EMI WLHG09, WLHG24, WLHG12 Installation, Operation And Maintenance Manual

WLCG/WLHG

High-Efciency Ductless Split System High-Wall Air Handlers

Straight cool / Heat pump nominal capacities

WLHG09 WLHG12 WLHG24

Units

9,000 12,000 18,000 23,800 Btuh

2.6 3.5 5.3 7.0 kW

Straight cooling only

WLCG30 WLCG36

Units

28,200

33,600

Btuh

8.3 9.8 kW

Installation, Operation and

Maintenance Manual

ECR International Inc

2201 Dwyer Ave.

Utica, NY 13501

www.enviromaster.com

An ISO 9001-2008 Certified Company

P/N 240008111, Rev. G [06/18/10]

WLCG/WLHG

WLCG/WLHG

High-Wall Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 2 P/N 240008111, Rev. G [06/18/10]

Contents

To the Installer

Retain this manual and warranty for

future reference. Before leaving the premises, review this manual to be sure the unit

has been installed correctly and run the

unit for one complete cycle to make sure

it functions properly.

To obtain technical service or warranty

assistance during or aer the installation

of this unit, contact your local representative. For a local representative listing, visit

our web site:

www.enviromaster.com

For further assistance call:

1-800-228-9364

When calling for assistance, please have

the following information ready:

Model Number _____________

Serial Number _____________

Date of installation ___________

IMPORTANT

Shipping damage MUST

be reported to the carrier

IMMEDIATELY.

Examine the exterior. Remove

cover and examine piping for

signs of damage.

NOTICE

The EMI series high efficiency air

handler is backed by EMI and ECR

International is tested, rated, and certied in accordance with AHRI Standard

210/240-2008 and UL-1995.

Due to ongoing product development,

product designs and specications may

change without notice.

Please contact the factory for more

information.

Contents . . . . . . . . . . . . . . . . . . . . . . 2

Read Before Proceeding . . . . . . . . . . . . 3

Verify Unit Before Installing . . . . . . . . . . 4

Piston/Orifice Replacement

(when required). . . . . . . . . . . . . . . . . . 6

Mounting the Unit . . . . . . . . . . . . . . . . 7

Electrical Wiring. . . . . . . . . . . . . . . . . . 9

Refrigerant Piping . . . . . . . . . . . . . . . 14

Refrigerant Processing . . . . . . . . . . . . 17

Reassemble the WLCG/WLHG Cabinet . . 18

Initial Start-Up. . . . . . . . . . . . . . . . . . 19

WLCG/WLHG Controller Overview . . . . . 20

Setting the Controller . . . . . . . . . . . . . 22

Unit-Mounted Controller Operation . . . . 25

Wall Thermostat Operation . . . . . . . . . 29

Controller Features. . . . . . . . . . . . . . . 32

Controller Fault Conditions . . . . . . . . . 33

Maintenance. . . . . . . . . . . . . . . . . . . 34

Troubleshooting . . . . . . . . . . . . . . . . 36

Frequently Asked Questions. . . . . . . . . 40

Specifications and Dimensions . . . . . . . 42

WLCG/WLHG System Options . . . . . . . . 44

Test Unit Performance Data Sheet . . . . . 46

EMI’s Product Line . . . . . . . . . . . . . . . 47

Indoor Units . . . . . . . . . . . . . . . . . . . 47

Outdoor Units . . . . . . . . . . . . . . . . . . 47

WLCG/WLHG

High-Wall Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008111, Rev. G [06/18/10] 3

Read Before Proceeding

Recognize this symbol as an indication of

important safety information.

WARNING

Completely read all instructions

prior to assembling, installing, operating, or repairing this product.

Inspect all parts for damage prior to

installation and start-up. e EMI series high eciency air handler must be

installed ONLY by qualied installation

personnel.

DANGER

Tampering with this unit is danger-

ous

. Tampering voids all warranties.

DO NOT aempt to modify or change

this unit in any way.

DANGER

e EMI series must:

Be connected to a properly grounded •

electrical supply with the proper

voltage as stated on the rating plate.

Have proper overcurrent protection •

(time-delay fuse/HACR Breaker) as

listed on the rating plate.

Failure to follow these instructions can

result in a re, explosion, or electrical

shock causing property damage, personal

injury, or death.

Safety Instructions

is manual is intended as an aid to qualied service personnel for proper installation, operation, and maintenance of the

EMI series high efficiency air handler.

Read these instructions thoroughly and

carefully before aempting installation or

operation.

Failure to follow these instructions may

result in improper installation, operation,

service, or maintenance, possibly resulting

in re, electrical shock, property damage,

personal injury, or death.

Read all instructions before using this

unit. Install or locate this unit only in accordance with these instructions. Use this

unit only for its intended use as described

in this manual.

Check the rating plate on the unit before

installation to make certain the voltage

shown is the same as the electric supply to

the unit. e rating plate is located on the

top panel only.

This unit must be connected only to a

properly grounded electrical supply. Do

not fail to properly ground this unit.

Turn o the electrical supply before servicing the unit.

Do not use the unit if it has damaged wiring, is not working properly, or has been

damaged or dropped.

WLCG/WLHG

High-Wall Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 4 P/N 240008111, Rev. G [06/18/10]

NOTICE

Check equipment for damage prior

to installation, if damaged contact the

wholesale distributor.

Product description

The WLCG/WLHG is available as a •

(DX) direct expansion straight cool or

heat pump.

It offers a contemporary design in a •

ductless type air handler and combines

aractive appearance with high eciency

conditioning for small to medium size

commercial or residential spaces.

The WLCG/WLHG is equipped with •

unit mounted infrared compatible controls which also supports 24V wall thermostat operation. Optional handheld

remote is available.

Heat pump models prov ide up to •

24,000 Btuh of cooling and 20,600 Btuh

of heating. Electric heat options are

available for up to 5 kW of supplemental

heat.

is air handler oers ease of installation, •

operation, and service.

It can be matched with EMI’s:•

Single-zone condensing units –

S1CG/S1HG 09–24 and S1CG

30-36.

Dual-zone condensing units –

S2CH/S2HH side discharge.

Multi-zone, top discharge condens- –

ing units T2CG/T2HG, T3CG/

T3HG, or T4CG/T4HG.

All EMI air handlers are backed by ECR •

International Inc. and are tested, rated,

and certied in accordance with AHRI

standards 210/240-2008 and UL 1995.

