EMI UNHG09, UNHG12, UNHG18, UNCG-30, UNHG24 Installation, Operation And Maintenance Manual

UNCG/UNHG

High Efficiency Ductless Split System Universal Air Handler

UNHG0g i UNHG12 i UNHG18 i UNHG24

UNCG-30

8_3

Installation, Operation and

Maintenance Manual

UNCG/UNHG

P/N 240007753, Rev. A [0515091

Contents ...................... 2

Read Before Proceeding ............ 3

Verify Unit Before installing .......... 4

Piston/Orifice Replacement (when required)..6

Mounting the Unit ................ 7

Electrical Wiring ................. 12

Condensate Piping ............... 17

Refrigerant Piping ............... 18

Refrigerant Processing ............ 21

Reassemble the UNCG/UNHG Cabinet . . 22

Initial Start-Up .................. 23

UNCG/UNHG Controller Overview ..... 24

Setting the Controller ............. 26

Unit-Mounted Controller Operation .... 29

Remote Thermostat Operation ....... 33

AmericaSeries Controller Features ...... 36

AmericaSeries Controller Fault Conditions. 37

Maintenance ................... 38

Troubleshooting ................ 40

Frequently Asked Questions ......... 44

Specifications and Dimensions ....... 46

UNCG/UNHG System Options ........ 48

Test Unit Performance Data Sheet ..... 50

EMI's Product Line ............... 51

Indoor Units ................... 51

Outdoor Units .................. 51

shippingdo ogoMust

bo opo todtot.o orHor

INMEDIATELY.

Examine the exterior. Remove

cover and examine compressor

and piping for signs of damage.

_it_eEMI AmericaSeries high eNciency

air handlers is backed by EMi and

ECR international and is tested and

rated in accordance with AHR1 Standard

210/240 and UL-1995.

Due to ongoing product development,

product designs and specifications may

change without notice.

Please contact the f;actory for more

information.

iiiiiiiiiiiiiiiii

Retain this manual and warranty for

future reference. Befk_releaving the prem-

ises, review this manual to be sure the unit

has been installed correctly and run the

unit t_brone complete cycle to make sure

it _nctions properly.

To obtain technical service or warranty

assistance during or after the installation

ofthis unit, contact your local representa-

tive. For alocal representative listing, visit

our web site:

Www._nviro m;_ ster.¢om

For _rther assistancecall:

1-800-223-9364

"When calling _r assistance, please have

the following information ready:

Model Number

Serial Number

Date of installation

Comfort where it cour_ts 2 R!N 240007753, Bey A [05£509I

compmetemyreadaH instructions

prior to assemMing, instamming,oper=

ating, or repairing this product.

Inspect all parts for damage prior to

......................installation and start-up. The EMI

._ericaSeries high eNciency airhandles

must be installed ONLY by qualified

installation personnel

Tampering with this unit is da_ger-

ous. Tampering voids all warranties.

DO NOT attempt to modify or change

this unit in any way.

ilhe EMI AmericaSeries must:

Be connected to aproperly grounded

electrical supply with the proper

voltage as stated on the rating plate.

• Have proper overcurrent protection

(time-delay fase/HACR Breaker) as

listed on the rating plate.

Failure to follow these instructions can

result in a fire, explosion, or electrical

shock causingproperty damage, personal

injury_ or death.

'-_ismanualisintendedasanaidtoqua>

fledservice personnel for proper installa-

tion, operation, and maintenance of the

EMI AmericaSeries high efficiency air

handles. Read these instructions thor-

oughly and carefully before attempting

installation or operation.

ailuretofollowtheseinstructionsmay

result in improper installation, operation,

service, or maintenance, possibly resulting

infire,electricalshock,propertydamage,

iiiiiiiiiiiiiiiill

iiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiii

iiiiiiiiiiiiiiiiii

personal injury, or death.

Read all instructions before using this

unit. Install or locate this unit only in ac-

cordance with these instructions. Use this

unit only for its intended use as described

in this manual

Check the rating plate on the unit before

installation to make certain the voltage

shown is the same as the electric supply to

the unit. The rating plate is located on the

top panel only.

This unit must be connected only to a

properly grounded electrical supply. Do

not fail to properly ground this unit.

_l_rn offthe electrical supplybefore servic-

ing the unit.

Do not use the unit if it has damaged wir-

ing, is not working properly, or has been

damaged or dropped.

:'/N 240007753, Bey, A [05_ 50% 3 I'_$ade i_ the OoA

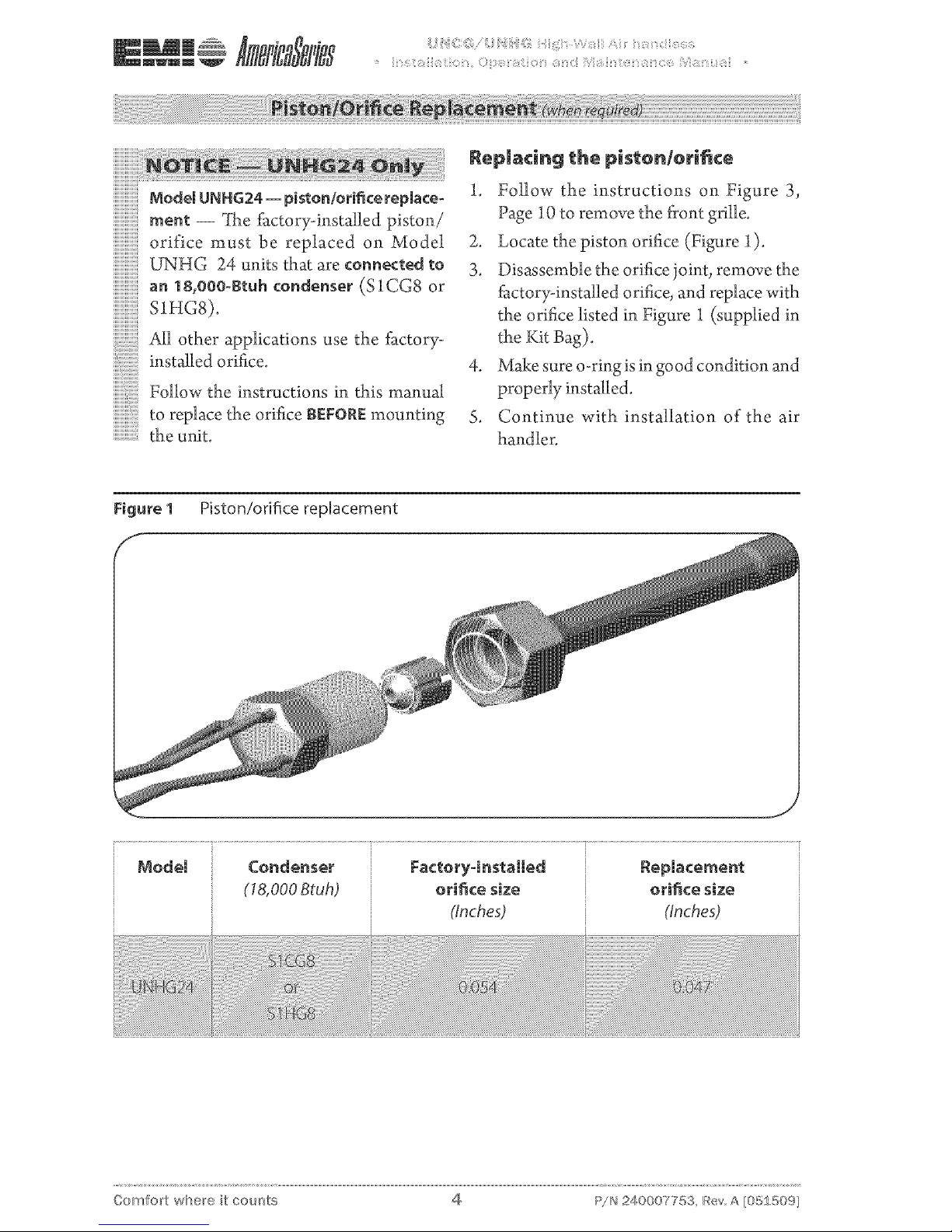

_odelUNHG24=piston/orificerepiace-

m_m-- _he_ctory-instaHedpiston/

orificemustbereplacedonMode_

UNHG 24 units that are connected to

.adl other applications use the factory-

installed orifice.

