EMI KWHA12AO, KWC24DO, KWCA12AO, KWHA09AO, KWHA18DO Installation, Operating And Maintanance Manual

...

HIGH WALL COOLING

DUCTLESS

9,000, 12,000, 18(

24,000

...... :ii!¸I:::,I_(:

Enviromaster Internati(

5780 Success Dr,

Rome, NY 13440

www,enviromaster, com

mNSTALLATION, OPERATION AND MAINTENANCE MANUAL

P/N 240006537, Rev. 1.0 [01/07]

This manual is intended as an aid to a qualified service personnel for proper installation,

operation, and maintenance of EMI EnviroAir high efficiency R-410A Ductless Split

Systems. Carefully read these instructions before attempting installation or operation.

Failure to follow these instructions may result in improper installation, operation, or

maintenance, possibly resulting in fire, electrical shock, property damage, personal

injury, or death.

(1) Retain this manual for future reference.

(2) Before leaving the premises, review this

manual to be sure the unit has been

installed correctly and run the unit for

one complete cycle to make sure it

functions properly.

To obtain technical service or warranty

assistance during or after the installation

d this unit, check our website @ www.

enviromaster.com or call your installing

contractor or distributor. Our technical

service department may be contacted at

1-800-228-9364.

When calling for assistance, please have

the following information ready:

Indoor Unit

Model Number

Indoor Unit

Serial Number

Outdoor Unit

Model Number

Outdoor Unit

Serial Number

Date of installation

Read all instructions before using

the EMI EnviroAir high efficiency

system. Install or locate this sys-

tem only in accordance with these

instructions. Use this system only

for its intended use as described in

this manual.

Check rating plate for correct system

voltage before installing. Installa-

tion and operation of a system with

the incorrect voltage may result in

malfunction or other issues and will

void _he warranty.

The EMI EnviroAir system must

be connected only to a properly

grounded electrical supply. Do not

fail to properly ground this unit.

Turn off the electrical supply be-

fore servicing the EMI EnviroAir

system.

Do not use the EMI EnviroAir

system if it has damaged wiring, is

not working properly, or has been

damaged or dropped.

[Save These/nstrucdons]

X,_ j

This symbol is an indicationof ,_"_

Important Safety Information.

TheEnviroAirsystemisanefficientduct-

lesssplitairconditioningsystemwithcooF

ingcapacitiesfrom9,000-24,000Btuhand

heatpumpcapacityof9,000-24,000Btuh.

Designedforquietoperationandboasting

compactdimensions,theEnviroAirsys-

temincludesadvancedfeatureslikeauto-

restart,fullfeatureremotecontrol.

oMain System Breaker: Sized per unit

requirements, to be mounted adjacent

to outdoor unit.

o Mounting Hardware: Wall anchors,

condenser pad.

oVacuum Pump

oGauge Set: R-410 specific.

o High Vo#age interconnect Wiling:

14 AWG wiring from outdoor unit to in-

door unit for power and control. *

oRefrigerant : R-410A required for addi-

tional line sets beyond 16 ft=

• Can be purchased through the factory asan

accessory, (partof the Tube Set Kit below)

Comprised of three standard components

the indoor high wall evaporator, the out

door condensing unit, and an infrared

handheld remote contro!. The EnviroAir

system is engineered to the highest per-

formance and reliability standards. The

evaporator is equipped with permanent

washable air filters as well as motorized

air sweep for enhanced air circulation, and

the condensing unit is equipped as stan-

dard with a high efficiency rotary compres-

sor.

Tube-Set Kit consisting of:

o Refrigerant Line Set - 25 feet of

suction and liquid line, both fully in-

sulated, and flare fittings supplied

on both ends.

ointerconnecting High Vo#age Wiring

- 25 feet supplied.

oAdd#ional Condensate Tubing - 6feet

extra supplied.

EMI recommends the EnviroAir system

for residential and light commercial cool-

ing applications. The EnviroAir system will

operate in standard cooling mode down to

60°F outdoor temperature.

o Matched System Consisting Of:

Evaporator section and condenser sec-

tion with remote control.

The EnviroAir system is backed with the

standard limited warranty that applies

to all EMI equipment. For a copy of this

limited warranty, please contact EMI cus-

tomer service or refer to the website at

_,_Nw.enviromaster, com.

Application:

Check the application of the unit prior to

installation, certain applications require

additional components or installation pa-

rameters, such as the need for external

condensate pump or if the system will

need to perform low ambient cooling at

outdoor temperatures below 6O°F.

