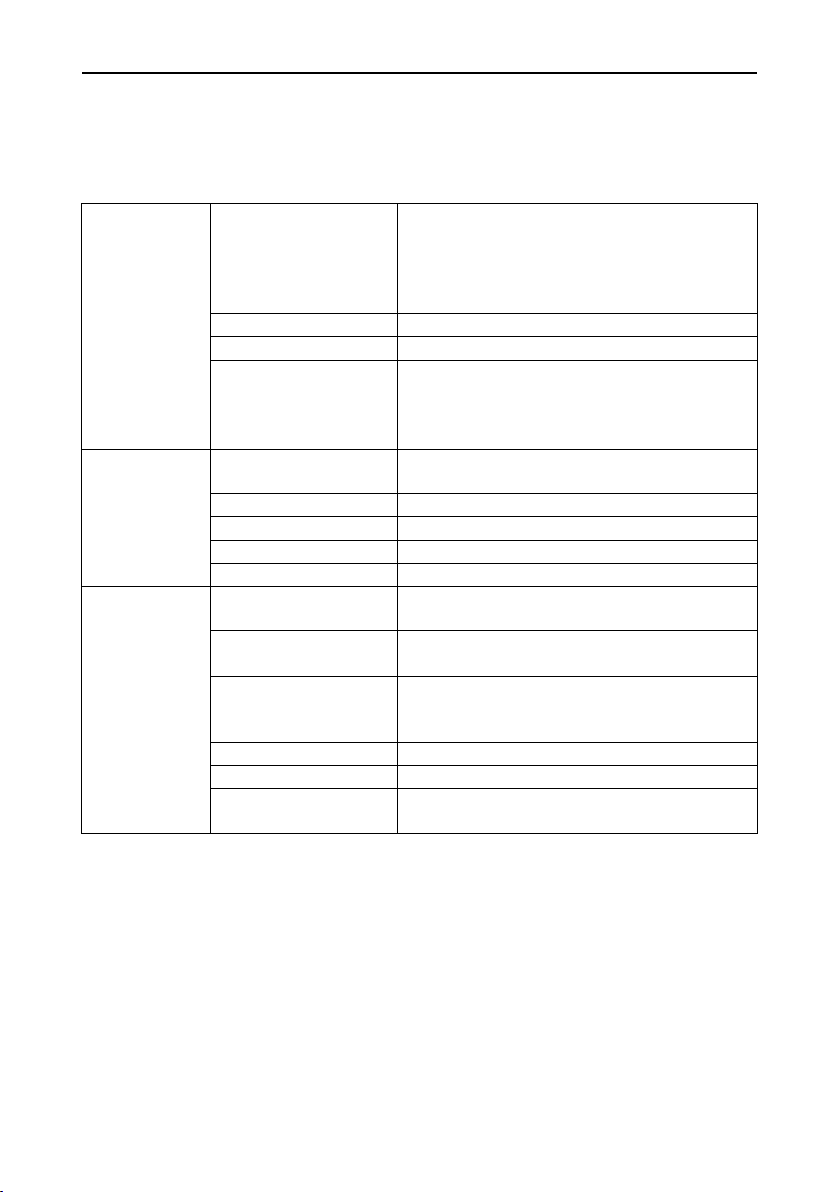

2.3 Information of Product Model

Table 2-1 Product model and technical data Emoton VSB23

Heavy Duty

150% 1 min. every 10 min.

Light Duty

120% 1 min.

Rated

Drive model

Rated

output

current

input

current

1-phase/

3-phase

Typical

motor

Rated

output

current

**

Note: The models VSB23-### can be used for either 1-phase or 3-phase.

* Power at 230V **= Contact CG for information.

Table 2-2 Product model and technical data Emotron VSB48

Drive model

Rated

output

current

Heavy Duty

Rated input

current

Typical

motor

Light Duty

Rated

output

current

Max

input

Fuse

Max

input

Fuse

Brake

unit

Brake

unit

* Power at 400 - 415V. ** = Contact CG for information

**

- 10 -

Emotron VSB Instruction Manual Chapter 2 Product Information

3-phase

AC220V/AC230V/AC240V

Rated input current

See Section 2.3

Frequency

50Hz/60Hz, tolerance ±5%

Continuous voltage fluctuation ±10%, short

as per the requirements of IEC61800-2

Standard applicable

motor (kW)

Rated current (A)

See Section 2.3

Output voltage (V)

3-phase: 0 - rated input voltage, error < ±3%

Output frequency (Hz)

0.00 - 600.00Hz; unit: 0.01Hz

Overload capacity

150% - 1min; 180% - 10s; 200% - 0.5s

Sensor-less vector control 1

Range of speed

regulation

Speed fluctuation

±0.3% (sensor-less vector control 1)

Torque response

< 10ms (sensor-less vector control 1)

0.5Hz: 180% (V/f control, sensor-less vector

control 1)

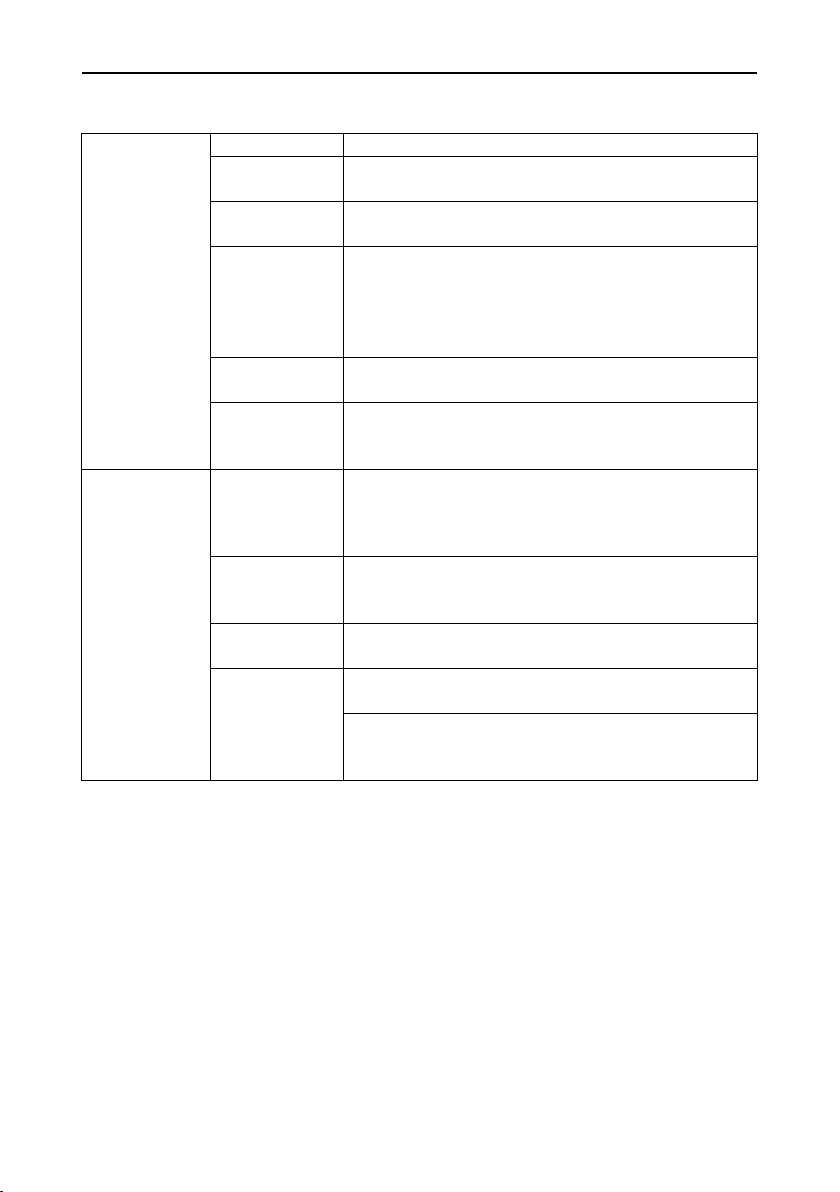

2.4 Technical Features of Emotron VSB

Power input

Power output

Control

characteristics

Table 2-3 Technical Features of Emotron VSB

AC208V/AC220V/AC230V/AC240V/AC380V/A

Rated input voltage

Allowable range of

voltage

V/f patterns

Speed accuracy

C400V/AC415V/AC440V/AC460V/AC480V

1-phase

fluctuation -15% to +10%, i.e. 323V - 528V;

Voltage out-of-balance rate <3%, distortion rate

See Section 2.3

V/f control

1:100 ( V/f control, sensor-less vector control 1)

±0.5% (V/f control)

±0.2% (sensor-less vector control 1)

Starting torque

- 11 -

Emotron VSB Instruction Manual Chapter 2 Product Information

Start frequency

0.00 - 600.00Hz

Accel/Decel

time

frequency

Digital setting + keypad ∧ / ∨

Analogue setting (AI)

methods

DC braking and then started

Ramp to stop

Ramp stop + DC brake

service time: 0.0~100.0s

DC braking start frequency: 0.00 - 600.00Hz

DC braking time: 0.0 - 30.00s

1 analog, current/voltage type selectable

1 digital output

1 relay output

frequency, etc

0.00 - 60000s

Basic

functions

Basic

functions

Carrier

Frequency

setting sources

Motor started

Motor stopped

methods

Dynamic

braking

capacity

DC braking

capacity

Input terminals

Output

terminals

0.7kHz - 12kHz

Digital setting + terminal UP/DOWN

Potentiometer

Communication

Started from starting frequency

Coast to stop

Brake unit threshold voltage:

400V input: 650V~750V

200V input: 325V~375V

DC braking current: 0.0 - 100.0%

4 digital inputs

1 analog output, voltage/current output selectable; can

output signals such as setting frequency, or output

- 12 -

Emotron VSB Instruction Manual Chapter 2 Product Information

autotuning, field-weakening control

Protection

functions

Indoors, no direct sunlight, free from dust, corrosive

drop or salt, etc.

