Page 1

Documentation Version 1.2.6Documentation Version 1.2.6

USER’S GUIDE

Documentation version 1.2.6

Page 2

2

INTRODUCTION

Documentation Version 1.2.6

INTRODUCTION

Page 3

Documentation Version 1.2.6Documentation Version 1.2.6

/ 3

INTRODUCTION

INTRODUCTION

• Objective:

Provide a visual guide of the dierent steps to set-up and get

started using the MicroDelta Rework 3D printer.

• Authors of this document :

eMotion Tech – http://www.emotion-tech.com

Hugo FLYE

Anthony BERNA

• Photographics credits :

Pictures and 3D representations made by eMotion Tech :

http://www.emotion-tech.com

• Sources :

http://reprap.org/wiki/RepRap

http://www.repetier.com/

• Licence :

MicroDelta Rework : CC BY-NC-SA 4.0

is document : CC BY-NC-SA 4.0

http://creativecommons.org/licenses/by-nc-sa/4.0/

• Update:

Last update : 09/10/2017

• Links :

You can nd more informations on the following links :

eMotion Tech’s website : http://www.emotion-tech.com

RepRap community : http://reprap.org/wiki/reprap

RepRap

Page 4

4

INTRODUCTION

Documentation Version 1.2.6

SUMMARY

INTRODUCTION 2

SUMMARY 4

SOFTWARE INSTALLATION 5

A. Software installation on Mac OS 6

PREPARATION 7

A. Files to copy on the TF card 8

B. Connecting your printer to Repetier-Host 9

C. Printer’s settings 11

D. Slicing settings 13

E. Motion test 15

F. Heating test 16

G. Charging lament 17

H. Extrusion test 18

I. Calibration process using command lines 19

PRINTING 22

A. Spool Holder Print 23

APPENDIX 27

Mounting of the spool holder 28

Spring lament pressure adjustment 30

Printing a 3D model 33

PID calculation 36

To go further 37

Maintenance 38

Recommandations 38

Restore the TF card 39

Page 5

Documentation Version 1.2.6Documentation Version 1.2.6

/ 5

SOFTWARE INSTALLATION

SOFTWARE

INSTALLATION

Page 6

6

SOFTWARE INSTALLATION

Documentation Version 1.2.6

Soware installation on Mac OS

Objective : Install the necessary soware to use the MicroDelta Rework on a Mac operating system computer.

1°) Dowload the latest version of Repetier-Host from the support section of eMotion Tech’s website (www.emotion-tech.com).

Support / MicroDelta Rework / Soware / Mac /

2°) Find all the necessary informations for the installation on the following link :

https://www.repetier.com/documentation/repetier-host-mac/installation-and-connection/

Note: the version of Repetier for Mac OS X is less developed than those on Windows / Linux. erefore the use of a virtual machine is advised to take

advantage of the latest updates and added options. However, we will guide you through this documentation for the installation of the ocial version

of Repetier for Mac OS X.

Page 7

Documentation Version 1.2.6Documentation Version 1.2.6

/ 7

PREPARATION

PREPARATION

Page 8

8

PREPARATION

Documentation Version 1.2.6

Files to copy on the TF card

1°) Go to the eMotion Tech’s website support section, then go to «MicroDelta Rework / Soware / Conguration» and download the corresponding conguration les to your MicroDelta Rework depending on it’s version and options.

2°) Connect your printer to the computer

3°) Once downloaded, unzip the le and copy all its content in the eMotronic’s TF card.

Objective : copy the required les in the eMotronic’s TF card.

Note: TF card is usually automatically detected and its content displayed once you connect your 3D printer to you computer. e

TF card generally appears as drive «NO NAME» but this can vary depending on your hardware.

4°) Press the «Reset» button on the 3D printer (located on one side of the lower plate).

Mac OS X : what you should have on the TF card aer this step

5°) Check that the device has been properly recognized by your operation system.