KWCA09A0

KWCA12A0

KWCA18D0

KWCA24D0

KWHA09A0

KWHA12A0

KWHA18D0

KWHA24D0

K1CA9000A00

K1CA2000A00

K1CA8000D00

K1CA4000D00

K1HA9000A00

K1HA2000A00

K1HA8000D00

K1HA4000D00

Cooling Only

Cooling Only

Cooling Only

Cooling Only

Heat Pump

Heat Pump

Heat Pump

Heat Pump

9,000

12,000

18,000

24,000

9,000

12,000

18,000

24,000

115zlz60

115zl-60

208/230-1-60

208/230-1z60

115-1-60

115-1-60

208/230zl-60

208/230-1-60

Example

EnviroAir Unit

Unit Style

W = High Waft Unit

Duty

C = Cooling Only

H = Heat Pump

Design Revision

A =R-4'10A

Capacity

09 = 9,000 Btuh

12 = 12,000 Btuh

18 = I8,000 Btuh

24 = 24,000 Btuh

Voltage

A = "115-I-60

(09 and "12only)

D = 208/230-"1-60

(18 and24 only)

Not Used

Example

EnviroAir Unit

Number of Zones

I = Single Zone

Duty

C = Cooling Only

H = Heat Pump

Design Revision

A = R-410A

Zone I Capacity

9 = 9,000 Btuh

2 = 12,000 Btuh

8 = 18,000 Btuh

4 = 24,000 Btuh

Not Used

Not Used

Not Used

Voltage

A = 115-1-60

(9 and 2 only)

D = 208/230-I-60

(8 and 4 only)

