Page 1

Energy Monitoring Products

®

www.emon.com

info@emon.com

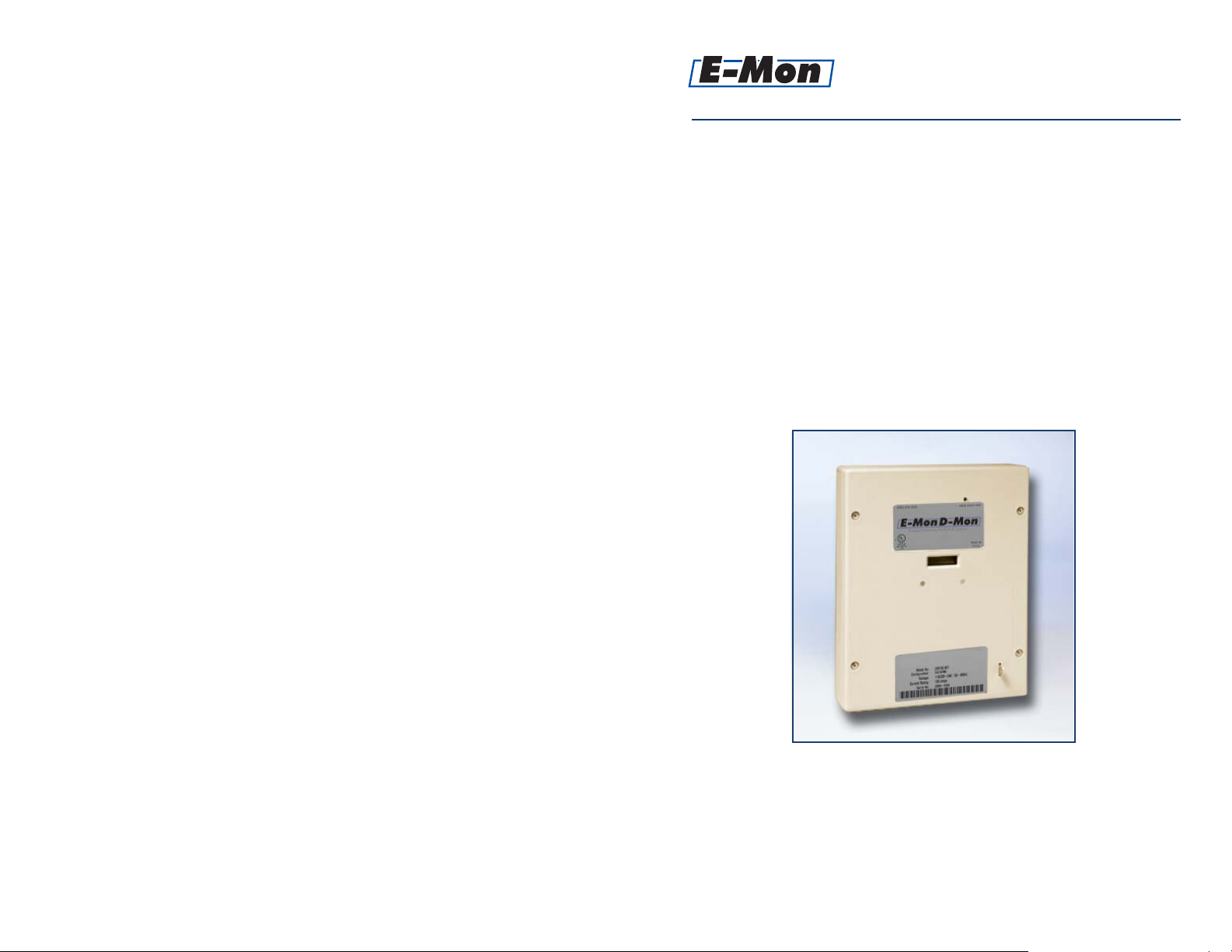

E-Mon D-Mon

®

Installation Manual

Class 4000 Single-Phase, Single-Point KWh Meter

Class 4100 Single Phase KWh Meter

with Built-In Wireless Communications

E-Mon, LLC

850 Town Center Drive

Langhorne, PA 19047

(800) 334-3666

www.emon.com - info@emon.com

11/08

E-Mon, LLC, 850 Town Center Drive, Langhorne, PA 19047

Page 2

Energy Monitoring Products

®

www.emon.com

info@emon.com

9.0 Meter Limited Warranty

Subject to the exclusions listed below, E-Mon will either repair or replace (at its

option) any product that it manufactures and which contains a defect in material

or workmanship.

