Emotron FDU 2.0

Variable Speed Drive

Instruction manual

English

Variable speed drive FDU 2.0

INSTRUCTION MANUAL - ENGLISH

Software version 4.0x

Document number: 01-3694-01

Edition: r2

Date of release: 01-04-2007

© Copyright Emotron AB 2005 - 2007

Emotron retains the right to change specifications and illustrations in the

text, without prior notification. The contents of this document may not

be copied without the explicit permission of Emotron AB.

Safety Instructions

Instruction manual

Read the instruction manual first!

Handling the variable speed drive

Installation, commissioning, demounting, taking measurements, etc, of or on the variable speed drive may only be carried out by personnel technically qualified for the task. The

installation must be carried out in accordance with local

standards.

Opening the variable speed drive

WARNING: Always switch off the mains voltage

before opening the variable speed drive and

wait at least 5 minutes to allow the buffer

capacitors to discharge.

Always take adequate precautions before opening the variable speed drive. Although the connections for the control

signals and the switches are isolated from the main voltage,

do not touch the control board when the variable speed

drive is switched on.

Precautions to be taken with a

connected motor

If work must be carried out on a connected motor or on the

driven machine, the mains voltage must always be disconnected from the variable speed drive first. Wait at least 5

minutes before starting work.

Earthing

The variable speed drive must always be earthed via the

mains safety earth connection.

Earth leakage current

This VSD has an earth leakage current which does exceeding

3.5 mA a.c. or 10 mA d.c. Therefore the minimum size of

the protective earth conductor must comply with the local

safety regulations for high leakage current equipment.

Residual current device (RCD)

compatibility

This product cause a d.c. current in the protective conductor. Where a residual current device (RCD) is used for protection in case of direct or indirect contact, only a Type B

RCD is allowed on the supply side of this product. Use

RCD of 300 mA minimum.

EMC Regulations

In order to comply with the EMC Directive, it is absolutely

necessary to follow the installation instructions. All installation descriptions in this manual follow the EMC Directive.

Mains voltage selection

The variable speed drive is suitable for use with the mains

voltage listed below. Adjustment of the mains voltage is not

necessary!

380-415 V

380-480 V

440-525 V

500-690 V

Voltage tests (Megger)

Do not carry out voltage tests (Megger) on the motor, before

all the motor cables have been disconnected from the variable speed drive.

Condensation

If the variable speed drive is moved from a cold (storage)

room to a room where it will be installed, condensation can

occur. This can result in sensitive components becoming

damp. Do not connect the mains voltage until all visible

dampness has evaporated.

Incorrect connection

The variable speed drive is not protected against incorrect

connection of the mains voltage, and in particular against

connection of the mains voltage to the motor outlets U, V

and W. The variable speed drive can be damaged in this way.

Power factor capacitors for improving

ϕ

cos

Remove all capacitors from the motor and the motor outlet.

Precautions during Autoreset

When the automatic reset is active, the motor will restart

automatically provided that the cause of the trip has been

removed. If necessary take the appropriate precautions.

Transport

To avoid damage, keep the variable speed drive in its original

packaging during transport. This packaging is specially

designed to absorb shocks during transport.

Emotron AB 01-3694-01r2 1

IT Mains supply

The variable speed drives can easily be connected to an IT

mains supply, (non-earthed neutral), please contact your

supplier for details.

Heat warning

Be aware of specific parts on the VSD having

high temperature.

DC-link residual voltage

WARNING: After switching off the mains

supply, dangerous voltage can still be present

in the VSD. When opening the VSD for

installing and/or commissioning activities wait

at least 5 minutes. In case of malfunction a qualified

technician should check the DC-link or wait for one hour

before dismantling the VSD for repair.

2 Emotron AB 01-3694-01r2

Contents

1. Introduction..................................................... 5

1.1 Delivery and unpacking ............................................ 5

1.2 Using of the instruction manual............................... 5

1.3 Type number.............................................................. 5

1.4 Standards .................................................................. 6

1.4.1 Product standard for EMC ........................................ 6

1.5 Dismantling and scrapping....................................... 7

1.5.1 Disposal of old electrical and electronic

equipment ................................................................. 7

1.6 Glossary ..................................................................... 8

1.6.1 Abbreviations and symbols....................................... 8

1.6.2 Definitions.................................................................. 8

2. Mounting ......................................................... 9

2.1 Lifting instructions..................................................... 9

2.2 Stand-alone units .................................................... 10

2.2.1 Cooling ..................................................................... 10

2.2.2 Mounting schemes.................................................. 11

2.3 Cabinet mounting.................................................... 13

2.3.1 Cooling ..................................................................... 13

2.3.2 Mounting schemes.................................................. 13

3. Installation ................................................... 17

3.1 Before installation................................................... 17

3.2 Cable connections................................................... 17

3.2.1 Motor cables............................................................ 17

3.2.2 Mains cables ........................................................... 19

3.3 Cable specifications................................................ 19

3.4 Stripping lengths ..................................................... 19

3.4.1 Dimension of cables and fuses.............................. 20

3.4.2 Tightening torque for mains and motor cables..... 20

3.5 Connect motor and mains cables .......................... 20

3.6 Thermal protection on the motor ........................... 21

3.7 Motors in parallel .................................................... 21

4. Control Connections.................................... 23

4.1 Control board........................................................... 23

4.2 Terminal connections ............................................. 24

4.3 Connection example ............................................... 25

4.4 Inputs configuration with the switches.................. 26

4.5 Connecting the Control Signals .............................. 26

4.5.1 Cables ...................................................................... 26

4.5.2 Types of control signals .......................................... 27

4.5.3 Screening................................................................. 27

4.5.4 Single-ended or double-ended connection? ......... 27

4.5.5 Current signals ((0)4-20 mA).................................. 28

4.5.6 Twisted cables......................................................... 28

4.6 Connecting options ................................................. 28

5. Getting Started ............................................ 29

5.1 Connect the mains and motor cables.................... 29

5.1.1 Mains cables ........................................................... 29

5.1.2 Motor cables............................................................ 29

5.2 Connect control cables ........................................... 29

5.3 Using the function keys .......................................... 30

5.4 Remote control........................................................ 30

5.4.1 Switch on the mains ............................................... 30

5.4.2 Set the Motor Data.................................................. 30

5.4.3 Run the VSD ............................................................ 30

5.5 Local control............................................................ 31

5.5.1 Switch on the mains ............................................... 31

5.5.2 Select manual control............................................. 31

5.5.3 Set the Motor Data.................................................. 31

5.5.4 Enter a Reference Value......................................... 31

5.5.5 Run the VSD ............................................................ 31

6. Applications.................................................. 33

6.1 Application overview ............................................... 33

6.1.1 Pumps...................................................................... 33

6.1.2 Fans ......................................................................... 33

6.1.3 Compressors ........................................................... 34

6.1.4 Blowers .................................................................... 34

7. Main Features .............................................. 35

7.1 Parameter sets........................................................ 35

7.1.1 One motor and one parameter set ........................ 36

7.1.2 One motor and two parameter sets....................... 36

7.1.3 Two motors and two parameter sets ..................... 36

7.1.4 Autoreset at trip ...................................................... 36

7.1.5 Reference priority.................................................... 36

7.1.6 Preset references.................................................... 37

7.2 Remote control functions ....................................... 37

7.3 Performing an Identification Run ........................... 39

7.4 Using the Control Panel Memory............................ 40

7.5 Load Monitor and Process Protection [400] ......... 40

7.5.1 Load Monitor [410]................................................. 40

7.6 Pump function ......................................................... 42

7.6.1 Introduction ............................................................. 42

7.6.2 Fixed MASTER ......................................................... 43

7.6.3 Alternating MASTER ................................................ 43

7.6.4 Feedback 'Status' input .......................................... 43

7.6.5 Fail safe operation .................................................. 44

7.6.6 PID control ............................................................... 45

7.6.7 Wiring Alternating Master ....................................... 46

7.6.8 Checklist And Tips ................................................... 47

7.6.9 Functional Examples of Start/Stop Transitions .... 48

8. EMC and Machine Directive........................ 51

8.1 EMC standards........................................................ 51

8.2 Stop categories and emergency stop .................... 51

9. Operation via the Control Panel.................. 53

9.1 General .................................................................... 53

9.2 The control panel .................................................... 53

9.2.1 The display............................................................... 53

9.2.2 Indications on the display....................................... 54

9.2.3 LED indicators ......................................................... 54

9.2.4 Control keys............................................................. 54

Emotron AB 01-3694-01r2 3

9.2.5 The Toggle and Loc/Rem Key ................................ 54

9.2.6 Function keys .......................................................... 55

9.3 The menu structure................................................. 56

9.3.1 The main menu ....................................................... 56

9.4 Programming during operation .............................. 56

9.5 Editing values in a menu ........................................ 56

9.6 Programming example............................................ 57

10. Serial communication ................................. 59

10.1 Parameter sets........................................................ 59

10.2 Motor data ............................................................... 59

10.3 Start and stop commands ...................................... 60

10.4 Reference signal ..................................................... 60

10.5 Description of the EInt formats .............................. 60

11. Functional Description................................ 63

11.1 Resolution of settings ............................................. 63

11.2 Preferred View [100]............................................... 63

11.2.1 1st Line [110].......................................................... 63

11.2.2 2nd Line [120] ........................................................ 63

11.3 Main Setup [200].................................................... 64

11.3.1 Operation [210]....................................................... 64

11.3.2 Remote Signal Level/Edge [21A]........................... 66

11.3.3 Motor Data [220] .................................................... 67

11.3.4 Motor Protection [230] ........................................... 71

11.3.5 Parameter Set Handling [240]............................... 73

11.3.6 Trip Autoreset/Trip Conditions [250]..................... 75

11.3.7 Serial Communication [260].................................. 81

11.4 Process and Application Parameters [300] .......... 83

11.4.1 Set/View Reference Value [310] ........................... 83

11.4.2 Process Settings [320] ........................................... 83

11.4.3 Start/Stop settings [330] ....................................... 87

11.4.4 Mechanical brake control....................................... 90

11.4.5 Speed [340]............................................................. 92

11.4.6 Torques [350].......................................................... 94

11.4.7 Preset References [360] ........................................ 96

11.4.8 PID Process Control [380] ...................................... 97

11.4.9 Pump/Fan Control [390] ...................................... 100

11.5 Load Monitor and Process Protection [400]....... 106

11.5.1 Load Monitor [410]............................................... 106

11.5.2 Process Protection [420]...................................... 111

11.6 I/Os and Virtual Connections [500] ..................... 112

11.6.1 Analogue Inputs [510].......................................... 112

11.6.2 Digital Inputs [520]............................................... 118

11.6.3 Analogue Outputs [530] ....................................... 119

11.6.4 Digital Outputs [540] ............................................ 123

11.6.5 Relays [550] .......................................................... 124

11.6.6 Virtual Connections [560]..................................... 125

11.7 Logical Functions and Timers [600] .................... 126

11.7.1 Comparators [610] ............................................... 126

11.7.2 Logic Output Y [620] ............................................. 130

11.7.3 Logic Output Z [630]............................................. 132

11.7.4 Timer1 [640] ......................................................... 133

11.7.5 Timer2 [650] ......................................................... 135

11.8 View Operation/Status [700] ............................... 136

11.8.1 Operation [710]..................................................... 136

11.8.2 Status [720] .......................................................... 138

11.8.3 Stored values [730] .............................................. 140

11.9 View Trip Log [800] ............................................... 142

11.9.1 Trip Message log [810]......................................... 142

11.9.2 Trip Messages [820] - [890] ................................ 143

11.9.3 Reset Trip Log [8A0] ............................................. 143

11.10 System Data [900]................................................ 143

11.10.1 VSD Data [920] ..................................................... 143

12. Troubleshooting, Diagnoses and

Maintenance .............................................. 145

12.1 Trips, warnings and limits..................................... 145

12.2 Trip conditions, causes and remedial action ...... 146

12.2.1 Technically qualified personnel............................ 146

12.2.2 Opening the variable speed drive ........................ 146

12.2.3 Precautions to take with a connected motor ...... 146

12.2.4 Autoreset Trip ........................................................ 146

12.3 Maintenance ......................................................... 149

13. Options........................................................ 151

13.1 Protection class IP54............................................ 151

13.2 Options for the control panel................................ 152

13.3 EmoSoftCom.......................................................... 152

13.4 Brake chopper....................................................... 152

13.5 I/O Board ............................................................... 153

13.6 Output coils ........................................................... 153

13.7 Serial communication and fieldbus ..................... 153

13.8 Standby supply option .......................................... 153

13.9 Safe Stop option.................................................... 153

13.10 Crane option board ............................................... 155

13.11 Encoder.................................................................. 155

13.12 PTC/PT100 ............................................................ 155

14. Technical Data ........................................... 157

14.1 Electrical specifications related to model........... 157

14.2 General electrical specifications.......................... 159

14.3 Operation at higher temperatures ....................... 160

14.4 Operation at higher switching frequency............. 160

14.5 Dimensions and Weights...................................... 161

14.6 Environmental conditions..................................... 161

14.7 Fuses, cable cross-sections and glands .............. 162

14.8 Control signals....................................................... 163

15. Menu List .................................................... 165

Index 171

4 Emotron AB 01-3694-01r2

1. Introduction

FDU is used most commonly to control and protect pump

and fan applications that put high demands on flow control,

process uptime and low maintenance costs. It can also be

used for e.g. compressors and blowers. Several options are

available, listed in chapter 13. page 151, that enable you to

customize the variable speed drive for your specific needs.

NOTE: Read this instruction manual carefully before

starting installation, connection or working with the

variable speed drive.

The following symbols can appear in this manual. Always

read these first before continuing:

NOTE: Additional information as an aid to avoid

problems.

CAUTION: Failure to follow these instructions

!

can result in malfunction or damage to the

variable speed drive.

WARNING: Failure to follow these instructions

can result in serious injury to the user in addition

to serious damage to the variable speed drive.

HOT SURFACE:

The variable speed drives are delivered with a template for

positioning the fixing holes on a flat surface. Check that all

items are present and that the type number is correct.

