EMI WLCA User Manual

NOMINAL CAPACITIES:

CAH/CAHW: 9,000 - 48,000 Btuh

CAF/CAF4: 8,000 - 36,000 Btuh

EMI DUCTLESS SPLIT SYSTEM

CASSETTE EVAPORATOR

INSTALLATION MANUAL/OPERATING INSTRUCTIONS

P/N# 240-4235 Rev. 1.6 [1/05]

SPARE PARTS: For ease of identification when ordering

spare parts or contacting Enviromaster International LLC

about your unit, please quote the model number and serial

number. This information can be found on the rating plate

attached to your unit.

PRODUCT DESCRIPTION

The EMI Cassette series is available in nominal capacities

of 9,000 to 48,000 Btuh in DX refrigeration and reverse cycle

heat pump (CAH) or DX with hot water coil (CAHW) versions; also available are two pipe chilled water (CAF) and

four pipe chilled and hot water versions (CAF4) in 8,000 to

36,000 Btuh capacities; and, depending on the model, electric heat can also be factory fitted as an option. Designed for

low noise levels, easy installation and maintenance and a

slimline fascia, all ensure minimum obtrusion into the working environment.

CONTROLS AND COMPONENTS

GENERAL STATEMENT

IMPORTANT: The information contained in this

manual is critical to the correct operation and maintenance of the EMI cassette and should be read by

all persons responsible for the installation, start up

and maintenance of the unit.

SAFETY: The equipment has been designed and manufac-

tured to meet international safety standards but, like any

mechanical/electrical equipment, care must be taken if you

are to obtain the best results.

1. Service and maintenance of this equipment should only

be carried out by skilled personnel.

2. When working with any air conditioning unit ensure that

the electrical disconnect supplying the unit is switched

off prior to servicing or repair work and that there is no

power to any part of the equipment. In the case of a DX

system, both the indoor and outdoor units should be

switched off.

3. Also ensure that there are no other power feeds to the

unit such as fire alarm circuits, BMS circuits, etc.

4. Electrical installation, start up and maintenance work on

this equipment should be undertaken by competent and

trained personnel in accordance with local relevant

standards and codes of practice.

LOW VOL T TRANSFORMER (Standard): 24 V olt.

ELECTRO-MECHANICAL (Standard): Thermostat options

are cooling only , cooling and one stage auxiliary heat, cooling and one stage mechanical heating (heat pump system)

or cooling and two stage heating (heat pump & second stage

auxiliary heat). An optional thermost at can be obtained through

EMI or your local distributor.

NOTE: Make sure the thermostat is suitable for unit operation (i.e., cooling only , cooling/electric heat, etc.)

MICROPROCESSOR (Optional): A custom designed microprocessor is fitted to the cassette to enable room conditions to be maintained at a user defined setpoint. Communication to the controller is by a hand held infrared transmitter,

which includes a wall mounting bracket as standard.

The microprocessor allows five operating modes. These

modes are - fan only , dry cooling, cooling only , heating only

and heating/cooling auto changeover for maximum versatility . A temperature setpoint between 58°F - 90°F can also be

selected.

The microprocessor monitors indoor coil temperature and

return air temperature. In heat pump units, a 24V AC signal

from the condensing unit is also monitored to signal the indoor unit that defrost of the outdoor coil is taking place. This

allows the same micro to control both heat pump and cooling only units. The receiver contains a self diagnostic feature. When a low indoor coil temperature is detected the

cooling action is stopped. If a sensor fails then an alarm is

EMI@ENVIROMASTER.COMENVIROMASTER INTERNATIONAL LLC 1

displayed on the fascia mounted receiver. The microprocessor also limits the number of compressor starts per hour to

reduce wear on the compressor.

The infrared transmitter is used to switch the unit on/off,

change temperature settings, fan speed, operating mode and

to toggle the motorized air sweep (where fitted). The microprocessor also has a built-in clock which can be activated to

enable the unit to be programmed with up to two separate

operating periods for the days of the week (Mon-Fri). The

clock provides On/Off unit operation and is not a night set

back or occupied/unoccupied control function. Mon-Fri will

operate as a ‘block’ of days and cannot be programmed

independently of one another. Saturdays and Sundays can

each be programmed with up to two separate operating periods and are programmed independently of weekdays and

each other.

A fascia mounted receiver displays On/Off, cool or heat and

timer/alarm status.

FIL TERS: Wire framed filters are fitted. These are reusable

and may be vacuum cleaned.

CONDENSA TE PUMP: A condensate pump is fitted to carry

water out of the unit. The pump is fixed to a mounting bracket

which can be withdrawn from the side of the chassis and

incorporates an inspection hole to allow a visual check of

the pump during operation. A float switch is fitted to stop the

cooling action should the pump become blocked or fail.

loosening the four M5 screws retaining the fascia in place.

The fascia can now be slid sideways and pulled away from

the chassis. When removing the Cassette chassis from the

box the four corner brackets should be utilized for lifting. In

order to protect the fascia from dirt and damage, it should be

returned to the box until it is ready to be installed.

