EMI UNHV09, UNHV12, UNHV18, UNHV24 Installation, Operation And Maintenance Manual

UNHV

V

p

A

r

Variable Speed Ductless Split System

ariable Speed Ductless S

Air Handler

ir Handle

Straight Cool / Heat Pump Nominal Capacities

UNHV09 UNHV12 UNHV18 UNHV24 Units

9,000 12,000 18,000 24,000 Btuh

2.6 3.5 5.3 7.0 kW

8,800 10,000 18,000 21,000 Btuh

2.5 2.6 5.0 5.6 kW

Installation, Operation and

Maintenance Manual

lit System

COOL

HEAT

An ISO 9001-2008 Certifi ed Company

ECRInternational,Inc.

2201 Dwyer Avenue,

Utica NY 13501

web site: www.ecrinternational.com

P/N# 240009098, Rev. C [08/08/2012]

TABLE OF CONTENTS

Receiving Information .................................................................................................................. 3

Important Safety Information ........................................................................................................ 4

Dimensional/Physical Data ............................................................................................................ 5

General Product Information ......................................................................................................... 6

Unit Mounting ............................................................................................................................. 8

Ceiling Mounted .......................................................................................................................... 8

Wall Mounted .............................................................................................................................. 8

Condensate Piping ......................................................................................................................10

Refrigerant Piping .......................................................................................................................11

Refrigerant Processing .................................................................................................................13

Electrical Wiring .........................................................................................................................15

Cabinet Re-Assembly ..................................................................................................................20

Condenser Operation ..................................................................................................................21

Initial Start-Up ...........................................................................................................................23

UNHV Controller .........................................................................................................................24

Wired Wall Controller ..................................................................................................................25

Setting The Controller .................................................................................................................27

Hand Held Controller Operation ....................................................................................................29

Wired Wall Controller Operation ....................................................................................................32

Controller Features .....................................................................................................................33

Controller Fault Conditions ...........................................................................................................34

Maintenance ..............................................................................................................................35

Troubleshooting ..........................................................................................................................36

Frequently Asked Questions .........................................................................................................38

Specifi cations And Dimensions .....................................................................................................39

UNHV System Options .................................................................................................................40

Test Unit Performance Data Sheet .................................................................................................41

Check our website frequently for updates: www.enviromaster.com

Information and specifi cations outlined in this manual in effect at the

time of printing of this manual. Manufacturer reserves the right to

discontinue, change specifi cations or system design at any time without

notice and without incurring any obligation, whatsoever.

2

RECEIVING INFORMATION

Shipping damage MUST be reported to the carrier IMMEDIATELY.

Examine exterior.

Remove cover and examine compressor and piping for signs of damage.

General Information

Installation shall be completed by qualifi ed agency. Retain

this manual and warranty for future reference.

Installer review this manual to verify unit has been installed

correctly. Run unit for one complete cycle to verify proper

function.

To obtain technical service or warranty assistance during or

after installation, contact your local representative.

Visit our web site www.enviromaster.com for local

representative listing.

For further assistance call 1-800-325-5479.

When calling for assistance, please have following

information ready:

Model Number_________________________

Serial Number_________________________

Date of installation______________________

3

IMPORTANT SAFETY INFORMATION

Become Familiar With Symbols

Identifying Potential Hazards.

!

All fi eld wiring shall conform to requirements of authority

having jurisdiction or in absence of such requirements:

• United States - National Electrical Code, ANSI/NFPA 70

• Canada - CSA C22.1 Canadian Electrical Code Part 1.

!

WARNING

Fire and electrical shock hazard. Improper

assembly and/or installation could result in death or

serious injury. Read this manual and understand all

requirements before beginning installation.

Become Familiar With Symbols

Identifying Potential Hazards.

!

DANGER

Indicates a hazardous situation which, if not

avoided, WILL result in death or serious injury.

Safety Information

• Installation by qualifi ed personnel.

• Turn off electrical supply before servicing unit.

• Inspect all parts for damage prior to installation and

start-up.

Do not use unit if it has damaged wiring, is not working

properly, or has been damaged or dropped.

• Connect to properly grounded electrical supply with

proper voltage as stated on rating plate.

• Have proper over-current protection (i.e. time- delay

fuse/HACR Breaker) as listed on Rating Plate.

• Connect unit to properly grounded electrical supply. Do

not fail to properly ground this unit.

• Check the rating plate on the unit before installation to

verify voltage shown is same as electric supply to the

unit. Rating plate is located on top panel only.

• Tampering voids all warranties.

!

WARNING

Tampering with this unit is dangerous and could

result in serious injury or death. Do not modify or

change this unit.

!

WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

!

CAUTION

Indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE

Indicates information which should be followed to

ensure proper installation and operation.

