Emko Elektronik A.S.. ESM-4430 Instruction Manual

ESM- 48x48 DIN 1/164430 Process Controller

Instruction Manual. ENG ESM-4430 02 V07 04/08

- 4 4 digits process set (SV) display

(TC, RTD, mV , V , mA )

- Dual or multi point calibration for Voltage / Current input

- Adaptation of PID coefficients to the system with Auto-tune and

Self-tune

- Manual/Automatic mode selection for control outputs

- Programmable heating, cooling and alarm functions for control

outputs

ZZ Z

Z

- Bumpless transfer

digits process (PV) and

- Universal process input

- Configurable ON/OFF, P, PI, PD and PID control forms

ESM-4430 48 x 48 1/16 DIN

Universal Input PID Process Controller

2

Instruction manual of ESM-4430 Process Controller consists of two main sections.

Explanation of these sections are below. Also, there are other sections which include order

information and technical specifications of the device. All titles and page numbers in instruction

manual are in “ ” section. User canreach to any title with section number.

Physical dimensions, panel mounting, electrical wiring , physical and

electrical installation of the device to the system are explained i

User interface of the device, how to access to the parameters, description of parameters

are explained i

CONTENTS

Installation:

Operation and Parameters:

of the device

n this section.

n this section.

Also in these sections, there are warnings to prevent serious injury while doing the

physical and electrical mounting or using the device.

Explanation of the symbols which are used in these sections are given below.

This symbol is used to determine the dangerous situations as a result of an electric

shock. User must pay attention to these warnings definitely.

a

c

This symbol is used for safety warnings. User must pay attention to these

warnings.

This symbol is used to determine the important notes about functions and usage of

the device

ABOUT INSTRUCTION MANUAL

i

1.PREFACE............................................................................................................................................

2.INSTALLATION....................................................................................................................................

3.ELECTRICAL WIRINGS......................................................................................................................

4.OUTPUT CONNECTION FORMS IN ESM-4430 PROCESS CONTROLLER....................................

5.DEFINITION OF FRONT PANEL AND ACCESSING TO THE PARAMETERS..................................

1.1 GENERAL SPECIFICATIONS

1.2 ORDERING INFORMATION

1.3 WARRANTY

1.4 MAINTENANCE

2.1 GENERAL DESCRIPTION

2.2 DIMENSIONS

2.3 PANEL CUT-OUT

2.4 ENVIRONMENTAL RATINGS

2.5 PANEL MOUNTING

2.6 INSTALLATION MOUNTING CLAMP

2.7 REMOVING FROM THE PANEL

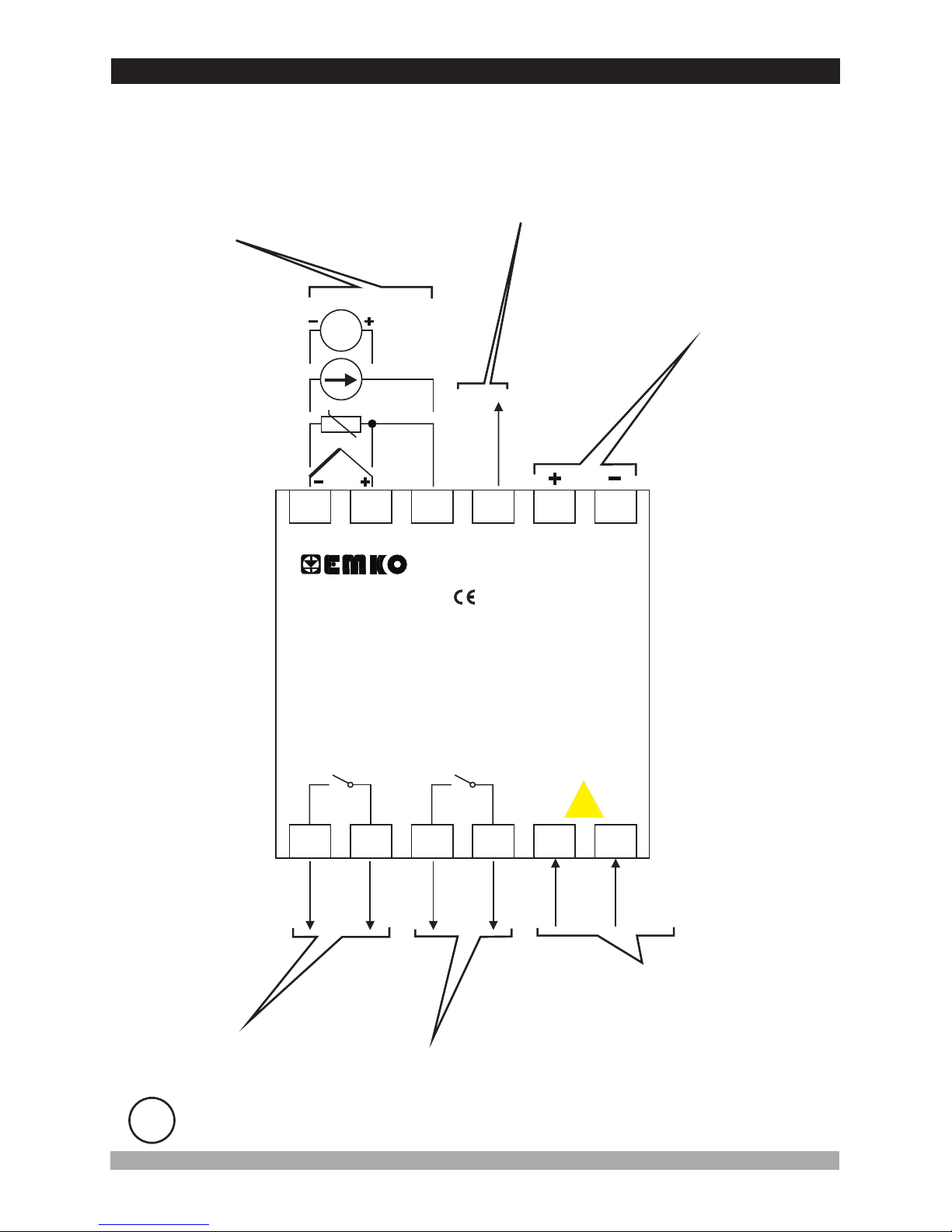

3.1 TERMINAL LAYOUT AND CONNECTION INSTRUCTION

3.2 ELECTRICAL WIRING DIAGRAM

3.3 VIEW OF THE LABELS

3.4 CONNECTION OF DEVICE SUPPLY VOLTAGE INPUT

3.5 PROCESS INPUT CONNECTION

3.5.1 TC (THERMOCOUPLE) CONNECTION

3.5.2 RTD CONNECTION

3.5.3 PROCESS INPUT CONNECTION OF SERIAL TRANSMITTERS WITH CURRENT

OUTPUT (LOOP POWERED)