BLANKING OFF: When branch ducting is to be used,

two polystyrene pieces for blanking off fascia openings are Included with the fascia packing. Up to two

opposing sides may be blanked off.

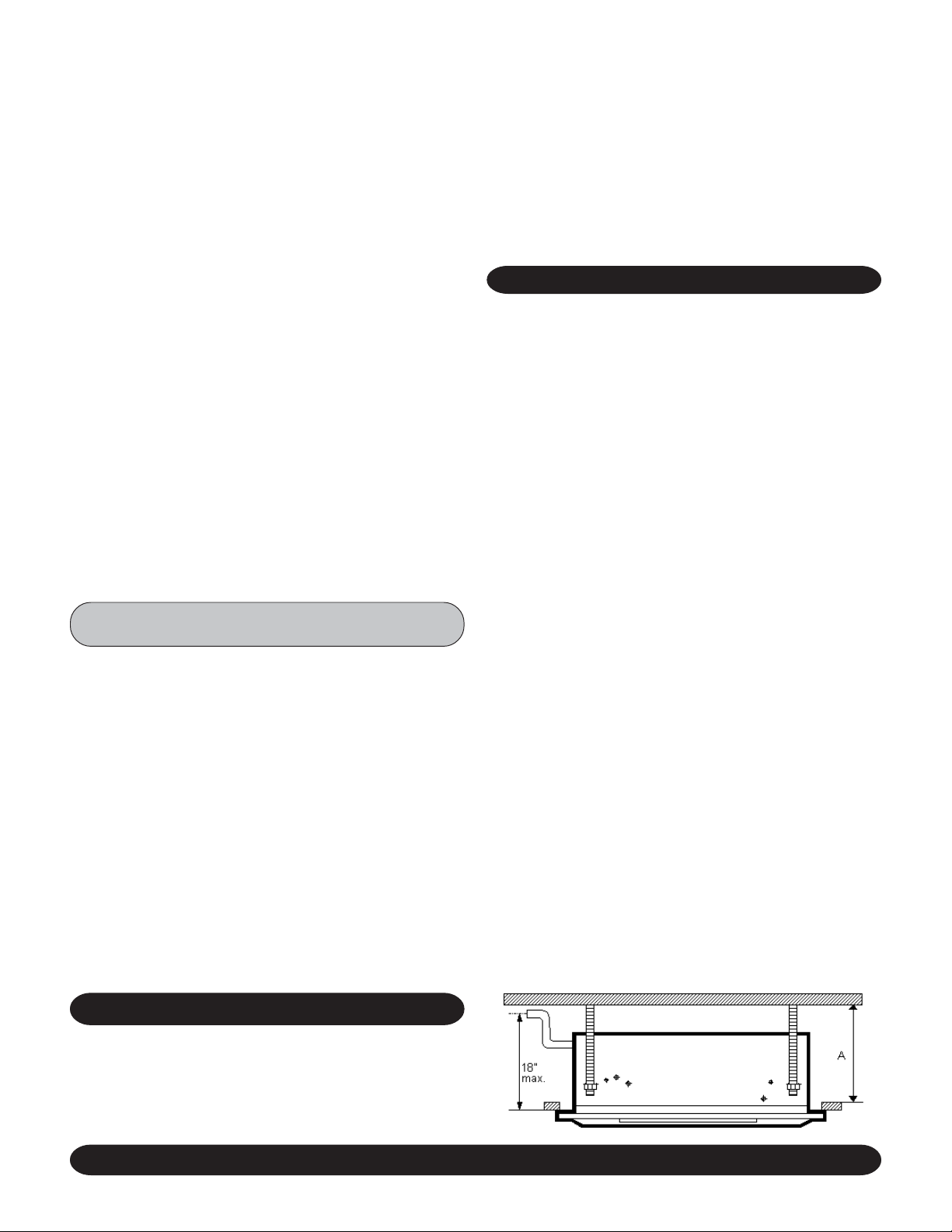

POSITIONING

CASSETTE - The Cassette installation position should

be selected with the following points in mind:

1. Pipe work, electrical connections and condensate pump

access panel should be readily accessible.

2. When installing a unit with an externally mounted

electrical control panel, ensure that sufficient access to

the panel is provided for maintenance purposes. Access

to the condensate pump access panel should be

provided on all model sizes.

3. The unit should not be positioned less than 5 ft. from a

wall or similar obstruction, or in a position where the

discharge air could blow directly on the thermostat.

IMPORTANT: TOT AL LIFT FOR THIS PUMP

IS 18” OR LESS.

AIR V ANES: Air outlet vanes are manufactured from alumi-

num and covered with nylon flock to prevent condensation

from forming. Vanes are manually adjustable on the 2 x 2

model units or driven by an electric motor on all other model

units. Where fitted, the motorized air vanes can be set to

auto sweep or can be stopped in a fixed position.

HEATING: The cassette may be fitted with either electric

heaters or a hot water coil. It is recommended that heat

pumps be fitted with the electric heat option to offset the

defrost cycle. Electric heaters are fitted with over-heat cut

out switches.

