Page 1

Multi

Multi----Mon

MultiMulti

Mon

MonMon

Multiple Circuit Energy Monitor

Installation and Operation Manual

BG0547 Rev. A1

Page 2

LIMITED WARRANTY

The manufacturer offers the customer a 24-month functional warranty on the instrument for

faulty workmanship or parts from date of dispatch from the distributor. In all cases, this

warranty is valid for 36 months from the date of production. This warranty is on a return to

factory basis.

This warranty is only applicable to Multi-Mon instruments using Multi-Mon current

transformers.

The manufacturer does not accept liability for any damage caused by instrument

malfunction. The manufacturer accepts no responsibility for the suitability of the instrument

to the application for which it was purchased.

Failure to install, set up or operate the instrument according to the instructions herein will

void the warranty.

Only a duly authorized representative of the manufacturer may open your instrument. The

unit should only be opened in a fully anti-static environment. Failure to do so may damage

the electronic components and will void the warranty.

The greatest care has been taken to manufacture and calibrate your instrument. However,

these instructions do not cover all possible contingencies that may arise during installation,

operation or maintenance, and all details and variations of this equipment are not covered

by these instructions.

For additional information regarding installation, operation or maintenance of this

instrument, contact the manufacturer or your local representative or distributor.

WARNING

WARNING

WARNINGWARNING

Read the instructions in this manual before performing installation and take note of the

Read the instructions in this manual before performing installation and take note of the

Read the instructions in this manual before performing installation and take note of the Read the instructions in this manual before performing installation and take note of the

following precautions:

following precautions:

following precautions:following precautions:

Mult

Multiiii----Mon

Mon is intended for measurements performed in building installations, relating to

MultMult

measurement category III (UL61010

measurement category III (UL61010----1, 6.7.

measurement category III (UL61010measurement category III (UL61010

Ensure that all incoming AC power

Ensure that all incoming AC power and other power source

Ensure that all incoming AC powerEnsure that all incoming AC power

performing any work on the instrument. Failure to do so may result in serious or even

performing any work on the instrument. Failure to do so may result in serious or even

performing any work on the instrument. Failure to do so may result in serious or even performing any work on the instrument. Failure to do so may result in serious or even

fatal injury and/or equipment damage.

fatal injury and/or equipment damage.

fatal injury and/or equipment damage. fatal injury and/or equipment damage.

Before

Before connectin

BeforeBefore

the instrument to ensure that your instrument is equipped with the appropriate rating

the instrument to ensure that your instrument is equipped with the appropriate rating

the instrument to ensure that your instrument is equipped with the appropriate rating the instrument to ensure that your instrument is equipped with the appropriate rating

input voltages and currents.

input voltages and currents.

input voltages and currents.input voltages and currents.

Under

Under no circumstances should the instr

UnderUnder

if it is damaged.

if it is damaged.

if it is damaged.if it is damaged.

To prevent

To prevent potential fire or shock haz ard, do not expose the

To prevent To prevent

moisture.

moisture.

moisture.moisture.

While installing

While installing Multi

While installing While installing

transformer

transformer, the external current transformer secondary output

transformertransformer

to

to be

toto

voltages, possibly resulting in equipment damage, fire and even

voltages, possibly resulting in equipment damage, fire and even serious or fatal inj

voltages, possibly resulting in equipment damage, fire and even voltages, possibly resulting in equipment damage, fire and even

Ensure that the current transformer wiring is secured using an external strain relief to

Ensure that the current transformer wiring is secured using an external strain relief to

Ensure that the current transformer wiring is secured using an external strain relief to Ensure that the current transformer wiring is secured using an external strain relief to

reduce mechanical strain on the screw terminals

reduce mechanical strain on the screw terminals, if necessary.

reduce mechanical strain on the screw terminalsreduce mechanical strain on the screw terminals

Only qualified personnel familiar with the instrument and its associated electrical

Only qualified personnel familiar with the instrument and its associated electrical

Only qualified personnel familiar with the instrument and its associated electricalOnly qualified personnel familiar with the instrument and its associated electrical

equipment must perform setup procedures

equipment must perform setup procedures.

equipment must perform setup proceduresequipment must perform setup procedures

Do not open the instrument under any circumstances when it is

Do not open the instrument under any circumstances when it is connected to a

Do not open the instrument under any circumstances when it isDo not open the instrument under any circumstances when it is

power

power source

powerpower

Do not use the instrument for primary protection functions where failure of the device

Do not use the instrument for primary protection functions where failure of the device

Do not use the instrument for primary protection functions where failure of the device Do not use the instrument for primary protection functions where failure of the device

can c

can cause fire, injury or death. The instrument can only be used for secondary

can ccan c

protection if needed.

protection if needed.

protection if needed. protection if needed.

Read this manual thoroughly before connecting the device to the current carrying circuits.

Read this manual thoroughly before connecting the device to the current carrying circuits.

Read this manual thoroughly before connecting the device to the current carrying circuits. Read this manual thoroughly before connecting the device to the current carrying circuits.

During operation of the device, hazardous voltages are present on in

During operation of the device, hazardous voltages are present on input terminals

During operation of the device, hazardous voltages are present on inDuring operation of the device, hazardous voltages are present on in

to observe precautions can result in serious or even fatal injury or damage to equipment.

to observe precautions can result in serious or even fatal injury or damage to equipment.

to observe precautions can result in serious or even fatal injury or damage to equipment.to observe precautions can result in serious or even fatal injury or damage to equipment.

is intended for measurements performed in building installations, relating to

MonMon

is intended for measurements performed in building installations, relating to is intended for measurements performed in building installations, relating to

connecting the instrument to the power

connectinconnectin

no circumstances should the instr ument be connected to

no circumstances should the instrno circumstances should the instr

be open circuit when the primary is energized. An open circuit can cause high

open circuit when the primary is energized. An open circuit can cause high

bebe

open circuit when the primary is energized. An open circuit can cause high open circuit when the primary is energized. An open circuit can cause high

source....

source source

ause fire, injury or death. The instrument can only be used for secondary

ause fire, injury or death. The instrument can only be used for secondary ause fire, injury or death. The instrument can only be used for secondary

g the instrument to the power source

g the instrument to the powerg the instrument to the power

potential fire or shock hazard, do not expose the instrument to

potential fire or shock hazard, do not expose thepotential fire or shock hazard, do not expose the

Multi----Mon CTs

Mon CTs to the

MultiMulti

, the external current transformer secondary output must never be

, the external current transformer secondary output , the external current transformer secondary output

Mon CTsMon CTs

1, 6.7.4).

4).

1, 6.7.1, 6.7.

4).4).

and other power sources are turned OFF before

and other power source and other power source

source, check the labels at the front of

source source

ument be conn ected to a p ower

ument be conn ected toument be conn ected to

to the secondary

secondary of an external

to the to the

secondary secondary

of an external third party

of an external of an external

, if necessary.

, if necessary., if necessary.

s are turned OFF before

s are turned OFF before s are turned OFF before

, check the labels at the front of

, check the labels at the front of , check the labels at the front of

a power source

a powera power

instrument to rain or

instrument toinstrument to

third party cu

third party third party

must never be allowed

must never bemust never be

serious or fatal injury

serious or fatal injserious or fatal inj

connected to a

connected to a connected to a

put terminals. Failure

put terminalsput terminals

current

rrent

cucu

rrent rrent

allowed

allowed allowed

. Failure

. Failure . Failure

source

sourcesource

rain or

rain or rain or

ury.

uryury

.

. .

All trademarks are property of their respective owners.

August 2013

2

Multi-Mon Multiple Circuit Energy Monitor

Page 3

Table of Contents

Table of Contents

Table of ContentsTable of Contents

Chapter 1

Chapter 1 General Information

Chapter 1Chapter 1

Labeling

Labeling ............................................................................................................... 8

LabelingLabeling

Chapter 2

Chapter 2 Installation

Chapter 2Chapter 2

Mechanical Installation

Mechanical Installation ........................................................................................ 9

Mechanical InstallationMechanical Installation

Electrical Installation

Electrical Installation .......................................................................................... 12

Electrical InstallationElectrical Installation

Communications

Communications ................................................................................................ 16

CommunicationsCommunications

RS-485 Connection.................................................................................................... 16

RS232 Connection..................................................................................................... 18

Modem Connection....................................................................................................18

Ethernet Connection .................................................................................................. 19

Controls and Indicators

Controls and Indicators...................................................................................... 20

Controls and IndicatorsControls and Indicators

Indicator LEDs ........................................................................................................... 20

Energy Pulse LED......................................................................................................20

Front Panel Display.................................................................................................... 20

Device Settings

Device Settings.................................................................................................. 21

Device SettingsDevice Settings

Password .................................................................................................................. 21

Submeter System ...................................................................................................... 21

Submeter Addressing................................................................................................. 21

Basic Device Settings ................................................................................................ 22

Energy/TOU System .................................................................................................. 22

Device Diagnostics

Device Diagnostics ............................................................................................ 22

Device DiagnosticsDevice Diagnostics

General Information............................................................ 7

General InformationGeneral Information

Installation .......................................................................... 9

InstallationInstallation

Chapter 3

Chapter 3 Multi

Chapter 3Chapter 3

Startup Diagnostics

Startup Diagnostics............................................................................................ 23

Startup DiagnosticsStartup Diagnostics

Display Features

Display Features................................................................................................ 23

Display FeaturesDisplay Features

Submeter Displays..................................................................................................... 23

Display Update .......................................................................................................... 23

Auto Return ...............................................................................................................23

Auto Scroll................................................................................................................. 23

Backlight....................................................................................................................23

Navigation Buttons

Navigation Buttons............................................................................................. 23

Navigation ButtonsNavigation Buttons

Display Views

Display Views .................................................................................................... 24

Display ViewsDisplay Views

Navigating in Menus

Navigating in Menus .......................................................................................... 28

Navigating in MenusNavigating in Menus

Entering Numbers......................................................................................................28

Entering a Password .................................................................................................. 28

Selecting Menus ........................................................................................................ 28

Viewing and Changing Setup Items ............................................................................ 29

Menu Operations

Menu Operations ............................................................................................... 29

Menu OperationsMenu Operations

Submeter Channel Assignments................................................................................. 29

Reset ........................................................................................................................30

Real Time Clock Setting............................................................................................. 31

Basic Device Settings ................................................................................................ 31

Transformer Correction .............................................................................................. 31

Device Options .......................................................................................................... 32

Communication Ports.................................................................................................32

Local Network Settings............................................................................................... 33

Local Settings ............................................................................................................ 33

Meter Security ...........................................................................................................34

Display Settings......................................................................................................... 34

Multi----Mon Display Operations

Mon Display Operations........................................... 23

MultiMulti

Mon Display OperationsMon Display Operations

Chapter 4

Chapter 4 Power Software Configuration tool

Chapter 4Chapter 4

Multi-Mon Multiple Circuit Energy Monitor

Power Software Configuration tool ................................... 36

Power Software Configuration toolPower Software Configuration tool

3

Page 4

Setting up your Submeters

Setting up your Submeters ................................................................................ 36

Setting up your SubmetersSetting up your Submeters

Setting up Communic

Setting up Communications

Setting up CommunicSetting up Communic

Communicating through a Serial Port.......................................................................... 37

Communicating through the Internet ...........................................................................38

Preparing Setups

Preparing Setups ............................................................................................... 39

Preparing SetupsPreparing Setups

Downloading Setups .................................................................................................. 39

Uploading Setups ...................................................................................................... 39

Authorization

Authorization...................................................................................................... 39

AuthorizationAuthorization

Changing Port Settings

Changing Port Settings...................................................................................... 40

Changing Port SettingsChanging Port Settings

Setting Up Communication Ports ................................................................................ 40

Setting Up the Local Network .....................................................................................41

Configuring eXpertPower Client..................................................................................41

General Meter Setup

General Meter Setup ......................................................................................... 43

General Meter SetupGeneral Meter Setup

Basic Meter Setup......................................................................................................43

Channel Assignments ................................................................................................ 44

Transformer Correction .............................................................................................. 45

Local Settings ............................................................................................................ 46

Using Alarm/Control Setpoints....................................................................................47

Configuring

Configuring Billing Energy and TOU Registers

Configuring Configuring

Setting up Total and Tariff Registers........................................................................... 49

Configuring the Daily Tariff Schedule.......................................................................... 51

Configuring the Season Tariff Schedule ...................................................................... 51

Configuring Data Recorders

Configuring Data Recorders .............................................................................. 52

Configuring Data RecordersConfiguring Data Recorders

Re

Remote Device Control

mote Device Control...................................................................................... 53

ReRe

mote Device Controlmote Device Control

Viewing and Clearing Device Diagnostics ................................................................... 53

Updating the Clock.....................................................................................................54

Administration

Administration .................................................................................................... 55

AdministrationAdministration

Upgrading Device Firmware

Upgrading Device Firmware .............................................................................. 55

Upgrading Device FirmwareUpgrading Device Firmware

Data Monitoring

Data Monitoring ................................................................................................. 58

Data MonitoringData Monitoring

Viewing Real-Time Data.............................................................................................58

Retrieving Log Files ................................................................................................... 58

Billing Energy and TOU Registers ................................................. 49

Billing Energy and TOU RegistersBilling Energy and TOU Registers

ations............................................................................... 36

ationsations

Appendix A

Appendix A Technical Specifications

Appendix AAppendix A

Appendix B

Appendix B CT Connection Template

Appendix BAppendix B

Appendix C

Appendix C Parameters for Data Monitoring and Logging

Appendix CAppendix C

Appendix D

Appendix D Setpoint Triggers and Actions

Appendix DAppendix D

Appendix E

Appendix E Data Scales

Appendix EAppendix E

Appendix F

Appendix F Device Diagnostic Codes

Appendix FAppendix F

Technical Specifications ................................................ 61

Technical SpecificationsTechnical Specifications

CT Connection Template ............................................... 64

CT Connection TemplateCT Connection Template

Parameters for Data Monitoring and Logging ................ 65

Parameters for Data Monitoring and LoggingParameters for Data Monitoring and Logging

Setpoint Triggers and Actions........................................ 69

Setpoint Triggers and ActionsSetpoint Triggers and Actions

Data Scales.................................................................... 70