0 - 2000m

1000 meters

temperature

Relative

humidity

Vibration

Less than 5.9m/s2 (0.6g)

Storage

temperature

rated Amps

Installation

Wall-mounted, DIN-rail

IP grade

IP20

Cooling

method

various master & auxiliary commands and their switch, a variety of

Accel/Decel curves optional, analog auto correction, 8-step speed

Featured

functions

programmable, three faults history, over excitation brake, over voltage stall

protection, under voltage stall protection, restart upon power loss, skip

frequency, frequency binding, four kinds of Accel/Decel time, process PID,

Refer to Chapter 7- Troubleshooting

Environment

Others

Place of

operation

Altitude

Ambient

Efficiency at

gases, flammable gases, oil mist, water vapor, water

De-rate 1% for every 100m when the altitude is above

-10°C - 50°C

0 - 95%, no condensation

-40°C to +70°C

At rated Amps ≥93%

Forced air cooling

- 13 -

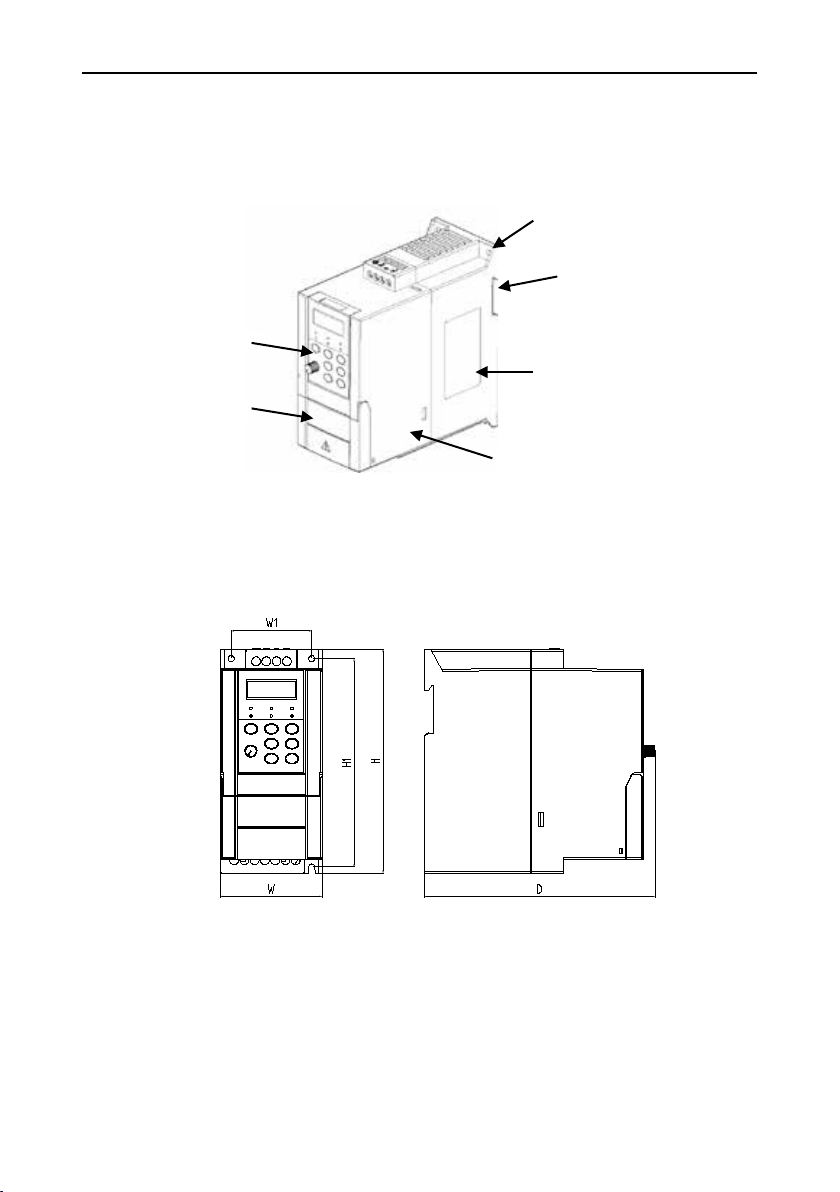

Emotron VSB Instruction Manual Chapter 2 Product Information

Cover

Mounting holes

DIN-rail groove

Nameplate

Middle casing

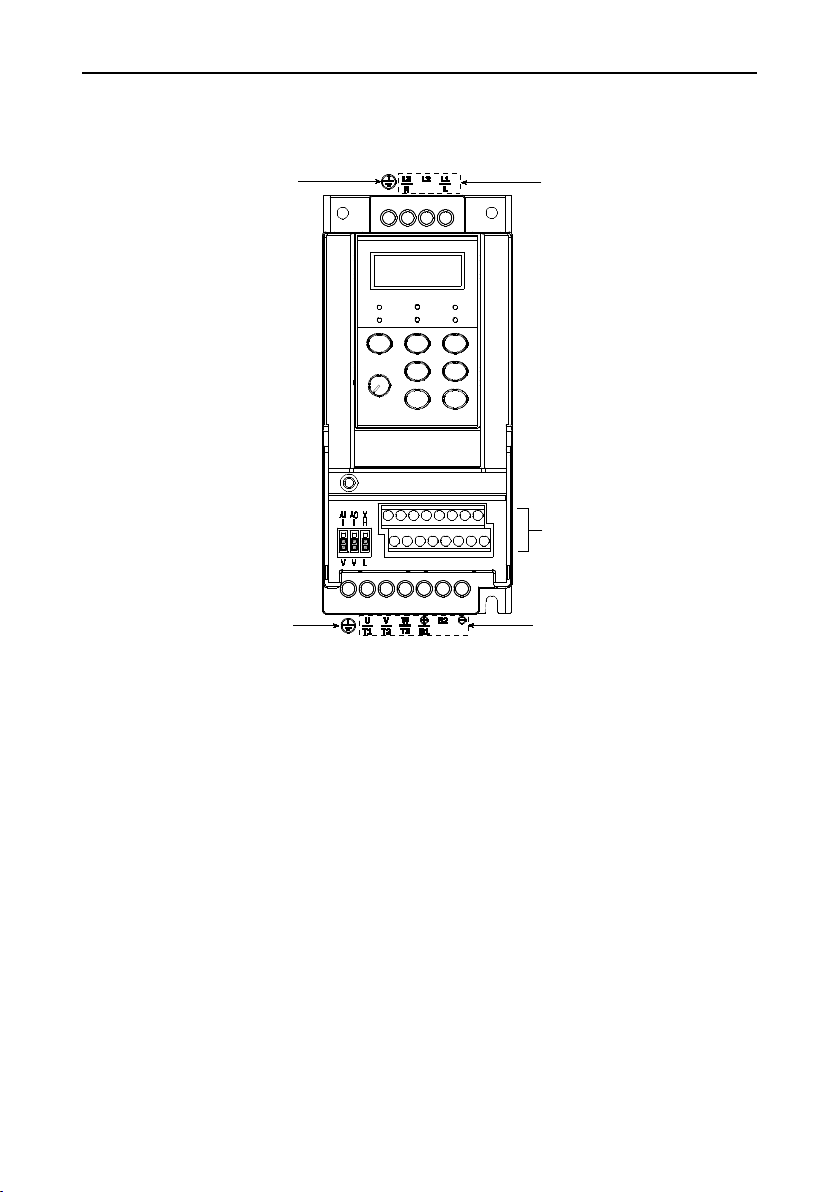

Keypad

2.5 Parts Drawing

Fig. 2-3 Parts explanation

2.6 Appearance, Mounting Dimensions and Weight

Fig. 2-4 External dimensions

- 14 -

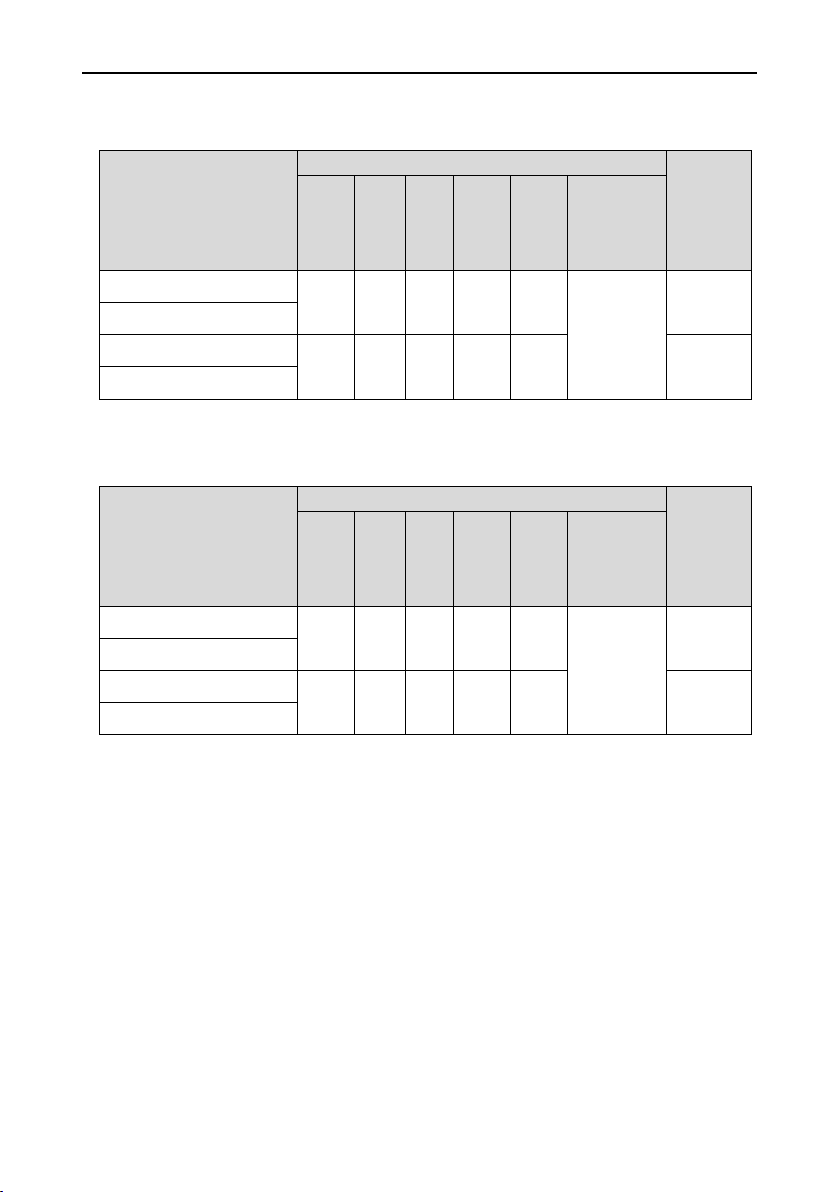

Emotron VSB Instruction Manual Chapter 2 Product Information

External and installation dimensions (mm)

(kg)

External and installation dimensions (mm)

(kg)

