Page 1

62-0389-05

Class 2000 Meter

KWH & KWH/DEMAND METER

INSTALLATION INSTRUCTIONS

E-Mon

850 Town Center Drive

Langhome, PA 19047

(800)334-3666

www.emon.com

Page 2

CLASS 2000 METER

Dear Valued Customer,

We are pleased that you chose to buy one of our products, and want you to be just as

pleased with owning it. Before installing your new E-Mon product, please read the

information on the following pages carefully.

We believe that you will find the E-Mon D-Mon meters easy to install and to use for

monitoring and evaluating your electrical usage.

To be sure that you are 100% satisfied with your products, we provide toll-free

technical and sales support Monday through Friday, 8:00 am to 7:30 pm, EST: (800)

334-3666. You may also reach us via e-mail at info@emon.com.

If you have questions, we can handle them quickly and effectively with a telephone call.

Please let us try to help you BEFORE you remove your meter. And to help us help you,

we ask that you have all relevant information on hand when you call (model or part

numbers, nature of difficulty, etc.)

Be sure to forward this manual to the owner after installation is complete, so that they

may use it as a reference guide when reading the E-Mon D-Mon meter.

Thank you.

62-0389-05 2

Page 3

CLASS 2000 METER

TABLE OF CONTENTS

Section 1.0 Pre-Installation Information 4

Section 2.0 Safety Label Definitions and Information 6

Section 3.0 Precautionary and Safety Information 7

Section 4.0 Meter Installation 8

Section 4.1 Mounting the Meter 8

Section 4.2 Main Power Board Connections 8

Section 4.3 Current Sensor Installation & Wiring 11

Section 4.4 MAINS Line Voltage & Current Sensor Wiring

Diagrams

Section 4.5 Installation Overview 15

Section 4.6 Check Polarity of the Current Sensor 15

Section 5.0 Monitoring Multiple Loads with One Meter 19

Section 6.0 KWh Meter Features & Functions 21

Section 6.1 KWh Meter Display Features 21

Section 6.2 How to Read the kWh Meter 22

Section 6.3 KWh Meter Hardware Functions 23

Section 6.4 Class 1000 and Class 2000 Pulse Output Removable

Two-Screw Terminal Plug

Section 7.0 KWh/Demand Meter Features & Functions* 26

Section 7.1 KWh/Demand Meter Display Functions 26

Section 7.2 How to Read the kWh/Demand Meter 27

Section 7.3 Demand Display Set-Up 28

Section 7.4 Demand Reset 30

Section 7.5 Test Mode 32

Section 8.0 Preventative/Scheduled Maintenance 34

Section 9.0 Lithium Battery Replacement Instructions 35

Section 10.0 Troubleshooting Guide 37

Section 10.1 Line Voltage Diagnostics 38

Section 11.0 High Voltage Metering 41

Section 12.0 Frequently Asked Questions 44

Section 13.0 Meter Technical Specifications 46

Section 14.0 Meter Limited Warranty 49

* Applies to meters equipped with the Demand option.

14

24

3 62-0389-05

Page 4

CLASS 2000 METER

1.0 PRE-INSTALLATION INFORMATION

The E-Mon D-Mon® Class 2000 kWh/Demand meter is a 3-element meter used to

monitor electric power usage of individual loads after the utility meter. Installation

must only be performed by qualified personnel and in accordance with these

instructions and all applicable local and national electrical codes. E-Mon or its

representatives assume no responsibility for damages or injury resulting from the

improper installation of this meter.

Meters are supplied in a UL Type 1 steel enclosure appropriate for indoor installation

where it will not be affected by the elements, such as moisture and extreme

temperatures.

Units designated by the “R” suffix on the model number have an extended

environmental operating range and are enclosed in a NEMA 4X enclosure to

accommodate outdoor environments.

Verify the input voltage rating and configuration on the meter label to ensure it is

suitable for the intended electrical services. For example, Class 2000 meters labeled

for 208V service MUST NOT be installed on service feeds of 480V and vice versa.

Verify the current sensors are sized suitably for the load to be monitored. Compare the

color of the arrows on the current sensors to the chart below to confirm the correct

current sensor is being used.

Sensor Arrow Color Code Sensor Rating

Brown 100 Amp

Red 200 Amp

Yellow 400 Amp

Black 800 Amp

Blue 1600 Amp

White/Black 3200 Amp

Meter Labeled: Works On:

120/240V 120/240V, 1 Phase

208V 208V, 3 Phase

240V 240V, 3 Phase

400V (380, 415) 400V, 3 Phase

480V 480V, 3 Phase

600V 600V, 3 Phase

62-0389-05 4

Page 5

CLASS 2000 METER

CAUTION

WARNING

M33177

MAIN POWER

BOARD

DISPLAY AND

KEYBOARD

Internal circuit card components are extremely sensitive to electrostatic

discharge. Prior to handling or touching internal circuitry, discharge any

static buildup on your person. To discharge yourself, touch a grounded

metal object such as conduit or an earth grounded metal enclosure.

Use of this instrument, Class 2000, in a manner inconsistent with this

manual or not specified by the manufacturer in writing, can cause

permanent damage to the unit and/or serious injury to the operator. The

protection and safety features provided by this equipment may become

impaired or otherwise compromised.

NOTE: If any trouble arises during installation or functional verification opera-

tions, do not immediately remove unit. Before removing the unit, contact E-Mon’s technical support department at (800) 334-3666. E-Mon’s

technical department will assist you in detailed troubleshooting of the

Class 2000 installation.

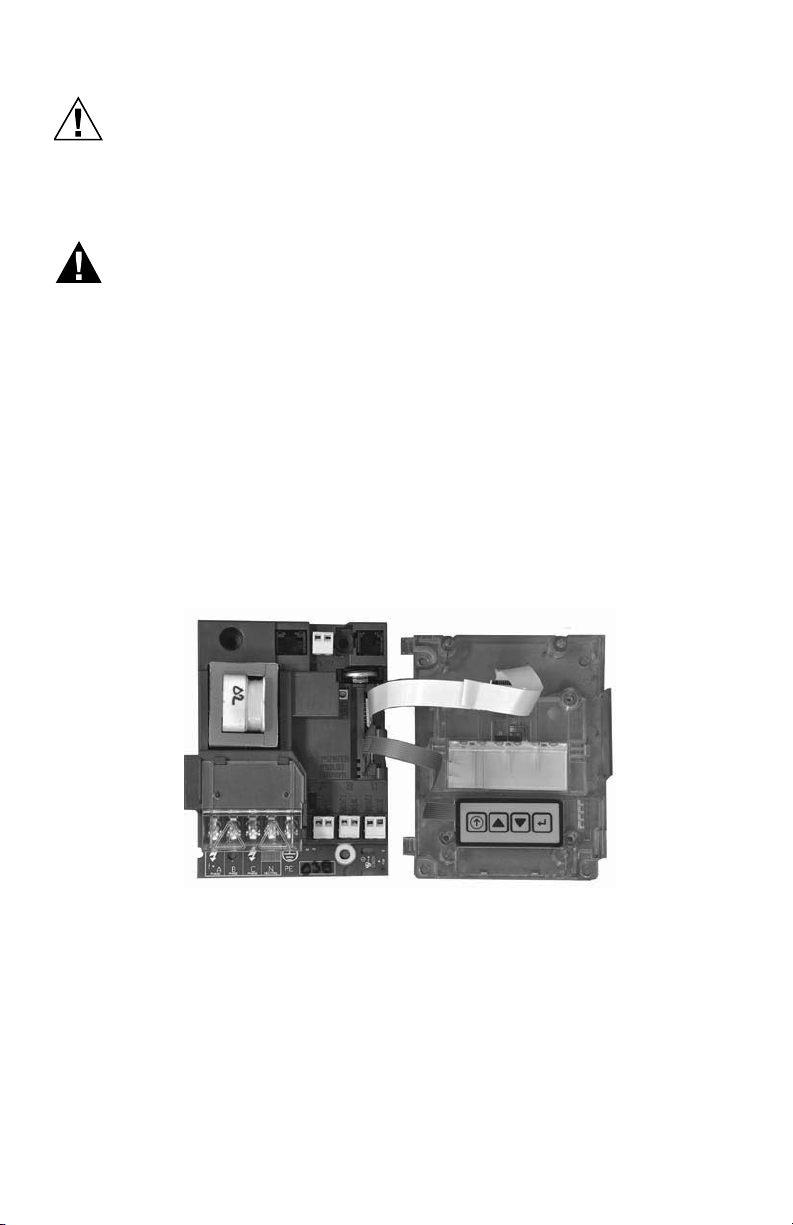

1.1 Internal Electronic Assemblies

The unit is comprised of a Main Power Board, Display Board and Keyboard. All circuit

cards are mounted inside a UL Type 1 (standard) or NEMA 4X (optional) enclosure.

Fig. 1. Power Supply Board and Display Board.

NOTE: Units are supplied in a UL Type 1 metal enclosure suitable for indoor

applications only. Units supplied in the optional NEMA 4X fiberglass

enclosure are suitable for either indoor or outdoor applications, within

the defined specifications. Refer to Section 12.0 for a definition of suitable environmental conditions for indoor and outdoor units.