1.2 Using of the instruction

manual

Within this instruction manual the abbreviation “VSD” is

used to indicate the complete variable speed drive as a single

unit.

Check that the software version number on the first page of

this manual matches the software version in the variable

speed drive.

With help of the index and the contents it is easy to track

individual functions and to find out how to use and set

them.

The Quick Setup Card can be put in a cabinet door, so that

it is always easy to access in case of an emergency.

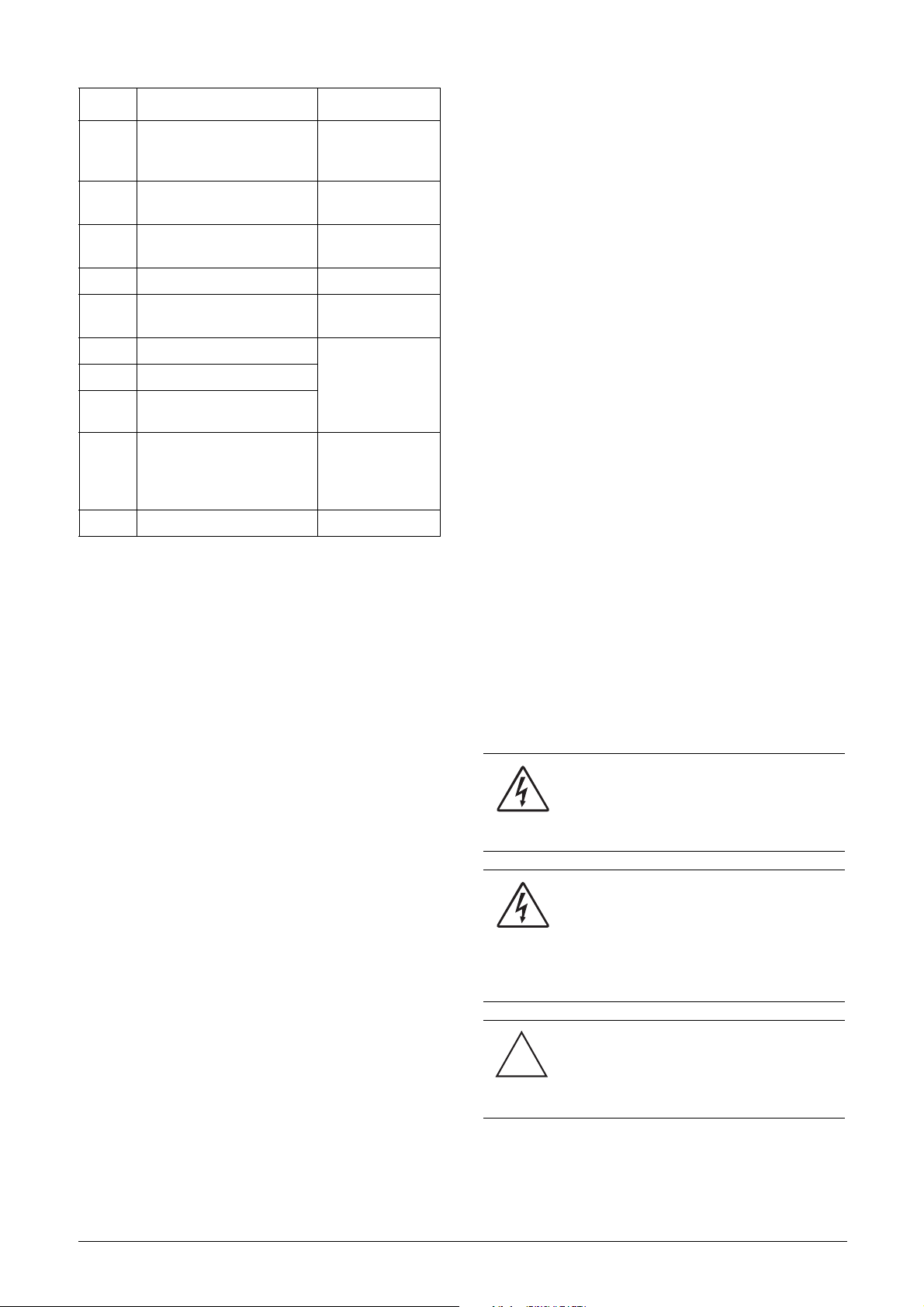

1.3 Type number

Fig. 1 gives an example of the type code numbering used on

all variable speed drives

type of the drive can be determined. This identification will

be required for type specific information when mounting

and installing. The code number is located on the product

label, on the front of the unit.

. With this code number the exact

Users

This instruction manual is intended for:

• installation engineers

• maintenance engineers

•operators

• service engineers

Motors

The variable speed drive is suitable for use with standard 3phase asynchronous motors. Under certain conditions it is

possible to use other types of motors. Contact your supplier

for details.

1.1 Delivery and unpacking

Check for any visible signs of damage. Inform your supplier

immediately of any damage found. Do not install the variable speed drive if damage is found.

FDU48-175-54 C E B S T A V C E P N A

12345678910111213141516

Fig. 1 Type number

Position Configuration

1VSD type

2Supply voltage

3 Rated current (A) continuous

4 Protection class

5 Control panel

6 EMC option

FDU

VFX

40=400 V mains

48=400 V mains

50=500 V mains

-003=2.5 A

-

-1500=1500 A

20=IP20

54=IP54

–=Blank CP

C=Standard CP

E=Standard EMC

F=Extended EMC

I=IT-Net

Emotron AB 01-3694-01r2 Introduction 5

Position Configuration

7 Brake chopper option

8 Stand-by power supply option

–=Brake N.C

B=Brake

D=DC interface

-=No SBS

S=SBS included

1.4 Standards

The variable speed drives described in this instruction manual comply with the standards listed in Table 1. For the declarations of conformity and manufacturer’s certificate,

contact your supplier for more information or visit

www.emotron.com.

9 Safe stop option

10 Brand label

11 Coated boards, option

12 Option position 1 N=No option

13 Option position 2

14 Option position 3

15

16 Software type

Option position, communication

–=No safe stop

T=Safe stop incl.

–=No coating

V=Coated boards

C=Crane I/O

E=Encoder

P=PTC/PT100

I=Extended I/O

N=No option

D=DeviceNet

P=Profibus

S=RS232/485

1.4.1Product standard for EMC

Product standard EN(IEC)61800-3, second edition of 2004

defines the :

First Environment (Extended EMC) as environment that

includes domestic premises. It also includes establishments

directly connected without intermediate transformers to a

low voltage power supply network that supplies buildings

used for domestic purposes.

Second Environment (Standard EMC) includes all other

establishments.

Category C2: Power Drive System (PDS) of rated voltage<1.000 V, which is neither a plug in device nor a movable

device and, when used in the first environment, is intended

to be installed and commissioned only by a professional.

Category C3: PDS of rated voltage <1.000 V, intended for

use in the second environment and not intended for use in

the first environment.

Category C4: PDS or rated voltage equal or above 1.000 V,

or rated current equal to or above 400 A, or intended for use

in complex systems in the second environment.

The variable speed drive complies with the product standard

EN(IEC) 61800-3:2004 (Any kind of metal screened cable

may be used). The standard variable speed drive is designed

to meet the requirements according to category C3.

WARNING: In a domestic environment this

product may cause radio interference, in

which case it may be necessary to take

adequate additional measures.

WARNING: The standard VSD, complying with

category C3, is not intended to be used on a

low-voltage public network which supplies

domestic premises; radio interference is

expected if used in such a network. Contact

your supplier if you need additional

measures.

CAUTION: In order to comply fully with the

standards stated in the Manufacturer’s

!

Declaration ANNEX IIB, the installation

instructions detailed in this instruction

manual must be followed to the letter.

6Introduction Emotron AB 01-3694-01r2

Ta b le 1 St an d ar d s

Market Standard Description

Machine Directive 98/37/EEC

European

All

Russian GOST R For all sizes

EMC Directive 2004/108/EEC

Low Voltage Directive 2006/95/EC

WEEE Directive 2002/96/EC

Safety of machinery - Electrical equipment of machines

EN 60204-1

EN(IEC)61800-3:2004

EN50178

(<90 A)

EN(IEC)61800-5-1

≥90 A)

(

IEC 60721-3-3

Part 1: General requirements.

Machine Directive: Manufacturer’s certificate

Adjustable speed electrical power drive systems

Part 3: EMC requirements and specific test methods.

EMC Directive: Declaration of Conformity and

Electronic equipment for use in power installations.

Low Voltage Directive: Declaration of Conformity and

Adjustable speed electrical power drive systems Part 5-1.

Safety requirements - Electrical, thermal and energy.

Low Voltage Directive: Declaration of Conformity and

Classification of environmental conditions. Air quality chemical vapours, unit in

operation. Chemical gases 3C1, Solid particles 3S2.

Optional with coated boards

Unit in operation. Chemical gases Class 3C2, Solid particles 3S2.

acc. to Appendix IIB

CE marking

CE marking

CE marking

1.5 Dismantling and scrapping

The enclosures of the drives are made from recyclable material as aluminium, iron and plastic. Each drive contains a

number of components demanding special treatment, for

example electrolytic capacitors. The circuit boards contain

small amounts of tin and lead. Any local or national regulations in force for the disposal and recycling of these materials

must be complied with.

1.5.1 Disposal of old electrical and

electronic equipment

This information is applicable in the European Union and

other European countries with separate collection systems.

This symbol on the product or on its packaging indicates

that this product shall be treated according to the WEEE

Directive. It must be taken to the applicable collection point

for the recycling of electrical and electronic equipment. By

ensuring this product is disposed of correctly, you will help

prevent potentially negative consequences for the environment and human health, which could otherwise be caused

by inappropriate waste handling of this product. The recycling of materials will help to conserve natural resources. For

more detailed information about recycling this product,

please contact the local distributor of the product or visit our

home page www.emotron.com.

Emotron AB 01-3694-01r2 Introduction 7

1.6 Glossary

1.6.1Abbreviations and symbols

In this manual the following abbreviations are used:

1.6.2 Definitions

In this manual the following definitions for current, torque

and frequency are used:

Table 3 Definitions

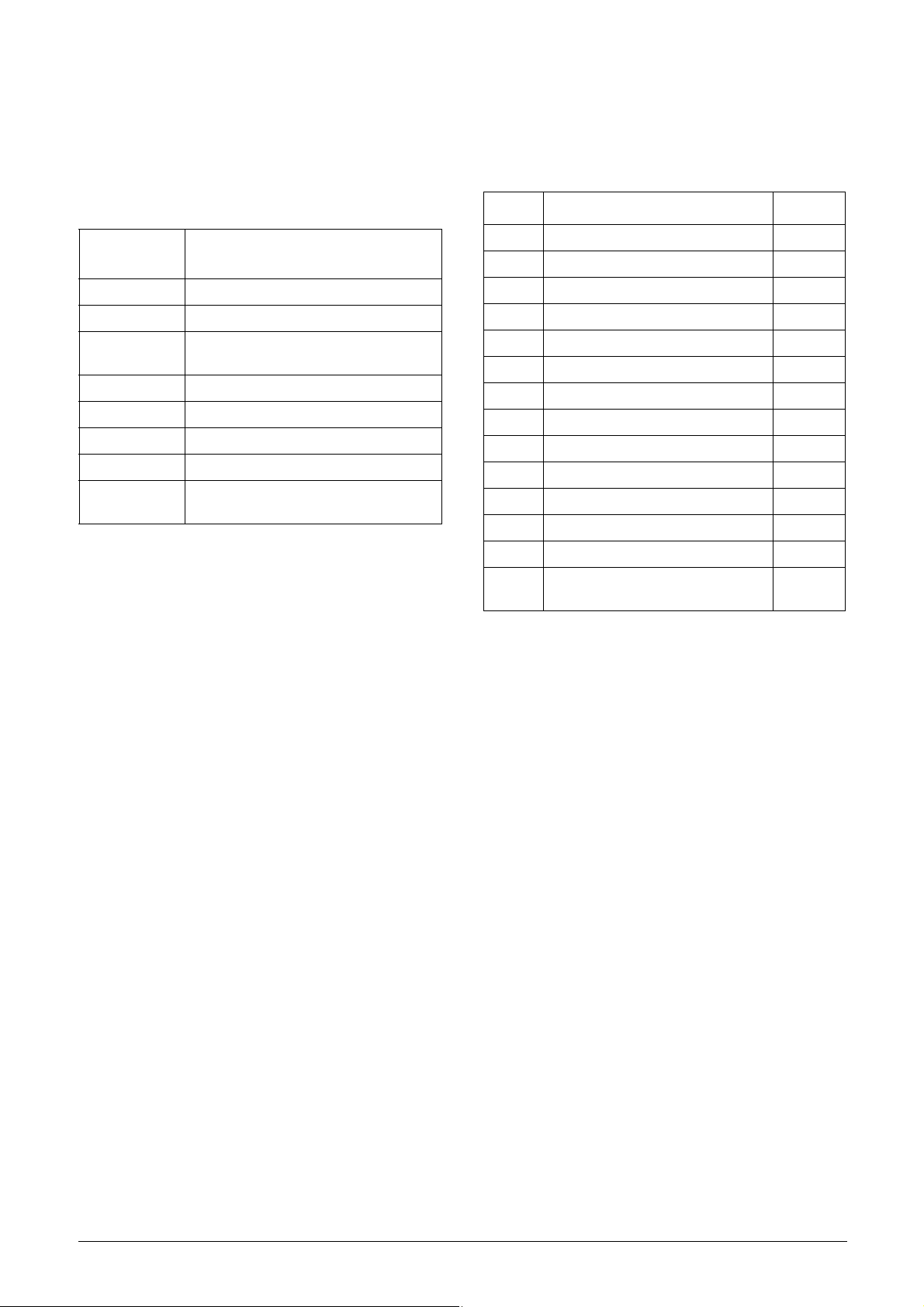

Table 2 Abbreviations

Abbreviation/

symbol

DSP Digital signals processor

VSD Variable speed drive

CP

EInt Communication format

UInt Communication format

Int Communication format

Long Communication format

Control panel, the programming and presentation unit on the VSD

The function cannot be changed in run

mode

Description

Name Description Quantity

I

IN

I

NOM

I

MOT

P

NOM

P

MOT

T

NOM

T

MOT

f

OUT

f

MOT

n

MOT

I

CL

Speed Actual motor speed rpm

Torque Actual motor torque Nm

Sync

speed

Nominal input current of VSD A, RMS

Nominal output current of VSD A, RMS

Nominal motor current A, RMS

Nominal power of VSD kW

Motor power kW

Nominal torque of motor Nm

Motor torque Nm

Output frequency of VSD Hz

Nominal frequency of motor Hz

Nominal speed of motor rpm

Maximum output current for 60s A, RMS

Synchronous speed of the motor rpm

8Introduction Emotron AB 01-3694-01r2

2. Mounting

This chapter describes how to mount the VSD.