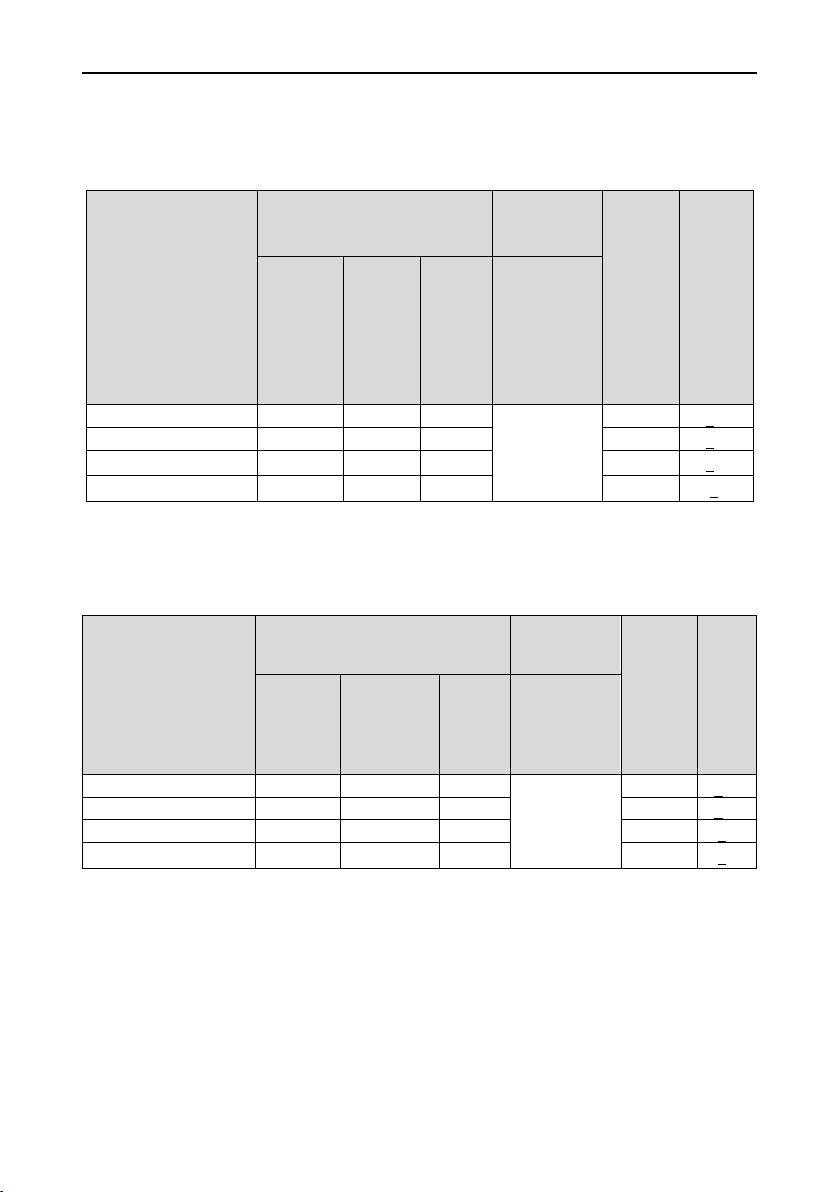

Table 2-4 Appearance, mounting dimensions and weight for

Emotron VSB23

Model

W H D W1 H1

VSU23-003-20CNB

75 166 168 59 154

VSU23-005-20CNB

VSU23-008-20CNB

85 188 172 69 175 2.0

VSU23-011 -20CNB

Mounting

hole dia.

Weight

d

1.4

4.5

Table 2-5 Appearance, mounting dimensions and weight for

Emotron VSB48

Model

W H D W1 H1

VSU48-003-20CNB

75 166 168 59 154

VSU48-004-20CNB

VSU48-006-20CNB

85 188 172 69 175 2.0

VSU48-009-20CNB

Mounting

hole dia.

Weight

d

1.4

4.5

- 15 -

Emotron VSB Instruction Manual Chapter 2 Product Information

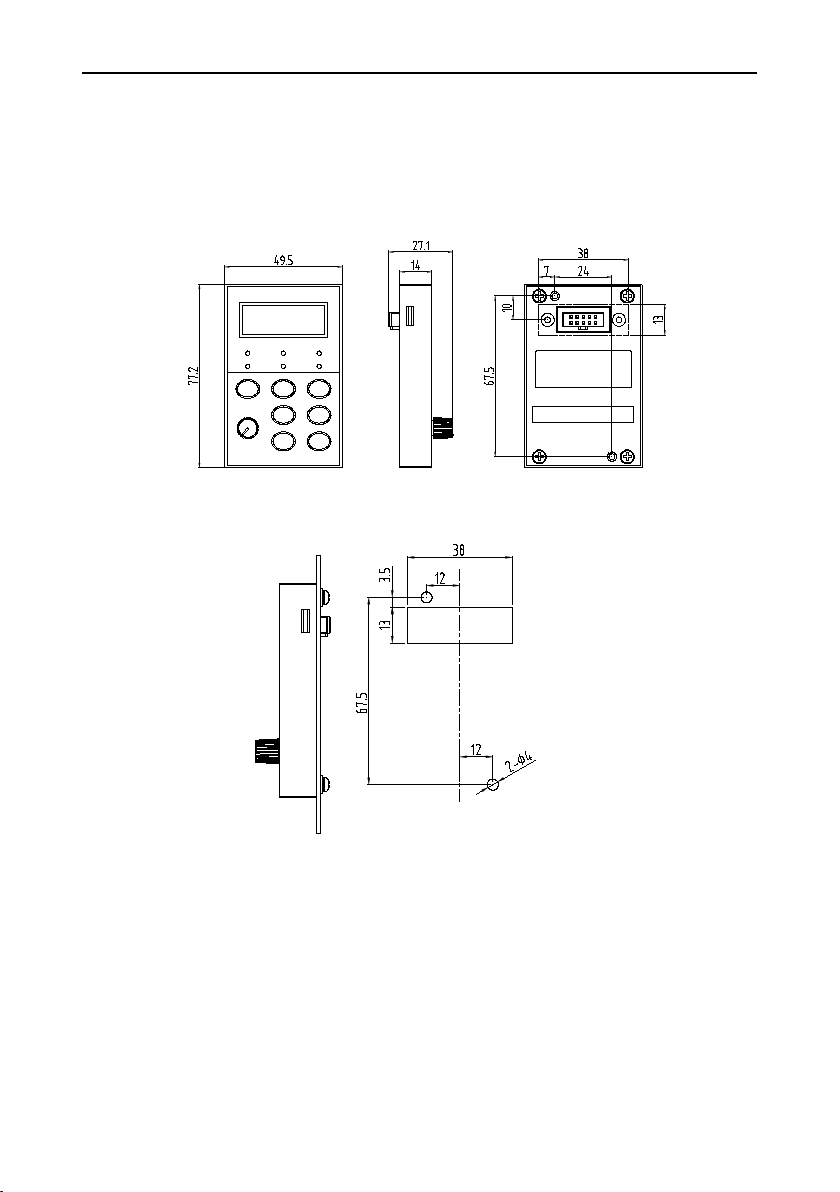

2.7 External Dimensions of Keypad

Keypad model of general purpose Emotron VSB series AC motor drive is KBU-BX2

whose appearance and external dimensions are shown in Fig. 2-5.

Fig. 2-5 External dimensions of KBU-BX2

Fig. 2-6 Cabinet hole dimensions when remote keypad mounting required

- 16 -

Emotron VSB Instruction Manual Chapter 2 Product Information

Ventilation

clearance

Ventilation

clearance

Fixing buckle

DIN-rail

Chapter 3 Installation and W iring

3.1 Installation Environm ent

1) Ambient temperature is in the range of -10°C - 50°C.

2) Drive should be installed on surface of flame retardant object, with adequate surrounding

space for heat dissipation.

3) Installation should be performed where vibration is less than 5.9m/s

4) Protect from moisture and direct sunlight.

5) Do not install in areas with

6) Do not expose to an atmosphere with flammable gases, corrosive gases, explosive gases

or other harmful gases.

grease dirt, dust, metal particles, or salty substances

3.2 Minimum Mounting Clearances

To ensure favorable heat dissipation, mount the drive upright on a flat, vertical and level surface

as per Fig. 3.1.

Emotron VSB series can be wall-mounted or DIN-rail mounted. When installation is performed

inside cabinet, the product shall be mounted side by side to the greatest extent while adequate

surrounding space shall be preserved for favorable heat dissipation.

2

(0.6g).

Fig. 3-1 Minimum mounting clearances

- 17 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

ATTENTION:

If a number of drives are mounted in one cabinet, parallel side-by-side mounting is

recommended

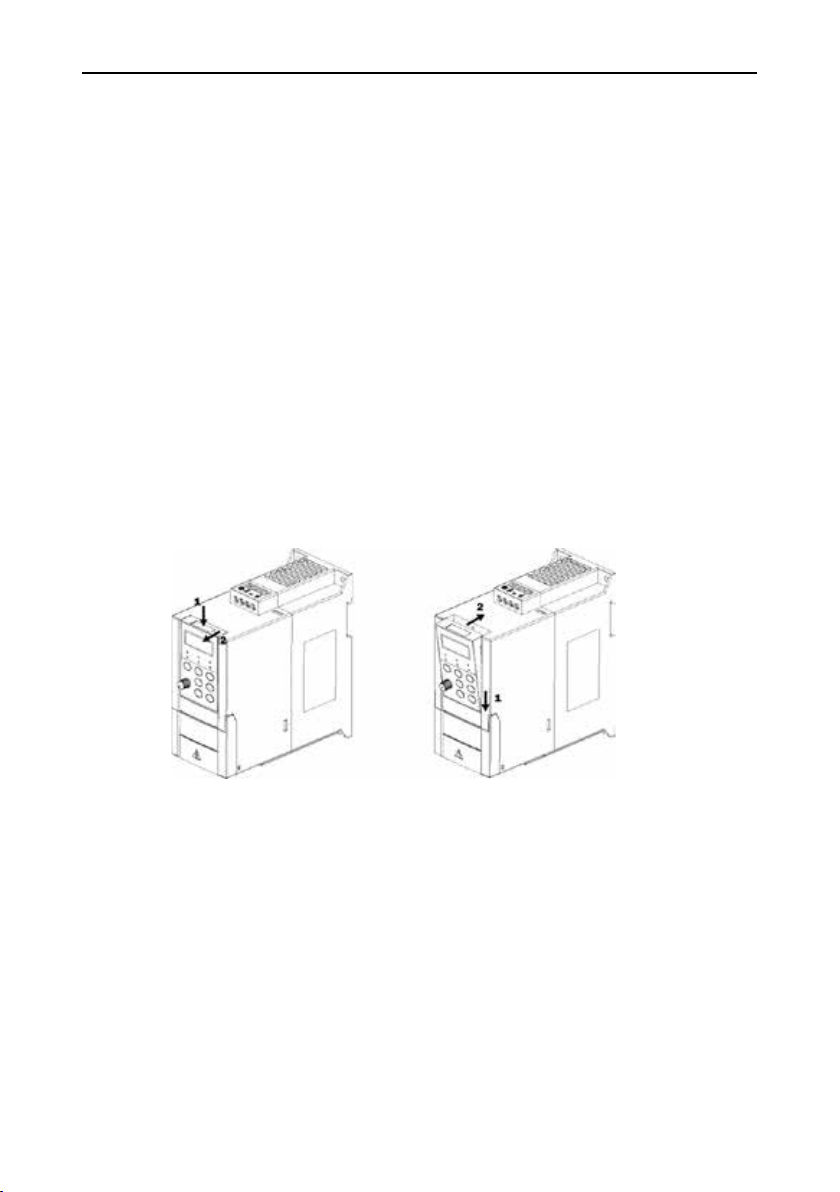

3.3 Remove & Mount Keypad and Cover

3.3.1 Remove and Mount Keypad

Remove keypad

Press the buckle of keypad as indicated by number "1" in Fig. 3-2, then pull the keypad out

to release as indicated by "2".