3.5.4 PROCESS INPUT CONNECTION OF 3-WIRE TRANSMITTERS WITH CURRENT

OUTPUT

3.5.5 CONNECTION OF TRANSMITTERS WITH VOLTAGE OUTPUT TO PROCESS

INPUT

3.6 GALVANIC ISOLATION TEST VALUES OF ESM-4430 PROCESS CONTROLLER

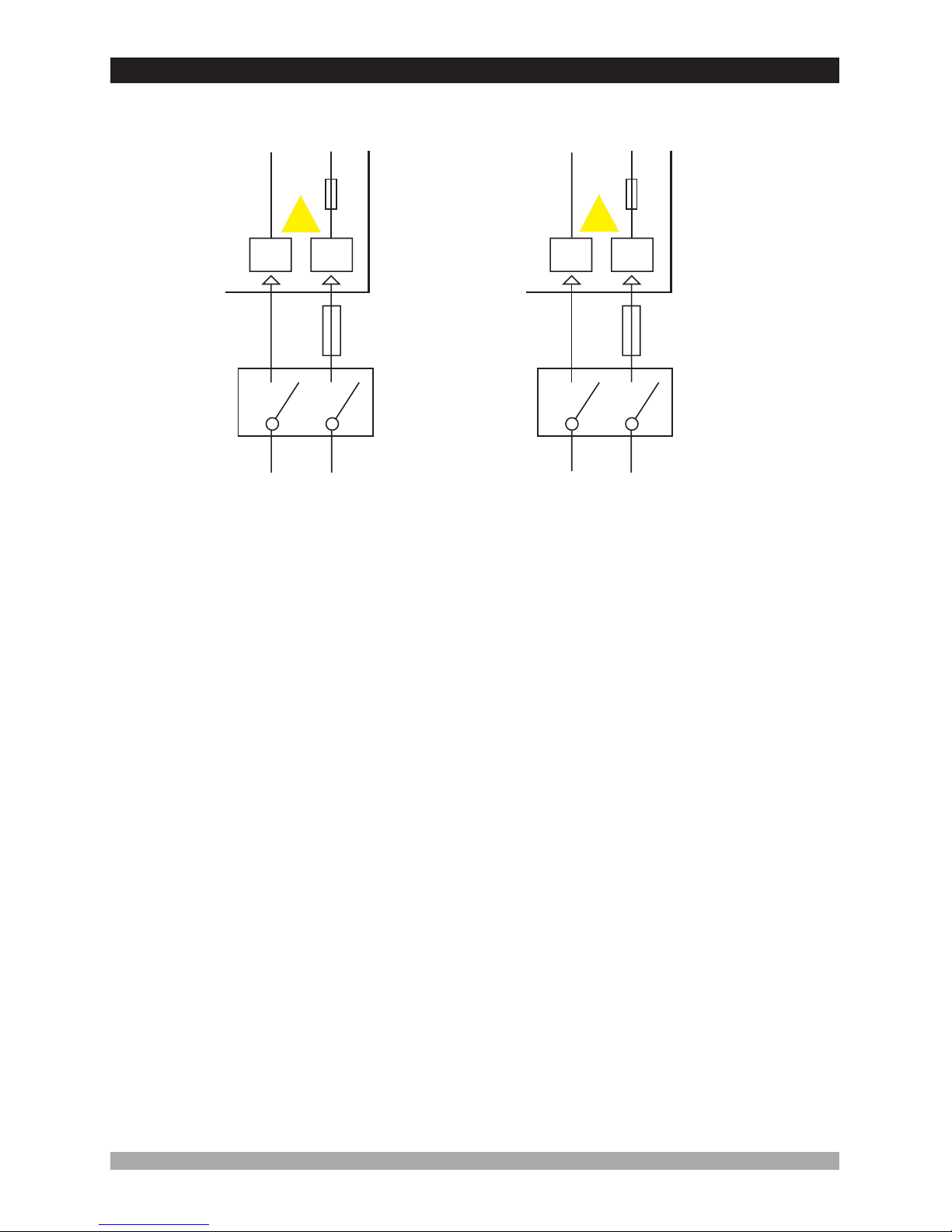

4.1 PROCESS OUTPUT (SSR DRIVER OUTPUT) CONNECTION

4.2 ALARM OUTPUT -1 RELAY CONNECTION

4.3 PROCESS OUTPUT OR ALARM OUTPUT -2 RELAY CONNECTION

5.1 DEFINITION OF FRONT PANEL

5.2 OBSERVATION OF SOFTWARE REVISION ON THE BOTTOM DISPLAY WHEN POWER

IS ON

5.3 ADJUSTMENT OF PROCESS AND ALARM SET VALUES

5.4 EASY ACCESS DIAGRAM FOR PROGRAM PARAMETERS

5.5 ACCESSING TO THE TECHNICIAN MENU

5.6 CHANGING AND SAVING PARAMETERS

6.1 PROCESS / ALARM SET PARAMETERS

6.2 TECHNICIAN PARAMETERS

6.2.1 SELECTION OF PID TUNE AND OPERATION FORM

6.2.2 FUNCTION SELECTION FOR TOP AND BOTTOM DISPLAY

6.2.3 PROCESS INPUT TYPE AND RELEVANT PARAMETERS WITH PROCESS INPUT

6.2.4 PID CONFIGURATION PARAMETERS

6.2.5 PROCESS OUTPUT CONFIGURATION PARAMETERS

6.2.6 ALARM OUTPUT - 1 CONFIGURATION PARAMETERS

6.2.7 ALARM OUTPUT - 2 CONFIGURATION PARAMETERS

6.2.8 GENERAL PARAMETERS

6.2.9 TECHNICIAN PASSWORD

6.PARAMETERS.....................................................................................................................................

7.FAILURE MESSAGES IN ESM-4430 PROCESS CONTROLLERS...................................................

8.SPECIFICATIONS................................................................................................................................

CONTENTS

Page 5

Page 41

Page 21

Page 13

Page 8

Page 23

Page 64

Page 66

3

4

Manufacturer Company Name : Emko Elektronik A.S..

Manufacturer Company Address: DOSAB, Karanfil Sokak, No:6, 16369 Bursa, Turkiye

The manufacturer hereby declares that the product conforms to the following

standards and conditions.

Product Name : Process Controller

Model Number : ESM-4430

Type Number : ESM-4430

Product Category : Electrical equipment for measurement, control and

laboratory use

Conforms to the following directives :

73 / 23 / EEC The Low Voltage Directive as amended by 93 / 68 / EEC

89 / 336 / EEC The Electromagnetic Compatibility Directive

Has been designed and manufactured according to the following specifications

EN 61000-6-4:2001 EMC Generic Emission Standard for the Industrial Environment

EN 61000-6-2:2001 EMC Generic Immunity Standard for the Industrial Environment

EN 61010-1:2001 Safety Requirements for electrical equipment for measurement,

control and laboratory use

EU DECLARATION OF CONFORMITY

5

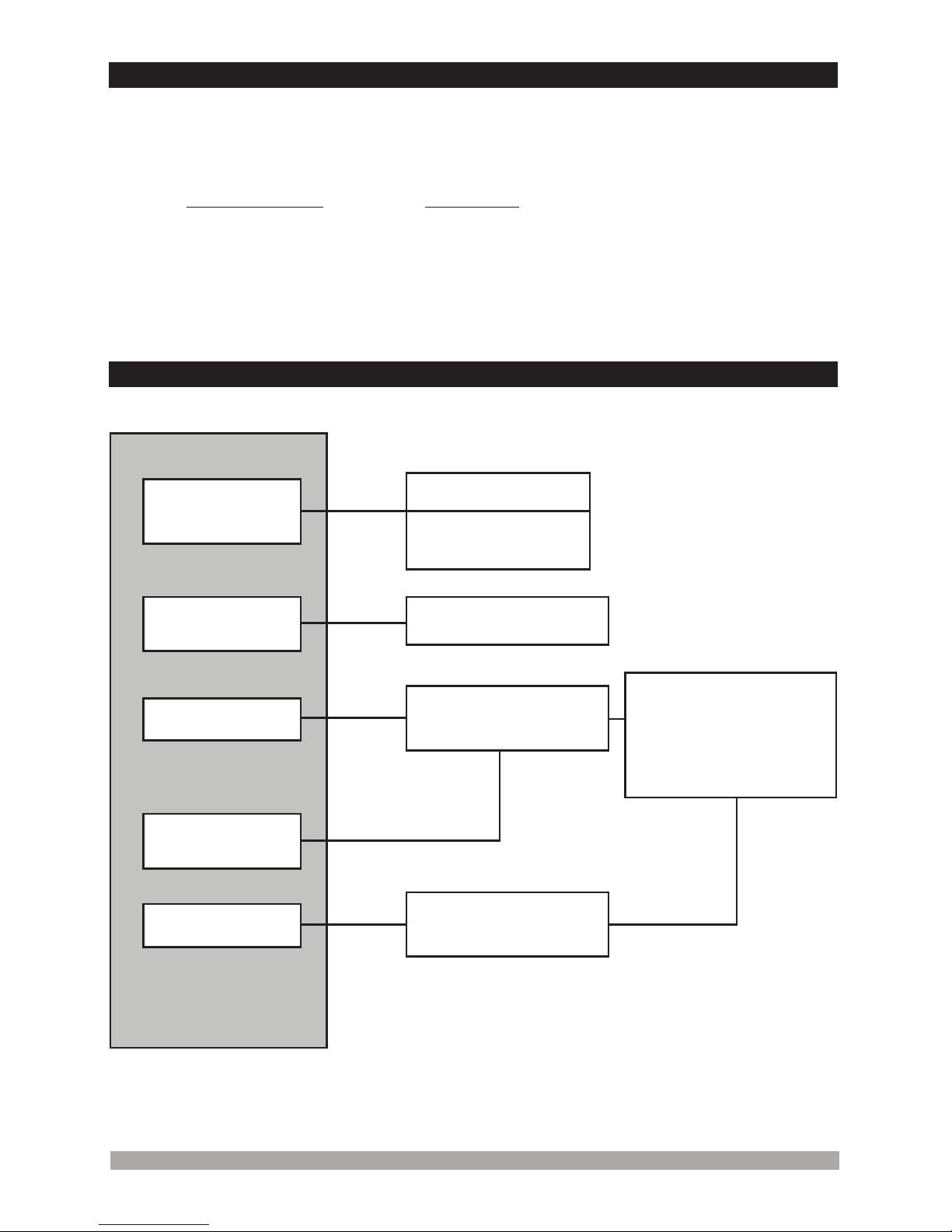

ESM series process controllers are designed for measuring and controlling temperature

and any process value.They can be used in many applications with their universal process input,

control outputs, selectable alarm functions.