4

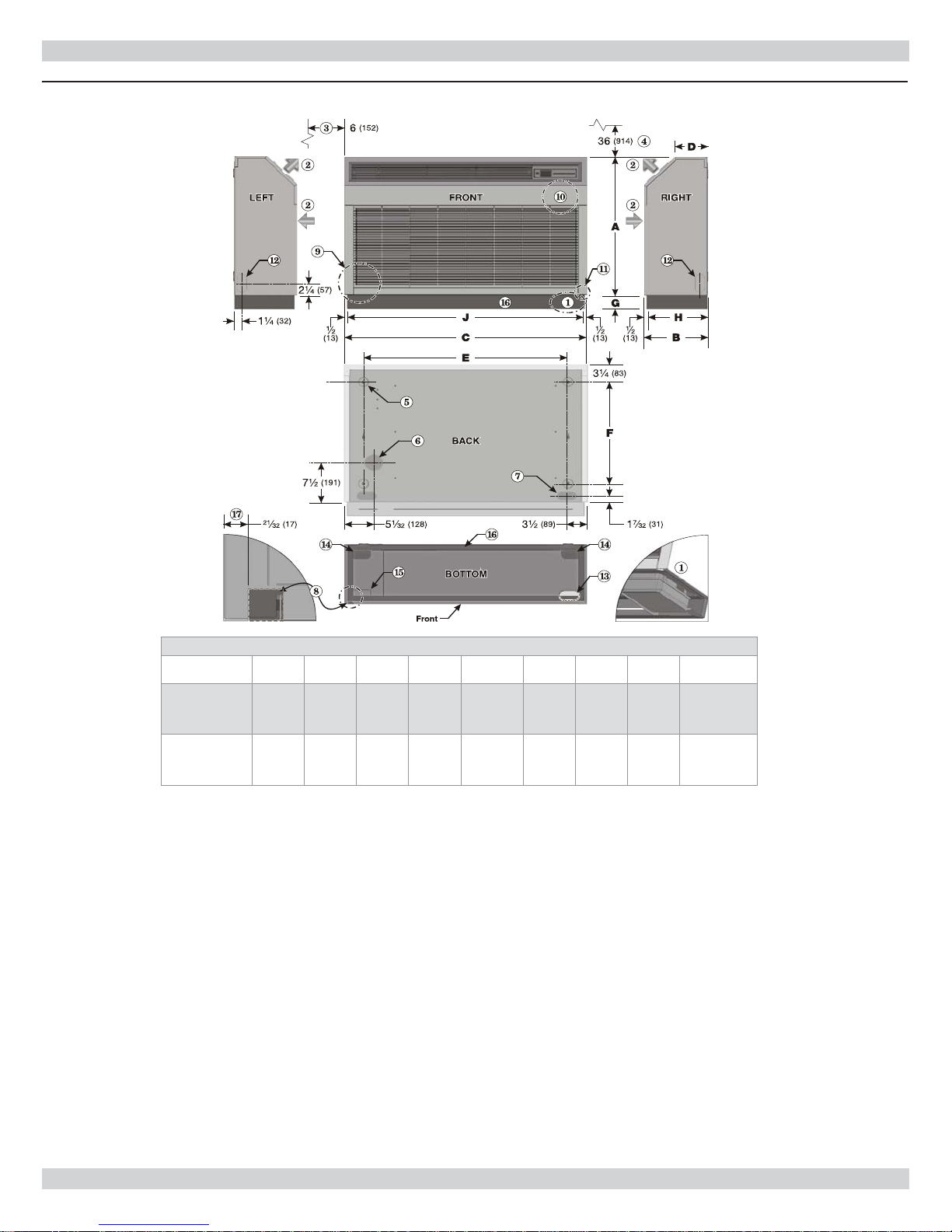

DIMENSIONAL/PHYSICAL DATA

Figure 1 - Dimensions, Openings And Knockouts

Model A B C D E F G H J

UNHV09/12

UNHV18/24

1.

Optional condensate pump fl oor

26”

(660)

26”

(660)

mount location (requires toe kick kit).

2.

Supply and return air fl ow directions.

3.

Minimum clearance for air fl ow and

access — BOTH sides of cabinet.

4.

Minimum clearance — insure

minimum clearance of 36" (914 mm)

above supply air outlet and in front of

return air inlet for air fl ow and access.

5.

Clearance holes (4) for securing unit

to wall or ceiling, using appropriate

hardware 11/

6.

Knockout, 3" (76 mm), for optional

"

diameter.

16

customer supplied/installed fresh air

intake device.

7.

1⅝" x 3 ⅜" knockout each side of

rear panel for refrigeration tubing,

condensate drainage and/or power.

DIMENSIONS — Inches (mm)

11”

(279)

11”

(279)

41 ½”

(1054)

51 ½”

(1308)

8.

Opening, ⅞" x ⅞" bottom right front

5 ½”

(140)

5 ½”

(140)

35”

(887)

45”

(1141)

corner of cabinet, for condensate

drain tube routing when unit is ceiling

mounted

9.

Refrigeration and condensate draining

connections are located in this area

10.

Electrical connections are located in

this area

11.

Location of item 7, above

12.

1⅝" x 3⅜" knockout each side panel

for refrigeration tubing, condensate

drainage and/or power

13.

1⅝" x 3⅜" knockout at bottom

left front for refrigeration tubing,

condensate drainage and/or power,

used when unit is ceiling mounted.

Pump kit riser fl anges do not interfere

with knockouts.

19 3/16”

(487)

19 3/16”

(487)

2 ½”

(64)

2 ½”

(64)

10

7

/16”

(265)

10

7

/16”

(265)

14.

40 ½”

(1029)

50 ½”

(1283)

1⅝ "x 3⅜" knockouts at

bottom left rear each side for

refrigeration tubing, condensate

drainage and/or power; pump

kit riser fl anges do not interfere

with knockouts.

15.

1⅝" x 3⅜" knockout at bottom

right front for refrigeration

tubing, condensate drainage

and/or power, most often used

when unit is ceiling mounted;

pump kit riser fl anges do not

interfere with knockouts

16.

Optional toe kick — with 1"

bottom fl ange; recessed ½"on

front and sides, fl ush at rear.

17.

Distance from side of cabinet to

⅞" x ⅞" opening.

5

GENERAL PRODUCT INFORMATION

Product Description

• UNHV is available as (DX) direct expansion straight cool

or heat pump.