Data ScalesData Scales

Device Diagnostic Codes ............................................... 71

Device Diagnostic CodesDevice Diagnostic Codes

4

Multi-Mon Multiple Circuit Energy Monitor

Page 5

This package contains

This package contains

This package contains This package contains

Mult

Multiiii----Mon

Mon

MultMult

MonMon

High

Highly

ly Accura

HighHigh

options refer to HACS_Datasheet catalog

options refer to HACS_Datasheet catalog

options refer to HACS_Datasheet catalogoptions refer to HACS_Datasheet catalog

Accurate

lyly

Accura Accura

te Current Sensors

Current Sensors ---- HACS

tete

Current Sensors Current Sensors

HACS

HACS ---- 100A

HACS HACS

100A –––– (solid core) Internal Hole

(solid core) Internal Hole ∅∅∅∅12 mm (0.47")

100A 100A

(solid core) Internal Hole (solid core) Internal Hole

HACS

HACS ---- 100

HACS HACS

HACS

HACS ---- 400A

HACS HACS

100A

A –––– (solid core) Internal Hole

(solid core) Internal Hole ∅∅∅∅23 mm (0.91")

100 100

A A

(solid core) Internal Hole (solid core) Internal Hole

400A –––– (solid core) Internal Hole

(solid core) Internal Hole ∅∅∅∅26 mm (1.02")

400A 400A

(solid core) Internal Hole (solid core) Internal Hole

HACS

HACS HACS

1111

according to your request, for more

according to your request, for more

according to your request, for more according to your request, for more

12 mm (0.47")

12 mm (0.47")12 mm (0.47")

23 mm (0.91")

23 mm (0.91")23 mm (0.91")

26 mm (1.02")

26 mm (1.02")26 mm (1.02")

HACS

HACS ---- 100A

HACS HACS

100A –––– (solid core) Internal Hole

(solid core) Internal Hole ∅∅∅∅16 mm (0.63")

100A 100A

(solid core) Internal Hole (solid core) Internal Hole

1

HACS – proprietary current transformer

Multi-Mon Multiple Circuit Energy Monitor

16 mm (0.63")

16 mm (0.63")16 mm (0.63")

5

Page 6

Designator Label Sets

HACS designator label set

-

to attach to the HACS

Designator Label Sets

Designator Label SetsDesignator Label Sets

10

19

20

21

22

23

24

25

26

28

29

30

31

32

33

34

35

1

11

2

12

3

13

4

14

5

15

6

16

7

17

8

18

27

9

Cable designator tie-marker

36

6

Multi-Mon Multiple Circuit Energy Monitor

Page 7

Chapter 1 General Information

Chapter

Chapter 1

Chapter Chapter

1 General Information

General Information

1 1

General InformationGeneral Information

The Multi-Mon is a 3-phase, multi-channel, multi-function energy meter

suitable for use in single-phase and multi-phase electrical networks.

Meter highlights

Meter highlights

Meter highlightsMeter highlights

Fea

Features

FeaFea

• Multi-channel submetering – up to 36 single-phase or 18 two-phase

or 12 three-phase submeters in a single device. Any combination of

single-, two-, and three-phase consumers can be chosen up to a

total of 36 current inputs.

• Automatic totalization energy from different sub-consumers

tures

turestures

• Calibrated to meet Class 0.5S active energy and Class 1 reactive

energy meter accuracy

• 3-phase/2-phase/single-phase meters (true RMS, volts, amps,

power, power factor, neutral current)

• Ampere/Volt demand meter

• Time-of-Use, 4 energy/demand registers x 6 tariffs1, 4 seasons x 4

types of days, 8 tariff changes per day, easy programmable tariff

schedule

• Import/export energy and power demands

• Automatic 120–day daily profile for import/export2 energy and

maximum demand readings (total and tariff registers) separate for

each submeter

• Event recorder for logging internal diagnostic events and setpoint

operations

• Data recorders; programmable periodical data logs separate for

each submeter

• Embedded programmable controller (4 control setpoints,

programmable thresholds and delays) separate for each submeter

• Easy to read 2-row x 16 characters LCD display with backlight

(Multi-Mon only)

• 50/60 Hz operation

• Internal clock, keeping the clock running over one week without

external power

• Highly Accurate Current Transformer with overvoltage protection

diodes to avoid any damage while disconnecting the primary

current sensor

• Standard RS-485 serial port

• Optional second communication port. Communication options

available:

RS-232

RS-422/485

56K Dial-up modem

Ethernet 10/100BaseT

• Modbus RTU and Modbus ASCII communication protocols

• Easy field upgrading device firmware through any communication

port

1

From Firmware version 18.4.1

2

From Firmware version 18.5.1

Multi-Mon Multiple Circuit Energy Monitor

7

Page 8

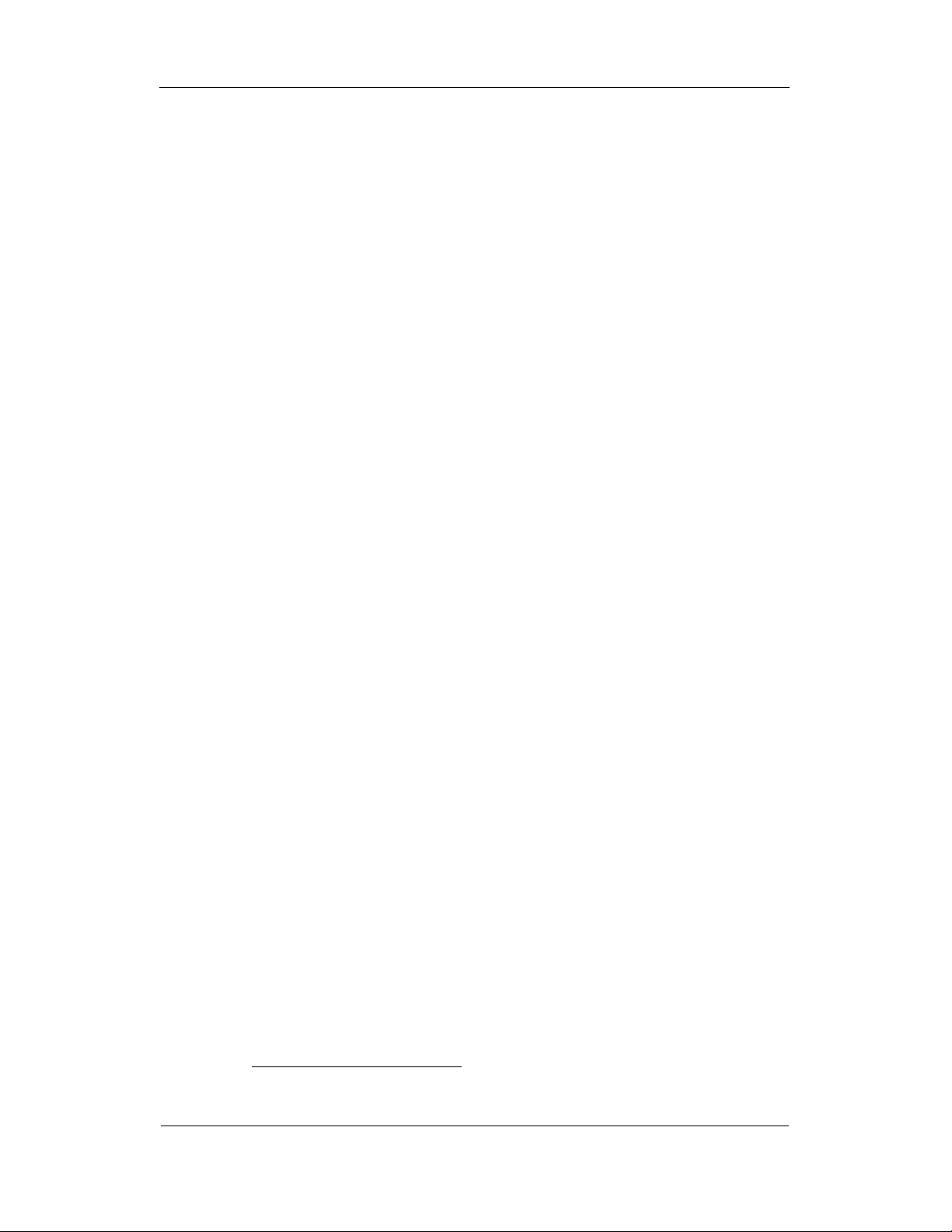

Chapter 1 General Information

Labeling

Labeling

LabelingLabeling

Figure 1

Figure 1----1 Device label

Figure 1Figure 1

1 Device label –––– Wye wiring configuration

1 Device label1 Device label

Wye wiring configuration

Wye wiring configuration Wye wiring configuration

Figure 1

Figure 1----2222 Device label

Figure 1Figure 1

Device label –––– Wye/Delta wiring configuration

Device label Device label

Wye/Delta wiring configuration

Wye/Delta wiring configuration Wye/Delta wiring configuration

8

Multi-Mon Multiple Circuit Energy Monitor

Page 9

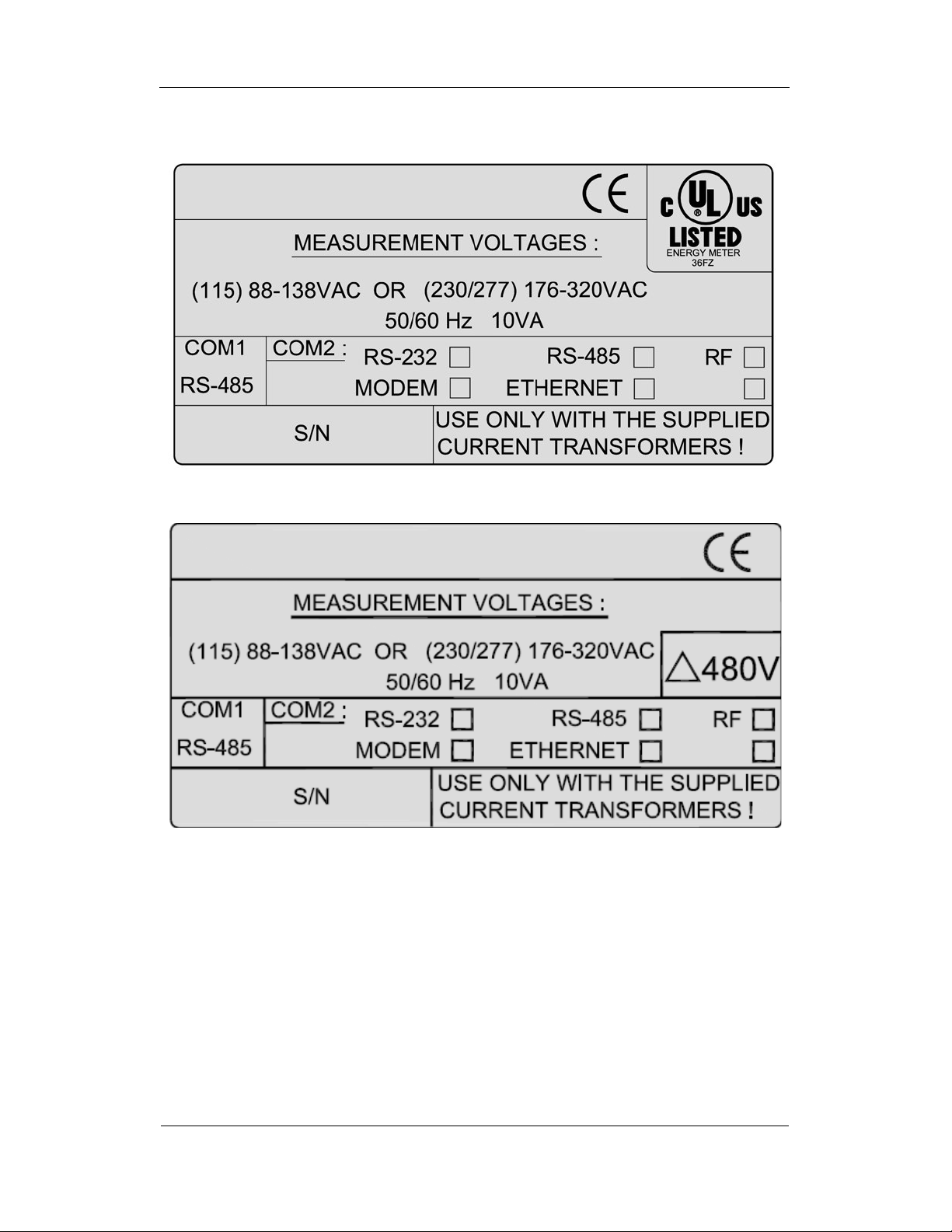

Chapter 2 Installation

Chapter

Chapter 2

Chapter Chapter

Mechanical Installation

Mechanical Installation

Mechanical InstallationMechanical Installation

2 Instal

Installation

2 2

InstalInstal

lation

lationlation

Mechanical Installation

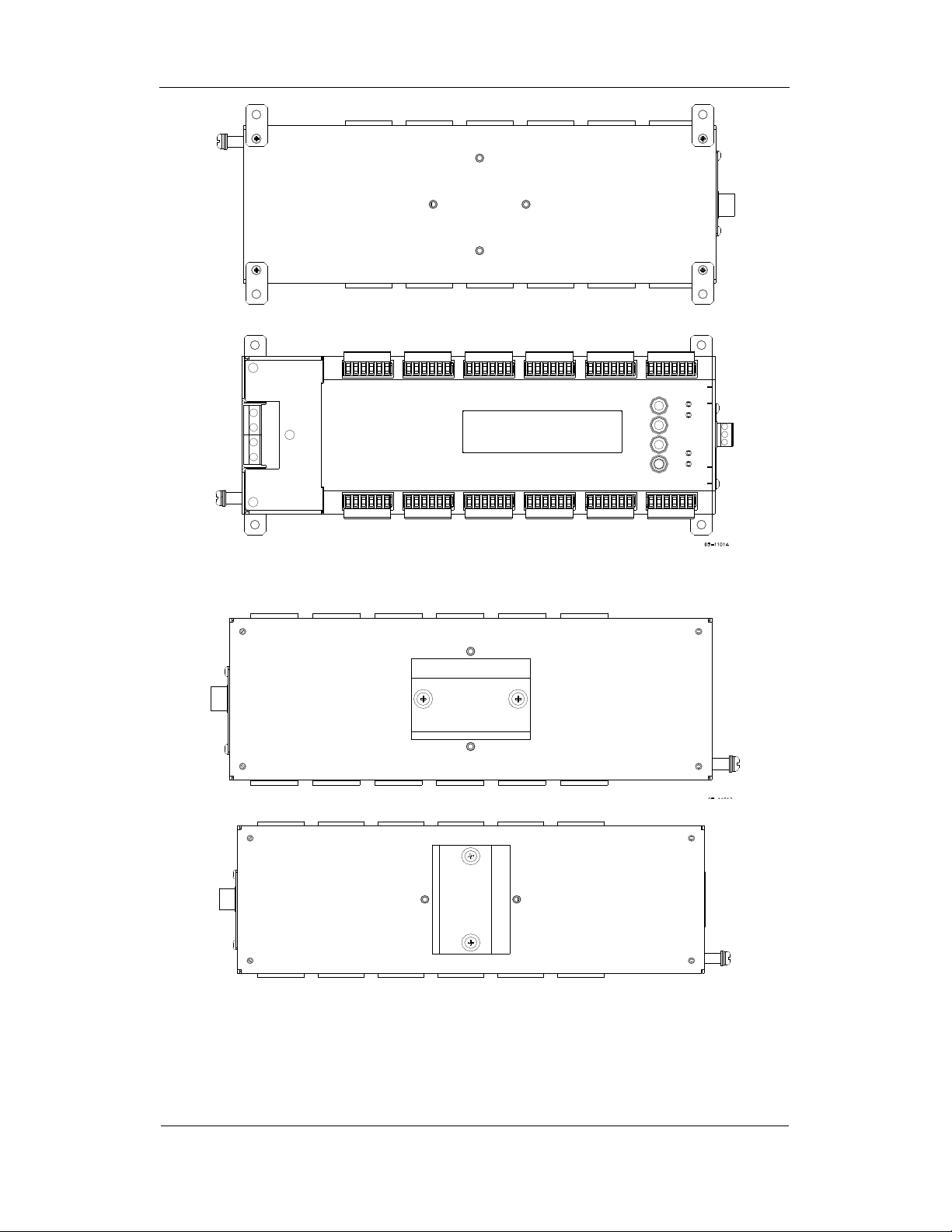

Figure 2

Figure 2----1

Figure 2Figure 2

Multi-Mon Multiple Circuit Energy Monitor

1 Multi

Multi----Mon

1 1

MultiMulti

Mon dimensions

dimensions

MonMon

dimensions dimensions

9

Page 10

Chapter 2 Installation

Mechanical Installation

Figure 2

Figure 2----2 Wall mounting

Figure 2Figure 2

2 Wall mounting

2 Wall mounting 2 Wall mounting

Figure 2

Figure 2----3 DIN rail mounting

Figure 2Figure 2

3 DIN rail mounting

3 DIN rail mounting3 DIN rail mounting

10

Multi-Mon Multiple Circuit Energy Monitor

Page 11

Chapter 2 Installation

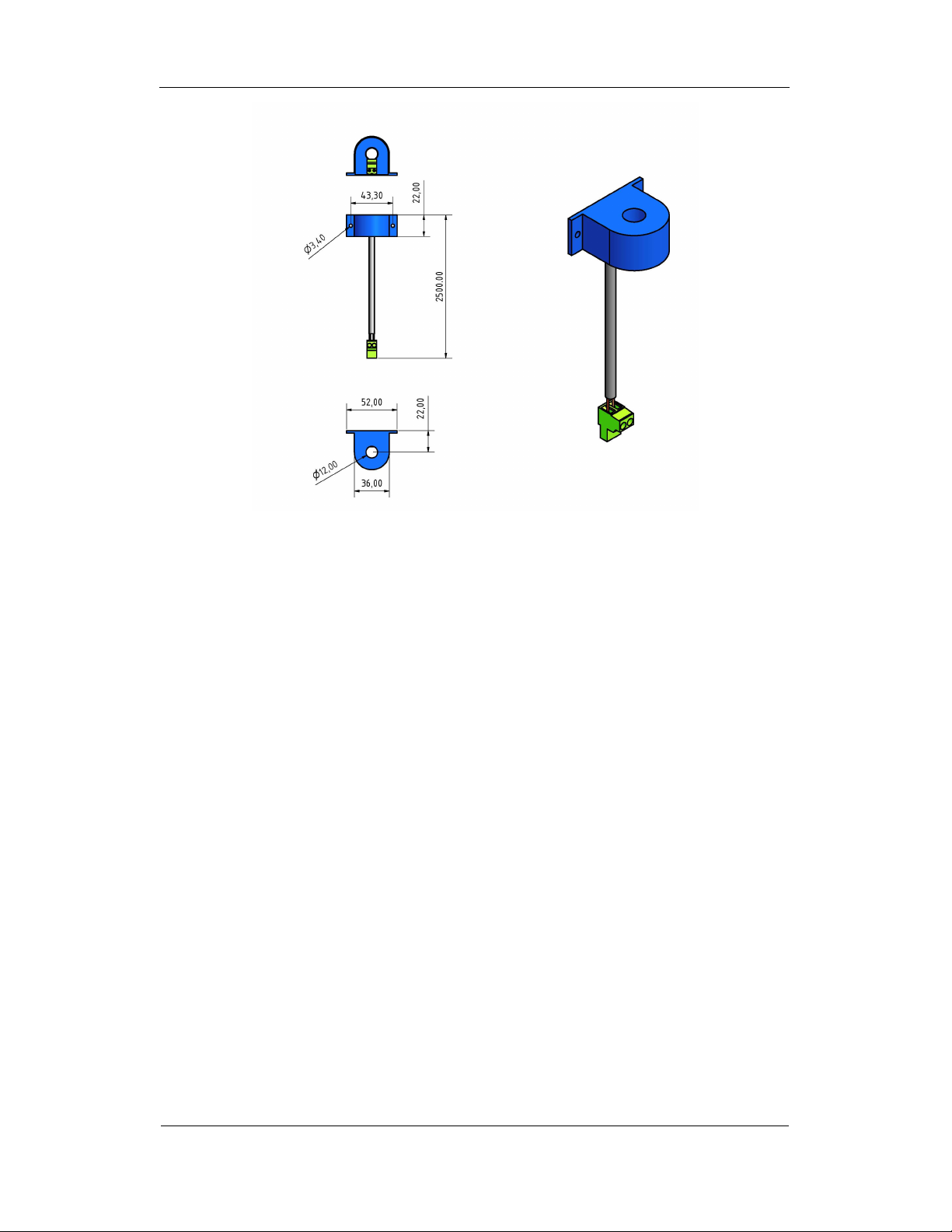

Figure 2

Figure 2----4 Single

Figure 2Figure 2

4 Single HACS

4 Single 4 Single

HACS dimensions

HACSHACS

dimensions

dimensions dimensions

Multi-Mon Multiple Circuit Energy Monitor

11

Page 12

Chapter 2 Installation

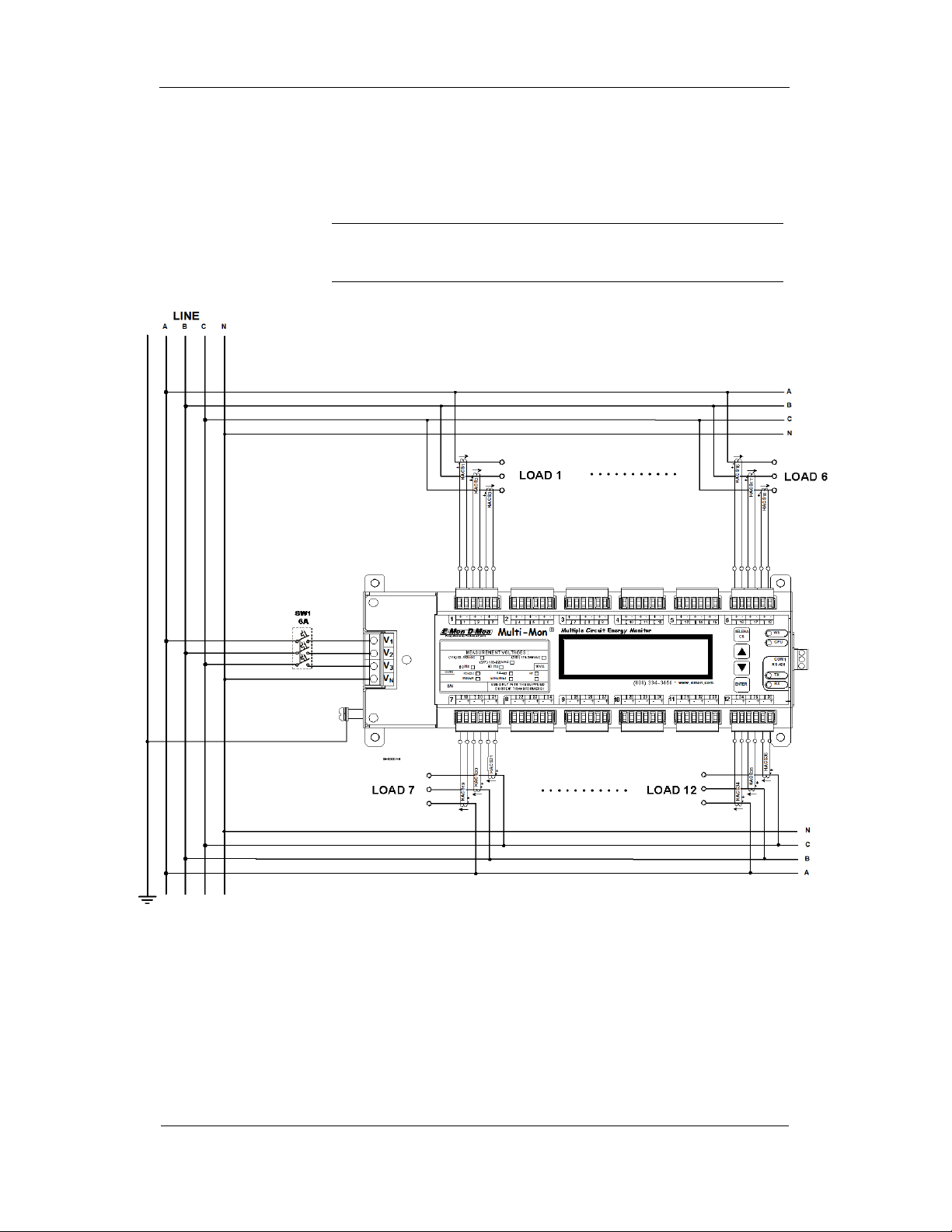

Electrical Installation

Electrical Installation

Electrical InstallationElectrical Installation

Multi-Mon offers maximum flexibility of current connections by using the

variety of Highly Accurate Current Transformer (HACS) options and by wiring

any Highly Accurate Current Transformer to any current input of the device.

The following drawings present applications serviced by the Multi-Mon.

Befor

Before installation ensure that all incoming power

e installation ensure that all incoming power source

BeforBefor

e installation ensure that all incoming powere installation ensure that all incoming power

Failure to observe this practice can result in serious or even fatal injury and

Failure to observe this practice can result in serious or even fatal injury and

Failure to observe this practice can result in serious or even fatal injury and Failure to observe this practice can result in serious or even fatal injury and

damage to equipment.

damage to equipment.

damage to equipment.damage to equipment.

Electrical Installation

sources are shut OFF.

s are shut OFF.

source source

s are shut OFF. s are shut OFF.