Controls

0 = Standard

Condenser Coil

0 = StandardAI/Cu

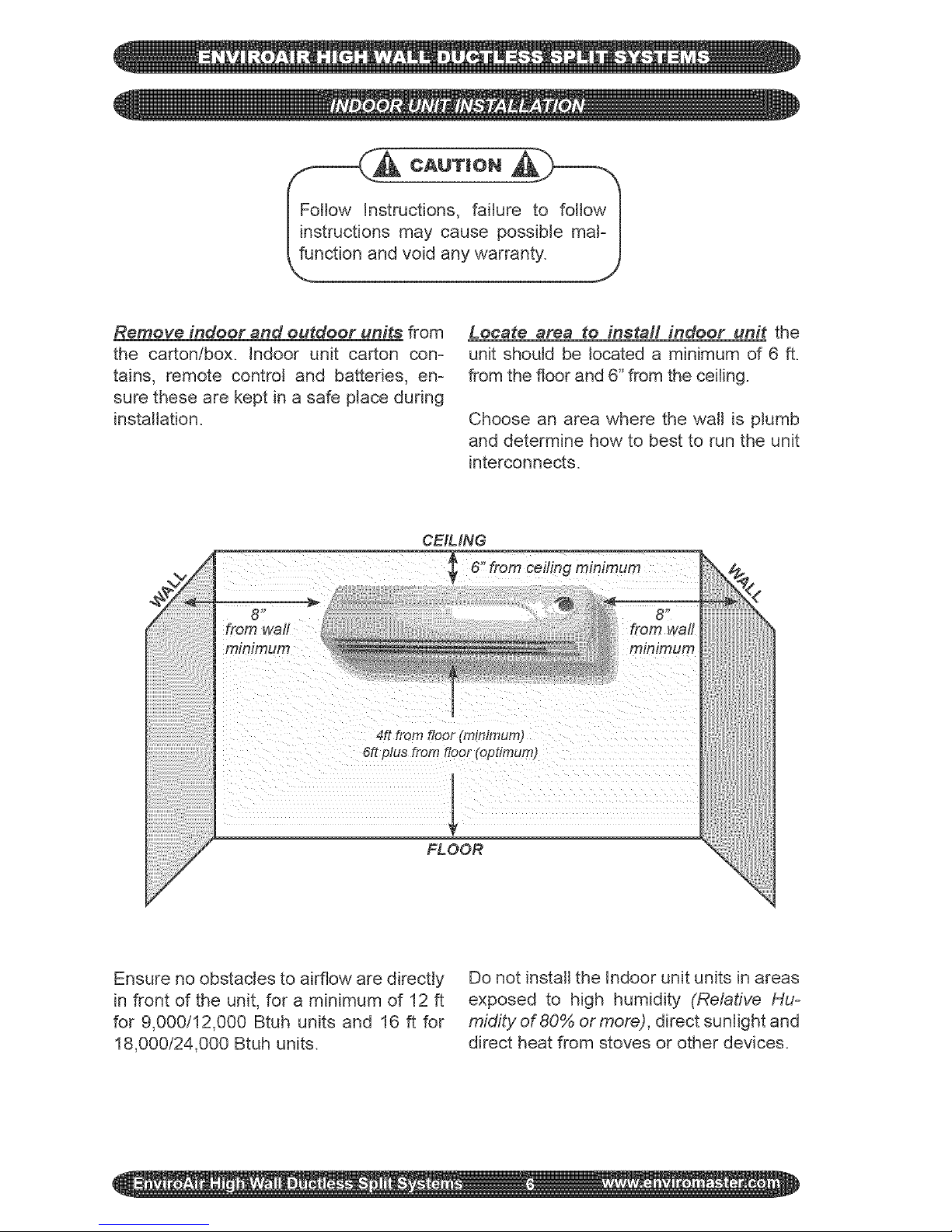

Determine the best location for mounting

the indoor unit, it must be located a mini-

mum of 4ft (6 ft or more recomended) from

the floor and no less than 6" from ceiling.

Pay attention to the air circulation in the

room, 9,000 & 12,000 Btuh units throw air

15ft, 18,000 & 24,000 Btuh units throw air

25ft, ensure no obstacles to airflow exist.

Locate the indoor and outdoor units as close

together as possible, maximum line set run

and lift MUST NOT BE EXCEEDED. Deter-

mine how the interconnect piping, wiring

and condensate hose are to be run.

Units are supplied with a wireless remote

control, which communicates with the unit

microprocessor control. The return air

temperature sensor mounted in the in-

door unit provides input to the control for

system operation.

Several modes of operation are available

to the end user depending on the type of

comfort required. All unit operating func-

tions are controlled via the remote con-

trol. Refer to "_System Operation" section

of this manual.

KWCA/K 1CA 09/12

KWCA/K1 CA 18/24

KWHA/K1HA 09/12

KWHA/K1 HA 18/24

35 Feet

50 Feet

35 Feet

50 Feet

17 Feet

17 Feet

17 Feet

17 Feet

Ensure that all panels can be removed for

service as required.

Cerdffeadon:

All EnviroAir Ductless Splits are certified

by UL under UL Standard 1995. Per-

formance is varified by CSA under ARI

210/240 test standard.

Low Ambient Contro#

Please consult the factory for availability of

approved method of low ambient cooling

operation.

Condensate Pump:

It is recommended to use the supplied

condensate drain hose in a gravity fed

method whenever possible. If this can

not be done then a field installed pump

that is external to the evaporator would

be required.

structions,failureto followI

s maycausepossiblemat=I

ndvoidanywarranty. J

J

Remove indoor and outdoor units from

the carton/box, indoor unit carton con-

tains, remote controt and batteries, en-

sure these are kept in a safe place during

installation.

Locate area to install indoor unit the

unit should be located a minimum of 6 ft.

from the floor and 6" from the ceiling.

Choose an area where the watt is plumb

and determine how to best to run the unit

interconnects.

CEIMNG

ceiling minimum

6" from

from wall

minimum

4R from floor (minimum)

6R plus from floor (optimum)

FLOOR

Ensure no obstacles to airflow are directly

in front of the unit, for a minimum of 12 ft

for 9,000/12,000 Btuh units and 16 ft for

18,000t24,000 Btuh units.

Do not install the Indoor unit units in areas

exposed to high humidity (Relative Hu=

midity of 80% or more), direct sunlight and

direct heat from stoves or other devices.