Verify Unit Before Installing

Controls and components

(Factory-installed or supplied)

Large LCD Backlit Display•

Single unit-mounted control package, •

congurable to either unit mount or wall

thermostat operation, increasing installation exibility.

NOTICE

Unit mount control — If the control is

congured for unit mount control DO

NOT connect a wall thermostat to the

unit. See Figure 28, Page 22.

Unit mount control can be used in cool-•

ing only, cooling with electric heat, heat

pump, or heat pump with second stage

electric heat applications.

Operational range set point temperature •

adjustable between 55°F(13°C) and 90°F

(32°C)in one-degree increments.

Infrared-compatible controller allows use •

of optional IR hand held controller.

NOTICE

Unit-mounted controls are fully functional without the handheld remote.

Operation modes include Heat, Cool, •

Dry, Fan and Auto Change-over.

Fan Operation – Auto/On. High or Low •

speed fan

Fan Purge – Fan remains on for 60 sec-•

onds aer Heat/Cool call is dropped for

improved eciency (Auto mode only)

Room air sampling Selectable time •

intervals ensure the fan will cycle on periodically, in Auto Fan Mode to help eliminate room temperature stratication.

Selectable Fahrenheit (°F) or Celsius (°C) •

temperature scale.

Dry mode – Operates cooling and electric •

heat simultaneously to remove humidity.

Optional electric heat must be selected.

Anti-Short Cycle Compressor Protec-•

tion.

WLCG/WLHG

High-Wall Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008111, Rev. G [06/18/10] 5

Verify Unit Before Installing (continued)

Minimum on time for heating and cooling •

Helps eliminate room temperature droop

and system short cycling.

Freeze Protection – Prevents air handler •

freeze up.

Test operation – Allows ease of testing af-•

ter installation (all timers are reduced).

Non-volatile back-up memory will main-•

tain control seings for an indenite period during a power outage. When power

is restored the equipment will resume

operation aer a three-minute compressor time delay.

7-day programmable with copy feature.•

Filter change indicator: A timer feature •

indicates when the lter should be cleaned

according to the selected time.

Motorized supply louver with optional •

sweep or six stationary seings.

Modular design – reduces parts required •

for control package. Deco panel, relay

board, ribbon cables and microprocessor

are combined into one package.

Integral condensate pump safety-switch •

connection where-by the microprocessor monitors the condensate pump safety

switch and displays an error code when a

fault occurs. (Applies only with optional

condensate pump)

CEC (California Energy Commission) •

compliant

Condensate drain pan over ow protec-•

tion

Cabinet Features:

Durable ABS plastic cabinet with a galva-•

nized steel sub-chassis.

Easily accessible, washable, reusable, •

nylon mesh lter.

Horizontal discharge louver, constructed •

of high temperature ABS plastic, that can

be set to oscillate, or can be parked in six

pre-set positions.

Manually adjustable vertical discharge •

ns.

Easy access to pipe chase area from cabi-•

net boom allows piping connections and

condensate pump installation with the

unit mounted on the wall.

Easily removable end-cap for access to •

control area for installation and service.

Condensate drain pan constructed of gal-•

vanized steel (G90U), with anti-corrosion

coating.

Modular snap-in, 7-day programmable •

control with large backlit LCD display,

a “Change lter” display feature and selectable Fahrenheit (°F), or Celsius (°C)

temperature scale.

Optional Equipment

Condensate pump (eld installed only)•

24V wall thermostat •

Electric heat with automatic reset high •

temperature cutout and redundant high

temperature fuse link (when heat option

is selected, factory installed only)

Hand-held infrared controller.•

Installer Supplied Items

Low voltage wiring (18 AWG minimum •

required)

High voltage power supply wiring•

Mounting screws and fasteners•

Condensate piping•

Refrigerant piping (if not supplied)•

Refrigerant (for interconnect charge)•

WLCG/WLHG

High-Wall Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 6 P/N 240008111, Rev. G [06/18/10]