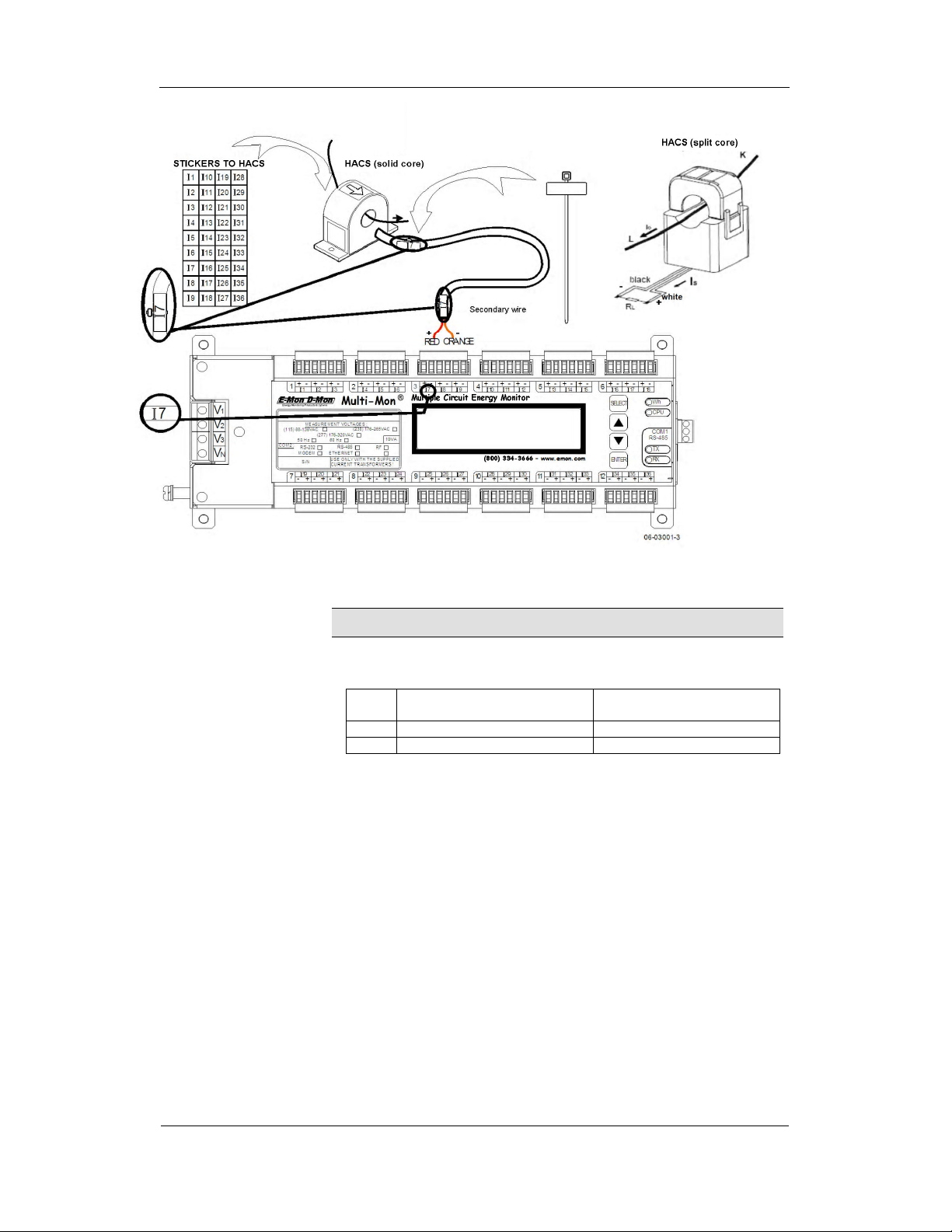

Figure 2

Figure 2----5555aaaa Typical Electrical Installation

Figure 2Figure 2

12

Typical Electrical Installation –––– Wye

Typical Electrical Installation Typical Electrical Installation

Multi-Mon Multiple Circuit Energy Monitor

Wye wiring

Wye Wye

wiring

wiring wiring

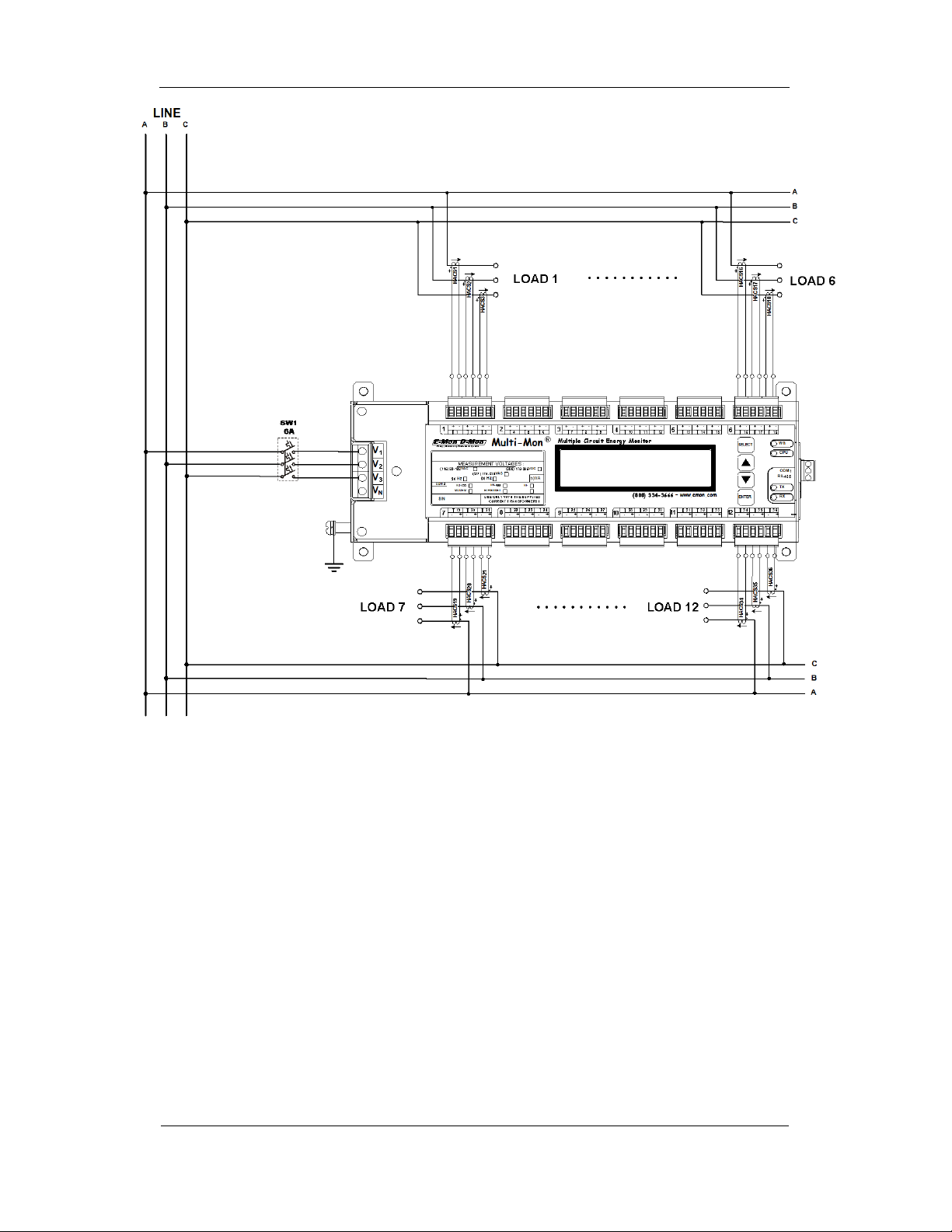

Page 13

Chapter 2 Installation

Electrical Installation

Figure 2

Figure 2----5555bbbb Typical Electrical Installation

Figure 2Figure 2

Multi-Mon Multiple Circuit Energy Monitor

Typical Electrical Installation –––– Delta wiring

Typical Electrical Installation Typical Electrical Installation

Delta wiring

Delta wiring Delta wiring

13

Page 14

Chapter 2 Installation

Electrical Installation

Figure 2

Figure 2----6 Single

Figure 2Figure 2

6 Single Highly Accurate Current Transformer

6 Single 6 Single

Highly Accurate Current Transformer wiring and labeling

Highly Accurate Current TransformerHighly Accurate Current Transformer

USE ONLY WITH SUPPLIED BFM CURRENT TRANSFORMERS!

USE ONLY WITH SUPPLIED BFM CURRENT TRANSFORMERS!

USE ONLY WITH SUPPLIED BFM CURRENT TRANSFORMERS!USE ONLY WITH SUPPLIED BFM CURRENT TRANSFORMERS!

Connect the wires to the + and - inlets according to the following polarity

colors:

Polarity

Polarity

PolarityPolarity

It is recommended to mark the cables and CTs with the supplied tie markers.

CTs stickers I1 through I36 correspond to the Multi-Mon current inputs with

matching labels. Cable stickers 1 through 12 correspond to the Multi-Mon

current terminal blocks with matching labels.

Use the table from Appendix B to annotate your input assignments and

wiring connections.

Label

Labeling example:

LabelLabel

Assume you want to connect three HACSs to the device terminal block 3 so

these three HACSs would be connected to the device inputs I7, I8, and I9

respectively:

1. Take a CT connection cable, attach a tie wrap marker to each side of

2. Put the CT label stickers I7, I8, and I9 directly on HACSs to indicate that

Solid Core

Solid Core Current Transformer

Solid Core Solid Core

++++ RED WHITE

---- ORANGE BLACK

ing example:

ing example: ing example:

the cable and mark them as 3 to indicate that it should be connected to

the device terminal block 3.

these HACSs will be associated with the device current terminals I7, I8,

and I9.

Current Transformer

Current TransformerCurrent Transformer

secondary

secondary

secondarysecondary

wiring and labeling

wiring and labeling wiring and labeling

Split Core

Split Core Current Transformer

Split Core Split Core

Current Transformer

Current TransformerCurrent Transformer

secondary

secondary

secondarysecondary

14

Multi-Mon Multiple Circuit Energy Monitor

Page 15

Chapter 2 Installation

Electrical Installation

Safety Req

Safety Requirements

Safety ReqSafety Req

To ensure safety requirements the Multi-Mon must be grounded - the

protective ground terminal should be connected to protective earth with a

copper conductor or strap with minimal length (less than 1 m desirable) and

cross-section 5.3 mm

The properly marked external 3-pole disconnect device with circuit-breaker

and a fuse 6A, 600V in every pole should be installed between voltage

measurement terminals and power lines, located as close as possible (less

than 2 m recommended) to the Multi-Mon, as shown in figure 2-5 .

uirements

uirementsuirements

2

(AWG10) at least.

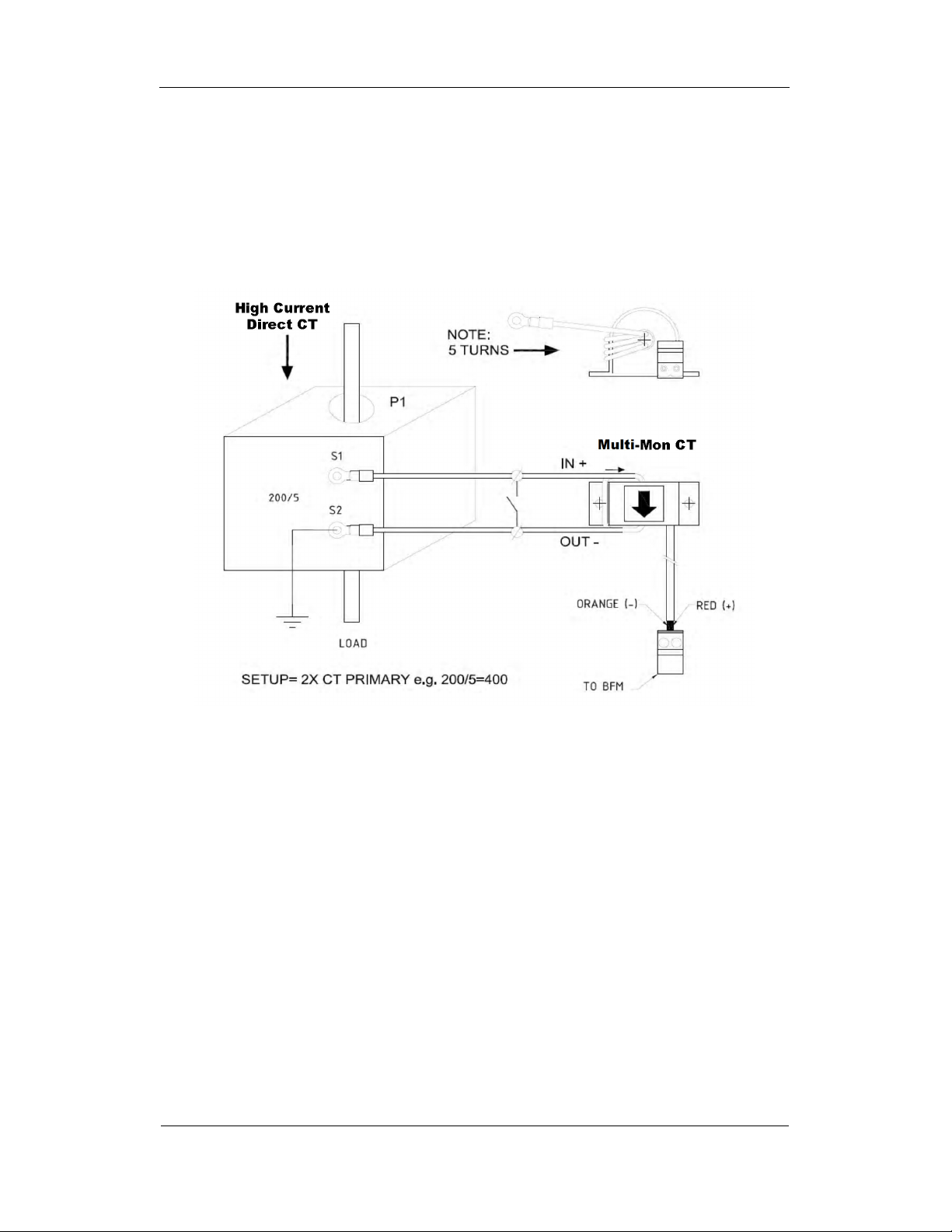

Figure 2

Figure 2----7 External

Figure 2Figure 2

7 External CT

7 External 7 External

CT connection to

CTCT

Multi-Mon Multiple Circuit Energy Monitor

connection to meter CT

connection to connection to

meter CT

meter CTmeter CT

15

Page 16

Chapter 2 Installation

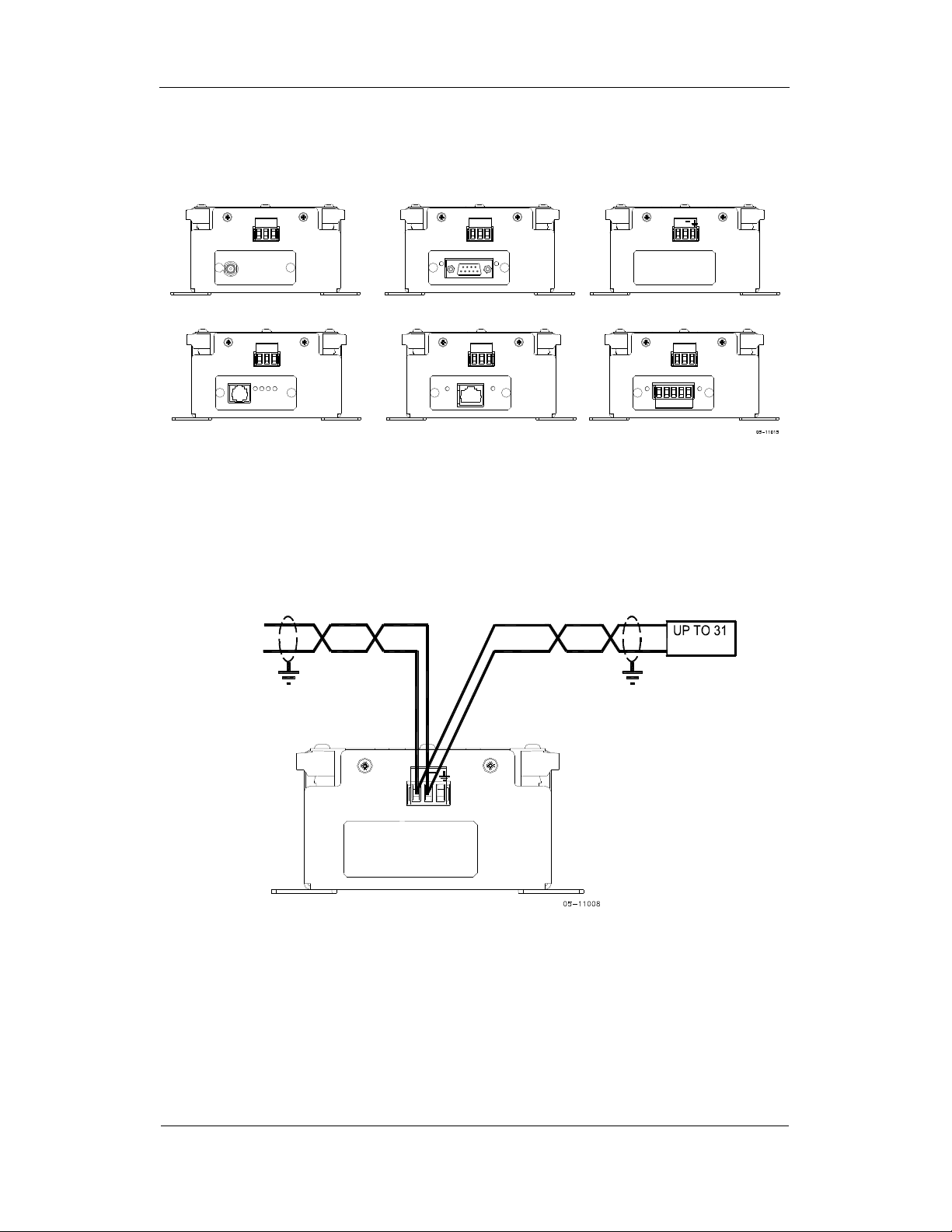

DEVICES

485

)

PC

+

Communications

Communications

CommunicationsCommunications

Several communication options are available for the Multi-Mon.

