EMI VPAC, VPHP Installation, Operation & Maintenance Manual

VPAC/VPHP

SINGLEPACKAGE

VERTICALAIRCONDITIONER/HEATPUMP

Straight Cool/Heat Pump

Nominal Capacities: 9,000-12,00015,000-17,000-19,000-24,000 Btuh

FOR NEW CONSTRUCTION ONLY

Enviromaster International LLC

5780 Success Dr.

Rome, NY 13440

INSTALLATION,OPERATIONANDMAINTENANCEMANUAL

Email: info@retroaire.com

VPAC/VPHP

An ISO 9001-2000 Certified Company

P/N# 240004198, Rev. 1.9 [06/06]

VPAC/VPHP SINGLE PACKAGE VERTICAL AIR CONDITIONER/HEAT PUMP

INSTALLATION , OPERATION, AND SPECIFICATION MANUAL

P/N# 240004198, Rev. 1.9 [06/06]

Shipping Damage MUST be Reported to the Carrier IMMEDIATELY!!!

Examine the exterior. Remove cover and examine compressor and piping for signs of damage.

This manual is intended as an aid to qualified service

personnel for proper installation, operation, and maintenance

of the VPAC/VPHP Packaged Terminal Air Conditioner

(PTAC). Read these instructions thoroughly and carefully

before attempting installation or operation. Failure to

follow these instructions may result in improper installation,

operation, service, or maintenance, possibly resulting in

fire, electrical shock, property damage, personal injury, or

death.

TO THE INSTALLER

(1) Retain this manual and warranty for future refer-

ence.

(2) Before leaving the premises, review this manual

to be sure the unit has been installed correctly

and run the unit for one complete cycle to make

sure it functions properly.

To obtain technical service or warranty assistance

during or after the installation of this unit, contact

your local representative.

retroaire.com for a local representative listing. For

further assistance call 1-800-228-9364.

Visit our website www.

SAFETY INSTRUCTIONS

Read all instructions before using the VPAC/VPHP

PTAC. Install or locate this unit only in accordance

with these instructions. Use this unit only for its

intended use as described in this manual.

Check the rating plate on the VPAC/VPHP PTAC

before installation to make certain the voltage

shown is the same as the electric supply to the

unit.

The VPAC/VPHP PTAC must be connected only to

a properly grounded electrical supply. Do not fail

to properly ground this unit.

Turn off the electrical supply before servicing the

VPAC/VPHP PTAC.

Do not use the VPAC/VPHP PTAC if it has dam-

aged wiring, is not working properly, or has been

damaged or dropped.

[Save These Instructions]

When calling for assistance, please have the following information ready:

• Model Number_________________________

• Serial Number_________________________

• Date of installation______________________

Recognize this symbol as an indication

!

The Right Fit For Comfort

of important safety information

!

DANGER

!

The RetroAire PTAC must:

Be connected to a properly grounded

electrical supply with the proper voltage

as stated on the rating plate.

Have proper over current protection (i.e.

time- delay fuse/HACR-Breaker) as listed

on the Rating Plate.

Failure to follow these instructions can result

in a fire, explosion, or electrical shock causing

property damage, personal injury, or death.

2

!

www.retroaire.com

TABLE OF CONTENTS

To the Installer and Safety Instructions ....................2

Warnings and Installer Responsibilities ...................3

Controls and Components ......................................4

Product Description, Air System .............................4

Heat-exchanger, Refrigeration, Electrical Wiring ....4

Insection, Installation Instructions ........................5-9

Sequence of Operation ....................................10-12

Cleaning and Maintenance .................................... 12

Troubleshooting .................................................... 12

Specifications and Dimensions ........................13-14

Warranty ............................................................... 15

MODIFICATION AND TAMPERING

DANGER

!

Tampering with the VPAC/VPHP is dangerous

and may result in serious injury or death. Tampering voids all warranties. Do not attempt to

modify or change this unit in any way.

IMPORTANT SAFETY FEATURE

!