The following exclusions apply:

Dear Valued Customer,

We are pleased that you chose to buy one of our products, and want you

to be just as pleased with owning it. Before installing your new E-Mon

product, please read the information on the following pages carefully.

We believe that you will fi nd the E-Mon D-Mon meters easy to install and

to use for monitoring and evaluating your electrical usage.

To be sure that you are 100% satisfi ed with your products, we provide

toll-free technical and sales support Monday through Friday, 8:00 am

to 7:30 pm, EST: (800) 334-3666. You may also reach us via email at

info@emon.com.

If you have questions, we can handle them quickly and effectively with

a telephone call. Please let us try to help you BEFORE you remove

your meter. And to help us help you, we ask that you have all relevant

information on hand when you call (model or part numbers, nature of

diffi culty, etc.)

Be sure to forward this manual to the owner after installation is complete,

so that they may use it as a reference guide when reading the E-Mon

D-Mon meter.

Thank you.

®

Energy Monitoring Products

1. This Limited Warranty is only effective for a period of (5) fi ve years following the date

of manufacture when installed in accordance with manufacturer’s instructions by qualifi ed

personnel.

2. E-Mon must be notifi ed of the defect within ninety (90) days after the defect becomes

apparent or known.

3. Buyer’s remedies shall be limited to repair or replacement of the product or component which failed to conform to E-mon’s express warranty set forth above.

4. Buyer shall be responsible for all freight costs and shall bear all risk of loss or damage

to returned goods while in transit.

5. This Limited Warranty does not cover installation, removal, reinstallation, or labor

costs, and excludes normal wear and tear. Buyer shall provide labor for the removal of the

defective component or item and installation of its replacement at no charge to E-Mon.

6. This Limited Warranty does not cover any product if: (i) a product is altered or modifi ed from its original manufactured condition, (ii) any repairs, alterations or other work has

been performed by Buyer or others on such item, other than work performed with E-Mon’s

authorization and according to its approved procedures; (iii) the alleged defect is a result

of abuse, misuse, improper maintenance, improper installation, accident or the negligence

of any party; (iv) damaged as a result of events beyond E-Mon’s control or other force

majeure events or (v) used in conjunction with equipment, components, accessories, parts

or materials not supplied or approved by E-Mon.

7. This Limited Warranty is limited to the obligation to repair or replace the manufactured

product. This is the sole and exclusive remedy for any breach of warranty. IN NO EVENT

SHALL E-MON BE LIABLE FOR ANY INDIRECT, INCIDENTAL, SPECIAL, CONSEQUENTIAL OR PUNITIVE DAMAGES (INCLUDING ANY DAMAGE FOR LOST PROFITS)

ARISING OUT OF OR IN CONNECTION WITH THE FURNISHING OF PRODUCTS,

PARTS OR SERVICES, OR THE PERFORMANCE, USE OF, OR INABILITY TO USE ANY

PRODUCTS, PARTS OR SERVICES, SALE OF OR OTHERWISE, WHETHER BASED IN

CONTRACT, WARRANTY, TORT, INCLUDING WITHOUT LIMITATION, NEGLIGENCE,

OR ANY OTHER LEGAL OR EQUITABLE THEORY.

8. EXCEPT AS EXPRESSLY PROVIDED HEREIN, E-MON MAKES NO WARRANTY OF

ANY KIND, EXPRESS OR IMPLIED WITH RESPECT TO ANY PRODUCTS, PARTS OR

SERVICES PROVIDED BY E-MON INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

PRODUCTS OR COMPONENTS DISTRIBUTED, BUT NOT MANUFACTURED, BY

E-MON ARE NOT WARRANTED BY E-MON AND BUYER MUST INSTEAD RELY ON

THE REPRESENTATIONS AND WARRANTIES, IF ANY, PROVIDED DIRECTLY TO THE

BUYER BY THE MANUFACTURER OF SUCH PRODUCT OR COMPONENT.