• Unit is equipped with unit mounted infrared compatible

controls which support 24V Wired Wall Controller

operation. Optional handheld remote is available.

• Heat pump models provide up to 24, 000 Btuh of cooling

and 21,000 Btuh of heating. Electric heat options are

available for up to 5 kW of supplemental heat.

Can be matched with EMI’s:

• Single-zone condensing units — S1HV 09-24.

• Condensers include common discharge port.

• Heat pump circuits include common suction port.

Controls And Components

Cabinet Features:

(Factory-Installed Or Supplied)

• Single unit-mounted control package, confi gurable

to either unit mount or remote Wired Wall Controller

operation.

• Unit mount control can be used in cooling only, cooling

with electric heat, heat pump, or heat pump with second

stage electric heat applications.

• Operational range set point temperature adjustable

between 55°F (13°C) and 90°F (32°C) in one-degree

increments.

• Infrared-compatible controller allows use of IR hand

held controller.

• Operation modes include Heat, Cool, Dry, Fan and Auto

Change-over.

Optional Equipment

rate condition speeds for set-ups and charging.

• Non-volatile back-up memory maintains control settings

for indefi nite period during power outage. When power

is restored equipment resumes operation after threeminute compressor time delay.

• 7-day programmable with copy feature.

• Filter change indicator: Timer indicates when fi lter

should be cleaned.

• Integral condensate pump safety-switch connection

microprocessor monitors condensate pump safety switch

and displays error code when fault occurs. (Only with

optional condensate pump).

• CEC (California Energy Commission) compliant.

• Condensate drain pan over fl ow protection.

• Accessible, washable, reusable, nylon mesh fi lter.

• Access to piping connections and condensate pump

allow installation with unit mounted in place.

• Condensate drain pan constructed of galvanized steel

(G90U), anti-corrosion coating.

• Condensate pump (fi eld installed only).

• 24V Wired Wall Controller.

• Electric heat with automatic reset high temperature

cutout and redundant high temperature fuse link (when

heat option is selected, factory installed only).

• Fan Operation – Auto/On. High, Medium or Low speed

fan.

• Fan Purge – Fan remains on for 60 seconds after Heat/

Cool call is dropped. (Auto mode only)

• Room air sampling — Selectable time intervals insure

fan will cycle on periodically, in Auto Fan Mode.

• Selectable Fahrenheit (°F) or Celsius (°C) temperature

scale.

• Dry mode – Operates cooling and electric heat

simultaneously to remove humidity.

• Anti-Short Cycle Compressor Protection.

• Minimum ON time for heating and cooling eliminates

room temperature droop and system short cycling.

• Freeze Protection – Prevents air handlers freeze up.

• Test operation – Allows testing after installation. Runs at

Installer Supplied Items

• Low voltage wiring (18 AWG minimum required).

• High voltage power supply wiring.

• Mounting screws and fasteners.

• Condensate piping.

• Refrigerant piping (if not supplied). Both tubes need

to be insulated.

• Refrigerant (for interconnect charge) R410A.