Some application fields and applications which theyare used are below:

1.Preface

Glass PID Process Control

Plastic

Petro-Chemistry

Textile

Automative

Machine production industries

Application Fields Applications

Alarm Out-1

(Relay Output)

Process Input

Power Supply

Input

Standard

1.1 General Specifications

ESM-4430

Standard

Standard

Heating-Cooling Function

ON/OFF, PID Operation

Auto-Tune, Self-Tune

Automatic/Manual Operation

Process Out

(SSR Driver Output)

Process Out or

Alarm Out-2

(Relay Output)

Standard

Universal Supply Input

100-240 V , 50/60HzV

Low Voltage (optional)

Supply Input

24V 50/60Hz ,24VVZ

Universal Process Input

TC,RTD, Voltage/CurrentZ

Control Output

Alarm Output

Control Output

ESM-4430 (48x48 DIN 1/16)

Supply Voltage

A

A

20

1

0

Configurable (Table-1) Table-1

None

BC D E FG HI //UVWZ/

/

Input Type

Output-1

Serial Communication

Scale

BC

E

HI

D

All order information of ESM-4430 are

given on the table at left. User may form

appropriate device configuration from

information and codes that at the table and

convert it to the ordering codes.

Firstly, supply voltage then other

specifications must be determined. Please

fill the order code blanks according to your

needs.

Please contact us, if your needs are

out of the standards.

1.2 Ordering Information

1

01

Output-2

FG

Output-3

02

100-240V (-15%;+10%) 50/60HzV

24 V (-15%;+10%) 50/60Hz 24V (-15%;+10%)VZ

1

2

Customer (Maximum 240V (-15%;+10%))50/60HzV

9

01 02

c

Table-1

21

39

41

40

42

43

44

45

22

23

25

27

28

29

31

33

35

37

24

26

30

32

34

36

38

L ,Fe Const DIN43710

PT 100 , IEC751(ITS90)

0...50 mV Z

PT 100 , IEC751(ITS90)

0...5 V Z

0...10 V Z

0...20 mA Z

4...20 mA Z

L ,Fe Const DIN43710

J ,Fe CuNi IEC584.1(ITS90)

K ,NiCr Ni IEC584.1(ITS90)

R ,Pt13%Rh Pt IEC584.1(ITS90)

S ,Pt10%Rh Pt IEC584.1(ITS90)

T ,Cu CuNi IEC584.1(ITS90)

B ,Pt30%Rh Pt6%Rh IEC584.1(ITS90)

E ,NiCr CuNi IEC584.1(ITS90)

N ,Nicrosil Nisil IEC584.1(ITS90)

C , (ITS90)

T ,Cu CuNi IEC584.1(ITS90)

B ,Pt30%Rh Pt6%Rh IEC584.1(ITS90)

E ,NiCr CuNi IEC584.1(ITS90)

N ,Nicrosil Nisil IEC584.1(ITS90)

C , (ITS90)

J ,Fe CuNi IEC584.1(ITS90)

K ,NiCr Ni IEC584.1(ITS90)

-100°C,850°C

-200°C,650°C

-1999,9999

-199.9°C,650.0°C

-100.0°C,850.0°C

-200°C,900°C

-200°C,1300°C

0°C,1700°C

0°C,1700°C

-200°C,400°C

44°C,1800°C

-150°C,700°C

-200°C,1300°C

0°C,2300°C

-199.9°C,900.0°C

-199.9°C,999.9°C

-199.9°C,400.0°C

44.0°C,999.9°C

-150.0°C,700.0°C

-199.9°C,999.9°C

0.0°C,999.9°C

-148°F ,1562°F

-328°F,1202°F

-199.9°F,999.9°F

-148.0°F,999.9°F

-328°F,1652°F

-328°F,2372°F

32°F,3092°F

32°F,3092°F

-328°F,752°F

111°F,3272°F

-238°F,1292°F

-328°F,2372°F

32°F,3261°F

-199.9°F,999.9°F

-199.9°F,999.9°F

-199.9°F,752.0°F

111.0°F,999.9°F

-199.9°F,999.9°F

-199.9°F,999.9°F

32.0°F,999.9°F

Input Type(TC)

Input Type(RTD)

Input Type( Voltage and Current)Z

Scale(°C)

Scale(°C)

Scale

Scale(°F)

Scale(°F)

BC

BC

BC

-1999,9999

-1999,9999

-1999,9999

-1999,9999

0

Relay Output (5A@250 V at resistive load)V

Relay Output (5A@250 V at resistive load)V

SSR Driver Output ( Maximum 15V ,15mA )Z

6

V

Z

Symbol means Vac,

Symbol means Vdc

Symbol means Vac and VdcW

7

1.3 Warranty

EMKO Elektronik warrants that the equipment delivered is free from defects in material and

workmanship. This warranty is provided for a period of two years. The warranty period starts from

the delivery date. This warranty is in force if duty and responsibilities which are determined in

warranty document and instruction manual performs by the customer completely.

1.4 Maintenance

Repairs should only be performed by trained and specialized personnel. Cut power to the device

before accessing internal parts.

Do not clean the case with hydrocarbon-based solvents (Petrol, Trichlorethylene etc.). Use of

these solvents can reduce the mechanical reliability of the device. Use a cloth dampened in ethyl

alcohol or water to clean the external plastic case.

8

In package ,

- One piece unit

- Two pieces mounting clamps

- One piece instruction manual

A visual inspection of this product for possible damage occured during shipment is

recommended before installation. It is your responsibility to ensure that qualified

mechanical and electrical technicians install this product.

If there is danger of serious accident resulting from a failure or defect in this unit, power

off the system and the electrical connection of the device from the system.

The unit is normally supplied without a power switch ora fuse. Use power switch andfuse

as required.

Be sure to use the rated power supply voltage to protect the unit against damage and to

prevent failure.

Keep the power off until all of the wiring is completed so that electric shock and trouble

with the unit can be prevented.

Never attempt to disassemble, modify or repair this unit. Tampering with the unit may

results in malfunction, electric shock or fire.

Do not use the unit in combustible or explosive gaseous atmospheres.

During the equipment is putted in hole on the metal panel while mechanical installation

some metal burrs can cause injury on hands, you must be careful.

Montage of the product on a system must be done with it’s fixing clamps. Do not do the

montage of the device with inappropriate fixing clamp. Be sure that device will not fall

while doing the montage.

It is your responsibility if this equipment is used in a manner not specified in this

instruction manual.

separate

Before beginning installation of this product, please read the instruction

manual and warnings below carefully.