Mount k eypad

Slightly slant the keypad in the direction as indicated by number "1" in Fig. 3-3 and align it

to clamping port at lower part of keypad bracket, then press it in as indicated by "2". When

a "click" sound heard, it indicates clamping has been properly made.

Fig. 3-2 Remove keypad Fig. 3-3 Mount keypad

- 18 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

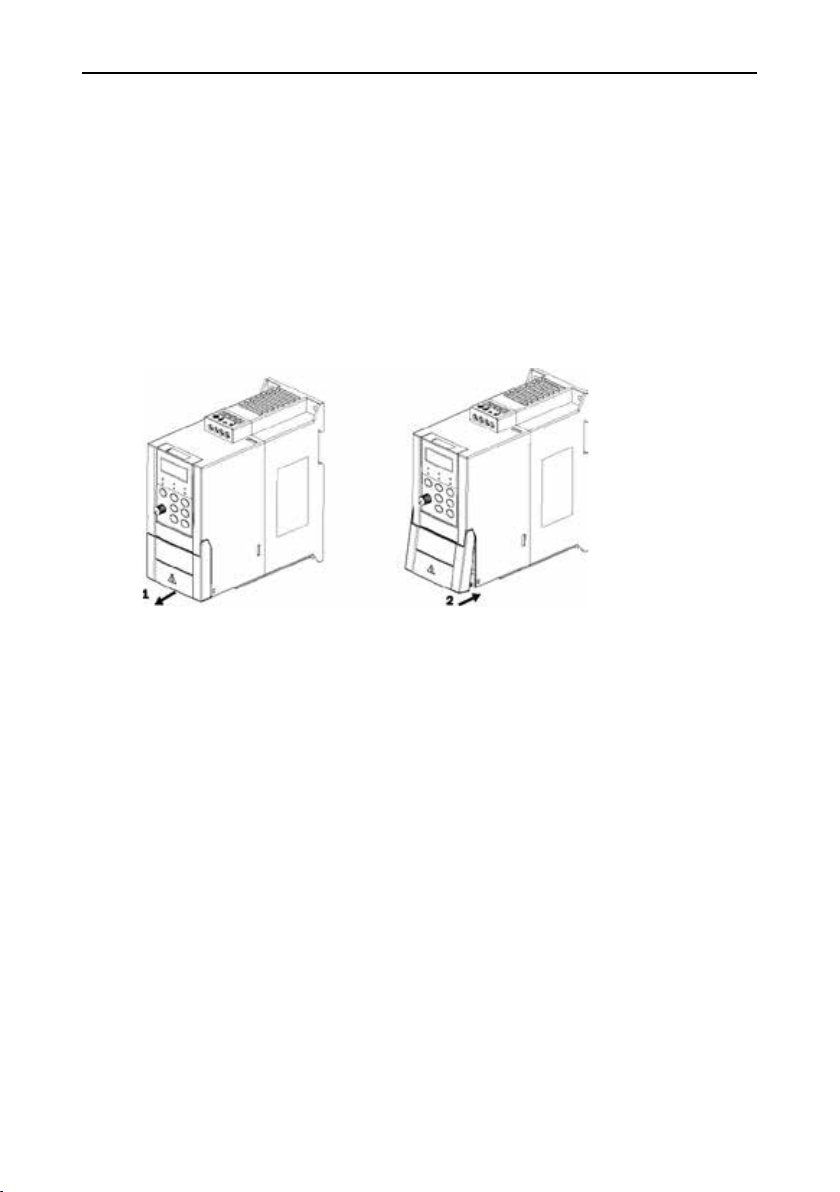

3.3.2 Open & Close Cover

Open the cover

Pull out as indicated by “1” in Fig. 3-4 a) with thumb.

Close the cover

After the completion of wiring, press the cover as indicated by “1” in Fig. 3-4 b). When there

is a “click” sound, it indicates clamping has been well completed.

a) open the cover b) close the cover

Fig. 3-4 Open and close the cover

- 19 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

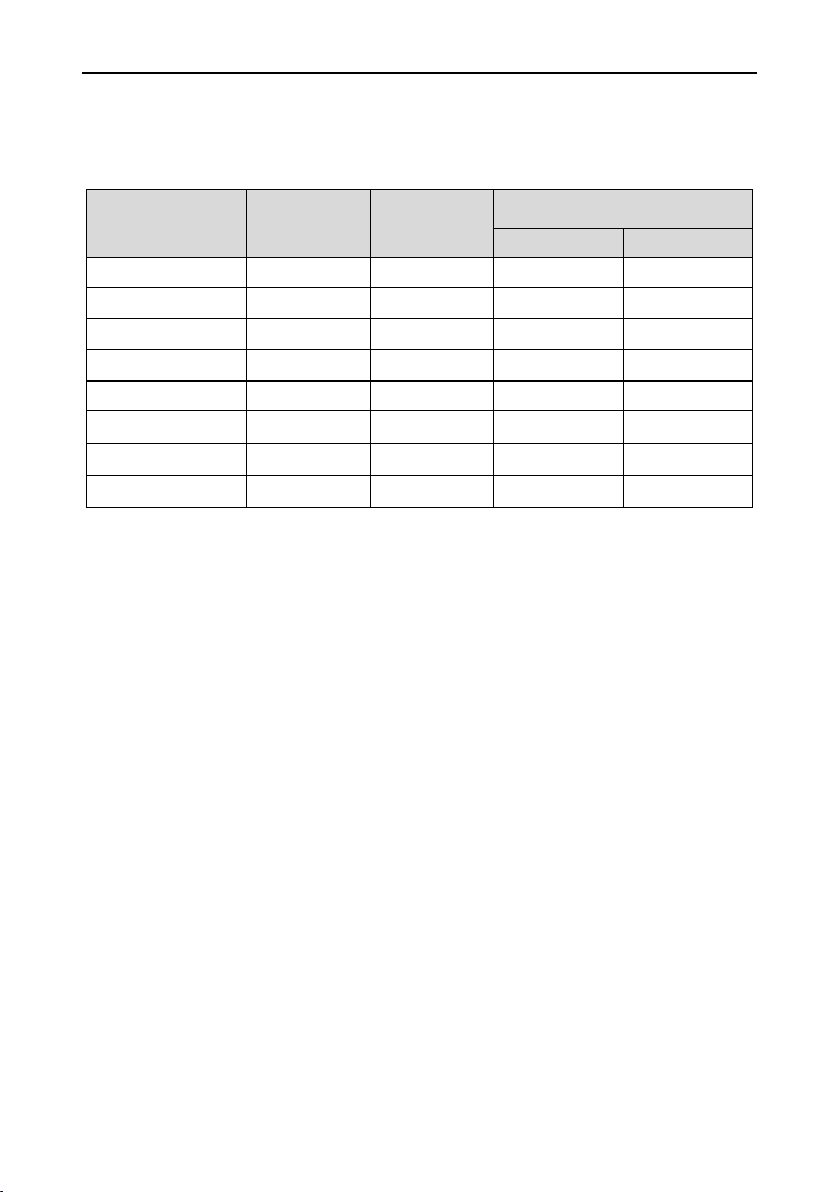

3.4 Selection of Peripheral Devices

Table 3-1 S election of peripheral devices

Model Breaker(A) Contactor(A)

Brake unit

Power(W) Resistor(Ω)

VSU23-003-20CNB

VSU23-005-20CNB

VSU23-008-20CNB

VSU23-011-20CNB

VSU48-003-20CNB 16 10 300 ≥150

VSU48-004-20CNB

VSU48-006-20CNB

VSU48-009-20CNB

* All models have inbuilt brake unit, and brake resistors should be sourced. Strictly conform to the requirement in the

Failure to comply may result in equipment damage.

form.