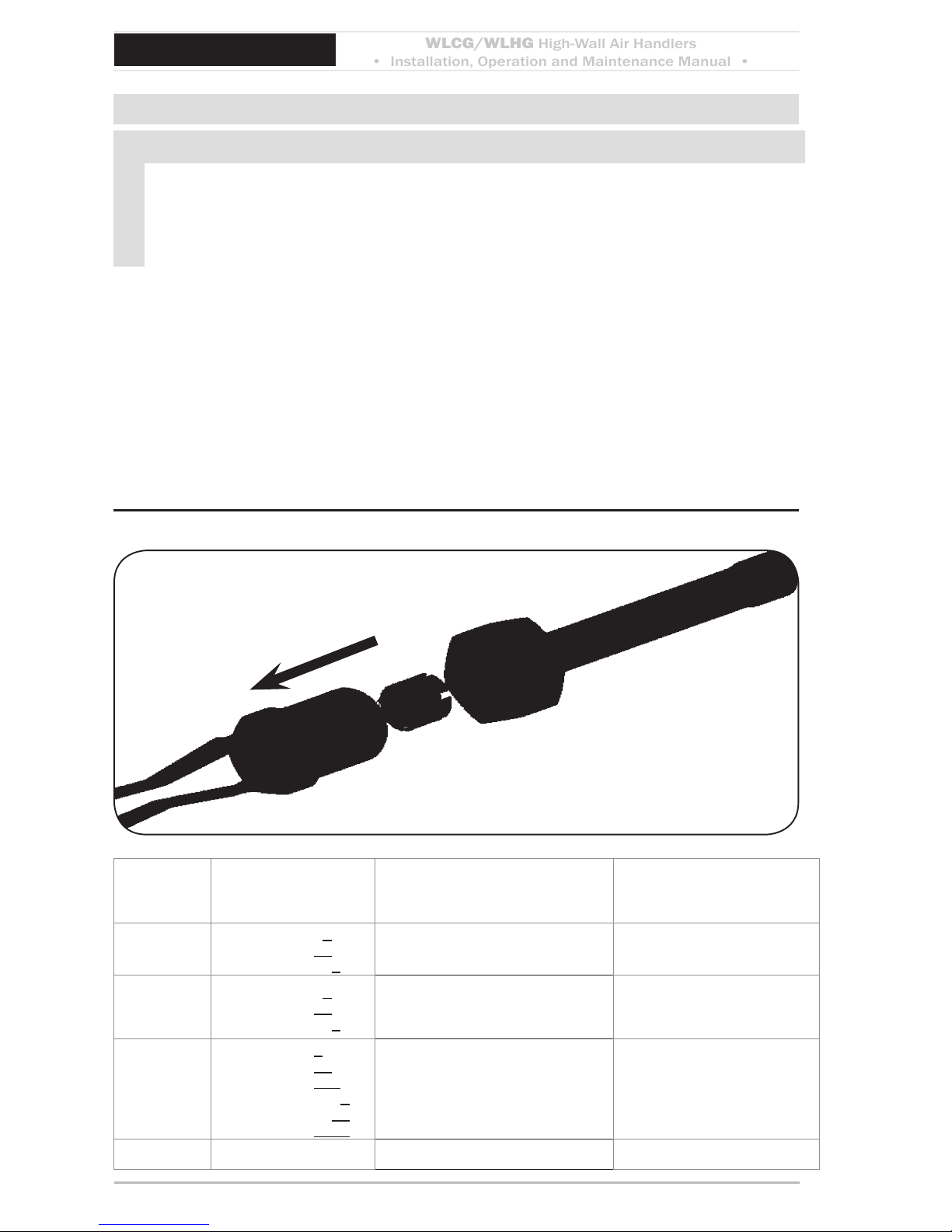

Piston/Orifice Replacement (when required)

NOTICE — WLHG24 ONLY

Piston/ Orifice replacement e factory-installed piston/orice must be replaced on

Air-Handler / Condenser combitnations noted in table below

. All other applications are

to use the factory-installed orice. To replace the orifce in the noted models use instructions and chart as follows.

Replacing the piston/orifice

Follow the instructions on page 9 to remove the le end cap.1.

e piston orice (Figure 1, pg. 6) is located in the upper le corner of the unit.2.

Disassemble the orice joint, remove the factory-installed orice, and replace with the 3.

orice listed in Figure 1 (supplied in the Kit Bag). Make sure o-ring is in good condition

and properly installed.

e end cap can remain o while mounting and installing the unit.4.

Piston/orifice replacementFigure 1

Model Condenser Factory-installed orifice size

(Inches)

Replacement orifice size

(Inches)

WLH_24

T2C/T2HG2400

T2C/T2HG4400

T3C/T3HG2240

0.054” 0.056”

WLH_24

T2C/T2HG9800

T2C/T2HG8800

T3C/T3HG9980

0.054” 0.049”

WLHA12

T2C/T2HG2400

T3C/T3HG2240

T3C/T3HG2220

T4C/T4HG9992

T4C/T4HG9922

T4C/T4HG2222

0.042” 0.044”

WLH_24 S1C/S1HG8000 0.054” 0.047”

To Air

Handler

WLCG/WLHG

High-Wall Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008111, Rev. G [06/18/10] 7

Mounting the Unit

Before installing, consider:

Determine the best location for mounting •

the unit for room air circulation.

Locate outdoor and indoor units as close •

together as possible.

Determine how power wire (high and •

low voltage) condensate drainage, and

refrigerant piping may be run to and from

the unit.

WLCG/WLHG - Ensure that intercon-•

nect tubing is within the limits given in

(Table 1, pg. 7)

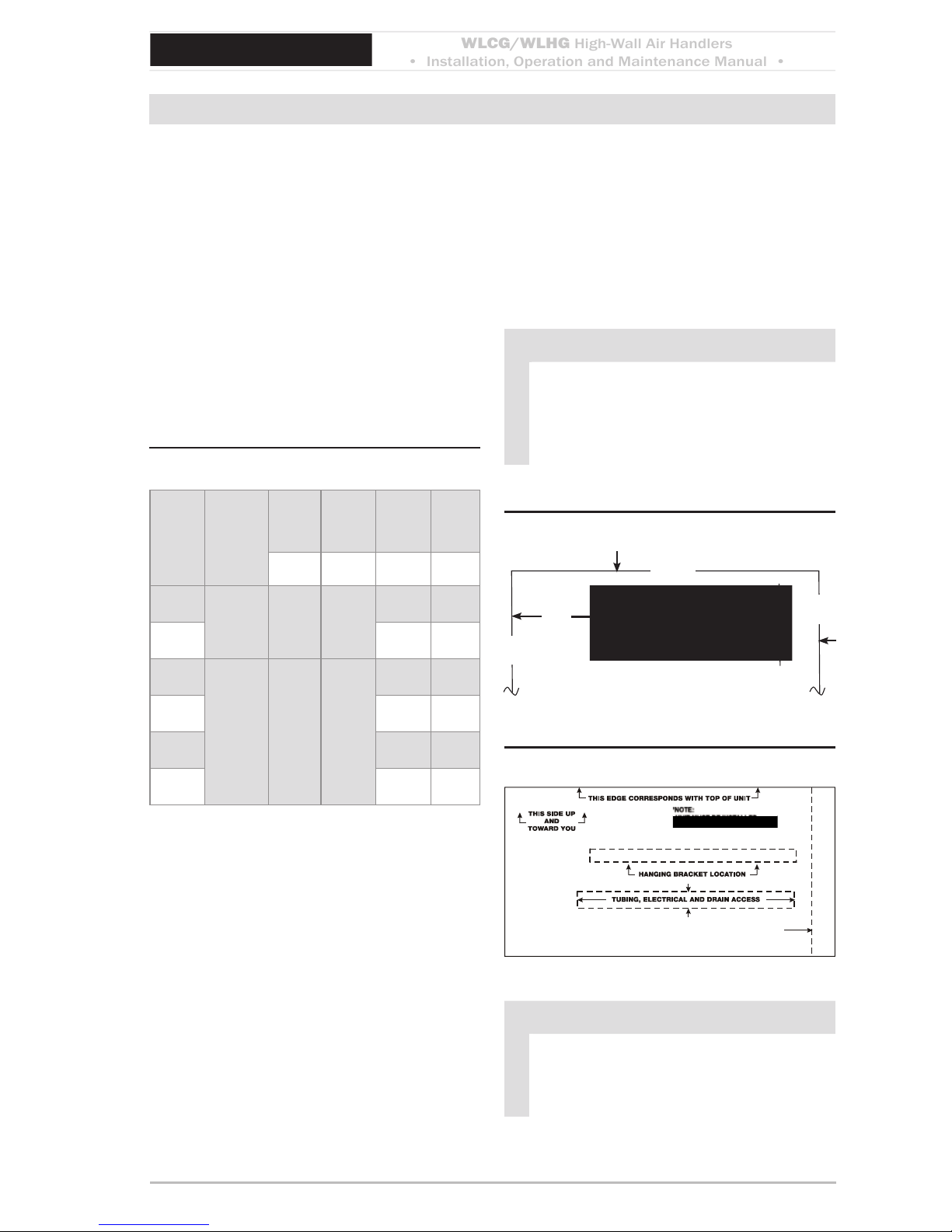

Tubing specificationsTable 1

S1CG

or

S2CG

Model

Max.