Page 9

Documentation Version 1.2.6Documentation Version 1.2.6

/ 9

PREPARATION

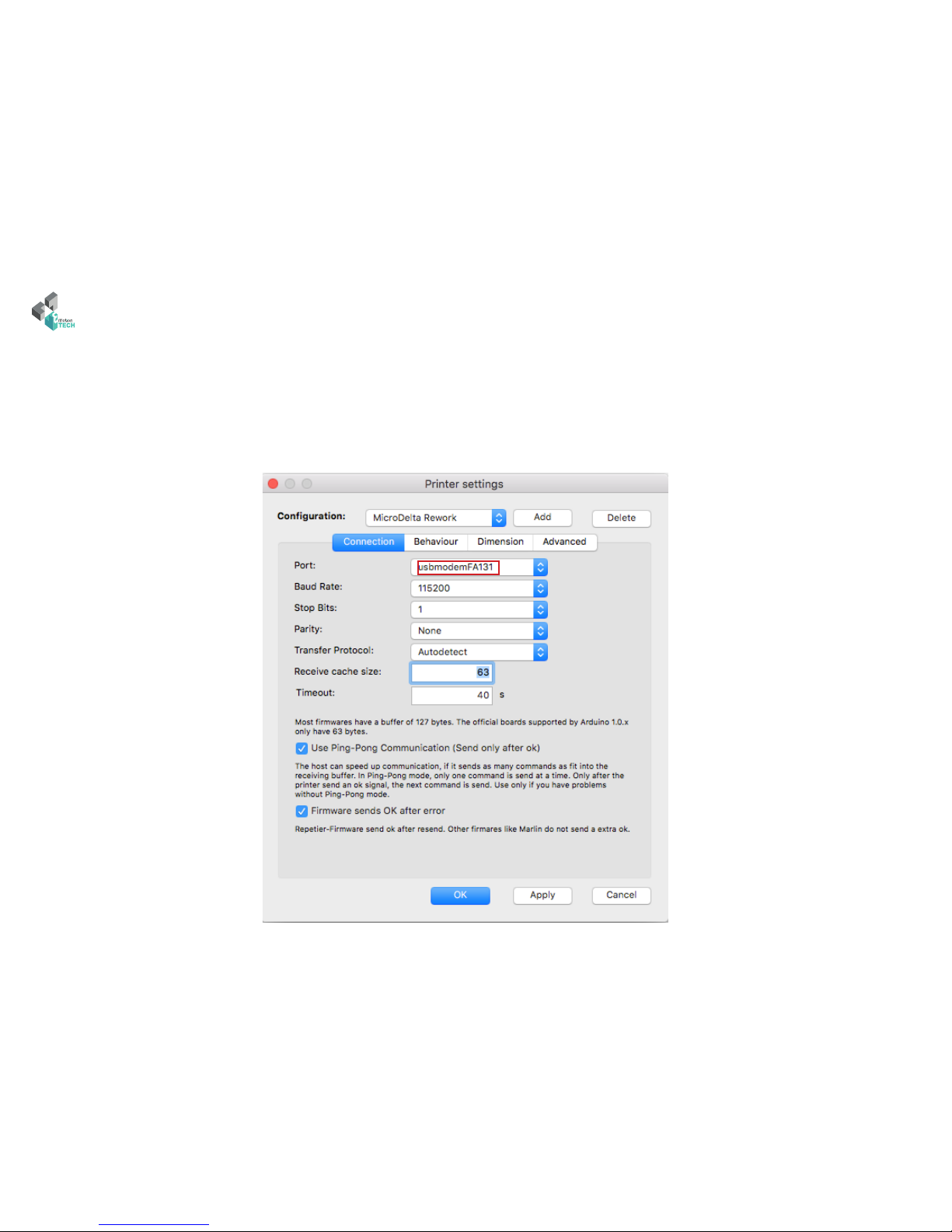

Connecting your printer to Repetier-Host

1°) Run Repetier-Host soware.

2°) Go to «Cong» then «Printer Settings».

3°) Check that all the parameters correspond to those on the image below. Select the COM port assigned to your MicroDelta Rework.