6

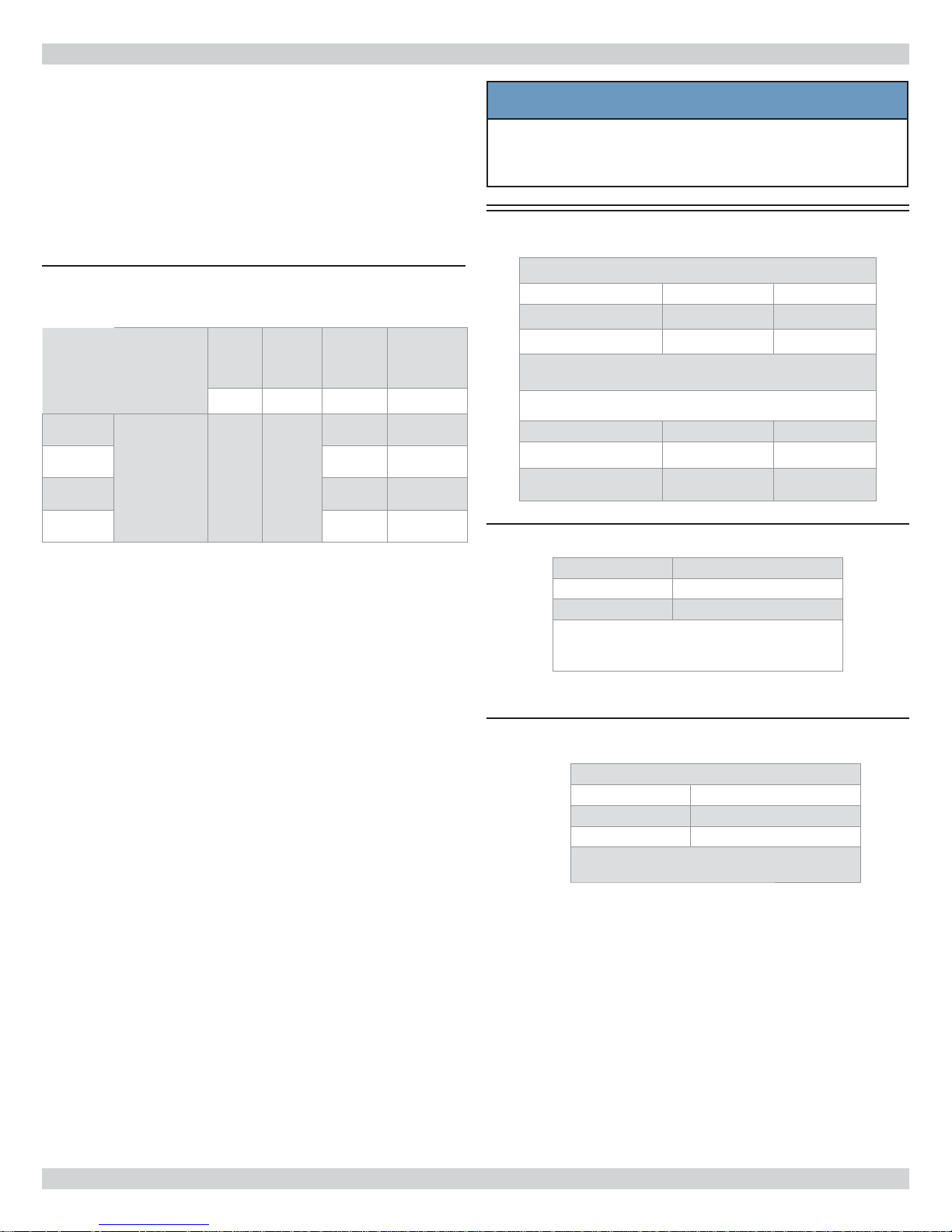

GENERAL PRODUCT INFORMATION

Installation Considerations

• Determine best location for mounting unit for room air

circulation.

• Locate outdoor and indoor units as close together as

possible.

• Determine wiring, drainage and piping placement.

• Insure interconnect tubing is within listed limits. See

Table 1 .

Table 1 - Tubing Specifi cations - Both Tubes

Insulated

S1CV/

S1HV

or

Model

09

12 1/4" 1/2"

18 3/8" 5/8" *

24 3/8" 5/8" *

* Bush down at air handler

• Position unit as close as possible to center (left-toright) of wall. Grille on unit front must be accessible for

servicing.

Max.

Length

Equivalent

Feet

100’

(30 m)

Max.

Lift

“H” “P” O.D. O.D.

35’

(11

m)

Max.

Trap

Height

20’

(6 m)

Liquid

Line

1/4" 1/2"

Suction

Line

Condensate Pump Kit Option

• Verify condensate pump purchased with unit See

Table 2 .

• Floor-mounted units with fl oor-mounted condensate

pump optional toe kick kit. See Table 2 .

NOTICE

If excessive noise or vibration from unit mounted to

masonry block wall, verify unit is plumb and level. If

noise or vibration persists, contact distributor.

Table 2 - Condensate Pump Kits, UNHV 09-24

Floor-Mounted Units

Air Handler 208/230v 115v

09 / 12 550001727 550001728

18 / 24 550001727 550001727

Toe kick kit is required when condensate pump is

mounted below fl oor-mounted air handler.

Ceiling-Mounted Units

Air Handler 208/230v 115v

09 / 12 240006200 240006199

18 / 24 240006200 240006199

Table 3 - Toe Kick Kits

Air Handler Part number

09 / 12

18 / 24

Required when condensate pump is

mounted below fl oor-mounted air

handler.

Table 4 - Drain Pan Extension Kits

550001785

550001786

Optional Toe Kick Kit

• For fl oor-mounted UNHV units use optional toe kick kit.

See Table 3 .

• Toe kick kit is required if fl oor mounting a condensate

pump under fl oor-mounted UNHV air handler.

Site Preparation

• Mount unit to vertical surface plumb and level to

prevent unit vibration and potential noise.

• Mount unit directly to smooth surface such as wallboard

or similar material.

• Mounting to masonry block wall,provide smooth

barrier between unit and masonry block surface to

absorb potential vibration and prevent formation of

condensation on the wall.

• Unit can be suspended from ceiling using threaded

rods.

7

Ceiling Mounted Units

Air Handler

09/12

18 / 24

Recommended when unit is ceiling

mounted

Kit #

550001915

550001916

UNIT MOUNTING

Unit Mounting Instructions

1.

Optimal unit location:

• Locate unit in area with unrestricted air fl ow to the

space.

• Unit may be recessed into wall or ceiling by no more

than 5½” (140mm).

2.