Page 12

Page 3

8.0 Important Information For The Owner

To better assist the building owner/manager, the installer should complete the following

information and forward the installation manual to the building owner/manager for future

reference.

Table Of Contents

Section 1.0 Introduction Page 1

Product Information

Item Installed: ______________________________________________

Model Number: ______________________________________________

Serial Number: ______________________________________________

Date of Installation: ______________________________________________

Installer Information

Installed By: Company: ______________________________________

Name: _________________________________________

Phone: _________________________________________

Application Information

Purpose Of Installation: _______________________________________________

_______________________________________________

_______________________________________________

Notes/Comments: _______________________________________________

_______________________________________________

_______________________________________________

Section 1.1 Internal Electronic Assemblies Page 2-3

Section 2.0 Meter Technical Specifi cations Page 4

Section 3.0 Safety Label Defi nitions Page 5

Section 4.0 Precautionary and Safety Information Page 5

Section 5.0 Meter Installation Page 6

Section 5.1 Mounting the Meter Page 6

Section 5.2 Main Power Board Connections Page 6-7

Section 5.3 Current Sensor Installation and Wiring Page 7-9

Section 5.4 Main Power Page 9

Section 6.0 Features & Operating Guide Page 9

Section 6.1 Class 4100 Wireless Option Page 9

Section 7.0 Troubleshooting Guide Page 10

Section 8.0 Information For The Owner/Manager Page 11

Section 9.0 Meter Limited Warranty Page 12

_______________________________________________

Page 11

Page 4

1.0 Introduction

7.0 Troubleshooting Guide

The E-Mon D-Mon Class 4000/4100 meter is a 1 or 2-element meter with

optional RF wireless communications (Class 4100). The device is used to monitor electric power usage of individual loads after the utility meter and display kWh

consumption on a direct reading digital display. With the Class 4100 wireless RF

option, it will provide kWh and kW data for automatic meter reading. Installation

must only be performed by qualifi ed personnel and in accordance with these

instructions and all applicable local and national electrical codes. E-Mon

and its representatives assume no responsibility for damages or injury resulting

from the improper installation of this meter.

Verify the input voltage rating and confi guration on the unit panel label to ensure

that it is suitable for the intended electrical service. Class 4000/4100 meters

labeled for 120/208V service MUST NOT be installed on service feeds of

277/480 volts.

Verify that the Class 4000/4100 meter’s current sensors are sized suitably for the

load to be monitored. Compare the color of the arrows on the current sensors to

the chart below to confi rm the correct sensor is being used.

Sensor Arrow Color code Sensor Rating (Amps)

Brown 100 A

Red 200 A

Table 1.0.1. Sensor arrow color codes.

CAUTION: Internal circuit components are extremely sensitive to

electrostatic discharge. Prior to handling or touching

internal circuitry, discharge any static buildup on your

person. To discharge yourself, touch a grounded metal

object such as conduit or an earth-grounded metal

enclosure.

WARNING: Use of this instrument, the E-Mon D-Mon Class 4000/4100

meter, in a manner inconsistent with this manual or not

specifi ed by the manufacturer in writing, can cause

permanent damage to the unit and/or serious injury to the

operator. The protection and safety features provided by

this equipment may become impaired or otherwise

compromised.

The Class 4000/4100 electronic kilowatt-hour meter is calibrated and tested

at the factory before being packaged and shipped. If installed properly and in

accordance with these installation instructions, the Class 4000/4100 meter will

provide years of trouble-free service. If the meter should not function, the following guide will assist in troubleshooting the installation. If, after following the

procedures below, the meter still does not function, please call E-Mon’s technical

department at (800) 334-3666 BEFORE removing the meter.

Problem Procedure to follow

1. Display reads all ZEROs, A. Determine if the load is suffi cient

or is not incrementing. to update the display (A load of

less than 1% of the meter rating

may require 24 hours to change

the display reading.