INSTALLER RESPONSIBILITIES

This manual has been prepared to acquaint you with the

installation, operation and maintenance of this VPAC/

VPHP PTAC and to provide important safety information

in these areas.

We urge you to read all of the instructions thoroughly before

attempting the installation or operation of this unit. This

manual should be kept for future reference.

The manufacturer of this unit will not be liable for any dam

ages caused by failure to comply with the installation and

operating instructions outlined in this manual.

A rating plate identifying this VPAC/VPHP PTAC can be

found on the unit. When referring to your unit, always have

the information listed on the rating plate readily available.

Power Cord With Integral Safety Protection

All PTACs rated 250

to the power supply are equipped with a power cord

with integral safety protection as standard. Providing

personal shock protection as well as arcing and

fire prevention, the device is designed to sense

any damage in the line cord and disconnect power

before a fire can occur. Tested in accordance with

Underwriters Laboratories, the cord set also offers a

unique “passive” operation, meaning the unit does not

-

require resetting if main power is interrupted.

WARNING - A DAMAGED POWER SUPPLY CORD

MUST BE REPLACED WITH A NEW CORD FROM

THE MANUFACTURER, AND NOT REPAIRED.

Each power cord should be checked before every

use. Follow the instructions in the order listed on the

device.

WARNING - DO NOT USE THE PRODUCT IF THE

UNIT FAILS THE TEST.

V or less that are cord connected

Completely read all instructions prior to assembling, installing, operating, or repairing

this product. Inspect all parts for damage prior to

installation and start-up. The VPAC/VPHP PTAC

must be installed ONLY by qualified installation

personnel.

VPAC/VPHP

WARNING

!

3

!

Made in Rome, New York, USA

PRODUCT DESCRIPTION

ELECTRICAL WIRING Continued

The VPAC/VPHP Single Package Vertical Air Conditioner (SPVAC) and Heat Pump (SPVHP) creates new options in layout and space utilization. The VPAC/VPHP offers

low cost operation and quiet, comfortable air distribution,

especially when used in multi-room suites, apartments,

healthcare facilities, and homes.

Framed into a concealed closet enclosure for low operating sound levels, the VPAC/VPHP’s vertical discharge

vent allows ducting to the top of the room(s) for superior air

circulation and distribution. Multiple air supply grilles can

distribute air when used with a soffit and intake grilles can

be located on either of the two sides of the enclosure.

The VPAC/VPHP offers an economic benefit when used

in a multi-room suite by supplying conditioned air to more

than one room without the need to install another unit. This

is also a design advantage since the second room does

not need an exterior wall for a second unit.

Each system is supplied with a ready-to-install wall

sleeve and a condenser side air louver. The cabinet is

constructed with 20 gauge galvanized steel with a G-90U

corrosion resistant rating. The unit is designed with serviceability on three sides (front, left, and right). The insulated top

discharge evaporator compartment provides quiet ducted,

conditioned air delivery to other room location(s).

AIR SYSTEMS

Motors are thermally protected PSC type. Air stream

surfaces are insulated with 1/4 inch fiberglass or 1/8 inch

volara. The evaporator fan is a forward curved type directly

mounted to the motor shaft. The condenser propeller and

slinger ring (for condensate re-evaporation) utilize a blowthru design for improved efficiency.

IM PORTANT:

condensate drain system will be used. The standard

VPAC/VPHP is designed to evaporate condensate by

slinging it onto the warm condenser coil.

Co nsult the factor y if an internal

ELECTRICAL WIRING

All field wiring must be done in accordance to NEC and

local codes. Check the unit rating plate for circuit ampacity

and breaker or fuse size. Use only HACR type breakers.

Select the proper wire for the ampacity rating. If a plug and

receptacle are used check the proper fit.

The unit is wired for 230V primary voltage from

the factory. The transformer must be rewired by the

installer if the jobsite voltage is 208V.

Each vertical stack unit is equipped for a 24V wall

thermostat connection. Units are shipped with a twenty

foot plenum rated thermostat wire utilizing a quick connect

plug to the unit.