16 10 70 ≥200

25 16 70 ≥200

32 25 260 ≥100

40 32 260 ≥75

16 10 450 ≥100

16 10 600 ≥75

40 32 600 ≥75

- 20 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

Control circuit terminals

Main circuit

input

Grounding terminal

Grounding terminal

Main circuit

output

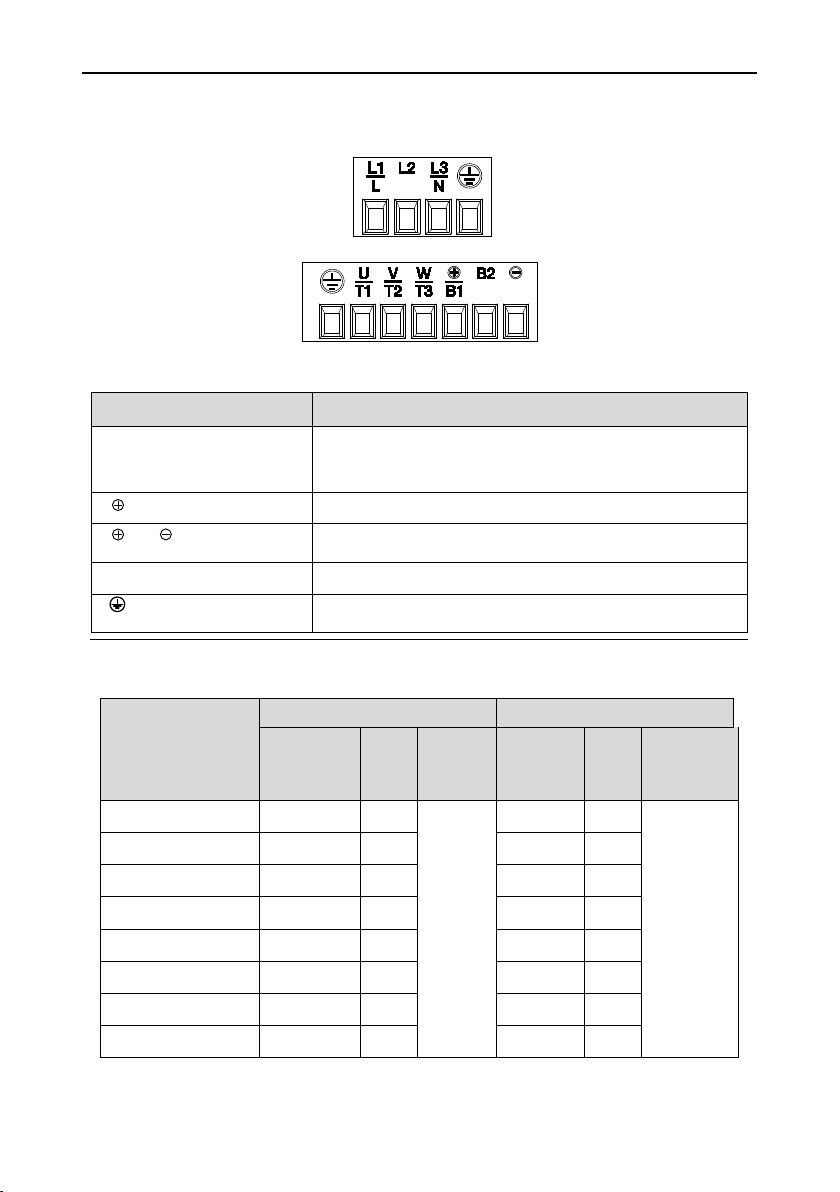

3.5 Term inal Configuration

terminals

terminals

Fig. 3-5 Terminal configuration.

- 21 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

WARNING

be in

comply may result in faults and/or equipment damage.

ATTENTION

mounted.

3.6 Main Circuit Terminals and Wiring

Only qualified personnel familiar with AC motor drives are allowed to implement wiring.

Failure to comply may result in equipment damage and/or personnel injury even death.

Wiring should be in strict accordance with this manual, otherwise hazard of electric

shock or equipment damage exists.

Make sure input power supply has been completely disconnected before wiring

operation. Failure to comply will result in personnel injury even death.

All wiring operations and lines should comply with EMC and national and local industrial

safety regulations and/or electrical codes. The conductor diameter should

accordance with recommendations of this manual. Otherwise, hazard of equipment

damage, fire, and/or personnel injury exists.

Since leakage current of the drive may exceed 3.5mA, for safety's sake, the drive and

the motor must be grounded so as to avoid hazard of electric shock.

Be sure to perform wiring in strict accordance with the drive terminal marks. Never

connect three-phase power supply to output terminals U/T1, V/T2 and W/T3. Failure to

comply will result in equipment damage.

Only mount braking resistors at terminals /B1and B2.

Wiring screws and bolts for main circuit terminals must be screwed tightly. Failure to

Signal wires should to the best of possibility be away from main power lines. In the

event that this cannot be ensured, vertical cross arrangement should be adopted,

reducing EMI interference to the signal wires as much as possible.

In case the motor cable exceeds 100m, an appropriate output reactor should be

- 22 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

mm2

requirement

mm2

/B1、B2

/B1、

3.6.1 Main Circuit Terminals

Fig. 3-6 Main circuit terminals

Terminal marks Designation and function of terminals

L1/L、L2、L3/N

U/T1、V/T2、W/T3 Triphase AC output terminals

Uniphase/Triphase AC power supply input (connect L1/L,

L3/N when the input is uniphase)

Brake resistor wiring terminals

DC power supply input terminals

Ground terminal PE

3.6.4 Terminal Screws and Wiring Requirement

Drive model

VSB23-003-20CNB

VSB23-005-20CNB

VSB23-008-20CNB

VSB23-011-20CNB

VSB48-003-20CNB

VSB48-004-20CNB

VSB48-006-20CNB

VSB48-009-20CNB

Table 3-2 Terminal screws and wiring requirement

Power terminal Ground terminal

Cable

requirement

2.5 M3.5

2.5 M3.5 2.5 M3.5

4 M3.5 2.5 M3.5

6 M3.5 4 M3.5

2.5 M3.5 2.5 M3.5

4 M3.5 4 M3.5

6 M3.5 6 M3.5

6 M3.5 6 M3.5

Screw

Torque

Nm/Lb-In

0.8 ±0.05/

7 ±0.5

Cable

Screw

2.5 M3.5

Torque

Nm/Lb-In

0.8 ±0.05/

7 ±0.5

- 23 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

WARNING

be in

RA, RB and RC.

ATTENTION

interference to the signal wires as much as possible.

3.7 Control Terminal Wirin g

Only qualified personnel familiar with AC motor drives are allowed to implement wiring.

Failure to comply may result in equipment damage and/or personnel injury even death.

Wiring should be in strict accordance with this manual, otherwise hazard of electric

shock or equipment damage exists.

Make sure input power supply has been completely disconnected before wiring

operation. Failure to comply will result in personnel injury even death.

All wiring operations and lines should comply with EMC and national and local industrial

safety regulations and/or electrical codes. The conductor diameter should

accordance with recommendations of this manual. Otherwise, hazard of equipment

damage, fire, and/or personnel injury exists.

Screws or bolts for terminal wiring must be screwed tightly.

AC 220V signal is prohibited from connecting to other terminals than control terminals

Signal wires should to the best of possibility be away from main power lines. If this

cannot be ensured, vertical cross arrangement should be adopted, reducing EMI

- 24 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

3.7.2 W iring Diagram

Fig. 3-7 Wiring diagram.

- 25 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

Category

Terminal

Terminal

designation

Specification

Maximum output current 25mA

should be larger than 400Ω

0~20mA: input impedance - 500Ω, maximum

input current - 25mA

0~10V: input impedance - 100kΩ, maximum

input voltage - 12.5V

Can be jumped between 0~20mA and 0~10V,

factory default: 0~10V

Can be jumped between 0~20 mA and 0

10V, factory default: 0~10V

input

RS485

+

RS485

-

RS485

grounding

3.8 Control Term inal Specification

Table 3-3 C ontrol terminal specification

10.3V ±3%

+10V

Analog input

reference voltage

The resistance of external potentiometer

Analog

input

Analog

output

Digital

Digital

output

Relay

output

GND Analog ground Connect with GND interiorly

AI Analog input

0~20mA: impedance - 200Ω-500Ω

AO Analog output

GND Analog ground Connect with GND interiorly

+24V +24V

COM +24V ground Connect with COM interiorly

X1~X4

Y

RA/RB/RC Control board

485+

Digital input

Terminal 1~4

Open collector

output

relay output

differential signal

0~10V: impedance- 10kΩ

24V±10%

Maximal load 100mA

Input: 24VDC, 5mA

Freq range: 0~200Hz

Voltage range: 22V~26V

Voltage range: 0~24V

Current voltage: 0~50mA

RA-RB: NC; RA-RC: NO

Contact capacity: 250VAC/3A, 30VDC/3A

Rate:

4800/9600/19200/38400/57600/115200bps

~

Terminal

RS485

Interface

485−

GND

differential signal

communication

shileded

Maximum distance - 500m (standard network

cable used)

Connected with GND interiorly

- 26 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

Category

Terminal

Terminal

designation

Specification

485 communication

shield grounding

Maximum communication distance is 5m

when connected to Keypad

485

shield grounding

Isolated from COM interiorly

Use GTAKE dedicated cable

Keypad

interface

GND

CN4 Keypad interface

GND

communication

3.9 Control Terminal Usage

3.9.1 Lay-out of Control Terminals

Fig. 3-8 Lay-out of control terminals

3.9.2 Control Terminal S crew and W iring Requirement

Table 3-4 Terminal screw and wiring specification

Cable type Cable requirement (mm2) Screw Torque (Nm/Lb-In)

Shielded cable 1.0 M3 0.5 / 4.3

3.9.3 Instructions of Analogue Input/Output Terminals

Being particularly vulnerable to noise, analog input & output signals cables should be as short

as possible, shielded, and their shielded layers should be properly grounded close to the side

of drive. The cables should not exceed 20m.

Control cables shall be kept no less than 20cm away from main circuit and strong current

- 27 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

lines (e.g. power lines, motor lines, relay lines and contactor lines) and should not be arranged

in parallel with strong current lines. In case it is inevitable to intersect strong current line,

vertical wiring is recommended to avoid drive faults as a result of noise.

Where analog input & output signals are severely interfered, the side of analog signal

source should be provided with filter capacitor or ferrite core.

3.9.4 Instructions of Digital Input/Output Terminals

Digital input & output signals cables should be as short as possible, shielded, and their

shielded layers should be properly grounded close to the side of drive. The cables should not

exceed 20m. When active drive is selected, take necessary filtering measures against power

crosstalk, for which dry contact control is recommended.

Control cables shall be kept no less than 20cm away from main circuit and strong current

lines (e.g. power lines, motor lines, relay lines and contactor lines) and should not be arranged

in parallel with strong current lines. In case it is inevitable to intersect strong current line,

vertical wiring is recommended to avoid drive faults as a result of noise. Operating instructions

for switching value input terminal

In structions of digital input terminal

Dry contact

Fig. 3-9 X terminal high activated

- 28 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

X

1

X

4

+

5V

GND

Drive

Shielded Cable

Near-end Grounded

+

-

+24V

Opto

+5V

GND

+-

Opto

1

4

External Controller

Jumper

L

X

H

COM

+24V

Fig. 3-10 X terminal low activated

Open collector

ATTENTION:

Fig. 3-11 Open collector PNP wiring

When selecting OC PNP wiring, dip switch should be switched to H terminal.

- 29 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

X1

X4

COM

+5V

GND

Drive

Shielded Cable

Near-end Grounded

+

-

Opto

+5V

GND

+-

Opto

1

4

External Controller

LH

COM

+24

V

Jumper

X

Fig. 3-12 Open collector PNP wiring

ATTENTION:

When selecting OC NPN wiring, dip switch should be switched to L terminal.

- 30 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

I nstructions of digital output terminal

Instructions of Y output terminal

a) Internal power supply b) External power supply

Fig. 3-13 Wiring when Y output with pull-up resistor

a) Internal power supply b) External power supply

Fig. 3-14 Wiring when Y output drive relay

ATTENTION:

When relay coil voltage is lower than 24V, a resistor as voltage divider selected based on

coil impedance should be mounted between relay and output terminal,.

W iring instruction of relay output terminal

RA/RB/RC are relay contacts. RA and RB are normally closed, while RA and RC are

normally open. See parameter C1-02 for details.