Follow the instructions in this manual

toreplacetheorifice_EFOREmounting

the unit.

Rep_a¢in_ {he Dis{on/orifice

1. Follow the instructions on Figure 3,

Page 10 to remove the front grille.

2. Locate the piston orifice (Figure 1).

3. Disassemble the orifice joint, remove the

factory-installed orifice, and replace with

the orifice listed in Figure I (supplied in

the Kit Bag).

4. Make sure o-ringis in good condition and

properly installed.

S. Continue with installation of the air

handler.

Figure I Piston/orifice replacement

_ode_ Condenser Factoryqnstalled Replacement

(18,000Btuh) orifice size orifice size

(Inches.} (Inches.}

Oomfort where it cou;'_ts 4 P!N 240007753, Bey A [05£50%

+ The AmericaSeries UNCG/UNHG

is available as a (Dx) direct expansion

straight cool and heat pump.

+ It offers a contemporary design in a

ductless type air handlers and combines

attractive appearance with high eNciency

conditioning for small to medium size

commercial or residential spaces.

The UNCG/UNHG is equipped with

unit mounted infrared compatible con-

trols which also supports 24V remote wall

thermostat operation. Optional handheld

remote is available.

Heat pump models provide up to

23,800 Bmh of cooling and 20,800 Btuh

of heating. Electric heat options are

available for up to S kW of supplemental

heat.

This American-made air handler of+

fers ease of installation, operation, and

service.

it can be matched with EMI's:

- Single-zone condensing units --

S1CG/SIHG 09-24 and $1CG 30.

Controls and components

{Factory-instaRed or supplied)

+ Large LCD Bacldit Display

Single unit-mounted control package,

configurable to either unit mount or re-

mote wall thermostat operation, increas-

ing installation flexibility.

Urlit mourfl: control -- Ifthe control is

configured for unit mount control DO

NOT connect a wall thermostat to the

unit. See Figure 27, Page 26+

+ Unit control can be used in cooling only,

cooling with electric heat, heat pump, or

heat pump with second stage electric heat

applications.

Operational range set point temperature

adjustable between SS°F and 90°F in one-

degree increments+

+ Infrared-compatible controller allows use

of optional IR hand held controller.

11111111111111111

S2CG/S2HG side discharge.

- Multi-zone, top discharge condens-

ing units -- T2CG/T2HG, T3CG/

T3HG, or T4CG/T4HG+

All EMI air handlers are backed by En-

viromaster international LLC and are

tested and rated in accordance with AR1

standards 210/240 and UL 199S+

Dual-zone condensing units -- +++++++++++++++++Unit-mounted controls are fhlly l_nc-

+++++++++++++++++tional without the handheld remote.

+ Operation modes include Heat, Cool,

Dry, Fan and Auto Change-over+

Fan Operation - Auto/On+ High or Low

speed fan

Fan Purge - Fan remains on for 60 sec-

onds after Heat/Cool call is dropped for

improved eNciency (Auto mode only)

Room air sampling -- Selectable time

intervals ensure the fan will cycle on peri-

odically, in Auto Fan Mode to help elimi-

nate room temperature stratification+

• Selectable Fahrenheit (°F) orCelsius (°C)

temperature scale.

• Drymode- Operates coolingand electric

heat simultaneously to remove humidity.

Optional electric heat must be selected.

• Anti-Short Cycle Compressor Protec-

tion.

c

:_/N 240007753, Bey A [05150% 5 Made i_ the OoA

• Minimum on time forbearing and cooling

Helps eliminate room temperature drop

and system short cycling.

• Freeze Protection - Prevents airhandlers

freeze up.

• Test operation- Allows easeoftesting af-

ter installaion (alltimers are reduced).

• Non-volatile back-up memory willmain-

tain control se_ings for an indefinite pe-

riod during apower outage. When power

is restored the equipment will resume

operation after a three-minute compres-

sor time delay.

• 7-dayprogrammable with copyfeature.

• Filter change indicator: A timer feature

indicaes when the filter shouldbe cleaned

according to the selected time.

• Modular design- reduces parts required

for control package. Deco panel, relay

board, ribbon cablesand microprocessor

are combined into one package.

• integral condensae pump safety-switch

connection where-by the microproces-

sor monitors the condensate pump safety

switch and displays an error code when a

fault occurs. (.Appliesonly with optional

condensae pump).

• CEC (California Energy Commission)

compliant.

• Condensae drainpan over flowprotec-

tion.

Optional Equipment

• Condensate pump (field installed only).

• 24V remote wall thermostat.

• Electric heat with automatic reset high

temperature cutout and redundant high

temperature _se link (when heat option

is selected).

• Hand-held infrared controller.

The control is configured for unit-

mountedcontrol(factorydefault).DO

NOT connect a wall thermostat to the

unit without changing configuration.

installer Supplied items

• Low voltage wiring (18 awg required).

• High voltage power supply wiring.

• Mounting screws and fasteners.

• Condensate piping.

• Refrigerant piping (if not supplied).

• Refrigerant (for interconnect charge).

Check equipment for damage prior

..................to installation, if damaged contact the

iiiiiiiiiiiiiiii_

wholesale distributor.

Cabinet Features:

• Easily accessible, washable, reusable,

nylon mesh filter.

• Easy access to piping connections and

condensate pump allows installation with

the unit mounted in place.

• Condensate drain pan constructed ofgal-

vanized steel (G90U), with anti-corrosion

coating.

• Modular snap-in, 7-day programmable

control with large bacldit LCD display,

a "Change filter" display feature and se-

lectable Fahrenheit (°F), or Celsius (°C)

temperature scale.

_e_ore ir_{aRin_, ¢o_sider:

• Determinethebestlocation_brmounting

the unit for room air circulation.

Locate outdoor and indoor units as close

together as possible.

Determine how power wire (high and

low voltage) condensate drainage, and

refrigerant piping maybe mn to and from

the unit.

• UNCG/UNHG - Ensure that intercon-

nect tubing is within the limits listed in

Table 2, Page 7.