2.Installation

c

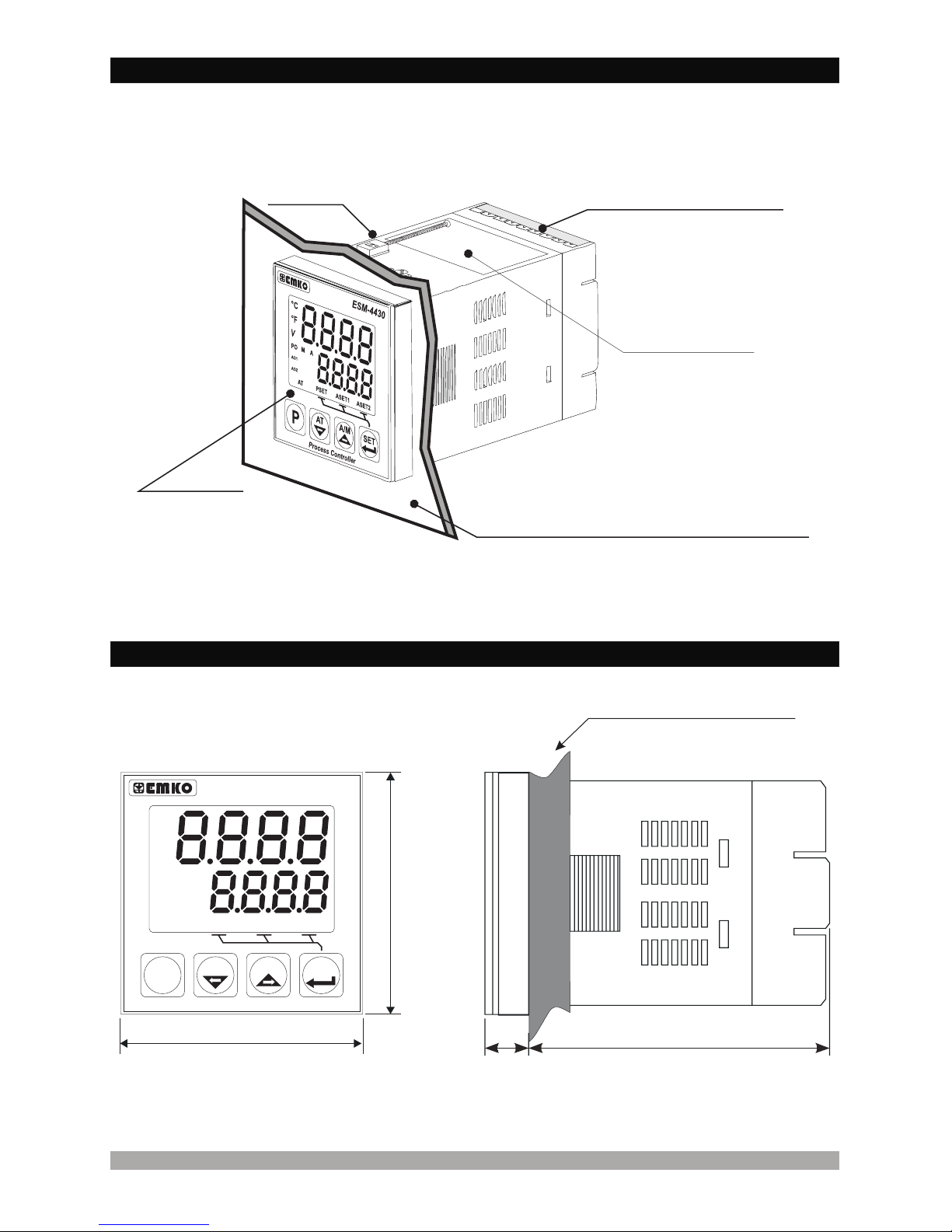

2.1 General Description

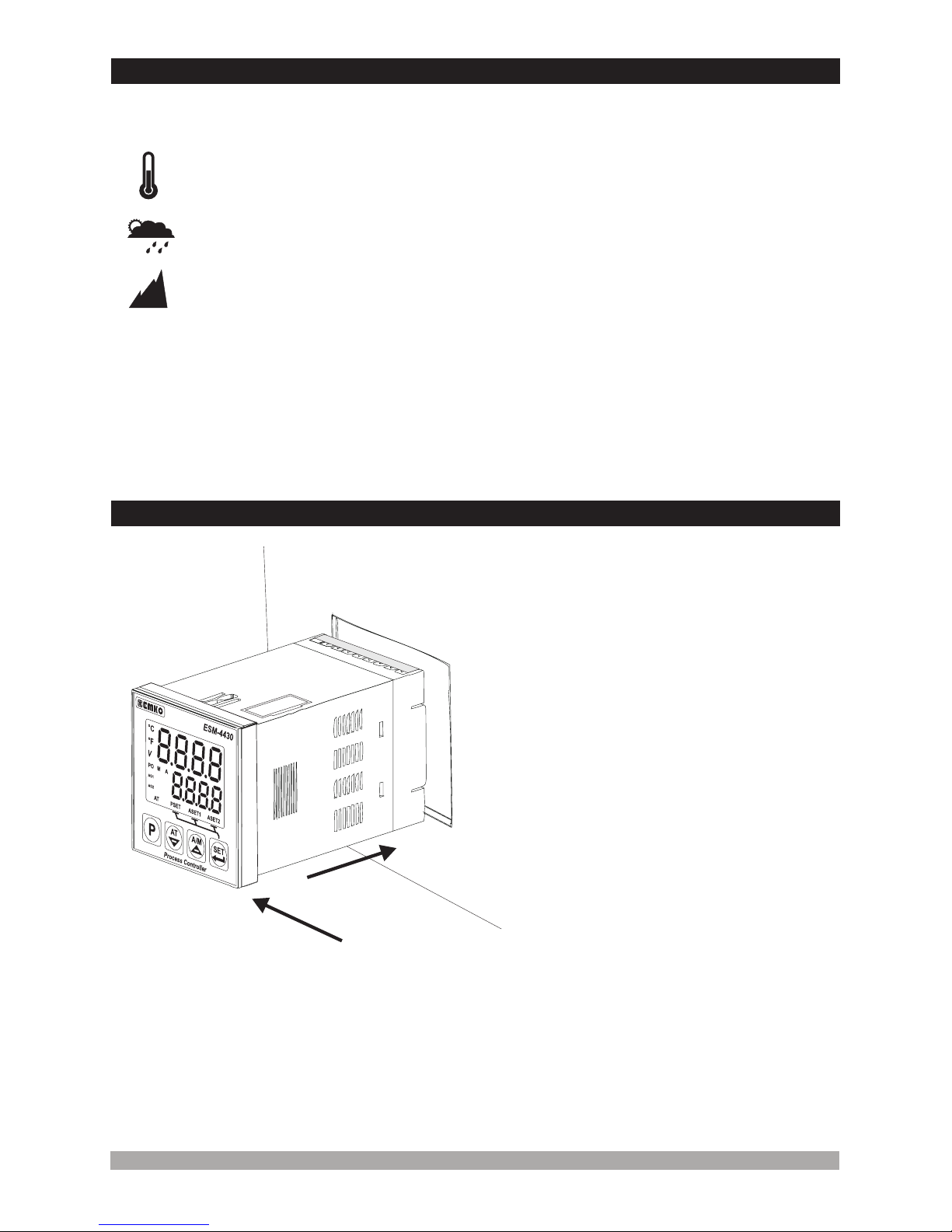

2.2 Dimensions

Maximum 5 0.2 inchmm /

48 mm/ 1.89 inch

48mm/ 1.89 inch

76mm / 2.99 inch11.5±1mm/0.45 inch

9

Product Label

Terminal protection cover

Mounting Clamp

Front Panel

IP65 protection

NEMA 4X

Panel surface

(maximum thickness 5mm / 0.2 inch)

°C

°F

V

PO

AO1

AO2

A

AT PSET ASET1 ASET2

M

SET

P

ESM-4430

Process Controller

AT A/ M

65 mm/2.56 inch (min)

46 mm/1.81 inch (min)

46 mm/1.81 inch (min)

