EMI S1C, S1H User Manual

S1C/S1H Single-Zone & S2C Dual-Zone

SiDe DiSCHarge DuCtleSS Split SyStem

ConDenSing unitS

Straight Cool/heat pump S1C/S1h

Nominal Circuit Capacities S1C/S1H:

9,000, 12,000, 18,000, 24,000 Btuh and

S1C 30-36 Btuh

Cooling only S2C

Nominal Circuit Capacities:

9,000-12,000 Btuh

S1C/S1h

Enviromaster International LLC

inStallation, operation anD maintenanCe manual

5780 Success Dr.

Rome, NY 13440

www.enviromaster.com

S2C

An ISO 9001-2000 Certied Company

P/N# 240005897 Rev. B [05/08]

S1C/S1H Single-Zone & S2C DUal-Zone

inStallation, operation anD maintenanCe manUal

This manual is intended as an aid to a qualied service personnel for proper installation,

operation, and maintenance of EMI AmericaSeries high efciency condensing units.

Carefully read these instructions before attempting installation or operation. Failure

to follow these instructions may result in improper installation, operation, service, or

maintenance, possibly resulting in re, electrical shock, property damage, personal

injury, or death.

Shipping Damage MUST be Reported to the Carrier IMMEDIATELY!!!

Examine the exterior. Remove cover and examine compressor and piping

for signs of damage.

ConDenSing UnitS

to tHe inStaller

(1) Retain this manual and warranty for future

reference.

(2) Before leaving the premises, review this

manual to be sure the unit has been

installed correctly and run the unit for

one complete cycle to make sure it

functions properly.

To obtain technical service or warranty

assistance during or after the installation

of this unit, check our website @ www.

enviromaster.com or call your installing

contractor or distributor. Our technical

service department may be contacted at

1-800-228-9364.

When calling for assistance, please have

the following information ready:

• Model Number___________________

• Serial Number___________________

• Date of installation________________

Danger

!

tampering with the emi americaSeries condensing unit is dangerous and may result in serious injury

or death. tampering voids all warranties. Do not attempt to modify or

change this unit in any way.

!

SaFetY inStrUCtionS

Read all instructions before using

the EMI AmericaSeries high ef-

ciency condensing unit. Install or

locate this unit only in accordance

with these instructions. Use this

unit only for its intended use as

described in this manual.

Check the rating plate on the EMI

AmericaSeries condensing unit

before installation to make certain

the voltage shown is the same as

the electric supply to the unit.

The EMI AmericaSeries condens-

ing unit must be connected only to

a properly grounded electrical sup-

ply. Do not fail to properly ground

this unit.

Turn off the electrical supply before

servicing the EMI AmericaSeries

condensing unit.

Do not use the EMI AmericaSeries

condensing unit if it has damaged

wiring, is not working properly, or

has been damaged or dropped.

[Save these instructions]

2

www.enviromaster.comSide Discharge Condensers

proDUCt DeSCription

The AmericaSeries S1C/H and S2C

condensing units are, air-cooled, vertically

arranged side discharge, high efciency

units designed specically to meet or ex-

ceed a 13 SEER rating.

The S1C 9,000-36,000 Btuh and S1H

9,000-24,000 Btuh capacity condensing unit

will provide cooling for a single evaporator,

as identied in the "S1C Specications and

Dimensions" section on pages 23-24.

The S2C 18,000 (99) - 21,000 (92) and

23,000 (22) Btuh capacity condensing units

will provide cooling for two evaporators, as

identied on page 25 in the "S2C Specica-

tions and Dimensions" section. The S1C/H

and S2C are quiet units that can be recom-

mended for both commercial and residential

applications.