ATTENTION:

In case inductive load (e.g. electromagnetic relay or contactor) is to be driven, a surge

voltage absorbing circuit such as RC absorbing circuit, piezoresistor or fly-wheel diode etc.

shall be mounted. Absorbing devices should be mounted close to the end of relay or

contactor.

- 31 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

H means X terminal high input activated, while L low

activated

3.10 Instruction of Signal Switches

Fig. 3-15 Jumper diagram of signal switching

Designation Function

AI I: current input (0 - 20mA); V: voltage input (0 - 10V) 0 - 10V

AO I: current output (0 - 20mA); V: voltage output (0 - 10V) 0 - 10V

X

Default

setting

H

3.11 EMI Solutions

Due to its working principle, the drive will inevitably produce certain noise that may influence

and disturb other equipment. Moreover, since the internal weak electric signal of drive is also

susceptible to the interference of drive itself and other equipment, EMI problems shall be

inevitable. In order to reduce or avoid the interference of drive to external environment and

protect drive against interference from external environment, this section makes a brief

description of noise abatement, ground handling, leakage current suppression and the

application of power line filters.

3.11.1 Noise Abatement

When peripheral equipment and drive share the power supply of one system, noise from

drive may be transmitted to other equipment in this system via power lines and result in

misoperation and/or faults. In such a case, the following measures could be taken:

1) Mount input noise filter at input terminal of the drive;

2) Mount power supply filter at power input terminal of affected equipment;

3) Use isolation transformer to isolate the noise transmission path between other

equipment and the drive.

As the wiring of peripheral equipment and drive constitutes a circuit, the unavoidable

earthing leakage current of inverter will cause equipment misoperation and/or faults.

- 32 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

变频器

其它设备

PE PE

Drive

Other

Disconnect the grounding connection of equipment may avoid this misoperation and/or

faults

Sensitive equipment and signal lines shall be mounted as far away from drive as possible.

Signal lines should be provided with shielded layer and reliably grounded. Alternatively,

signal cable could be put into metallic conduits between which the distance shall be no

less than 20cm, and shall be kept as far away from drive and its peripheral devices, cables

as possible. Never make signal lines in parallel with power lines or bundle them up.

Signal lines must orthogonally cross power lines if this cross inevitable.

Motor cables shall be placed in thick protective screen like more than 2mm-thick pipelines

or buried cement groove, also, power lines can be put into metallic conduit and grounded

well with shielded cables.

Use 4-core motor cables of which one is grounded at close side of the drive and the other

side is connected to motor enclosure.

Input and output terminals of drive are respectively equipped with radio noise filter and

linear noise filter. For example, ferrite common mode choke can restrain radiation noise of

power lines.

3.11.2 Grounding

Recommended ground electrode is shown in the figure below:

Devices

Use to the fullest extent the maximum standard size of grounding cables to reduce the

impedance of grounding system;

Grounding wires should be as short as possible;

Grounding point shall be as close to the drive as possible;

One wire of 4-core motor cables shall be grounded at the drive side and connected to

grounding terminal of motor at the other side. Better effect will be achieved if motor and drive

are provided with dedicated ground electrodes;

When grounding terminals of various parts of system are linked together, leakage current

turns into a noise source that may influence other equipment in the system, thus, grounding

terminals of the drive and other vulnerable equipment should be separated.

Grounding cable shall be kept away from inlet & output of noise-sensitive equipment.

3.11.3 Leakage Current Suppression

Leakage current passes through the line-to-line and ground distributed capacitors at input &

output sides of drive, and its size is associated with the capacitance of distributed capacitor and

Fig. 3-16 Ground

- 33 -

Emotron VSB Instruction Manual Chapter 3 Installation and wiring

the carrier frequency. Leakage current is classified into ground leakage current and line-to-line

leakage current.

Ground leakage current not only circulates inside drive system, but may also influence other

equipment via ground loop. Such a leakage current may result in malfunction of RCD and

other equipment. The higher the carrier frequency of drive is, the bigger the ground leakage

current would be. The longer the motor cables and the bigger the parasitic capacitance are,

the bigger the ground leakage current would be. Therefore, the most immediate and effective

method for suppression of ground leakage current is to reduce carrier frequency and

minimize the length of motor cables.

The higher harmonics of line-to-line leakage current that passes through between cables at

output side of drive will Accel the aging of cables and may bring about malfunction of other

equipment. The higher the carrier frequency of drive is, the bigger the line-to-line leakage

current would be. The longer the motor cables and the bigger the parasitic capacitance are,

the bigger the line-to-line leakage current would be. Therefore, the most immediate and

effective method for suppression of ground leakage current is to reduce carrier frequency and

minimize the length of motor cable. Line-to-line leakage current can also be effectively

suppressed by mounting additional output reactors.

3.11.4 Use of Power Supply Filter

Since AC drives may generate strong interference and are also sensitive to outside

interference, power supply filters are recommended. Pay close attention to the following

instructions during the use:

Enclosure of the filter needs to be reliably grounded;

Input lines of the filter shall be kept as far away from output lines as possible so as to avoid

mutual coupling;

Filter shall be as close to the drive side as possible;

Filter and drive must be connected to the same common ground.

- 34 -

Emotron VSB Instruction Manual Chapter 4 Operation and Run instructions

Chapter 4 Operation and Run Instructions

4.1 Operation of Keypad

As a human-machine interface, keypad is the main part for the drive to receive command and

display parameters.

Fig. 4-1 Keypad

- 36 -

Emotron VSB Instruction Manual Chapter 4 Operation and Run instructions

Symbol

Key name

Meaning

1) Parameter code edition enter

2) Confirmation of parameter value settings

1) Return

1) Increment of selected digital of parameter code

3) Increment of set frequency

1) Decrement of selected digital of parameter code

3) Decrement of set frequency

1) Selection of parameter code serial digital

4) Fault status switched to parameter displayed status

1) Stop

2) Fault reset

RUN

STOP

RESET

4.1.1 Key F unctions on Keypad

On keypad there are 7 keys and 1 knob whose functions are as shown in Table 4-1.

Table 4-1 Key functions on ke ypad

Enter key

Escape key

Up key

Down key

2) Invalidate parameter editing value

2) Increment of selected digital of parameter value

2) Decrement of selected digital of parameter value

Shift key

Run key Run

Stop/reset key

Potentiometer

2) Selection of parameter value edited digital

3) Selection of stop/run-status displayed parameters

1) Frequency command source

2) Process PID setting

- 37 -

Emotron VSB Instruction Manual Chapter 4 Operation and Run instructions

A

Current indicator

ON: currently displayed parameter is current

V

Voltage indicator

ON: currently displayed parameter is voltage

ON: currently displayed parameter is run speed

Flash: currently displayed parameter is set speed

A+V

Percentage indicator

ON: currently displayed parameter is percentage

All OFF

No unit

No unit

ON: Run

Flash: Stopping

ON: If the drive in stop status, forward command

Flash: Forward is switching to reverse

ON: If the drive in stop status, reverse command

Flash: Reverse is switching to forward

4.1.2 Keypad Indicators

Keypad is furnished with 6 indicators whose descriptions are as stated below

Table 4-2 Description of indicators

Indicator Designation Meaning

ON: currently displayed parameter is run frequency

Hz Frequency indicator

Hz+A Run speed indicator

or the unit of current parameter is frequency

Flash: currently displayed parameter is set

frequency

RUN Run status indicator

FWD Forward indicator

REV Reverse indicator

OFF: Stopped

enabled. If the drive in run status, the drive is

running forward

enabled. If the drive in run status, the drive is

running reversely.

- 38 -

Emotron VSB Instruction Manual Chapter 4 Operation and Run instructions

LoC-1

Keypad locked 1 (full locked)

P-SEt

Password has been set

STOP/RESET)

(all locked except STOP/RESET)

(all locked except shift key)

exclusive)

(motor parameter inclusive)

4.2 Potentiometer Setting

Potentiometer could be frequency setting source or process PID setting programmed by

related parameters. When b0-01 is set to 3, potentiometer is source of master frequency

command. When b0-03 is set to 4, potentiometer is source of auxiliary frequency command.

When unit’s place, decade, or hundreds’ place of b1-01 is set to 4, potentiometer would be

working as frequency setting source of corresponding run command source.

4.3 Prompt Message Status

Prompt message status shall be displayed at the completion of some certain operations. For

instance, "dEFt2" would be displayed upon the completion of “restore to factory default (motor

parameters inclusive)

Table 4-3 Prompt messages

Characters Meaning Characters Meaning

Keypad locked 2

LoC-2

(all locked except RUN,

P-CLr Password cleared

LoC-3

LoC-4

PrtCt Keypad protection dEFt1

UnLoC Unlock keypad dEFt2

LoU Drive undervoltage

Table 4-3 shows meanings of the characters displayed on Keypad.

Keypad locked 3

Keypad locked 4

TUNE Autotuning

CLr-F Clear fault record

Restore to factory default

(motor parameters

Restore to factory default

- 39 -

Emotron VSB Instruction Manual Chapter 4 Operation and Run instructions

4.4 Parameter Setting

4.4.1 Parameter System

Emotron VSB series drive parameter group: A0, b0~b2, C0~C4, d0~d2, E0~E1, F0~F1, H0,

L0~L1, U0~U1. Each parameter group contains a number of parameters. Parameter codes are

identified by the combination "parameter group character + parameter subgroup number +

parameter number". For instance, "F1-07" indicates the seventh parameter code at subgroup 1,

group F.

4.4.2 Parameter Displayed Structure

Parameters and the parameter values are subject to a two-tier structure. Parameters

correspond to first-tier display, while parameter values correspond to second-tier display.

The first-tier display is as shown in Fig. 4-2, while the second-tier as Fig. 4-3:

Fig. 4-2 First-tier parameter display

Fig. 4-3 Second-tier parameter display ("3" is the value of b0-00)

- 40 -

Emotron VSB Instruction Manual Chapter 4 Operation and Run instructions

4.5 Initial Power up

Perform wiring in strict accordance with technical requirements as set forth in Chapter 3 -

Installation and Wiring.

4.5.1 Examples for Quick setup

The following are examples for Quick setup with wiring and parameter settings. For more

detailed information, see “Chapter 6 Specification of parameters”.

4.5.1.1 Analogue speed reference 0-10V to AI

1. Set Signal switch AI to V see chapter 3.10 Instruction of Signal Switches.

2. Connect analogue reference signal + to AI and - to GND. If manual potentiometer

(10kOhm) is used connect the mid point to AI and ends to +10V and GND. see Fig

4.4.