FRESH AIR CONNECTION: Fresh air may be introduced to

the unit by the addition of ducts connected to the fresh air

knockouts on the Cassette case. It is usually advised that

the fresh air volume is approximately 10% of the unit’s published maximum air flow.

SITE INSTALLATION

UNPACKING: The cassette fascia and main chassis are

supplied together for increased protection. Remove the banding straps and lift the cardboard lid. Remove the bubble wrap

and polystyrene packing pieces to expose the unit. The fascia should be unpacked first by unclipping the inlet grille and

4. The unit should not be positioned directly above any

obstructions.

5. The condensate drain should have sufficient fall (1” per

10’) in any horizontal run between Cassette and drain.

Maximum condensate pump lift is 18".

6. There should be sufficient room above the false ceiling

for installing the Cassette as shown below (see

“dimensions” in this IOM for cabinet sizing):

Small Cabinet A = 12-3/4” min.

Medium Cabinet A = 1 1-1/2” min.

Large Cabinet A = 13-1/2” min.

ELECTRO-MECHANICAL THERMOST AT - In addition to positioning the Cassette correctly , it is very important to locate

the wall mounted thermostat in the optimum position to ensure good temperature control. Therefore the installation

should be selected with the following points in mind:

EMI@ENVIROMASTER.COMENVIROMASTER INTERNATIONAL LLC 2

1. Position the thermostat approximately 5 ft. above floor

level.

2. Do not position thermostat where it can be directly

affected by the unit’s discharge air stream.

3. A void external walls and drafts from windows and doors.

4. Avoid positioning near shelves and curtains as these

restrict air movement.

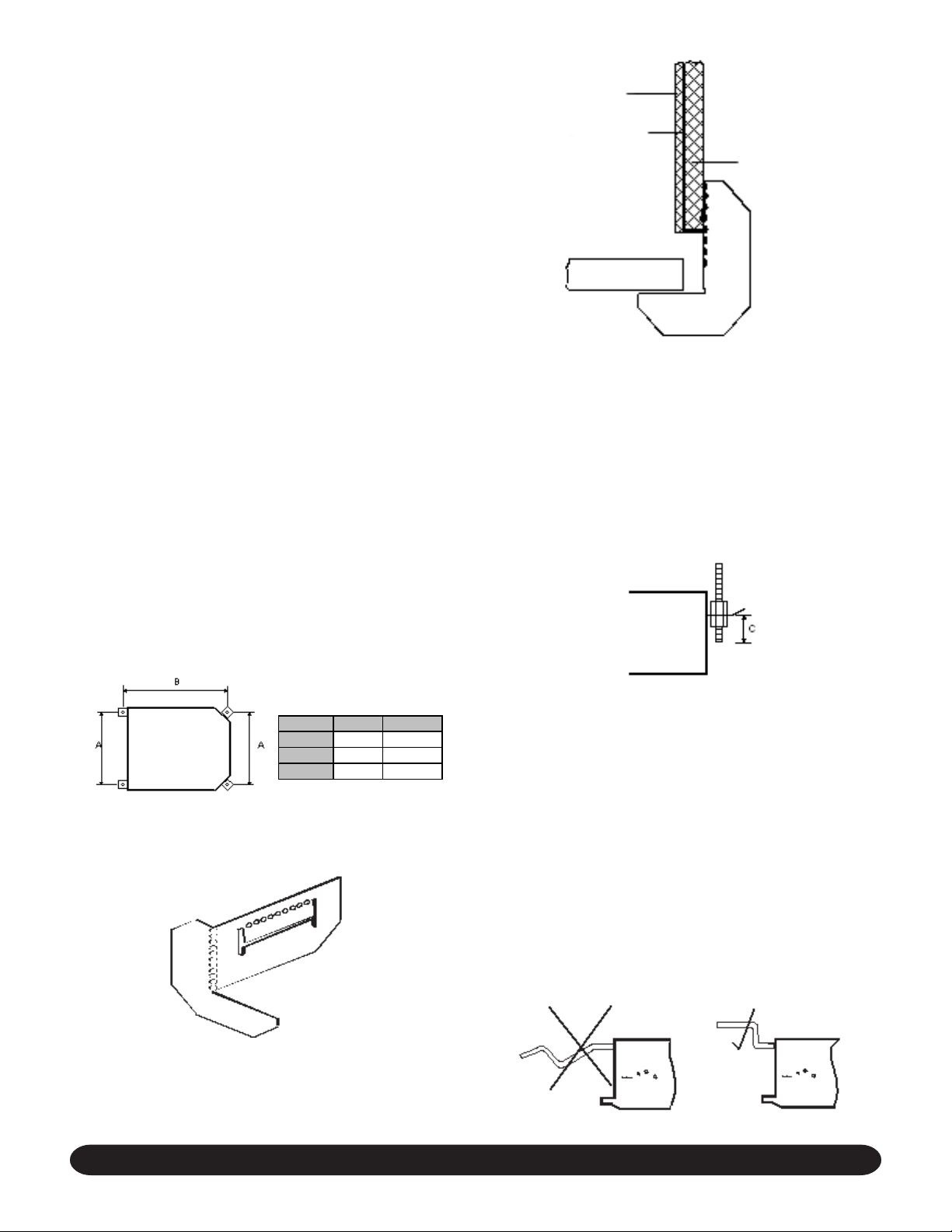

OUTER CASE

INSULATION

CASSETTE CASE

INNER CASE INSULATION

5. Avoid heat sources (direct sunlight, heaters, dimmer

switches, etc.)

