Emotron VS10 and VS30

AC drive

Operation instruction

Valid from software vers ion 04.01.xx.xx

2 01-6203-01R3, CG Drives & Automation

Contents

1. General information ..................................................................................................................... 13

1.1. Read first, then start ........................................................................................................................ 13

2. Safety instructions ........................................................................................................................ 14

2.1. Basic safety measures...................................................................................................................... 14

2.2. Residual hazards .............................................................................................................................. 15

2.3. Application as directed .................................................................................................................... 15

3. Mounting ..................................................................................................................................... 16

3.1. Important notes ............................................................................................................................... 16

3.2. Electrical installation ....................................................................................................................... 17

3.2.1. 1-phase mains connection 230/240 V ..................................................................................... 17

3.2.1.1. Connection plan ............................................................................................................... 17

3.2.1.2. Fusing and terminal data ................................................................................................. 18

3.2.2. 1/3-phase mains connection 230/240 V ................................................................................. 20

3.2.2.1. Connection plan ............................................................................................................... 20

3.2.2.2. Fusing and terminal data ................................................................................................. 21

3.2.3. 3-phase mains connection 400 V............................................................................................. 23

3.2.3.1. Connection plan ............................................................................................................... 23

3.2.3.2. Fusing and terminal data ................................................................................................. 24

3.2.4. 3-phase mains connection 480 V............................................................................................. 27

3.2.4.1. Connection plan ............................................................................................................... 27

3.2.4.2. Fusing and terminal data ................................................................................................. 28

3.2.5. CANopen/Modbus RTU ........................................................................................................... 31

4. Commissioning ............................................................................................................................. 32

4.1. Important notes ............................................................................................................................... 32

4.2. Operating interfaces ........................................................................................................................ 33

4.2.1. Keypad ..................................................................................................................................... 33

2.2. Engineering tool »Emotron EASY Starter« .............................................................................. 34

4.

4.2.2.1. Generate a connection between inverter and »Emotron Easy starter« ......................... 35

4.3. Parameter setting ............................................................................................................................ 37

4.3.1. General notes on parameters .................................................................................................. 37

4.3.2. Basic inverter settings.............................................................................................................. 39

4.3.3. Basic motor settings ................................................................................................................ 42

4.3.4. Function assignment of the inputs and outputs ..................................................................... 43

4.4. Keypad parameter list ..................................................................................................................... 46

4.5. Save parameter settings in the memory module ............................................................................ 73

4.5.1. Save parameter settings with keypad ..................................................................................... 73

4.5.2. Save parameter settings with »Emotron Easy starter« ........................................................... 73

5. Diagnostics and fault elimination .................................................................................................. 74

5.1. LED status display ............................................................................................................................ 74

5.2. Diagnostics parameter ..................................................................................................................... 75

5.2.1. Logbook ................................................................................................................................... 76

5.2.2. Error history buffer .................................................................................................................. 77

5.2.3. Inverter diagnostics ................................................................................................................. 81

5.2.4. Network diagnostics ................................................................................................................ 85

5.2.4.1. CANopen diagnostics ....................................................................................................... 86

5.2.4.2. Modbus diagnostics ......................................................................................................... 89

5.2.5. Diagnostics of the inputs and outputs ..................................................................................... 90

5.2.5.1. Digital inputs and outputs ............................................................................................... 90

5.2.5.2. Analog inputs and outputs .............................................................................................. 91

5.2.6. Wireless-LAN diagnostics......................................................................................................... 93

5.2.7. Setpoint diagnostic .................................................................................................................. 94

5.2.8. Process controller status ......................................................................................................... 95

5.2.9. Sequencer diagnostics ............................................................................................................. 96

5.2.10. Device identification ................................................................................................................ 97

5.2.11. Device overload monitoring (i*t) ............................................................................................. 98

5.2.12. Heatsink Temperature Monitoring .......................................................................................... 99

5.2.13. Life-diagnosis ........................................................................................................................... 99

5.3. Error handling ................................................................................................................................ 100

5.3.1. Error types ............................................................................................................................. 100

5.3.2. E

rror configuration ................................................................................................................ 101

5.3.3. Error reset .............................................................................................................................. 101

5.3.4. Keypad error messages ......................................................................................................... 102

5.4. Data handling ................................................................................................................................. 103

6. Basic setting ............................................................................................................................... 106

6.1. Mains voltage ................................................................................................................................ 106

6.2. Control source selection ................................................................................................................ 108

6.3. Selection of setpoint source .......................................................................................................... 109

6.3.1. Keypad setpoint default setting ............................................................................................ 113

6.4. Starting/stopping performance ..................................................................................................... 114

6.4.1. Starting performance ............................................................................................................ 114

6.4.2. Stopping performance ........................................................................................................... 116

4 01-6203-01R3, CG Drives & Automation

6.5. Frequency limits and ramp times .................................................................................................. 117

6.6. Quick stop ...................................................................................................................................... 120

6.7. S-shaped ramps ............................................................................................................................. 122

6.8. Optical device identification .......................................................................................................... 123

7. Motor control ............................................................................................................................. 124

7.1. Motor data ..................................................................................................................................... 125

7.1.1. Manual setting of the motor data ......................................................................................... 125

7.2. Motor control selection ................................................................................................................. 126

7.2.1. V/f characteristic control (VFC) ............................................................................................. 127

7.2.1.1. Linear V/f characteristic ................................................................................................. 128

7.2.1.2. Square-law V/f characteristic ........................................................................................ 130

7.2.1.3. User-definable V/f characteristic ................................................................................... 132

7.2.1.4. V/f characteristic control energy-saving (VFC Eco) ....................................................... 133

7.2.2. Sensorless vector control (SLVC) ........................................................................................... 134

7.2.3. Sensorless control for synchronous motors (SL-PSM) ........................................................... 137

7.2.3.1. Stall monitoring ............................................................................................................. 140

7.3. Optimisation of motor control ...................................................................................................... 141

7.3.1. V/f voltage boost ................................................................................................................... 142

7.3.2. Skip frequencies..................................................................................................................... 143

7.3.3. Optimising the stalling behaviour.......................................................................................... 145

7.3.4. Slip compensation ................................................................................................................. 147

7.3.5. Oscillation damping ............................................................................................................... 149

7.3.6. Synchronous motor: Pole position identification (PPI) ......................................................... 150

7.3.6.1. Pole position identification (PPI) without movement ................................................... 151

7.4. Optimisation of the control loops .................................................................................................. 152

7.4.1. Options for optimized motor tuning ..................................................................................... 155

7.4.1.1. Tu

ning of the motor and the speed controller .............................................................. 156

7.4.1.2. Automatic motor identification (energized) .................................................................. 157

7.4.1.3. Automatic motor calibration (non-energized) ............................................................... 158

7.4.2. Inverter Characteristics .......................................................................................................... 159

7.4.3. Motor equivalent circuit diagram data .................................................................................. 160

7.4.4. Motor controller settings ....................................................................................................... 161

7.4.4.1. Current controller .......................................................................................................... 161

7.4.4.2. Field controller ............................................................................................................... 161

7.4.4.3. Field weakening controller ............................................................................................ 162

7.4.4.4. Field weakening controller (advanced) ......................................................................... 162

7.4.4.5. Imax controller ............................................................................................................... 163

7.4.4.6. Flying restart controller ................................................................................................. 164

7.4.4.7. SLVC controller .............................................................................................................. 164

7.4.4.8. Torque control w/ freq. limit ......................................................................................... 165

7.4.4.9. Slip controller ................................................................................................................. 169

7.4.5. 7Speed controller .................................................................................................................. 170

7.5. Motor rotating direction ................................................................................................................ 171

7.6. Switching frequency changeover ................................................................................................... 172

7.7. Motor protection ........................................................................................................................... 173

7.7.1. Motor overload monitoring (i²*t) .......................................................................................... 173

7.7.1.1. Speed compensation for protecting motors at low speed ............................................ 175

7.7.2. Current limits ......................................................................................................................... 177

7.7.3. Overcurrent monitoring ......................................................................................................... 179

7.7.4. Motor phase failure detection ............................................................................................... 180

7.7.5. Motor speed monitoring ....................................................................................................... 181

7.7.6. Motor torque monitoring ...................................................................................................... 182

8. Configuring the network ............................................................................................................. 183

8.1. General network settings ............................................................................................................... 184

8.2. Predefined process data words ..................................................................................................... 202

8.2.1. Device profile CiA 402 ............................................................................................................ 203

8.2.2. AC Drive Profile ...................................................................................................................... 204

8.2.2.1. Customer specific configurations .................................................................................. 205

8.2.3. Further process data .............................................................................................................. 206

8.3. Parameter access monitoring (PAM) ............................................................................................. 211

8.4. Acyclic data exchange .................................................................................................................... 212

5. CANopen ........................................................................................................................................ 213

8.

8.5.1. CANopen introduction ........................................................................................................... 213

8.5.2. CANopen node address ......................................................................................................... 214

8.5.3. CANopen baud rate ............................................................................................................... 214

8.5.3.1. CANopen initialisation ................................................................................................... 215

8.5.4. CANopen diagnostics ............................................................................................................. 216

8.5.5. CANopen emergency telegram .............................................................................................. 217

8.5.6. CANopen heartbeat protocol ................................................................................................ 217

8.5.7. CANopen process data objects .............................................................................................. 219

8.5.8. CANopen data mapping ......................................................................................................... 224

8.5.9. CANopen service data objects ............................................................................................... 227

8.5.10. CANopen error responses ...................................................................................................... 229

8.5.11. CANopen diagnostic counter ................................................................................................. 230

8.5.12. CANopen LED status displays ................................................................................................. 231

6 01-6203-01R3, CG Drives & Automation

8.5.13. Resetting the CANopen interface .......................................................................................... 232

8.5.14. CANopen short setup ............................................................................................................ 233

8.6. Modbus RTU .................................................................................................................................. 236

8.6.1. Modbus RTU introduction ..................................................................................................... 236

8.6.2. Modbus RTU node address.................................................................................................... 236

8.6.3. Modbus RTU baud rate .......................................................................................................... 237

8.6.4. Modbus RTU data format ...................................................................................................... 238

8.6.5. Modbus RTU time-out monitoring ........................................................................................ 238

8.6.6. Modbus RTU diagnostics ....................................................................................................... 238

8.6.7. Modbus RTU function codes.................................................................................................. 241

8.6.8. Modbus RTU data mapping ................................................................................................... 242

8.6.9. Modbus RTU LED status displays ........................................................................................... 246

8.6.10. Reset Modbus RTU interface ................................................................................................. 246

8.6.11. Modbus RTU response time .................................................................................................. 246

8.6.12. Short setup of Modbus RTU .................................................................................................. 247

9. Configuring the process controller ............................................................................................... 249

9.1. Basic process controller settings .................................................................................................... 250

9.2. Process controller idle state and rinse function ............................................................................ 256

9.2.1. Process controller idle state .................................................................................................. 256

9.2.2. Process controller rinse function ........................................................................................... 257

10. Additional functions ................................................................................................................ 258

10.1. Device Commands ..................................................................................................................... 259

10.1.1.1. 10.1.1 Reset parameters to default ............................................................................... 259

10.1.1.2. Details ............................................................................................................................ 259

1.2. Saving/loading the parameter settings .................................................................................. 260

10.