Before mounting it is recommended that the installation is

planned out first.

• Be sure that the VSD suits the mounting location.

• The mounting site must support the weight of the VSD.

• Will the VSD continuously withstand vibrations and/or

shocks?

• Consider using a vibration damper.

• Check ambient conditions, ratings, required cooling air

flow, compatibility of the motor, etc.

• Know how the VSD will be lifted and transported.

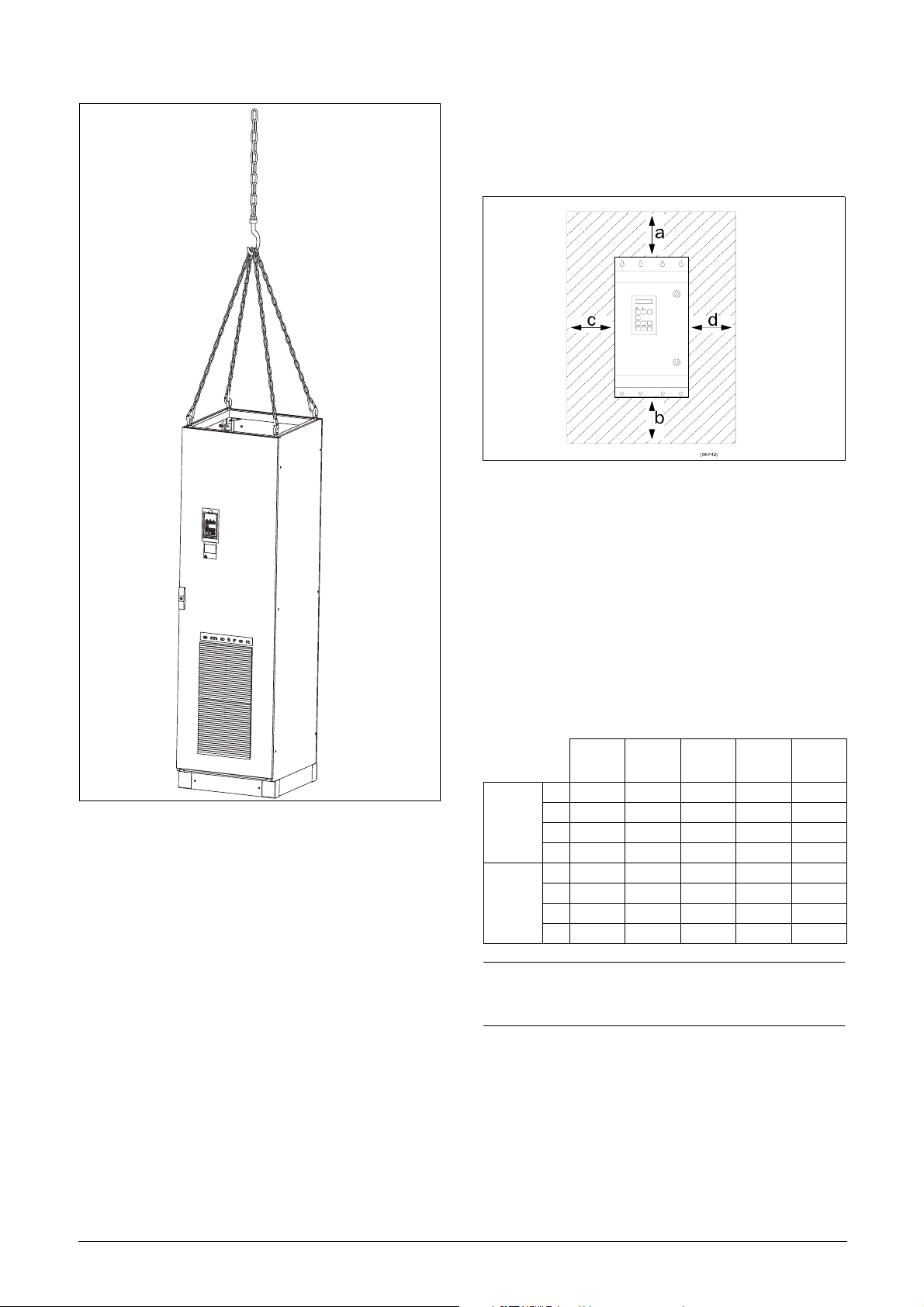

2.1 Lifting instructions

Note: To prevent personal risks and any damage to the

unit during lifting, it is advised that the lifting methods

described below are used.

Recommended for VSD models -090 to -250

Recommended for VSD models -300 to -1500

*

*

*

Load: 56 to 74 kg

Fig. 3 Remove the roof plate.

*

A

DETAIL A

Fig. 4 Remove roofunit

Fig. 2 Lifting VSD model -090 to -250

Emotron AB 01-3694-01r2 Mounting 9

2.2 Stand-alone units

The VSD must be mounted in a vertical position against a

flat surface. Use the template (delivered together with the

VSD) to mark out the position of the fixing holes.

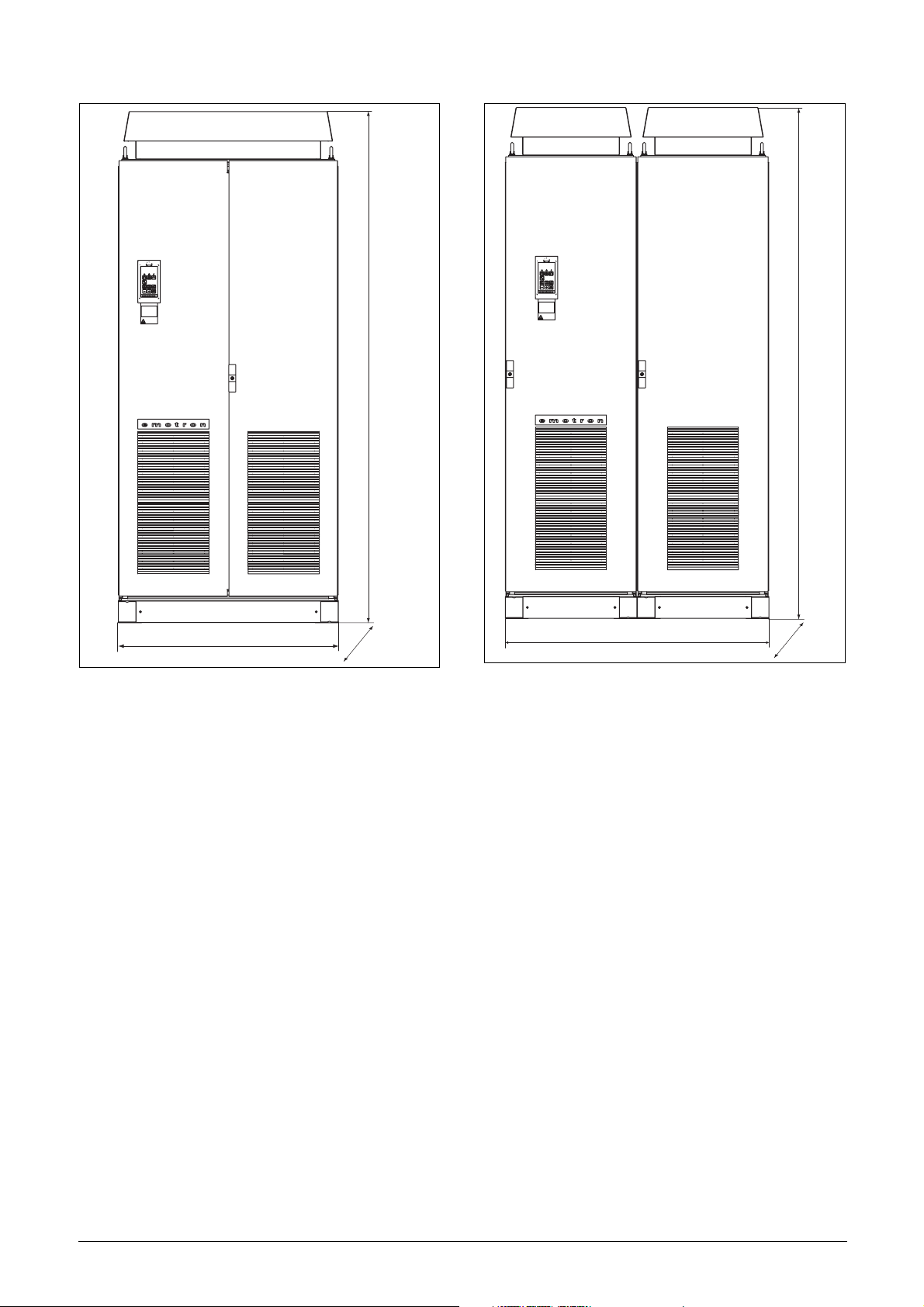

Fig. 6 Variable speed drive mounting models 003 to 250

2.2.1 Cooling

Fig. 6 shows the minimum free space required around the

VSD for the models 003 to 250 in order to guarantee adequate cooling. Because the fans blow the air from the bottom to the top it is advisable not to position an air inlet

immediately above an air outlet.

The following minimum separation between two variable

speed drives, a VSD and a non-dissipating wall must be

maintained:

Fig. 5 Lifting VSD model -300 to -1500

Table 4 Mounting and cooling

003-

013

FDUFDU

(mm)

FDUwall

(mm)

NOTE: When a 300 to 1500 model is placed between two

walls, a minimum distance at each side of 200 mm must

be maintained.

a 200 200 200 200 100

b 200 200 200 200 0

c 30 0 30 0 0

d 30 0 30 0 0

a 100 100 100 100 100

b 100 100 100 100 0

c 30 0 30 0 0

d 30 0 30 0 0

018-

037

046-

073

090-

250

300-

1500

10 Mounting Emotron AB 01-3694-01r2

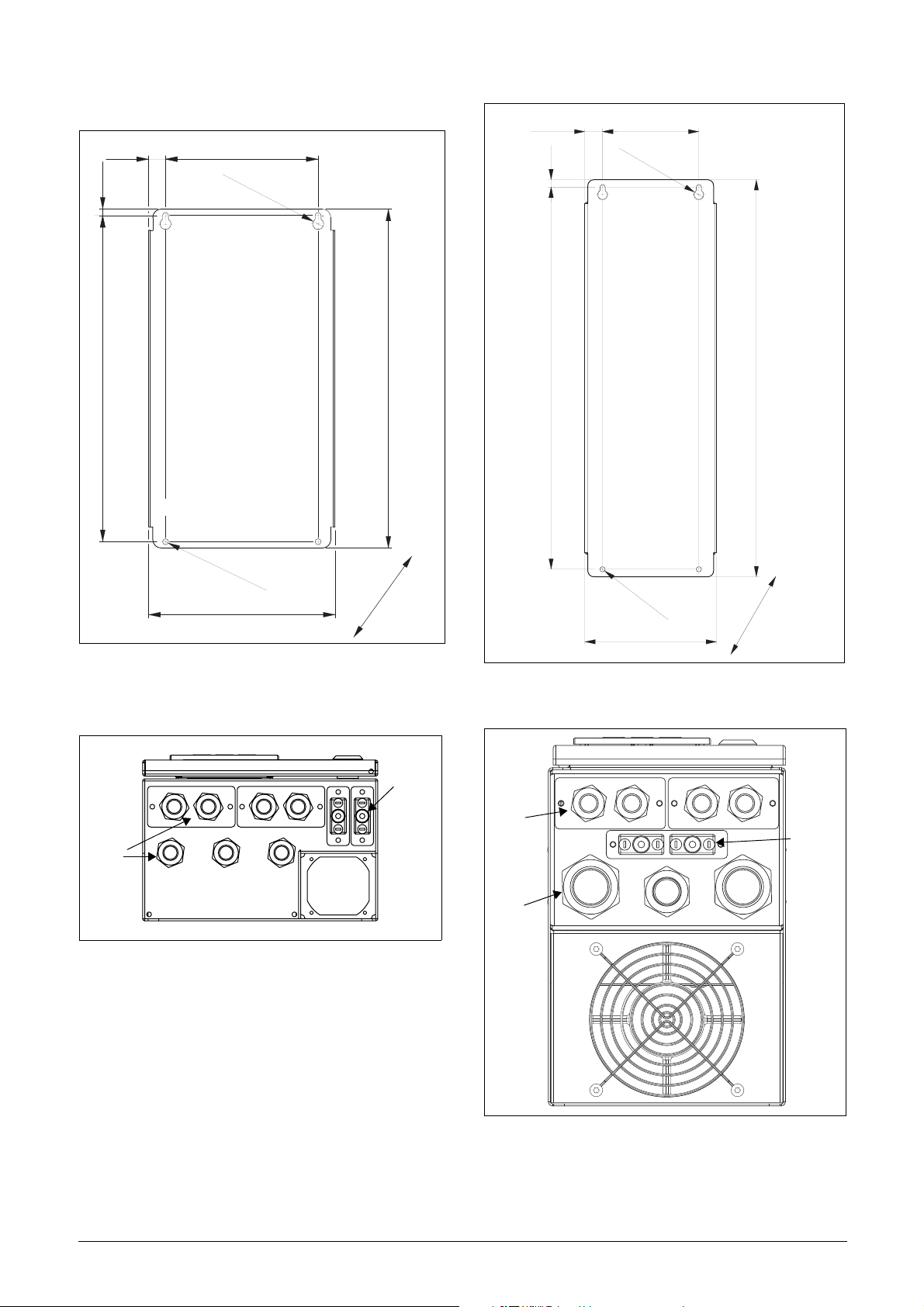

2.2.2 Mounting schemes

20 180

Ø 13 (2x)

7,5385

23,75 128,5

Ø 13 (2x)

10510

Ø 7 (4x)

220

Fig. 7 VSD models 003 - 013 (X1)

Glands

M20

400

154,5

External

Interface

Ø 7 (4x)

176

Fig. 9 VSD models 018 - 037 (S2)

Glands

M20

530

273

External

Interface

Glands

M25

M32M32

Fig. 8 Cable interface for mains, motor and communication,

VSD models 003 - 013(X1)

Fig. 10 Cable interface for mains, motor and communication,

VSD models 018 - 037 (S2).