5 62-0389-05

Page 6

CLASS 2000 METER

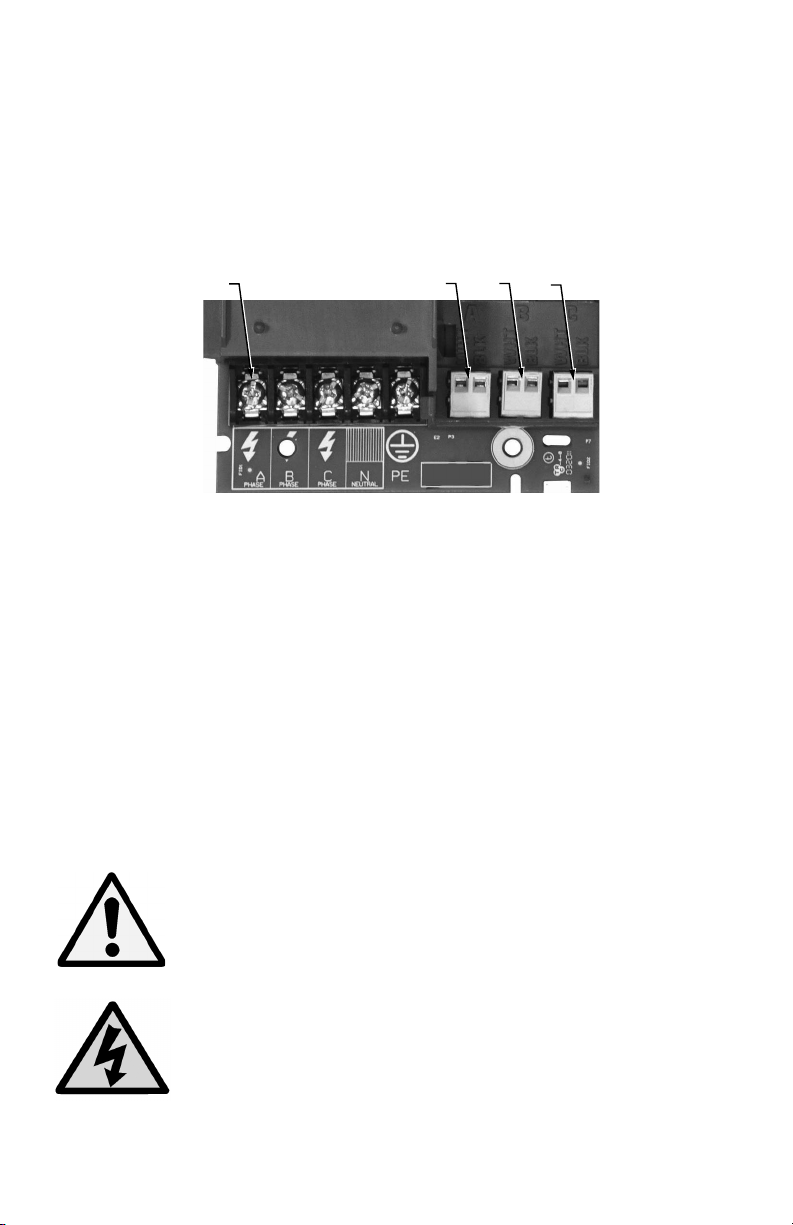

1.1.1 Main Power Board

Connections to this board include the MAINS Input Voltage, Current Sensors, external

IDR interface and Isolated Pulse Output. The MAINS input terminals are covered with

a protective shield for safety purposes. The current sensor assemblies interface to

three header connectors, labeled A, B, and C along with conductor color indication.

Each header connector input corresponds to an input voltage phase, so care must be

taken to ensure each current sensor is connected to the correct input header.

TB3

TB1

Fig. 2. Standard Configuration.

TB2

TB4

M33178

1.1.2 Display Board

The display connects to the main power board via a flex-ribbon cable and is mounted

on the inside of the enclosure door. The LCD readout indicates the cumulative kWh

and instantaneous kW value on kWh meters. The LCD readout indicates cumulative

kWh, peak demand and instantaneous kW values on kWh/ Demand meters).

2.0 SAFETY LABEL DEFINITIONS AND INFORMATION

The Green Class meter may contain one or more of the following labels. Operator(s)

should familiarize themselves with the meaning of each label to minimize risk.

The presence of this label is a cautionary indicator identifying a

danger risk. The manual should be consulted prior to proceeding.

The presence of this label indicates an electrical shock hazard exists

in the location or area where the label is placed. Prior to proceeding,

the MAINS power must be disconnected and the manual consulted for

safety information.

62-0389-05 6

Page 7

CLASS 2000 METER

CAUTION

WARNING

WARNING

WARNING

3.0 PRECAUTIONARY AND SAFETY INFORMATION

Internal circuit card components are extremely sensitive to electrostatic

discharge. Be careful not to touch internal circuitry prior to discharging

any static buildup on your person. To discharge yourself, touch a

grounded metal object such as conduit or an earth-grounded metal

enclosure.

High voltages present on main PCB terminal block TB1 screw terminals.

Risk of serious injury and/or electrical shock exists. Prior to performing

any wiring operations, review all contents of the user manual and deenergize the MAINS power switch. Only qualified personnel should

perform installation wiring. Installation wiring must comply with all local

and national electrical codes.

Failure to ground the enclosure creates a possible shock hazard. Do not

operate the Class 2000 meter without a protective earth wire attached

securely to the PE terminal screw. After installing protective earth wiring,

secure the screw tightly (7in-lb torque.)

NEVER open front panel of unit while unit has MAINS power applied.

Failure to comply can increase the risk of serious injury and/or electrical

shock.

7 62-0389-05

Page 8

CLASS 2000 METER

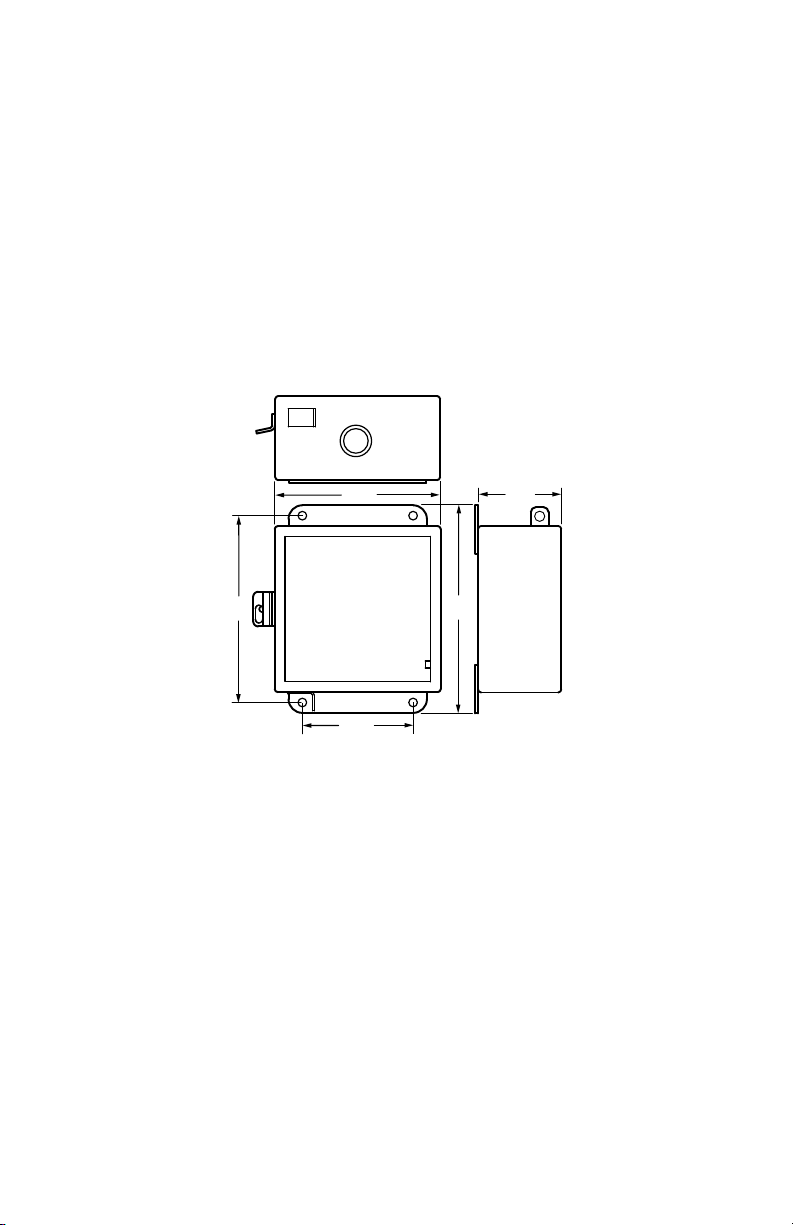

3 (76)

7-1/2

(191)

M33627

6 (152)

4 (102)

6-3/4

(171)

4.0 METER INSTALLATION

4.1 Mounting the Meter

Using the appropriate sized mounting hardware, fasten the Class 2000 meter

enclosure to the selected mounting surface. The four mounting holes are centered

6.75” H x 4” W. The mounting hole spacing is identical for either the UL Type 1 or

NEMA 4X enclosure.

NOTE: Only the NEMA 4X plastic enclosed unit is suitable for outdoor environ-

mental conditions. Units housed in UL Type 1 JIC steel enclosures must

only be installed in indoor environments where it will not be affected by

the elements, such as moisture and extreme temperatures.

Fig. 3. Enclosure Dimensions.

4.2 Main Power Board Connections

1. Install a temporary ground for ESD (Electrostatic Discharge) protection. With all

circuits de-energized, connect a temporary protective earth ground connection

for ESD protection. Prior to performing any unit wiring, be sure to discharge any

static on your person.

2. Install the Class 2000 Protective Earth Ground. Connect an earth ground wire to

the Class 2000 protective earth ground terminal screw located on the right side

of the line voltage terminal block. After installing the protective earth ground wire,

securely fasten the protective earth ground screw.

62-0389-05 8

Page 9

CLASS 2000 METER

WARNING

Failure to attach the protective earth ground wire securely to the

enclosure creates a potential shock hazard. Do not operate the Class

2000 meter without a protective earth ground connection securely

installed.