Oomfort where it cour_ts @ P!N 240007753, Bey A [05£50%

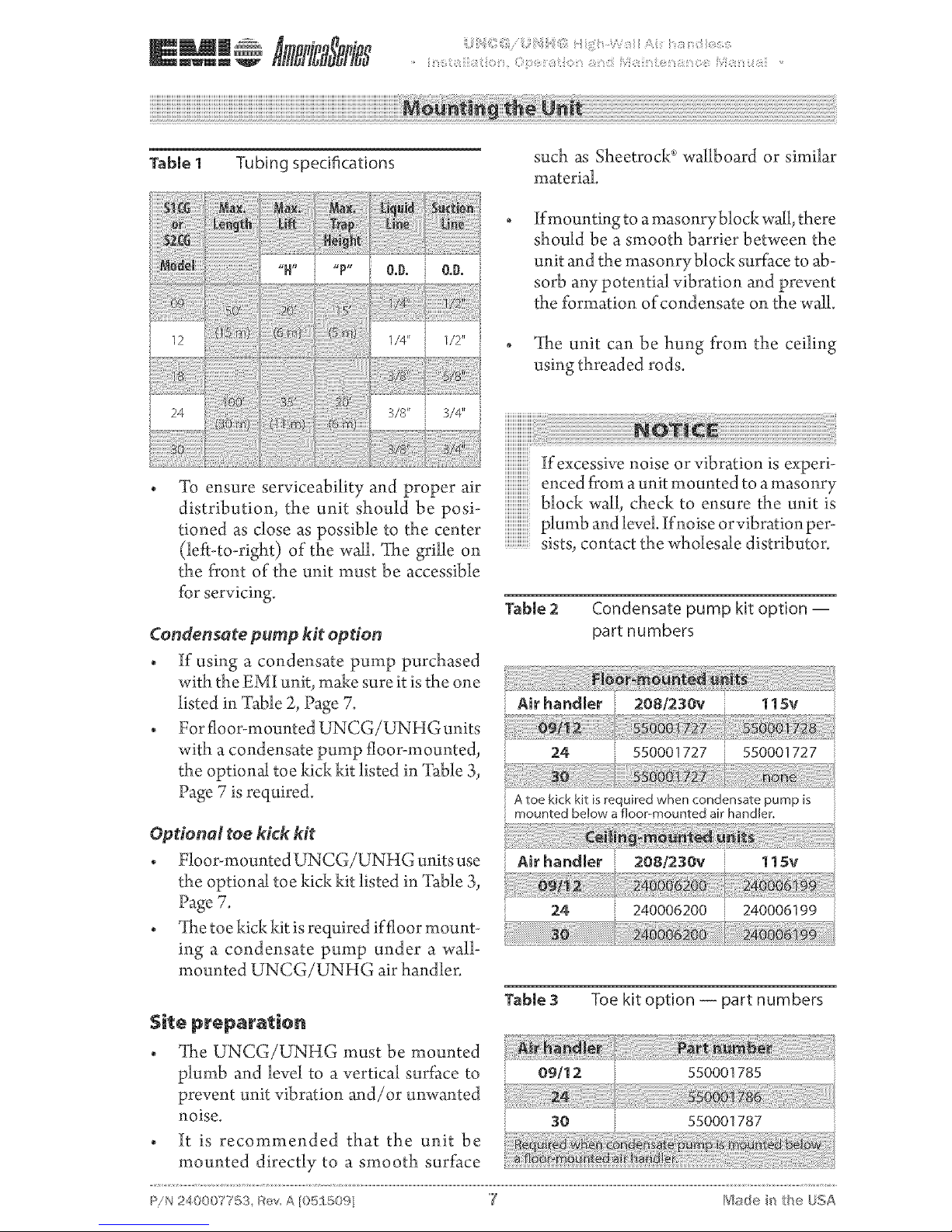

Table 1 Tubing specifications

O.D. O.D.

12

24

To ensure serviceability and proper air

distribution, the unit should be posi-

tioned as close as possible to the center

(left-to-right) of the wall. ?{laegrille on

the front of the unit must be accessible

for servicing.

Condensate pump kit option

• if using a condensate pump purchased

with the EMI unit, make sure it is the one

listed in "Fable 2, Page 7.

• For floor-mounted UNCG/UNHG units

with a condensate pump floor-mounted,

the optional toe kick kit listed in "Fable 3,

Page 7 is required.

Optional toekick Mt

• Floor-mountedUNCG/UNHG unitsuse

the optional toe kick kit listed in "Fable 3,

Page 7.

• _[he toe kick kit isrequired if floor mount-

ing a condensate pump under a wall-

mounted UNCG/UNHG air handler.

such as Sheetrock _ wallboard or similar

material.

If mounting to amasonryblock wall, there

should be a smooth barrier between the

unit and the masonryblock surface to ab-

sorb any potential vibration and prevent

the formation of condensate on the wall.

tltae unit can be hung from the ceiling

using threaded rods.

If excessive noise or vibration is experi-

enced from a unit mounted to a masonry

iiiiiiiiiiiiiiii_

block wall, check to ensure the unit is

plumb and level If noise orvibration per-

sists, contact the wholesale distributor.