Installation of the S1C/H and S2C

condensing units is simplied by a 24v

control interconnection from the evaporator

and multiple units can be lined up in close

proximity to an exterior wall. Service valves

are recessed to reduce tampering and

all 9,000-12,000 Btuh units are equipped

with a Duratec Performance Package that

includes an oversized suction accumula-

tor with surge bafes and enhanced oil

management, a factory installed solid core

lter drier and loss of charge switch. A eld

installed crankcase heater is standard on

S1H 09 &12 (Thermostatically controlled)

models, and is available as optional equip-

ment on other models.

inStaller SUpplieD itemS

• Power wiring

• Low volt wiring (18 awg minimum)

• Secure mounting pad or foundation

• Refrigerant piping (if not purchased

from EMI)

• High Volt Disconnect

• Refrigerant for charging interconnect

piping (see charge table on page 10)

itemS For ConSiDeration

ControlS anD ComponentS

(Factory Installed or Supplied)

• Compressor and fan motor contactor

• Run capacitor

• Loss of charge switch (09 - 12 only)

• Low voltage terminal connections

• Large capacity suction accumulator

(09 - 12 only)

• Solid core lter drier (09 - 12 only)

• Thermostatically controlled crankcase

heater (09 - 12 S1H’s)

• H.P.S. (High pressure switch)

- Standard on S1H’s (heat pumps)

- Standard on S1C’s 18K and above.

• Low Ambient controls

down to 32º F

stalled

on all S1H’s (heat pumps)

Thermostatically controlled crankcase

heater – This feature energizes the crank-

case heater only when needed, removes

the heater from the electrical circuit at

conditions where it’s not required, saving

unnecessary Watts, and increasing overall

system efciency.

for operation

standard,

factory in-

SYStem optionS

• Field installed crankcase heater

for straight cool units (standard on

9,000-12,000 Btuh S1H’s Thermostati-

cally controlled)

• Straight cool hard start (standard on

all S1H’s)

• 115v (9,000-12,000 Btuh only)

• Copper/copper coils (sea coast use)

• Low Ambient controls

to 32º F

, specify this option for S1C or

for operation down

S2C systems (standard on S1H’s) that

will be operated in cooling mode at

outside temperatures below 60º F

(eld

installed kit)

•

Low Ambient

for operation down to 0º F

for S1C, S1H or S2C systems (consult

factory for availability)

low ambient controls are required when

the system is asked to cool at outdoor temperatures below 60º F, this may cause dam-

age to the compressor and coil, and may

Side Discharge Condensers

3

www.enviromaster.com

SYStem optionS (cont.)

void the warranty. A Field Installed LowAmbient kit is good for operation down to

32º F.

This is accomplished by cycling the

condenser fan on and off, which will in turn

maintain a constant low side pressure pro-

viding a steady cooling effect and keeping

the air handler from frosting-up.

itemS For ConSiDeration

• Locate the unit as close to the indoor

section as possible. (See Tubing

Specications chart on pape 7.)

• If the unit is used for low ambient cool-

ing down to 32°F, this option must be

specied to prevent system damage.

• Avoid high trafc areas and prevailing

wind locations.

• Surface must be at and level.

• Mount unit above typical snow fall

levels.

Ensure free ow of air through the unit.

Air must not recirculate from discharge to

intake. Air is drawn through the coil and

side discharged through the fan grille. a

minimum 48" clearance is necessary for

the condenser discharge. rear intake

(coil side) clearance is 12" minimum.

Consider how power will be run to the unit

from the power source. Refrigerant piping

should be a direct line to the indoor unit.