CEILING OPENING: Before beginning the installation, inspect the unit location, test the strength of the unit

mountings (see “Mechanical Information” in this IOM). An

opening in the false ceiling will then have to be cut to the

following sizes:

Small Cabinet 23-1/4” x 23-1/4”

Medium Cabinet 33-7/8” x 33-7/8”

Large Cabinet 46 x 33-7/8”

A template for ceiling cut-out and rod positions can be found

with the Cassette unit.

NOTE: Make sure the ceiling grid is supported separately

from the Cassette. The ceiling must not be supported by

any part of the Cassette unit, fascia or any associated wiring or pipe work.

The hanger bolts can now be installed (use 3/8 all thread

rod) at the centers shown below:

FALSE CEILING

GUIDE IN

POSITION

NOTE: If the ceiling is not level or even, it is important

that the Cassette is installed level to ensure correct

pump operation and to maintain fan clearances. Any

slight discrepancy between the Cassette and ceiling

will be taken up by the fascia foam seal.

Secure unit in position with locknuts and washers on either

side of the Cassette bracket. Ensure threaded rod does not

protrude more than 2” (dimension C) below the mounting

bracket.

CABINET A B

SMALL

MEDIUM

LARGE

19-1/2" 23"

29-5/8" 31-1/2"

29-5/8" 43-11/16"

Prepare the installation guides by folding the metal bracket

by hand along the row of holes.

FOLDED GUIDE

The Cassette can now be lifted onto the hanging rods and

leveled at the correct distance from the ceiling with the aid of

the installation guides as shown.

The unit can now be piped up in accordance with good refrigeration and/or plumbing practices.

CONDENSA TE PIPEWORK: The Cassette is supplied with

a 1/2" diameter flexible PVC hose for connection to copper

or plastic drain pipework. When installing the Cassette the

following points should be remembered:

1. Maximum pump lift is 18”.

2. The highest point in the condensate pipework should be

as close to the unit as possible. This prevents a large

volume of water draining back into the unit when it is

switched off.

EMI@ENVIROMASTER.COMENVIROMASTER INTERNATIONAL LLC 3

3. Condensate pipework should slope downwards in the

direction of water flow with a minimum gradient of (1” per

10’). There must not be any uphill gradients other than

in the first 18” of pipework from the Cassette.

4. When multiple Cassettes are connected to a common

condensate drain, ensure the drain is large enough to

cope with the volume of condensate from several

Cassettes. It is also recommended to have an air vent in

the condensate pipework to prevent any air locks.

DUCT COLLARS: Branch duct and fresh air duct collars

can be attached to the Cassette chassis by following the

steps below:

1. Refer to the relevant illustration for your Cassette (pages

6 -7 in this IOM) to become familiarized with knock-out

hole locations.

2. The insulation is pre-cut to aid location and removal of

the relevant section. Rub hand across surface of

insulation to reveal exact location of knock-out.

3. Remove the metal knockout from the chassis.

4. Attach the duct collar to the chassis using self tapping

screws.

NOTE: Branch ducts are round and 5 - 6” in diameter.

Fresh Air ducts are square and 3” in diameter.

INSULATION: Refrigerant, chilled water and condensate

pipes should be insulated right up to the Cassette chassis.

Chilled water valves must also be insulated to prevent sweating.