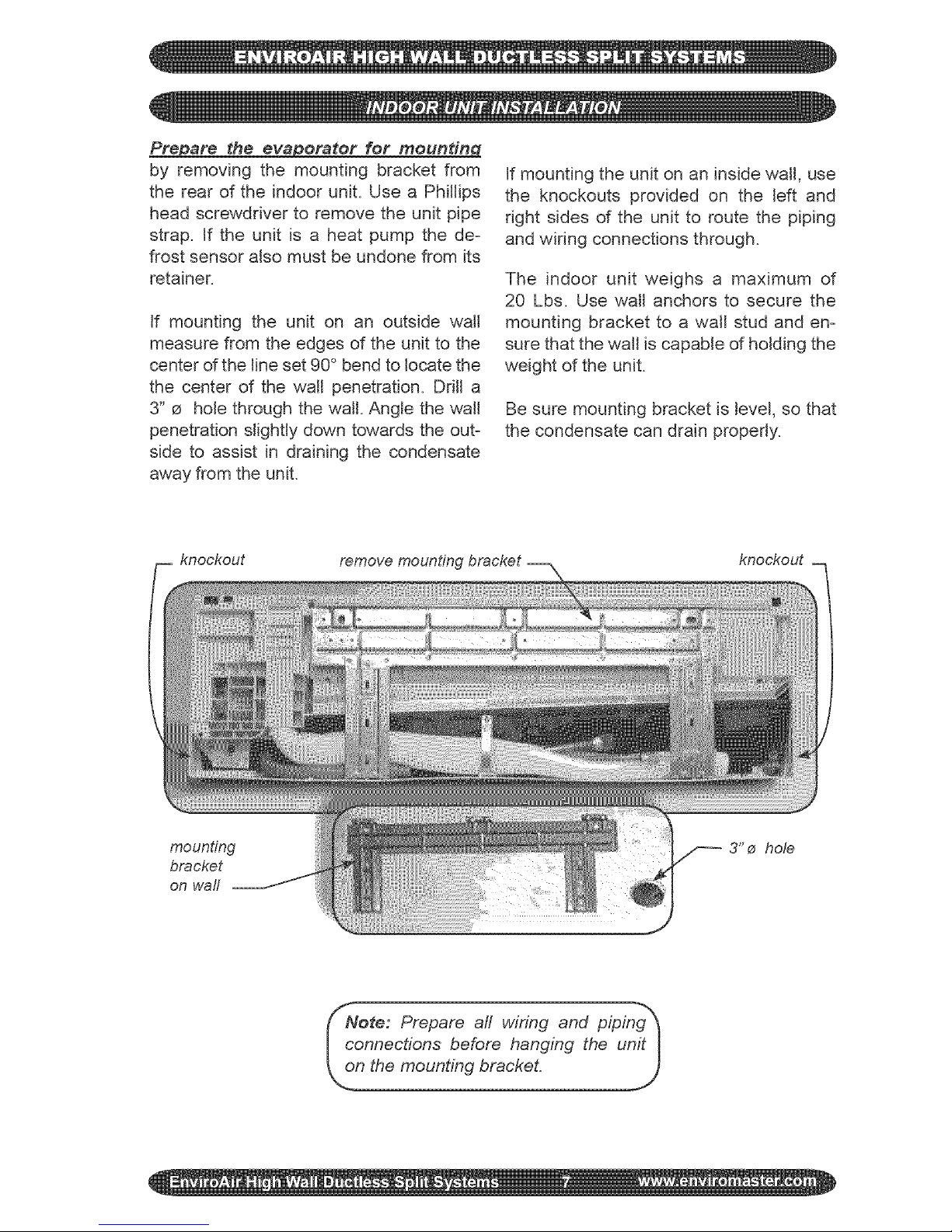

Prepare the evaporator for moundng

by removing the mounting bracket from

the rear of the indoor unit. Use a Phillips

head screwdriver to remove the unit pipe

strap. If the unit is a heat pump the de-

frost sensor also must be undone from its

retainer.

If mounting the unit on an outside wall

measure from the edges of the unit to the

center of the line set 90° bend to locate the

the center of the wall penetration. Drill a

3" e hole through the wall. Angle the wall

penetration slightly down towards the out-

side to assist in draining the condensate

away from the unit.

If mounting the unit on an inside walt, use

the knockouts provided on the left and

right sides d the unit to route the piping

and wiring connections through.

The indoor unit weighs a maximum of

20 Lbs. Use watt anchors to secure the

mounting bracket to a watt stud and en-

sure that the wall is capable of holding the

weight of the unit.

Be sure mounting bracket is level, so that

the condensate can drain properly.