Table 2

Condensate pump kit option --

part numbers

Air handler 208/230v

24 550001727

11Sv

550001727

;; A toe kick kit is required when condensate pump is

mounted beJow a floor-mounted air handler,

Air handler 208/230v 115v

24 240006200 240006199

Table 3 Toe kit option -- part numbers

• _ltle UNCG/UNHG must be mounted

plumb and level to a vertical surface to 09/12

prevent unit vibration and/or unwanted

noise. 30

• It is recommended that the unit be

mounted directly to a smooth surface

c

:_/N 240007T5a, Rev A [05_50% 7 I"_de i_ the [}o_A

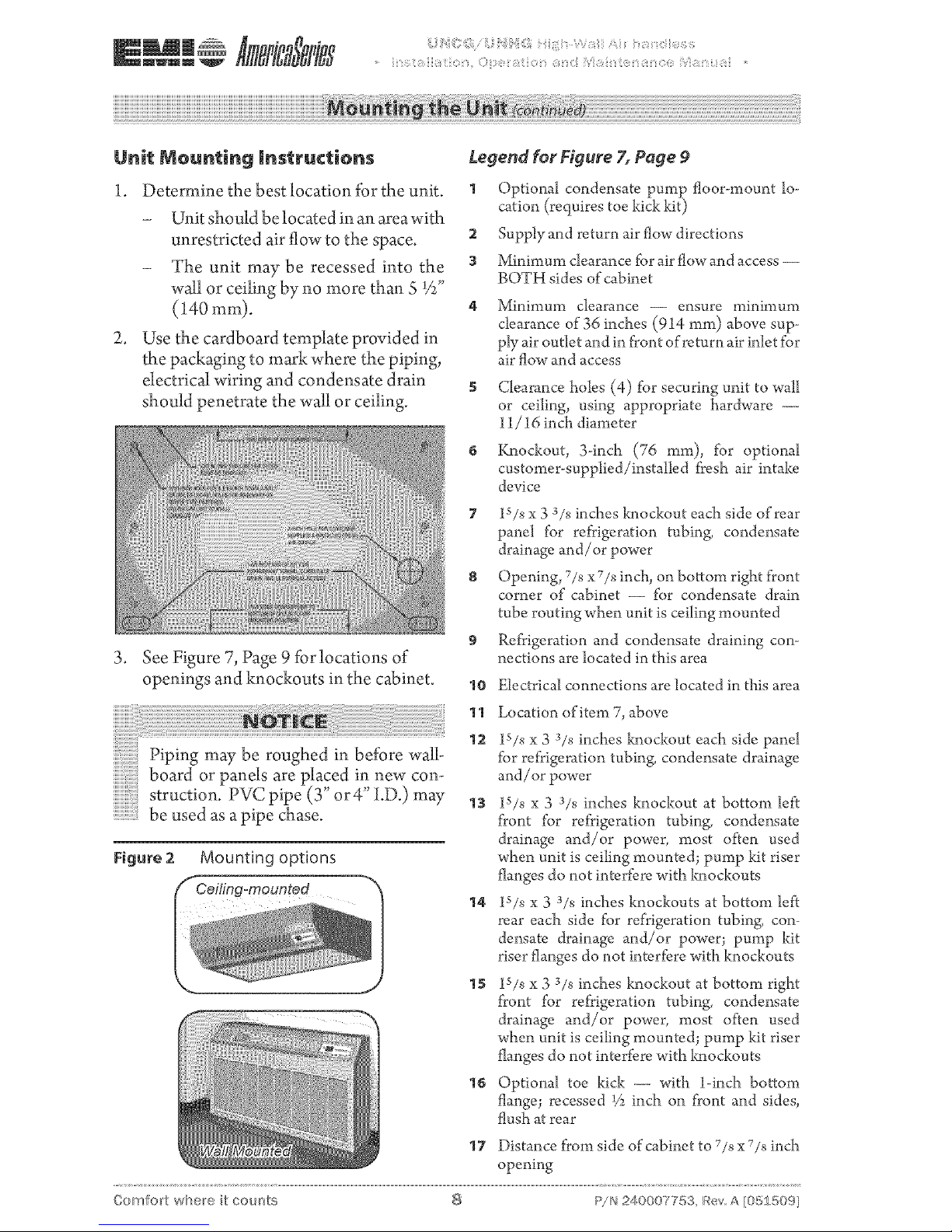

Unit Mounting instructions

1. Determine the best location for the unit.

Unit should be located in an area with

unrestricted air flow to the space.

The unit may be recessed into the

wall or ceiling by no more than 5 1/2"

(140 ram).

2.

Use the cardboard template provided in

the packaging to mark where the piping,

electrical wiring and condensate drain

should penetrate the wall or ceiling.

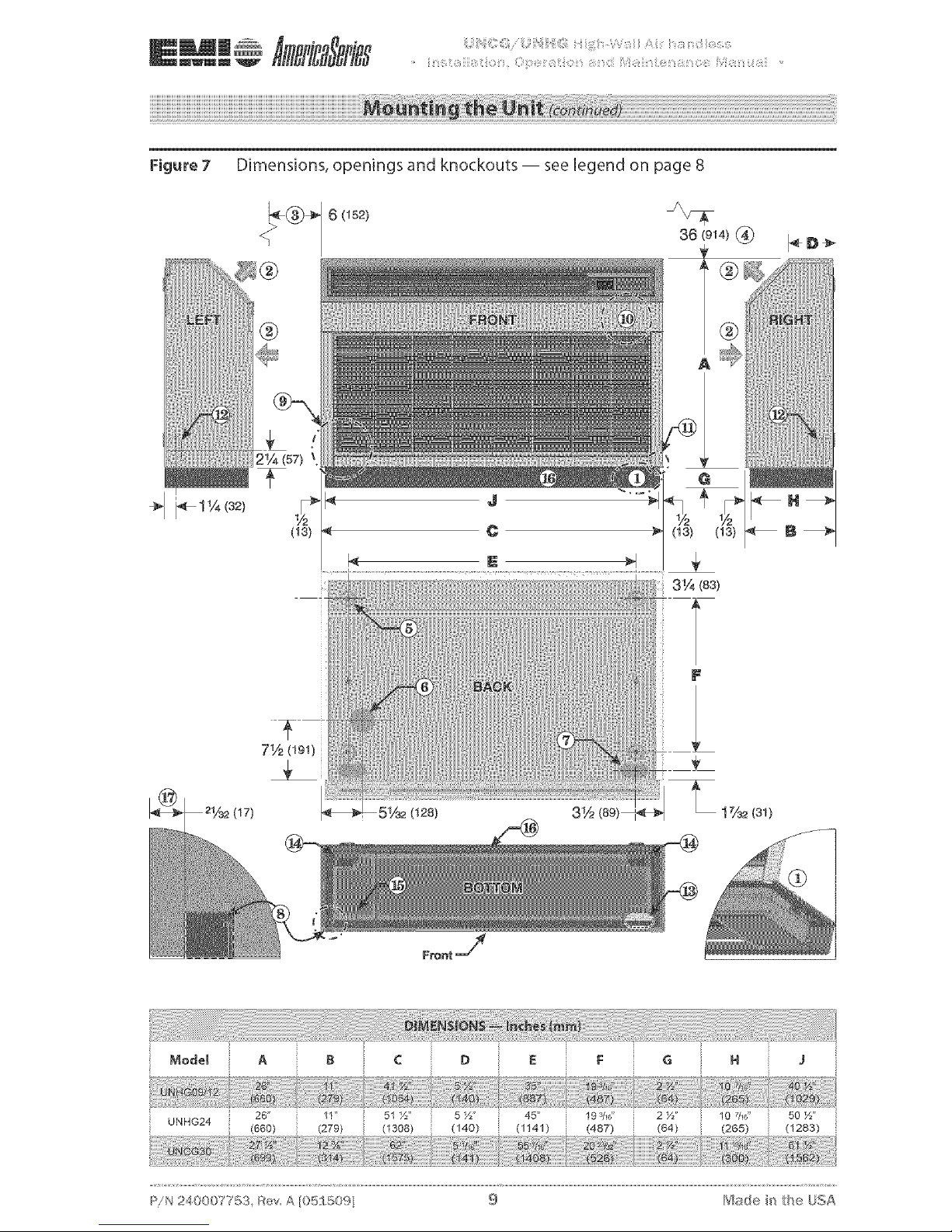

Legend for Figure 7, Page 9

1 Optional condensate pumi_ floor-laount lo-

cation (requires toe kick kit)

2 Supply and return air flow directions

3 Minimum clearance for air flow and access --

BOTH sides of cabinet

Minimum clearance -- ensure minimum

clearance of 36 inches (914 ram) above sup-

ply air outlet and in front of return air inlet for

air flow and access

Clearance holes (4) for securing unit to wall

or ceiling, using appropriate hardware --

11/16 inch diameter

Knockout, 3-inch (76 ram), for optional

customer-supplied/installed fresh air intake

device

3.

7 lS/s x 3 3/s inches knockout each side of rear

panel for refrigeration tubing, condensate

drainage and/or power

8 Opening, 7/s x 7/8 inch, on bottom right front

corner of cabinet -- for condensate drain

tube routing when unit is ceiling mounted

9

See Figure 7, Page 9 _k_rlocations of

openings and knockouts in the cabinet, 10

Refrigeration and condensate draining con-

nections are located in this area

Electrical connections are located in this area

Piping may be roughed in before wall-

board or panels are placed in new con-

struction. PVC pipe (3" or4" i.D.) may

be used as apipe chase.