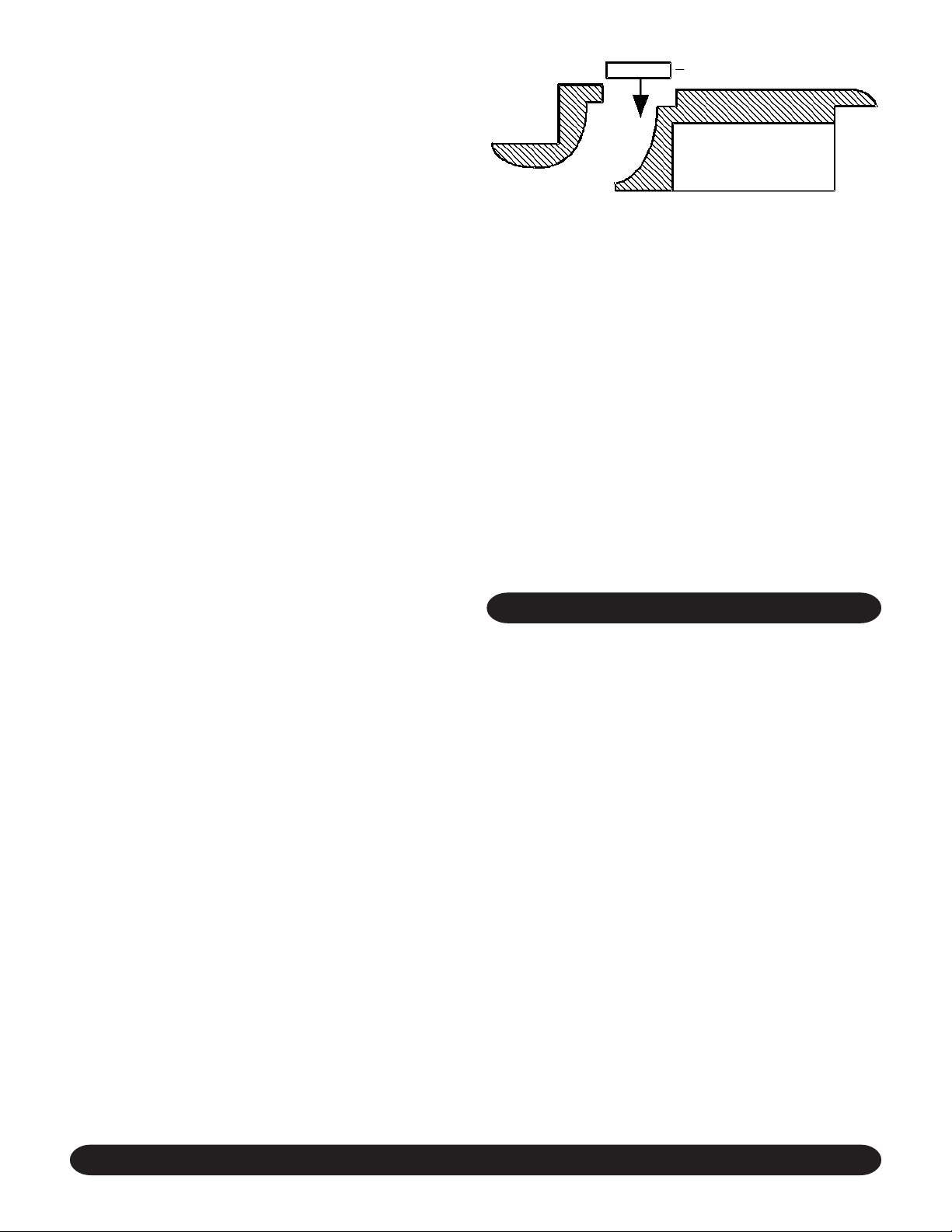

ASSEMBLY: Once the services have been connected the

four fascia mounting bolts can be unscrewed approximately

1” from the condensate tray support channels.

The fascia can now be unpacked ready for fitting to the Cassette chassis. Ensure the black fir tree fasteners holding

the fascia polystyrene are pushed in firmly in case of transit

vibration. If a fascia aperture needs blanking off, then take

one of the polystyrene blanking pieces and push it into the

recess in the polystyrene fascia insulation. Fit by removing

the inlet grilles and filters, locating the four fascia mounting

bolts on the chassis through the four keyhole brackets on

the fascia and then sliding the fascia sideways until it locks

into position.

NOTE: Up to two non-adjacent sides can be blanked

off.

NOTE: On electro-mechanical units, the fascia must

be installed with the EMI logo along the same edge of

the unit as the electrical panel. On units fitted with

microprocessor controls, orient the fascia with the display panel along the same edge of the unit as the

electrical panel.

FASCIA BLANKING PIECE

SECTION THROUGH FASCIA

Before tightening the fascia to the unit, connect the two halves

of the vane motor’s plug and socket connection (where applicable).

On microprocessor controlled units, ensure that the display

panel cable is routed to the electrical panel and securely

fastened to its connector on the microprocessor circuit board.

(Refer to the unit’s electrical wiring schematic). Take care

to ensure that the connector is connected in the proper orientation and that the wires are not routed such that they

may become trapped, cut, broken or chaffed.

The fascia can now be tightened up to the Cassette chassis

until a good seal is obtained between fascia and chassis.

NOTE: Do not over tighten the bolts. To do so may

cause damage to the fascia.

With filters in place, the inlet grilles can now be fitted to the

fascia to complete the installation.

ELECTRICAL DATA

(See Appendix 1 on page 18 for wiring charts and instructions.)

All power and interconnecting wiring between units should

be carried out to conform with local/national electrical codes.

A fused and dedicated electrical supply of the appropriate

phase, frequency and voltage should be installed by the customer. It is also recommended that a local disconnect switch

be connected within 3’ of the unit. In some areas this may

be a code requirement.

EMI equipment in its standard form is designed for an electrical supply of 208-230V , 1Ph, 60Hz. When connection to a

115V, 1Ph, 60Hz supply is necessary, a factory mounted

buck boost transformer will be fitted to the unit.

The wires should be capable of carrying the maximum load

current under non-fault conditions at the stipulated voltages.

Avoid large voltage drops on cable runs, particularly in low

voltage wiring. The correct cable size must be used to ensure a voltage drop of less than 1 volt in the control wiring.