knockout remove mounting

knockout

mounting

bracket

on wall

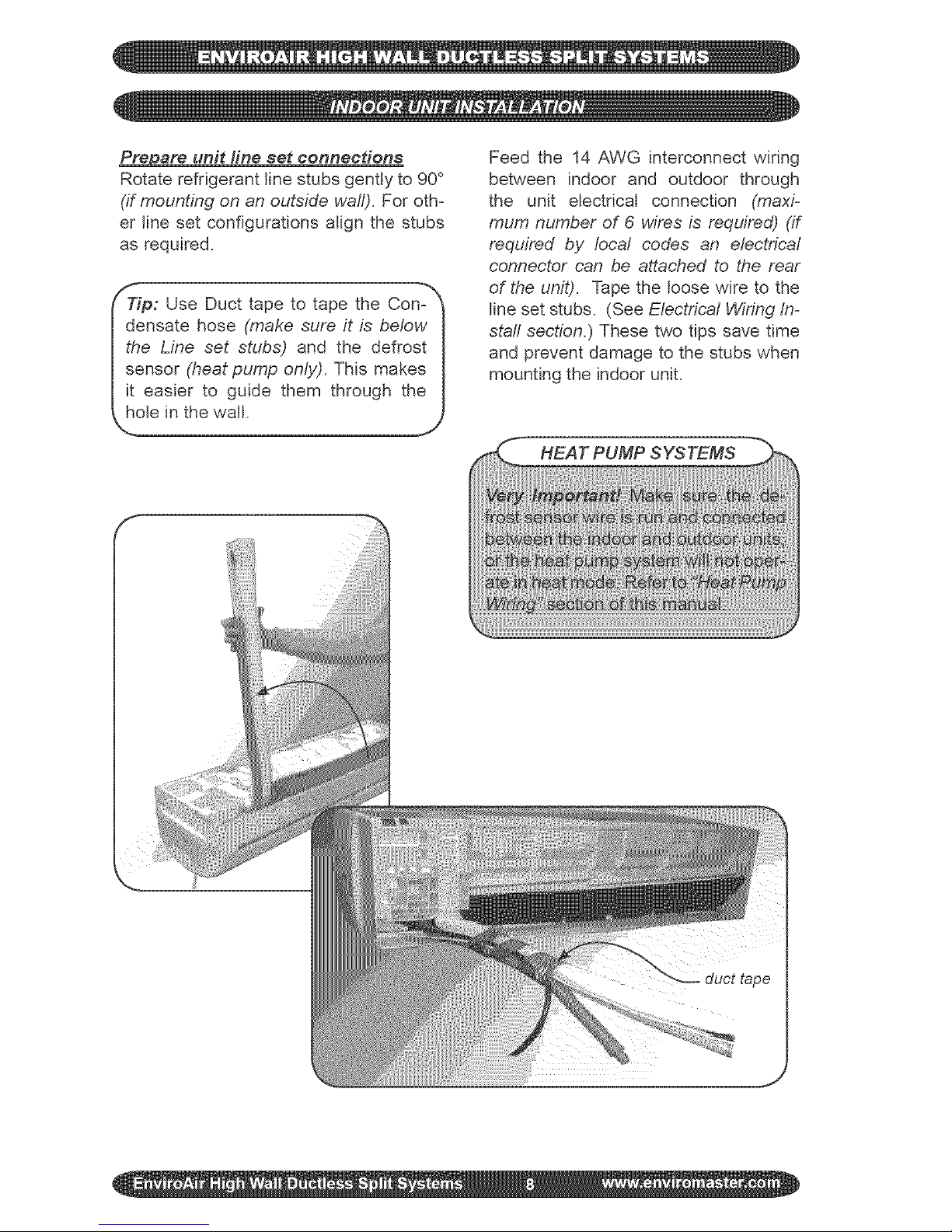

_are unit fine set connections

Rotate refrigerant line stubs gently to 90°

(if mounting on an outside wall). For oth-

er line set configurations align the stubs

as required.

ieP:Use Duct tape to tape the Con-_

nsate hose (make sure it is below I

I the Line set stubs) and the defrost I

I sensor (heat pump only). This makes I

I it easier to guide them through the I

f

i !!!

Feed the 14 AWG interconnect wiring

between indoor and outdoor through

the unit electrical connection (maxi-

mum number of 6 wires is required) (if

required by local codes an electrica/

connector can be attached to the rear

of the unit). Tape the loose wire to the

line set stubs. (See Electrica/Wiring In-

staff section.) These two tips save time

and prevent damage to the stubs when

mounting the indoor unit.