B. Check the current sensor

installation.

C. Be sure that the current &

voltage inputs have proper

phase relationship.

D. Check wiring to voltage

terminals.

E. Check circuit breaker or fuses.

F. Test source for correct voltage.

2. Display reads only a fraction A. Check the supply voltage to be

of the power consumed. sure that it is on 24 hours a day.

B. Check the current sensors for

installation and polarity.

C. Check the current sensor to

verify that it is the correct amp

rating.

D. Check the sensor wiring to the

terminal block in the meter

(verify color coding white-to white and black-to-black.)

Note: If any troubles arise during the installation or functional

verifi cation operations, do not immediately remove the unit.

Before removing the unit, contact E-Mon’s technical support

and/or engineering department at (800) 334-3666. E-Mon’s

technical department will assist you in detailed troubleshooting

of the Class 4000/4100 meter installation and assist you in

getting the unit operating correctly.

Page 1

Page 10

Page 5

5.3.2 Current Sensor Wiring (continued)

1.1 Internal Electronic Assemblies

NOTE: When the E-Mon D-Mon® Class 4000/4100 meter is installed where the

tenant has access to the electrical panel powering the meter, it is suggested that

a dedicated breaker NOT be used to power the meter, as a dedicated breaker

can be shut off and stop the meter from recording. If a dedicated breaker must

be used, it should be a lockable style.

5.4 Main Power

After the meter circuit wiring has been examined for correctness, power may be

applied to the circuit board. If the monitored circuit is under load, the LED in the

meter’s upper right hand corner will actively blink - indicating the amount of load

by the frequency of its pulse. A heavy load will blink faster than a light load. Very

light loads will result in an extended blink time.

6.0 Features & Operating Guide

The 6-digit display shows the

kilowatt-hours consumed by

Load Indicating

LED

the metered load.

The blinking LED indicator

provides a visual pulse signal

of the meter’s load. A heavier

6-Digit Display

kWh Reading

load will increase the blink

frequency.

Sealing T ab

* The sealing tab provides the

(Optional)

meter with a location to install

a utility type security seal.

NOTE: Depending on the amount of power being used, a period of time will

elapse before the meter registers. In the case of light loading, this could be as

much as several hours.

6.1 RF Wireless Metering Option (Class 4100)

The unit is comprised of one or two subassembly boards, the meter board and

the optional RF board (Class 4100). Both circuit cards are mounted inside the

non-metallic enclosure.

Note: Units are suitable for indoor applications only.

RF Board

(Class 4100)

Meter

Board

Figure 1.1 Internal electronic assemblies.

1.1.1 Meter Board

Connections to this board include the MAINS input voltage and current

sensors. The MAINS input terminals (TB1) are covered with a protective clear

shield for safety purposes. The current sensor assemblies interface to two

header connections, TB2, and TB3. Each header connector input corresponds

to an input voltage phase; care must be exercised to ensure that each current

sensor is connected to the correct input header.

Figure 1.1.1 Meter board connections.

When the meter is ordered with the RF option (Class 4100), it will be provided

with a factory installed 900 mHz RF module for AMR (Automatic Meter

Reading.) This module is pre-wired to the meter and will be active when the

meter is powered.

This module is designed to be used with E-Mon Energy™ software and an

available RF Wireless Gateway for either on-site reading or through an internet

connection. The system requires factory start-up services. Contact E-Mon for

additional details.

Page 9

TB1

TB2 & TB3

Page 2

Page 6

1.1.1 Meter Board (continued)

5.3.1 Installing the Split-Core Current Sensor Assembly (continued)

The Class 4000/4100 meter displays electrical consumption (kWh) on its 6-digit,

electro-mechanical display, and is read directly - without multipliers. An LED on

the board pulses in response to the load, with the speed of the pulse indicating

the amount of load (a heavier load will blink more rapidly).