RS485

RF

Communications

+

RS485

Tx

Rx

RS232

RS485

NONE

RS485

RS

RS----485 Connection

485 Connection

RSRS

485 Connection485 Connection

(PLC

RS-

DIAL-UP

MODEM

TELEPHON

RS485

ETHERNET

Figure 2

Figure 2----8 Communication options

Figure 2Figure 2

8 Communication options

8 Communication options 8 Communication options

RS485

RS485/422

+

-

16

Figure 2

Figure 2----9 RS

Figure 2Figure 2

9 RS----485 2

9 RS9 RS

485 2----wire connection

wire connection

485 2485 2

wire connectionwire connection

Multi-Mon Multiple Circuit Energy Monitor

Page 17

Chapter 2 Installation

RS-422 / RS-485

RS-232

RXD

TXD

MASTER

RXD

COMMUNICATION CONVERTER

BFM136 BFM136

CONVERTER

RS485/422-232

Rt1

SHLD

SHLD

-

-

+

POWER

TX ENABLE

TXD

SUPPLY

L

POWER

N

RS485RS232

CABLE MAXIMUM LENGTH 1000M

UP TO 32 POWERMETERS

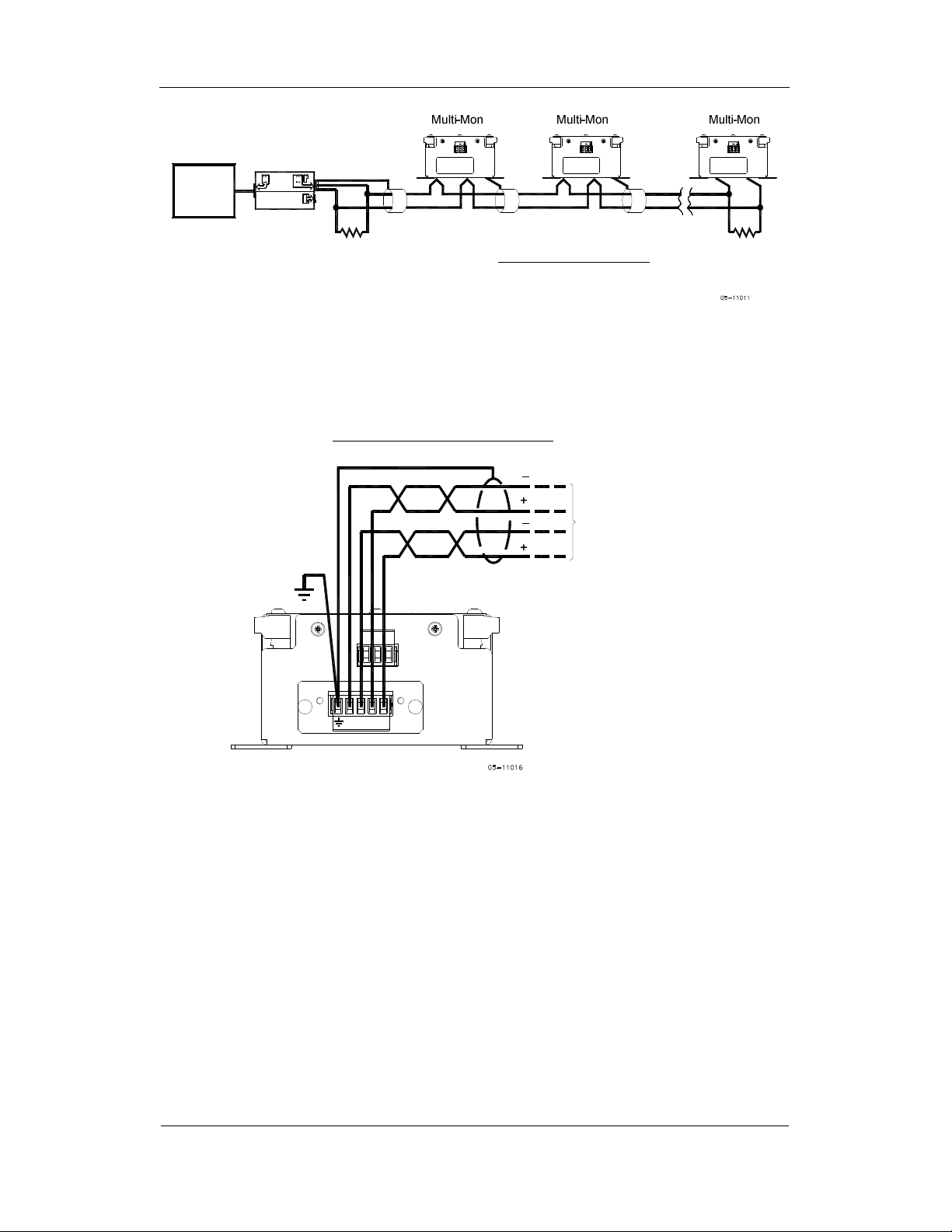

Figure 2

Figure 2----10 RS

Figure 2Figure 2

10 RS----485 multidrop connection

10 RS10 RS

485 multidrop connection

485 multidrop connection485 multidrop connection

RS-422 COMMUNICATION PORT

4 WIRE CONNECTION

Communications

BFM136

+ + +

SHLD SHLD

+

1,R

R 2=200-500 Ohm, 0.5W

t

-

+

t

Rx

TO COMMUNICATION

SYSTEM

Tx

-

+

2

R

t

Rx

-Rx +Rx

Figure 2

Figure 2----11 RS

Figure 2Figure 2

Tx

+Tx-Tx

11 RS----422/485 4

11 RS11 RS

422/485 4----wire connection

422/485 4422/485 4

Multi-Mon Multiple Circuit Energy Monitor

wire connection

wire connectionwire connection

17

Page 18

Chapter 2 Installation

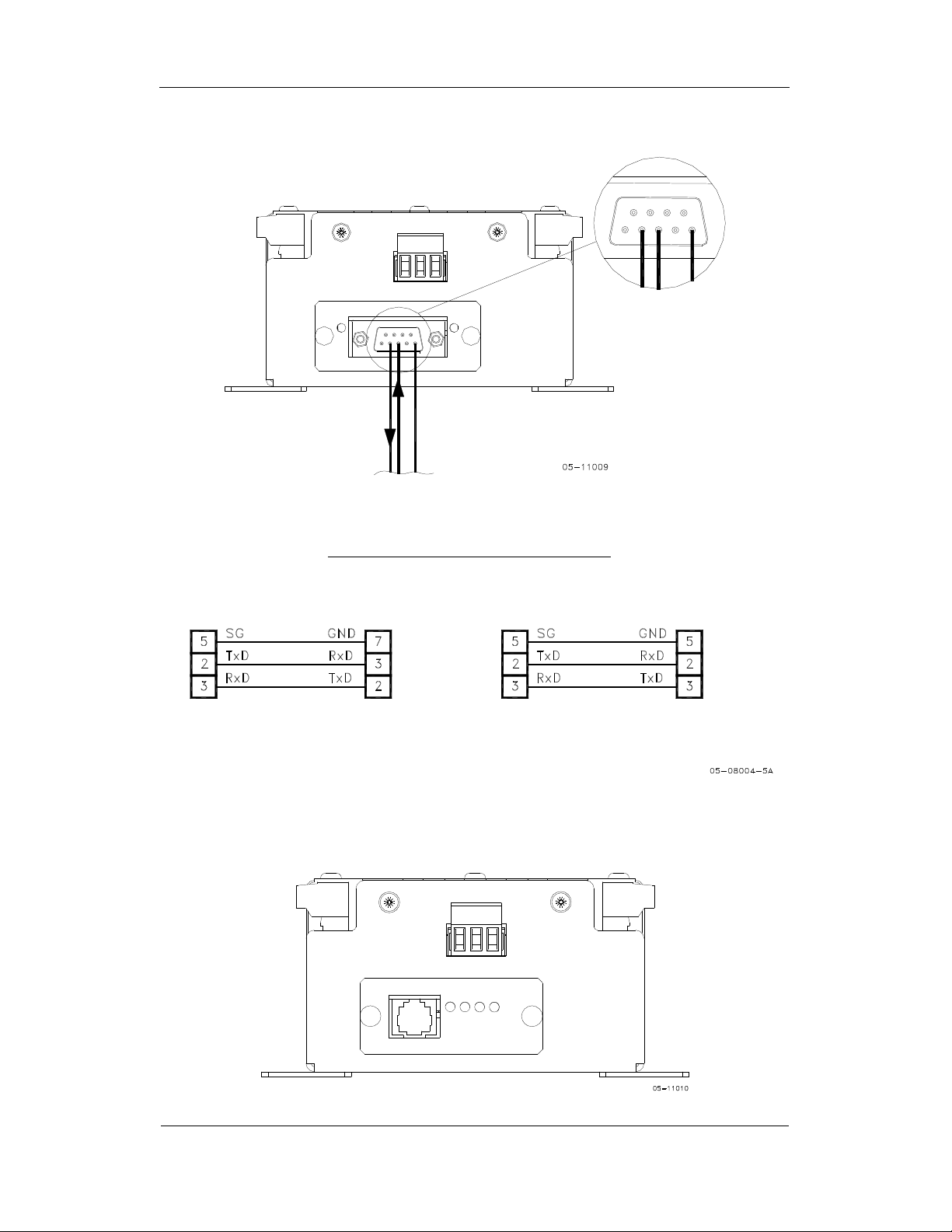

RS232 Connection

RS232 Connection

RS232 ConnectionRS232 Connection

Communications

6 87 9

51 2 3 4

Tx

Rx

SG

RX

TX

Figure 2

Figure 2----12 RS

Figure 2Figure 2

COMPUTER CONNECTIONS RS-232

Multi-Mon

EM610

RS232

MALE CON.

RS-232 SIMPLE 3-WIRE

CONNECTION 25-PIN CONNECTION 9-PIN

IBM PC/COMPATIBLE

25-PIN DB25

FEMALE CON.

Figure 2

Figure 2----13 RS

Figure 2Figure 2

12 RS----232 connection

12 RS12 RS

13 RS----23

13 RS13 RS

232 connection

232 connection232 connection

Multi-Mon

EM610

RS232

MALE CON.

RS-232 SIMPLE 3-WIRE

232 cable drawings

2 cable drawings

2323

2 cable drawings2 cable drawings

IBM PC/COMPATIBLE

9-PIN DB9

FEMALE CON.