Page 10

10

PREPARATION

Documentation Version 1.2.6

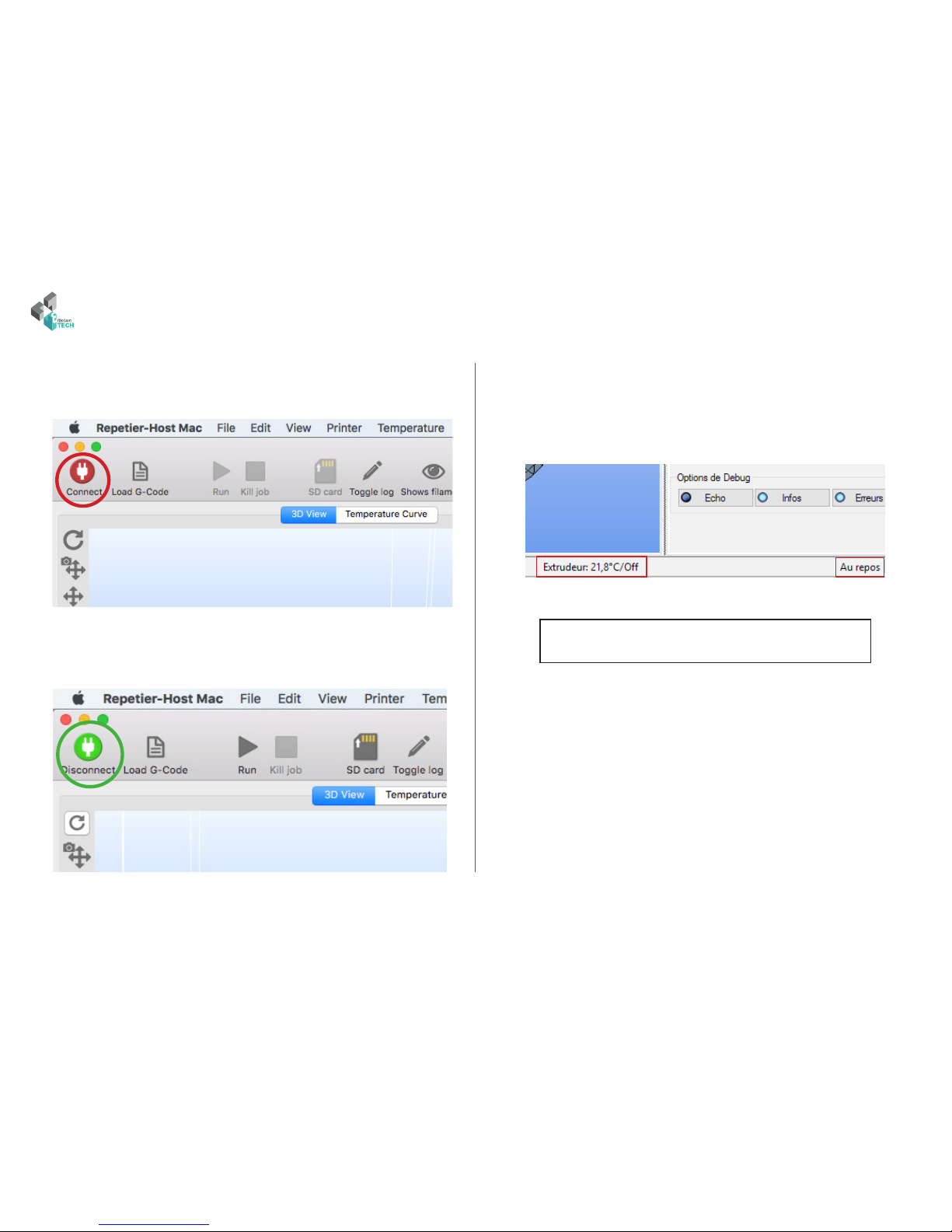

4°) Click on Connect.

is one should change color, becomes green when connected :

5°) Check on the bottom of the screen that the extruder’s temperature

is consistent (logical value) and the printer’s status is «Idle» as shown

below:

If you have a Heated Bed, its temperature will be displayed

next to the extruder’s.