Figure 2 Mounting options

11 Location of item 7, above

lS/s x 3 3/s inches knockout each side panel

for refrigeration tubing, condensate drainage

and/or power

13 lS/8 x 3 3/s inches knockout at bottom left

front for refrigeration tubing, condensate

drainage and/or power, most often used

when unit is ceiling mounted; pump kit riser

flanges do not interfere with knockouts

14 lS/8 x 3 3/s inches knockouts at bottom left

rear each side for refrigeration tubing, con-

densate drainage and/or power; pump kit

riser flanges do not interfere with knockouts

15 lS/8 x 3 3/s inches knockout at bottom right

front for refrigeration tubing, condensate

drainage and/or power, most often used

when unit is ceiling mounted; pump kit riser

flanges do not interfere with knockouts

16 Optional toe kick --- with 1-inch bottom

flange; recessed % inch on front and sides,

flush at rear

17 Distance from side of cabinet to 7/8x 7/s inch

opening

Comfort where it cour_ts 8 P!N24000TT5_, _ev A[05:1_509]

Figure 7 Dimensions, openings and knockouts -- see legend on page 8

36 (914)

r

(13)

3V4(83)

3½

26" 11" 51 ½" 193/16" 2½" 10 7/16" 50 ½"

c

:_/N240007753, RevA[05S50% 9 I"£_adein the UoA

Donotinsta theunitin ocationswhere

curtainsordrapeswillobstructthesup-

pIyairgrille. Thismaycauseairtorecir-

culate without cooling the room, and

mayresult in premature system failure.

4.

S.

6.

Determine the appropriate hole size and

cut through the wall or ceiling.

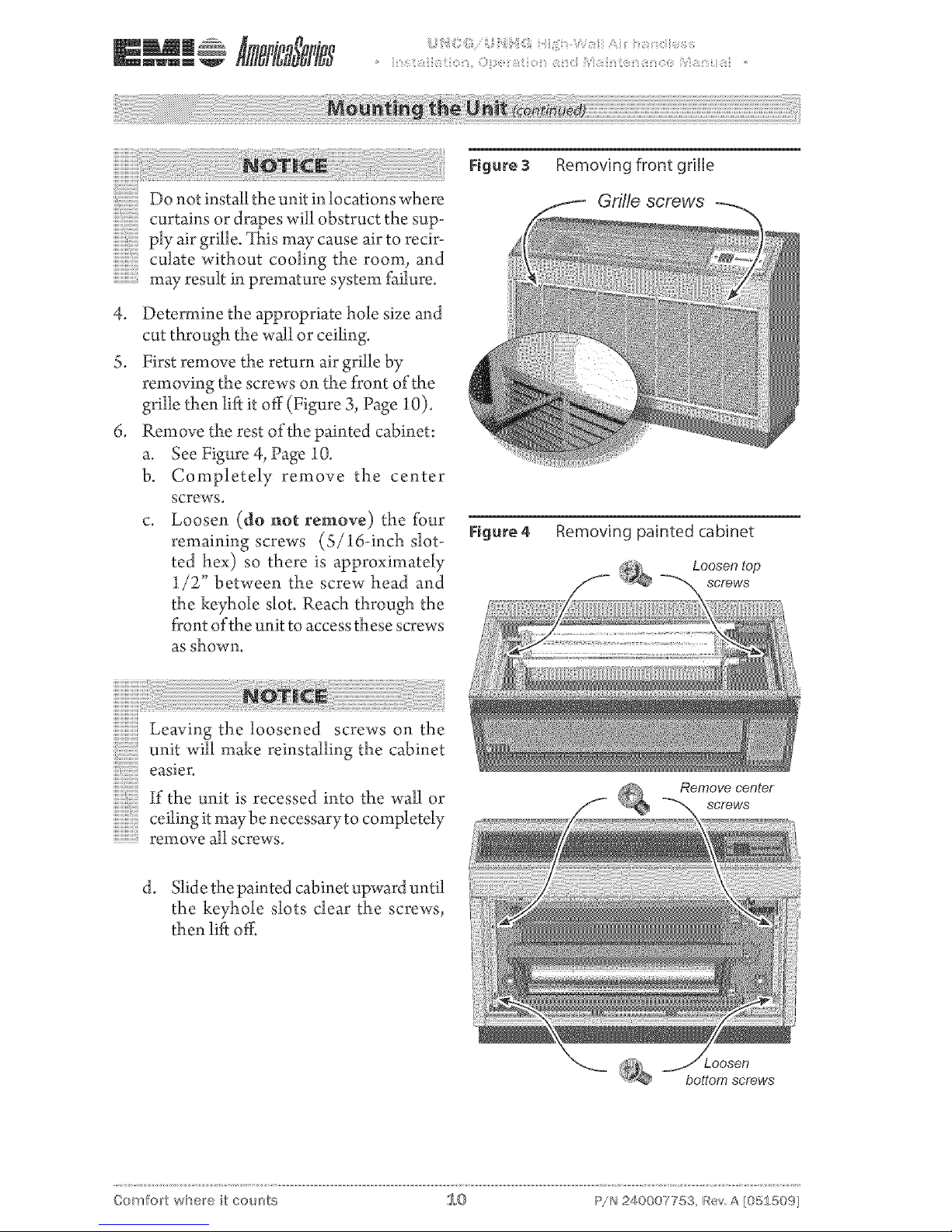

First remove the return air grille by

removing the screws on the front of the

grille then lift it off (Figure 3, Page 10).

Remove the rest of the painted cabinet:

a. See Figure 4, Page 10.

b. Completely remove the center

screws.

c. Loosen (do not remove) the t_ur

remaining screws (S/16-inch slot-

ted hex) so there is approximately

1/2" between the screw head and

the keyhole slot. Reach through the

front of the unit to access these screws

as ShOWn.

iiiiiiiiiiiiiiiiiiii!i!:i i!iiiiiiiii iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii!!ii!!ii i ! ! i iii! i !! !! !!i!i!iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii!!i!i!i!!i!!i!!i!!i!! i i i i i i i i i i i ! !i ! !!! ! i i i

_!_:_;_:_:_:_:_:_1_Lb_::_:_ '.................................__:_::_

Leaving the loosened screws on the

unitwillmakereinstallingthe cabinet

easier.

If the unit is recessed into the wall or

ceilingitmaybenecessarytocompletely

remove all screws.

d. Slide the painted cabinet upward until

the keyhole slots dear the screws,

then lift off.