3. Wire Entry.

a. Two openings exist on the unit enclosure, one for 1/2” conduit and one for 3/

4” conduit. The 3/4” conduit opening located on the bottom of the enclosure

is used to bring in MAINS Power (voltage lines to power meter) and current

sensor wiring. The 1/2” conduit opening located on the top of the enclosure

is used to interface low voltage signals, such as the IDR interface and isolated pulse output. (Outdoor enclosures equipped with one 3/4” conduit

opening on bottom of enclosure only.)

b. Route the appropriate cabling to and through the respective enclosure open-

ing. The conduit and fittings interfacing the enclosure entrances must be UL

listed and properly sized to the enclosure port diameter, The interfacing fitting must use a gasket seal ring to interface between the conduit fitting and

the enclosure entry point. After installing the conduit fitting and conduit, verify

that the conduit fittings are aligned properly to their respective enclosure

entrance ports and tightened securely to prevent moisture entry. VERIFY

that each conduit slip nut is securely tightened to its respective conduit fitting.

c. Outdoor applications require the use of the optional 4X enclosure. The same

principles outlined for indoor meter installations as defined in the aforementioned paragraph carry over and apply to outdoor installations with one

exception. The exception is that the conduit and fittings for outdoor installations require an outdoor material rating and approval for 4X applications.

4. Unit MAINS Wiring (Voltage Wiring Connections)

a. Remove the shield located over the phase A,B and C screw terminals on the

main power board. This shield can be removed by pulling back on the latch

on the right side of the shield and lifting up on the front. Wire each connection to the terminal block with stranded wire 14-12 AWG, rated at 600 VAC.

b. Strip back all wire insulation to expose between 1/4” and 3/8” of the copper

conductors. Gently twist each wire to prevent fraying. Insert the conductors

into their respective terminal block position and tighten down the terminal

block screw to securely fasten the conductor. The terminal block is clearly

labeled PHASE A, PHASE B, PHASE C and NEUTRAL.

c. Connect the NEUTRAL wire to the appropriate terminal block position.

NOTE: For Delta MAINS input wiring, DO NOT connect the NEUTRAL wire.

Remove the terminal block screw for this position.

9 62-0389-05

Page 10

CLASS 2000 METER

d. Connect the AC mains power wires (Phase A, Phase B and Phase C) to their

respective positions as labeled on terminal block.Tighten the screws to 7 inlb of torque.

e. After all conductors are connected to their respective terminal block positions

and tightened down, verify that each terminal block screw is securely fastened by gently tugging on each conductor. Verify no conductor wires are

frayed or are shorting to adjacent terminal block positions.

5. External Switch Mechanism/In-Line Fuse Installation

a. To ensure a safe installation, the Class 2000 meter requires an external

switch mechanism, such as a circuit breaker, be installed on the Class 2000

MAINS input wiring. The switch mechanism must be installed in close proximity to the meter and easily reachable for the operator. This device must

also be marked as the disconnecting device for the Class 2000 meter.

b. Install 1/10 Amp Slow Activation in line fuses with the suitable voltage rating

for each conductor phase at the MAINS input to the meter. The fuses must

be labeled to indicate voltage and current rating as well as element characteristics. The fuse element must be slow activating type.

6. Once the MAINS wiring is complete, replace the clear Lexan protective shield

over terminal block TB1 and close the enclosure front panel. Secure the enclosure cover using the locking mechanism. Activate the external circuit breaker or

equivalent switch to apply AC MAINS power to the unit.

7. The Class 2000 meter display should turn on and indicate total kWh accumulation reading.

NOTE: On demand meters (meters ordered with "-D-") the unit display, clock

and other critical configuration parameters will be set once the unit

installation and wiring is complete.

8. Using an AC Voltmeter, verify the input voltage readings are within the limits

specified below.

Meter Input Voltage

Configuration Nominal Voltage Limits (+/- 10%)

120/208V, 3 Ph, 4 Wire 120 VAC (L-N) 108 to 132 VAC

277/480V, 3 Ph, 4 Wire 277 VAC (L-N) 249 to 305 VAC

240V, 3 Ph, 3 Wire 240 VAC (L-L) 216 to 264 VAC

480V, 3 Ph, 3 Wire 480 VAC (L-L) 432 to 528 VAC

347/600V, 3 Ph, 4 Wire

347 VAC (L-N) 540 to 660 VAC

(WYE Only)

9. Remove power from the unit by de-energizing the external switch.

NOTE: For 3-Wire systems, the voltages are measured Phase to Phase. On 4-

Wire systems the voltages are measured Phase to Neutral.

62-0389-05 10

Page 11

CLASS 2000 METER

4.3 Current Sensor Installation & Wiring

Once the AC voltages have been confirmed to be within acceptable limits, you are

ready to install the current sensors. The MAIN power board contains three header

connectors located at the bottom right of the board. The connectors are labeled A, B,

and C along with conductor color indication. This format must be followed in order for

the meter to function correctly.

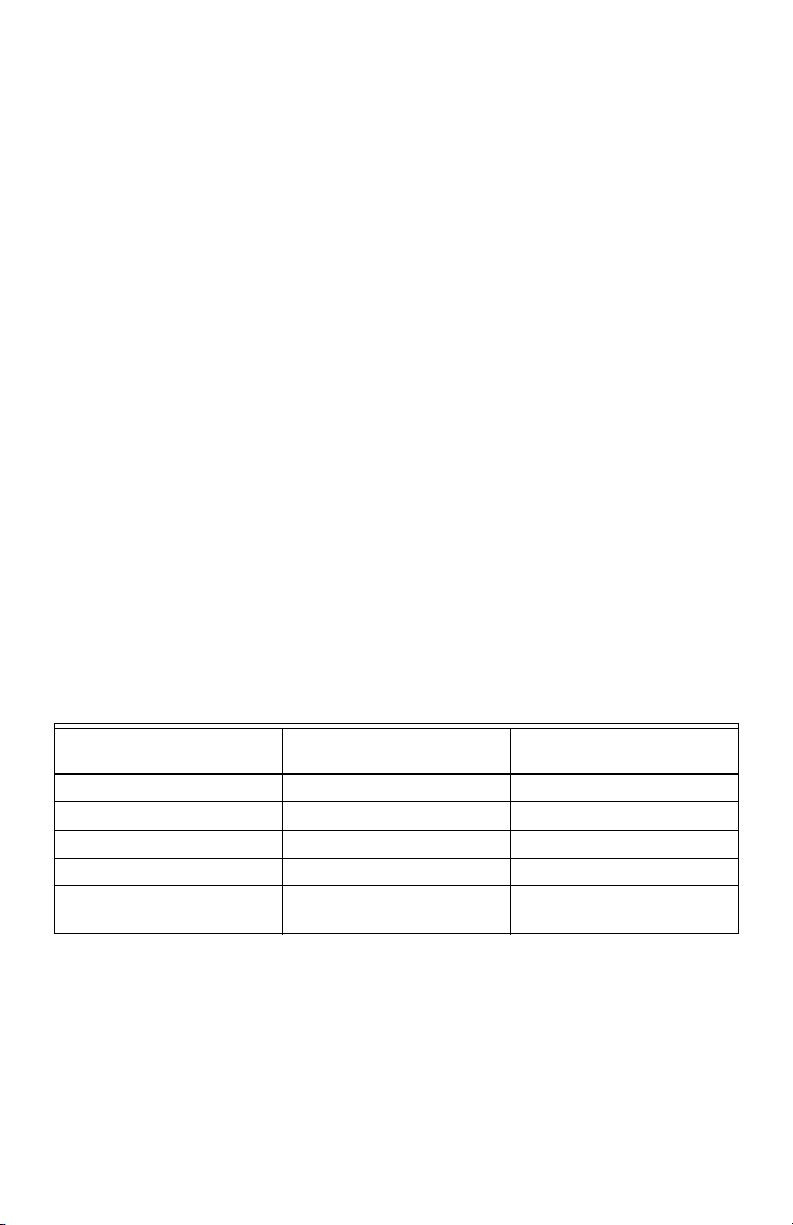

The Class 2000 meter will be used with one of two basic types of current sensors:

a. Split-Core Current Sensor: This sensor opens so that it can be attached

around the circuit conductor being monitored without interrupting power.

Unless otherwise specified, all Class 2000 meters are supplied with this

sensor type.

b. Solid-Core Current Sensor: This sensor does not open and requires the

monitored conductor be removed from the circuit to install the current sensor.

This type is only supplied when specified at time of order.

NOTE: The unit serial label specifies if the unit is set up for split or solid core

current sensors. See ordering information for details.

Both types of current sensors output a 0-2 VAC signal proportional to the current being

measured.

The current sensors must be matched with the voltage phases. The A phase sensor

must be monitoring the same phase as the A phase voltage. B & C phase sensors

must also monitor the same phase as their respective voltage inputs.

11 62-0389-05

Page 12

CLASS 2000 METER

M33213

LOAD

SOURCE

4.3.1 Installing the Split-Core Current Sensor Assembly

Each phase being monitored will require one two-piece current sensor assembly.

Therefore, a three-phase meter will require three (3) assemblies. Open the two-piece

current sensor assembly by releasing the nylon clamp using a flat head screwdriver.

Fig. 4. Split-Core Current Sensor Assembly.

1. Reassemble the current sensor assembly around the conductor(s) to be moni-

tored. Ensure the current sensor halves marked “Load” are both facing the load

side of the conductor. The colored arrow will be on the source side of the conductor being monitored and MUST be pointed in a clockwise direction around

the conductor being monitored. Tighten the nylon clamp to complete the assembly.

Fig. 5. Arrow On The Current Sensor Assembly.

IMPORTANT:

When looking from the source side of the conductor(s) being monitored, you

should see the arrow on the current sensor assembly. The arrow should be

pointing in a clockwise direction around the conductor(s) being monitored. If

the arrow is not positioned on the source side, inaccurate readings will result.

62-0389-05 12

Page 13

CLASS 2000 METER

4.3.2 Installing the Solid-Core Current Sensor Assembly

The optional solid-core current sensors can be installed in the same applications as

the standard split-core units, however, the conductors that they are monitoring must

first be disconnected.

NOTE: Under no circumstances is this operation to take place without shutting

off the power to the conductor(s) being monitored.

With the power off, disconnect the conductor from its breaker or terminal. Slide the

solid-core current sensor over the conductor, making sure that the indicator on the

sensor is pointing in the direction of the load. After this is done, reconnect the

conductor and verify that it is properly installed.