Page 11

Documentation Version 1.2.6Documentation Version 1.2.6

/ 11

PREPARATION

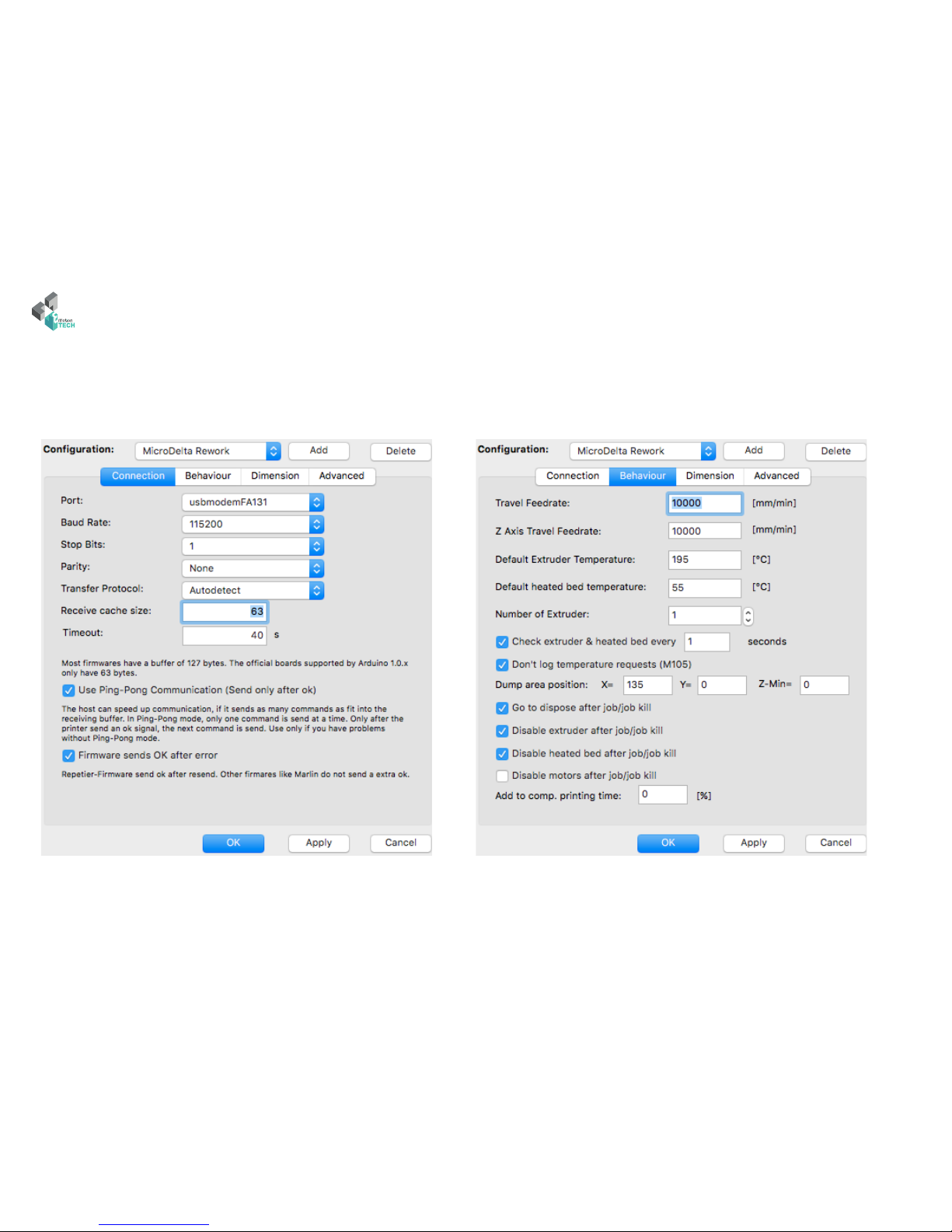

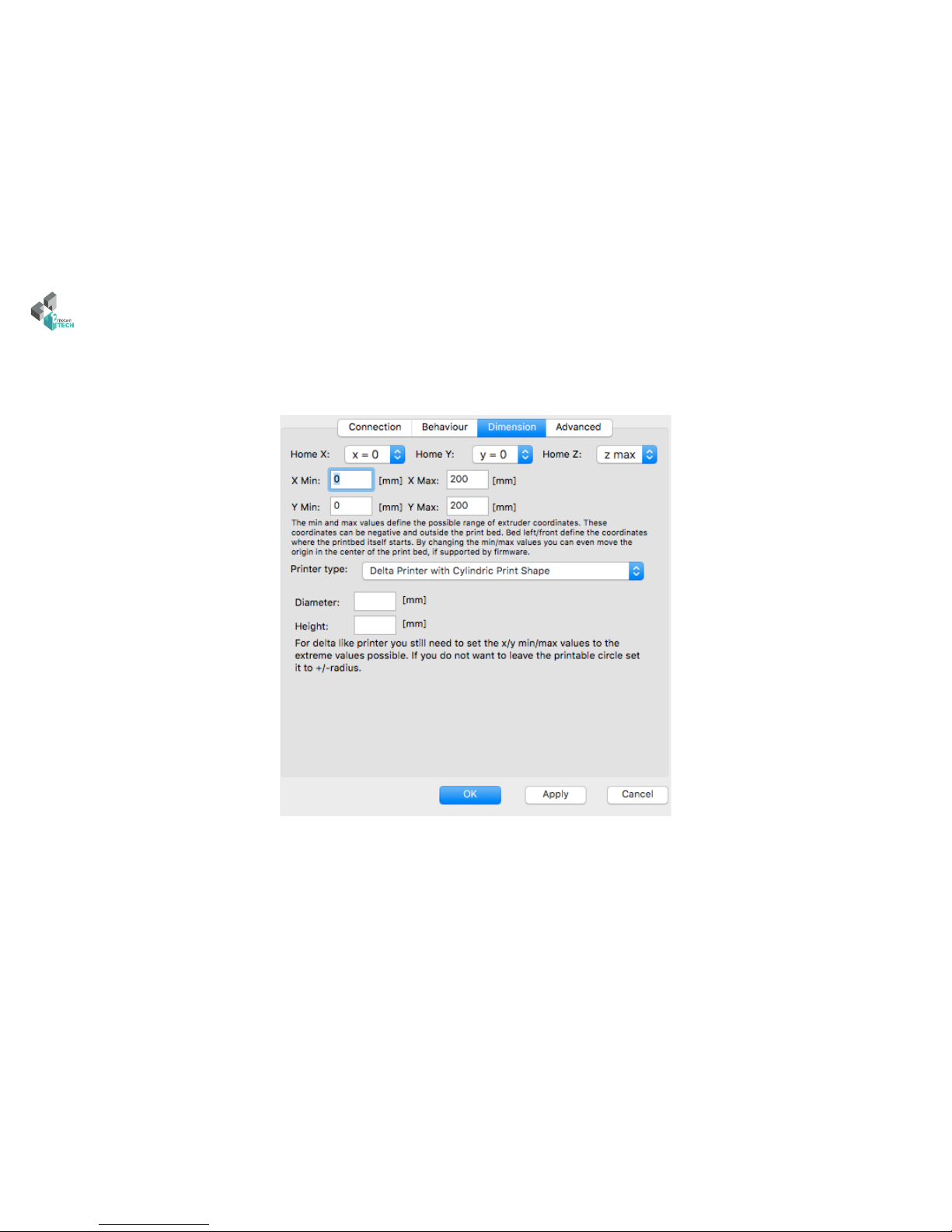

Printer’s Settings

A manual set-up of the printer is required. Please follow the following steps:

Page 12

12

PREPARATION

Documentation Version 1.2.6

220

150

Page 13

Documentation Version 1.2.6Documentation Version 1.2.6

/ 13

PREPARATION

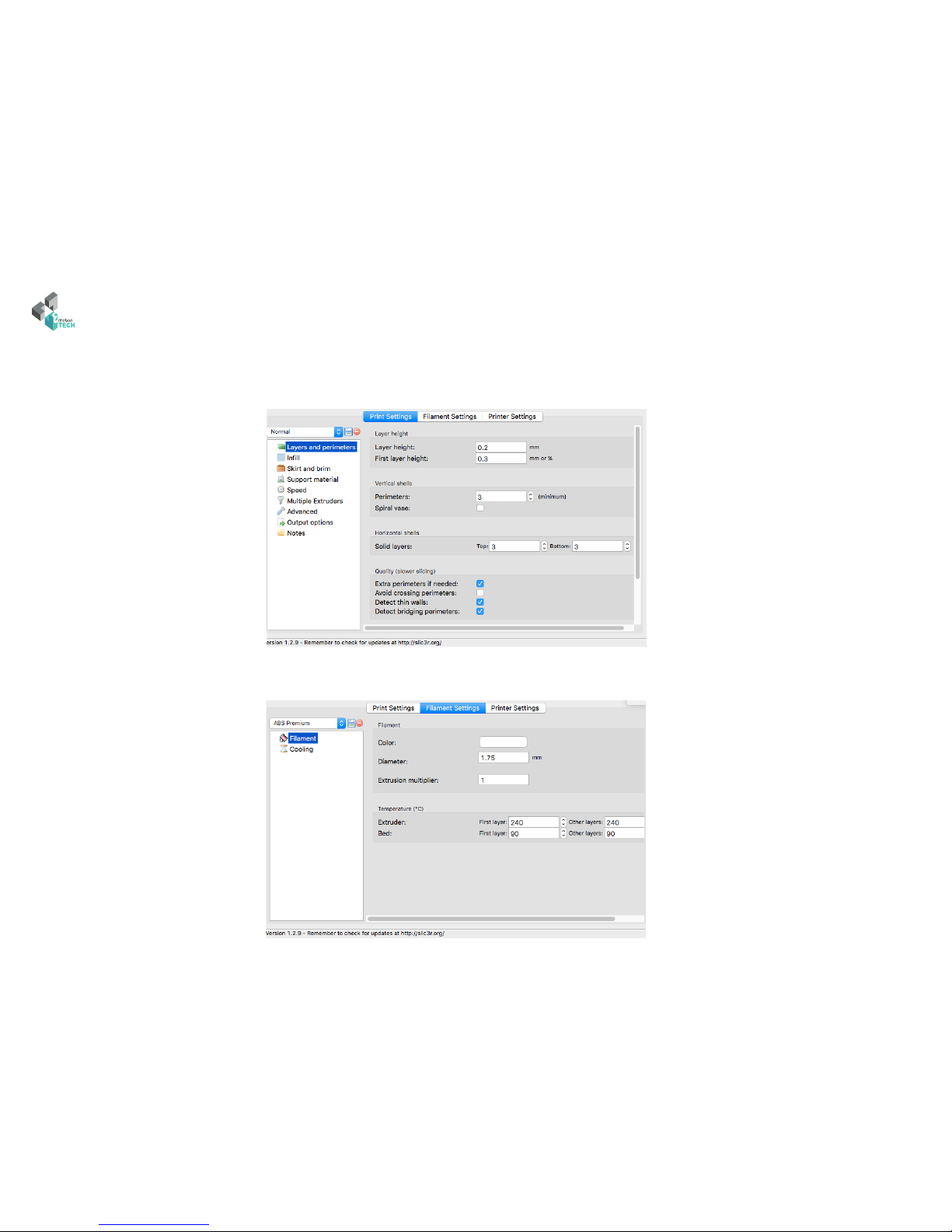

Slicing Settings

Go to the slicer tab, and click on the «Conguration» button.