inStallation inStrUCtionS

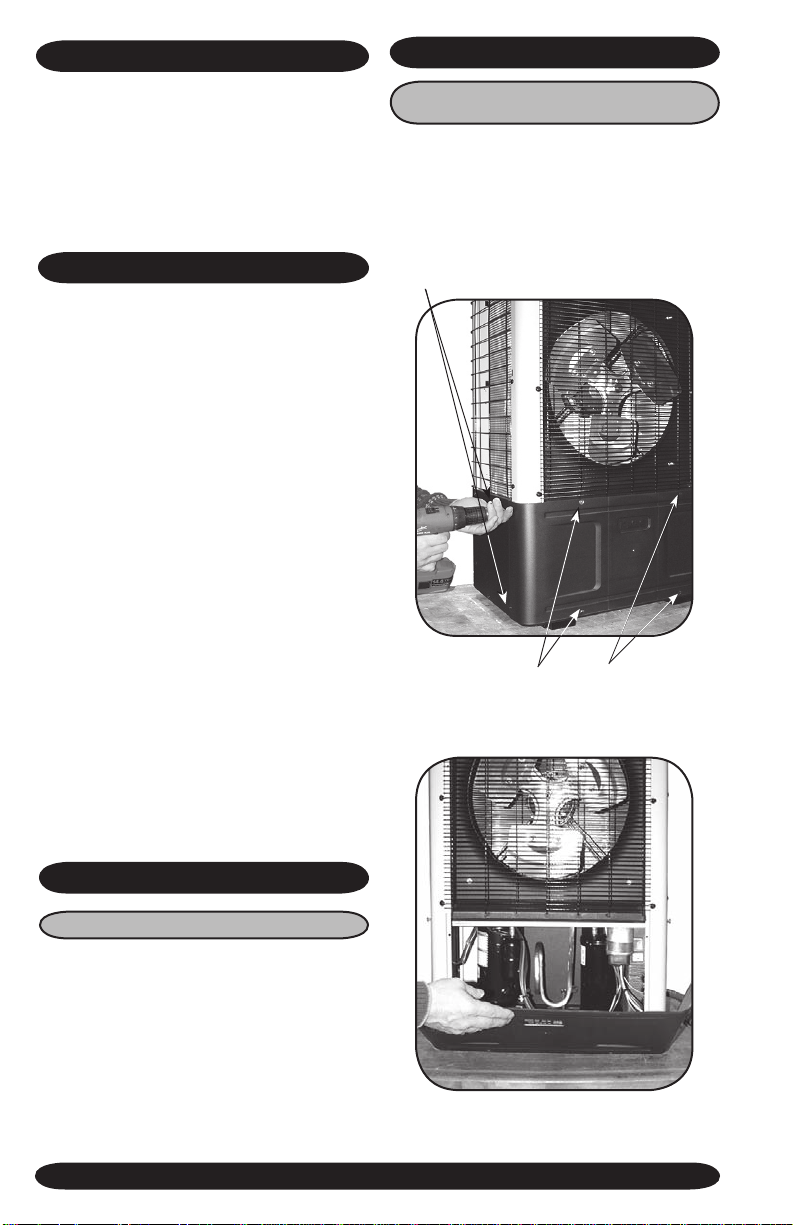

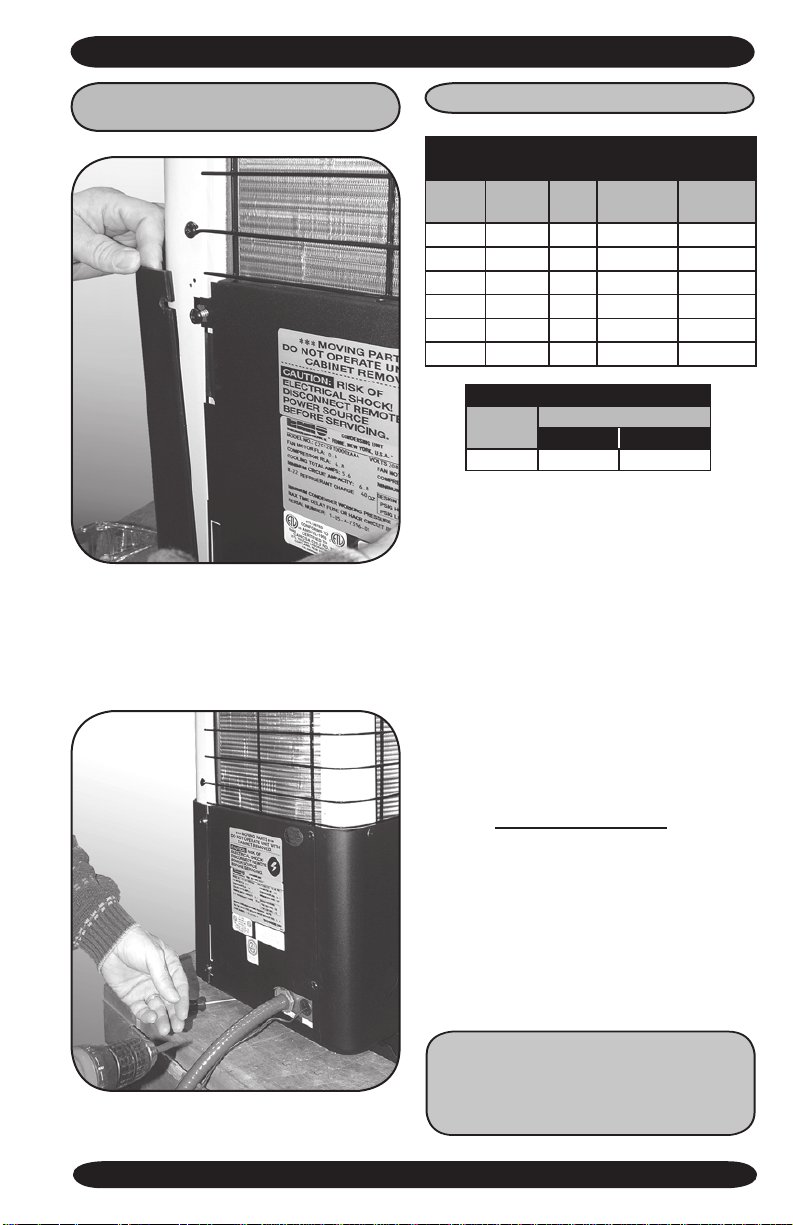

Unit moUnting inStrUCtionS

S1C is shown

Side discharge unit allows for per-

manent mounting through the feet. This is

highly recommended due to the vertical

design of the unit.

1. Loosen the screws on left and right sides

of the front panel. (Do not remove these

screws.)

2. Remove the screws on the front of the

panel.

3. To remove front panel:

inStallation inStrUCtionS

Site preparation

1. Place the unit on a at concrete surface

or pad if on the ground. Roof mounting

should use a build up platform to avoid

intake of hot air from the roof.

2. In areas of heavy snowfall, condensers should be set above the level of

maximum anticipated snowfall (12"

is usually adequate).

4. Slide front panel forward to clear side

screws and remove.