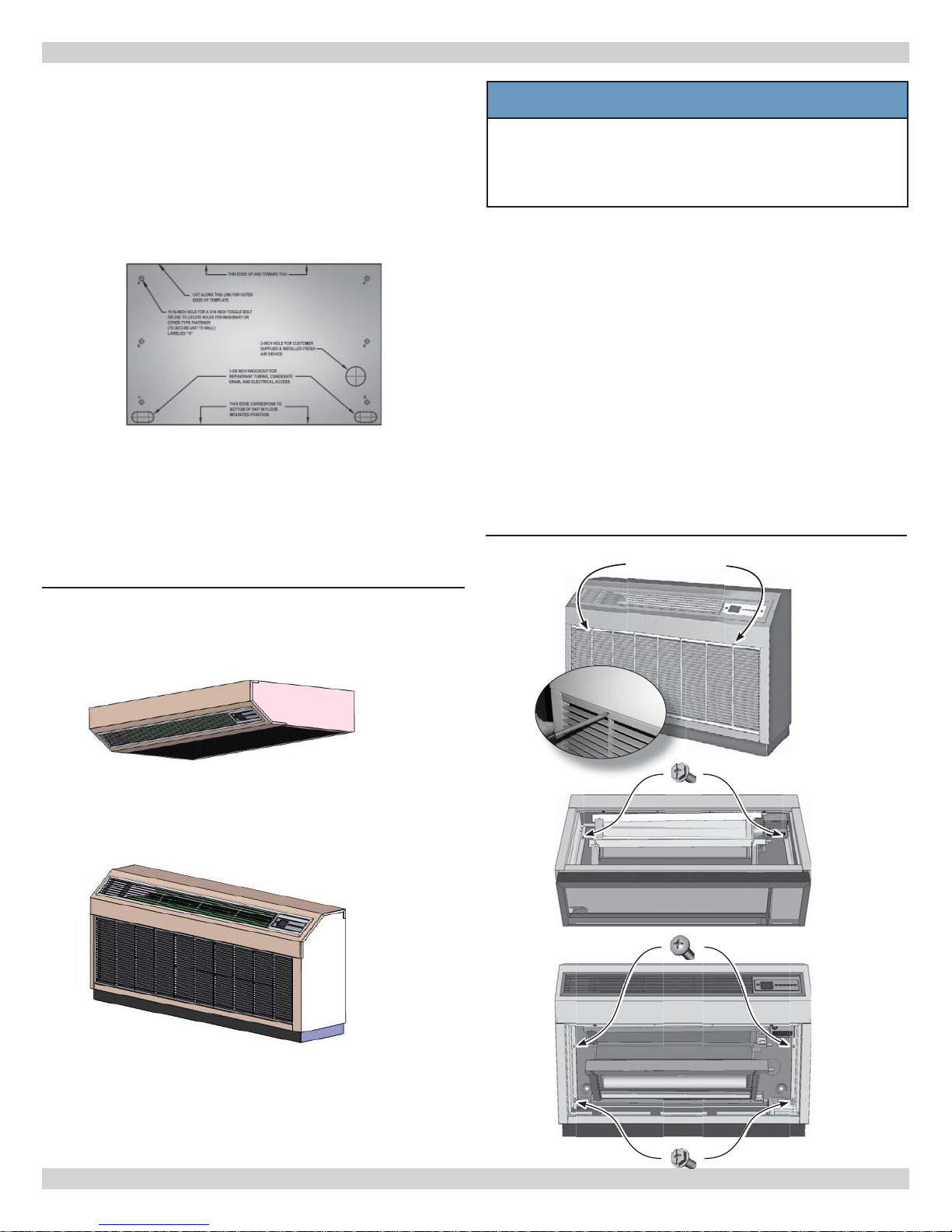

Use cardboard template provided in packaging to mark

where piping, electrical wiring and condensate drain

should penetrate wall or ceiling.

3.

See Figure 1, Page 5 for locations of cabinet openings

and knockouts.

4.

New construction - Piping may be roughed in before

wallboard or panels are placed. PVC pipe (3” or 4”

I.D.) may be used as pipe chase.

NOTICE

Do not install unit in location where curtains or

drapes obstruct supply air grille. This may cause air

to recirculate without cooling the room, and may

result in premature system failure.

5.

Determine appropriate hole size. Cut through wall or

ceiling.

6.