Emotron AB 01-3694-01r2 Mounting 11

10570

30 160

Ø 13 (2x)

Membrane cable

gland M60

Ø 7 (4x)

220

590

284,5

275

314

10

925

22,5

Ø16(3)

240

120

Ø9(6x)

952,50

30

922,50

Fig. 13 VSD models 090 - 175 including cable interface for

mains, motor and communication (E)

Fig. 11 VSD models 046 - 073 (X2)

External

Glands

M20

Glands

M40

Interface

Fig. 12 Cable interface for mains, motor and communication,

VSD models 046 - 073 (X2)

12 Mounting Emotron AB 01-3694-01r2

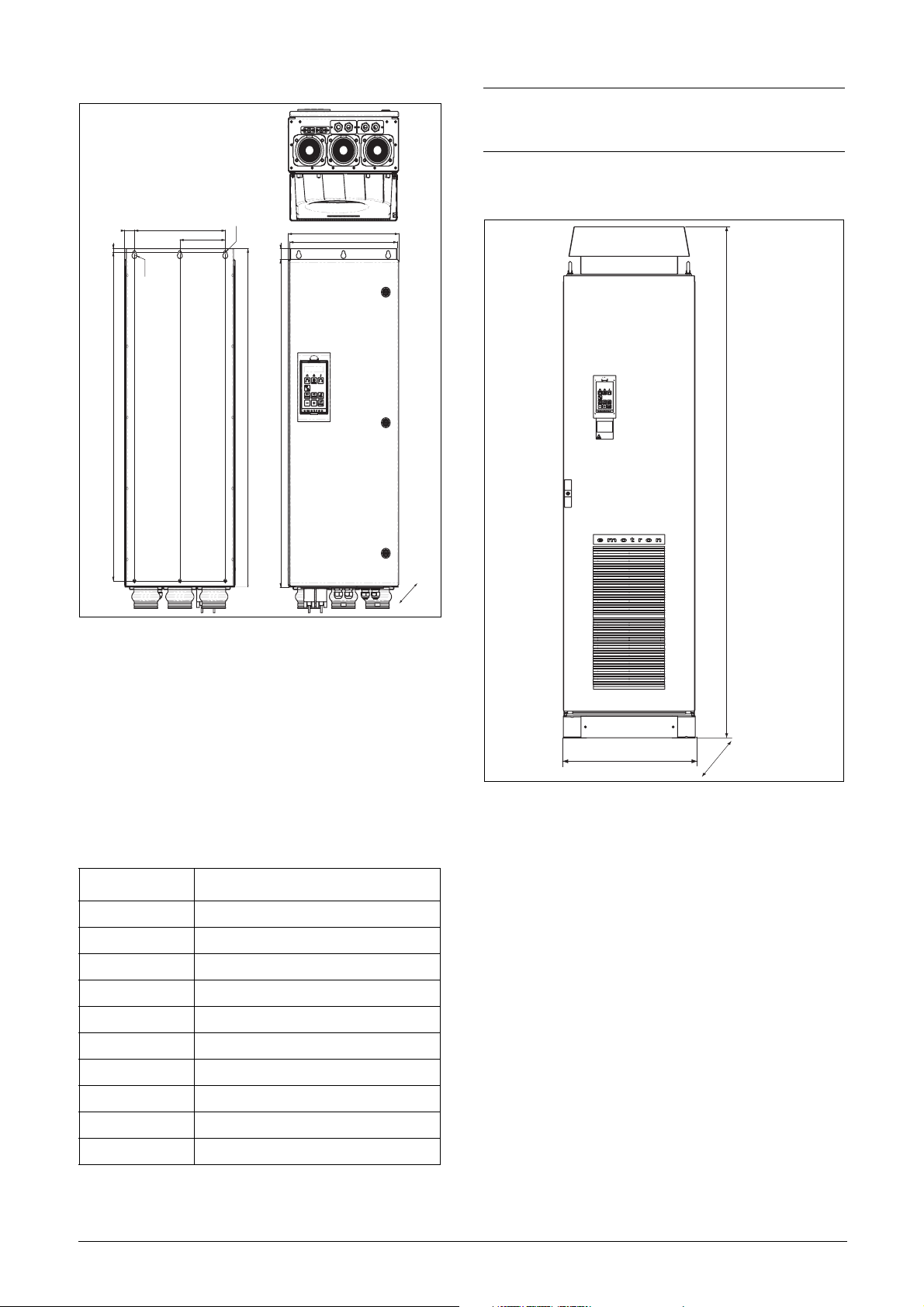

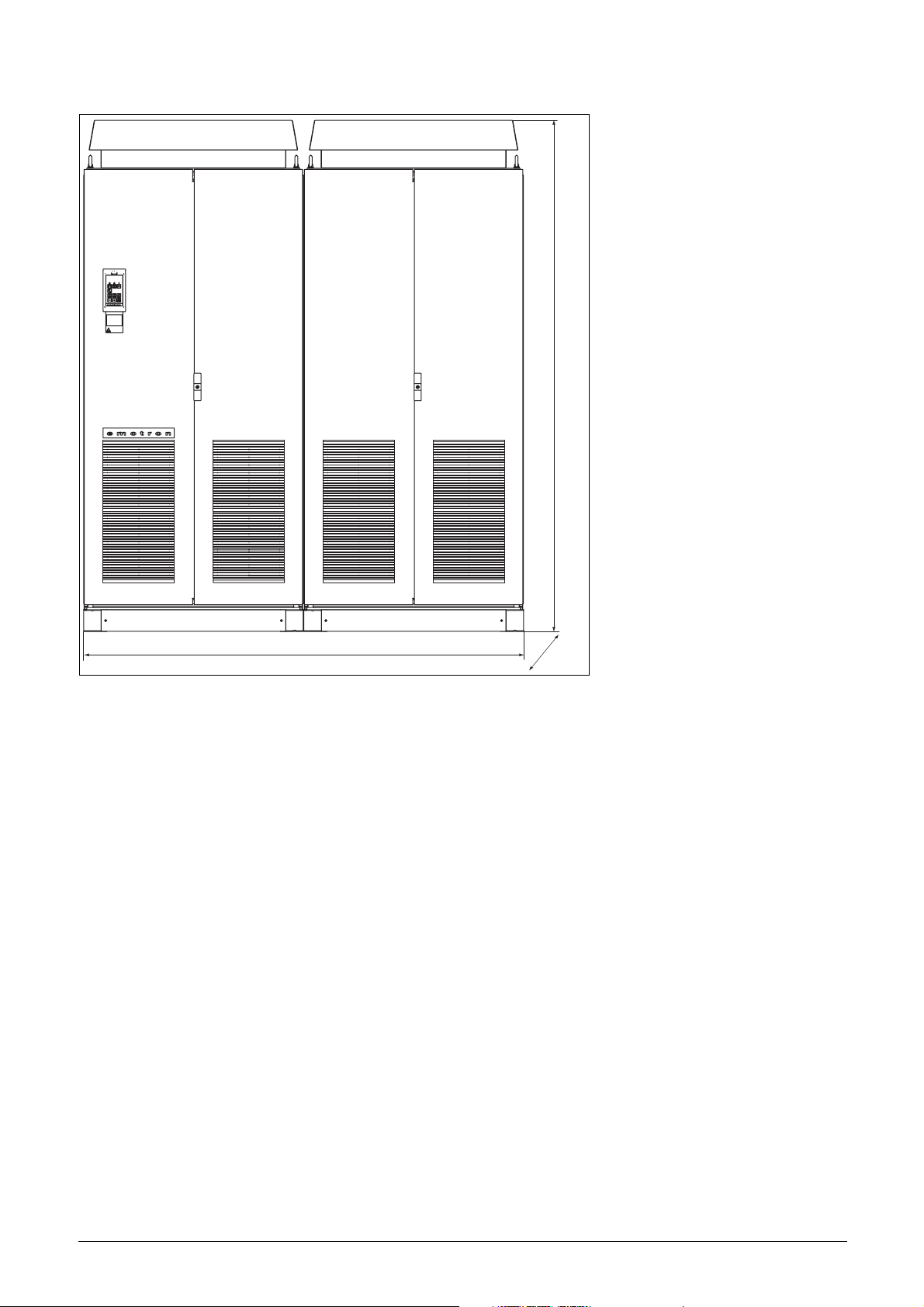

Cable dimensions 27-66 mm

NOTE: For the models 860 to 1500 the mentioned

amount of air flow should be divided equally over the two

cabinets.

2.3.2 Mounting schemes

22.50

10

925

Ø16(3x)

300

Ø9(x6)

150

30

922,50

952,50

344,5

335

314

Fig. 14 VSD models 210 - 250 including cable interface for

mains, motor and communication (F)

2320

2.3 Cabinet mounting

2.3.1 Cooling

If the variable speed drive is installed in a cabinet, the rate of

airflow supplied by the cooling fans must be taken into consideration.

Table 5 Flow rates cooling fans

FDU Model Flow rate [m3/hour]

003 – 013 40

018 – 037 150

046 – 073 165

090 – 175 510

210 – 250 800

300 – 375 1020

430 – 500 1600

600 – 750 2400

860 – 1k0 3200

1200 – 1500 4800

600

600

Fig. 15 VSD models 300 - 500 (G and H)

Emotron AB 01-3694-01r2 Mounting 13

2320

2320

1000

Fig. 16 VSD models 600 - 750 (I)

600

1200

Fig. 17 VSD models 860 - 1000 (J)

600

14 Mounting Emotron AB 01-3694-01r2

2320

2000

Fig. 18 VSD models 1200 - 1500 (K)

600

Emotron AB 01-3694-01r2 Mounting 15

16 Mounting Emotron AB 01-3694-01r2

3. Installation

The description of installation in this chapter complies with

the EMC standards and the Machine Directive.

Select cable type and screening according to the EMC

requirements valid for the environment where the VSD is

installed.

3.1 Before installation

Read the following checklist and think through your application before installation.

• External or internal control.

• Long motor cables (>100m).

• Motors in parallel.

• Functions.

• Suitable VSD size in proportion to the motor/applica-

tion.

• Mount separately supplied option boards according to

the instructions in the appropriate option manual.

If the VSD is temporarily stored before being connected,

please check the technical data for environmental conditions. If the VSD is moved from a cold storage room to the

room where it is to be installed, condensation can form on

it. Allow the VSD to become fully acclimatised and wait

until any visible condensation has evaporated before connecting the mains voltage.

3.2 Cable connections

• Dimension the cables and fuses in accordance with the

nominal output current of the motor. See table 43, page

162.

• Keep the motor cable between VSD and motor as short

as possible.

• The screening must be connected with a large contact

surface of preferable 360× and always at both ends, to

the motor housing and the VSD housing. When painted

mounting plates are used, do not be afraid to scrape

away the paint to obtain as large contact surface as possible at all mounting points for items such as saddles and

the bare cable screening. Relying just on the connection

made by the screw thread is not sufficient.

NOTE: It is important that the motor housing has the

same earth potential as the other parts of the machine.

• The litz connection is only necessary if the mounting

plate is painted. All the variable speed drives have an

unpainted back side and are therefore suitable for

mounting on an unpainted mounting plate.

Connect the motor cables according to U - U, V - V and

W - W.

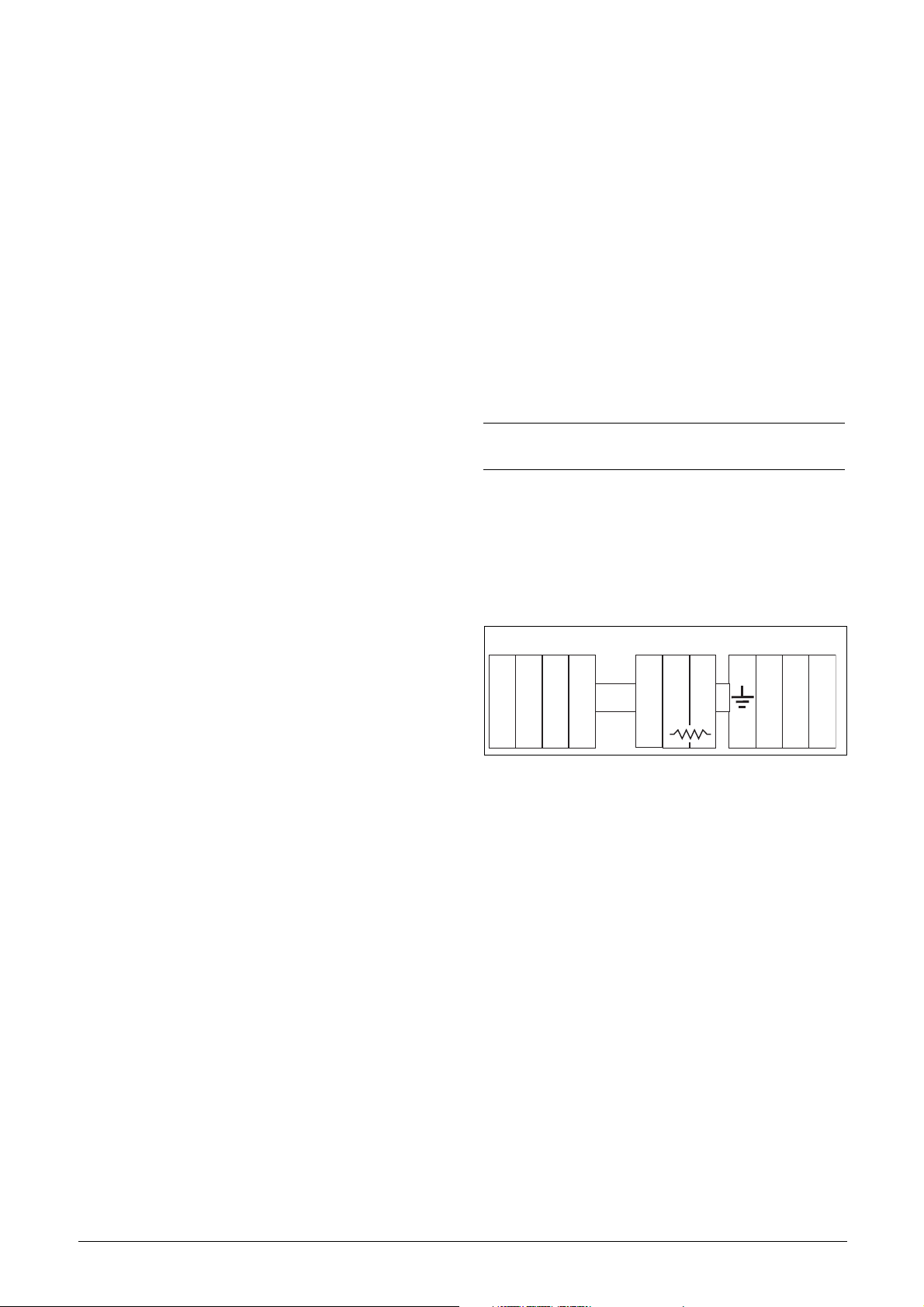

OPTION

DC

L2 L3 PEL1 U V WR

DC

-

+

3.2.1 Motor cables

To comply with the EMC emission standards the variable

speed drive is provided with a RFI mains filter. The motor

cables must also be screened and connected on both sides. In

this way a so-called “Faraday cage” is created around the

VSD, motor cables and motor. The RFI currents are now

fed back to their source (the IGBTs) so the system stays

within the emission levels.