3. Connect start signals: RunFWD to DigitalIn1 and Run REV to DigitalIn2. If none or both

DigIn1 and DigIn2 are activated = Stop

Fig 4-4 Connect pot. to +10V, GND and AI terminal

- 41 -

Emotron VSB Instruction Manual Chapter 4 Operation and Run instructions

Application parameter settings as below.

Table 4-4

Parameter

b0-01 Master frequency reference source 2: AI

b0-08 Maximum frequency set value 50Hz *

b0-10 Minimum frequency set value 0Hz *

b1-00 Run command source 1: Terminal

b2-01 Acceleration time 1 set value 6s *

b2-02 Deceleration time 1 set value 6s *

C0-01 Digital input X1 function 3: FWD

C0-02 Digital input X2 function 4: REV

C2-00 Analogue input curve 00 * AI curve 1

C2-01 Maximum input of curve 1 100% *

C2-02 Set value(reference) corresponding to

maximum input of

curve 1

Designation Set Value Comment

Digital inputs

control

(2 point curve)

100% *

C2-03 Minimum input of curve 1 0% *

C2-04 Set value (reference) corresponding to

minimum input of curve 1

0% *

* = default value

- 42 -

Emotron VSB Instruction Manual Chapter 4 Operation and Run instructions

4.5.1.2 Analogue speed reference 4-20 mA to AI

1. Set Signal switch A0 to I, see chapter 3.10 Instruction of Signal Switches.

2. Connect analogue reference signal: + to AI and - to GND

3. Connect start signals: Run FWD to DigitalIn1and Run REV to DigitalIn2. If none or both

DigIn1 and DigIn2 are activated = Stop.

Fig 4-5. Connection for Analogue speed reference 4-20mA to AI

- 43 -

Emotron VSB Instruction Manual Chapter 4 Operation and Run instructions

Application parameter settings as below.

Table 4-5

Parameter Designation Set Value Comment

b0-01 Master frequency reference

sour ce

b0-08 Maximum frequency set value 50Hz *

b0-10 Minimum frequency set value 0Hz *

b1-00 Run command source 1: Terminal control Digital inputs

b2-01 Acceleration time 1 set value 6s *

b2-02 Deceleration time 1 set value 6s *

C0-01 Digital input X1 function 3: FWD

C0-02 Digital input X2 function 4 : REV

C2-00 Analogue input curve 00 * AI curve 1

C2-01 Maximum input of curve 1 100% * 20mA

C2-02 Set value corresponding to

maximum input of curve 1

C2-03 Mini mum input of curve 1 20% * =4/20

2: AI

(2 point curve)

100% *

C2-04 Set value corresponding to

minimum input of cur ve 1

* = default value

0% *

- 44 -

Emotron VSB Instruction Manual Chapter 4 Operation and Run instructions

4.5.1.3 4 preset speeds and Start/Stop by Digital Inputs

1. Connect RUN contact SB2 between +24V and Digital Input 1.

2. Connect REVERSE selection contact between +24V and Digital Input 2.

3. Connect Preset bit0 contact between +24V and Digital Input 3.

4. Connect Preset bit1 contact between +24V and Digital Input 4.

Fig. 4-6. Connection for 4 preset speeds and start/stop by DI

- 45 -

Emotron VSB Instruction Manual Chapter 4 Operation and Run instructions

Parameter

Designation

Set Value

Comment

b0-01

Master frequency reference source

8: Multi-step speed

Preset speeds

Application parameter settings as below.

Table 4-6

b0-08 Maximum frequency set valu e 50Hz *

b0-10 Minimum frequency se t valu e 0 Hz *

b1-00 Run command source 1: Terminal control Digital inputs

b2-01 Acceleration time 1 se t value 6s *

b2-02 Deceleration time 1 set val ue 6s *

C0-01 Digital input X1 function 3: FW D Star t button SB2

C0-02 Digital input X2 function 4: REW Reverse direcion

C0-03 Digital input X3 function 5: Mul ti-ste p Bit 0, speed selection

C0-04 Digital input X4 function 15:Multi- step

C0-19 FWD/REV terminal control mode 3: Two-wire mode 2

F1-00 Source for Preset frequency 0 0*: Digital setti ng F1-02

F1-01 Source for Preset frequency 1 0*: Digital setting F1-03

F1-02 Preset frequency 0 Set <Speed 0> Bit1=0, Bit0=0

F1-03 Preset frequency 1 Set <Speed 1> Bit1=0, Bit0=1

F1-04 Preset frequency 2 Set <Speed 2> Bit1=1, Bit0=0

F1-05 Preset frequency 3 Set <Speed 3> Bit1=1, Bit0=1

* = default value

Bit 1, speed selection

- 46 -

Emotron VSB Instruction Manual Chapter 5 List of Parameters

Category

Parameter group

Related pages

Group A: system parameter

A0: system parameters

P- 48 -; P- 70 -

b0: frequency command

P- 48 -; P- 71 -

b1: start/stop control

P- 50 -; P- 84 -

b2: Accel/Decel parameters

P- 51 -; P- 89 -

C0: digital input

P- 52 -; P- 95 -

C1: digital output

P- 54 -; P- 95 -

C2: analog input

P- 55 -; P- 102 -

C3: analog output

P- 56 -; P- 107 -

C4: automatic correction of

analog input

P- 56 -; P- 109 -

d0: motor parameter

P- 57 -; P- 111 -

d1: motor V/f control parameters

P- 58 -; P- 115 -

d2: motor vector control

parameters

P- 59 -; P- 120 -

Group E: enhanced

parameters

E0: enhanced function

P- 59 -; P- 124 -

F0: process PID

P- 61 -; P- 131 -

F1: multi-step frequency

P- 62 -; P- 136 -

Group H: communication

parameters

H0: MODBUS communication

parameters

P- 63 -; P- 138 -

Group L: keypad keys and

display

L0: keypad keys

P- 64 -; P- 140 -

L1: LED display setting

P- 65 -; P- 141 -

U0: status monitoring

P- 66 -; P- 143 -

U1: fault history

P- 67 -; P- 146 -

Chapter 5 List of Parameters

Emotron VS parameter groups are listed below:

Group b: setting of running

parameters

Group C: input and output

terminals

Group d: motor and control

parameters

function and protection

Group F: application

Group U: monitoring

E1: protection parameters P- 60 -; P- 126 -

- 47 -

Emotron VSB Instruction Manual Chapter 5 List of Parameters

default

Group A0: System Parameter

A0-00

Setting of user password

0~FFFF

0000 △

Parameter

programming allowed

Parameter

0: No operation

inclusive)

Motor control technique

0: V/f control

1: Sensor-less vector control

Group b Setting of Run Parameters

Group b0 Frequency Command

Frequency

0: Master frequency command

auxiliary computation result

ATTENTION:

Change attribute:

"△" means the value of this parameter can be modified in stop and running status of drive;

"×" means the value of this parameter cannot be modified when drive is running;

"■" means this parameter is a measured value that cannot be modified;

Factory default value: The value when restored to factory default. Neither measured

parameter value nor recorded value will be restored.

Scope: the scope of setting and display of parameters

Param

A0-02

A0-03

Designation Range

Group A: System Parameter

0: All parameter programming

protection

initialization

allowed

1: Only A0-00 and this parameter

1: Clear fault history

2: Restore all parameters to factory

default (motor parameters

exclusive)

3: Restore all parameters to factory

default (motor parameters

Factory

0 ×

0 ×

Attr

A0-09

b0-00

command pattern

1: Master & auxiliary computation

result

2: Switch between master and

auxiliary command

3: Switch between master frequency

command, and master & auxiliary

computation result

4: Switch between auxiliary

frequency command, and master &

- 48 -

0 ×

0 ×

Emotron VSB Instruction Manual Chapter 5 List of Parameters

Factory

default

Master frequency command source

02) + terminal

9: Communication

Digital setting of

Lower limit frequency ~ upper limit

frequency

A

source

10: Communication

Digital setting of

Lower limit frequency ~ upper limit

frequency

1: Relative to master frequency

b0-06

Coeff of auxiliary frequency

0.0%~100.0%

100.0%

×

Computation of master and auxiliary

frequency

3: Min {master, auxiliary}

b0-08

Maximum frequency

Upper limit frequency ~600.00Hz

50.00Hz

×

Upper limit frequency

frequency

b0-10

Lower limit frequency

0.00Hz~upper limit frequency

0.00Hz

×

Operation

frequency lower than lower limit

frequency

2: Stop

Time-delay of stop when command

frequency lower than lower limit

frequency

b0-13

Lower limit of skip frequency band 1

0.00Hz~upper limit frequency

0.00Hz

×

b0-14

Upper limit of skip frequency band 1

0.00Hz~upper limit frequency

0.00Hz

×

Param

b0-01

b0-02

b0-03

b0-04

b0-05 Range of auxiliary frequency

uxiliary frequency command

Designation Range

master frequency

auxiliary frequency

0: Digital setting (b0-02) +

adjustment on keypad

1: Digital setting (b0-

UP/DOWN adjustment

2: Analog input AI

3: Potentiometer

6: Process PID output

8: Multi-step speed

0: No command

1: Digital setting (b0-04) + ∧/∨

adjustment on keypad

2: Digital setting (b0-04) + terminal

UP/DOWN adjustment

3: Analog input AI

4: Keypad potentiometer input

7: Process PID output

9: Multi-step speed

0: Relative to maximum frequency

Attr

3 ×

50.00Hz △

0 ×

0.00Hz △

0 ×

b0-07

b0-09

b0-11

b0-12

when command

0: Master + auxiliary

1: Master - auxiliary

2: Max {master, auxiliary}

Lower limit frequency ~ maximum

0: Run at lower limit frequency

1: Run at 0 Hz

0.0s ~ 6553.5s 0.0s ×

0 ×

50.00Hz ×

0 ×

- 49 -

Emotron VSB Instruction Manual Chapter 5 List of Parameters

Factory

default

b0-15

Lower limit of skip frequency band 2

0.00Hz~upper limit frequency

0.00Hz

×

b0-16

Upper limit of skip frequency band 2

0.00Hz~upper limit frequency

0.00Hz

×

b0-17

Lower limit of skip frequency band 3

0.00Hz~upper limit frequency

0.00Hz

×

b0-18

Upper limit of skip frequency band 3

0.00Hz~upper limit frequency

0.00Hz

×

b0-19

Jog frequency

0.00Hz~upper limit frequency

5.00Hz

Group b1 Start/Stop Control

Run command

2: Communication control

Binding of run command and

frequency

Unit's place: frequency command

(same

unit's place)