Run the black and white wires from the solid-core current sensors and install them

according to the standard installation diagram. When this is completed, the power to

the monitored conductor can be turned back on.

Fig. 6. Solid-core Current Sensor.

4.3.3 Current Sensor Wiring

Once all the current sensors are installed on their appropriate phase conductors, you

can begin terminating the current sensors on to the Class 2000 main power board.

The current sensor leads can be extended up to 2,000 feet (using #14-22 AWG wire)

for remote monitoring applications. Consult your local electrical codes for proper wire

sizing (#22 AWG twisted pair wire with a black and white conductor, rated for 600 VAC

recommended.)

The current sensor connection points are located on the bottom right of the main

power board. Three removable plugs exist, one for each current sensor phase input.

The header portions of the connectors are labeled A, B and C. Text on the plastic cover

of each of the connectors instruct you which terminal of the plug is for the white

conductor and which terminal is wired to the black conductor. Once each current

sensor is wired to its respective plug, insert each plug into the appropriate header,

verifying polarity as they are installed (see section 4.6).

13 62-0389-05

Page 14

CLASS 2000 METER

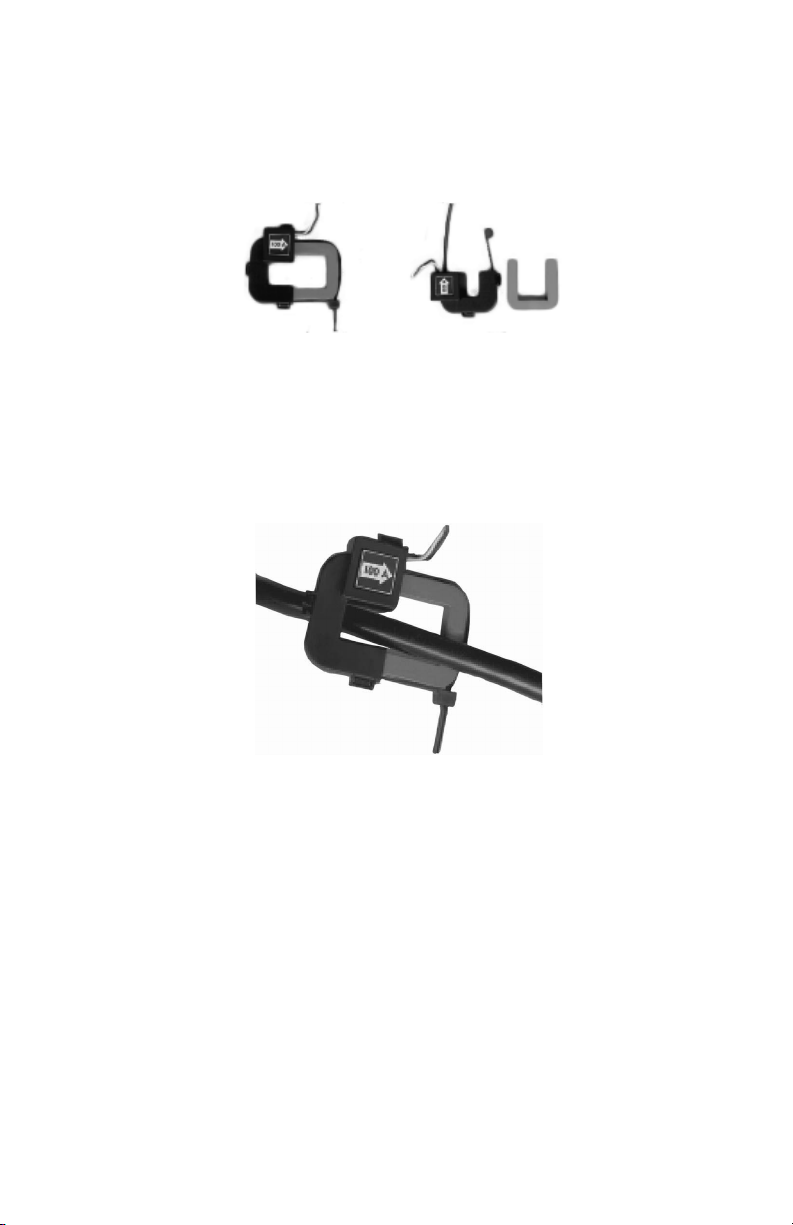

LINE VOLTAGE

CURRENT SENSORS

N

LOAD SOURCE

M33185

3-PHASE, 4-WIRE INSTALLATION DIAGRAM

NOTES:

LINE VOLTAGE CONNECTIONS: #14-12 AWG

SENSOR CONNECTIONS: B = BLACK LEAD W = WHITE LEAD

NEUTRAL NOT USED IN DELTA SYSTEM. REMOVE NEUTRAL TERMINAL

BLOCK SCREW FOR DELTA SYSTEMS.

1/10A 600 VAC INLINE FUSE PER CONDUCTOR. LITTLEFUSE PART

NUMBER KLDR.100.

1

1

1

1

C

W B W B

N

PE

W B

LINE VOLTAGE

CURRENT SENSORS

LOAD SOURCE

M33186

3-PHASE, 3-WIRE INSTALLATION DIAGRAM

NOTES:

LINE VOLTAGE CONNECTIONS: #14-12 AWG

SENSOR CONNECTIONS: B = BLACK LEAD W = WHITE LEAD

NEUTRAL NOT USED IN DELTA SYSTEM. REMOVE NEUTRAL TERMINAL

BLOCK SCREW FOR DELTA SYSTEMS.

1/10A 600 VAC INLINE FUSE PER CONDUCTOR. LITTLEFUSE PART

NUMBER KLDR, 100.

1

1

1

1

W B W B

N

PE

W B

4.4 MAINS Line Voltage & Current Sensor Wiring Diagrams

Fig. 7. 3-Phase, 4-Wire Installation Diagram.

Fig. 8. 3-Phase, 3-Wire Installation Diagram.

62-0389-05 14

Page 15

CLASS 2000 METER

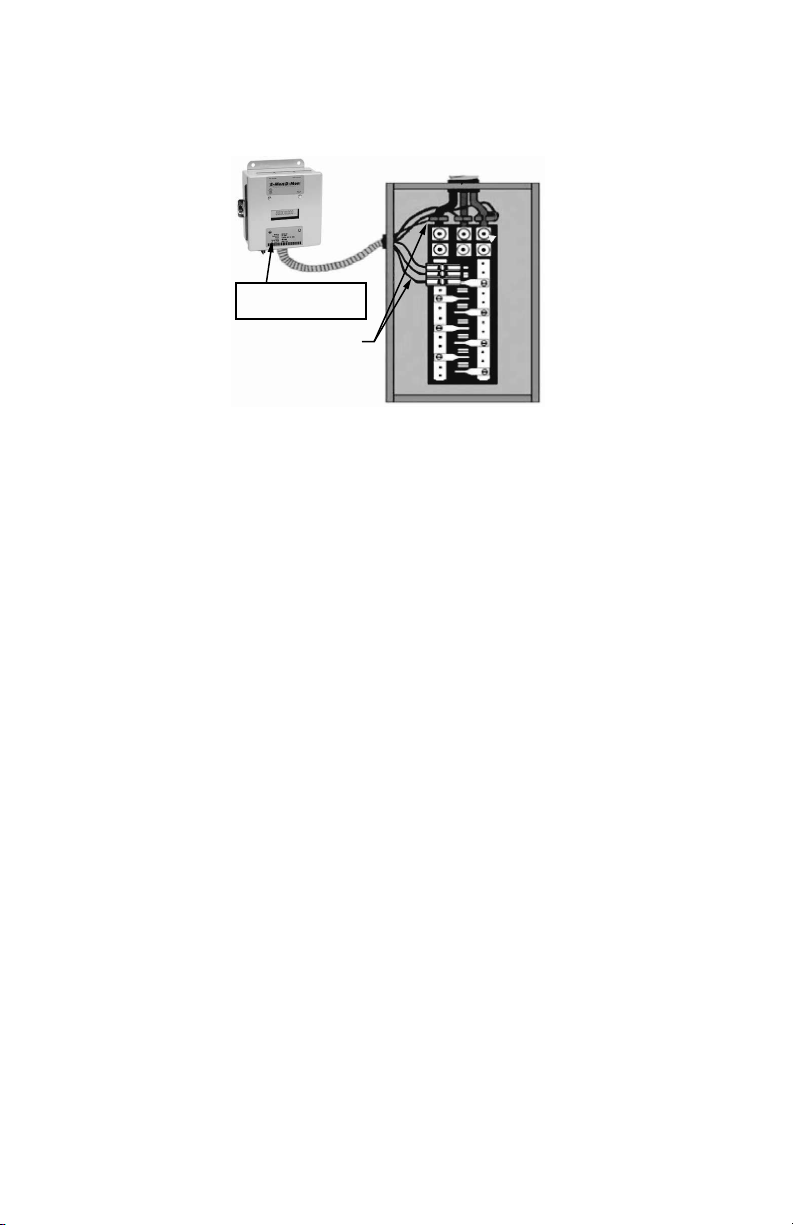

M34224

METER TERMINAL

BLOCK CONNECTIONS

CURRENT SENSOR AND

VOLTAGE CONNECTIONS

4.5 Installation Overview

Fig. 9. Install Overview.

4.6 Check Polarity of the Current Sensor.

Verify all phases are loaded by at least 1% of meter rated load, check the polarity of

the sensors.

Test the sensors wires one pair at a time, verifying polarity, phase rotation and

correspondence to line input.

The A/C line voltage power may be left on to the meter as long as the protective clear

shield is installed to cover the line side meter power supply terminals for safety. Extra

care must be taken when working around live circuits.

15 62-0389-05

Page 16

CLASS 2000 METER

1. Disconnect the Gray current sensor plugs for current sensor B and C phase

inputs (see Fig. 10).

POWER LED

PULSE LED

ERROR LED

M34955

Fig. 10. Error LED

With only the A sensor wires connected to the sensor A input verify if the error LED is

clear (Green LED is off).