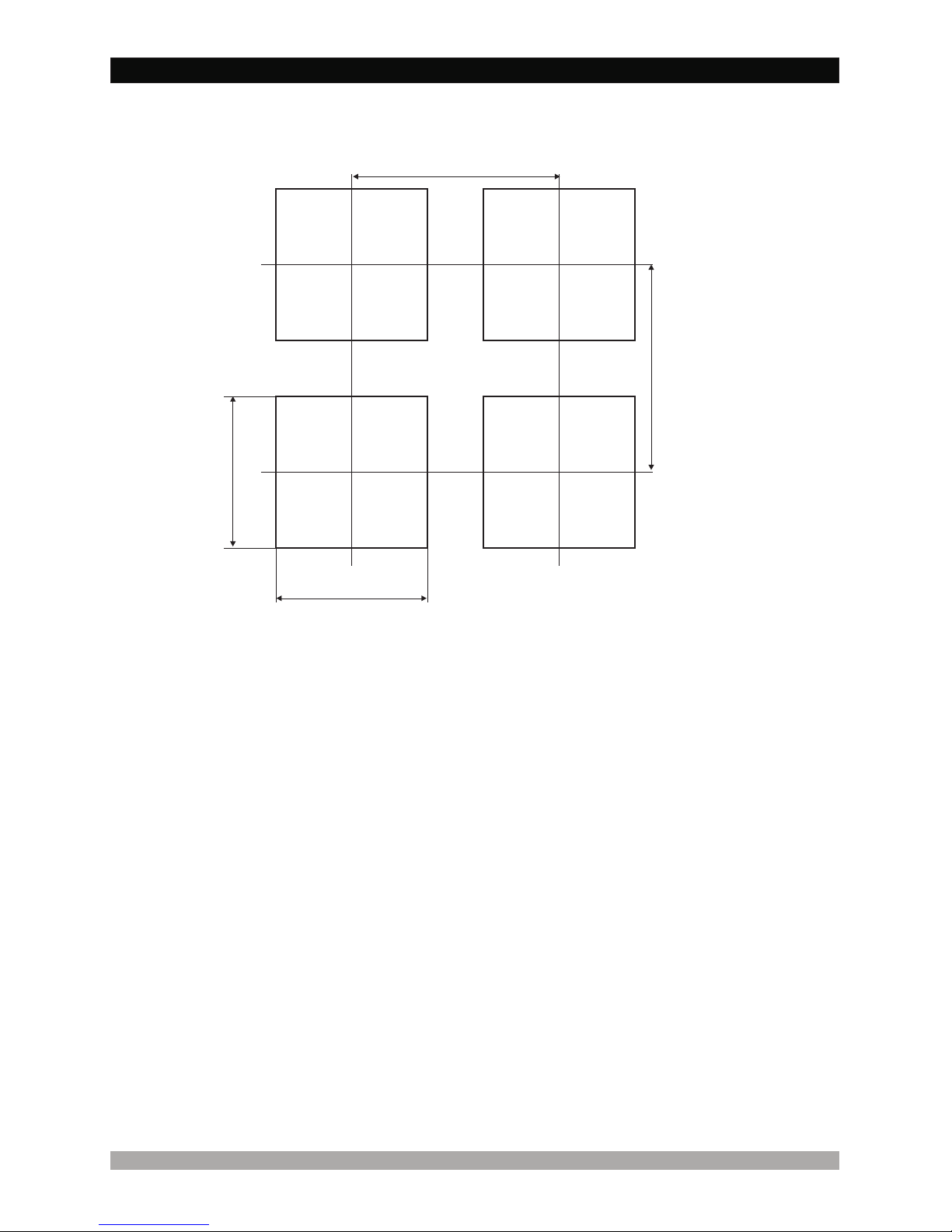

2.3 Panel Cut-Out

10

65 mm/2.56 inch (min)

c

1

2

3

11

During installation into a metal panel, care should be taken to avoid injury from

metal burrs which might be present. The equipment can loosen from vibration

and become dislodged if installation parts are not properly tightened. These

precautions for the safety of the person who does the panel mounting.

2.5 Panel Mounting

Operating Temperature :

Max. Operating Humidity :

Altitude :

0to50°C

90 Rh (non-condensing)

Up to 2000m.

%

Operating Conditions

Forbidden Conditions:

Corrosive atmosphere

Explosive atmosphere

Home applications (The unit is only for industrial applications)

2.4 Environmental Ratings

c

1-Before mounting the device in your

panel, make sure that the cut-out is of the

right size.

2-Check front panel gasket position

3-Insert the device through the cut-out. If

the mounting clamp are on the unit, put out

them before inserting the unit to the panel.

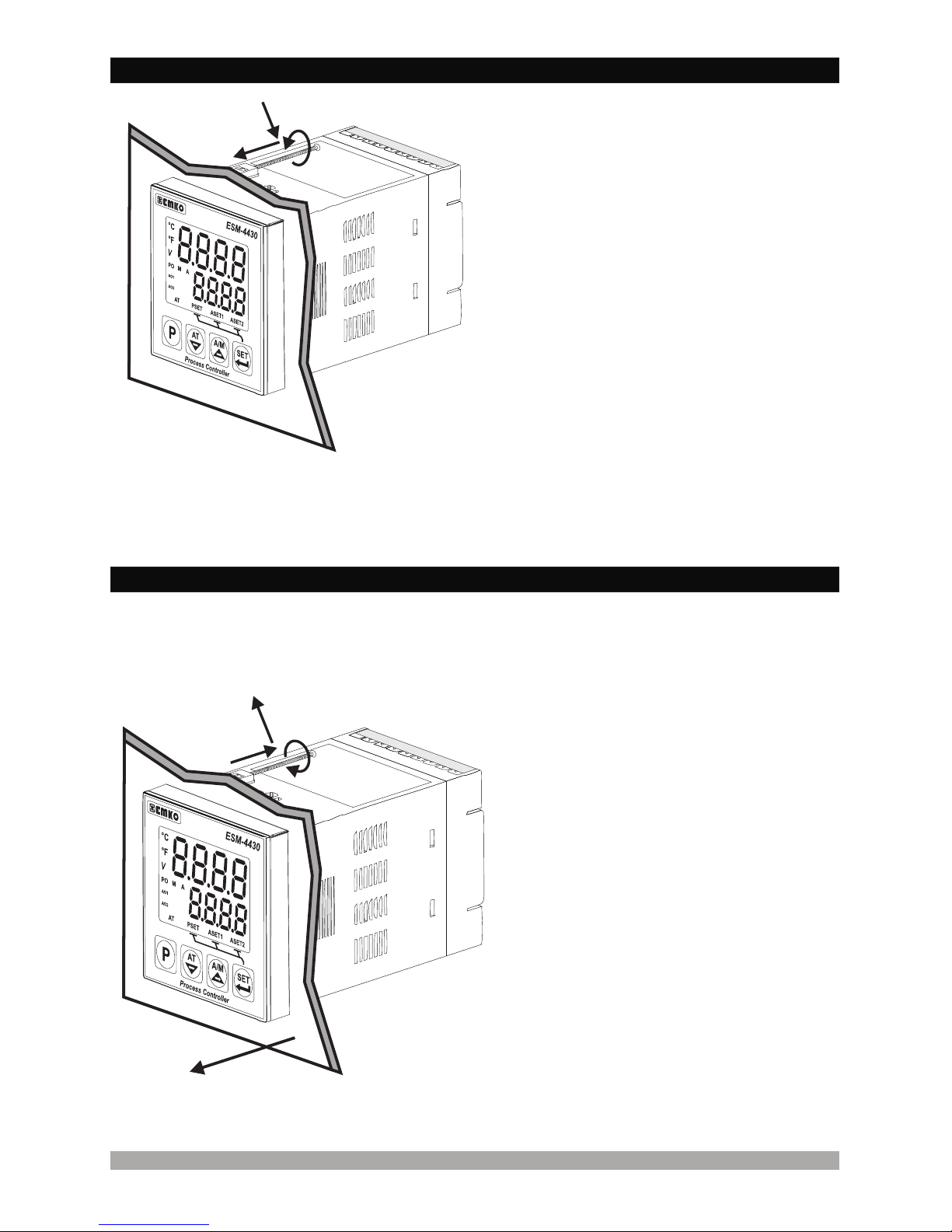

2.6 Installation Mounting Clamp

2.7 Removing from the Panel

c

c

12

1-Loosen the screws.

2-Pull mounting clamps from top and bottom

fixing sockets.

3-Pull the unit through the front side of the

panel

Before starting to remove the unit from panel, power off the unit and the

related system.

Montage of the unit to a system must be done with it’s own fixing clamps. Do

not do the montage of the device with inappropriate fixing clamps. Be sure

that device will not fall while doing the montage.

The unit is designed for panel mounting.

1-Insert the unit in the panel cut-out from the

front side.