1.1.2 RF Board (Class 4100)

The optional RF board (Class 4100) connects to the meter board via two pair of

conductors. One pair supplies power (5 VDC) to the RF board and the other pair

supplies a pulse signal that is stored as interval data. The accumulated data is

normally transmitted on a daily basis through its on-board antenna. This data is

transmitted pier-to-pier, then utilized for AMR (Automatic Meter Reading). The

RF board operates in the 900 MHz range with a maximum transmitting power of

100 mw.

5 VDC In

Figure 1.1.2 RF Board (Class 4100)

Pulse In

Antenna

2. Reassemble the current sensor assembly around the conductor(s) to be

monitored. Ensure the current sensor halves marked “Load” are both

facing the load side of the conductor. The colored arrow will be on the

source side of the conductor being monitored and MUST be pointed in a

clockwise direction around the conductor being monitored. Tighten the

nylon clamp to complete the assembly.

IMPORTANT: When looking from the source side of the conductor(s)

being monitored, you should see the arrow on the current

sensor assembly. The arrow should be pointing in a

clockwise direction around the conductor(s) being

monitored. If the arrow is not positioned on the source

side, inaccurate readings will result.

5.3.2 Current Sensor Wiring

Once the current sensors are installed onto their appropriate phase conductors,

you can begin terminating the current sensors onto the Class 4000/4100 meter

board using the two-screw removable terminal plug. The current sensor leads

can be extended up to 2,000 feet from the meter. To extend the length of the

wires, use #22 AWG twisted-pair wire with one white and one black wire.

Page 3

The current sensor connected to TB2 must be on the same phase as the MAINS

voltage terminal A and the current sensor connected to TB3 must be on the same

phase as the MAINS voltage terminal B. Failure to do so may result in inaccurate

readings.

1-Phase, 2-Wire Connection

120-Volt or 277-Volt Single-Phase

Line Voltage Current Sensors

C

AB

LOAD SOURCE

A

W B N

B

W B

A

N

Single-Phase, 3-Wire Connection

120/240-Volt Single-Phase

Line Voltage

AB

**

LOAD SOURCE

C

Current Sensors

A

W B W B N

B

A

B

N

Page 8

Page 7

5.2 Meter Board Connections (continued)

2.0 Meter Technical Specifi cations

3. External Switch Mechanism/In-Line Fuse Installation

To ensure a safe installation, the Class 4000/4100 requires an external

switch mechanism, such as a circuit breaker (max. 15 amps), be

installed to the Class 4000/4100 MAINS input wiring. The switch

mechanism must be installed in close proximity to the Class 4000/4100

and easily reachable for the operator. This device must also be marked

as the disconnecting device for the Class 4000/4100. Install 1/10 amp

Slow Activation inline fuses with the suitable voltage rating for

each conductor Phase at the MAINS input to the meter. The fuses must

be labeled to indicate voltage and current rating as well as element

characteristics. The fuse element must be slow activating type.

5.3 Current Sensor Installation & Wiring

The meter board contains two plug-in connectors located at the bottom center

of the board, TB2 and TB3. (See Figure 1.1.1) Connector TB2 is the input for

Phase A, and TB3 is the input for Phase B.

The Class 4000/4100 meter can be used with two types of current sensors:

1. Split-core current sensor. This sensor opens so that it can be attached

around the circuit being monitored without interrupting power. Unless

otherwise specifi ed, all Class 4000/4100 meters are supplied with this

sensor type.

2. Solid-core current sensor. This sensor does not open and requires the

monitored conductor to be removed from the circuit to install the current

sensor. This type is only supplied when specifi ed at time of order.

5.3.1 Installing the Split-Core Current Sensor Assembly

1. Each phase being monitored will require one two-piece current sensor

assembly. Open the two-piece current sensor assembly by releasing

the nylon clamp using a fl athead screwdriver.