If Error LED is clear then the A sensor input leads polarity is correct.

If the Error LED does not clear, then disconnect the gray plug and reverse the input

leads for A sensor by putting the white leads on the black input and the black leads on

the white input, (swapped polarity). If it clears, the “Sensor Error” then mark this pair

with a piece of masking tape as the A sensor and note polarity. Next disconnect the

gray plug for the A input. Marking them with tape as A and noting the polarity.

62-0389-05 16

Page 17

CLASS 2000 METER

Repeat the process for the B sensor gray plug. Connect only the B sensor plug to the B

phase current senor input terminal with the correct polarity (white to white and black to

black) the sensor error remains clears then the B sensor input leads polarity is correct

(see Fig. 11).

POWER LED

PULSE LED

ERROR LED

M34957

Fig. 11. Error LED

If the Error LED illuminates then reverse the input leads for B sensor by putting the

white leads on the black input and the black leads on the white input, (swapped

polarity). If it clears, the Error LED then tag as the B phase plug and take the gray plug

off the input marking them as B and note polarity to identify them later.

17 62-0389-05

Page 18

CLASS 2000 METER

POWER LED

PULSE LED

ERROR LED

M34958

Repeat the process for the C sensor gray plug. With only the C sensor plug connected

if the sensor error remains clear then the C sensor input and the polarity is correct (see

Fig. 12).

Fig. 12. The green power LED blinks this is normal.

If the Error LED illuminates disconnect the plug and reverse the wires for C sensor by

putting the white leads on the black input and the black leads on the white input,

(swapped polarity). When Error LED is clear leave the sensor C plug plugged into “C”

phase current sensor input C.

Reconnect sensor A and sensor B plugs as you had previously identified them for

phase and polarity.

The error should now be clear.

Class 2000 meters may only use one or two sensors depending on the applications.

Please see the appropriate installation manual for wiring configurations in these type

applications. “Check Install” message will always be present in single phase

applications on a Class 2000 meter and will not affect the meter accuracy.

62-0389-05 18

Page 19

CLASS 2000 METER

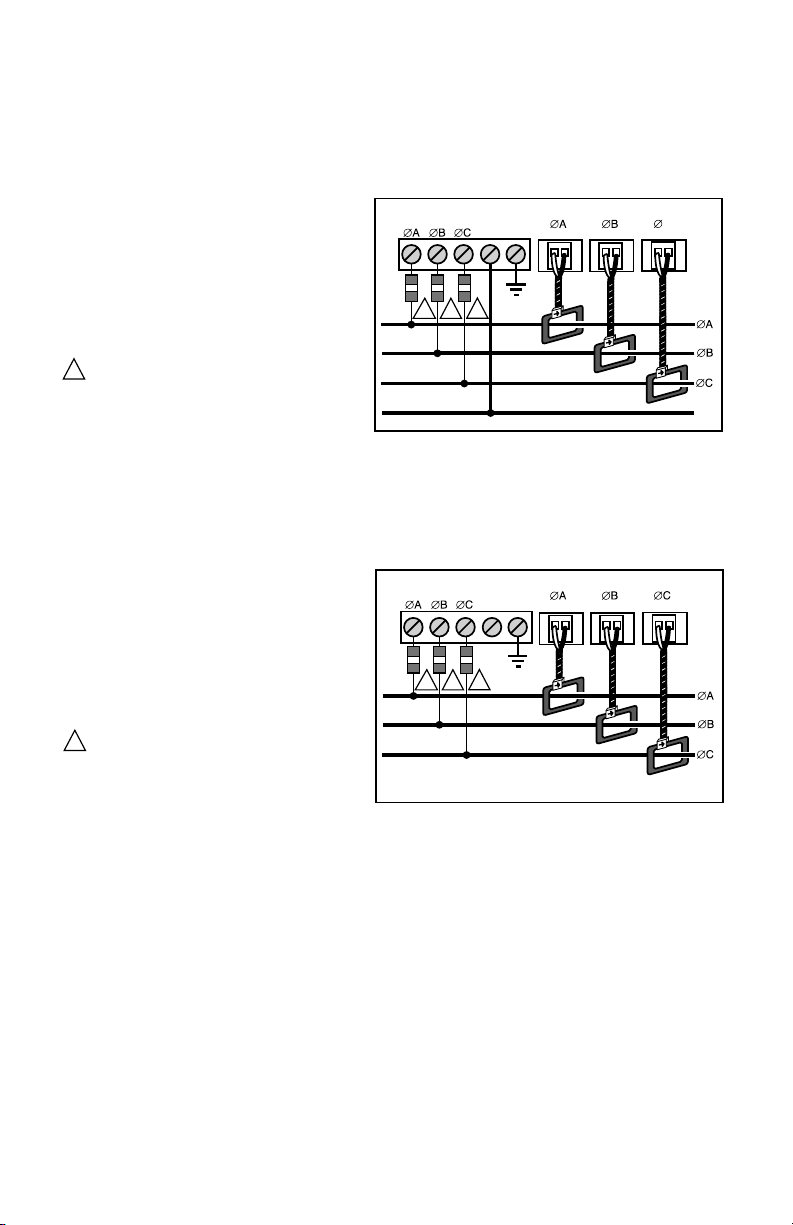

5.0 MONITORING MULTIPLE LOADS WITH ONE METER

The Class 2000 meter provides extreme flexibility by allowing additional sets of current

sensors to be used in parallel so that multiple load locations can be monitored by one

meter. This feature allows a totalized display readout from two or more load circuits.

You may use parallel sensors to monitor specific breakers from one panel, specific

breakers from more than one panel, two or more complete panels, etc.

When paralleling current sensors, the following rules must be followed for accurate

readings:

Rule 1: Current sensors must be installed in complete sets of three, with a maximum of

three sensors installed in parallel per phase.

Rule 2: All sensors used in parallel must be of the same amperage rating (i.e. 100

amp, 200 amp, etc.) The rating is determined by the current rating (amperage) of the

Class 2000 meter. For example, a 200 amp meter must use extra sets of 200 amp

current sensors.

Rule 3: All locations being monitored must have the same power source. A 480 volt

meter cannot monitor a 208 volt load nor can a meter monitor two 480 or 208 volt loads

if they are from different originating power sources or from different transformers.

Rule 4: The display readings must be multiplied by the number of sets of current

sensors installed. E.g. meter reading of 5 kWh with 2 sets of current sensors....5 x 2 =

10 kWh (actual usage.)

NOTE: One set of current sensors equates to three sensors, one per phase.

The multiplier only applies when extra sets of current sensors are

installed on one meter. Therefore, if you are using only one set of three

sensors (one per phase) the multiplier is not required.

19 62-0389-05

Page 20

CLASS 2000 METER

LINE VOLTAGE

Ø

A

Ø

B

LOAD SOURCE

N

LOAD A

LOAD B

CURRENT SENSORS

LOAD SOURCE

Ø

A

Ø

B

N

M33187

ØC

ØC

Ø

AØBØC

ØAØBØ

C

W B W B W BN

PE

Fig. 13. Multiple Loads with one Meter.

62-0389-05 20

Page 21

CLASS 2000 METER

6.0 KWH METER FEATURES & FUNCTIONS

6.1 KWh Meter Display Features

Fig. 14. Normal Mode (kWh Reading).

The Class 2000 kWh meter display requires no multiplier and shows kilowatt-hours

consumed. See section 6.2 for information on calculating cost based on kWh usage.

Fig. 15. KW Load Mode (Current Load in kW).

The Class 2000 kWh meter LOAD display shows the present circuit load in kilowatts.

.

Fig. 16. Start Up Mode.

When initially powered on, the Class 2000 meter will display the startup screens.

This screen indicates the meter voltage, amps and service configuration. It will remain

on for approximately five seconds before switching to the version screen, after which

the meter enters the normal operating mode.

21 62-0389-05

Page 22

CLASS 2000 METER

6.2 How to Read the kWh Meter

Fig. 17. Readings are Displayed in Whole Numbers.

The Class 2000 kWh meter displays readings in whole numbers, there are no

decimals.

To find the dollar cost for the power used by the load(s) being monitored, you must first

find out what the cost per kWh is in your area (this cost can be found on your utility

electric bill, or call your local utility and ask for their cost per kilowatt hour.) Simply

multiply the cost per kWh by the kWh reading from the E-Mon D-Mon meter. The

resultant figure is the dollar cost for power used by the load(s) being monitored by this

meter.

Example:

8-digit display reading 00000017

Cost per kWh from utility $0.12100

17 x $0.121 = $2.06

NOTE: THE FOLLOWING ONLY APPLIES TO METERS USING MORE THAN ONE

SET OF CURRENT SENSORS. For meters using parallel current sensors

you must multiply the kWh display reading by the number of sets of current sensors installed.

Example: 250 (meter display reading) x 2 (sets of sensors in parallel) = 500 kWh 500

kWh x $0.121 (utility cost per kWh) = $60.50

62-0389-05 22

Page 23

CLASS 2000 METER

M33212

ERROR

LED

METER

PULSE LED

POWER

ON LED

IDR JACK

PULSE OUTPUT

CALIBRATION

JACK

SEE

DESCRIPTIONS

ABOVE

HEADER

CONNECTOR

(CURRENT

SENSORS)

MAIN

POWER

TERMINAL

BLOCK

RESET BUTTON

6.3 KWh Meter Hardware Functions

IDR Jack 8-pin RJ-45-used to connect kWh meter to the E-Mon

Energy automatic meter reading system.

Pulse Output Optically isolated output pulse for connection to BAS or

peripheral equipment.

Calibration Jack Connector J11 is for factory calibration only, and is not

a user accessible port. Silicon plug is not to be

removed.

Reset Resets kWh and kW demand.

Power On LED When lit, indicates power to meter is on.

Meter Pulse LED Blinks to show the meter load. Blink rate increases with

load.

Error LED When lit, indicates that the current sensor is backwards

or on the incorrect phase.

Fig. 18. Hardware Functions.