10.1.2.1. 10.1.3 Device commands for parameter change-over .................................................. 263

10.1.3. Delete logbook ....................................................................................................................... 264

10.2. Keypad ....................................................................................................................................... 265

10.2.1. Keypad language selection .................................................................................................... 265

10.2.2. Keypad setpoint increment.................................................................................................... 265

10.2.3. Keypad scaling of speed display ............................................................................................ 265

10.2.4. Keypad status display............................................................................................................. 265

10.2.5. Keypad Configuration of R/F and CTRL buttons .................................................................... 266

10.3. Wireless LAN (WLAN) ................................................................................................................ 269

10.3.1. WLAN LED status displays ...................................................................................................... 269

10.3.2. WLAN basic settings ............................................................................................................... 270

10.3.2.1. Resetting WLAN settings to default setting ................................................................... 272

10.3.3. WLAN access point mode ...................................................................................................... 273

10.3.3.1. Establishing a direct WLAN connection between Emotron Easy starter PC and inverter

274

10.3.4. WLAN client mode ................................................................................................................. 276

10.4. DC braking .................................................................................................................................. 278

10.4.1. Example 1: Automatic DC braking when the motor is started .............................................. 280

10.4.2. Example 2: Automatic DC braking when the motor is stopped ............................................. 281

10.5. Brake energy management ........................................................................................................ 283

10.5.1. Stopping the deceleration ramp function generator ............................................................. 284

10.5.2. Inverter motor brake ............................................................................................................. 285

10.6. Load loss detection .................................................................................................................... 286

10.7. Access protection ...................................................................................................................... 287

10.7.1. Write access protection ......................................................................................................... 287

10.7.1.1. Write access protection in the »Emotron Easy starter« ............................................... 289

10.7.1.2. Write access protection in the keypad .......................................................................... 292

10.7.1.3. Configuring the write access protection with the keypad ............................................. 293

10.8. Favorites .................................................................................................................................... 296

10.8.1. Accessing the "Favorites" with the keypad ............................................................................ 296

10.8.2. Favorites parameter list (default setting) .............................................................................. 297

10.8.3. Configuring the "Favorites" ................................................................................................... 299

10.9. Parameter change-over ............................................................................................................. 302

10.9.1. Example: Selective control of several motors with one inverter ........................................... 313

10.10. Device profile CiA 402 ................................................................................................................ 315

10.11. Holding brake control ................................................................................................................ 318

10.11.1. Basic setting ....................................................................................................................... 319

10.

11.2. "Automatic" brake mode (automatic operation) .............................................................. 320

10.11.3. Brake holding load ............................................................................................................. 322

10.11.3.1. General mode of operation ........................................................................................... 323

10.11.4. Brake closing level.............................................................................................................. 324

10.11.5. Manual release of the holding brake ................................................................................. 326

10.12. Flying restart circuit ................................................................................................................... 327

10.13. Timeout für fault reaction ......................................................................................................... 329

10.14. Automatic restart ....................................................................................................................... 330

10.15. Mains failure control .................................................................................................................. 331

10.15.1. Activating the mains failure control................................................................................... 333

10.15.2. Restart protection .............................................................................................................. 334

10.15.3. Fast mains recovery ........................................................................................................... 334

10.15.4. Commissioning the mains failure control .......................................................................... 335

10.16. Process data ............................................................................................................................... 336

8 01-6203-01R3, CG Drives & Automation

10.16.1. Position counter ................................................................................................................. 336

10.17. Firmware download ................................................................................................................... 337

10.17.1. Firmware download with »Emotron Easy starter (Firmware loader)« .............................. 337

10.18. Additive voltage impression ...................................................................................................... 338

10.18.1. Example: Using the function with a 400-V inverter ........................................................... 339

10.19. Parameter for engineering tools ................................................................................................ 340

11. Sequencer ............................................................................................................................... 343

11.1. Segment configuration .............................................................................................................. 346

11.2. Sequence configuration ............................................................................................................. 356

11.3. Sequencer basic settings ............................................................................................................ 371

12. Flexible I/O configuration ........................................................................................................ 374

12.1. Control source change-over ....................................................................................................... 375

12.1.1. Example 1: Change-over from terminal control to keypad control ....................................... 378

12.1.2. Example 2: Change-over from terminal control to network control ..................................... 379

12.2. Start / stop motor ...................................................................................................................... 380

12.2.1. Example 1: Start/stop (1 signal) and reversal ........................................................................ 386

12.2.2. Example 2: Start forward/start reverse/stop (edge-controlled) ............................................ 387

12.2.3. Example 3: Run forward/Run reverse/stop (status-controlled) ............................................. 389

12.2.4. Example 4: Quick stop ........................................................................................................... 391

12.2.5. Example 5: Jog forward/Jog reverse ...................................................................................... 393

12.2.6. Example 6: Enable inverter .................................................................................................... 395

12.3. Setpoint change-over ................................................................................................................. 396

3.1. Priority of the setpoint sources ............................................................................................. 398

12.

12.3.2. Analog input setpoint source ................................................................................................. 398

12.3.3. Keypad setpoint source ......................................................................................................... 401

12.3.4. Network setpoint source ....................................................................................................... 403

12.3.5. Setpoint source of preset setpoints ....................................................................................... 404

12.3.6. Motor potentiometer setpoint source (MOP) ....................................................................... 409

12.3.7. Setpoint source segment setpoints ....................................................................................... 413

12.4. Reset error ................................................................................................................................. 415

12.5. Activating DC braking manually ................................................................................................. 417

12.6. Releasing holding brake manually ............................................................................................. 419

12.7. Activating ramp 2 manually ....................................................................................................... 421

12.8. Triggering a user-defined fault .................................................................................................. 423

12.9. Functions for parameter change-over ....................................................................................... 424

12.9.1. Example 1: Activation via command (only when disabled) ................................................... 426

12.9.2. Example 2: Activation via command (immediately) .............................................................. 428

12.9.3. Example 3: Activation if the selection is changed (only if the inverter is disabled) .............. 429

12.9.4. Example 4: Activation if the selection is changed (immediately) .......................................... 431

12.10. Process controller function selection ........................................................................................ 433

12.11. Sequencer control functions ...................................................................................................... 436

12.12. Frequency threshold for "Frequency threshold exceeded" trigger ........................................... 441

12.13. Configuration of digital inputs ................................................................................................... 443

12.14. Configuration of analog inputs .................................................................................................. 444

12.14.1. Analog input 1.................................................................................................................... 444

12.14.1.1. Example 1: Input range 0 ... 10 V ≡ setting range 0 ... 50 Hz ....................................... 446

12.14.1.2. Example 2: Input range 0 ... 10 V ≡ setting range -40 ... +40 Hz .................................. 446

12.14.1.3. Example 3: Error detection ............................................................................................ 447

12.14.2. Analog input 2.................................................................................................................... 448

12.15. Configuration of digital outputs ................................................................................................ 450

12.15.1. Relay .................................................................................................................................. 450

12.15.2. Digital output 1 .................................................................................................................. 454

12.15.3. NetWordOUT1 status word ............................................................................................... 454

12.16. Configuration of analog outputs................................................................................................ 459

12.16.1. Analog output 1 ................................................................................................................. 459

12.16.1.1. Example 1: Output voltage 0 ... 10 V ≡ output frequency 0 ... 100 Hz ........................ 461

12.16.1.2. Example 2: Output voltage 2 ... 10 V ≡ output frequency 30 ... 60 Hz ........................ 461

13. Technical data ......................................................................................................................... 462

13.1. Standards and operating conditions .......................................................................................... 462

13.1.1. Protection of persons and device protection ........................................................................ 462

13.1.2. EMC data................................................................................................................................ 462

13.1.3. Motor connection .................................................................................................................. 462

13.1.4. E

nvironmental conditions ...................................................................................................... 463

13.1.5. Electrical supply conditions ................................................................................................... 463

13.2. 1-phase mains connection 230/240 V ....................................................................................... 464

13.2.1. Rated data .............................................................................................................................. 464

13.3. 1/3-phase mains connection 230/240 V ................................................................................... 465

13.3.1. Rated data .............................................................................................................................. 465

13.4. 3-phase mains connection 400 V ............................................................................................... 466

13.4.1. Rated data .............................................................................................................................. 466

13.5. 3-phase mains connection 480 V ............................................................................................... 468

13.5.1. Rated data .............................................................................................................................. 468

14. Appendix ................................................................................................................................ 470

14.1. Operate and parameterise the inverter with keypad ................................................................ 470

14.1.1. Keypad operating mode ........................................................................................................ 471

14.1.1.1. Keypad status display ..................................................................................................... 471

10 01-6203-01R3, CG Drives & Automation

14.1.1.2. Function of keypad keys in operating mode .................................................................. 472

14.1.1.3. Error reset with keypad ................................................................................................. 473

14.1.2. Keypad parameterisation mode ............................................................................................ 474

14.1.2.1. Parameter groups .......................................................................................................... 474

14.1.2.2. Function of the keypad keys in the parameterisation mode ......................................... 475

14.1.2.3. Save parameter settings with keypad ............................................................................ 476

14.1.2.4. Display of status words on keypad ................................................................................ 477

14.2. Error codes ................................................................................................................................. 478

14.3. Parameter attribute list .............................................................................................................. 488

12 01-6203-01R3, CG Drives & Automation

1. General information

1.1. Read first, then start

WARNING!

Read this documentation thoroughly before carrying out the installation and commissioning.

Please observe the safety instructions!

Information and tools with regard to the CG products can be found on the

Internet:

http://www.emotron.com Download

2. Safety instructions

2.1. Basic safety measures

Disregarding the following basic safety measures may lead to severe personal injury and

dam age to material assets!

The product

• must only be used as directed.

• must never be commissioned if they display signs of damage.

• must never be technically modified.

• must never be commissioned if they are not fully mounted.

• must never be operated without required covers.

Connect/disconnect all pluggable terminals only in deenergised condition. Only remove

the product from the installation in the deenergised state.

Insulation resistance tests between 24 V control potential and PE: According to EN

61800−5−1, the maximum test voltage must not exceed 110 V DC.

Observe all specifications of the corresponding documentation supplied. This is the

precondition for safe and trouble-free operation and for obtaining the product features

specified.

The procedural notes and circuit details described in this document are only proposals. It

is up to the user to check whether they can be adapted to the particular applications.

Drives & Automation does not take any responsibility for the suitability of the procedures

and circuit proposals described.

The product must only be used by qualified personnel. IEC 60364 or CENELEC HD 384

define the skills of these persons:

• They are familiar with installing, mounting, commissioning, and operating the product.

• They have the corresponding qualifications for their work.

• They know and can apply all regulations for the prevention of accidents, directives, and

laws applicable at the place of use.

Please observe the specific notes in the other chapters!

Notes used:

DANGER!

This note refers to an imminent danger which, if not avoided, may result in death or serious injury.

WARNING!

This note refers to a danger which, if not avoided, may result in death or serious injury.

CAUTION!

This note refers to a danger which, if not avoided, may result in minor or moderate injury.

NOTICE

This note refers to a danger which, if not avoided, may result in damage to property.

14 01-6203-01R3, CG Drives & Automation

2.2. Residual hazards

The user must take the residual hazards mentioned into consideration in the risk

assessment for his/her machine/system.

If the above is disregarded, this can lead to severe injuries to persons and damage to

material assets!

Product

Observe the warning labels on the product!