Make sure to modify you Slic3r conguration values in respect with the following gures.

Save

Page 14

14

PREPARATION

Documentation Version 1.2.6

Save

Save

Page 15

Documentation Version 1.2.6Documentation Version 1.2.6

/ 15

PREPARATION

Motion test

1°) Go to the «Print Panel» tab and click on the «Home All» (is should

initialize your printer = move all axes to origin).

2°) Make sure that EVERY slider moves up till hitting its coresponding endstop.

Keep a nger on the «Reset» button in case of a malfunction.

Page 16

16

PREPARATION

Documentation Version 1.2.6

Heating Test

1°) Go to «Print Panel» tab, click on «Heat on» (Extruder heater activation) as shown below:

2°) Check that the target temperature is reached :

195

If the target temperature is not reached or the actual temperature varies

greatly around the target temperature, perform a PID calculation (see

appendix).

Page 17

Documentation Version 1.2.6Documentation Version 1.2.6

/ 17

PREPARATION

Charging lament

2°) Disengage the extruder

Disengage by pushing

here

3°) Insert the lament in the extruder’s inlet and

push it as far as possible

inlet

4°) If you encounter a hard point while inserting the lament,

engage the extruder and turn the drive wheel until the lament

gets to the nozzle, melted lament should start coming out

Drive

wheel

Filament tip

Filament

1°) Cut the tip of the lament with a certain angle

to make its insertion in the extruder easier

5°) Tighten the spring strongly by turning the knurled screw.

Note: if the knurled screw is not tight enough, the lament will be badly driven

Knurled screw

Page 18

18

PREPARATION

Documentation Version 1.2.6

Extrusion test

1°) In the «Print panel» tab, perform a extrusion of 50mm.

If this is not the case, adjust accordingly the tension exerted on the lament

from extruder, and this by turning the Knurled Screw of the extruder.

2°) Verify that melted lament comes out of the nozzle regularly.

195

195

50

Page 19

Documentation Version 1.2.6Documentation Version 1.2.6

/ 19

PREPARATION

Calibration process using command lines

On mac OS computers the calibration processs must be done using Gcode commands, here’s how to do this:

1°) Make sure the printhead is at room temperature.

2°) Mount the calibration module on the printer’s core and plug the jack

connector on the eMotronic board

4°) Start the calibration using G32 command, it wil probe 3 points of the bed.

3°) Go to «Print Panel» tab. Home or initialize your printer using the G28

command.

G28

G32

Page 20

20

PREPARATION

Documentation Version 1.2.6

5°) When done, start the full bed calibration using G31 command, this

will probe multiple points of the bed to optimize the rst calibration. is

is known as grid compensation strategy.

6°) When done, save the grid values using M374 command.

7°) Remove and unplug the calibration module.

Maximum Z height

8°) Home or initialize your printer

G31

M374

Homing

Page 21

Documentation Version 1.2.6Documentation Version 1.2.6

/ 21

PREPARATION

10°) Move the printhead down using the commands shown below in the manual control tab.

Once the printhead is close enough from the paper, move the printhead down

slowly by jogging down of 0,1mm at a time, repeat until the printhead touches

the paper and holds it from moving.

M500

9°) Place a paper on the bed

11°) Set the maximum Z height using the M306 Z0 command

12°) Save using M500

e calibration process is meant to be done once and not

before every print. In some cases, the calibration could

become unaccurate, aer disassembling and reassembling

structural parts of you printer per example, you should

then calibrate again your printer.

Calibration may not be performed correctly. Usually, this

comes from the fact that it resides some mechanicals plays

on the machine. In this case, it will then be necessary to

review the mounting of the printer so as to ensure that eve-

rything is tight and without play (smooth rods, ball joints,

belts, pulleys, etc.).

In case of troubles during the calibration process :

Page 22

22

PREPARATION

Documentation Version 1.2.6

Objective : rene the height adjustment of the nozzle relative to the heatbed.

Description : if the material hangs too much or not hangs well enough to the 3dBedFix coating, you may need to adjust the nozzle height.

In the case the material doesn’t hang well to the coating, please send the following GCODE command lines in the dedicated input eld of the «Manual

Control» tab :

G1 Z0

M306 Z0.1

M500

In the case where the material hangs too much to the coating and is dicult to unhook :

G1 Z0.1

M306 Z0

M500

In both cases, the value «0.1» can be changed as necessary.

You will then be able to launch an impression and check the following points of details :

- material that does not hangs well to the 3dBedFix = nozzle too far from the 3dBedFix (adjust height)

- material that hangs too much on the 3dBedFix = nozzle too close to the coating (adjust height)

Precise adjustment of the maximum height

Input eld for sending GCODE command

Send

Page 23

Documentation Version 1.2.6Documentation Version 1.2.6

/ 23

PRINTING

PRINTING

Page 24

24

PRINTING

Documentation Version 1.2.6

Spool Holder print

1°) Load the Gcode called «spool_holder.gcode» from the TF card.