2- Insert the mounting clamps to the holes

that located top and bottom sides of device

and screw up the fixing screws until the unit

completely immobile within the panel

1

2

2

1

3

1

7

2

8

3

9410511

6

12

0.5 Nm

a

13

3.Electrical Wirings

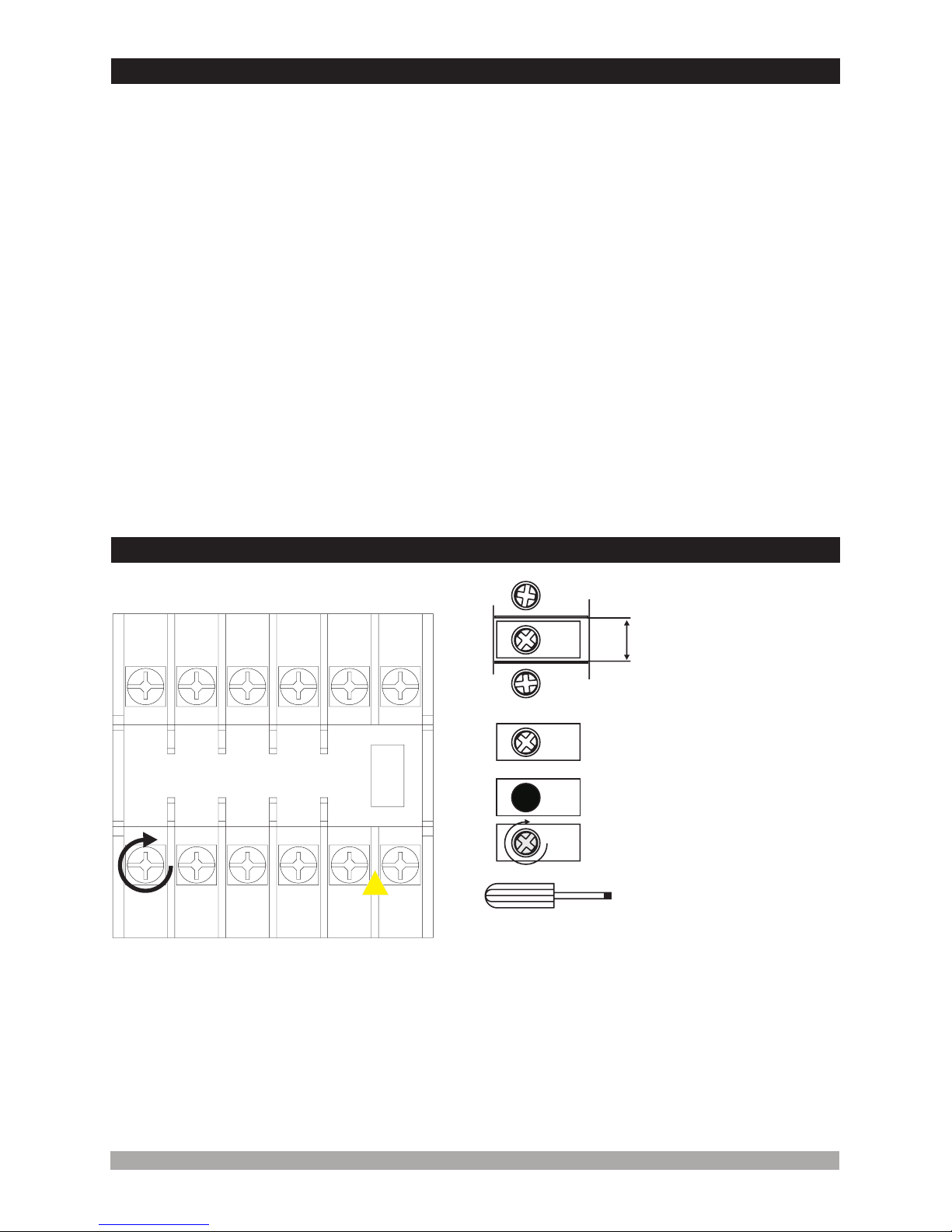

3.1 Terminal Layout and Connection Instructions

You must ensure that the device is correctly configured for your application.

Incorrect configuration could result in damage to the process being

controlled, and/or personal injury. It is your responsibility, as the installer, to

ensure that the configuration is correct.

Parameters of the device has factory default values. These parameters must

be set according to the system’s needs.

Only qualified personnel and technicians should work on this equipment.

This equipment contains internal circuits with voltage dangerous to human

life. There is severe danger for human life in the case of unauthorized

intervention.

Be sure to use the rated power supply voltage to protect the unit against

damage and to prevent failure.

Keep the power off until all of the wiring is completed so that electric shock

and trouble with the unit can be prevented.

c

c

c

c

6 mm / 0.236 inch

Wire Size:

18AWG/ 1 mm²

Solid /Stranded

12 screws terminal M3

Torque 0.5 Nm

Screw driver 0.8x3mm

1

7

2

8

3

9

4

10

5

11

6

12

TC

Pt-100

0 to 20mA Z

0 to 50mV

0to10VZZ

CAT II

P/N : ESM-4430

Y

a

c

5A@250V V

Process Out

(Alarm Out-2)

Process Out

Alarm Out-1

5A@250V V

Process input is in CAT II class

i

CNO CNO

14

3.2 Electrical Wiring Diagram

Universal

Process Input

(TC, RTD, Voltage / Current)Z

Sensor or Transmitter

Supply Voltage

Process Output

SSR Driver Output

Electrical wiring of the device must be the same as ‘Electrical Wiring Diagram’

below to prevent damage to the process being controlled and personnel injury.

c

Process Output or

Alarm Output-2 Relay

Alarm Output-1

Relay

Max 15V ,15mAZ

Supply Voltage Input

100-240V (- ) 50/60Hz

24 V (- 50/60Hz - 6VA

24V (-

(It must be determined in order)

V

V

Z

15%;+10%

15%;+10%)

15%;+10%) - 6W

-6VA

15V Z

±10%

Max 50mA

3.3 View of the Labels

15

mA Z

Max. 15V ,15mAZ

Max.50mA

15 VZ

±10%

3.4 Connection of Device Supply Voltage Input

16

c

c

c

100 - 240 V

(-15%;+10%) 50/60 Hz

V

24V (-15%;+10%) 50/60HzV

11

NL

12

Note-1

Y

11

L

12

Y

c

or 24V (-15%;+10%)Z

c

a

a

External

Fuse

(1 A T)V

External

Fuse

(24V : 1 A T)

(24V : 1 A T)

VV

ZZ

Note-2

N

Fuse

Fuse

Note-3

Note-3

Universal Supply

Voltage Connection

Low Voltage 24 V

Supply Voltage Input

W

Supply Voltage

Power

Supply

Switch

Power

Supply

Switch

Note-1

Supply Voltage

Note-1 :

Note-2 : “L” N”

There is an internal 33R fusible flameproof resistor in 100-240 V 50/60Hz supply

voltage input

There is an internal 4R7 fusible flameproof resistor in 24V 50/60Hz , 24V supply voltage

input

is(+),” is(-)for24V supply voltage

W

W

V

VZ

Z

Note-3 : External fuse is recommended.

Make sure that the power supply voltage is the same indicated on the

instrument.

Switch on the power supply only after that all the electrical connections have

been completed.

Supply voltage range must be determined in order. While installing the unit,

supply voltage range must be controlled and appropriate supply voltage must

be applied to the unit. Controlling prevents damages in unit and system and

possible accidents as a result of incorrect supply voltage.

There is no power supply switch on the device. So a power supply switch must

be added to the supply voltage input. In accordance with the safety regulations,

the power supply switch shall bring the identification of the relevant

instrument.Power supply switch shall be easily accessible by the user.

Power switch must be two poled for seperating phase and neutral. On/Off

condition of power switch is very important in electrical connection. On/Off

condition of power switch must be signed for preventing the wrong connection.

If an external fuse is used, it must be on phase connection in supply input.

If an external fuse is used, it must be on (+) line connection in supplyinput.

V

Z

The instrument is protected with an internal fuse (Please refer to Note1 for

information). In case of failure it is suggested to return the instrument to the

manufacturer for repair.