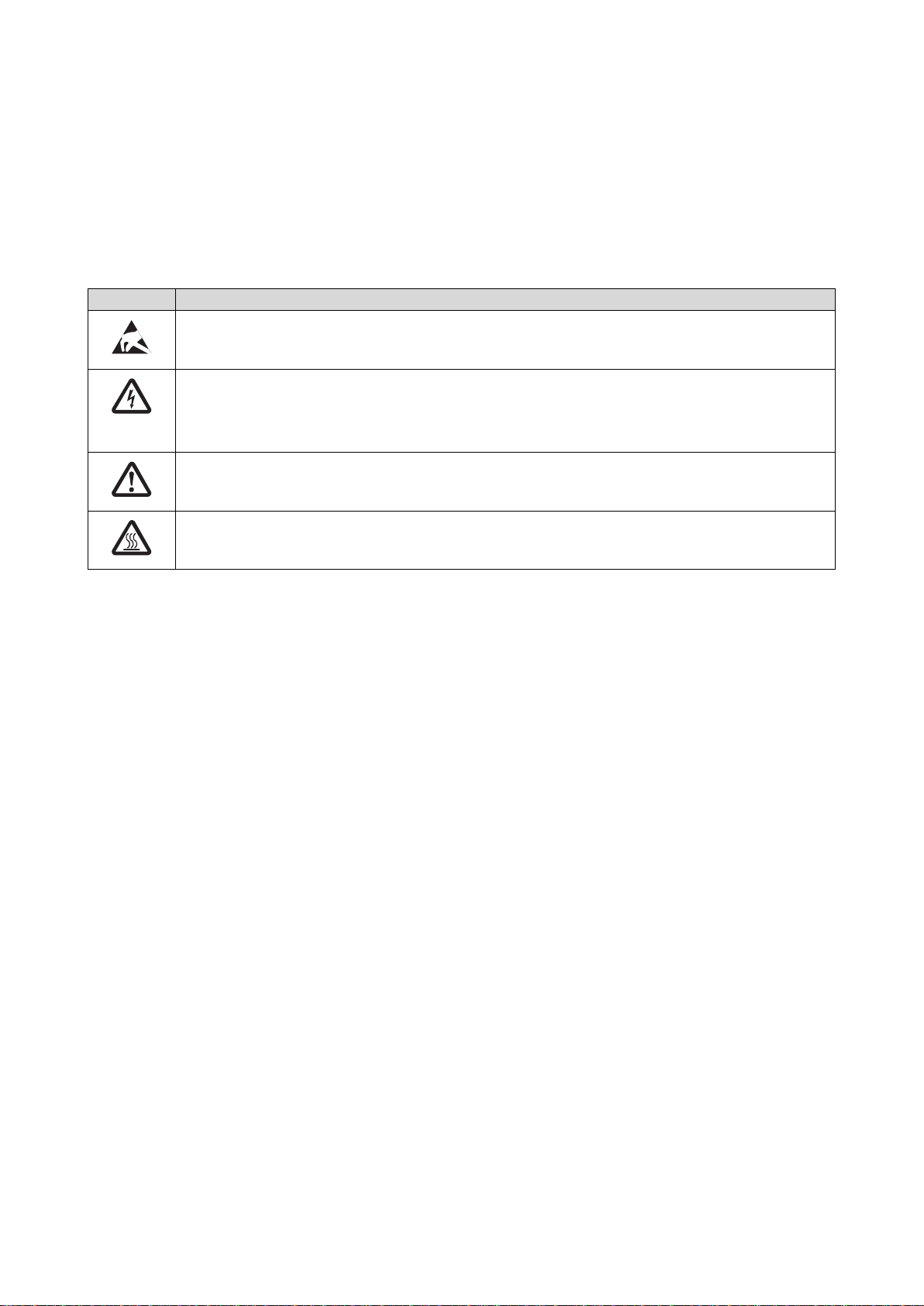

Icon Description

Electrostatic sensitive devices:

Before working on the product, the staff must ensure to be free of electrostatic charge!

Dangerous electrical voltage

Before working on the product, check if no voltage is applied to the power terminals!

After mains disconnection, the power terminals carry the hazardous electrical voltage given on the product!

High leakage current:

Carry out fixed installation and PE connection in compliance with EN 61800−5−1 or EN 60204−1!

Hot surface:

Use personal protective equipment or wait until devices have cooled down!

Motor

If there is a short circuit of two power transistors, a residual movement of up to

180°/number of pole pairs can occur at the motor! (For 4-pole motor: residual movement

max. 180°/2 = 90°).

2.3. Application as directed

• The product must only be operated under the operating conditions prescribed in this

documentation.

• The product meets the protection requirements of 2014/35/EU: Low-Voltage Directive.

• The product is not a machine in terms of 2006/42/EC: Machinery Directive.

• Commissioning or starting the operation as directed of a machine with the product is

not permitted until it has been ensured that the machine meets the regulations of the

EC Directive 2006/42/EC: Machinery Directive; observe EN 60204−1.

• Commissioning or starting the operation as directed is only allowed when there is

compliance with the EMC Directive 2014/30/EU.

• The harmonised standard EN 61800−5−1 is used for the inverters.

• The product is not a household appliance, but is only designed as component for

commercial or professional use in terms of EN 61000−3−2.

• The product can be used according to the technical data if drive systems have to

comply with categories according to EN 61800−3.

In residential areas, the product may cause EMC interferences. The operator is

responsible for taking interference suppression measures.

3. Mounting

3.1. Important notes

DANGER!

Dangerous electrical voltage

Possible consequence: death or severe injuries

All work on the inverter must only be carried out in the deenergised state.

After switching off the mains voltage, wait for at least 3 minutes before you start working.

16 01-6203-01R3, CG Drives & Automation

3.2. Electrical installation

3.2.1. 1-phase mains connection 230/240 V

3.2.1.1. Connection plan

The wiring diagram is valid for Emotron VS10 inverters.