HEAT PUMP SYSTEMS

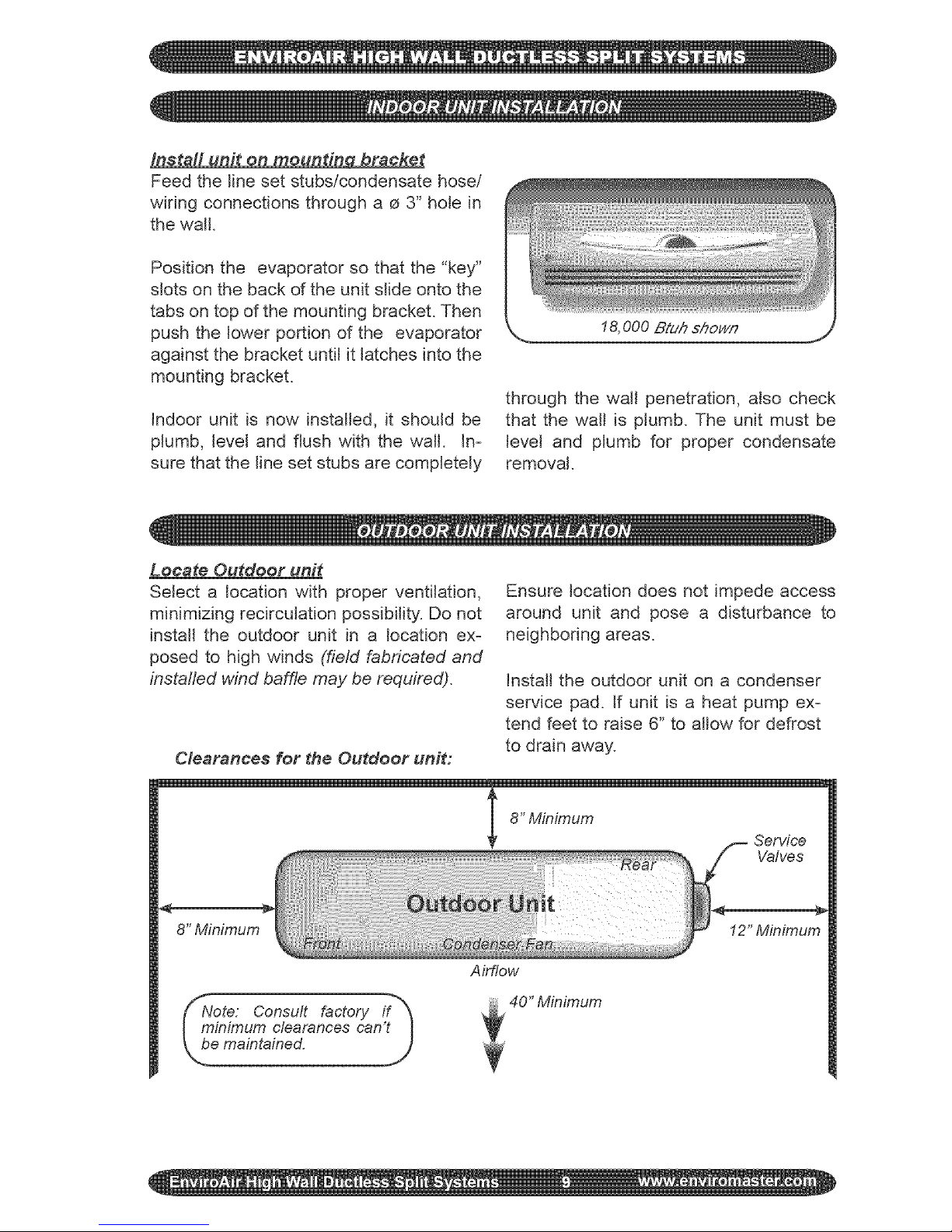

Install unit on mounting bracket

Feed the line set stubs/condensate hose/

wiring connections through a o 3" hole in

the walt.

Position the evaporator so that the "key"

slots on the back of the unit slide onto the

tabs on top of the mounting bracket. Then

push the lower portion of the evaporator

against the bracket until it latches into the

mounting bracket.

indoor unit is now installed, it should be

ptumb, level and flush with the wait. in-

sure that the line set stubs are completely

through the watt penetration, also check

that the watt is plumb. The unit must be

level and plumb for proper condensate

removal.

Locate Outdoor unit

Select a location with proper ventilation,

minimizing recircutation possibility. Do not

install the outdoor unit in a location ex-

posed to high winds (field fabricated and

installed wind baffle may be required).

Clearances for the Outdoor unit:

Ensure location does not impede access

around unit and pose a disturbance to

neighboring areas.

Install the outdoor unit on a condenser

service pad. If unit is a heat pump ex-

tend feet to raise 6" to allow for defrost

to drain away.

8" Minimum

Ote: Consult factory if"_

inimum clearances can't I

maintained. )