Recommendations for selecting motor

cables

• Use screened cables according to specification in table 7.

Use symmetrical shielded cable; three phase conductors

and a concentric or otherwise symmetrically constructed

PE conductor, and a shield.

• When the conductivity of the cable shield is <50% of the

conductivity of the phase conductor, a separate PE conductor is required.

• Use heat-resistant cables, +60°C or higher.

Fig. 19

Switches between the motor and the

VSD

If the motor cables are to be interrupted by maintenance

switches, output coils, etc., it is necessary that the screening

is continued by using metal housing, metal mounting plates,

etc. as shown in the Fig. 21.

Fig. 22 shows an example when there is no metal mounting

plate used (e.g. if IP54 variable speed drives are used). It is

important to keep the “circuit” closed, by using metal housing and cable glands.

Emotron AB 01-3694-01r2 Installation 17

VSD built into cabinet

r

O

Screening of motor cable

Screening of signal cables

Fig. 20 Screening of cables for models 018 - 037.

Pay special attention to the following points:

• If paint must be removed, steps must be taken to prevent

subsequent corrosion. Repaint after making connections!

• The fastening of the whole variable speed drive housing

must be electrically connected with the mounting plate

over an area which is as large as possible. For this purpose

the removal of paint is necessary. An alternative method

is to connect the variable speed drive housing to the

mounting plate with as short a length of litz wire as possible.

• Try to avoid interruptions in the screening wherever possible.

RFI-Filter

(option)

Mains

Litze

Mains

(L1,L2,L3,PE)

VSD

Motor

Metal coupling

nut

Brake resisto

(option)

Metal cable glands

Output coil (option)

Screened cables

Unpainted mounting

plate

Metal connector housing

Motor

Fig. 21 Variable speed drive in a cabinet on a mounting plate

Fig. 22 shows an example when there is no metal mounting

plate used (e.g. if IP54 variable speed drives are used). It is

important to keep the “circuit” closed, by using metal housing and cable glands.

• If the variable speed drive is mounted in a standard cabinet, the internal wiring must comply with the EMC

standard. Fig. 21 shows an example of a VSD built into a

cabinet.

VSD

RFI-Filter

Mains

Metal cable glands

Screened cables

Metal housing

utput

coils

(option)

Metal connector housing

Motor

Metal cable gland

Mains

Brake

resistor

(option)

Fig. 22 Variable speed drive as stand alone

18 Installation Emotron AB 01-3694-01r2

Placing of motor cables

Keep the motor cables as far away from other cables as possible, especially from control signals. The minimum distance

between motor cables and control cables is 30 cm.

Avoid placing the motor cables in parallel with other cables.

The power cables should cross other cables at an angle of

90°.

Long motor cables

If the connection to the motor is longer than 100 m (40 m

for models 003-013), it is possible that capacitive current

peaks will cause tripping at overcurrent. Using output coils

can prevent this. Contact the supplier for appropriate coils.

Switching in motor cables

Switching in the motor connections is not advisable. In the

event that it cannot be avoided (e.g. emergency or maintenance switches) only switch if the current is zero. If this is

not done, the VSD can trip as a result of current peaks.

3.2.2 Mains cables

Dimension the mains and motor cables according to local

regulations. The cable must be able to carry the VSD load

current.

Recommendations for selecting mains

cables

• To fulfil EMC purposes it is not necessary to use

screened mains cables.

• Use heat-resistant cables, +60°C or higher.

• Dimension the cables and fuses in accordance with local

regulations and the nominal output current of the

motor. See table 43, page 162.

• The litz connection is only necessary if the mounting

plate is painted. All the variable speed drives have an

unpainted back side and are therefore suitable for

mounting on an unpainted mounting plate.

Connect the mains cables according to Fig. 23. The VSD

has a built-in RFI mains filter that complies with category

C3 which suits the Second Environment standard.

Table 6 Mains and motor connection

L1,L2,L3

PE

U, V, W

(DC-),DC+,R

NOTE: The Brake and DC-link Terminals are only fitted if

the Brake Chopper Option is built-in.

Mains supply, 3 -phase

Safety earth (protected earth)

Motor earth

Motor output, 3-phase

Brake resistor, DC-link

connections (optional)

WARNING: The Brake Resistor must be

connected between terminals DC+ and R.

WARNING: In order to work safely, the mains

earth must be connected to PE and the

motor earth to .

3.3 Cable specifications

Table 7 Cable specifications

Cable Cable specification

Mains

Motor

Control

Power cable suitable for fixed installation for the

voltage used.

Symmetrical three conductor cable with concentric protection (PE) wire or a four conductor cable

with compact low-impedance concentric shield

for the voltage used.

Control cable with low-impedance shield,

screened.

3.4 Stripping lengths

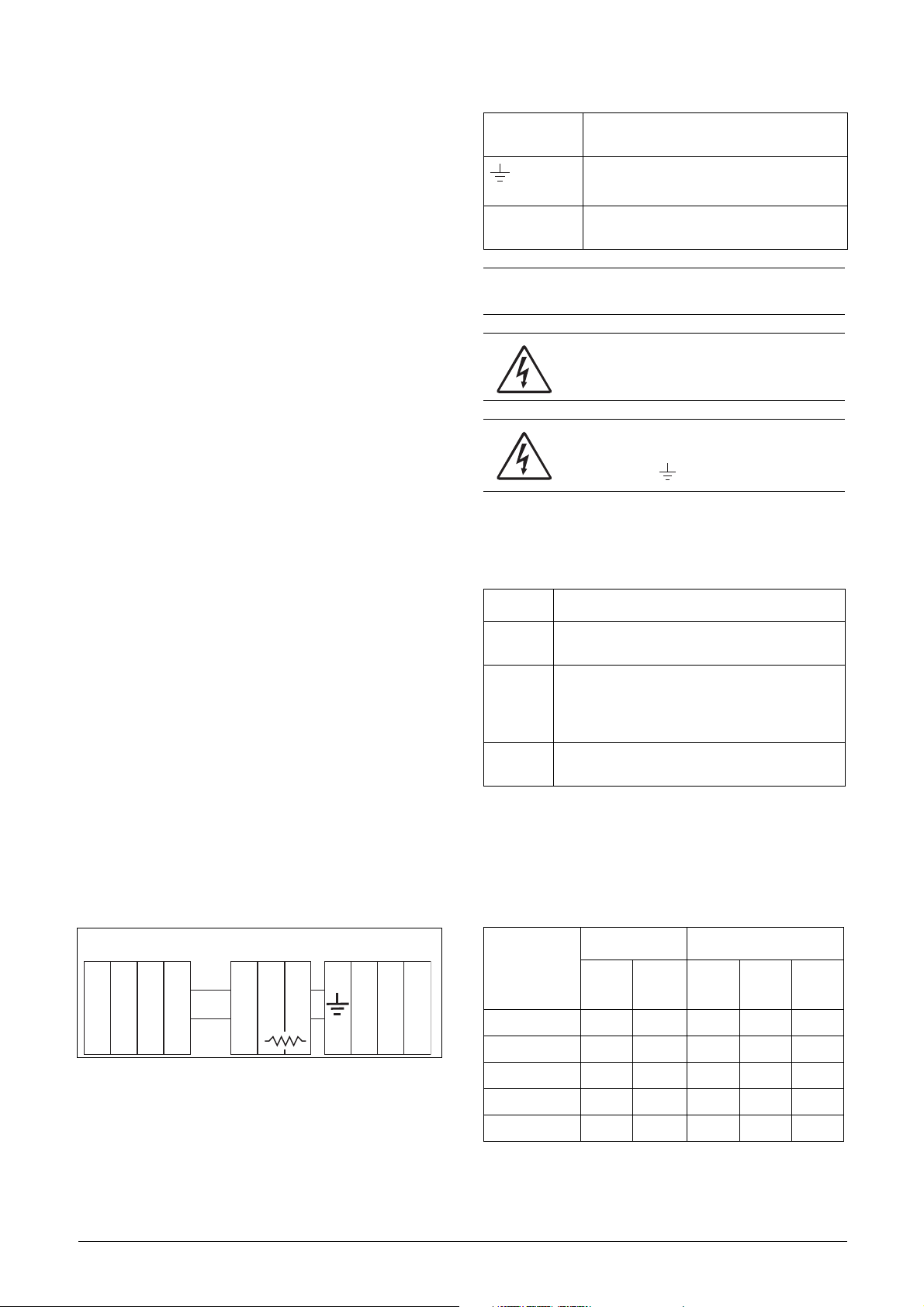

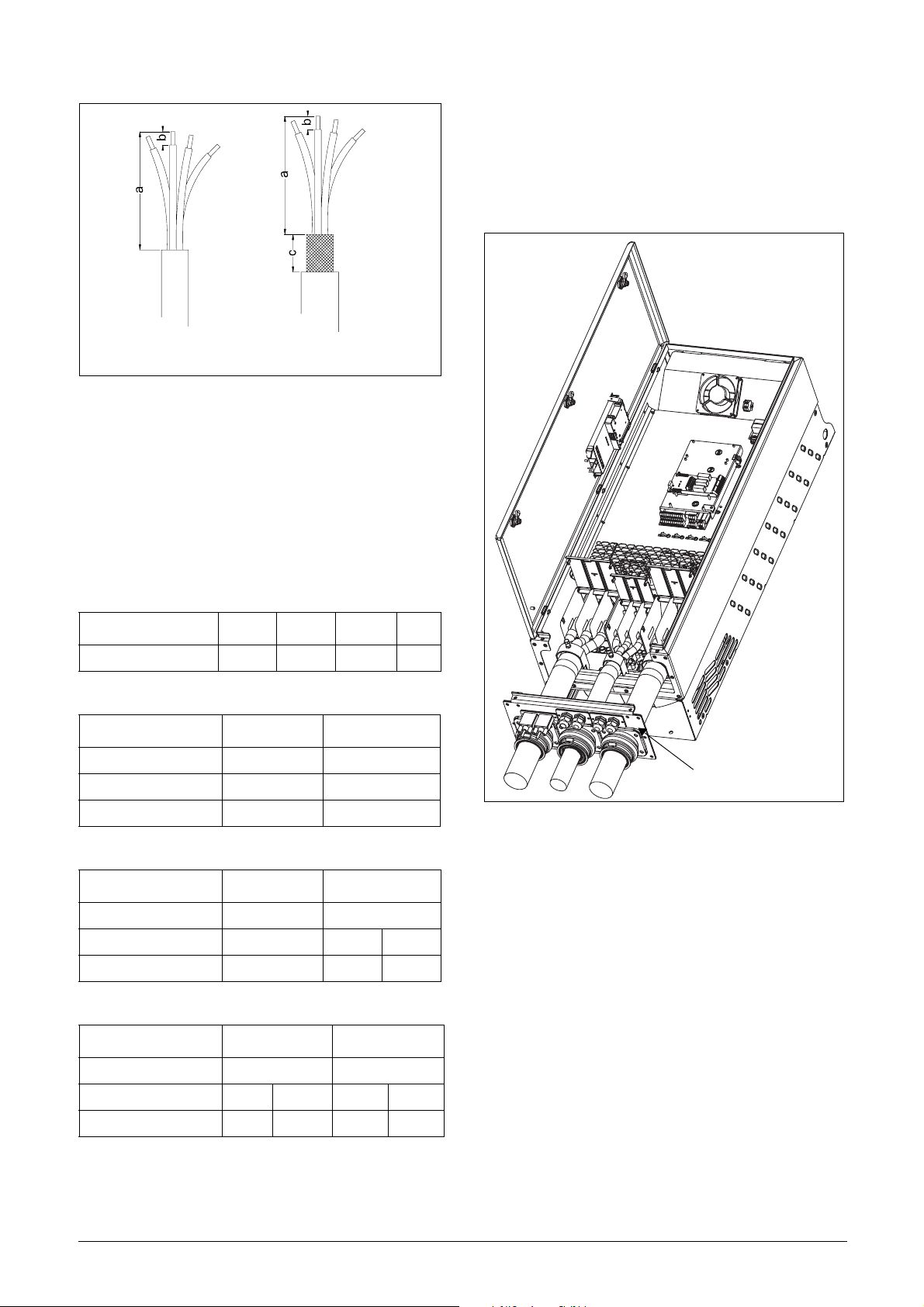

Fig. 24 indicates the recommended stripping lengths for

motor and mains cables.