Fig. 1: Wiring example

S1 Run/Stop

Fx Fuses

Q1 Mains contactor

--Dashed line = options

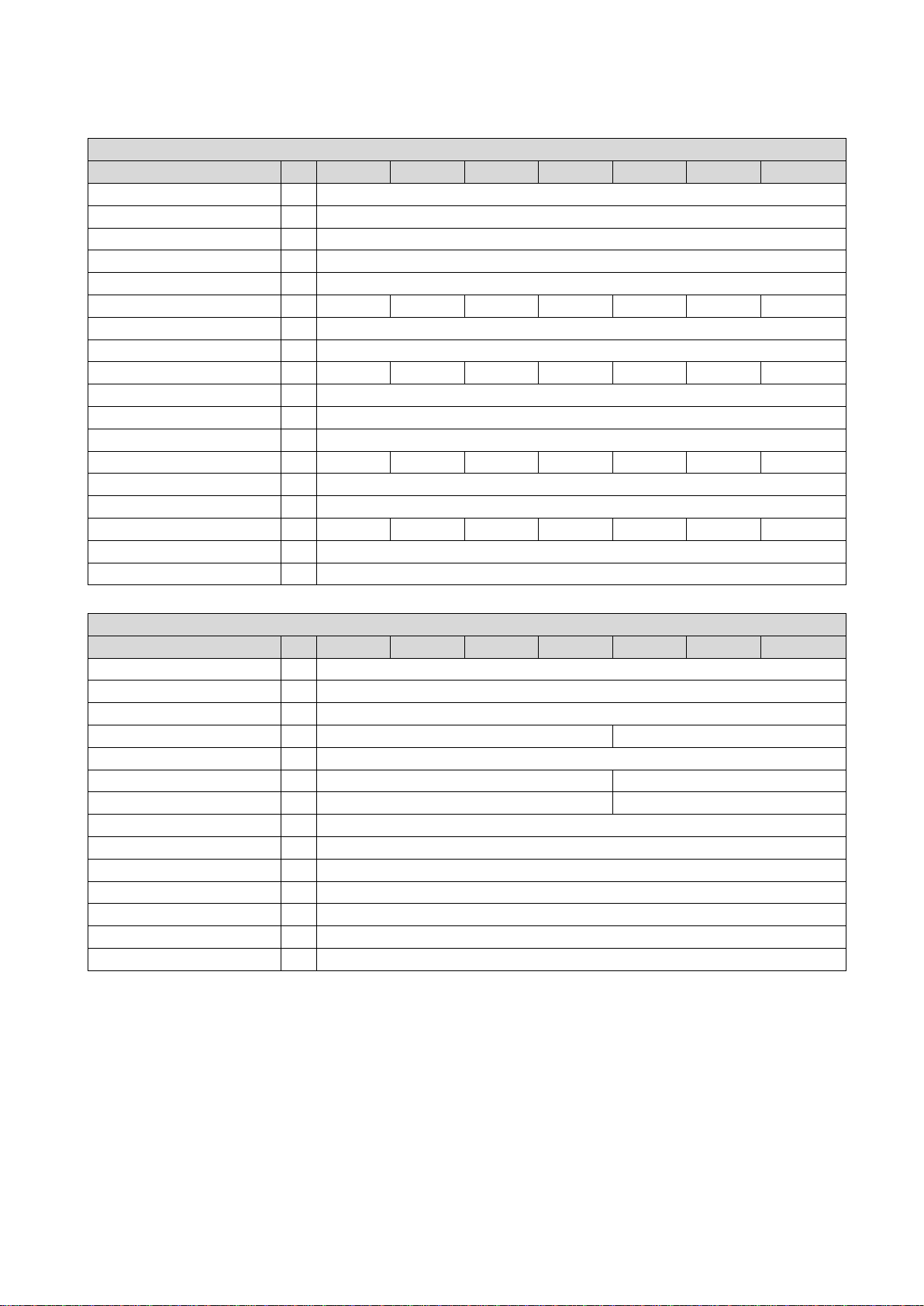

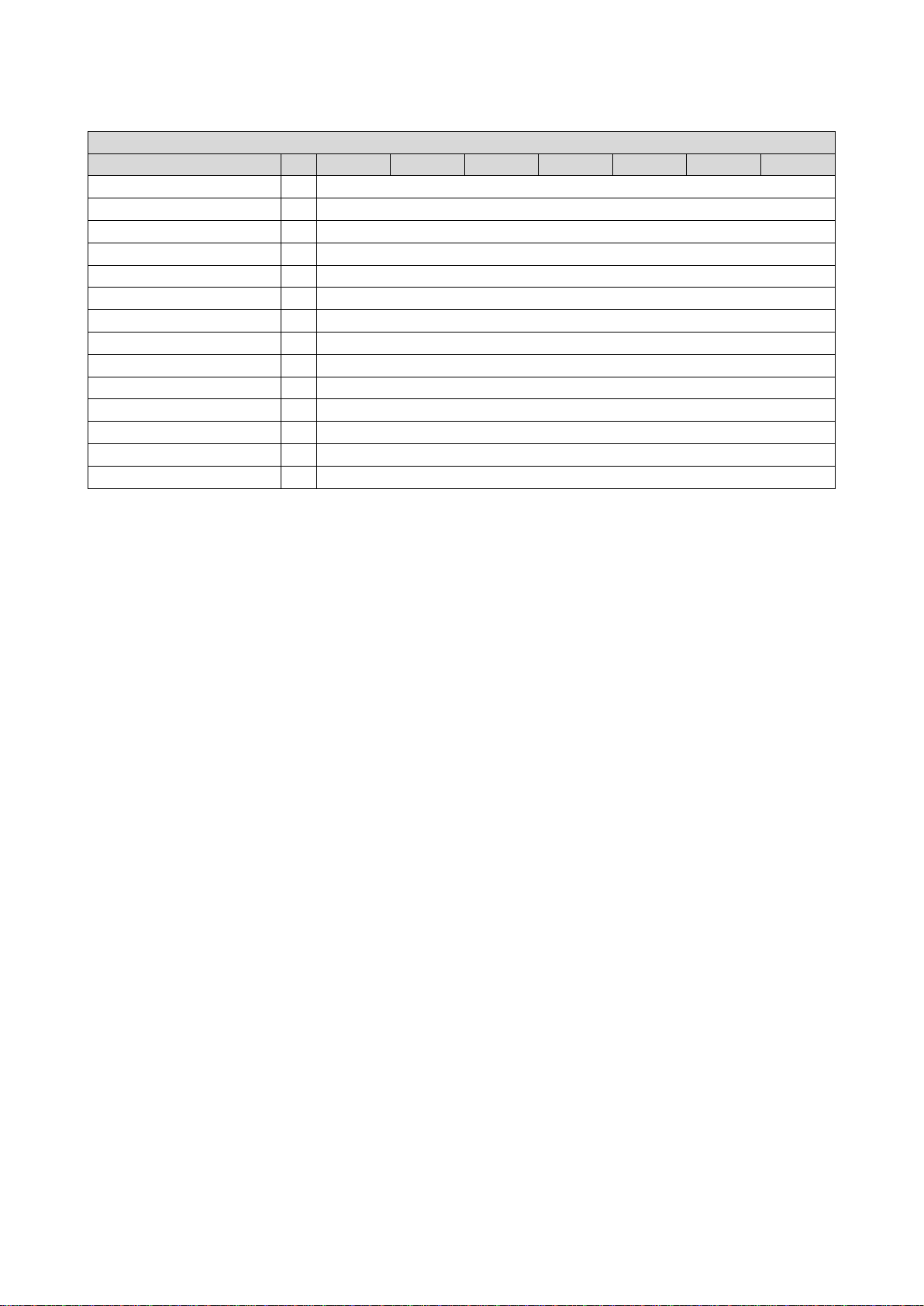

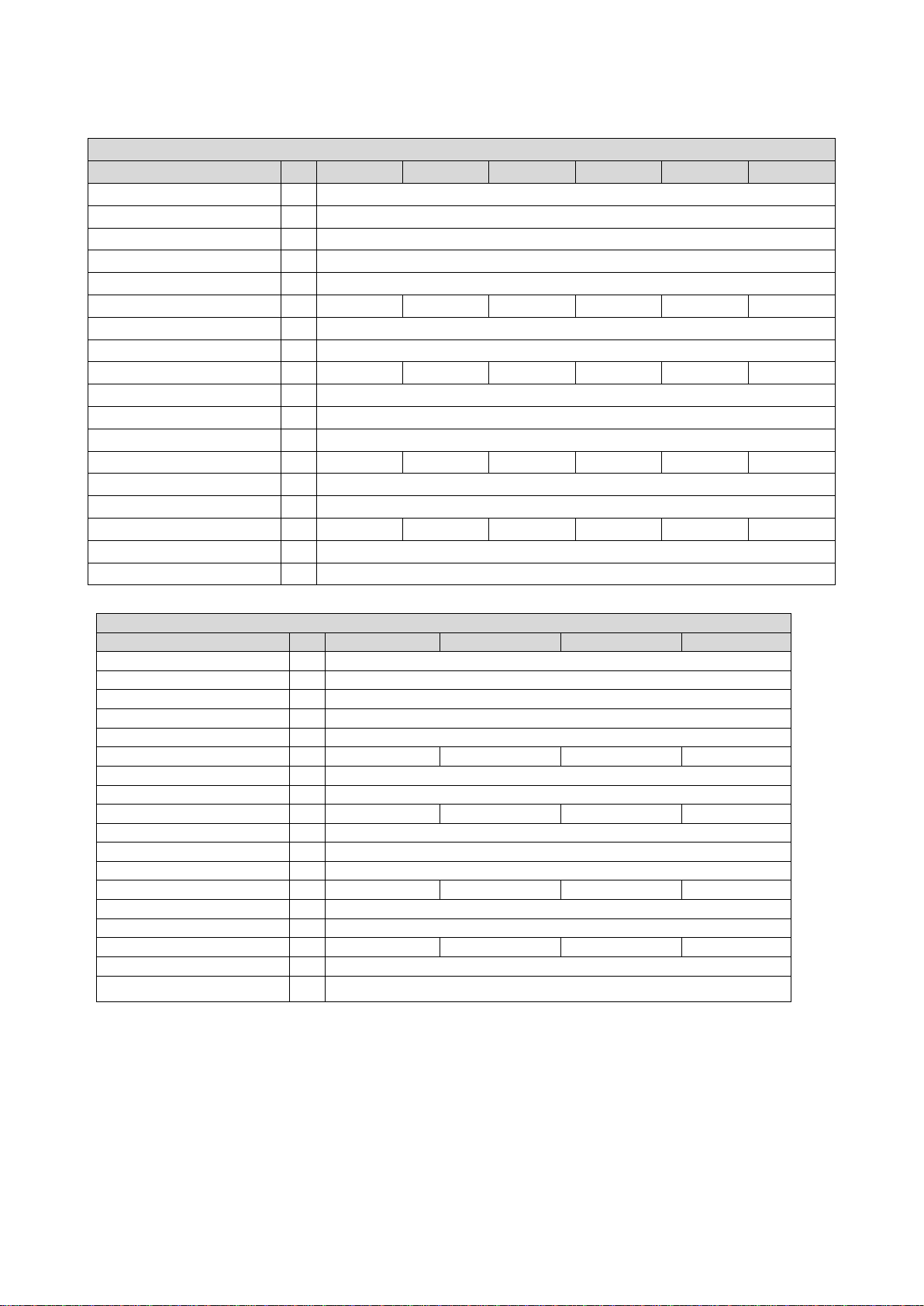

3.2.1.2. Fusing and terminal data

Fuse data

Inverter

Cable installation in compliance with

EN 60204-1

Laying system

B2

Fuse

Characteristics

gG/gL or gRL

Max. rated current

A

10

10

16

16

25

25

25

Circuit breaker

Max. rated current

A

10

10

16

16

25

25

25

operation

with mains choke

Fuse

Characteristics

gG/gL or gRL

10 10 16 16 25 25 25

Circuit breaker

Characteristics

B

Max. rated current

A

10

10

16

16

25

25

25

Earth-leakage circuit breaker

Mains connection

Inverter

Connection

X100

Min. cable cross-section

mm² 1 Max. cable cross-section

mm²

2.5

6

Stripping length

mm 8 Tightening torque

Nm

0.5

0.7

Connection

PE

Connection type

PE screw

Min. cable cross-section

mm² 1 Max. cable cross-section

mm²

6

Tightening torque

Nm

1.2

Required tool

0.8 x 5.5

VS10-23-1P7 VS10-23-2P4 VS10-23-3P2 VS10-23-4P2 VS10-23-6P0 VS10-23-7P0 VS10-023-9P6

operation

Characteristics

Max. rated current

1-phase mains connection

without mains choke

B

A

≥ 30 mA, type A or B

VS10-23-1P7 VS10-23-2P4 VS10-23-3P2 VS10-23-4P2 VS10-23-6P0 VS10-23-7P0 VS10-023-9P6

Connection type

Required tool

Stripping length

mm

0.5 x 3.0

pluggable screw terminal

0.6 x 3.5

10

18 01-6203-01R3, CG Drives & Automation

Motor connection

Connection

X105

Connection type

pluggable screw terminal

Min. cable cross-section

mm² 1 Max. cable cross-section

mm²

2.5

Tightening torque

Nm

0.5

Required tool

0.5 x 3.0

Connection

PE

Connection type

PE screw

Max. cable cross-section

mm²

6

Stripping length

mm

10

Tightening torque

Nm

1.2

Required tool

0.8 x 5.5

Inverter

Stripping length

Min. cable cross-section

VS10-23-1P7 VS10-23-2P4 VS10-23-3P2 VS10-23-4P2 VS10-23-6P0 VS10-23-7P0 VS10-023-9P6

mm

mm²

8

1

3.2.2. 1/3-phase mains connection 230/240 V

Emotron VS30-23 inverters do not have an integrated EMC filter in the AC mains

supply.

In order to comply with the EMC requirements according to EN 61800−3, an external

EMC filter according to IEC EN 60939 has to be used.

The user must prove that the EN 61800−3 requirements for conformity are fulfilled.

3.2.2.1. Connection plan

The wiring diagram is valid for Emotron VS30 inverters.