Airflow

40" Minimum

12" Minimum

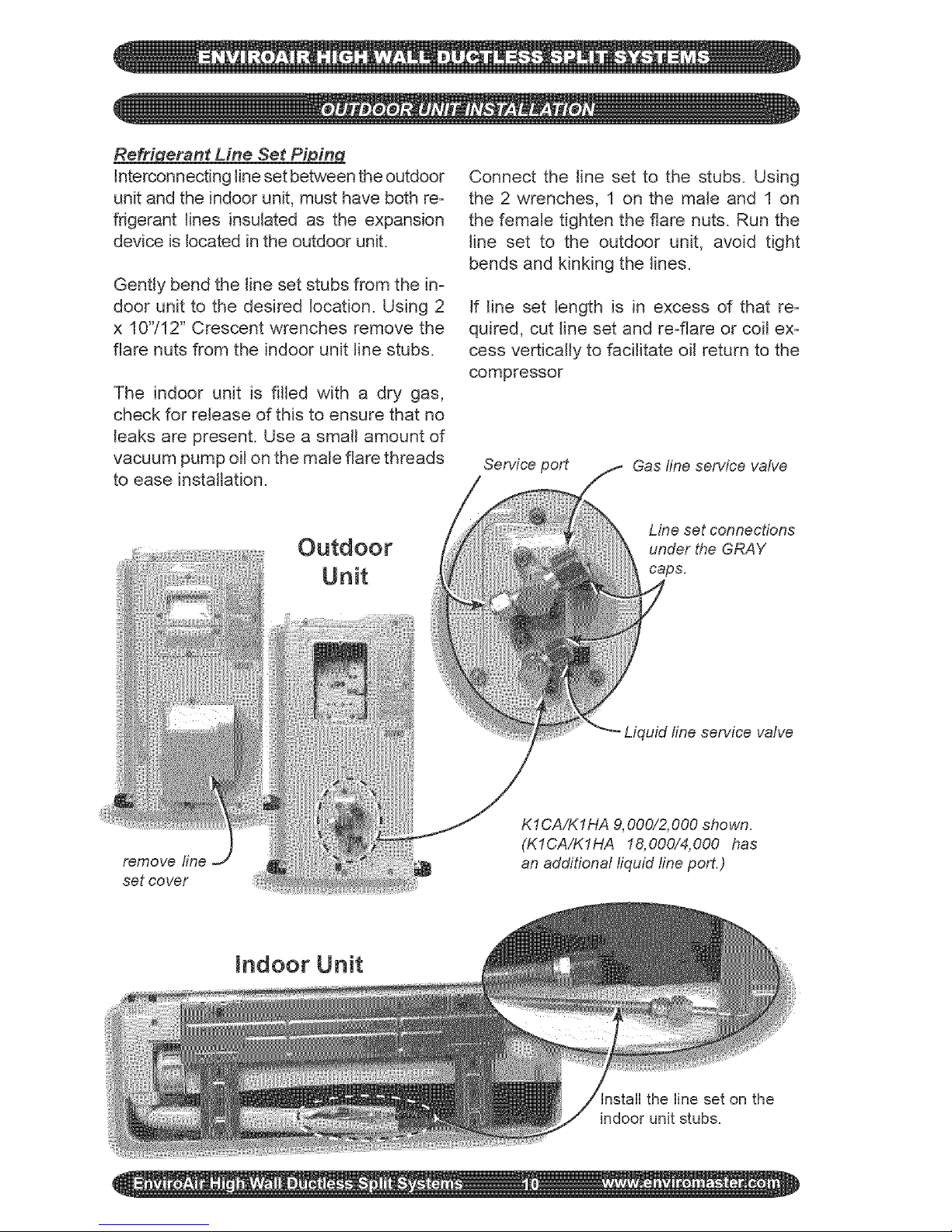

Re_nt Line Set Pi in

interconnectingline set between the outdoor

unit and the indoor unit, must have both re-

frigerant lines insulated as the expansion

device is located in the outdoor unit.

Gently bend the tine set stubs from the in-

door unit to the desired location. Using 2

x 10"/12" Crescent wrenches remove the

flare nuts from the indoor unit tine stubs.

The indoor unit is filled with a dry gas,

check for retease of this to ensure that no

leaks are present. Use a smatt amount of

vacuum pump oil on the male flare threads

to ease installation.

Outdoor

Unit

Connect the line set to the stubs. Using

the 2 wrenches, 1 on the male and 1 on

the female tighten the flare nuts. Run the

tine set to the outdoor unit, avoid tight

bends and kinking the lines.

If line set length is in excess of that re-

quired, cut line set and re-flare or coil ex-

cess vertically to facilitate oit return to the

compressor

Service port

Gas line service vahe

Line set connections

under the GRAY

caps.

set cover

Indoor Unit

Install the line set on the

indoor unit stubs.

Evacuation

Gauges can now be attached to the service

ports - SERVICE PORTS HAVE A 5/16"

CONNECTION TO GAUGES, which is dif-

ferent from the norm for R-22. You will need

specific hoses or an adaptor for the 5/16"

connection.

Once the gauges are attached the line

set can be leak checked using Nitrogen

at 300 psig. Evacuate the unit and inter-

connect down to a minimum of 400-500

Microns, break vacuum with Nitrogen to

further leak check.

Re-evacuate the system down to 300-400

Microns or lower for a period of one hour.

This is an R-410A System it is essential

that a deep vacuum be pulled on the sys-

tem to remove all traces of moisture. See

"System Start-Up" section to fine-tune the

refrigerant charge.