4

www.enviromaster.comSide Discharge Condensers

inStallation inStrUCtionS

Unit moUnting inStrUCtionS

Continued

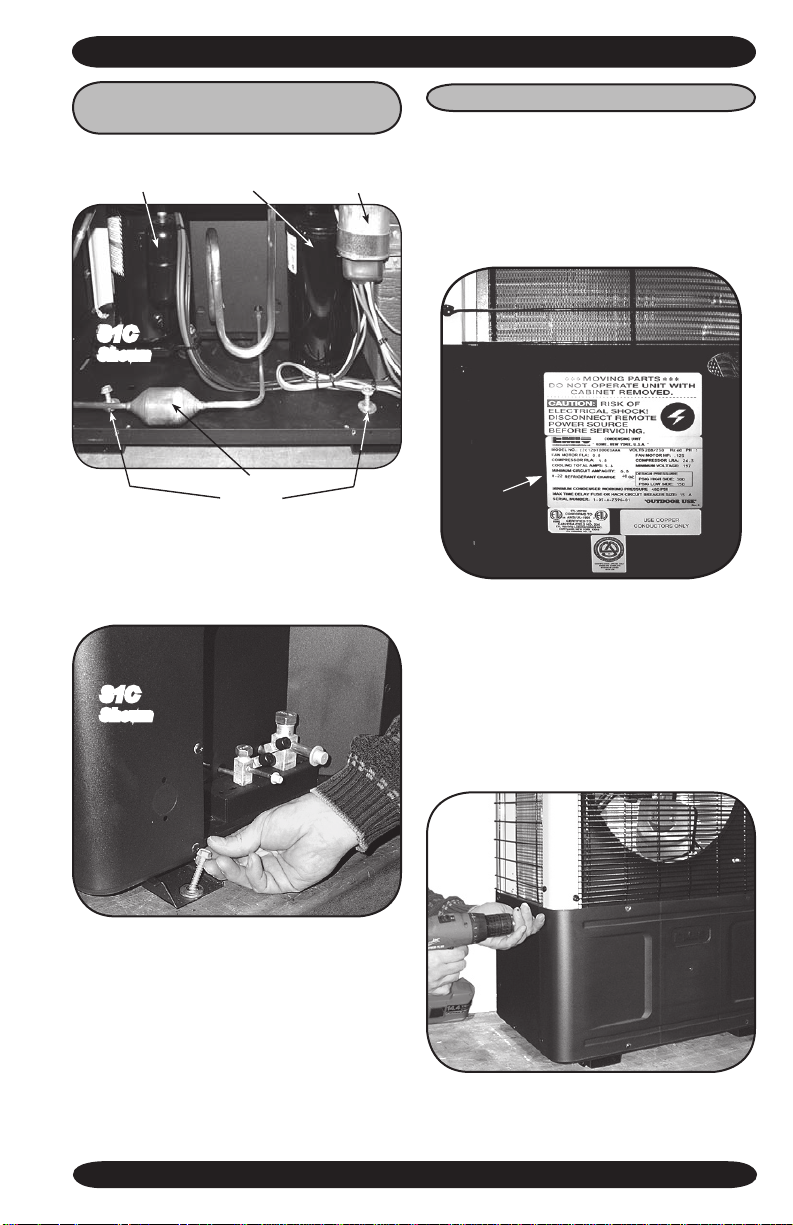

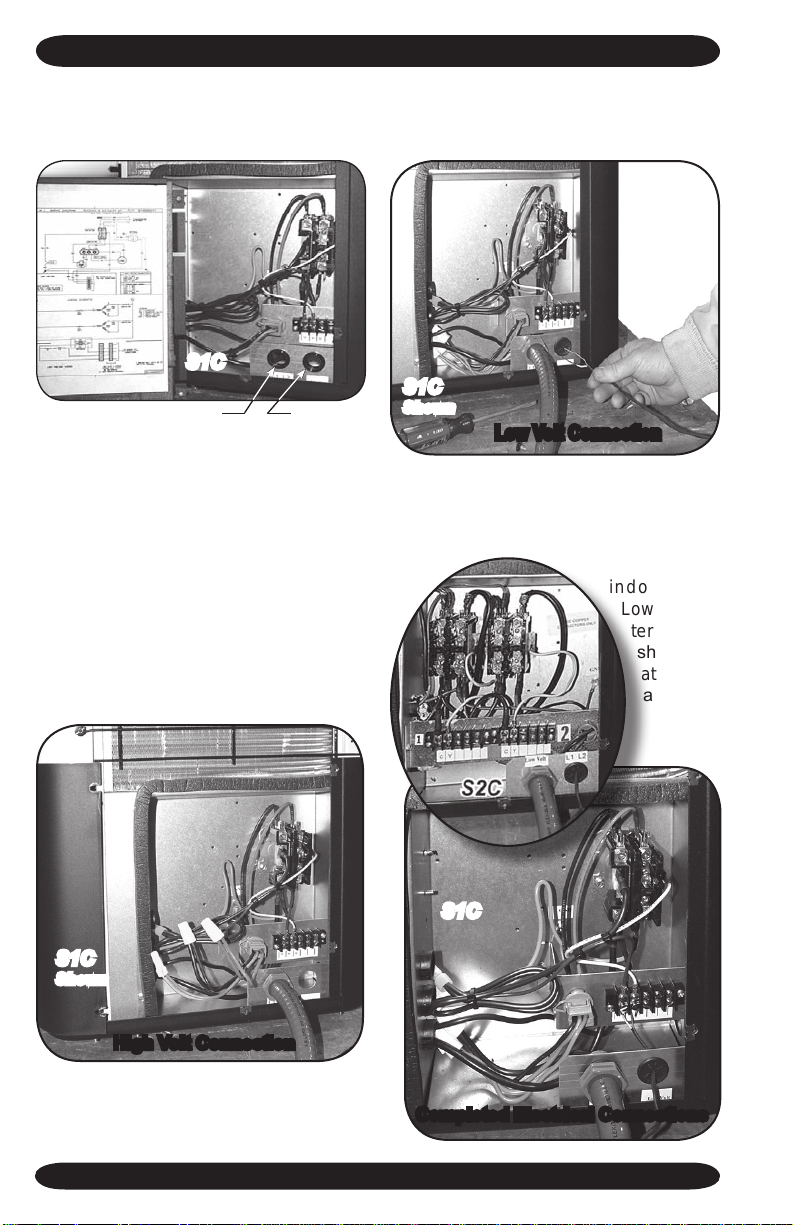

Compressor

Accumulator Capacitor

S1C

Shown

Filter Drier

Lag Bolts

5. Insert lag bolts through the holes in

the bottom of the unit and tighten to

secure.