Length

Equivalent

Feet

Max.

Lift

Max.

Trap

Height

Liquid

Line

Suction

Line

“H” “P” O.D. O.D.

09

50’

(15 m)

20’

(6 m)

15’

(5 m)

1/4" 1/2"

12 1/4" 1/2"

18

100’

(30 m)

35’

(11 m)

20’

(6 m)

3/8" 5/8"

24 3/8" 3/4"

30 3/8" 3/4"

36 3/8" 3/4"

To ensure serviceability and proper air •

distribution, the unit should be positioned as close as possible to the center

(left-to-right) of the wall. Minimum

distance from the ceiling is stated on the

template provided with the unit packaging. e cabinet le and right end caps

must be accessible for removal without

obstruction. (See Figure 2, Page 7.)

Site preparation

e WLCG/WLHG must be mounted plumb

and level to a vertical surface to prevent unit

vibration and/or unwanted noise. It is recommended that the unit be mounted directly to a

NOTICE

If excessive noise or vibration is experienced from a unit mounted to a masonry

block wall, check to ensure the unit is

plumb and level. If noise or vibration persists, contact the wholesale distributor.

Minimum service clearancesFigure 2

Ceiling

wall

wall

4” Minimum

10”

Minimum

6”

Min.

Mounting templateFigure 3

NOTICE

Piping may be roughed in before wallboard or panels are placed in new construction. PVC pipe (3” or 4” I.D.) may

be used as a pipe chase.

smooth surface such as Sheetrock® wallboard

or similar material. If mounting to a masonry

block wall, there should be a smooth barrier between the unit and the masonry block

surface to absorb any potential vibration and

prevent the formation of condensate on the

wall.

WLCG/WLHG

High-Wall Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 8 P/N 240008111, Rev. G [06/18/10]

Mounting the Unit (continued)

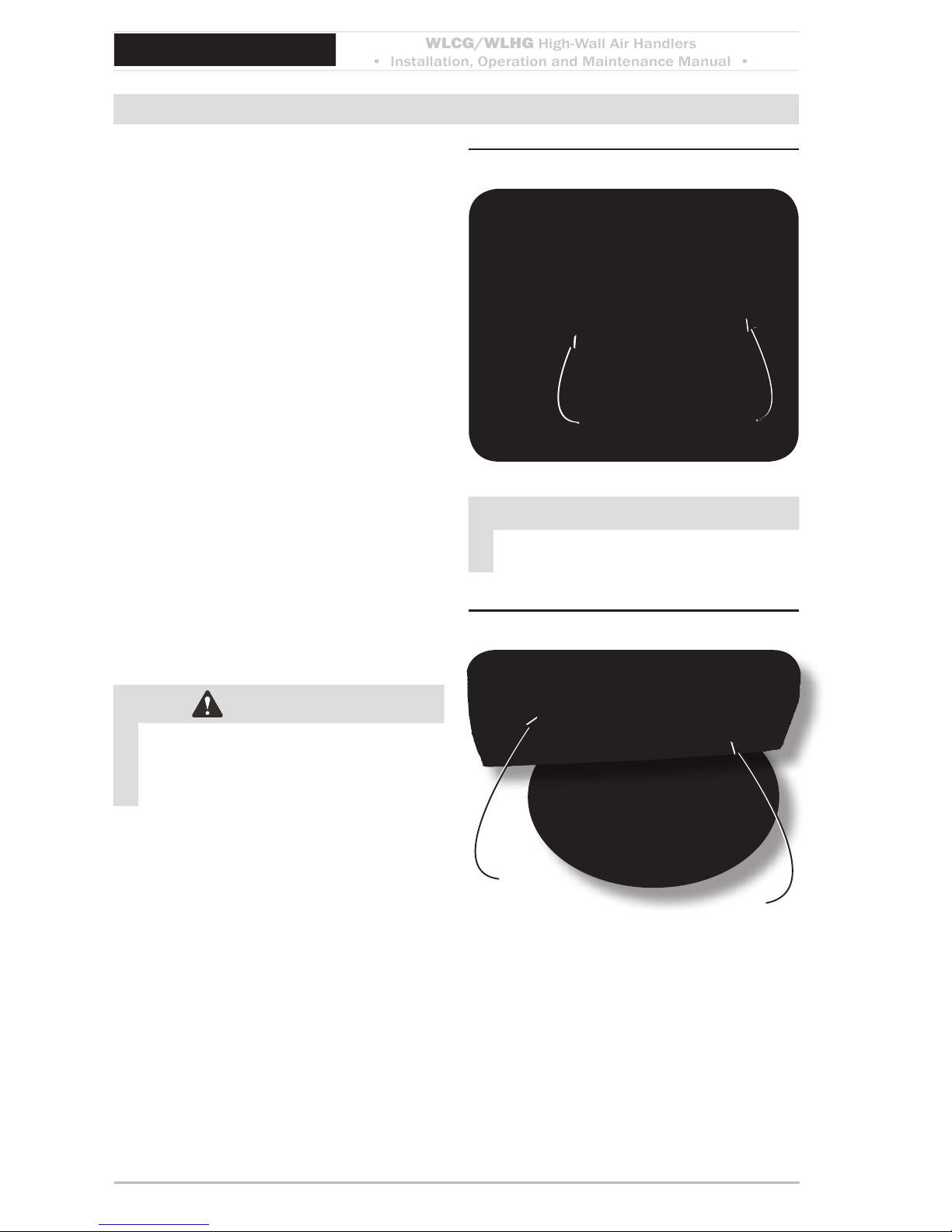

Unit Mounting Instructions

Aer determining the best location for 1.

the unit, use the cardboard template

provided in the packaging (Figure 3,

Page 7).