STANDARD CONTROLS AND COMPONENTS

• Cooling or heat pump chassis w/high efficiency rotary

or reciprocating type compressor

• Indoor/outdoor mounting anodized outdoor louver for

field installation (optional colors available)

• Manual fresh air damper (located on service panel

below evaporator coil)

• Front mounted control box (unless otherwise specified)

• Microprocessor control board

- Fan purge: Fan remains on for 60 seconds after

heat/cool call is dropped (“Auto” mode only)

- Universal control board: circuit board can be used

in either a straight cool electric, hydronic heat, or

cooling/heat pump application.

- Anti-short cycle compressor protection

- Random start timer: prevents multiple units from

simultaneous start-ups

- Freeze protection: prevents evaporator freeze

ups

- Low ambient lockout

- Test operation: allows ease of testing after installation (all timers are eliminated)

- Compatible with fossil fuel, electric heat, mercury

or electronic thermostats

• Temperature sensitive drain pan valve for heating condensate disposal (VPHP only)

• Wall sleeve

WARNING

!

Before accessing the control compartment, disconnect

power to the unit. Failure to do so could result in serious

injury or electrical shock.

The Right Fit For Comfort

!

OPTIONAL CONTROLS AND COMPONENTS

• Hydronic heat coil

• Electric heat coil

• Painted outdoor air louver

• Wall thermostat (digital or mercury bulb)

• Power disconnect

• EMS management relay

• Casters (for easy maneuverability )

• Return air access panel (standard white or custom

colors available)

4

www.retroaire.com

INSTALLATION FOR NEW CONSTRUCTION

INSPECTION

Carefully check the shipment against the bill of lading.

Make sure all chassis, wall sleeves, and louvers (as well as

any options) have been received. Inspect each component

for damage. The carrier must make proper notation on

the delivery receipt of all damage identified and complete

a carrier inspection report. Concealed damage must be

reported to the carrier within 15 days of the receipt of the

shipment.

IMPORTANT:

The purchaser must notify the EMI traffic

department of all damage and is responsible for filing

any necessary claims with the carrier.