You are about to start your rst print.

You will be print the spool holder, which will be mounted on the top plate of the MicroDelta Rework.

Page 25

Documentation Version 1.2.6Documentation Version 1.2.6

/ 25

PRINTING

2°) Click on «Run» to start the print.

Print will begin, your printer will initialize (homing) and start heating the extruder and eventualy the Heat bed.

Page 26

26

PRINTING

Documentation Version 1.2.6

CONGRATULATIONS !

You successfully printed your rst

object !

Go to the «Appendix» to nd explanations about mounting the

spool holder.

Page 27

Documentation Version 1.2.6Documentation Version 1.2.6

/ 27

Appendix

Appendix

Page 28

28

Appendix

Documentation Version 1.2.6

M3x8mm screw

Objective : mount the spool holder on the top plate

Thrust bearing

Printed spool holder part

Mounting of the spool holder

Page 29

Documentation Version 1.2.6Documentation Version 1.2.6

/ 29

Appendix

Result

Page 30

30

Appendix

Documentation Version 1.2.6

1°) Relieve the spring pressure completely by unscrewing the horizontal knurled screw of the eMostruder

2°) In the Repetier-Host soware, with the 3D printer connected and turned on, from the «Manual control» tab, ask for a target temperature dedi-

cated to the used lament and wait until it is reached.

3°) If some lament is already engaged in the machine, remove it and cut it o to an healthy base not marked by the driving wheel.

(with the end of the new lament bevelled in the winding direction of the spool or sample provided)

Spring lament pressure adjustment (eMostruder)

Objective : adjust the pressure exerted by the spring on the lament so that the drive is optimal and does not cause abnormalities.

Description : depending on the type of lament used (PLA, G-FIL, ABS, etc.) and especially its hardness, it will be necessary to adjust the spring

pressure so that the driving wheel does not mark the lament too much and does not block in its passage to the nozzle. is method ensures that

the lament drive is operational while exerting pressure on the lament as low as possible.

195

Page 31

Documentation Version 1.2.6Documentation Version 1.2.6

/ 31

Appendix

4°) Engage the new unmarked lament to the nozzle.

5°) Always in the «Manual Control» tab of Repetier-Host, ask for one or more slow extrusions of 100 mm.

6°) At the same time, observe the lament coming out of the nozzle and check that the extrusion is continuous and homogeneous at a speed corresponding to

the speed of the driving wheel.

Click the button to extrude

100

Page 32

32

Appendix

Documentation Version 1.2.6

7°) If the lament does not come out of the nozzle: tighten the screw a little more until it is homogeneous.

Page 33

Documentation Version 1.2.6Documentation Version 1.2.6

/ 33

Appendix

Printing a 3D model

2°) Import your model on Repetier-Host :

• In the «Object placement» tab, click on «Add STL le»

• Select your desired 3D model le and open

1°) Download a 3D part, we suggest you the eMotion Tech’s keyring :

https://data.emotion-tech.com/p/Ressources_3D_eMotion_Tech/Porte_clef_eMotion-Tech.stl

Virtual representation

of the objet on the print

surface

List of the objects your added

Prerequisite : Fully calibrated 3D printer

Page 34

34

Appendix

Documentation Version 1.2.6

2°) You can edit your object with many options :

3°) Slice your object with the pre-congured Slic3r prole :

• In the «Slicer» tab, select «Slice with Slic3r».

When done click on «Slice with CuraEngine»

Page 35

Documentation Version 1.2.6Documentation Version 1.2.6

/ 35

Appendix

4°) When slicing is done, a virtualization of the printed object is generated, only one thing le is to click on «Print» button.

Page 36

36

Appendix

Documentation Version 1.2.6

To go further

On regular basis updates for your MicroDelta Rework are uploaded on our website. You can nd them in the «Support» section of

the site, under «MicroDelta Rework / improvements.»

Do not hesitate to regularly check that folder to keep your printer up-to-date.

PID calculation

By GCODE commands :

1°) Make sure the print head temperature is at room temperature.

2°) Disable the secondary fans.

3°) In the «Manual control» tab, use the input eld for sending GCODE commands :

Send the following command : M303 E0 S250 C8

Details :

• E0 = extruder number 1

• S250 = target temperature at 250°C

• C8 = 8 cycles of regulations around the target temperature

Once the command is sent, Repetier-Host logs will show you the progress of the calculation.

When the calculation is nished, the new values P, I and D are indicated in the logs.