Mark where the piping, electrical wiring 2.

and condensate drain should penetrate

the wall.

Determine the appropriate hole size and 3.

cut through the wall.

Use the supplied wall bracket. For 4.

shipping purposes, the wall bracket is

fastened to the back of the unit.

Secure the bracket to the wall with 5.

the appropriate screws (for wood) or

anchors (for masonry). Ensure the

bracket is mounted in a manner that will

support the weight of the unit (Figure 4,

Page 8).

To mount the unit to the bracket, align 6.

the mounting slot on the back of the

unit over the bracket and make certain

it ts properly (Figure 5, Page 8).

WARNING

Replace all panels aer installation or

servicing. Panels must remain on the

unit at all times while powered and in

operation.

Wall hanging bracketFigure 4

Remove and discard

these screws

NOTICE

e wall hanging bracket is not located

in the center of the unit.

Mounting to wall bracketFigure 5

Mounting

slot

Slot for piping

WLCG/WLHG

High-Wall Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008111, Rev. G [06/18/10] 9

Electrical Wiring

Before removing end capFigure 6

Helpful Tip:

Prior to remov-

ing the end

cap and

bottom

use a

small

board to

prop the unit

away from the wall.

Removing end cap

Figure 7

Rotate louver down to expose Figure 8

screw

NOTICE

All electrical wiring must be run according to NEC and local codes.

Site preparation for wiring

WARNING

Electrical shock hazard Make sure the

power is o before proceeding.

Check the unit rating plate for minimum 1.

circuit ampacity and breaker or time delay

fuse size. Use only HACR type breakers.

Select the proper wire for the ampacity

rating.

Each unit must have a separate branch 2.

circuit protected by a time delay fuse or

breaker. Refer to the unit rating plate for

the proper wire and breaker or time delay

fuse size.

Inspect the existing wiring for any defects 3.

such as cut or frayed wires. Replace if any

such wiring if found.

e le end cap of the unit needs to be 4.

removed to access wiring diagram and

electrical wiring. is requires removal

of three screws (Figure 6, Page 9 and

Figure 7, Page 9).

Rotate louver down to expose the third 5.

screw (Figure 8, Page 9).

Once the screws are removed, slide the 6.

le end cap o to expose control box and

locate the wiring diagram on the inside

of the end cap.

NOTICE

On units rated 208/230V, the primary

side of the transformer is factory wired

for 230V. For a 208V power supply,

the transformer tap must be changed

from orange to red. Refer to the wiring

diagram located on the inside of the le

end cap of the unit.

WLCG/WLHG

High-Wall Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 10 P/N 240008111, Rev. G [06/18/10]

Electrical Wiring (continued)

Wiring diagram locationFigure 9

control box

Remove screw

Wiring connectionsFigure 10

Low Voltage

connections

Ground

L1

L2

Connect wiring

To access High and Low volt wiring re-1.

move the screw on the front of the control

box. (Figure 9, pg. 10)

High voltage electrical wiring

Refer to the wiring diagram to connect the 1.

power wire to Black L1 and the other wire

to Red or White (115V) L2 at the power

connector location. (Figure 10, pg. 10)

Connect the ground wire to the ground 2.

lug or lead at the same location in the

control box.

WARNING

Terminate ALL unused wires with a wire

nut or crimp connector.

Low voltage electrical wiring

(for unit-mounted controls)

The 24V control transformer is located 1.

in the air handler. is provides low Volt

control power to both the air handler

and condenser. Depending on the models selected, the low volt interconnect

control wiring may be eected. (Figure

10, pg. 10)

NOTICE

All low voltage interconnect wiring must

be at least 18 AWG.

WLCG/WLHG

High-Wall Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008111, Rev. G [06/18/10] 11

Electrical Wiring (continued)

Units with or without heat

NOTICE

All low voltage interconnect wiring must

be at least 18 AWG.