Once the refrigeration pipe work is complete, the electrical

supply can be connected by routing the cable through the

appropriate casing hole and connecting the supply and ground

cables to the unit’s power terminals. On the medium and

large cabinets, it will be necessary to remove the insulated

condensate tray support rail, adjacent to the casing hole.

EMI@ENVIROMASTER.COMENVIROMASTER INTERNATIONAL LLC 4

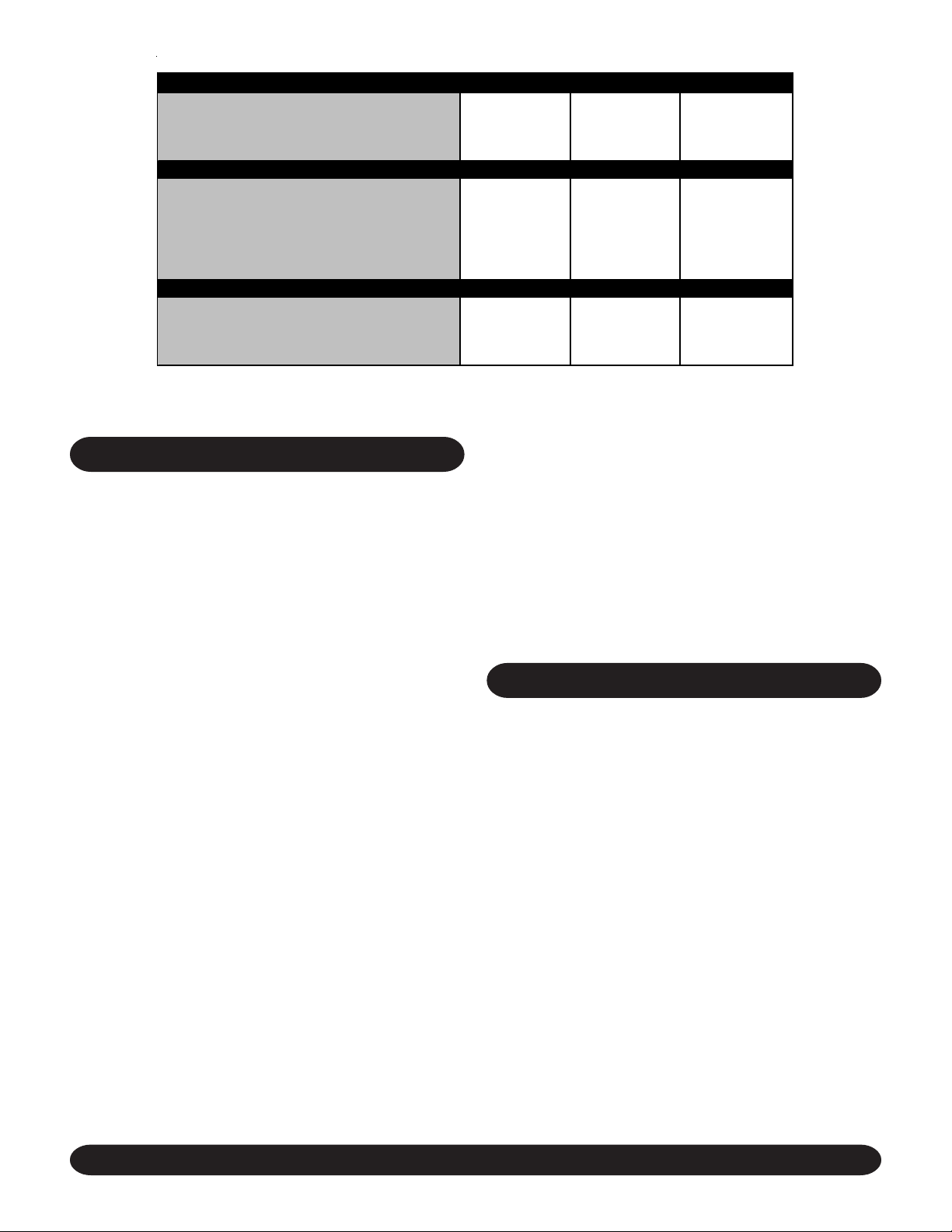

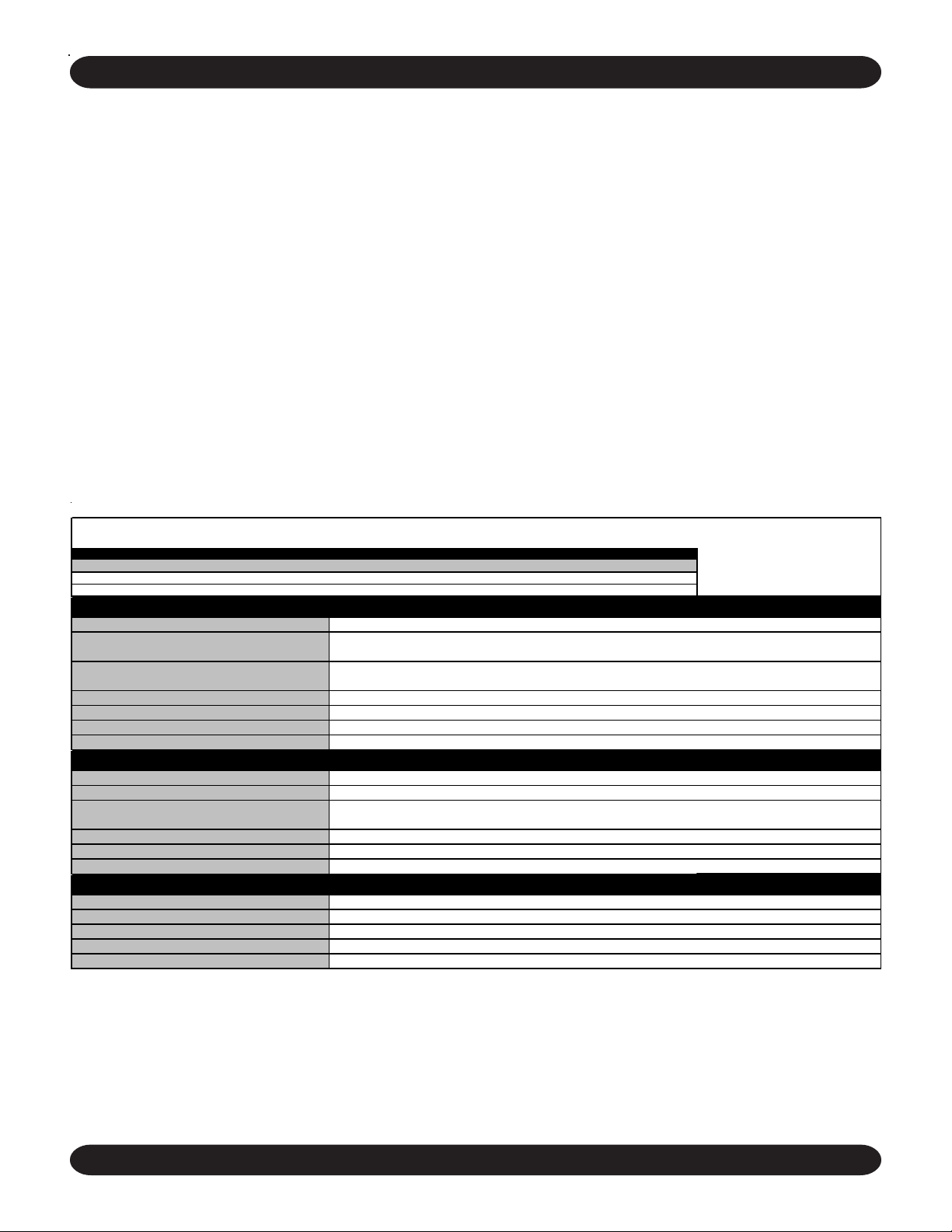

ELECTRICAL SPECIFICATION S

E

E

STANDARD UNIT DATA

POWER SUPPLY 230V/1PH/60HZ 230V/1PH/60HZ 230V/1PH/60HZ

FULL LOAD AMPS A 0.4 0.6 0.9

MIN. CIRCUIT AMPACITY (MCA) A 0.5 0.75 1.13

REC. FUS

WITH OPTIONAL ELECTRIC HEAT

POWER SUPPLY 230V/1PH/60HZ 230V/1PH/60HZ 230V/1PH/60HZ

ELECTRIC HEAT CAPACITY KW 1.5 3.0 5.0

HEATER AMPS A 6.52 13.1 21.7

FULL LOAD AM PS A 7.0 13.7 22.6

MIN. CIRCUIT AMPACITY (MCA) A 8.8 17.1 28.3

REC. FUSE WITH HEAT A 15 20 30

WITH OPTIONAL BOOST TRANSFORMER

POWER SUPPLY 115V/1PH/60HZ 115V/1PH/60HZ 115V/1PH/60HZ

FULL LOAD AMPS A 0.8 1.2 1.8