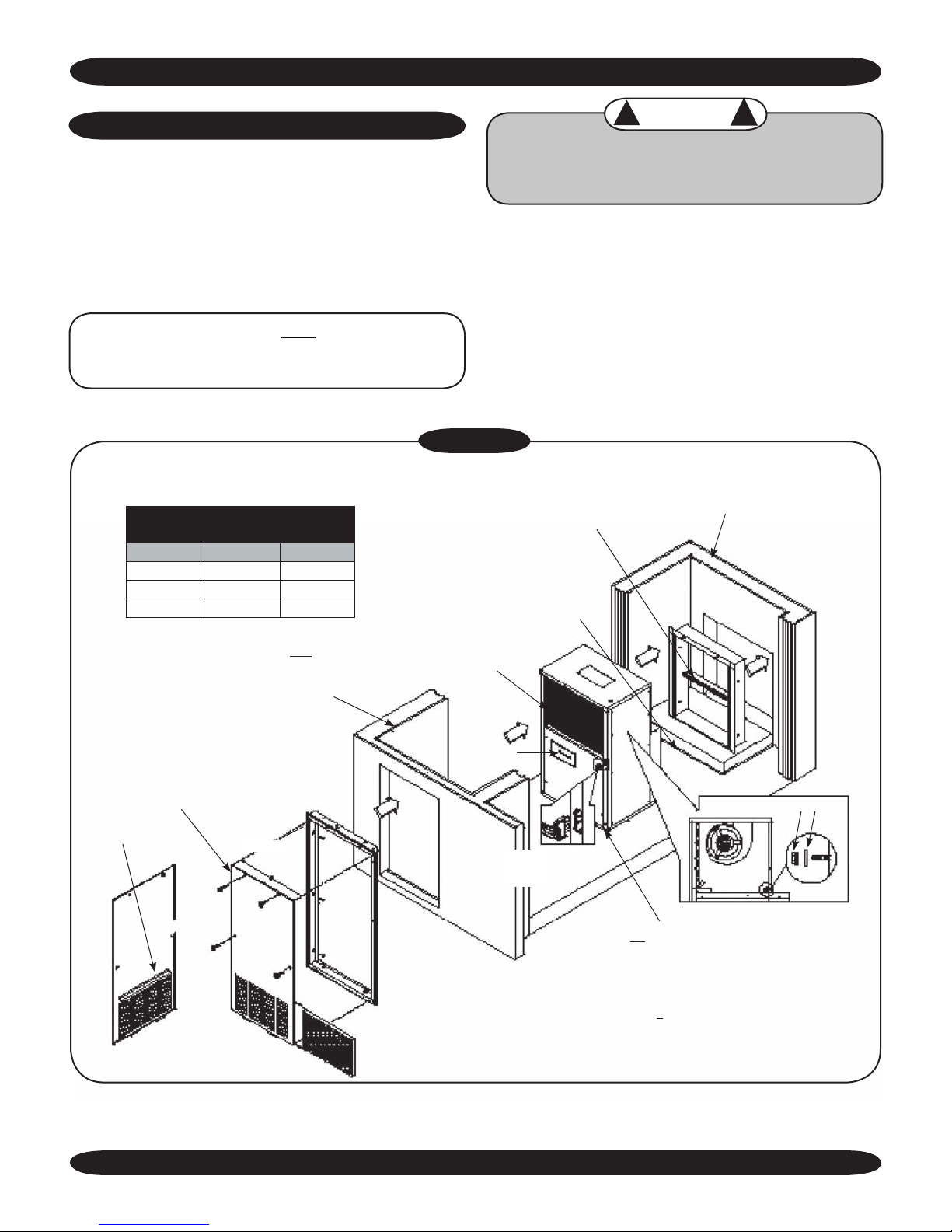

Figure 1

EXPLODED VIEW OF TYPICAL INSTALLATION

VPAC/VPHP ROUGH WALL

SLEEVE OPENING

Unit Size Width Height

9-15 26.125” 26.125”

17 26.125” 26.625”

19-24 26.125” 33.625”

For proper intake air flow on the VPAC/VPHP

09-17, a minimum spacing of 4” must be maintained between the enclosure and the unit.

For VPAC/VPHP 19-24, use 6” minimum spac

ing between the enclosure and the unit.

-

Platform (Supplied By Installer)

Note: Height = Floor To Bottom

Of Wall Opening

CAUTION

!

!

Avoid possibility of electric shock and personal injury.

Disconnect all power before removing chassis or per

forming any cleaning, servicing, or maintenance.

Enviromaster International recommends installing the

unit before any carpentry work is started for the enclosure.

It is very important for proper air flow and sound levels that

a minimum clearance of 4” (09-17) or 6” (19-24) between

the enclosure and the chassis be maintained. It is also very

important that the rough opening in the wall for the wall

sleeve and louver be the correct dimension and in the exact

position necessary for installation. (Figure 1)

Minimum overall wall thickness must be at

least 5” for straight cool models and 6½” for

heat pumps. (Consult factory if minimum

O.D. Air Splitter Baffle

Evaporator Coil

wall thickness cannot be met.)

-

Access Panel (Optional)

Filter Slide (On Back)

Rear View of Door

VPAC/VPHP

Lagging Holes

Manual Fresh

Air Door

(2) 1/4 - 20 Serrated Nuts Washer

T-stat Connections

(different on

VPAC/VPHP 24)

External line cord (min. 48”) located at bottom

right for front and right hand controls or bottom

left for left hand controls

For a VPAC/VPHP with optional hydronic heat attached to the supply air panel:

It is still necessary to maintain minimum spacing between the enclosure and the unit

for proper air flow but additional space is recommended for the hydronic option. Refer

to Page 5 of these instructions to determine spacing for serviceability and access to

piping connections.

5

Made in Rome, New York, USA

Loading...

Loading...