S1C

Shown

eleCtriCal Wiring

1. All electrical wiring must be run accord-

ing to NEC and local codes.

2. Refer to the unit rating plate for voltage,

minimum circuit ampacity and over cur-

rent protection requirements.

Rating

Plate

3. Use only HACR type breakers or time

delay fuses. Select the wire size accord-

ing to the ampacity rating.

4. To access electrical connections and

wiring diagram:

a) Remove the screws on the side panel

adjacent to the back panel.

6. Insert lag bolts through the holes in the

feet on the back of the unit and tighten

to secure.

7. Replace the front panel, do not tighten

the side screws at this time.

Side Discharge Condensers

b) The screws adjacent to the front

panel should already be loose (don't

remove them).

5

www.enviromaster.com

inStallation inStrUCtionS

c. Slide the side panel out to access the

high/low electrical connections and

wire diagram.

S1C

High Volt

plastic edge guards

Note: Remove the plastic edge guards

from the holes and replace with a watertight strain relief tting (High V) and a split

grommet tting (low V)

5. Power should be run to a weather proof

disconnect box usually within 3 feet of

the unit.

6. From the disconnect box, run the power

through the 7/8" hole on the side of the

unit and into the electrical box and an-

chor with the strain relief tting.

Low Volt

8. Check wiring diagram for the required

number of low voltage wires to be run

between indoor and outdoor sections.

S1C

Shown

low Volt Connection

9. Connect the 24 volt wiring matching color

to color. Refer to the wiring diagram on

the inside panel of the condenser, and

a l s o refer to the wirin g

diagram on the

indoor unit.

Low volt in-

terconnect

should be

at least 18

awg.

S1C

Shown

High Volt Connection

7. Run wires to the high volt pigtail in the con-

trol box and attach L1 and L2 connections.

Also run green wire to ground wire.

S1C

Completed electrical Connections

6

www.enviromaster.comSide Discharge Condensers

inStallation inStrUCtionS

eleCtriCal Wiring

Continued

10. To replace side panel slide the slotted

holes of the panel onto the loosened

screws of the front panel so that the

edge of the front panel covers the edge

of the side panel.