Fig. 2: Wiring example

S1 Run/Stop

Fx Fuses

Q1 Mains contactor

--Dashed line = options

20 01-6203-01R3, CG Drives & Automation

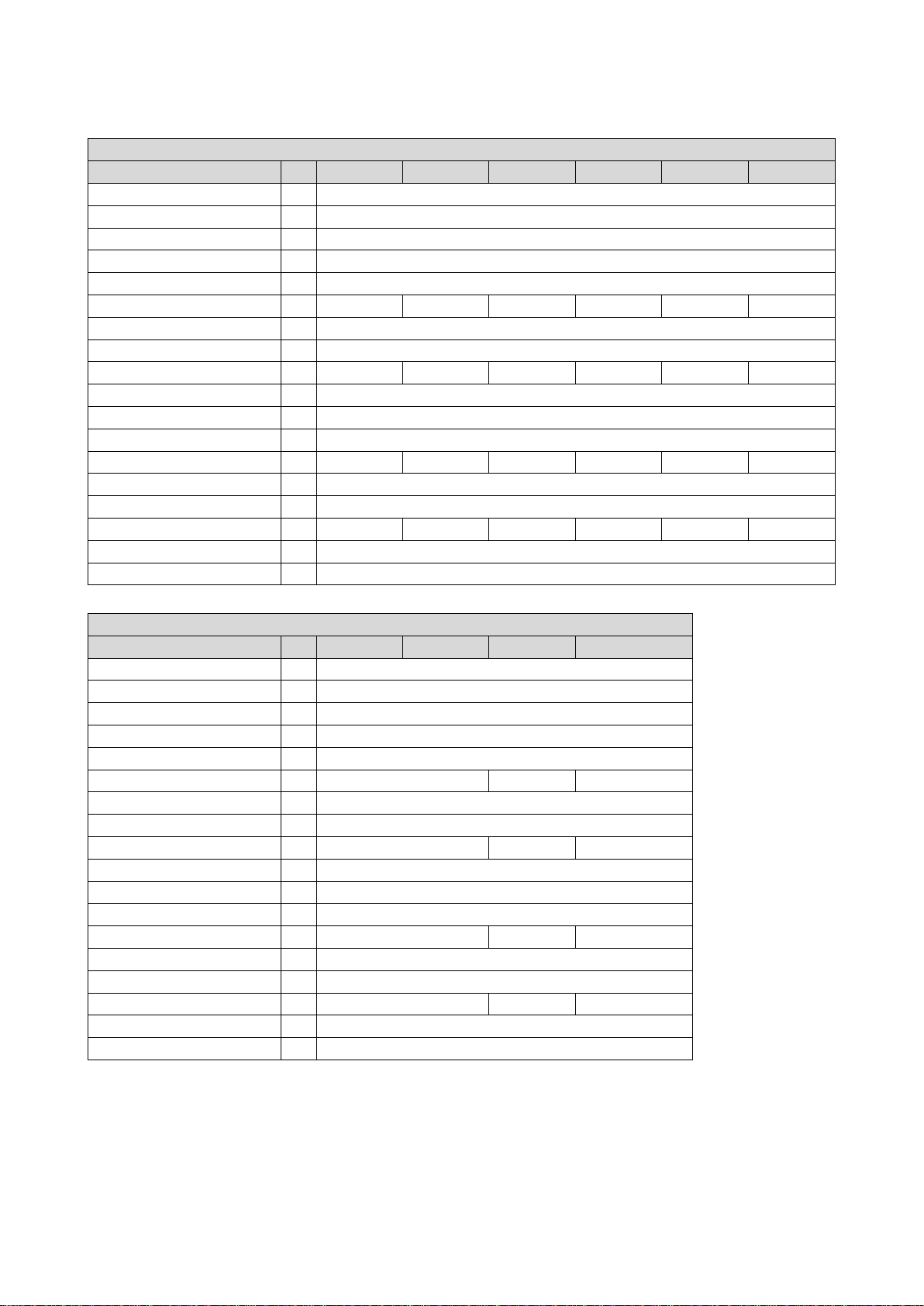

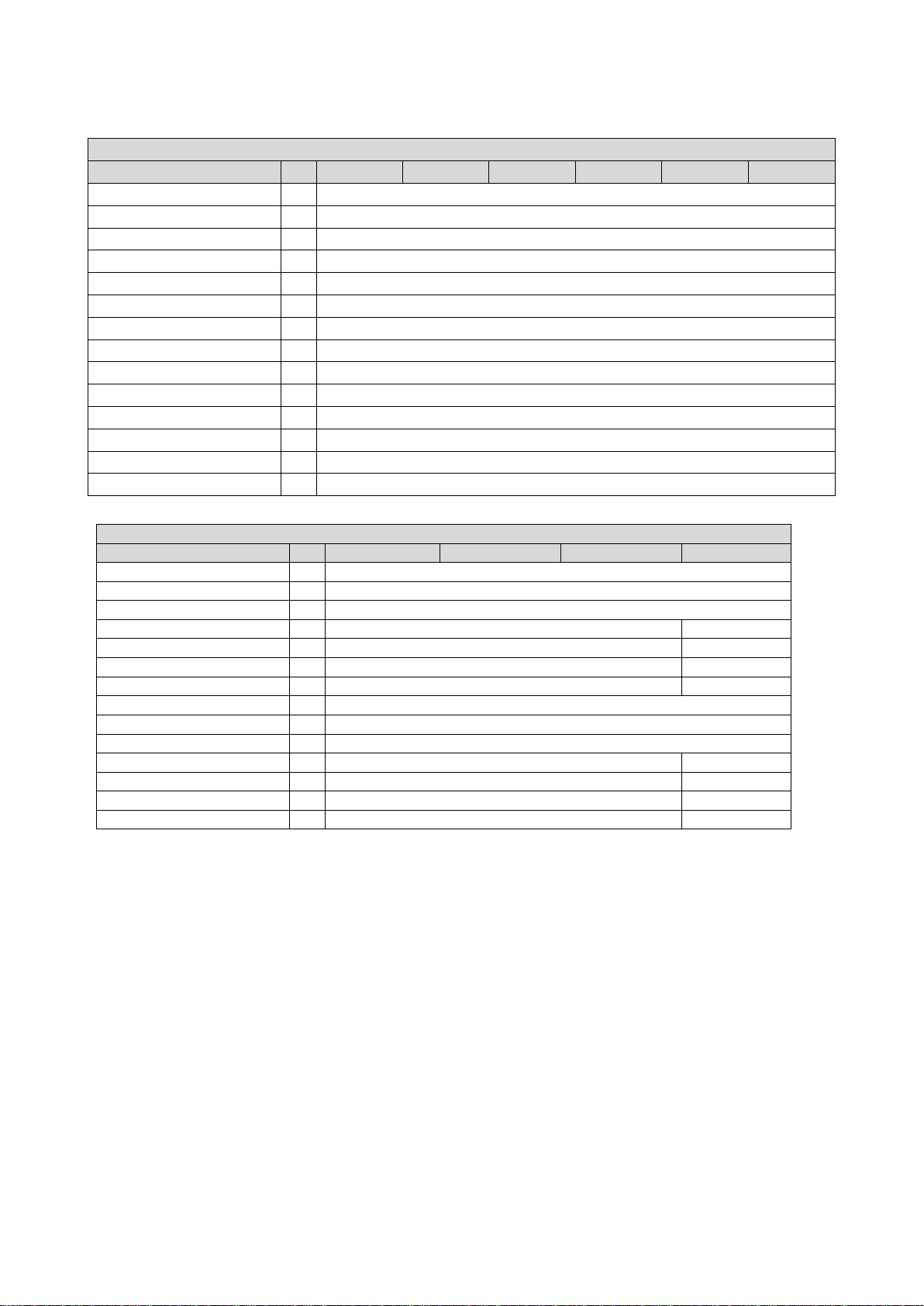

3.2.2.2. Fusing and terminal data

Fuse data

Inverter

Cable installation in compliance with

EN 60204-1

Laying system

B2

Fuse

Characteristics

gG/gL or gRL

Max. rated current

A

10

10

16

16

25

25

25

Circuit breaker

Max. rated current

A

10

10

16

16

25

25

25

operation

with mains choke

Fuse

Characteristics

gG/gL or gRL

10 10 16 16 25 25 25

Circuit breaker

Characteristics

B

Max. rated current

A

10

10

16

16

25

25

25

Earth-leakage circuit breaker

3-phase mains connection

≥ 30 mA, type B

Mains connection

Inverter

Connection type

pluggable screw terminal

Min. cable cross-section

mm² 1 Max. cable cross-section

mm²

2.5

6

Stripping length

mm

8

Required tool

0.5 x 3.0

0.6 x 3.5

Connection

PE

Connection type

PE screw

Min. cable cross-section

mm²

1

Stripping length

mm

10

Tightening torque

Nm

1.2

Required tool

0.8 x 5.5

VS30-23-1P7 VS30-23-2P4 VS30-23-3P2 VS30-23-4P2 VS30-23-6P0 VS30-23-7P0 VS30-23-9P6

operation

Characteristics

Max. rated current

1-phase mains connection

Connection

without mains choke

B

A

≥ 30 mA, type A or B

VS30-23-1P7 VS30-23-2P4 VS30-23-3P2 VS30-23-4P2 VS30-23-6P0 VS30-23-7P0 VS30-23-9P6

X100

Tightening torque

Max. cable cross-section

Nm

mm²

0.5

0.7

6

Motor connection

Connection

X105

Connection type

pluggable screw terminal

Min. cable cross-section

mm² 1 Max. cable cross-section

mm²

2.5

Tightening torque

Nm

0.5

Required tool

0.5 x 3.0

Connection

PE

Connection type

PE screw

Max. cable cross-section

mm²

6

Stripping length

mm

10

Tightening torque

Nm

1.2

Required tool

0.8 x 5.5

Inverter

Stripping length

Min. cable cross-section

VS30-23-1P7 VS30-23-2P4 VS30-23-3P2 VS30-23-4P2 VS30-23-6P0 VS30-23-7P0 VS30-23-9P6

mm

mm²

8

1

22 01-6203-01R3, CG Drives & Automation

3.2.3. 3-phase mains connection 400 V

3.2.3.1. Connection plan

The wiring diagram is valid forEmotron VS30 inverters.