17

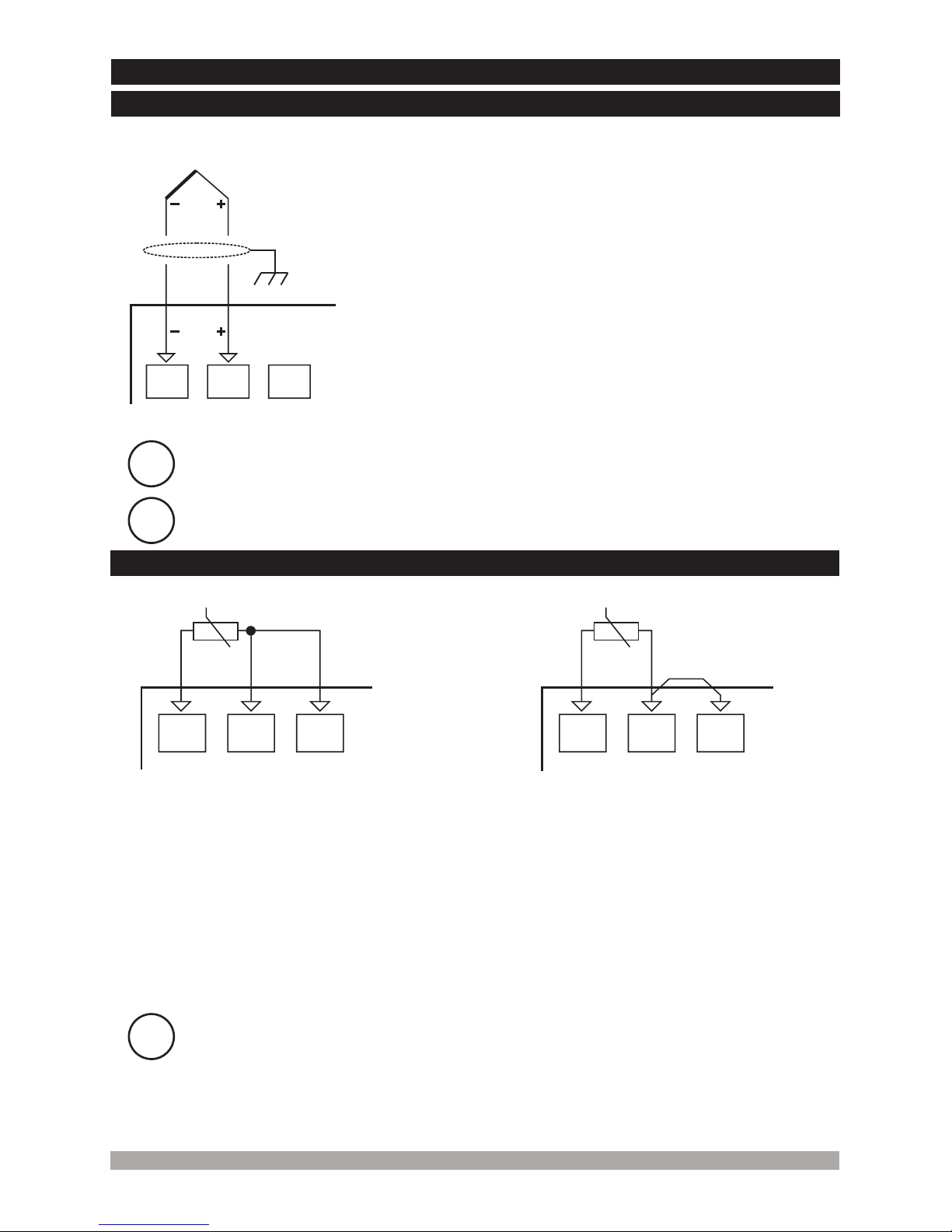

3.5 Process Input Connection

3.5.2 RTD Connection

Note 1 :

Note 2 :

Note 3 :

In 3-wire system, use always cables of the same diameter (min 1mm²) Always use

wires of the same gauge and type whether a 2-wire or 3-wire system.

Install a jumper between terminals 2 and 3 when using a 2-wire RTD.

If the distance is longer than 10 meters, use 3-wire system

3-wire Pt-100 connection

(with line compensation)

(Max. Line impedance is 10 )W

2-wire Pt-100 connection

(without line compensation)

112233

Note 1

Note 2

3.5.1 TC (Thermocouple) Connection

123

TC

Connect the wires with the polarity as shown in the

figure at left.

Always use compensation wire corresponding to the thermocouple used. If

present, the shield must be connected to a proper ground.

