EMI S2H User Manual

S2H

ductLeSS SpLit SYStem

duaL-Zone Heat pump condenSinG unit

P/N# 240006613, Rev. A [06/08]

Compressors - Hermetically sealed high efciency

rotary compressors. Motors are PSC type with inherent

overload protection.

Condenser Fan/Motor - The condenser fan is a large

diameter, high efciency propeller type, which is directly

connected to the totally enclosed PSC motor. The S2H

units are draw-through airow design and the PSC motor

is tted with internal overload protection.

Condenser Coil - Condenser coils are seamless cop-

per tubing arranged in staggered conguration with

enhanced aluminum ns tested to 460psig. The tubes

are mechanically expanded for secure bonding to the

n shoulder.

Heat pump

Nominal Capacities:

9,000 and 12,000 Btuh

DESCRIPTION

EMI offers the nest high capacity dual zone outdoor

units in the ductless split market, the S2H High Capacity

Condensing Unit. The S2H allows the installation of two

circuits from a single outside location when space or aesthetic requirements limit the use of locations. The S2H has

easy access interconnect valves on the back of the unit

and each zone is independent so no mixing of refrigerant

will occur. All 9,000 and 12,000 Btuh units are equipped

with the Duratec Performance package which includes a

large capacity suction accumulator with surge bafes and

enhanced oil management and a factory installed solid

core lter drier.

All EMI products are subject to ongoing develop-

ment programs so design and specications may

change without notice.

Cabinet -

• Vertically arranged side discharge

CONDENSER STANDARD FEATURES

Refrigeration Circuits - The S2H is delivered with

pre-charged refrigerant for the condenser coils and

evaporators while charging of eld installed piping is

required. Unit refrigeration service valves are solid brass

for sweat connection. Solid core lter driers are factory

installed on all models.

Refrigerant Run Options - The standard system will

support refrigerant runs to the inside unit of 35’ of lift,

up to 100’ of interconnect.

Reverse Cycle Operation S2H - A four-way reversing

valve, solenoid activated by 24v, is energized for cooling operation. A TXV with internal check valve provides

proven operation through all temperature ranges when

in the heat pump mode.

Controls and Components:

• Compressor and fan motor contactor

• Capacitor

• Low Voltage terminals for evaporator

interconnection

• Large capacity suction accumulators

• Factory installed solid core lter drier

• Heat pump circuits equipped with thermostatically

controlled crankcase heater

• Common suction pressure access point

• Hard Start Assist

• Scratch and dent resistant injection molded front access panel

• Powder coated (2,000 hour salt spray tested) 18 and

20 gauge aluminized steel

• Concealed service valves

• Easy access hose connections at 45° from valve body

SpecificationS and performance

SYSTEM OPTIONS

• Sea Coast Style Coated Coils / Copper-Copper coils

• Wind Bafes - Louvers•

Web: http://www.enviromaster.comEnviromaster International LLC

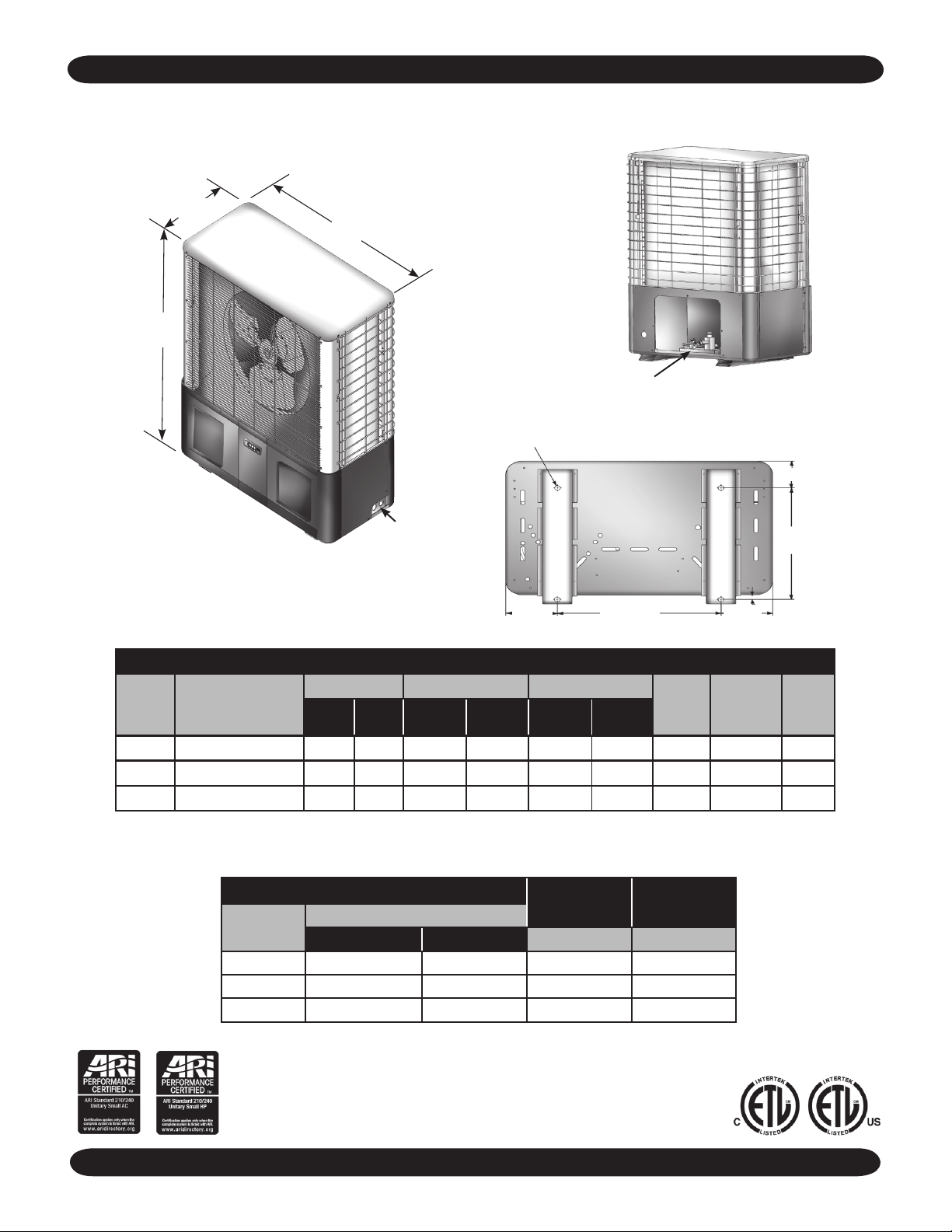

15”

44”

Front of unit

S2H DIMENSIONS AND SPECIFICATIONS

NOTE: All EMI products are subject to ongoing development programs so design and

specications may change without notice.

38”

Easy access interconnects

on back of unit

1/2” Diameter Lag Holes

Electrical

connections

3.00”

12.44”

28.74”

MODEL

(1)

VOLTS/HZ/PHASE

4.63”

S2H

ELECTRICAL SPECIFICATIONS

FAN COMPRESSOR 1 COMPRESSOR 2

RLA HP RLA LRA RLA LRA

TOTAL

AMPS

4.63”

MIN. CIR.

AMPS

(2)

HACR

BRKR

9900 208-230/60/1 1.8 0.33 3.4 23 3.4 23 8.6 9.5 15

2200 208-230/60/1 1.8 0.33 4.3 27 4.3 27 10.4 11.5 15

9200 208-230/60/1 1.8 0.33 3.4 23 4.3 27 9.5 10.6 15

(1) Circuit Designators: 9 = 9,000 Btuh • 2 = 12,000 Btuh (ex. - Model 9200 consists of one 9,000 Btuh compressor and one 12,000 Btuh compressor)

(2) Always refer to the rating plate for Minimum Circuit Ampacity on all multiple compressor units.

S2H PIPING SPECIFICATIONS

Model#

9900 1/4” 1/2”

2200 1/4” 1/2”

9200 1/4” 1/2”

Line Sizes

Liquid Suction

SOUND DATA

dBA Lbs.

64

65

65

SHIPPING

WEIGHT

159

197

187

Made in Rome, New York, USAS2HA High Capacity Condensing Unit

Loading...

Loading...