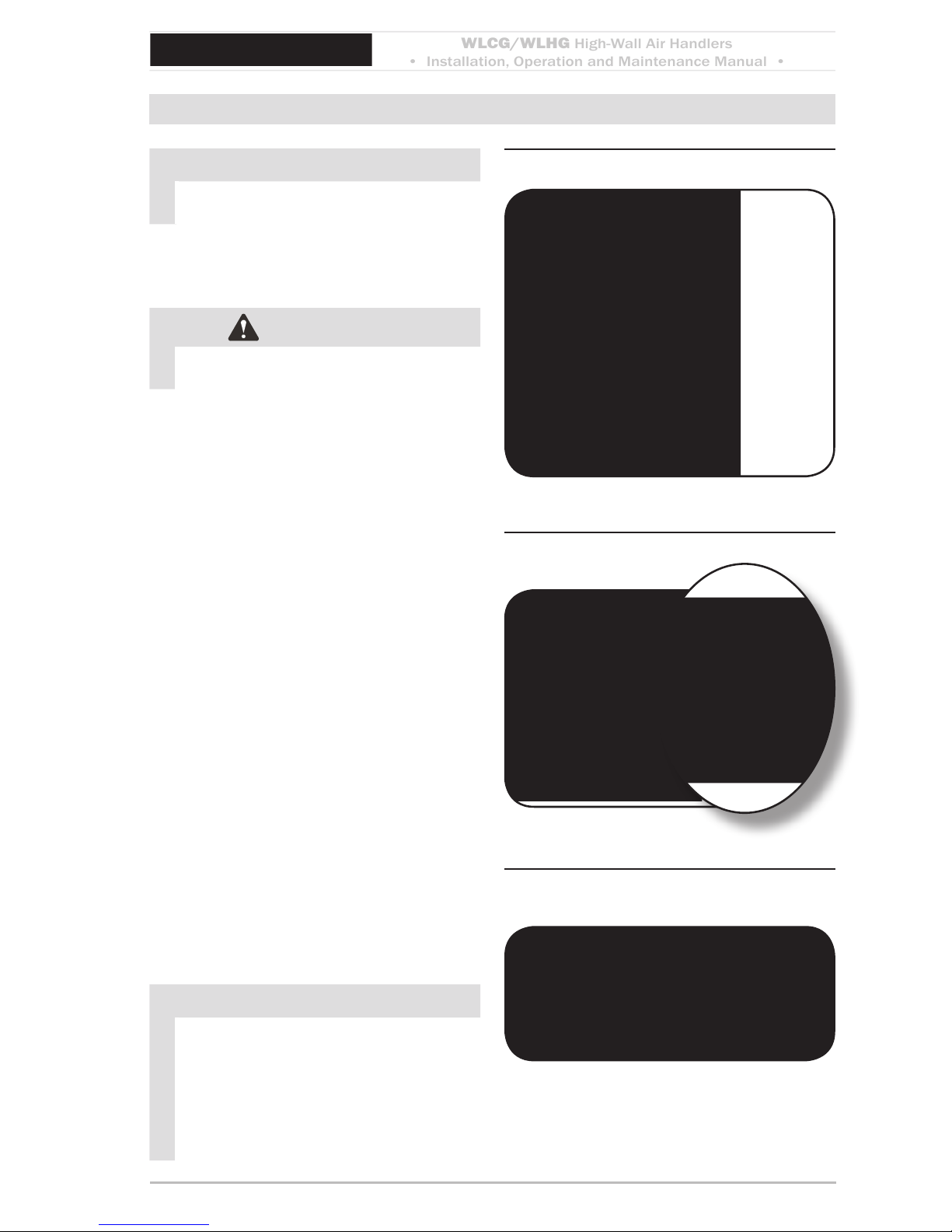

Cooling-only

Cooling only units utilize two low volt interconnecting wires between the indoor and

outdoor units.

Wires designated “Y” (yellow) and “C”

(brown) of the air handler should be connected to the corresponding “Y” (yellow)

and “C” (brown) wires or terminals of the

condenser (Figure 11, Page 11).

Other wires or terminals such as “R” (red) or

“O” (orange) may not be needed and should

be protected by a wire nut from making

contact with the junction box or other metal

surfaces.

Heat pump connection

Heat Pump Connection: In addition to the

“Y” and “C” connections required for cooling,

heat pumps require a reversing valve control

wire “O” (orange) that is energized in the

cooling mode.

If the indoor unit has an electric heater, then

a ”W” (white) wire connection will also be

needed to energize the indoor electric heat.

If a wall thermostat is used.

Heat pumps models require an “R” connection between the indoor and outdoor unit to

provide power to the defrost control board in

the condenser (Figure 12, Page 11).

Unit-mounted controls — Figure 11

cooling only

Unit-mounted controls — Figure 12

heat pump connection, twostage heating

WLCG/WLHG

High-Wall Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 12 P/N 240008111, Rev. G [06/18/10]

Electrical Wiring (continued)

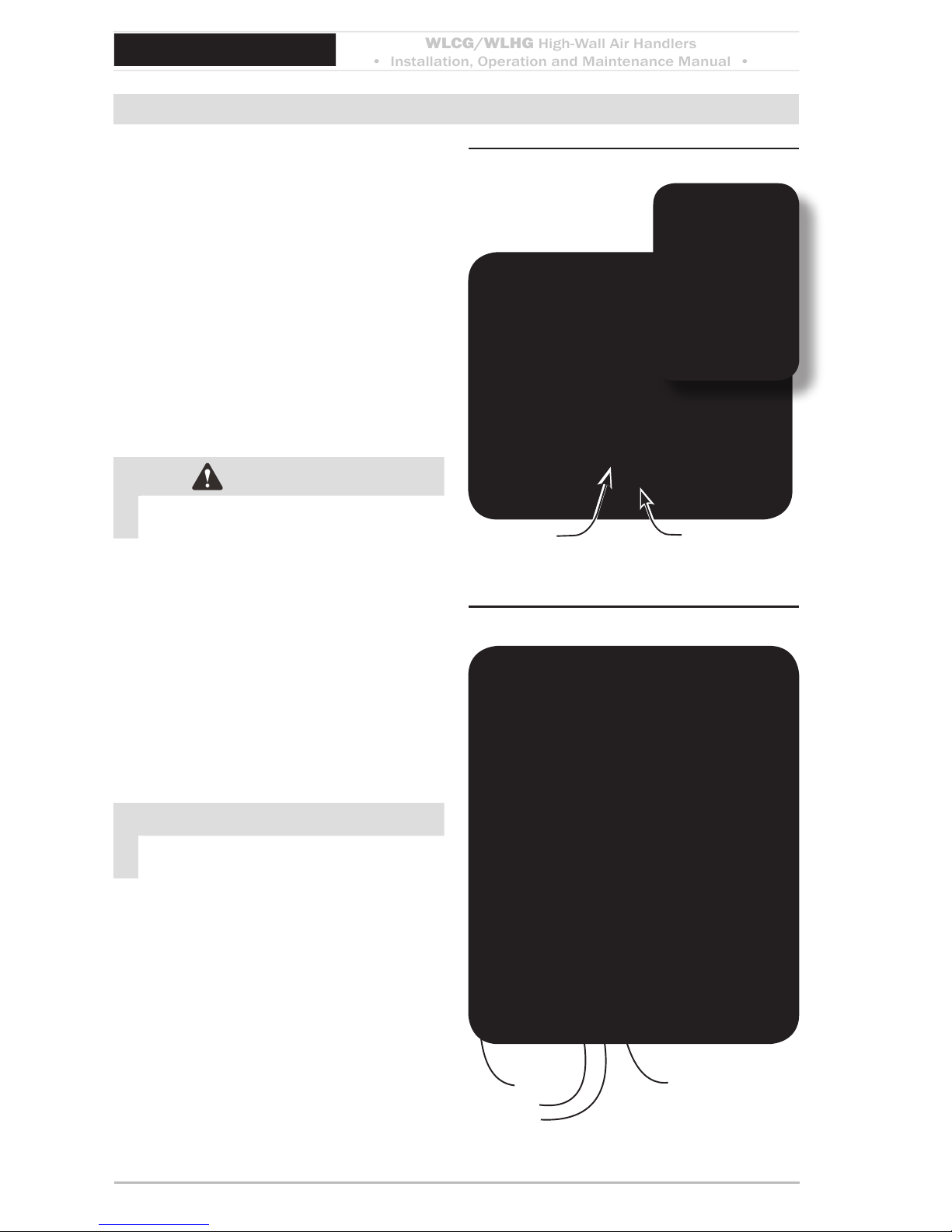

Wall thermostat controls

For remote wall mounted thermostat layout see (Figure 13, pg. 12)

NOTICE

All low voltage interconnect wiring must

be at least 18 AWG.