i

Input resistance is greater than 10M W

i

Input resistance is greater than 10M W

i

Pt-100 Pt-100

18

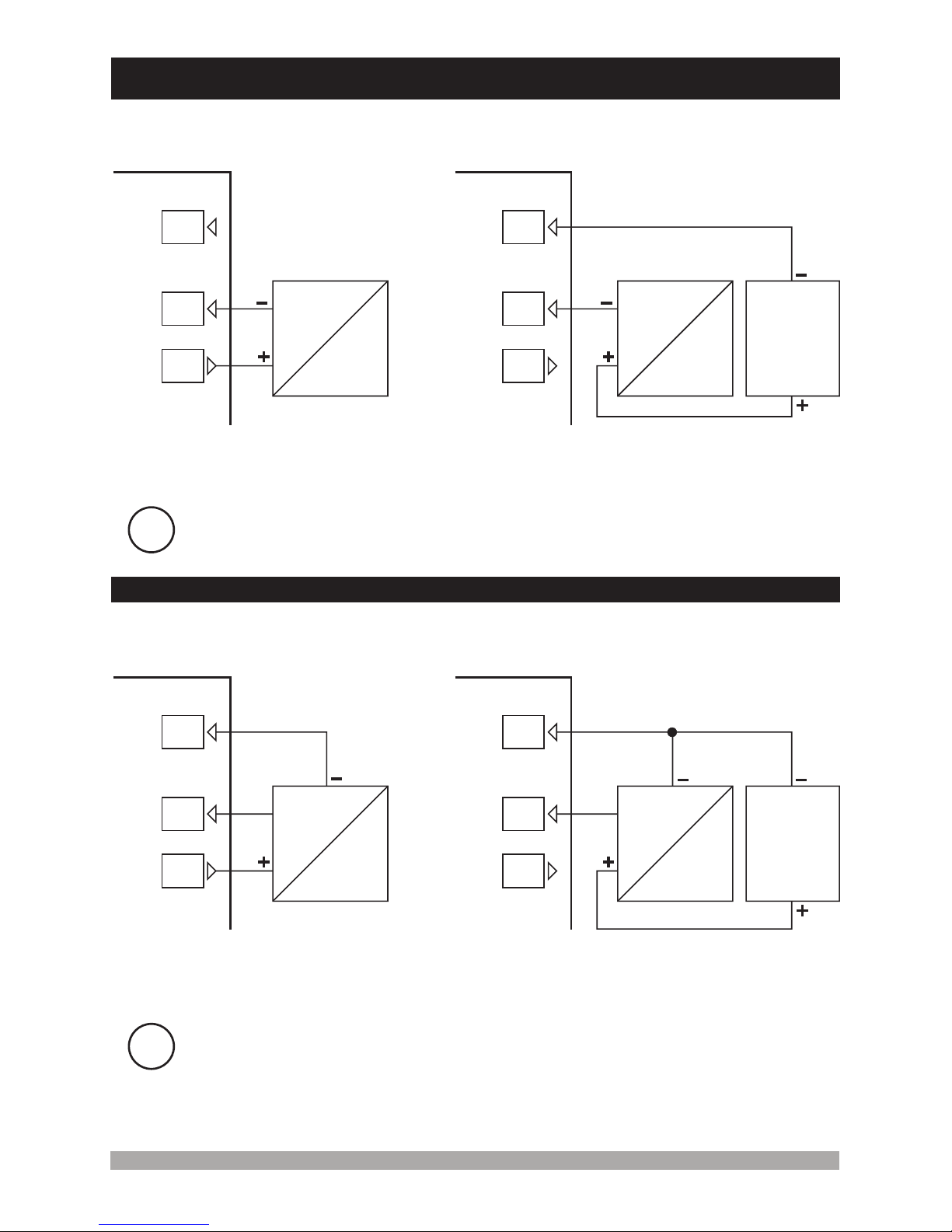

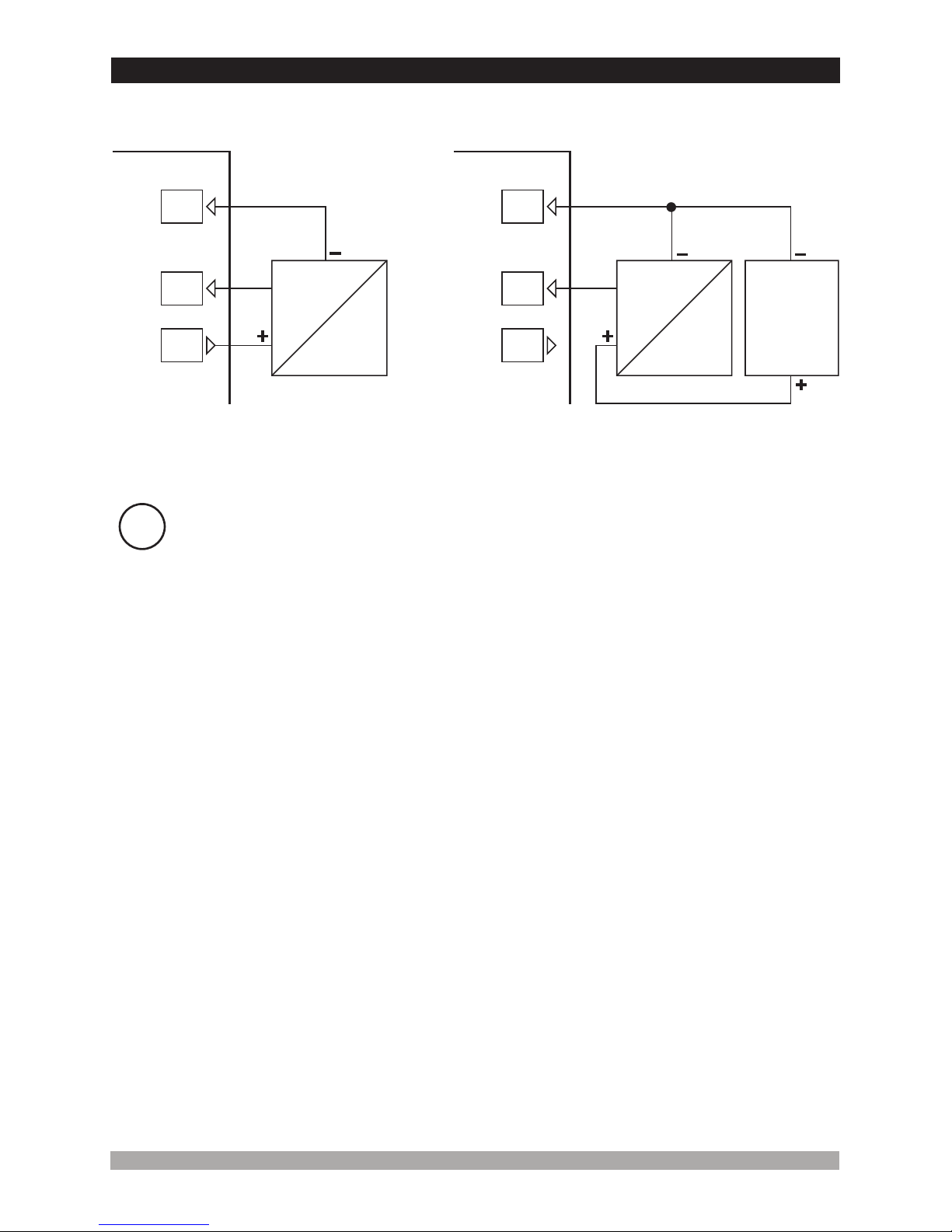

3.5.4 Process Input Connection of 3-wire Transmitters with Current Output

Transmitter connection by using supply

voltage on the device

Transmitter connection by using external supply

voltage source.

Transmitter

Transmitter

External

Power

Supply

Note-1

mAZ

PV PV

11

33

44

3.5.3 Process Input Connection of Serial Transmitters with Current Output (Loop

Powered)

Transmitter connection by using supply

voltage on the device

Transmitter connection by using external supply

voltage source.

Transmitter Transmitter

External

Power

Supply

Note-1

mAZ

mAZ

PV PV

11

33

44

Note 1 : External power supply must be selected according to supply voltage range and

required current for transmitter.

Note-1 : External power supply must be selected according to supply voltage range and

required current for transmitter.

Input resistance is 2R7 .W

i

Input resistance is 2R7 .W

i

mAZ

15 V

Maks. 50mA

Z ±10%

15 V

Maks. 50mA

Z ±10%

15 V

Maks. 50mA

Z ±10%

15 V

Maks. 50mA

Z ±10%

19

3.5.5 Connection of Transmitters with Voltage Output to Process Input

Transmitter connection by using supply

voltage on the device

Transmitter connection by using external supply

voltage source.

Transmitter

Transmitter

External

Power

Supply

Note-1

mV, VZ mV, VZ

PV PV

11

22

44

Note-1 : External power supply must be selected according to supply voltage range and

required current for transmitter.

Input resistance is greater than 10M for 0...50mV

Input resistance is greater than 43K for 0...10V

W

W

Z

Z

i

15 V

Maks. 50mA

Z ±10%

15 V

Maks. 50mA

Z ±10%

20

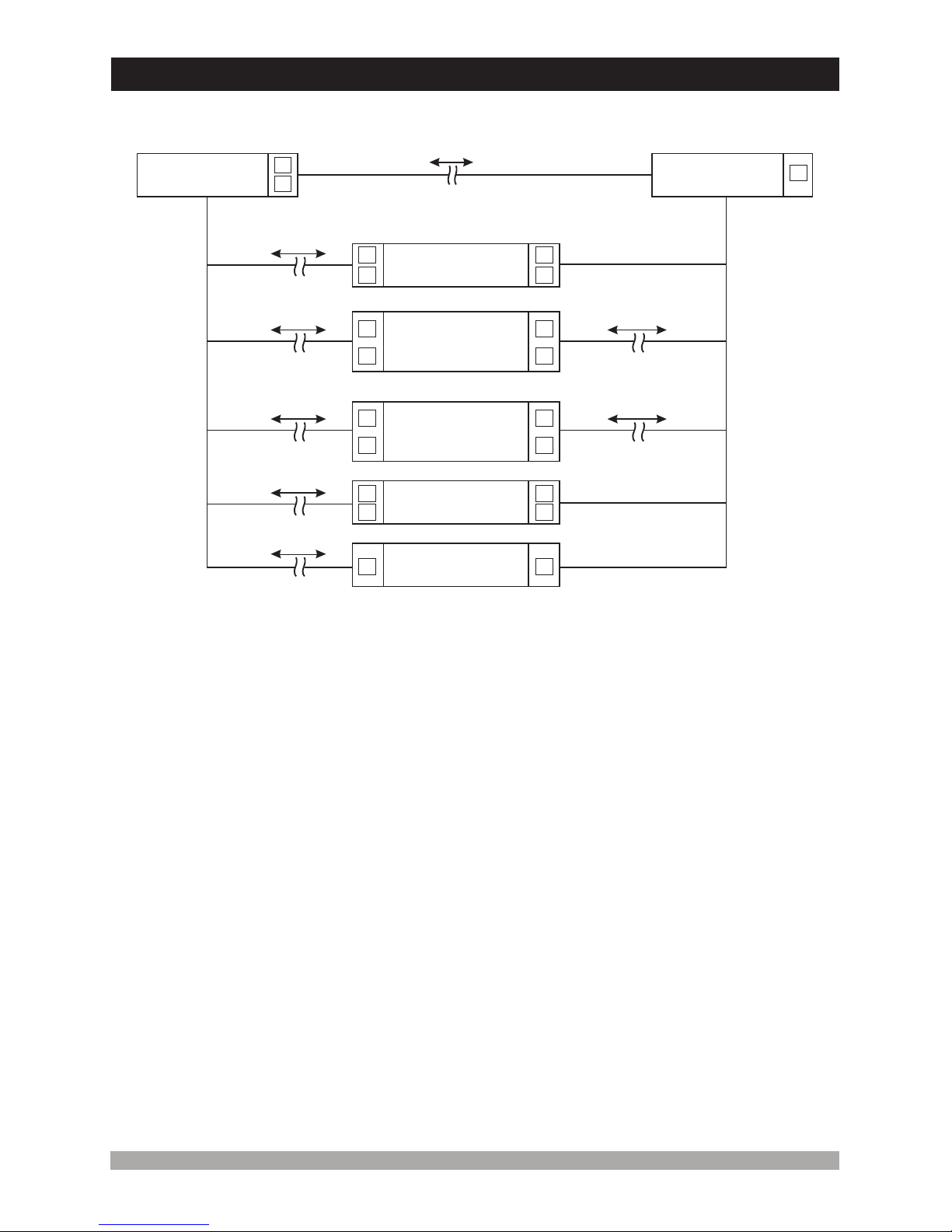

3.6 Galvanic Isolation Test Values of 4430ESM- Process Controller

Supply Input

Process Output

(SSR Driver Output)

Process Output or

Alarm Output-2

Relay

Analogue

Inputs

Alarm Output-1

Relay

15V Voltage

Output

Z

11

12

Ground

1

2

3

2000 ( ESM-4430 1 )

5

V For . .....V

00V ( For ESM-4430.2..... )V

2000V V

2000V V

2000V V

2000V V

2000V V

2000V V

2000V V

5

6

5

6

7

8

2

3

44

7

8

9

10

9

10

Loading...

Loading...