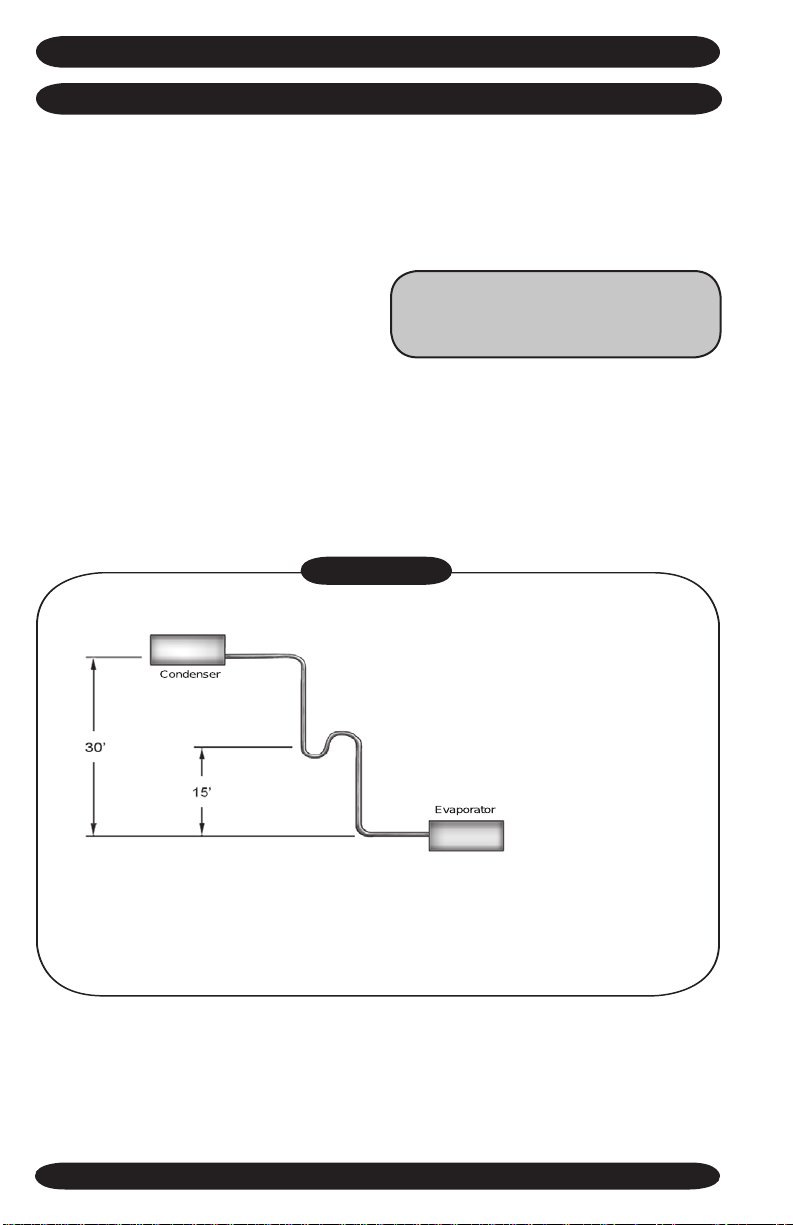

reFrigerant piping

interConneCting tUbing

SpeCiFiCationS

S1

maX.

max.

model

length

09 100’ 35’ 1/4" 1/2"

12 100’ 35’ 1/4" 1/2"

18 100’ 35’ 3/8" 5/8"

24 100’ 35’ 3/8" 3/4"

30 100’ 35’ 3/8" 3/4"

36 100’ 35’ 3/8" 3/4"

S2C tUbing SpeCiFiCationS

Circuit

Size

09, 12 1/4” 1/2”

liquid

lift

line o.D.

line Sizes o.D.

liquid Suction

Suction

line o.D.

The system will support refriger-

ant runs to the inside unit of up to 100'

equivalent feet with a 35' rise included.

The units are furnished with sweat con-

nections and are equipped with refrigerant

valves and Schrader ttings for charging

and taking pressure readings. The follow-

ing precautions should be made:

• Be certain no burrs remain on the

ttings.

• Use only clean refrigeration tubing.

• Use tube benders to guard against

kinking.

• Avoid piping on wet and rainy days

and insulate suction line. Be certain

that plastic end caps remain in place

when inserting through wall openings.

Isolate tubing from transmitting vibra-

tion to the building or unit and avoid

contact with sharp edges. refrigera-

tion valves should be wrapped with

a wet rag "heat sink" to protect

valves while brazing.

11. Fasten all remaining loose screws.

Side Discharge Condensers

note: It is recommended that a

lter drier be installed in liquid line, at

the indoor unit on models that a lter

drier is not already factory installed

(i.e. 18K and larger).

7

www.enviromaster.com

Condenser

Evaporator

inStallation inStrUCtionS

p-trap inStallation

• A P-trap is recommended when the suc-

tion riser is equal to or greater than 20

feet in height.

• When the condenser is installed above

the evaporator, the P-trap will help the

return of oil back to the compressor.

• The placement of the P-trap should be

at the halfway mark of the suction riser.

For example if the suction riser is 30 feet

tall then a P-trap is recommended at the

15 foot mark of the suction riser (see

Figure 1).

• A P-trap may be fabricated using (2) street

elbows and (2) regular elbow. A prefab-

Figure 1

Condenser

ricated trap may be purchased from a

wholesaler or distributor however the trap

should be shallow as the (3) elbow con-

guration. Each elbow is approximately

2 equivalent feet. One P-trap is equal to

approximately 12 equivalent feet.

note: Avoid excessive oil buildup.

The P-trap should have a shallow depth

and a short horizontal section.

• P-traps are not required at the foot of the

hot gas risers due to increased oil ow at

higher temperatures.