Fig. 3: Wiring example

S1 Run/Stop

Fx Fuses

Q1 Mains contactor

--Dashed line = options

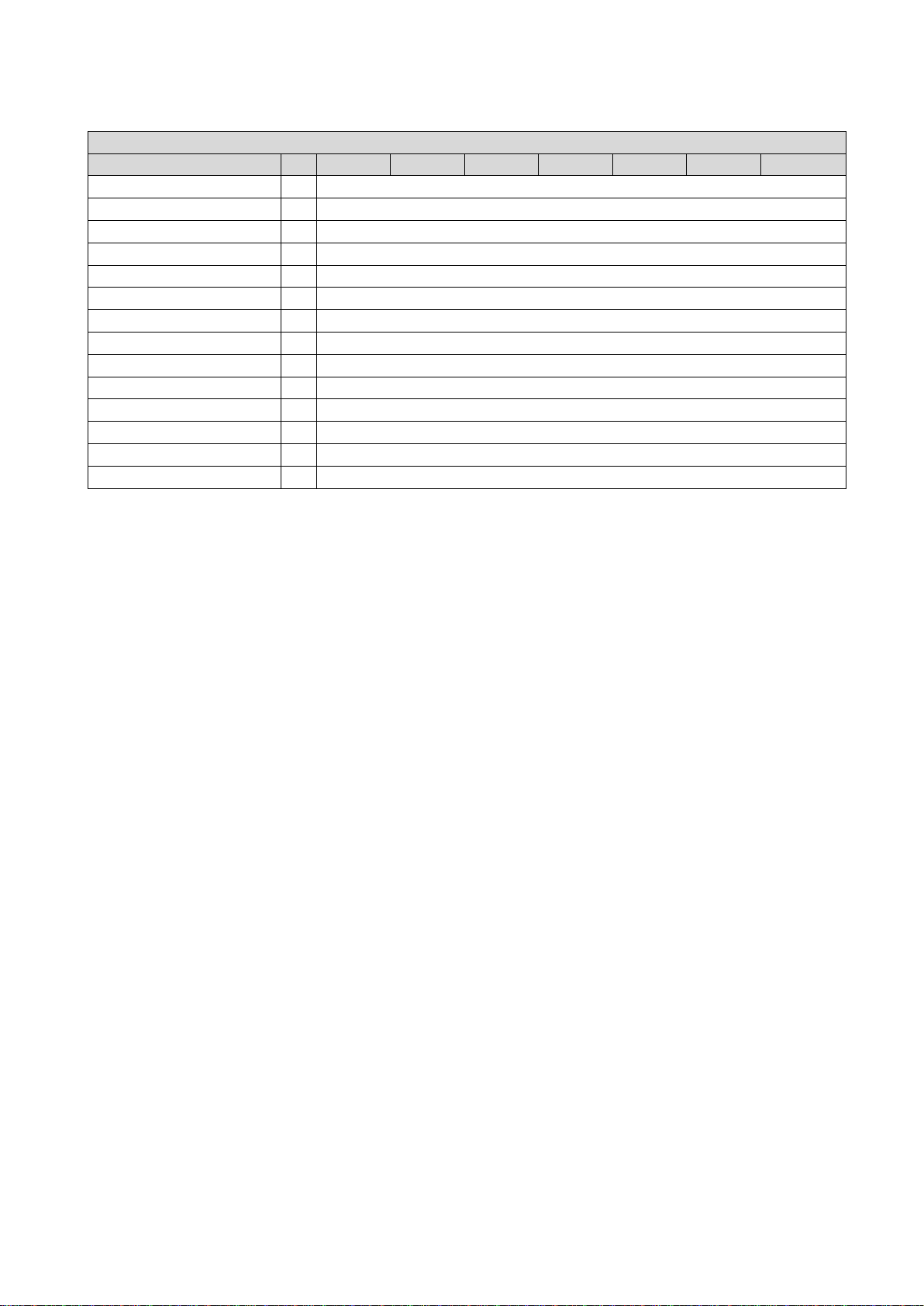

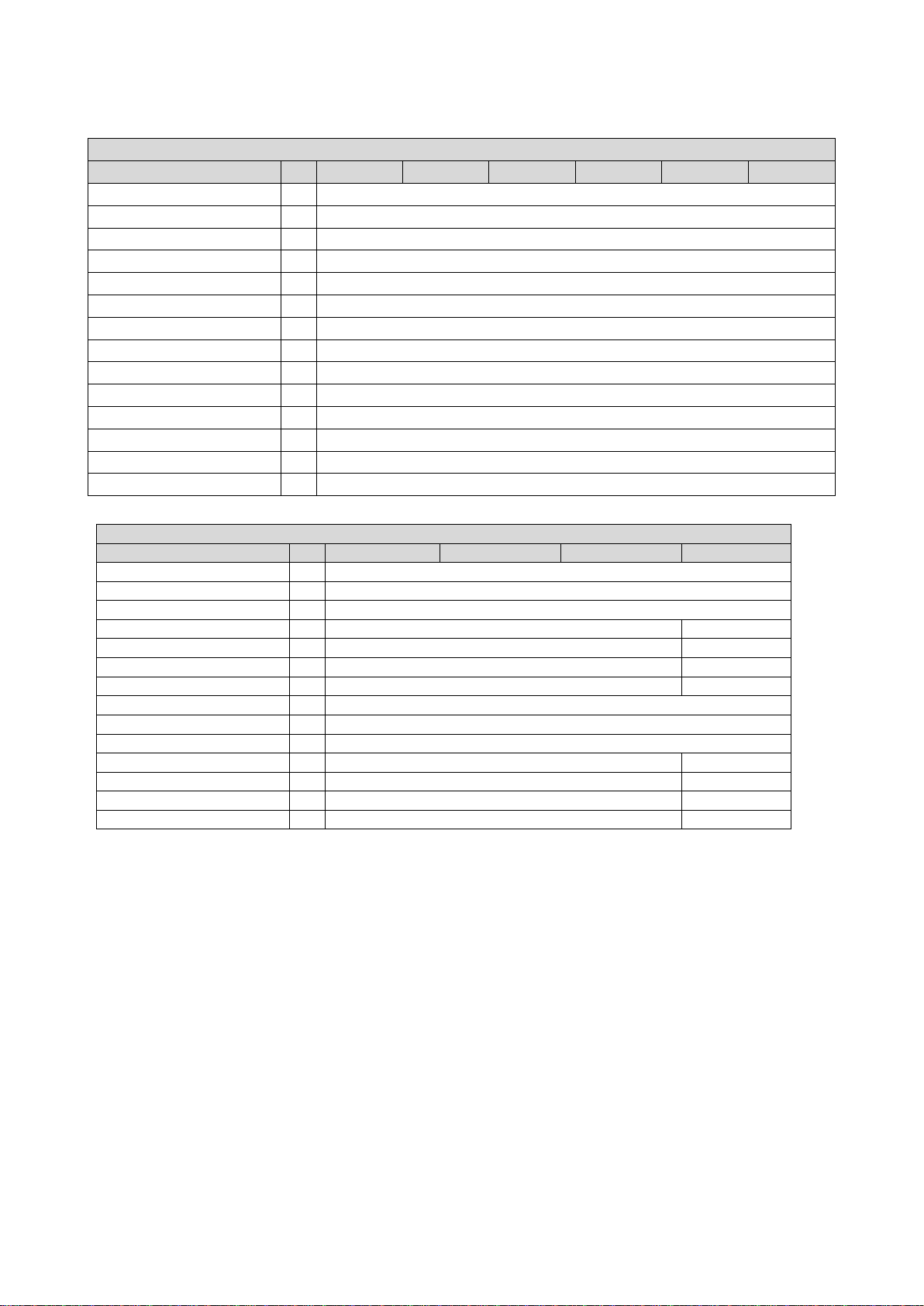

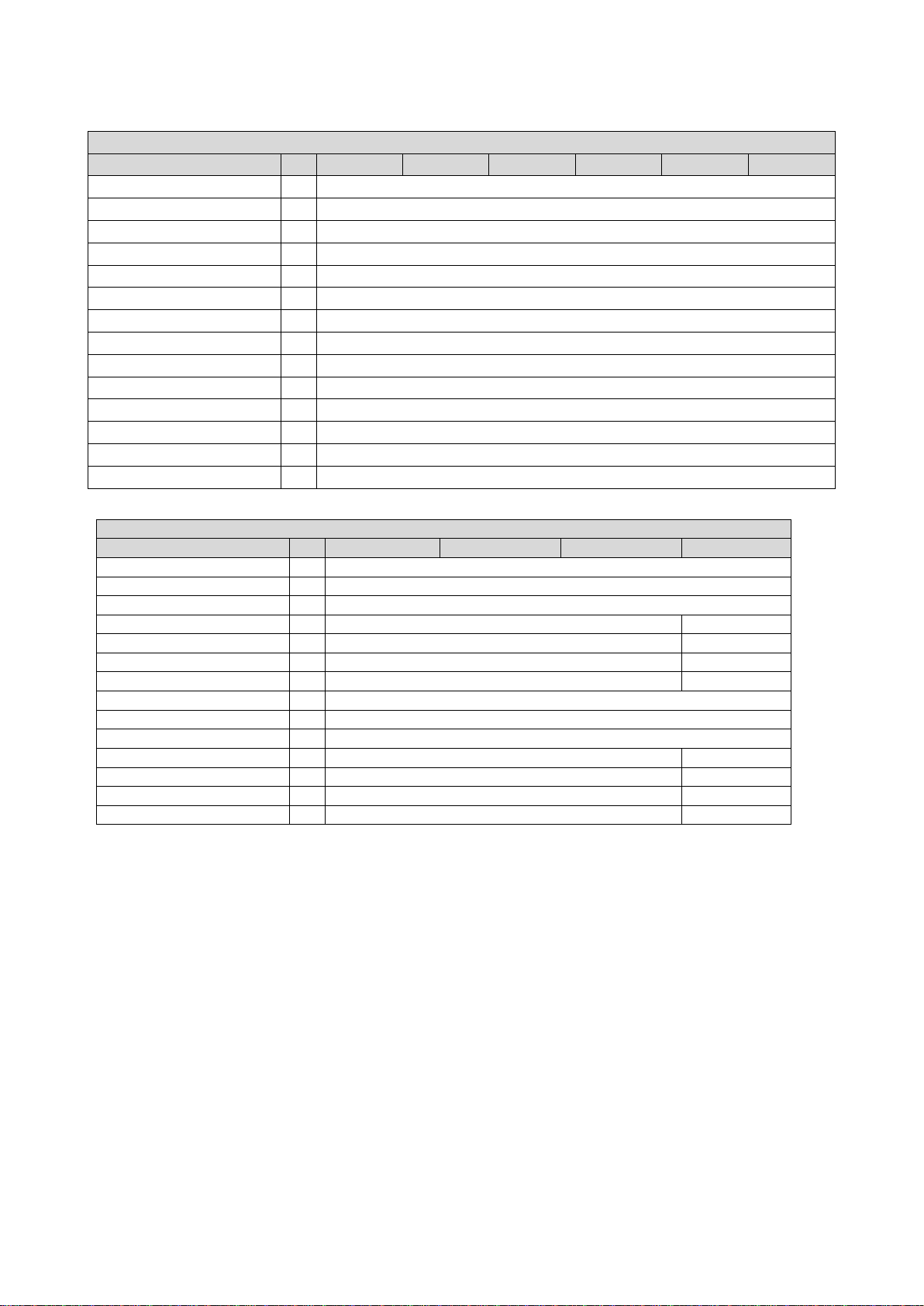

3.2.3.2. Fusing and terminal data

Fuse data

Inverter

Cable installation in compliance with

EN 60204-1

Laying system

B2

Fuse

Characteristics

gG/gL or gRL

Max. rated current

A

10

10

10

16

16

16

Circuit breaker

Max. rated current

A

10

10

10

16

16

16

operation

with mains choke

Fuse

Characteristics

gG/gL or gRL

10 10 10 16 16 16

Circuit breaker

Characteristics

B

Max. rated current

A

10

10

10

16

16

16

Earth-leakage circuit breaker

Fuse data

Inverter

Cable installation in compliance with

E N 60204-1

B2

operation

without mains choke

Fuse

Characteristics

gG/gL or gRL

Max. rated current A 6

16

35

Characteristics

B

Max. rated current A 6

16

35

operation

with mains choke

Fuse

gG/gL or gRL

Max. rated current A 6

16

35

Circuit breaker

Characteristics

B

Max. rated current A 6

16

35

3-phase mains connection

≥ 30 mA, type B

VS30-40-1P3 VS30-40-1P8 VS30-40-2P4 VS30-40-3P2 VS30-40-3P9 VS30-40-5P6

operation

Characteristics

Max. rated current

3-phase mains connection

without mains choke

B

A

≥ 30 mA, type B

VS30-40-7P3 VS30-40-9P5 VS30-40-013 VS30-40-016

Laying system

Circuit breaker

Characteristics

Earth-leakage circuit breaker

24 01-6203-01R3, CG Drives & Automation

Mains connection

Inverter

Connection

X100

Connection type

pluggable screw terminal

Max. cable cross-section

mm²

2.5

Stripping length

mm

8

Tightening torque

Nm

0.5

Required tool

0.5 x 3.0

Connection type

PE screw

Min. cable cross-section

mm²

1

Max. cable cross-section

mm² 6 Stripping length

mm

10

Required tool

0.8 x 5.5

Mains connection

Inverter

Connection

X100

Connection type

Screw terminal

Min. cable cross-section

mm²

1.5

Max. cable cross-section

mm²

6

16

Tightening torque

Nm

0.5

1.2

Required tool

0.6 x 3.5

0.8 x 4.0

Connection type

PE-screw

Min. cable cross-section

mm²

1.5

Max. cable cross-section

mm²

6

16

Stripping length

mm

10

11

Tightening torque

Nm

1.2

3.4

Required tool

0.8 x 5.5

PZ2

VS30-40-1P3 VS30-40-1P8 VS30-40-2P4 VS30-40-3P2 VS30-40-3P9 VS30-40-5P6

Min. cable cross-section

Connection

Tightening torque

mm²

Nm

1

PE

1.2

VS30-40-7P3 VS30-40-9P5 VS30-40-013 VS30-40-016

Stripping length mm 9 11

Connection

PE

Motor connection

Inverter

Connection

X105

Connection type

pluggable screw terminal

Min. cable cross-section

mm² 1 Max. cable cross-section

mm²

2.5

Stripping length

mm 8 Tightening torque

Nm

0.5

Required tool

0.5 x 3.0

Connection

PE

Connection type

PE screw

Min. cable cross-section

mm² 1 Max. cable cross-section

mm² 6 Stripping length

mm

10

Tightening torque

Nm

1.2

Required tool

0.8 x 5.5

Motor connection

Inverter

X105

Connection type

Screw terminal

Min. cable cross-section

mm²

1.5

Max. cable cross-section

mm²

6

16

Stripping length

mm

9

11

Tightening torque

Nm

0.5

1.2

Required tool

0.6 x 3.5

0.8 x 4.0

Connection

PE

Connection type

PE screw

Min. cable cross-section

mm²

1.5

16

Stripping length

mm

10

11

Tightening torque

Nm

1.2

3.4

Required tool

0.8 x 5.5

PZ2

VS30-40-1P3 VS30-40-1P8 VS30-40-2P4 VS30-40-3P2 VS30-40-3P9 VS30-40-5P6

VS30-40-7P3 VS30-40-9P5 VS30-40-013 VS30-40-016

Connection

Max. cable cross-section mm² 6

26 01-6203-01R3, CG Drives & Automation

3.2.4. 3-phase mains connection 480 V

3.2.4.1. Connection plan

The wiring diagram is valid for Emotron VS30 inverters.