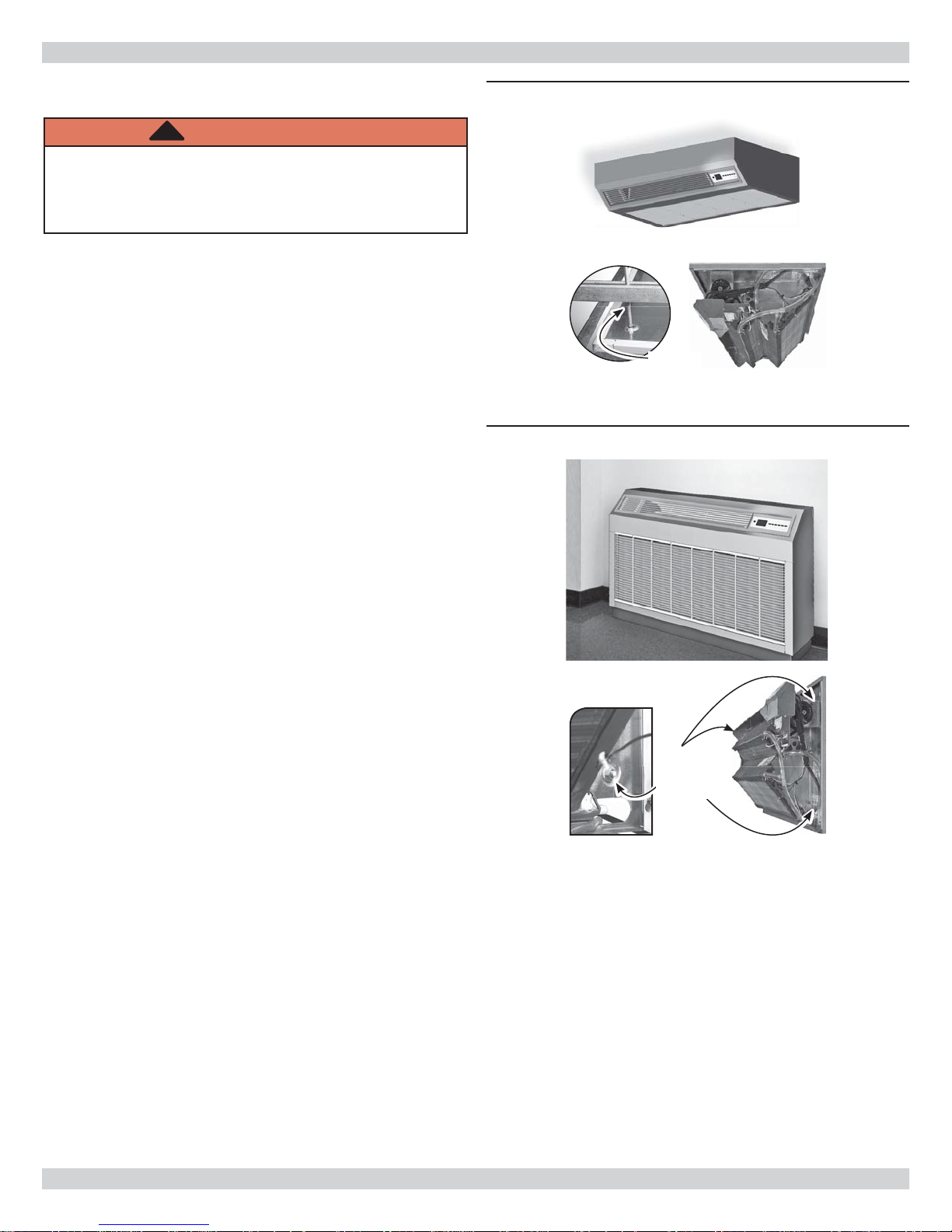

Remove return air grille by removing screws on front of

grille. Lift grille off. See Figure 3 .

7.

Remove rest of painted cabinet. See Figure 3 :

A. Completely remove center screws.

B. Loosen (do not remove) four remaining screws

(5/16" slotted hex) so there is approximately

1/2” between screw head and keyhole slot. Reach

through front of unit to access screws as shown.

C. Leaving loosened screws on unit will make

reinstalling the cabinet easier.

D. If unit is recessed into wall or ceiling it may be

necessary to completely remove all screws.

E. Slide painted cabinet upward until keyhole slots

clear screws. Lift off.

Figure 3 Removing Front Grill

Grille screws

Figure 2 - Mounting Options

Ceiling Mounted

Wall Mounted

Loosen top

screws

Remove center

screws

Loosen

bottom screws

8

UNIT MOUNTING

Unit Mounting Instructions

!

WARNING

Electrical shock hazard. Replace all panels after

installation or servicing. Panels must remain on unit

at all time while powered and in operation. Failure to

do so could result in death or serious injury.

Ceiling Mounting

Threaded rods may be inserted through mounting holes to

suspend unit from ceiling supports. Verify unit is mounted

to support its' weight. See Figure 4 .

Wall Mounting

Secure unit to wall with wood screws or anchors for

masonry using mounting holes located in back panel of

unit. See Figure 5 .

Figure 4 Ceiling Mounting

Threaded

Rod

Figure 5 Wall Mounting

Mounting

holes (2

each side)

9

CONDENSATE PIPING

T

UNHV is supplied with two ½" I.D. fl exible PVC hoses for

connection to copper or plastic condensate drain pipe work.

• Each drain line is labeled and plugged at the factory.

• Unplug appropriate line and connect to condensate

drain.

• Consider following information when installing UNHV:

A. Install with highest point in condensate hose at

unit’s drain pan. Insures proper drainage.

B. Slope condensate hose down in the direction of

water fl ow with minimum gradient of 1” (5mm) per

10’ (1m). There must not be any uphill gradients.

C. When multiple units are connected to common

condensate drain, insure drain is large enough

to handle volume of condensate from all units.

Recommend having air vent in condensate hose to

prevent air locks.

D. If using accessory condensate pump, follow pump

manufacturer instructions.

Use condensate hose tie downs in ceiling mount

applications.

Figure 6 Condensate Piping

Condensate

Hoses

Condensate hose tie down

and knock-out for ceiling

mount application

Two sets of labeled

condensate hoses,

fl oor or ceiling

mount. Check the

Condensate hose

label (fl oor mount

shown)

label to ensure correct hose is used

for the application.

10

REFRIGERANT PIPING

line

Piping Preparation

• Avoid piping on wet and rainy days.

• Use only clean, refrigeration-grade copper tubing.

• Use tubing benders to guard against kinking.

• Verify no burrs remain on fi ttings.

• Cap ends of lines until ready for connections. Verify

plastic end caps remain in place when inserting through

wall openings.

• Insulate both lines.

• Isolate tubing from transmitting vibration to building or

unit and avoid contact with sharp edges.

• Wrap refrigeration valves with wet rag “heat sink” to

protect valves while brazing. See Figure 9, Page 12

• DO NOT use suction line size larger than condenser

service valve connection. This can harm compressor.

Install reducer, when used, only at air handler

connection.

• Mount and level per instructions. See “UNIT

MOUNTING” on page 8 .

Figure 7 Refrigerant Connections

Liquid line

Suction line

• See Figure 7 locations of piping connections in UNHV

unit.

Knockout for piping removed

See Figure 1, Page 5 for locations of all knockouts and

openings in the cabinet.

11

REFRIGERANT PIPING

Line Sizing

1.

Size lines per Table 12, Page 39 .

2.

Match suction line size with condenser service valve

connection.

• When matching UNHV18 or 24 with 18,000 or

24,000-Btuh condenser, use 5/8" suction line, with

reducer installed at indoor connection.

3.

Changes in diameter of tubing must be made at

indoor connection. Line-set diameter is determined by

condenser service valve size.

Refrigerant Piping

1.

Clean the ends of tubing and insert into fi ttings. See

Figure 8 .

2.

Protect valves by wrapping with a wet rag “heat sink”

before brazing. See Figure 9 .

3.

Use a shield to protect the paint as shown in Figure 9 .

(The shield can be made from scrap metal.)

4.

Braze tubing into fi ttings.

Pressure test all fi eld installed piping with nitrogen. Using

suitable vacuum pump, evacuate tubing and indoor unit to

500 microns or less, with service valves remaining front

seated (closed).