23 62-0389-05

Page 24

CLASS 2000 METER

6.4 Fixed Pulse Value guide for Class 1000 & 2000,

kWh & or kW Demand Meter

Color Code Key of Sensor Arrow Must Match the Amperage of Meter:

Purple White Brown Red Yellow Black Blue Two Blue

25 Amp 50 Amp 100 Amp 200 Amp 400 Amp 800 Amp 1600 Amp 3200 Amp

Watt Hours per Pulse

0.48828 0.97656 1.95312 3.90625 7.81250 15.6250 31.2500 62.500

Pulse output signal is a 50/50 duty cycle. This means that whatever the time is

between pulses (based on load) the ON time will be 50% of that time. As an example,

if there were 9 seconds between pulses, the ON time would be 4.5 seconds. The OFF

time would be of the same amount.

TWO-POSITION REMOVEABLE

SCREW TERMINAL PLUG

(FIXED PULSE OUTPUT)

M34959

Fig. 19. Two-position removable screw terminal plug

(Fixed Pulse Output).

There is no voltage on the output of the pulse connection. It is referred to as a “dry”

contact. It is, however, not a physical contact. As an electronic contact equivalent,

there is a polarity associated with it because it is designed to function with a DC signal

from the BAS. The interface range is from 4.5 to 28 VDC, with a maximum of 50 mA.

62-0389-05 24

Page 25

Fig. 20. Hardware Functions.

M33183

MENU

UP

DOWN

SELECT

CLASS 2000 METER

25 62-0389-05

Page 26

CLASS 2000 METER

7.0 KWH/DEMAND METER FEATURES & FUNCTIONS*

(*Applies to meters equipped with the Demand Option [-D-],

for example: E20-208400-J-D-KIT.)

7.1 KWh/Demand Meter Display Functions

The Class 2000 kWh/Demand meter has a single display window that cycles through

the energy data screens. The meter will cycle through five (5) separate screens. The

screens are described below.

KWh display shows the amount of energy

consumed in kilowatt hours (kWh). Reading is

in whole numbers, there are no decimals and

the meter requires no multipliers.

LOAD display shows the present circuit load

in kilowatts.

KW display shows the electrical Demand in

kilowatts (kW). Demand interval is either 15

minutes, 30 minutes or 60 minutes. (Default is

15 minutes.)

Time display shows the time of the day that

the demand peak occurred.

Date display shows the date of the demand

(kW) peak.

Fig. 21. KWh/Demand Meter Display Functions.

62-0389-05 26

Page 27

CLASS 2000 METER

7.2 How to Read the kWh/Demand Meter

Fig. 22. KWh Reading.

The Class 2000 kWh meter displays readings in whole numbers, there are no

decimals.

To find the dollar cost for the power used by the load(s) being monitored, you must first

find out what the cost per kWh is in your area (this cost can be found on your utility

electric bill, or call your local utility and ask for their cost per kilowatt hour.) Simply

multiply the cost per kWh by the kWh reading from the E-Mon D-Mon meter. The

resultant figure is the dollar cost for power used by the load(s) being monitored by this

meter.

Example:

8-digit display reading 00000017

Cost per kWh from utility $0.12100

17 x $0.121 = $2.06

Fig. 23. KW (Demand) Reading.

The kW (Demand) reading is the peak usage over a specified time period (15 minute

standard, 30 minute and 60 minute optional). While kWh costs are interpreted as

cents, Kilowatt costs are usually represented in dollars, and interpretation of demand

costs are based on your utility’s tariff and rate structures. You will need to contact your

utility to see how your utility structures their kilowatt demand charges to ensure proper

allocation of costs utilizing data from the E-Mon D-Mon meter.

NOTE: THE FOLLOWING ONLY APPLIES TO METERS USING MORE THAN ONE

SET OF CURRENT SENSORS.

For meters using parallel current sensors you must multiply the kWh display reading by

the number of sets of current sensors installed. With Demand meters, the PEAK

Demand is also multiplied by the number of sets of current sensors installed.

Example:

17(meter display reading) x 2 (sets of sensors in parallel) = 34 kWh

34 kWh x $0.121 (utility cost per kWh) = $4.12

27 62-0389-05

Page 28

CLASS 2000 METER

HOME

DOWN

ENTER

UP

7.3 Demand Display Set-Up

The demand meter display is set-up using the four buttons located on the meter

display board which is mounted on the door inside the meter enclosure.

STEP 1: Press the HOME button to enter the menu screen.

STEP 2: Press the DOWN button to enter the setup screen.

STEP 3: Press the ENTER button to enter the DATE screen.

STEP 4: Press the Enter button to cycle between the day, month, and year. Press the

UP and DOWN buttons to change their respective numbers.

STEP 5: When the numbers have been changed, press ENTER again to save the

changes.

62-0389-05 28

Page 29

CLASS 2000 METER

STEP 6: Press the DOWN button to access the TIME screen.

STEP 7: Press ENTER to cycle between the hour, minutes, and day of week selection

Use the UP and DOWN buttons to change the selection.

STEP 8:When the changes are completed press the ENTER button to save the

changes.

STEP 9: Press ENTER to enter the DEMAND INTERVAL screen.

STEP 10: Press ENTER again to access the interval selection screen. Use the UP and

DOWN buttons to select the appropriate interval time. (default is 15 min.)

STEP 11:When the appropriate demand interval has been chosen, press ENTER to

save the changes.

29 62-0389-05

Page 30

CLASS 2000 METER

STEP 12: Press the HOME button to return to the setup screen.

STEP 13: Press the UP arrow to display the MENU screen.

STEP 14: Press the ENTER button to enter the normal display screen.

7.4 Demand RESET

STEP 1: Press the HOME button to access the Series 2000 MENU screen.

62-0389-05 30

Page 31

CLASS 2000 METER

STEP 2: Use the UP and DOWN buttons to access the CHECKOUT screen.

STEP 3: Press the ENTER button to access the kw RESET screen.

STEP 4: Press ENTER to access the RESET select screen. Use the UP and DOWN

buttons to select “yes” or “no”. Press ENTER to save the selection. “Change stored”

will be displayed after pressing ENTER.

STEP 5: Press the HOME button to return to the menu screens. Use UP and Down to

select the STATUS screen.

STEP 6: Press ENTER to return to the normal display.

31 62-0389-05

Page 32

CLASS 2000 METER

MENU

UP

DOWN

SELECT

7.5 Test Mode

Fig. 24. Press and release both the Up and Down

arrow buttons simultaneously to activate the Test Mode.

Test Mode activates a 3-screen auto scrolling display. Each of the 3-screens will

display for five-seconds then returning the LCD to normal scrolling mode kWh and kW

LOAD displays.

1. Test Mode screen one: LCD Segment Test (32 zeros)

0000000000000000

0000000000000000

2. Test Mode screen two: Calibration Parameters

(example Model E20-208100-JKIT display 208V 100A)

0000000000000000

0000000000000000

3. Test Mode screen three: Firmware Version (Class 2000 V1.03)

0000000000000000

0000000000000000

62-0389-05 32

Page 33

CLASS 2000 METER

M33183

MENU

UP

DOWN

SELECT

7.5.1 Test Mode Menu, Setup, And Checkout Features

A delay of twenty-seconds between any button choice and the screen will

automatically return to normal kWh and kW LOAD mode.

Press and release Menu Button displays MENU.

CL2000

MENU

Press and release Down Button displays SETUP.

CL2000

SETUP

Press & release the Down Button again displays CHECKOUT.

CL2000

CHECKOUT

Press & release the left Select Button displays CHECKOUT VOLTS A.

CHECKOUT

VOLTS A 121.3V

Press & release the Down Button displays CHECKOUT VOLTS B.

CHECKOUT

VOLTS B 0.3V

Press & release the Down Button displays CHECKOUT VOLTS C.

CHECKOUT

VOLTS C 0.2V

33 62-0389-05

Page 34

CLASS 2000 METER

Press & release Down Button again displays CHECKOUT AMPS A.

CHECKOUT

AMPS A 0.2V

Press & release Down Button again displays CHECKOUT AMPS B.

CHECKOUT

AMPS B 0.2V

Press & release Down Button again displays CHECKOUT AMPS C.

CHECKOUT

AMPS C 0.2V

This concludes the Class 2000 kWh meter advanced display features and instructions.

8.0 PREVENTATIVE/SCHEDULED MAINTENANCE

The Class 2000 kWh/Demand meter is shipped in a calibrated, tested and fully

functional condition.

- No field adjustments are required.

- No preventative or scheduled maintenance is required.

- No cleaning or decontamination procedures are required for this instrument.

62-0389-05 34

Page 35

CLASS 2000 METER

BATTERY

M33208

9.0 LITHIUM BATTERY REPLACEMENT INSTRUCTIONS

(*Applies to meters equipped with the Demand Option [-D-],

for example: E20-208400-J-D-KIT.)

The Class 2000 kWh/Demand meter has a Lithium Battery Cell, which is used to retain

the contents of SRAM and the RTC during power outages. The battery has a life

expectancy of greater than 5 years.

Fig. 25. Battery Location.

Nominal Working Voltage 3 Vdc Output

Nominal Current Capacity 225 mAHr

Cell Chemical Manganese Dioxide Lithium

Operating Temperature Range -30 to +60 Degrees Celsius

Manufacturer Panasonic

Manufacturer’s Part Number CR2032

Fig. 26. Battery Specifications at 25 Degrees Celsius.

35 62-0389-05

Page 36

CLASS 2000 METER

WARNING

WARNING: Only replace battery with Panasonic part number CR2032

only. Use of another battery may present a risk or explosion. See owners

manual for safety instructions. Internal circuit card components are

extremely sensitive to electrostatic discharge. Be careful not to touch

internal circuitry prior to discharging any static buildup on your person.

To discharge yourself, touch a grounded metal object such as conduit or

a metal enclosure exterior.

The battery cell is mounted in a coin cell on the upper right side of the main power

board. Replace the battery if the low battery warning is on display.

Fig. 27. Low Battery Display.