Table 8 Stripping lengths for mains and motor cables

OPTION

Model

DC

L2 L3 PEL1 U V WR

Fig. 23 Mains and motor connections

Emotron AB 01-3694-01r2 Installation 19

DC

-

+

003–013 60 8 60 8 31

018–037 115 12 115 12 32

046–073 130 11 130 11 34

090-175 160 16 160 16 41

210–250 170 24 170 24 46

Mains cable Motor cable

a

(mm)b (mm)a (mm)b (mm)c (mm)

MotorMains

(06-F45-cables only)

Fig. 24 Stripping lengths for cables

3.4.1 Dimension of cables and fuses

Please refer to the chapter Technical data, section 14.7, page

162.

3.4.2 Tightening torque for mains and

motor cables

3.5 Connect motor and mains

cables

VSD model 090 to 250

To simplify the connection of thick motor and mains cables

to the VSD model 090-250 the cable interface can be

removed.

Table 9 Model 003 to 073

003-013 018-037 046-060 073

Tightening torque, Nm 0.5 1.5 1.5 3.2

Table 10 Model 90 to 109

Brake chopper Mains/motor

Block, mm

Cable diameter, mm

Tightening torque, Nm 14 14

2

2

95 95

16-95 35-95

Table 11 Model 146 to 175

Brake chopper Mains/motor

Block, mm

Cable diameter, mm

Tightening torque, Nm 14 14 24

2

2

95 150

16-95 35-95 120-150

Table 12 Model 210 to 250

Brake chopper Mains/motor

Block, mm

Cable diameter, mm

Tightening torque, Nm 14 24 14 24

2

2

150 240

35-95 120-150 35-70 95-240

Cable interface

Fig. 25 Connecting motor and mains cables

1. Remove the cable interface from the housing.

2. Put the cables through the glands.

3. Strip the cable according to Table 8.

4. Connect and tighten the cable in the clamp.

5. Put the cable interface in place and secure with the

screws.

20 Installation Emotron AB 01-3694-01r2

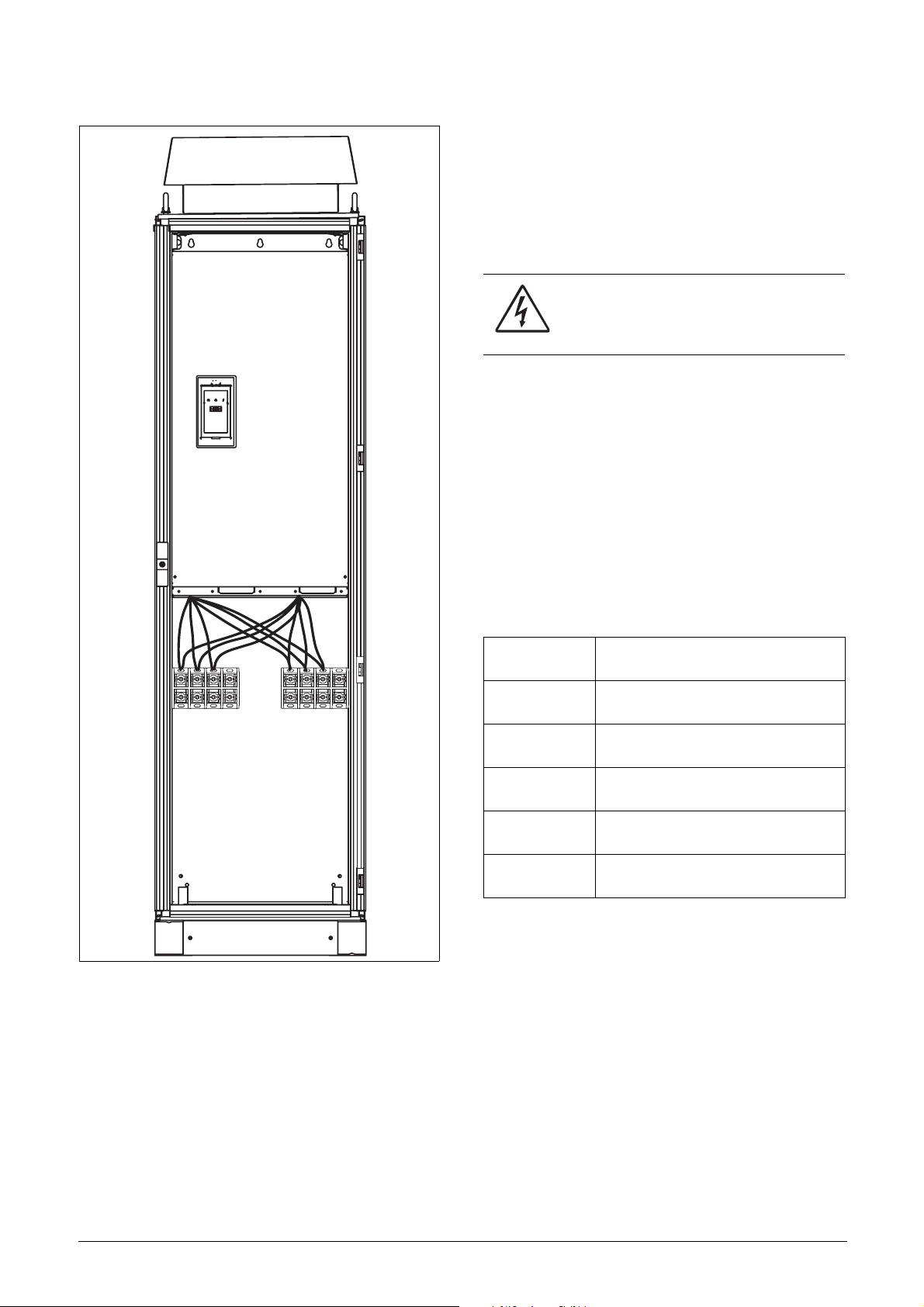

VSD model 300 to 1500

3.6 Thermal protection on the

motor

Standard motors are normally fitted with an internal fan.

The cooling capacity of this built-in fan is dependent on the

frequency of the motor. At low frequency, the cooling capacity will be insufficient for nominal loads. Please contact the

motor supplier for the cooling characteristics of the motor at

lower frequency.

WARNING: Depending on the cooling

characteristics of the motor, the application,

the speed and the load, it may be necessary

to use forced cooling on the motor.

Motor thermistors offer better thermal protection for the

motor. Depending on the type of motor thermistor fitted,

the optional PTC input may be used. The motor thermistor

gives a thermal protection independent of the speed of the

motor, thus of the speed of the motor fan. See the functions,

Motor I

2

t type [231] and Motor I2t current [232].

3.7 Motors in parallel

It is possible to have motors in parallel as long as the total

current does not exceed the nominal value of the VSD. The

following has to be taken into account when setting the

motor data:

L1 L2 L3 PE PE U V W

Fig. 26 Connecting motor and mains cables

VSD models 300 to 1500 are supplied with Klockner Moeller K3x240/4 power clamps.

For all type of wires to be connected the stripping length

should be 32 mm.

Menu [221]

Motor Voltage:

Menu [222]

Motor Frequency:

Menu [223]

Motor Power:

Menu [224]

Motor Current:

Menu [225]

Motor Speed:

Menu [227]

Motor Cos PHI:

The motors in parallel must have the

same motor voltage.

The motors in parallel must have the

same motor frequency.

Add the motor power values for the

motors in parallel.

Add the current for the motors in parallel.

Set the average speed for the motors in

parallel.

Set the average Cos PHI value for the

motors in parallel.

Emotron AB 01-3694-01r2 Installation 21

22 Installation Emotron AB 01-3694-01r2

4. Control Connections

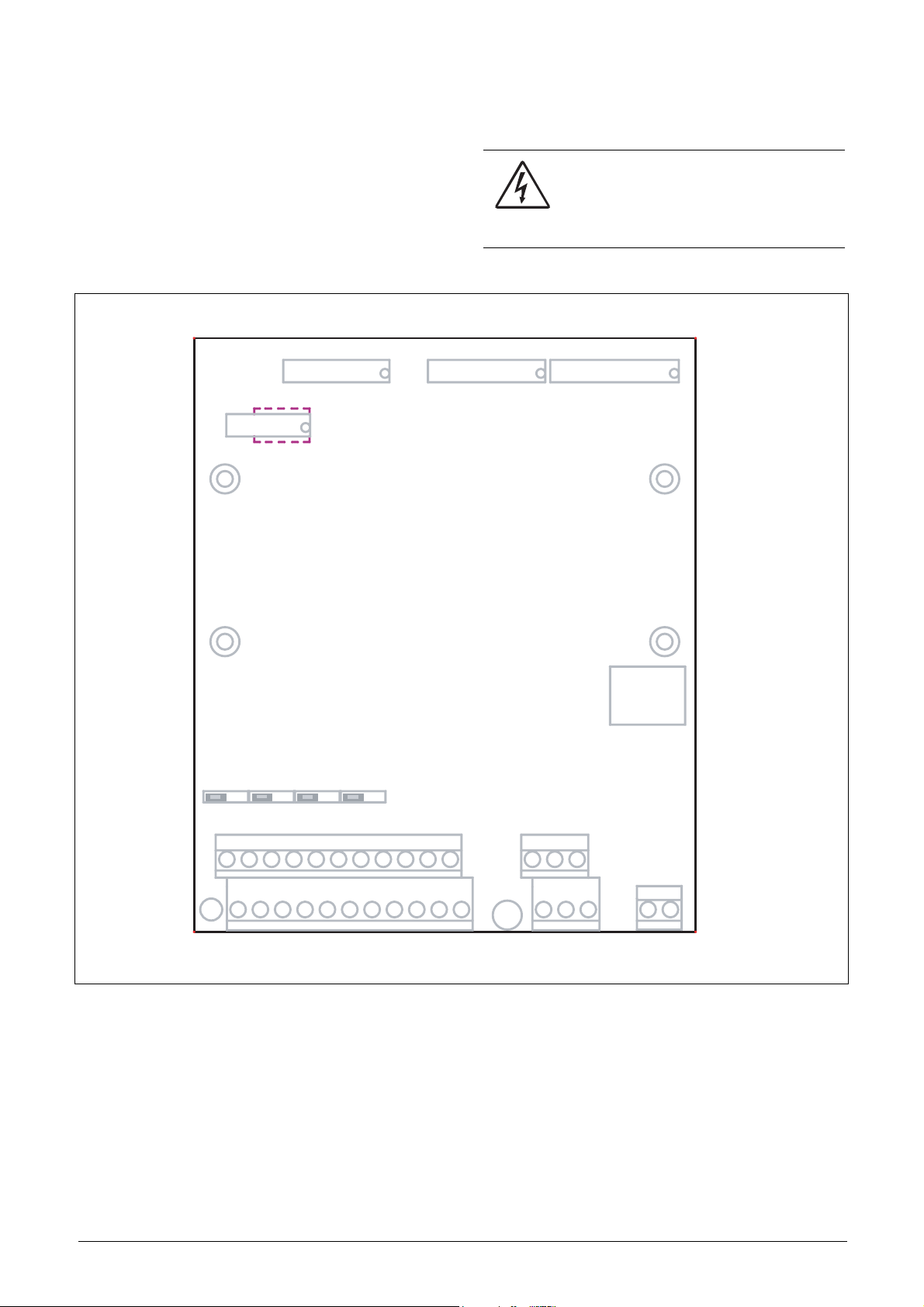

4.1 Control board

Fig. 27 shows the layout of the control board which is where

the parts most important to the user are located. Although

the control board is galvanically isolated from the mains, for

safety reasons do not make changes while the mains supply

is on!

X5

X4

Communication

Option

WARNING: Always switch off the mains

voltage and wait at least 5 minutes to allow

the buffer capacitors to discharge before

connecting the control signals or changing

position of the switches.

X6

X7

I

12

1

X1

Fig. 27 Control board layout

Switches

S3 S4

S2S1

II

U

I

UU

X8

Control

Panel

U

Control

signals

22

11

X2

41

42 43

31 32

Relay outputs

33

X3

51

52

Emotron AB 01-3694-01r2 Control Connections 23

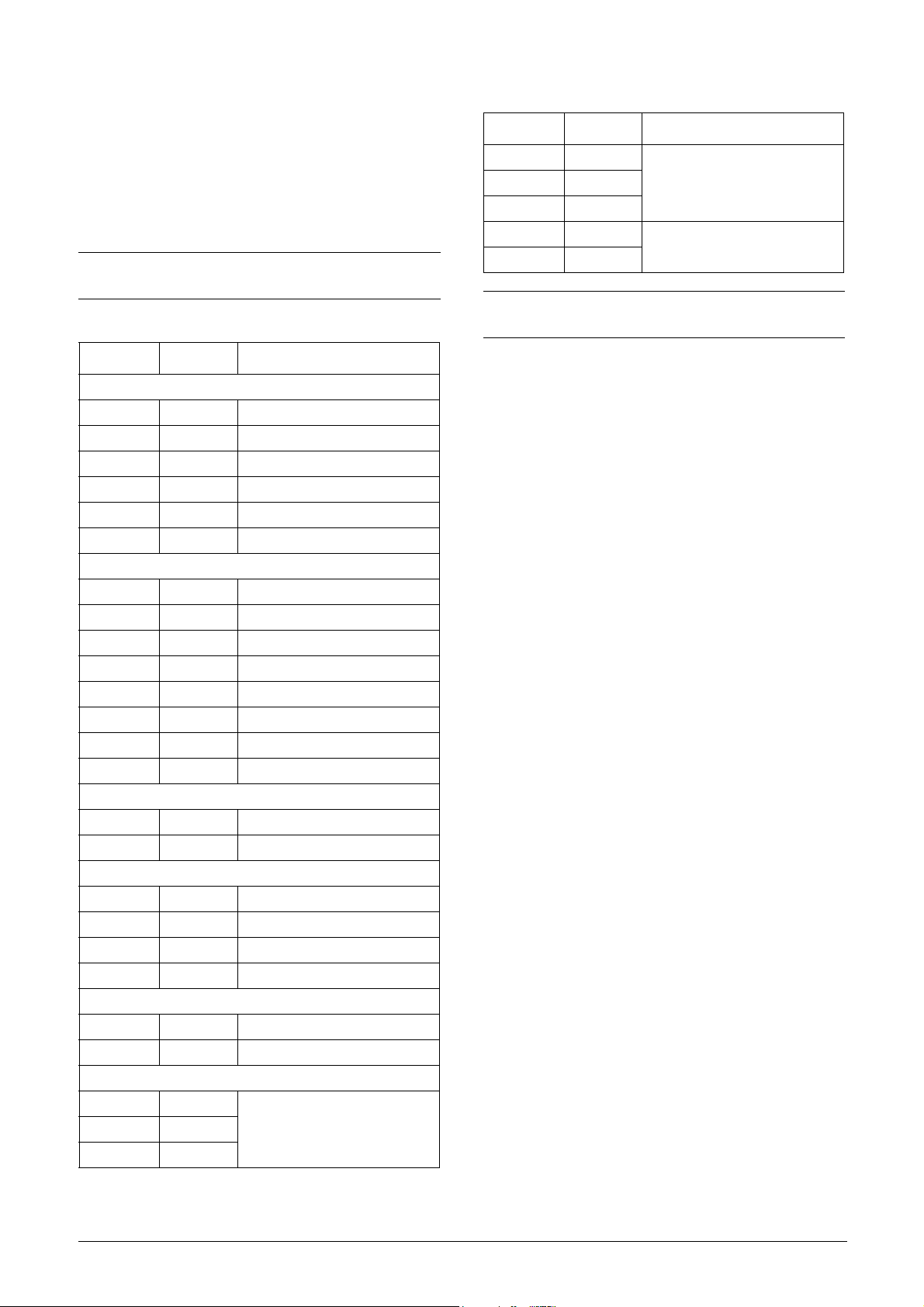

4.2 Terminal connections

The terminal strip for connecting the control signals is

accessible after opening the front panel.