Modem Connection

Modem Connection

Modem ConnectionModem Connection

18

Multi-Mon Multiple Circuit Energy Monitor

Page 19

Chapter 2 Installation

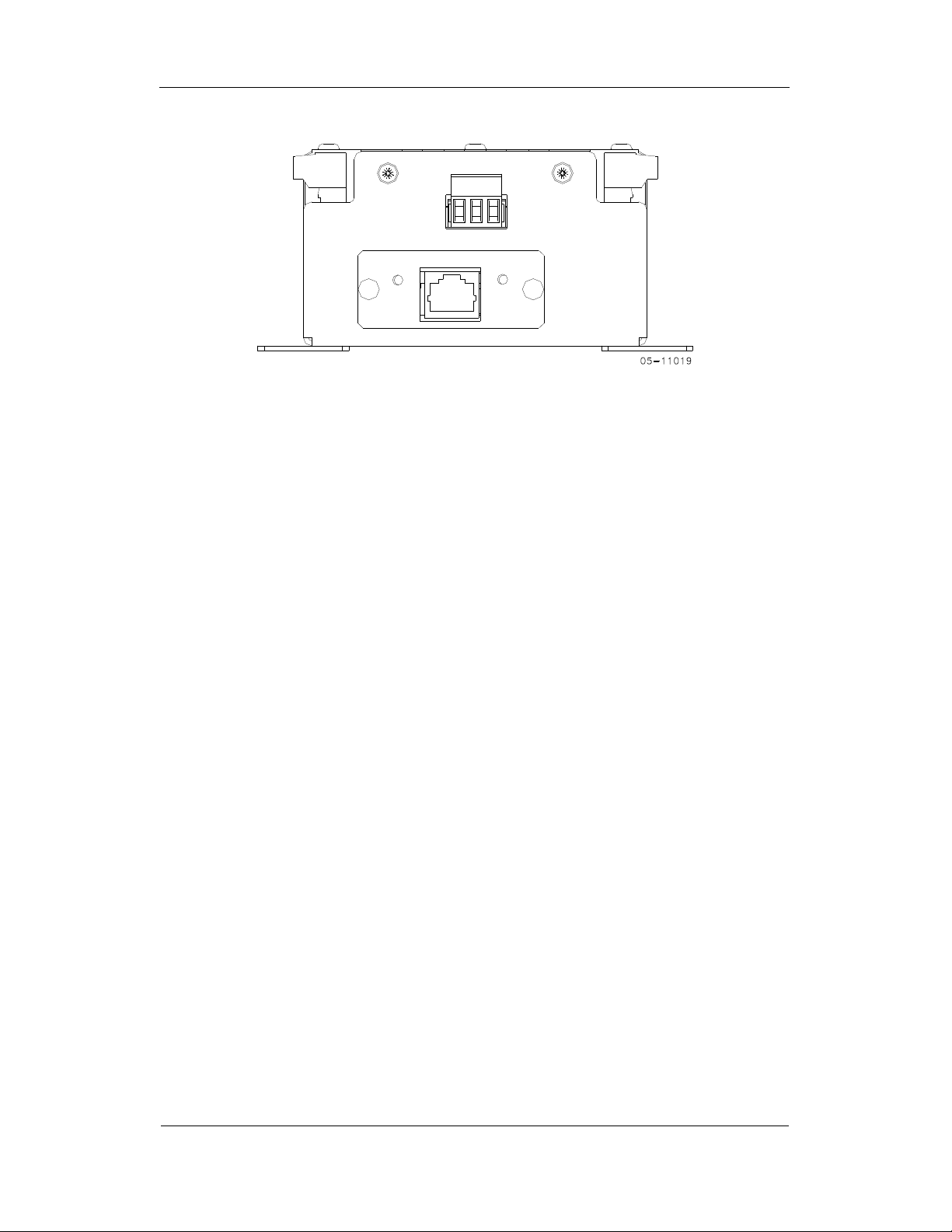

Ethernet Connection

Ethernet Connection

Ethernet ConnectionEthernet Connection

Communications

RS485

ETHERNET

Multi-Mon Multiple Circuit Energy Monitor

19

Page 20

Chapter 2 Installation

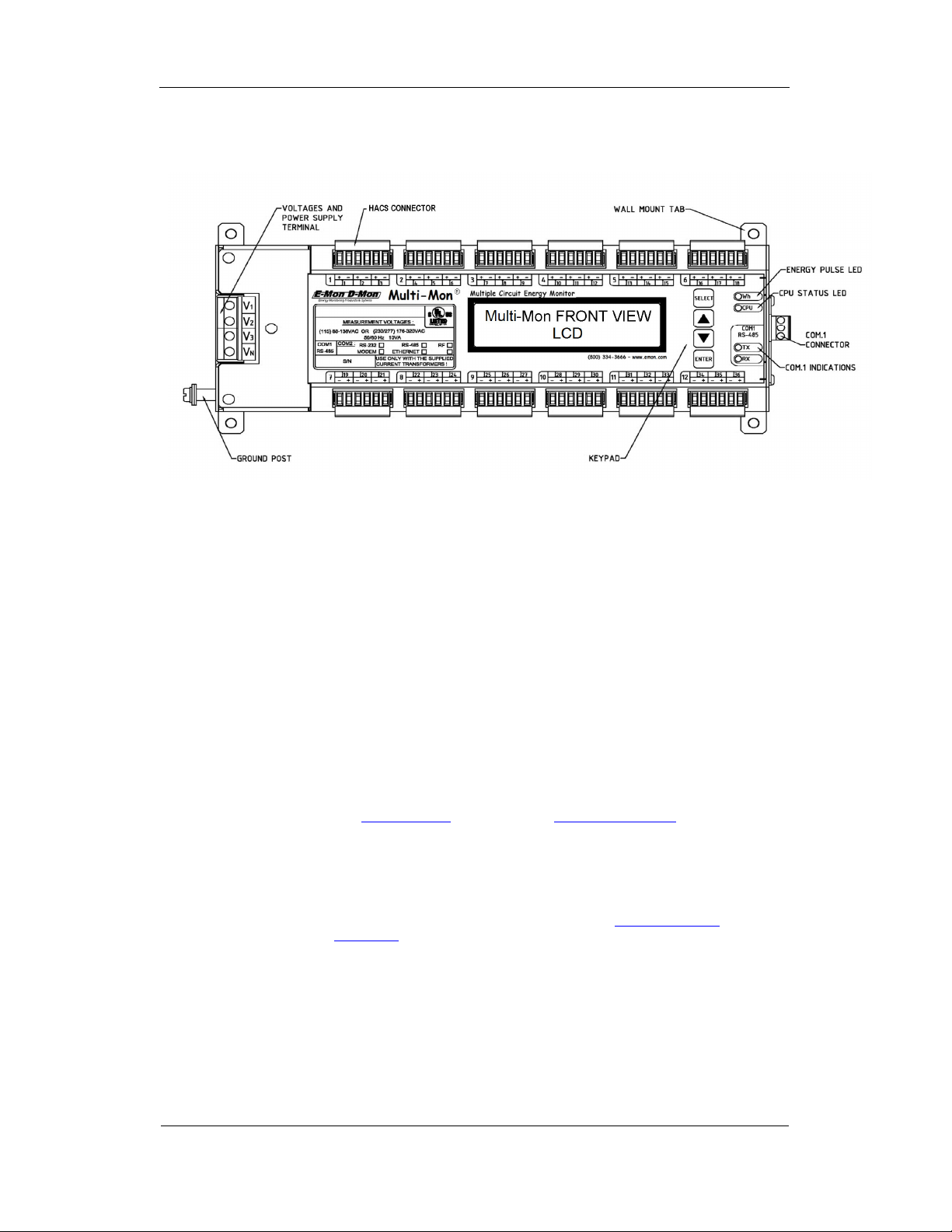

Controls and Indicators

Controls and Indicators

Controls and IndicatorsControls and Indicators

Figure 2

Figure 2----14

Figure 2Figure 2

14 Multi

Multi----Mon

14 14

MultiMulti

Mon Front View

Front View

MonMon

Front View Front View

Controls and Indicators

Indicator LEDs

Indicator LEDs

Indicator LEDsIndicator LEDs

Energy Pulse LED

Energy Pulse LED

Energy Pulse LEDEnergy Pulse LED

Front Panel Display

Front Panel Display

Front Panel DisplayFront Panel Display

The flashing yellow CPU LED shows that the device is operational and is

functioning normally.

The green TX and RX LEDs indicate activity on the COM1 communication

port. The LEDs flash when the port is receiving or transmitting data.

The red “Wh” LED flashes at a user-programmed rate when a load is applied

to the device. In normal mode, the LED pulses indicate imported Wh for a

selected submeter. In energy test mode, the LED pulses indicate either

imported Wh, or imported (inductive) varh for a selected submeter. Energy

test mode is used for testing the device energy measurement accuracy. In

test mode, the energy and demand accumulators do not account for

consumed energy.

See Device Options in Chapter 3 and General Meter Setup in Chapter 4 on

how to put the device into energy test mode and how to select the LED pulse

rate and a submeter for testing.

The Multi-Mon is provided with an LCD display and four push buttons that

are used for local meter reading and setup. See Multi-Mon Display

Operations in Chapter 3 for information on using the front panel display.

20

Multi-Mon Multiple Circuit Energy Monitor

Page 21

Chapter 2 Installation

Device Settings

Device Settings

Device SettingsDevice Settings

Password

Password

PasswordPassword

Submeter System

Submeter System

Submeter SystemSubmeter System

Device Settings

Before operating your Multi-Mon, provide the device with information about

your particular environment. The device front display (see Display

Operations (Multi-Mon)) and the supplementary Power Software (see Power

Software Application Software) allow you to configure the Multi-Mon for your

particular use.

The Multi-Mon configuration setups are secured by a factory-preset

password. Contact your dealer for your primary password. Later, you will be

able to change the password via the device Access Menu (see Meter

Security).

The Multi-Mon provides up to 36 submeters with separate measurement and

energy registers. Each submeter can service current inputs dedicated to a

particular consumer (metering submeter) or be used as a totalization meter

for automatic totalization of energy from different sub-consumers (totalization

submeter). Additionally, the Multi-Mon provides four more totalization

submeters (37 through 40) that you can use for totalization purposes when

all 36 metering submeters have been utilized.

A submeter remains inactive while there are no current inputs associated

with the submeter (see Channel Assignments), or until you link another

submeter as a source to its energy registers making it a totalization submeter

(see Setting up Total and Tariff Registers). The Channel Assignment setup

allows you to link one to three current inputs to each submeter and to specify

the primary rating of the current transformers. A totalization submeter

provides totalization of energy from any number of metering and totalization

submeters.

By default, your device is configured for 12 three-phase metering submeters

with 100A (maximum) current inputs (50A nominal rating).

Submeter

Submeter Addressing

SubmeterSubmeter

Addressing

Addressing Addressing

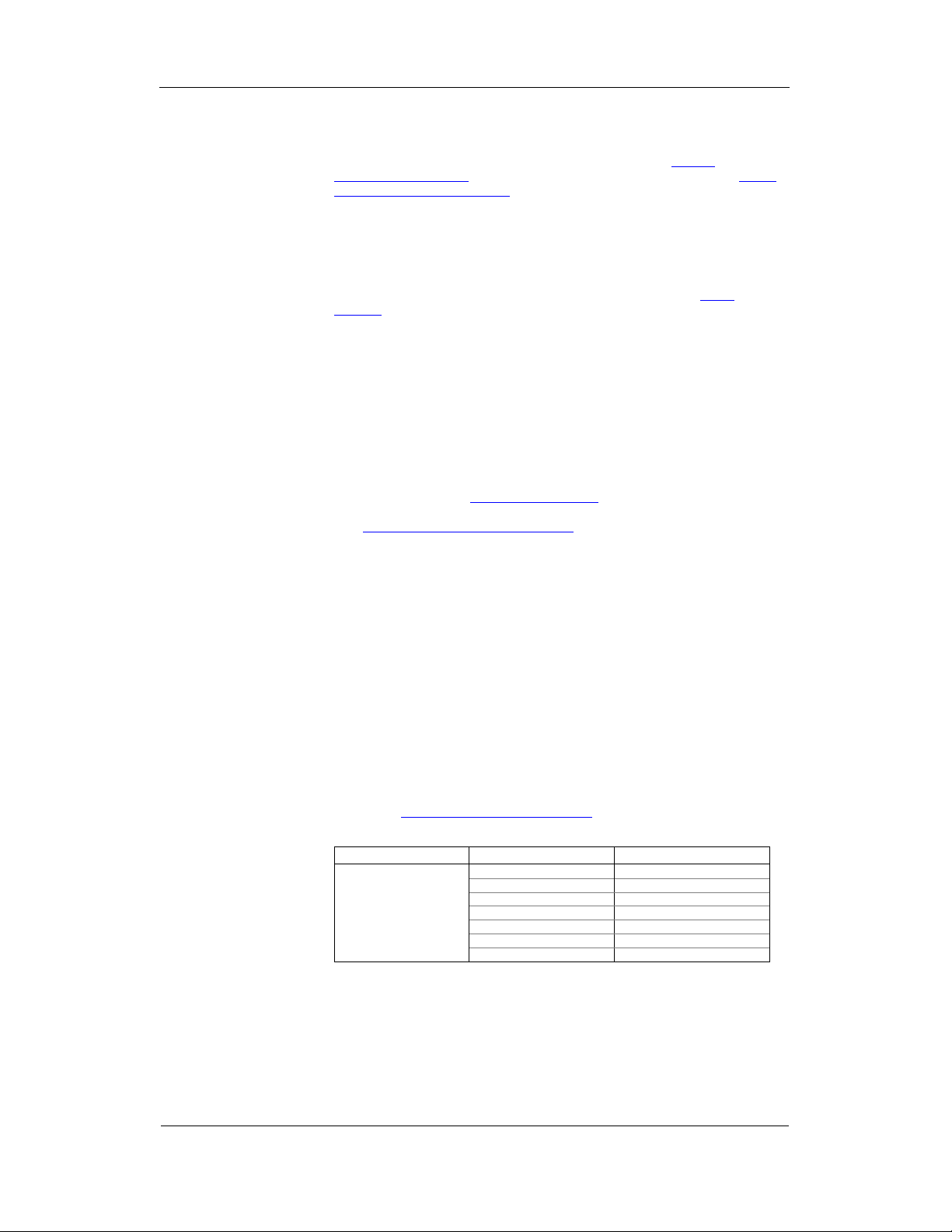

The Multi-Mon uses the Modbus communication protocol for data

transmission and accessing setups through communications. A full

description of the communications protocol is found in the Multi-Mon

Modbus Reference Guide provided with your device.

Each active submeter in the Multi-Mon is assigned a unique communication

address that allows accessing its private registers and setups. All submeter

addresses are assigned automatically in a sequential order starting with the

device base address that is programmed through the device Communication

Setup (see Setting Up Communication Ports ). The following table illustrates

submeter addressing in the device with the base address N.

Device Ba

Device Base Address

Device BaDevice Ba

N

Your device is factory preset to address 1 and occupies the range of

addresses 1 through 12, configured for 12 three-phase submeters.

NOTES

NOTES

NOTESNOTES

1111.... Device setup settings, excluding the alarm setpoints and data log setup,

se Address Submeter Number

se Addressse Address

Device setup settings, excluding the alarm setpoints and data log setup,

Device setup settings, excluding the alarm setpoints and data log setup, Device setup settings, excluding the alarm setpoints and data log setup,

are shared across all submeters. Though you can read or write them

are shared across all submeters. Though you can read or write them

are shared across all submeters. Though you can read or write them are shared across all submeters. Though you can read or write them

using any submeter address, your changes affect all submeters in the

using any submeter address, your changes affect all submeters in the

using any submeter address, your changes affect all submeters in the using any submeter address, your changes affect all submeters in the

device.

device.

device. device.

Submeter Number Submeter Address

Submeter NumberSubmeter Number

SM 1 N

SM 2 N+1

…

SM 36 N+35

SM 37 N+36

…

SM 40 N+39

Submeter Address

Submeter AddressSubmeter Address

Multi-Mon Multiple Circuit Energy Monitor

21

Page 22

Chapter 2 Installation

Basic Device Settings

Basic Device Settings

Basic Device SettingsBasic Device Settings

Energy/TOU System

Energy/TOU System

Energy/TOU SystemEnergy/TOU System

Device Diagnostics

2222.... When using the ExpertPower

When using the ExpertPower client, submeter address 99 on the

When using the ExpertPowerWhen using the ExpertPower

Ethernet port COM2 is reserved for the

Ethernet port COM2 is reserved for the Multi

Ethernet port COM2 is reserved for the Ethernet port COM2 is reserved for the

fall inside the range of the submeter addresses for this port.

fall inside the range of the submeter addresses for this port.

fall inside the range of the submeter addresses for this port.fall inside the range of the submeter addresses for this port.

Select your submeters (both metering and totalization) in a sequence without

gaps so that your device does not occupy unnecessary network addresses.

If you connect a number of devices to a serial network, allocate a range of

addresses for each device so that they do not overlap. For example, if you

use three devices with 12 submeters in each one, assign the base address 1

to the first device, the address 13 to the second, and the address 25 to the

third device so that they will occupy three non-overlapped address ranges 1

through12, 13 through 24, and 25 through 36.

For proper device operation, select the correct power frequency (see Basic

Device Settings) and set the correct primary ratings for device current inputs

(see Channel Assignments) before you connect the device to your network.

The Multi-Mon provides 4 separate billing energy (total/summary and

parallel tariff and maximum demand) registers for each individual submeter.

Each register can be linked to any internal energy source or another

submeter. The first billing register in your meter is linked to the kWh

accumulator by default. Other registers are not operational unless you

configure them through the Energy/TOU Setup (see Configuring Billing

Energy and TOU Registers).

client, submeter address 99 on the

client, submeter address 99 on the client, submeter address 99 on the

Multi----Mon

Mon router and must not

MultiMulti

router and must not

MonMon

router and must not router and must not

Device Diagnostics

Device Diagnostics

Device DiagnosticsDevice Diagnostics

Device diagnostic messages may appear as a result of the Multi-Mon built-in

diagnostic tests performed during start-up and device operation. See Device

Diagnostic Codes in Appendix F for the list of diagnostic codes and their

meanings.