Use the following procedure to replace the battery cell

STEP 1: Disconnect power from the meter at the unit external circuit breaker.

STEP 2: Remove the battery from its holder and place on a non-conductive surface.

STEP 3: Install new battery into the battery holder.

NOTE: Care should be taken to insure that the replacement battery is installed

with the plus (+) symbol on the battery facing down. No damage to unit

or battery will occur if battery is inadvertently installed in the wrong

direction.

STEP 4: Dispose of the used battery in accordance with the manufacturers’

(Panasonic) instructions.

62-0389-05 36

Page 37

CLASS 2000 METER

10.0 TROUBLESHOOTING GUIDE

The Class 2000 kWh/Demand meter is calibrated and tested at the factory before

being packaged and shipped. If installed properly and in accordance with these

installation instructions, your Class 2000 meter should provide years of trouble free

service. If the meter should not function, the following guide will assist in

troubleshooting the installation.

Problem Procedure to follow

1. Display window is blank. Check wiring to voltage terminals.

Check circuit breakers or fuses.

Verify that the power is turned on.

Test source for correct voltage.

2. Display shows incomplete figures or

numbers other than zeros when power is

turned on.

3. Display reading all zeros (00000000) Determine if load is sufficient to update

4. Display reads only a fraction of

consumption

Press RESET button located on door

inside meter enclosure (5 sec.)

the display.

Check RESET button to ensure there are

no wires or other objects pressing against

it when the door is closed.

Check the current sensors for installation

and polarity.

Be sure the current and voltage inputs

have the proper phase relationship.

Check wiring to voltage terminals.

Check circuit breaker or fuses.

Test source for correct voltage.

Check the supply voltage to be sure that it

is on continuously 24 hrs/day.

Check the current sensors for installation

and polarity.

Check sensor wiring to the terminal strip

in meter (color coding B & W.)

NOTE: If you still need assistance after performing the above troubleshooting

procedures, do not remove the unit. Before removing the unit, contact

E-Mon’s technical support department at (800) 334-3666, our support

experts will assist you in detailed troubleshooting of the meter installation and assist you in getting the unit operating correctly

37 62-0389-05

Page 38

CLASS 2000 METER

CAUTION

10.1 Line Voltage Diagnostics

E-Mon meters detect the direction of rotation of three-phase power. The proper phase

sequence must be A-B-C.

The AC power input must be in proper phase sequence A, B, C. If incorrect, the display

will read “Check Install.” See Fig. 28.

Fig. 28. Check Install Error.

How to Verify & Resolve a Phase Sequence Error

Dangerous voltage is present inside the meter!

The following steps are for Qualified Electrical Service Personnel only.

1. Have the electrician unplug or disconnect all three current sensors at the meter

input terminal.

2. If the meter still displays “Check Install” without any sensors connected the

utility power or transformer is connected counter clockwise (CBA) reverse phase

rotation.

3. Disconnect the power to the meter line voltage inputs. Swap A & C line inputs.

Power up the meter and verify there is not a “Check Install” displayed on the LCD

screen.

4. If reverse rotation line condition was present in step 2 and corrected in step 3

then swap the sensor inputs plugs A and C. Plug sensor “A” plug into the sensor

“C” input and plug sensor “C” plug into the “A” input. This will now match the line

phase correspondence.

NOTE: A light load or no load can cause the “Check Install” message to be dis-

played.

62-0389-05 38

Page 39

CLASS 2000 METER

A light load or circuit with no load will cause the “Check Install” to be displayed, for

example a transformer with no load. The meter must have at least 1% load for each

current sensor. For example model number E20-208200-(J or R)-KIT is 200 amp rated;

each of the current sensors must have at least two amps flowing though them to verify

installation. If the “Check Install” message goes off with 1% or more load, then there is

no issue with installation. “Check Install” was due to a light load; this is normal and will

turn back on during light load condition.

Intermittent “Check Install” message displays for a while and then goes off? This is

very typical with air conditioning monitoring applications. With modern air conditioning

systems a condenser coil-cooling fan runs on single-phase power and the compressor

runs off three-phase power. The “Check Install” displays when the fan is running and

will remain on until the compressor motor cycles back on. This is to be expected and is

normal.

“Check Install” display is still on with 1% load and phase rotation sequence A-B-C

verified in steps 1-4, then check for correct Current Sensor Installation.

Is the Current Sensor(s) clamped around the wire backwards?

Assemble the current sensor halves around the conductor(s) to be monitored. Ensure

each of the current sensor halves marked “Load” (Load Side is shown with two arrows

see Fig. 29) are both facing the load side of the conductor. (The load is the side of

the conductor where the equipment you are monitoring is located.)

When removing the spit-core Current Sensor halves, DO NOT cut the tie wrap! The

head of the cable tie has a release tab. Push down on the tab to release the green

colored core.

39 62-0389-05

Page 40

CLASS 2000 METER

How do I know line from load?

Generally speaking, “line” is the power coming in or “upstream” to a circuit breaker/

fuse/disconnect/etc. “Load is the power going out (“downstream”) of the device that

interrupts power. If you put a voltage meter on each side (presuming that your switch/

breaker/fuse/whatever is working correctly), then when you switch it on and off, the

load side is what goes on and off and the line side is what stays hot no matter what

(see Fig. 29).

Fig. 29. Line/Load

62-0389-05 40

Page 41

CLASS 2000 METER

11.0 HIGH VOLTAGE METERING

kWh Meter Installation Instructions for Use with E-MON Meters in High Voltage Applications

The E-MON model number containing “12025HV” kWh meter is designed to be used

for monitoring high voltage (2400, 4160, 13200, etc) circuits, either “stand alone” or in

an AMR application.

This meter is intended to be used with the appropriate high voltage Potential

Transformers (PTs) and Current Transformers CTs) supplied by others. The meter

application is centered around a 120 VAC secondary output from the high voltage PTs

and a 5 amp secondary output from the high voltage CTs.

Items addressed by this document include the installation of meters with model

number containing “12025HV” on high voltage circuits as well as the calculations to

provide the correct meter multiplier based on the PT and CT sizes used on the high

voltage conductors.

Installation should be performed by qualified personnel and only according to all

applicable electrical codes.

High Voltage CTs (supplied by others) reduce the primary current (amps) to a directly

proportional 0~5 amp secondary output. As an example, a 0~400 amp primary

becomes a 0~5 amp proportional signal from the secondary output. In our application,

the high voltage CT secondary is installed as a continuous “loop”, with a single

conductor connected to both secondary terminals.

To convert the 0~5 amp signal to a 0~ 2 volt signal, E-MON’s Current Sensors are

installed on the CT secondary conductor. A set of 25 amp sensors is used in this

application. These sensors have the high voltage CT secondary conductor passed

through them five (5) times (see below) by looping the secondary conductor as shown

in the drawing. The reason for this is so that the 5 amp secondary now appears to the

current sensor as a 0~25 amp signal. This creates a conversion of the CT’s primary

current to a directly proportional 0~ 2 volt signal which is utilized by the E-MON meter.

The example from the first paragraph has now become a 400 amp to 2 volt device, by

this technique.

41 62-0389-05

Page 42

CLASS 2000 METER

M34227

Fig. 30. High Voltage CTs.

Fig. 31. Wiring Diagram For 3-wire High Voltage Circuits.

62-0389-05 42

M34228

Page 43

CLASS 2000 METER

This special high voltage meter installation shows the correct wiring procedure for 3wire high voltage circuits. In this application, the 2 element meter connection is used

on the secondary circuits of the user supplied high voltage PTs and CTs.

The E-MON meter used in this application is the model containing “12025 HV”.

Installation of these meters requires the use of two (2) current sensors mounted on the

secondaries of the high voltage Current Transformers. See the drawing above for

proper wiring. For correct operation, the meter must be installed correctly.

This special high voltage meter installation utilizes high voltage PTs (Potential

Transformers) and CTs (Current Transformers) supplied by others. The E-MON meter

is installed using the secondary outputs of these devices.

High voltage PTs reduce the primary voltage (4160v, 13200v, etc.) to a Secondary

output of 120v. This secondary is connected to the E-MON meter voltage inputs as

shown in the wiring diagram. High voltage CTs reduce the primary current (amps) to a

directly proportional 0~5 amp output. As an example, a 0~400 amp primary becomes a

0~5 amp proportional signal from the secondary output. This allows much smaller

wiring to be utilized in the meter hookup. The high voltage CT secondary is installed as

a continuous “loop”, with a single lead connected to both secondary terminals.

E-MON meters accept a 0~2 volt signal from their Current Sensors. To convert the 0~5

amp signal, the Current Sensors are installed on the CT secondary lead. A set of 25

amp sensors is used in this application. These sensors have the high voltage CT

secondary lead passed through them five (5) times by looping the wire as shown in the

drawing. This allows a direct conversion of the CTs primary current to a directly

proportional 0~2 volt signal, which is used by the meter.

Since there is a signal ratio introduced by the high voltage CTs and PTs, it will be

necessary to multiply the number on the meter’s display for a correct reading. The

meter multiplier is calculated by using the CT ratio and the PT Ratio. [PTr x CTr /

Number of Secondary Lead Passes Through Sensor]. The E-MON 25 amp HV kWh

meter with 5 wraps of the high voltage CT secondary will have its multiplier calculated

by the formula shown below.

EXAMPLE: CT = 400:5 = 80:1 (CTr = 80)

PT = 4200:120 = 35:1 (PTr = 35)

Wraps (Passes) = 5

METER MULTIPLIER = PTr x (CTr/Wraps)

35 x (80/5)

35 x (16) = 560

43 62-0389-05

Page 44

CLASS 2000 METER

12.0 FREQUENTLY ASKED QUESTIONS

Q. When providing line voltage to the meter, can I tap off of the same breaker I am

monitoring?

A. Yes, the voltage can be pulled from the same breaker being monitored.

Q. Can the meter’s line voltage wires be run in the same conduit as the sensor leads?

A. Yes, there will be no effect on the meter if the sensor leads and line voltage wires

are run in the same conduit.