Removing front grille

Gri//e screws

Figure 4 Removing painted cabinet

Loosen top

screws

Remove center

screws

bottom screws

Comfort where it cour_ts 1,,,0 P!N 240007753, Bey A :05150%

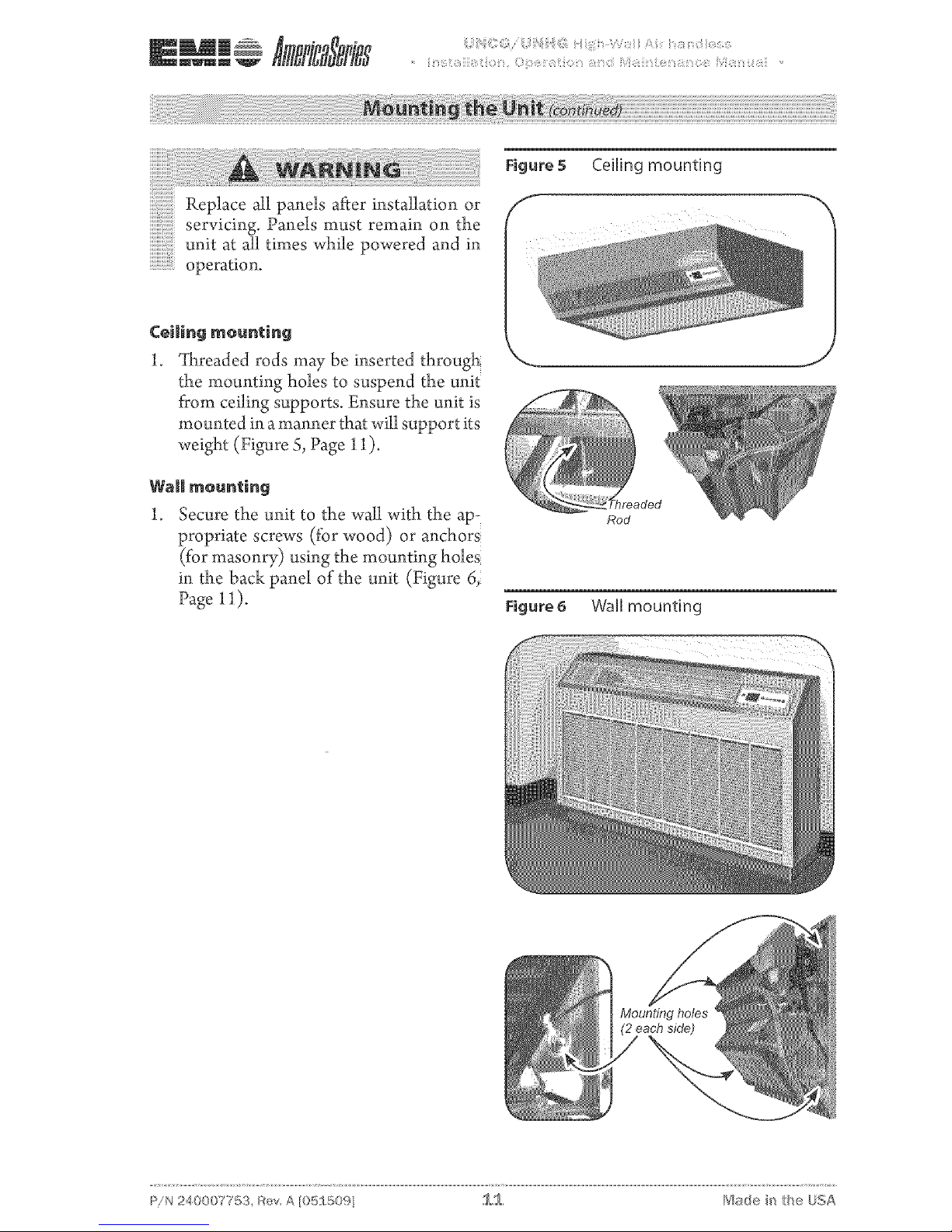

Replace all panels after installation or

servicing. Panels must remain on the

unit at all times while powered and in

operation.

Figure 5 Ceiling mounting

Ceiling meunting

].

_[lareaded rods may be inserted through

the mounting holes to suspend the unit

from ceiling supports. Ensure the unit is

mounted in a manner that will support its

weight (Figure S, Page 11 ).

Wall mounting

1. Secure the unit to the wail with the ap-

propriate screws (for wood) or anchors

(for masonry) using the mounting holes

in the back panel of the unit (Figure 6,

Page 11).

,._ j

Rod

Figure 6 Wail mounting

c

:_/N 240007753, Rev A [05_50% 1,,,1 I"_$adei_ the Uo_A

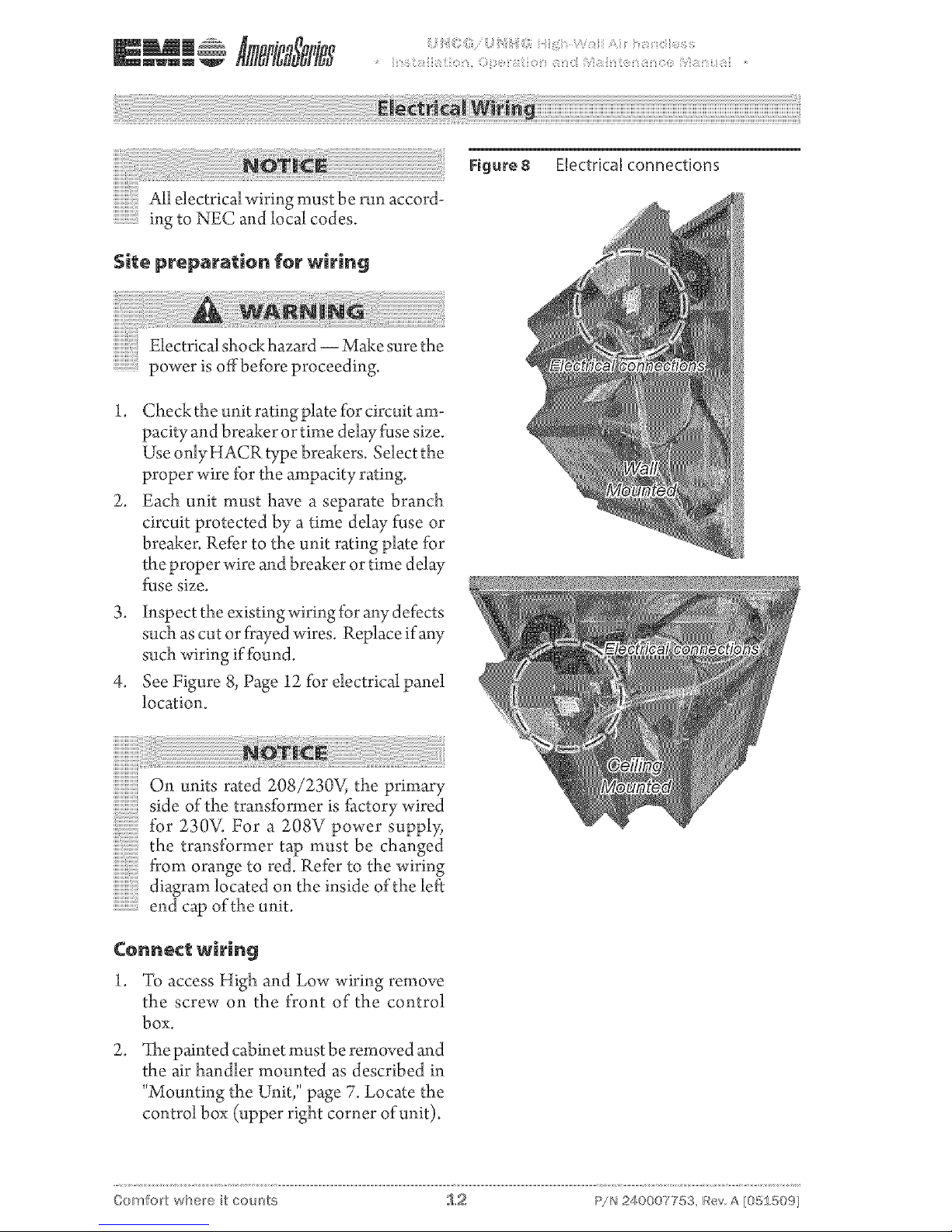

WWm m _ _ ii !!_!iii;ii_!:iiiii_!:i_:ii0 iii_ Ci_ii:_ii?_i__i!:ii;ii _::_iii_ _i!:ii_'i_:;{ii_fii¸_!i!iii:i_ii::_ilii:i__i;i!i:i_0 _ii_ i_fii¸_!i!i:i_ib_;_ti_ii ....