The device diagnostics status is stored in a non-volatile register, which may

be inspected and cleared via Power Software, from the meter display or from

a user application. All diagnostic events with time stamps are also recorded

in the device Event log and can be inspected via Power Software (see

Retrieving the Event Log in Chapter 4).

See Diagnostics Display and Reset in Chapter 3 on how to inspect and clear

the device diagnostics status from the display. See Viewing and Clearing

Device Diagnostics in Chapter 4 on how to inspect and clear the device

diagnostics status via Power Software. Refer to the Multi-Mon Modbus

Reference Guide for the diagnostic register address and layout.

In the event of a device fault, check the fault reason and clear the device

diagnostics. In the event of a time fault, update the device clock. In the event

of a configuration reset, check the setup affected by the fault via the device

Event log, and then verify the setup data.

Hardware failures are normally non-critical recoverable faults that do not

cause a system failure but may cause data loss. Hardware failures are often

caused by excessive electrical noise in the region of the device.

If the device continuously resets itself, contact your local distributor.

22

Multi-Mon Multiple Circuit Energy Monitor

Page 23

Chapter 3 Multi-Mon Display Operations

Chapter

Chapter 3

Chapter Chapter

Startup Diagnostics

Startup Diagnostics

Startup DiagnosticsStartup Diagnostics

Display Features

Display Features

Display FeaturesDisplay Features

Submeter Displays

Submeter Displays

Submeter DisplaysSubmeter Displays

3 Multi

Multi----Mon

3 3

MultiMulti

After applying power to the meter, a start-up diagnostic message is

displayed for one second. “Power Up” indicates a normal power-up

sequence. You can observe the list of device diagnostic codes recorded

during restart and device operation via the Status Display.

See Device Diagnostic Codes in Appendix F for the list of diagnostic

messages.

The multifunctional 2x16 alphanumeric LCD display with backlight allows

easy read outs of the measurement parameters both in the dark and under

sunlight. The menu-driven multi-page display allows viewing numerous

measurement parameters by scrolling through display screens and pages.

In display mode, the display shows readings for the currently selected

submeter. Its number is indicated at the upper-left corner of the display. To

scroll through active submeters, press and hold the SELECT button, and

then use the UP/DOWN buttons to move to another submeter.

Mon Display Operations

MonMon

Startup Diagnostics

Display Operations

Display Operations Display Operations

Display Update

Display Update

Display UpdateDisplay Update

The display is updated by default once per second; you can adjust the

display update rate via the Display Setup Menu.

Auto Return

Auto Return

Auto ReturnAuto Return

If no buttons are pressed for 5 minutes and the display Auto Return option is

not disabled, the display will automatically return to the real-time screen

mode from any other measurement display or programming mode. The Auto

Return option can be disabled through the Display Setup Menu.

Auto Scroll

Auto Scroll

Auto ScrollAuto Scroll

If no buttons are pressed for 30 seconds while the display is in the real-time

screen mode, and the Auto Scroll option is enabled in the Multi-Mon, the

measurement display will scroll automatically through all submeters. The

scroll interval can be adjusted through the Display Setup Menu. To stop auto

scrolling, press any button.

Backlight

Backlight

BacklightBacklight

If no buttons are pressed for 1 minute, the Multi-Mon turns the backlight off.

To restore the backlight, press any button briefly.

Navigation Buttons

Navigation Buttons

Navigation ButtonsNavigation Buttons

The Multi-Mon has four push buttons that are normally used to navigate

between screen modes and pages. In programming mode, the buttons allow

you to navigate through device setup menus and to change the device

settings.

The SELECT button functionality:

• In display mode

Multi-Mon Multiple Circuit Energy Monitor

23

Page 24

Chapter 3 Multi-Mon Display Operations

Hold down the SELECT button, and then use the UP or DOWN

button to scroll through the submeters.

Press the SELECT button for more than 5 seconds to enter

programming mode.

• In programming mode

Press briefly the SELECT button to highlight/activate a menu item or

to highlight a digit for changing when entering numbers.

The UP and DOWN buttons functionality:

• In display mode

Press briefly the UP or DOWN button to scroll through the display

pages.

Hold down the SELECT button and then press briefly the UP or

DOWN button to scroll through the submeters.

Press the UP and DOWN buttons together to move to the default

display page.

• In programming mode

Use the UP and DOWN buttons to scrolls through the menu options

or to change a selected digit when entering numbers.

The ENTER button functionality:

• In display mode

Press briefly the ENTER button to scrolls through the different screen

modes

• In programming mode

Press briefly the ENTER button to select a highlighted menu item and

to enter a submenu, or to store a changed item.

Display Views

Display Views

Display Views

Display ViewsDisplay Views

The Multi-Mon display has 5 multi-page screen modes for viewing numerous

measurement parameters shown in the following tables. Scroll through the

screen modes by briefly pressing the ENTER button. Scroll through the

display pages within the selected mode by briefly pressing the UP and

DOWN buttons.

Summary/TOU Energy

Summary/TOU Energy

Summary/TOU EnergySummary/TOU Energy

Page

Page

Page Page

№№№№

1 Reg.1 kWh

2 Reg.1 kWh

3 Reg.1 kWh

4 Reg.1 kWh

5 Reg.1 kWh

6 Reg.1 kWh

7 Reg.1 kWh

8 Reg.2 kvarh

9 Reg.2 kvarh

10 Reg.2 kvarh

Page content

Page content Description

Page contentPage content

Reg.1 kWh

Reg.1 kWhReg.1 kWh

Trf.1 32.535

Trf.1 32.535

Trf.1 32.535Trf.1 32.535

Reg.1 kWh

Reg.1 kWhReg.1 kWh

Trf.2

Trf.2 7.465

7.465

Trf.2 Trf.2

7.4657.465

Reg.1 kWh

Reg.1 kWhReg.1 kWh

Trf.3 0.535

Trf.3 0.535

Trf.3 0.535Trf.3 0.535

Reg.1 kWh

Reg.1 kWhReg.1 kWh

Trf.4 0.465

Trf.4 0.465

Trf.4 0.465Trf.4 0.465

Reg.1 kWh

Reg.1 kWhReg.1 kWh

Trf.

Trf.5555 0.

0.777

777

Trf.Trf.

0. 0.

777777

Reg.1 kWh

Reg.1 kWhReg.1 kWh

Trf.

Trf.6666

1111.535

.535

Trf.Trf.

.535.535

Reg.1 kWh

Reg.1 kWhReg.1 kWh

Tot.

Tot. 43.312

43.312

Tot. Tot.

43.31243.312

Reg.2 kvarh

Reg.2 kvarhReg.2 kvarh

Trf.1 0.100

Trf.1 0.100

Trf.1 0.100Trf.1 0.100

Reg.2 kvarh

Reg.2 kvarhReg.2 kvarh

Trf.2 0.117

Trf.2 0.117

Trf.2 0.117Trf.2 0.117

Reg.2 kvarh

Reg.2 kvarhReg.2 kvarh

Trf.3 0.235

Trf.3 0.235

Trf.3 0.235Trf.3 0.235

KWH

Tariff 1

KWH

Tariff 2

KWH

Tariff 3

KWH

Tariff 4

KWH

Tariff 5

KWH

Tariff 6

KWH

Total

kvarh

Tariff 1

kvarh

Tariff 2

kvarh

Tariff 3

Description

DescriptionDescription

24

Multi-Mon Multiple Circuit Energy Monitor

Page 25

Chapter 3 Multi-Mon Display Operations

Page

Page

Page Page

№№№№

11 Reg.2 kvarh

12 Reg.2 kvarh

13 Reg.2 kvarh

14 Reg.2 kvarh

15 Reg.3 kVAh

16 Reg.3 kVAh

17 Reg.3 kVAh

18 Reg.3 kVAh

19 Reg.3 kVAh

20 Reg.3 kVAh

21 Reg.3 kVAh

Page content

Page content Description

Page contentPage content

Reg.2 kvarh

Reg.2 kvarhReg.2 kvarh

Trf.4 0.050

Trf.4 0.050

Trf.4 0.050Trf.4 0.050

Reg.2 kvarh

Reg.2 kvarhReg.2 kvarh

Trf.

Trf.5555 0.235

0.235

Trf.Trf.

0.235 0.235

Reg.2 kvarh

Reg.2 kvarhReg.2 kvarh

Trf.

Trf.6666 0.050

0.050

Trf.Trf.

0.050 0.050

Reg.2 kvarh

Reg.2 kvarhReg.2 kvarh

Tot.

Tot. 0.787

0.787

Tot. Tot.

0.7870.787

Reg.3 kVAh

Reg.3 kVAhReg.3 kVAh

Trf.1 32.535

Trf.1 32.535

Trf.1 32.535Trf.1 32.535

Reg.3 kVAh

Reg.3 kVAhReg.3 kVAh

Trf.2 7.469

Trf.2 7.469

Trf.2 7.469Trf.2 7.469

Reg.3 kVAh

Reg.3 kVAhReg.3 kVAh

Trf.3 0.584

Trf.3 0.584

Trf.3 0.584 Trf.3 0.584

Reg.3 kVAh

Reg.3 kVAhReg.3 kVAh

Trf.4 0.468

Trf.4 0.468

Trf.4 0.468Trf.4 0.468

Reg.3 kVAh

Reg.3 kVAhReg.3 kVAh

Trf.

Trf.5555 0.584

0.584

Trf.Trf.

0.584 0.584

Reg.3 kVAh

Reg.3 kVAhReg.3 kVAh

TTTTrf.

rf.6666 0.468

0.468

rf.rf.

0.468 0.468

Reg.3 kVAh

Reg.3 kVAhReg.3 kVAh

Tot.

Tot. 42.575

42.575

Tot. Tot.

42.57542.575

Summary/TOU Energy

Summary/TOU Energy

Summary/TOU EnergySummary/TOU Energy

kvarh

Tariff 4

kvarh

Tariff 5

kvarh

Tariff 6

Kvarh

Total

kVAh

Tariff 1

kVAh

Tariff 2

kVAh

Tariff 3

kVAh

Tariff 4

kVAh

Tariff 5

kVAh

Tariff 6

kVAh

Total

ENTER

Description

DescriptionDescription

Display Views

Real Time Measurements

Real Time Measurements

Real Time MeasurementsReal Time Measurements

Page

Page

Page Page

№№№№

1 V1 120.5 V

2 V2 120.5 V

3 V3 120.5 V

4 V L12 208.1 V

5 V L23 208.1 V

6 V L31 208.1 V

7 I1 neg 5.58 A

8 I2 neg 7.70 A

9 I3 neg 5.58 A

10 Tot. kW 1.558

11 Tot.PF 0.997

12 Tot. kVA 1.601

13 Tot. kvar 0.097

14 Freq. 60.00 Hz

15 V1.Ang 0.0

16 V2. Ang

17 V3. Ang 120.0

Page content

Page content Description

Page contentPage content

V1 120.5 V Volts

V1 120.5 VV1 120.5 V

V2 120.5 V Volts

V2 120.5 VV2 120.5 V

V3 120.5 V Volts

V3 120.5 VV3 120.5 V

V L12 208.1 V Line to line volts

V L12 208.1 VV L12 208.1 V

V L23 208.1 V Line to line volts

V L23 208.1 VV L23 208.1 V

V L31 208.1 V Line to line volts

V L31 208.1 VV L31 208.1 V

I1 neg 5.58 A

I1 neg 5.58 AI1 neg 5.58 A

I2 neg 7.70 A

I2 neg 7.70 AI2 neg 7.70 A

I3 neg 5.58 A

I3 neg 5.58 AI3 neg 5.58 A

Tot. kW 1.558 Total kW

Tot. kW 1.558 Tot. kW 1.558

Tot.PF 0.997 Total power factor

Tot.PF 0.997Tot.PF 0.997

Tot. kVA 1.601 Total kVA

Tot. kVA 1.601 Tot. kVA 1.601

Tot. kvar 0.097 Total kvar

Tot. kvar 0.097 Tot. kvar 0.097

Freq. 60.00 Hz Frequency

Freq. 60.00 HzFreq. 60.00 Hz

V1.Ang 0.0

V1.Ang 0.0V1.Ang 0.0

I1. Ang 0.0

I1. Ang 0.0

I1. Ang 0.0I1. Ang 0.0

V2. Ang ----120.0

V2. Ang V2. Ang

I2. Ang

I2. Ang ----120.0

I2. Ang I2. Ang

V3. Ang 120.0

V3. Ang 120.0V3. Ang 120.0

I3. Ang 120.0

I3. Ang 120.0

I3. Ang 120.0I3. Ang 120.0

120.0

120.0120.0

120.0

120.0120.0

Amps. The neg

of a reverse current connection.

Amps. The neg

of a reverse current connection.

Amps. The neg

of a reverse current connection.

Phase 1 angles

Phase 2 angles

Phase 3 angles

ENTER

Description

DescriptionDescription

neg label appears in the case

neg neg

neg label appears in the case

neg neg

neg label appears in the case

neg neg

Multi-Mon Multiple Circuit Energy Monitor

25

Page 26

Chapter 3 Multi-Mon Display Operations

Page

Page

Page Page

№№№№

1 Reg.1 MD kW

2 Reg.1 MD kW

3 Reg.1 MD kW

4 Reg.1 MD kW

5 Reg.1 MD kW

6 Reg.1 MD kW

7 Reg.1 MD kW

8 Reg.2 MD kvar

9 Reg.2 MD kvar

10 Reg.2 MD kvar

11 Reg.2 MD kvar

12 Reg.2 MD kvar

13 Reg.2 MD kvar

14 Reg.2 MD kvar

15 Reg.3 MD kVA

16 Reg.3 MD

17 Reg.3 MD kVA

18 Reg.3 MD kVA

19 Reg.3 MD kVA

20 Reg.3 MD kVA

21 Reg.3 MD kVA

Page content

Page content Description

Page contentPage content

Reg.1 MD kW

Reg.1 MD kWReg.1 MD kW

Trf.1 32.535

Trf.1 32.535

Trf.1 32.535Trf.1 32.535

Reg.1 MD kW

Reg.1 MD kWReg.1 MD kW

Trf.2 7.465

Trf.2 7.465

Trf.2 7.465Trf.2 7.465

Reg.1 MD kW

Reg.1 MD kWReg.1 MD kW

Trf.3 0.535

Trf.3 0.535

Trf.3 0.535Trf.3 0.535

Reg.1 MD kW

Reg.1 MD kWReg.1 MD kW

Trf.4 0.465

Trf.4 0.465

Trf.4 0.465Trf.4 0.465

Reg.1 MD kW

Reg.1 MD kWReg.1 MD kW

Trf.