Fig. 4: Wiring example

S1 Run/Stop

Fx Fuses

Q1 Mains contactor

--Dashed line = options

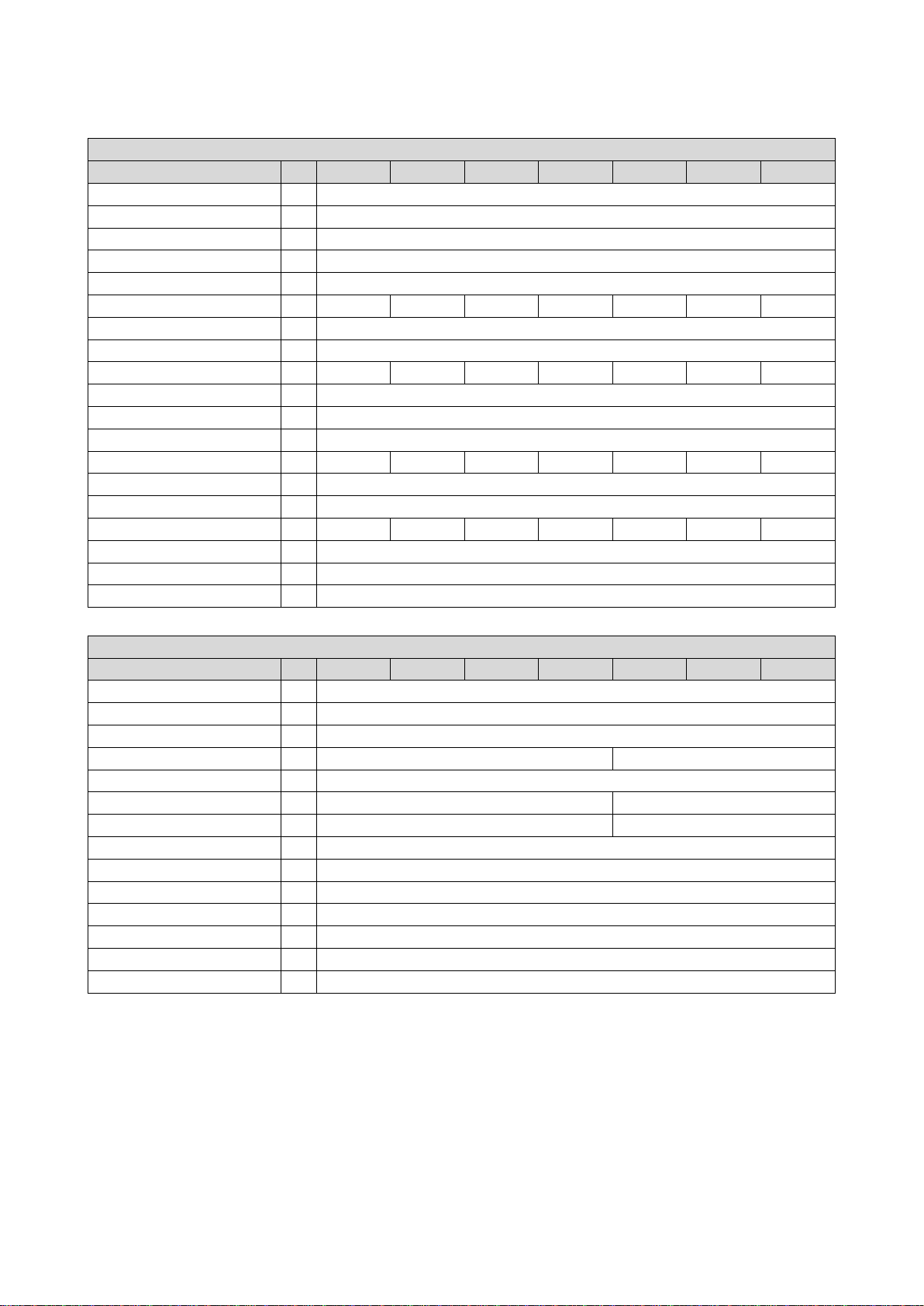

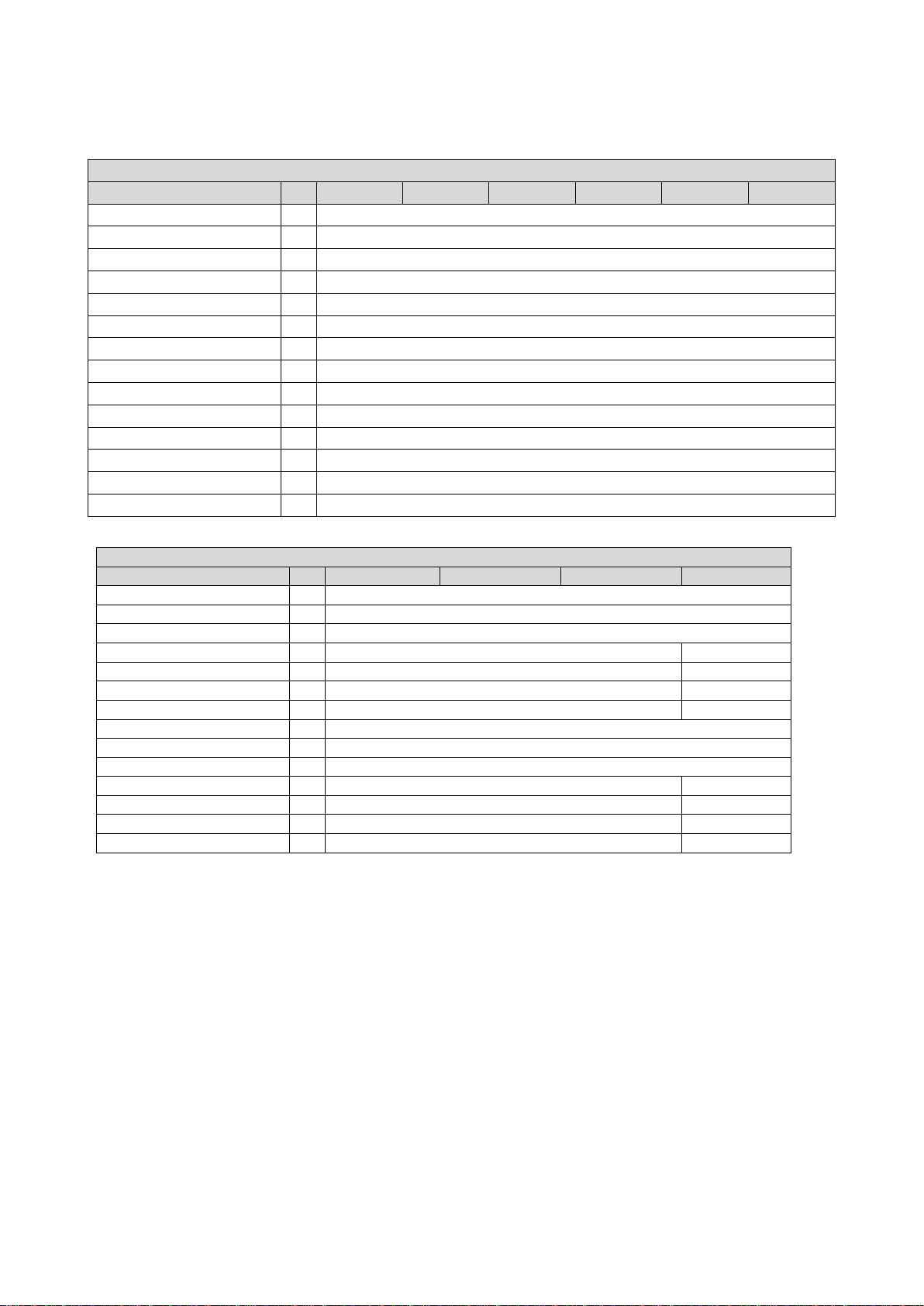

3.2.4.2. Fusing and terminal data

Fuse data

Inverter

Cable installation in compliance with

EN 60204-1

Laying system

B2

Fuse

Characteristics

gG/gL or gRL

Max. rated current

A

10

10

10

16

16

16

Circuit breaker

Max. rated current

A

10

10

10

16

16

16

operation

with mains choke

Fuse

Characteristics

gG/gL or gRL

10 10 16 16 16

Circuit breaker

Characteristics

B

Max. rated current

A

10

10

10

16

16

16

Earth-leakage circuit breaker

Fuse data

Inverter

VS30-40-7P3

VS30-40-9P5

VS30-40-013

VS30-40-016

Cable installation in compliance with

EN 60204-1

Laying system

B2

without mains choke

Fuse

Characteristics

gG/gL or gRL

Circuit breaker

Characteristics

B

Max. rated current

A

25

25

25

32

operation

with mains choke

Fuse

Characteristics

gG/gL or gRL

Circuit breaker

Characteristics

B

Earth-leakage circuit breaker

3-phase mains connection

≥ 30 mA, type B

VS30-40-1P3 VS30-40-1P8 VS30-40-2P4 VS30-40-3P2 VS30-40-3P9 VS30-40-5P6

operation

Characteristics

Max. rated current

3-phase mains connection

without mains choke

B

A

10

≥ 30 mA, type B

operation

Max. rated current A 25 25 25 32

Max. rated current A 25 25 25 32

Max. rated current A 25 25 25 32

28 01-6203-01R3, CG Drives & Automation

Mains connection

Inverter

Connection

X100

Connection type

pluggable screw terminal

Max. cable cross-section

mm²

2.5

Stripping length

mm

8

Tightening torque

Nm

0.5

Required tool

0.5 x 3.0

Connection type

PE screw

Min. cable cross-section

mm²

1

Max. cable cross-section

mm² 6 Stripping length

mm

10

Required tool

0.8 x 5.5

Mains connection

Inverter

Connection

X100

Connection type

Screw terminal

Min. cable cross-section

mm²

1.5

Max. cable cross-section

mm²

6

16

Tightening torque

Nm

0.5

1.2

Required tool

0.6 x 3.5

0.8 x 4.0

Connection type

PE-screw

Min. cable cross-section

mm²

1.5

Max. cable cross-section

mm²

6

16

Stripping length

mm

10

11

Tightening torque

Nm

1.2

3.4

Required tool

0.8 x 5.5

PZ2

VS30-40-1P3 VS30-40-1P8 VS30-40-2P4 VS30-40-3P2 VS30-40-3P9 VS30-40-5P6

Min. cable cross-section

Connection

Tightening torque

mm²

Nm

1

PE

1.2

VS30-40-7P3 VS30-40-9P5 VS30-40-013 VS30-40-016

Stripping length mm 9 11

Connection

PE

Motor connection

Connection

X105

Connection type

pluggable screw terminal

Min. cable cross-section

mm² 1 Max. cable cross-section

mm²

2.5

Tightening torque

Nm

0.5

Required tool

0.5 x 3.0

Connection

PE

Connection type

PE screw

Max. cable cross-section

mm²

6

Stripping length

mm

10

Tightening torque

Nm

1.2

Required tool

0.8 x 5.5

Motor connection

Inverter

Connection

X105

Screw terminal

Min. cable cross-section

mm²

1.5

Max. cable cross-section

mm²

6

16

11

Tightening torque

Nm

0.5

1.2

Required tool

0.6 x 3.5

0.8 x 4.0

Connection

PE

Connection type

PE screw

Min. cable cross-section

mm²

1.5

Max. cable cross-section

mm²

6

16

11

Tightening torque

Nm

1.2

3.4

Required tool

0.8 x 5.5

PZ2

Inverter

Stripping length

Min. cable cross-section

Connection type

VS30-40-1P3 VS30-40-1P8 VS30-40-2P4 VS30-40-3P2 VS30-40-3P9 VS30-40-5P6

mm

mm²

VS30-40-7P3 VS30-40-9P5 VS30-40-013 VS30-40-016

8

1

Stripping length mm 9

Stripping length mm 10

30 01-6203-01R3, CG Drives & Automation

3.2.5. CANopen/Modbus RTU

Line

Terminal description

CANopen/Modbus

Connection

X216

Connection type

pluggable spring

terminal

Min. cable cross-section

mm²

0.5

Max. cable cross-section

mm²

2.5

Stripping length

mm

10

Required tool

0.4 x 2.5

Typical topologies

Tightening torque

Nm

-

Basic network settings

1. Select network CANopen or Modbus using the switch on the front of the inverter

2. Set node address and baud rate via the corresponding parameters.

The network must be terminated with a 120 Ω resistor at the physically first and last

node.