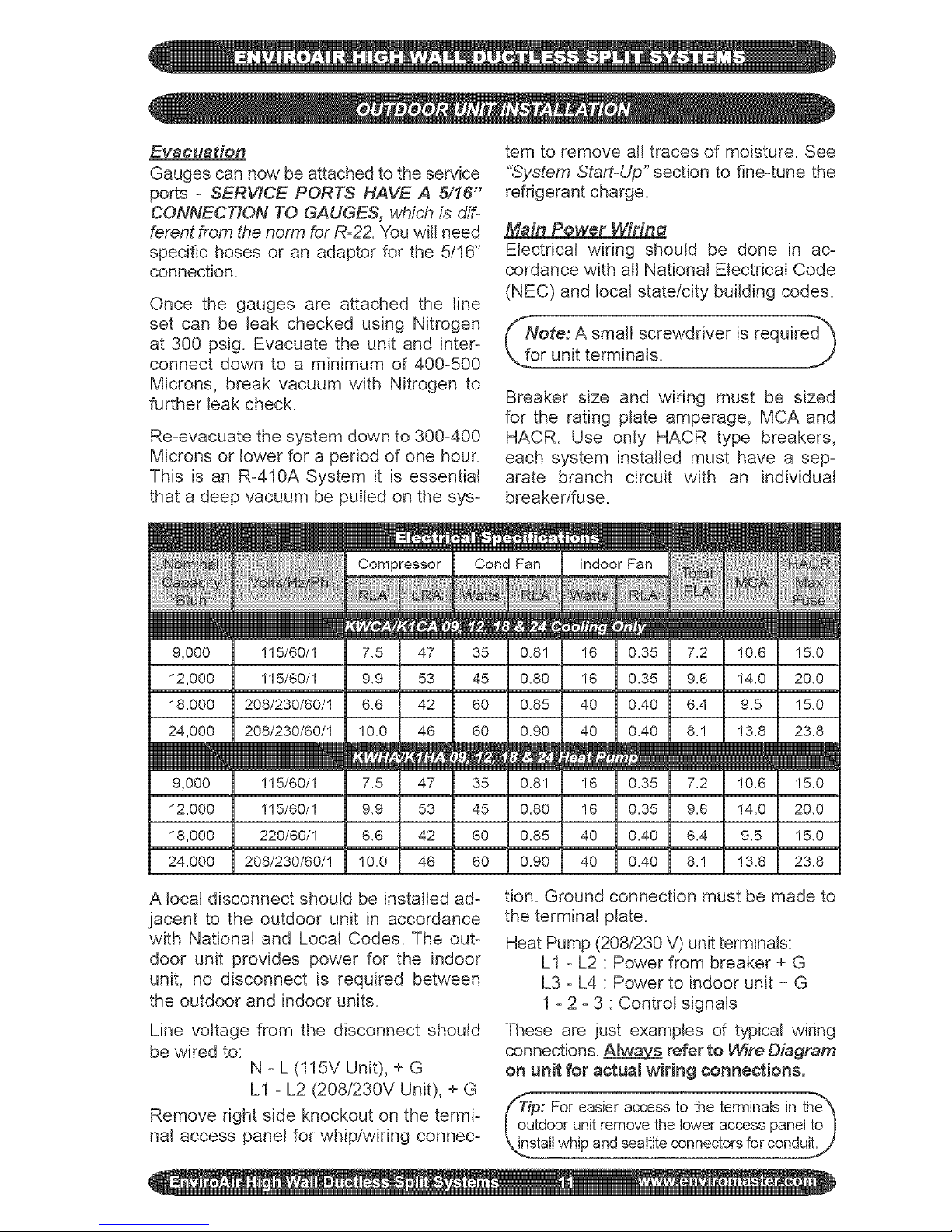

Main Power Wirin_

Electrical wiring should be done in ac-

cordance with all National Electrical Code

(NEC) and local state!city building codes.

_Note: A small screwdriver is required_

Breaker size and wiring must be sized

for the rating plate amperage, MCA and

HACR. Use only HACR type breakers,

each system installed must have a sep-

arate branch circuit with an individual

breaker/fuse.

9,000

2,000

8,000

!4,000

9,000

2,000

8,000

!4,000

115/80/1

115/80/1

220/60/!

208/230/80/!

7,2

9,6

6,4

8,1

7,2

9,6

6,4

8,1

A local disconnect should be installed ad-

jacent to the outdoor unit in accordance

with National and Local Codes. The out-

door unit provides power for the indoor

unit, no disconnect is required between

the outdoor and indoor units.

Line voltage from the disconnect should

be wired to:

N - L (115V Unit), + G

LI - L2 (208/230V Unit), + G

Remove right side knockout on the termi-

nal access panel for whip/wiring connec-

tion. Ground connection must be made to

the terminal plate.

Heat Pump (208,/230V) unit terminals:

LI - L2 : Power from breaker + G

L3 - L4 : Power to indoor unit + G

1- 2 - 3 : Control signals

These are just examples of typical wiring

connections. Alway_ refer to Wire Diagram

on unit for actuamwiring connections.

: Foreasieraccessto the terminalsinthe_

oorunitremovethe loweraccesspaneltoJ

Loading...

Loading...