Electrical connections

Electrical shock hazard -- Make sure the

power is offbefbre proceeding.

1. Check the unit rating plate for circuit am-

pacity and breaker or time delay fEse size.

Use onlyHACRtype breakers. Selectthe

proper wire fk_rthe ampacity rating.

2. Each unit must have a separate branch

circuit protected by a time delay fEse or

breaker. Refer to the unit rating plate for

the proper wire and breaker or time delay

fuse size.

3. inspect the existing wiring fbr any defects

such as cut or flayed wires. Replace if any

such wiring if found.

4. See Figure 8, Page 12 for electrical panel

location.

iiiiiiiiiiiiiiiiii

On units rated 208/230V, the primary

sideofthetransfbrmerisfactorywired

fk_r 230V. For a 208V power supply_

the transformertap mustbe changed

from orange to red. Ref)r to the wiring

diagramlocatedontheinsideoftheleft

end cap of the unit.

Ce_e¢_ wiring

1. To access High and Low wiring remove

the screw on the front of the control

box.

2.

_[he painted cabinet must be removed and

the air handler mounted as described in

"Mounting the Unit," page 7. Locate the

control box (upper right corner of unit).

Comfort where it cour_ts 1.2 P!N 240007753, Bey A [05£509]

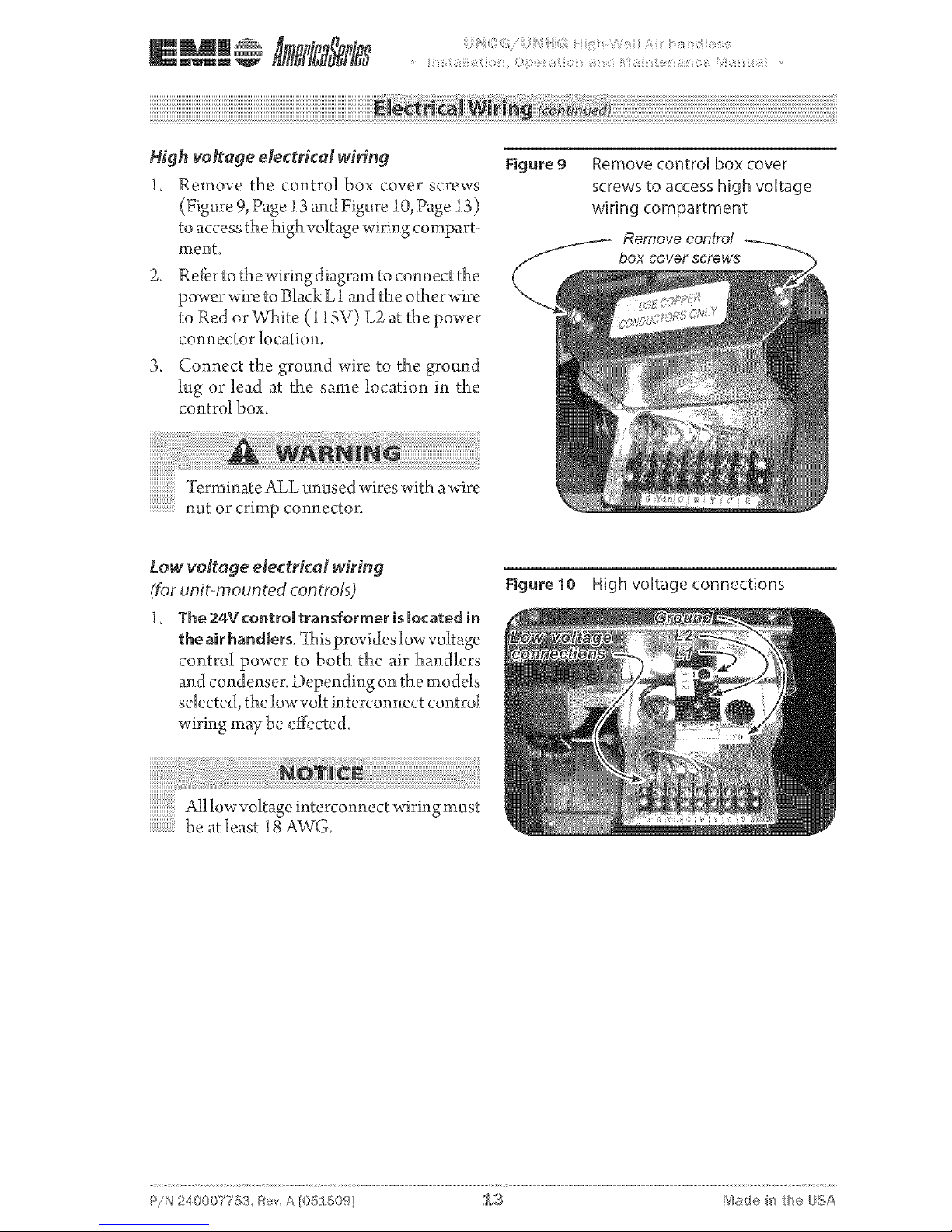

High volfage electrical wiring

1. Remove the control box cover screws

(Figure 9, Page 13 and Figure 10, Page 13)

to access the high voltage wiring compart-

ment.

2.

Refer to the wiring diagram to connect the

power wire to Black L 1 and the other wire

to Red or VVl_ite(11SV) L2 at the power

connector location.

3. Connect the ground wire to the ground

lug or lead at the same location in the

control box.

Figure 9

Remove control box cover

screws to access high voltage

wiring compartment

Remove contro!

box cover screws

Terminate ALL unused wires with awire

nut or crimp connector.

Low voltage electrical wiring

(for unit-moun ted controis)

1. The 24V controJ transformer is located in

the air handlers. _ltxisprovides low voltage

control power to both the air handlers

and condenser. Depending on the models

selected, the low volt interconnect control

wiring ruay be effected.

Figure 10 High voltage connections

All low voltage interconnect wiring must

be at least 18 AWG.

c

:_/N 240007753, Bey A [05_50% 1.3 1"_$8d@ i_ the OoA

Units with or without heat

llowvoltageinterconnectwiringmust

be at least 18 AWG.

Cooling-only

Cooling only units utilize two low volt in-

terconnecting wires between the indoor and

outdoor units.

Wires designated "¥" (yellow) and "C"

(brown) of the air handler should be con-

nected to the corresponding "Y" (yellow)

and "C" (brown) wires or terminals of the

condenser (Figure 11, Page 14).

Other wires or terminals such as "R" (red) or

"O" (orange) may not be needed and should

be protected by a wire nut from making

contact with the iunction box or other metal

surfaces.

Heat pump connection

Heat Pump Connection: In addition to the

"Y" and "C" connections required for cooling!

heat pumps require a reversing valve control

wire "O" (orange) that is energized in the

cooling mode.

Kthe indoor unit has an electric heater! then

a "W" (white) wire connection will also be

needed to energize the indoor electric heat.

Ka remote thermostat is used.

Heat pumps models require an "R" conneco

tion between the indoor and outdoor unit to

provide power to the defrost control board in

the condenser (Figure 12, Page 14).

Figure 11 Unit-mounted controls--

cooling only

Unit mount control configuration

Straight Cool Applications

O.D, UNIT __ ID. UNIT

1 l I (_o WNr _ 1

NOT USED (G) GRN @ I

!