Figure 8 Clean ends of tubing

Figure 9 Place Wet Rag “Heat Sink" Over

Valves Plus A Sheet Metal Shield To

Protect Paint

Shield

Wet rag heat sink

NOTICE

Pressure test all fi eld installed piping with nitrogen.

Using suitable vacuum pump, evacuate tubing and

indoor unit to 500 microns or less, with service

valves remaining front seated (closed).

12

REFRIGERANT PROCESSING

Refrigerant Processing

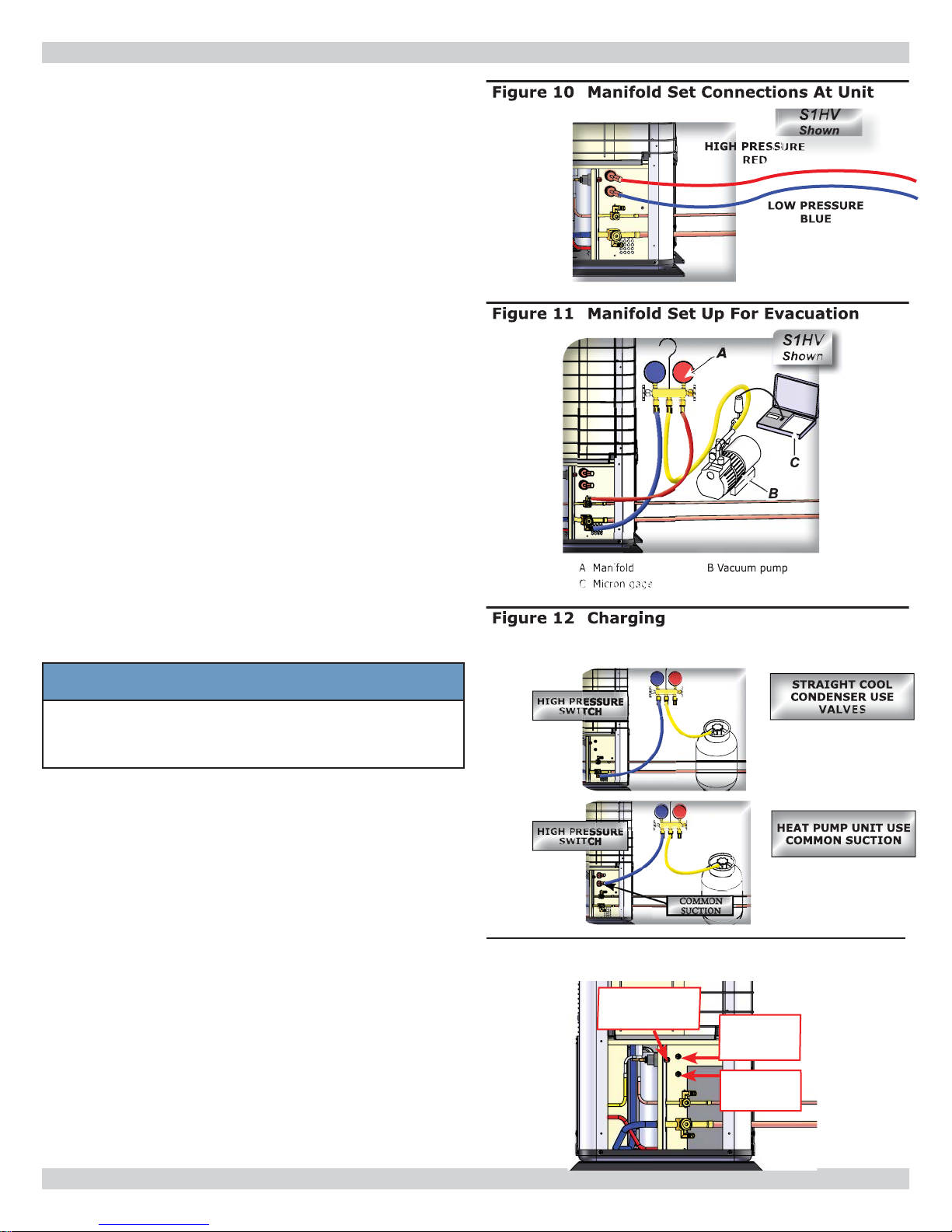

1.

Attach manifold set, vacuum pump, & Micron Gauge.

See Figure 10.

2.

Evacuate line to 500 microns or less to insure all

moisture has been removed and there are no leaks.

See Figure 11.

A. Evacuate

B. Pressurize with 100psi N2 or Nitrogen

C. Evacuate again

D. Charge with R410A

3.

Verify evacuation and leak free joints. Back-seat valves

(counter-clockwise) to open and allow factory charge to

fi ll lines and indoor unit. See Figure 13.

Refer to refrigerant charge table for specifi ed charge.

4.

Charge to proper weight. Charge based on feet of

interconnect. Only add/remove R410A in liquid

form. See Table 5, Page 14 .

5.

Install all panels removed to this point. Panels are required for proper air fl ow.

All systems require fi eld charge adjustments. Refer to

“Refrigerant Charge Tables” for proper weight charge

and Operation Charts for proper system pressures and

temperatures at different outdoor conditions. Sub-cool

should be used for fi nal system charge.

Charge with dial-a-charge or weighed in with scale.

NOTICE

It is illegal to discharge refrigerant into the

atmosphere. Use proper reclaiming methods &

equipment when installing or servicing this unit.

Units are delivered pre-charged with refrigerant for

condenser coil and air handler. Charging of fi eld installed

piping is required. Refer to refrigerant charge table for

proper amount to be added for applications interconnect

piping. Unit service valves are solid brass, for sweat

connections.