MIN. CIRCUIT AMPACITY (MCA) A 1.0 1.5 2.26

REC. FUS

(1) STANDARD UNIT FITTED WITH OPTIONAL ELECTRIC HEATING ELEMENTS. AV AILABLE WITH 230V M ODEL UNITS ONLY.

(2) STANDARD UNIT FITTED WITH OPTIO NAL BOOS T TRANSFORMER FOR CONNECTI O N TO A 115V ELECTRICAL SUP P LY. ELECTRIC HEAT

IS NO T AVAILABLE WITH THIS O PTION.

1

A151515

2

A151515

SMALL MED IU M LARGE

SMALL MED IU M LARGE

SMALL MED IU M LARGE

REFRIGERATION SYSTEM (DX UNITS)

PIPE INSTALLATION NOTES

1. When cooling only or heat pump units are being installed,

it is usually only necessary to insulate the suction line.

However, if the liquid line is subject to high temperature

or exposed to direct sunlight, this should also be

insulated.

2. Maximum equivalent pipe run should be no more than

100’, with a maximum rise of 35’.

3. Horizontal pipe runs should be slightly inclined, so as

to encourage oil to flow in the direction of the compressor,

for better oil return.

4. Good refrigeration practices must be employed to ensure

the correct pressure drop and good oil return.