30'

15'

8

Evaporator

www.enviromaster.comSide Discharge Condensers

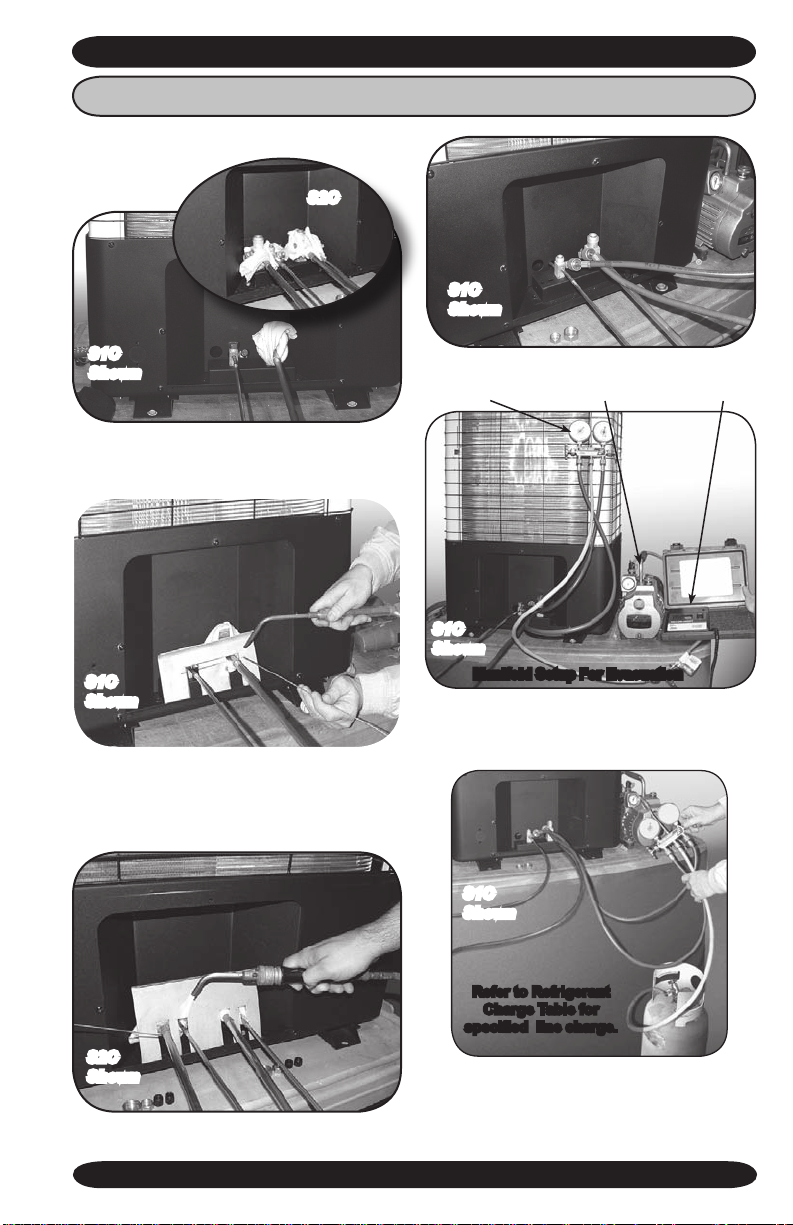

inStallation inStrUCtionS

reFrigerant piping

Continued

1. Clean the ends of tubing and insert into

ttings.

S2C

S1C

Shown

S1C

Shown

2. Protect the valves by wrapping with a

wet rag "heat sink" before brazing.

S1C

Shown

3. We recommend the use of a shield (can

be made from some scrap metal) to

protect the paint.

5. Attach manifold set.

Manifold

S1C

Shown

Vaccum Pump Micron Gage

manifold Setup For evacuation

6. Evacuate line to 500 microns or less to

ensure all moisture has been removed

and there are no leaks.

S1C

Shown

S2C

Shown

4. Braze tubing into ttings.

Side Discharge Condensers

refer to refrigerant

Charge table for

specied line charge.

Refrigerant

7. Once certain of a good evacuation and

leak free joints, back-seat the valves

(counter-clockwise) to open and allow

factory charge to ll lines and indoor unit.

9

www.enviromaster.com

Loading...

Loading...