1: Reverse

Reverse disabled

0: Reverse enabled

1: Reverse disabled

b1-04

Dead time of forward and reverse

0.0s~3600.0s

0.0s △

Start method

0: From start frequency

3: Flying start (Spin start)

b1-06

Start frequency

0.00Hz~upper limit frequency

0.00Hz

×

b1-07

Holding time of start frequency

0.0s~3600.0s

0.0s △

b1-08

DC brake current at start

0.0%~100.0%

0.0% △

b1-09

DC brake time at start

0.00s~30.00s

0.00s △

Param

b1-00

b1-01

Designation Range

command

Attr

△

0: Keypad control

1: Terminal control

source bundled under keypad

control:

0: No binding

1: Digital setting (b0-02) + ∧/∨

adjustment on keypad

2: Digital setting (b0-02) + terminal

UP/DOWN adjustment

3: Analog input AI

4: Keypad potentiometer input

7: Process PID output

9: Multi-step frequency

A: Communication input

Decade: frequency command source

bundled under terminal control

as unit's place)

Hundreds place: frequency

command source bundled under

communication control (same as

0 ×

000 ×

b1-02 Run direction

b1-03

b1-05

0: Forward

1: DC injection brake then start

- 50 -

0 △

0 ×

0 ×

Emotron VSB Instruction Manual Chapter 5 List of Parameters

Factory

default

b1-10

Flying start current

0.0% - 200.0%

100% △

B1-11

Flying start time

0.1s – 20.0s

2.0s △

Stop

2: Ramp to stop + DC brake

b1-14

Start frequency of DC brake stop

0.00Hz~upper limit frequency

0.00Hz

×

b1-15

Brake current

0.0%~100.0%

0.0% △

b1-16

Brake time

0.00s~30.00s

0.00s △

1: Enabled

0: Disabled

1: Enabled

Dynamic brak

400V: 650V~750V, default: 720V

defined

Auto restart when power up again

after power loss

0: Disabled

1: Enabled

Waiting time

power up again

Group b2 Accel/Decel Parameters

Accel/Decel

b2-01

Accel time 1

0s~600.00s/6000.0s/60000s

6.0s △

b2-02

Decel time 1

0s~600.00s/6000.0s/60000s

6.0s △

b2-03

Accel time 2

0s~600.00s/6000.0s/60000s

6.0s △

b2-04

Decel time 2

0s~600.00s/6000.0s/60000s

6.0s △

b2-05

Accel time 3

0s~600.00s/6000.0s/60000s

6.0s △

b2-06

Decel time 3

0s~600.00s/6000.0s/60000s

6.0s △

b2-07

Accel time 4

0s~600.00s/6000.0s/60000s

6.0s △

b2-08

Decel time 4

0s~600.00s/6000.0s/60000s

6.0s △

Decel time when emergency stop

enabled

0s~600.00s/6000.0s/60000s

b2-10

Jog Accel time

0s~600.00s/6000.0s/60000s

6.0s △

b2-11

Jog Decel time

0s~600.00s/6000.0s/60000s

6.0s △

Accel

2: S-curve Accel/Decel

Accel time switching frequency of

broken-line Accel/Decel

b2-14

Decel time switching frequency of

0.00Hz~upper limit frequency

0.00Hz

Param

b1-13

b1-17 Overexcitation brake

b1-18 Dynamic brake

b1-19

b1-20

b1-21

b2-00

Designation Range

method

e threshold voltage

of auto restart when

time resolution

Attr

0: Ramp to stop

1: Coast to stop

0: Disabled

200V: 325V~375V, default: 375V

0.0s~10.0s 0.0s △

0: 0.01s

1: 0.1s

2: 1s

0 ×

1 ×

0 ×

Model

0 ×

1 ×

×

b2-09

b2-12

b2-13

/Decele curve selection

0: Linear Accel/Decel

1: Broken-line Accel/Decel

0.00Hz~upper limit frequency 0.00Hz △

- 51 -

6.0s △

0 ×

△

Emotron VSB Instruction Manual Chapter 5 List of Parameters

Factory

default

broken-line Accel/Decel

Time of first segment of Accel

S-curve

△

T

S-curve

△

Time of first segment of Decel

S-curve

△

T

S-curve

△

Group C Input and Output Terminals

Group C0 Digital Input

Enabled condition of run command

terminals

0: Trigger edge detected + ON

1: ON detected

F

28: Run command switched to

F

F

F

F

enabled

Param

b2-15

b2-16

b2-17

b2-18

C0-00

C0-01

C0-02

C0-03

C0-04

C0-08

Designation Range

0.00s~60.00s 0.20s

ime of last segment of Accel

ime of last segment of Decel

when power up

unction of terminal X1

unction of terminal X2 4 ×

unction of terminal X3 1 ×

unction of terminal X4 23 ×

unction of terminal AI (Digital

)

0.00s~60.00s 0.20s

0.00s~60.00s 0.20s

0.00s~60.00s 0.20s

detected

0: No function

1: JOG forward

2: JOG reverse

3: Run forward (FWD)

4: Run reverse (REV)

5: Three-wire control

6: Run suspended

7: External stop

8: Emergency stop

9: Stop command + DC brake

10: DC brake stop

11: Coast to stop

12: Terminal UP

13: Terminal DOWN

14: Clear UP/DOWN (including

keypad ∧/∨) adjustment

15: Multi-step frequency terminal 1

16: Multi-step frequency terminal 2

17: Multi-step frequency terminal 3

19: Accel/Decel time determinant 1

20: Accel/Decel time determinant 2

21: Accel/Decel disabled(ramp stop

not inclusive)

22: External fault input

23: Fault reset (RESET)

27: Run command switched to

keypad control

Attr

0 ×

3 ×

0 ×

- 52 -

Emotron VSB Instruction Manual Chapter 5 List of Parameters

Factory

default

69: DC brake in running

Run terminal is ON

x

C0-11

Filtering time of digital input terminal

0.000s~1.000s

0.010s

△

C0-12

Delay time of terminal X1

0.0s~3600.0s

0.0s

△

C0-13

Delay time of terminal X2

0.0s~3600.0s

0.0s

△

Digital

setting 1

Unit's place: X1

place: X4 (same as unit's

place)

Digit

setting

1: Negative logic

Terminal UP/DOWN frequency

adjustment

Unit's place: action when stop

function

0: run direction can not be changed

Param

Run or not when drive restored

C0-09

C0-14

Designation Range

input terminal enabled status

terminal control

29: Run command switched to

communication control

30: Frequency command pattern shift

31: Master frequency command

switched to digital setting b0-02

32: Auxiliary frequency command

switched to digital setting b0-04

33: PID adjustment direction

34: PID paused

35: PID integration paused

36: PID parameter switch

68: Run prohibited

0: Run if trig edge +ON

1: Run as long as

0: Negative logic

1: Positive logic

Decade: X2 (same as unit's place)

Hundreds place: X3 (same as unit's

place)

Thousands

Attr

0

1111 ×

C0-16

C0-17

al input terminal enabled status

2

treatment

Unit's place: AI

0: Positive logic

0: Clear

1: Holding

Decade: action on power loss

0: Clear

1: Holding

Hundreds place: integral

0: No integral function

1: Integral function enabled

Thousands place: run direction

0 ×

0100 △

- 53 -

Emotron VSB Instruction Manual Chapter 5 List of Parameters

Factory

default

1: run direction can be changed

T

adjustment

FWD/REV terminal control

3: Three-wire mode 2

Option

000~10F

Unit's place: BIT0~BIT3: X1~X4

Hundreds place: AI

Group C1 Digital Output

C1-00

Y output function

0: No output

attained

0

△

C

Param

C0-18

C0-19

C0-20

C1-02

Designation Range

erminal UP/DOWN frequency

step size

mode

of virtual input terminal

ontrol board relay output function 14 △

0.00Hz/s~100.00Hz/s

0: Two-wire mode 1

1: Two-wire mode 2

2: Three-wire mode 1

0: Actual terminal in effect

1: Virtual terminal in effect

Decade: Reserved

1: Drive undervoltage

2: Drive running preparation

completed

3: Drive is running

4: Drive in 0Hz running (no output at

stop)

5: Drive in 0Hz running (output at

stop)

6: Run direction

7: Frequency attained

8: Upper limit frequency attained

9: Lower limit frequency attained

10: Frequency higher than FDT 1

11: Frequency higher than FDT 2

12: Reserved

13: Torque limited

14: Fault output

15: Alarm output

16: Drive (motor) overloaded

prealarm

17: Drive overtemperature prealarm

18: Zero current detection

19: X1

20: X2

25: Consecutive running time

0.10 Hz/s △

000 ×

Attr

0 ×

- 54 -

Emotron VSB Instruction Manual Chapter 5 List of Parameters

Factory

default

attained

C1-04

Y output time delay

0.0s~3600.0s

0.0s

△

C1-06

Relay output time delay

0.0s~3600.0s

0.0s

△

Enabled

Detective

doubling technology

Unit's place: FDT1 detective object

1: Detected speed value

C1-10

FDT1 upper bound

0.00Hz~maximum frequency

50.00Hz

△

C1-11

FDT1 lower bound

0.00Hz~maximum frequency

49.00Hz

△

C1-12

FDT2 upper bound

0.00Hz~maximum frequency

25.00Hz

△

C1-13

FDT2 lower bound

0.00Hz~maximum frequency

24.00Hz

△

Detection w

attained

C1-15

Zero current detection level

0.0%~50.0%

5.0%

△

C1-16

Zero current detection time

0.01s~50.00s

0.50s

△

Group C2 Analog Input

A

(same as unit's place)

C2-01

Maximum input of curve 1

Minimum input of curve 1 ~ 110.0%

100.0%

×

Corresponding s

maximum input

C2-03

Minimum input of curve 1

-110.0% ~ maximum input of curve 1

0.0%

×

Corresponding s

minimum input

C

curve 2~110.0%

Param

C1-08

C1-09

C1-14

Designation Range

26: Accumulative running time

Unit's place: Y

0: Positive logic

state of digital output

object of frequency

(FDT)

idth of frequency

1: Negative logic

Decade: Reserved

Hundreds place: control board relay

output (same as unit's place)

0: Set value of speed (frequency

after Accel/Decel)

1: Detected speed value

Decade: FDT2 detective object

0: Set value of speed (frequency

after Accel/Decel)

0.00Hz~maximum frequency 2.50Hz △

Attr

000 ×

00 △

C2-00

C2-02

C2-04

C2-05

nalog input curve selection

et value of curve 1

et value of curve 1

urve 2 maximum input

Unit's place: AI input curve

0: Curve 1 (2 points)

1: Curve 2 (4 points)

Decade: Potentiometer input curve

-100.0%~100.0% 100.0% ×