The table describes the default functions for the signals. The

inputs and outputs are programmable for other functions as

described in chapter 11. page 63. For signal specifications

refer to chapter 14. page 157.

NOTE: The maximum total combined current for outputs

11, 20 and 21 is 100mA.

Table 13 Control signals

Terminal Name Function (Default)

Outputs

1 +10 V +10 VDC supply voltage

6 -10 V -10 VDC supply voltage

7 Common Signal ground

11 +24 V +24 VDC supply voltage

12 Common Signal ground

15 Common Signal ground

Digital inputs

8DigIn 1RunL (reverse)

9DigIn 2RunR (forward)

10 DigIn 3 Off

16 DigIn 4 Off

17 DigIn 5 Off

18 DigIn 6 Off

19 DigIn 7 Off

22 DigIn 8 RESET

Digital outputs

20 DigOut 1 Ready

21 DigOut 2 Brake

Analogue inputs

2AnIn 1Process Ref

3AnIn 2Off

4AnIn 3Off

5AnIn 4Off

Analogue outputs

13 Speed Min speed to max speed

14 Torque 0 to max torque

Relay outputs

31 N/C 1

32 COM 1

33 N/O 1

Relay 1 output

Trip, active when the VSD is in a

TRIP condition.

Table 13 Control signals

Terminal Name Function (Default)

41 N/C 2

42 COM 2

43 N/O 2

51 COM 3

52 N/O 3

NOTE: N/C is opened when the relay is active and N/O is

closed when the relay is active.

Relay 2 output

Run, active when the VSD is

started.

Relay 3 output

Off

24 Control Connections Emotron AB 01-3694-01r2

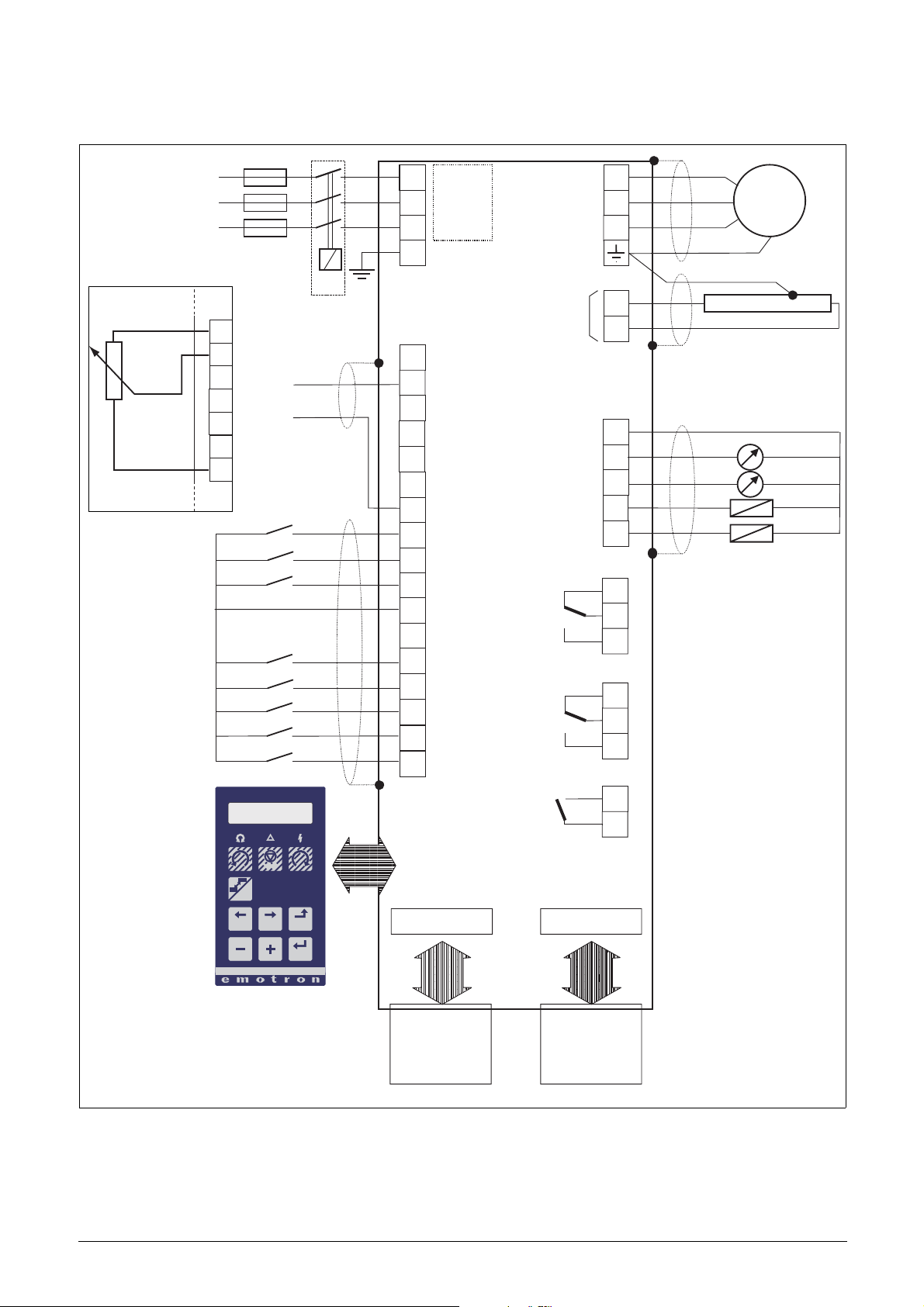

4.3 Connection example

Fig. 28 gives an overall view of a VSD connection example.

L1L3L1

RFI-

L2

filter

PE

Alternative for

potentiometer control Optional

1

2

3

4

5

6

7

0 - 10 V

4 - 20 mA

+10 VDC

1

AnIn 1

2

AnIn 2

3

AnIn 3

4

AnIn 4

5

-10 VDC

6

Common

7

DigIn 1:RunL*

8

DigIn 2:RunR*

9

DigIn3

10

+24 VDC

11

Common

15

DigIn 4

16

DigIn 5

17

DigIn 6

18

DigIn 7

19

DigIn 8:Reset*

22

Common

AnOut 1

AnOut 2

DigOut 1

DigOut 2

Relay 1

Relay 2

U

V

W

DC+

R

12

13

21

14

20

21

31

32

33

41

42

43

Motor

PREV NEXT ESC

* Default setting

Fig. 28 Connection example

Relay 3

51

52

RESET

LOC/

REM

Comm. options

ENTER

Fieldbus option

or PC

Other options

Option board

NG_06-F27

Emotron AB 01-3694-01r2 Control Connections 25

4.4 Inputs configuration

4.5 Connecting the Control

with the switches

The switches S1 to S4 are used to set the input configuration

for the 4 analogue inputs AnIn1, AnIn2, AnIn3 and AnIn4

as described in table 14. See Fig. 27 for the location of the

switches.

Table 14 Switch settings

Input Signal type Switch

AnIn1

AnIn2

AnIn3

AnIn4

Voltage

Current (default)

Voltage

Current (default)

Voltage

Current (default)

Voltage

Current (default)

S1

S1

S2

S2

S3

S3

S4

S4

I

U

I

U

I

U

I

U

I

U

I

U

I

U

I

U

Signals

4.5.1 Cables

The standard control signal connections are suitable for

stranded flexible wire up to 1.5 mm

2.5 mm

2

.

2

and for solid wire up to

NOTE: Scaling and offset of AnIn1 - AnIn4 can be

configured using the software. See menus [512], [515],

[518] and [51B] in section 11.6, page 112.

NOTE: the 2 analogue outputs AnOut 1 and AnOut 2 can

be configured via the software. See menu [530]

section 11.6.3, page 119

Control signals

Fig. 29 Connecting the control signals

NOTE: The screening of control signal cables is

necessary to comply with the immunity levels given in

the EMC Directive (it reduces the noise level).

NOTE: Control cables must be separated from motor and

mains cables.

26 Control Connections Emotron AB 01-3694-01r2

4.5.2 Types of control signals

Always make a distinction between the different types of signals. Because the different types of signals can adversely

affect each other, use a separate cable for each type. This is

often more practical because, for example, the cable from a

pressure sensor may be connected directly to the variable

speed drive.

We can distinguish between the following types of control

signals:

4.5.4 Single-ended or double-ended

connection?

In principle, the same measures applied to motot cables

must be applied to all control signal cables, in accordance

with the EMC-Directives.

For all signal cables as mentioned in section 4.5.2 the best

results are obtained if the screening is connected to both

ends. See Fig. 30.

Analogue inputs

Voltage or current signals, (0-10 V, 0/4-20 mA) normally

used as control signals for speed, torque and PID feedback

signals.

Analogue outputs

Voltage or current signals, (0-10 V, 0/4-20 mA) which

change slowly or only occasionally in value. In general, these

are control or measurement signals.

Digital

Voltage or current signals (0-10 V, 0-24 V, 0/4-20 mA)

which can have only two values (high or low) and only occasionally change in value.

Data

Usually voltage signals (0-5 V, 0-10 V) which change rapidly

and at a high frequency, generally data signals such as

RS232, RS485, Profibus, etc.

Relay

Relay contacts (0-250 VAC) can switch highly inductive

loads (auxiliary relay, lamp, valve, brake, etc.).

Signal

type

Maximum wire size

Tightening

torque

Cable type

NOTE: Each installation must be examined carefully

before applying the proper EMC measurements.

Control board

Pressure

sensor

(example)

External control

(e.g. in metal housing)

Analogue Rigid cable:

Digital Screened

Data Screened

Relay Not screened

0.14-2.5 mm

Flexible cable:

0.14-1.5 mm

Cable with ferrule:

0.25-1.5 mm

2

2

2

0.5 Nm

Screened

Example:

The relay output from a variable speed drive which controls

an auxiliary relay can, at the moment of switching, form a

source of interference (emission) for a measurement signal

from, for example, a pressure sensor. Therefore it is advised

to separate wiring and screening to reduce disturbances.

4.5.3 Screening

For all signal cables the best results are obtained if the

screening is connected to both ends: the VSD side and the at

the source (e.g. PLC, or computer). See Fig. 30.

It is strongly recommended that the signal cables be allowed

to cross mains and motor cables at a 90° angle. Do not let

the signal cable go in parallel with the mains and motor

cable.

Control consol

Fig. 30 Electro Magnetic (EM) screening of control signal

cables.

Emotron AB 01-3694-01r2 Control Connections 27

4.5.5 Current signals ((0)4-20 mA)

A current signal like (0)4-20 mA is less sensitive to disturbances than a 0-10 V signal, because it is connected to an

input which has a lower impedance (250 Ω) than a voltage

signal (20 kΩ). It is therefore strongly advised to use current

control signals if the cables are longer than a few metres.

4.5.6 Twisted cables

Analogue and digital signals are less sensitive to interference

if the cables carrying them are “twisted”. This is certainly to

be recommended if screening cannot be used. By twisting

the wires the exposed areas are minimised. This means that

in the current circuit for any possible High Frequency (HF)

interference fields, no voltage can be induced. For a PLC it

is therefore important that the return wire remains in proximity to the signal wire. It is important that the pair of wires

is fully twisted over 360°.

4.6 Connecting options

The option cards are connected by the optional connectors

X4 or X5 on the control board see Fig. 27, page 23 and

mounted above the control board. The inputs and outputs

of the option cards are connected in the same way as other

control signals.

28 Control Connections Emotron AB 01-3694-01r2

5. Getting Started

This chapter is a step by step guide that will show you the

quickest way to get the motor shaft turning. We will show

you two examples, remote control and manual control.

We assume that the VSD is mounted on a wall or in a cabinet as in the chapter 2. page 9.

First there is general information of how to connect mains,

motor and control cables. The next section describes how to

use the function keys on the control panel. The subsequent

examples covering remote control and manual control

describe how to program/set the motor data and run the

VSD and motor.

5.1 Connect the mains and

motor cables

Dimension the mains and motor cables according to local

regulations. The cable must be able to carry the VSD load

current.

5.1.1 Mains cables

1. Connect the mains cables as in Fig. 31. The VSD has a

built-in RFI mains filter that complies with category C3

which suits the Second Environment standard.

5.2 Connect control cables

Here you will make up the minimum wiring for starting. In

this example the motor/VSD will run with right rotation.

To comply with the EMC standard, use screened control

cables with plaited flexible wire up to 1.5 mm

up to 2.5 mm

2

.