4°) Send the following GCODE command to save : M500

If you have the LCD screen :

In the menu of the screen is integrated an option to directly calculate the PID.

Just go to the «Calibrate / PID hotend» menu.

Preamble : e PID values are necessary for the temperature control of the heating elements. If you nd that the target temperature is

di cult to reach or the actual temperature varies a lot around the target temperature, it may be useful to recalculate the PID values.

Page 37

Documentation Version 1.2.6Documentation Version 1.2.6

/ 37

Appendix

PID calculation

By GCODE commands :

1°) Make sure the print head temperature is at room temperature.

2°) Disable the secondary fans.

3°) In the «Manual control» tab, use the input eld for sending GCODE commands :

Send the following command : M303 E0 S250 C8

Details :

• E0 = extruder number 1

• S250 = target temperature at 250°C

• C8 = 8 cycles of regulations around the target temperature

Once the command is sent, Repetier-Host logs will show you the progress of the calculation.

When the calculation is nished, the new values P, I and D are indicated in the logs.

4°) Send the following GCODE command to save : M500

If you have the LCD screen :

In the menu of the screen is integrated an option to directly calculate the PID.

Just go to the «Calibrate / PID hotend» menu.

Preamble : e PID values are necessary for the temperature control of the heating elements. If you nd that the target temperature is

di cult to reach or the actual temperature varies a lot around the target temperature, it may be useful to recalculate the PID values.

Page 38

38

Appendix

Documentation Version 1.2.6

Maintenance

A monthly maintenance of the 3D printer is recommended.

Below are some recommendations:

Using a brush, dedust the following:

• Emotronic board

• All the fans to ensure a good airow

• Cold part of the printhead

- To clean the printhead follow the guide dedicated to the Hexagon hotend on the following link:

http://data.emotion-tech.com/highlights_fr/Hexagon%20-%20Notice%20montage-debouchage.pdf

- Clean the teeth of the drive wheel using a sharp ended tool like a needle tip, the end of tweezers or a cutter blade.

- Check & tighten the screws of the 3D printer.

- Lubricate the various mechanical transmission elements with multipurpose grease.

Recommandations

Turning o your 3D printer :

After printing, if you want to turn o the machine, wait until the print head cools down to room temperature to

ensure that the print head doesnt get clugged.

Transport :

If the printer has to be transported by car or another mean of transport in which it could be subject to vibration, it is

recommended to unplug all the motors from the eMotronic board to avoid damaging it.

Troubleshooting :

A FAQ on the MicroDelta Rework is available on our website in the «Support» section, please refer to it

to troubleshoot your printer, most problems could be solved through this tool !

Page 39

Documentation Version 1.2.6Documentation Version 1.2.6

/ 39

Appendix

Restore the TF card

1°) Remove the TF card by pressing it, you will hear a click indicating that the card is no longer locked and can be removed without damage to

the reader.

Objective : prepare the les of the TF card again in order to eliminate the corrupted les and defective cells.

Description : for various reasons, the les present in the TF card and / or the cells of this card can be damaged. You will nd through this proce-

dure how to restore the TF card and the necessary les to MicroDelta Rework.

Press to eject and pull

2°) en read this TF card with an external drive on your computer (very useful because the formatting is too long by USB cable).

3°) Perform a formatting of the TF card in MS-DOS FAT format using the tool named «Disk Utility».

Select the Micro TF card

Make sure that options are

congured as shown

Click the «Erase» button

Click on «Erase»

Page 40

40

Appendix

Documentation Version 1.2.6

4°) Download the latest rmware on our website «reprap-3d-printer.com» in the support section, in the tree dedicated to your machine.

Firmware for heating bed with or without LCD

Firmware without heating bed with or without LCD

5°) Go inside the rmware folder, select all the les and nally copy them to the root of the TF card.

6°) Eject the TF card (right click on the TF card then «Eject»).

7°) Disconnect the Micro TF card reader from the computer.

Click here

Page 41

Documentation Version 1.2.6Documentation Version 1.2.6

/ 41

Appendix

9°) Insert the TF card into the eMotronic drive.

Press to the click

(the card is locked)

10°) Press the «Reset» button located on the lower metal part to take into account the new rmware.

11°) In the TF card, make sure that the «rmware.bin» le is changed to «rmware.cur».

12°) On the eMotronic board, between the USB connector and the auto-leveling sensor connector, make sure that:

- LED1 remains on

- LED2 and LED3 ash continuously

- LED4 remains on

LED1

LED2

LED3

LED4

LEDs

From there, the eMotronic card should be recognized by the Device Manager and the contents of the TF card should be displayed in the Files Explorer. It will then only remain to realize again the calibration of the 3D printer.

Page 42

42

Appendix

Documentation Version 1.2.6

Thank you for choosing us!

www.emotion-tech.com

Loading...

Loading...