Trf.5555 0.535

0.535

Trf.Trf.

0.535 0.535

Reg.1 MD kW

Reg.1 MD kWReg.1 MD kW

Trf.

Trf.6666 0.465

0.465

Trf.Trf.

0.465 0.465

Reg.1 MD kW

Reg.1 MD kWReg.1 MD kW

Tot.

Tot. 42.

42.00

Tot. Tot.

42.42.

Reg.2 MD kvar

Reg.2 MD kvarReg.2 MD kvar

Trf.1 0.100

Trf.1 0.100

Trf.1 0.100Trf.1 0.100

Reg.2 MD kvar

Reg.2 MD kvarReg.2 MD kvar

Trf.2 0.117

Trf.2 0.117

Trf.2 0.117Trf.2 0.117

Reg.2 MD kvar

Reg.2 MD kvarReg.2 MD kvar

Trf.3 0.235

Trf.3 0.235

Trf.3 0.235Trf.3 0.235

Reg.2 MD kvar

Reg.2 MD kvarReg.2 MD kvar

Trf.4 0.050

Trf.4 0.050

Trf.4 0.050Trf.4 0.050

Reg.2 MD kvar

Reg.2 MD kvarReg.2 MD kvar

Trf.

Trf.5555 0.235

0.235

Trf.Trf.

0.235 0.235

Reg.2 MD kvar

Reg.2 MD kvarReg.2 MD kvar

Trf.

Trf.6666 0.050

0.050

Trf.Trf.

0.050 0.050

Reg.2 MD kvar

Reg.2 MD kvarReg.2 MD kvar

Tot. 0.

Tot. 0.787

Tot. 0.Tot. 0.

Reg.3 MD kVA

Reg.3 MD kVAReg.3 MD kVA

Trf.1 32.535

Trf.1 32.535

Trf.1 32.535Trf.1 32.535

Reg.3 MD kVA

Reg.3 MD Reg.3 MD

Trf.2 7.469

Trf.2 7.469

Trf.2 7.469Trf.2 7.469

Reg.3 MD kVA

Reg.3 MD kVAReg.3 MD kVA

Trf.3 0.584

Trf.3 0.584

Trf.3 0.584 Trf.3 0.584

Reg.3 MD kVA

Reg.3 MD kVAReg.3 MD kVA

Trf.4 0.468

Trf.4 0.468

Trf.4 0.468Trf.4 0.468

Reg.3 MD kVA

Reg.3 MD kVAReg.3 MD kVA

Trf.

Trf.5555 0.584

0.584

Trf.Trf.

0.584 0.584

Reg.3 MD kVA

Reg.3 MD kVAReg.3 MD kVA

Trf.

Trf.6666 0.468

0.468

Trf.Trf.

0.468 0.468

Reg.3 MD kVA

Reg.3 MD kVAReg.3 MD kVA

Tot.

Tot. 42.575

42.575

Tot. Tot.

42.57542.575

Summary/TOU Max. Demands

Summary/TOU Max. Demands

Summary/TOU Max. DemandsSummary/TOU Max. Demands

KW maximum demand

Tariff 1

KW maximum demand

Tariff 2

KW maximum demand

Tariff 3

KW maximum demand

Tariff 4

KW maximum demand

Tariff 5

KW maximum demand

Tariff 6

KW maximum demand

000000

0000

787

787787

kVA

kVAkVA

Total

kvar maximum demand

Tariff 1

kvar maximum demand

Tariff 2

kvar maximum demand

Tariff 3

kvar maximum demand

Tariff 4

kvar maximum demand

Tariff 5

kvar maximum demand

Tariff 6

kvar maximum demand

Total

kVA maximum demand

Tariff 1

kVA maximum demand

Tariff 2

kVA maximum demand

Tariff 3

kVA maximum demand

Tariff 4

kVA maximum demand

Tariff 5

kVA maximum demand

Tariff 6

kVA maximum demand

Total

ENTER

Description

DescriptionDescription

Display Views

26

Multi-Mon Multiple Circuit Energy Monitor

Page 27

Chapter 3 Multi-Mon Display Operations

Total Energy and Maximum Demand Registers

Total Energy and Maximum Demand Registers

Total Energy and Maximum Demand RegistersTotal Energy and Maximum Demand Registers

Page

Page

Page Page

№№№№

1 Total kWh:

2 Total kvarh:

2 Total kVA:

3 Max.Dmd kW

4 Max.Dmd kvar

5 Max.Dmd kVA

6 Max.Dmd I1, A

7 Max.

8 Max.Dmd I3, A

9 Max.Dmd V1, V

10 Max.Dmd V2, V

11 Max.Dmd V3, V

Page

Page

Page Page

№№№№

1 Diagnostics

2 S/N

3 S/W V1

4 COM1:

5 COM2: Ethernet

6 Ph1 Ph2 Ph3

Page content

Page content Description

Page contentPage content

Total kWh:

Total kWh:Total kWh:

124100.0

124100.0

124100.0 124100.0

Total kvarh:

Total kvarh:Total kvarh:

124.0

124.0

124.0 124.0

Total kVA:

Total kVA:Total kVA:

124100.0

124100.0

124100.0 124100.0

Max.Dmd kW

Max.Dmd kWMax.Dmd kW

25.588

25.588

25.588 25.588

Max.Dmd kvar

Max.Dmd kvarMax.Dmd kvar

4.709

4.709

4.709 4.709

Max.Dmd kVA

Max.Dmd kVAMax.Dmd kVA

26.017

26.017

26.017 26.017

Max.Dmd I1, A

Max.Dmd I1, AMax.Dmd I1, A

15.58

15.58

15.58 15.58

Max.Dmd I2, A

Dmd I2, A

Max.Max.

Dmd I2, ADmd I2, A

15.58

15.58

15.58 15.58

Max.Dmd I3, A

Max.Dmd I3, AMax.Dmd I3, A

15.58

15.58

15.58 15.58

Max.Dmd V1, V

Max.Dmd V1, VMax.Dmd V1, V

120.5

120.5

120.5 120.5

Max.Dmd V2, V

Max.Dmd V2, VMax.Dmd V2, V

120.5

120.5

120.5 120.5

Max.Dmd V3, V

Max.Dmd V3, VMax.Dmd V3, V

120.5

120.5

120.5 120.5

Page content

Page content Description

Page contentPage content

Diagnostics

DiagnosticsDiagnostics

3333

S/N 999956456

S/N S/N

S/W V18.5.1

S/W V1S/W V1

Boot:

Boot: V1.

Boot: Boot:

COM1:

COM1: COM1:

A1, Bd19.2

A1, Bd19.2

A1, Bd19.2A1, Bd19.2

COM2: Ethernet

COM2: EthernetCOM2: Ethernet

192.168.0.203

192.168.0.203

192.168.0.203192.168.0.203

Ph1 Ph2 Ph3

Ph1 Ph2 Ph3Ph1 Ph2 Ph3

I1 I2 I3

I1 I2 I3

I1 I2 I3 I1 I2 I3

Description

DescriptionDescription

Total kWh

Total kvarh

Total kVAh

Total kW maximum demand

Total kvar maximum demand

Total kVA maximum demand

Ampere maximum demand

Ampere maximum demand

Ampere maximum demand

Volt maximum demand

Volt maximum demand

Volt maximum demand

ENTER

Service Display

Service Display

Service DisplayService Display

Description

DescriptionDescription

Device diagnostics. See Diagnostics

Display below.

56456 Device serial number

5645656456

8.5.1

8.5.18.5.1

V1.2222....1111

V1. V1.

Software version

Boot loader version

COM1 port: address and baud rate

COM2 port: node address and net ID, or

IP address

Submeter phase current assignments

Display Views

Di

Diagnostics Display

agnostics Display

DiDi

agnostics Displayagnostics Display

The diagnostics display shows a list of the device diagnostic codes recorded

as a result of the meter self-test diagnostics. The diagnostics page is only

displayed if errors were detected.

See Device Diagnostic Codes in Appendix F for the list of diagnostic codes

and their meanings. See Device Diagnostics in Chapter 2 for more

information on the Multi-Mon built-in diagnostics. See Reset in Chapter 3 on

how to clear the device diagnostics status from the display.

Multi-Mon Multiple Circuit Energy Monitor

27

Page 28

Chapter 3 Multi-Mon Display Operations

Enter Password

00000000

Options

Exit

COM1

Exit

COM1

Protoc

ol

Options

Exit

Options

Exit

Navigating in Menus

Navigating in Menus

Navigating in MenusNavigating in Menus

The Multi-Mon setup is menu-driven. To enter the setup menus, press the

SELECT button for more than 5 seconds.

Entering Numbers

Entering Numbers

Entering NumbersEntering Numbers

Each digit in numbers is adjusted separately with the UP/DOWN buttons. A

brief press on the button increments or decrements the highlighted digit by

one. A highlighted digit is flashing twice per second. To move to the next

digit, press briefly the SELECT button.

When the number is set to a desired value, press briefly the ENTER button

to store your new setting.

Entering a Password

Entering a Password

Entering a PasswordEntering a Password

The setup menus are secured by an 8-digit user password. If the password

entered is correct, you will move to the main menu, otherwise you will return

to the display mode.

Selecting Menus

Selecting Menus

Selecting MenusSelecting Menus

The main menu is represented by two entries; the left item shows a menu

list, while the right item is an assisting exit window that allows easy returning

to the display mode. Flashing highlights a currently active menu item (in the

following diagrams, a highlighted item is pointed out by using a bold font). To

highlight a desired menu item, press briefly the SELECT button.

ENTER

Modbus RTU

SELECT

To select a menu entry from the menu list:

1. Highlight the left item by briefly pressing the SELECT button if it is not

highlighted yet.

2. Scroll through the menu list by briefly pressing the UP and DOWN

buttons until the desired menu entry appears.

3. Press the ENTER button.

To exit the main menu:

1. Highlight the Exit item by briefly pressing the SELECT button.

2. Press the ENTER button.

Navigating in Menus

28

ENTER

Multi-Mon Multiple Circuit Energy Monitor

Page 29

Chapter 3 Multi-Mon Display Operations

COM1

Protocol

COM1

Address

COM1 Address

COM1 Address

COM1

Address

SubMeter

Exit

SubMeter

SM 1

SubMeter

SM 4

SubMeter SM 4

Viewing and Changing Setup Items

Viewing and Changing Setup Items

Viewing and Changing Setup ItemsViewing and Changing Setup Items

A second level menu normally consists of three items: the upper-left static

Modbus RTU

1

SELECT

001

126

ENTER

126

ENTER

COM1 Exit

item indicates the menu name, while the upper-right item represents a list of

setup parameters you can scroll through, and the lower item shows the

present parameter value.

To select a parameter you want to view or change:

1. Highlight the upper-right item by briefly pressing the SELECT button if

the item is not highlighted yet.

2. Scroll through the parameter list with the UP/DOWN buttons until the

desired parameter name appears.

To change the selected parameter:

1. Press the SELECT button briefly to highlight the lower item.

2. If a number represents the parameter value, highlight a desired digit by

briefly pressing the SELECT button, then adjust the digit to the desired

value by the UP and DOWN buttons.

3. If a name represents the parameter value, select the desired value by

the UP and DOWN buttons.

4. Press the ENTER button to store your selection. You return to the

parameter list to select another parameter or return to the main menu.

To exit the menu:

1. Highlight the menu name (upper-left item) by pressing briefly the

SELECT button.

2. Press the ENTER button.

Menu Operations

Menu Operations

Menu Operations

Menu OperationsMenu Operations

Submeter Channel Assignments

Submeter Channel Assignments

Submeter Channel AssignmentsSubmeter Channel Assignments

This menu allows you to link the device current terminals to submeters so

they can monitor them. Additionally, the menu allows you to specify the

primary current rating of the current transformers connected to the device

terminals. The number of the selected current inputs for a submeter specifies

ENTER

Phase L1 I1

Phase L1 I1

SELECT

Phase L1 I1

if it will be a single-, two-, or three-phase meter.

Always select your submeters in a sequence without gaps so that your

Always select your submeters in a sequence without gaps so that your

Always select your submeters in a sequence without gaps so that your Always select your submeters in a sequence without gaps so that your

device does not occupy unnecessary network addresses.

device does not occupy unnecessary network addresses.

device does not occupy unnecessary network addresses.device does not occupy unnecessary network addresses.

To enter the menu, select the SubMeter entry from the main menu, and then

press the ENTER button.

To select a parameter you want to view or change:

1. Highlight the upper-right item by using the SELECT button.

2. Select the submeter you wish to configure with the UP/DOWN buttons.

3. Highlight the lower-left item by briefly pressing the SELECT button.

4. Scroll through the parameter list with the UP/DOWN buttons until the

desired parameter name appears.

To change the selected parameter:

1. Highlight the lower-right item by using the SELECT button.

Multi-Mon Multiple Circuit Energy Monitor

29

Page 30

Chapter 3 Multi-Mon Display Operations

R

eset

SM 1

Reset

SM 4

Reset

SM 4

Reset

SM 4

Reset

SM 4

Reset

SM 4

SubMeter SM 4

SubMeter SM 4

SubMeter SM 4

2. To link a current input to a submeter, select the desired input ID with the

UP/DOWN buttons.

SELECT

Phase L1 I1

Phase L1 I10

ENTER

Phase L1 10

Reset

Reset

ResetReset

Diag. Do

Diag. Do

SELECT

Diag. Do

Pow.Dmd Do

SELECT

Pow.Dmd Do

ENTER

3. To change the CT primary rating, highlight desired digits by briefly

pressing the SELECT button, then adjust them to the desired value with

the UP/DOWN buttons.

4. Press the ENTER button to store your selection. You return to the

parameter list to select another parameter or return to the main menu.

To exit the menu, highlight the menu name (upper-left item) with the

SELECT button, and then press the ENTER button.

The following table lists available options.

Label

Label Parameter

LabelLabel

Phase L1

Phase L1

Phase L1Phase L1

Phase L2

Phase L2

Phase L2Phase L2

Phase L3

Phase L3

Phase L3Phase L3

CT

CT CT primary

CTCT

1

The device is pre-configured for twelve three-phase submeters.

2