• Measure all heat pump saturated suction pressures at

Common Suction Port not vapor service valve.

• Common Suction Port includes pressure drop and

temperature increase through reversing valve resulting

in more accurate and complete system charge.

• Port may also be used to charge system in heating

mode when both sides of line set are at high system

pressures or to determine saturated evaporator

pressure while in heating mode.

Figure 13 Common Suction, Common

Discharge, & High Pressure Switch

HIGH PRESSURE

SWITCH

COMMON

DISCHARGE

PORT

COMMON

SUCTION

PORT

13

REFRIGERANT PROCESSING

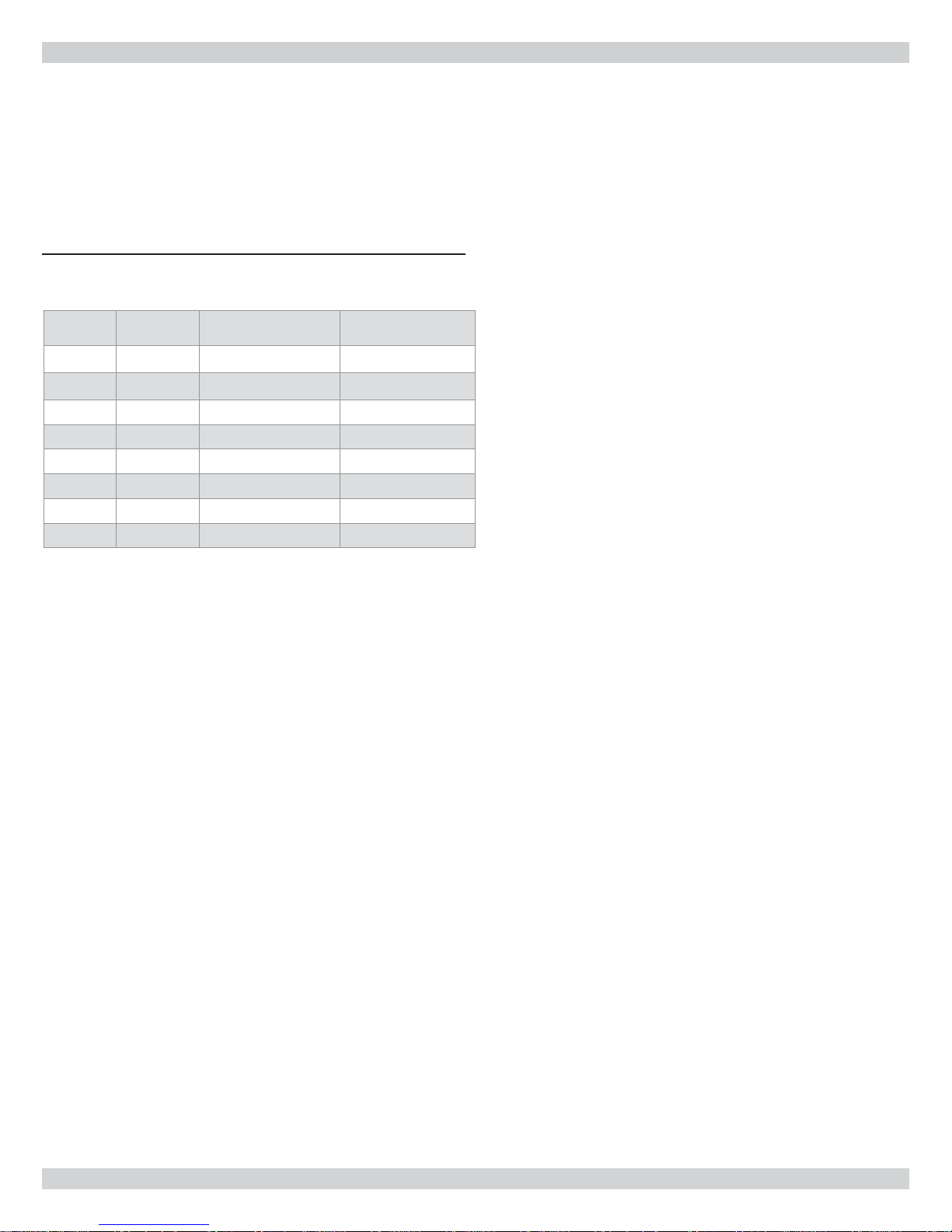

Use following example to fi nd charge adjustment and

system charge for any air handles and tubing length.

Line Adjustment = (Line Charge/FT) x Line Length

System Total = Factory Charge + Line Adjustment

Round to nearest ounce and allow for gauges and hoses.

Table 5 - S1CV / S1HV R410A Refrigerant

Charge Table

Condenser

S1CV9000 UNHV09 .25 oz./ft 23 g/m) 39.5oz (1120g)

S1CV2000 UNHV12 .25 oz./ft 23 g/m) 39.5oz (1120g)

S1CV8000 UNHV18 .64 oz./ft 59 g/m) 54.0oz (1531g)

S1CV4000 UNHV24 .64 oz./ft (59 g/m) 54.0oz (1531g)

S1HV9000 UNHV09 .25 oz./ft (23 g/m) 39.5oz (1120g)

S1HV2000 UNHV12 .25 oz./ft 23 g/m) 39.5oz (1120g)

S1HV8000 UNHV18 .64 oz./ft (59 g/m) 54.0oz (1531g)

S1HV4000 UNHV24 .64 oz./ft (59 g/m) 54.0oz (1531g)

Wall Unit

Pairing

Line Charge

Per Foot

Factory

Charge

14

Loading...

Loading...