Q. Can the meter communication wires and line voltage wires be run in the same

conduit?

A. It is NOT recommended to run these wires together due to noise concerns and their

effects on the communications signal integrity. Communication wires can be routed

separately using the 1/2” conduit port.

Q. How do I find the cost for kWh and kW to bill my tenants?

A. Your local utility bill should list the cost per kWh and kW. If not, simply call your utility

and ask them to provide you with the cost per kWh and kW.

Q. What size wire do I use for the line voltage leads?

A. These wires are normally #14 AWG, but be sure to consult your local electrical

codes for proper sizing requirements.

Q. What size wire should I use to extend the current sensor leads?

A. These wires are normally sized at #14-22 AWG, twisted pair arrangement. Consult

your local electrical codes for proper sizing requirements.

62-0389-05 44

Page 45

CLASS 2000 METER

Q. The load I need to monitor has parallel feeds. How do I install the current sensors

for this application?

A. There are two ways you can monitor parallel feeds. One method is to clamp the

sensors around all feed wires for each phase (no additional reading multiplier

required). The second way to monitor parallel feeds is to clamp the sensor around one

of the feed wires for each phase, and when you read the kWh meter the final reading

must be multiplied by the number of feed wires for each phase.

Q. I have two subpanels I would like to monitor with one meter. These subpanels are

fed by different transformers in the building. Can I parallel sensors and monitor both

panels with one meter?

A. No. These panels cannot be monitored by one meter because they are different

power sources. When you parallel current sensors, all loads must be from the same

voltage source.

Q. I have 5 breakers in one subpanel I would like to monitor with one meter. Can this

be done without having to parallel current sensors?

A. Yes. Simply run all the breaker wires through one set of current sensors. Make sure

all A phase circuits are run through the A phase sensor, and the same for B & C

phases. The meter should be sized by the highest amount of current being monitored

by one sensor.

Q. I’ve gone through the troubleshooting guides and I still can’t get my meter to work.

What should I do?

A. Before removing the unit, contact E-Mon’s technical support department at (800)

334-3666. Our technical support experts will assist you in detailed troubleshooting of

the meter installation and assist you in getting the meter functional without having to

remove and return the unit.

45 62-0389-05

Page 46

CLASS 2000 METER

13.0 METER TECHNICAL SPECIFICATIONS

Ordering Information: Define brand, class, input voltage, current sensor

amperage, enclosure type, and sensor type in the format A-BB-CCC-DDDD-E-FGGG where:

A = Brand: E for E-Mon

BB = Class: 20 for Class 2000

CCC = Input Voltage: 120, 208, 480 or 600

DDDD = Amperage: 100, 200,400,800,1600, or 3200

E = Enclosure Type: J = standard metal, R= 4X raintite, M = MMU

F = Demand Option: D for Demand “blank” for kWh meter

GGG = sensor type: KIT = split-core, SCS= solid core “blank” = none supplied

EXAMPLE:

E-MON

CLASS 2000 METER

INPUT VOLTAGE (480V)

AMPERAGE (100 AMPS)

ENCLOSURE TYPE (STANDARD METAL)

DEMAND METER

SENSOR TYPE (SPLIT CORE)

E 20 480 100 J D KIT

M34230

62-0389-05 46

Page 47

CLASS 2000 METER

Input Voltage

3-wire (Delta) Or 4-wire (Wye)

Configuration

Mains Voltage Input Up To 480 VAC RMS Available

Input Power 6 VA Maximum Rating

Current Sensor

Up To 3200 Amps RMS AC Available

Rating

Power Factor 0.5 Leading Or Lagging

Line Frequency 50-60 Hz

Metering Accuracy Meets ANSI C12.20

Voltage Operating

+/-10% Of Rated Load

Range

Temperature Range -20 C To +50 C (Standard indoor enclosure):

Temperature Range -20 C To +70 CNEMA 4X (NEMA 4X outdoor enclosure)

Relative Humidity

0-95% Non-condensing

Range

Altitude 2000 Meters Maximum

Voltage Overload +25% Continuously: +100% For 20 Cycles

Current Sensor

100% For 1 Minute Without Damaging Meter

Overload

Pollution Degree Degree 2 In Accordance With IEC 664

Installation

Category 111

(Overvoltage)

Category

Measurement

Category 111

Category

Enclosure Material Indoor Housing Rating (Standard): NEMA 12

Outdoor Housing Rating (Optional): NEMA 4X

Display Readout KWh Accumulated

Standard Ranges 4-Wire Wye, 120/208 VAC: 100, 200, 400, 800,1600,3200 Amp

2 Phase, 120/240 VAC: 100, 200, 400, 800,1600,3200 Amp

4-Wire Wye, 277/480 VAC: 100, 200, 400, 800,1600,3200 Amp

3-Wire Delta, 220/240 VAC: 100, 200,400,800,1600,3200 Amp

3-Wire Delta, 480 VAC: 100, 200, 400, 800,1600,3200 Amp

4-Wire Wye, 600 VAC: 100, 200, 400, 800,1600 Amp

47 62-0389-05

Page 48

CLASS 2000 METER

Modem Interface Cable: UL-listed Telephone Cord,

6-cond. 300 VAC, Stranded

Cond. 22-26 AWG.

Cable Connector: RJ-45 male IDC

Input/Output Voltage: +5 VDC/18 VAC

Ckt Input Isolation 5.3K VAC for 1 Minute

Baud Rate: 9600

IDR Interface Port Cable: UL-listed/rated Telephone

Cord. 4-cond.

Input/output Voltage: Ground-isolated +/-5.4VDC

Cable Connector: RF-45 Male IDC Or Screw

Terminal Termination

Circuit Input Isolation: 5.3kVAC

Circuit output Isolation: 21.5kVAC

Isolated Pulse/Alarm Outputs

(TB5, TB6):

Output Voltage Potential: 0 VDC to +5 VDC Logic Levels

Mating Plug Connector: Weidmuller PN: 152876

Signal Isolation Voltage: 5.3K VAC for 1 Minute

Recommended

In-line Fuse

Manufacturer: Littlefuse

Mfg. Part No: KLDR.100

Rating: 100mA, Time-delay, 600VAC

Cartridge Fuse

Battery Cell Description: Non-rechargeable Cell Used

For Memory Retention

Manufacturer: Eagle-Picher

Mfg Part No: LTC-3PN-S2

Working Voltage: 3.5VDC

Current Capacity 350mAhr

Electrolyte: Lithium Thionyl Nitrate

62-0389-05 48

Page 49

CLASS 2000 METER

14.0 LIMITED METER WARRANTY

Subject to the exclusions listed below, E-Mon will either repair or replace (at its option)

any product that it manufactures and which contains a defect in material or

workmanship.

The following exclusions apply:

1. This Limited Warranty is only effective for a period of (5) five years following the

date of manufacture when installed in accordance with manufacturer’s instructions by qualified personnel.

2. E-Mon must be notified of the defect within ninety (90) days after the defect

becomes apparent or known.

3. Buyer’s remedies shall be limited to repair or replacement of the product or component which failed to conform to E-Mon’s express warranty set forth above.

4. Buyer shall be responsible for all freight costs and shall bear all risk of loss or

damage to returned goods while in transit.

5. This Limited Warranty does not cover installation, removal, reinstallation, or labor

costs, and excludes normal wear and tear. Buyer shall provide labor for the

removal of the defective component or item and installation of its replacement at

no charge to E-Mon.

6. This Limited Warranty does not cover any product if: (i) a product is altered or

modified from its original manufactured condition, (ii) any repairs, alterations or

other work has been performed by Buyer or others on such item, other than work

performed with E-Mon’s authorization and according to its approved procedures;

(iii) the alleged defect is a result of abuse, misuse, improper maintenance,

improper installation, accident or the negligence of any party; (iv) damaged as a

result of events beyond E-Mon’s control or other force majeure events or (v) used

in conjunction with equipment, components, accessories, parts or materials not

supplied or approved by E-Mon.

7. This Limited Warranty is limited to the obligation to repair or replace the manufactured product. This is the sole and exclusive remedy for any breach of warranty. IN NO EVENT SHALL E-MON BE LIABLE FOR ANY INDIRECT,

INCIDENTAL, SPECIAL, CONSEQUENTIAL OR PUNITIVE DAMAGES

(INCLUDING ANY DAMAGE FOR LOST PROFITS) ARISING OUT OF OR IN

CONNECTION WITH THE FURNISHING OF PRODUCTS, PARTS OR SERVICES, OR THE PERFORMANCE, USE OF, OR INABILITY TO USE ANY

PRODUCTS, PARTS OR SERVICES, SALE OF OR OTHERWISE, WHETHER

BASED IN CONTRACT, WARRANTY, TORT, INCLUDING WITHOUT LIMITATION, NEGLIGENCE, OR ANY OTHER LEGAL OR EQUITABLE THEORY.

8. EXCEPT AS EXPRESSLY PROVIDED HEREIN, E-MON MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED WITH RESPECT TO ANY

PRODUCTS, PARTS OR SERVICES PROVIDED BY E-MON INCLUDING, BUT

NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. PRODUCTS OR COMPONENTS

DISTRIBUTED, BUT NOT MANUFACTURED, BY E-MON ARE NOT WARRANTED BY E-MON AND BUYER MUST INSTEAD RELY ON THE REPRESENTATIONS AND WARRANTIES, IF ANY, PROVIDED DIRECTLY TO THE

BUYER BY THE MANUFACTURER OF SUCH PRODUCT OR COMPONENT.

49 62-0389-05

Page 50

CLASS 2000 METER

62-0389-05 50

Page 51

CLASS 2000 METER

51 62-0389-05

Page 52

CLASS 2000 METER

E-Mon

850 Town Center Drive

Langhorne, PA 19047

www.emon.com

info@emon.com

® U.S. Registered Trademark

© 2014 E-Mon

62-0389—05 M.S. Rev. 01-14

Printed in United States

Loading...

Loading...