NOTICE

Unit mount control — If the control

is configured for unit mount control

DO NOT connect a wall thermostat to

the unit.

The 24V control transformer is located in the

air handler unit

. is provides low volt control

power to both the air handler and condenser.

Depending on the models selected, the interconnect control wiring may be eected.

NOTICE

For wall thermostat mode, the key pad

will have limited operation (see Sequence of Operation Wall-mounted

thermostat, page 29).

Choosing a remote wall-mounted

thermostat

See page 29 for wall thermostat selection

information.

Depending on the thermostat required or selected, air handlers may utilize four to six low

volt interconnecting wires between the indoor

unit, thermostat and outdoor unit.

Some thermostats do not require the use of

the “C” (brown) connection. In this case,

ensure that any unused wires are insulated

with a wire nut to prevent them from making

contact with the junction box or other metal

surfaces.

Wall-mounted thermostat Figure 13

configuration —

cooling only

WLCG/WLHG

High-Wall Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008111, Rev. G [06/18/10] 13

Electrical Wiring (continued)

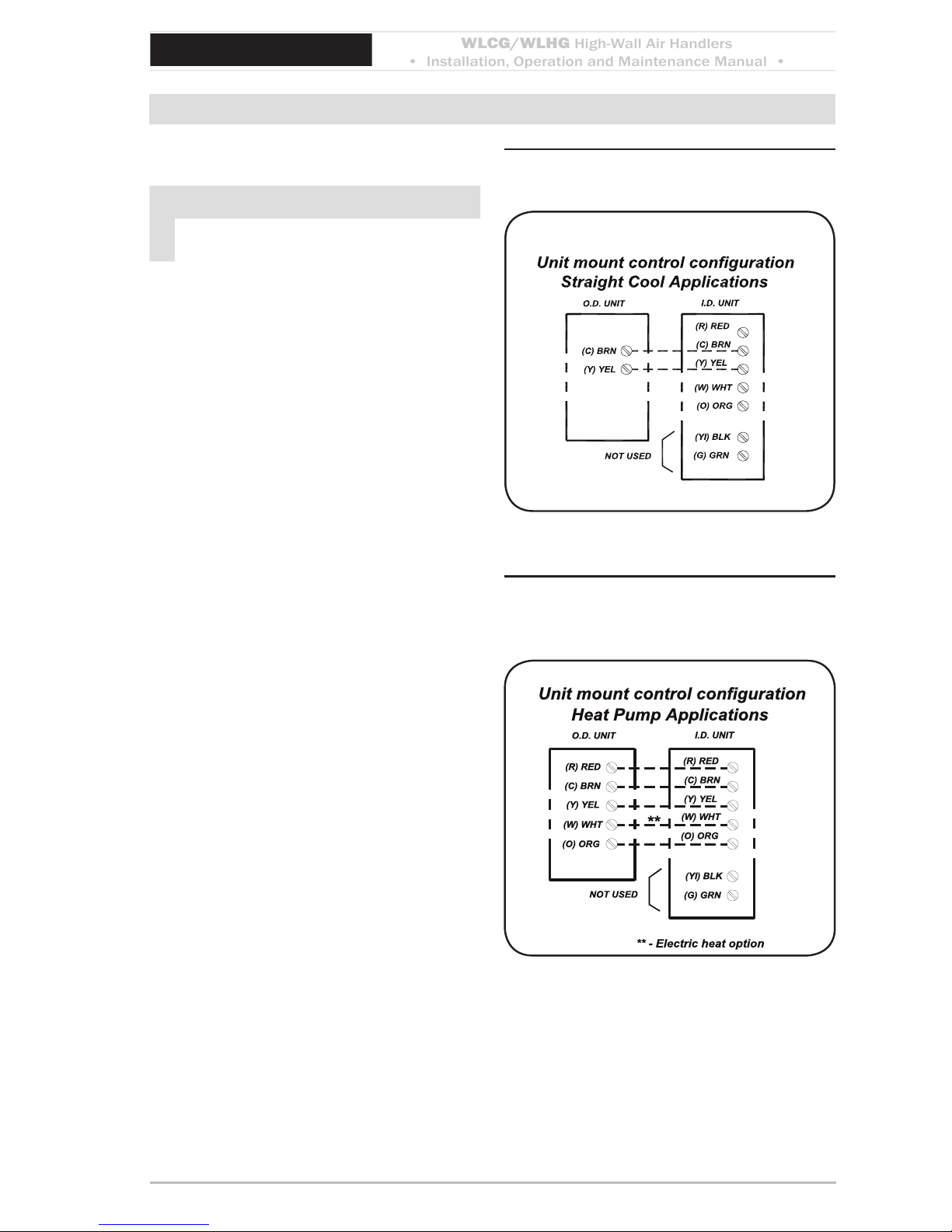

Electric heat applications

(Figure 14, Page 13)

If the indoor unit has electric heat then a “W”

connection is required between the thermostat and indoor unit.

Some thermostats do not require the use of

the “C” (brown) connection.