Connect resistor to terminals CH/TB and CL/TA.

4. Commissioning

4.1. Important notes

WARNING!

Incorrect wiring can cause unexpected states during the commissioning phase.

Possible consequence: death, severe injuries or damage to property

Check the following before switching on the mains voltage:

Is the wiring complete and correct?

Are there no short circuits and earth faults?

Is the motor circuit configuration (star/delta) adapted to the output voltage of the inverter?

Is the motor connected in-phase (direction of rotation)?

Does the "emergency stop" function of the entire plant operate correctly?

WARNING!

Incorrect settings during commissioning may cause unexpected and dangerous motor and system movements.

Possible consequence: death, severe injuries or damage to property

Clear hazardous area.

Observe safety instructions and safety clearances.

32 01-6203-01R3, CG Drives & Automation

4.2. Operating interfaces

Commissioning the inverter requires an operator-process interface.

4.2.1. Keypad

The keypad is an easy means for the local operation, parameterisation, and diagnostics of

the inverter.

• The keypad is simply connected to the diagnostic interface on the front of the inverter.

• The keypad can also be connected and removed during operation.

Detailed information on the keypad can be found in the appendix:

Operate and parameterise the inverter with keypad

446

4.2.2. Engineering tool »Emotron EASY Starter«

The »Emotron Easy starter« is a PC software that is especially designed for the

commissioning and maintenance of the inverter.

The »Emotron Easy starter« PC software can be found on the Internet:

http://easystarter.emotron.com

Sample screenshot:

34 01-6203-01R3, CG Drives & Automation

4.2.2.1. Generate a connection between inverter and »Emotron Easy starter«

For commissioning the inverter with the »Emotron Easy starter«, a communication link

with the inverter is required. This can be established in a wired or wireless manner via

WLAN.

Preconditions

• For the wired communication with the inverter, the USB module and a USB 2.0 cable (A

plug on Micro-B plug) are required.

• For the wireless communication with the inverter, the WLAN module is required.

Moreover, the PC on which the »Emotron Easy starter« is installed must be wirelessenabled.

Details

The following instructions describe the connection establishment via the USB module.

• Parameterising without motor operation does not require a mains voltage: If you

connect the inverter directly to the PC without a hub, The USB interface of the PC is

sufficient for the voltage supply.

•

Instructions for the connection establishment via the WLAN module can be found in

251

the chapter "Wireless LAN (WLAN)".

How to establish a communication to the inverter via USB:

Preconditions for commissioning:

• The functional test described in the mounting and switch-on instructions has been

completed successfully (without any errors or faults).

• The inverter is ready for operation (mains voltage is switched on).

Accessories required for commissioning:

• USB module

• USB 2.0 cable (A-plug on micro B-plug)

• PC with installed »Emotron Easy starter« software

1. Plug the USB module onto the front of the inverter (interface X16).

2. Use a USB cable to connect the inverter to the PC on which »Emotron Easy starter« is

installed:

• Plug the micro B plug of the USB cable into the socket of the USB module.

• Plug the other end into a free USB type A-socket of the PC.

3. Start »Emotron Easy starter«.

• The "Add devices" dialog is shown.

4. Select the "

USB - USB with module 01-6180-00" connection:

5. Click the Insert button.

»Emotron Easy starter« searches for connected devices via the communication path

selected. When the connection has been established successfully, the inverter is displayed

in the device list of »Emotron Easy starter«. The inverter parameters can now be accessed

via the tabs of »Emotron Easy starter«.

36 01-6203-01R3, CG Drives & Automation

4.3. Parameter setting

Parameter

Name / value range / [default setting]

Info

Index:Subindex

Parameter designation

•

Optional information with regard to the parameter.

Explanations & notes with regard to the parameter.

Parameter

Name / value range / [default setting]

Info

Index:Subindex

Parameter designation

•

Optional information with regard to the parameter.

Explanations & notes with regard to the parameter.

set. Other values are not permissible.

0

Designation of selection 0

Optionally: Explanations & notes with regard to the corresponding

1

Designation of selection 1

As a part of a machine with a speed-variable drive system, the inverter must be adapted

to its drive task. The adaptation process of the inverter is carried out by changing

parameters.

Optionally these parameters can be accessed by means of the keypad or »Emotron Easy

starter«. If the inverter is provided with a network option, access can also be effected by a

higher-level Controller via the corresponding network.

Certain device commands or settings which might cause a critical state of the drive

behaviour can only be carried our when the inverter is inhibited.

4.3.1. General notes on parameters

Each parameter features a 16-bit index as address. Under this address, the parameter is

stored in the object directory of the inverter.

• Parameters that belong together functionally are combined in a data set. These

parameters are additionally provided with an 8-bit subindex.

• The colon is used as a separator between the index and subindex Example:

"0x2540:001"

• There are parameters the setting of which can be changed, and (diagnostic) parameters

which can only be read.

Parameterisation using the keypad

• All parameters which can be accessed by means of the keypad are provided with a

"Display code", the first digit of the display code specifying the group in which the

parameter can be found on the keypad.

• In the documentation, the display code — if available — is specified in brackets behind

the address. Example: "0x2915 (P210.00)".

Keypad parameterisation mode

450

Structure of the parameter descriptions in this documentation

• The parameter descriptions in this documentation are structured in table form.

• The representation distinguishes parameters with a setting range, text, selection list,

and bit-coded display.

• The default setting of parameters with a write access feature is shown in bold.

• The display code as well as the short keypad designation of the parameter which is

limited to 16 characters, are — if available — shown in brackets.

Example: parameters with a setting range

(display code)

(abbreviated keypad designation)

Minimum value ... [default setting] ... maximum value

Example: parameters with a selection list

(display code)

(abbreviated keypad designation)

2 Designation of selection 2

Note: The corresponding selection number (here 0, 1, or 2) must be

selection.

The default selection is shown in bold.

Example: parameters with a bit-coded display

Parameter

Name / value range / [default setting]

Info

Index:Subindex

Parameter designation

•

Optional information with regard to the parameter.

Explanations & notes with regard to the parameter.

Bit 1

Designation of bit 1

Bit 2

Designation of bit 2

...

...

Bit 15

Designation of bit 15

(display code)

(abbreviated keypad designation)

Bit 0 Designation of bit 0

Optionally: Explanations & notes with regard to the corresponding bit.

Parameter overview lists in this documentation

Keypad parameter list: for the parameterisation using the keypad, contains a list of all

•

parameters which can also be accessed by means of the keypad.

•

Parameter attribute list: contains a list of all inverter parameters. This list in particular

38

includes some information that is relevant for the reading and writing of parameters

464

via the network.

38 01-6203-01R3, CG Drives & Automation

4.3.2. Basic inverter settings

Parameter

Name / value range / [default setting]

Info

inhibi

ted.

0

230 Veff

1

400 Veff 2

0x2838:001

Start/stop configuration: Start method

ted.

Behaviour after start command.

0

Normal

After start command, the standard ramps are active.

•

Deceleration time 1 can be set in 0x2918 (P221.00).

1

DC braking

After start command, the "DC braking" function is active for the time set

2

Flying restart circuit

After the start command, the flying restart circuit is active.

0x2838:002

Start/stop configuration: Start at power-up

(Start/stop confg: Start at powerup)

Starting performance after switching on the mains voltage.

0

Off

No automatic start after switching on mains voltage. In addition to the

inverter enable, a renewed start command is always required to start the

motor.

1

On

Automatic start of the motor after switching on the mains voltage if the

inverter is enabled and a start command exists.

0x2838:003

Start/stop configuration: Stop method

(Start/stop confg: Stop method)

Behaviour after the "Stop" command.

0

Coasting

The motor becomes torqueless (coasts down to standstill).

1

Standard ramp

The motor is brought to a standstill with deceleration time 1 (or

0x283A

Limitation of rotation

(Limit. rotation)

Optional restriction of the rotating direction.

0

Only clockwise (CW)

The motor can only be rotated clockwise (CW). The transfer of negative

for this rotating direction.

1

Both rotation directions

Check the following basic settings of the inverter and adapt them, if required.

0x2540:001

(P208.01)

(P203.01)

(P203.02)

Mains settings: Rated mains voltage

(Mains settings: Mains voltage)

Setting can only be changed if the inverter is

•

480 Veff

(Start/stop confg: Start method)

Setting can only be changed if the inverter is

•

inhibi

Selection of the mains voltage for actuating the inverter.

•

Acceleration time 1 can be set in 0x2917 (P220.00).

in 0x2B84:002 (P704.02).

DC braking

262

The flying restart function makes it possible to restart a coasting motor

during operation without speed feedback. Synchronicity between the

inverter and motor is coordinated so that the transition to the rotating

motor is effected without jerk at the time of connection.

Flying restart circuit

311

(P203.03)

(P304.00)

2 Quick stop ramp

deceleration time 2, if activated).

•

Deceleration time 1 can be set in 0x2918 (P221.00).

•

Deceleration time 2 can be set in 0x291A (P223.00).

Frequency limits and ramp times

100

The motor is brought to a standstill with the deceleration time set for

the "Quick stop" function.

•

Deceleration time for quick stop can be set in 0x291C (P225.00).

The "quick stop" function can also be activated manually, for instance

•

via a digital input.

Quick stop

103

frequency and PID setpoints to the motor control is prevented.

This function takes effect after the "Invert rotation" function

•

(0x2631:013 (P400.13)).

Since this function only prevents negative setpoints, counter-

•

clock

wise rotation (CCW) is possible if the motor has been wired

Both directions of motor rotation are enabled.

Parameter

Name / value range / [default setting]

Info

0x2860:001

Frequency control: Default setpoint source

Selection of the standard setpoint source for operating mode "MS:

1

Keypad

The setpoint is specified locally by the keypad.

2

Analog input 1

The setpoint is defined as analog signal via the analog input 1.

3

Analog input 2

The setpoint is defined as analog signal via the analog input 2.

5

Network

The setpoint is defined as process data object via the network.

11

Frequency preset 1

For the setpoint selection, preset values can be parameterised and

12