Figure 12 Unit-mounted controls--

heat pump connection, two-

stage heating

F

Unit mount contro/ configuration

Heat Pump Applications

O,D. UNIT LD, UNIT

[ (g) YEL /;;-- 4

NOT USED (gO BLK

** - E/ectric heat o_tion

J

J

Comfort where it cour_ts 1,,,4 P!N 240007753, Bey A [05£509]

Remote thermestat centrols

.............................Unit mount control If the control

iiiiiiiiiii:i:i:i:i:i:i:iis configured for unit mount control

iiiiiiiiiiiiiiiiiiiiiiiii!i!i!!iDON©Tconnectawallthermostatto

the unit.

The 24V control transformer is located in the

air handier unit. 7his provides lowvolt control

power to both the air handler and condenser.

Depending on the models selected, the inter-

connect control wiring may be effected.

Figure13 Remotewall=mounted thermo-

stat configuration --

cooling only

Remote wall mounted thermostat configuration

Straight Cool Applications

O,D, UNIT i.D. UNIT OPTIONAL WALL T'STAT

* - Some thermostats do not

use a "C _ terminal

Choosing a remote wall=mounted

thermostat

See page 33 for wall thermostat control

operation.

Depending on the thermostat required or se-

lected, air handlers may utilize four to six low

volt interconnectingwires between the indoor

unit, thermostat and outdoor unit.

Some thermostats do not require the use of

the "C" (brown) connection. In this case,

ensure that any unused wires are insulated

with a wire nut to prevent them from making

contact with the junction box or other metal

surfaces.

c

:_/N 240007753, Bey, A [05_ 50% 1.5 1"_$sde i_ the Oo,A

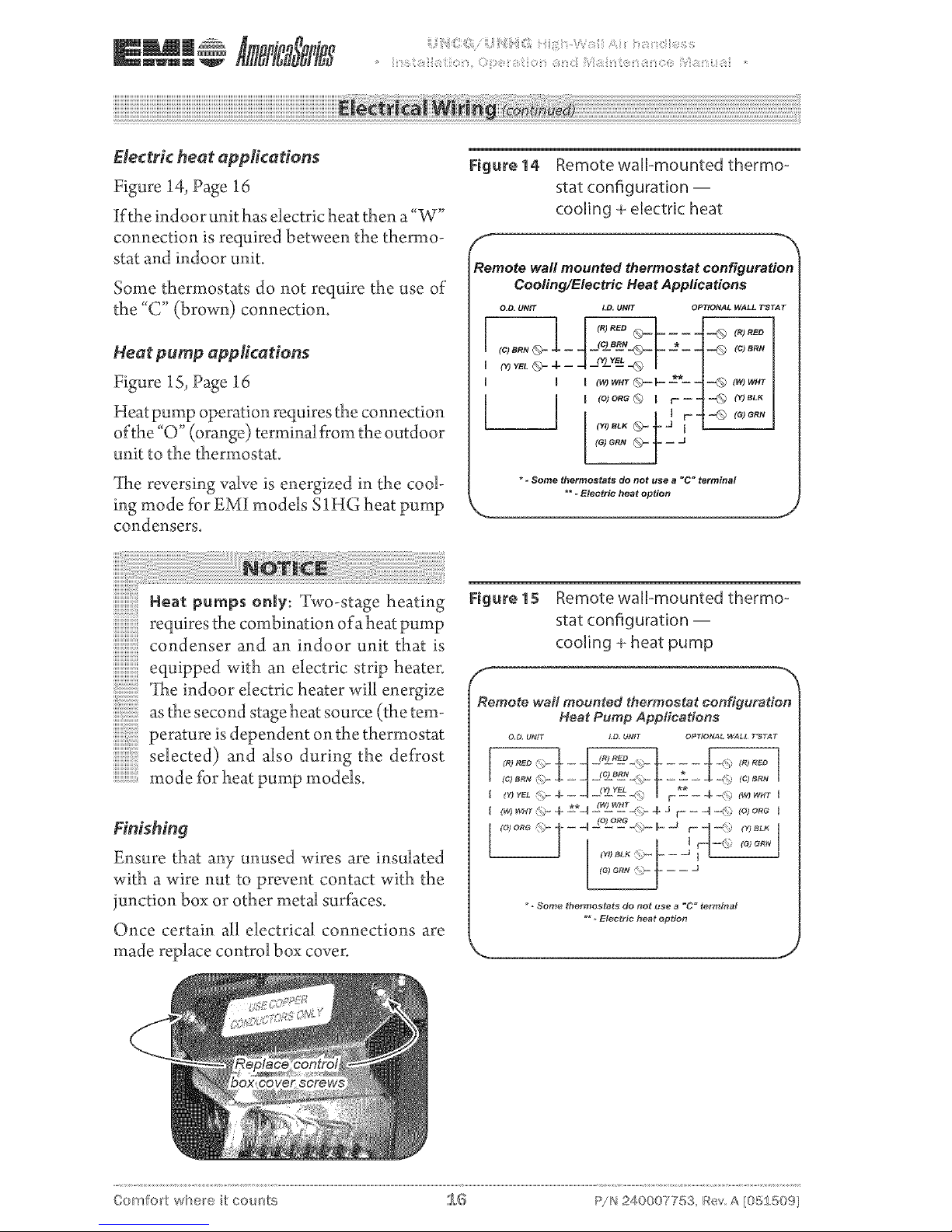

Electric heat applications

Figure 14, Page 16

If the indoor unit has electric heat then a"W"

connection is required between the thermo-

stat and indoor unit.

Some thermostats do not require the use of

the "C" (brown) connection.

Heat pump appfications

Figure 15, Page 16

Heat pump operation requires the connection

ofthe "O" (orange) terminal from the outdoor

unit to the thermostat.

_[he reversing valve is energized in the cool-

ing mode for EMI models SIHG heat pump

condensers.

Figure 14 Remote wall=mounted thermo=

stat configuration --

cooling + electric heat

Remote wall mounted thermostat configuration

Cooling/Electric Heat Applications

O,O. UNIT LD, UNIT OPTIONAL WALL T'STAT

* - Some thermostats do not use a "C" terminal

\ ... ,oot,oooo,opt,oo J

Heat pureps only: Two-stage heating

requires the combination of aheat pump

condenser and an indoor unit that is

equipped with an electric strip heater.

_Ihe indoor electric heater will energize

as the second stage heat source (the tem-

perature is dependent on the thermostat

selected) and also during the de*¥ost

mode for heat pump models.

Finishing

Ensure that any unused wires are insulated

with a wire nut to prevent contact with the

junction box or other metal surfaces.

Once certain all electrical connections are

made replace control box cover.

Figure 15 Remote wall=mounted thermo=

stat configuration --

cooling + heat pump

Remote wall mounted thermostat configuration

Heat Pump Applications

OD UNIT ID UNIT Of_T_ONAt WA_L TSTAT

F -- -- -_ -4\¢ (_ wHr [

I (w) w_T 4 ±*q 2wL_E_<_- 4- J r- - 4 _ to) ore I

* _ Some _hermos_ats do l_ot use a _C _ terminal

** _ Electrfc hea_ option

J

Comfort where it cour_ts 1,,,@ P/N 240007753, Rev A [05250%

Loading...

Loading...