3. Connect a reference value between terminals 7 (Common) and 2 (AnIn 1) as in Fig. 32.

4. Connect an external start button between terminal 11

(+24 VDC) and 9 (DigIn1, RUNR) as inFig. 32.

X1

1

Reference

0-10 V

Start (RunR)

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

2

or solid wire

5.1.2 Motor cables

2. Connect the motor cables as in Fig. 31. To comply with

the EMC Directive you have to use screened cables and

the motor cable screen has to be connected on both

sides: to the housing of the motor and the housing of the

VSD.

DC

L2 L3 PEL1 U V WR

Fig. 31 Connection of mains and motor cables

Table 15 Mains and motor connection

L1,L2,L3

PE

U, V, W

Mains supply, 3 -phase

Safety earth

Motor earth

Motor output, 3-phase

WARNING: In order to work safely the mains

earth must be connected to PE and the motor

earth to .

DC

-

+

Fig. 32 Wiring

X3

X2

41

31

42

32

43

33

51

52

Emotron AB 01-3694-01r2 Getting Started 29

5.3 Using the function keys

PREV

ENTER

NEXT

ESC

ENTER

ENTER

NEXT

ENTER

ESC

NEXT

PREV

NEXT

ENTER

NEXT

ENTER

ENTER

ENTER

RESET

100

Fig. 33 Example of menu navigation when entering motor

voltage

step to lower menu level or confirm changed setting

step to higher menu level or ignore changed setting

step to next menu on the same level

NEXT

step to previous menu on the same level

PREV

increase value or change selection

ENTER

200

210

ENTER

300

220

ESC

221

ENTER

3. Press to display menu [221] and set motor voltage.

ENTER

4. Change the value using the and keys. Confirm

with .

ENTER

5. Set motor frequency [222].

6. Set motor power [223].

7. Set motor current [224].

8. Set motor speed [225].

9. Set power factor (cos ϕ) [227].

10. [229] Motor ID run: Choose Short, confirm with

ENTER

and give start command .

The VSD will now measure some motor parameters.

The motor makes some beeping sounds but does not

rotate. When the ID run is finished after about one

minute ("Test Run OK!" is displayed), press to continue.

11. Use AnIn1 as input for the reference value. The default

range is 4-20 mA. If you need a 0-10 V reference value,

change switch (S1) on control board and set [512] Anln

1 Set-up to 0-10V/4-20mA.

12. Switch off power supply.

13. Connect digital and analogue inputs/outputs as in

Fig. 32.

14. Ready!

15. Switch on power supply.

decrease value or change selection

5.4 Remote control

In this example external signals are used to control the VSD/

motor.

A standard 4-pole motor for 400 V, an external start button

and a reference value will also be used.

5.4.1 Switch on the mains

Close the door to the VSD. Once the mains is switched on,

the internal fan in the VSD will run for 5 seconds.

5.4.2 Set the Motor Data

Enter correct motor data for the connected motor. The

motor data is used in the calculation of complete operational

data in the VSD.

Change settings using the keys on the control panel. For further information about the control panel and menu structure, see the chapter 9. page 53.

Menu [100], Preferred View is displayed when started.

5.4.3 Run the VSD

Now the installation is finished, and you can press the start

button to start the motor.

When the motor is running the main connections are OK.

1. Press to display menu [200], Main Setup.

2. Press and then to display menu [220], Motor

ENTER

Data.

30 Getting Started Emotron AB 01-3694-01r2

5.5 Local control

NEXT

ENTER

ENTER

NEXT

ENTER

NEXT

ENTER

ESC

NEXT

ENTER

ENTER

NEXT

ESC

PREV

NEXT

ENTER

Manual control via the control panel can be used to carry

out a test run.

Use a 400 V motor and the control panel.

5.5.1 Switch on the mains

Close the door to the VSD. Once the mains is switched on,

the VSD is started and the internal fan will run for 5 seconds.

5.5.2 Select manual control

Menu [100], Preferred View is displayed when started.

1. Press to display menu [200], Main Setup.

2. Press to display menu [210], Operation.

3. Press to display menu [211], Language.

ENTER

ENTER

4. Press to display menu [214], Reference Control.

5. Select Keyboard using the key and press to con-

ENTER

firm.

6. Press to get to menu [215], Run/Stop Control.

7. Select Keyboard using the key and press to con-

ENTER

firm.

8. Press to get to previous menu level and then to

ESC

display menu [220], Motor Data.

5.5.3 Set the Motor Data

Enter correct motor data for the connected motor.

9. Press to display menu [221].

10. Change the value using the and keys. Confirm

11. Press to display menu [222].

12. Repeat step 9 and 10 until all motor data is entered.

13. Press twice and then to display menu [100], Pre-

ENTER

with .

ENTER

ESC

ferred View.

5.5.4 Enter a Reference Value

Enter a reference value.

14. Press until menu [300], Process is displayed.

15. Press to display menu [310], Set/View reference

ENTER

value.

16. Use the and keys to enter 300 rpm. We select a

low value to check the rotation direction without damaging the motor.

5.5.5 Run the VSD

Press the key on the control panel to run the motor.

Whe the motor is running the main connections are OK.

Emotron AB 01-3694-01r2 Getting Started 31

32 Getting Started Emotron AB 01-3694-01r2

6. Applications

This chapter contains tables giving an overview of many different applications/duties in which it is suitable to use variable speed drives from Emotron. Further on you will find

6.1 Application overview

6.1.1Pumps

Challenge Emotron FDU solution Menu

High start currents require larger fuses and cables.

Cause stress on equipment and higher energy cost.

Dry-running, cavitation and overheating damage

the pump and cause downtime.

Sludge sticks to impeller when pump has been running at low speed or been stationary for a while.

Reduces the pump’s efficiency.

Motor runs at same speed despite varying

demands in pressure/flow. Energy is lost and

equipment stressed.

Process inefficiency due to e.g. a blocked pipe, a

valve not fully opened or a worn impeller.

Water hammer damages the pump when stopped.

Mechanical stress on pipes, valves, gaskets, seals.

Torque control reduces start current. Same fuses

can be used as those required for the motor.

Pump Curve Protection detects deviation. Sends

warning or activates safety stop.

Automatic pump rinsing function: pump is set to

run at full speed at certain intervals, then return

to normal speed.

PID continuously adapts pressure/flow to the

level required. Sleep function activated when

none is needed.

Pump Curve Protection detects deviation. Warning is sent or safety stop activated.

Smooth linear stops protect the equipment. Eliminates need for costly motorized valves.

application examples of the most common applications and

solutions.

331–336, 351

411–419, 41C– 1C9

362–368, 560, 640

320, 380, 342, 354

411–419, 41C–41C9

331–336

6.1.2 Fans

Challenge Emotron FDU solution Menu

High start currents require larger fuses and cables.

Cause stress on equipment and higher energy cost.

Starting a fan rotating in the wrong direction can be

critical, e.g. a tunnel fan in event of a fire.

Draft causes turned off fan to rotate the wrong way.

Starting causes high current peaks and mechanical

stress.

Regulating pressure/flow with dampers causes

high energy consumption and equipment wear.

Motor runs at same speed despite varying

demands in pressure/flow. Energy is lost and

equipment stressed.

Process inefficiency due to e.g. a blocked filter, a

damper not fully opened or a worn belt.

Torque control reduces start current. Same fuses

can be used as those required for the motor.

Fan is started at low speed to ensure correct

direction and proper function.

Motor is gradually slowed to complete stop before

starting. Avoids blown fuses and breakdown.

Automatic regulation of pressure/flow with motor

speed gives more exact control.

PID continuously adapts to the level required.

Sleep function is activated when none is needed.

Load Curve Protection detects deviation. Warning

is sent or safety stop activated.

331–336, 351

219, 341

219, 33A, 335

321, 354

320, 380, 342, 354

411–419, 41C–41C9

Emotron AB 01-3694-01r2 Applications 33

6.1.3 Compressors

Challenge Emotron FDU solution Menu

High start currents require larger fuses and cables.

Cause stress on equipment and higher energy cost.

Compressor is damaged when cooling media

enters the compressor screw.

Pressure is higher than needed, causing leaks,

stress on the equipment and excessive air use.

Motor runs at same speed when no air is compressed. Energy is lost and equipment stressed.

Process inefficiency and energy wasted due to e.g.

the compressor idling.

6.1.4 Blowers

Challenge Emotron FDU solution Menu

High start currents require larger fuses and cables.

Cause stress on equipment and higher energy cost.

Difficult to compensate for pressure fluctuations.

Wasted energy and risk of production stop.

Motor runs at same speed despite varying

demands. Energy is lost and equipment stressed.

Torque control reduces start current. Same fuses

can be used as those required for the motor.

Overload situation is quickly detected and safety

stop can be activated to avoid breakdown.

Load Curve Protection function detects deviation.

Warning is sent or safety stop activated.

PID continuously adapts to the level required.

Sleep function activated when none is needed.

Load Curve Protection quickly detects deviation.

Warning is sent or safety stop activated.

Torque control reduces start current. Same fuses

can be used as those required for the motor.

PID function continuously adapts pressure to the

level required.

PID continuously adapts air flow to level required.

Sleep function activated when none is needed.

331– 36, 351

411–41A

411–419, 41C–41C9

320, 380, 342, 354

411–419, 41C–41C9

331–336, 351

320, 380

320, 380, 342, 354

Process inefficiency due to e.g. a broken damper, a

valve not fully opened or a worn belt.

Load Curve Protection quickly detects deviation.

Warning is sent or safety stop activated.

411–419 , 41C–41C9

34 Applications Emotron AB 01-3694-01r2

7. Main Features

This chapter contains descriptions of the main features of

the VSD.

7.1 Parameter sets

Parameter sets are used if an application requires different

settings for different modes. For example, a machine can be

used for producing different products and thus requires two

or more maximum speeds and acceleration/deceleration

times. With the four parameter sets different control options

can be configured with respect to quickly changing the

behaviour of the VSD. It is possible to adapt the VSD

online to altered machine behaviour. This is based on the

fact that at any desired moment any one of the four parameter sets can be activated during Run or Stop, via the digital

inputs or the control panel and menu [241].

Each parameter set can be selected externally via a digital

input. Parameter sets can be changed during operation and

stored in the control panel.

NOTE: The only data not included in the parameter set is

Motor data 1-4 (entered separately), language,

communication settings, selected set, local remote, and

keyboard locked.

Select and copy parameter set

The parameter set selection is done in menu [241], Select

Set. First select the main set in menu [241], normally A.

Adjust all settings for the application. Usually most parameters are common and therefore it saves a lot of work by copying set A>B in menu [242]. When parameter set A is

copied to set B you only change the parameters in the set

that need to be changed. Repeat for C and D if used.

With menu [242], Copy Set, it is easy to copy the complete

contents of a single parameter set to another parameter set.

If, for example, the parameter sets are selected via digital

inputs, DigIn 3 is set to Set Ctrl 1 in menu [523] and DigIn

4 is set to Set Ctrl 2 in menu [524], they are activated as in

Table 16.

Table 16 Parameter set

Parameter set Set Ctrl 1 Set Ctrl 2

A00

B10

C01

D11

Define parameter sets

When using parameter sets you first decide how to select different parameter sets. The parameter sets can be selected via

the control panel, via digital inputs or via serial communication. All digital inputs and virtual inputs can be configured

to select parameter set. The function of the digital inputs is

defined in the menu [520].

Fig. 34 shows the way the parameter sets are activated via

any digital input configured to Set Ctrl 1 or Set Ctrl 2.

Parameter Set A

11

10

16

+24 V

Set Ctrl1

Set Ctrl2

Run/Stop

-

Torques

-

Controllers

-

Limits/Prot.

-

-Max Alarm

{

Set B

Set C

Set D

(NG06-F03_1)

NOTE: The selection via the digital inputs is immediately

activated. The new parameter settings will be activated

on-line, also during Run.

NOTE: The default parameter set is parameter set A.

Examples

Different parameter sets can be used to easily change the

setup of an VSD to adapt quickly to different application

requirements. For example when

• a process needs optimized settings in different stages of

the process, to

- increase the process quality

- increase control accuracy

- lower maintenance costs

- increase operator safety

With these settings a large number of options are available.

Some ideas are given here:

Multi frequency selection

Within a single parameter set the 7 preset references can be

selected via the digital inputs. In combination with the

parameter sets, 28 preset references can be selected using all

4 digital inputs: DigIn1, 2 and 3 for selecting preset reference within one parameter set and DigIn 4 and DigIn 5 for

selecting the parameter sets.

Fig. 34 Selecting the parameter sets

Emotron AB 01-3694-01r2 Main Features 35

Bottling machine with 3 different products

Use 3 parameter sets for 3 different Jog reference when the

machine needs to be set up. The 4th parameter set can be

used for “normal” remote control when the machine is running at full production.

Manual - automatic control

If in an application something is filled up manually and then

the level is automatically controlled using PID regulation,

this is solved using one parameter set for the manual control

and one for the automatic control

7.1.1 One motor and one parameter

set

This is the most common application for pumps and fans.

Once default motor M1 and parameter set A have been

selected:

1. Enter the settings for motor data.

2. Enter the settings for other parameters e.g. inputs and

outputs

7.1.2 One motor and two parameter

sets

This application is useful if you for example have a machine

running at two different speeds for different products.

Once default motor M1 is selected:

5. Select M2 in menu [212].

6. Enter motor data and settings for other parameters e.g.

inputs and outputs.

7.1 . 4 Autores et at tri p

For several non-critical application-related failure conditions, it is possible to automatically generate a reset command to overcome the fault condition. The selection can be

made in menu [250]. In this menu the maximum number of

automatically generated restarts allowed can be set, see menu

[251], after this the VSD will stay in fault condition because

external assistance is required.

Example

The motor is protected by an internal protection for thermal

overload. When this protection is activated, the VSD should

wait until the motor is cooled down enough before resuming

normal operation. When this problem occurs three times in

a short period of time, external assistance is required.

The following settings should be applied:

• Insert maximum number of restarts; set menu [251] to

3.

•Activate Motor I

[25A] to 300 s.

• Set relay 1, menu [551] to AutoRst Trip; a signal will be

available when the maximum number of restarts is