PRESSURE TESTING: When installation is complete, fill

the Cassette and interconnecting pipework with dry nitrogen

to a pressure of 150 PSIG . Record the pressure over a period of time (a minimum period of 60 minutes should be sufficient to detect any major leaks, however, ideally 24 hours

should be allowed). If there is any reduction in pressure,

trace the leak and repair before conducting a further pressure test.

EVACUATION: Evacuation should be carried out with a high

vacuum pump. The pump should be connected to the high

and low pressure sides of the system via a gauge manifold

fitted with compound gauges. A high vacuum gauge should

be fitted to the system at the furthest point from the vacuum

pump.

Triple evacuation should be used to ensure that all contaminants are removed or at least reduced to significantly low

proportions.

The vacuum pump should be operated until a pressure of

500 microns absolute pressure is reached, at which time

the vacuum pump should be stopped and the vacuum broken with oxygen free nitrogen until the pressure rises above

zero.

The above operation should be repeated a second time.

The system should then be evacuated a third time but this

time to 100 microns absolute pressure. After stopping the

pump, open the condensing unit’s service valves to break

the vacuum.

START UP PROCEDURES

PRE-START: Once installation is complete it is important

that the following pre-start checks are made.

1. All pipe work is complete and insulated where necessary.

2. All fans are able to rot ate freely .

3. The Cassette and interconnecting pipe work have

been evacuated correctly and the Condensing Unit’s

service valves are open (DX units only).

4. All electrical connections (both power and control)

are properly terminated.

5. All condensate drains are inst alled correctly .

6. The power supply is of the correct voltage and frequency .

7. The units are properly grounded in accordance with

current electrical codes.

EMI@ENVIROMASTER.COMENVIROMASTER INTERNATIONAL LLC 5

E

O

CO

OJEC

START UP PROCEDURES

8. For microprocessor controlled units, check that

the display panel cable is properly connected to

Once the above pre-start checks have been carried out satisfactorily , the main start up operation can begin.

the microprocessor main circuit board and that the

jumper links are correctly set (refer to unit wiring

schematic). If the links are set incorrectly , remove

main power before making any changes.

9. For microprocessor controlled units, check that

the battery on the main circuit board is in place

and properly connected. Check also that the batteries are installed in the infrared unit.

STAR T UP SHEET EXAMPLE

EMI CASSETTE - CAH/W, CAF/ 4

TO BE COMPLETED IN CONJUNCTION WIT H START UP PROCEDUR

TECHNICIAN:

M

DEL/SERIA L NO:

1.0 PRE START UP CHECKLIST

1.1 UN I T CONDITI ON SATIS FA CTORY

1.2 PRESSURE TEST WI T H DRY NIT RO G EN

1.3 DESIGN WATER FLOW AVAILABLE IF

CHILLED W ATER UNIT

1.4 VOLTAGE AT O UT D O OR UNIT

1.5 VOLTAGE AT I NDOOR UNI T

1.6 ELECTRICA L CO NNECTI O NS T IGHT

1.7 JUMPERS SET CORRECTLY (MICRO ONLY)

2.0 START UP CHECKLIST - INDOOR UNIT

2.1 DISA BLE COMPRESSOR SIGNAL

2.2 ON/OFF WORKS

2.3 INDOOR UNIT : THREE F ANS SPEEDS

AVAIL ABLE (MICRO ONLY)

2.4 VA NE SWEEP FUNCTIONS

2.5 TIMER FUNCTIONS OPERATE (MI CRO ONLY)

2.6 CONDENSATE PUMP OPERATES

3.0 START UP CHECKLIST - OUTDOOR UNIT

3.1 OPERA T I NG PRESSURES

3.2 SUCTI O N

3.3 DISCHARGE

3.4 AM BIENT TEM PERAT URE

35. INDOOR AI R TEMPERATURE

: A START UP SHEET FOR EVERY UNIT MUST BE RETURNED TO EMI TO VALIDATE THE WARRANTY .

NOTE

RETURN ONE COPY TO EM I AND RETAIN ORIGINAL FOR YOUR REC OR DS

(REFE R TO THE RELE VANT O UTDOOR UNIT M ANUAL AND, IN ADDITION, NO TE THE FOLLOW ING:

MPANY:

PR

T:

COMMENT:

INITIAL TEST

PRESSURE

IMPORTANT: The jumper links referenced in step

8 must be correctly set before applying mains

power, to ensure correct operation of unit. (micro

units only)

DATE:

FINAL TEST

PRESSURE

ENVIROMASTER INTERNATIONAL LLC

HT TP://WWW.ENVIROMASTER.C OM

TE S T DU RATIO N

5780 SUCCESS DRIVE

ROM E, NY 13440

TEL: 1-800-228-9364

FAX: 1-800-232-9364

YES/NO

YES/NO

YES/NO

YES/NO

YES/NO

YES/NO

YES/NO

GPM

V

V

PSIG

PSIG

ºF

ºF

EMI@ENVIROMASTER.COMENVIROMASTER INTERNATIONAL LLC 6

Loading...

Loading...