Ordering Information: Defi ne input voltage, current sensor rating and the RF

option, in the format C-xxx-yyyy-zz, where

xxx=input voltage (120 or 208 [120/208/240])

yyy=current sensor rating (100, 200)

zz=designated option (W=none [Class 4000], WT (RF transceiver [Class 4100])

Example: 3 208 200 W

Number of conductors (3)

Input Voltage (208)

Current Sensor (200A)

RF Transceiver (none)

C = number of conductors (2 or 3)

Input Voltage Confi guration 2-wire 120-volt, 3-wire 120/240-volt, 3-wire 120/208 volt

MAINS Voltage Input Up to 240 VAC

Input Power 6 VA maximum rating

Current Sensor Rating Up to 200 amps RMS AC available

Power Factor 0.5 leading or lagging

Line Frequency 50-60 Hz

Metering Accuracy Certifi ed to ANSI C12.16 (+/-1% from 1-100% of rated load)

Voltage Operating Range +/-10% of rated load

Temperature Range -20 degrees C to +50 degrees C

Relative Humidity Range 0-95% non-condensing

Altitude 2000 meters maximum

Voltage Overload +25% continuously; +100% for 20 cycles

Current Sensor Overload 100% for 1 minute without damaging meter

Pollution Degree Degree 2 in accordance with IEC 664

Installation (Overvoltage) Category Category III

Measurement Category Category III

Enclosure Material ABS 94VO

Display Readout 6-digit electro-mechanical

Standard Ranges (2-wire) 120 VAC, 100, 200 Amp

(3-wire) 120/208/240 VAC, 100, 200 Amp

Modem Interface None

RS-485 Serial Communications None

Load Control None

Recommended In-Line Fuse Manufacturer: Littlefuse

Mfg Part No.: 313.100

Rating: 100mA, Slo-Blo, 250 VAC cartridge fuse

Page 7

Table 2.0.1 Class 4000/4100 meter technical specifi cations.

Page 4

Page 8

3.0 Safety Label Defi nitions and Information

5.0 Meter Installation

The Class 4000/4100 meter may contain one or more of the following labels.

Operator(s) should familiarize themselves with the meaning of each label to

minimize risk.

The presence of this label is a cautionary indicator

identifying a danger risk. The manual should be

consulted prior to proceeding.

The presence of this label indicates an electrical

shock hazard exists in the location or area where

the label is placed. Prior to proceeding, the MAINS

power must be disconnected and the manual

consulted for safety information.

4.0 Precautionary/Safety Information

5.1 Mounting the Class 4000/4100 Meter

Use appropriately sized mounting hardware to fasten the Class 4000/4100

enclosure to the selected mounting surface. The four mounting holes are located

inside the enclosure and are accessed by removing the cover. The mounting

holes are centered 6 13/16” H x 4 13/16” W.

NOTE: Units must only be installed in indoor environments, where they will not

be affected by the elements.

5.2 Meter Board Connections

1. Wire Entry:

Two 1/2” conduit openings are located on the back of the unit enclosure.

These openings are used for bringing in MAINS power and for current

sensor wiring. Route the appropriate cabling to and through the

respective enclosure opening.

After installing the conduit fi tting and conduit, verify that each conduit

slip nut is securely tightened to its respective conduit fi tting.

2. Unit MAINS wiring:

The 4-position terminal block TB1, located at the bottom left corner of

the meter board, is clearly labeled A, B, C, N (neutral). AWG 14 or 12

gauge (stranded) conductors are typically utilized for this connection.

WARNING: High voltages present on main PCB terminal block TB1.

Risk of serious injury and/or electrical shock exists. Prior

to performing any wiring operations, review all contents of

the user manual and de-energize the MAINS power switch.

Only qualifi ed personnel should perform installation

wiring. Installation wiring must comply with all local and

national electrical codes.

WARNING: NEVER open front panel of unit while unit has MAINS

power applied. Failure to comply can increase the risk of

serious injury and/or electrical shock.

Page 5

Figure 5.2.1.

Terminal block TB1.

A. Connect the NEUTRAL wire to the appropriate terminal block position.

B. On 2-wire, 120 VAC installations, connect the AC main power wire to the

Phase A position as labeled on terminal block TB1. On 3-wire 120/208

VAC installations connect the AC main power wires to Phase A and

Phase B positions on terminal block TB1. After all conductors are

connected to their respective terminal block positions and tightened

down, verify that each terminal block screw is securely fastened by

gently tugging on each conductor. Verify that no conductor wires

are frayed or shorting to adjacent terminal block positions.

Page 6

Loading...

Loading...