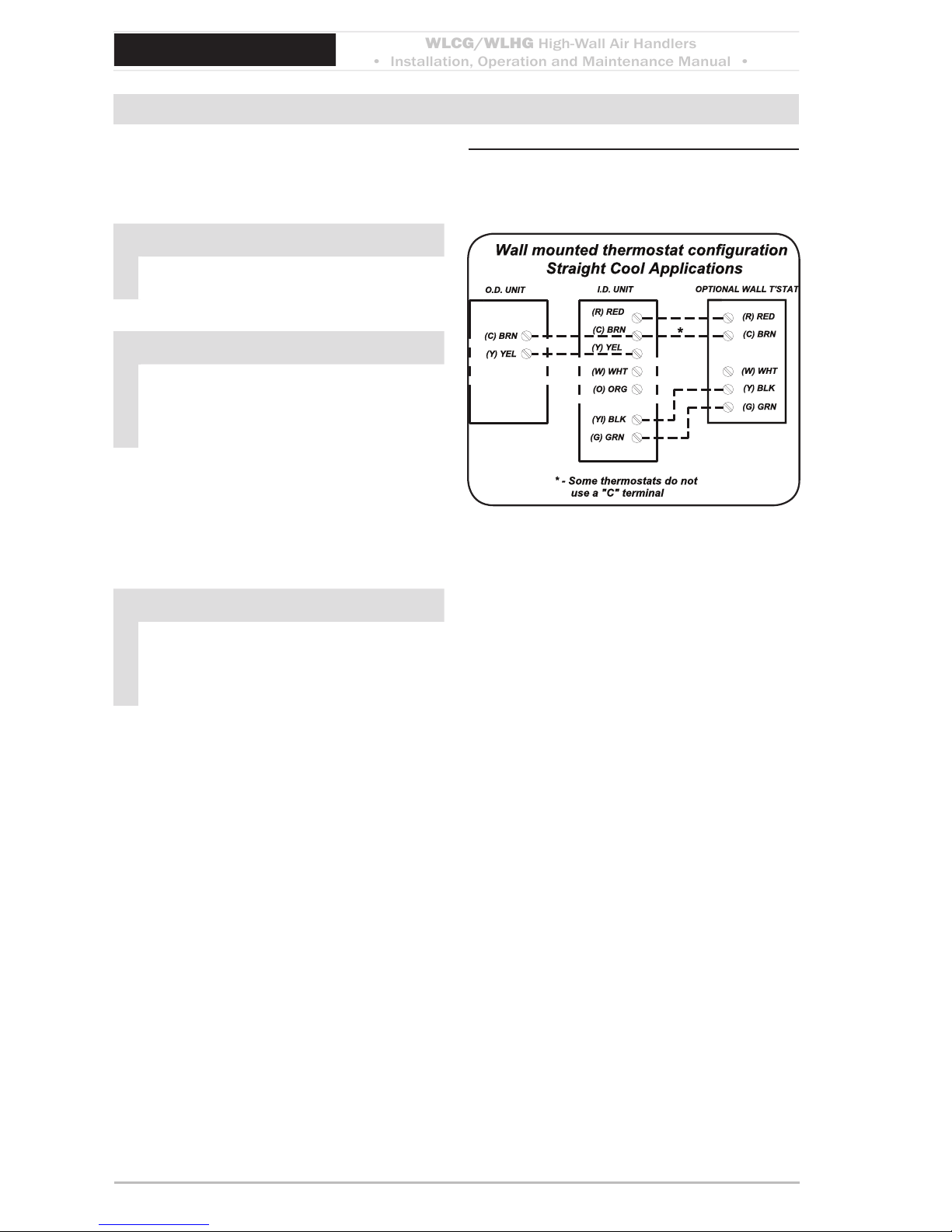

Heat pump applications

(Figure 15, Page 13)

Heat pump operation requires the connection

of the “O” (orange) terminal from the outdoor

unit to the thermostat.

e reversing valve is energized in the cooling mode for EMI models S1HG heat pump

condensers.

NOTICE

Heat pumps only: Two-stage heating

requires the combination of a heat pump

condenser and an indoor unit that is

equipped with an electric strip heater.

e indoor electric heater will energize

as the second stage heat source (the temperature is dependent on the thermostat

selected) and also during the defrost

mode for all heat pump models.

Finishing

Ensure that any unused wires are insulated

with a wire nut to prevent contact with the

junction box or other metal surfaces.

Once certain all electrical connections are

made replace control box cover.

control box

Replace screw

Wall-mounted thermostat Figure 14

configuration —

cooling + electric heat

Wall-mounted thermostat Figure 15

configuration —

cooling + heat pump

WLCG/WLHG

High-Wall Air Handlers

• Installation, Operation and Maintenance Manual •

Comfort where it counts 14 P/N 240008111, Rev. G [06/18/10]

Refrigerant Piping

CAUTION

Avoid piping on wet and rainy days.•

Use only clean, refrigeration-grade •

copper tubing.

Use tubing benders to guard against •

kinking.

Be certain no burrs remain on the •

ings.

Cap ends of lines until ready for con-•

nections. Be certain that plastic end

caps remain in place when inserting

through wall openings.

Insulate the suction line.•

Isolate tubing from transmiing vibra-•

tion to the building or unit and avoid

contact with sharp edges.

Wrap refrigeration valves with a wet •

rag “heat sink” to protect valves while

brazing. (See Figure 14, Page 15.)

DO NOT use a suction line size larger •

than the condenser service valve connection. is can harm the compressor. Install a reducer, when used, only

on the inside connection.

Preparing for piping

With the unit mounted and leveled per 1.

instructions beginning on page 7.

Leave the le end cap o of the unit to 2.

allow removal of the boom panel.

Remove the Phillips-heads screws on the 3.

boom of the unit and remove the boom

panel (Figure 16, Page 14).

See (Figure 17, Page 14) for locations of 4.

the piping connections in the WLCG/

WLHG unit.

Removing bottom panelFigure 16

Piping connections at unitFigure 17

Suction line

(When a reducing bushing is required, install

only here, at the indoor suction-line connection.)

Liquid line

condensate drain

WLCG/WLHG

High-Wall Air Handlers

• Installation, Operation and Maintenance Manual •

P/N 240008111, Rev. G [06/18/10] 15

Refrigerant Piping (continued)

Clean ends of tubingFigure 18

Place wet rag “heat shield” over Figure 19

valves plus a sheet metal shield

to protect paint

Wet rag heat sink

Shield

NOTICE

e WLCG/WLHG is equipped with

a Flo Rater piston expansion device or

TXV. Connections are sweat type.

Line sizing

Size lines per (Table 7, Page 43).1.

e suction line size must match the con-2.

denser service valve connection.

When matching the WLHG24 with a.

an 18,000-Btuh condenser, you must

use a 5/8-inch suction line, with a

reducer installed as shown in (Figure 17, Page 14).

Refrigerant piping

Clean the ends of tubing and insert into 1.

ings (Figure 18 page 15).

Before brazing (Figure 19 page 15):2.

Protect valves by wrapping with a wet a.

rag “heat sink” before brazing.

Use a shield to protect the paint as b.

shown. (e shield can be made from

scrap metal.)

Braze tubing into ings, using a continu-3.

ous nitrogen purge.

e suction line must be insulated the 4.

entire length with closed cell, foam tube

insulation.

Do not insulate the liquid line.5.

Connect the outdoor unit according to 6.

the instructions supplied with unit.

All horizontal piping runs must be level 7.

and without dips to trap the oil.

CAUTION

Pressure test all eld installed piping with nitrogen. Using a suitable vacuum pump,

evacuate the tubing and indoor unit to 500 microns or less, with service valves remaining

front seated (closed).

Loading...

Loading...